ENGINE MECHANICAL

B ENGINE

A

EM

SECTION EM

CONTENTS

PRECAUTIONS .......................................................... 3

Precautions for Drain Engine Coolant ...................... 3

Precautions for Disconnecting Fuel Piping .............. 3

Precautions for Removal and Disassembly ............. 3

Precautions for Inspection, Repair and Replace-

ment ......................................................................... 3

Precautions for Assembly and Installation ............... 3

Parts Requiring Angle Tightening ............................. 3

Precautions for Liquid Gasket .................................. 4

REMOVAL OF LIQUID GASKET SEALING .......... 4

LIQUID GASKET APPLICATION PROCEDURE ..... 4

PREPARATION .............................. .................... ......... 5

Special Service Tools ............................................... 5

Commercial Service Tools ........................................ 7

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .......................... ...................... 9

NVH Troubleshooting —Engine Noise ..................... 9

Use the Chart Below to Help You Find the Cause

of the Symptom. ....................................... ....... ....... 10

DRIVE BELTS ............................................................11

Checking Drive Belts ...............................................11

Tension Adjustment .................................................11

AL TERNATOR AND AI/C COMPRESSOR BEL T ... 12

POWER STEERING OIL PUMP BELT ............... 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 13

AIR CLEANER AND AIR DUCT ............................... 14

Removal and Installation ........................................ 14

REMOVAL ........................................................... 14

INSPECTION AFTER REMOVAL ....................... 15

INSTALLATION ................................................... 15

Changing Air Cleaner Filter .................................... 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 15

