Nissan Pathfinder 2003 User Manual

GI

FRONT & REAR SUSPENSION

MA

EM

CONTENTS

FRONT SUSPENSION ....................................................3

Precautions..................................................................3

PRECAUTIONS

Preparation ..................................................................3

SPECIAL SERVICE TOOLS

COMMERCIAL SERVICE TOOLS

Noise, Vibration and Harshness (NVH)

Troubleshooting...........................................................4

NVH TROUBLESHOOTING CHART

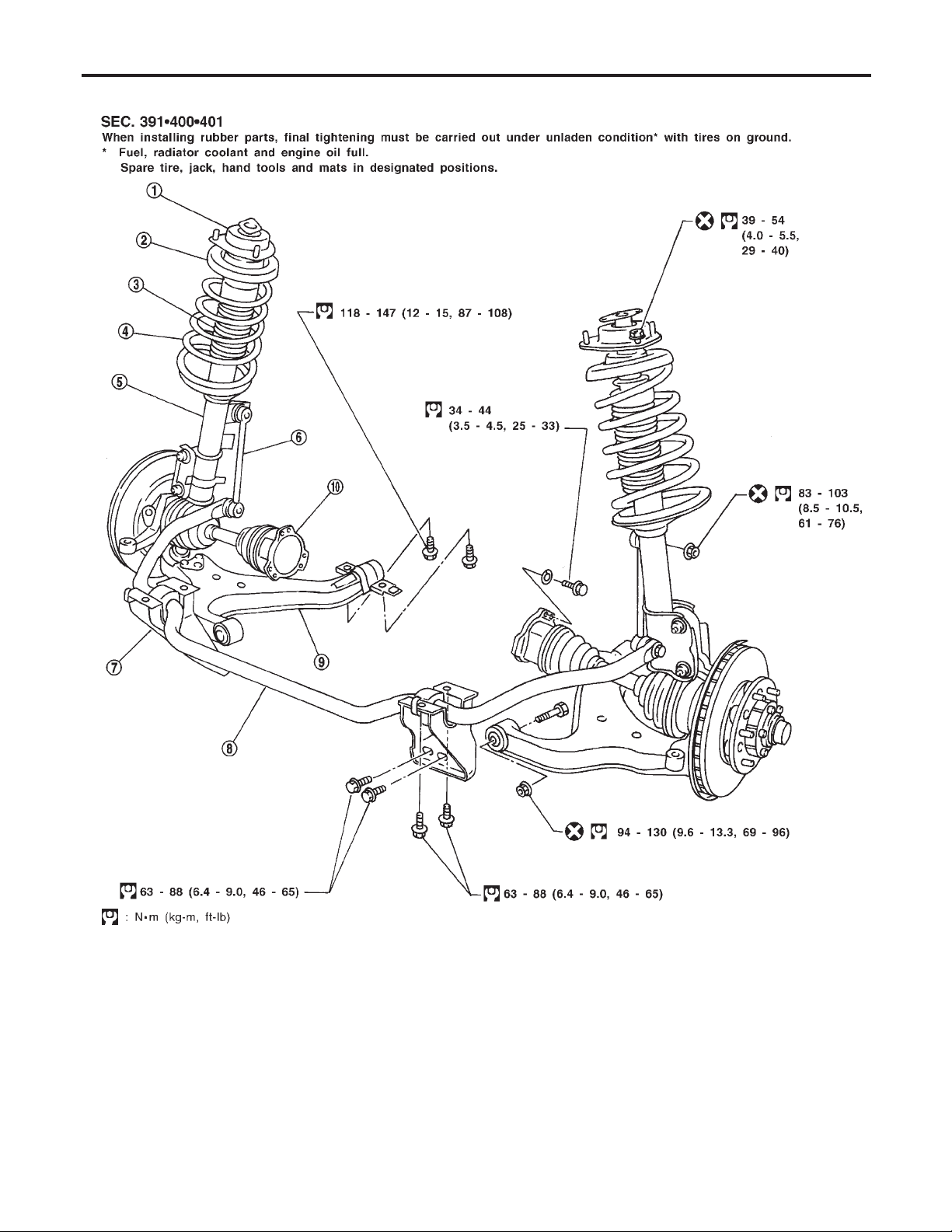

Components.................................................................5

.........................................................................5

2WD

.........................................................................6

4WD

On-vehicle Service.......................................................7

FRONT SUSPENSION PARTS

FRONT WHEEL ALIGNMENT

Coil Spring and Strut Assembly.................................10

COMPONENTS

REMOVAL

DISASSEMBLY

INSPECTION

ASSEMBLY

Stabilizer Bar .............................................................13

REMOVAL AND INSTALLATION

INSPECTION

Transverse Link and Lower Ball Joint.......................14

REMOVAL AND INSTALLATION

INSPECTION

Low Tire Pressure Warning System..........................16

SYSTEM COMPONENTS

SYSTEM DESCRIPTION

Trouble Diagnoses.....................................................18

WIRING DIAGRAM

LOW TIRE PRESSURE WARNING CONTROL

UNIT INPUT/OUTPUT SIGNAL STANDARD

ID REGISTRATION PROCEDURE

SELF-DIAGNOSIS

HOW TO PERFORM TROUBLE DIAGNOSIS FOR

QUICK AND ACCURATE REPAIR

PRELIMINARY CHECK

MALFUNCTION CODE/SYMPTOM CHART

Trouble Diagnoses for Self-diagnostic Items.............27

.........................................................3

........................................3

................................3

............................4

...................................7

.....................................8

.......................................................10

...............................................................12

........................................................12

...........................................................12

.............................................................13

...............................13

...........................................................14

...............................14

...........................................................15

.........................................16

..........................................16

..................................................18

..............20

............................20

...................................................23

.............................25

............................................26

...............27

SECTION

INSPECTION 1: TRANSMITTER OR TIRE

PRESSURE WARNING CONTROL UNIT

INSPECTION 2: TRANSMITTER-1

INSPECTION 3: TRANSMITTER-2

INSPECTION 4: LOW TIRE PRESSURE

WARNING CONTROL UNIT

Trouble Diagnoses for Symptoms.............................30

INSPECTION 1: WARNING LAMP DOES NOT

COME ON WHEN IGNITION SWITCH IS TURNED

.........................................................................30

ON.

INSPECTION 2: WARNING LAMP STAYS ON

WHEN IGNITION SWITCH IS TURNED ON.

INSPECTION 3: WARNING LAMP BLINKS WHEN

IGNITION SWITCH IS TURNED ON.

INSPECTION 4: TAIL LAMP BLINKS WHEN

IGNITION SWITCH IS TURNED ON.

INSPECTION 5: ID REGISTRATION CANNOT BE

COMPLETED.

