OKI OKIPAGE 6w Repair manual

OKIPAGE6w

LED Page Printer

Troubleshooting Manual

with Component Parts List

(OEL)

All specifications are subject to change without notice.

CONTENTS

1. OUTLINE.....................................................................................................1

2. TOOLS........................................................................................................1

3. CIRCUIT DESCRIPTION............................................................................2

3.1 Outline.....................................................................................................................2

3.2 CPU and Memory....................................................................................................4

3.3 Reset Control...........................................................................................................6

3.4 EEPROM Control.....................................................................................................7

3.5 Centronics Parallel Interface....................................................................................8

3.6 Front Operator Panel...............................................................................................9

3.7 LED Head Control.................................................................................................10

3.8 Motor and clutch control........................................................................................12

3.9 Fuser Temperature Control....................................................................................14

3.10Sensor Control.......................................................................................................17

3.11Cover Open...........................................................................................................18

3.12Power Supply Part.................................................................................................19

4. TROUBLESHOOTING..............................................................................21

4.1 Troubleshooting Table............................................................................................21

4.2 Troubleshooting Flowchart.....................................................................................23

5. CIRCUIT DIAGRAM..................................................................................27

6. COMPONENT PARTS LIST AND LAYOUT.............................................. 36

6.1 HUK PCB ............................................................................................................

6.2 P2H PCB

6.3 P6L PCB

............................................................................................................

............................................................................................................

37

41

46

1. OUTLINE

This manual has been written to provide guidance for troubleshooting of the OKIPAGE6w Printer

(primarily for its printed circuit boards), on an assumption that the reader is knowledgeable of the

printer. Read the maintenance manual for this printer if necessary.

Note:

1. High voltage power supply board and power supply unit containing a high voltage power

supply is dangerous. From the viewpoint of the safety standards, the local repairing of a

defective board is not allowed. Thus, the objects to be locally repaired as a result of

troubleshooting are switches.

2. TOOLS

For troubleshooting the printer, the tools listed below may be needed in addition to general

maintenance tools.

