Northstar Technologies

8700 GPS Position Sensor

8800 Series Beacon Sensors

8900 Series GPS/DGPS Position Sensors

Technical Reference Manual

Revision H

May 1, 1997

Part No. GM8900

© 1997 Northstar Technologies

a division of CMC Electronics, Inc.

Northstar Technologies

30 Sudbury Road

Acton, Massachusetts 01720

Sales: 508/897-6600

Service: 508/897-7251

Fax: 508/897-7241

Revision history

Date Pages Revision

May 1, 1997 ALL H

Ordering information

To receive additional copies of this publication, order the Northstar Sensors Technical Reference Manual (Part No. GM8900).

Limited warranty policy

Northstar 8700, 8800 series, and 8900 series sensors

Northstar Technologies, a division of CMC Electronics, Inc., warrants its family of 8700, 8800 series, and 8900 series sensors to be

free from defects in materials and workmanship for a period of

two (2) years. This warranty applies to the original purchaser and

to any subsequent owner during the warranty period, which

begins on the date of shipment of the unit, F.O.B. Acton, Massachusetts, to an authorized Northstar dealer.

During the unit’s warranty period, Northstar will repair or replace,

at its option, any part of the unit it finds to be defective due to

faulty material (s) or workmanship. All such repairs and/or

replacements will be performed by Northstar free-of-charge to the

owner, excluding freight costs incurred in shipping to the factory.

Return shipments from Northstar to points within the United

States are made via ground transportation, freight prepaid. Special

shipping charges (overnight, two-day, and so on) are the responsibility of the owner.

To be covered by this warranty, the Northstar equipment must

have been in normal use. The warranty does not apply to units

with defects caused by improper installation, physical damage,

abuse, tampering, lightning, or other abnormal electrical discharge, or to units with defaced or altered serial numbers, or to

units repaired by unauthorized persons or repaired in a manner

that violates Northstar’s recommended service procedures.

All repairs and/or replacements made under this warranty must

be performed at Northstar’s facilities in Acton, Massachusetts.

Performance of warranty work elsewhere will not be authorized,

and Northstar will not pay for any charges for such work. Northstar will not be responsible for payment of any charges imposed

by a Northstar dealer or other party for services requested by

and/or performed for a unit’s owner in connection with this warranty. Such services might include removal or the unit from a

vehicle, inspection, packaging, handling, reinstallation, and the

like.

Northstar assumes no responsibility for any consequential losses

of any nature with respect to any of its products or services sold,

rendered, or delivered. The foregoing is the only warranty

expressed or implied. No other warranty exists.

* Certain Northstar control heads are warranty-protected against

damage due to water leakage, provided the head has not been

tampered with.

Table of Contents

Section 1 - About this manual . . . . . . . . . . . . . . . . . . . . 1

1.1 Scope of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.3 Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.4 Glossary and acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.5 Registration card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.6 Service and repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Section 2 - Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Northstar 8700. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Northstar 8800 series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.3 Northstar 8900 series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.4 Sensor dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.5 Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.6 Interfacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Section 3 - Packaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Northstar 8700 parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Northstar 8800 series parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Northstar 8900 series parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Section 4 - GPS receivers. . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Northstar 8700 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.2 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.3 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Section 5 - Beacon receivers . . . . . . . . . . . . . . . . . . . . . 15

5.1 Northstar 8800 series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.1 About the Northstar 8801 . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.1.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.1.4 Operating modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Section 6 - GPS/beacon combination receivers . . 19

6.1 Northstar 8900 series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.1 About the Northstar 8901 . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.2 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1.3 Technical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Section 7 - Antennas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 GPS antenna (AN145) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2.2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2.3 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2.4 Mounting location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.3 GPS antenna (AN150) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.3 Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.4 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.3.5 Mounting location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.4 GPS/DGPS combination antenna (AN190/AN200) . . . . . . . . 24

7.4.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.4.2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4.3 Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4.4 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.4.5 Mounting location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.5 DGPS-only H-field antenna (AN195). . . . . . . . . . . . . . . . . . . . 25

7.5.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.5.2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

7.5.3 Cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.5.4 Mounting location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.6 Whip antenna (8410 ACU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.6.1 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.6.2 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

7.6.3 Cable length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7.6.4 Mounting location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Section 8 - Input/output configurations . . . . . . . . . . 29

8.1 I/O ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.2 Sensor signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

8.3 Standard configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.4 Configuration details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.5 Connector pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.6 Input and output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.6.1 RTCM SC-104 output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.6.2 BDM control input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.6.3 BDM monitor input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.6.4 BDM monitor output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.6.5 GPS auxiliary input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.6.6 GPS auxiliary output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.6.7 GPS primary input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.6.8 GPS primary output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.6.9 Remote POWER ON control . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.6.10 DC power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.6.11 Time mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Section 9 - Connector pinouts. . . . . . . . . . . . . . . . . . . . 37

9.1 Standard pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1.1 Wiring power control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1.2 8700 connector pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

