Page 1

PC2000-PC/104 Data Sheet

Description

The Ocean Optics OEM PC2000-PC/104 Spectrometer includes the linear CCD-array optical bench,

plus the digital interface necessary to function on a PC/104 bus. The result is a compact, flexible

system with no moving parts that's easily integrated as an OEM component.

The PC2000-PC/104 spectrometer is a unique combination of technologies providing users with both

an unusually high spectral response and good optical resolution in a single package. The electronics

have been designed for considerable flexibility in connecting to various PC2000-PC/104 series

modules as well as external interfaces. The PC2000-PC/104 can be directly coupled to as many as

seven "slave" spectrometer channels of various designs. The information included in this guide

provides detailed instructions on the connection and operation of the PC2000-PC/104.

The detector used in the PC2000-PC/104 spectrometer is a high-sensitivity 2048-element CCD array

from Sony, product number ILX511. (For complete details on this detector, visit Sony’s web site at

http://www.sel.sony.com/semi/PDF/ILX511.pdf. However, Ocean Optics applies a coating to all

ILX511 detectors, so the optical sensitivity could vary from that specified in the Sony datasheet).

000-00000-000-05-0704 1

Page 2

PC2000-PC/104 Data Sheet

Features

High sensitivity of up to 90 photons/counts

An optical resolution of 3 pixels (FWHM)

A wide variety of optics available

• 14 gratings

• 6 slit widths

• 3 detector coatings

• 6 optical filters

Integration times from 2 to >30,000 milliseconds

Modular design allows up to 7 slave spectrometer channels to operate from one master

