Page 1

Programmes After Market Services

NHA–3 Series Transceivers

Disassembly &

Troubleshooting

Issue 2 06/98

Page 2

NHA–3

PAMS

Disassembly & Troubleshooting

Technical Documentation

Contents

Disassembly Instructions 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TroubleShooting Section 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Setup 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Chart 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault 1 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Fault 2 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault 1 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Fault 2 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Call Set–up Fault 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Logic Fault 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Earphone Level/Modulation Level Fault 14. . . . . . . . . . . . . . . . . . . . . . .

Display or Keypad Fault 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Call Set–up Fault 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

Issue 2 06/98

Page 3

PAMS

NHA–3

Technical Documentation

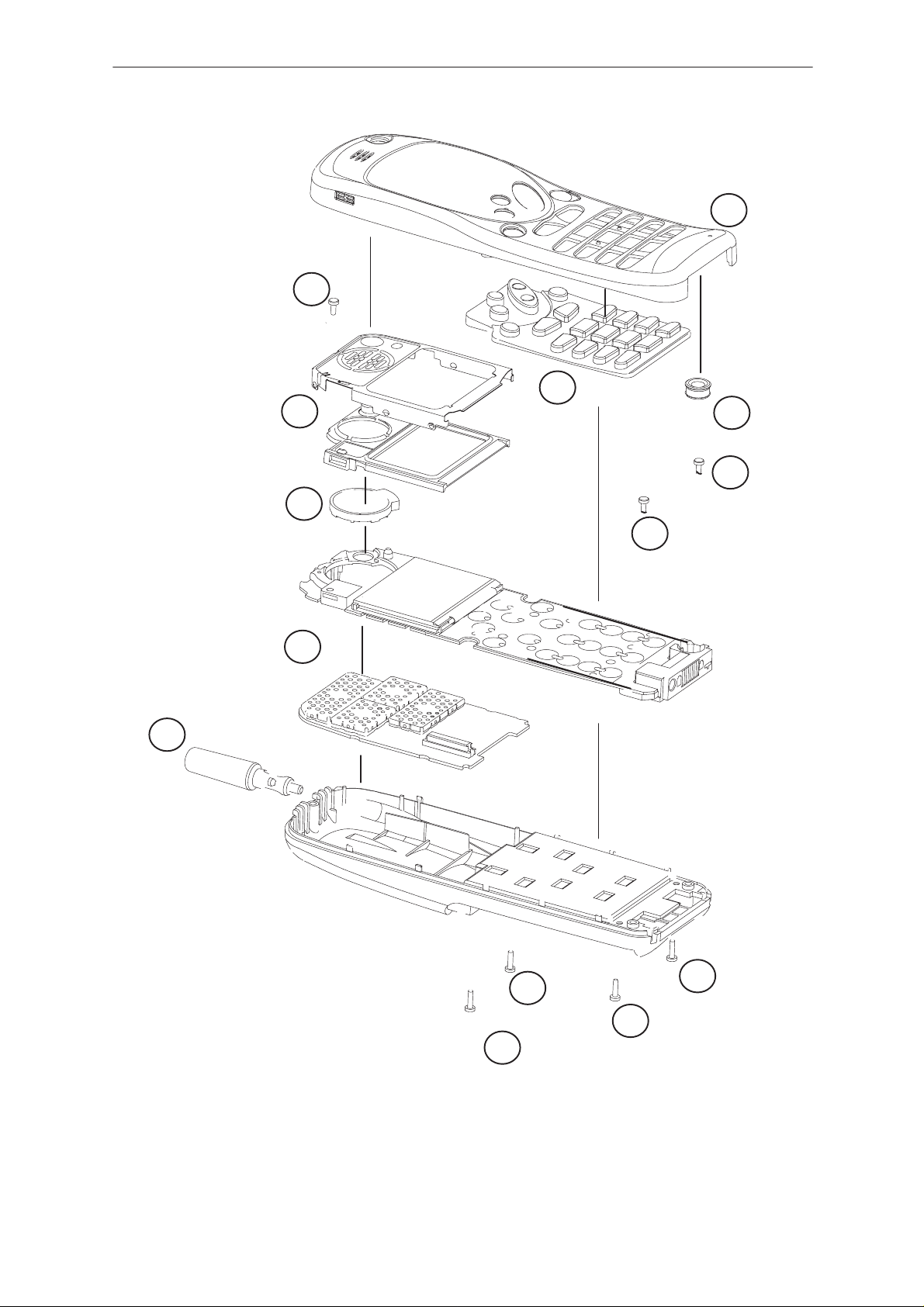

Disassembly Instructions

1. Antenna

Rotate anti–clockwise approximately 90 degrees and remove from top of

phone.

2. A Cover

A. Remove the battery pack (not shown).

B. Remove the four silver Torx screws. (2B)

C. Lift the A cover from the bottom end and it will come off.

D. The keymat is now loose.

3. Microphone

The microphone will now pull out of the system connector.

( Contact is made by two springs.)

4. PCB’s

Disassembly & Troubleshooting

A. Remove the three black Torx screws. (4A)

B. The UI and Engine PCB’s will lift out of the B cover. The PCB’s are held

together by a 44 way connector and can be pulled apart.

5. Engine PCB

The lids of the RF screens are removeable, however, once a lid has been

removed we recommended that you either solder it back to the frame of

the shield or replace it.

6. UI PCB

A. The metal speaker retainer is clipped to the PCB in six positions and

can be removed by easing it from the PCB.

B. The rubber gasket and the speaker are now free to be removed.

Issue 2 06/98

Page 3

