Oliver 709 Service Manual

Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 709

MINI SUPREME

BREAD SLICER

0709S20000-CV

MODEL 709 MINI SUPREME BREAD SLICER

INDEX

SAFETY INSTRUCTIONS.......................................................................... 0709S20025

DEFINITIONS ........................................................................................... GEN 931118

INSTALLATION INSTRUCTIONS ............................................................. 0709S20026

SPECIFICATIONS .................................................................................... 0709S20027

OPERATING INSTRUCTIONS.................................................................. 0709S20028

ADJUSTMENTS........................................................................................ 0709S20029

Slices Vary In Thickness .............................................................. 0709S20029-1/3

Limit Switch and Actuating Flag Adjustment.................................. 0709S20029-2/3

MAINTENANCE ......................................................................................... 0709S20030

Removing Blade Frames ............................................................... 0709S20030-1/4

Replacing Blade Frames ............................................................... 0709S20030-2/4

Changing Blades ........................................................................... 0709S20030-3/4

Lubrication........... .......................................................................... 0709S20030-4/4

Cleaning...... .................................................................................. 0709S20030-4/4

TROUBLE SHOOTING ............................................................................. 0709S20031

The Slicer Will Not Start ................................................................ 0709S20031-1/2

Motor Runs But Blade Frames Do Not Move ................................ 0709S20031-1/2

The Slicer Will Not Stop ................................................................ 0709S20031-1/2

The Slicer Starts But Stops Too Soon ........................................... 0709S20031-2/2

Bread Slices Vary In Thickness ..................................................... 0709S20031-2/2

WIRING DIAGRAMS ................................................................................ 0709S20032

1 Phase, 60 Hertz, 115 VAC ......................................................... 0709S20032-1/2

1 Phase, 60 Hertz, 230 VAC ......................................................... 0709S20032-2/2

1 Phase, 50 Hertz, 220 VAC ......................................................... 0709S20032-2/2

RECOMMENDED SPARE PARTS ............................................................ 0709S20033

ASSEMBLY DRAWINGS .......................................................................... 0709S20044

FRAME.............................................................................................................. 1/15

BLADE FRAMES................................................................................................ 4/15

WORKING PARTS.............................................................................................. 8/15

PUSHER ……………………………………………………………………………... 12/15

ELECTRICAL…………………………………………………………………………..15/15

REPLACEMENT PARTS LIST .................................................................. 0709S20034

WARRANTY.............................................................................................. GEN 040228

WARRANTY PROCEDURE.................................................................... GEN 040226

RETURN PARTS POLICY...................................................................... GEN 040227

REV. 7/26/10

0709S20024

MODEL 709 MINI SUPREME BREAD SLICER

SAFETY INSTRUCTIONS

Every effort has been made by Oliver Products Company to provide you with a safe

machine. However, it is essential that machine operators and maintenance personnel

observe the following safety precautions.

1. Read this manual before attempting to operate your slicer. Never allow an untrained

person to operate this machine.

2. Make sure that the machine is only connected to a properly grounded electrical

supply source of sufficient capacity for the load the slicer will put on it. Always

unplug the machine when it is not in use.

3. Always make sure the machine has been disconnected from the power supply

before cleaning or servicing.

4. Always keep your hands away from the moving parts of the machine while it is in

operation

5. All guards must be in place before starting the machine.

6. Do not wear loose fitting clothing while operating the machine. Shirt tails should be

tucked in.

7. To prevent injury handle knife blades with care and never touch moving knives.

8. Use only proper replacement parts.

In addition to these general safety instructions, also follow the more specific safety

instructions given for the different areas of the machine in the operating instructions.

0709S20025

GENERAL

DEFINITIONS

The use of the words WARNING, CAUTION, and NOTE in this manual should be guided

by the following.

WARNING

AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH MAY

RESULT IN PERSONAL INJURY IF NOT CAREFULLY FOLLOWED.

CAUTION

AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH MAY

RESULT IN DAMAGE TO EQUIPMENT IF NOT CAREFULLY FOLLOWED.

NOTE

AN OPERATING PROCEDURE, TECHNIQUE, ETC., WHICH IS CONSIDERED

ESSENTIAL TO EMPHASIZE.