channel

2MHz, 12 bit A/D, ± ½ bit accuracy

Supports free-running an 3 external trigger modes

Digital Interface

Memory mapped registers

Interrupt driven

2,048 deep FIFOs for on board storage

Can acquire spectra simultaneously from all 8 channels at reduced pixel density

Strobe signals for external synchronization

2 000-00000-000-05-0704

Page 3

PC2000-PC/104 Data Sheet

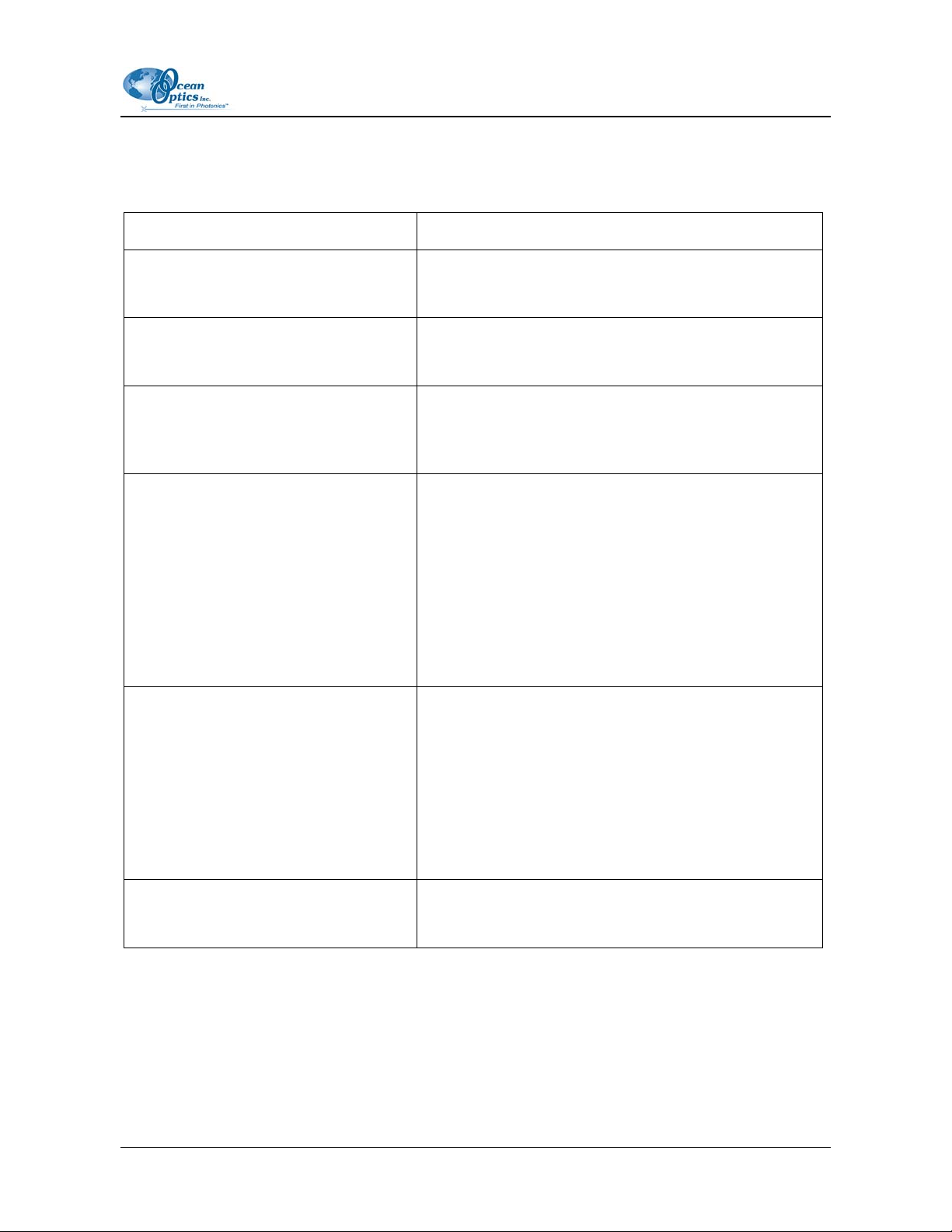

Specifications

Specifications Criteria

Absolute Maximum Ratings:

V

CC

Voltage on any pin

Physical Specifications:

Physical Dimensions (no enclosure)

Weight

Power:

Power requirement (master)

Supply voltage

Power-up time

Spectrometer:

Design

Focal length (input)

Focal length (output)

Input Fiber Connector

Gratings

Entrance Slit

Detector

Filters

Spectroscopic:

Integration Time

Dynamic Range

Signal-to-Noise

Readout Noise (single dark spectrum)

Resolution (FWHM)

Stray Light

Spectrometer Channels

Environmental Conditions:

Temperature

Humidity

+ 5.5 VDC

Vcc + 0.2 VDC

4.05 (W) x 3.78 (L) x 0.70 (H) inches

200 g

250 mA at +5 VDC

4.5 – 5.5 V

3 msec

Asymmetric crossed Czerny-Turner

42mm

68mm (75, 83 and 90 mm focal lengths are also available)

SMA 905

14 different gratings

5, 10, 25, 50, 100, or 200 µm slits. (Slits are optional. In the

absence of a slit, the fiber acts as the entrance slit.)

Sony ILX511 CCD

Selection of Long Pass Filters to eliminate 2

3 – >30,000 msec

8

2 x 10

250:1 single acquisition

3.5 counts RMS, 20 counts peak-to-peak

0.03 – 10.0 nm varies by configuration

<0.05% at 600 nm; <0.10% at 435 nm

8 (master plus 7 slaves)

-30° to +70° C Storage & -10° to +60° C Operation

0% - 90% noncondensing

nd

order (optional)

000-00000-000-05-0704 3

Page 4

PC2000-PC/104 Data Sheet

Electrical Pinouts

J2 Electrical Connector

Pin I/O Function Pin I/O Function

1 I Analog Channel 1 14 Gnd

2 I Analog Channel 2 15 N/C Reserved – D2

3 I Analog Channel 3 16 N/C Reserved – D0

4 I Analog Channel 4 17 O Continuous Strobe

5 I Analog Channel 5 18 I External Hardware Trigger

6 I Analog Channel 6 19 O Array Clock Output

7 I Analog Channel 7 20 O Lamp Enable - S0

8 Vcc 21 O Single Strobe

9 O CCD Temperature 22 I External Sync Input

10 Vcc 23 O Read Out Gate

11 Gnd 24 N/C Reserved – D1

12 N/C 25 N/C Reserved – D3

13 Gnd 26 I Software Trigger

J2 on PC104 is Samtec #STMM-113-02-S-D-RA, the mating part is a ribbon cable #TCSD-13-D(length)-01--other mating options are SQT,SQW,ESQT,TLE,SMM,MMS

Pin Function Description

Function Description

Analog Channel 0 - 7

V

CC

GND The ground (supply voltage return) or case ground.