INTAKE MANIFOLD COLLECTOR .......................... 16

Removal and Installation ........................................ 16

REMOVAL ........................................................... 17

INSPECTION AFTER REMOVAL ....................... 19

INSTALLATION ................................................... 19

ENGINE MECHANICAL

INTAKE MANIFOLD ................................................. 21

Removal and Installation ........................................ 21

REMOVAL ........................................................... 21

INSPECTION AFTER REMOVAL .......................21

INSTALLATION ................................................... 22

EXHAUST MANIFOLD AND THREE WAY CATA-

LYST ........... ................................. .......................... ....23

Removal and Installation ........................................ 23

REMOVAL ........................................................... 23

INSPECTION AFTER REMOVAL .......................25

INSTALLATION ................................................... 25

OIL PAN AND OIL STRAINER ................................. 28

Removal and Installation ........................................ 28

REMOVAL ........................................................... 28

INSPECTION AFTER REMOVAL .......................33

INSTALLATION ................................................... 33

INSPECTION AFTER INSTALLATION ................ 36

IGNITION COIL .............................................. ....... .... 37

Removal and Installation ........................................ 37

REMOVAL ........................................................... 37

INSTALLATION ................................................... 37

SPARK PLUG (PLATINUM-TIPPED TYPE) .............38

Removal and Installation ........................................ 38

REMOVAL ........................................................... 38

INSPECTION AFTER REMOVAL .......................38

INSTALLATION ................................................... 39

FUEL INJECTOR AND FUEL TUBE ........................40

Removal and Installation ........................................ 40

REMOVAL ........................................................... 40

INSTALLATION ................................................... 43

INSPECTION AFTER INSTALLATION ................ 45

ROCKER COVER .....................................................46

Removal and Installation ........................................ 46

REMOVAL ........................................................... 46

INSTALLATION ................................................... 47

FRONT TIMING CHAIN CASE ................................. 49

Removal and Installation ........................................ 49

REMOVAL ........................................................... 49

INSTALLATION ................................................... 52

INSPECTION AFTER INSTALLATION ................ 57

C

D

E

F

G

H

I

J

K

L

M

Revision: 2004 November 2004 Murano

EM-1

TIMING CHAIN .......................................................... 58

Removal and Installation ........................................58

REMOVAL ...........................................................59

INSPECTION AFTER REMOVAL ........................65

INSTALLATION ................................ ............. .......66

INSPECTION AFTER INSTALLATION ................75

CAMSHAFT .............................. ...... ....... ....................77

Removal and Installation ........................................77

REMOVAL ...........................................................77

INSPECTION AFTER REMOVAL ........................79

INSTALLATION ................................ ............. .......82

INSPECTION AFTER INSTALLATION ................85

Valve Clearance ......................................................85

INSPECTION ............................ ............. ..............85

ADJUSTMENT ....................................................88

OIL SEAL ..................................................................90

Removal and Installation of Valve Oil Seal .............90

REMOVAL ...........................................................90

INSTALLATION ................................ ............. .......90

Removal and Installation of Front Oil Seal .............91

REMOVAL ...........................................................91

INSTALLATION ................................ ............. .......91

Removal and Installation of Rear Oil Seal ..............91

REMOVAL ...........................................................91

INSTALLATION ................................ ............. .......92

CYLINDER HEAD ..................................................... 93

On-Vehicle Service .................................................93

CHECKING COMPRESSION PRESSURE .........93

Removal and Installation ........................................94

REMOVAL ...........................................................94

INSPECTION AFTER REMOVAL ........................95

INSTALLATION ................................ ............. .......96

INSPECTION AFTER INSTALLATION ................98

Disassembly and Assembly .................................... 98

DISASSEMBLY ................................................... 99

ASSEMBLY ......................................................... 99

Inspection After Disassembly ...............................101

VALVE DIMENSIONS ............................ ....... .....101

VALVE GUIDE CLEARANCE ....................... .....101

VALVE GUIDE REPLACEMENT ........... ....... .....101

VALVE SEAT CONTACT ....................... ....... .....103

VALVE SEAT REPLACE ME NT .........................103

VALVE SPRING SQUARENESS .......................104

VALVE SPRING DIMENSIONS AND VALVE

SPRING PRESSURE LOAD .............................104

ENGINE ASSEMBLY ..............................................105

Removal and Installation ......................................105

REMOVAL .........................................................106

INSTALLATION ................................ ............. .....109

INSPECTION AFTER INSTALLATION ..............109

CYLINDER BLOCK .................................................110

Disassembly and Assembly ..................................110

DISASSEMBLY ................................................ .. 111

ASSEMBLY ...................................................... ..116

How to Select Piston and Bearing ........................122

DESCRIPTION ..................................................122

HOW TO SELECT PISTON ...............................122

HOW TO SELECT CONNECTING ROD BEAR-

ING .....................................................................123

HOW TO SELECT MAIN BEARING ..................124

Inspection After Disassembly ................................127

CRANKSHAFT END PLAY ................................127

CONNECTING ROD SIDE CLEARANCE .........127

PISTON TO PISTON PIN OIL CLEARANCE .....127

PISTON RING SIDE CLEARANCE ...................128

PISTON RING END GAP ..................................128

CONNECTING ROD BEND AND TORSION .....129

CONNECTING ROD BIG END DIAMETER ......129

CONNECTING ROD BUSHING OIL CLEAR-

ANCE .............................. ...................................129

CYLINDER BLOCK DISTORTION ....................130

MAIN BEARING HOUSING INNER DIAMETER .131

PISTON TO CYLINDER BORE CLEARANCE ..131

CRANKSHAFT MAIN JOURNAL DIAMETER ...132

CRANKSHAFT PIN JOURNAL DIAMETER ......133

CRANKSHAFT OUT-OF-ROUND AND TAPER .133

CRANKSHAFT RUNOUT ..................................133

CONNECTING ROD BEARING OIL CLEAR-

ANCE .............................. ...................................133

MAIN BEARING OIL CLEARANCE ...................134

CRUSH HEIGHT OF MAIN BEARING ..............135

CRUSH HEIGHT OF CONNECTING ROD

BEARING ........................ ...................................135

MAIN BEARING CAP BOL T OUTER DIAMETER .135

CONNECTING ROD BOLT OUTER DIAMETER .136

DRIVE PLATE ....................................................136

OIL JET ..............................................................136

OIL JET RELIEF VALVE ....................................136

SERVICE DATA AND SPECIFICATIONS (SDS) ....137

Standard and Limit ................................................137

GENERAL SPECIFICATIONS ...........................137

DRIVE BELT ......................................................138

INTAKE MANIFOLD CO LLECTOR, INTAKE

MANIFOLD AND EXHAUST MANIFOLD ..........138

SPARK PLUG .................................................. ..138

CAMSHAFT AND CAMSHAFT BEARING ....... ..139

CYLINDER HEAD ........................ ....... ...... ....... ..141

CYLINDER BLOCK ................ ............................144

PISTON, PISTON RING AND PISTON PIN ......145

CONNECTING ROD ..........................................146

CRANKSHAFT ....................... ...... ....... ...... ....... ..147

MAIN BEARING .................................................148

CONNECTING ROD BEARING .......... ...... ....... ..149

Tightening Torque .................................................149

Revision: 2004 November 2004 Murano

EM-2

PRECAUTIONS

PRECAUTIONS PFP:00001

Precautions for Drain Engine Coolant ABS00A7M

Drain engine coolant when engine is cooled.

Precautions for Disconnecting Fuel Piping ABS00A7N

● Before starting work, make sure no fire or spark producing items are in the work area.

● Release fuel pressure before disconnecting and disassembly.

● After disconnecting pipes, plug openings to stop fuel leakage.

A

EM

C

Precautions for Removal and Disassembly ABS00A7O

● When instructed to use SST, use specified tools. Always be careful to work safely, avoid forceful or unin-

structed operations.

● Exercise maximum care to avoid damage to mating or sliding surfaces.

● Cover openings of engine system with ta pe or equivalent, if necessary, to seal out foreign materials.

● Mark and arrange disassembly parts in an organized way for easy troubleshooting and re-assembly.

● When looseni ng nu t s an d b ol t s, a s a b as ic ru le , st a r t wit h the on e fu rt he st o ut si de , the n th e on e d iag on al ly

opposite, and so on. If the order of loosening is specified, do exactly as specified. Power tools may be

used in the step.

Precautions for Inspection, Repair and Replacement ABS00A7P

Before repairing or repla cing, thorou ghly inspec t parts. Inspect new repl acement parts in the s ame way, and

replace if necessary.

Precautions for Assembly an d Installation ABS00A7Q

● Use torque wrench to tighten bolts or nuts to specification.

● When tightening nuts and bolts, as a basic rule, equally tighten in several different steps starting with the

ones in center, then ones on inside and outside diagonally in this order. If the order of tightening is specified, do exactly as spe ci fied.

● Replace with new gasket, packing, oil seal or O-ring.

● Thoroughly wa sh, c lean , an d air- bl ow eac h p art. Care ful ly ch eck en gin e oil o r en gine coolan t p ass ages for

any restriction and blockage.

● Avoid damaging sliding or mating surfaces. Completely remove foreign materials such as cloth lint or dust.

Before assembly, oil sliding surfaces well.

● Release air within route when refilling after draining engine coolant.

● After repairing, start engine and increase engine speed to check engine coolant, fuel, engine oil, and

exhaust gases for leakage.

D

E

F

G

H

I

J

K

L

Parts Requiring Angle Tightening ABS00A7R

● Use angle wrench [SST: KV10112100 (BT8653-A)] f o r the final tightening of the following engine parts:

– Cylinder head bolts

– Main bearing cap bolts

– Connecting rod cap bolts

– Crankshaft pulley bolt (No angle wrench is required as bolt flange is provided with notches for angle tight-

ening)

● Do not use a torque value for final tigh ten in g.

● The torque value for these parts are for a preliminary step.

● Ensure thread and seat surfaces are clean and coated with engine oil.