Page 4

NHA–3

PAMS

Disassembly & Troubleshooting

4A

6A

6B

Technical Documentation

2C

2D

3

4A

4A

4B

1

2B

2B

Page 4

2B

2B

Issue 2 06/98

Page 5

PAMS

NHA–3

Technical Documentation

Troubleshooting Section

The purpose is to define fault block of the module and then find out the

broken component. The trouble shooting diagram has been planned so

that the fault, whatever it is, can be found by as simple measurements as

possible.

The flow diagrams give you the overview of the blocks. The purpose is

that you proceed through the flow diagram so that, if your answer is YES

for the asked question, go straight to the next level, but if your answer is

NO, you have to go the subbranch.

Required servicing equipment:

– NHA–3 Wintesla Service Software (product code: 8400597)

– Variable Power Supply Unit

– Digital multimeter

– Oscilloscope

Disassembly & Troubleshooting

– H700 Service Accessories

– MJS–2 Test Frame (NMP Part Number 0775095)

– RS232/MBUS adapter

– CMT/Marconi

– RF Spectrum Analyser

– Spectrum Analyser Probe HP85024A (300Khz to 3Ghz, attenuation

10:1)

Equipment Setup

In order for the faultfinding sections to be accurate, the servicing

equipment that is being used must be set to an identical state to when the

measurements were initially carried out. This section contains the settings

for the relevant faultfinding sections.

Issue 2 06/98

Page 5

Page 6

NHA–3

PAMS

Disassembly & Troubleshooting

Notes

Test Analyser Set Up

Generate – RF signal 881.400MHz, level –50dBm, 1KHz Tone – 8Khz deviation Connect

ADS–1 (Rx Audio) to AF Input and measure 1KHz tone (pk to pk)

Wintesla Set Up

Set phone to Local mode.

Set phone to Channel 380.

Audio set up as follows: Ex. Audio – ON

Tx. Audio – ON

Compressor – ON

Expander – ON

PA – ON

Level 2 – Volume Mid, X Mic

Notes T

Test Analyser Set Up

Set Tx Frequency to 836.400Mhz

Reciever Fault 1&2

ransmitter Fault 1&2

Technical Documentation

Wintesla Set Up

Set phone to Local mode.

Set phone to Channel 380.

Turn Tx On.

Page 6

Issue 2 06/98

Page 7

PAMS

NHA–3

Technical Documentation

General Chart

START

Will the phone turn into

Local Mode ?

Is phone Receiver OK?

Is phone transmitting OK?