GEN931118

MODEL 709 MINI SUPREME BREAD SLICER

INSTALLATION INSTRUCTIONS

WARNING

THE SLICER IS HEAVY. USE PROPER LIFTING TECHNIQUES, KEEP

BACK STRAIGHT, KNEES BENT, AND LIFT WITH YOUR LEGS. USE

GLOVES TO PROTECT YOUR HANDS.

Lift the slicer from its resting surface with one person standing on each end of the slicer,

(front and back), set the slicer onto the counter or table as close as possible to its

desired location.

CAUTION

BEFORE PLACING THE SLICER ON A TABLE OR COUNTER, MAKE SURE

THE TABLE OR COUNTER CAN SUPPORT THE SLICER’S WEIGHT WHICH

IS APPROXIMATELY 115 POUNDS.

Should the machine not be in its desired location, carefully slide the machine to its final

location.

The machine may now be connected to a properly grounded power supply of the same

voltage and of sufficient capacity for the load which the slicer will put on it. See the

electrical requirements on the “Oliver Nameplate” on the rear of the machine. DO NOT

USE EXTENSION CORDS.

WARNING

BEFORE ATTEMPTING TO SLICE BREAD READ THE “OPERATION”

SECTION OF THIS MANUAL.

0709S20026

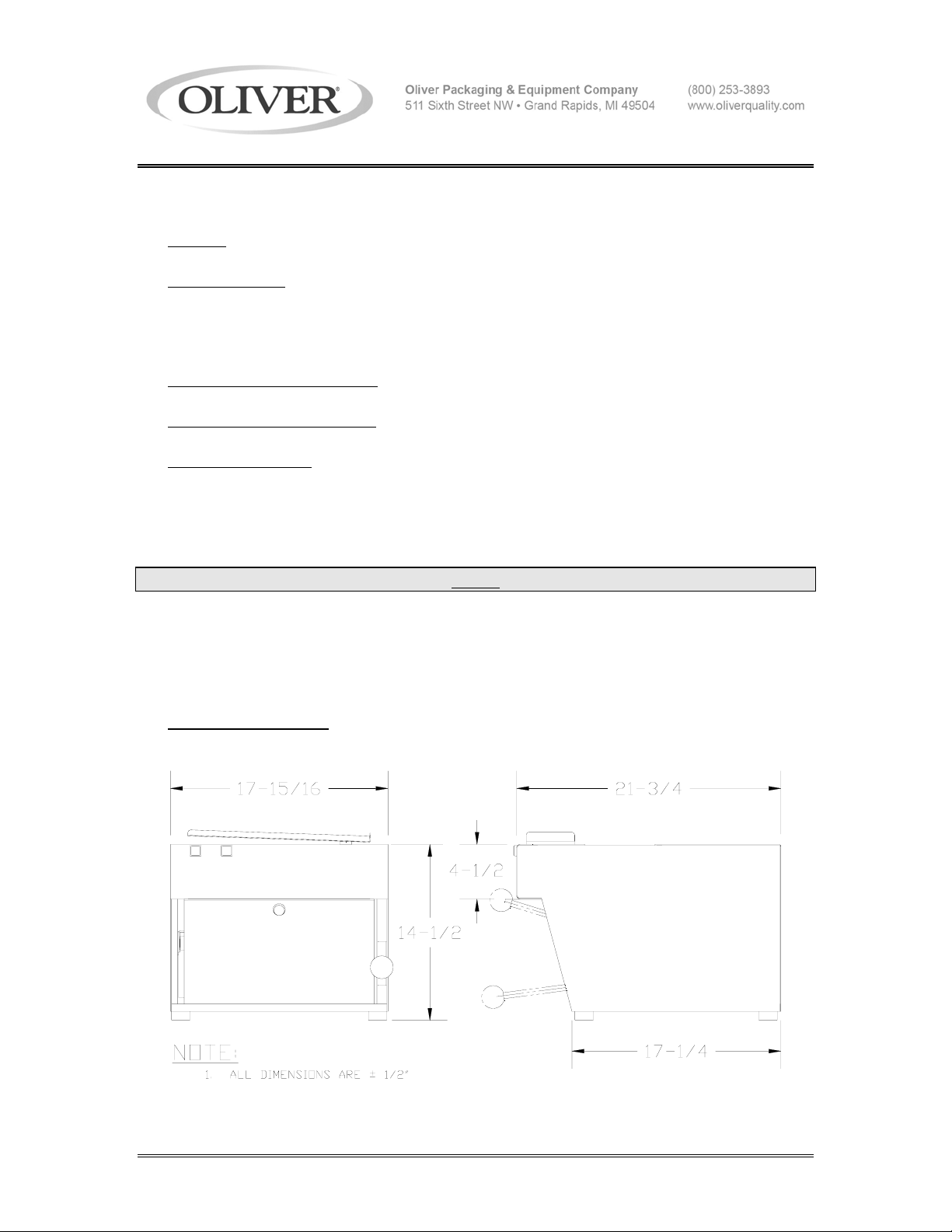

MODEL 709 MINI SUPREME BREAD SLICER

SPECIFICATIONS

• Weight:

(Approximate) ----------------------------------------------------------- (115) pounds

• Slice Spacings:

Standard ---------------------------------------------------------------------------------------- 1/2”

Available at extra cost ------------------------------------ 3/8” (min.), 7/16”, 5/8”, 3/4”, 1”

Others --------------------------------------------------------------------------- Consult Factory

• Standard Electrical Service:

-------------------- 1/5 HP, 1-60-115 Volts AC, 2 Amps.

• Optional Electrical Services

: --------------------------------------------------- Consult factory

• Product Capacities

:

Length -------------------------------------------------------------------------------------- 14-5/8”

*Width --------------------------------------------------------------------------------------- 5-1/4”