Revision: 2004 November 2004 Murano

EM-3

M

PRECAUTIONS

Precautions for Liquid Gasket ABS00A7S

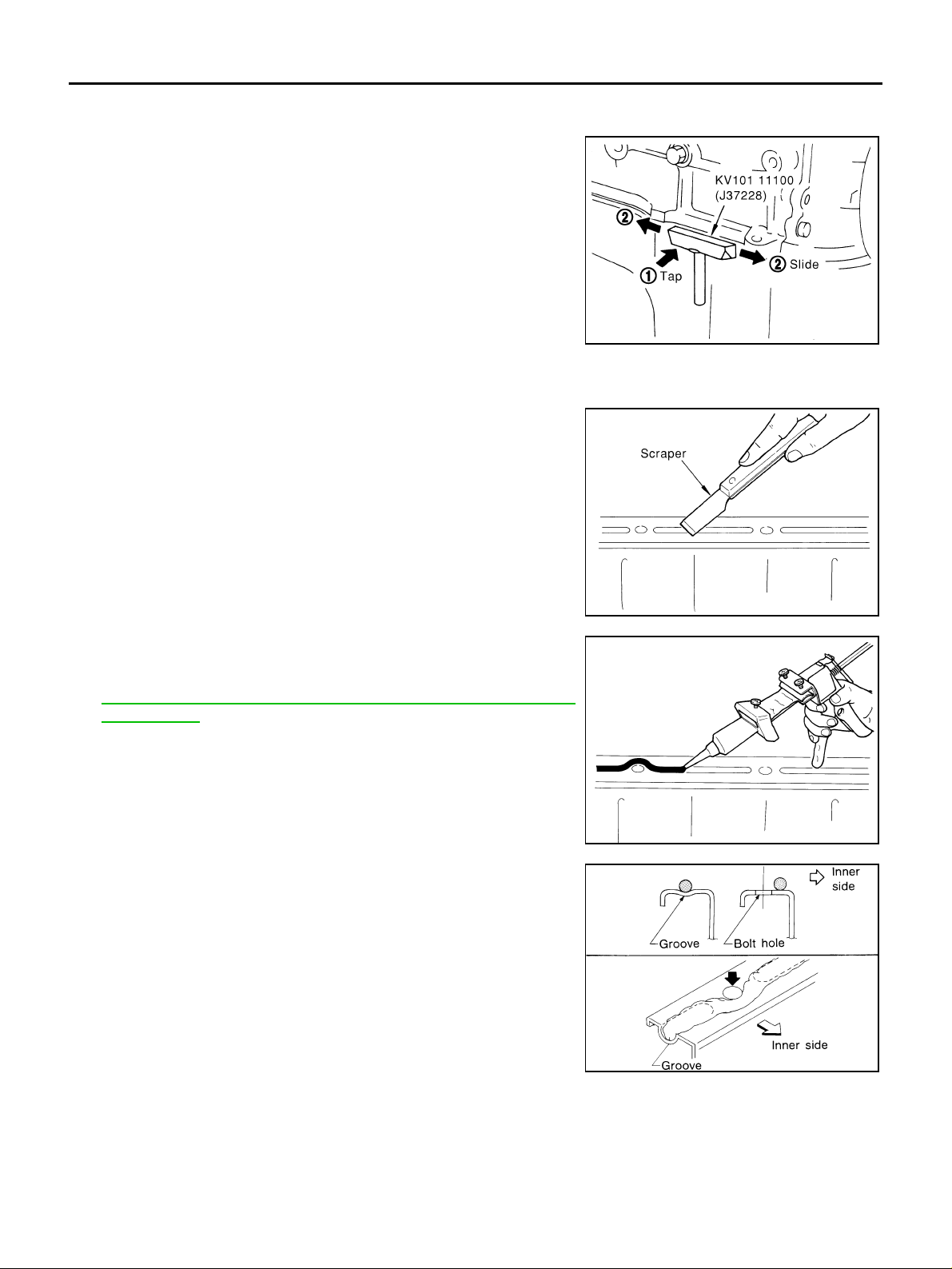

REMOVAL OF LIQUID GASKET SEALING

● After removing mounting nuts and bolts, separate the mating

surface using seal cutter [SST] and remove old liquid gasket

sealing.

CAUTION:

Be careful not to damage the mating surfaces.

● Tap seal cutter to insert it, and then slide it by tapping on the

side as shown in the figure.

● In areas where seal cutter [SST] is difficult to use, use plastic

hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason tool such as screwdriver is

used, be careful not to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Using scraper, remove old liquid gasket adhering to the gasket

application surface and the mating surface.

● Remove liquid g asket co mpletely from th e groov e of the g as-

ket application surface, mounting bolts, and bolt holes.

2. Wipe the liquid gasket application surface and the mating surface with white gasoline (lighting and heating use) to remove

adhering moisture, grease and foreign ma terials.

PBIC0002E

3. Attach liquid gasket tube to tube presser [SST: WS39930000

(—)].

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-47, "

RECOMMENDED CHEMICAL PRODUCTS AND

SEALANTS" .

4. Apply liqui d gasket withou t breaks to the spec ified locatio n with

the specified dimensions.

● If there is a groove for liquid ga sket application, apply liqui d

gasket to the groove .

● As for bolt holes, normally apply liquid gasket inside the

holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of this manual.

● Within 5 minutes of liquid gasket application, install the mating

component.

● If liquid gasket protrudes, wipe it off immediately.

● Do not retighten mounting bolts or nuts after the installation.

● After 30 minu te s o r mo re h ave passed from the installation, fill

engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe

them.

PBIC0003E

EMA0622D

SEM159F

Revision: 2004 November 2004 Murano

EM-4

PREPARATION

PREPARATION PFP:00002

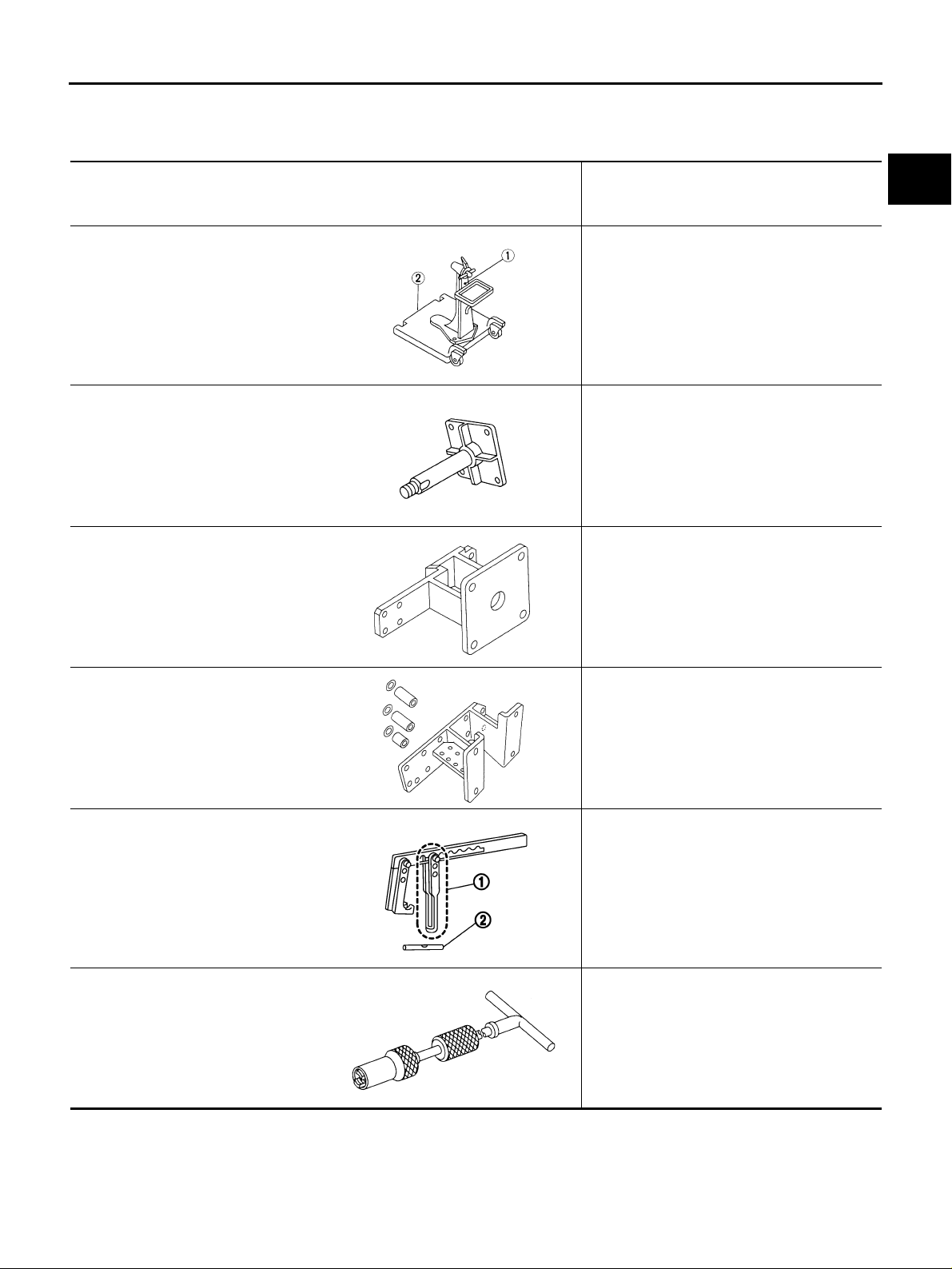

Special Service Tools ABS00A7T

The actual shapes of Kent-Moore tools may differ from those of spec ial ser vi ce tool s illust rat ed here.