Service Data and Specifications (SDS).....................34

GENERAL SPECIFICATIONS (FRONT)

WHEEL ALIGNMENT (UNLADEN*1)

LOWER BALL JOINT

WHEELARCH HEIGHT (UNLADEN*)

WHEEL RUNOUT AVERAGE*

REAR SUSPENSION.....................................................37

Precautions................................................................37

PRECAUTIONS

Preparation ................................................................37

COMMERCIAL SERVICE TOOLS

Noise, Vibration and Harshness (NVH)

Troubleshooting.........................................................37

Components...............................................................38

On-vehicle Service.....................................................38

REAR SUSPENSION PARTS

Removal and Installation...........................................39

Coil Spring and Shock Absorber ...............................40

COMPONENTS

REMOVAL AND INSTALLATION

INSPECTION

Upper Link, Lower Link and Panhard Rod................41

INSPECTION

.........................................................34

.......................................................37

.......................................................40

...........................................................41

...........................................................41

SU

...................27

............................28

............................29

......................................29

..............31

.........................33

.........................34

.....................34

..........................34

...............................................35

.........................35

..................................36

..............................37

...................................38

...............................41

LC

EC

FE

CL

MT

AT

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS (Cont’d)

BUSHING REPLACEMENT

INSTALLATION

Stabilizer Bar .............................................................42

REMOVAL AND INSTALLATION

........................................................42

.......................................41

...............................42

Low Tire Pressure Warning System..........................42

Service Data and Specifications (SDS).....................43

GENERAL SPECIFICATIONS (REAR)

.......................43

SU-2

FRONT SUSPENSION

Precautions

Precautions

PRECAUTIONS

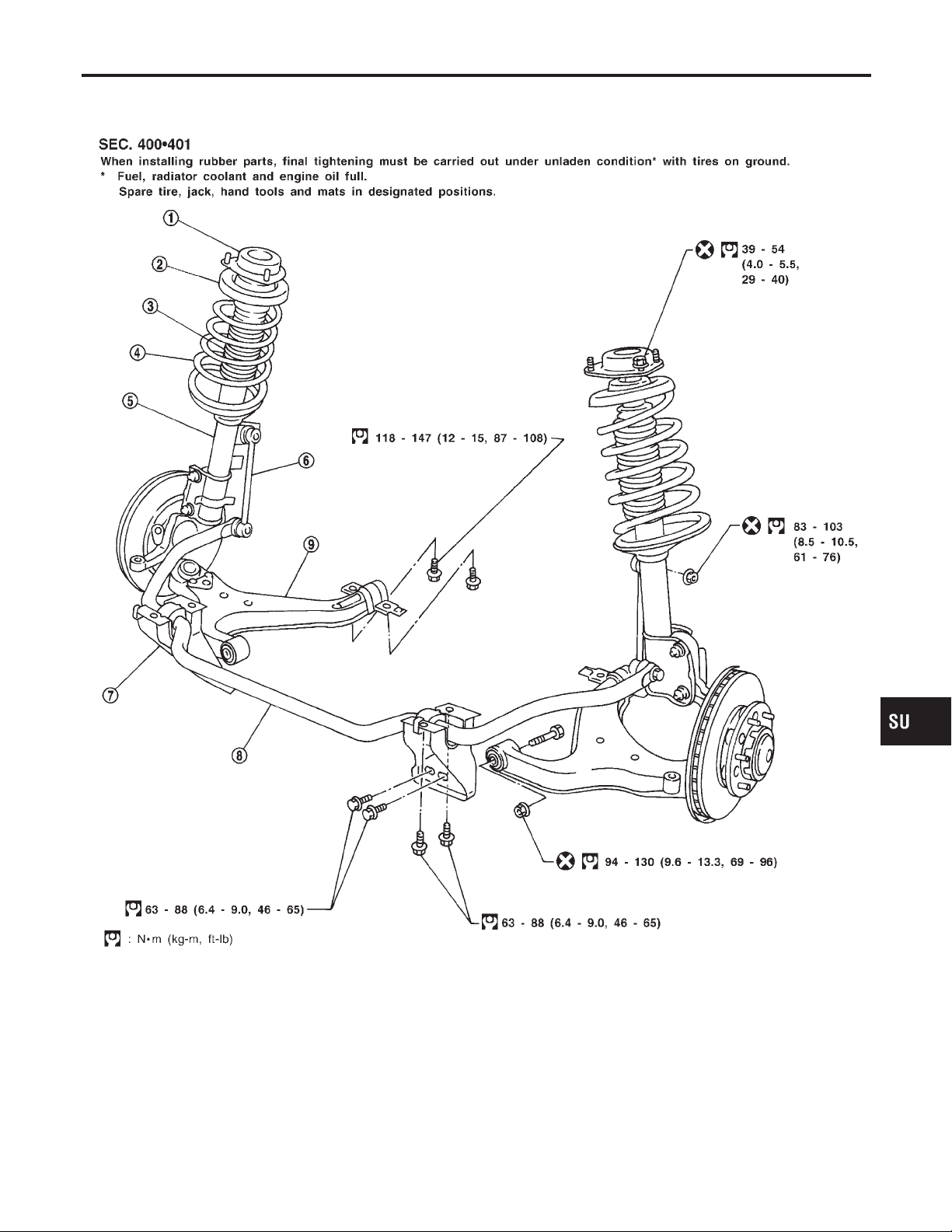

I When installing rubber parts, final tightening must be car-

ried out under unladen condition* with tires on ground.

*Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

I Use flare nut wrench when removing and installing brake

tubes.

I After installing removed suspension parts, check wheel

SBR686C

alignment and adjust if necessary.

I Always torque brake lines when installing.

Preparation

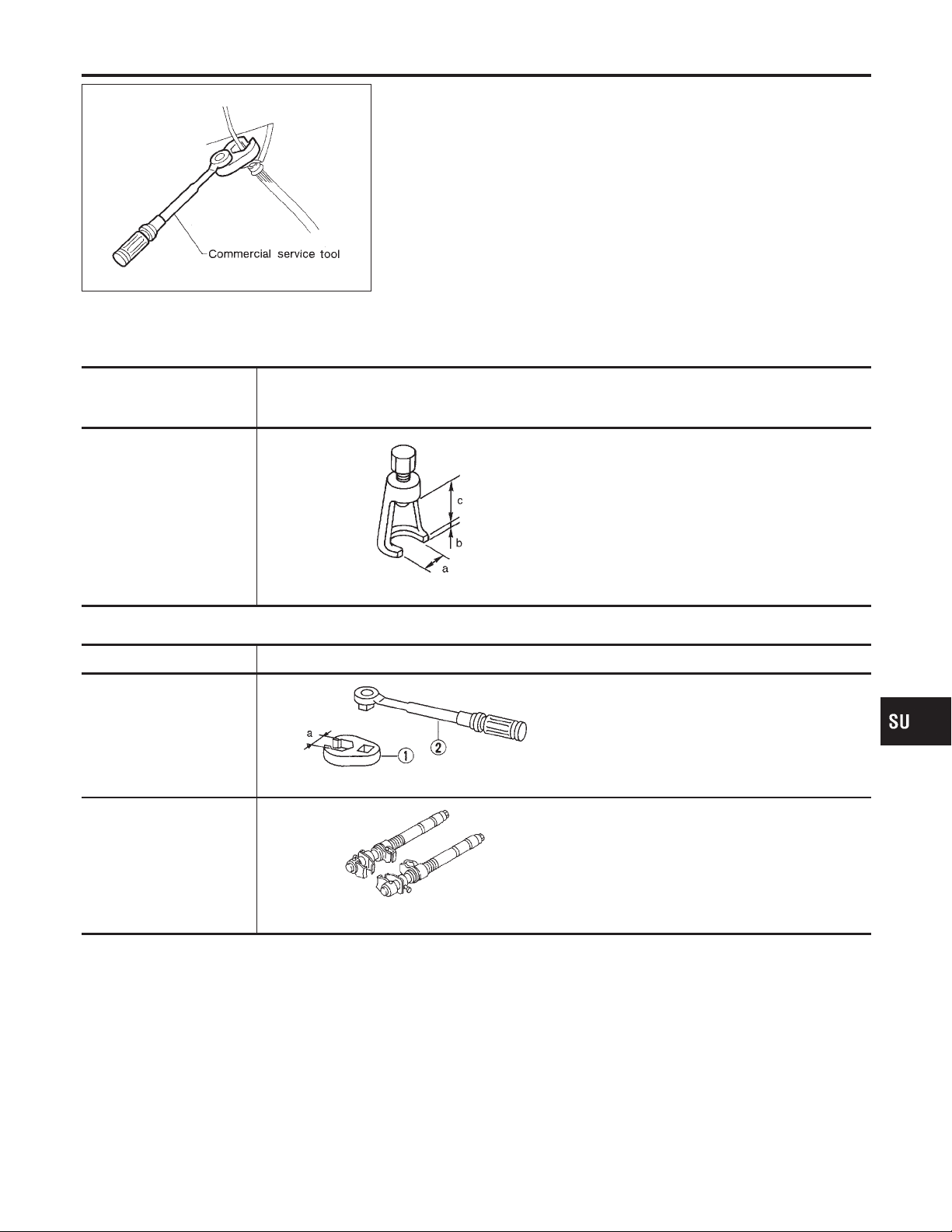

SPECIAL SERVICE TOOLS

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool name

ST29020001

(J24319-01)

