Oliver 4680 Owner's Manual

4680 Band Resaw

Owner’s Manual

Oliver Machinery M-4680 10/2013

Seattle, WA Copyright 2013

info@olivermachinery.net www.olivermachinery.net

Warranty

Oliver makes every effort possible to assure that its equipment meets the highest possible standards of

quality and durability. All products sold by Oliver are warranted to the original customer to be free from

defects for a period of 2 (two) years on all parts, excluding electronics and motors, which are warranted for

1 year. Oliver’s obligation under this warranty shall be exclusively limited to repairing or replacing (at Ol-

iver’s option) products which are determined by Oliver to be defective upon delivery F.O.B. (return freight

paid by customer) to Oliver, and on inspection by Oliver. This warranty does not apply to defects due,

directly or indirectly, to misuse, abuse, negligence, accidents, unauthorized repairs, alterations, lack of

maintenance, acts of nature, or items that would normally be consumed or require replacement due to

normal wear. In no event shall Oliver be liable for death, personal or property injury, or damages arising

from the use of its products.

Warning

Read this manual thoroughly before operating the machine. Oliver Machinery disclaims any liability for

machines that have been altered or abused. Oliver Machinery reserves the right to effect at any time,

without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

For More Information

Oliver Machinery is always adding new Industrial Woodworking products to the line. For complete,

up-to-date product information, check with your local Oliver Machinery distributor, or visit

www.olivermachinery.net

SECTION 1:SPECIFICATION

4

SECTION 2:SAFETY

5~8

SECTION 3:CIRCUIT REQUIREMENTS

9

SECTION 4:GENERAL INFORMATION

10

SECTION 5:MACHINE FEATURES

11~12

SECTION 6:INSTALLATION

13~15

SECTION 7:CONTROL PANEL SYSTEM

16~17

SECTION 8:ADJUSTMENT INSTRUCTION

18~24

SECTION 9:MAINTENANCE

24~29

SECTION 10:OPTIONAL-MIST COOLANT SYSTEM

30~31

4

SECTION 1:SPECIFICATIONS

----------------------------------------------------------------------------------

Model

SINGLE HEAD BAND SAW

Max. Workpiece Size

300mm(W) x 250mm(H)(12"x10")

Conveyor Belt Size

285mm(W) x 5470mm(L)

Saw Wheel Diameter

28"

Saw Wheel Width

1"

Saw Blade Size

168"( L )x1"( W )

Dust Hood Diameter

4"x4

Main Specifications:Digital Readout Type

CH-525

In-feed Speed

5~25M/m

Controlling Blade Tension

Hydraulic System

Main Motor:Horsepower

20HP

Voltage / Cycle / Phase

Hydraulic System Motor:In-feed Speed

OMP200

Horsepower

3HP

Construction:Base Construction

Steel

Saw Wheel

Steel

Conveyor Belt

Steel

Conveyor Table

Rubber

Saw Blade Guide

Steel

Machine Dimensions

210cm(L) x 112cm(W) x 100cm(T)

286cm(L) x 64cm(W) x 60cm(T)

Machine Weight

700kgs

200kgs

Packing Type

Pallet

Packing Dimensions

210cm(L ) x 112cm(W) x 114cm(T)

287cm(L) x 65cm(W) x 77cm(T)

Packing Weight

780kgs

280kgs

Country of Origin

Taiwan

Warranty

1 year

5

SECTION 2:SAFETY

----------------------------------------------------------------------------------

WARNING:

For Your Own Safety, Read Instruction Manual before Operating this Equipment

The purpose of safety symbols is to attract your attention to possible hazardous conditions. This manual

uses a series of symbols and signal words which are intended to convey the level of importance of the

safety messages. The progression of symbols is described below. Remember that safety messages by

themselves do not eliminate danger and are not a substitute for proper accident prevention measures.

DANGER:

Indicates an imminently hazardous situation which, if not avoided, WILL result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation which, if not avoided, COULD result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation which, if not avoided, MAY result in minor or moderate injury.

It may also be used to alert against unsafe practices.

NOTICE:

This symbol is used to alert the user to useful information about proper operation of the equipment.