9.1.3 8800 connector pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

9.1.4 8900 connector pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

9.1.5 Alternate connector pinouts for the 8900. . . . . . . . . . . . . . 40

Section 10 - NMEA protocols

10.1 Beacon monitor control messages. . . . . . . . . . . . . . . . . . . . . 43

10.1.1 NMEA 0183 format control messages . . . . . . . . . . . . . . . . 43

10.2 GPS serial protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.2.1 Input sentences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

10.2.2 Output sentences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Section 11 - Beacon receiver binary protocol

11.1 Beacon receivers (8800 series and 8900 series) . . . . . . . . . 61

11.1.1 Binary control messages . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11.2 GPS binary protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Section 12 - 8X00 engine monitor program

12.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12.1.1 BDM data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12.1.2 GPS data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

12.1.3 Satellite data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

12.1.4 Function key tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

12.2 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

12.2.1 Hardware and software requirements . . . . . . . . . . . . . . . . 64

12.2.2 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

12.2.3 About data files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12.2.4 About scrolling data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

12.2.5 About the monitor message line . . . . . . . . . . . . . . . . . . . . 65

12.3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

. . . . . . . . . . . . . . . . . . . . . 43

. . . . . 61

. . . . . . 63

Section 13 - Glossary

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Section 14 - Abbreviations and initialisms

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

. . . . . . . 69

Tables

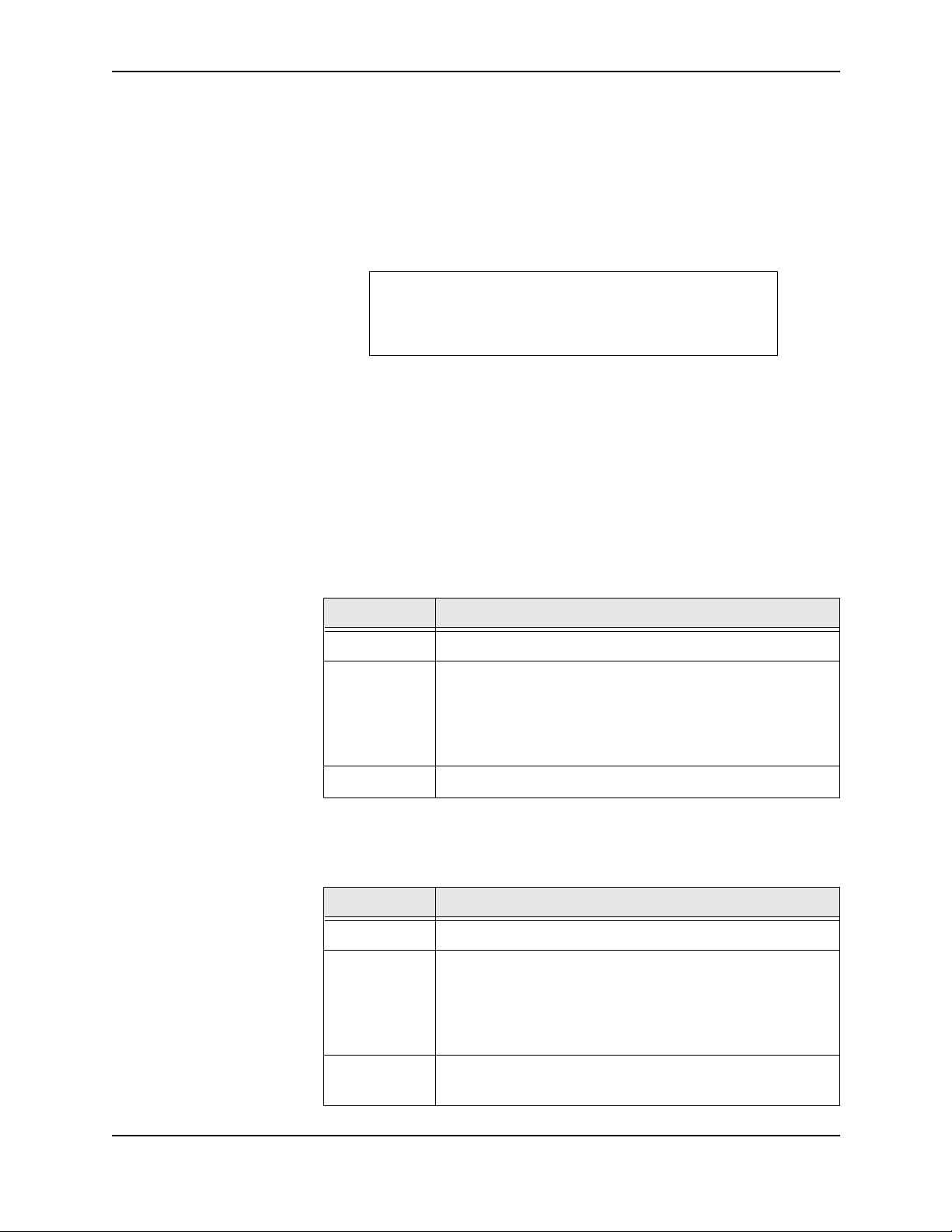

Table 1 — 8700 parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 2 — 8800 parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Table 3 — 8801 parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 4 — 8900 parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Table 5 — 8901 parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 6 — I/O ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Table 7 — Standard configurations. . . . . . . . . . . . . . . . . . . . 30