Yes

Yes

No

No

No

Disassembly & Troubleshooting

Baseband Fault

Go to Receiver

Go to Transmitter Fault 1

Earphone level /

modulation

Is display / keypad

working ?

Call set–up ?

Yes

Yes

Yes

Yes

No

No

No

Earphone level or

modulation fault

Display or keypad fault

Call set–up fault

Issue 2 06/98

END

Page 7

Page 8

NHA–3

PAMS

Disassembly & Troubleshooting

Receiver Fault 1

soldering of

Check

V14

Yes

2.9Volts

Is N203 pin5

Is V14 pin3

Are VRXI

and RXBIAS

( V700/c ) 3.65 V

No

Yes

2.78Volts

Yes

( V700/b ) 2.6 V ?

Check : N203 pin1 =

– loading of Vrx

Vbatt, pin3 = logic1

– if OK, change N203

L8Check V14 pin3

Check :R47, R61,

N5 pin4

2.78Volts

Is ( VCC )

Yes

L5, C87, R51, R55, C93, C99

soldering of N5/pin9 and R63

Check IF demodulator circuit

Technical Documentation

–solderings of N5

– 2nd IF line N5/

Check :

Is there at

–the operation betwee

V11, C96 and C94

– d.c. voltages

– check solderings of Z18

Check :

3–5–10–11

–N5 at different pins

45 MHz ?

C705 – 60dBm

AF signal at

Noise or AF signal

No No No No No

Input to Receiver is –50dBm

*measured with 10:1 divider

Receiver fault

Simplex sens.

Yes

R63 RXAF line

D400/pin46 EarP

Yes

( TX off ) OK?

Earphone

level fault

Yes

No

No

Transmitter

fault

OK ?

TX spectrum

=2.78V

Test point

0.7 – 4.5Volts

RXVCO, middle channel

No

fault 2

Receiver

Yes

Replace duplex

filter Z10

Yes

Injection level

at C82 –20dBm

minimum

No

Check solderings of

G2,R42,C67

and C82

Yes

Is there at

44.55 MHz

N5/pin2 –34dBm

No

Check solderings

of R46,C79, C81, C84

and L6

Check also N5

?

pins 1 and 2.

V701,L3,C96 and C83

Check solderings of Z17

Yes

Is there level

No

Check the operation

No No

at Z17 –75dBm

between the aerial

and Z17

Yes

Yes Yes

C96 –88dBm

Check level at

45 MHz. OK ?

Page 8

Issue 2 06/98

Page 9

PAMS

NHA–3

Technical Documentation

Receiver Fault 2

Receiver fault 1

Check N3

Pin 18

5.2V?

Yes

Are N3

pins 4 and 14

2.7V?

Yes

Control signals

of N3/pins 8, 11, 12

13, 19 ( pin 8 –17dBm*/

14.85 MHz )

OK ?

Disassembly & Troubleshooting

*measured with 10:1 divider

No

No

No

Check NegVClk line

320kHz 3Vp–p

at C108

Check :

R37, R38 and Vrx

Check following lines for connectivity to

CTRLU D300

– N3/SYNDAT pin 12

– N3/SYNCLK pin 11

– N3/SYNDATENX pin 13

– N3/LOCKDET pin 19

Yes

Resistance

between N3/pin 3

and C32 5.6kOhms

Yes

Is RXVCO

oscillating at

C67?

Yes

Is level to

prescaler N3/

pin 6 – 30dBm* ?

Yes

Faulty Synthesiser N3

No

No

No

Fault in loop filter

Check:C30,

R35,C29,R16,C32

Check VCO supply voltage

at C61

Check C67 and C57

Issue 2 06/98

Page 9

Page 10

NHA–3

PAMS

Disassembly & Troubleshooting

Transmitter Fault 1

Baseband problem

No output on PWM

OK

Check soldering of R2/C7

NO

YES

V4 >1 Volt ?

Measure voltage at pin5

<1.5V

OK

Check PA soldering N1

C11/C6/C4 ?

Check soldering

on C20/C23/C5/C2

OK OK

soldering

Check Duplexer

Technical Documentation

NO

re–solder

NO

re–solder

NO

re–solder

Replace N1

if necessary

on N1 and reflow

Check connections

<3V ?

