Page 1

OKIPAGE 8c Plus

/ OKICOLOR 8

Color LED Page Printer

MAINTENANCE

MANUAL

ODA/OEL/INT

1999.8.12 Rev.1

41057601TH Rev.1 1 / 199

Page 2

Rev.No. Date Corrected items Person in

No. Page Description of change change

1 1999.8.12 ISSUE E4 Yamazaki

41057601TH Rev.1 2 /

Page 3

PREFACE

This maintenance manual provides procedures and techniques for the troubleshooting, maintenance, and

repair of OKICOLOR 8 / OKIPAGE 8c Plus.

This manual is written for maintenance personnel, but it should always be accompanied with the

OKICOLOR 8 / OKIPAGE 8c Plus User’s Manual for procedures for handling and operating OKICOLOR

8 / OKIPAGE 8c Plus. For repairing each component of OKICOLOR 8 / OKIPAGE 8c Plus, see the

Troubleshooting manual.

[Notices]

The contents of this manual are subject to change without prior notice.

Although reasonable efforts have been taken in the preparation of this manual to assure its accuracy, this

manual may still contain some errors and omissions. OKI will not be liable for any damage caused or

alleged to be caused, by the customer or any other person using this maintenance manual to repair,

modify, or alter OKICOLOR 8 / OKIPAGE 8c Plus in any manner.

[Warning]

Many parts of OKICOLOR 8 / OKIPAGE 8c Plus are very sensitive and can be easily damaged by improper

servicing. We strongly suggest that OKICOLOR 8 / OKIPAGE 8c Plus be serviced by OKI’s authorized

technical service engineers.

41057601TH Rev.1 3 /

Page 4

CONTENTS

1. SPECIFICATIONS ............................................................................................ 7

1.1 Basic System Configuration............................................................................................. 7

1.2 Printer Specifications .......................................................................................................8

1.3 Option Specifications ....................................................................................................... 9

1.4 Basic Specifications....................................................................................................... 10

2. OPERATION................................................................................................... 12

2.1 Main Control Board (PCE PCB)..................................................................................... 13

2.2 Engine Control Board (PX4 PCB) .................................................................................. 16

2.3 Power/Units.................................................................................................................... 17

2.4 Mechanical Processes................................................................................................... 18

2.4.1 Electrophotographic processing mechanism .................................................... 19

2.4.2 Paper running process ..................................................................................... 25

2.5 Sensors.......................................................................................................................... 34

2.5.1 Paper related sensors ...................................................................................... 34

2.5.2 Other sensors ................................................................................................... 35

2.6 Correction of Color Deviation......................................................................................... 36

2.7 Transfer Control according to Environmental Changes

(Room Temperatures and Relative Humidities)............................................................. 36

2.8 Form Jam Detection....................................................................................................... 37

2.9 Cover Opening............................................................................................................... 37

2.10 Toner Low Detection...................................................................................................... 38

2.11 Page Size Detection ...................................................................................................... 39

2.12 Power-on Processing..................................................................................................... 40

2.12.1 Self-diagnostic test ........................................................................................... 40

3. PARTS REPLACEMENT................................................................................41

3.1 Precautions for Parts Replacement ............................................................................... 41

3.2 Parts Layout................................................................................................................... 43

3.3 How to Change Parts..................................................................................................... 47

3.3.1 Cover Assy Rear .............................................................................................. 48

3.3.2 Motor-Fan (80-25) ............................................................................................ 49

3.3.3 Paper Eject Assy .............................................................................................. 50

3.3.4 Cover Assy Stacker, Guide Eject FD Assy....................................................... 51

3.3.5 Frame Assy Upper............................................................................................ 52

3.3.6 Plate Support Assy ........................................................................................... 53

3.3.7 Limiter 2way (L), (R) / Plate Guide (L) , (R) ...................................................... 54

3.3.8 Cover ............................................................................................................... 55

3.3.9 PCB Assy : PCE ............................................................................................... 56

3.3.10 Motor Fan (CU)................................................................................................. 57

3.3.11 PXF PCB/PX4 PCB .......................................................................................... 58

3.3.12 Gear Heat Assy ................................................................................................ 59

3.3.13 Main Motor (A), (B) Assy .................................................................................. 60

3.3.14 Gear One-way (Z30)......................................................................................... 61

3.3.15 Motor Assy BT .................................................................................................. 62

3.3.16 Power Supply Unit, Holder Inlet, Sheet Insulation............................................ 63

3.3.17 Sensor Assy Box Toner .................................................................................... 64

3.3.18 Square-shaped Connector ............................................................................... 65

41057601TH Rev.1 4 /

Page 5

3.3.19 Hopping Motor .................................................................................................. 66

3.3.20 Gear One-way .................................................................................................. 67

3.3.21 Feeder Unit Front ............................................................................................. 68

3.3.22 Manual Feed Hopper Assy ............................................................................... 69

3.3.23 Guide Paper Input Assy.................................................................................... 70

3.3.24 Two Lever Input Sensors, Lever 2nd Feed Sensor .......................................... 71

3.3.25 Roller Registration, Roller Assy Hopping ......................................................... 72

3.3.26 Roller Hopping.................................................................................................. 73

3.3.27 PXU PCB/PXM PCB, Lever Resist Sensor ...................................................... 74

3.3.28 Paper End Lever............................................................................................... 75

3.3.29 PCO PCB (Operator Panel).............................................................................. 76

3.3.30 Holder Gear Toner Assy................................................................................... 77

3.3.31 Plate Latch Lever (FD), Spring Latch Lever (FD) ............................................. 78

3.3.32 Belt Cassette Assy ........................................................................................... 79

3.3.33 High Voltage Power Supply Unit, Bracket HV (BT) Assy ................................. 80

3.3.34 Eraser Bracket Assy, Eraser Bracket (KCM) Assy ........................................... 81

3.3.35 Shaft Link.......................................................................................................... 82

3.3.36 Contact (BL-R) Assy, Contact (CL-R) Assy ...................................................... 83

3.3.37 Contact (BL-L) Assy, Contact (CL-L) Assy ....................................................... 84

3.3.38 Contact SB Assy............................................................................................... 85

3.3.39 PXC PCB .......................................................................................................... 86

3.3.40 Heat Unit Assy.................................................................................................. 87

3.3.41 Oil Roller Assy .................................................................................................. 88

3.3.42 Lever Lock Heat (L)/(R), Guide Side Heat, Spring Lock................................... 89

3.3.43 PXL PCB .......................................................................................................... 90

3.3.44 Heat Unit Guide Assy ....................................................................................... 91

3.3.45 Holder LED Assy, LED Head............................................................................ 92

4. ADJUSTMENTS ............................................................................................. 93

4.1 Maintenance Modes and Their Functions...................................................................... 93

4.1.1 User maintenance mode .................................................................................. 93

4.1.2 System maintenance mode .............................................................................. 95

4.1.3 Engine maintenance mode ............................................................................... 97

4.2 Adjustments after Parts Replacement ......................................................................... 100

4.2.1 Confirm the LED head driving time................................................................. 100

4.2.2 Color deviation correction............................................................................... 102

5. PERIODIC MAINTENANCE ......................................................................... 105

5.1 Periodically Replaced Parts ......................................................................................... 105

5.2 Cleaning....................................................................................................................... 105

5.3 Cleaning the LED Lens Array ...................................................................................... 105

5.4 Cleaning the Pickup Roller........................................................................................... 105

6. TROUBLESHOOTING PROCEDURES ....................................................... 106

6.1 Troubleshooting Tips ................................................................................................... 106

6.2 Points to Check before Correcting Image Problems.................................................... 106

6.3 Tips for Correcting Image Problems ............................................................................ 106

6.4 Preparation for Troubleshooting .................................................................................. 107

6.5 Troubleshooting Flow................................................................................................... 107

6.5.1 LCD status message/trouble list..................................................................... 107

6.5.2 LCD message troubleshooting ....................................................................... 116

6.5.3 Image troubleshooting .................................................................................... 129

41057601TH Rev.1 5 /

Page 6

7. WIRING DIAGRAM...................................................................................... 146

7.1 Resistance Check ........................................................................................................ 146

7.2 Program/Font ROM Location ....................................................................................... 150

8. Parts List...................................................................................................... 154

Appendix A CENTRONICS PARALLEL INTERFACE.................................... 175

Appendix B HIGH CAPACITY SECOND PAPER FEEDER ........................... 179

1. OUTLINE ......................................................................................................179

1.1 Functions ..................................................................................................................... 179

1.2 External View and Component Names........................................................................ 179

2. MECHANISM DESCRIPTION ...................................................................... 180

2.1 General Mechanicsm................................................................................................... 180

2.2 Hopper Mechanism...................................................................................................... 181

3. PARTS REPLACEMENT..............................................................................182

3.1 Precautions Concerning Parts Replacement............................................................... 182

3.2 Parts Layout................................................................................................................. 184

3.3 Parts Replacement Methods........................................................................................ 185

3.3.1 Idle rollers ....................................................................................................... 186

3.3.2 AOLT-PCB...................................................................................................... 187

3.3.3 Hopping motor ................................................................................................ 188

3.3.4 Feed roller ...................................................................................................... 189

3.3.5 Hopping roller ................................................................................................. 190

3.3.6 Side frame (L) assy ........................................................................................ 191

3.3.7 Side frame (R) assy........................................................................................ 192

4. TROUBLESHOOTING.................................................................................. 193

4.1 Precautions Prior to the Troubleshooting..................................................................... 193

4.2 Preparations for the Troubleshooting........................................................................... 193

4.3 Troubleshooting Method .............................................................................................. 194

4.3.1 LCD Status Message List ............................................................................... 194

4.3.2 Troubleshooting Flow ..................................................................................... 195

5. CONNECTION DIAGRAM............................................................................ 196

5.1 Interconnection Diagram.............................................................................................. 196

5.2 PCB Layout.................................................................................................................. 197

6. PARTS LIST ................................................................................................. 198

41057601TH Rev.1 6 /

Page 7

M

M M

M M

M M

M

LED head

Discharging indicators

Centronics

interface

HSP

Controller

Junction board

Pulse motors

Engine controller

Low-voltage

power unit

Fixing unit

High-voltage

power unit

Second tray

Belt unit

<Sensors, switches, and thermistors>

Paper width sensor

Form size detector (4 bits)

Form end sensor

FF form end

FF home switch

Form feed sensor 1

Form feed sensor 2

Write sensor

Ejection sensor

Toner Low (Y.M.C.K)

EP Up/Down (Y.M.C.K)

Waste toner sensor

Resist Up/Down

Cover open switch (High-voltage

interlock switch)

Heater temperature thermistor

Backup temperature thermistor

Environment temperature sensor

Environment humidity sensor

Oil Roller switch

Fixing unit interlock switch

Waste toner box switch

Y-EP unit M-EP unit C-EP unit B-EP unit

PSIMM

x2

interface

SIMM

x4

interface

Y EP M EP C EP K EP BELT HEATER REGIST FF

Operator panel

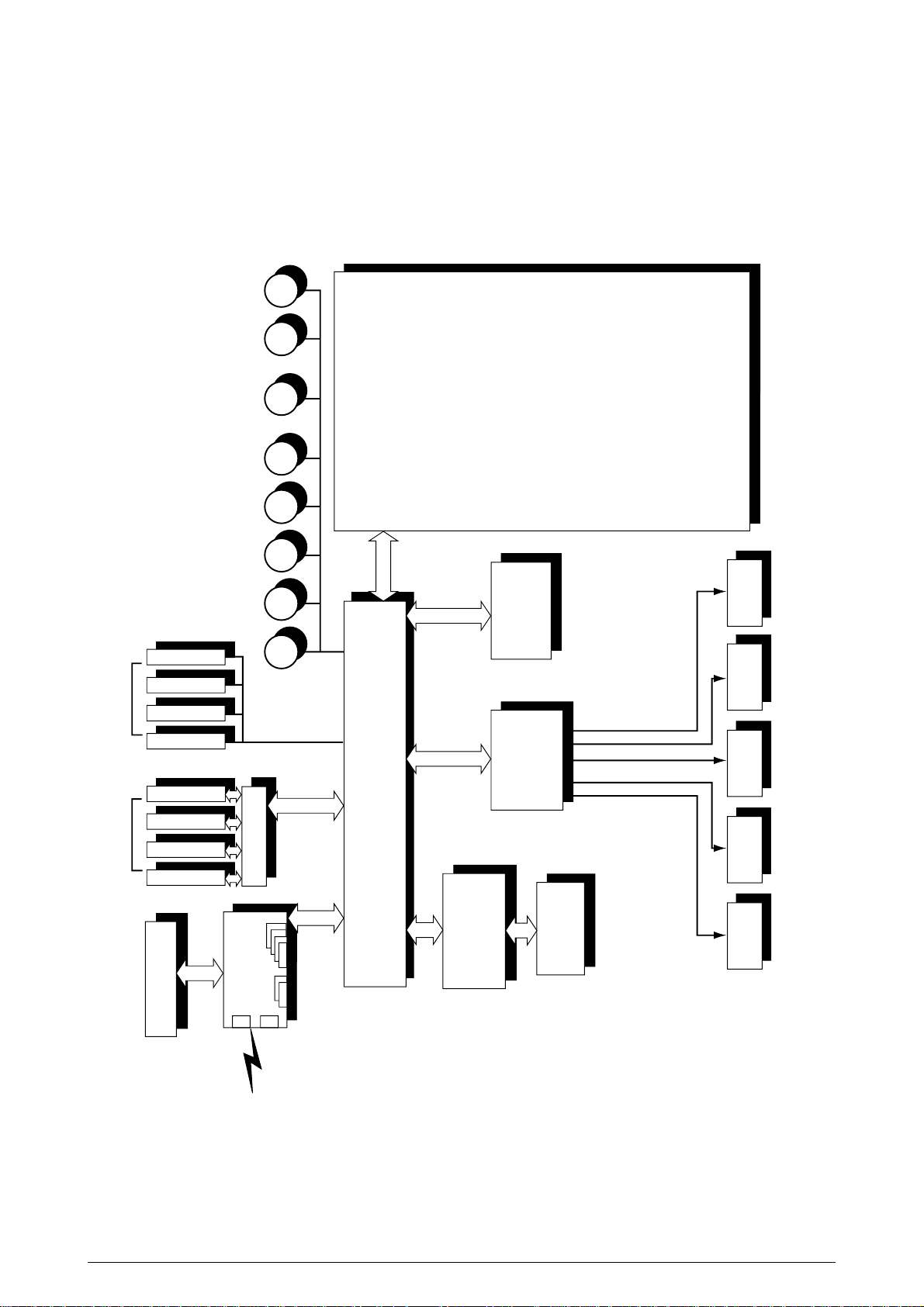

1. SPECIFICATIONS

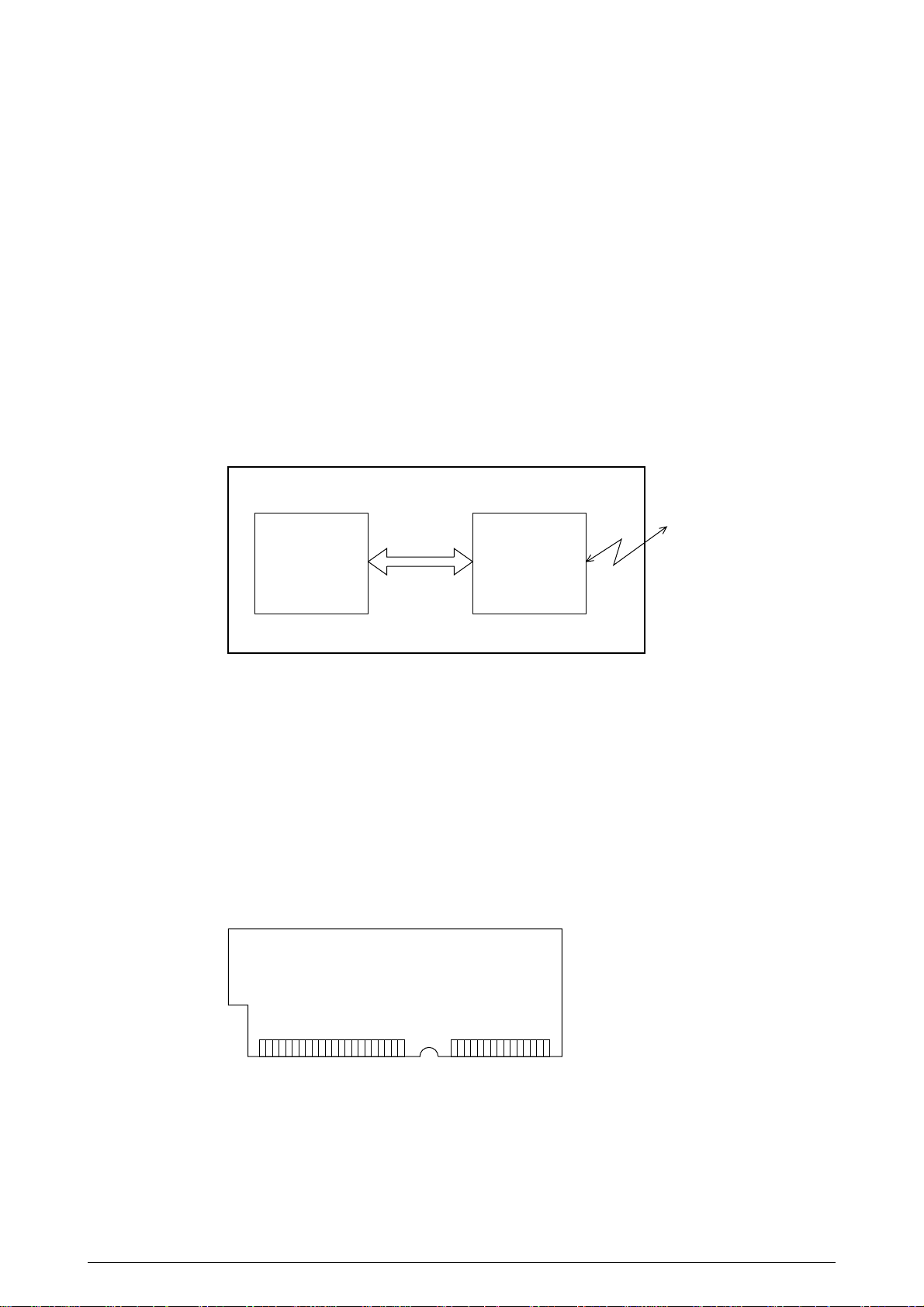

1.1 Basic System Configuration

The basic system configuration of OKICOLOR 8 / OKIPAGE 8c Plus is illustrated in Figure 1.1.