WARNING:

Safety Instructions for Power Tools

1. Keep guards in place and in working order.

2. Remove adjusting keys and wrenches. Form habit of checking to see that keys and adjusting wrenches

are removed from tool before turning on.

3. Keep work area clean. Cluttered areas and benches invite accidents.

4. Do not use in dangerous environment. Do not use power tools in damp or wet locations, or where any

flammable or noxious fumes may exist. Keep work area well lighted.

5. Keep children and visitors away. All children and visitors should be kept at a safe distance from work

area.

6. Make workshop child proof with padlocks, master switches, or by removing starter keys.

7. Do not force tool. It will do the job better and safer at the rate for which it was designed.

8. Use right tool. Do not force tool or attachment to do a job for which it was not designed.

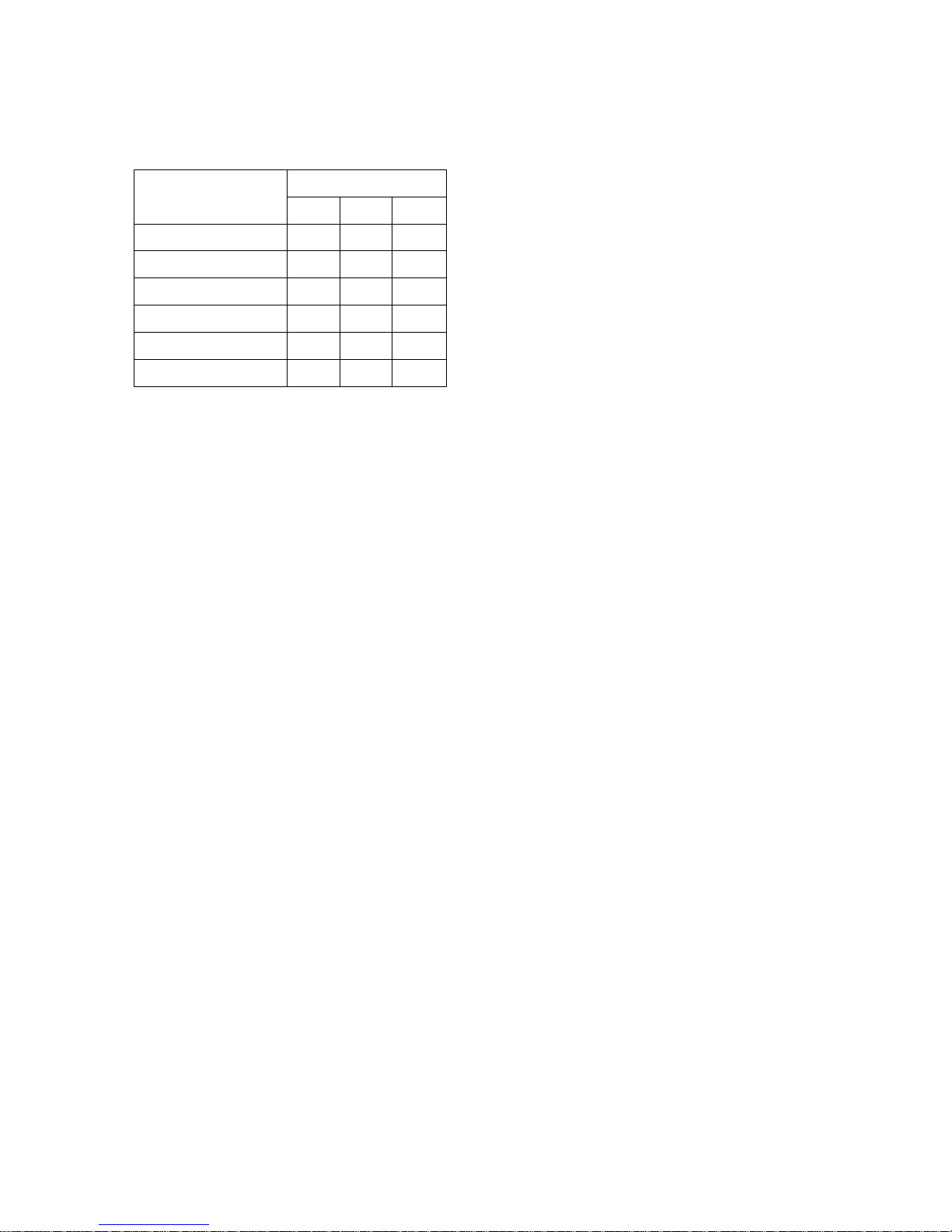

9. Use proper extension cord. Make sure your extension cord is in good condition. Conductor size should

be in accordance with the chart below. The amperage rating should be listed on the motor or tool

6

nameplate. An undersized cord will cause a drop in line voltage resulting in loss of power and

overheating. Your extension cord must also contain a ground wire and plug pin. Always repair or

replace extension cords if they become damaged.

