Grand Rapids, Michigan, U.S.A. 49504-5298

USER’S OPERATING AND INSTRUCTION MANUAL

MODEL 703

CLUSTER BUN

SLICER

703S20000-CV

MODEL 0703 CLUSTER BUN SLICER

INDEX

Section

Page Number

Description/Specification............................................................................ 0703S20014

Safety Instructions......................................................................................0703S20002

Setup & Operation......................................................................................0703S20003

Maintenance...............................................................................................0703S20004

Troubleshooting..........................................................................................0703S20015

Replacement Parts List............................................................................0703S20016-1

Assembly Drawing...................................................................................0703S20016-2

Electrical Diagram 115V…………………………………………..…………..0703S20018-1

Electrical Diagram 230V………………………………………………….......0703S20018-2

Warranty.................................................................................................... GEN 040225

Warranty Procedure …………………………………………………………… GEN 040226

Returned Parts Policy................................................................................ GEN 040227

0703S20017-1

MODEL 0703 CLUSTER BUN SLICER

DESCRIPTION / SPECIFICATION

Description

The Cluster Bun Slicer will slice two-wide groups of buns in a single operation leaving a

hinge on the buns in the middle. Two, four, six, eight or more buns can be sliced at one

time speeding the packaging process. The slicer can also be used for single bun

slicing.

The Model 703 Cluster Bun Slicer has a painted, welded steel frame. The chute, blade

and all other contact parts are stainless steel.

The slicer's blades are driven by two 1/3 HP, TENV, single phase, capacitor start,

thermoelectrically protected motors.

Physical specifications

Size: 29-3/8" long x 23-3/4" wide x 22-3/8" high

Weight: Approx. 150 lbs.

Product Capacities:

Cluster buns 9-3/4" (max.) 4" (min.) wide x 3-1/8 (max.) high

Single buns 4-7/8" (max.) 2" (min.) wide x 3-1/8 (max.) high

Cut height above table 5/8" (min.) 1-1/2" (max.)

Hinge approximately 1/2" (all buns)

Electrical Specifications

Note: Other electric’s are available (consult factory)

(2) 1/3 HP motors

1/50-60/115 12 amps standard, or 1/50-60/230 6 amps standard

0703S20014-1

OLIVER PRODUCTS COMPANY

MODEL 703 CLUSTER BUN SLICER

SAFETY INSTRUCTIONS

Every effort has been made by Oliver Products Company to provide

you with a safe machine. It is essential, however, that machine

operators and maintenance personnel observe the following safety

precautions.

1. Before attempting to operate your slicer read this

manual. Never allow an untrained person to operate this

machine.

2. CAUTION! If an extension cord will be used with this

slicer, the cord must be of a wire size no smaller than

#14 gauge and be no longer than (5) meters, (15 feet).

3. Make sure that the machine is only connected to a

properly grounded electrical supply source of sufficient

capacity for the load the slicer will put on it. Always

unplug the machine when it is not in use.

4. Always make sure the machine has been disconnected from

the power supply before cleaning or servicing.

5. Never stick your hand or any other objects into either

end of the chute. Keep your hands away from the moving

parts of the machine.

6. Never attempt to adjust or service this machine until the

blades have stopped.

7. All guards must be in place before starting the machine.

8. Handle knife blades with care. Do not touch the moving

knives.

9. Use only proper replacement parts.

10. In addition to these general safety instructions, also

follow the more specific safety instructions given for

the different areas of the machine in the operating

instructions.

Rev. 4-26-91 0703S20002

OLIVER PRODUCTS COMPANY

MODEL 703 CLUSTER BUN SLICER

SETUP & OPERATION

Removing the Slicer from the Skid

The slicer is bolted to the skid with four 1/4-20 bolts. Using a

pad to prevent damage to the finish of the slicer, carefully tip

the slicer onto its side. Never pick the slicer up or attempt to

move the slicer by its chute, always lift the slicer by its

frame. Remember, the slicer is heavy so use proper lifting

techniques to prevent personal injury. After tipping the slicer

on its side remove the four bolts securing the skid and remove

the skid.