Figure 1.1

41057601TH Rev.1 7/

Page 8

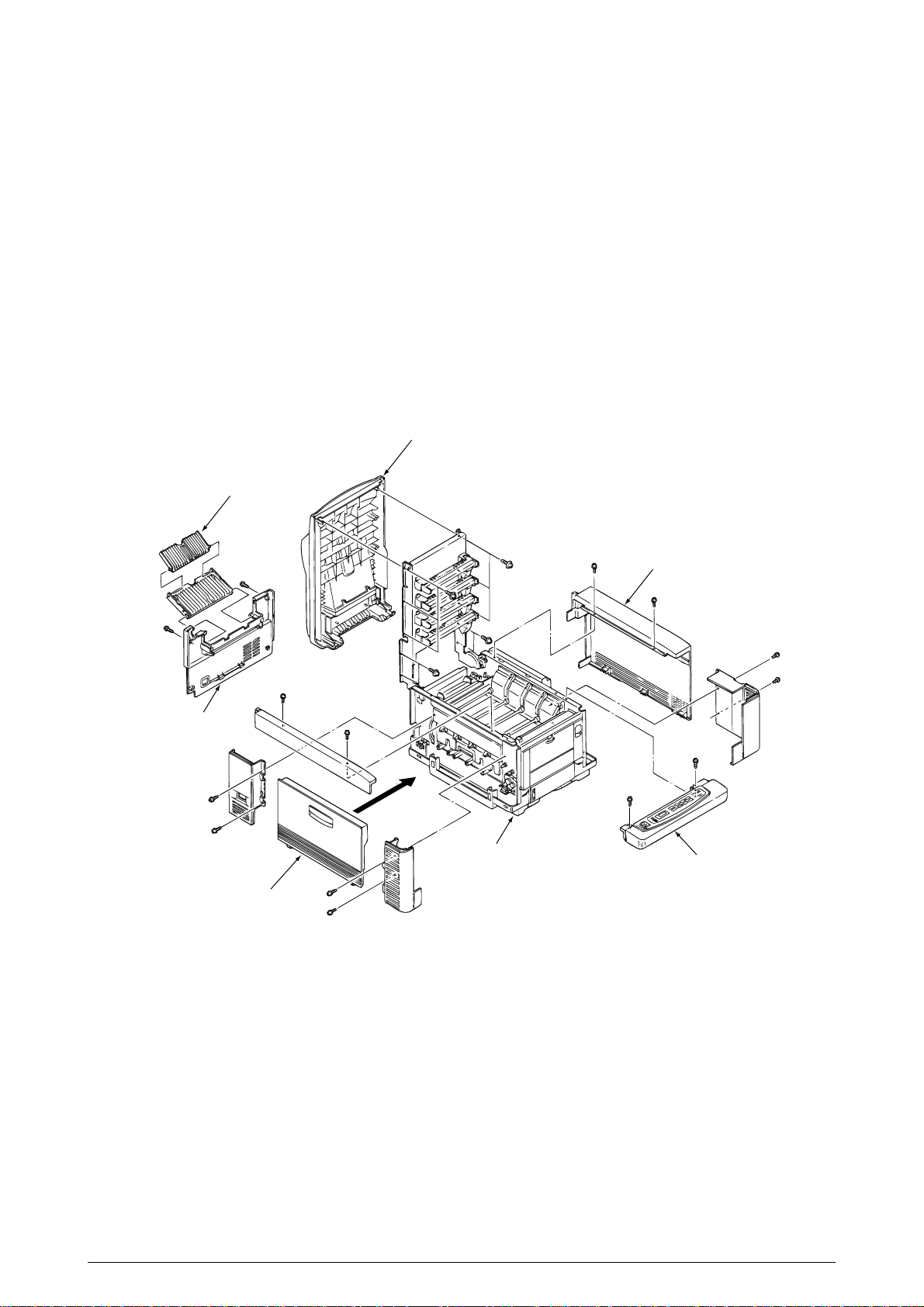

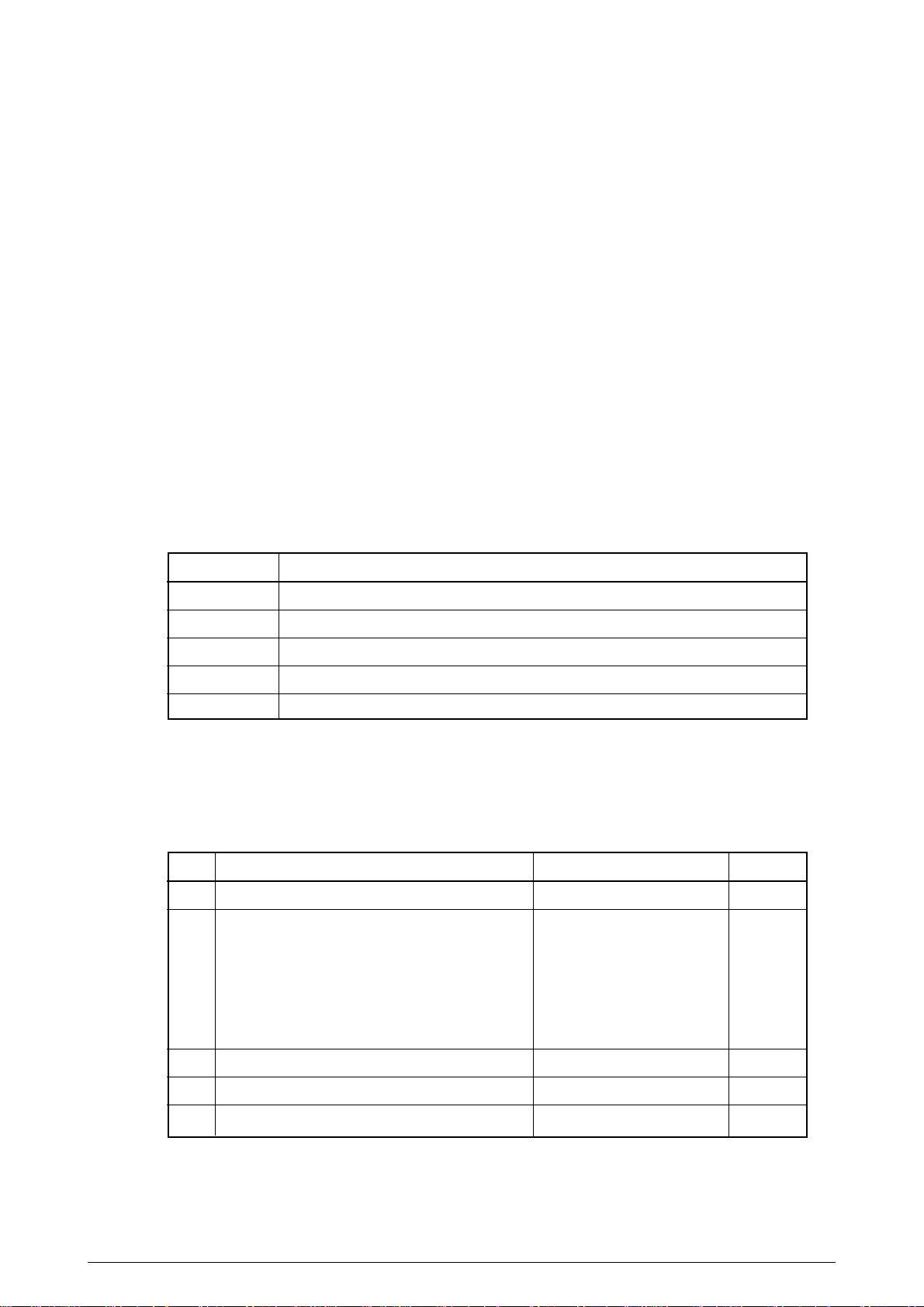

1.2 Printer Specifications

This printer unit is composed with the following hardware.

• Electro-photographric processor

• Paper feeder

• Controller (CU part / PU Part)

• Operator panel

• Power board (High voltage part / PU part)

Figure 1-2 show the printer unit configuration.

Face-up Stacker Assy

Stacker Cover Assy

I/F Cover Assy

Rear Cover

Side Cover (L) Assy

Base Unit

Figure 1.2

Operator Panel Assy

41057601TH Rev.1 8/

Page 9

1.3 Option Specifications

Options available for OKICOLOR 8 / OKIPAGE 8c Plus are as follows.

(1) 2nd-Feeder

(2) RAM SIMM module (72 pin SIMM, 4MB/8MB/16MB/32MB)

* Make sure to use a set of 2 of the same volume size modules.

41057601TH Rev.1 9/

Page 10

1.4 Basic Specifications

(1) Dimensions

Width: 18.8" (478mm) Length: 24.5" (622mm) Height: 15.6" (396mm)

(2) Weight

Approx. 48kg (106lbs)

(3) Form

Type: Ordinary paper (Hammermill 24lbs) and OHP (Only CG3710)

Recommended paper (for color printing)

Color laser paper (20lb to 24lbs)

Note: The printout color tones are dependent upon the whiteness of the print

paper

Sizes: Letter, Legal (13"or 14"), Executive, A4, A5, B5, and A6 (1st tray and front feeder)

Reams: 1st tray 20lbs to 28lbs

2nd tray 20lbs to 28lbs

Front feeder 20lbs to 44lbs

(5) Printing speed

8 pages per minute (5 pages per minute: OHP/ 34lbs ~44lbs, 123g/m2~166g/m2)

(6) Resolution

600 dots per inch x 600 dots per inch

(7) Input voltage

120VAC +5.5%, -15%

230VAC ±10%

(8) Power consumption

Peak W

Typical operation W

Idle W

Power-save mode W

(9) Frequency

50Hz or 60Hz +2%, -2%

(10) Noises

Operating: 54dB (without 2nd tray), 55dB (with 2nd tray)

Standby: 45dB

Power-saving: 43dB

(11) Expendibles and service life

Toner cartridge: Approx. 1800 pages (5% duty) (each of Y, M, C, and K)

(Approx. 1000 sheets for the first)

Image drum: Up to 12,000 pages (5% duty, continuous) (each of Y, M, C, and K)

Waste Toner Box: Up to 25,000 Sheets

(under typical printout conditions: Single images of 5% density,

equivalent to printout using 14 toner cartridges)

Oil Roller Unit: Up to 10,000 sheets (Life defined in the number of actually printed

paper sheets)

(12) Periodically-replaced parts

Heat Unit Assy: 60,000 pages

Belt Cassette Assy: 50,000 pages

41057601TH Rev.1 10/

Page 11

(13) Temperatures and relative humidities

Temperature

Temperature conditions

Temperature (in _F) Temperature (in _C) Remarks

Operating

Non-operating

Storage (1 year max.)

Delivery (1 month max.)

Delivery (1 month max.)

50 to 89.6

32 to 109.4

14 to 109.4

-20 to 122

-20 to 122

Humidity

Humidity condition

Relative humidity (%) Wet-bulb temperature Remarks

Operating

Non-operating

Storage

Delivery

20 to 80

10 to 90

10 to 90

10 to 90

for the packed unit only

10 to 32

0 to 43

-10 to 43

-29 to 50

-29 to 50

25

26.8

35

40

17_C to 27_C (for assurance

of full-color printout quality)

Power off

with drum and toner

without drum and toner and

Belt Cassette Assy

with drum and toner

50% to 70% (for assurance of

full-color printout quality)

Power off

(14) Printer life

3,000,000 (A4) pages or 5 years

41057601TH Rev.1 11/

Page 12

2. OPERATION

AC-IN AC switch

Crimp-style terminal

PXL board

PXL

Ejection sensor

LED head: Y M C K

Discharging lamp: Y M C K

Heat roller

thermistor

Backup roller

thermistor

Heater unit

SUMi card x 4

PD6 board

Y600 14P

YPOW 12P

M600 14P

MPOW 12P

C600 14P

CPOW 12P

K600 14P

KPOW 12P

HEAD1 13P HEAD2 14P HEADPOW 12P HEAD3 15P

FF form

sensor

Toner sensor x 4

ID sensor x 4

Low-voltage power supply

6P

6P'

JST3P

FAN 1

FAN 2

3P

Oil PAD MSW

FF

motor

Paper supply sensor board

FF Pos MSW

PXM board

40095001YU

REG.POS

sensor

Resist

motor

Y-IDU

motor

M-IDU

motor

C-IDU

motor

K-IDU

motor

Belt

motor

Heat

motor

PXF board

JODEN 8P

FSENS 8P

TONER

14P

PXFIF 30P

OPTION 7P

PENDTNR 6P

PX4 board

2nd tray

(option)

Form end

sensor

Waste toner

sensor

YIDREG

8P

MCKID

12P

HETBELT

8P

HEAD3

15P

HEAD2

14P

HEAD1

13P

HEADPOW

12P

FF 12P

PXFIF 30P

HVOLT 16P COVOPN 2P PSIZE 6P

High-voltage power supply

PXC board

Form size detector

Cover open

MSW

PCE

Operator

panel

PCO

board

CM

6P

PU 40P

72PX2

PS SIMM

72PX4

D-RAM SIMM

64P

OKI HSP

36P

Parallel

CUIF 40P

POWER 30P

THE.RM 6P

RSENS 7P

Interlock switch

UPDOWN

12P

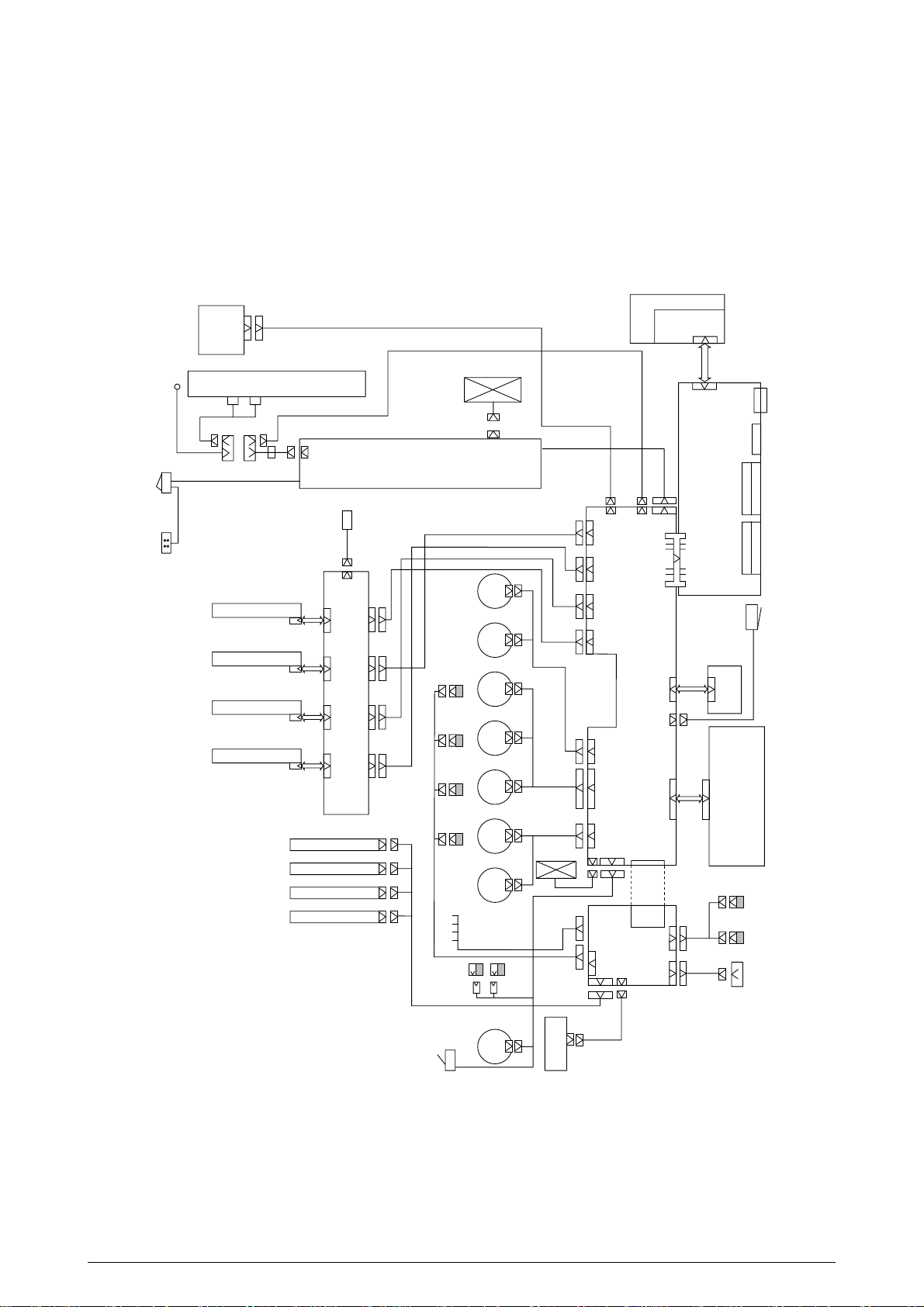

OKICOLOR 8 / OKIPAGE 8c Plus is a tandem color electrophotographic page printer, using 4992LED technologies , OPC, dry single-component non-magnetic developing, roller transfer, heatcompression fixing and so on. The printing method used is a Black Writing method which applies

light beams to printout areas.

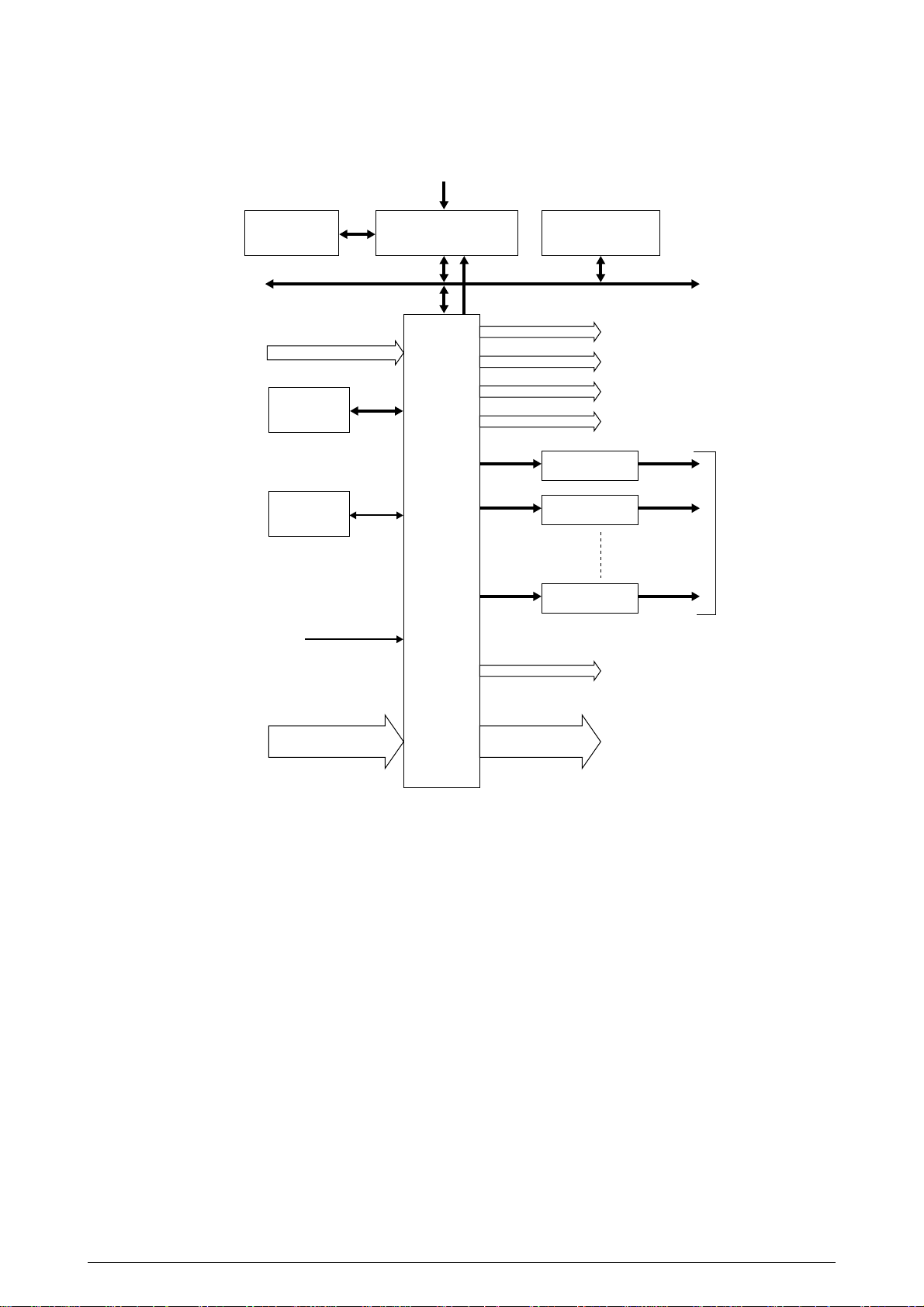

Figure 2.1 shows the functional block diagram of OKICOLOR 8 / OKIPAGE 8c Plus.

