Oliver 4420 Owner's Manual

4420 16” Planer

Owner’s Manual

Oliver Machinery M-4630 9/2019

Seattle, WA Copyright 2019

info@olivermachinery.net www.olivermachinery.net

1

Warranty

Oliver makes every effort possible to assure that its equipment meets the highest possible standards of

quality and durability. All products sold by Oliver are warranted to the original customer to be free from

defects for a period of 2 (two) years on all parts, excluding electronics and motors, which are warranted for 1

year. Oliver’s obligation under this warranty shall be exclusively limited to repairing or replacing (at Oliver’s

option) products which are determined by Oliver to be defective upon delivery F.O.B. (return freight paid by

customer) to Oliver, and on inspection by Oliver. This warranty does not apply to defects due, directly or

indirectly, to misuse, abuse, negligence, accidents, unauthorized repairs, alterations, lack of maintenance,

acts of nature, or items that would normally be consumed or require replacement due to normal wear. In no

event shall Oliver be liable for death, personal or property injury, or damages arising from the use of its

products.

Warning

Read this manual thoroughly before operating the machine. Oliver Machinery disclaims any liability for

machines that have been altered or abused. Oliver Machinery reserves the right to effect at any time, without

prior notice, those alterations to parts, fittings, and accessory equipment which they may deem necessary for

any reason whatsoever.

For More Information

Oliver Machinery is always adding new Industrial Woodworking products to the line. For complete, up-todate product information, check with your local Oliver Machinery distributor, or visit www.olivermachinery.net

.

PROP 65 NOTICE:

WARNING: Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to the State of California to cause cancer and birth defects or other reproductive

harm.

Some examples of these chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically treated lumber.

Your risk from exposure to these chemicals varies, depending on how often you do this type of work. To

reduce

your exposure, work in a well-ventilated area and with approved safety equipment, such as dust masks that

are

specially designed to filter out microscopic particles. For more information go to www.P65Warnings.ca.gov.

All efforts have been made to ensure that the information in this catalog is accurate. However, Oliver

Machinery does not guarantee the accuracy of this information and reserves the right to change information in

this catalog without notification.

2

For Your Own Safety Read Instruction Manual Before Operating This Tool

Read this manual completely and observe all warning labels on the machine. This machine has made every

attempt to provide a safe, reliable, easy-to-use piece of machinery. Safety, however, is ultimately the

responsibility of the individual machine operator. As with any piece of machinery, the operator must exercise

caution, patience, and common sense to safely run the machine. Before operating this product, become

familiar with the safety rules in the following sections.

1. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

2. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet locations,

or expose them to rain. Keep work area well lighted.

3. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

4. MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter keys.

5. USE RIGHT TOOL Don't force tool or attachment to do a job for which it was not designed.

6. WEAR PROPER APPAREL Do not wear loose clothing, gloves, neckties, rings, bracelets, or

other jewelry which may get caught in moving parts. Nonslip footwear is recommended. Wear

protective hair covering to contain long hair.

7. ALW AYS USE SAFETY GLASSES. Also use face or dust mask if cutting operation is dusty.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

8. SECURE WORK. Use clamps or a vise to hold work when practical. It's safer than using your

hand and it frees both hands to operate tool.

9. DON'T OVERREACH. Keep proper footing and balance at all times.

10. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest performance.

Follow instructions for lubricating and changing accessories.

11. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch is in off position

before plugging in.

12. USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended

accessories. The use of improper accessories may cause risk of injury to persons.

13. CHECK DAMAGED PARTS. Before further use of the tool, a guard or other part that is

damaged should be carefully checked to determine that it will operate properly and perform its

intended function - check for alignment of moving parts, binding of moving parts, breakage of

parts, mounting, and any other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced.

14. DIRECTION OF FEED. Feed work into a blade or cutter against the direction of rotation of the

blade or cutter only.

15. NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don't leave tool until it

comes to a complete stop.

16. Wear eye protection.

3

17. KEEP GUARDS IN PLACE and in working order.

18. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and

adjusting wrenches are removed from tool before turning it on.

19. DON'T FORCE TOOL It will do the job better and safer at the rate for which it was designed.

20. DISCONNECT TOOLS before servicing; when changing accessories, such as blades, bits,

cutters, and the like.