Tool number

(Kent-Moore No.)

Tool name

Description

A

EM

ST0501S000

(—)

Engine stand assembly

1. ST05011000

(—)

Engine stand

2. ST05012000

(—)

Base

KV10106500

(—)

Engine stand shaft

KV10117000

(J41262)

Engine sub-attachment

KV10117001

(—)

Engine sub-attachment

NT042

NT028

NT373

Disassembling and assembling engi ne

KV10117000 has been replaced with

KV10117001 (KV10117000 is no longer in

production, but it is usable).

Installing on cylinder block

C

D

E

F

G

H

I

J

KV10116200

(J26336-A)

Valve spring compressor

1. KV10115900

(J26336-20)

Attachment

2.KV10109220

(—)

Adapter

KV10107902

(J38959)

Valve oil seal puller

NT372

PBIC1650E

NT011

Disassembling valve mechani sm

Part (1) is a component of KV10116200

(J26336-A), but Part (2) is not so.

Replacing valve oil seal

K

L

M

Revision: 2004 November 2004 Murano

EM-5

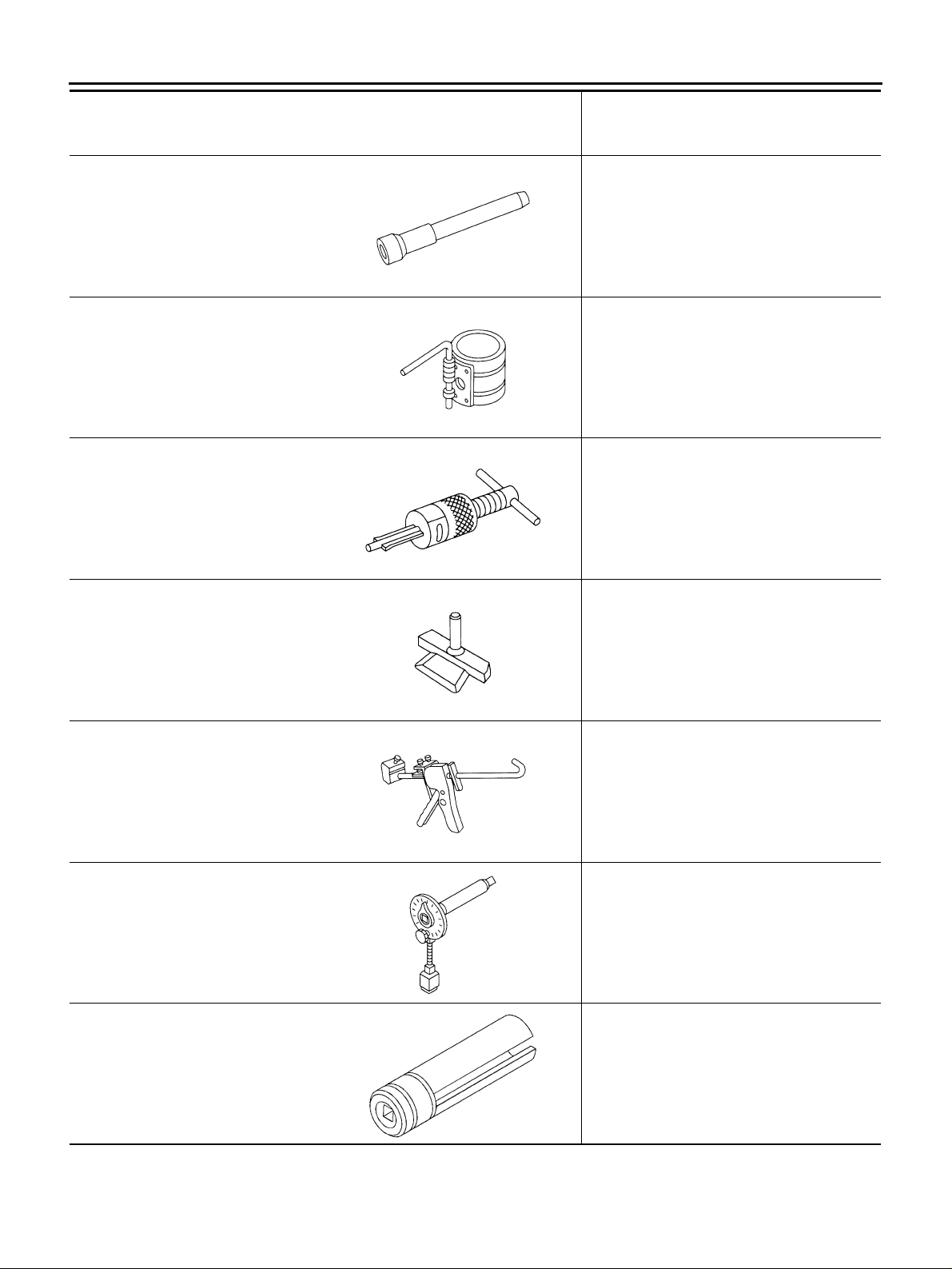

Tool number

(Kent-Moore No.)

Tool name

PREPARATION

Description

—

(J39386)

Valve oil seal drift

EM03470000

(J8037)

Piston ring compressor

ST16610001

(J23907)

Pilot bushing puller

KV10111100

(J37228)

Seal cutter

Installing valve oil seal

NT024

Installing piston assembly into cylinder bore

NT044

Removing pilot converter

NT045

Removing oil pan (lower and upper), front

and rear timing chain case, etc.

WS39930000

(—)

Tube presser

KV10112100

(BT8653-A)

Angle wrench

KV10117100

(J3647-A)

