Page 1

OKIPAGE

4 /4

LED Page Printer

Maintenance Manual

OEL/INT

Approval

All specifications are subject to change without notice.

40245101TH

Page 2

HP, LaserJet and PCL5e are trademarks of Hewlett-Packard Co.

Page 3

PREFACE

This Maintenance Manual describes the field maintenance methods for LED Page Printers.

This manual is written for use by service persons. Please note that you should refer to the Printer

Handbook for the handling and operating methods of the equipment.

Page 4

CONTENTS

1. CONFIGURATION..................................................................................... 1 - 1

1.1 System Configuration ........................................................................ 1 - 1

1.2. Printer Configuration.......................................................................... 1 - 2

1.3 Option................................................................................................. 1 - 3

1.4 Specification ...................................................................................... 1 - 4

1.5 Safety Standards ............................................................................... 1 - 6

1.5.1 Certification Label.................................................................................... 1 - 6

1.5.2 Warning Label ......................................................................................... 1 - 6

2. OPERATION DESCRIPTION .................................................................... 2 - 1

2.1 Main Control Board............................................................................ 2 - 4

2.2 Power Supply Unit ............................................................................. 2 - 5

2.3 High-Voltage Power Supply Board .................................................... 2 - 5

2.4 Electro-Photographic Processor........................................................ 2 - 7

2.5 Electro-Photographic Process ........................................................... 2 - 11

2.5.1 Explanation of Each Process Operation.................................................. 2 - 13

2.6 Paper Jam Detection ......................................................................... 2 - 19

2.7 Toner Low Detection.......................................................................... 2 - 21

2.8 Cover Open ....................................................................................... 2 - 22

3. PARTS REPLACEMENT........................................................................... 3 - 1

3.1 Precautions for Parts Replacement................................................... 3 - 1

3.2 Parts Layout....................................................................................... 3 - 3

3.3 Replacing Parts ................................................................................. 3 - 6

3.3.1 Hopper Plate ........................................................................................... 3 - 6

3.3.2 LED Head and Head Spring.................................................................... 3 - 7

3.3.3 Transfer Roller.........................................................................................3 - 8

3.3.4 Upper Cover Assy ................................................................................... 3 - 9

3.3.5 High-Voltage Power Supply Board .......................................................... 3 - 10

3.3.6 Top Cover Assy and Flat Cable Assy...................................................... 3 - 11

3.3.7 Paper Holder ........................................................................................... 3 - 12

3.3.8 Side Plate M and Idle Gear ..................................................................... 3 - 13

3.3.9 Heat Assy ................................................................................................ 3 - 14

3.3.10 Drive Shaft E (Eject) and Eject Roller ..................................................... 3 - 17

3.3.11 Pressure Roller B (Back Up Roller)......................................................... 3 - 18

3.3.12 Separator Guide ...................................................................................... 3 - 19

3.3.13 Pulse Motor (Main) .................................................................................. 3 - 21

3.3.14 Hopping Shaft Assy ................................................................................. 3 - 22

3.3.15 Resist Roller ............................................................................................ 3 - 23

3.3.16 Paper Sensor E, Paper Sensor Exit and Toner Sensor Assy ................. 3 - 24

3.3.17 Base Plate ............................................................................................... 3 - 25

Page 5

4. ADJUSTMENT........................................................................................... 4 - 1

4.1 Adjustment Types and Functions ...................................................... 4 - 1

4.1.1 Printer Driver ........................................................................................... 4 - 1

4.1.2 Engine Maintenance Utility ...................................................................... 4 - 3

4.2 Adjustment When Replacing a Part................................................... 4 - 3

4.2.1 Setting LED Head Drive Time ................................................................. 4 - 3

4.2.2 Setting the LED Head Dot Count ............................................................ 4 - 4

4.2.3 Uploading and Downloading EEPROM Data .......................................... 4 - 5

5. PERIODICAL MAINTENANCE ................................................................. 5 - 1

5.1 Periodical Replacement Parts ........................................................... 5 - 1

5.2 Cleaning............................................................................................. 5 - 1

5.2.1 Cleaning of LED Lens Array .................................................................... 5 - 1

6. TROUBLESHOOTING PROCEDURES .................................................... 6 - 1

6.1 Troubleshooting Tips ......................................................................... 6 - 1

6.2 Check Points Before Correcting Image Problems ............................. 6 - 1

6.3 Notes When Correcting Image Problems .......................................... 6 - 1

6.4 Preparation Before Troubleshooting.................................................. 6 - 1

6.5 Troubleshooting................................................................................. 6 - 2

6.5.1 Status Monitor Message List ................................................................... 6 - 2

6.5.2 Status Message Troubleshooting ............................................................ 6 - 6

6.5.3 Image Troubleshooting ............................................................................ 6 - 13

7. WIRING DIAGRAM................................................................................... 7 - 1

7.1 Interconnect Signal Diagram ............................................................. 7 - 1

7.2 PCB Layout........................................................................................ 7 - 3

7.2.1 Main Control Board (HBMC-2 PCB)(OKIPAGE 4w plus) ........................ 7 - 3

7.2.2 Main Control Board (HBMC-3 PCB)(OKIPAGE 4m) ............................... 7 - 4

7.2.3 High-Voltage Power Sapply Board .......................................................... 7 - 5

8. PARTS LIST .............................................................................................. 8 - 1

APPENDIX A LOCAL PRINTING ............................................................... A - 1

APPENDIX B PARALLEL INTERFACE ..................................................... B - 1

APPENDIX C MACINTOSH INTERFACE................................................... C - 1

APPENDIX D MAINTENANCE UTILITY ..................................................... D - 1

Page 6

1. CONFIGURATION

Page 7

1. CONFIGURATION

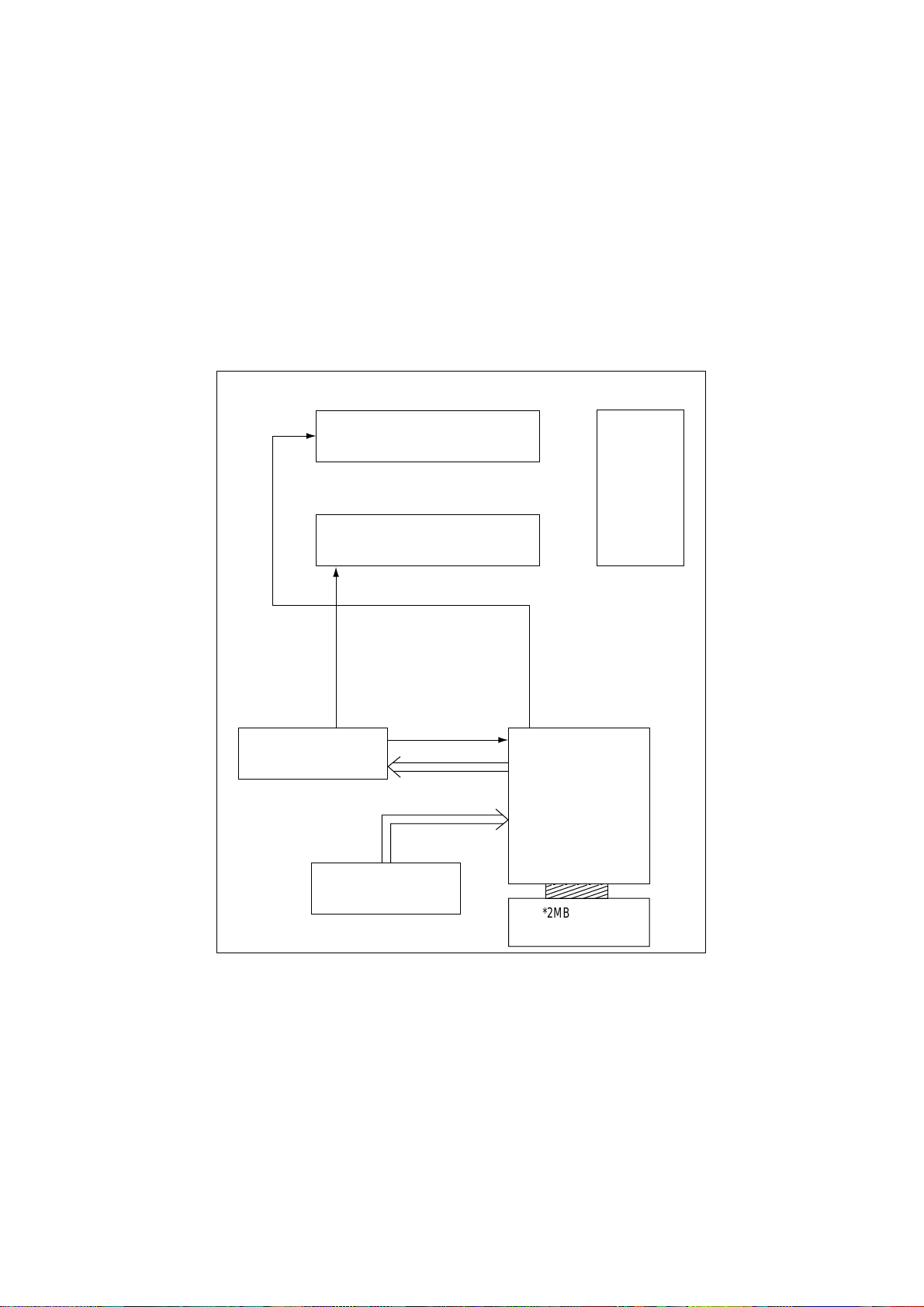

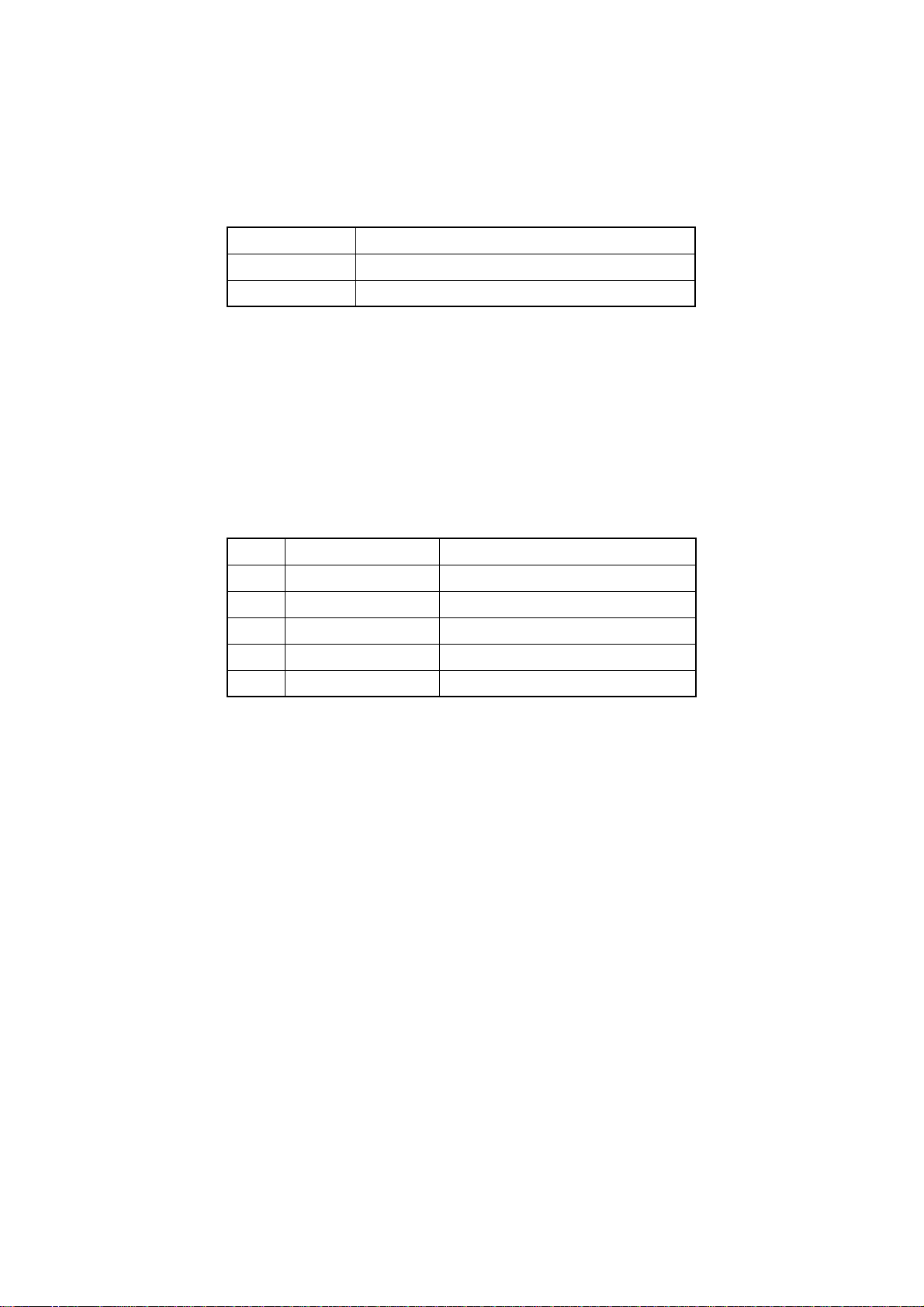

1.1 System Configuration

The OKIPAGE 4w Plus/4m consists of a control block, a power supply unit, and an engine block.

(See Figure 1-1.)

ENGINE UNIT

Paper Feed Mechanism

Hopper

Plate

Electro-photographic

Processor

High-Voltage Power

Supply Board

Power Supply Unit

Main Control Board

*2MB Memory

Expansion Board

*: Option (OKIPAGE 4m Only)

Figure 1-1

1 - 1

Page 8

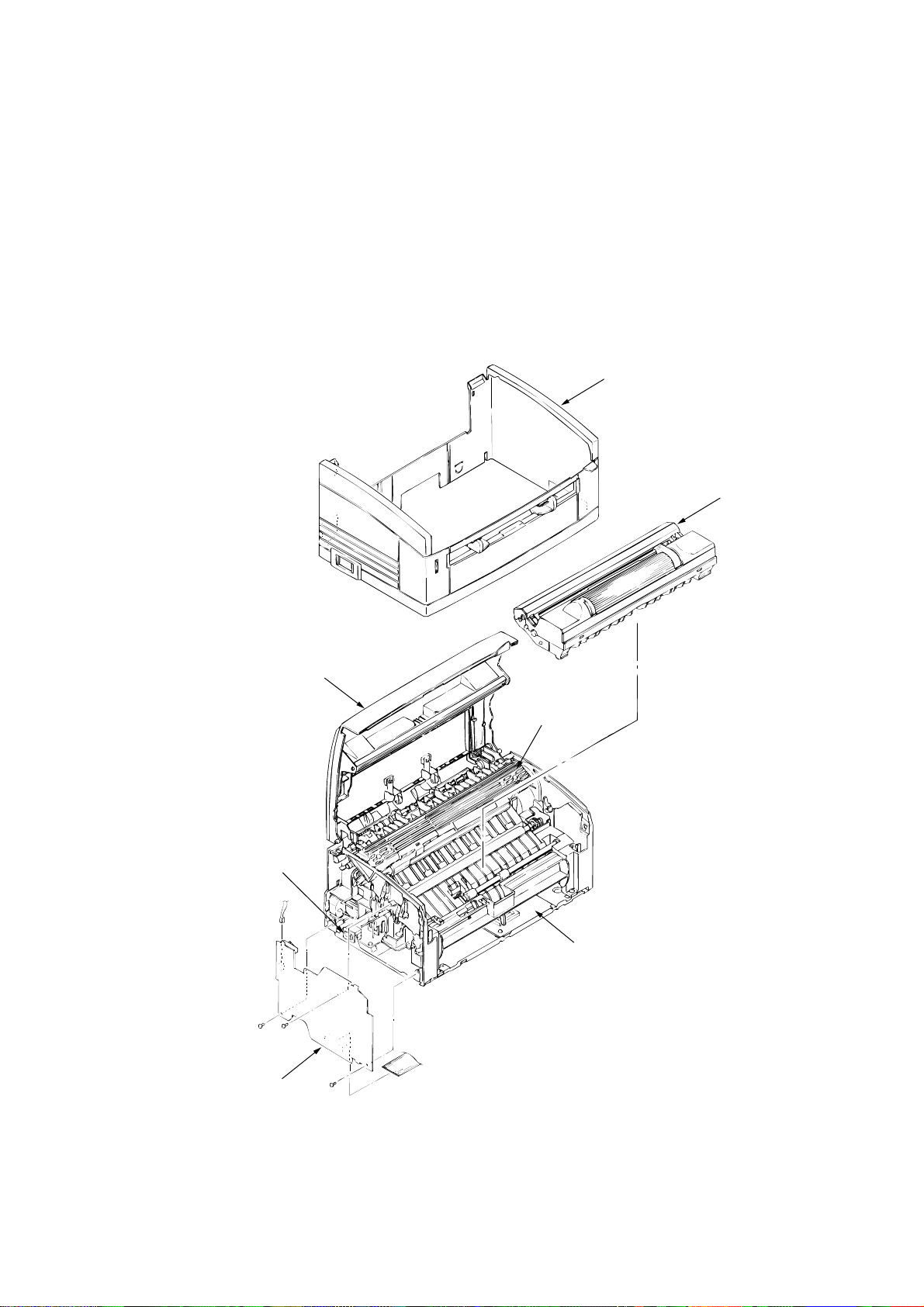

1.2 Printer Configuration

The printer unit consists of the following five hardware components:

• Electro-Photographic Processor

• Paper Feeder

• Main Control Board

• High-Voltage Power Supply Board

• Power Supply Unit

Figure 1-2 is the configuration of the printer unit.