21. NEVER STAND ON TOOL. Serious injury could occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals, work in a well-ventilated area, and work with

approved safety equipment, such as those dust masks that are specifically designed to filter out

microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

CAUTION: (This means that if precautions are not heeded, it may result in minor or moderate

injury and/or possible machine damage)

WARNING: (This means that if precautions are not heeded, it could result in serious injury or

possibly even death).

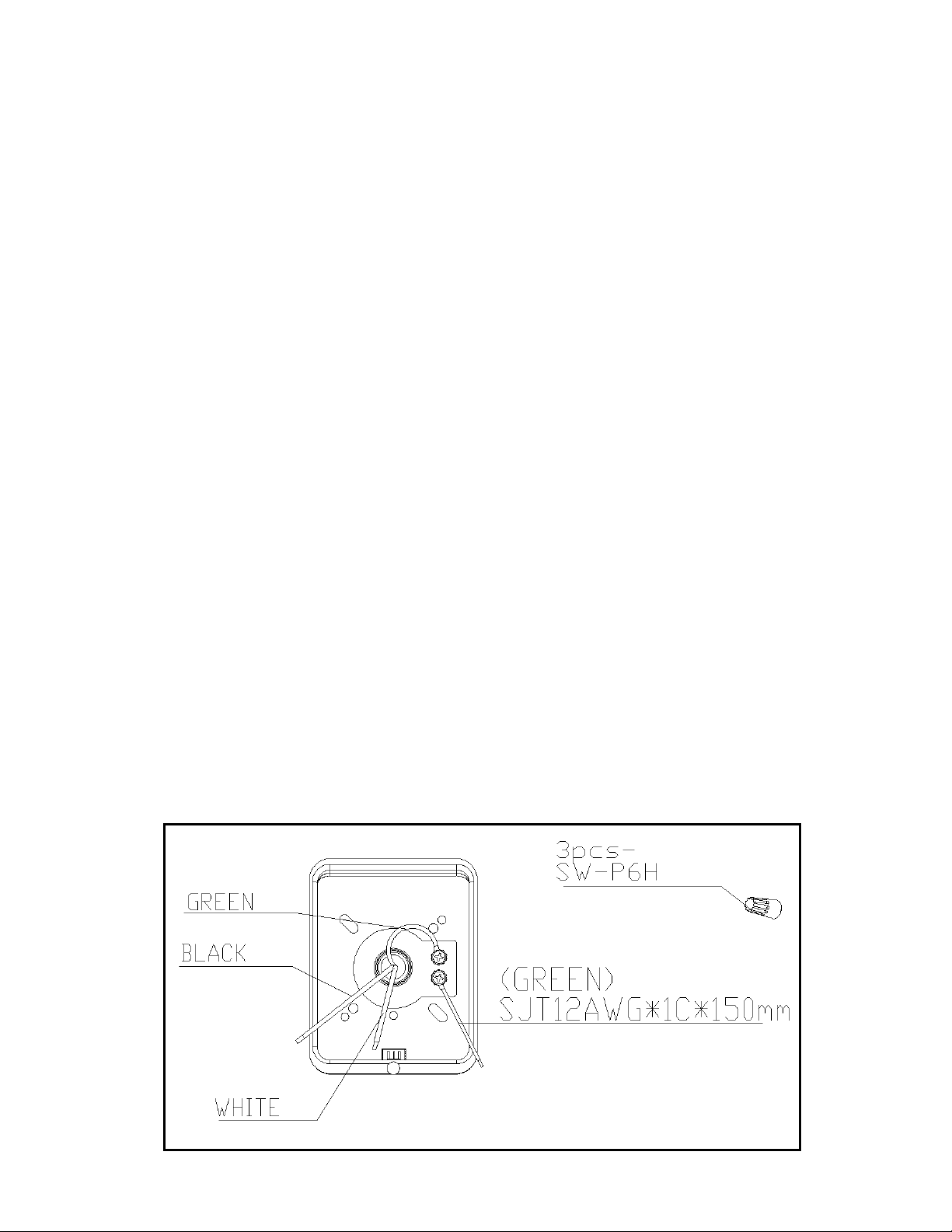

Grounding

This tool should be connected to a grounded metal permanent wiring system; or to a system having

an equipment-grounding conductor.

