Oliver 4060 Owner's Manual

4060 16” Professional Tablesaw

Owner’s Manual

Oliver Machinery M-4060 09/2008

Seattle, WA Copyright 2003

info@olivermachinery.net www.olivermachinery.net

Warranty

Oliver makes every effort possible to assure that its equipment meets the highest possible standards of

quality and durability. All products sold by Oliver are warranted to the original customer to be free from

defects for a period of 2 (two) years on all parts, excluding electronics and motors, which are warranted

for 1 year. Oliver’s obligation under this warranty shall be exclusively limited to repairing or replacing (at

Oliver’s option) products which are determined by Oliver to be defective upon delivery F.O.B. (return

freight paid by customer) to Oliver, and on inspection by Oliver. This warranty does not apply to defects

due, directly or indirectly, to misuse, abuse, negligence, accidents, unauthorized repairs, alterations, lack

of maintenance, acts of nature, or items that would normally be consumed or require replacement due to

normal wear. In no event shall Oliver be liable for death, personal or property injury, or damages arising

from the use of its products.

Warning

Read this manual thoroughly before operating the machine. Oliver Machinery disclaims any liability for

machines that have been altered or abused. Oliver Machinery reserves the right to effect at any time,

without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

For More Information

Oliver Machinery is always adding new Industrial Woodworking products to the line. For complete, up-todate product information, check with your local Oliver Machinery distributor, or visit

www.olivermachinery.net

2

WARNING

Read this manual completely and observe all warning labels on the machine. Oliver Machinery has made

every attempt to provide a safe, reliable, easy-to-use piece of machinery. Safety, however, is ultimately

the responsibility of the individual machine operator. As with any piece of machinery, the operator must

exercise caution, patience, and common sense to safely run the machine. Before operating this product,

become familiar with the safety rules in the following sections.

• Always keep guards in place and in proper operating condition.

• Use blade guard for every applicable operation including all through cuts. If guard is removed

for special non-through cuts such as dado and rabbet cuts, replace before further use of the

saw.

• Keep hands out of line with the saw blade.

• Use a push stick.

• Do not perform any operation freehand.

• Never reach around or over the saw blade.

1. If you are not properly trained in the use of a tablesaw do not use until the proper training has been

obtained.

2. Read, understand and follow the safety instructions found in this manual. Know the limitations and

hazards associated with this machine.

3. Electrical grounding: Make certain that the machine frame is electrically grounded and that a

ground lead is included in the incoming electrical service. In cases where a cord and plug are used,

make certain that the grounding plug connects to a suitable ground. Follow the grounding procedure

indicated in the National Electrical Code.

4. Eye safety: Wear an approved safety shield, goggles, or glasses to protect eyes. Common

eyeglasses are only impact-resistant, they are not safety glasses.

5. Personal protection: Before operating the machine, remove tie, rings, watch and other jewelry and

roll up sleeves above the elbows. Remove all loose outer clothing and confine long hair. Protective

type footwear should be used. Where the noise exceeds the level of exposure allowed in Section

1910.95 of the OSHA Regulations, use hearing protective devices. Do not wear gloves.

6. Guards: Keep the machine guards in place for every operation for which they can be used. If any

guards are removed for maintenance, DO NOT OPERATE the machine until the guards are

reinstalled.

7. Work area: Keep the floor around the machine clean and free of scrap material, saw dust, oil and

other liquids to minimize the danger of tripping or slipping. Be sure the table is free of all scrap,

foreign material and tools before starting to use the machine. Make certain the work area is well

lighted and that a proper exhaust system is used to minimize dust. Use anti-skid floor strips on the

floor area where the operator normally stands and mark off machine work area. Provide adequate

work space around the machine.

8. Material condition: Do not attempt to saw boards with loose knots or with nails or other foreign

material. Do not attempt to saw twisted, warped, bowed stock.

9. Operator position: Maintain a balanced stance and keep your body under control at all times.

10. Before starting: Before turning on machine, remove all extra equipment such as keys, wrenches,

scraps, and cleaning rags away from the machine.

3

11. Careless acts: Give the work you are doing your undivided attention. Looking around, carrying on a

conversation, and “horseplay” are careless acts that can result in serious injury.

12. Disconnect all power sources: Before performing any service, maintenance, adjustments or when

changing blades. A machine under repair should be RED TAGGED to show it should not be used

until the maintenance is complete.