Minimum gauge for extension cords

AMP RATING

LENGTH

25ft

50ft

100ft

0-6

16

16

14

7-10

16

16

14

11-12

16

16

14

13-16

14

12

12

17-20

12

12

10

21-30

10

10

No

10. Wear proper apparel. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry

which may get caught in moving parts. Non-slip footwear is recommended. Wear protective hair

covering to contain long hair.

11. Always use safety glasses. Also use face or dust mask if cutting operation is dusty. Everyday

eyeglasses only have impact resistant lenses, they are not safety glasses.

12. Secure work. Use clamps or a vise to hold work when practical. It is safer than using your hand and

frees both hands to operate tool.

13. Do not overreach. Keep proper footing and balance at all times.

14. Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow

instructions for lubricating and changing accessories.

15. Use recommended accessories. Consult the instruction manual for recommended accessories. The use

of improper accessories may cause risk of injury.

16. Reduce the risk of unintentional starting. On machines with magnetic contact starting switches there

is a risk of starting if the machine is bumped or jarred. Always disconnect from power source before

adjusting or servicing. Make sure switch is in off position before reconnecting.

17. Many woodworking tools can “kickback” the workpiece toward the operator if not handled properly.

Know what conditions can create “kickback” and know how to avoid them. Read the manual

accompanying the machine thoroughly.

18. Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function. Check

for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other

conditions that may affect its operation. A guard or other part that is damaged should be properly

repaired or replaced.

19. Never leave tool running unattended. Turn power off. Do not leave tool until it comes to a complete

stop.

20. Never operate a machine when tired, or under the influence of drugs or alcohol. Full mental alertness

is required at all times when running a machine.

21. Never allow unsupervised or untrained personnel to operate the machine. Make sure any instructions

HP-11P 7

you give in regards to the operation of the machine are approved, correct, safe, and clearly

understood.

WARNING:

Additional Safety Instructions for Bandsaw

1. Do not operate with dull or badly worn blades. Dull blades require more demand on the motor and are

less likely to cut precisely. Inspect blades before each use.

2. Never position fingers or thumbs in line with the cut. Serious personal injury could occur.

3. Do not operate this bandsaw without wheel guards, pulley guards, and blade guards in place.

4. When replacing blades, make sure the teeth face toward the front of the saw.

5. Cuts should always be fully supported against the side of the conveyor table and by the pressure rollers.

6. Do not back workpiece away from the blade while the saw is running. If you need to back the work out,

stop the bandsaw and wait for the blade to stop. Do not twist or put excessive stress on blade while

backing work away.

7. Blade should be running at full speed before beginning a cut.

8. Always feed stock evenly and smoothly. Do not change conveyor speeds during a cut.

9. This machine is not designed to cut metal or other material except wood.

10. Do not manually stop or slow blade after turning the saw off. Allow it to come to a complete stop

before you leave it unattended.

11. All inspections, adjustments, and maintenance must be done with the power off and the circuit breaker

shut off. Wait for all moving parts to come to a complete stop.

12. Habits – good and bad – are hard to break. Develop good habits in your shop and safety will become

second- nature to you.

13. If at any time you are experiencing difficulties performing the intended operation, stop using the

bandsaw. Then contact our service department or ask a qualified expert how the operation should be

performed.

14. Make sure blade is properly tensioned before operating machine.

15. Keep loose clothing and long hair away from moving conveyors!

WARNING:

Like all power tools, there is danger associated with the Model HP-11P. Accidents are frequently caused

by lack of familiarity or failure to pay attention. Use this tool with respect and caution to lessen the

possibility of operator injury. If normal safety precautions are overlooked or ignored, serious personal

injury may occur.