Upper Cover Assy

EP Unit

Top Cover Assy

Power Supply Unit

High-Voltage Power

Supply Board

Heat Assy

Main Control Board

1 - 2

Page 9

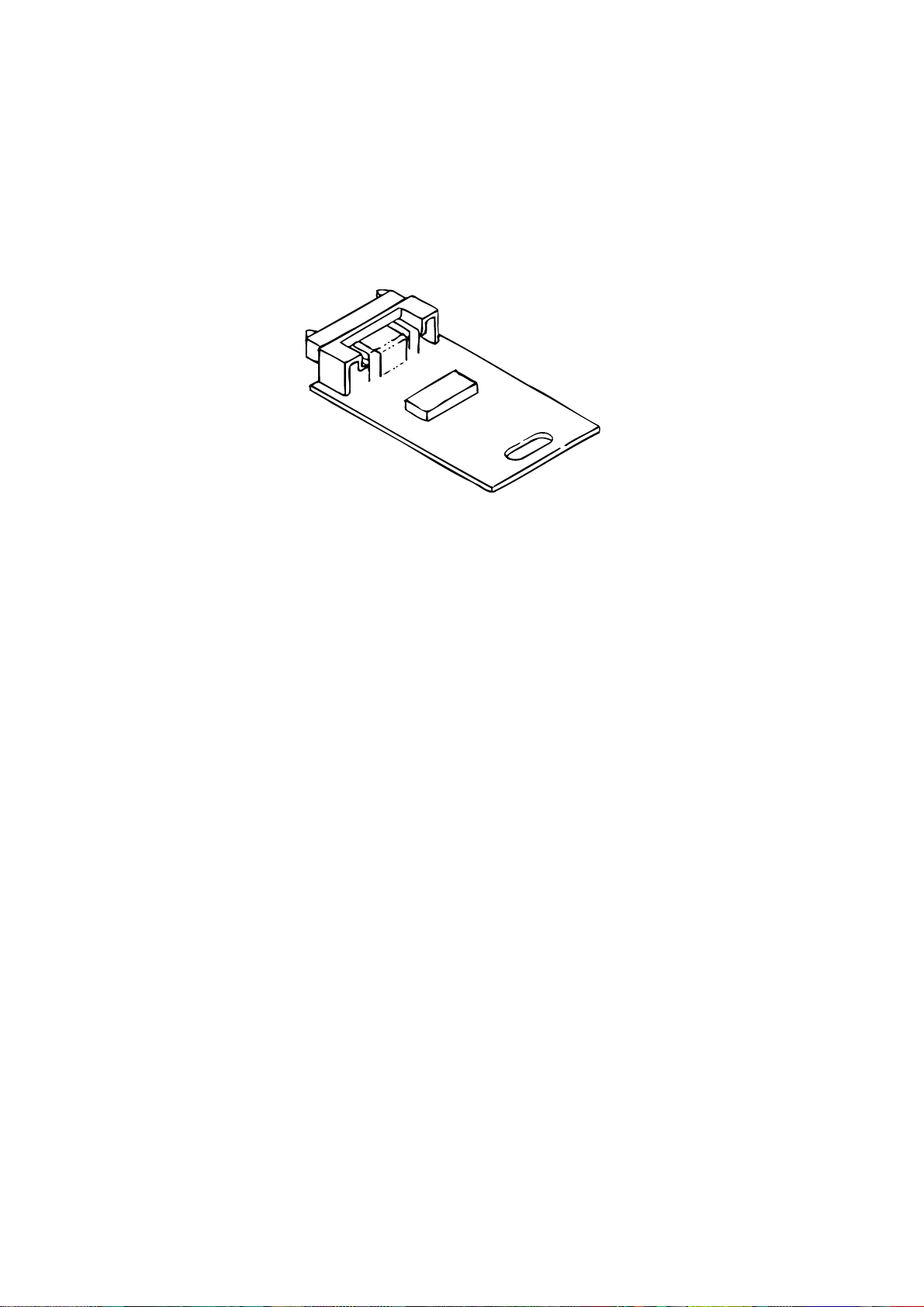

1.3 Option

(1) 2MB HBRB-PCB Option Memory Board(Only OKIpage 4m)

1 - 3

Page 10

1.4 Specification

(1) Type Desktop

(2) Outside dimensions Height 5.9” (150 mm)

(excludes protruding Width 12.2” (310 mm)

portion) Depth 7.5” (191 mm)

(3) Weight 3.8 kg

(4) Development method Dry non-magnetic development system

Exposure method LED stationary head

(5) Paper used <Type>

• Standard paper

– Xerox 4200 (20 lbs)

• Application paper (manual face-up feed)

– Label

– Envelope

– OHP paper (Transparency)

<Size>

14" (355.6 mm) (Max.) x 8.5" (215.9 mm)

<Thickness>

– Automatic feed: 16 to 28 lbs (60 to 90 g/m2)

– Manual feed: Label, Envelope, OHP paper (trans-

parency)

(6) Printing speed First print: 23 seconds (A4) (after warm-up)

Continuous print: 4 sheets/minute (A4)

Warm-up time: 40 seconds (120 VAC for ODA, 230

VAC for OEL/INT) (at room tempera-

ture 77 ˚F (25 ˚C))

(7) Paper feeding method Automatic paper feed or manual paper feed

(8) Paper delivery method Face down

(9) Resolution 300 dpi x 300 dpi, 600 dpi x 600 dpi (quasi)

(10) Power input 230 VAC +15%, -14% (for OEL/INT)

120 VAC +6%, -15% (for ODA)

(11) Power consumption Peak: 450W

Typical operation: 100W

Idle: 30W

Power save mode: 5W

1 - 4

Page 11

(12)Temperature and humidity

Humidity

During operation

In storage

Caution:

Temperature and humidity in storage are measured with the OKIPAGE 4w plus/4m

being packed; they are valid for one year.

Temperature

10 to 32 ˚C

–10 to +43 ˚C

20 to 80% RH (relative humidity)

10 to 90% RH (relative humidity)

No condensation is permissible.

(13)Noise During operation: 48 dB (A) or less

Standby: 38 dB (A) or less

(14)Consumables Toner cartridge kit 1,000 (5% duty)

Image drum cartridge 10,000 (at continuouts printing)

1 - 5

Page 12

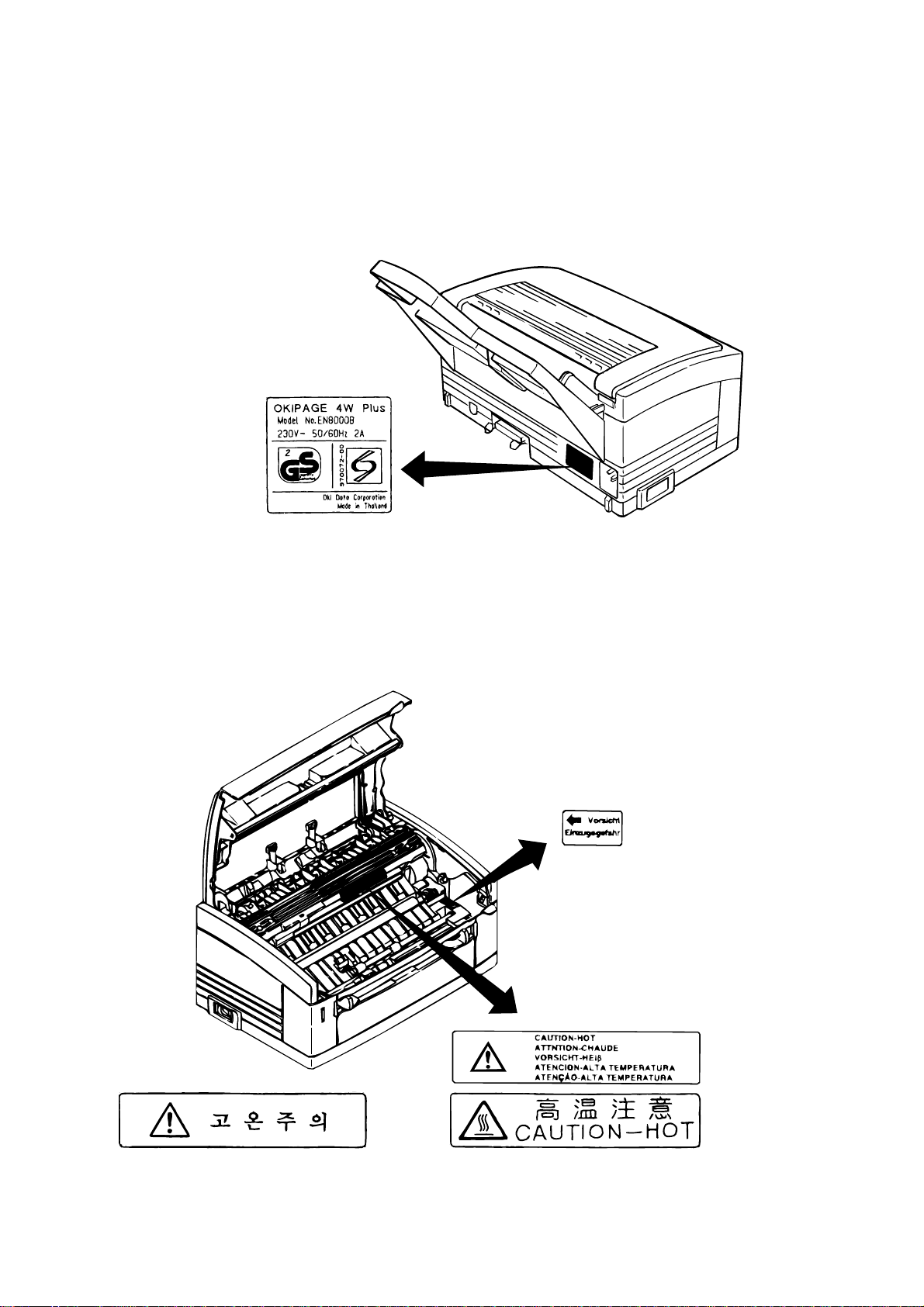

1.5 Safety Standards

1.5.1 Certification Label

The safety certification label is affixed to the following location of the OKIPAGE 4w:

OKI-INT

4w Plus

1.5.2 Warning Label

Warning labels are affixed to the locations that may cause bodily injury.

During maintenance, do work with enough care while following instructions on these warning

labels.

For OEL

1 - 6

For OEL, OKI-INT

For China, TAIWANFor Korea

Page 13

2. OPERATION DESCRIPTION

Page 14

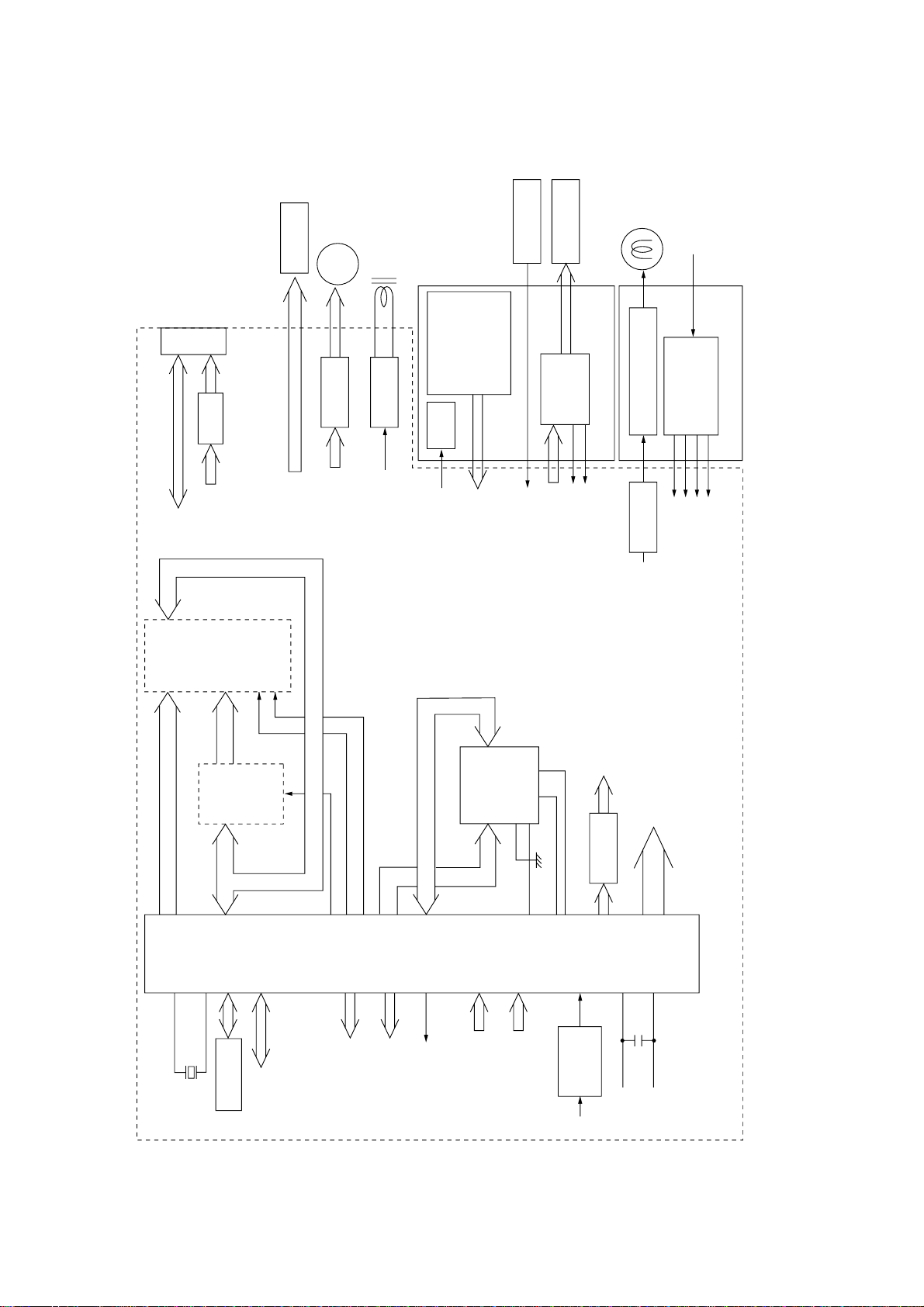

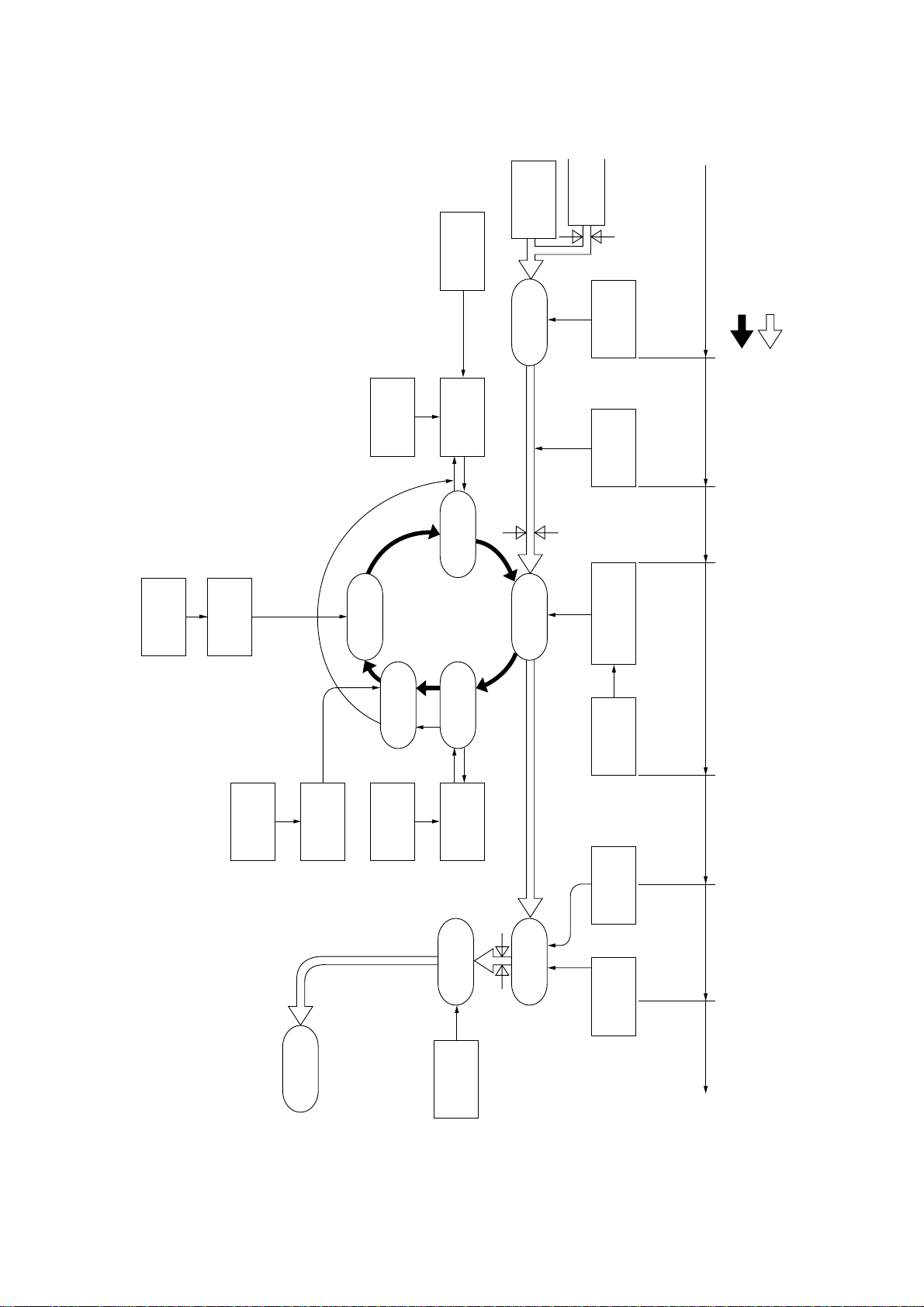

2. OPERATION DESCRIPTION

The OKIPAGE 4w Plus/4m consists of a main control board, a high-voltage power supply board,

a power supply unit, and an electro-photographic processor. The OKIPAGE 4w Plus/4m receives

print data from a higher-level interface and sequentially stores it in memory. The OKIPAGE 4w

Plus/4m decodes and edits the received data while storing print data from the interface in

memory. It sequentially transfers the edited data to the LED head for each dot line. The electrophotographic processor then prints the data on sheets of paper.