Ball joint remover

Description

Removing tie-rod outer end and lower ball joint

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

GI

NASU0001

MA

EM

LC

EC

NASU0002

FE

CL

MT

AT

NT694

COMMERCIAL SERVICE TOOLS

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Spring compressor

NT717

TF

PD

NASU0003

AX

Removing and installing each brake piping

a: 10 mm (0.39 in)

BR

Removing and installing coil spring

ST

RS

BT

HA

SU-3

SC

EL

IDX

FRONT SUSPENSION

Noise, Vibration and Harshness (NVH) Troubleshooting

Noise, Vibration and Harshness (NVH)

Troubleshooting

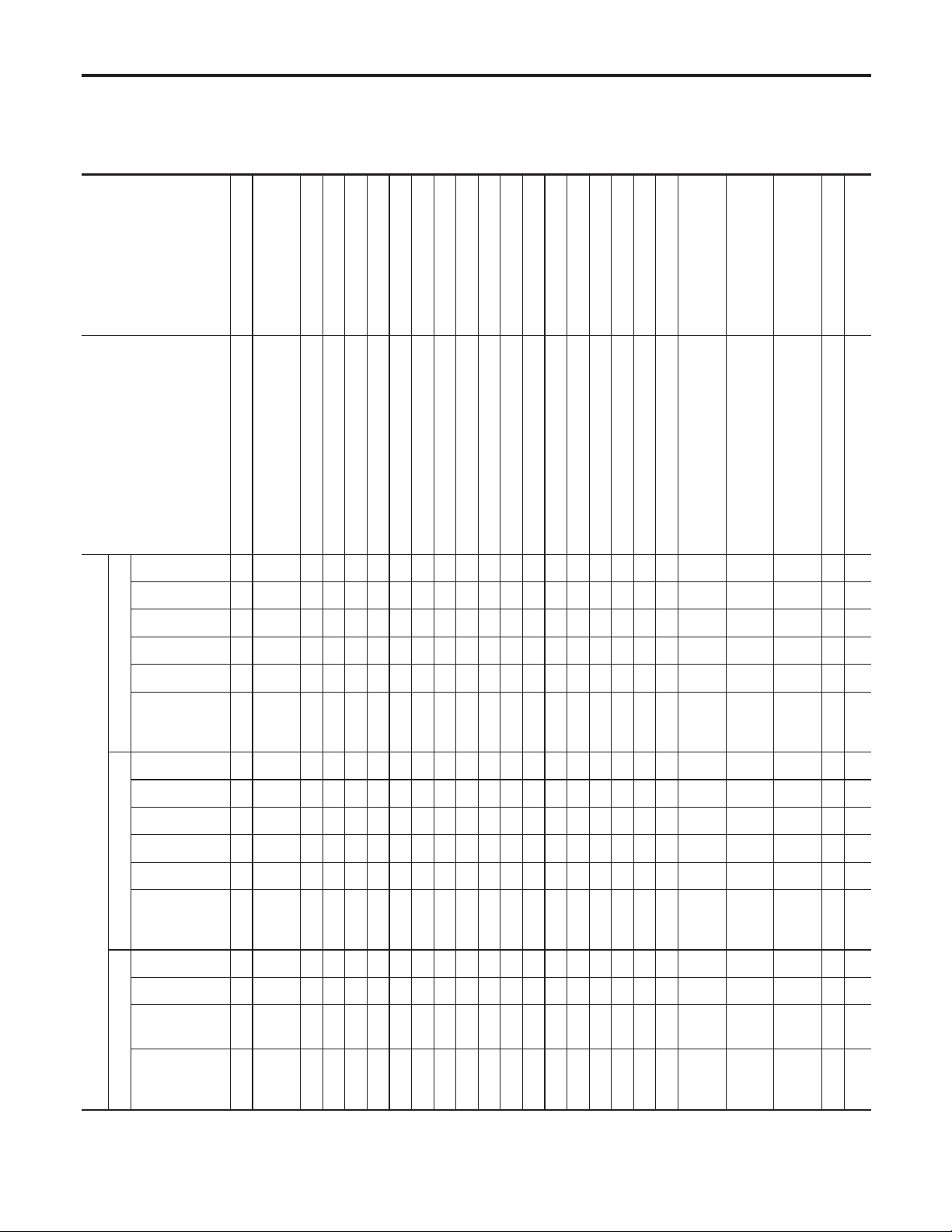

NVH TROUBLESHOOTING CHART

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

=NASU0035

NASU0035S01

Reference page

SU-5, 38

Possible Cause and

SUSPECTED PARTS

Improper installation, looseness

Noise × × ×××× ×××× × × ××

Shake ×××× × × ×× × ×××

Vibration × × ××× × ×× × ×

Shimmy ×××× × × × ×××

Judder ××× × × ×××

SUSPENSION

Poor quality

ride or handling

× × ××× ×× × × ×

—

SU-10, 40

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

—

—

SU-10, 40

Parts interference

Spring fatigue

Suspension looseness

SU-8

Incorrect wheel alignment

SU-8

SU-13, 42

Stabilizer bar fatigue

Out-of-round

—

———

Imbalance

Incorrect air pressure

Uneven tire wear

—

—

Deformation or damage

Non-uniformity

Incorrect tire size

AX-3

PD-4

PD-4

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AX-3

in this chart.

Refer to SUSPENSION

AXLE

SUSPENSION

in this chart.

Refer to TIRES

TIRES

in this chart.