41057601TH Rev.1 12/

Figure 2.1

Page 13

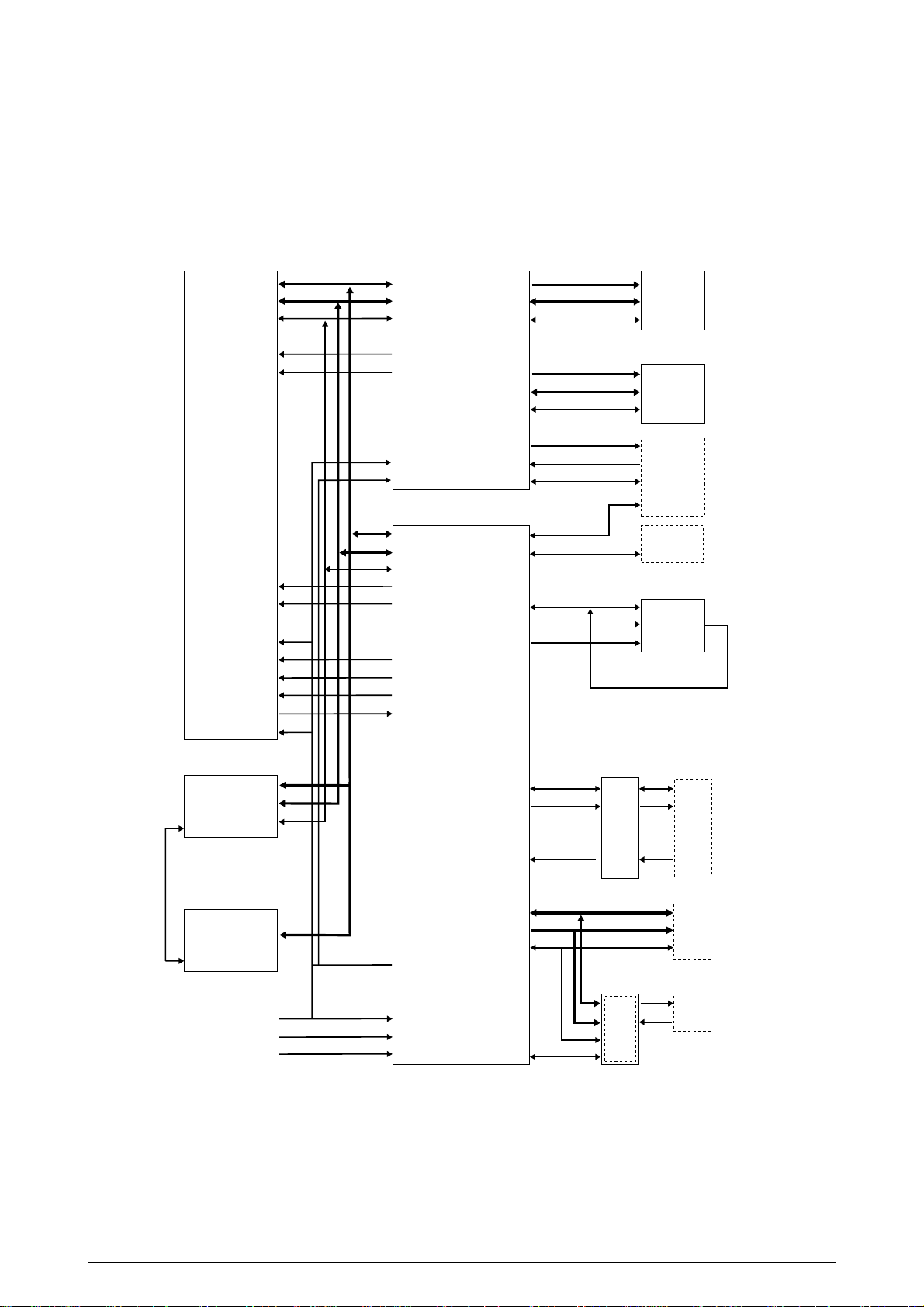

2.1 Main Control Board (PCE PCB)

The control board consists of a CPU (µPD30500S2-200) block, a memory control LSI block, an

interface control LSI block, a DRAM block, an EEPROM block, a mask ROM block, and an interface

block. Figure 2.2 shows the functional block diagram of the main control board (PCE PCB).

MPU Memory controller ROM, Flash Max 32M

SysAD

SysCmd

Control

NMI

INTO

µ

PD30500

S2-200

ExtReg

INT1

Reset

ColdReset

VCCOK

ModeIn

ModeClock

MasterClock

2nd cache controller

SysAD

SysCmd

Control

Control

64

9

5

1

1

1

1

64

9

5

1

1

1

1

1

1

SysAD

SysCmd

Control

uPD94704

NMI

S1-001-F6

INT

CLK

RST

Interface controller

SysAD

SysCmd

Control

ExtReq

INT

ColdReset

VCCOK

ModeIn

ModeClk

uPU66044

GN-014-LMU

A

D

Control

A

D

Control

WDATA

FSYNC

Control

PU I/F

OP I/F

EEPD

EEPCLK

EEPCS0

PD

PCO

PCI

22

64

11

11

64

25

8

4

4

9

4

1

1

1

8

5

4

D-RAM Max 144M

74LVC161284 Bi-Centro

WDATA

ESYNC

Control

Operator

panel

DI

CLK DO

CS

Engine

EE-PROM

2nd cache

Control

Reset circuit

SysAD

OSC

DIP SW

16

D

18

A

12

1

Reset

1

CLK

1

RSTIN

2

M

C

10

(TE6135 (6137), 16550, 53C80)

OKI HSP

Host I/F(Not installed)

Figure 2.2

41057601TH Rev.1 13/

Page 14

(1) CPU

The CPU is a 64-bit RISC architecture processor (provided by NEC). It inputs a frequency

of 50MHz and runs at 200MHz. It transfers data to and from memory at 50MHz.

(2) OTP ROM

The otp ROM block consists of four 16Mbit (1M x 16bits) chips and its total size is 8M bytes.

The chips are mounted on the PCE-PCB by means of IC sockets and store programs and

character fonts.

(3) DRAM

The DRAM block consists of eight 16Mbit (1M x 16bits) chips and its total size is 16M bytes.

The chips are mounted on the PCE-PCB and can be expanded up to 144M bytes by adding

the 32M byte SIMMs to the SIMM slots on the PCE-PCB.

(4) EEPROM

The EEPROM block consists of 16K-bit chips mounted on a board by means of IC sockets

and stores the following:

- Menu data

- Counter values

- Adjustment values

(5) Flash ROM

The Flash ROM block consists of four 4M bit (256K x 16bits) chips and its total size is 2M

bytes. The chips are mounted on the PCE-PCB and are used for storing fonts, macro and

demo pages.

(6) Memory control LSI

This block mainly consists of memory control, CPU control, compression and decompression, and video interface functions.

(7) Interface control LSI

This block mainly consists of PU interface control, operator panel interface control, EEPROM

control, parallel interface control, and HSP control functions.

(8) Host interface

This printer has the following interfaces to the host.

• Centronics bidirectional parallel interface

• HSP interface (Option)

The single effective interface or the automatic interface select mode can be selected using

the menu. If the busy state of the printer continues for a long time period, the buffer near-full

control releases the busy status at constant intervals even if the host side is busy so as not

to cause interface time-out at the host side.

(a) Centronics bidirectional parallel interface

This is an interface conforming to IEEE-1284 and provides either unidirectional and

bidirectional communications according to each of the following communication modes.

• Compatibility mode

Unidirectional communications from the host to the printer.

• Nibble mode

This mode transfers 4-bit wide data from the printer to the host. In this mode, each

bit of 1-byte data is transmits in the form of two nibbles using ERROR, BUSY, FAULT,

and SELECT signal leads. This mode can provide bidirectional operation in

combination with the compatibility mode.

41057601TH Rev.1 14/

Page 15

• ECP mode

This mode provides the asynchronous bidirectional interface and transmits and

receives 1-byte data using eight data signal leads under semi-duplex control by the

host.

When the power is turned on, the compatibility mode is automatically selected. The

change to another mode from the compatibility mode is made through negotiation.

(When the BI DIRECTION is set to ENABLE in the menu, this change can be performed.)

(For the electrical/physical characteristics of this interface, see APPENDIX B)

(b) HSP interface (Option)

This interface (slot) is an OKI unique universal interface that provides the platform to

connect various of boards (including those supplied by third venders) such as the LAN

connection expansion board and SCSI expansion board.

Any expansion boards compatible with this interface can be mounted on the Control

board in the piggyback board from without modifying the program at the printer side. The

conceptual diagram of the HSP interface is shown in Fig. 2-3.

Printer

Network, etc.

Control board

LAN

expansion board

HSP

interface

Figure 2.3

(For the electrical/physical characteristics of the HSP interface, see the HSP interface

technical manual.)

(9) 2nd Cache and 2nd Cache Controller

This printer has 2nd Cache unit which type is Write Through Cache and size is 512 KByte.

Thereare any difference between the instruction and data.

All of the CPU read/ write accesses are cached to same 2nd Cache memory.

(10) RAM module

• Pin layout

1363772

• Basic specificaton

- Type: 72 pins SIMM (32 bits buss width)

- Access time: 60ns, 70ns, 80ns

- Capacity: 4, 8, 16 or 32MB

- Parity: None

41057601TH Rev.1 15/

Page 16

2.2 Engine Control Board (PX4 PCB)

NM93C66N-NW

CPU BUS

VIDEO I/F

(Heater temperatures and envirnment humidity and temperature)

EEPROM

VIDEO MEM

HM658512

OSC 28MHz

RESET

ANALOG INPUT

CPU

MSM65524

(containing AD converter)

INT

LSI

MB87D

113PFV

MT DRIVER

MTD2005F

MT DRIVER

MTD2005F

MT DRIVER

MTD2005F

ROM

27512

Y HEAD I/F (3.3V)

M HEAD I/F (3.3V)

C HEAD I/F (3.3V)

B HEAD I/F (3.3V)

PULSE MOTOR x 8

HIGH-VOLTAGE POWER SUPPLY

SERIAL INTERFACE (2 channels)

GENERAL INPUT PORT

GENERAL OUTPUT PORT

Figure 2.4

The engine control block (PU) is controlled by the engine control board (PX4 PCB) which consists

of a CPU (MSM65524), general purpose LSI chips, EPROM, EEPROM, pulse motor drivers, and

video memory. (See Figure 2.4.)

(1) CPU

This is an 8-bit CPU (OKI MSM65524) containing the AD converter and controls the whole

system.

(2) General-purpose LSI

This LSI (MB87D113PFV) is provided in the printer engine control block and has controllerengine video interface, LED interface, motor control, sensor input, video memory control,

main scanning color correction, skew correction, high-voltage power control, and OST-EX2

functions.

41057601TH Rev.1 16/

Page 17

(3) EPROM

This EPROM (27C512-150) has a storage capacity of 512K bits and stores programs for the

PU block.

(4) EEPROM

This EEPROM (NM93C66N-NW) having a storage capacity of 4K bits is mounted on the

board by means of IC socket and stores adjustment values etc.

(5) Pulse motor drivers

These drivers (MTD2005F) drive eight pulse motors for moving up and down the EP and

transferring medium.

(6) Video memory

This SRAM receives print data through video interface and stores it.

2.3 Power/Units

The power supply unit comprises of the low voltage power supply unit which consists of an AC filter

circuit, low voltage power supply circuit and heater driver circuit, and the high voltage power supply

unit.

(1) Low voltage power supply unit

This circuit generates the following voltages.

Output voltage Use

+3.3 V CU Unit CPU, LED HEAD

+5 V Logic circuit supply voltage

+32 V Motor and fan drive voltage and source voltage for high-voltage supply, discharge lamp

+12 V HSP, OP Amp, high voltage power supply

–12 V HSP

(2) High voltage power supply unit

This circuit generates the following voltages necessary for electro-photographic processing

from +32 V in accordance with the control sequence from the control board. When cover open

state is detected, +32 V supply is automatically interrupted to stop the supply of all the highvoltage outputs.

Output Voltage Use Remarks

CH -1.35 KV ± 50V Voltage applied to charging roller

DB Normal paper Voltage applied to developing roller

Y. M. C : -250V/+300V, -232V/+300V(First paper. Y only)

K : -275V/+300V

Transparency

Y. M. C. : -200V/+300V, K. : -250V/+300V

SB Y. M. C.K : -650V/0V Voltage applied to toner supply roller

TR 0 to 4 KV Voltage applied to transfer roller Variable

FIX 0 to 2.5 KV Voltage applied to transfer roller Variable

41057601TH Rev.1 17/

Page 18

2.4 Mechanical Processes

Paper

ejection

roller

Paper

ejection

(Face down)

Power

supply

Charging

roller

Cleaning

blade

Paper

path

selection

Heat roller

Ejection

roller

Fixing

Backup roller

Control signal

LED head

Developing

roller

Power

supply

Toner

cartridge

Transfer

roller

Paper

resist

Resist

roller 1

Paper

feed

Hopping

roller

Power

supply

Resist

roller 2

Paper ejection Fixing Cleaning Transferring

Paper pickup

Paper conveying Paper hopping

Movement of

paper

Rotation of

OPC drum

Transferring

Charging

Exposure

Developing

Cleaning

Paper ejection

sensor

Form feed sensor 1

Paper

ejection

(Face up)

Form feed sensor 2

Front

feeder

Paper

cassette

Paper

resist

Paper

pickup

(FF, 1ST, 2ND)

Write sensor

x 4

Y M C K

Figure 2.5 shows the mechanical processes of OKICOLOR 8/ OKIPAGE 8c Plus.

41057601TH Rev.1 18/

Figure 2.5

Page 19

2.4.1 Electrophotographic processing mechanism

(1) Electrophotographic processes

Each process of the electrophotographic processing mechanism is outlined below.

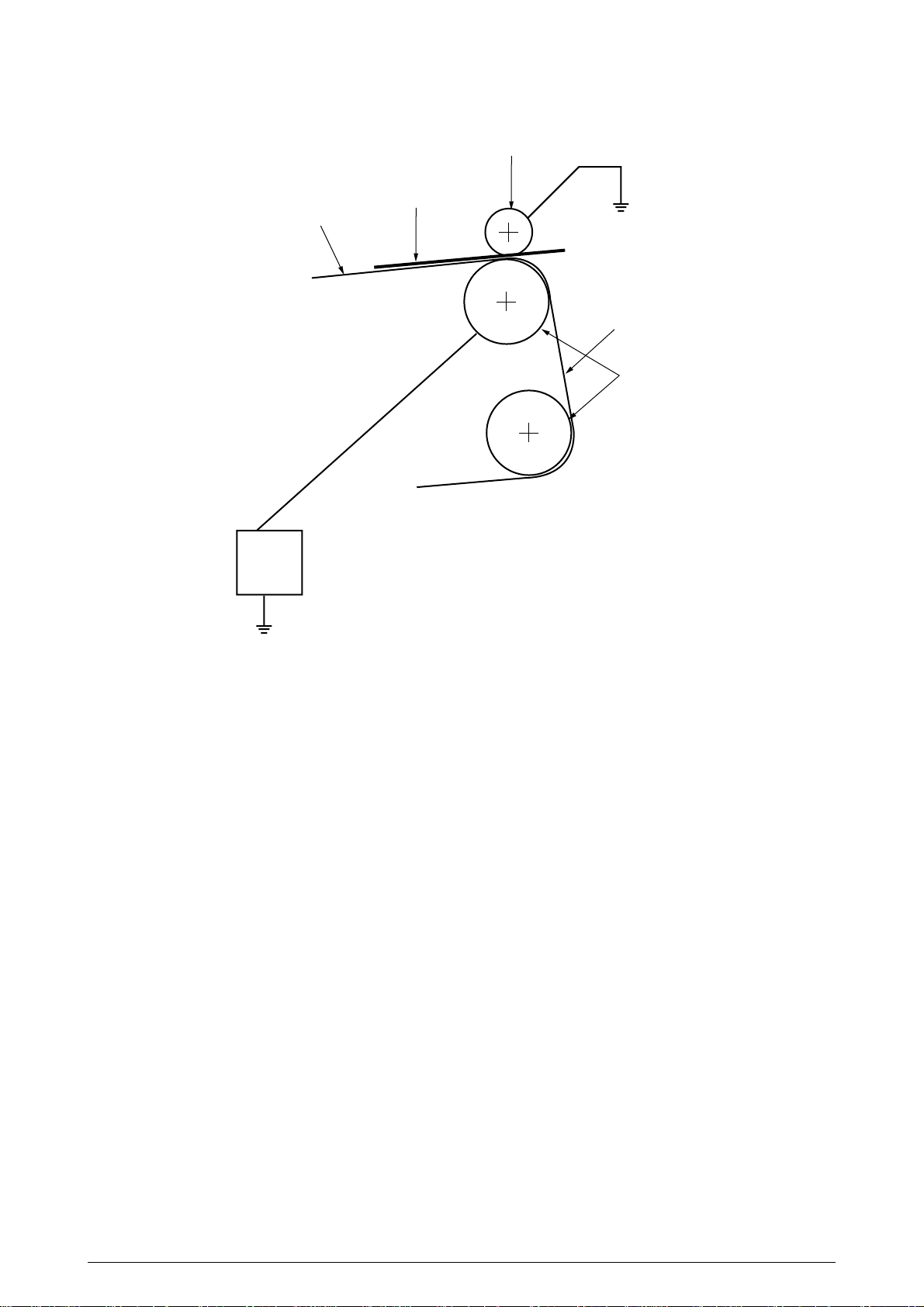

1 Paper pickup

This process causes the roller to give a DC voltage to the paper to have a negative charge.

With this negative charge, the paper is electrostatically attracted to the roller.

2 Charging

This process gives a DC voltage to the CH roller so that the OPC drum may have a uniform

negative charge on its surface.

3 Exposure

This process causes the LED head to apply light beams according to image signals to the

negatively-charged surface of the OPC drum. The negative charge on the illuminated

surface of the OPC drum is reduced according to magnitudes of the light beams.

Thus, a latent image is formed on the surface of the OPC drum according to the resulting

surface potentials.

4 Developing and recovery of excessive toner

This process applies negatively-charged toner to the surface of the OPC drum. The toner

is electrostatically attracted to the latent image to form a visible image on the surface of

the OPC drum. Simultaneously, this process electrostatically transfers excessive toner

from the OPC drum to the developing roller.

5 Transferring

This process fits paper to the surface of the OPC drum, applies positive charge (opposite

to the charge of the toner) to the back side of the paper from the transfer roller. The toner

image is transferred to the paper.

6 Cleaning

Cleaning blade scrapes off the remaining toner from the OPC drum which has been used

to transfer.

7 Fixing

This process fixes the toner image on the paper by pressing and fusing the image.