The display of the higher-level host is used for device operation and status display.

Figure 2-1 is the block diagram of the OKIPAGE 4w Plus/4m.

2 - 1

Page 15

EEPROM

Parallel

I/F

LED head

Main motor

Electromagnetic

clutch

Sensors

TEMP

TR-VSEN

TR-ISEN

Reset

circuit

10 MHz

MSM65917

(nX-8 core)

Address

latch

EPROM

(52 KByte)

OE

CS

A8 ~ A15

AD0 ~ AD7 A0 ~ A7

D0 ~ D3

A0 ~ A10

D0 ~ D7

D-RAM

(512 KB: For INT)

(128 KB: For OEL)

Driver High-voltage power I/F

LED

HEAT ON

5V

5V

OVL

CN

Parallel

I/F

Parallel

I/F

LED head

Main motor

Electromagnetic

clutch

LS07

Driver

Main motor

Electromagnetic

clutch

LED head

Driver

Driver

AC output ON/OFF

Switching

power supply

<Power Supply Unit>

<Main Control Board>

<High-voltage Power Supply Board>

LED

Thermistor

EP cartridge

Heater

(Halogen lamp)

AC

(120 V/230 V)

Manual feed sensor

Paper sensor

Outlet sensor

Toner sensor

Cover open switch

LED

Sensors

TEMP

High-voltage

power I/F

TR-VSEN

TR-ISEN

HEAT ON

+24 V

+5 V

0VL

0VP

M

High voltage

power

supply

Figure 2-1 Block Diagram (OKIPAGE 4w Plus)

2 - 2

Page 16

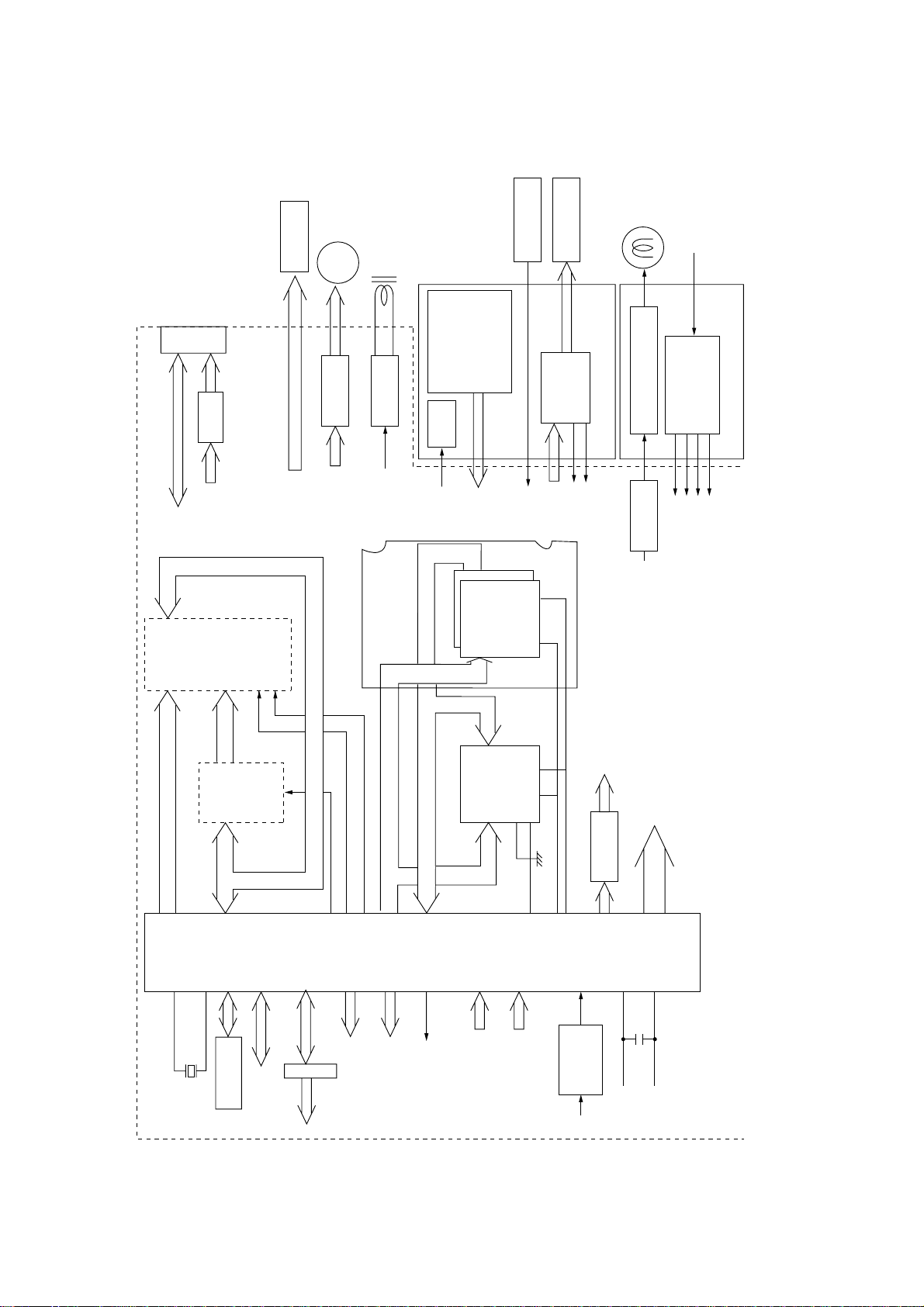

EEPROM

Parallel

I/F

LED head

Main motor

Electromagnetic

clutch

Sensors

TEMP

TR-VSEN

TR-ISEN

Reset

circuit

10 MHz

MSM65917

(nX-8 core)

Address

latch

EPROM

(52 KByte)

OE

CS

A8 ~ A15

AD0 ~ AD7 A0 ~ A7

D0 ~ D3

A0 ~ A10

D0 ~ D7

D-RAM

(512 KByte)

D-RAM

(2 MByte)

Driver High-voltage power I/F

LED

HEAT ON

5V

5V

OVL

CN

Parallel

I/F

Parallel

I/F

LED head

Main motor

Electromagnetic

clutch

LS07

Driver

Main motor

Electromagnetic

clutch

LED head

Driver

Driver

AC output ON/OFF

Switching

power supply

<Power Supply Unit>

<Main Control Board>

<High-voltage Power Supply Board>

LED

Thermistor

EP cartridge

Heater

(Halogen lamp)

AC

(120 V/230 V)

Manual feed sensor

Paper sensor

Outlet sensor

Toner sensor

Cover open switch

LED

Sensors

TEMP

High-voltage

power I/F

TR-VSEN

TR-ISEN

HEAT ON

+24 V

+5 V

0VL

0VP

M

High voltage

power

supply

option

Driver IC

Mac I/F

(Option RAM-PCB)

Figure 2-1 Block Diagram (OKIPAGE 4m)

2 - 3

Page 17

2.1 Main Control Board

The main control board consists of a one-chip CPU, a program ROM, a DRAM, an EEPROM, a

host interface circuit, and a mechanism driving circuit. The mechanism driving circuit consists of

a LED head, a main motor, and an electromagnetic clutch.

(1) One-chip CPU

The one-chip CPU is a custom CPU (8-bit internal bus, 8-bit external bus, 10-MHz clock)

incorporating mask ROM and CPU peripheral devices. This CPU has the functions listed in

the table below.

Built-in Device Function

DRAM controller

DMA controller

Parallel interface controller

Video output port

LED STB output port

Timer

I/O port

A/D converter

(2) Program ROM

Program ROM contains a program for the equipment. EPROM is used as program ROM.

When mask ROM in the one-chip CPU explained in (1) above is valid, the EPROM is not

mounted. (For details on short wiring setting, see Section 7.2.)

(3) DRAM

DRAM is used as resident memory.

Controls DRAM.

Transfers image data from Parallel I/F to DRAM, from DRAM to a video output port and

between CPU and DRAM.

Controls the parallel interface.

Controls LED head.

Generates various control timings for monitoring paper feeding and a paper size.

Inputs and outputs the sensor signals and motor signals, etc.

Also performs I/O for EEPROM.

Inputs the feedback signals from a high-voltage generation circuit and thermistor signal.

(4) EEPROM

EEPROM holds the following data:

• Menu data

• Counter value

• Adjustment value

(5) Parallel interface

The parallel interface receives parallel data from the host; it conforms to the IEEE1284

specification.

(6) Macintosh interface <only OKIPAGE 4m>

Mcintosh interfacce receives serial data from the host ; it conforms to the IEEE1284.

2 - 4

Page 18

2.2 Power Supply Unit

The power supply unit supplies +5 V and +24 V to the main control board according to 230 VAC

/120 VAC.

Output voltage Application

+5 V

+24 V

Used to generate a logic circuit and a high voltage.

Used to drive the motor and electromagnetic clutch.

The power supply unit also contains a heater drive circuit.

2.3 High-Voltage Power Supply Board

(1) High-Voltage power supply circuit

The high-voltage power supply circuit generates the following voltages required for the

electro-photographic processor from +5 V according to the control sequence from the main

control board. When the cover is open, +5 V supply is automatically interrupted to stop high-

voltage output.

Output Application

CH

–1.35 KV

DB

–300 V/+300 V

SB

–450 V/ 0 V

CB

+400 V

TR

+500 V ~ +3.5 KV/–750 V

Voltage

Voltage to be applied to a charge roller.

Voltage to be applied to a developing roller.

Voltage to be applied to a sponge roller.

Voltage to be applied to a cleaning roller.

Voltage to be applied to a transfer roller.

Caution:

The TR voltage varies with medium and transfer roller impedance.

2 - 5

Page 19

(2) Sensors

The high-voltage power supply board consists of the high-voltage power supply circuit that

supplies power to the electro-photographic processor system and the photosensor that

detects a paper feeding system and toners.

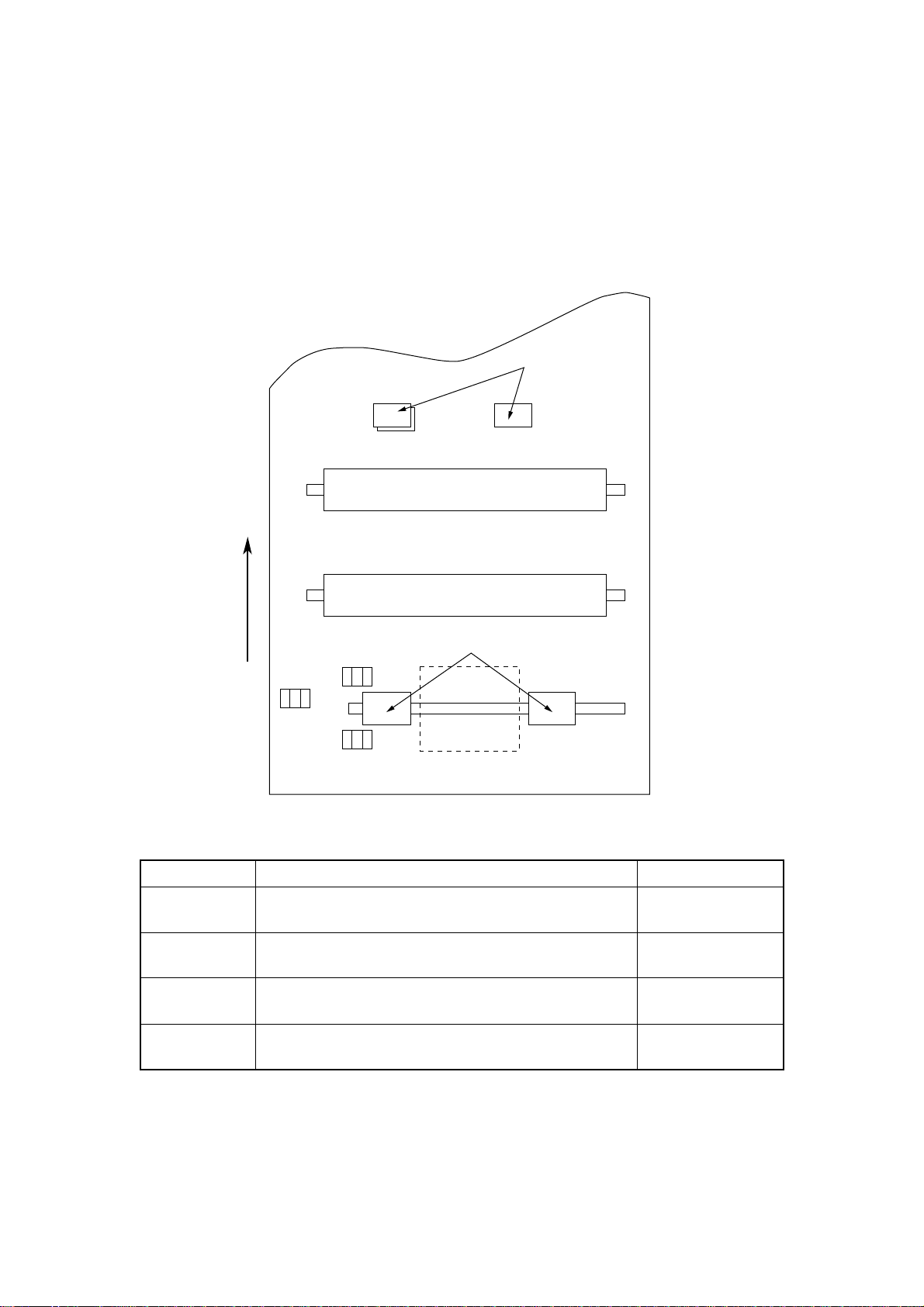

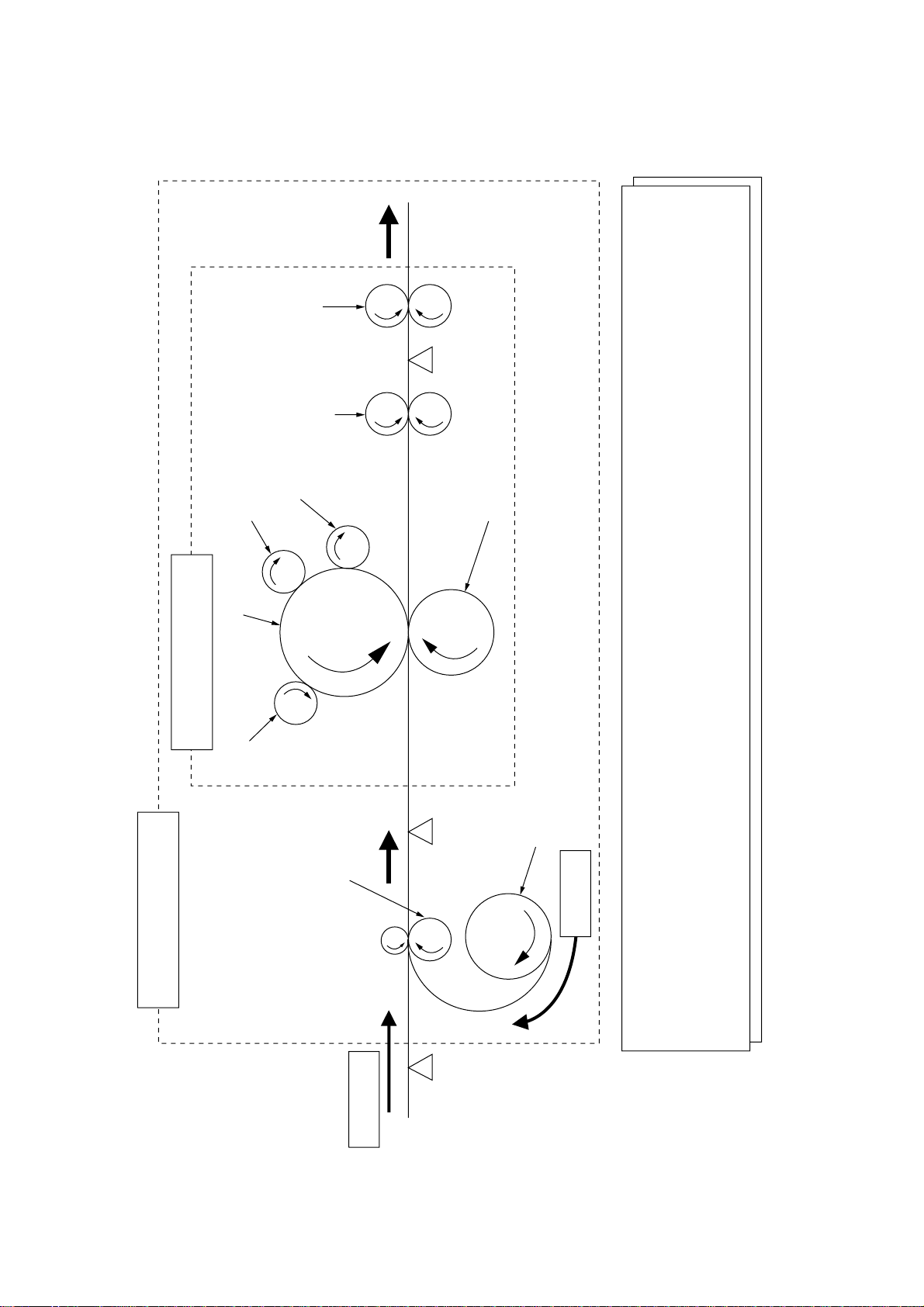

Figure 2-2 shows the sensor layout drawing.