*Height -------------------------------------------------------------------------------------- 5-1/4”

NOTE

*WIDTH AND HEIGHT DIMENSIONS ARE FOR A SQUARE PRODUCT.

LOWER AND WIDER PRODUCTS MAY ALSO BE SLICED BY TAKING

CARE IN LOADING THE PRODUCT. INDIVIDUAL DETERMINATIONS

WOULD HAVE TO BE MADE.

• Machine dimensions:

Revised 6-14-07

0709S20027

MODEL 709 MINI SUPREME BREAD SLICER

OPERATING INSTRUCTIONS

WARNING

ALWAYS USE CARE WHENEVER WORKING NEAR THE CUTTING KNIVES.

To operate the machine, stand in front of the machine and grasp the lever with your right

hand. Pull the lever from its lowest position to the upper limit of its travel. Using your left

hand, load the product into the machine.

WARNING

NEVER

START THE MACHINE BEFORE LOADING THE PRODUCT.

Make sure that the product does not hang over either edge of the cradle. While holding

the lever in the upper-most position, (the machine will not start unless this is done),

push the START button with your left hand.

NOTE

ONCE THE MACHINE HAS BEEN STARTED, THE MACHINE CAN BE

STOPPED BY PUSHING THE “STOP”

BUTTON.

After starting, move the lever downward slowly until the product contacts the knives.

Once the product has contacted the knives move the handle down using moderate force

to slice the bread.

CAUTION

EXCESSIVE DOWNWARD FORCE SHOULD NOT BE USED AS DAMAGE

TO THE MACHINE OR PRODUCT MAY RESULT.

When the slicing operation is complete, and the handle is at its lowest position, the

machine will automatically stop. The cradle will stay in the upper most position so that

both hands can be used to grasp the sliced product and remove it from the top of the

cradle. The product can then be moved to the bagging scoop mounted on the front of

the machine which will ease packaging of your product.

0709S20028

MODEL 709 MINI SUPREME BREAD SLICER

ADJUSTMENTS

WARNING

ALWAYS

UNPLUG THE SLICER WHEN ADJUSTING OR SERVICING.

• Slices Vary In Thickness:

NOTE

IN ONLY THREE SITUATIONS SHOULD IT BECOME NECESSARY TO

ADJUST THE BLADE FRAMES FOR A VARIANCE IN SLICE THICKNESS.