13. Job completion: If the operator leaves the machine area for any reason, the tablesaw should be

turned "off" and the blade should come to a complete stop before their departure. The key should be

placed in the “off” position, removed and given to a supervisor to prevent any unauthorized use of the

tablesaw.

14. Replacement parts: Use only genuine Oliver Machinery factory authorized replacement parts and

accessories; otherwise the warranty and guarantee is null and void.

15. Misuse: Do not use this Oliver tablesaw for other than its intended use. If used for other purposes,

Oliver disclaims any real or implied warranty and holds itself harmless for any injury or damage which

may result from that use.

16. Drugs, alcohol and medication: Do not operate this machine while under the influence of drugs,

alcohol, or any medication.

17. This machine is deigned for cutting wood products only. Do not use to cut any kind of metal or

substance other then wood.

18. Never start the saw while a workpiece is in contact with the blade.

19. Raise or lower the blade only when the machine has been turned “off” and the blade has come to a

complete stop.

20. Miter Gauge and Rip Fence: Never use the miter gauge and rip fence at the same time.

21. Damaged Saw Blade: Never use a damaged saw blade or one that has been dropped. Check the

saw blade for cracks or missing teeth. Do not use a cracked or dull blade or one with missing teeth.

Make sure the blade is securely locked on the arbor.

22. Make sure the blade is running in the proper direction. Refer to the arrow on the blade. The teeth

should be pointing down when viewing from the front of the saw.

23. Alignment: Check the alignment of the splitter to the blade. Also, check the alignment of the fence

to the miter slot.

24. Health hazards: Some dust created by power sanding, sawing, grinding, drilling and other

construction activities contains chemicals known to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paint.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce

your exposure to these chemicals, work in a well-ventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

CAUTION: (This means that if precautions are not heeded, it may result in minor or moderate injury

and/or possible machine damage)

WARNING: (This means that if precautions are not heeded, it could result in serious injury or possibly

even death).

4

Table of Contents Page Number

Warranty......................................................................................................................................................2

Warnings..................................................................................................................................................3-4

Table of Contents........................................................................................................................................5

Specifications...............................................................................................................................................5

Contents of the Shipping Containers...........................................................................................................6

Machine Preparation and Setup..................................................................................................................7

Extension Wing Assembly...........................................................................................................................7

Handwheel Assembly..................................................................................................................................7

Rail Assembly..............................................................................................................................................8

Fence Assembly and Adjustment................................................................................................................9

Adjusting the Scale Reader.........................................................................................................................9

Adjusting 45° and 90° Stops......................................................................................................................10

Splitter and Blade Guard Assembly...........................................................................................................11

Miter Gauge...............................................................................................................................................12

Controls.....................................................................................................................................................12

Dust Collection...........................................................................................................................................12

Electrical Connections...............................................................................................................................13

Replacing the Blade...................................................................................................................................13

Maintenance..............................................................................................................................................14

Troubleshooting....................................................................................................................................15-16

Specifications

Model Number.......................................................................................................................................4060

Blade Diameter (In)...................................................................................................................................16”

Arbor Diameter (In)....................................................................................................................................1"

Maximum Depth of Cut at 90 Degrees (In)...........................................................................................5-1/2"

Maximum Depth of Cut at 45 Degrees (In)...........................................................................................4-1/4"

Maximum Cut to the Right of Blade..........................................................................................................52”

Dust Port Diameter (In)................................................................................................................................4

Table Dimensions w/Extensions (LxW).....................................................................................48-1/2” x 38”

Table Height (In)...................................................................................................................................36-½”

Blade Tilt...............................................................................................................................................Right

Arbor Speed RPM.................................................................................................................................3,450

Overall Dimensions (with fence & rails attached)............................................................85”L x 55"W x 42”H

Gross Weight.........................................................................................................................................1040

5

Contents of the Shipping Containers

Oliver 4060, 16” Professional Tablesaw

Saw

Once the top is removed the saw will be as

shown. Inspect for freight damage and call

the freight carrier if any.