Exit roller

Outlet sensor

Heat roller

Transfer roller

Paper sensor

Toner

sensor

assy

Manual feed sensor

Paper feeding direction

Feed roller

Hopping

roller

Figure 2-2

Sensor Function Sensing State

Manual feed

sensor

Paper sensor

Outlet sensor

Toner sensor

Monitors whether paper was inserted into the manual feed sensor

section.

Detects the leading part of the paper.

Monitors paper feeding.

Monitors paper feeding and the paper size according to the paper

sensor arrival and passing time.

Detects the low toner status.

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

ON: Paper exists.

OFF: No paper exists.

ON (long): Toner low

OFF (short): Toner High

2 - 6

Page 20

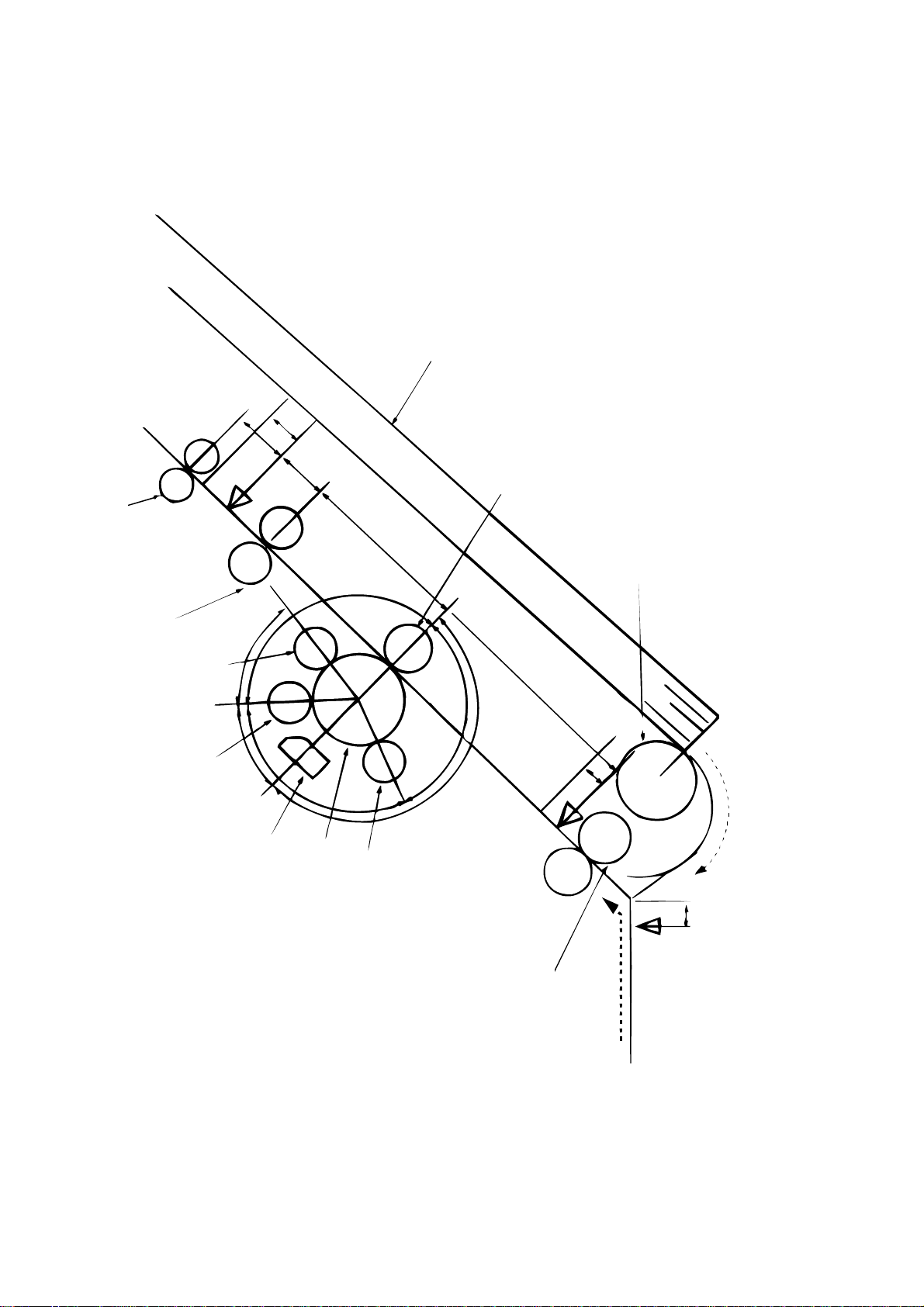

2.4 Electro-Photographic Processor

The electro-photographic processor prints out the image data to be sent from the main control

board on sheets of paper. Figure 2-3 shows the layout drawing of the electro-photographic

processor.

(1) Image drum unit

The image drum unit makes a toner adhere to the formed electrostatic latent image with static

electricity. This electrostatic latent image is formed by the lights irradiated from LED heads.

(2) Electromagnetic clutch

The electromagnetic clutch controls the rotation of the hopping roller according to signals

from the control block.

2 - 7

Page 21

Exit roller

Heat roller

(ø 19.910)

6.85

10

OFF

ON

26.50

Outlet sensor

Cleaning roller

(ø 9.000)

Charge roller

(ø 9.000)

6.77

LED head

Drum roller

(ø 16.000)

Developing roller

(ø 14.000)

17.23

12.72

23.18

20.32

64.60

Single tray

Transfer roller

(ø 15.000)

Hopping roller

OFF

32.00

10

Tray printing

10

ON

OFF

Manual feed sensor

Manual

printing

Feed roller

Paper sensor

2 - 8

Figure 2-3 Layout Drawing of Electro-Photographic Processor

Page 22

(3) Pulse motor (Main)

This pulse motor of 48 steps/rotation is two-phase excited by the signal from the main control

board; it performs feeding control by switching normal rotation to reverse rotation or vice

versa and turning on/off the electromagnetic clutch. The relationship between the main

motor, electromagnetic clutch, resist gear, drum gear, hopping roller is shown in the table

below and on the subsequent pages.

Main Motor Electromagnetic Clutch

Normal rotation

Reverse rotation

OFF

ON

OFF

Hopping Roller

Non-rotation

Rotation

Non-rotation

Regist Gear Drum Gear Operation

Non-rotation

Rotation

Rotation

Rotation

Rotation

Rotation

Warm-up

Hopping

Prinitng

(4) LED head

The shift and latch registers receive image data from the main control board for each dot line.

2,560 or 2,496 LEDs are driven to radiate the image drum.

(5) Heat Assy

The heat Assy consists of a heater, a heat roller, a thermistor, and a thermostat.

The power supply unit supplies AC voltage to the heater according to the HEATON signal

from the main control board to heat the heat roller. The main control board monitors the heat

roller temperature via the thermistor and keeps the temperature constant by turning on/off

the heater AC voltage supply.

If the heat roller temperature rises abnormally, the thermostat of the heater voltage supply

circuit functions to forcibly suspend the AC voltage supply.

2 - 9

Page 23

Exit roller

Heat roller

Transfer roller

Cleaning roller

CH roller

Drum roller

Developing roller

Outlet

sensor

Paper sensor

Hopping roller

TRAY printing

Feed roller

Manual

feed

sensor

Manual printing

2

Roller to be driven by reverse

rotation of pulse motor (Main)

1

Motor to be driven by normal

rotation of pulse motor (main)

Roller control by pulse motor (main)

1

Normal rotation of pulse motor (main): Drum roller, transfer roller, cleaning roller, CH roller, developing roller, heat roller, exit roller rotation

2

Reverse rotation of pulse motor (main): Drum roller, transfer roller, cleaning roller, CH roller, developing roller, heat roller, exit roller, feed roller,

hopping roller rotation

Hopping operation from the tray, however, is performed when the electromagnetic clutch is turned on.

Figure 2-4 Schematic Drawing of OKIPAGE4w Plus/4m Paper Feeding

2 - 10

Page 24

2.5 Electro-Photographic Process

(1) Electro-photographic process

The electro-photographic process is outlined below.

1 Charging

The surface of the OPC drum is charged negatively and uniformly by applying the DC

voltage to the CH roller.

2 Exposure

Light emitted from the LED head irradiates the negatively charged surface of the OPC

drum. The surface potential of the irradiated surface attenuates to form the electrostatic

latent image corresponding to the image signal.

3 Development and residual toner recovery

The negatively charged toner is brought into contact with the OPC drum, adhering to the

electrostatic latent image on the OPC drum by static electricity. This adhesion causes

the electrostatic latent image to change to a visible image.

At the same time, the residual toner on the OPC drum is attracted to the developing

rollerby static electricity.

4 Transfer

When paper is placed over the image drum surface, the positive charge which is

opposite in polarity to that of the toner, is applied to the reverse side by the transfer roller.

The toner is attracted by the positive charge and is transferred onto the paper. This

results in the transfer of the toner image formed on the image drum onto the paper.

5 Cleaning

The cleaning roller temporarily attracts the residual toner on the transferred OPC drum

with static electricity, then returns the toner to the OPC drum.

6 Fusing

The transferred unfused toner image is fused to a sheet of paper by applying heat and

pressure to the image.

Figure 2-5 is a flow for the electro-photographic process.

2 - 11

Page 25

Paper

holder

section

Manual feed

Control signal

LED head

Power

supply

Exposure

Toner

cartridge

roller

Developing

Paper

supply

Transfer

Manual feed

roller

Hopping

Feed roller

Paper sensor

Transfer roller

sensor

: OPC drum rotation direction

: Paper feeding path

Power

supply

roller

Charge

Paper delivery

Charging

Power

supply

Cleaning Development

roller

Cleaning

Paper feeding

Outlet sensor

roller

Paper eject

Fusing

Power

supply

roller

Back-up

Heat roller

Figure 2-5 Flow for Electro-Photographic Process

Paper ejection Fusing Cleaning Transfer Development Paper feed Paper hopping

2 - 12

Page 26

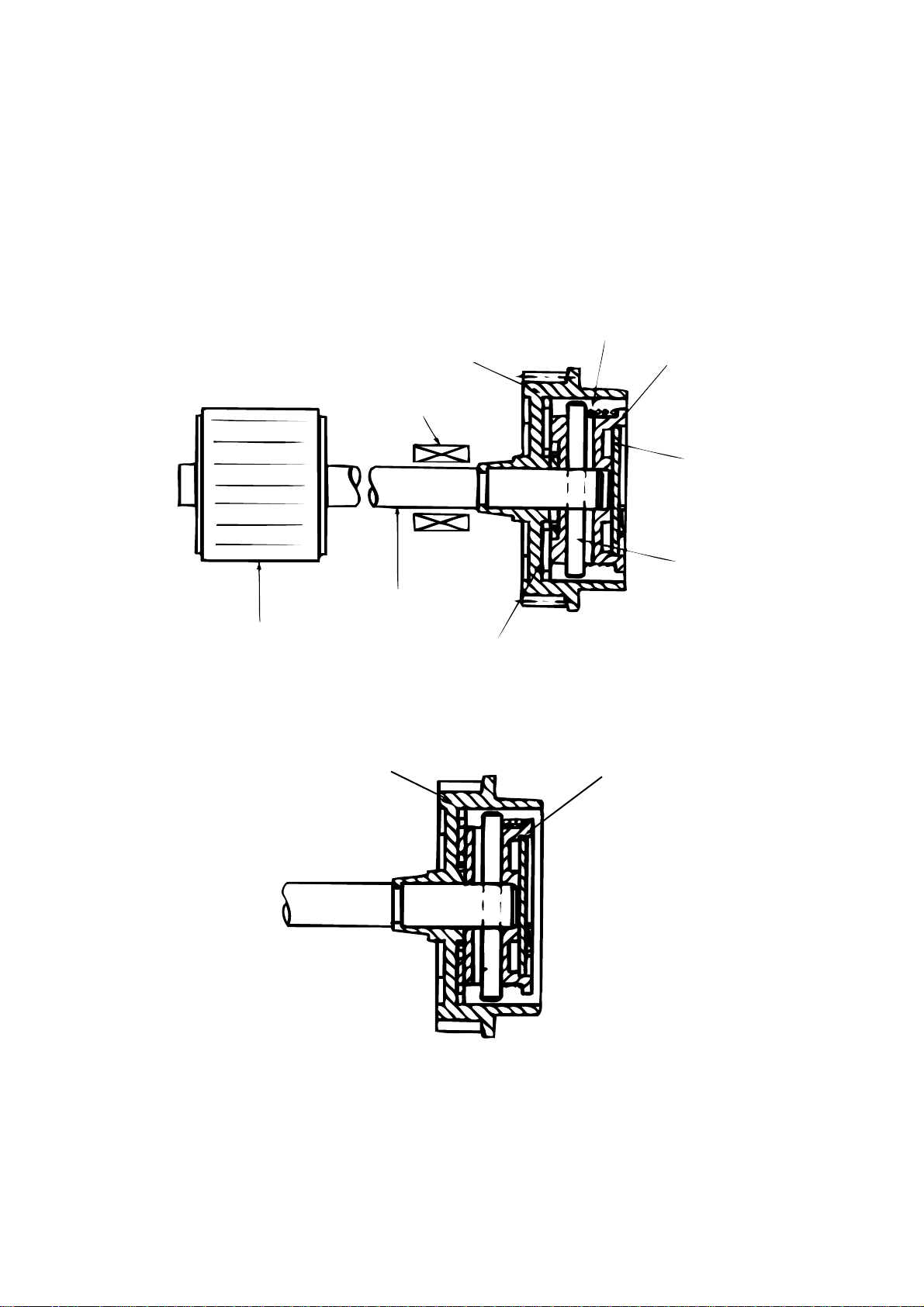

2.5.1 Explanation of Each Process Operation

(1) Hopping

As shown in the figure below, the clutch for hopping is turned on/off according to current ON/

OFF to a coil.

When the clutch is OFF

Coil

Hopping gear

Spring for resetting

Clutch plate

Magnetic

substance plate

Pin

Hopping roller

When the clutch is ON

Hopping shaft

Hopping gear

Engagement section

Clutch plate

When the clutch is on, the hopping gear engages with the clutch plate to rotate the hopping

roller.

When the clutch is off, the hopping gear is separated from the clutch plate by the spring for

resetting, disabling the rotation of the hopping roller.

2 - 13

Page 27

(2) Printing and warm-up

At warm-up

Triple gear

Transfer gear

Resist gear

Idle gear

Planetary gear

a

Pulse motor (main)

Hopping gear

a"

a'

Gear A

Rotate the pulse motor (main) in the a direction. The planetary gear rotates in the a’ direction,

dislocating its position in the a” direction. This causes the planetary gear to be separated from

gear A. The hopping gear will not rotate. The triple gear and transfer gear rotate via the idle

gear to drive the EP unit.

At printing

Transfer gear

Resist gear

Hopping gear

Triple gear

b"

b'

Gear A

The paper is further advanced in synchronization to the print data.