Table 8 — Configuration 7 . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 9 — Configuration 6 . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Table 10 — Configuration 5 . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 11 — Configuration 4 . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 12 — Configuration 3 . . . . . . . . . . . . . . . . . . . . . . . . . 32

Table 13 — Hardware pin numbers/signal levels . . . . . . . . . 33

Table 14 — 8700 connector pinouts/config. 3 . . . . . . . . . . . 37

Table 15 — 8800 power/interface connector pins/config. 5. 38

Table 16 — 8900 standard connector pinouts/config. 7 . . . . 39

Table 17 — 8900 alternate connector pinouts/config. 6 . . . . 40

Table 18 — 8900 alternate connector pinouts/config. 4 . . . . 41

Table 19 — Command parameters . . . . . . . . . . . . . . . . . . . . 44

Table 20 — Command parameter examples. . . . . . . . . . . . . 44

Table 21 — Approved sentence structure. . . . . . . . . . . . . . . 45

Table 22 — NMEA field definitions. . . . . . . . . . . . . . . . . . . 45

Table 23 — Primary port input sentences. . . . . . . . . . . . . . . 47

Table 24 — Character/baud rate . . . . . . . . . . . . . . . . . . . . . . 47

Table 25 — Initialization command . . . . . . . . . . . . . . . . . . . 48

Table 26 — Example B sentence contents . . . . . . . . . . . . . . 48

Table 27 — Output-configuration message identifiers. . . . . 49

Table 28 — Set output configuration command. . . . . . . . . . 50

Table 29 — Switch to reprogramming mode command. . . . 50

Table 30 — NVM command. . . . . . . . . . . . . . . . . . . . . . . . . 50

Table 31 — Character/element . . . . . . . . . . . . . . . . . . . . . . . 51

Table 32 — Radio-beacon command message . . . . . . . . . . . 51

Table 33 — Primary-port output sentences. . . . . . . . . . . . . . 52

Table 34 — Navigation status sentence . . . . . . . . . . . . . . . . 53

Table 35 — Self-test sentence. . . . . . . . . . . . . . . . . . . . . . . . 54

Table 36 — Radio-beacon proprietary sentence. . . . . . . . . . 54

Table 37 — GPS-fix data sentence . . . . . . . . . . . . . . . . . . . . 55

Table 38 — Example N sentence . . . . . . . . . . . . . . . . . . . . . 56

Table 39 — Geographic position sentence . . . . . . . . . . . . . . 56

Table 40 — GPS DOP and active satellite sentence. . . . . . . 57

Table 41 — GPS-satellites-in-view sentence . . . . . . . . . . . . 57

Table 42 — MSS radio-beacon signal status sentence . . . . . 58

Table 43 — Recommended-minimum-specific sentence . . . 59

Table 44 — Track made good/ground-speed sentence . . . . . 59

Table 45 — UTC time, data, and local time-zone sentence . 60

Figures

Figure 1 - 8700/8800 series/8900 series dimensions . . . . . . . 4

Figure 2 - 8700 ALLSTAR engine operating modes . . . . . . 12

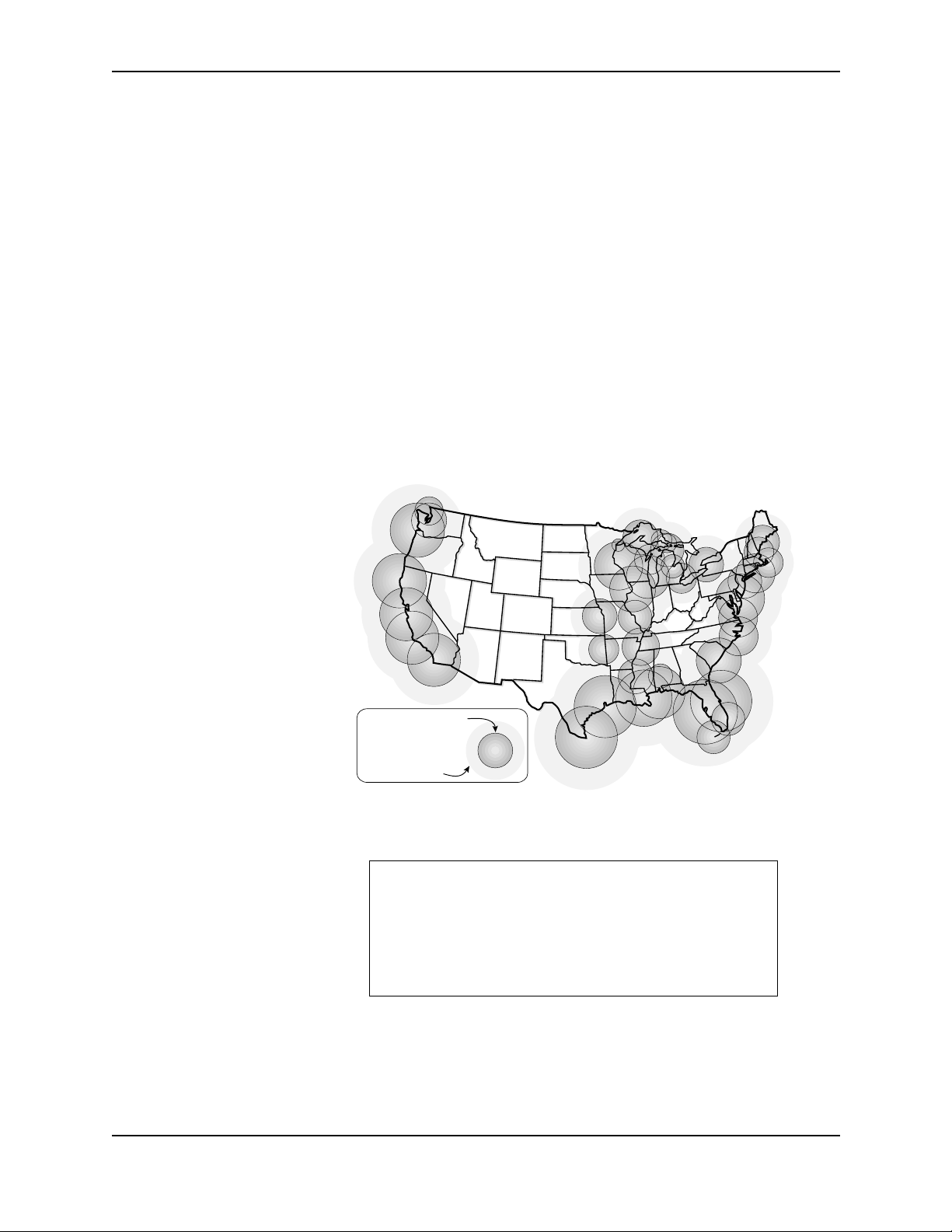

Figure 3 - Radio-beacon coverage map . . . . . . . . . . . . . . . . 15

Figure 4 - Northstar AN145 antenna . . . . . . . . . . . . . . . . . . 23

Figure 5 - Northstar AN150 antenna . . . . . . . . . . . . . . . . . . 24

Figure 6 - AN190 combination antenna . . . . . . . . . . . . . . . . 25

Figure 7 - Northstar AN195 H-Field antenna . . . . . . . . . . . . 26