Refer to ROAD WHEEL

ROAD WHEEL

ST-6

BR-7

BRAKES

STEERING

Noise × ЧЧЧЧЧЧ ×××× × × ××

Shake × ЧЧЧЧЧ ×× ×× × × ××

Vibration ×××××× ×

Shimmy × ЧЧЧЧЧЧЧ × × × ××

Symptom

TIRES

Judder × ЧЧЧЧЧ × × × × ××

Poor quality

ride or handling

Noise × ×× × ×××× × × ××

Shake × ×× × × ×× × × ××

Shimmy, Jud-

der

Poor quality

ROAD WHEEL

ride or handling

×: Applicable

× ЧЧЧЧЧ × × × ×

×××××××××

×××××××

SU-4

FRONT SUSPENSION

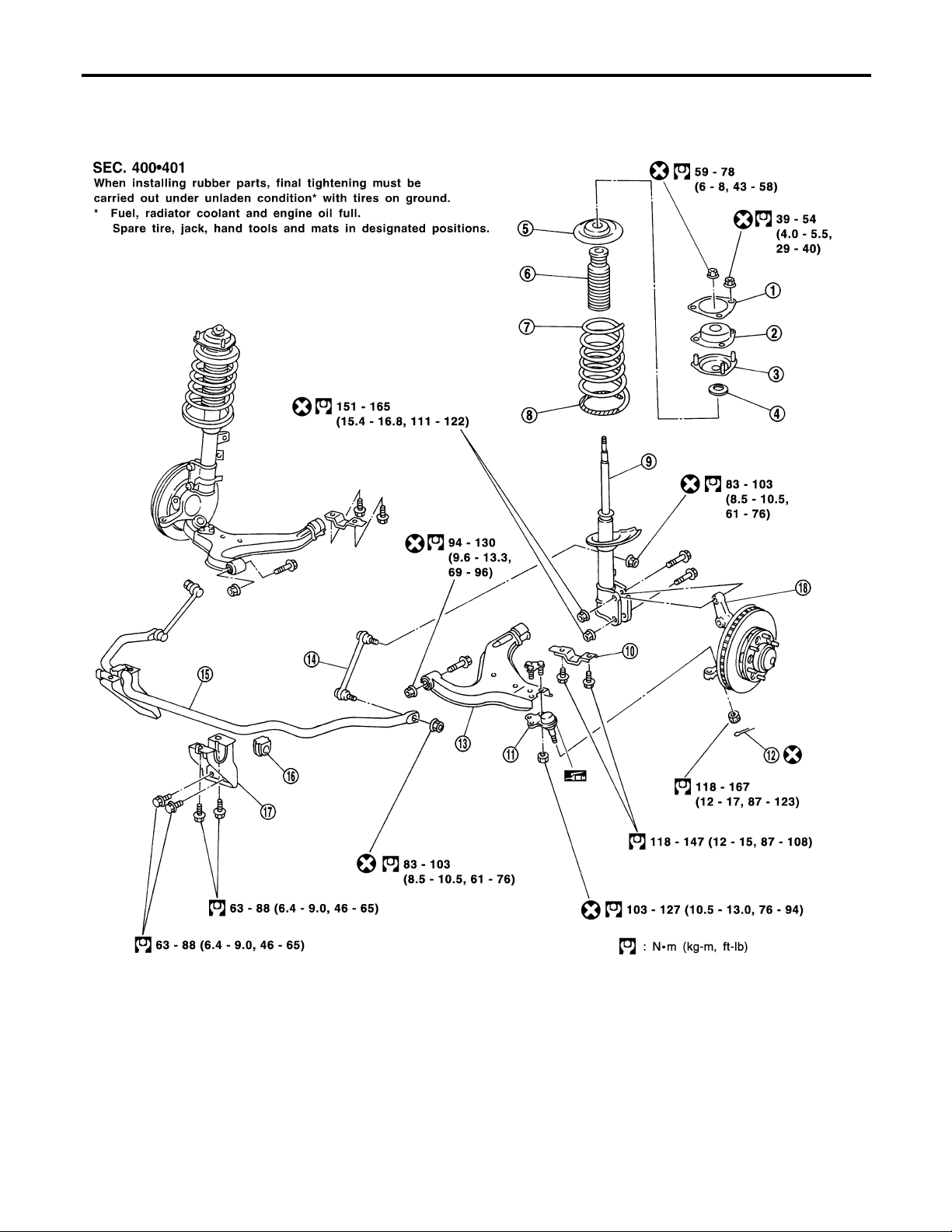

Components

2WD

Components

NASU0004

NASU0004S01

GI

MA

EM

LC

EC

FE

CL

MT

AT

1. Strut mounting insulator

2. Spring upper seat

3. Bound bumper

4. Coil spring

5. Strut assembly

6. Stabilizer connecting rod

7. Bracket

8. Stabilizer bar

9. Transverse link

SFA743B

TF

PD

AX

BR

ST

RS

BT

HA

SU-5

SC

EL

IDX

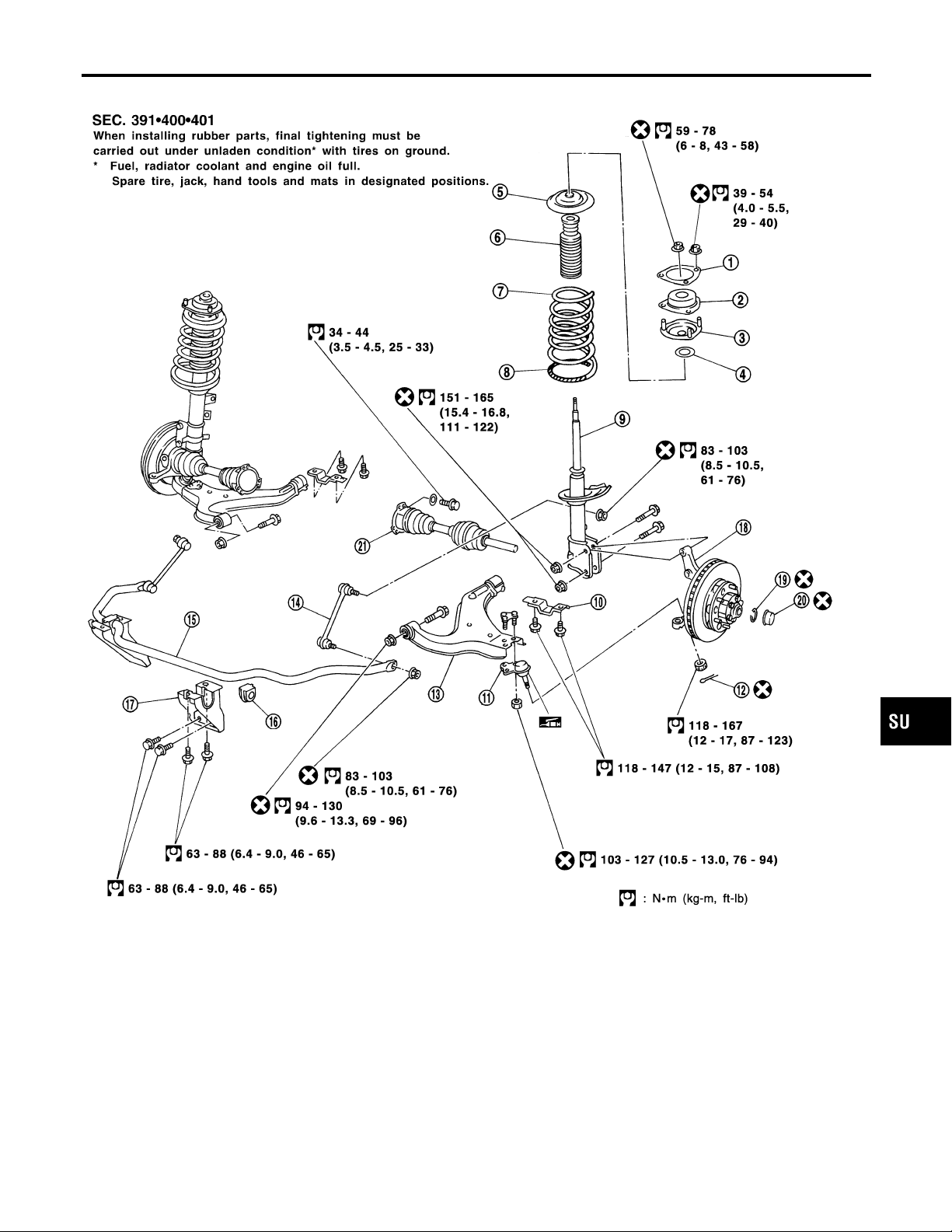

Components (Cont’d)