Lamp Enable Software-controlled TTL signal commonly used for activation of Light Sources

Software Trigger

Single Strobe

Continuous Strobe

External Hardware Trigger

External Sync Input Trigger

CCD Temperature

The analog signals that correspond to the output from the 8 spectrometer

channels. Inputs for channels 1-7 are available on J1.

The positive supply voltage +5VDC.

Active high TTL input signal used to trigger the acquisition system in the

External Software Trigger mode.

TTL output signal used to pulse a strobe that is high at the start of each

integration period.

TTL output signal used to pulse a strobe that is divided down from the Master

Clock signal.

TTL trigger signal (rising edge trigger input) used in External Hardware Trigger

mode.

TTL signal used to define the integration time (time between rising edges)

when using the External Synchronization Trigger mode.

Analog signal generated from an LM35 mounted in close proximity to the

CCD. The analog output is 10mv/C.

4 000-00000-000-05-0704

Page 5

PC2000-PC/104 Data Sheet

Interface Information

Pixel Definition

A series of pixels in the beginning of the scan have been covered with an opaque material to

compensate for thermal induced drift of the baseline signal. As the PC2000-PC/104 warms up, the

baseline signal will shift slowly downward a few counts depending on the external environment.

(Temperature-regulated units do not exhibit this shift.) The baseline signal is set between 50 and 100

counts at the time of manufacture. If the baseline signal is manually adjusted, it should be left high

enough to allow for system drift. The following is a description of all of the pixels:

Pixel Description

0–1 Not usable

2–24 Optical black pixels

24–25 Transition pixels

26–2674 Optical active pixels

It is important to note that Ocean Optics A/D products only digitize the first 2048 pixels, as they all

have a 2048 x 16 FIFO buffer.

Analog Section

The PC2000-PC/104 is capable of supporting the output of up to 8 spectrometer channels (master

channel plus 7 slave channels). The spectrometer channel is determined by switch SW2. Within a

stack, there should be only one spectrometer on any given channel. The master spectrometer is

hardwired to the master channel (channel 0). Each spectrometer generates an analog signal (-2.5 +2.5V), which corresponds to the input spectra.

Clock Signals

Master Clock

The frequency of this clock is set via software. The A/D rate is one-half that of the Master Clock. The

maximum rate for the Master Clock is 4MHz, which equates to an A/D rate of 2 MHz. A

recommended minimum frequency is 100 kHz.

Integration Clock

The frequency of this clock is set via software. The period for the integration time clock should be

longer than 4100 master clock periods in order to read the entire array. This equates to 1.1ms.

000-00000-000-05-0704 5

Page 6

PC2000-PC/104 Data Sheet

Strobe Signals

Single Strobe

The Single Strobe signal is a TTL HIGH pulse that occurs at the start of each integration period. This

pulse occurs 2 master clock cycles after the start of the integration period. The pulse is not generated

unless The Lamp Enable (S0) signal is set (Digital 1-TTL HIGH) in software.

Continuous Strobe

The Continuous Strobe signal is a pulse-train (50% duty cycle) whose frequency is determined by

software.

Synchronizing Strobe Events

For some applications it is necessary to view pulsed sources. If the application requires more than one

pulse per integration period, exercise care to insure a stable signal. The integration time must be set so

that an equal number of strobe events occurs during any given integration period. This synchronization

only occurs when the integration period is a multiple of a power of 2, since the strobe signal is the

master clock divided by a power of 2.

Triggering Modes

The PC2000-PC/104 supports four triggering modes, which are defined by the state of the software

controlled S0 and S1. Details of each triggering mode are discussed below.

Mode S1 S0

Normal 0 X

Software Trigger 0 X

Ext Synchronization 1 0

Ext Hardware Trigger 1 1

Normal (S1:S0 = 0:X)

In this mode, the PC2000-PC/104 uses the user-supplied integration clock (DB25: pin 23) and

continuously scans the CCD array.