Figure 8 - Northstar 8410 ACU . . . . . . . . . . . . . . . . . . . . . . 27

Figure 9 - 8X00 ALLSTAR engine monitor screen . . . . . . . 63

Section 1 - About this manual

To use this manual effectively, please read this entire two-page section

first. This document doesn’t contain basic installation information. If

you’re looking for instructions about mounting the sensors and antennas,

connecting the cables, or other details on interfacing the Northstar sensors to other Northstar receivers, please refer to the corresponding North-

star Installation Manual.

1.1 Scope of this manual

Section 1 - About this manual

1.1.1 Audience

1.1.2 Contents

The Northstar Sensors Technical Reference Manual is intended for readers

with a good technical knowledge of the components of GPS consumer

navigational instruments. This audience includes engineers and other

technical product-development persons in original equipment manufacturer (OEM) environments; experienced dealers of marine, land-based, or

other navigational equipment; and small start-up companies, all looking

for ways to interface their products with Northstar sensors.

This manual presents this technical information in a logical, easy-to-use

format; each section is organized for access to specific information. In this

way, you can go directly to the source of that information without sifting

through unnecessary levels to find what you need.

The manual covers the following products:

• Northstar 8700 GPS Position Sensor

• Northstar 8800 Series Beacon Sensors

• Northstar 8900 Series GPS/DGPS Position Sensors

Additional high-level information about antennas, pinouts and configurations, NMEA protocol, beacon binary protocol, RS-422 and RS-232 interfaces, and the 8X00 ALLSTAR Engine Monitor Program is all contained

within this manual. In fact, if you own this Northstar Sensors Technical

Reference Manual, you should have received a copy of the Northstar

8X00 ALLSTAR Engine Monitor Program. (If you didn’t receive this program, call the Northstar sales department and order Northstar Part Number GS8900, shipped on a 3-½ inch diskette at no charge.)

This document supersedes the Northstar Installation and Operation Man-

ual (Northstar Part Number GM8900, Revision G).

1.1.3 Conventions

05/01/97 REV H PAGE 1

The conventions listed below are used throughout the manual to consistently refer to certain information, as follows:

and

NOTE

reader information. Be sure to read the information in these note and

caution boxes.

NMEA command is the bold typeface used when the text refers to a com-

mand given to, or output by, the sensors;

(without bold) used when a table refers to a command given to, or output

by, the sensors.

CAUTION

are the headings for text boxes containing important

NMEA command is the typeface

Section 1 - About this manual

1.1.4 Glossary and acronyms

1.1.5 Registration card

1.1.6 Service and repair

This manual contains two separate sections to clarify technical terms,

abbreviations, acronyms, and initialisms. Each new term is defined when

it first appears; however, a term once defined is not redefined each time it

appears. Consequently, you may want to refer to the back of this manual

if you find a term you don’t understand.