FRONT SUSPENSION

4WD

NASU0004S02

1. Strut mounting insulator

2. Spring upper seat

3. Bound bumper

4. Coil spring

5. Strut assembly

6. Stabilizer connecting rod

7. Bracket

SU-6

SFA744B

8. Stabilizer bar

9. Transverse link

10. Drive shaft

FRONT SUSPENSION

On-vehicle Service

SMA525A

SFA392B

On-vehicle Service

FRONT SUSPENSION PARTS

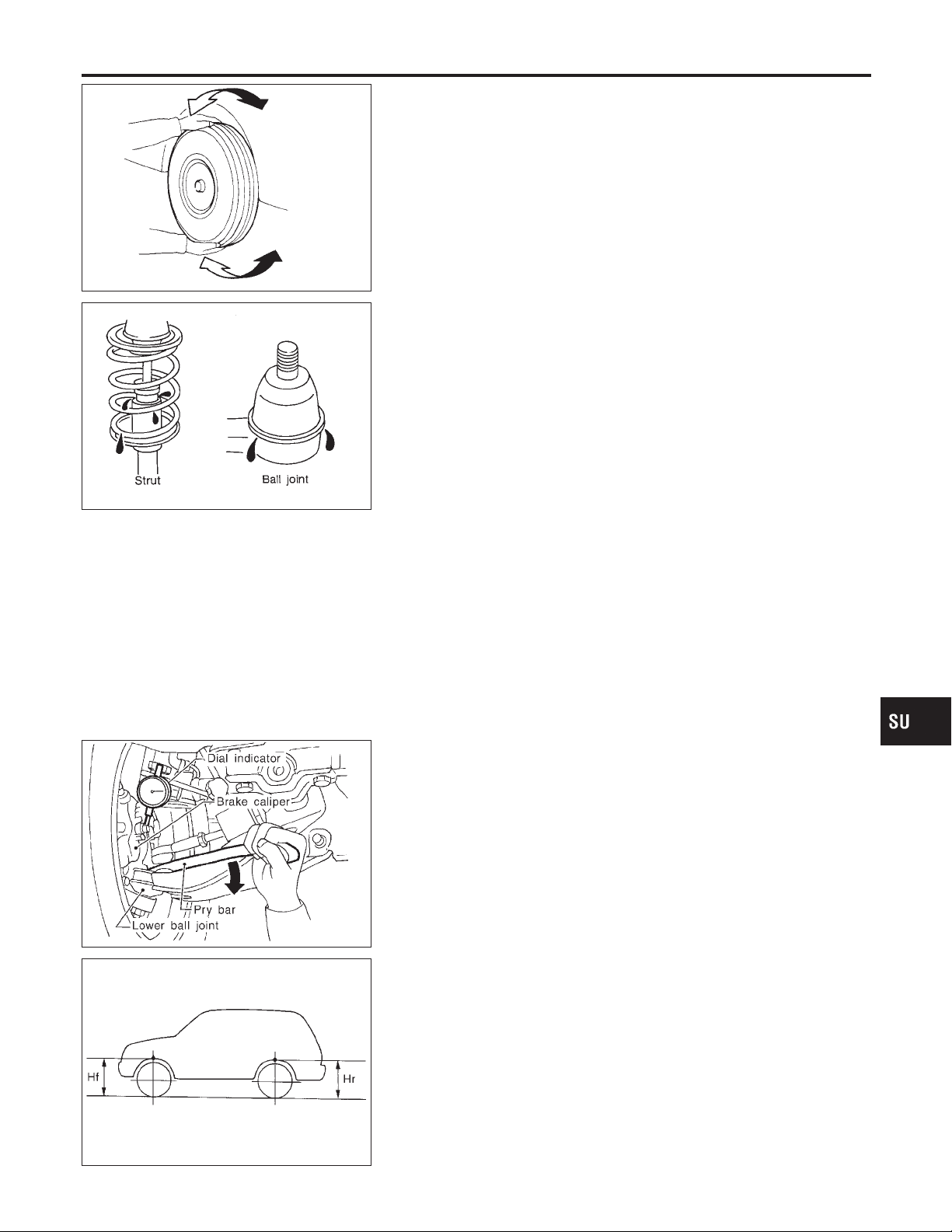

Check front axle and front suspension parts for excessive play,

cracks, wear and other damage.

1. Shake each front wheel to check for excessive play.

2. Retighten all axle and suspensions nuts and bolts to the specified torque.

Tightening torque:

Refer to “Components”, SU-10.

3. Check strut (shock absorber) for oil leakage and other damage.

4. Check suspension ball joint for grease leakage and ball joint

dust cover for cracks and other damage.

If ball joint dust cover is cracked or damaged, replace ball joint

assembly.

5. Check suspension ball joint end play.

a. Jack up front of vehicle and set the stands.

b. Clamp dial indicator onto transverse link and place indicator tip

on lower edge of brake caliper.

c. Make sure front wheels are straight and brake pedal is

depressed.

NASU0005

GI

MA

EM

LC

EC

FE

CL

MT

AT

SFA745B

SFA746B

d. Place a pry bar between transverse link and knuckle.

e. While raising and releasing pry bar, observe maximum dial

indicator value.

Vertical end play:

0mm(0in)

If ball joint vertical end play exists, remove lower ball joint

assembly and recheck the ball joint. Refer to “Tranverse Link

and Lower Ball Joint”, SU-14.

6. Check spring height from top of wheelarch to ground using the

following procedure.

a. Park vehicle on a level surface with vehicle unladen*.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

b. Check tires for proper inflation and wear (tread wear indicator

must not be showing).

c. Bounce vehicle up and down several times and measure

dimensions Hf and Hr. Refer to SDS, SU-35.

Spring height is not adjustable. If out of specification, check for

worn springs and suspension parts.

TF

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

SU-7

On-vehicle Service (Cont’d)