External Software Trigger (S1:S0 = 0:X)

In this mode, the PC2000-PC/104 uses the normal integration clock. Since this mode is under software

control its functionality can be software defined. In this mode, Ocean Optics software, waits until the

Software Trigger Input (D3) line goes HIGH before it acquires an acquisition. The amount of delay

between the trigger pulse and when a spectrum is acquired is indeterminate because the delay is

dependent upon (1) how fast the software polls the D3 line and recognizes it is HIGH and (2) the

amount of time until the start of the next integration period. The integration time is under user control

in this mode. This mode must be implemented in the software that controls the data acquisition.

6 000-00000-000-05-0704

Page 7

PC2000-PC/104 Data Sheet

External Synchronization (S1:S0 = 1:0)

In this mode, the effective integration time is the time between rising edges of the signal applied to the

External Synchronization pin (J2:Pin 22). This mode is useful for synchronizing the integration time to

an external clock source.

External Hardware Trigger (S1:S0 = 1:1)

In this mode, the PC2000-PC/104 uses an internally generated integration clock that is triggered by the

rising edge of the External Hardware Trigger signal (J2:pin 18). On the rising edge of this signal, the

internal logic resets the CCD array, integrates for 2.1ms and then clocks out the array.

CCD Detector Temperature

Also available is an optional temperature sensor, which when included is located directly under the

detector. The output of this signal is fed to H2: pin 6. The typical error of the sensor is

o

25

C. The output is calibrated directly in oC with a scale factor of 10 mV/oC.

o

±

C around

Software Interface

Overview

The PC2000-PC104 employ a memory mapped set of registers, which control all of the functionality.

The register definition is shown in

Communications with the spectrometer are through a base address, which is defined by switch

settings.

Performing an 8-bit read from this port will provide the state of the Software Trigger input on the D3

line (i.e., Read Value & 0x04 to determine Trigger Input line state).

Software Trigger Port (base + 5) Bit Description

Read Spectral Data (base + 6) Bit Description

Performing a 16-bit read from this port will return one spectral data point. To obtain full spectra

perform 2048 reads after interrupt initiation. Raw data format is signed—invert bit 11 to convert to

unsigned (i.e. Data Value XOR’ed with 0x0800).

Table 1. PC2000-PC104 Programming Registers.

Channel Rotation Port (base + 7) Bit Description

Byte wide writes to this port activates or deactivates the rotator. If activated, the value written

determines the number of channels rotated through.

000-00000-000-05-0704 7

Page 8

PC2000-PC/104 Data Sheet

Value Written Function

0 Disables channel rotation

9 (0x09) Rotates channels 0 and 1

10 (0x0A) Rotates channels 0 through 2

11 (0x0B) Rotates channels 0 through 3

12 (0x0C) Rotates channels 0 through 4

13 (0x0D) Rotates channels 0 through 5

14 (0x0E) Rotates channels 0 through 6

15 (0x0F) Rotates channels 0 through 7

Table 2. Switch Settings for Base Address and IRQ illustrates how to configure the switch settings for

the desired base address. Once a spectra is acquired and ready to be readout, the spectrometer

generates an IRQ. The specific IRQ is defined by switch setting as listed in

Settings

.