Make sure you fill out the owner’s registration card included with the

sensor and return it to Northstar Technologies. We must have your complete mailing address (not just a company name) so we can send you any

future product information.

In case of an operating problem with a Northstar sensor, you may contact

your dealer or return the sensor to the Northstar factory for diagnosis

and repair. Be as complete and accurate as possible when you describe an

operating problem. If you need immediate assistance, feel free to call

Northstar service at (508) 897-7251.

Each sensor is covered by a two-year limited warranty, which, in summary, states that if a sensor is returned to the factory by the owner during

the warranty period, Northstar will repair or replace, free-of-charge, any

part found to be defective due to faulty materials or workmanship, if the

sensor has been properly installed and hasn’t been abused. The only cost

to the owner will be the one-way shipping charges that might be imposed

by the dealer.

Shipments to Northstar Technologies should be made to the following

address:

Northstar Technologies, 30 Sudbury Road, Acton, MA 01720

If you have special overnight or two-day shipping requirements (UPS or

Federal Express), please call the Northstar factory for turnaround time

and freight costs before shipping your sensor.

Refer to the Limited Warranty Policy at the beginning of this manual for

further details on warranty and service policies and procedures.

PAGE 2 05/01/97 REV H

2.1 Overview

Section 2 - Introduction

Section 2 - Introduction

Northstar’s family of position sensors, comprised of models 8700, the

8800 series, and the 8900 series, features self-contained, 12-channel GPS

modules with two-channel, automatic, medium-frequency radio-beacon

receivers, packaged in rugged “black box” aluminum enclosures.

These high-performance units provide reliable GPS and/or DGPS positioning for the following applications:

• Custom OEM systems requiring superior, “all-in-view” GPS perfor-

mance

• Automatic vehicle location (AVL) and monitoring systems, including

railroads, highways, emergency, public transportation, and trucking

• Mobile ground information systems (GIS) data acquisition, including

asset management and mapping

• Precision agriculture, including yield mapping, yield monitoring, and

sampling

• Forestry, including aerial spraying, planting, and forest mapping

• Surveying/mapping, including aerial, highway, and legal surveys;

utility mapping

• Marine navigation

2.1.1 Northstar 8700

2.1.2 Northstar

8800 series

2.1.3 Northstar

8900 series

The Northstar 8700 is a 12-parallel-channel, DGPS-ready, fast-acquisition

GPS receiver that continuously tracks all available satellites. The 8700

accepts DGPS corrections from any source of Radio Technical Commission for Maritime Services (RTCM) SC-104 data. See Section 4, “GPS

Receivers,” for complete information about the Northstar 8700.

The Northstar 8800 series (comprised of either the 8800 or the 8801, an

8800 bundled for agricultural applications) is a two-channel, auto-tuning,

Minimum Shift Keying (MSK) radio-beacon receiver, also known as a beacon demodulator, or BDM, which supplies fully automatic differential

corrections for an external DGPS-ready receiver. While the 8800 series’

Channel 1 processes real-time corrections, Channel 2 automatically

searches for alternates. The 8800 series works worldwide with beacons

that conform to the SC-104 specification.

See Section 5, “Beacon Receivers” for complete information about the

Northstar 8800 series.

Northstar combines the 8700 and the 8800 to form the Northstar 8900

series of sensors, which provide optimum performance in self-contained,

fully automatic DGPS units. See Section 6, “GPS/Beacon Combination

Receivers” for complete information about the Northstar 8900 series.

05/01/97 REV H PAGE 3

Section 2 - Introduction

(A

l dimensions in inches

)

2.1.4 Sensor dimensions

The sensors share common dimensions as outlined below.

• Height = 2.0 inches

• Width = 4.6 inches

• Depth = 8.9 inches

• Weight < 2 pounds

2.1.5 Power

l

FIGURE 1 - 8700/8800 series/8900 series dimensions

Each sensor is easy to use: Just connect the antenna and supply the

power.

CAUTION!

Before you apply power to the system, double-check

all wiring. A small, but significant number of units

sustain damage because of incorrectly wired connections. This damage isn’t covered under warranty. Be

sure you don’t apply primary voltage directly to any

of the signal input/output wires of the GPS sensor;

this may vaporize circuit-board conductors within

the sensor.

Status indicator light

NOTE:

The information below only applies to the Northstar

8800 series and 8900 series sensors; NOT to the

Northstar 8700 sensor.

PAGE 4 05/01/97 REV H

Section 2 - Introduction

The status indicator light illuminates when the unit’s power is turned on.

When you first turn power on, the light turns green for just a few seconds. The light then turns red, and stays red as long as the sensor is

searching for a beacon. Once the sensor has locked onto a beacon, the

light will then turn green.

Another function of the status indicator light is flashing red/green. The

light will only flash red/green if the beacon antenna (not GPS) is open or

shorted. Check your antenna or antenna wiring to determine the problem, if you see the flashing red/green light. Once the problem has been

fixed, the light will turn red for as long as several minutes, while the sensor searches for a beacon. The light will return to green once it has locked

onto a beacon.