Oscilloscope Frequency response 100 MHz or higher

Soldering iron A slender tip type, 15-20 watts

Tool Remarks

- 1 -

3. CIRCUIT DESCRIPTION

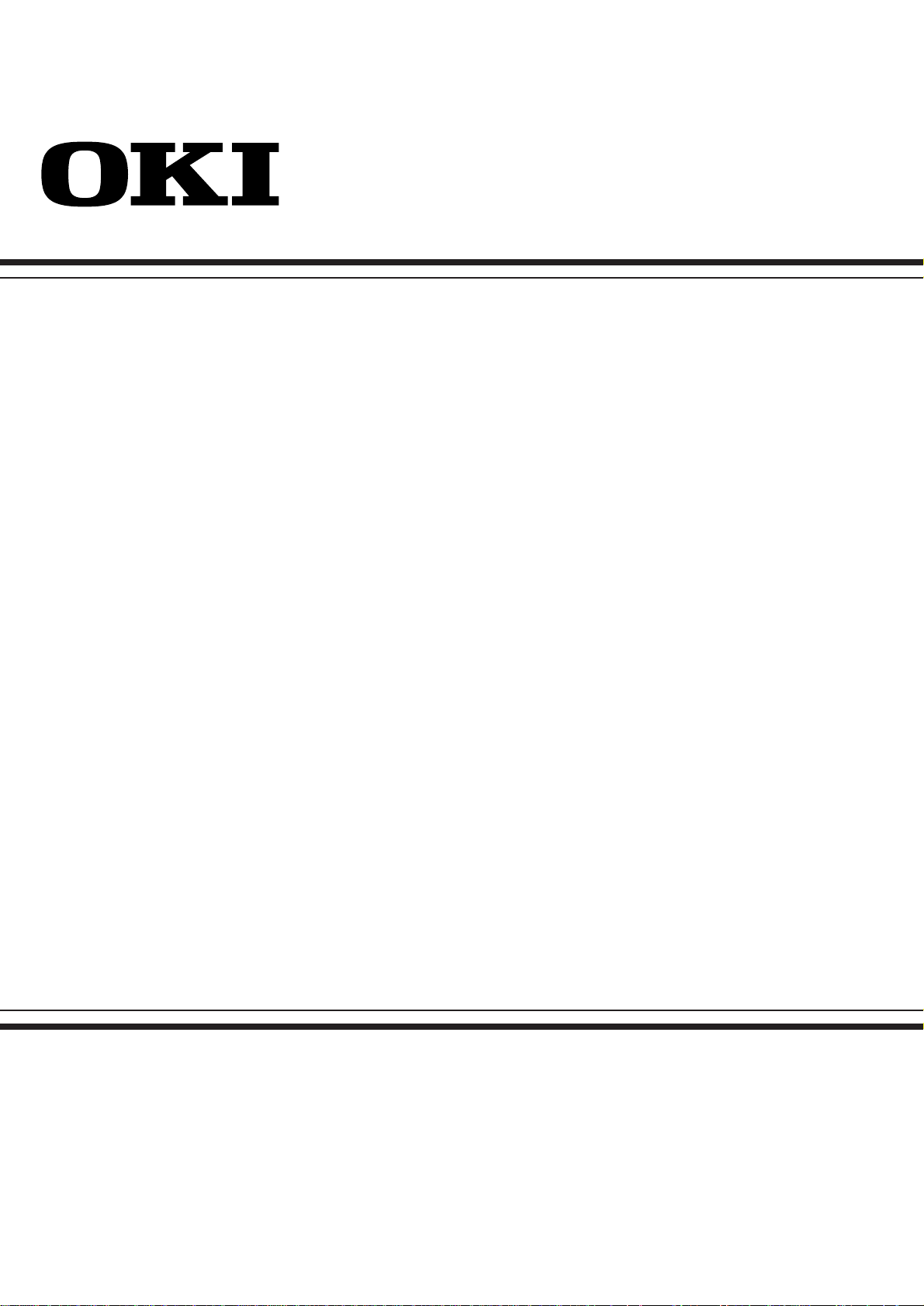

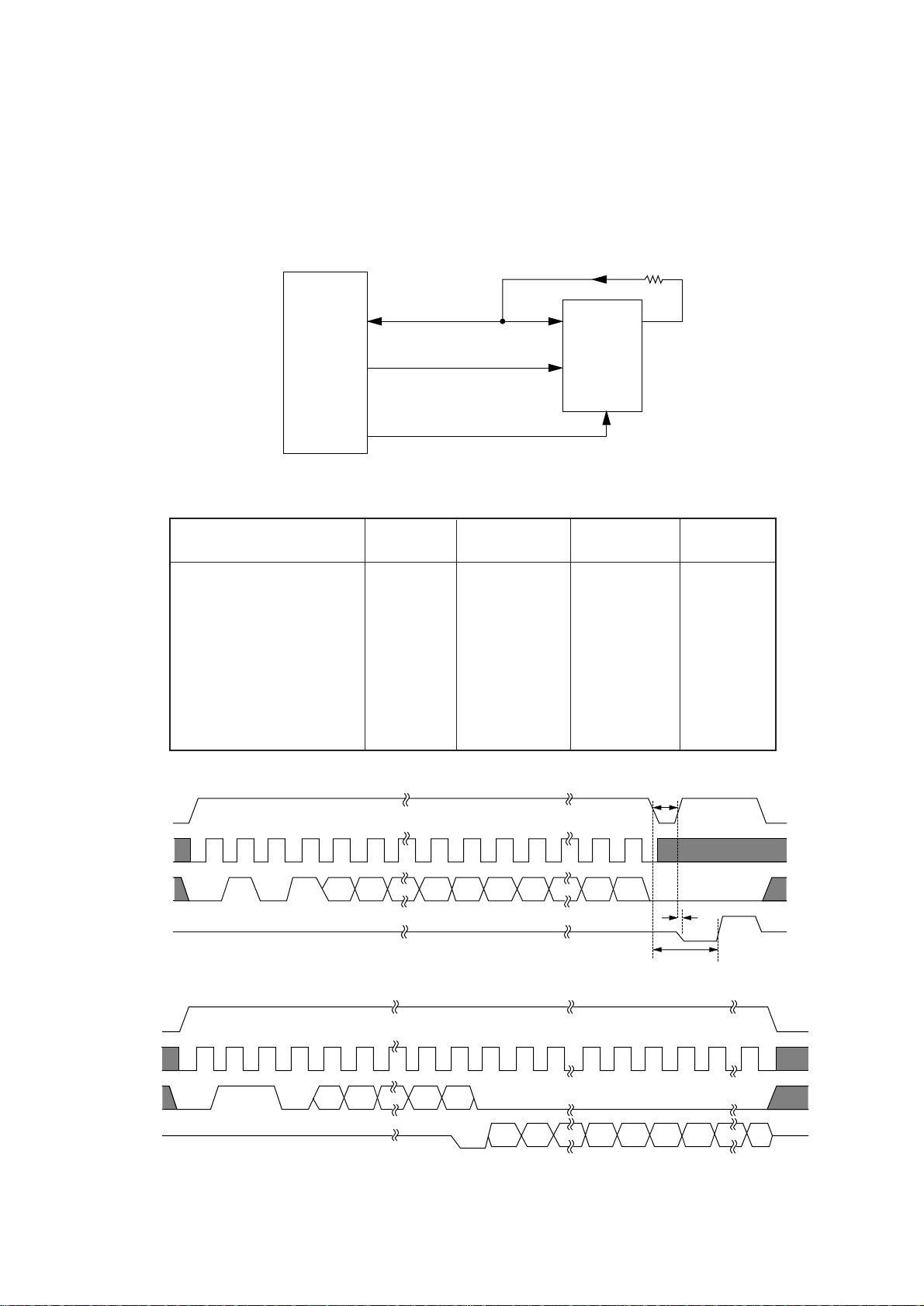

3.1 Outline

The circuit of OKIPAGE6w consists of a main control board, a main high voltage power supply

board,a syb-high voltage power supply board and a power supply unit. The block diagram is

shown in Fig. 3-1. The main control board controls the reception and transmission of data with

a host I/f and processes command analysis, bit image development, raster buffer read. It also

controls the engine and high voltage outputs.

(1)Reception and transmission control

The main control board has one parallel I/F port which is compliant to the IEEE 1284

specification.

An interface task stores all data received from the host into a receive buffer first, and returns

the printer status upon request of the host.

(2)Command analysis processing

The OKIPAGE6w printer has the following emulation mode.

Hiper-W: OKI original

An edit task fetches data from the receive buffer, analizes commands, and sets I/O registers.

(3)Raster data processing

The decompression circuit in the CPU expands the compressed data and stores the data into

the raster buffer.

(4)Raster data transfer

The LED head control circuit in the CPU sends the data stored in the raster buffer to the LED

head.

(5)High voltage control (main, sub)

The high voltage control circuit in the CPU.

The high voltage power supply board generates high voltage outputs, and have sensors, LED for

display.

The power supply unit generates +26VDC output, +5DC output.

- 2 -

Motor

Parallel

I/F

PLUNGER

CN4

LED HEAD

HEAD1CN8

0V5V

LS07

+5V+26V

Motor Driver

MTD2005F

PCB H63-ONLY

Internal

MASK ROM

62KB

OSC

16MHz

0VP0V

CN7

CPU

(nX8)

RST

EEPROM

Serial I/F

DRAM Bus

(Data : 4)

(Address : 11)

1kb

DRAM

512kB

DRAM

1M x 4

HC125

CN2

High Voltage Power Unit

Power Supply Unit

Figure 3-1 OKIPAGE6w Block Diagram

- 3 -

P2H

CN10CN1

High Voltage Power Unit

P6L

ID Unit

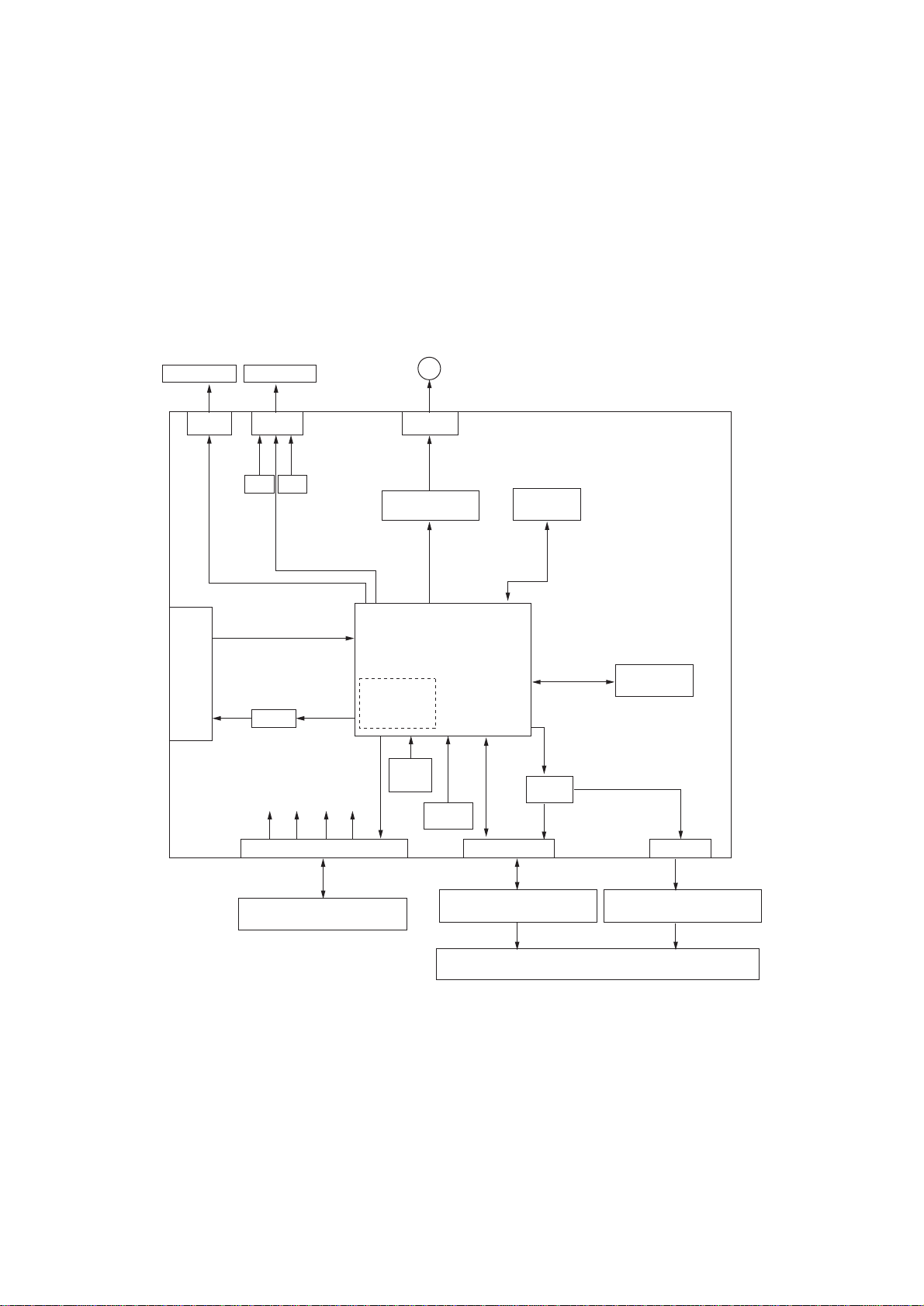

3.2 CPU and Memory

(1)CPU (MSM65917)