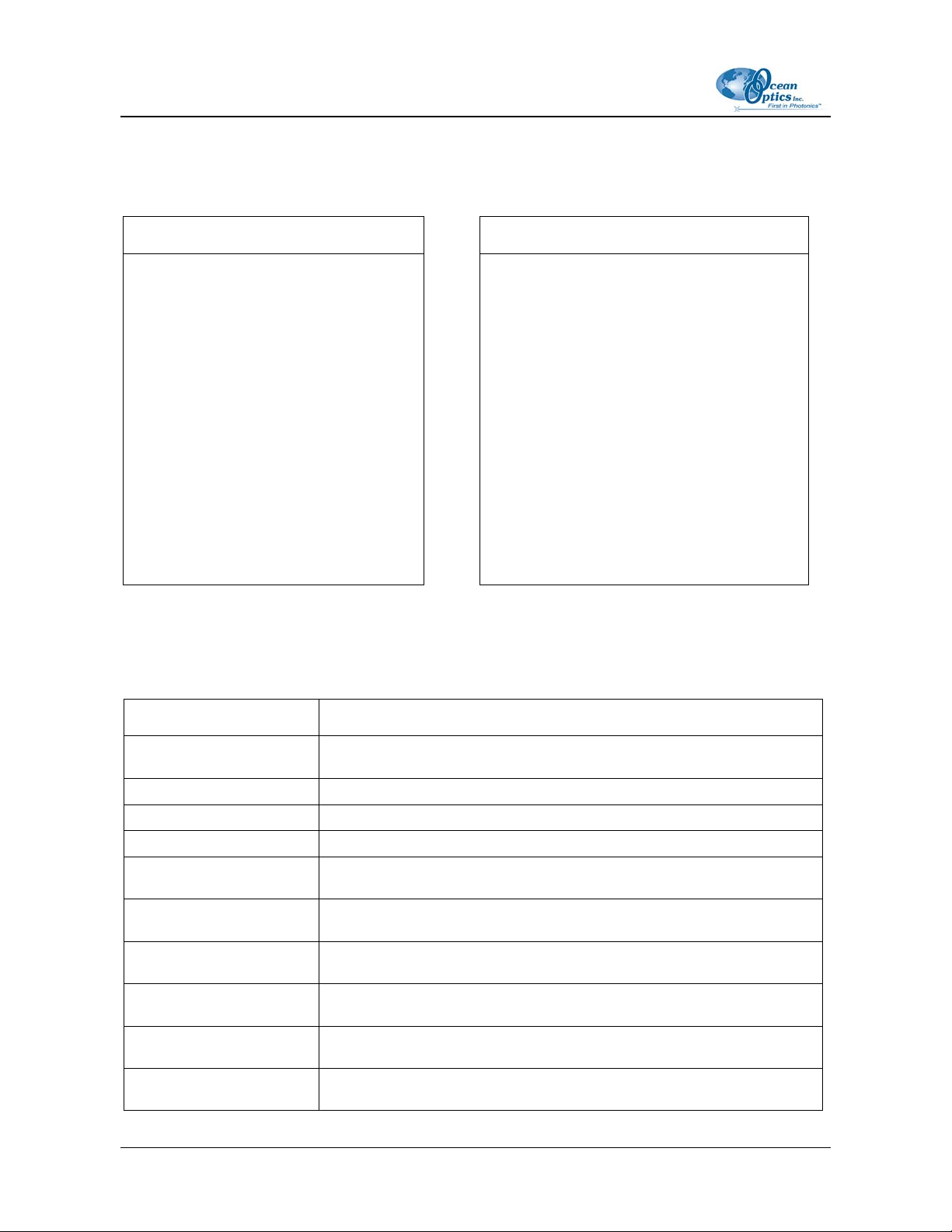

Table 1. PC2000-PC104 Programming Registers

Port Address PC2000-PC104 Register Description

IRQ Interrupt Request

base + 0 Master Clock Counter Port (base frequency is 8 MHz)

base + 1 Continuous Strobe Counter Port (base frequency is 976 Hz)

base + 2 Integration Clock Counter port (base frequency is 976 Hz)

base + 3 N/A

base + 4 Command port (output only)

base + 5 Software Trigger Digital Input port (bit 3 only)

base + 6 Read Spectral Data (WORD Access)

base + 7 Channel rotation command port

Counter Ports (Base – Base +2) Description

Output frequency of counter is base frequency divided by the 16bit value written to this port. Limits

for the various counters along with the corresponding counter value are provided below.

Counter Min Typical Max

Master Clock 4Mhz 2 4Mhz 2

Continuous Strobe

2.048ms period

2

Integration Clock

8 000-00000-000-05-0704

3.072ms period

3

Page 9

PC2000-PC/104 Data Sheet

Command Port (Base +4) Bit Description

Writes to this 8-bit port control the spectrometer’s functionality.