41057601TH Rev.1 19/

Page 20

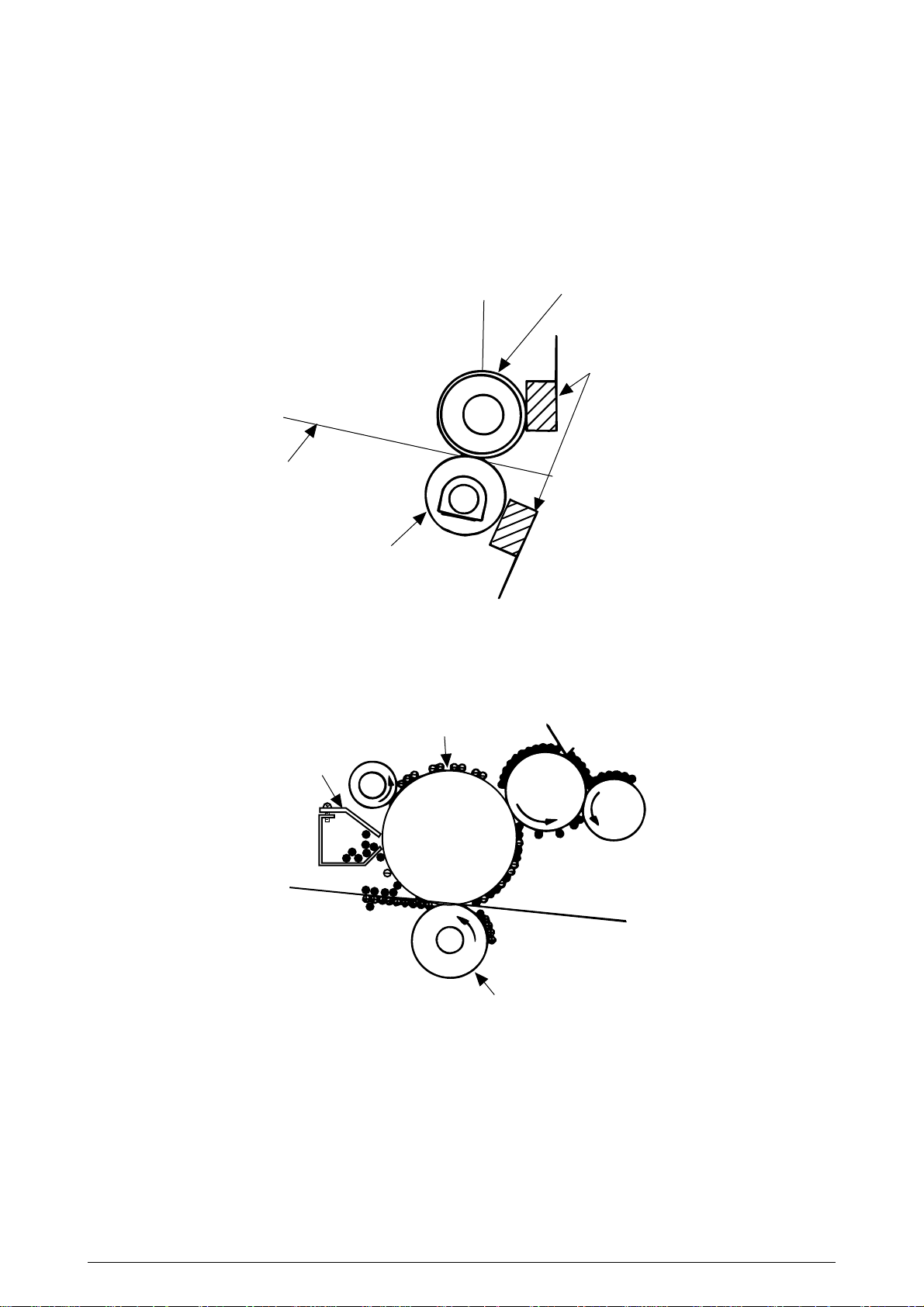

(2) Paper pickup

Pickup roller

Paper (medium)

Conveying belt

A

Conveying belt

Driven roller

B

Power

supply

A DC voltage (0V to 2KV) is applied to the driven roller A to positive charge the lower surface

of the paper. The negatively-charged paper is electrostatically attracted to the pickup roller.

With this, the paper is in close-contact with the conveying Belt and conveyed steadily.

41057601TH Rev.1 20/

Page 21

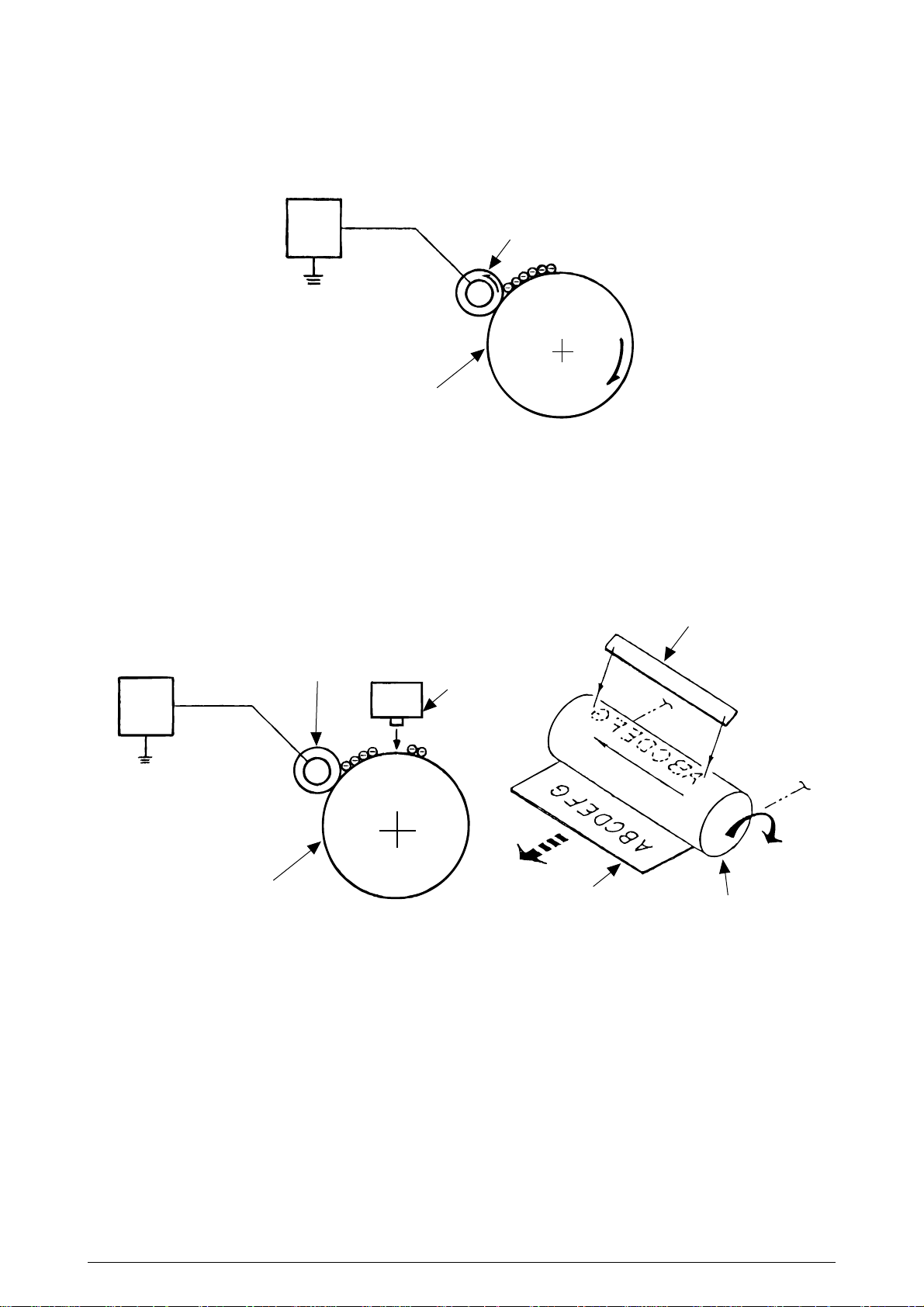

(3) Charging

This process applies a DC voltage to the charging roller in contact with the surface of the OPC

drum.

Power

supply

unit

OPC drum

Charging roller

(4) Exposure

The light beams from the LED head are applied to the surface of the OPC drum which is

charged negatively. The negative charge on the illuminated surface of the OPC drum is

reduced according to magnitudes of the light beams and a latent image is formed on the

surface of the OPC drum according to the resulting surface potentials.

Power

supply

unit

Charging roller

OPC drum

LED head

Paper

LED head

OPC drum

41057601TH Rev.1 21/

Page 22

(5) Developing

This process applies toner to the latent image on the surface of the drum to convey it into a

toner image. Developing is carried out on the surface of the OPC drum at which the OPC drum

is in contact with the developing roller.

1 The sponge roller transfers toner to the developing roller. The toner is charged

negatively.

Developing toner blade

Charging roller

Sponge roller

Developing roller

OPC drum

2 The toner blade scrapes away excessive toner on the developing roller to form a thin

film of toner on the surface of the developing roller.

3 The toner is attracted to the latent image on the surface of the OPC drum at which

the OPC drum is in contact with the developing roller. The latent image on the

surface of the OPC drum is made visible with the toner.

41057601TH Rev.1 22/

Page 23

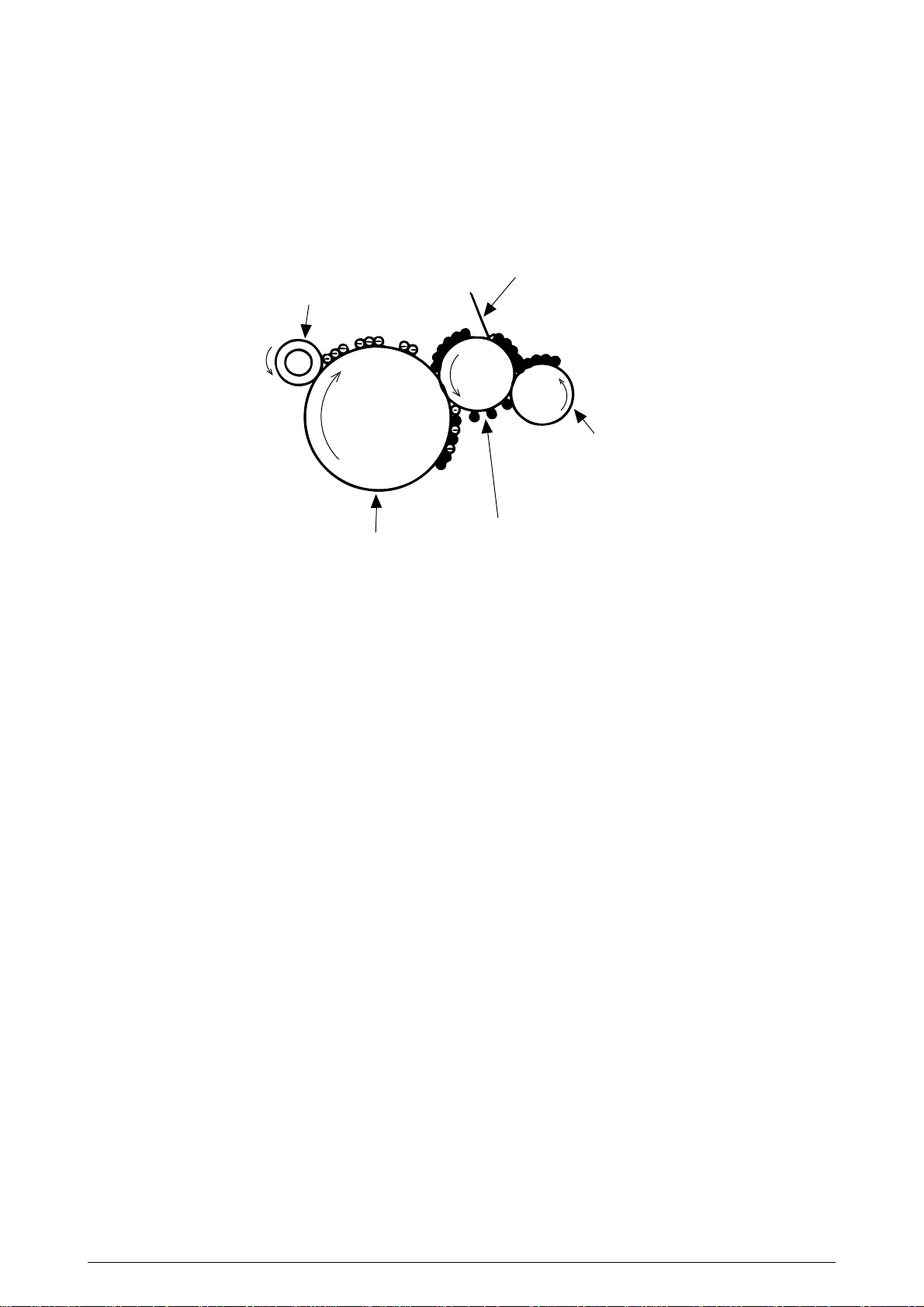

(6) Transferring

The transfer roller made of conductive sponge presses the paper

against the surface of the OPC drum so that the paper may be close contact with the surface

of the OPC drum.

This process fits the paper to the surface of the OPC drum by the transfer roller and applies

positive charge (opposite to the charge of the toner) from under the paper.

When a positive high voltage is applied to the transfer roller from the power supply, the

positive charge induced on the transfer roller jumps to the upper surface of the paper at which

the transfer roller touches the paper and attracts the negatively-charged toner from the

surface of the OPC drum onto the surface of the paper.

OPC drum

Conveying belt

Paper

Transfer roller

Power

supply unit

41057601TH Rev.1 23/

Page 24

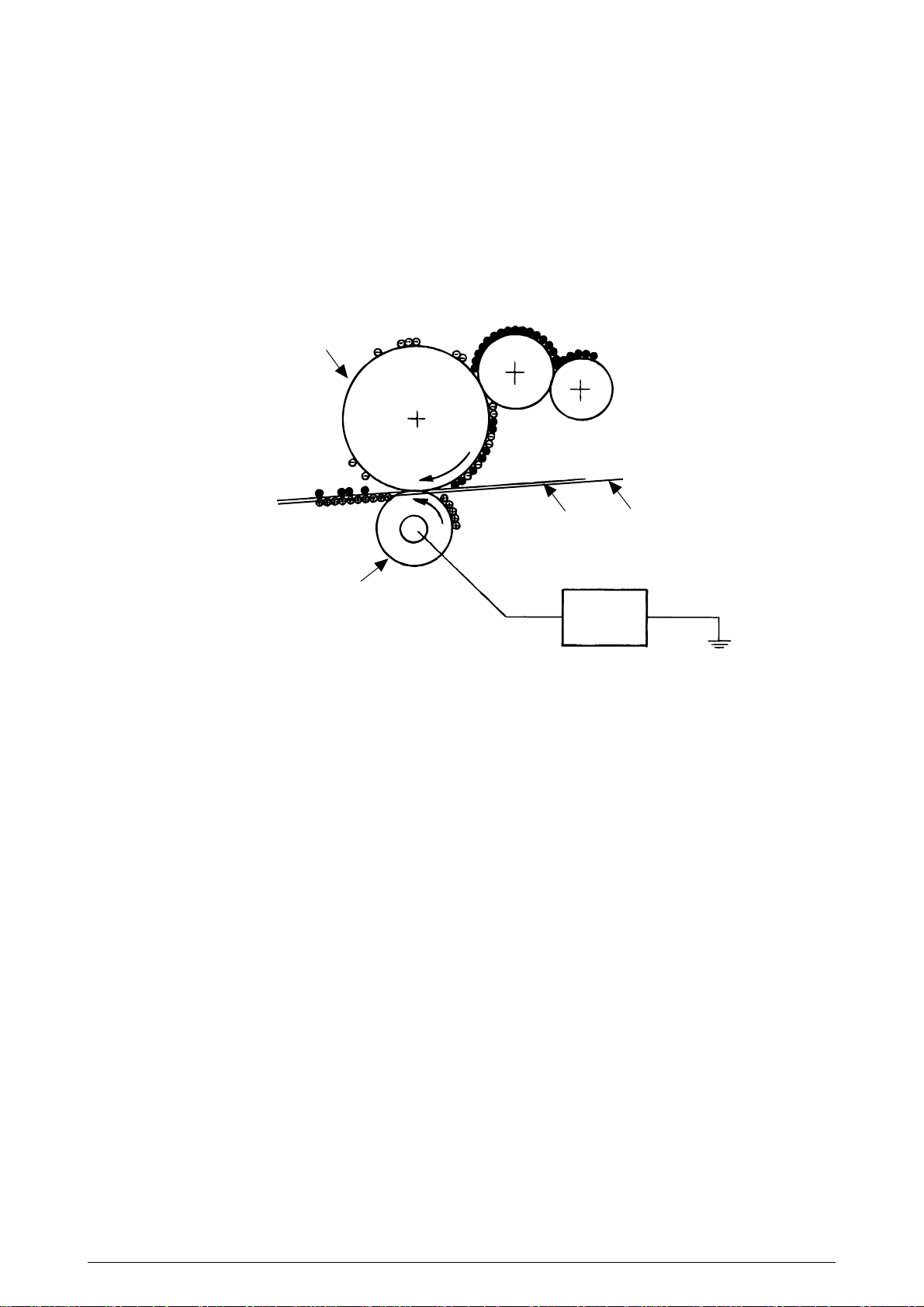

(7) Fixing The toner image just transferred to the paper is fused and fixed to the paper while

the paper is passing through the gap between the heat roller and the backup roller.

The teflon-coated surface of the heat roller is heated up by the 800-watt heater (or a

halogen lamp) provided in the heat roller. The temperature of the heat roller surface is

controlled by a thermistor in contact with the surface of the heat roller. A thermostat is

provided for safety. When the heat roller temperature goes higher than the preset

temperature, the thermostat opens and shut off power to the heater in the heat roller.

The backup roller is evenly pushed against the heat roller by two end springs.

Heater

Paper

Backup roller

Heat roller

Thermistor

(8) Cleaning

The toner which remains on the OPC Drum without being fused is scraped by a cleaning blade

and discarded in the waste toner tank.