CPU core nX-8

CPU clock 16 MHz

Data bus width External 8 bits, Internal 8 bits

(2)Program ROM

ROM capacity 64k-bytes

ROM type 512 kbits (64k x 8 bits)

Access time 90 nsec

(3)Resident RAM

RAM capacity 512k bytes (1M x 4 bits D-RAM one piece)

RAM type 4M bits (1M x 4 bits)

Access time 60 ns

- 4 -

CPU

IC 6

ALE

RDN

ROCS

DA10

DWR

CAS

AD00 to AD07

LS373

IC3

A08 to A15

DD00 to DD03

DA00 to DA09

A00 to A07

IC2

EPROM

(64k x 8 bits)

IC11

DRAM

(1M x 4 bits)

RAS0

RAS1

RAS2

Main Control Board

Figure 3-2 Block Diagram of CPU & Memory in OKIPAGE6w

- 5 -

3.3 Reset Control

When power is turned on, RST-N signal is generated by IC5.

+5V+5V

IC6

+5V

Power ON

IC5

1

3

2

Power OFF

63

CPU

RSTN

RST-N

- 6 -

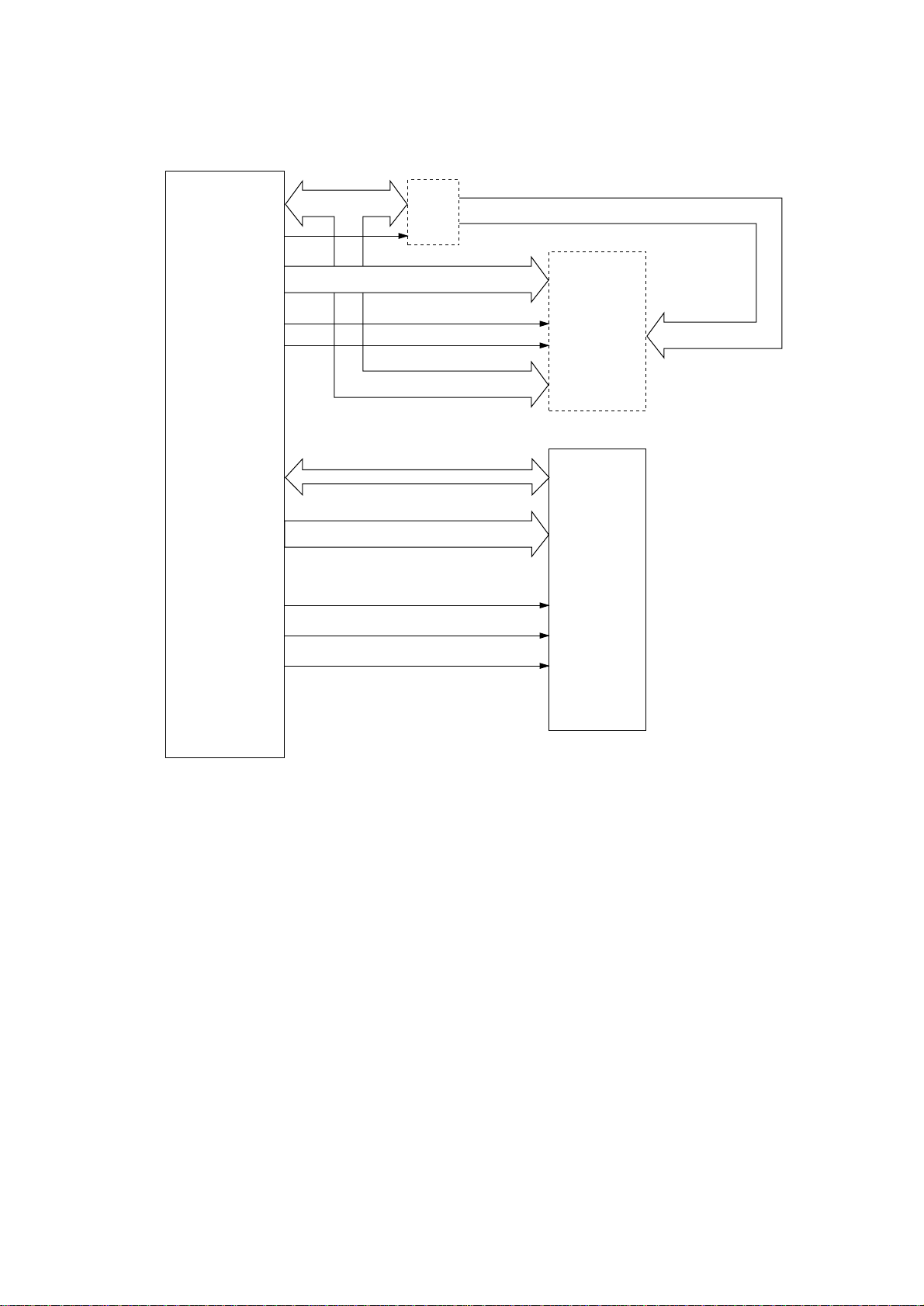

3.4 EEPROM Control

The BR93LC46A on the main control board is an electrical erasable/programmable ROM of 64bit x 16-bit configuration. Data input to and output from the ROM are bidirectionally transferred

in units of 16 bits through I/O port (EEPRMDT-P) in serial transmission synchronized with a clock

signal from the CPU.

The EEPROM operates in the following instruction modes.

Instruction Start bit Operation Address Data

Read (READ) 1 10 A5 to A0

Write Enabled (WEN) 1 00 11XXXX

Write (WRITE) 1 01 A5 to A0 D15 to D0

Write All Address (WRAL) 1 00 01XXXX D15 to D0

Write Disabled (WDS) 1 00 00XXXX

Erase 1 11 A5 to A0

Chip Erasable (ERAL) 1 00 10XXXX

IC6

CPU

39

38

37

EEPRMDT-P

EEPRMCS-P

EEPRMCLK-P

code

3

DI DO

EEPROM

1

CS

IC4

4

SK

2

Write cycle timing (WRITE)

CS

SK

DI

DO

1 2 4 9 10 25

10 1

HIGH-Z

Read cycle timing (READ)

CS

SK

DI

DO

HIGH-Z

12

110

A5 A4 A1 A0 D15

4

A5 A4 A1 A0

910

- 7 -

Min. 450 ns

D14

D15 D14 D1 D00 D15 D14

D1 D0

Max. 500 ns

BUSY READY

Max. 10 ms

25 26

STATUS

3.5 Parallel Interface

Parallel data is received from a host system via parallel interface which is compliant to the

IEEE1284 specification.