4

Table of Contents Page Number

Warranty ........................................................................................................................................................ 2

Warnings .................................................................................................................................................... 3-4

Table of Contents .......................................................................................................................................... 5

Specifications ................................................................................................................................................ 5

Receiving the planer ..................................................................................................................................... 6

Unpacking the Machine ................................................................................................................................. 6

Machine Preparation and Setup .................................................................................................................... 7

Assembly ....................................................................................................................................................... 7

Knife Replacement ........................................................................................................................................ 8

Switch safety lock .......................................................................................................................................... 8

Lubrication Schedule ..................................................................................................................................... 9

Depth of Cut ................................................................................................................................................ 10

Pulley Alignment.......................................................................................................................................... 10

V-belt Tensioning ........................................................................................................................................ 10

Feed Speed ................................................................................................................................................. 11

Return Rollers ............................................................................................................................................. 11

Feed Rollers ................................................................................................................................................ 11

Table Rollers ............................................................................................................................................... 12

Table Parallelism ......................................................................................................................................... 12

Feed Rollers and Chip breaker ................................................................................................................... 13

Adjustment of Chip Breaker .................................................................................................................. 14

Adjustment of Feed Rollers .................................................................................................................. 14

Digital Readout ............................................................................................................................................ 15

Parts ....................................................................................................................................................... 16-25

Specifications

Stock No. ........................................................................................ (5HP, 1Ph Helical Cutterhead) 4420.001

Maximum Stock Width (in.) ......................................................................................................................... 16

Maximum Depth of Cut (in.) ....................................................................................................................... 1/8

Maximum Stock Thickness (in.) .................................................................................................................... 6

Minimum Stock Thickness (in.) .................................................................................................................. 1/8

Minimum Stock Length (in.) .......................................................................................................................... 6

Dust Port Diameter (in.) ................................................................................................................................ 4

Minimum CFM Required ........................................................................................................................... 600

Feed Speeds (FPM) ........................................................................................................................ 16 and 20

Bed Rollers ................................................................................................................................. 2, Adjustable

Overall Dimension When Assembled (L x W x H in.) ............................................................ 48 x 28 x 43-1/2

Cutterhead Diameter (in.) ........................................................................................................................ 2-7/8

Number of Knives ........................................................................................................................................ 90

Cutterhead Speed (RPM) ........................................................................................................................ 4800

Motor ............................................................................................................................. 5HP, 1Ph, 220V Only

Gross Weight (lbs.).................................................................................................................................... 675

5

16” PLANER

Thank you for choosing this planer.

This unit is carefully tested and inspected before

shipment and if properly used and maintained, will

provide you with many years of reliable service. To

ensure optimum performance and trouble free

operation a reasonable amount of care and attention is

required. To get the most from your new planer, please

take the time to read this manual before assembling,

installing and operating the unit.

UNPACKING AND CLEANING

To ensure maximum performance from your 16" planer,

clean it properly; and install it accurately before use. As

soon as you receive the planer, we recommend you

follow these procedures:

1. Remove the contents of the shipping container.

2. Report damage, if any to your local distributor.

3. Clean all rust protected surfaces with a mild solvent

or kerosene. Do not use lacquer thinner; paint thinner,

or gasoline. These will damage painted surfaces.

4. To prevent rust, apply a light coating of paste wax to

surface.