OPC drum

Cleaning blade

Transfer roller

41057601TH Rev.1 24/

Page 25

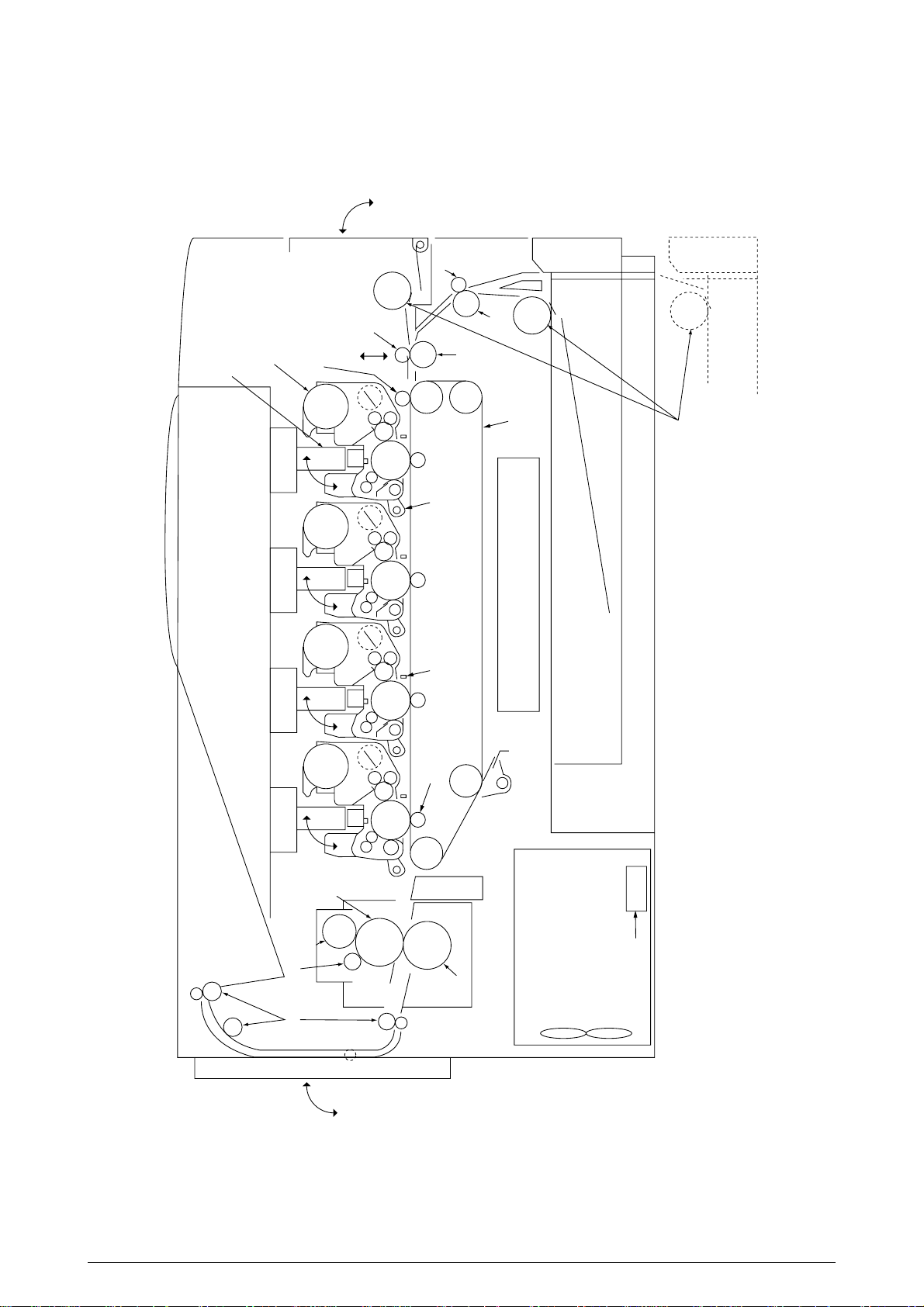

2.4.2 Paper running process

face down stacker

oil roller

fuser

low-voltage power supply

AC switch

transfer roller

x

4 light rejector

x

4

transfer belt unit

ID unit up / down actuater

belt cleaning

high voltage power supply

pick up roller

pinch roller up / down

transfer belt

1st tray

2nd tray

front feeder

KCMY

I/D unit

LED Head

pinch roller 2

pinch roller 1

regist

roller 2

regist

roller 1

hopping roller

backup roller

Eject roller

oil cleaning roller

heat roller

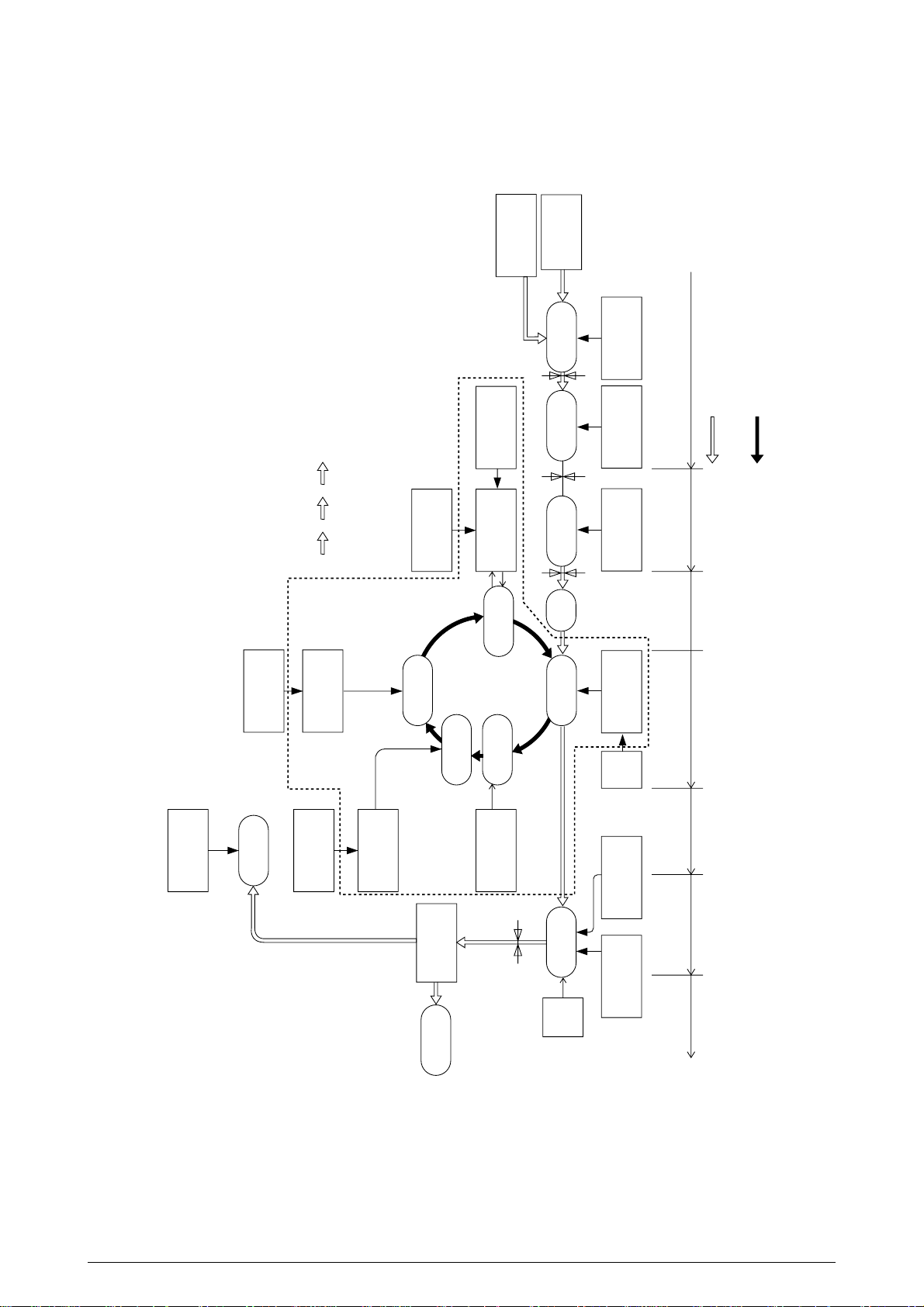

Figure 2.6 shows how paper moves in the OKICOLOR 8/ OKIPAGE 8c Plus.

Figure 2.6 Paper Route

41057601TH Rev.1 25/

Page 26

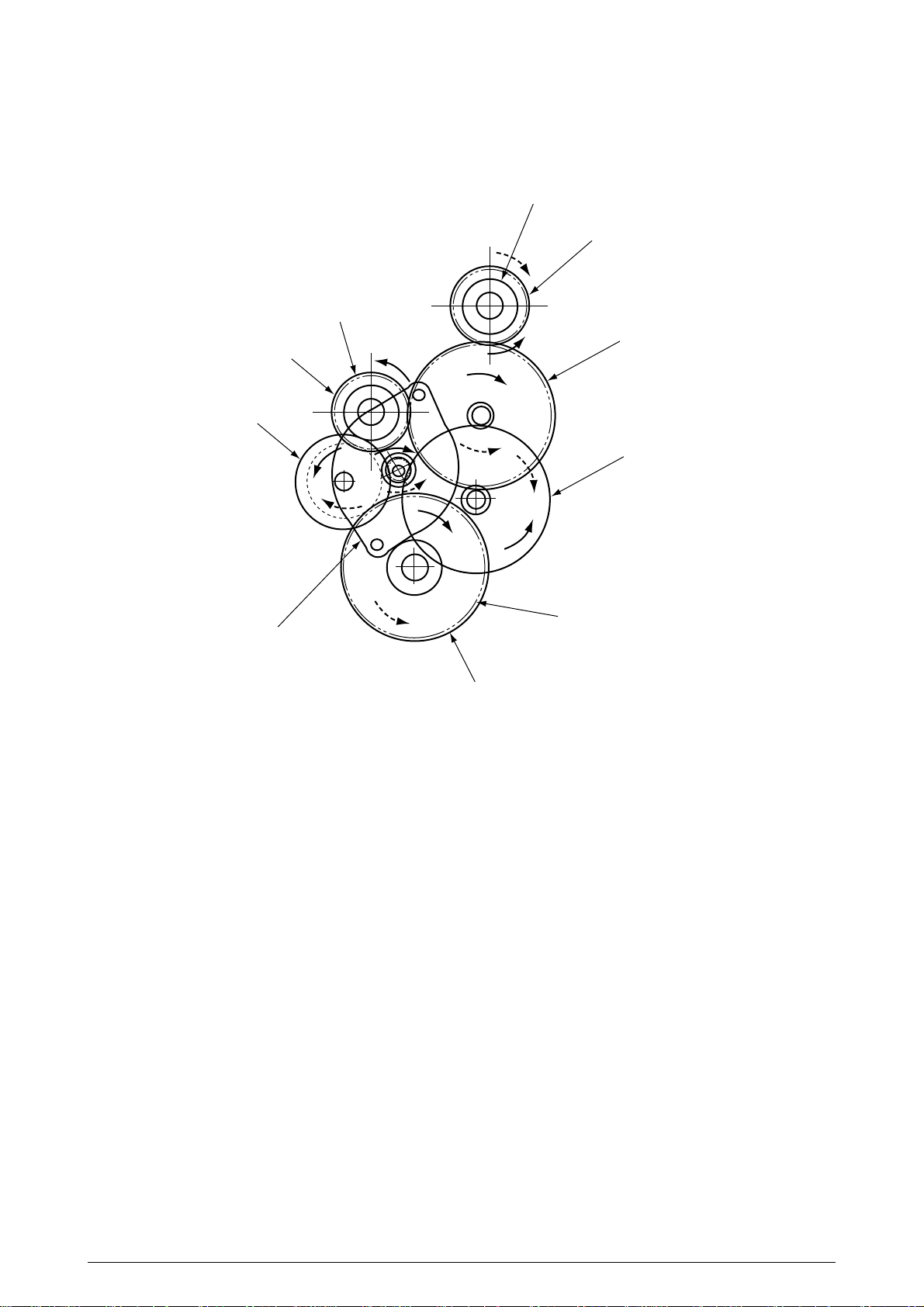

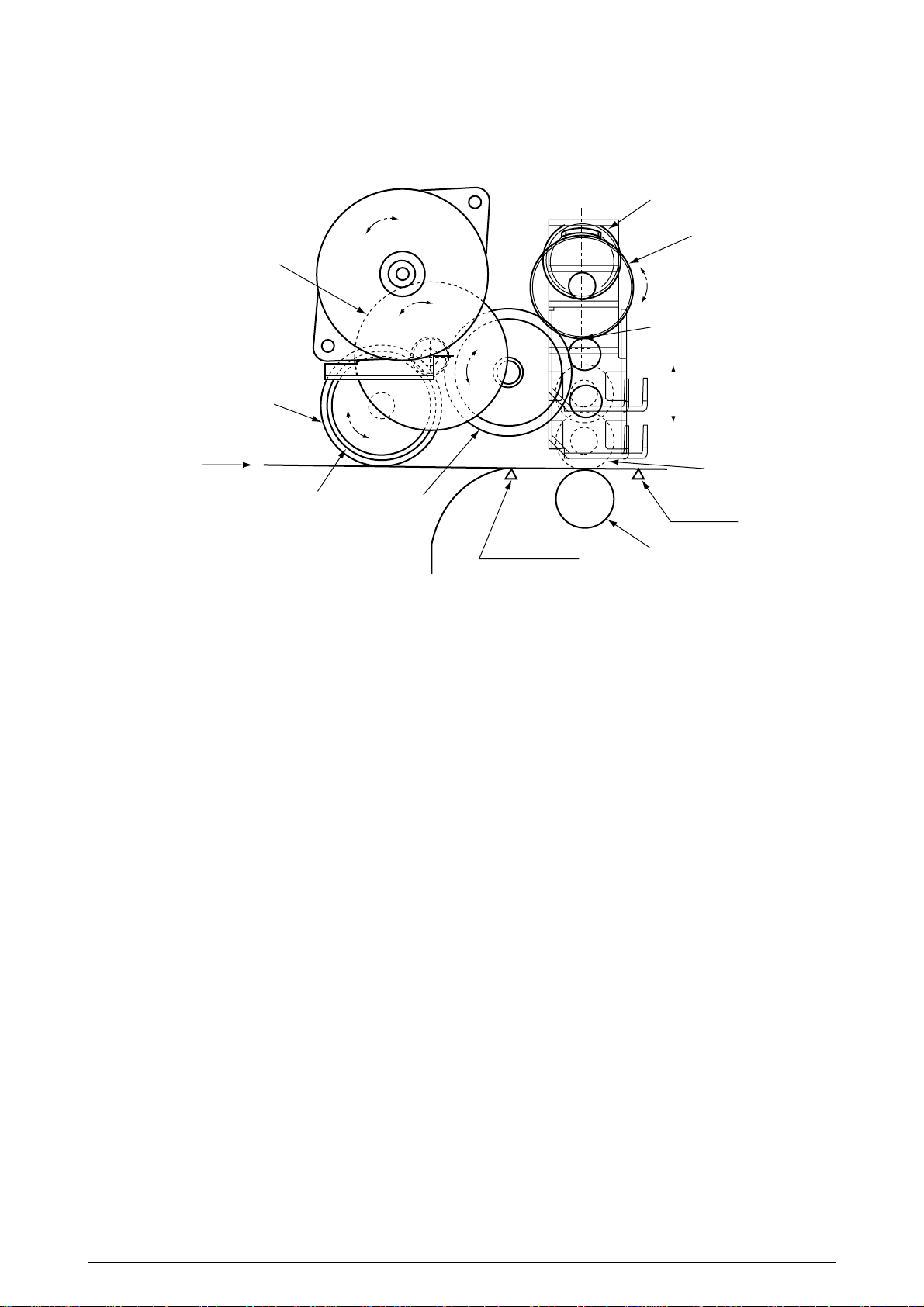

(1) Paper hopping and transfer and up/down movement of pinch roller 2

Paper is hopped and delivered by the mechanism shown below. This mechanism is driven

by a single pulse motor.

Resist roller 2

One-way gear C

Resist roller 1

Idle gear C

One-way gear B

Idle gear A

a

b

Idle gear B

First hopping roller

Pulse motor

One-way gear A

The pulse motor turns in the arrow direction (a) and drives the hopping roller in the direction of

“b.” The hopping roller drives the resist roller.

Each of the one-way clutch gears A, B, and C has a one-way clutch to prevent the rollers from

rotating reversely.

41057601TH Rev.1 26/

Page 27

(a) Hopping

1 The pulse motor turns in the arrow direction of “a” (counterclockwise) and drives the

hopping roller to move the paper until the Entrance sensor turns on. Although the oneway gears B and C are also driven, the resist roller 2 does not turn because the

reverse rotations of the one-way clutch gears are not transmitted to the resist roller.

2 After the Entrance sensor turns on, the hopping roller keeps on feeding the paper until

it hit the resist roller 1. (This operation corrects any paper skew.)

One-way gear C

Resist roller 1

Resist roller 2

One-way gear B

Entrance sensor

Paper

a

First hopping roller

(b) Conveying

1 After paper hopping is completed, the pulse motor turns right (in the direction of “b”)

to drive the resist rollers 1 and 2. The resist rollers feed the paper until the Form

sensor turns on.

Although the one-way gear A is also driven, the hopping roller does not turn because

of the one-way clutch.

2 The paper is further fed in synchronism with the print data.

Form sensor

Resist roller 1

Resist roller 2

b

Paper

First hopping roller

One-way gear A

41057601TH Rev.1 27/

Page 28

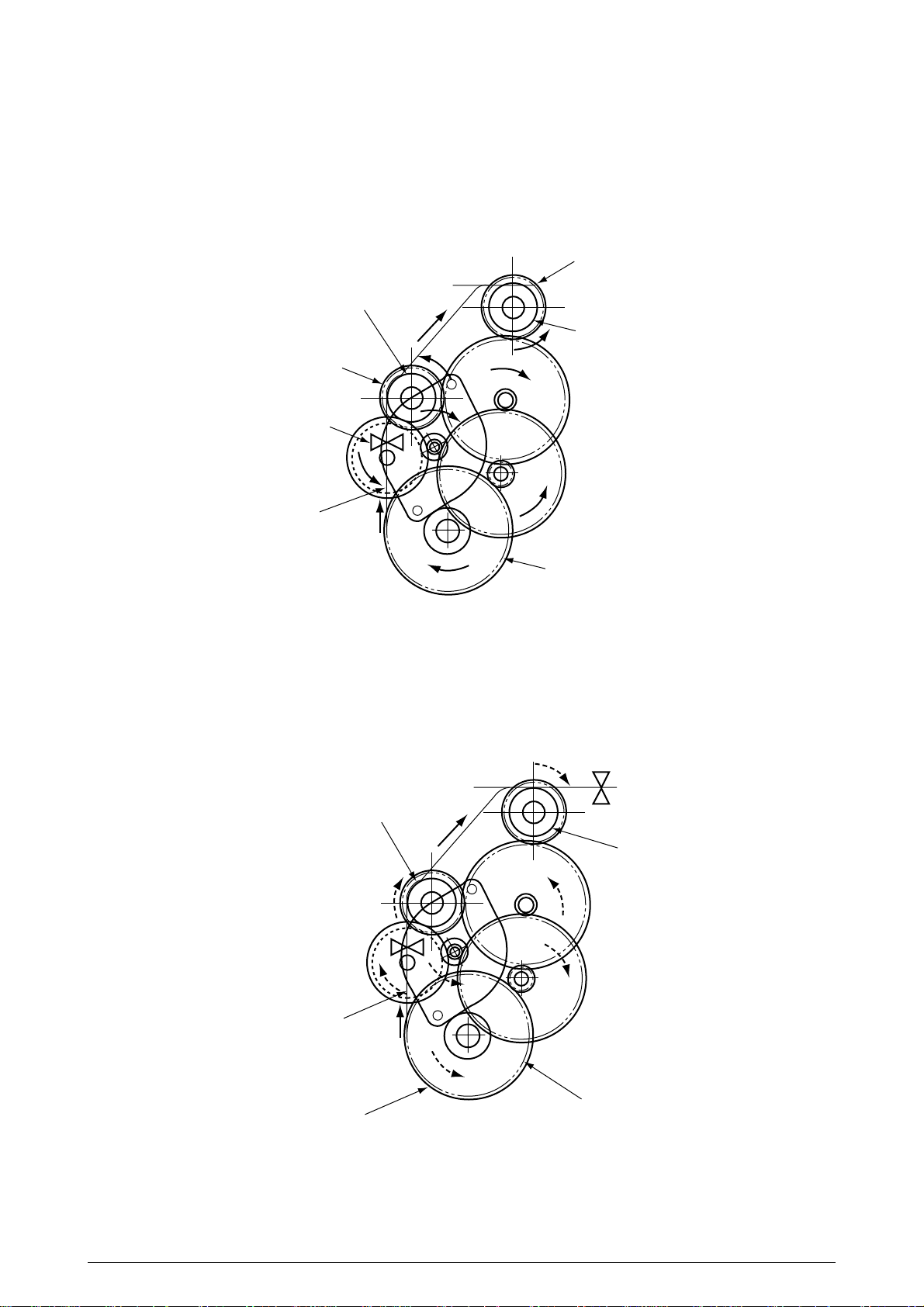

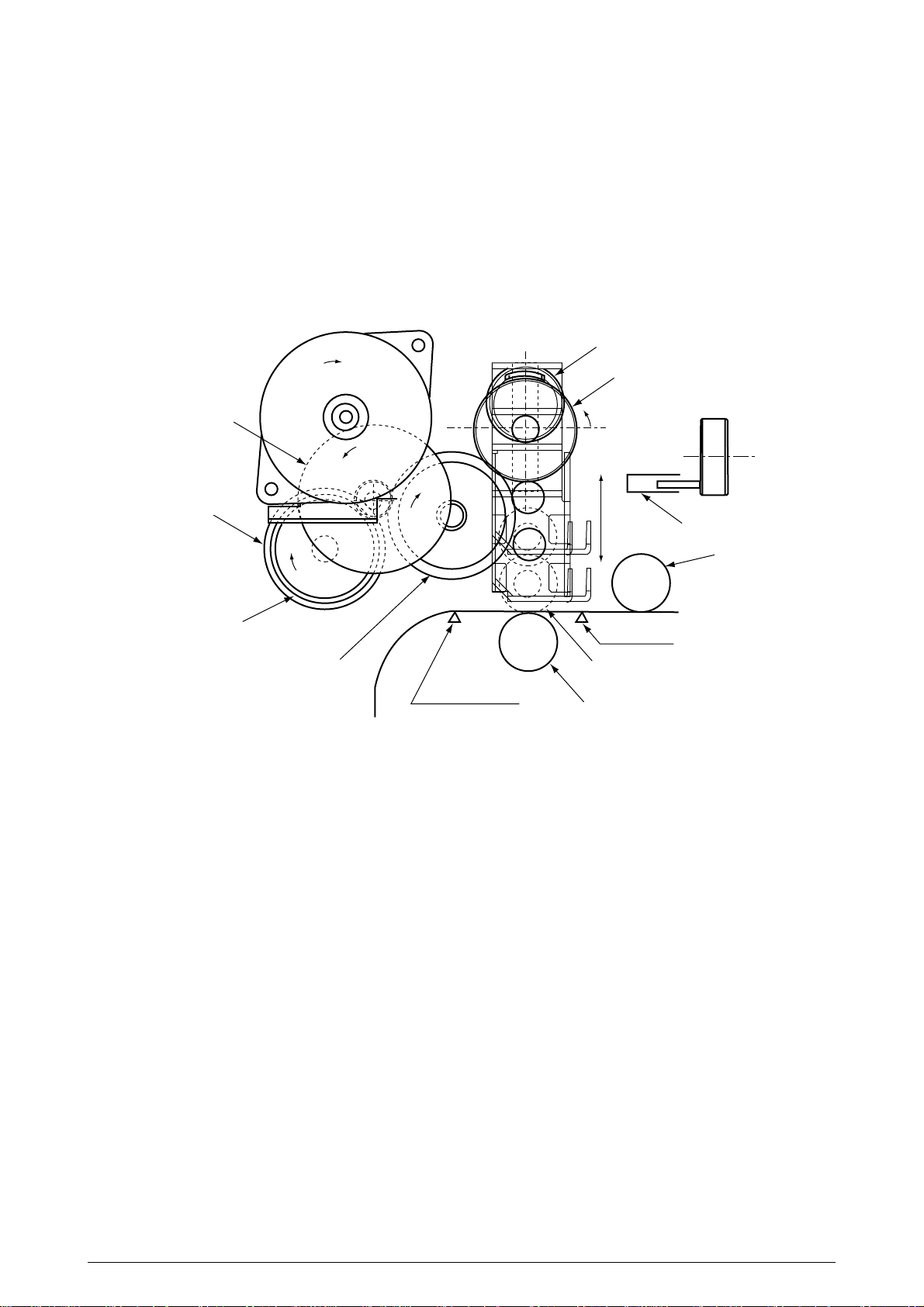

(2) The hopping operation of the front feeder and the up/down operation of the pinch roller 2 are

performed by a single pulse motor, as shown below.