IC6

CPU

65 to 68, 71 to 74

64

78

77

79

80

81

82

83

84

PSTB-N

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFD-N

PDATA1-P to PDATA8-P

+5V or High level

IC7

2 to 9

11

10

12

13

32

31

36

14

18

CN4

1

DATA8-P

to

DATA1-P

STB-N

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFEED-N

+5V

Compatible mode

The CPU sets a BUSY-P signal to ON at the same time when it reads the parallel data (PDATA1P to PDATA 8-P) from the parallel port at the fall of PSTB-N signal. Furthermore, it makes the

store processing of received data into a receive buffer terminate within a certain fixed time and

outputs an ACK-N signal, setting the BUSY-P signal to OFF.

PARALLEL DATA

(DATA BITs 1 to 8)

0.5 µs min.

DATA STROBE

0.5 µs min.

0.5 µs max.

BUSY

0 min.

ACKNOWLEDGE

0.5 µs to 10 µs

0.5 µs min.

0.5 µs min.

0 min.

0 min.

0 min.

- 8 -

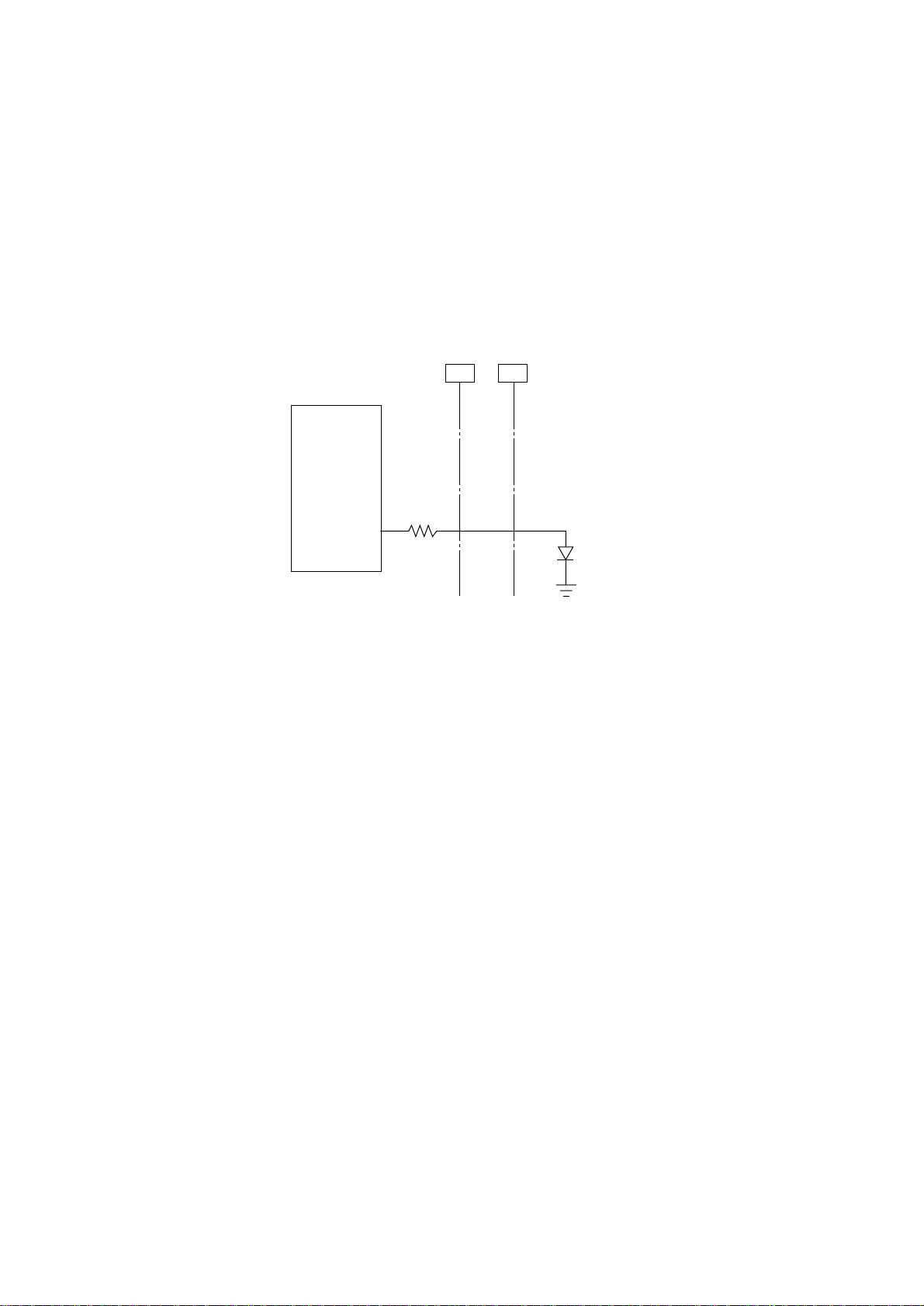

3.6 LED Lamp Control

There is an LED lamp on the high voltage power supply board which is connected to and controled

by the CPU on the main control board.

The light from the LED lamp can be seen on the Lens Cover through the LED Lens.