Your machine was shipped with, (loose), four rubber feet and

their mounting hardware. Put one foot, secured with a hex bolt

and a lockwasher, at each of the brackets to which the skid was

mounted. After attaching all four feet the machine may be

carefully returned to its upright position.

Again using proper lifting techniques two people should be able

to move the slicer to the counter or table where it will be used.

Before moving the slicer it should be verified that this work

surface will be able to support the full weight of the slicer.

Before attempting to operate the machine make sure that all

operators have read this manual.

Adjustments

1. Adjusting Blade Height

The blade height above the table is adjusted by altering

the position of the table itself. This can be done by

loosening the four-prong locking knob and then rotating

the handwheel which is located below the locking knob in

the direction desired. Both can be found on the front of

the machine. When the table is at its lowest position

you will get a bottom slice of approximately 1-1/2". At

its highest position the bottom slice will be about 5/8".

After setting the table at the desired height secure it

in that position by retightening the locking knob.

0703S20003-1

2. Adjusting the Guides

When slicing double wide buns the guides should be set so

as to center the product on the chute. Place the product

in the center of the chute, loosen the knobs securing the

guides and slide each to within about 1/4" of the

product, retighten the knobs. As buns tend to vary in

size make sure that the largest expected group of buns

will slide freely down the chute and will not be caught

by guides which are set to tightly.

The guides should be set in a similar fashion for slicing

single buns, with the following exceptions. First the

guide with the longest brackets and closed slots should

be moved to its inner most position and secured. The

remaining guide should then be moved into the product

until you have 1/4" clearance on each side as was done on

the cluster buns above.

3. Adjusting the Overhead Holddown

The overhead holddown is adjusted by turning the two

knobs on the top of the machine, thus raising or lowering

the holddown. Normally the holddown can only be used on

product wider than 6". On product over 6" wide the

holddown should be lowered to within 1/4" of the largest

product to be sliced. This will allow the product to

slide freely down the chute yet preventing product "hop".

When slicing product below 6" in width the holddown

should be moved to its upper most position out of the way

of the side guides.

Operating Instructions

After the adjustments are made you are ready to begin slicing.

Start the motor by turning the on-off switch to the "ON"

position. Insert the product through the opening at the top of

the chute and allow it to slide down the chute into the blade.

Warning If the buns resist sliding freely into the blade

Never

stick your hand into the chute to aid them. Instead do

one of the following things.

1. Add additional buns to advance the first into slicing

position.

2. Add a little flour or corn meal to the top surface of the

table to aid bun movement.

0703S20003-2

Remember, if product should jam in the machine NEVER clear it

with your hands, instead, turn the machine off, disconnect it

from the power supply and wait until you are sure blade rotation

has stopped. Then clear the machine by using some type of flat

instrument (wood or plastic preferred).

Should the sliced bun stop under the discharge doors the next bun

through the blade will generally dislodge it.

0703S20003-3

OLIVER PRODUCTS COMPANY

MODEL 703 CLUSTER BUN SLICER

MAINTENANCE

Warning Never attempt to clean or service this machine until

it

has been disconnected from the power supply and you are

sure the blades have stopped. Also remember to use

care whenever you are working near the blades.

Cleaning

Use a mild detergent solution or spray cleaner on all exterior

and interior surfaces as necessary. Periodically remove the

overhead guard assembly and brush, or vacuum all foreign material

from below the chute and from the blade compartments.

Lubrication

No lubrication is required. The motor is equipped with

pre-lubricated sealed bearings which require NO lubrication--DO

NOT attempt to oil or grease the motor

Changing a Blade

Warning Do not attempt to service this machine until it has

been

disconnected from the power supply.

1. Remove the overhead guard assembly by removing the six

hex head screws which hold it in place, three on each

side over the blade. Lift the assembly clear of the

machine and set it one side.