Heated oxygen sensor wrench

NT046

Pressing the tube of liquid gasket

NT052

Tightening bolts for bearing cap, cylinder

head, etc. in angle

NT014

Loosening or tightening air fuel ratio sensor 1

For 22 mm (0.87 in) width hexagon nut

NT379

Revision: 2004 November 2004 Murano

EM-6

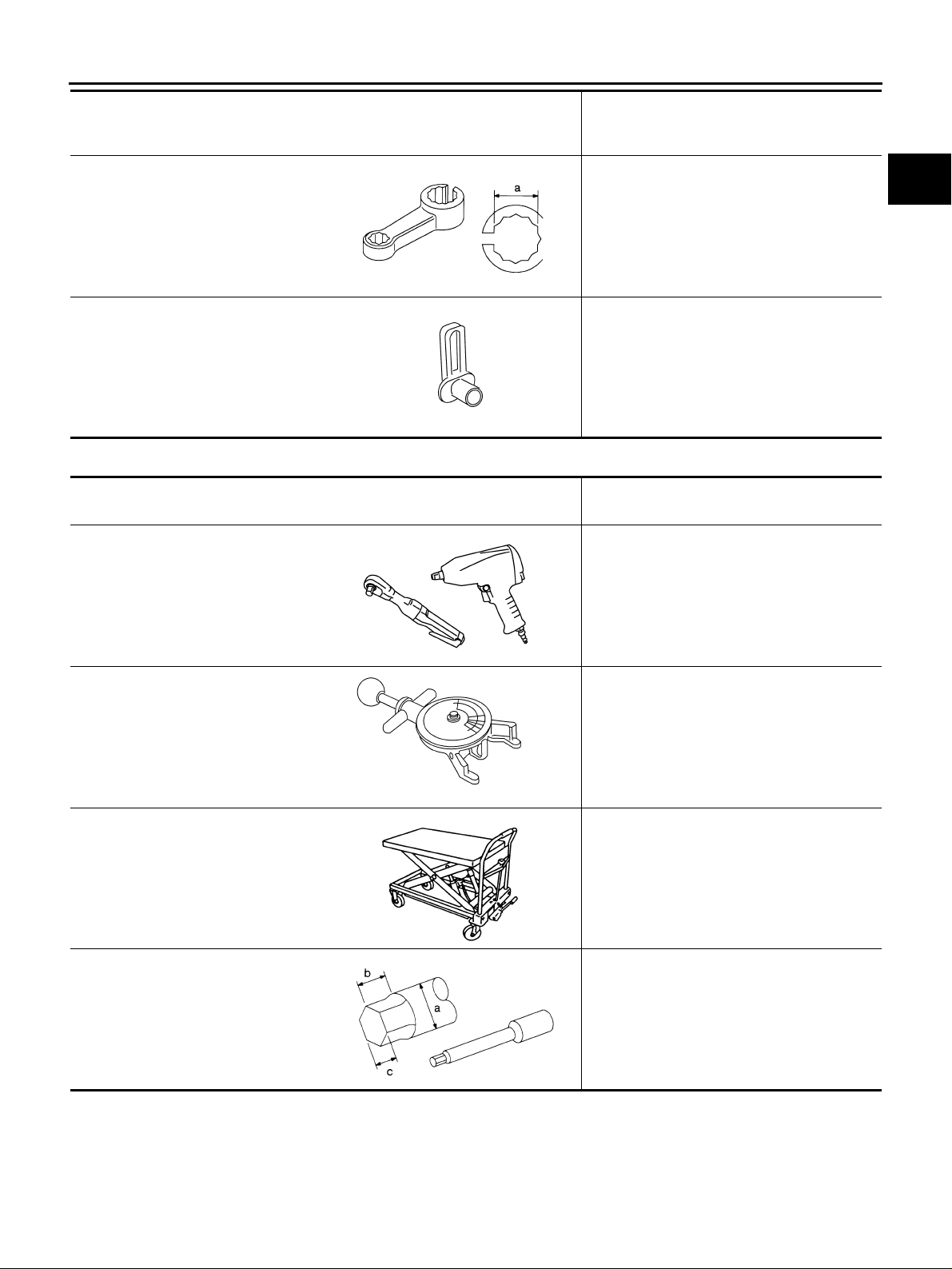

PREPARATION

Tool number

(Kent-Moore No.)

Tool name

KV10114400

(J38365)

Heated oxygen sensor wrench

NT636

—

(J-45488)

Quick connector release

PBIC0198E

Description

Loosening or tightening heated oxygen

sensor 2

a: 22 mm (0.87 in)

Removing fuel tube quick connectors in

engine room

Commercial Service Tools ABS00A7U

(Kent-Moore No.)

Tool name

(—)

Power tool

Description

Loosening bolts and nuts

A

EM

C

D

E

F

G

H

(BT3373-F)

Belt tension gauge

(—)

Manual lift table caddy

(J24239-01)

Cylinder head bolt wrench

PBIC0190E

AMA126

ZZA1210D

NT583

Checking drive belt tension

Removing and installing engine

Loosening and tightening cylinder head bo lt,

and used with angle wrench [SST:

KV10112100 (BT8653-A)]

a: 13 (0.51) dia.

b: 12 (0.47)

c: 10 (0.39)

Unit: mm (in)

I

J

K

L

M

Revision: 2004 November 2004 Murano

EM-7

PREPARATION

(Kent-Moore No.)

Tool name

(—)

Spark plug wrench

(—)

Valve seat cutter set

(—)

Piston ring expander

(—)

Valve guide drift

Description

Removing and installing spark plug

NT047

Finishing valve seat dimensions

NT048

Removing and installing piston ring

NT030

Removing and installing valve guide

Intake and Exhaust:

a: 9.5 mm (0.374 in) dia.

b: 5.5 mm (0.217 in) dia.

(—)

Valve guide reamer

(J-43897-18)

(J-43897-12)

Oxygen sensor thread cleaner

(—)

Anti-seize lubricant (Permatex 133AR

or equivalent meeting MIL

specification MIL-A-907)

NT015

NT016

AEM488

AEM489

(1): Reaming valve guide inner hole

(2): Reaming hole for oversize valve guid e

Intake and Exhaust:

1 : 6.0 mm (0.236 in) dia.

d

2 : 10.2 mm (0.402 in) dia.

d

Reconditioning the exhaust system thre ads

before installing a new heated oxygen sensor

(Use with anti-seize lubricant shown below.)