Cam

b

a

Idle gear A

One-way clutch gear B

Sensor position

From front

Hopping roller

One-way clutch gear A Idle gear B

Entrance sensor

Up/down

Pinch roller

Form sensor

Resist roller 2

When the pulse motor of the front feeder turns right (in the direction of “A”), the front hopping

roller turns left (in the direction of “b”) to drive the cam. This cam moves up and down

the pinch roller 2. The one-way clutch gears are made to turn only in a preset direction by

means of the one-way clutches.

41057601TH Rev.1 28/

Page 29

(a) First and second hopping rollers

1 When the front edge of the paper passes by the pickup roller, the pulse motor of the

front feeder turns left (in the direction of “b” to drive the cam. The cam moves up the

pinch roller 2. Although the one-way clutch gear A is also rotating, the hopping roller

of the front feeder does not rotate by means of the one-way clutch.

2 When the rear edge of the paper passes by the Entrance sensor 2, the pulse motor

of the front feeder turns left (in the direction of “b”) to drive the cam. The cam moves

down the pinch roller 2 until it is sensed by the sensor. Although the one-way clutch

gear A is also rotating, the hopping roller of the front feeder does not rotate by means

of the one-way clutch.

Cam

b

One-way clutch gear B

Idle gear A

Hopping roller

One-way clutch gear A

Idle gear B

b

b

Paper from the tray

b

Entrance sensor 2

b

Up

Cam

Sensor

Pickup roller

Form sensor

Pinch roller 2

Resist roller 2

41057601TH Rev.1 29/

Page 30

(b) Front feeder hopping

1 The pulse motor of the front feeder turns right (in the direction of “a” to drive the

Idle gear A

Hopping roller

One-way clutch gear A

Paper from front feeder

hopping roller. The paper is fed until the Entrance sensor 2 turns on. Although the

one-way clutch gear B is also rotating, the pinch roller 2 does not drive the up/down

cam by means of the one-way clutch.

After turning on the Entrance sensor, the paper is further fed until it hits the resist roller

2. (This operation corrects any paper skew.)

One-way clutch gear B

a

b

Cam

Sensor

Pickup roller 2

Form sensor

Idle gear B

Entrance sensor 2

Resist roller 2

(c) Conveying

1 After paper hopping is completed, the pulse motor turns right (in the direction of “b”)

to drive the resist rollers 1 and 2. The resist rollers feed the paper until the Form

sensor turns on.

2 Although the one-way gear A is also driven, the first hopping roller does not turn

because of the one-way clutch.

Paper

b

Form sensor

Resist roller 2

One-way gear A First hopping roller

41057601TH Rev.1 30/

Page 31

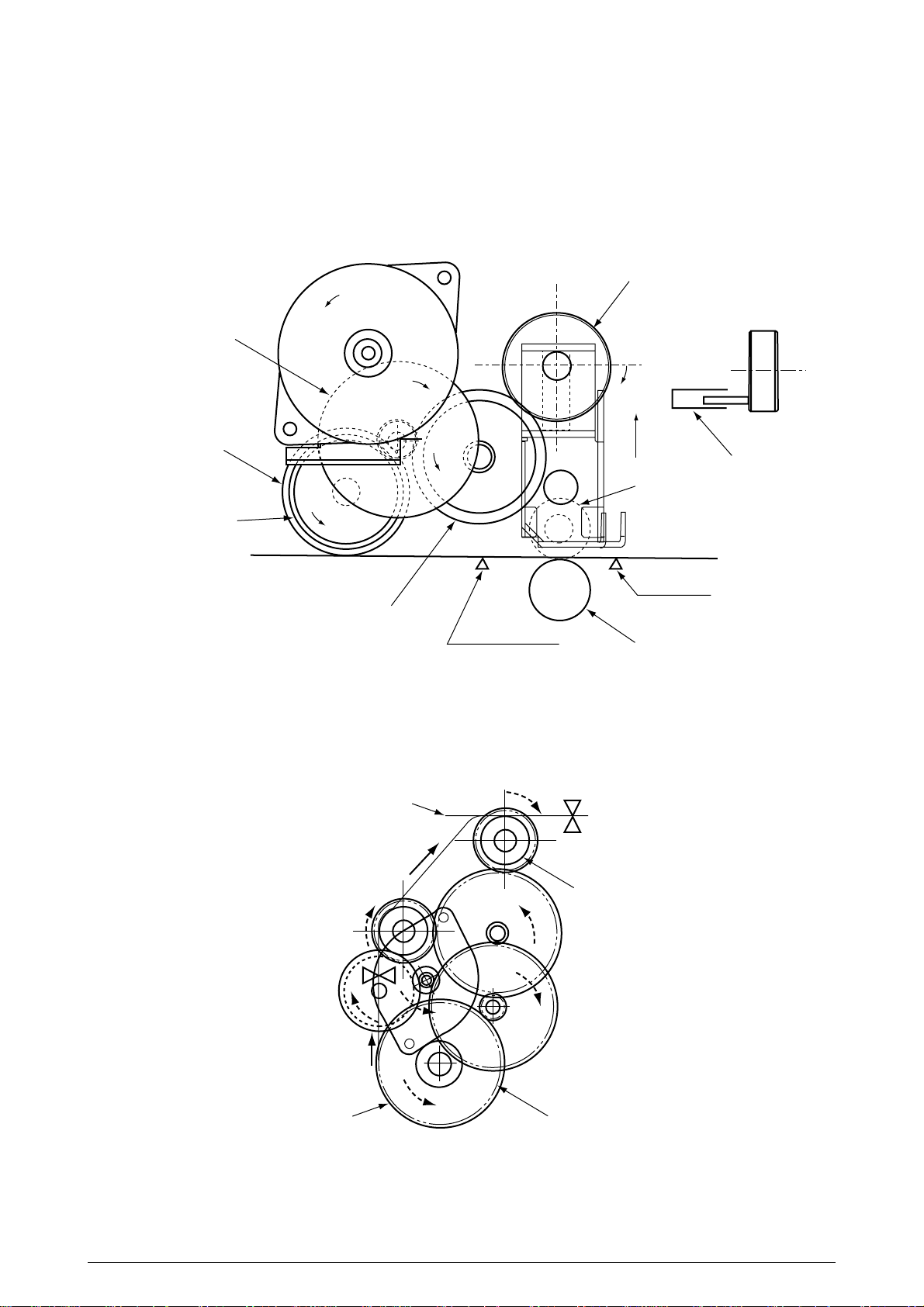

(2) Up/down movement of the I/D unit and rotation of the EP drum

The up/down movement of the I/D unit and the rotation of the EP

drum are performed by a mechanism shown below. (See Figure 2.6-a) This mechanism is

driven by a single pulse motor.

When the pulse motor turns left (CCW), the up/down gear turns left (in the direction of “a”) and

the up/down lever (see Figure 2.6-b) moves up (in the direction of “ ”). The up/down lever

pushes up the up/down actuator of the I/O unit. The I/D unit moves up as shown in Figure

2.6-b. The EP drum rotates freely.

a

Up/down gear

Z53/44

b

Z25/75

CCW

Pulse motor

CW

Z67/43/24

EP drum gear

CCW

Figure 2.6-a

When the pulse motor (see Figure 2.6-a) turns right (CW), the EP drum gear turns left (CCW)

and the up/down gear (one-way gear) is released. The weight of the I/D unit is applied to the

up/down lever via the up/down actuator of the I/O unit. The free up/down gear turns right (in

the direction “b” in Figure 2.6-a) and the I/D unit goes down until the up/down actuator of the

I/D unit is stopped by the up/down lever. (See Figure 2.6-c.) During this, the image is

transferred onto the running paper.

41057601TH Rev.1 31/

Page 32

I/D unit up/down actuator

Up/down lever

Up/down lever

I/D unit

Figure 2.6-b

I/D unit

Figure 2.6-c

41057601TH Rev.1 32/

Page 33

(3) Lubrication and cleaning of fixing, ejecting, and heat rollers

a

a

Ejection roller

Oil cleaning roller

a

a

Face-down stacker

Oil roller

a

Hear roller

a

a

The fixing roller, the ejecting

roller, and the heat roller are lubricated and cleaned by a single

pulse motor.

When the heat roller pulse motor

turns right (in the direction of “a”),

the heat roller and the backup

roller turn left (in the direction of

“a”) to fix a toner image onto the

paper.

At the same time, three ejection

rollers turn right (in the direction

of “a”) to eject the paper. The oil

roller and the oil cleaning roller

turn left (in the direction of “a”) to

supply oil to the surface of the

heat roller and clean the surface.

Backup roller

Heat motor

Fixer

41057601TH Rev.1 33/

Page 34

2.5 Sensors

2.5.1 Paper related sensors

Ejection roller

Heat roller

Exit sensor

Backup roller

Sensor

FF sensor 1/2

(Entrance sensor 1/2)

Form width sensor

Write sensor

Ejection sensor

K drum C drumM drumY drum

Driving roller

Driven rollers

Belt cleaning blade

Function

Detects the front edge of an incoming paper and determines

timing to change from hopping to conveying.

Senses the width of the paper sheet.

Detects the front edge of the conveyed paper sheet and determines the

length of the paper sheet from elapsed time before the front edge of the

paper reaches the sensor.

Detects the front and rear edges of a paper sheet and determines

whether the paper is ejected.

Conveying belt

Write sensor

Pickup roller

Pinch roller 2

Resist roller 2

FF sensor 2

First hopping roller

Second hopping roller

Sensor status

ON: Front edge detected

OFF: Front edge not detected

ON: A4 size or bigger

OFF: Smaller than A4 size

ON: Form present

OFF: Form absent

ON: Form present

OFF: Form ejected

FF hopping roller

Form width sensor

Pinch roller 1

Resist roller 1

FF sensor 1

Auxiliary rollers

41057601TH Rev.1 34/

Page 35

2.5.2 Other sensors

1 Form end sensor

This sensor checks whether the paper cassette is empty.

2 FF form end sensor

This sensor checks whether the front feeder has paper.

3 FF home switch

This microswitch checks whether the front feeder stage is in the up or down position.

4 EP up/down sensor (one for each color Y, M, C, K)

This sensor checks whether the I/D unit is in the up or down position.

5 Waste toner sensor

This sensor judges whether the waste toner cartridge is full by measuring a time period at

which the sensor lever turns on periodically. When the time period falls under a preset

value, the system judges that the waste toner cartridge is full and displays the “waste

toner full” message.

6 Resist up/down sensor

This sensor detects the up or down position of the resist roller 2.

7 Temperature sensor

Refer to 2.8 (Transfer Control according to Environmental Changes).

8 Humidity sensor

Refer to 2.8 (Transfer Control according to Environmental Changes).

41057601TH Rev.1 35/

Page 36

2.6 Correction of Color Deviation

OKIPAGE 8c is equipped with an array of I/D units which cannot be from generation of color

deviations. This mechanically caused color deviation is corrected electronically as shown

below.

(1) Color deviations to be corrected

1 Color deviation in the X axis (Positional error of the LED head)

2 Diagonal color deviation (Positional error of the LED head)

3 Color deviation in the Y axis (Positional errors of the I/D units and light receivers)

(2) Method of correction Print out the preset color chart, compare the printed color chart by

the original color chart, and enter the amount of color deviation of each color from the

operator panel or from the host computer. OKIPAGE 8c calculates correction values from

the entered values and changes the write timing of each color (cyan, magenta, and

yellow) relative to black.

2.7 Transfer Control according to Environmental Changes (Room Temperatures and

Relative Humidities)

OKIPAGE 8c measures the room temperature and humidity by the room temperature sensor

and the room humidity sensor, calculates an optimum transfer voltage according to the obtained environmental conditions and realtime-controls printing with the optimum transfer

voltage.

41057601TH Rev.1 36/

Page 37

2.8 Form Jam Detection

OKICOLOR 8/ OKIPAGE 8c Plus checks for a paper jam when the page printer is powered on

and during printing. When finding a paper jam, OKICOLOR 8/ OKIPAGE 8c Plus immediately

stops the printing process. To recover the printer, open the cover, find and remove the

jammed paper, then close the cover.

Error

Form feed jam

Convey jam

Ejection jam

Form size error

Three hopping operations are made, but the Form Feed sensor (Entrance) does not turn on a preset

time after the Form Feed sensor 1 turns on.

The ejection sensor does not turn on a preset time period after the Write sensor detects the front end

of paper.

The ejection sensor detected the front edge of the paper but does not detect the rear edge of the paper

for a preset time period.

The form size obtained by measuring the time period before the rear edge of the paper passes by the

Form Feed sensor 2 after the front edge of the paper passed the Write sensor is longer by 45mm than

the specified form length.

2.9 Cover Opening

When the upper, side, or front cover of OKICOLOR 8/ OKIPAGE 8c Plus is opened, the Cover

Open microswitch turns off, a voltage of 32V to the high-voltage power supply is shut off, and

all high-voltage outputs are shut off. At the same time, the CPU receives a signal (CVOPN)

indicating the status of the microswitch and performs the cover open process.

PX4-PCB

CPU

65524

+32V

Conditions

Upper cover

microswitch

Side cover

microswitch

Front cover

microswitch

P4.7

12

COVOPN (2P)

High-voltage power supply board

HVOLT (16P)

detect

circuit

High-voltage power supply unit

41057601TH Rev.1 37/

Page 38

2.10 Toner Low Detection

• Composition

The device consists of the stirring gear which rotates at a constant rate, the stirring bar and

the magnet on the stirring bar. The stirring bar rotates through the engagement of concave

in the stirring gear.

Magnet

Stirring Bar Stirring Gear

• Operation

Toner Low is detected by monitoring the time interval of the encounter of the magnet set on

the sensor lever and the magnet on the stirring bar.

Stirring Gear Section

Operation during toner full state

• The stirring bar rotates due to the interlocking

with the stirring gear.

• Even when the magnet on the stirring bar

reaches the maximum height, since the other

side is being dipped in the toner, the stirring bar

is pushed by the stirring gear.

Stirring Bar

Toner Sensor

Concave

Sensor Lever

Stirring Bar

Operation during toner low state

• When the stirring bar reaches the maximum

height, since there is no resistance provided by

the toner on the other side, it falls to the minimum height due to its own weight. Because of

this, the time interval during which it is in encounter with the magnet of the sensor lever

becomes long. By monitoring this time interval,

toner low can be detected.

41057601TH Rev.1 38/

Sensor Lever

Page 39

TONER FULL state

TNRSNS

t1

1.965 SEC.

t1 < 0.74 SEC (Y)

t1 < 1.165 SEC (M, C, K)

TONER LOW state

TNRSNS

t1

1.965 SEC.

t1 > 0.74 SEC (Y)

t1 > 1.165 SEC (M, C, K)

• When the toner low state is detected for 2 times consecutively, Toner Low is established.

• When the toner full state is detected for 2 times consecutively, Toner Low is cancelled.

• When there is no change with the toner sensor for 2 cycles (1.965 sec. x 2) or more, then the

Toner Sensor Alarm is activated.

• The toner sensor is not monitored while the drum motor is in halt.

2.11 Page Size Detection

The four tab pieces are driven according to the setting position of the paper guide through the cam

interlocked with the paper guide of the paper cassette.

When the paper cassette is inserted into the printer, the state of the tab pieces is detected by the

microswitch to recognize the paper size.

State of Microswitches Paper size

SW1 SW2 SW3 SW4

0111Letter

0101Executive

0011A4

1110Legal 14

1011Legal 13

1101B5

1100A5

1001A6

41057601TH Rev.1 39/

Page 40

2.12 Power-on Processing

2.12.1 Self-diagnostic test

(1) Initial test

The following checks are automatically performed when the OKICOLOR 8 / OKIPAGE 8c

Plus page printer is powered on:

(a) ROM check

(b) RAM check

(c) EEPROM check

(d) Flash ROM check

(2) ROM check

(a) Checks ROM by comparing the sum of bits in the received data unit by the number of bits

in the transferred data unit.

(3) RAM check

(a) Checks RAM by writing a preset data pattern in RAM, reading the contents of RAM, and

comparing the data read from RAM by the data written in RAM. (Write-read test)

(b) Checks optional RAM if it is installed.

(c) Checks resident RAM by exclusively ORing high and low addresses (to prepare 16-bit

data units), writing a preset 16-bit data pattern in RAM, reading the contents of RAM, and

comparing the data read from RAM by the data written in RAM. Checks optional RAM

by writing and reading 32-bit fixed patterns (“5555h” and “aaaah”) in optional RAM.

(4) EEPROM check

(a) Checks ID numbers stored in the fixed addresses of EEPROM.

(b) Checks the content of the menu area by control firmware and the engine area by engine

firmware.

(5) Flash ROM check

Checks Flash ROM by writing a present data pattern in Flash ROM, reading the contents

ofFlash ROM, and comparing the data read from Flash ROM by the data written in Flash

ROM. (Write-read test).

(6) Option unit check

Checks whether the optional units (such as the second tray, PS SIMM, and so on) have been

installed before entering the operation mode.

41057601TH Rev.1 40/

Page 41

3. PARTS REPLACEMENT

The section explains the procedures for replacement of parts, assemblies, and units in the field.

Only the removal procedures are explained here. Reverse the procedure for the installation.

3.1 Precautions for Parts Replacement

(1) Before starting parts replacement, remove the AC cable and interface cable.

(a) Remove the AC cable in the following procedure:

i) Turn off ("o") the power switch of the printer

ii) Disconnect the AC inlet plug of the AC cable from the AC receptacle.

iii) Disconnect the AC cable and interface cable from the printer.

(b) Reconnect the printer in the following procedure.

i) Connect the AC cable and interface cable to the printer.

ii) Connect the AC inlet plug to the AC receptacle.

iii) Turn on ("l") the power switch of the printer.

Disconnect

(2) Do not try disassembly as long as the printer is operating normally.

(3) Do not remove unnecessary parts: try to keep disassembly to a minimum.

(4) Use specified service tools.

(5) When disassembling, follow the determined sequence. Otherwise, parts may be damaged.

(6) Since screws, collars and other small parts are likely to be lost, they should temporarily be

(7) When handling ICs such as microprocessors, ROM and RAM, and circuit boards, do not wear

(8) Do not place printed circuit boards directly on the equipment or floor.