CN1

main control board high voltage power supply board

IC6

CPU

LED-P

41

CN1

- 9 -

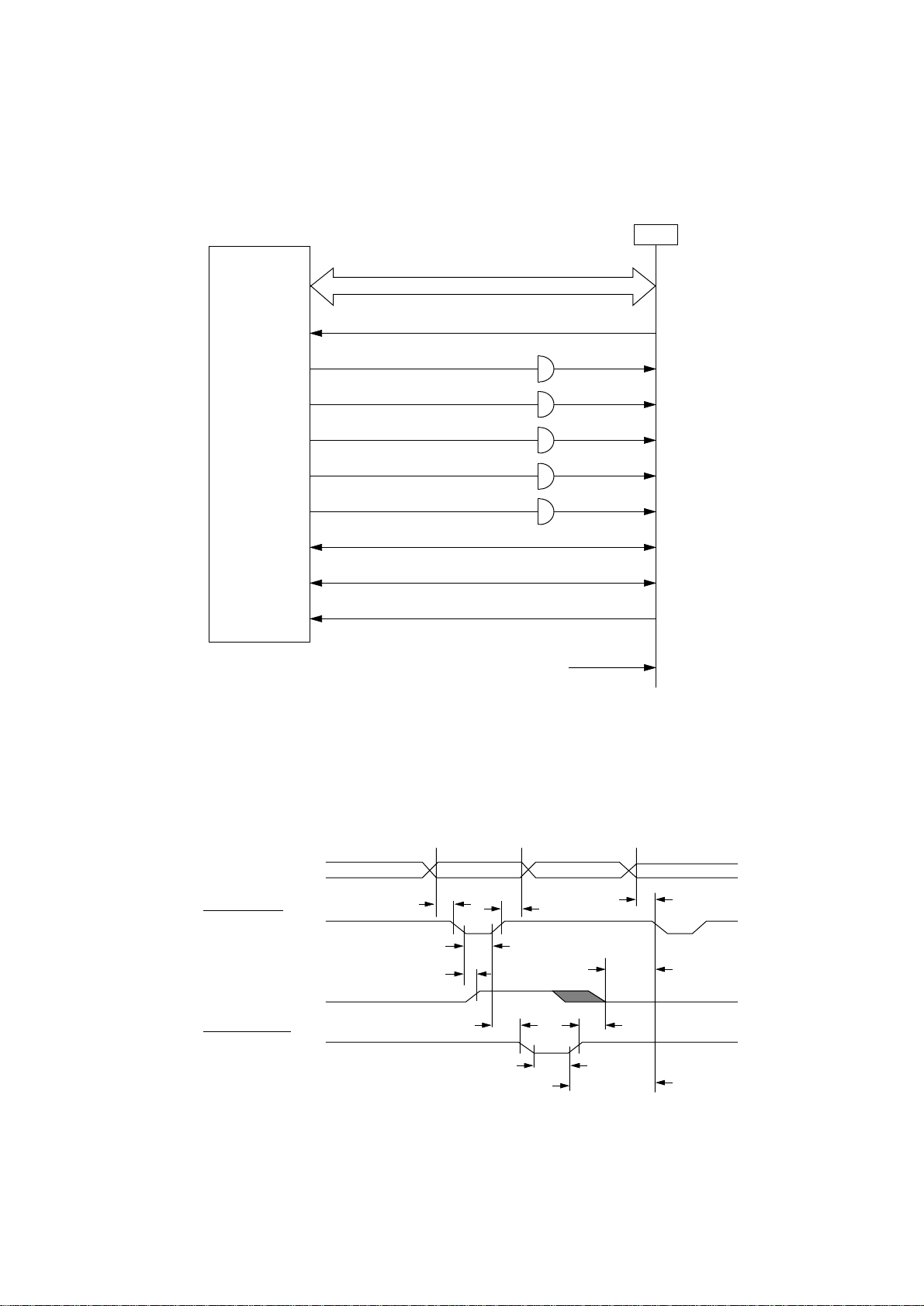

3.7 LED Head Control

An LED correcting head, which is capable of correcting the illumination of the LED for each dot,

is being used in this printer. LED illumination correction function of 16 steps is carried out by using

an EEPROM which is installed in the LSI that maintains the LED illumination correction values,

and an LED correction drivers (MSM6731BWAF or MSM6732BWAF) together as a pair.

The LED correcting head consists of the correction control LSI (MSM6730WAF), LED drivers

(MSM6731BWAF or MSM6732BWAF), and an LED array.