The status indicator light in the 8800 and 8900 sensors refers to beacon

status, not GPS status.

2.1.6 Interfacing

You can interface Northstar position sensors to a wide variety of external

devices, such as navigators, computers, yield monitors, and so on. These

external devices, or host systems, receive and process the data from the

sensor, and in some applications, may control the sensor.

Each sensor has two, full-duplex serial I/O ports that may be connected to

a host system in a variety of ways and for different applications. The function of each I/O port is determined by a Programmed Array Logic (PAL)

chip that acts as a matrix switch, which can configure the I/O port to several configurations.

All three sensors use identical I/O hardware and circuitry, configured for

specific applications by jumper options controlling the PAL chip. Any one

of the eight standard configurations (see Section 8, “Input/Output Configurations” for a complete list of standard configurations) is selectable from

combinations of three jumper pins located on the 25-pin data/power connector.

The standard, recommended configuration for each sensor described in

this manual is further described in its corresponding Northstar Installa-

tion Manual. Custom configurations also may be available for large quantities of sensors as special orders.

05/01/97 REV H PAGE 5

Section 2 - Introduction

PAGE 6 05/01/97 REV H

3.1 Housing

Section 3 - Packaging

Section 3 - Packaging

The sensor is housed in a rugged aluminum enclosure with a mounting

flange.

NOTE:

The housing isn’t completely waterproof, so keep the

sensor away from direct contact with water spray or

splash.

The sensor enclosure includes keyhole slots, located at the rear of the

sensors, which aid in installations of limited access. You can mount the

sensors either horizontally or vertically; see Figure 1 in Section 2, “Introduction,” for case and mounting dimensions.

Northstar ships each sensor system with the following parts; check with

Northstar if these parts aren’t included with your sensor.

3.2 Northstar 8700 parts

Part # Description

8700–A 8700 GPS position sensor

8700–PK

KS130

KS131

KS133

GM630 Northstar 8700 GPS Sensor Installation Manual

8700 parts kit, consisting of:

3.3 Northstar 8800 series parts

Part # Description

8800–A 8800 beacon sensor

8900–PK

8900 series parts kit, consisting of:

Table 1: 8700 parts

25-pin female DB–25 connector

DB–25 shielded junction shell

DB-25 short screw lock for KS131

Table 2: 8800 parts

KS130

KS131

KS133

8410 Optional DGPS antenna coupling unit (ACU) used

05/01/97 REV H PAGE 7

25-pin female DB-25 connector

DB–25 shielded junction shell

DB-25 short screw lock for KS131

with four-foot whip antenna

Section 3 - Packaging

WC100 DGPS antenna connecting cable (RG-58U coaxial, 25

feet). Standard with 8410

AN195 Optional H-field DGPS-only antenna with 20 feet of

RG-59U coaxial cable

GM635 Northstar 8800 and 8801 Beacon Receivers Installa-

tion Manual

Table 3: 8801 parts

Part # Description

8800–A 8800 beacon sensor

8801-CA Interface cable with nine-pin I/O connector and

power leads

AN195 H-field DGPS-only antenna with 20 feet of RG-59U

coaxial cable

GM635 Northstar 8800 and 8801 Beacon Receivers Installa-

tion Manual

3.4 Northstar 8900 series parts

Part # Description

8900–A 8900 integrated GPS/DGPS position sensor

8900–PK

KS130

KS131

KS133

8410 Optional DG PS antenna coupling unit (not used with

WC100 DGPS antenna connecting cable (RG-58U coaxial, 25

AN145 Optional GPS antenna (includes 25 feet of RG-59U

AN150 Optional GPS active antenna (includes 50 feet of

8900 parts kit, consisting of:

combo antenna).

feet). Not used with combo antenna. Standard with

8410.

cable)

RG-59U cable)

Table 4: 8900 parts

25-pin female DB-25 connector

DB–25 shielded junction shell

Short screw lock for KS131

AN190 Optional GPS/DGPS combo antenna with external

splitter. Includes 50 feet of RG-59U cable.

AN195 Optional H-field DGPS-only antenna. Includes 20

feet of RG-59U cable.

PAGE 8 05/01/97 REV H

Section 3 - Packaging

GM640 Northstar 8900 DGPS Sensor Installation Manual

8902-CA Optional interfacing cable for connecting to North-

star 800 series GPS-ready Lorans (only supplied with

units for connection to 800-GPS or 800X-GPS, if

specified at time of order.

Table 5: 8901 parts

Part # Description

8901-A 8901 integrated GPS/DGPS position sensor with

internal splitter

AN200 Combination antenna with 20 feet of RG-59U coaxial

cable

GM-625 Northstar 8901/8901AL Ag DGPS Sensors Field Instal-

lation Manual

8901-CA Optional interfacing cable for agricultural applica-

tions

8903-CA Optional interfacing cable for AgLeader applications

(included with Northstar 8901AL sensor)

05/01/97 REV H PAGE 9

Section 3 - Packaging

PAGE 10 05/01/97 REV H

Section 4 - GPS receivers

4.1 Northstar 8700

The Northstar 8700 GPS position sensor decodes satellite radio signals,

and provides three-dimensional position, velocity, time, and other status

information at a maximum rate of once per second.