Connect

attached to the orginal positions.

gloves that are likely to generate static electricity.

41057601TH Rev.1 41/

Page 42

[Service Tools]

Table 3-1 shows the tools required for field replacement of printed circuit boards and units.

Table 3-1 Service Tools

No.

1

2

3

4

5

6

7 1

8

9

No. 1-100 Philips

screwdriver

No. 2-200 Philips

screwdriver, Magnetized

No. 3-100 screwdriver

No. 5-200 screwdriver

Digital multimeter

Pliers

Handy cleaner

LED Head cleaner

P/N 4PB4083-2248P1

Tweezers

Q' ty Place of use RemarksService Tools

1

2~2.5 mm screws

1

3~5 mm screws

1

1

1

1

1

Cleans LED head

1

41057601TH Rev.1 42/

Page 43

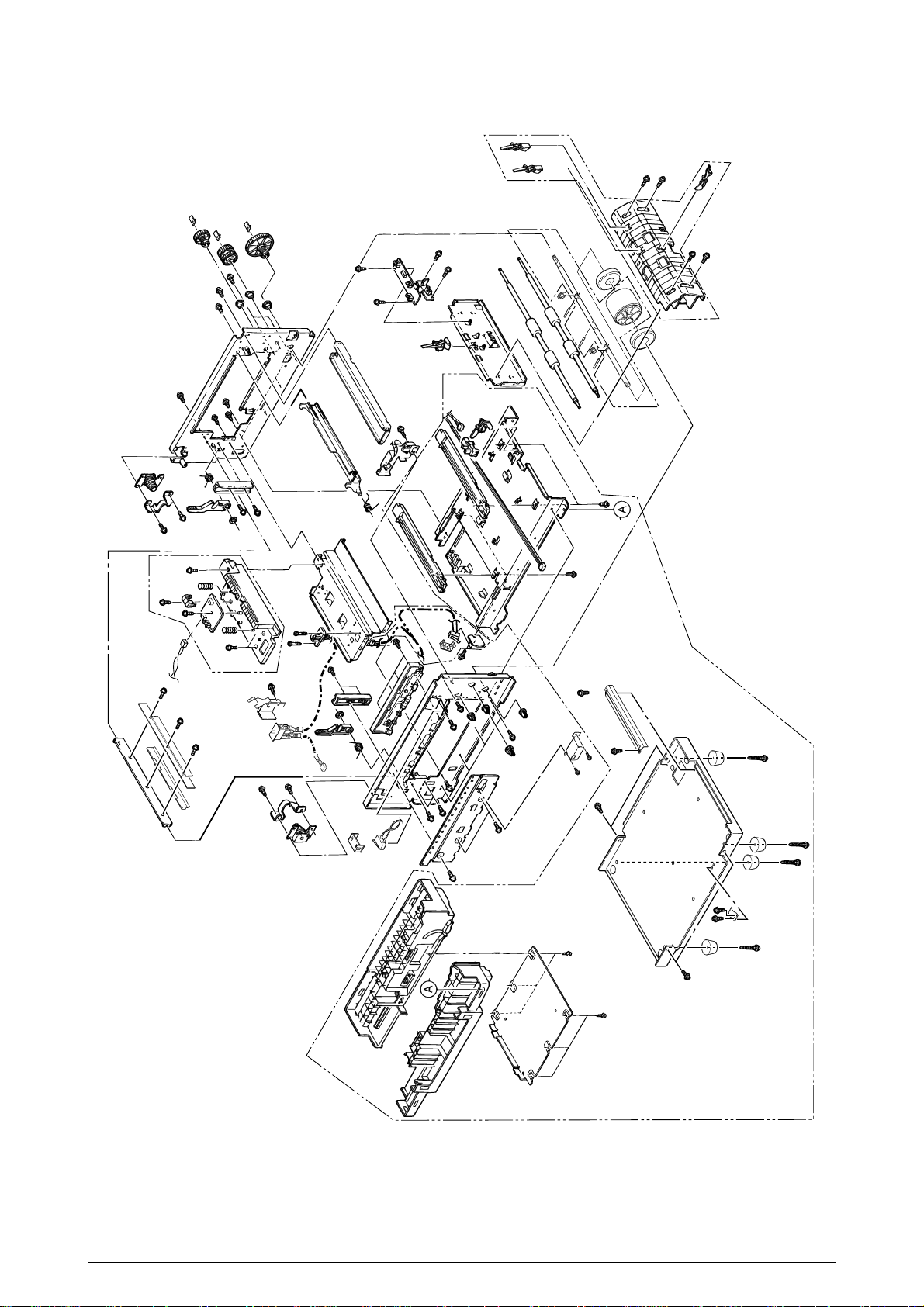

3.2 Parts Layout

Figure 3-1

41057601TH Rev.1 43/

Page 44

Figure 3-2

41057601TH Rev.1 44/

Page 45

Figure 3-3

41057601TH Rev.1 45/

Page 46

Figure 3-4

41057601TH Rev.1 46/

Page 47

3.3 How to Change Parts

Printer Unit

Cover Assy Rear (3.3.1)

Cover (3.3.8)

Belt Cassette Assy (3.3.32)

Heat Unit Assy (3.3.40)

Oil Roller Assy (3.3.41)

Holder LED Assy (3.3.45)

Frame Assy Upper (3.3.5) Plate Support Assy (3.3.6) Limiter 2Way (L), (R) (3.3.7)

/Plate Guide (L) ,(R)

Motor Fan (80-25) (3.3.2)

Paper Eject Assy (3.3.3)

Cover Assy Stacker (3.3.4)

Guide Eject FD Assy

PCB Assy : PCE (3.3.9)

Power Supply Unit (3.3.16)

Hopping Motor (3.3.19)

Feeder Unit Front (3.3.21)

Manual Hopper Assy (3.3.22)

PCO PCB (3.3.29)

Holder Gear Toner Assy (3.3.30)

Plate Latch Lever (FD) (3.3.31)

High Voltage Power Supply Unit (3.3.33)

Eraser BKT Assy (3.3.34)

Lever Lock Heat L, R (3.3.42)

PXL PCB (3.3.43)

Heat Unit Guide Assy (3.3.44)

Moter Fan (3.3.10)

PXF PCB / PX4 PCB (3.3.11)

Gear Heat Assy (3.3.12)

Main Motor (A),(B) Assy (3.3.13)

Gear Oneway (Z30) (3.3.14)

Motor Assy BT (3.3.15)

Sensor Assy BOX Toner (3.3.17)

Square-shaped connector (3.3.18)

Gear One-way (3.3.20)

Guide Paper Input Assy (3.3.23)

Lever Input Sensor (3.3.24)

Lever 2nd Feed Sensor

Roller Registration

Roller Assy Hopping (3.3.25)

PXU PCB/PXM PCB (3.3.27)

Roller Hopping (3.3.26)

Paper End Lever (3.3.28)

Shaft Link, Lever Link (3.3.35)

Contact (BL-R, CL-R) Assy (3.3.36)

Contact (BL-L, CL-L) Assy (3.3.37)

Contact SB Assy (3.3.38)

PXC PCB (3.3.39)

This section explains how to change parts and assemblies appearing in the disassembly diagram

below.

41057601TH Rev.1 47/

Page 48

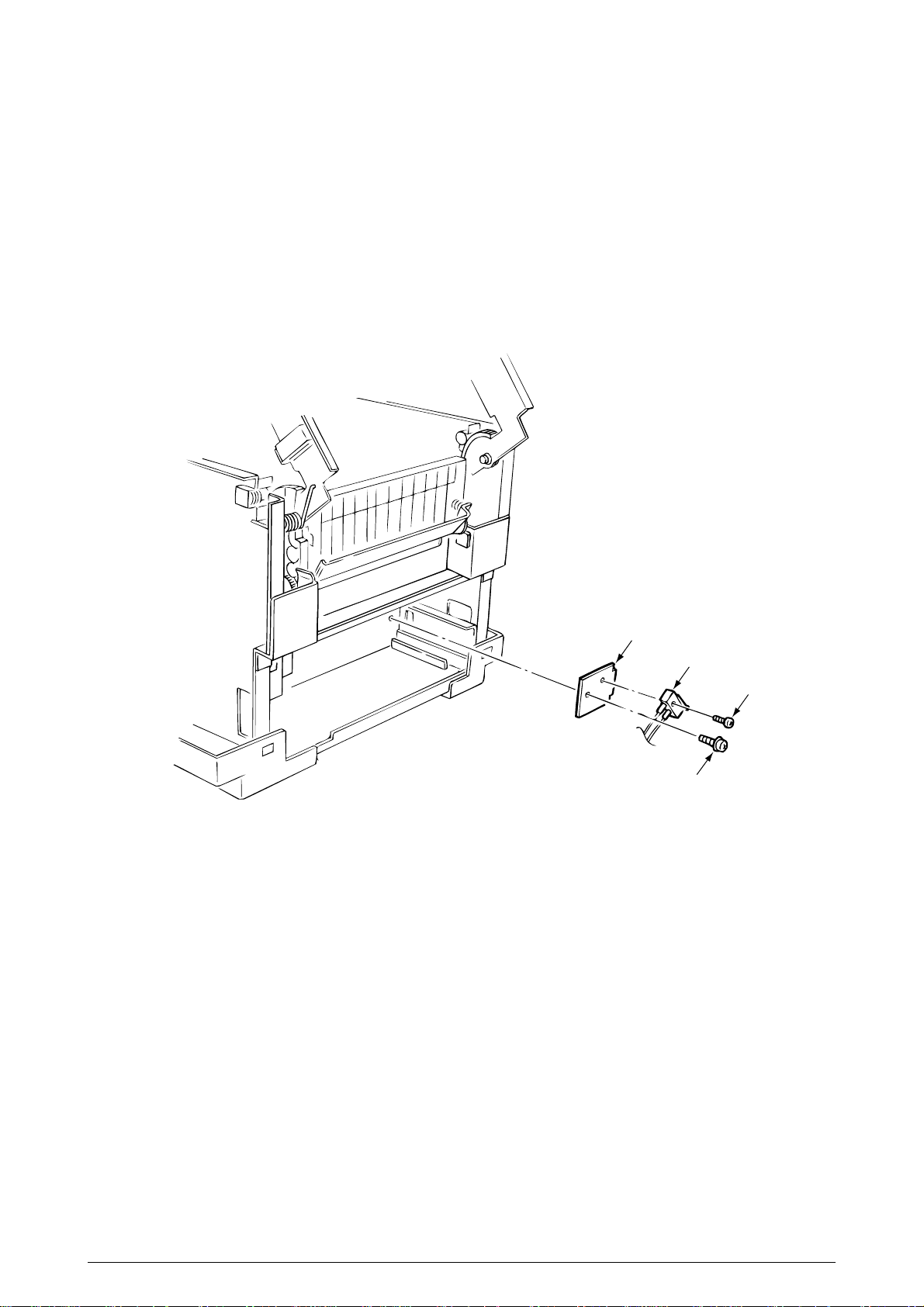

3.3.1 Cover Assy Rear

1. Unscrew 2 screws 1 then lift the cover assy rear 2 a little bit, then remove the cover assy

rear by releasing the lock of two claws.

Figure 3.3.1 Cover Assy Rear

2

1

41057601TH Rev.1 48/

Page 49

3.3.2 Motor-Fan (80-25)

1. Remove the cover assy rear. (See 3.3.1)

2. Unscrew 2 screws 1.

3. Detach the motor-fan 2 from the guide with its right side lifted then draw the motor-fan.

4. Unplug the cable 3 then remove the motor-fan 2.

3

Figure 3.3.2 Motor-Fan (80-25)

2

1

41057601TH Rev.1 49/

Page 50

3.3.3 Paper Eject Assy

The paper eject assy comprises the frame eject assy and the guide paper eject assy.

1. Remove the cover assy rear. (See 3.3.1)

2. Open the top cover.

3. Unscrew 4 screws 1 then remove the frame eject assy 2.

4. Remove the guide paper eject assy 3 by releasing the lock of one claw.

3

claw

Figure 3.3.3 Paper Eject Assy

1x2

2

1x2

41057601TH Rev.1 50/

Page 51

3.3.4 Cover Assy Stacker, Guide Eject FD Assy

Remove the belt cassette assy and the heat unit assy.

1. Remove the cover assy rear. (See 3.3.1)

2. Detach the cable from the cable clamp 1 by releasing its lock.

3. Unscrew 8 screws 2 then remove the cover assy stacker.

4. Unscrew 4 screws 4 then remove the guide eject FD assy 5.

3

2x6

4

5

4x4

1

2x2

Cable

Figure 3.3.4 Cover Assy Stacker, Guide Eject FD Assy

41057601TH Rev.1 51/

Page 52

3.3.5 Frame Assy Upper

1. Remove the cover assy rear. (See 3.3.1.)

2. Remove the cover assy stacker. (See 3.3.4.)

3. Remove the holder LED assy. (See 3.3.45.)

4. Detach the cable from the cable clamp 1 by releasing its lock.

5. Remove connections of 4 connector cables 2 and 4 cables 3.

6. Unscrew 4 screws 4 then remove the PCB 5.

7. Unscrew 2 screw 6 then remove Holder 7 by releasing the clamp of the claw.

8. Unscrew 4 screws 8 then remove the frame assy upper 9.

8x2

4x4

9

5

6

2

7

3

7

8x2

1

Cable

Figure 3.3.5 Frame Assy Upper

41057601TH Rev.1 52/

Page 53

3.3.6 Plate Support Assy

The plate support assemblies are provided right and left. The method of those replacements is the

same.

1. Remove the heat unit assy. (See 3.3.40)

2. Remove the cover assy rear. (See 3.3.1)

3. Remove the cover assy stacker. (See 3.3.4)

4. Remove the frame assy upper. (See 3.3.5)

5. Detach the cable from the cable clamp 1 by releasing its lock.

6. Unscrew 2 screws 2 then remove the plate support assy 3.

(Be careful not to lose the spring 4 which is removed with the plate support assy 3.)

4

4

3

2

2

3

1

Cable

Figure 3.3.6 Plate Support Assy

41057601TH Rev.1 53/

Page 54

3.3.7 Limiter 2way (L), (R) / Plate Guide (L) , (R)

1. Remove the plate support assy (L) and (R). (See 3.3.6)

2. Unscrew 2 screws 1 then remove the limiter 2way (L) 2 and the plate guide (L) 3.

3. Unscrew 2 screws 4 then remove limiter 2way (R) 5 and the plate guide (R) 6.

4

1

3

2

Figure 3.3.7 Limiter 2way (L), (R) / Plate Guide (L) , (R)

5

6

41057601TH Rev.1 54/

Page 55

3.3.8 Cover

Describes the method of removing the cover assy side (L)/(R), cover assy OP panel, cover front

(L)/(R) and the cover rear (L).

Remove the belt cassette assy and the heat unit assy.

1. Remove the cover assy rear. (See 3.3.1)

2. Remove the cover assy stacker. (See 3.3.4)

3. Unscrew 2 screws 1 then remove the frame side (L) 2.

4. Unscrew 2 screws 3 then release the lock of the claw with the cover assy side (R) 4 lifted

5. Unplug the operator panel cable 5 from the PCM PCB.

6. Open the FDR unit front in the arrow direction.

7. Unscrew 2 screws 6 then remove the cover assy OP panel7.

8. Unscrew 2 screws 8 then release the lock of the claw with the cover front (R) 9 pushed up

9. Unscrew 2 screws 0 then remove the cover front (L) A.

10. Unscrew 2 screws B then remove the cover rear (L) C.

11. Pull off the film E glued on the cassette guide.

11. Release the engagement with the guide by lifting the cover assy side (L) D, then remove the

a little bit, then remove the cover assy side (R).

then remove the cover front (R).

cover assy side (L).

C

6

1

7

5

3

2

4

8

9

A

Pushed Up

E

B

A

FDR Unit Front

A

D

0

Figure 3.3.8 Cover

41057601TH Rev.1 55/

Page 56

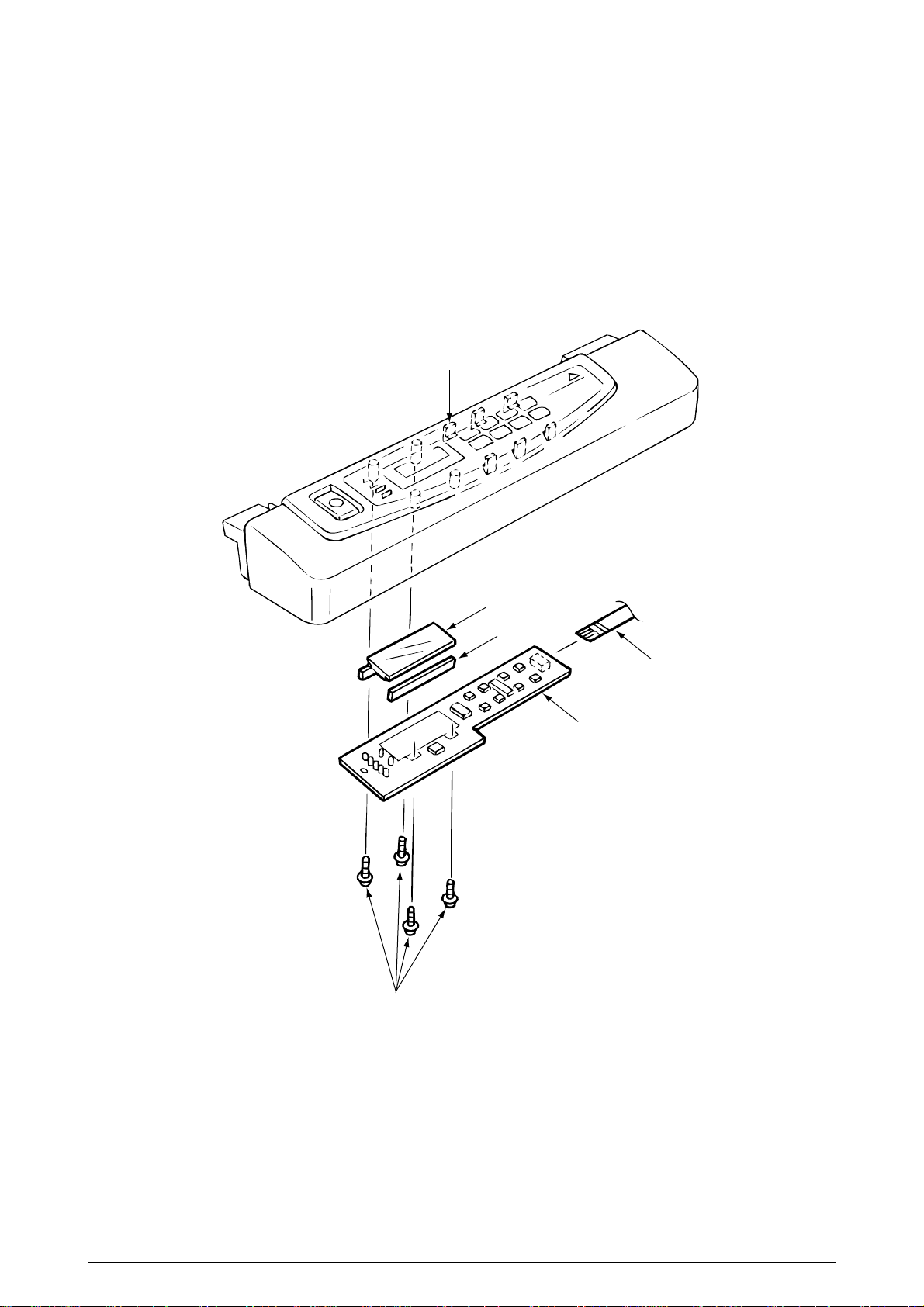

3.3.9 PCB Assy : PCE

Remove the belt cassette assy and the heat unit assy.

1. Open the top cover.

2. Unscrew 2 screws 1 to release the lock of the claw by lifting the cover assy side (R) 2 a little

bit, then remove the cover assy side (R).