a: J-43897-18 [18 mm (0.71 in) dia.] for

zirconia heated oxygen sensor

b: J-43897-12 [12 mm (0.47 in) dia.] for

titania heated oxygen sensor

Lubricating oxygen sensor thread cleani ng

tool when reconditioning exhaust syst em

threads

Revision: 2004 November 2004 Murano

EM-8

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING PFP:00003

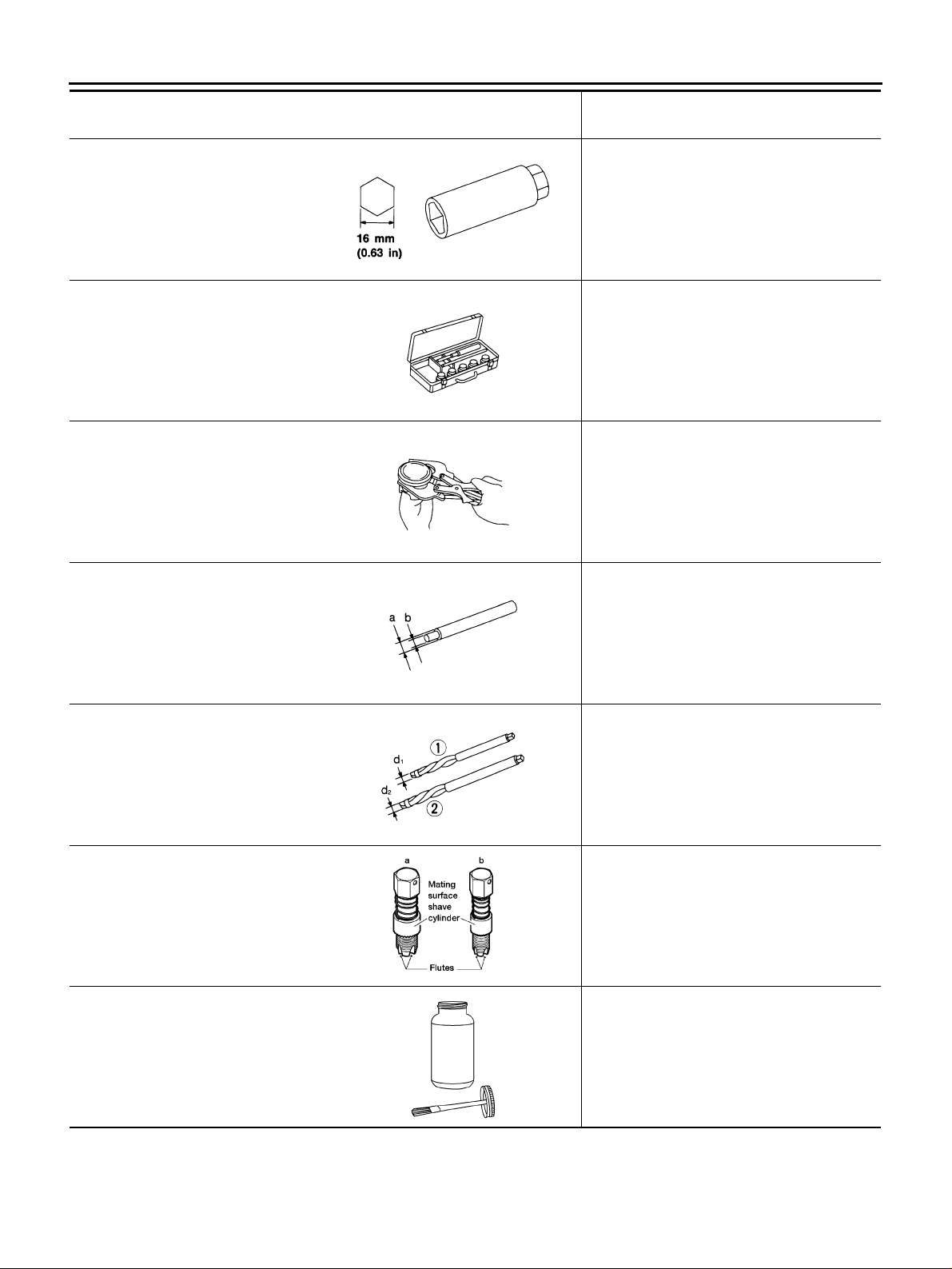

NVH Troubleshooting —Engine Noise ABS00327

A

EM

C

D

E

F

G

H

K

M

I

J

L

PBIC2543E

Revision: 2004 November 2004 Murano

EM-9

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

Use the Chart B elow to Help You Find the Cause of the Symptom. ABS00A7V

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessar y, repair or replace these parts.

Operating condition of engine

Location

of noise

Top of

engine

Rocker

cover

Cylinder

head

Crankshaft pulley

Cylinder

block

(Side of

engine)

Oil pan

Front of

engine

Timing

chain

case

Front of

engine

A: Closely related B: Related C: Sometimes related —: Not related

Type of

noise

Ticking or

clicking

Rattle C A — A B C

Slap or

knock

Slap or

rap

Knock A B C B B B

Knock A B — A B C

T apping or

ticking

Squeaking or fizzing

CreakingABABAB

Squall

Creak

Before

warm-

up

—A—BB—

After

warm-

CA—AB—

A——BB A

AA—BBB

AB—B—C

AB—BAB

up

When

start-

ing

When

idling

When

racing

While

driving

Source of

noise

Tappet

noise

Camshaft

bearing

noise

Piston pin

noise

Piston

slap noise

Connecting rod

bearing

noise

Main

bearing

noise

Timing

chain and

chain tensioner

noise

Drive belts

(Sticking

or slipping)

Drive belts

(Slipping)

Water

pump

noise

Check item

Valve clearance EM-85

Camshaft runout

Camshaft journal oil

clearance

Piston to piston pin oil

clearance

Connecting rod bushing oil clearance

Piston to cylinder bore

clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend

and torsion

Connecting rod bushing oil clearance

Connecting rod bearing oil clearance

Main bearing oil clearance

Crankshaft runout

Timing chain cracks

and wear

Timing chain tensioner

operation

Drive belts deflection

Idler pulley bearing

operation

Water pump operation

Refer-

ence page

EM-79

EM-79

EM-127

EM-129

EM-131

EM-128

EM-128

EM-129

EM-129

EM-133

EM-134

EM-133

EM-65

EM-58

EM-11

CO-22,

"WATER

PUMP"