>1.5V

measure voltage at pin8

N1

Vary PAC 300 to 800

YES

>25dBm ?

at antenna clip

Measure O/P Power

YES

Tx Frequency OK

Low output power ?

NO

NO

>3V

NO

>–15dBm

Measure RF @ C14

NO

YES

>–20dBm ?

pin5 on N1 (PA)

Check RF level at

YES

NO

V3/R13/R11

at pin2 V4 >2V

Measure voltage

if not suspect V2

on R67/C14/R8

Check soldering

YES

across R14

1V to 0.6V ?

Measure volt drop

YES

YES

NO

>–20dBm

Measure RF at C18

YES

NO

at C16/C17

>–16dBm ?

Measure RF level

YES

NO

>2.5V <3V

at C9 (PAEN)

Measure voltage

YES

NO

around C9 and fix

Check for S/Circuits

NO

level<2dBm

and replace if output

connections Z7

Check SAW filter

C16/C17

Replace V5

Fault

AMSA/Baseband

mid – mid band

Transmitter Fault

Set Phone to PL2

*measured with 10:1 divider (20dB pad – No Offset in analyser)

Page 10

YES

>650mA ?

No Output power

High Current

YES

Check Frequencies /

levels at J4/J5

J5 = 90MHz >–35dBm ?

J4 = 914 to 939MHz

>–35dBm ?

NO

NO

90MHz OK ?

YES

YES

TX Fault 2

>–25dBm

and level at J3

Check frequency

824MHz to 849MHz

900MHz OK ?

NO

NO

RX Fault 2

Measure volt drop

Pin5 N2 >2.5Volt ?

across R10 >0.1Volt

NO

around mixer N2

replace if necessary

Check connections

Issue 2 06/98

Page 11

Issue 2 06/98

Transmitter fault 1

Transmitter Fault 2

Technical Documentation

PAMS

Resistance between

N3/pin 17 and V7

cathode is about 1.5kOhms

Check d.c.voltages

Yes Yes

VTX at J6 and 2.8V at V5 collector

OK ?

Check the critical

components of VCO :

R25,R34,R39,C21,C56,

C53 and check N3/pin 15. (85–95MHz@

~70mV

Disassembly & Troubleshooting

NoNo

Check VTX regulator V201 and that VTXEN

Fault in loop filter

Page 11

is low

NHA–3

Page 12

Page 12

Call set–up fault

Call Set–up Fault

NHA–3

Disassembly & Troubleshooting

Issue 2 06/98

Will the phone

assume SERV –mode ?

Check:

– the operation of ST signal

– the operation of SAT signal

– the operation of Transmitter

– the operation of TXI line

– the operation of Synthesizer

– the operation of VCO

– if OK, change N2

Yes

No

Subscriber

data OK ?

RSSI

operative ?

Data detection

of N2 operative ?

Yes

Yes

Yes

No

No

No

If the reprogramming

impossible, check D2

control lines and

solder joints.

Check N700/12/RSSI line

and the operation of

D1 A/D converters ( pins 78–85 ).

Inspect the signal path from

N700/pin 9 DAF to N2/ pin27.

Check also other lines

from N2.

Technical Documentation

Replace N2.

PAMS

Page 13

Issue 2 06/98

CONDTIONS ASSUMED:

VBATT = 3.6V

VCH = 6V

Logic fault

Power drops off or

does power up at all

OK with power key

but doesn’t wake up

with Charger?

Check clock

signal of D400 pin95

0.8 Vpp/14.85 MHz

When power key pressed

Check :

VCH at N200pin1 =6V?

R200,R201,R202

D400pin74 =1.2V?

D300pin65 = 1.2V?

C300

D301,R388,R389

VL (N201 pin 5)

Check:

– soldering of G1

NO

– C50. R418

– N3 pin 8 loading

– if OK, change G1

2.9V?

NO

Check :

–N201pin3 = 3.6V?

–N201 / N202 soldering

–C206 OK?

= VBATT OK?

VRX (N203 pin 5)

2.9V?