Each of the 12 parallel channels continuously tracks a GPS satellite signal.

To support faster acquisition of GPS signals, the sensor makes provisions

for external initialization of data. Further, the sensor can use externally-provided differential corrections to reduce inherent GPS inaccuracies; WGS-84 (World Geodetic System) is used as its reference datum.

Section 4 - GPS receivers

4.1.1 Features

4.1.2 Technical specifications

• 12-channel correlator for “all-in-view” reception

• External antenna

• Code and carrier tracking of L1 GPS frequency (1,574.42 MHz) for

increased accuracy

• Very fast signal reacquisition after signal obscuration

• Two serial input/output data ports: One to transmit navigation data,

another for differential data input or other needs. Either one can be

used for maintenance (reprogramming mode).

Power requirements

• 10 to 40 VDC

• 6 watts power consumption

• 0°C to +55°C temperature range of operation

• Internal, two-amp fuse

Electrical requirements

The 8700’s power supply is protected against reverse-polarity power

inputs, and features a remote turn-on ability. The 8700 turns on whenever power is applied to pin 25, ground to pin 13, and remote-on pin 12 is

connected to a source of +5 to +40 VDC.

Dynamics

• Velocity: 1800 km/h

• Acceleration: 4 g

• Jerk: 2 m/sec

3

Position accuracy

• 3 m horizontal, with DGPS, 95 percent confidence

• 30 m horizontal, without Selective Availability (SA) imposed, 95 per-

cent confidence

• 100 m horizontal, with SA imposed, 95 percent confidence

05/01/97 REV H PAGE 11

Section 4 - GPS receivers

Acquisition time

• 60 seconds typical Time-To-First-Fix (TTFF) with current almanac

Reacquisition time

• < 1 second typical to re-acquire (5-second obscuration)

• < 3 seconds typical to re-acquire (60-second obscuration)

Sensitivity

• -124 to -130 dBm (antenna input level)

Coarse acquisition

• C/A code (1.023 MHz chip rate — code and carrier phase tracking)

Environment

• Operating temperature: Zero to 55° C

• Relative humidity: 95 percent (non-condensing)

4.1.3 Operating modes

The 8700 automatically switches between six operating modes:

• Self-test

• Initialization

• Acquisition

• Navigation (includes four sub-modes: differential 3-D, differential

2-D, 3-D nav, and 2-D altitude-hold)

• Dead reckoning

• Fault

FIGURE 2 - 8700 ALLSTAR engine operating modes

The six modes are described in detail below.

PAGE 12 05/01/97 REV H

Section 4 - GPS receivers

Self-test

Upon request from an external source via the GPS primary port, using

either RS-232 or RS-422, the 8700 enters self-test mode. This test requires

no more than 15 seconds. Upon completion, the 8700 reports the test

results on its primary port through an NMEA message that’s displayed on

the host PC, if available. Then, the 8700 proceeds either to initialization

mode if it passes the test, or to fault mode if it detects a problem.

Initialization

When either power is applied or the self-test mode is complete, the 8700

enters initialization mode. While in this mode, the 8700 retrieves satellite-orbit data stored in its EEPROM memory. To ensure accuracy, the

8700 performs integrity checks on all data retrieved from the EEPROM.

After initialization, the sensor enters acquisition mode.

Acquisition mode

Whenever sufficient real-time satellite data is available to produce an initial navigation solution, the 8700 enters acquisition mode. Acquisition

mode can be entered from initialization, navigation, or dead-reckoning

modes (see below for separate descriptions of navigation and dead-reckoning modes).

The 8700 uses almanac data (stored in EEPROM memory) that describes

the satellite orbits, which helps quickly acquire signals from the GPS satellites. After each satellite in view is acquired, the 8700 collects its ephemeris data by decoding the satellite down-link data message. When enough

satellites are being tracked, the unit computes position, velocity, and

time, then enters navigation mode.

If valid almanac data is absent, and the 8700 can’t acquire signals normally, it initiates a “search the sky” acquisition, attempting to acquire all

satellites in the GPS constellation. In search the sky, the TTFF typically is

less than five minutes. After it acquires each satellite, ephemeris data is

decoded from the satellite down-link message. When enough satellites

are being tracked, the 8700 enters navigation mode—although it exits to

fault mode if it detects a problem.

Navigation mode

The 8700 enters navigation mode whenever sufficient satellite information and measurement data is available to produce a GPS fix. The unit

enters navigation mode from acquisition or dead-reckoning modes, and

exits to dead-reckoning or fault mode.

Navigation mode consists of four sub-modes. The 8700 automatically

chooses the highest-performance sub-mode available for the satellite data

that it currently receives. On its primary port, it reports the current navigation sub-mode:

• 3-D Differential

This navigation mode has the highest performance. The 8700

operates in this mode when it receives data from at least four

satellites with adequate geometry and differential corrections.

Differential SC-104 corrections can be taken in the auxiliary data

port using either RS-232 or RS-422.