Bit Function

7 MUX address bit 2

6 Enable board interrupt (1=enabled)

5 Master reset to clear FIFO (1=reset)

4 MUX address bit 1

3 MUX address bit 0

2 Spectrometer mode control S1

1

0 Read enable (1=enabled)

Spectrometer mode control S0

Multiplexed as Strobe enable (1=enabled)

Software Trigger Port (base + 5) Bit Description

Performing an 8-bit read from this port will provide the state of the Software Trigger input on the D3

line (i.e., Read Value & 0x04 to determine Trigger Input line state).

Read Spectral Data (base + 6) Bit Description

Performing a 16-bit read from this port will return one spectral data point. To obtain full spectra

perform 2048 reads after interrupt initiation. Raw data format is signed—invert bit 11 to convert to

unsigned (i.e. Data Value XOR’ed with 0x0800).

Channel Rotation Port (base + 7) Bit Description

Byte wide writes to this port activates or deactivates the rotator. If activated, the value written

determines the number of channels rotated through.

000-00000-000-05-0704 9

Page 10

PC2000-PC/104 Data Sheet

Value Written Function

0 Disables channel rotation

9 (0x09) Rotates channels 0 and 1

10 (0x0A) Rotates channels 0 through 2

11 (0x0B) Rotates channels 0 through 3

12 (0x0C) Rotates channels 0 through 4

13 (0x0D) Rotates channels 0 through 5

14 (0x0E) Rotates channels 0 through 6

15 (0x0F) Rotates channels 0 through 7

Table 2. Switch Settings for Base Address and IRQ

Base Address Settings

Switches 1 – 6 of SW1 determine the base address, which is the weighted sum of these switches. The switch

position is negative logic (i.e. 1 is off). The factory default is 0x300 hex or 768 decimal.

Switch # Address line Value (hex) Value (decimal) Switch setting for 300

Switch position

hex

1 A4 10h 16 on 0

2 A5 20h 32 on 0

3 A6 40h 64 on 0

4 A7 80h 128 on 0

5 A8 100h 256 off 1

6 A9 200h 512 off 1

IRQ Interrupt Request Settings

The following matrix defines the different Interrupt Request settings by switch positions 7, 8, and 9. In

the default setting, the IRQ is set to 7. Combinations for IRQ settings follow.

Switch Settings

#7 #8 IRQ

0 0 3

1 0 4

0 1 5

1 1 7 (Default)

1 indicates a switch in the ON position

10 000-00000-000-05-0704

Page 11

PC2000-PC/104 Data Sheet

Counters

The PC2000-PC104 implemented the core of an 82C54 programmable timer in the FPGA to

implement the required clock signals. Refer to this data sheet for more detailed information. This

implementation requires no control word to be written to the counter. These timers use the equivalent

of control mode 3 (50% duty cycle) and the counters are always enabled. The base frequency for each

of the timers is shown in Table 1.

Programming

Pseudo-code programming for the PC2000-PC104 is provided in PC2000-PC/104 Programming

Sequence

.

PC2000-PC/104 Programming Sequence

This technical document describes the programming procedures necessary to control and PC2000PC104 spectrometer. This setup is functionally identical to the S2000 spectrometer and ADC1000 ISA

card. The pseudo-code examples below use the following definitions:

(Note: all numbers starting with "0x" are in hexidecimal.)

• source code is in this font

comments are in this font

• outport_byte(baseadd+1,0x13) -- outputs one byte of data to the specified port,

represented as an offset from the base address

• outport_word(baseadd+1,0xffff) -- outputs one word of data to the specified port,

represented as an offset from the base address

• inport_byte(baseadd+3) -- inputs one byte of data from the specified port,

represented as an offset from the base address

• inport_word(baseadd+5) -- inputs two bytes (one 16-bit word) of data from the

specified port, represented as an offset from the base address

• Variables:

baseadd -- the base address in decimal, 16-bit integer

dsf -- digital sample frequency, or A/D conversion frequency, 16-bit integer

fdc -- number of flashes per scan, 16-bit integer

cmd -- command to be sent to A/D card, 8-bit (unsigned) integer

average -- number of scans to average

oldvect -- stored interrupt vector

current_channel -- active spectrometer channel

indata -- data read from the A/D card

irq -- the interrupt number (interrupt request) of the ADC500/ADC1000/PC1000

ihandler -- the interrupt handler function

000-00000-000-05-0704 11

Page 12

PC2000-PC/104 Data Sheet

• Operators:

>> bit shift operator

== equal comparison operator

& bit-wise AND operator

^ bit-wise XOR operator

| bit-wise OR operator

One internal pseudo-code function is used --

CheckTriggerMode(). This function checks the trigger

mode and sets the appropriate spectrometer mode control bits (S0 and S1) in the command sent to the

ADC500/ADC1000 control port. The psuedo-code for this function is:

if trigger_mode = external_synchronization then cmd = cmd | 0x04

if trigger_mode = external_hardware_trigger then cmd = cmd | 0x06

if trigger_mode = software_trigger then cmd = cmd & 0xf9

if trigger_mode = no_trigger then cmd = cmd & 0xf9

Step 1: Initialize A/D Functions

outport_word(baseadd+1,0x0010)

outport_word(baseadd,0x0002)

cmd = 0x20

CheckTriggerMode()

outport_byte(baseadd+4,cmd)

delay(10)

cmd = 0x00

CheckTriggerMode()

outport_byte(baseadd+4,cmd)

Loads counter 1, which is set to a ~10 msec period.

Loads counter 0, which is set to 4Mhz

master reset

check the external trigger mode

send command to ADC500/ADC1000

delay for 10 msec to allow "settling"

cancel reset and leave disabled

check the external trigger mode

send command to ADC500/ADC1000

This function initializes the A/D card. First, the countinuous strobe counter (1) is loaded with a divisor

so that the resulting period is ~10 msec. Next the Master Clock counter is initialized to the fasted

possible value (4MHz). The A/D card is reset and disabled.

Step 2: Setup Integration Time

if dsf < 3 then dsf = 3

outport_word(baseadd+2,

dsf)

if dsf < 25 then delay(25)

else delay(12*dsf/10)

This function sets the integration time of the spectrometer. There must be a delay after this setting to

allow the previous integration period to complete before the new one begins.

make sure integration time is not below the allowable minimum

load counter 2, which defines the integration time

delay to allow the previous cycle to complete before we start the next

integration cycle

12 000-00000-000-05-0704

Page 13

PC2000-PC/104 Data Sheet

Step 3: Install Your Interrupt Vector

Consult your hardware documentation to determine how to do this correctly. Below is a sample C

function, which installs the interrupt service routine using Borland C 4.0 in a DOS environment.

disable()

oldvect = getvect(irq + 8)

setvect(irq + 8, ihandler)

if irq == 2 then outport_byte(0x21,

inport_byte(0x21) & 0xfb)

if irq == 3 then outport_byte(0x21,

inport_byte(0x21) & 0xf7)

if irq == 5 then outport_byte(0x21,

inport_byte(0x21) & 0xdf)

if irq == 7 then outport_byte(0x21,

inport_byte(0x21) & 0x7f)

enable()

disable interrupts during this change

save the old interrupt vector for the IRQ

set the interrupt vector to be the address of your

interrupt handler

unmask the correct IRQ

unmask the correct IRQ

unmask the correct IRQ

unmask the correct IRQ

reenable interrupts once done changing

After disabling interrupts, we store the old interrupt vector for the IRQ in oldvect. We then set the new

interrupt vector to a function called ihandler (described below). Then, we enable a specific interrupt by

changing the interrupt mask.

Step 4: Trigger a Data Acquisition Cycle

port = baseadd + 4

cmd = cmd & 0xe7

if current_channel between Master

and Slave3 then

cmd = cmd | current_channel << 3

cmd = cmd & 0x7f

else

cmd = cmd | current_channel << 3

cmd = cmd | 0x80

end if

identify the PC2000-PC104 control port

clear the channel bits

set the A/D MUX channel. If the MUX channel is

between 0 and 3, the highest order bit for the MUX

selection is set to 0, or else it is set to 1.