Revision: 2004 November 2004 Murano

EM-10

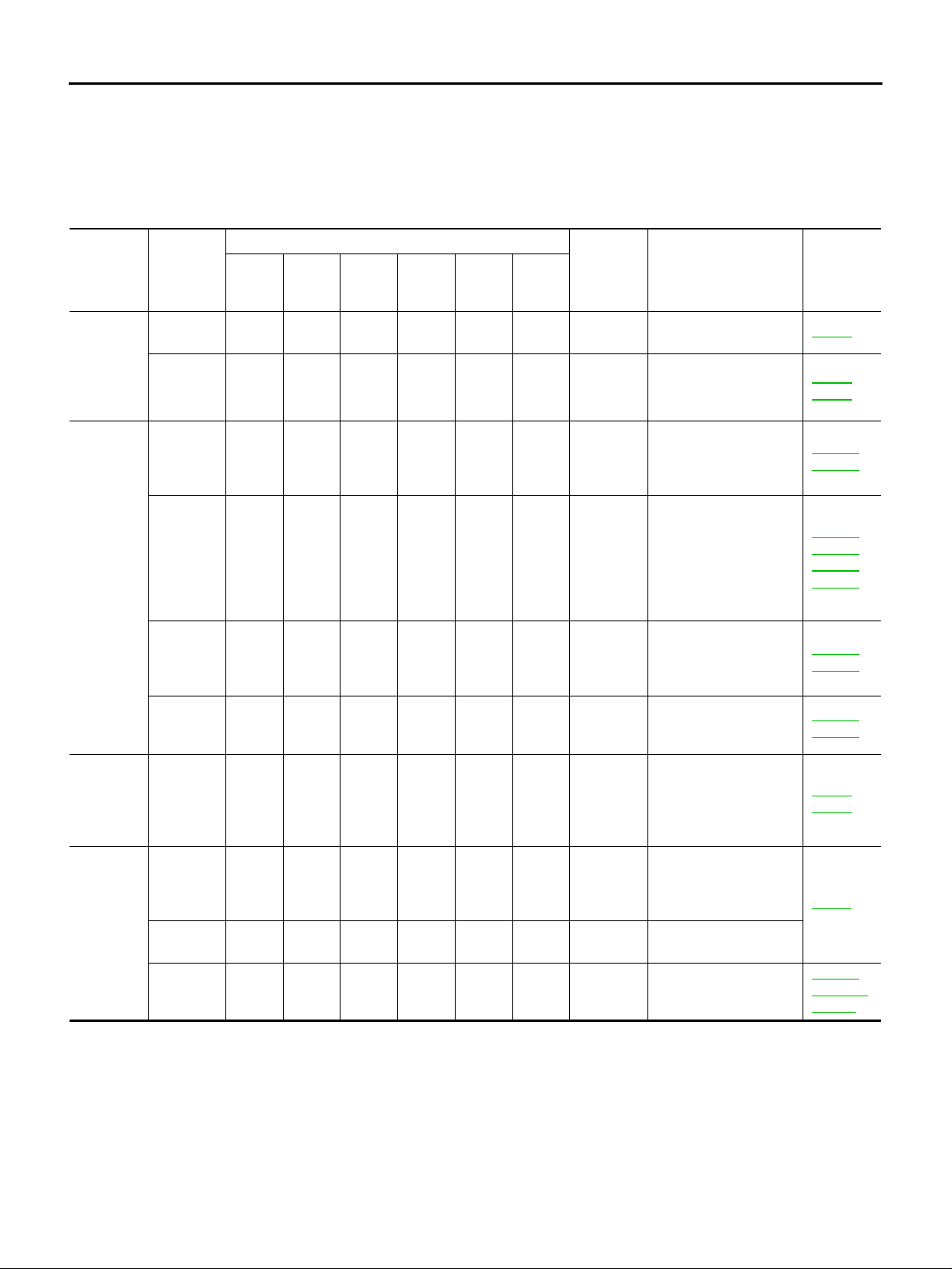

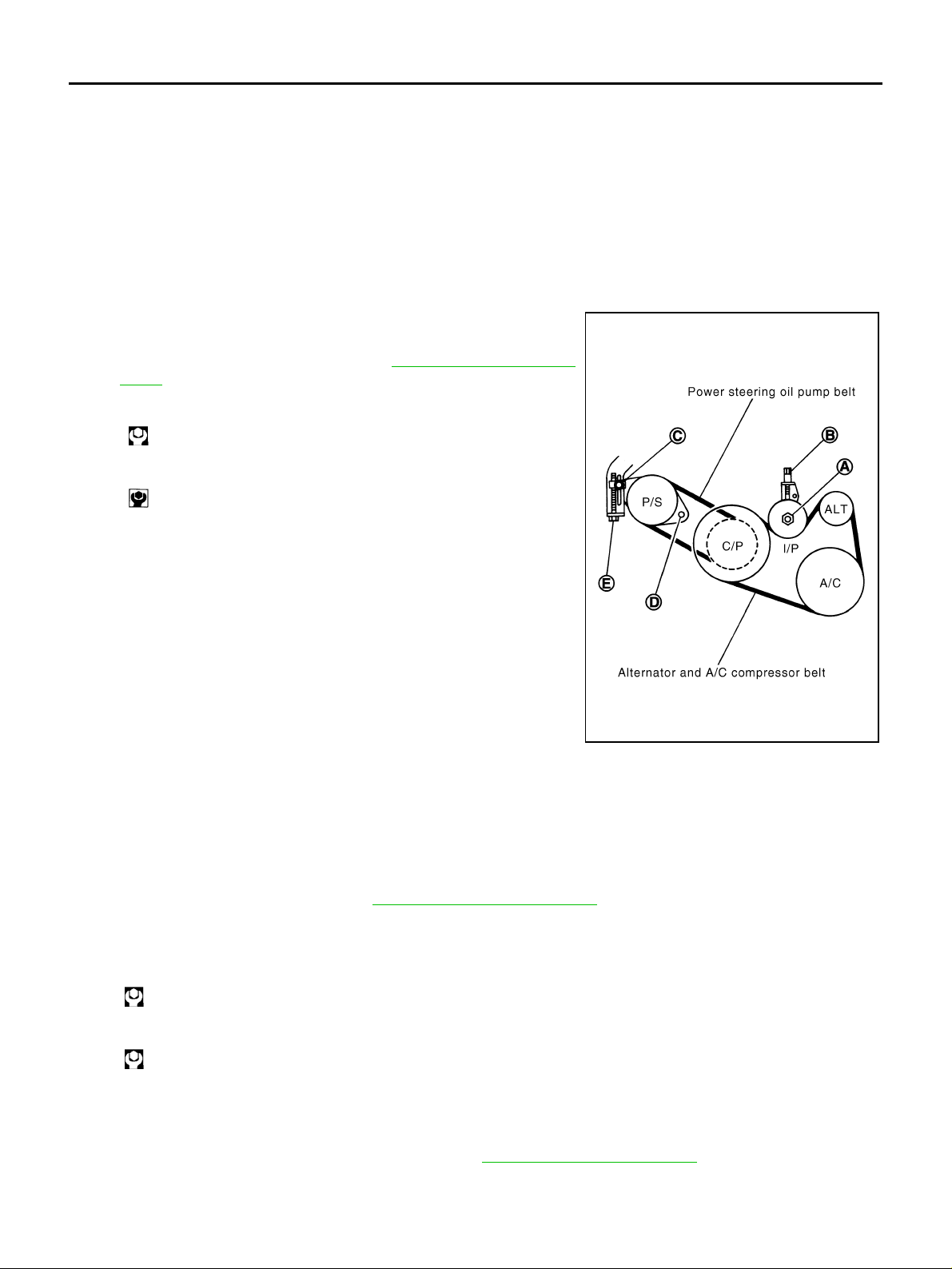

DRIVE BELTS

DRIVE BELTS PFP:02117

Checking Drive Belts ABS00329

WARNING:

Be sure to perform when the engine is stopped.

1. Inspect belts for cracks, fraying, wear and oil. If necessary, replace.

2. Inspect drive belt deflection or tension at a point on belt midway

between pulleys.

● Inspection s hould be done only when en gine is cold, or over

30 minutes after engine is stopped.

● Measure belt tension with tension gauge (BT3373-F or equiv-

alent) at points marked shown in the figure.

● When measuring deflection, apply 98 N (10 kg, 22 lb) at the

marked point.

● Adjust if belt deflectio n exceeds the limit or if belt tension is

not within specifications.

CAUTION:

● When checking belt deflection or tension immediately after installation, first adjust it to the

specified value. Then, after turn ing the crankshaft two turns or more, re-adjust to the s pecified

value to avoid variation in deflection between pulleys.

● Tighten idler pulley lock nut by hand and measure deflec-

tion or tension without looseness.

PBIC2449E

A

EM

C

D

E

F

G

Belt Deflection and Tension

Deflection adjustment Unit: mm (in) Tension adjustment* Unit: mm (in)

Used belt

Limit After adjustment Limit

Alternator and A/C

compressor

Power steering oil

pump

Applied pushing

force

*: If belt tension gauge cannot be installed at check points show n, ch eck dr iv e belt tensi on at different locat ion on th e bel t.

7 (0.28)

11 (0.43)

98 N (10 Kg, 22 lb) —

4.2 - 4.6

(0.17 - 0.18)

7.3 - 8

(0.29 - 0.30)

New belt

3.7 - 4.1

(0.15 - 0.16)

6.5 - 7.2

(0.26 - 0.28)

294 (30, 66)

196 (20, 44)

Used belt

After adjust-

ment

730 - 818

(74.5 - 83.5,

164 - 184)

495 - 583

(50.5 - 59.5,

111 - 131)

PBIC1162E

New belt

838 - 926

(85.5 - 94.5,

188 - 208)

603 - 691

(61.5 - 70.5,

135.6 - 155.4)

H

I

J

K

L

M

Tension Adjust me nt ABS0036V

Portion Belt tightening method for adjustment

Power steering oil pump belt Adjusting bolt on power steering oil pump

Alternator and air conditioner compressor belt Adjusting bolt on idler pulley

CAUTION:

● When belt is replaced with a new one, adjust it to value for “New belt” to accommodate for insuffi-

cient adaptability with pulley gr ooves.