2. Move each of the side guides to their inner most position

and retighten their securing knobs.

3. Using an "Allen" wrench remove the three screws securing

the blade to the hub and lift the blade from the machine.

4. The blade is replaced by reversing the above procedure.

5. When reinstalling the blades, make sure that the points

on the teeth are pointed in the opposite direction as the

rotation of the blade. Looking at the top of the motors,

(shaft end), with the top of the chute in the 12:00

o'clock position, the left hand motor rotates clockwise

while the right hand motor will be rotating counter

clockwise.

0703S20004

MODEL 0703 CLUSTER BUN SLICER

TROUBLESHOOTING

The slicer motor(s) will not start.

• Check to see if the machine is plugged in.

• If plugged in, is the outlet working? Test it with another, working, small appliance.

• Your slicer is protected by an overload in the on/off switch. To restart allow unit to

cool for approximately five minutes, press off button to reset the switch overload.

• Your slicer's motor is equipped with a thermal overload. Should the motor become

overheated it will stop. To restart allow the motor to cool for approximately five

minutes, then reset the overload by pressing the red button on the case of the motor.

• If you still can not find the problem have a qualified electrician check the unit's motor,

motor starter, and switch.

The slicer's motor(s) was running but suddenly stopped.

• Check to see if the machine's plug was accidentally removed.

• Your slicer is protected by an overload in the on/off switch. To restart allow unit to

cool for approximately five minutes, press off button to reset the switch overload.

• Your slicer's motor is equipped with a thermal overload. Should the motor become

overheated it will stop. To restart allow the motor to cool for approximately five

minutes, then reset the overload by pressing the red button on the case of the motor.

• If you still can not find the problem have a qualified electrician check the unit's motor,

motor starter, and switch.