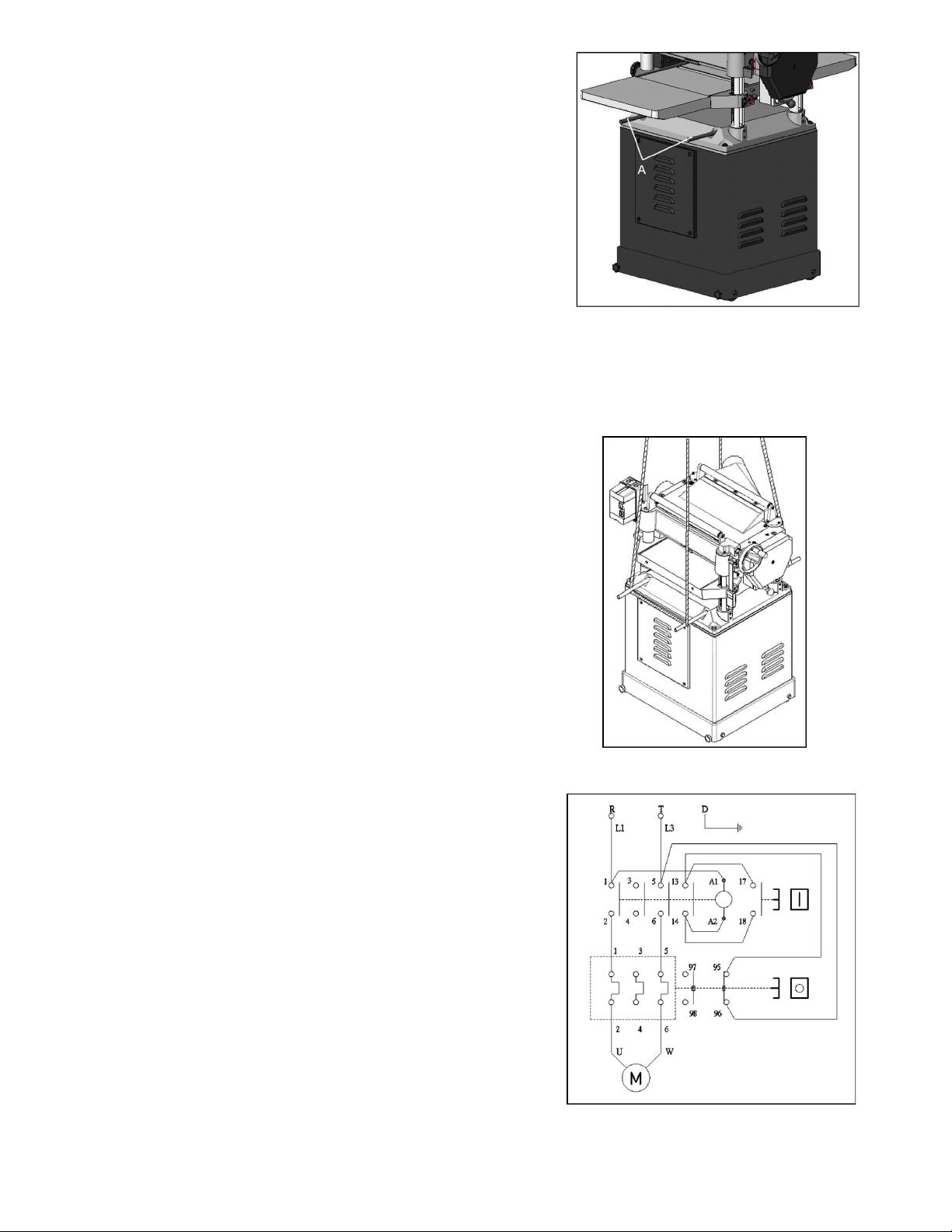

CARRIAGE

The planer has four lifting handles (A), that can be

pulled out when needed. (Fig.1)

USING A SLING

When using a sling to carry machine, lifting handles

must be pulled out (Fig.2). Try keeping sling parallel to

machine and hold steady.