FRONT SUSPENSION

SFA975B

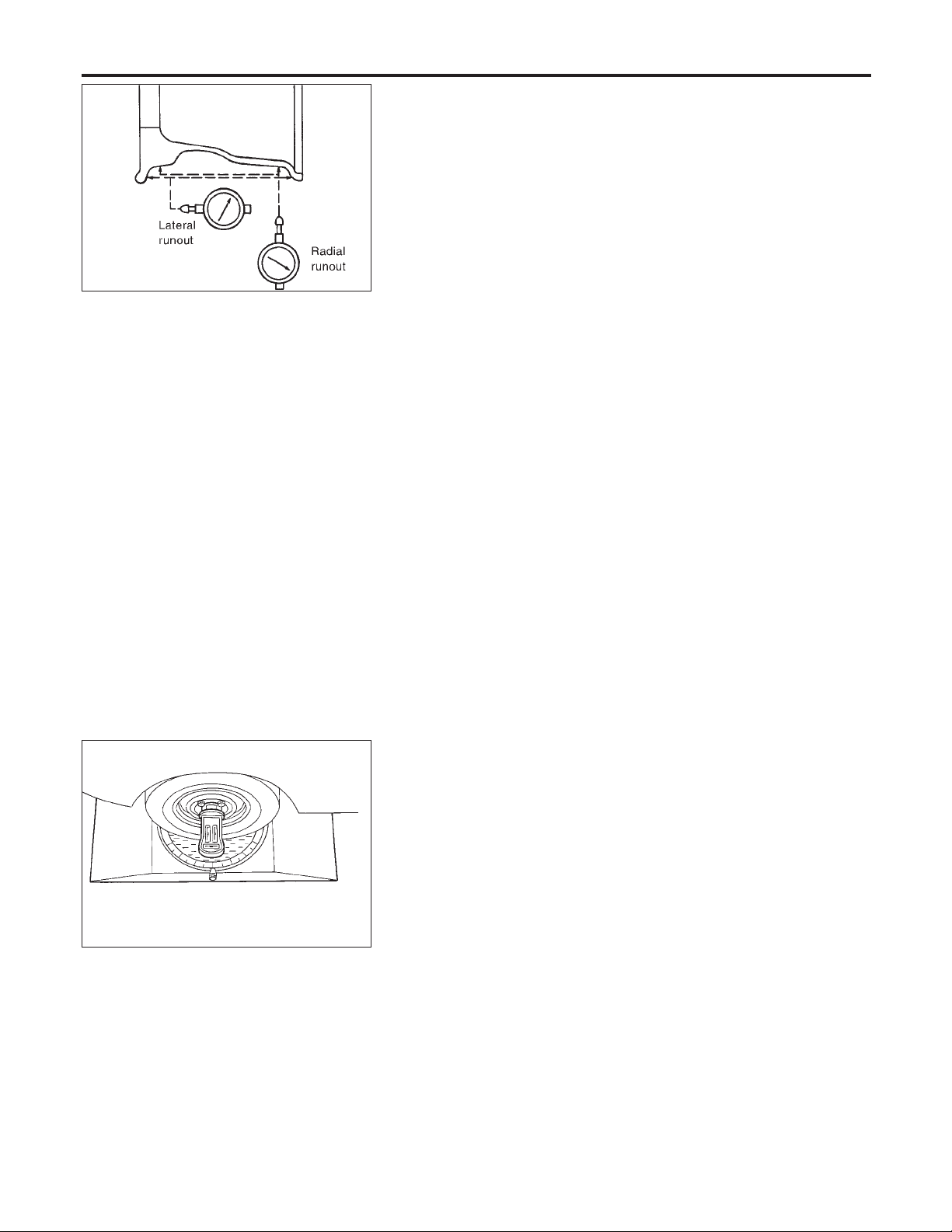

FRONT WHEEL ALIGNMENT

NASU0006

Before checking front wheel alignment, be sure to make a preliminary inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

Preliminary Inspection

NASU0006S01

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage.

If deformed, remove wheel and check wheel runout.

NOTE:

Measure both the inner and outer sides for the radial runout and

lateral runout, and confirm the figures are within the standards.

Wheel runout (Dial indicator value):

Refer to SDS, SU-36.

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

SFA894

Camber, Caster and Kingpin Inclination

NASU0006S02

Camber, caster and kingpin inclination are preset at factory

and cannot be adjusted.

1. Measure camber, caster and kingpin inclination of both right

and left wheels with a suitable alignment gauge.

Camber, Caster and Kingpin inclination:

Refer to SDS, SU-34.

2. If camber, caster or kingpin inclination is not within

specification, inspect front suspension parts. Replace damaged or worn out parts.

SU-8

FRONT SUSPENSION

On-vehicle Service (Cont’d)

SFA614B

SFA234AC

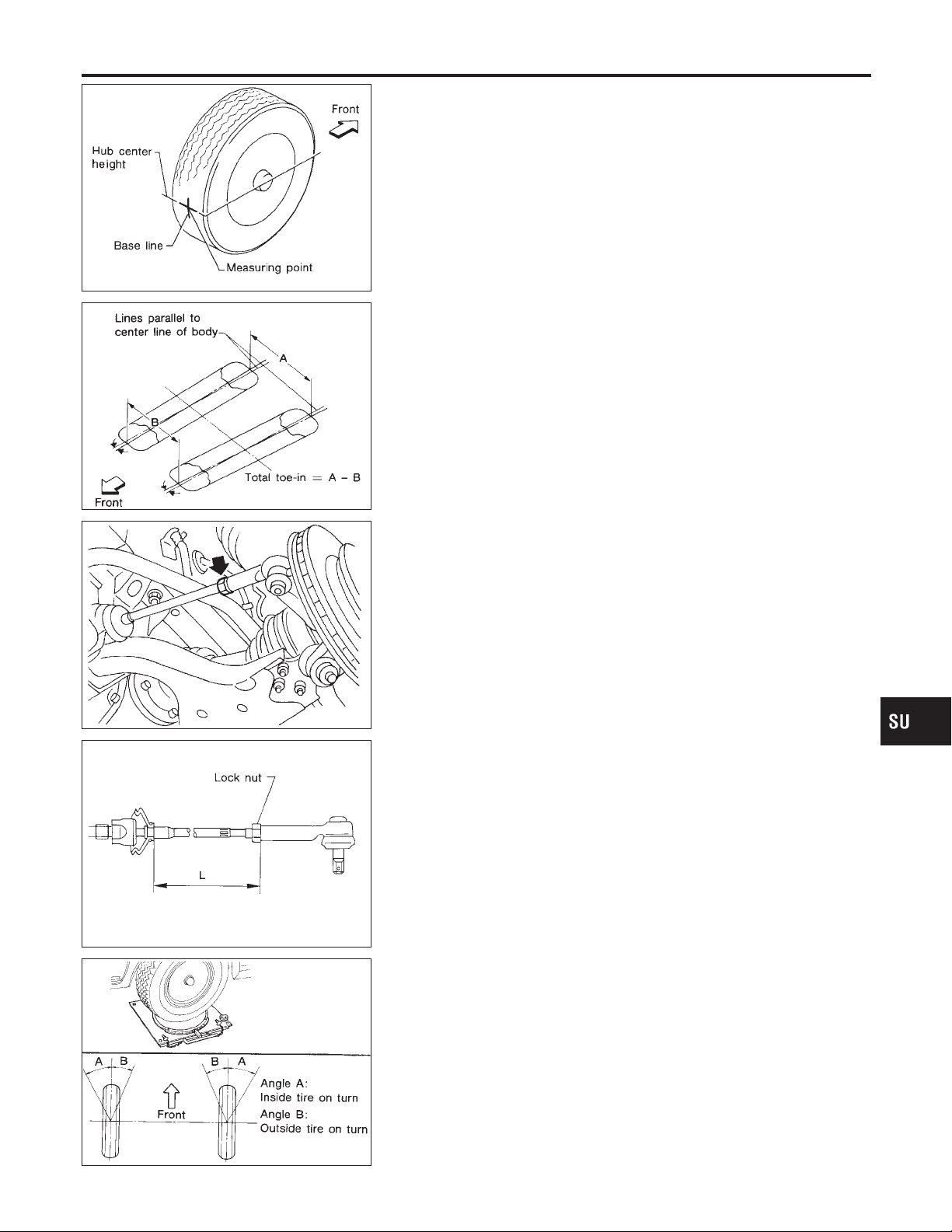

Toe-in

Measure toe-in using the following procedure.

WARNING:

I Always perform the following procedure on a flat surface.

I Make sure that no person is in front of the vehicle before

pushing it.

1. Bounce front of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at

the same height of hub center. This mark is a measuring point.

4. Measure distance “A” (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180

degrees (1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try

the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance “B” (front side).

Total toe-in:

Refer to SDS, SU-34.

7. Adjust toe-in by varying the length of steering tie-rods.

a. Loosen lock nuts.

b. Adjust toe-in by screwing tie-rods in and out.

NASU0006S03

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

SFA749B

SFA486A

SFA439BA

Make sure both tie-rods are the same length.

Standard length “L”:

Refer to ST-33, “Steering Gear and Linkage”.

c. Tighten lock nuts to specified torque.

Lock nut tightening torque:

RefertoST-18,“POWERSTEERINGGEAR AND LINKAGE”.

Front Wheel Turning Angle

Turning angle is set by stroke length of steering gear rack and

cannot be adjusted.

1. Set wheels in straight-ahead position. Then move vehicle forward until front wheels rest on turning radius gauge properly.

2. Rotate steering wheel all the way right and left; measure turning angle.

Do not hold the steering wheel on full lock for more than 15

seconds.

Wheel turning angle (Full turn):

Refer to SDS, SU-34.