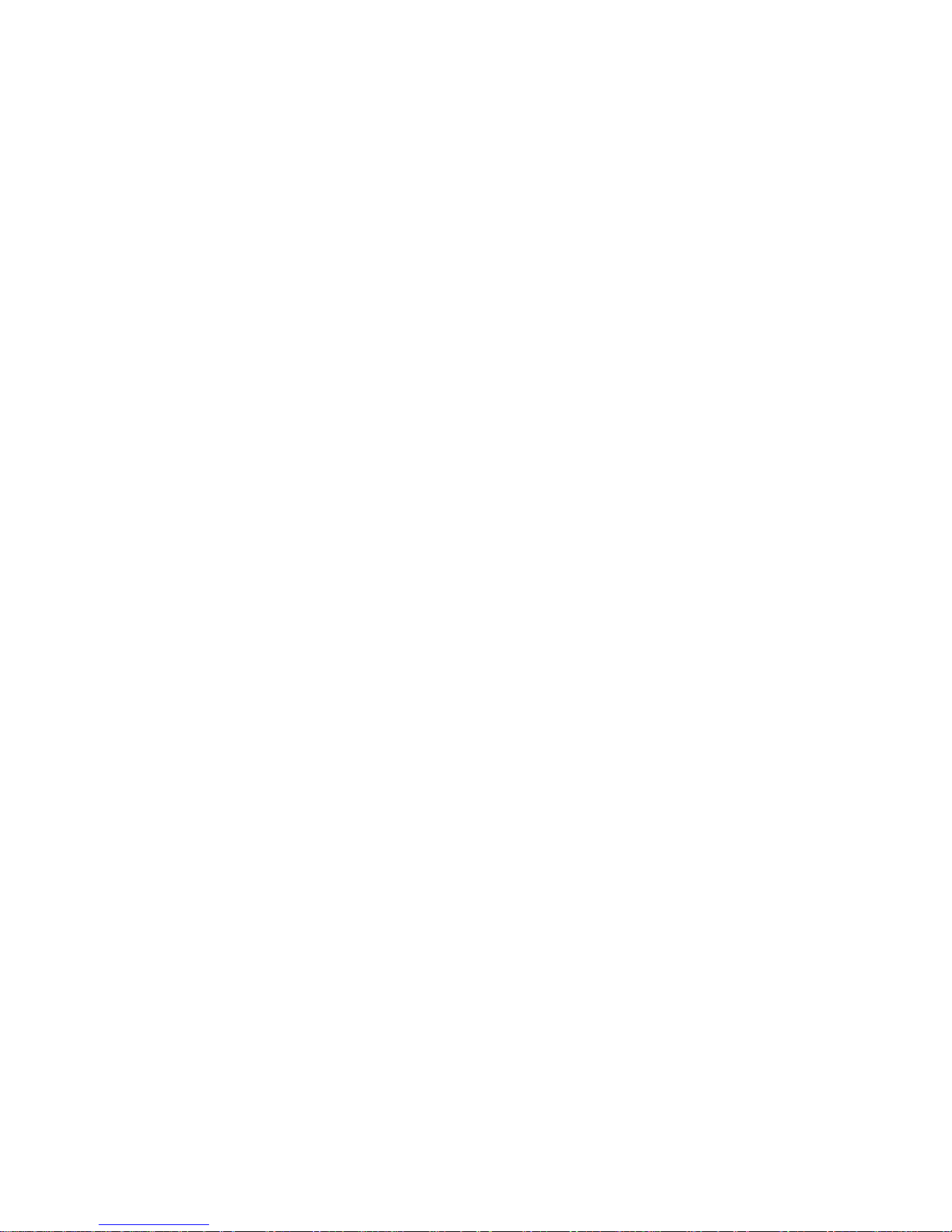

Contents

Speed handles

2. Angle height lock

3. Hardware packet (wings)

4. Hardware packet (rails)

5. Tools

6. Blade guard support bracket

7. Miter guage

Saw

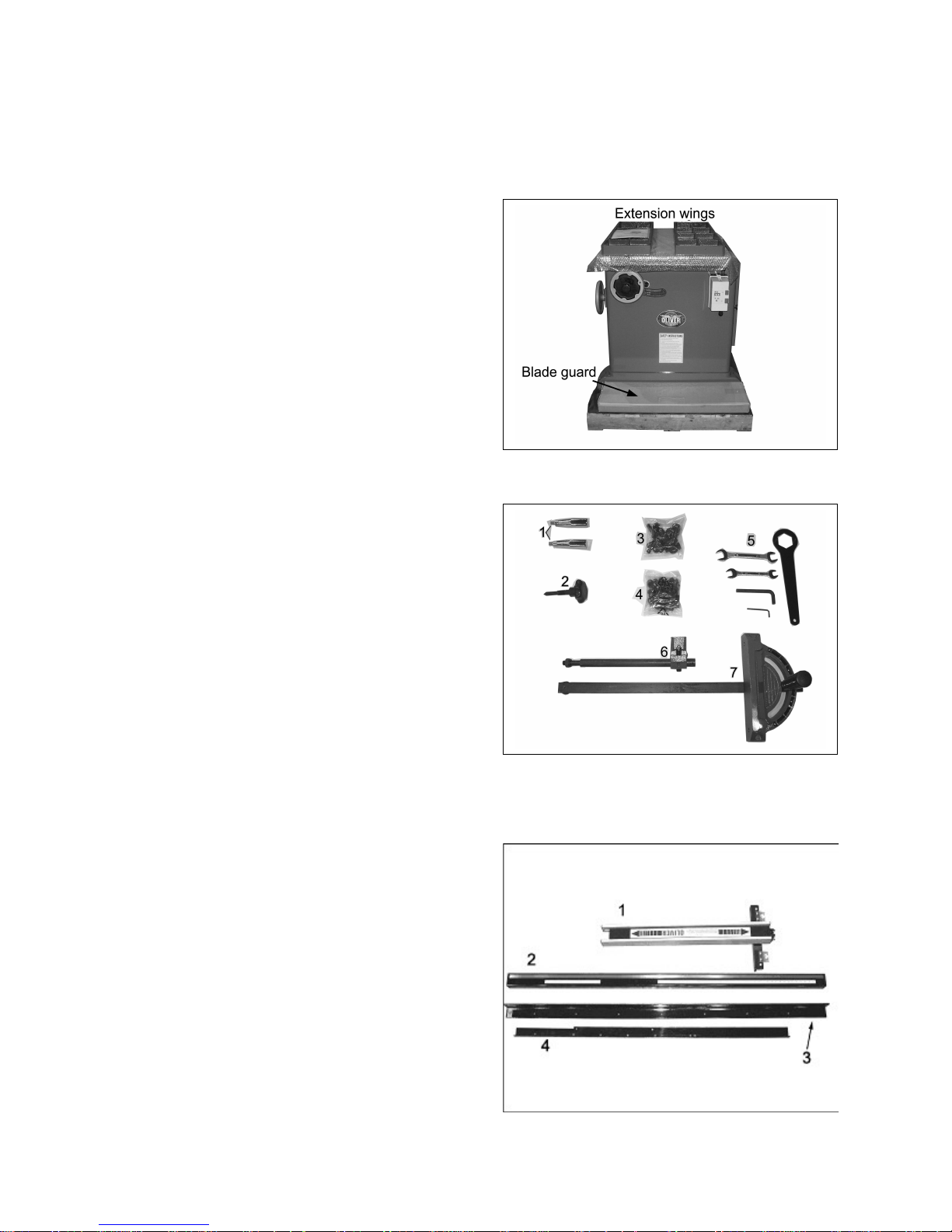

Fence and Rail Assembly

1. Fence

2. Front rail

3. Front rail support

4. Rear rail

Contents

Fence and Rail Assembly

6

Machine Preparation and Setup

WARNING!

The equipment used to lift this machine must

have a rated capacity at, or above the weight

of the tablesaw. Failure to comply may

cause serious injury!

The tablesaw must be positioned on a smooth,

level surface. The area must be well lit and

have plenty of room to maneuver with large

pieces of wood.

Level the saw front to back and side to side

using the supplied leveling bolts. Make sure the

saw is stable before being placed into service.

Clean all rust protected surfaces with a

commercial solvent. Do not use acetone,

gasoline, lacquer thinner or any type of

flammable solvent, or a cleaner that may

damage paint. Cover cleaned surfaces with

WD-40 or a 20W machine oil.

Pay particular attention to cleaning in the miter

slot and the faces of table and extension wing.

Figure 1

Extension Wing Assembly

1. Attach each extension wing to table using

the supplied hardware as shown in figure 1.

Snug but do not tighten the bolts.

2. Make sure the mating surfaces are flush at

both the top of the table and the front edge

of the table as shown in figure 2. If the bolts

have not been completely tightened, this can

be easily accomplished using a rubber

coated mallet or dead blow.

3. Fully tighten the bolts.

Handwheel Assembly

1. Screw in the speed handle and angle lock

knob into their respective holes as shown in

figure 3. Use the supplied wrench to

securely tighten the speed handle. Do the

same for both handwheels.