Idle gear

Planetary gear

b

Pulse motor (main)

2 - 14

Page 28

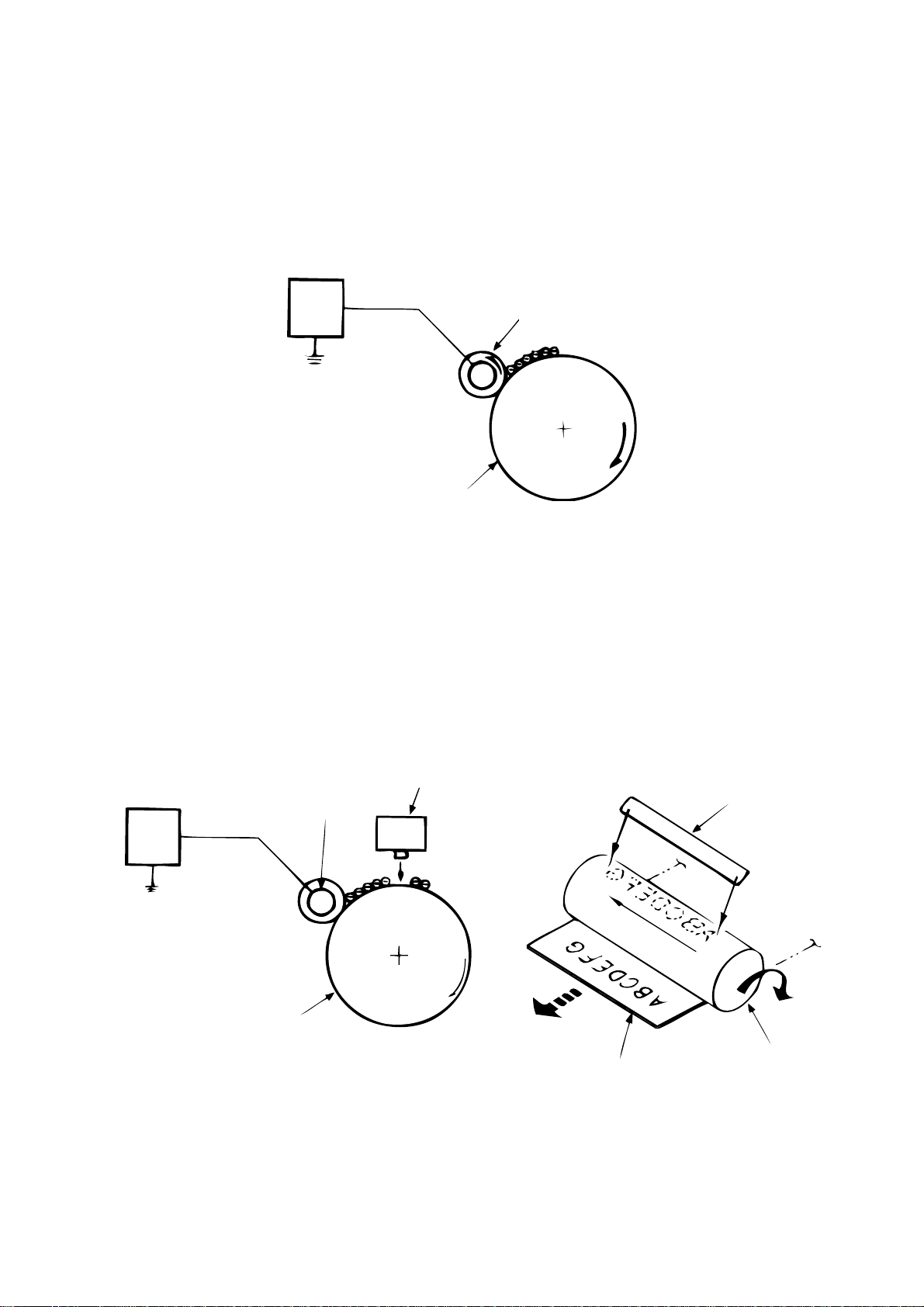

(3) Charging

Charging is performed by applying DC voltage to the charge roller that is in contact with the

surface of the OPC drum.

High-

voltage

power

supply

OPC drum

Charge roller

(4) Exposure

High-

voltage

power

supply

Light emitted from the LED head irradiates the negatively charged surface of the OPC drum.

The surface potential of the irradiated surface attenuates to form the electrostatic latent

image corresponding to the image signal.

LED head

Charge roller

OPC drum

LED head

2 - 15

Paper

OPC drum

Page 29

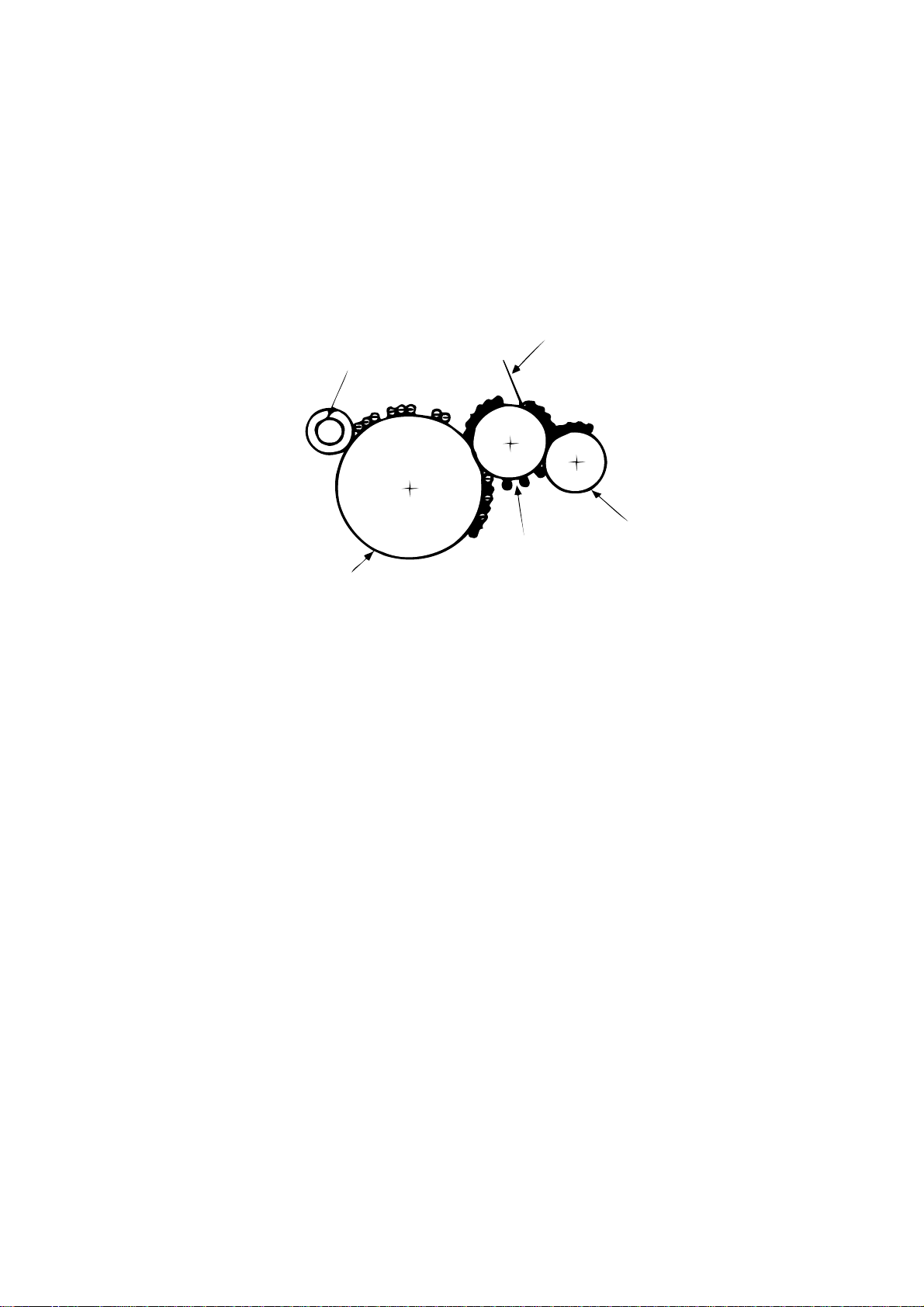

(5) Development

The electrostatic latent image on the surface of the OPC drum is changed to a visible toner

image by applying a toner to it. Development is performed in the contact part between the

OPC drum and developing roller.

1 The sponge roller negatively charges a toner and applies it to the developing roller.

Developing blade

Charge roller

Sponge roller

Developing roller

OPC drum

2 The toner applied to the developing roller is thin-coated by the developing blade.

3 A toner adheres to the exposure part of the OPC drum in the contact part between the

OPC drum and developing roller. This causes the electrostatic latent image to be

changed to a visible image.

2 - 16

Page 30

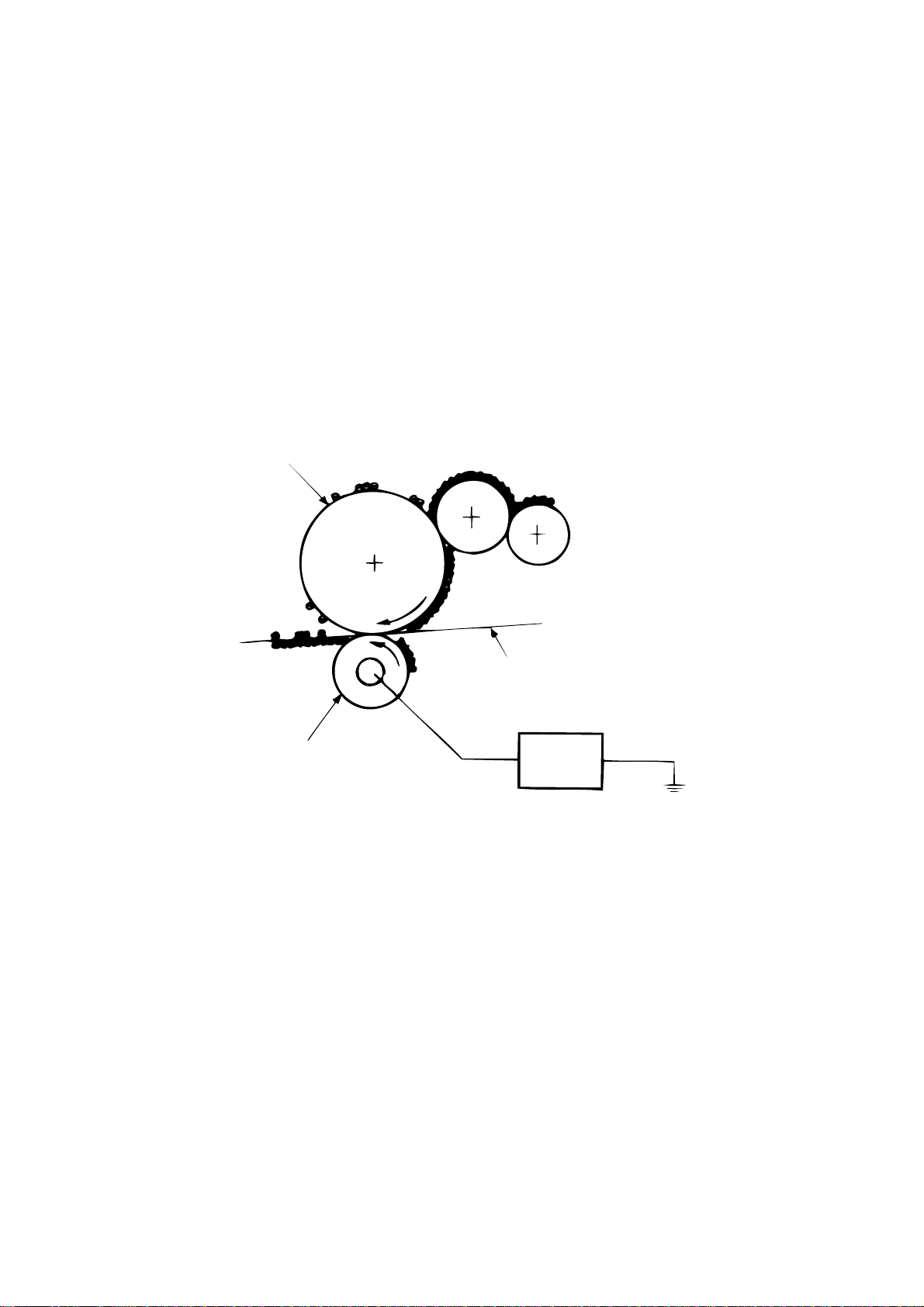

(6) Transfer

The transfer roller is composed of conductive sponge material. This roller is set so that the

surface of the OPC drum and sheets of paper will adhere closely.

A sheet of paper is placed on the surface of the OPC drum and the positive charge opposite

to the negative charge of a toner is applied from the reverse side by the transfer roller.

When a high negative voltage is applied from the power supply to the transfer roller, the

positive charge induced on the surface of the transfer roller moves to the paper side at the

contact part between the transfer roller and the sheet of paper. The positive charge on the

lower side of the sheet of paper then causes the negatively charged toner adhering to the

surface of the OPC drum to move to the upper side of the sheet. This enables transfer to the

sheet of paper.

OPC drum

Transfer roller

Paper

High-voltage

power supply

2 - 17

Page 31

(7) Fusing

The transferred unfused toner image is fused to a sheet of paper because heat and pressure

are applied when it passes between the heat roller and back-up roller.

The Teflon-coated heat roller contains a 400 W heater (Halogen lamp) that heats the heat

roller. The thermistor on the surface of the heat roller keeps the temperature of the heat roller

constant. A thermostat is also installed for safety. If temperature rises abnormally, this

thermostat opens to suspend voltage supply to the heater.

The back-up roller is pressurized to the heat roller by the pressure spring on each side.

Thermistor

Separation claw

Heat roller

Heater

Back-up roller

Pressure spring

(8) Cleaning

After transfer has terminated, the cleaning roller temporarily draws in the untransferred

residual toner adhering to the OPC drum with static electricity and then returns it to the OPC

drum.

OPC drum

Cleaning roller

High-voltage

power supply

Transfer roller

2 - 18

Page 32

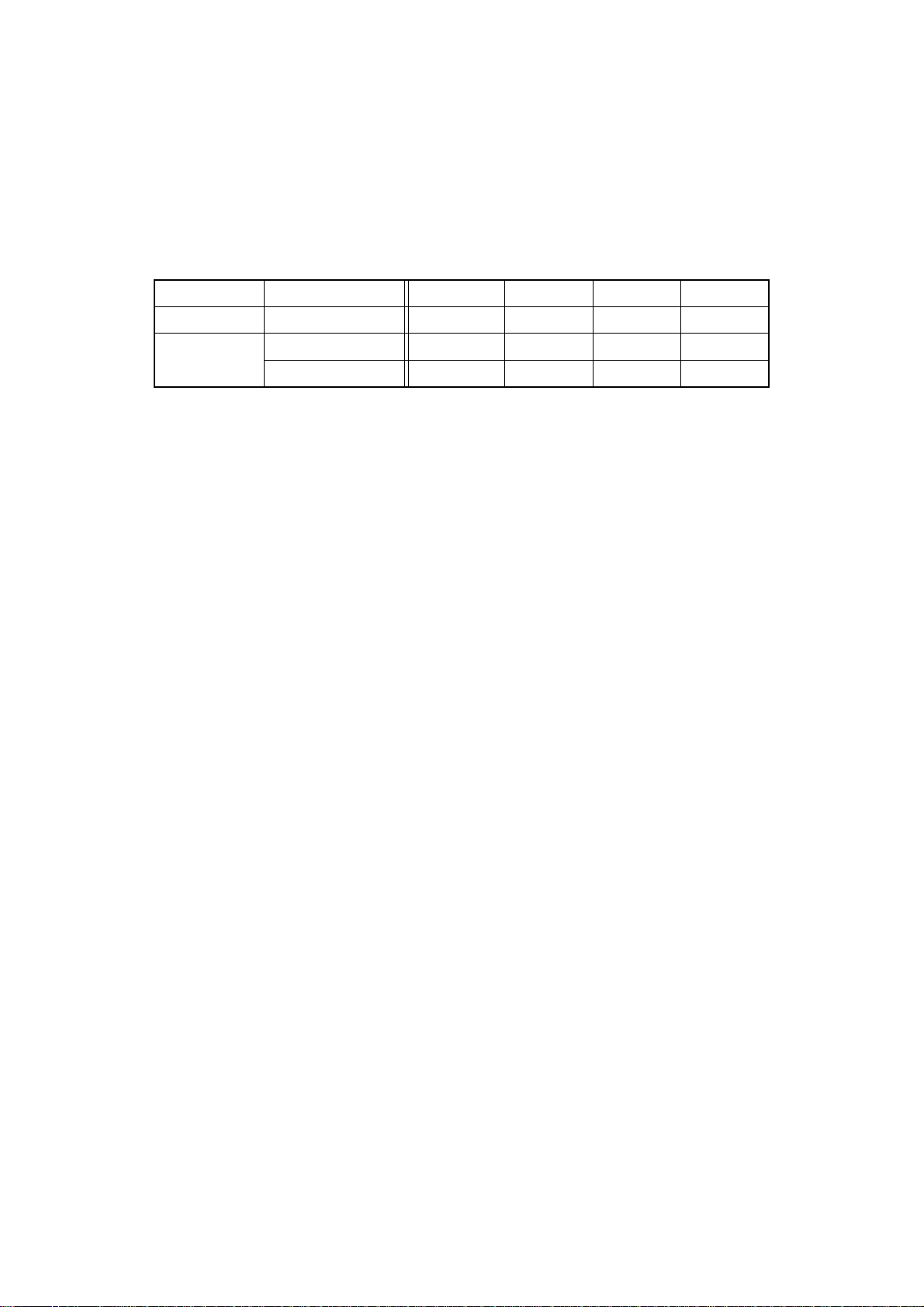

2.6 Paper Jam Detection

The OKIPAGE 4w Plus/4m monitors the paper status when the power supply is on and during

printing. In the following cases, the OKIPAGE 4w Plus/4m interrupts the printing process as a

paper jam. Printing can be recovered by opening the cover, removing the jammed paper, and

closing the cover.