MAGNETIC CONTACTOR CURCUIT

FI G. 3

- Single phase motor

- Power source: A,C in put

- Motor source : A,C, out put

- Grounding: D

Fig. 1

Fig. 2

Fig. 3

6

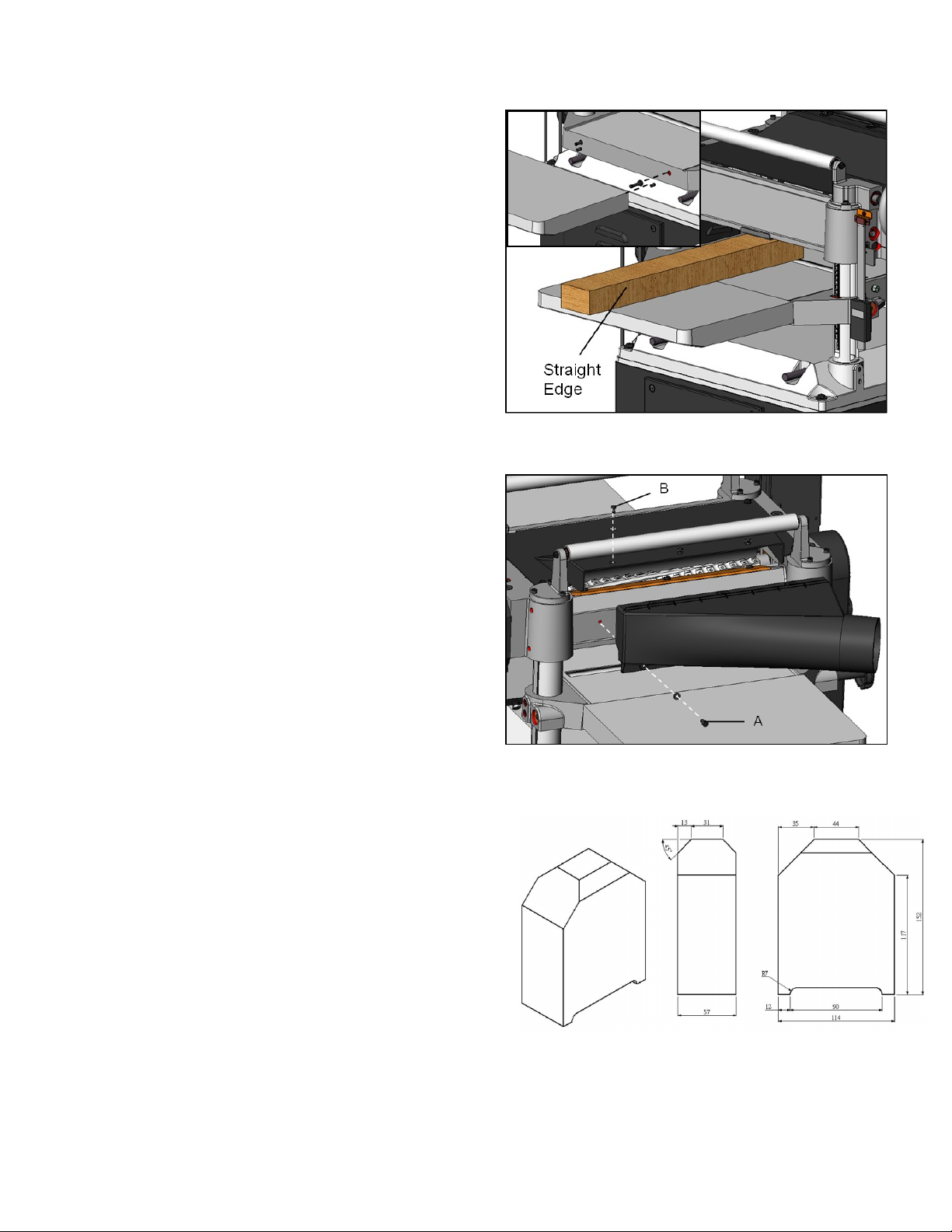

EXTENSION TABLE ASSEMBLY

Ask another person to provide assistance to hold an

extension table. Bolt the table to the machine using the

supplied bolts then place a straight edge on the table

as shown if Fig. 4. If they are not aligned, loosen the

bolts and adjust the alignment screws accordingly and

the tighten back the main bolts.

WARNING: Always disconnect the machine from

the power source before assembly or any servicing

to the machine.

DUST CHUTE ASSEMBLY

Mount the dust chute to the planer hood with hex head

screws and washers (A) & (B). Make sure the dust

collection system has sufficient capacity and

suction for your planer. Always turn on the

dust collection system before starting the planer.

Figure 5

Fig. 4

CONSTRUCTING GAUGE BLOCK

Your Oliver planer has been adjusted at the factory and

should not need adjustment. Typically poor

performance can be attributed to dull knives however if

the knives are in good order it may be time to check the

machine. Construct a guage block as shown if Fig. 6.

Machine adjustments are found further along in this

manual.