0703S20015-1

MODEL 0703 CLUSTER BUN SLICER

REPLACEMENT PARTS LIST

ITEM

NO. PART DESCRIPTION PART NUMBER

001 Adapter-Blade 0700-0002

002 Frame-Cluster Bun Slicer 0703-0001-101

003 Key-3/16 Sq. x 1-3/8" 4384-0406-1375

004 Screw-Soc. Set 5/16-18 x 1/4 5842-6143

005 Screw-Hex Hd StSt 1/4-20 x 3/4 5843-1003

006 Screw-Soc Hd StSt 1/4-20 x 1/2 5843-1541

007 Washer-1/4 Lock StSt 5851-9357

008 Foot-Rubber 5902-0021

009 Knife-72 Tooth StSt 7107-7050

101 Table 0703-0002

102 Wheel-Thumb 0703-0003

103 Plate-Adjusting 0703-0004

104 Guide-RH 0703-0005-0001

105 Guide-LH 0703-0005-0022

106 Screw-Clamp 4560-2508-1108

107 Bearing-Bronze Thrust 5254-3507

108 Nut-StSt Elastic Lock 5831-9091

109 Screw-Hex Hd 1/4-20 x 1/2 5842-150

110 Washer-1/4 STD. WROUGHT 5851-8402

111 Washer-1/4 Lock 5851-9008

112 Washer-1/4 Flat StSt 5851-9304

113 Handle-Kipp 5908-5004

201 Guard-Overhead 0703-0006

202 Guard-Chute 0703-0007

203 Holddown-Overhead 0703-0008

204 Bearing-Bronze Flange 5254-3110

205 Nut-StSt Acorn 1/2-13 5832-0583

206 Screw-Hex Hd StSt 1/4-20 x 1/2 5843-1001

207 Washer-1/2 Flat StSt 5851-9308

208 Washer-1/4 Lock StSt 5851-9357

209 Knob-4 Prong 5911-7103

210 Spring-Compression 7015-4103

211 Channel-Rubber 8" Lg 6516-0004

301 Scale-1 thru 8 6402-8003

302 Scale-8 thru 1 6402-8004

401 Motor-1/3 HP 1-50/60-115/230 6301-1641

407 Enclosure-Switch 0705-0008-1

409 Light-Pilot (115V) 5709-0190

409 Light-Pilot (230V) 5709-0191

410 Starter-Manual 10-16A (115V) 5709-3043

410 Starter-Manual 6.3-10A (230V) 5709-3042

0703S20016-1

MODEL 0703 CLUSTER BUN SLICER

0703S20016-2

MODEL 0703 CLUSTER BUN SLICER

WIRING DIAGRAM – 115V

0703C12003

0703S20018-1

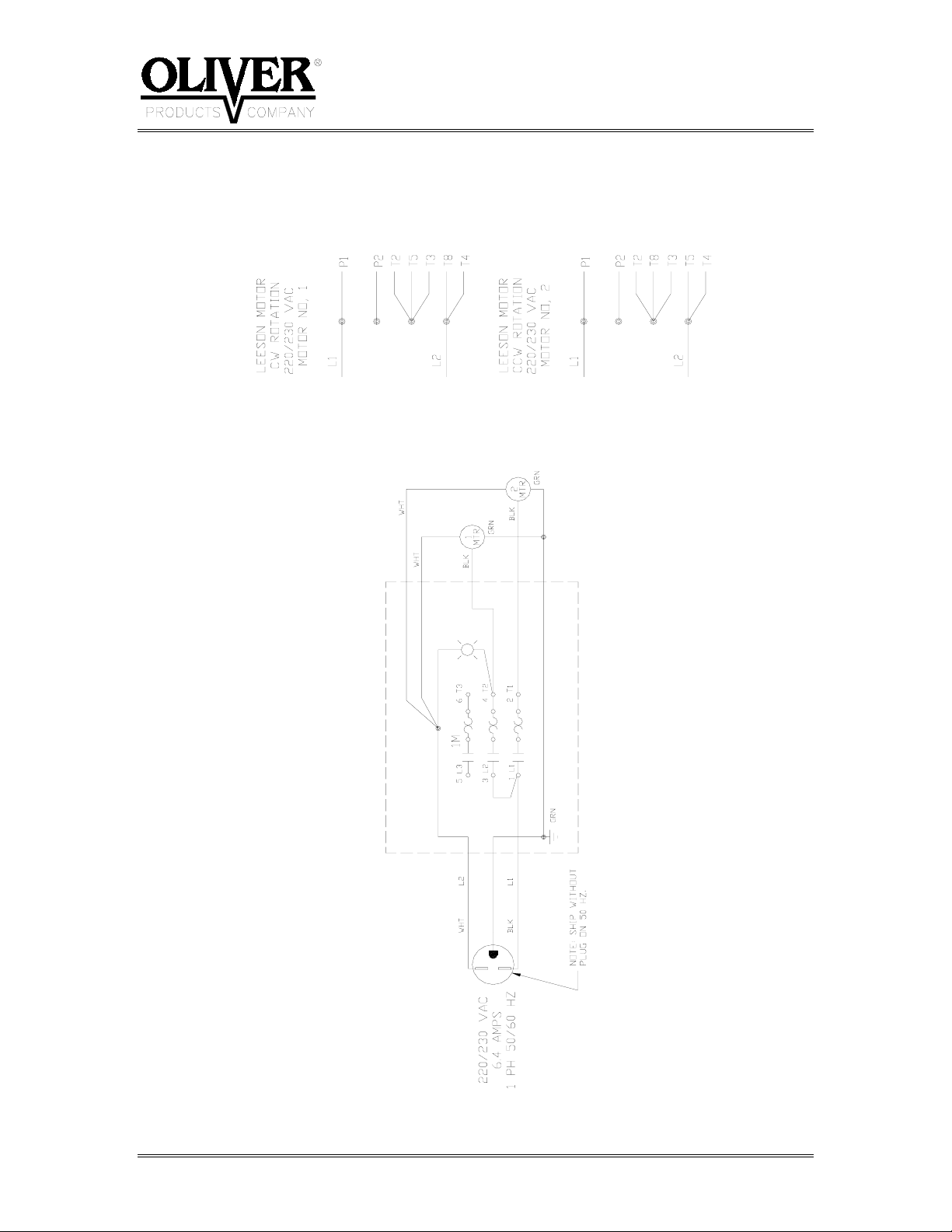

MODEL 0703 CLUSTER BUN SLICER

WIRING DIAGRAM – 230V

0703C12004

0703S20018-2

WARRANTY

PARTS

Oliver Products Company (Oliver) warrants that if any part of the equipment (other than a part not

manufactured by Oliver) proves to be defective (as defined below) within one year after shipment,

and if Buyer returns the defective part to Oliver within one year, Freight Prepaid to Oliver’s plant in

Grand Rapids, MI, then Oliver, shall, at Oliver’s option, either repair or replace the defective part, at

Oliver’s expense.

LABOR

Oliver further warrants that equipment properly installed in accordance with our special instructions,

which proves to be defective in material or workmanship under normal use within one (1) year from

installation or one (1) year and three (3) months from actual shipment date, whichever date comes

first, will be repaired by Oliver or an Oliver Authorized Service Dealer, in accordance with Oliver’s

published Service Schedule.

For purposes of this warranty, a defective part or defective equipment is a part or equipment which is