From

CPU

STRB0-N

STRB1-N

STRB2-N

STRB3-N

LOADI

CLOCKI

DATAI0

DATAI1

MSM6730

WAF

EEPROM

Correction

Values

LED Driver

MSM6732BWAF

LED Array

LED LED LED LED LED LED LED

LED Driver

MSM6731BWAF

Printing and correction data combined sign

Correction data signal line

LED Driver

MSM6731BWAF

LED Driver

MSM6732BWAF

- 10 -

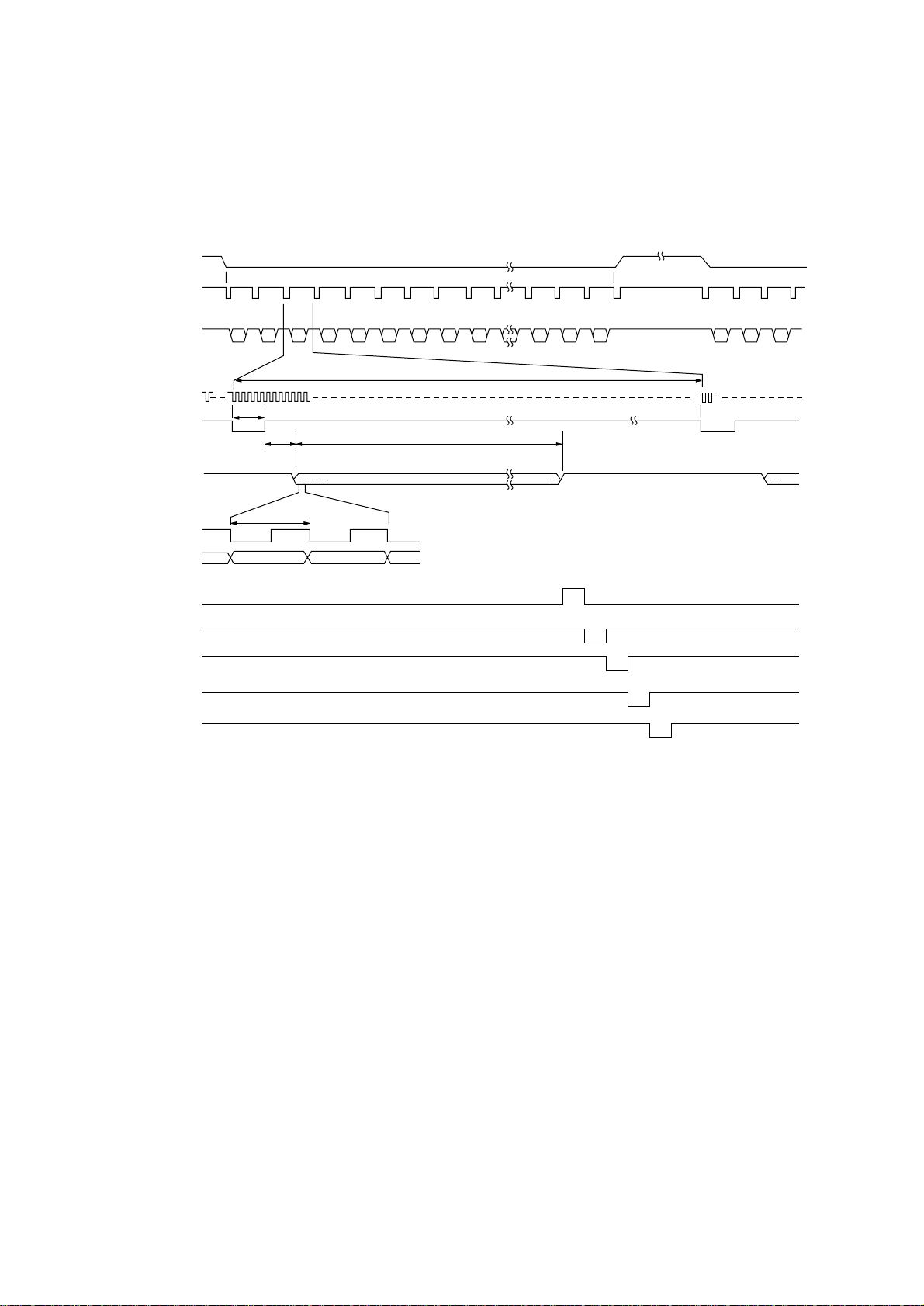

Page

synchronous

signal*

Line

synchronous

signal*

VDT-P

0.78 msec

VCLK-P

VDT-P

VCLK-P

VDT-P

VLD-P

VSTB4-N

VSTB3-N

VSTB2-N

VSTB1-N

* CPU internal signal

8 bits

8 bits

0.3 µs

4992 bits

- 11 -

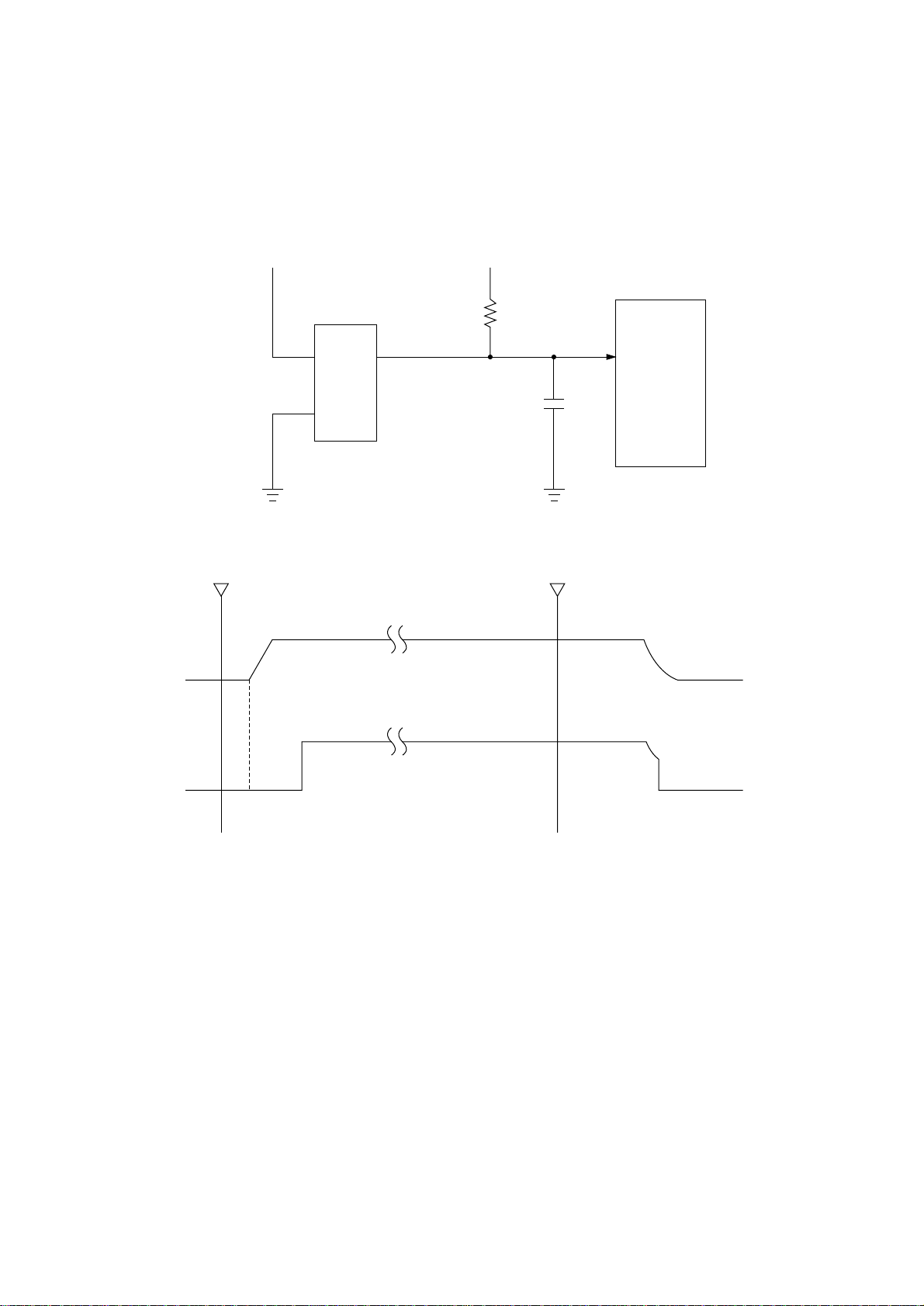

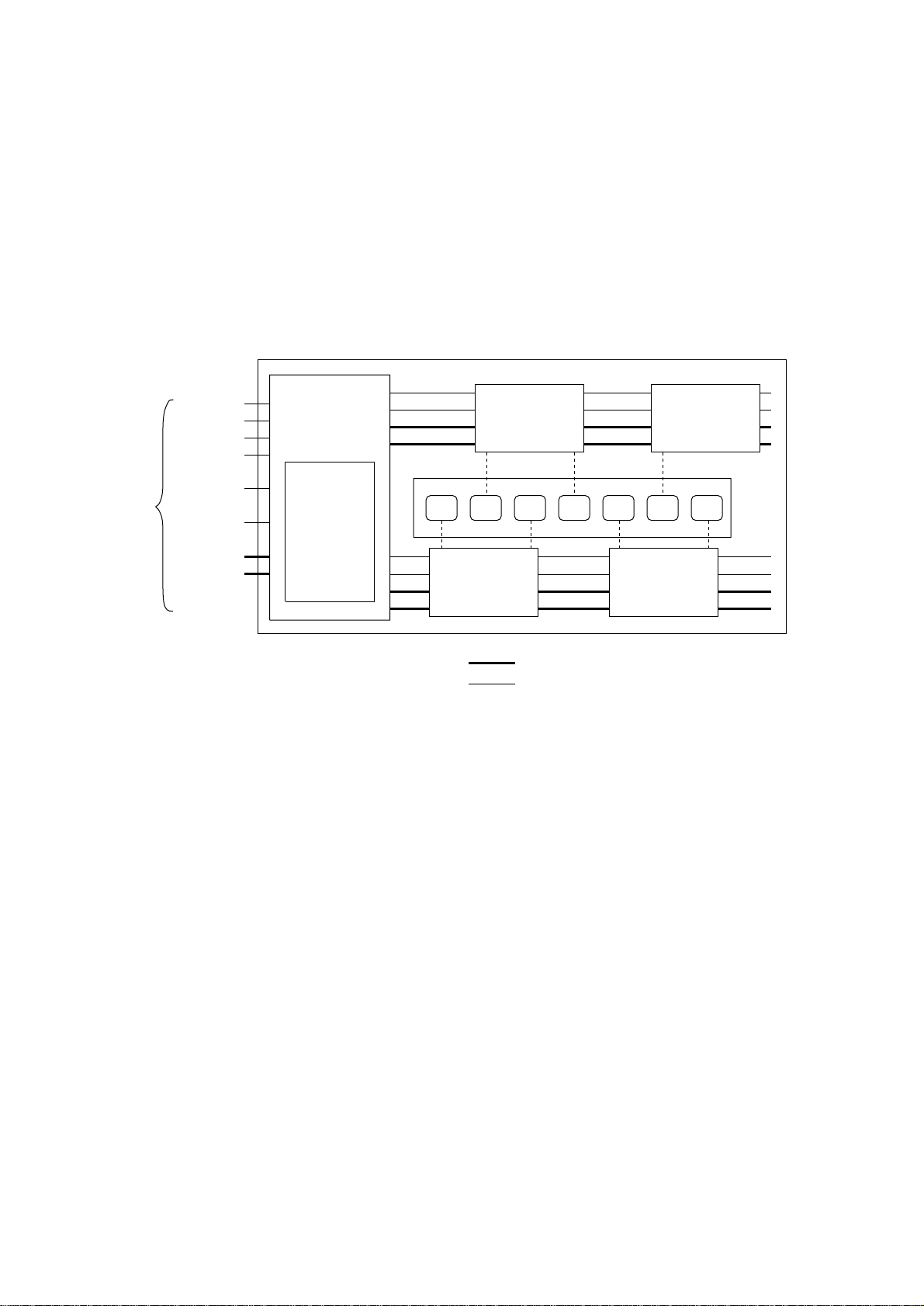

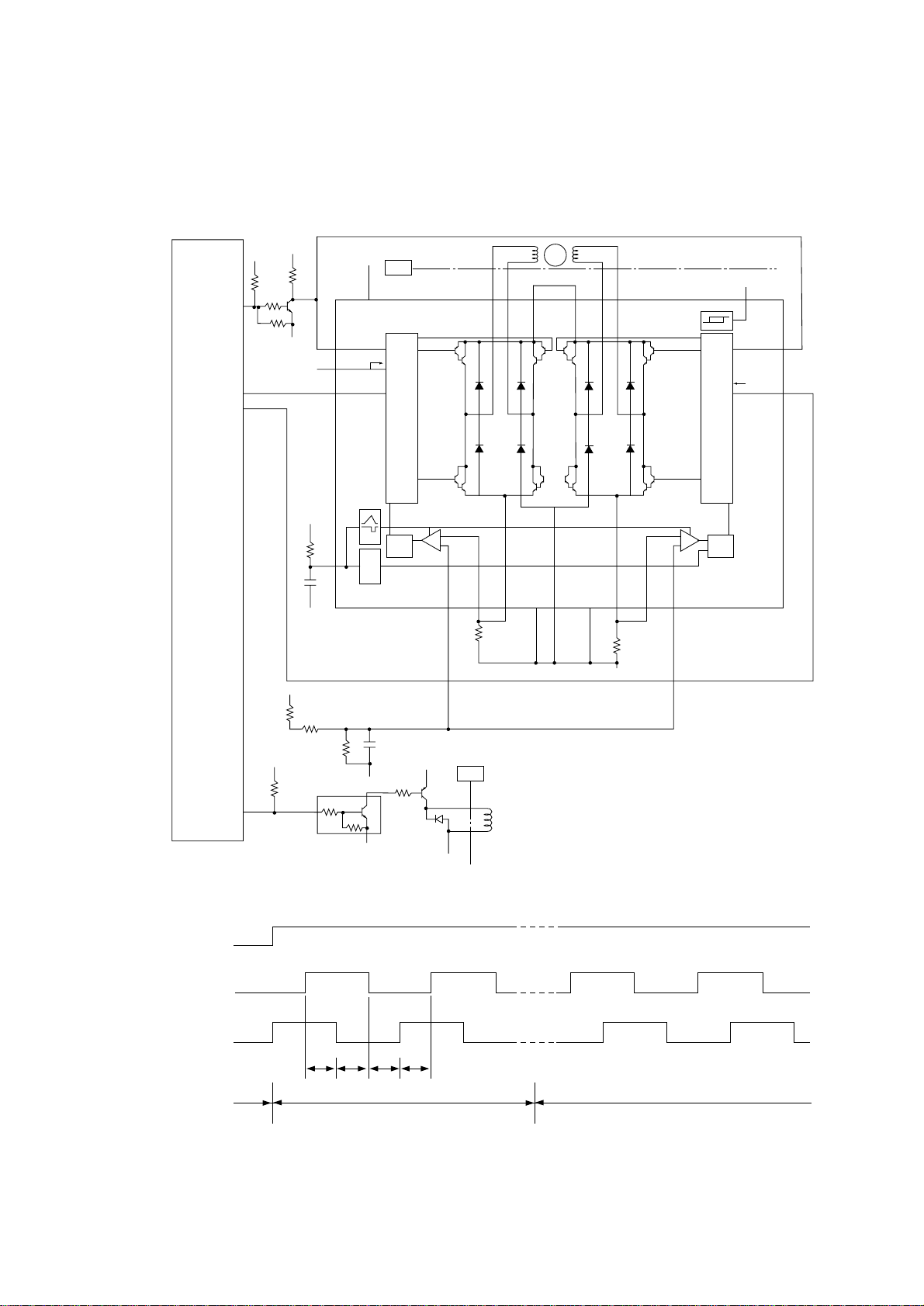

3.8 Motor and clutch control

The electromagnetic clutch is driven by a control signal from the CPU and the drive circuit shown

below.

The main motor is driven by the control signals from the CPU and the driver IC.

CPU

DMON

DMP1

DMP2

+5V

98

96

97

+5V

0V

+5V

Main Motor

8

Out4Vmm A Vmm B

+5V

IC10

27

18

26

+5V

19

ENA A

To Out3, 4Logic

DECAY

CN7

M

+26V OPEN

37 1 1412 24

Out2 Out3

Out1