1. IF THE BLADE FRAME GUIDE BARS BECOME LOOSE ALLOWING

THE FRAME TO MOVE.

2. IF THE BLADE FRAMES WERE REMOVED FROM THE MACHINE

AND REPLACED IN OPPOSITE POSITIONS.

3. THE BLADE FRAMES ARE BEING REPLACED WITH A DIFFERENT

SET OF BLADE FRAMES, SUCH AS IN A CONVERSION TO A

DIFFERENT SLICE WIDTH.

To correct the variance in slice thickness, remove the front and top covers which are

each held in place with four screws.

NOTE

A TABLE LIP IS ATTACHED BETWEEN THE TOP COVER AND THE

INFEED TABLE BY FRICTION, A SLIGHT PULL MAY BE REQUIRED

TO DISLODGE IT.

Next remove the lower screw from the holddown pivot block on each side of the

machine, also loosen the upper screw of the pivot block, but, do not remove it. When

this has been done you will be able to pivot the holddown out of the knives to allow

removal of the blade frames. Next remove the shoulder screw from the foot of the top

blade

frame, (the blade frame is connected to the rocker through a pivoting link on the

foot of the blade frame). Once disconnected the top blade frame can be removed by

sliding the frame forward out of the tracks.

WARNING

ALWAYS USE CARE WHENEVER WORKING NEAR THE CUTTING KNIVES.

0709S20029-1

MODEL 709 MINI SUPREME BREAD SLICER

• Slices Vary In Thickness: (Cont’d.):

At this point check the side to side movement of the lower blade frame: it should be at

the minimum which still allows free travel in the tracks. If the side to side movement

seems satisfactory check the centering of the frame. The distance from the side of the

blade frame to the machine’s side should be as close as possible to the same distance

on each side.

Should either of the above two situations need correction loosen

the four nuts, two on

each side, which secure the lower blade frame guide bars, (they are accessible from the

underside of the blade frame). Once loosened, the blade frame can be centered in the

machine, making sure that the guide bars are as far into the tracks as they will go, thus

limiting side to side movement. When the bars are as far into the tracks as reasonably

possible and the blade frame is centered in the machine, re-tighten the nuts. Re-check

the blade frame for proper centering, side to side movement and ease of travel.

When the lower blade frame has been found to be in its proper position, or, corrected to

the proper position, (if that was required), as described previously, re-install the upper

blade frame. Replace the shoulder screw and link at the foot of the blade frame,

replacing and tightening the nut and lock washer which secure the shoulder screw.

Check the distance between any three adjacent blades using a 12 inch or shorter ruler.

the outside blades should be the same distance from the center blade. If this is the case

the slices will be the same thickness, if the distance varies then the upper blade frame

must be adjusted side to side until the measured distances are equal.

To adjust the upper blade frame loosen

the four nuts, (two on each side), which secure

the blade frame guide bars. Once loosened the blade frame can be adjusted by moving

it slightly either right or left in the machine until the distances as measured above are

equal. Make sure the guide bars are as far into the tracks as they will go to limit side to

side movement. When the bars are as far into the tracks as possible and

the blade

spacing is equal, re-tighten the nuts. Re-check the blade frame for proper spacing, side

to side movement and ease of travel.

Rotate the holddown back into the knives. Replace and secure the four mounting

screws of the pivot blocks and replace the front and top covers securing each with the

four screws which were previously removed.

• Limit Switch and Actuating Flag Adjustment:

After disconnecting the slicer from the power supply, remove the rear cover from the

machine allowing access to the limit switch area.

• Limit Switch and Actuating Flag Adjustment (Cont’d.):

0709S20029-2

MODEL 709 MINI SUPREME BREAD SLICER

The actuating flag should trip the lower limit switch when the cradle handle is at the top

of its travel. The upper limit switch should be actuated when the cradle handle is at the

bottom of its travel. The tripping point of a limit switch can be detected by an internal

clicking sound made by the switch. Before attempting to adjust the flag or switches

make sure that the switch levers have not been bent, or, the switch otherwise damaged,

or, that the actuating flag is not just loose on the shaft.

Should switch adjustment be necessary they should be adjusted so that they are tripped

during normal movement of the cradle handle just before either end of the handle’s

travel.