Error

Cause of Error

Paper inlet jam ••Only the manual feed sensor detects "Paper exists" when the power supply is on.

The leading part of the paper does not reach the paper sensor although hopping

operation was performed three time.

Paper feed jam • The leading part of the paper does not reach the outlet sensor within a fixed time after it

has passed the paper sensor.

Paper outlet jam • The trailing part of the paper does not pass the outlet sensor within L mm after the

leading part of the paper has passed the outlet sensor.

2.52" (64 mm) L 15.77" (400.6 mm)

<=<

=

Paper size error • The trailing part of the paper does not pass the paper sensor within L mm after the

leading part of the paper has passed the paper sensor.

2.52" (64 mm) L 15.77" (400.6 mm)

<=<

=

Error

Type of Error

Supervisory Sensor

Reference Value

Pluse Minus

Paper feed error

Paper feed jam1

Paper size error

Paper outlet jam

Paper feed jam 2

Electromagnetic clutch ON/

Paper sensor ON

Paper sensor ON/

Outlet sensor ON

Paper sensor ON/

Paper sensor OFF

Outlet sensor ON/

Outlet sensor OFF

Paper end sensor OFF/

Outlet sensor OFF

2 - 19

69.8

122.9

2.52" (64 mm) L

<=<

=

15.77" (400.56 mm)

2.52" (64 mm) L

<=<

=

15.77" (400.56 mm)

121.9

35

20.0

—

45.0

20.0

—

—

—

45.0

20.0

Unit: mm

Page 33

Pulse motor

(main)

Normal

rotation

OFF

Reverse

rotation

Electromagnetic

clutch

Manual feed

sensor

Paper sensor

Outlet sensor

Operation mode

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Warm-up Paper feed Printing

Timing Chart for Paper Feed (Tray Feed)

2 - 20

Page 34

Paper Feed Check List

2.7 Toner Low Detection

• Hardware configuration of toner sensor

The figure below shows the hardware configuration of the toner sensor.

Photointerrupter

Image drum unit

Agitation bar (iron)

Magnet

Toner sensor lever

Hardware Configuration of Toner Sensor

• Toner detection method

(1) Toner sensor monitoring conditions are shown in the figure below.

Toner sensor

Magnet draw-in

t1

T

Caution:

The toner sensor is not monitored when the drum is inactive.

(a) When the toner-low state continues twice, Toner Low occurs. (This state is monitored

at a cycle of 40 milliseconds.)

(b) When the toner-full state continues twice, Toner Low is released. (This state is

monitored at a cycle of 40 milliseconds.)

(c) When the toner sensor does not change over two cycles (T x 2), the toner sensor

alarm state occurs.

(d) After the EP unit has been replaced (after the drum counter has been reset), Toner

Low is not detected when the drum counter indicates 1 to 100 counts.

2 - 21

Page 35

(2) The basic rotation cycle of the toner sensor is as follows:

2.8 Cover Open

Opening the stacker cover turns off the microswitch on the high-voltage power supply board to

suspend +5 V supply to the high voltage power supply. This results in the stop of all high-voltage

outputs. At the same time, the CVOPN signal is issued to notify the main control board of the

switch status and cover open processing is executed.

Basic rotation cycle of toner sensor

Toner low time

Toner full time

T time

4.9 sec.

t1 > 1.2 sec.

1.2 sec. > t1 > 0.28 sec.

2 - 22

Page 36

3. P ARTS REPLACEMENT

Page 37

3. PARTS REPLACEMENT

This chapter explains how to replace parts, assemblies, and units in the field.

The replacement procedures to be explained here include dismounting, not mounting. When

mounting parts, assemblies, and units, reverse the dismounting steps.

3.1 Precautions for Parts Replacement

(1) Be sure to dismount the AC cord and interface cable before replacing parts.

(a) Be sure to dismount the AC cord in the following procedures:

i) Turn off the POWER switch of the printer (“0“).

ii) Disconnect the AC inlet plug of the AC cord from the AC receptacle.

iii) Disconnect the AC cord and interface cable from the printer.

(b) Be sure to reconnect the printer in the following procedures:

i) Connect the AC cord and interface cable to the printer.

ii) Connect the AC inlet plug to the AC receptacle.

iii) Turn on the POWER switch of the printer (“|”).

Dismounting

OFF

ON

(2) Do not disassemble parts as long as the printer is operating normally.

(3) Minimize disassembling. (Only the parts indicated in the parts replacement procedures can

be dismounted.)

(4) Use only the specified maintenance tools.

(5) Disassemble parts in the specified sequence; otherwise, parts may be damaged.

(6) Temporarily tighten small parts such as screws and collars to the original locations because

they tend to be lost easily.

Reconnection

(7) When handling ICs such as CPUs, ROM, and RAM and PC boards, do not wear gloves that

easily cause static electricity.

(8) Do not place PC boards directly on devices and floors.

3 - 1

Page 38

[Maintenance Tools]

Table 3-1 lists the maintenance tools necessary for parts replacement.

Table 3-1 Maintenance Tools

No.

1

2

3

4

5

6

7

No. 1-100 Philips

screwdriver

No. 2-100 Philips

screwdriver

No. 3-100 Philips

screwdriver

No. 5-200 screwdriver

Digital multimeter (tester)

Pliers

Handy cleaner

Q'ty Use RemarksMaintenance Tools

1

1

1

1

1

1

1

2~2.5 mm screw

3~5 mm screw

[Maintenance Utility]

No.

1

Table 3-2 Maintenance Utility

Q'ty Use RemarksMaintenance Utility

Maintenance utility

1

3 - 2

Page 39

3.2 Parts Layout

This section explains the layout of main parts.

[Upper Cover Assy]

Hopper plate

Spur gear (A)

Guide slide (R)

Guide slide (L)

Upper cover

Figure 3-1

3 - 3

Page 40

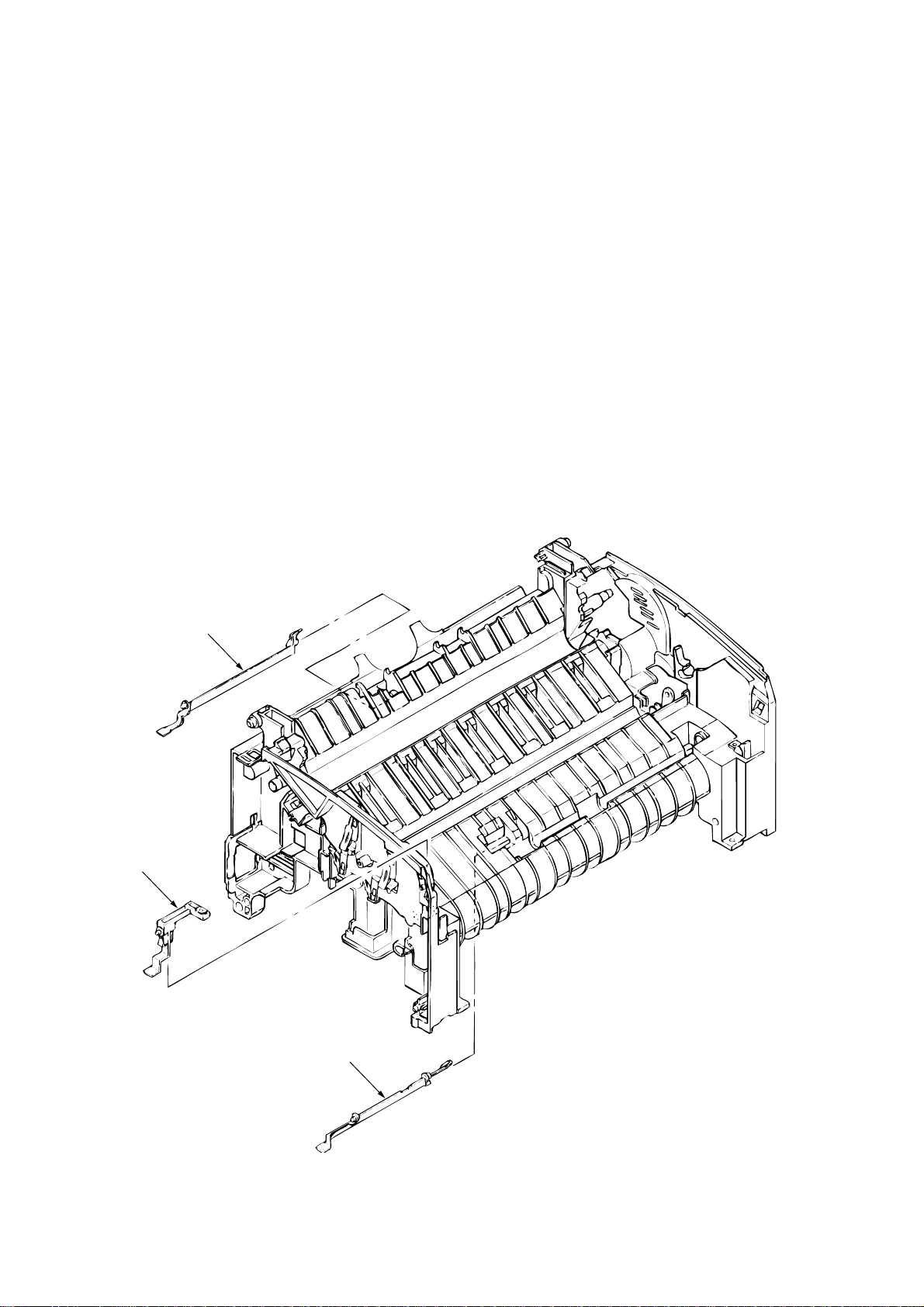

[Base Frame Unit]

Top cover assy

Paper guide (R)

LED head

Pressure roller (B)

(Back up roller)

Flat cable assy

Head spring

Heat assy

Paper guide (L)

Hopper

spring

Stopper spring

Transfer roller

Paper

holder

Resistration roller

Drive shaft E (eject)

Idle gear heat

Roller holder

Tension

plate

Slide plate M

Hopping

shaft

Magnet H

(hopping shaft)

assy

High-voltage power

supply board

Sheet guide

Figure 3-2

3 - 4

Hopping roller

Toner

Pulse motor

(main)

Power sensor E

cartridge

unit

EP unit

Page 41

[Base Plate Unit]

Power supply unit

Main control board

Figure 3-3

3 - 5

Base plate assy

Page 42

3.3 Replacing Parts

This section explains how to replace parts and assemblies.

3.3.1 Hopper Plate

(1) Remove two claws and dismount hopper plate 1.

1

3 - 6

Page 43

3.3.2 LED Head and Head Spring

(1) Open top cover assy 1.

(2) Dismount the left clamp and LED head 2. Then, dismount flat cable assy 3.

(3) Dismount two head springs 4.

2

3

4

1

4

3 - 7

Page 44

3.3.3 Transfer Roller

(1) Open top cover assy 1 and dismount EP unit 2.

(2) Remove the right claw. Then, dismount transfer roller 3, two resist bearings 4, and gear

T5.

2

5

4

1

3

4

Label

3 - 8

Page 45

3.3.4 Upper Cover Assy

(1) Turn off the power switch and unplug the AC cord from the AC socket.

(2) Disconnect interface cable 1.

(3) Open top cover assy 2 and dismount EP unit 3.

(4) Move paper guide (L) 4 and paper guide (R) 5 on the rear of the printer to the center.

(5) Remove two front claws of upper cover assy 6 and two rear screws A and lift upper cover

assy 6.

(6) Dismount spur gear (A) 7, guide slide (L) 8, and guide slide (R) 9.

(7) Dismount lamp 0.

7

A

1

9

8

6

A

0

3

2

5

4

3 - 9

Page 46

3.3.5 High-Voltage Power Supply Board

(1) Dismount upper cover assy. (See Section 3.3.4.)

(2) Remove three screws 1 and draw out high-voltage power supply board 2.

(3) Disconnect all the cables 3 from high-voltage power supply board 2 and dismount high-

voltage power supply board 2.

Caution:

3

Note the following when assembling the high-voltage power supply board:

• Mount the high-voltage power supply board with top cover assy removed or

open.

• Take care that cable 3 will not interfere with the paper sensor exit when it is

connected.

Paper sensor exit

1

2

3

1

3 - 10

Page 47

3.3.6 Top Cover Assy and Flat Cable Assy

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the LED head. (See Section 3.3.2.)

(3) Press the left clamp outward and dismount the engagement and top cover assy 1. (Tension

spring 2 also comes off at the same time.)

(4) Disconnect connector CN6 and dismount flat cable assy 3.

1

2

3

3 - 11

connector (CN6)

Page 48

3.3.7 Paper Holder

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount paper holder 1.

(3) Unlock and dismount paper guide (L) 2 and paper guide (R) 3.

(4) Remove the claw and dismount hopper spring 4.

(5) Remove the claw and dismount stopper spring 5.

4

3

5

1

2

3 - 12

Page 49

3.3.8 Side Plate M and Idle Gear

Perform parts replacement while making the base frame assy stand so that side plate M will face

upward.

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Remove two screws 1 and two claws, then dismount plate side M2.

(3) Dismount earth plate 3, two idle gears P4, idle gear M5, idle gear 3R6, idle gear 2R7,

and idle gear heat 8.

8

7

5

3

4

6

4

2

1

1

3 - 13

Page 50

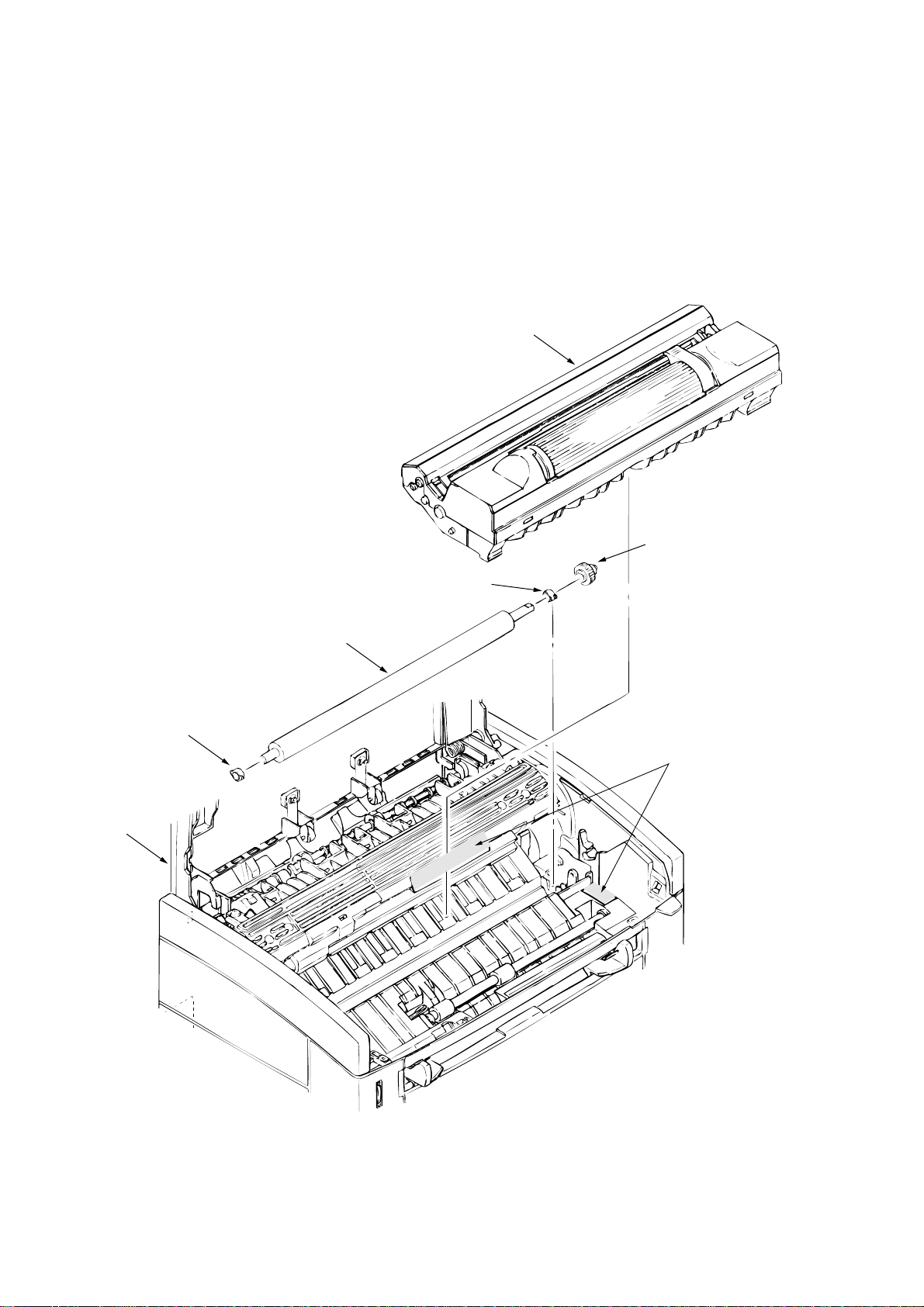

3.3.9 Heat Assy

This section explains how to dismount the heat assy and parts in the assy.