Fig. 5

Fig. 6

7

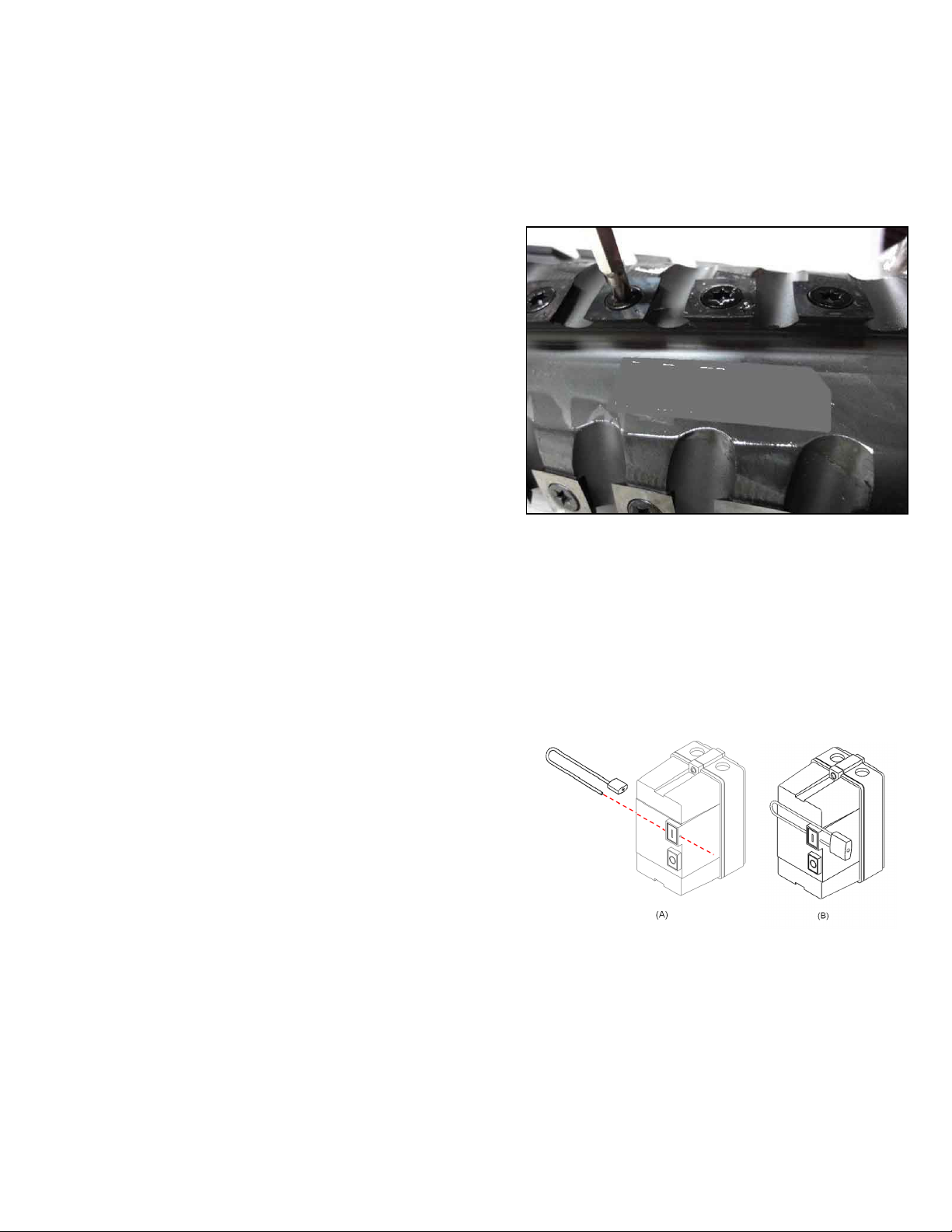

Knife Replacement

Knife inserts are dangerously

sharp. Use extreme caution when inspecting,

removing, or replacing knife inserts.

The knife inserts on the Jointer are four-sided. When

dull, simply remove each insert, rotate it 90° for a fresh

edge, and re-install it. No further adjustment is

necessary. Use the two provided torx wrench to

remove the knife insert screw. Use one of the torx

wrenches to help hold the cutterhead in Position, and

the other to remove the screw. See Fig. 7. It is

advisable to rotate all inserts at the same time to

maintain consistent cutting. However, if one or more

knife inserts develops a nick, rotate only those inserts

that are affected.

Each knife insert has an etched reference mark so you

can keep track of the rotations.

IMPORTANT:

clean saw dust from the screw, the insert, and the

cutterhead platform. Dust accumulation between

these elements can prevent the insert from seating

properly, and may affect the quality of the cut.

Before installing each screw, lightly coat the screw

threads with machine oil and wipe off any excess.

Securely tighten each screw which holds the knife

inserts before operating the jointer! Loose inserts

can be propelled at high speed from a rotating

cutterhead, causing injury.

When removing or rotating inserts,

SWITCH

The planer is equipped with magnetic

switch that will accept a safety padlock

(not included). See Fig. 8. To safeguard

your machine from unauthorized operation

and accidental starting by young children,

the use of a padlock is required.

Fig. 7

Fig. 8

8

Loading...

Loading...