YES

VCTCXO (G1) VDD

2.9V +/–0.1?

Logic Fault

Check :

NOYES

– LowbattRSTX (D400pin2) = 2.9V

– Regen (N203pin3) = 2.9V

– OnRstX (D400pin3) = 2.9V

– PwrKeyX (D400pin73) = 0 when power key press

– VRX current loading

– If Ok change N203

NOYES

Check :

– R17/C24 components

Technical Documentation

PAMS

Page 13

YES

Is BBRstX = 0

at D300pin48

YES

Check AMSA PLL Functions:

– D400pin96 =2.9V (also R408/C409)

– R401, C402,C403.

– D400pins 92/93

– D400 supply VL/VA pins

NO

approx 8mA

How long is phone current

Drawn for after power key press?

approx 3–4mA for 16secs?

NO MCU control of AMSA: Check:

– D300 VL/GND pins

– D300 Mode pins 44,45,47,49 = 2.9V

– 4.8MHz clock at D300pin51

– MCU/AMSA communication: D7:0,A5:0,CS,RdX,Wr,X

.

for <500mS

MCU function OK. check:

– INTX signal OK? (D300pin70)

– Battmon AD. D300pin66 = 1.45V?

– Row lines OK? (D400pins 14;18)

– soldering of D301,R388,R389

Disassembly & Troubleshooting

NHA–3

Page 14

NHA–3

PAMS

Disassembly & Troubleshooting

Earphone Level/Modulation Level Fault

TEST CONDITIONS:

Using Wintesla audio testing window:–

– voice modulation 2.9 kHz

– XMIC line 31mVrms / 1kHz

– VDTRIM = 8

– VOLUME = 8

– Compressor and expander enabled

D400pin58

XMIC

D400pin71

TXO (TxMOD)

Technical Documentation

ST 678mVpp

88mVpp

(31mVrms) (87mVrms)

C400

RXAF

184mVpp

(65mVrms) (171mVrms)

246mVpp

843mVpp

D400pin77

RXgain

SAT 170mVpp

D400pin49

HEAR

117mVpp

(41mVrms)

Page 14

Issue 2 06/98

Page 15

PAMS

NHA–3

Technical Documentation

Display or Keypad Fault

UI PCB FAULT IDENTIFIED

Display or keypad fault

No

Display OK ?

Yes

Check display module

bonding

Display OK ?

Yes

Disassembly & Troubleshooting

Check:

– X500 pin 33 (VBB)

– LCDCLK 160kHz?

– LCDRstX = logic 1?

No

– LCD serial comunication signals:

LCDEnX, LCDDC, LDCSDCLK, LCDSDA

– Contrast setting resistors R612 / R613

– C600 to C607

Lights OK ?

Yes

Keypad

Problem

Pulses on

COL3:0

after key pressed

Yes

ROW 0–4 should be normally 2.9V

Pulsing to 0V with

corresponding key depressed.

Check those lines.

No No

No

X500 pins 40,41

light0/1

>2.7V with

lights on

Yes

Check the operation of

switches V601, V602, V603

Check COL 0–3 lines from D400.

R600, R601, R602, R603, R604

Check:

engine module D300pins 35,36

and X200 pins40/41

Issue 2 06/98

Page 15

Page 16

Page 16

Call set–up fault

Call Set–up Fault

NHA–3

Disassembly & Troubleshooting

Issue 2 06/98

Will the phone

assume SERV –mode ?

Yes

Check:

– the operation of ST signal

– the operation of SAT signal

– the operation of Transmitter

– the operation of Synthesizer

– the operation of UHF and 90MHz VCOs

– Check AFC function / Tx frequency error (no AFC)

No

Subscriber

data OK ?

Yes

RSSI

operative ?

Yes

RX data OK on D400pin77?

Yes

No

No

No

If the reprogramming

impossible, check EEPROM (D301)

control lines and

solder joints.

Check N5 pin12 RSSI line

and the operation of

D300 ADC (pin60)

Technical Documentation

Inspect the signal path from

N5 pin9 RXAF to D400pin77 (RXgain)

Replace D400

PAMS

Loading...

Loading...