CheckTriggerMode()

outport_byte(port,cmd)

cmd = cmd & 0xbe

cmd = cmd | 0x20

CheckTriggerMode()

outport_byte(port,cmd)

cmd = cmd & 0xdf

CheckTriggerMode()

000-00000-000-05-0704 13

check the external trigger mode

set command to PC2000-PC104

disable triggers and interrupts

reset the FIFO buffer

check the external trigger mode

set command to PC2000-PC104

cancel the reset

check the external trigger mode

Page 14

PC2000-PC/104 Data Sheet

outport_byte(port,cmd)

cmd = cmd | 0x41

if external software triggering then

while inport_byte(baseadd + 5) & 8)

== 0 wait on this line

CheckTriggerMode()

if not scanning a dark spectrum or

using external triggering then

cmd = cmd | 2

outport_byte(port,cmd)

set command to PC2000-PC104

enable interrupts and triggers

if you are external triggering, constantly query the

digital input on pin 26 of the 26 pin connector to check

for it to go high (+5VDC)

check the external trigger mode

if you are scanning a dark spectrum or using an external

trigger mode do not turn on the flash

set command to PC2000-PC104

This function does a lot. First, it identifies the PC2000-PC104 control port as baseadd + 4. It then

clears the MUX address of the A/D, sets the MUX address of the A/D, turns off the flash-during-scan,

resets the FIFO buffer, cancels the FIFO reset, enables the triggers and interrupt (

IMPORTANT, as it is

what makes it all work), and waits for an external software trigger on pin 8

this is VERY

of the DSUB15 connector, if requested. The function then triggers a scan.

Step 5: Service the Interrupt

When a scan is completed, your program is notified by an interrupt. You MUST service this interrupt

IMMEDIATELY. The interrupt service routine (ISR) must be as short as possible. Do as little

processing as possible in the ISR. The following is our ISR.

cmd = cmd & 0xbe

CheckTriggerMode()

outport_byte(baseadd + 4,cmd)

enable()

for i = 0 to 2047

indata(i) = (inport_word(baseadd + 6)

^ 0x0800) & 0x0fff

next i

cmd = cmd & 0xbe

cmd = cmd | 0x20

CheckTriggerMode()

outport_byte(baseadd + 4,cmd)

cmd = cmd & 0xdf

CheckTriggerMode()

outport_byte(baseadd + 4,cmd)

outport_byte(0x20,0x20)

turn interrupts and triggers off

check the external trigger mode

stop the acquisition

restart interrupts

read 2048 data points from the FIFO buffer, convert to

unsigned values and mask off upper 4 bits (0-4095

value)

turn interrupts and triggers off

reset the A/D cards FIFO

check the external trigger mode

issue the command

cancel the reset

check the external trigger mode

issue the command

send a non-specific EOI (end of interrupt) to the 8259

interrupt controller chip

14 000-00000-000-05-0704

Page 15

PC2000-PC/104 Data Sheet

Many actions happen at interrupt time. First, we disable the PC2000-PC104 so that it does not

continue to scan. Then, we read the data from the FIFO. After the data is read, the spectrometer is

reset. You must be sure to tell the computer you have serviced the interrupt. That is done by issuing a

non-specific end-of-interrupt (EOI) to the 8259 interrupt controller chip by outport_byte(0x20,0x20).

At the end of this function, if you wish to immediately capture another scan, you can call the function

in

Step 4: Trigger a Data Acquisition Cycle after the outport_byte(0x20,0x20) function call.

Step 6: Remove the Interrupt Handler

When you are done with the driver communicating with the spectrometer, you must return the

interrupt vector to its original state. Again, this function will depend on your operating environment,

and we provide a sample in Borland C 4.0 for DOS.

Disable()

if irq == 2 then outport_byte(0x21,

inport_byte(0x21) | 0x04)

if irq == 3 then outport_byte(0x21,

inport_byte(0x21) | 0x08)

if irq == 5 then outport_byte(0x21,

inport_byte(0x21) | 0x20)

if irq == 7 then outport_byte(0x21,

inport_byte(0x21) | 0x21)

Setvect(irq + 8,oldvect)

enable()

disable interrupts during this change

mask the correct IRQ

mask the correct IRQ

mask the correct IRQ

mask the correct IRQ

restore the old interrupt vector

reenable interrupts once the change is

completed

000-00000-000-05-0704 15

Page 16

PC2000-PC/104 Data Sheet

16 000-00000-000-05-0704

Loading...

Loading...