05/01/97 REV H PAGE 13

Section 4 - GPS receivers

• 2-D Differential

When 3-D differential mode can’t be used, this is the

highest-performance navigation mode. The 8700 operates in this

mode when it receives data from only three satellites with adequate

geometry and differential corrections. SC-104 differential corrections

can be taken in on the auxiliary data port using either RS-232 or

RS-422.

• 3-D Nav

When sufficient differential corrections aren’t available, this is the

preferred navigation mode. The 8700 operates in this mode when it

receives data from at least four satellites with adequate geometry,

but no differential corrections.

• Altitude-Hold (2-D Nav)

This is the least-preferred navigation mode. If satellite

measurements are insufficient to produce a 3-D navigation solution,

but sufficient when altitude information is available, the 8700

operates in this mode, where the altitude is assumed constant.

Dead-reckoning mode

The 8700 enters dead-reckoning mode when it can’t remain in navigation

mode. The speed and direction of the vehicle are assumed constant to

allow the 8700 to provide an estimated position.

Fault mode

The 8700 enters fault mode from any mode—except initialization—when

and if the 8700 determines that one or more critical system faults are

affecting its outputs. Fault mode supersedes all others, and remains active

until the next power-down/power-up cycle.

PAGE 14 05/01/97 REV H

Section 5 - Beacon receivers

5.1 Northstar 8800 series

The Northstar 8800 series DGPS beacon sensor system receives corrections broadcast by land-based marine radio beacons situated along most

of the U.S. coastline and inland waterways (see Figure 3 below). GPS

receivers can use these corrections to improve their GPS accuracy to 10

meters or better, with three-meter accuracy 95 percent of the time commonly available.

The 8800 can significantly enhance the accuracy and performance of all

differential-capable GPS receivers that support the standard RTCM

SC-104 DGPS corrections format. DGPS corrections remove the errors

caused by atmospheric variations and Selective Availability, or SA. SA is

the intentional degradation of satellite signals by the U.S. Department of

Defense.

Section 5 - Beacon receivers

WA

OR

NV

CA

Approximate limit of

µV signal strength

75

Additional probable

coverage area for

µV sensitivity

20

MT

ID

UT

AZ

WY

NM

CO

ND

SD

TX

NE

KS

OK

MN

WI

MI

IA

MO

AR

LA

IL

MS

IN

TN

AL

KY

OH

GA

WV

PA

VA

NC

SC

FL

FIGURE 3 - Radio-beacon coverage map

NOTE:

Figure 3 is current as of 03/01/97. For the absolute latest in radio-beacon coverage information, please visit

the Northstar web site at http://www.north-

starcmc.com. Then, follow the “What’s new” link,

click on “Interesting web links,” and select the USCG

Navigation Center.

NY

ME

VT

NH

MA

CT

N

J

5.1.1 About the

Northstar 8801

The 8800 and 8801 sensors are functionally identical; the only difference

is their configuration. The 8800 can be used with either the Northstar

8410 ACU or the Northstar AN195 H-field antenna, and is intended primarily for marine applications. The 8801 is a bundled system intended

05/01/97 REV H PAGE 15

Section 5 - Beacon receivers

primarily for agricultural and other land-based applications. It includes

the AN195 H-field antenna and the Northstar 8801-CA cable assembly,

which provides a standard nine-pin connector to interface the 8800 to a

personal computer or other equipment designed to receive differential

corrections.

Because the two units are functionally identical, this section uses the

common term 8800 to refer to both models.

5.1.2 Features

5.1.3 Technical specifications

• Two channels

• Automatic evaluation of available radio-beacon signals

• Automatic selection of best stations

• Superior channel performance and impulse blanking techniques

Wiring diagrams on connecting the 8800 to Northstar GPS receivers are

provided in the Northstar 8800 and 8801 Beacon Receivers Installation

Manual (Northstar Part Number GM635); these receivers include the

Northstar 806, 806X, and Europa GPS navigators; and the Northstar 8000,

8100, 8300, 8700, and 9300 DGPS sensors used with the Northstar 800

and 9000 series navigators. For other receivers, use the Northstar diagrams as a guide, and consult the interfacing diagrams supplied with

your receiver. You can use the 8800 with any brand of GPS receiver that

supports the standard RTCM SC-104 DGPS corrections format.

NOTE:

Some Northstar units may require a software upgrade

for use with the 8800.

Power requirements

• 10 to 40 VDC input voltage

• 5 watts power consumption

• Remote turn-on ability

• 2-amp input fuse

Signal processing

• Two channels

• 283.5 - 325.0 kHz frequency range

• < 2 Hz tuning resolution

• Minimum signal strength: < 5 µV/m @ 100 bps

• > 100 dB dynamic range

• > 50 dB at 1 kHz adjacent channel rejection

• Acquisition time: Five seconds, manual command; 15 seconds, auto-

matic warm start; 15 minutes, automatic cold start (only at first turn

on after installation—time varies, depending on local beacon frequencies)

• Predictive variable-length noise blanker

PAGE 16 05/01/97 REV H

Loading...

Loading...