found by Oliver to have been defective in materials workmanship, if the defect materially impairs the

value of the equipment to Buyer. Oliver has no obligation as to parts or components not

manufactured by Oliver, but Oliver assigns to Buyer any warranties made to Oliver by the

manufacturer thereof.

This warranty does not apply to:

1. Damage caused by shipping or accident.

2. Damage resulting from improper installation or alteration.

3. Equipment misused, abused, altered, not maintained on a regular basis, operated carelessly, or

used in abnormal conditions.

4. Equipment used in conjunction with products of other manufacturers unless such use is approved

by Oliver Products in writing.

5. Periodic maintenance of equipment, including but not limited to lubrication, replacement of wear

items, and other adjustments required due to installation, set up, or normal wear.

6. Losses or damage resulting from malfunction.

The foregoing warranty is in lieu of all other warranties expressed or implied AND OLIVER MAKES

NO WARRANTY OF MERCHANTABILITY OR FITNESS FOR PURPOSE REGARDING THE

EQUIPMENT COVERED BY THIS WARRANTY. Oliver neither assumes nor authorizes any person

to assume for it any other obligations or liability in connection with said equipment. OLIVER SHALL

NOT BE LIABLE FOR LOSS OF TIME, INCONVENIENCE, COMMERCIAL LOSS, INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

GEN 040225

WARRANTY PROCEDURE

1. If a problem should occur, either the dealer or the end user must contact the Customer

Service Department and explain the problem.

2. The Customer Service Manager will determine if the warranty will apply to this particular

problem.

3. If the Customer Service Manager approves, a Work Authorization Number will be

generated, and the appropriate service agency will perform the service.

4. The service dealer will then complete an invoice and send it to the Customer Service

Department at Oliver Products Company.

5. The Customer Service Manager of Oliver Products Company will review the invoice and

returned parts, if applicable, and approve for payment.

GEN 040226

RETURNED PARTS POLICY

This policy applies to all parts returned to the factory whether for warranted credit,

replacement, repair or re-stocking.

Oliver Products Company requires that the customer obtain a Return Material Authorization

(RMA) number before returning any part. This number should appear on the shipping label

and inside the shipping carton as well. All parts are to be returned prepaid. Following this

procedure will insure prompt handling of all returned parts.

To obtain an RMA number contact the Repair Parts Deptartment toll free at (800) 253-3893.

Parts returned for re-stocking are subject to a RE-STOCKING CHARGE.

Thank you for your cooperation,

Repair Parts Manager

Oliver Products Company

GEN 040227

Loading...

Loading...