3. Unscrew 2 screws 8 to remove the plate shieled (CU) 9.

4. Unscrew 3 screws 3 to remove the plate shield 4.

5. Unplug the operator panel cable 5 from the PCE PCB.

6. Unscrew 8 screws 6 to remove the PCB assy : PCE 7.

8

9

1

7

5

6

Figure 3.3.9 PCB Assy : PCR

2

3

4

41057601TH Rev.1 56/

Page 57

3.3.10 Motor Fan (CU)

1. Open the top cover.

2. Remove the cover assy side (R), frame side (L), cover assy OP panel and the cover front (R).

(See 3.3.8)

3. Unplug the cable 1 and unscrew 2 screws 2, 2 collars 4 and then remove the motor fan

(CU) 3.

3

1

4

2

Figure 3.3.10 Motor Fan (CU)

41057601TH Rev.1 57/

Page 58

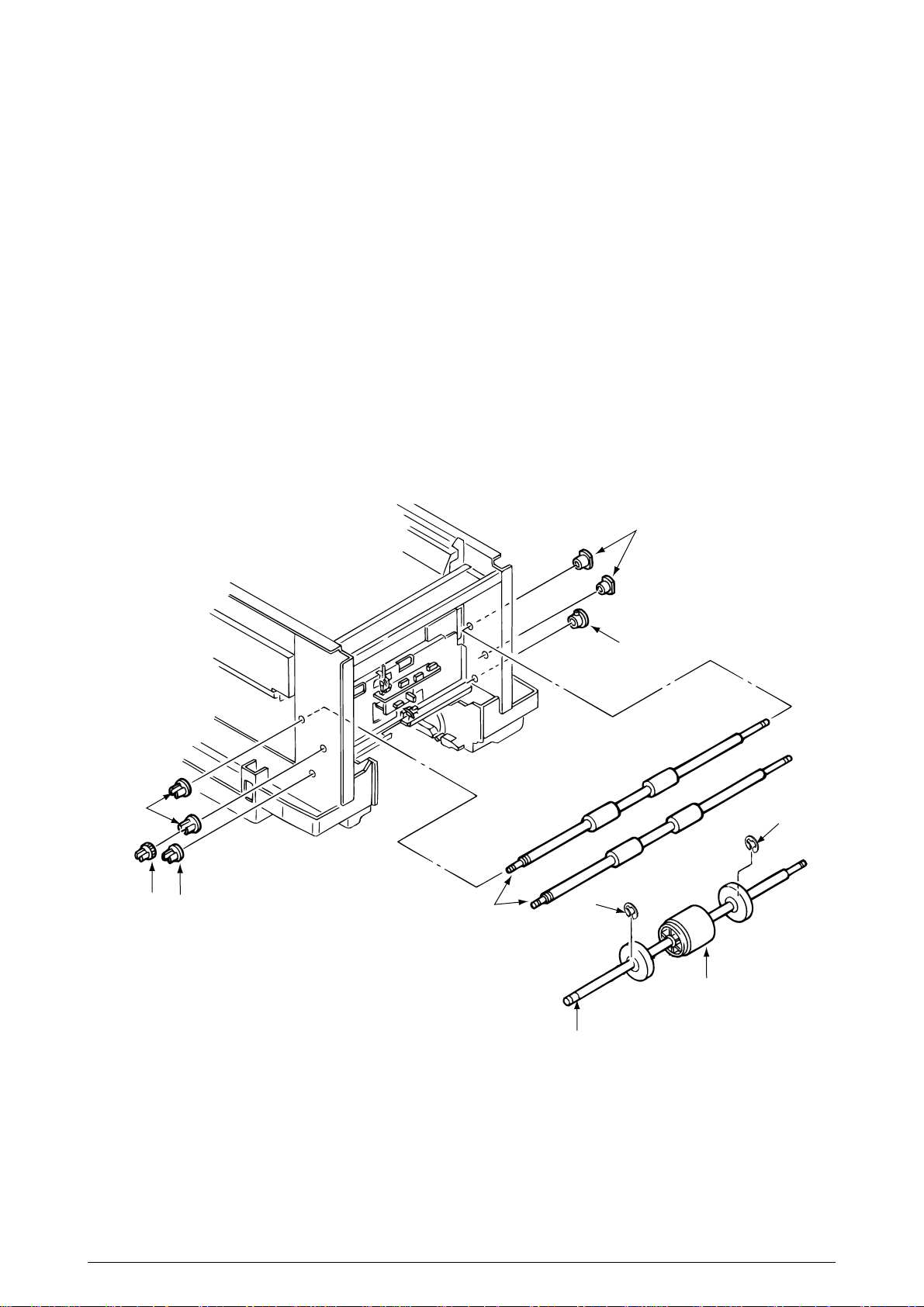

3.3.11 PXF PCB/PX4 PCB

Since the PXF PCB and PX4 PCB are connected with each other via the connector, remove them

at the same time.

1. Remove the PCB assy : PCE. (See 3.3.9)

2. Unscrew 5 screws 1 then remove the cover CU2.

3. Unplug all the cables 5 connected to the PXF PCB 3 and PX4 PCB 4.

4. Unscrew 5 screws 6 then remove the PXF PCB3 and PX4 PCB4 at the same time.

3

5

5

5

5

6

5

5

5

2

4

5

1

6

1

1

1

Figure 3.3.11 PXF PCB/PXS PCB

41057601TH Rev.1 58/

Page 59

3.3.12 Gear Heat Assy

1. Remove the cover assy side (R), cover assy OP panel, cover front (R) and the cover rear (L).

(See 3.3.8)

2. Remove the cover CU then unplug all the cables connected to the PXS PCB and unscrew 3

screws. (See 3.3.11)

3. Unplug all the cables connected to the PXF PCB then remove the PX4 PCB. (See 3.3.11)

(Be careful not to damage the connector when unplugging cables connected to the PXF

PCB.)

4. Remove the heat unit assy. (See 3.3.40)

5. Remove the guide paper eject assy. (See 3.3.3)

6. Remove the motor fan (80-25). (See 3.3.2)

7. Unscrew 5 screws 1 and unplug the cable 2 then remove the guide heat assy 3.

8. Unscrew 2 screws 4 then remove the motor (ID)5.

1

1

1

5

Figure 3.3.12 Gear Heat Assy

4

3

2

41057601TH Rev.1 59/

Page 60

3.3.13 Main Motor (A), (B) Assy

1. Remove the PXF PCB and PX4 PCB. (See 3.3.11)

2. Unscrew 4 screws 8 and remove 4 plate-Earth 9 and 4 lever Up/Dn 2 1.

3. Unplug all the cables 2 connected and unscrew 4 screws 3, then remove the main motor

(A) assy 4.

4. Unplug all the cables 5 connected and unscrew 3 screws 6, then remove the main motor

(B) assy 7.

5

2

2

4

3

2

3

1

7

9

5

1

8

6

5

1

6

1

9

8

Figure 3.3.13 Main Motor (A), (B) Assy

41057601TH Rev.1 60/

Page 61

3.3.14 Gear One-way (Z30)

Four gear one-ways (Z30) are provided but the method of those replacements is the same. Do not

disassemble the gear one-ways (Z30) because they are assemblies requires adjustment.

1. Remove the PCB assy : PCM. (See 3.3.9)

2. Remove the cover CU. (See 3.3.11)

3. Remove the 4 Plate-Earth and 4 lever Up/Dn 2. (See 3.3.13)

4. Release the lock with the shaft by spreading the claw, then remove the gear one-way (Z30)

1.

[Notice for mounting]

Mount the gear one-way (Z30) by fitting it with the shaft link turned in the arrow direction.

Shaft link

Figure 3.3.14 Gear One-way (Z30)

Claw

1

41057601TH Rev.1 61/

Page 62

3.3.15 Motor Assy BT

1. Remove the main motor (B) assy. (See 3.3.13)

2. Unplug 2 cables 1 connected and unscrew 2 screws 2, then remove the motor assy BT 3.

Figure 3.3.15 Motor Assy BT

3

1

2

41057601TH Rev.1 62/

Page 63

3.3.16 Power Supply Unit, Holder Inlet, Sheet Insulation

1. Remove the motor-fan (80-25). (See 3.3.2)

2. Remove the frame side (L), the cover assy side (R) and the cover rear (L). (See 3.3.8)

3. Unplug the cable 1.

4. Remove the holder inlet 3 by unscrewing 2 screws 2, then remove the power switch 4 and

unplug the AC socket 5.

5. Draw the power supply unit 7 by unscrewing 3 screws 6, then unplug the cable 8.

1

6

8

7

5

4

3

2

Figure 3.3.16 Power Supply Unit, Holder Inlet, Sheet Insulation

41057601TH Rev.1 63/

Page 64

3.3.17 Sensor Assy Box Toner

1. Remove the power supply unit. (See 3.3.16)

2. Unscrew the screw 1 then remove the sensor assy box toner 2 together with the bracket

3.

3. Unscrew the screw 4 then remove the sensor assy box toner 2.

Figure 3.3.17 Sensor Assy Box Toner

3

2

4

1

41057601TH Rev.1 64/

Page 65

3.3.18 Square-shaped Connector

Remove the heat unit assy.

1. Draw the power supply unit. (See 3.3.16) (Do not remove the power switch and AC socket

from the holder inlet.)

2. Unplug the cable 1.

3. Remove cable 2, screw 5 bracket 6 and cable 7 in order and then take off SW from bracket

6 to pull off square-shaped connector 4.

6

3

7

5

4

1

2

Figure 3.3.18 Square-shaped Connector

41057601TH Rev.1 65/

Page 66

3.3.19 Hopping Motor

1. Remove the cover assy side (R), cover assy OP panel and the cover front (R). (See 3.3.8)

2. Unscrew 2 screws 1 and unplug the cable 2, then remove the bracket hopping motor 3.

(Be careful not to lose the gears 5, 6 and 7 which slip off at this time.)

3. Unscrew 2 screws 8 then remove the hopping motor 3.

3

1

6

8

7

8

5

2

3

Figure 3.3.19 Hopping Motor

41057601TH Rev.1 66/

Page 67

3.3.20 Gear One-way

1. Remove the bracket hopping motor. (See 3.3.19)

2. Remove the spacer 4 first and release the locks with the shaft by spreading the claws of the

gear one-way 1, 2 and 3, then remove the gear one-ways.

3

Figure 3.3.20 Gear One-way

2

4

4

1

Claw

4

41057601TH Rev.1 67/

Page 68

3.3.21 Feeder Unit Front

1. Remove the cover assy side (R), cover assy OP panel, cover front (R) and the cover front (L).

(See 3.3.8.)

2. Remove the cover CU. (See 3.3.11)

3. Unscrew the screw 8 and remove the cable 9.

4. Unplug the cable 1 and unscrew the screw 2, then remove the bracket FF shaft 3.

5. Remove 2 E-rings 4 then remove the feeder unit front 5.

6. Unscrew each 2 screws 6 then remove 2 bracket FF links 7.

4

7

5

6

4

6

7

9

3

PXF

PX4

1

2

8

Figure 3.3.21 Feeder Unit Front

41057601TH Rev.1 68/

Page 69

3.3.22 Manual Feed Hopper Assy

1. Open the manual feed hopper assy.

2. Release the engagement between the holder and the link then remove the manual feed

hopper assy. (Be careful not to damage the holder.)

Link

Holder

1

Figure 3.3.22 Manual Feed Hopper Assy

41057601TH Rev.1 69/

Page 70

3.3.23 Guide Paper Input Assy

1. Remove the cover assy OP panel, cover front (R) and the cover front (L). (See 3.3.8)

2. Remove the feeder unit front. (See 3.3.21)

3. Unscrew 4 screws 1 then draw out the guide paper input assy 2 from the left side by rotating

its upper part . (Be careful not to damage the lever sensor resist.)

Lever Sensor Resist

1

2

1

Figure 3.3.23 Guide Paper Input Assy

41057601TH Rev.1 70/

Page 71

3.3.24 Two Lever Input Sensors, Lever 2nd Feed Sensor

1. Remove the guide paper input assy. (See 3.3.23)

2. Release the engagement with the guide by pressing 2 lever input sensors 2 in the arrow

direction, then remove them.

3. Release the engagement with the guide by pressing the lever 2nd feed sensor 2 in the arrow

direction, then remove the sensor.

1

2

Figure 3.3.24 Two Lever Input Sensors, Lever 2nd Feed Sensor

41057601TH Rev.1 71/

Page 72

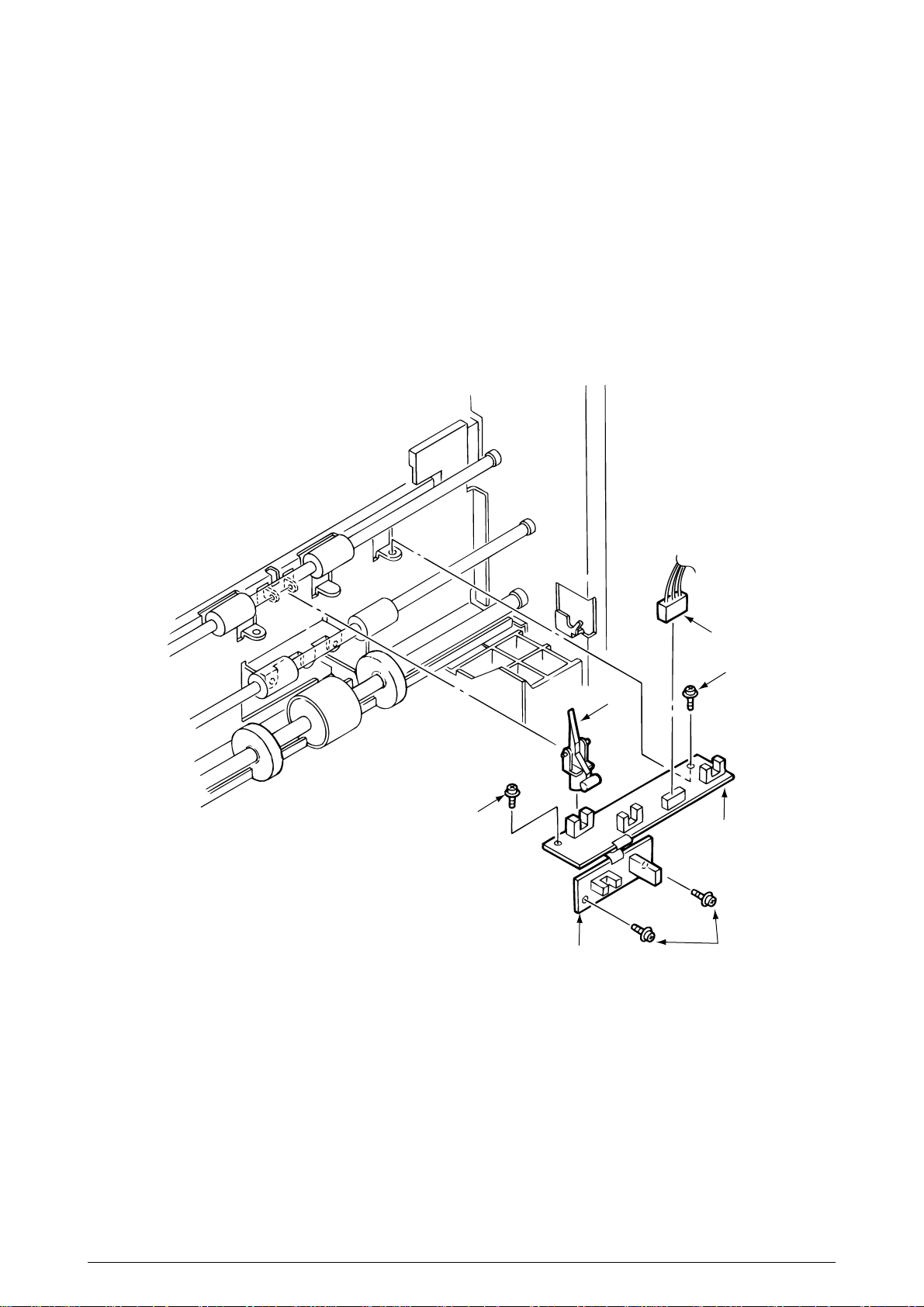

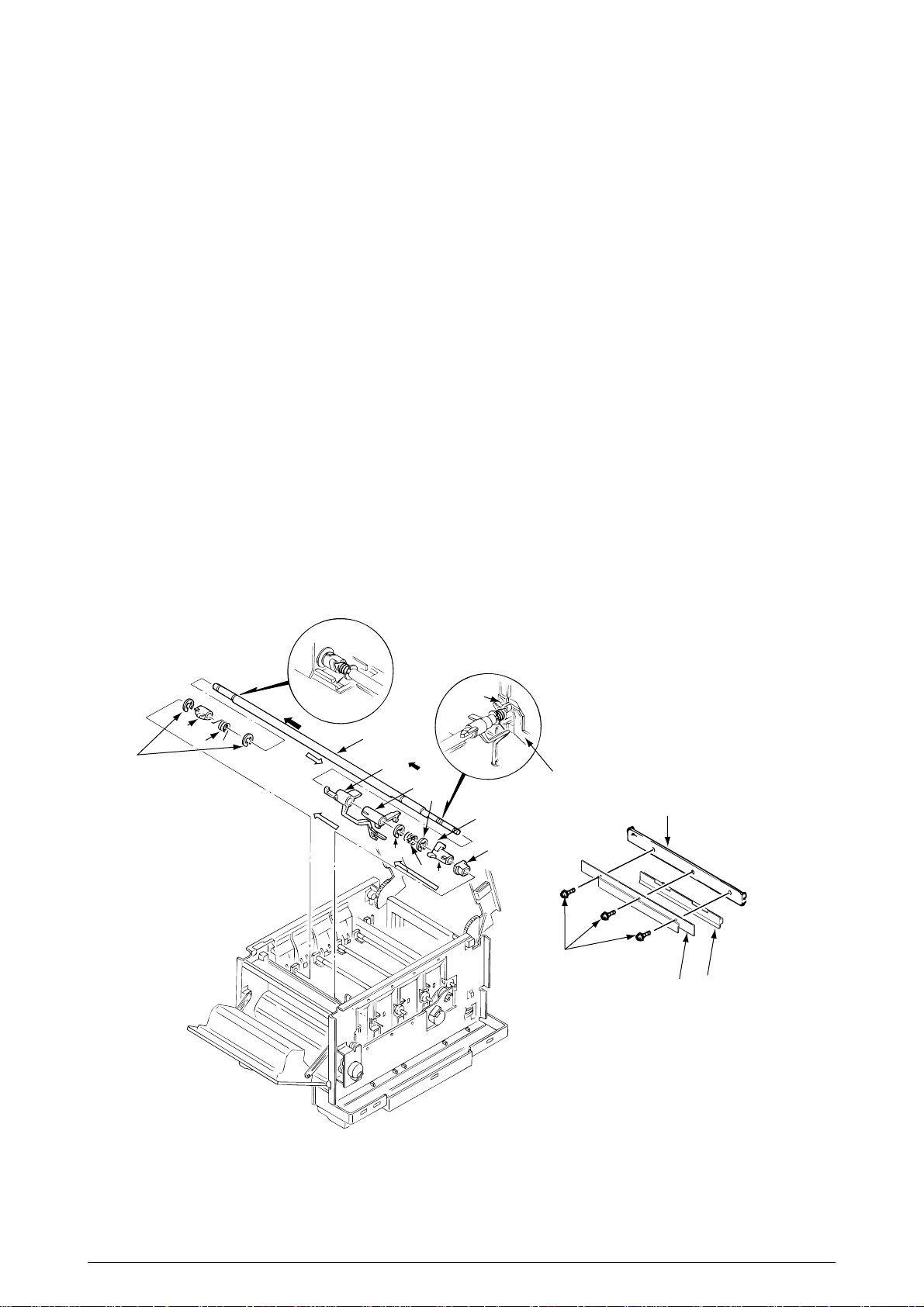

3.3.25 Roller Registration, Roller Assy Hopping