To adjust either of the limit switches or the actuating flag, use the following procedure.

Loosen the set screw in the actuating flag allowing it to rotate easily on the shaft. With

the cradle handle in its upper most position, loosen both of the screws securing the

lower limit switch. Once loosened move the switch until it is approximately in the center

of its travel and re-tighten the switch. Move the loosened actuating flag into the lower

switch lever until you hear it trip. Tighten the flag’s set screw. Re-check the operation of

the switch using the cradle handle. It should function as described above.

Should the upper limit switch need adjustment, (after setting the lower switch as

described above), loosen the two screws which secure it in position and with the cradle

handle in its lowest position move the switch into the flag until you hear it trip. Re-tighten

the screws and re-check the switch operation as before.

0709S20029-3

MODEL 709 MINI SUPREME BREAD SLICER

MAINTENANCE

WARNING

ALWAYS

UNPLUG THE SLICER BEFORE PERFORMING ANY TYPE

OF MAINTENANCE TASK.

• Removing Blade Frames:

Remove the top and front covers by removing the four screws which holds each in place.

The table lip should be removed with the top cover.

NOTE

A TABLE LIP IS ATTACHED BETWEEN THE TOP COVER AND THE

INFEED TABLE BY FRICTION, A SLIGHT PULL MAY BE REQUIRED

TO DISLODGE IT.

Next remove the lower screw from the holddown pivot block on each side of the

machine, also loosen the upper screws of the pivot blocks but do not remove them.

When this has been done you will be able to pivot the holddown out of the knives to

allow removal of the blade frames.

Remove the upper blade frame by removing the shoulder screw from the foot of the

blade frame, (the blade frame is connected to the rocker by means of a plastic link at the

“Foot” of the blade frame). Once the shoulder screw and link have been removed the

blade frame can be slid forward and removed from the tracks and from the machine.

WARNING

THE BLADES ARE EXTREMELY SHARP. ALWAYS

HANDLE THE

BLADE FRAMES WITH CARE.

To remove the lower blade frame, (see note below), you must first remove the four

screws from the infeed table. While this table does not have to be removed from the

machine it must be moved down out of the way to allow removal of the lower blade

frame.

NOTE

REMOVAL OF THE LOWER BLADE FRAME IS NOT

REQUIRED TO

CHANGE ITS BLADES.

0709S20030-1

MODEL 709 MINI SUPREME BREAD SLICER

• Removing Blade Frames (Cont’d.):

The final step is to remove the shoulder screw from the foot of the blade frame. Once

the shoulder screw is removed the link can be disconnected and moved out of the way.

This will allow removal of the lower blade frame.

• Replacing Blade Frames:

To replace the blade frames, reverse the removal procedures, (described above). Re-

install both blade frames and check for slice thickness variances. If the spaces between

all blades are not the same see the “Adjustment” section of this manual. If the spacing

is equal, if there is little side to side movement of the blade frames and they move freely

in the tracks, re-connect the links at the foot of each blade frame by re-installing the

shoulder screw. Replace the lockwasher and nut on each shoulder screw and tighten

securely.

Replace the infeed table and secure it in position by installing its four screws. Rotate the

holddown back into the knives and replace and/or tighten their mounting screws.

Replace the table lip making sure it does not rub on the sides of the blades where the

blades pass thorough it. Lastly replace the top and front covers securing them in place

using the four screws previously removed from each.

0709S20030-2

MODEL 709 MINI SUPREME BREAD SLICER

• Changing Blades:

WARNING

BLADES ARE EXTREMELY SHARP. ALWAYS

HANDLE WITH CARE.