NASU0006S04

PD

AX

BR

ST

RS

BT

HA

SC

EL

IDX

SU-9

Coil Spring and Strut Assembly

COMPONENTS

2WD

FRONT SUSPENSION

Coil Spring and Strut Assembly

NASU0007

NASU0007S01

1. Spacer

2. Strut mounting insulator

3. Bracket

4. Strut mounting bearing

5. Spring upper seat

6. Bound bumper

7. Coil spring

8. (Polyurethane tube)

9. Strut assembly

10. Bracket

11. Lower ball joint assembly

12. Cotter pin

SU-10

SSU052

13. Transverse link

14. Stabilizer connecting rod

15. Stabilizer bar

16. Bushing

17. Bracket

18. Knuckle spindle

FRONT SUSPENSION

Coil Spring and Strut Assembly (Cont’d)

4WD

NASU0007S02

GI

MA

EM

LC

EC

FE

CL

MT

AT

1. Spacer

2. Strut mounting insulator

3. Bracket

4. Strut mounting bearing

5. Spring upper seat

6. Bound bumper

7. Coil spring

8. (Polyurethane tube)

9. Strut assembly

10. Bracket

11. Lower ball joint assembly

12. Cotter pin

13. Transverse link

14. Stabilizer connecting rod

15. Stabilizer bar

16. Bushing

17. Bracket

18. Knuckle spindle

19. Snap ring

20. Hub cap

21. Drive shaft

TF

PD

AX

BR

ST

RS

SSU053

BT

HA

SC

SU-11

EL

IDX

Coil Spring and Strut Assembly (Cont’d)

FRONT SUSPENSION

SFA956A

SSU002

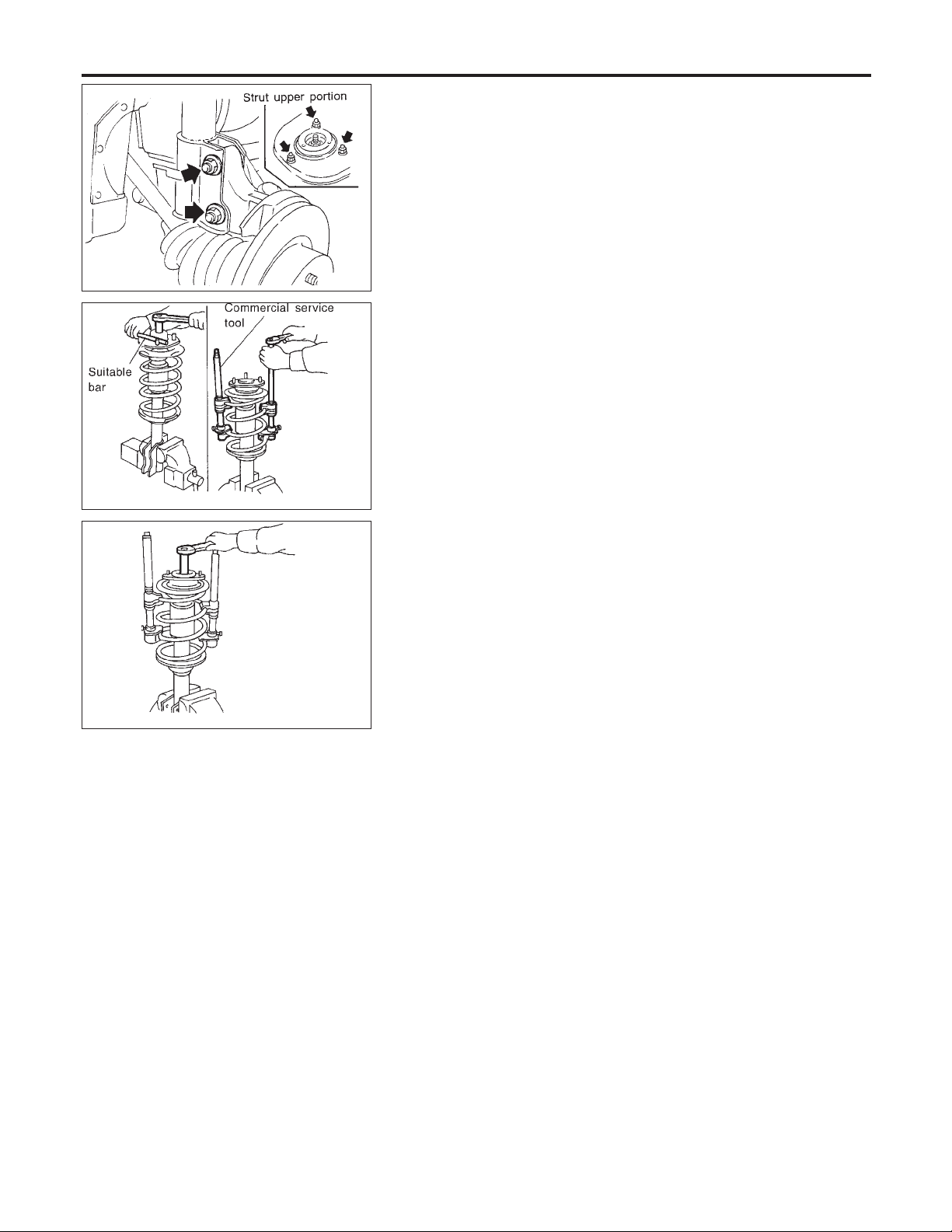

REMOVAL

NASU0008

1. Remove stabilizer connecting rod.

2. Remove strut assembly fixing bolts and nuts (to hood-ledge).

Do not remove piston rod lock nut on vehicle.

DISASSEMBLY

NASU0009

1. Set strut assembly on vise, then loosen piston rod lock nut.

WARNING:

Do not remove piston rod lock nut at this time.

2. Compress spring with tool so that the strut mounting insulator

can be turned by hand.

WARNING:

Make sure that the pawls of the two spring compressors are

firmly hooked on the spring. The spring compressors must be

tightened alternately so as not to tilt the spring.

3. Remove piston rod lock nut.

SSU003

INSPECTION

Strut Assembly

NASU0010

NASU0010S01

I Check for smooth operation through a full stroke, both com-

pression and extension.

I Check for oil leakage on welded and gland packing portion.

I Check piston rod for cracks, deformation and other damage.

I Replace if necessary.

Strut Mounting Insulator and Rubber Parts

NASU0010S02

I Check cemented rubber-to-metal portion for separation and

cracks. Check rubber parts for deterioration.

I Replace if necessary.

Strut Mounting Bearing

NASU0010S03

I Check thrust bearing parts for abnormal noise and excessive

rattle in axial direction.

I Replace if necessary.

Coil Spring

NASU0010S04

I Check for cracks, deformation and other damage. Replace if

necessary.

SU-12

FRONT SUSPENSION

Coil Spring and Strut Assembly (Cont’d)