CAUTION:

No list of safety guidelines can be complete. Every shop environment is different. Always consider safety

first, as it applies to your individual working conditions. Use this and other machinery with caution and

respect. Failure to do so could result in serious personal injury, damage to equipment, or poor work

results.

HP-11P 8

WARNING:

Additional Safety Instructions for Hydraulics

1. Be familiar with the hazards of hydraulic injection injuries. Leaking hydraulic fluid may have enough

pressure to penetrate skin. Never use your hands to check for suspected hydraulic leaks.

Hydraulic fluid that is injected into skin is a medical emergency that may cause infection, disability,

amputation or death.

The average injection injury may be a small wound that has barely broken the skin. Do not be fooled

by this type of injury. Immediately get to an emergency medical facility!

Minimizing the time between the injury and when the injected material is removed is critical to

minimizing the seriousness of the injury.

2. Use a piece of cardboard to check for suspected hydraulic leaks. Pressurized hydraulic fluid may cause

injection injuries and can be extremely hot. Never use your hands to check for suspected hydraulic

leaks.

3. Protect your eyes around hydraulic systems. Safety glasses may not always protect your eyes from hot,

pressurized fluid. The best way to protect yourself is to stay away from leaks until you can depressurize

the system.

4. Stop the machine if you notice a hydraulic leak. Allowing the machine to continue running with a leak

may increase the hazard of the situation.

5. Depressurize the hydraulic system before attempting to adjust any hydraulic lines or fittings. Stop the

resaw, open the conveyor speed valves, and make sure the pressure gauge reads 0 psi.

6. Depressurize the hydraulic system before attempting any maintenance or service. Stop the resaw, open

the conveyor speed valves, and make sure the pressure gauge reads 0 psi.

7. Regularly inspect and perform the proper maintenance on the hydraulic system. A well-maintained

hydraulic system will have much few problems and hazards than a neglected system.

8. Make sure any hydraulic system maintenance is performed in a clean and dust-free work area. Remove

any sawdust, grime or water from hydraulic system openings or components before maintenance.

Always use lint-free rags when wiping components.

9. Only use high pressure hydraulic hose and steel hydraulic fittings when replacing components in the

hydraulic system. Do not use brass or aluminum.

WARNING:

Additional Safety Instructions for Machine Lifting

1. Use enough capacity of forklift to raise or move the machine.

2. Pay special attention to the machine balance while in lifting.

3. Have another person to help guiding the way when lifting the machine.

4. Make sure the fork of the forklift protrudes over the machine bottom.

5. Do not raise the machine too high as this will cause poor stability.

6. Forklift should be driven by experienced personnel only.

9

SECTION 3:CIRCUIT REQUIREMENTS

-------------------------------------------------------------------------------------

WARNING:

Serious personal injury could occur if you connect your machine to the power source before you have

completed the setup process. Do not connect the machine to the power source until instructed to do so.

The Model is wirHG for 3-phase operation.

The Model has 20 HP main motor.

Circuit Breaker Requirements

Install your bandsaw on a dedicated circuit to reduce the possibility of overloading the circuit and tripping

the circuit breaker. However, if an unusual load does not exist, and the circuit breaker still trips, have the

circuit inspected by a qualified electrician. Never use a larger circuit breaker than stated below, or you

will increase the risk of fire.

Connection Type

Because of the high amperage draw from this machine, we recommend that you hardwire it directly to

your circuit breaker and install a locking shut-off lever near the machine as a way to quickly disconnect

the power.

Your factory Circuit Capacity

Always check to see if the wires in your circuit are capable of handling the amperage draw from your

machine, as well as any other machines that could be operating on the same circuit. If you are unsure,

consult a qualified electrician.

If the circuit breaker trips or the fuse blows regularly, your machine may be operating on a circuit that is

close to its amperage draw capacity. However, if an unusual amperage draw does not exist and a power

failure still occurs, refer to the troubleshooting section in this manual or contact a qualified electrician or

our service department.

CAUTION:

Be sure that your particular electrical configuration complies with local and state codes. The best way to

ensure compliance is to check with your local municipality or a licensed electrician.

Loading...

Loading...