SW1 SW3

SW1 SW3

PHASE A PHASE B

GATE CIRCUIT

SW4SW2

SW4SW2

+5V

0V

25

BRUNK

OSC

Current

Q

-

R

+

S

Sensor

Vref A Vref B

Vs A Vs BRs A Rs BLG A PG LG B

23 22 28 15 10 21 20TAB5

Current

Sensor

0V

ALARM

120°C 140°C

GATE CIRCUIT

RQ

+

S

ENA B

Signal of

DECACY

16

17

RMON

(1) Main motor

DMON-P

DMPH1-P

DMPH2-P

Rotation

+5V +26V

0V

99

0V

T0 T1 T2 T3

Forward rotation

CN8

Electromagnetic clutch

0VP

Reverse rotationStop

Operation at normal speed: T0 to T3 = 0.781 ms

- 12 -

(2) Motor drive control

Time T0 to T3 determines the motor speed, while the phase different direction between

phase signals DMPH1-P and DMPH2-P determines the rotation direction. DMON-P signal

control a motor coil current. According to the polarity of the phase signal, the coil current flow

as follows:

1) +26V → SW1 → motor coil → SW4 → resistor → earth, or,

2) +26V → SW3 → motor coil → SW2 → resistor → earth

The drop voltage across the resistor is input to comparator, where it is compared with a

reference voltage. If an overcurrent flows, a limiter operates to maintain it within a certain

fixed current.