SFA725B

SFA664AA

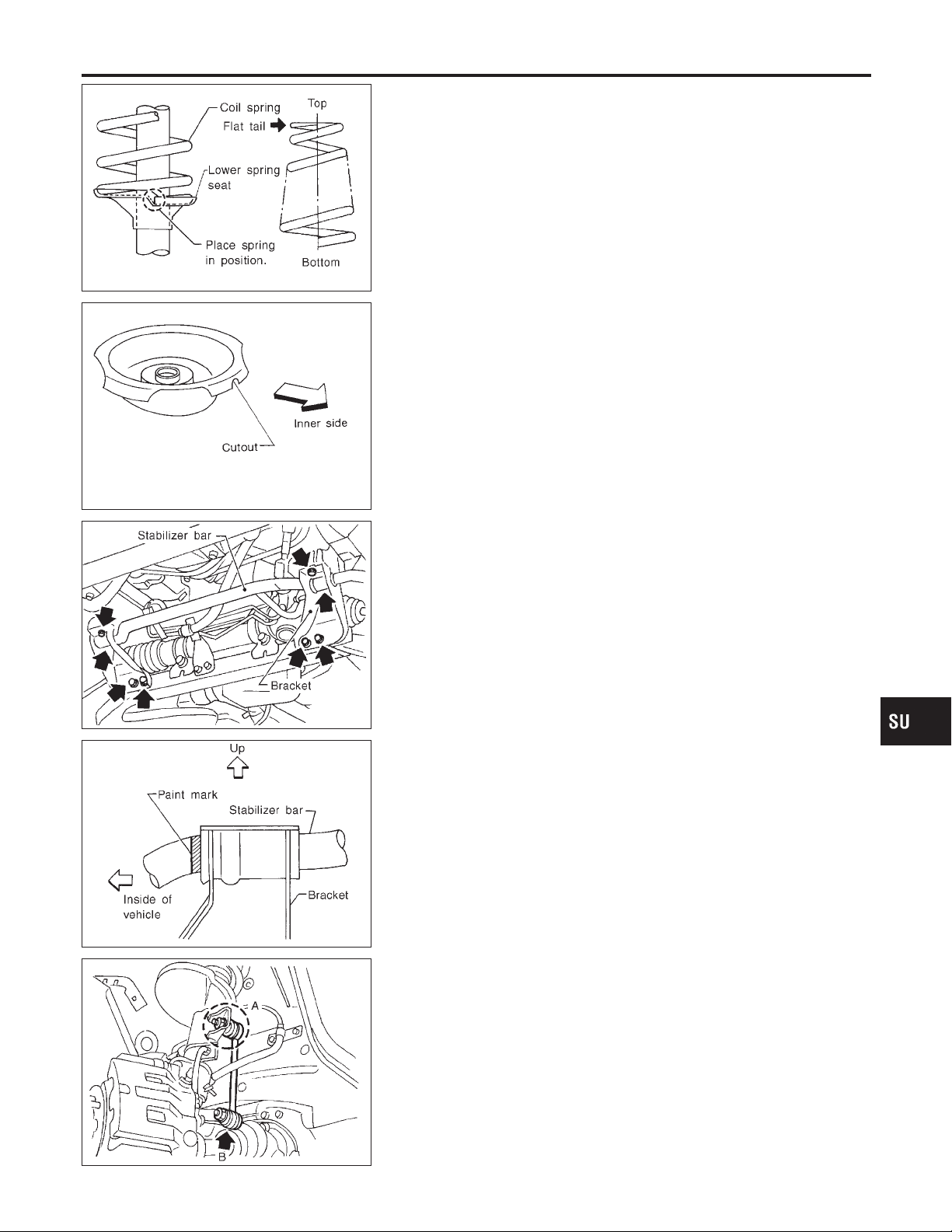

ASSEMBLY

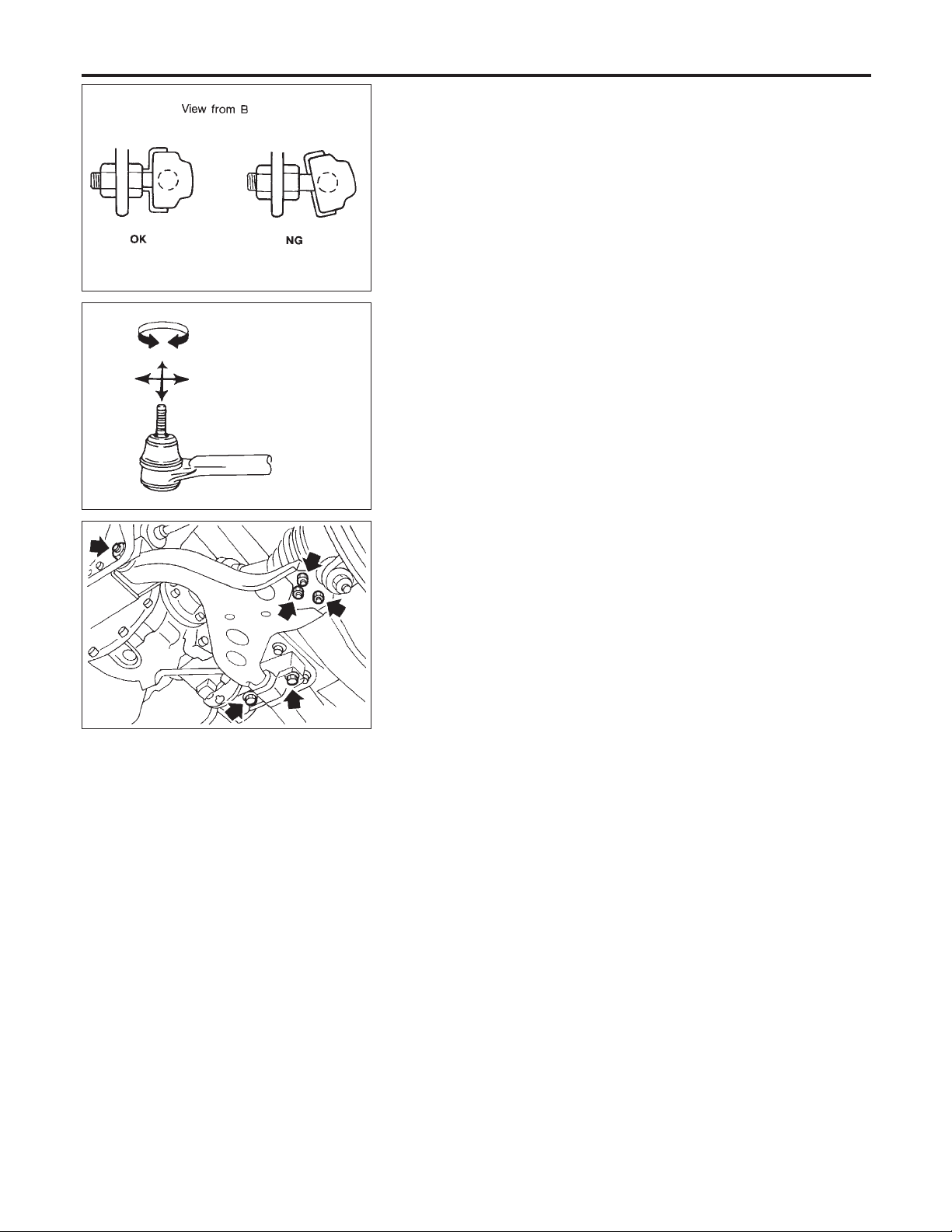

I When installing coil spring on strut, it must be positioned as

shown in the figure at left.

I Install upper spring seat with its cutout facing the inner side of

vehicle.

NASU0011

Stabilizer Bar

REMOVAL AND INSTALLATION

I Remove stabilizer bar and connecting rod.

NASU0012

GI

MA

EM

LC

EC

FE

CL

MT

AT

TF

SFA767B

SFA768B

PD

AX

I When installing stabilizer, make sure that paint mark and

bracket face in their correct directions.

BR

ST

RS

BT

I When removing and installing stabilizer bar fix portion A.

HA

SC

SFA769B

EL

IDX

SU-13

Stabilizer Bar (Cont’d)

SFA449BA

FRONT SUSPENSION

I Install stabilizer bar with ball joint socket properly placed.

INSPECTION

I Check stabilizer for deformation and cracks. Replace if neces-

sary.

I Check rubber bushings for deterioration and cracks. Replace

if necessary.

I Check ball joint can rotate in all directions. If movement is not

smooth and free, replace stabilizer bar connecting rod.

NASU0013

ARA027

SFA757B

Transverse Link and Lower Ball Joint

REMOVAL AND INSTALLATION

1. Separate drive shaft from knuckle. — 4WD —

Refer to AX-12, “Drive Shaft”.

2. Separate lower ball joint stud from knuckle.

3. Remove lower ball joint assembly from transverse link.

4. Remove transverse link.

5. During installation, final tightening must be carried out at curb

weight with tires on ground.

6. After installation, check wheel alignment.

Refer to “FRONT WHEELALIGNMENT”, “On-vehicle Service”,

SU-8.

NASU0014

SU-14

Loading...

Loading...