Figure 2

Figure 3

7

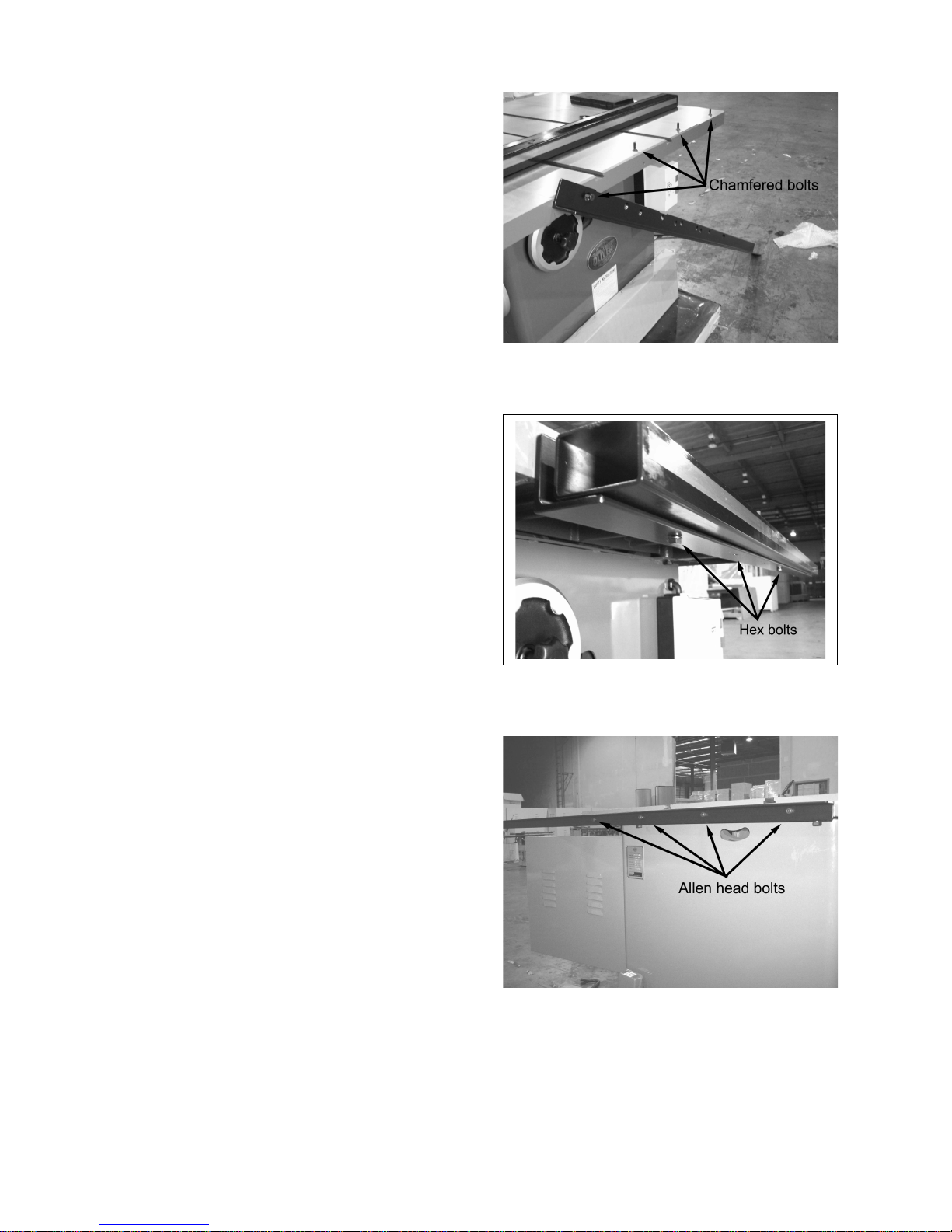

Rail Assembly

1. Install the front rail support to the saw using

the four supplied chamfered bolts found in

the hardware packet of the rails. It is easiest

to start with the first hole as shown in figure

4, using the floor to rest the end of the rail

on. Note that the rail comes pre-drilled for

use on other saws so it is a matter of lining

up the holes in the saw with the correct rail

holes.

2. Set the front guide on the support bracket as

shown in figure 5 and secure into place with

the seven hex bolts also provided in

hardware packet. Be careful when placing

the rail on the bracket that it does not fall off

when lining up the holes.

Figure 4

3. Install the rear guide as shown in figure 6

using the supplied hardware.

Figure 5

Figure 6

8

Loading...

Loading...