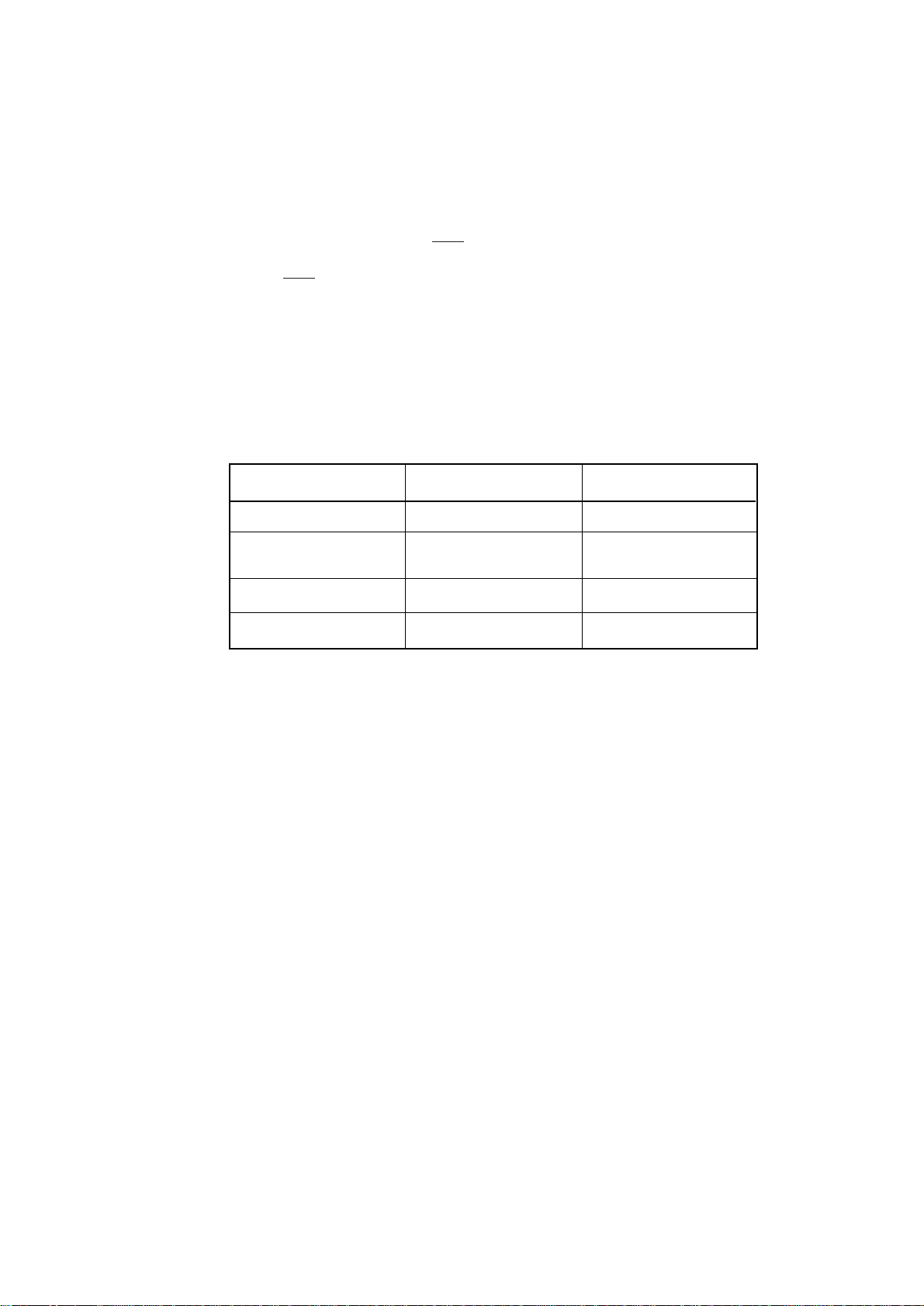

(3) Electromagnetic clutch control

Mechanical operation mode is switched by the combination of the clutch status and the

direction of motor rotation.

clutch status

off

off

on

on

rotation direction

Forward

Reverse

Forward

Reverse

operation mode

cleaning

Hopping from manual

feed slot

illegal operation

Hopping from tray

- 13 -

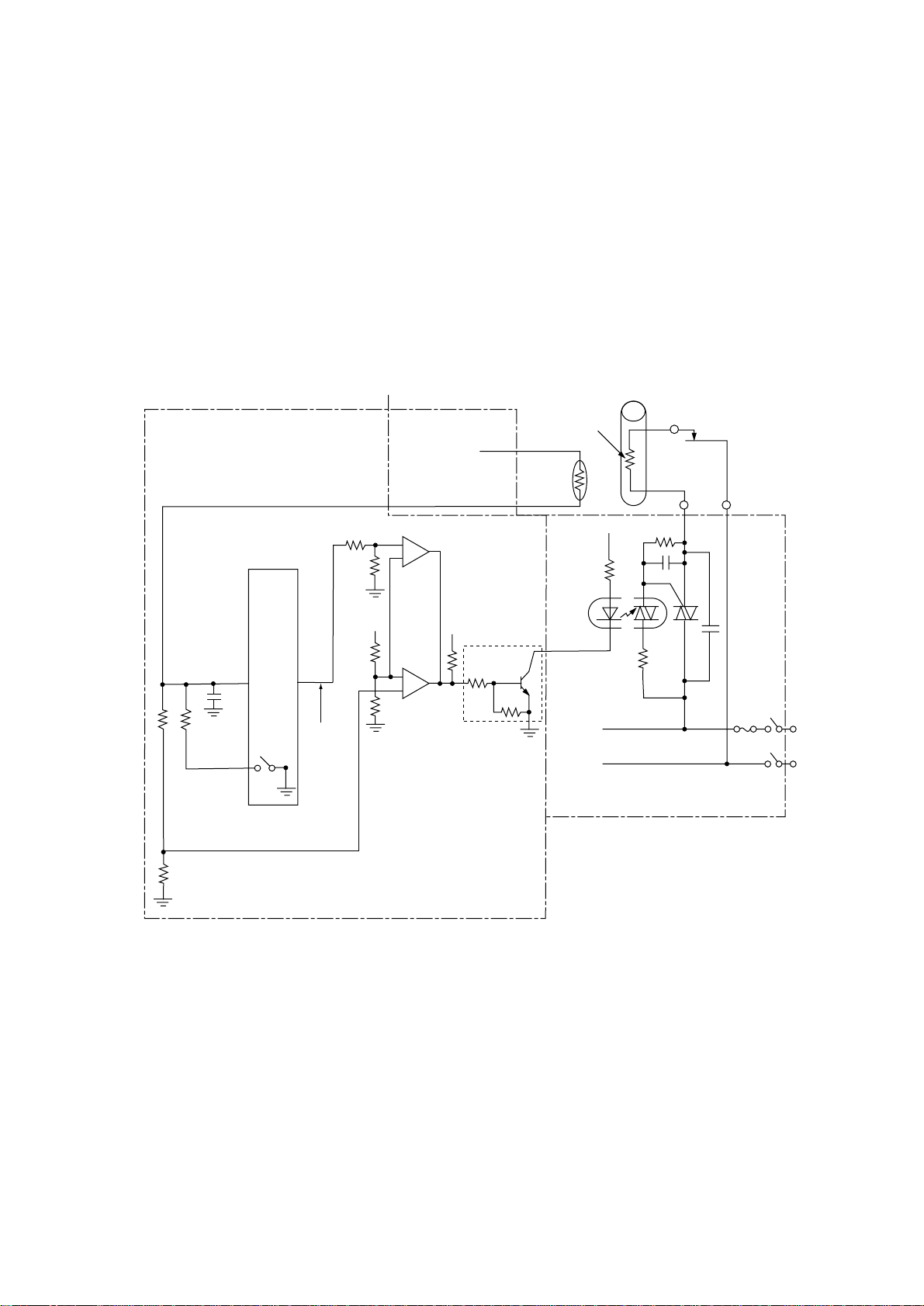

3.9 Fuser Temperature Control

The temperature change in a heat controller is converted into the electric potential TEMP

corresponding to the change in the resistance value of a thermistor, and the resultant potential

is fed back to the control circuit. The CPU performs ON/OFF control of the HEATON-P signal to

keep the heat roller temperature constant in accordance with the state at which the thermistor

voltage (TEMP) is read into directly by the AD converter of the CPU.

When the paper thickness is set on the menu of the host, the temperature is adjusted to the

targeted thickness accordingly.

Main Control Board

CPU

TEMP

27

AI4

(A/D)

THCHK-N

34

85

HEATON-P

High voltage power

supply board

IC20

5

+

6

-

7

+5V +5V

IC20

3

+

2

-

1

+5V

Thermistor

HEATON-N

Heater

Thermostat

Heat Roller

+5V

ACIN

Power supply unit

- 14 -

Loading...

Loading...