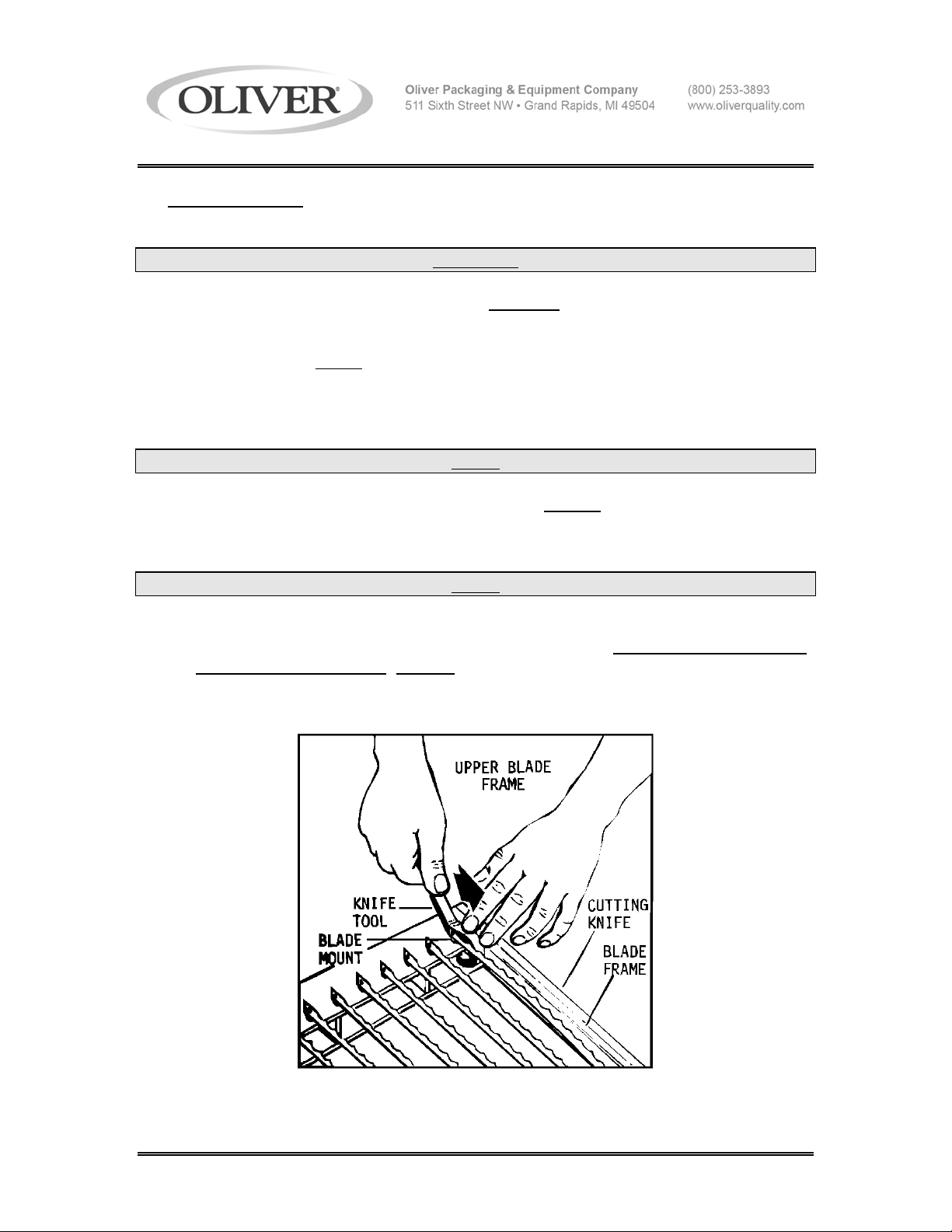

Remove and place the Upper

blade frame on a flat surface, (see blade frame removal

section). Insert the special knife tool into the blade frame, (See Illustration). Lifting up

on the knife tool will deflect the blade mount, reducing tension on the cutting knife.

Carefully remove the cutting knife from the blade mount.

NOTE

REMOVAL OF THE LOWER BLADE FRAME IS NOT

REQUIRED TO

CHANGE ITS BLADES.

NOTE

WHEN REPLACING ALL THE BLADES, ALWAYS REMOVE THE CENTER

BLADES FIRST AND WORK TOWARDS THE ENDS. REMOVE AND INSTALL

ONE BLADE AT A TIME, NEVER REMOVE ALL THE BLADES AT ONCE

AND THEN ATTEMPT TO REPLACE THEM ALL AT ONCE.

0709S20030-3

Loading...

Loading...