<Dismounting the heat assy>

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the high-voltage power supply board. (See Section 3.3.5.)

(3) Remove two screws 1, disconnect connector 2, and dismount heat assy 3.

<Dismounting parts in heat assy>

(4) Dismount heat separator D.

(5) Remove screw 4 and dismount terminal plate 6. (Handle heat assy 3 carefully because

Halogen lamp 7 comes off.)

(6) Turn left and right heat bearings 8 in the arrow direction to unlock. Then, dismount Halogen

lamp 7, heat bearing 8, heat roller 9, and heat gear C together. (Take care not to drop

Halogen lamp 7.)

(7) Dismount thermistor 0.

(8) Dismount the clamp, then thermostat A, heat contact B, and heat cord 5 together.

(9) Dismount heat contact B and heat cord 5 from thermostat A.

Caution:

Take care not to bend the claw when dismounting heat bearing 8.

3 - 14

Page 51

1

2

1

3

3 - 15

Page 52

Voltage display side

7

C

8

8

6

5

0

A

9

B

4

3 - 16

Page 53

3.3.10 Drive Shaft E (Eject) and Eject Roller

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount top cover assy. (See Section 3.3.6.)

(3) Remove two screws 1 from heat assy (Section 3.3.9), lift the heat assy, and dismount idle

gear E (A) 2 and idle gear E (B) 3.

(4) Unlock and dismount drive shaft E (Eject) 4.

(5) Dismount two eject rollers 5.

5

4

3

2

1

1

3 - 17

Page 54

3.3.11 Pressure Roller B (Back Up Roller)

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the high-voltage power supply board. (See Section 3.3.5.)

(3) Dismount the heat assy. (See Section 3.3.9.)

(4) Dismount the engagement with the left ground, then pressure roller B1. (Two bearing BUs

2 and two bias springs 3 also come off at the same time.)

2

1

3

3

2

3 - 18

Page 55

3.3.12 Separator Guide

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the high-voltage power supply board. (See Section 3.3.5.)

(3) Remove four screws 1.

(4) Dismount inlet 2 from base frame 3.

<Dismounting inlet 2>

Insert a screwdriver into the hole on the side of base frame 3, remove the inlet claw from

base frame 8, and dismount inlet 2.

(5) Disconnect three cables 4 and connector A and dismount base frame 3. Then, remove

screw 0 and disconnect FG cable B.

<Disconnecting connector A>

Dismount connector A by drawing it upward while pushing the clamp lever with a standard

screwdriver.

(6) Dismount the paper holder assy. (See Section 3.3.7.)

(7) Dismount two engagements and sheet guide 5.

(8) Dismount friction pad 6, compression spring S7, and separator guide 8.

(9) Dismount paper sensor E9.

3 - 19

Page 56

3

1

7

6

8

<Dismounting Inlet>

1

Screw driver

<Disconnecting Connector>

A

2

1

5

0

B

9

4

1

4

(–) Screw driver

Clamp lever

3 - 20

Page 57

3.3.13 Pulse Motor (Main)

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the high-voltage power supply board. (See Section 3.3.5.)

(3) Dismount side plate M. (See Section 3.3.8.)

(4) Dismount the base frame. (See Section 3.3.12.)

(5) Remove two screws 1 and dismount pulse motor (main) 2.

2

1

3 - 21

Page 58

3.3.14 Hopping Shaft Assy

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the high-voltage power supply board. (See Section 3.3.5.)

(3) Dismount the base frame. (See Section 3.3.12.)

(4) Dismount the paper holder assy. (See Section 3.3.7.)

(5) Dismount the sheet guide. (See Section 3.3.12.)

(6) Dismount side plate M. (See Section 3.3.8.)

(7) Raise up roller holder 3, slide hopping shaft assy 1, and dismount roller holder 3 and

hopping roller 4. (Knock pin 5 also comes off at the same time. Take care not to lose it.)

(8) Draw out hopping shaft assy 1 to the right and dismount magnet H6.

2

4

5

1

6

3

3 - 22

Page 59

3.3.15 Resist Roller

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount Idle gear R 3 and Gear R 4.

(3) Move resist roller 1 to the right and dismount it by lifting. (Two resist bearings 2 also come

off at the same time. Take care not to lose them.)

2

1

3

2

4

3 - 23

Page 60

3.3.16 Paper Sensor E, Paper Sensor Exit and Toner Sensor Assy

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the high-voltage power supply board. (See Section 3.3.5.)

(3) Dismount the base frame. (See Section 3.3.12.)

(4) Dismount the paper holder assy. (See Section 3.3.7.)

(5) Dismount the sheet guide. (See Section 3.3.12.)

(6) Dismount the heat assy. (See Section 3.3.9.)

(7) Dismount drive shaft E. (See Section 3.3.10.)

(8) Dismount paper sensor E1.

(9) Dismount paper sensor exit 2.

(10) Dismount toner sensor assy 3.

3

2

1

3 - 24

Page 61

3.3.17 Base Plate

(1) Dismount the upper cover assy. (See Section 3.3.4.)

(2) Dismount the base frame. (See Section 3.3.12.)

(3) Remove two screws 1, disconnect connector 2, and dismount power supply unit 3.

(4) Dismount insulation sheet 4.

(5) Remove two screws 5 and dismount main control board 6 from base plate 7.

3

2

5

6

1

1

4

5

7

3 - 25

Page 62

4. ADJUSTMENT

Page 63

4. ADJUSTMENT

This chapter explains adjustment necessary when a part is replaced.

This adjustment is made by changing the parameters values set in EEPROM on the main control

board. The printer driver or maintenance utility can be used to change these values.

Only servicemen and maintenance personnel can use the maintenance utility. This utility cannot

be made public for printer end users.

4.1 Adjustment Types and Functions

4.1.1 Printer Driver

(For Microsoft Windows)

This printer driver has the following functions:

• Drum counter reset

• Charge roller cleaning

Figure 4-1

(1) Drum counter reset

This function resets the life of the drum counter when the EP unit is replaced. Clicking the

“clear” button resets the life.

(2) Charge roller cleaning

This function cleans the charge roller of the EP unit; it is used when printing is unclear. For

details on how to operate this function, refer to “User’s Manual.”

4 - 1

Page 64

(For Macintosh) <only OKIPAGE4m>

(1) Drum counter reset

This function resets the life of the drum counter when the EP unit is replaced. Clicking the

“Reset” button resets the life.

(2) Charge roller cleaning

This function cleans the charge roller of the EP unit; it is used when printing is unclear. For

details on how to operate this function, refer to “User’s Manual.”

4 - 2

Page 65

4.1.2 Engine Maintenance Utility

See Appendix D.

4.2 Adjustment When Replacing a Part

The table below lists the parts that requires adjustment when they are replaced.

Part to be Replaced Adjustment

LED head

EP unit Reset the drum counter. (Refer to "User's Manual".)

Main control board Upload or download EEPROM data.

4.2.1 Setting LED Head Drive Time

Caution:

When the liminous intensity of a new LED head is the same as that of the old LED

head, do not set the LED head drive time.

Use “LED Head Making No.” in the engine menu tab of the maintenance driver to set the luminous

intensity displayed on the LED head as the LED head drive time. (See Figure 4-2.)

• Luminous intensity of LED head

Set the LED head drive time.

Set the LED head dot count.

Luminous intensity display

Figure 4-2

4 - 3

070

314

The last three digits indicate

the luminous intensity of the

LED head.

Page 66

4.2.2 Setting the LED Head Dot Count

There are two types of LED head dot count. Use the following label to identify these types. Use

“LED Head Width” in the engine menu table to set the LED head dot count. (See Figure 4-2.)

• Identifying the types of LED head dot count

Nallow Type (2496 dots)

1104G2

Full Type (2560 dots)

Figure 4-3

4 - 4

Page 67

4.2.3 Uploading and Downloading EEPROM Data

When the main control board is replaced, EEPROM data must be reflected on a new main control

board. Use “EEPROM Operations” in the option tab of the maintenance utility to reflect EEPROM

data on the new main control board. (See Figure 4-4.)

Reflect EEPROM data on the new main control board in the following procedures:

(1) Check that the printer and PC are connected by the parallel I/F, then execute the

maintenance utility.

(2) Click the "Option" button in "Main Menu Dialog".

(3) Click the “Upload” button (Upload EEPROM Data) in “EEPROM Operations.” (EEPROM

data read is completed.)

(4) The read EEPROM data is displayed in “Dialog” of the maintenance driver.

(5) Leave the display of the maintenance driver as is and replace the main control board.

(6) Click the “Download” button (Download EEPROM Data) in “EEPROM Operations”. (EEPROM

data write is completed.)

Depending on the level of a main control board failure (parallel I/O failure, etc.), however,

EEPROM data may be unable to be uploaded.

In such a case, use the maintenance utility to perform the following adjustment after replacing the

main control board:

• Setting the LED head drive time (Section 4.2.1)

• Setting the LED head dot count (Section 4.2.2)

• Setting specifications (ODA/OEL/INT-A/INT-L)

4 - 5

Page 68

5. PERIODICAL MAINTENANCE

Page 69

5. PERIODICAL MAINTENANCE

5.1 Periodical Replacement Parts

Table 5-1 lists the part and unit to be replaced periodically.

Table 5-1 Routine Replacement Parts

Part Name Replacement Time

Toner cartridge

EP unit

Caution:

Also reset the drum counter when replacing the EP unit.

When "Toner Low" is displayed.

When "Change Drum" is displayed.

5.2 Cleaning

Remove any toner or dirt and clean the circumference and inside of the printer with a waste cloth.

Caution:

5.2.1 Cleaning the LED Lens Array

When a white belt or a white stripe (void, light printing) occurs in the vertical direction of the print

surface, clean the LED lens array or replace the toner cartridge.

Caution:

Do not touch the OPC drum, LED lens array, and connector block of the LED head.

Be sure to use an LED head cleaner to clean the LED lens array.

Part to be Checked

Simultaneously

LED head Consumables

Remarks

Consumables

White belt or stripe

(void, light printing)

Figure 5-1

5 - 1

Page 70

(1) Set the LED head cleaner in the LED lens array, as shown in the figure below, and slide the

cleaner left and right several time to clean the head.

Caution:

Do not press the LED head cleaner against the LED lens array.

LED lens array

LED head cleaner

Figure 5-2

5 - 2

Page 71

6. TROUBLESHOOTING PROCEDURES

Page 72

6. TROUBLESHOOTING PROCEDURES

6.1 Troubleshooting Tips

(1) Check the basic check points written in the user’s manual.

(2) Gather detailed failure information as much as possible from the customer.

(3) Check the printer under the condition close to that under which the failure occurred.

6.2 Check Points Before Correcting Image Problems

(1) Is the printer running in proper ambient conditions?

(2) Are consumables (toner and EP unit) replaced correctly?

(3) Are sheets of paper normal?

(4) Is the EP unit set correctly?

6.3 Notes When Correcting Image Problems

(1) Do not touch the surface of the OPC drum nor place foreign matter on it.

(2) Do not expose the OPC drum to direct sunlight.

(3) Do not touch the fuser because it heats up during operation.

(4) Do not expose the image drum to light for more than five minutes at room temperature.

6.4 Preparation Before Troubleshooting

(1) Message display

The failure status of the OKIPAGE 4w plus /4m is displayed on the status monitor of the PC.

Take proper action according to the message displayed on the status monitor.

(2) LED display

The OKIPAGE 4w plus /4m is equipped with only one LED. This LED indicates one of the

following statuss:

Printer Status LED Indication

Ready Lighting

Printing in progress Blink (*1)

Recoverable alarm Blink (*2)

Unrecoverable alarm Blink (*3)

*1:

*2:

*3:

The LED blinks at a cycle of 1 second (0.5s ON)

from data reception to printing end.

The LED blinks at a cycle of 0.24 second (0.12s ON).

The LED blinks at a cycle of 0.24 second (0.12s ON).

6 - 1

Page 73

6.5 Troubleshooting

If a trouble occurs in the OKIPAGE 4w Plus/4m, troubleshoot according to the following

procedures:

Trouble

Trouble indicated by

the message displayed

on the status monitor.

Image problem (or

trouble not displayed on

the status monitor)

6.5.1 Status Monitor Message List

Table 6-1 lists the statuses and troubles to be displayed on the status monitor in the message

format.

Troubleshoot according to

"Status Monitor Message List"

(See Section 6.5.1.)

Perform detailed

troubleshooting according

to the troubleshooting flow.

(See Section 6.5.2.)

Troubleshoot according to

Section 6.5.3.

6 - 2

Page 74

Table 6-1

6 - 3

Category Status Message Display Content Remedy

Normal status 18 00

Warming Up

Online (Ready)

Power Save Mode

Toner Low

Toner Sensor

Change Drum

Manual Paper In

Printing In Progress

Ejection In Progress

Manual Request

Executive

Letter

Legal 14

Legal 13

A6

A5

A4

B5

Monarch

COM-10

DL

C5

COM-9

Status

Code

00 10

00 20

10 00

10 01

10 02

12 20

14 20

14 30

16 01

16 02

16 03

16 04

16 18

16 19

16 1A

16 21

16 50

16 51

16 5A

16 5B

16 7F

Warming-up status

Online (ready) status

Power save status

The toner amount of the toner cartridge is small.

The EP unit is not installed or the toner sensor is

faulty.

Life of EP drum

The paper is in the manual feed mode.

Printing in progress

Ejection in progress

Request the paper to be set in the manual feed

mode.

The paper sizes are as follows:

Executive, Letter, Legal 14, Legal 13, A4, A5, A6,

B5, Monarch, DL, C5, COM-10, COM-9

Normal operation

Normal operation

Normal operation

Normal operation

Replace the toner cartridge.

Install the EP unit or replace the toner sensor.

Replace the EP unit.

(

Note:

Normal operation

Normal operation

Set the requested paper in the manual feed mode.

Be sure to reset the drum counter after replacing the

EP unit.)

Page 75

Table 6-1 (Cont'd)

6 - 4

Category Status Message Display Content Remedy

Paper size error

Paper jam

Cover open

Buffer overflow

Paper Size Error

Paper Input Jam

Paper Feed Jam

Paper Exit Jam

Cover Open

Page Buffer Overflow

Print Over Run

Status

Code

30 00

31 00

32 00

33 00

4F 00

40 01

40 10

Paper of improper size was fed.

2.52" (64 mm) L 15.77" (400.56 mm)

A paper jam occurred when sheets of paper were

being supplied.

A paper jam occurred during paper feeding.

A paper jam occurred during paper ejection.

The upper cover is open.

The page buffer overflowed because there are a

large number of print data.

A print overrun occurred because print data is

complicated.

Check the paper. Also check whether more than one sheet of

paper were fed simultaneously. To release the error display,

open the cover, then close it. If this error occurs frequently, see

Section 6.5.2 3.

Check the paper. To release the error display, close the cover,

then close it. If this error occurs frequently, see Section 6.5.2

2-1.

Open the cover, then remove the jammed paper. To release

the error display, close the cover. If this error occurs frequently, see Section 6.5.2 2-2.

Open the cover, then remove the jammed paper. To release

the error display, close the cover. If this error occurs frequently, see Section 6.5.2 2-3.

To release the error display, close the cover. If this error

occurs frequently, replace the power supply board.

To release the error display, press the reset button on the

status motor of the printer driver. Install option RAM or reduce

the number of print data.

To release the error display, press the reset button on the

status motor of the printer driver. Simplify the print data format.

Device configuration error

Program ROM Check Error

Resident RAM Check Error

60 10

60 30

An error occurred during program ROM check.

An error occurred during resident RAM check.

Replace program ROM or the main control board. (When

replacing the main control board, also adjust EEPROM data.)

(See Section 4.2.4.)

Replace the main control board. (When replacing the main

control board, also adjust EEPROM data.) (See Section 4.2.4.)

Page 76

Table 6-1 (Cont'd)

Status

Category Status Message Display Content Remedy

Category Status Message Display Content Remedy

Status

Code

Code

6 - 5

Device configuration error 60 40

EEPROM Check Error

Option RAM Check Error

Fuser Error

Thermistor Error

Thermister Open Check Error

Thermister Short Check Error

Watch Dog Timeout Error

60 60

60 80

60 90

60 91

60 92

60 C0

An error occurred during EEPROM check.

An error occurred during option RAM check.

A heater timeout error occurred.

A thermistor error occurred.

The thermistor is open.

A thermistor short occurred.

A watchdog timeout occurred.

Replace the main control board. (When replacing the main

control board, also adjust EEPROM data.) (See Section

4.2.4.)

Check the connection of the Option RAM PC board. If the

option RAM PC board is faulty, replace it.

See Section 6.5.2 4.

Replace the thermistor of the heater Assy.

Replace the thermistor of the heater Assy.

Replace the thermistor of the heater Assy.

To release the error display, turn on the power supply again.

Replace the main control board.

Page 77

6.5.2 Status Message Troubleshooting

Some failures cannot be corrected according to the status message trouble list. Troubleshoot

these failures according to the following troubleshooting flowcharts:

No.

The OKIPAGE 4w Plus/4m malfunctions after the power supply has been turned on.

1.

Jam error

2.

Paper input jam

Paper feed jam

Paper exit jam

3. Paper size error

4. Fusing error

Caution:

When replacing the main control board troubleshooted according to the troubleshoot-

Item

ing flowcharts, also adjust EEPROM data. (See Section 4.2.4.)

Flowchart No.

1

2

-1

2

-2

2

-3

3

4

6 - 6

Page 78

1 The OKIPAGE 4w Plus/4m malfunctions after the power supply has been

turned on.

• Turn the power supply off, then on again.

• Is the LED lamp on?

• No Is the AC cable connected correctly?

• No Connect the AC cable correctly.

• Yes Is +5 V supplied between CN1 Pin 7 and CN1 Pin 13 of the high-voltage

power supply board?

(Pin 7: +5 V, Pin 13: 0 V)

• No Are the CN1 connectors of the high-voltage power supply board and

main control board connected correctly?

• No Connect the CN1 connectors correctly.

• Yes Is +5 V supplied between CN2 Pin 2 and CN2 Pin 3 of the main

control board?

(Pin 2: +5 V, Pin 3: 0 V)

• No Replace the power supply board.

• Yes Replace the main control board.

• Yes Is 1-2 V voltage supplied between CN1 Pin 2 and CN1 Pin 13 of the highvoltage power supply board?

• No Replace the main control board.

• Yes Replace the high-voltage power supply board.

• Yes Replace the main control board.

6 - 7

Page 79

[JAM error]

2-1 Paper input jam

• Does a paper input jam occur when the power supply is turned on?

• Yes Is the jammed paper on paper sensor E?

• Yes Remove the jammed paper.

• No Is paper sensor E (manual feed/paper) operating normally?

• No Replace paper sensor E (manual feed or paper).

• Yes Replace the high-voltage power supply board.

• No Does a paper input jam occur during paper loading?

• Yes Is the paper already fed to paper sensor E (manual feed)?

• Yes Is paper sensor E (manual feed) operating normally?

• No Replace paper sensor E (manual feed).

• Yes Check the gear block or replace high-voltage power supply board.

• No Is the paper already fed to paper sensor E (paper)?

• Yes Is paper sensor E (paper) operating normally?

• No Replace paper sensor E (paper).

• Yes Replace high-voltage power supply board.

• No Replace the stepping roller or friction pad.

• No Is the hopping roller rotating?

• Yes Check the coil resistance of magnet H. Is the resistance normal (about 120

Ω)?

• No Replace magnet H.

• Yes Is +24 V supplied between CN8 Pin 1 and CN8 Pin 2 of the main control

board?

• No Replace the main control board.

• No Check the gear block or replace the hopping shaft assy.

• No Are the CN7 connectors of the pulse motor (main) and main control board connected?

• No Connect the CN7 connectors correctly.

6 - 8

Page 80

• Yes Measure the resistance of the pulse motor (main). Is the resistance normal (about

12.6 Ω)?

• No Replace the pulse motor (main).

• Yes Replace the main control board.

6 - 9

Page 81

[JAM error]

2-2 Paper feed jam

• Does a paper feed jam occur when the power supply is turned on?

• Yes Is the jammed paper on paper sensor E (paper/exit)?

• Yes Remove the jammed paper.

• No Is paper sensor E (exit/paper) operating normally?

• No Replace paper sensor E (exit or paper).

• Yes Replace the high-voltage power supply board.

• No Has the paper arrived at paper sensor E (paper)?

• No Is the feed roller rotating?

• No Check the gear block.

• Yes Is the EP unit set correctly?

• No Set the EP unit correctly.

• Yes Check the gear block.

• Yes Has the paper arrived at the paper sensor (exit)?

• Yes Is the paper sensor (exit) operating normally?

• No Replace the paper sensor (exit).

• Yes Replace the high-voltage power supply board.

• No Check the gear block.

2-3 Paper exit jam

• Does a paper exit jam occur when the power supply is turned on?

• Yes Is the jammed paper on the paper sensor (exit)?

• Yes Remove the jammed paper.

• No Is the paper sensor (exit) operating normally?

• No Replace the paper sensor (exit).

• Yes Replace the high-voltage power supply board.

• No Check the gear block or replace the eject roller.

6 - 10

Page 82

3 Paper size error

• Is the paper of the specified size being use?

• No Use paper of the specified size.

• Yes Is paper sensor E (paper) operating normally?

• No Replace paper sensor E (paper) or clean the inlet sensor on the high-voltage

power supply board.

• Yes Is the paper sensor (exit) operating normally?

• No Replace the paper sensor (exit) or clean the outlet sensor on the high-voltage

power supply board.

• Yes Replace the high-voltage power supply board.

Exit roller

Paper sensor E (paper)

Toner

sensor

Assy

Paper sensor E (manual feed)

Paper feeding direction

Paper sensor (exit)

Heat roller

Transfer roller

Feed roller

Hopping

roller

6 - 11

Page 83

4 Heat assy error

• Turn the power supply off, then on again.

• Does the Halogen lamp of the heat assy go on?

• No Is the Halogen lamp or thermostat disconnected?

• Yes Replace the heat assy, Halogen lamp, or thermostat.

• No Replace the power supply unit.

• Yes Are the CN2 connectors of the power supply unit and main control board connected

correctly?

• No Connect the CN2 connectors correctly.

• Yes Replace the main control board.

6 - 12

Page 84

6.5.3 Image Troubleshooting

This section explains how to troubleshoot when an image problem is output as a result of the

printing.

Figure 6-3 is an example of image problem output.

Symptom

An image is light or blurred entirely. (Figure 6-3, A )

Dark background density (Figure 6-3, B )

A blank paper is output. (Figure 6-3, C )

Vertical block belt/black stripe (Figure 6-3, D )

Cyclical defect (Figure 6-3, E )

Print void

Poor fusing (An image is blurred or peeled off when it is touched.)

Vertical white belt/white stripe (Figure 6-3, F )

Flowchart No.

1

2

3

4

5

6

7

8

A Light or blurred

images entirely

D Black vertical stripes E Cyclical defect F White vertical belts

B Dark background

density

C Blank paper

or streaks

Figure 6-3 Image Problems

6 - 13

Page 85

1 An image is light or blurred entirely.

• Is the toner low? (Is "Toner Low" being displayed?)

• Yes Supply a toner.

• No Is the specified paper being used?

• No Use the specified paper.

• Yes Is the lens of the LED head dirty?

• Yes Clean the LED head.

• No Is the LED head installed correctly? (Check the CN6 connector of the main control

board.)

• No Install the LED head correctly.

• Yes Is the contact plate of the transfer roller in correct contact with the high-voltage

power supply board? (See Figure 6-4 F.)

• Yes Is the terminal of the EP unit in correct contact with the contact plate? (See Figure

6-4 A and B)?

• No Contact the terminal correctly.

• Yes Replace the transfer roller.

• Has this error been recovered?

• Yes End

• No Replace the EP unit.

• Has this error been recovered?

• Yes End

Caution:

• No Replace the main control board or high-voltage power supply board.

After replacing the EP unit, reset the drum counter. (Refer to

"Replacing the Drum Cartridge" in "User's Manual".)

6 - 14

Page 86

2 Dark background density

• Has the OPC drum being exposed to external light?

• Yes Set the OPC drum in the OKIPAGE 4w Plus/4m and wait for about 30 minutes.

• No Is the heat roller of the heat assy dirty?

• Yes Clean the heat roller.

• No Is the terminal of the EP unit in correct contact with the contact plate? (See Figure

6-4 D and Figure 6-5 D.)

• No Contact the terminal correctly.

• Yes Replace the EP unit.

• Has this error been recovered?

• Yes End

Caution:

• No Replace the main control board or high-voltage power supply board.

3 A blank paper is output.

• Is the LED head connected correctly. (Check the CN6 connector of the main control board.)

• No Connect the LED head correctly.

• Yes Is the terminal of the EP unit in correct contact with the contact plate? (See Figure

6-5 E.)

• No Contact the terminal correctly.

• Yes Replace the LED head.

• Has this error been recovered?

• Yes End

Caution:

After replacing the EP unit, reset the drum counter. (Refer to

"Replacing the Drum Cartridge" in "User's Manual".)

Set the LED head drive time when replacing the LED head. (See

Section 4.2.1.)

• No Replace the main control board or high-voltage power supply board.

6 - 15

Page 87

4 Vertical black belt/stripe

• Replace the EP unit.

• Has this error been recovered?

• Yes End

• No Replace the LED head.

• Has this error been recovered?

• Yes End

• No Replace the main control board or high-voltage power supply board.

5 Cyclic defect

EP drum

Developing roller 1.44" (36.6 mm) Replace the EP unit.

Toner supply roller 2.63" (66.8 mm) Replace the EP unit.

Charge roller 0.81" (20.6 mm) Replace the EP unit.

Caution:

Caution:

After replacing the EP unit, reset the drum counter. (Refer to

"Replacing the Drum Cartridge" in "User's Manual".)

Set the LED head drive time when replacing the LED head. (See

Section 4.2.1.)

Cycle

1.98" (50.3 mm)

Clean or replace the EP unit.

Remedy

Caution:

Cleaning roller 0.81" (20.6 mm) Replace the EP unit.

Transfer roller 1.71" (43.4 mm) Replace the EP unit.

Heat roller 2.46" (62.5 mm) Replace the heat roller.

Pressure roller B 1.98" (50.3 mm) Replace pressure roller B.

After replacing the EP unit, reset the drum counter. (Refer to "Replacing the Drum

Cartridge" in "User's Manual".)

6 - 16

Page 88

6 A blank paper is output.

• Is the contact plate of the transfer roller in correct contact with the high-voltage power supply

board?

• No Contact the contact plate of the transfer roller correctly.

• Yes Replace the transfer roller.

• Has this error been recovered?

• Yes End

• No Is the terminal of the EP unit in correct contact with the contact plate? (See Figure

6-4 A B C D E and Figure 6-5 A B C D E.)

• No Contact the terminal of the EP unit correctly.

• Yes Replace the EP unit.

• Has this error been recovered?

• Yes End

Caution:

• No Is the LED head installed correctly? (Check the CN6 connector the main control

board.)

• No Contact the LED head correctly.

• Yes Replace the LED head

• Has this error been recovered?

• Yes End

Caution:

• No Replace the main control board or high-voltage power supply board.

After replacing the EP unit, reset he drum counter. (Refer to

"Rplacing the Drum Cartridge" in "Users Manual".)

Set the LED head drive time when replacing the LED head. (See

Section 4.2.1.)

6 - 17

Page 89

7 Poor fusing

• Is the specified paper being used?

• No Use the specified paper. (xerox 4200 (20 lbs))

• Yes Is the bias spring normal? (Tension: 2.5 kg)

• No Replace the bias spring.

• Yes Are the heater connector of the heat assy and the CN1 connector of the power

supply unit connected correctly.

• No Connect the connectors correctly.

• Yes Replace the heat assy.

• Has this error been recovered?

• Yes End

• No Replace the main control board or high-voltage power supply board.

6 - 18

Page 90

8 Vertical white belt/spripe

• Is the lens of the LED head dirty?

• Yes Clean the LED head.

• No Is the contact plate of the transfer roller in correct contact with the high-voltage

power supply board? (See Figure 6-5 E.)

• No Contact the contact plate of the transfer roller correctly.

• Yes Replace the transfer roller.

• Has this error been recovered?

• Yes End

• No Is the LED head installed correctly? (Check the CN6 connector of the main control

board.)

• No Install the LED head correctly.

• Yes Replace the LED head.

• Has this error been recovered?

• Yes End

Caution:

• Yes Replace the EP unit.

• Has this error been recovered?

• Yes End

Caution:

• No Replace the main control board or high-voltage power supply board.

Set the LED head drive time when replacing the LED head. (See

Section 4.2.1.)

After replacing the EP unit, reset the drum counter. (Refer to

"Replacing the Drum Cartridge" in "User's Manual".)

6 - 19

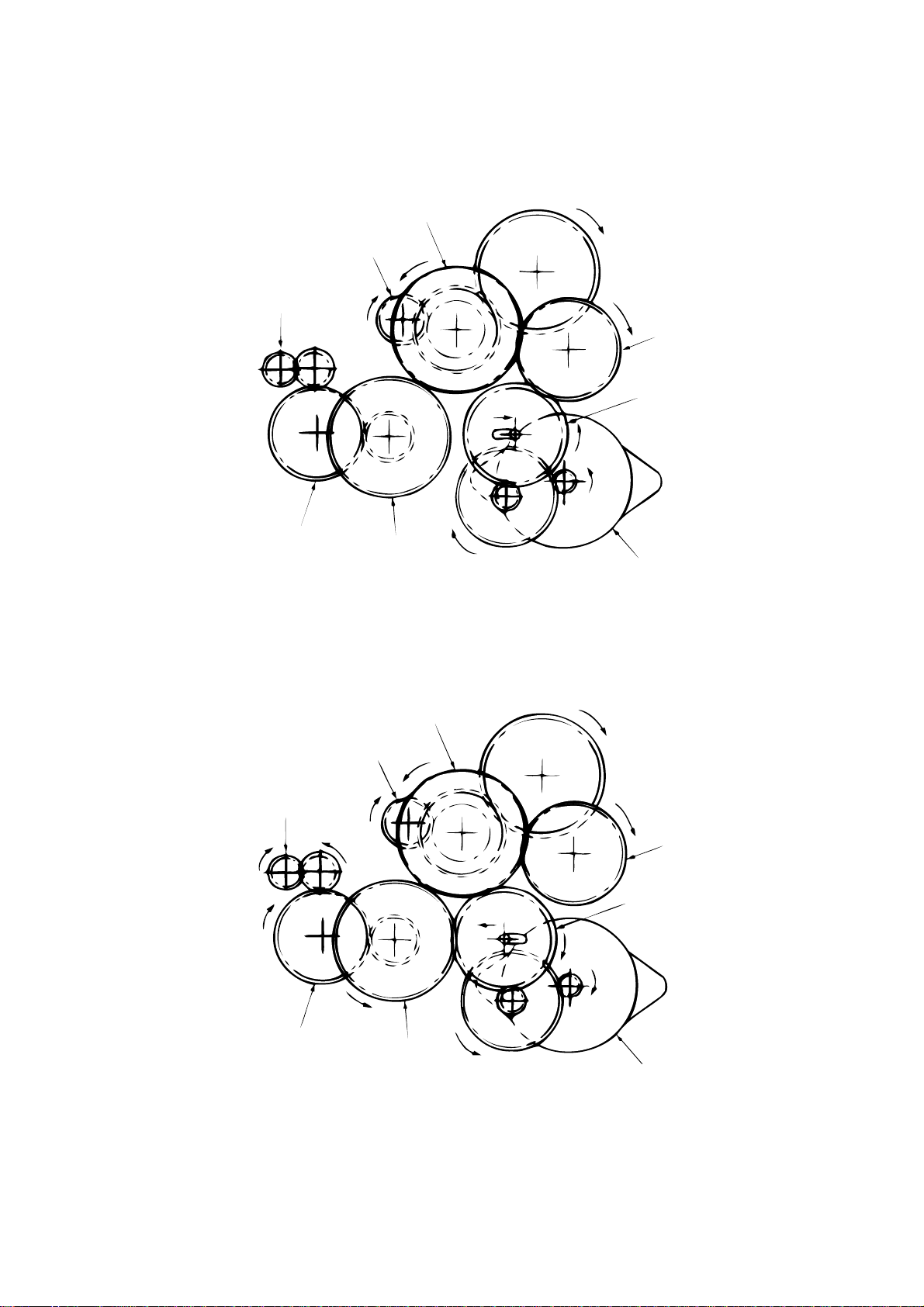

Page 91

Contents

: Toner Supply Roller

A

: Developing Roller

B

: Charge Roller

C

: Cleaning Roller

D

: Transfer Roller

E

: Heat Roller

F

Figure 6-4

6 - 20

Page 92

Contents

: Toner Supply Roller

A

: Developing Roller

B

: Charge Roller

C

: Cleaning Roller

D

: Ground (Drum)

E

E

Figure 6-5

6 - 21

Page 93

7. WIRING DIAGRAM

Page 94

7. WIRING DIAGRAM

7.1 (a)Interconnect Signal Diagram (OKIPAGE 4w Plus)

THERM

1

2

1

123 CV0PN-N

23

22

Thermistor

5V

2

222 LED-P

321 TNRSNS-N

420 SDB2-P

OPC Drum

Charge Roller

Transfer Roller

CN2 Thermistor

High-Voltage

519 PSIN-N

618 SDBI-P

717 5V

816 WRSNS-N

915 5V

1014 DBPWM-P

Developing Roller

Power

Supply Board

CN1 Control Interface

1113 TEMP

1212 TR-VSEN

1311 0V

1410 0V

1590V

168 TRIPWM-P

1770V

186 DCLED-P

Toner Supply Roller

Roller

Cleaning

–300V

DB

+400V

CB

23

2

–1350V

CHTRHR