Revision: 2004 November 2004 Murano

EM-11

DRIVE BELTS

● When deflection or tens ion of belt being used ex ce ed s “Li mit”, adjust it to v alu e for “A fter adjust-

ment”.

● When checking belt deflect ion or tensio n imme diately after installation, first adj ust it to the speci -

fied value. Then, after turni ng th e c rank sh aft two turns or mo re, re -ad jus t to th e s pec ifie d v alu e to

avoid variation in deflection between pulleys.

● When installing belt, make sure that it is correctly engaged with pulley groove.

● Keep engine oil, working fluid and engine coolant away from belt.

● Do not twist or bend belt excessively.

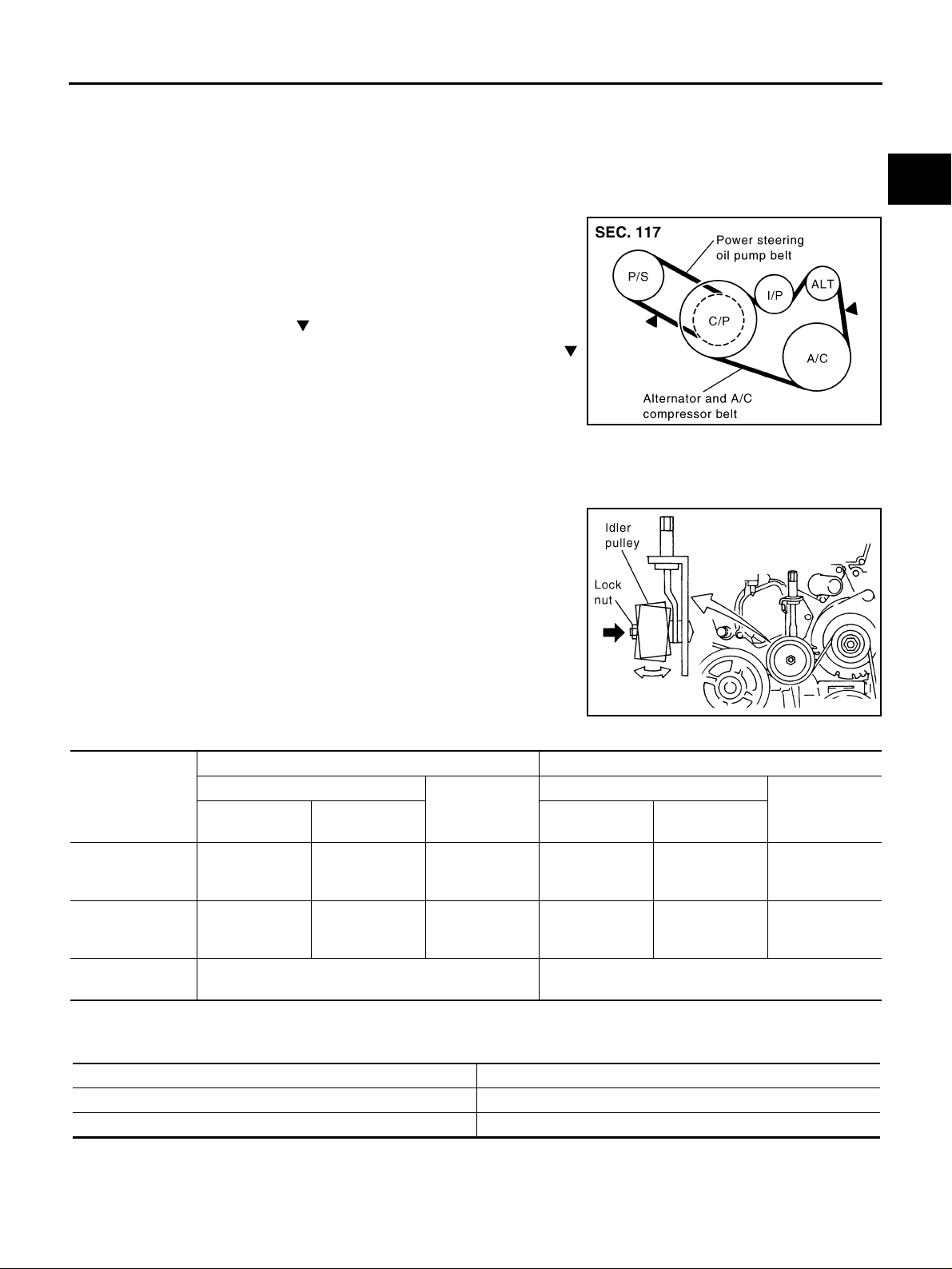

ALTERNATOR AND AI/C COMPRESSOR BELT

1. Remove splash guard (RH).

2. Loosen idler pulley lock nut (A) and adjust tension by turning

adjusting nut (B).

● For specified belt tension, refer to EM-11, "Checking Drive

Belts" .

3. Tighten lock nut (A).

: 34.8 N·m (3.5 kg-m, 26 ft-lb)

4. Tighten adjusting nut (B).

: 5.4 N·m (0.55 kg-m, 48 in-lb)

PBIC2450E

POWER STEERING OIL PUMP BELT

1. Remove splash guard (RH).

2. Loosen lock bolt (C).

3. Loosen power steering oil pump mounting bolt (D).

● Bolt head (D) is engine rear side.

4. Adjust tension by turning adjusti n g bolt (E).

● For specified belt tension, refer to EM-11, "Checking Drive Belts" .

NOTE:

Adjusting bolt (E) is loosened with counterclockwise rota tion.

5. Tigh ten lock bolt (C).

: 28.0 N·m (2.9 kg-m, 21 ft-lb)

6. Tighten power steering oil pump mounting bolt (D).

: 43.2 N·m (4.4 kg-m, 32 ft-lb)

Removal and Installation ABS0036W

REMOVAL

1. Remove splash guard (RH).

2. Fully loosen each b elt by follo wing the gu idel ine s in EM- 11, "

A/C compressor belt and then power steeri ng oil pump belt.

Tension Adjustm ent" . Rem ove al terna tor an d

Revision: 2004 November 2004 Murano

EM-12

DRIVE BELTS

CAUTION:

Grease is applied to idler pulley adjusting bolt. Be careful to keep grease away from belt.

INSTALLATION

1. Install each belt to pulley in the reverse order of removal.

CAUTION:

● Make sure belt is correctly engaged with the pulley groove.

● Make sure that for engine oil , working fluid and engine coolant do not adhere to belt and each

pulley groove.

2. Adjust belt tension. Refer to EM-11, "

3. Tighten each nuts and bolts to the specified torque.

4. Make sure that tension of each belt is within the standard. Refer to EM- 11, "

Tension Adjustment" .

Checking Drive Belts" .

A

EM

C

D

E

F

G

H

K

M

I

J

L

Revision: 2004 November 2004 Murano

EM-13

AIR CLEANER AND AIR DUCT

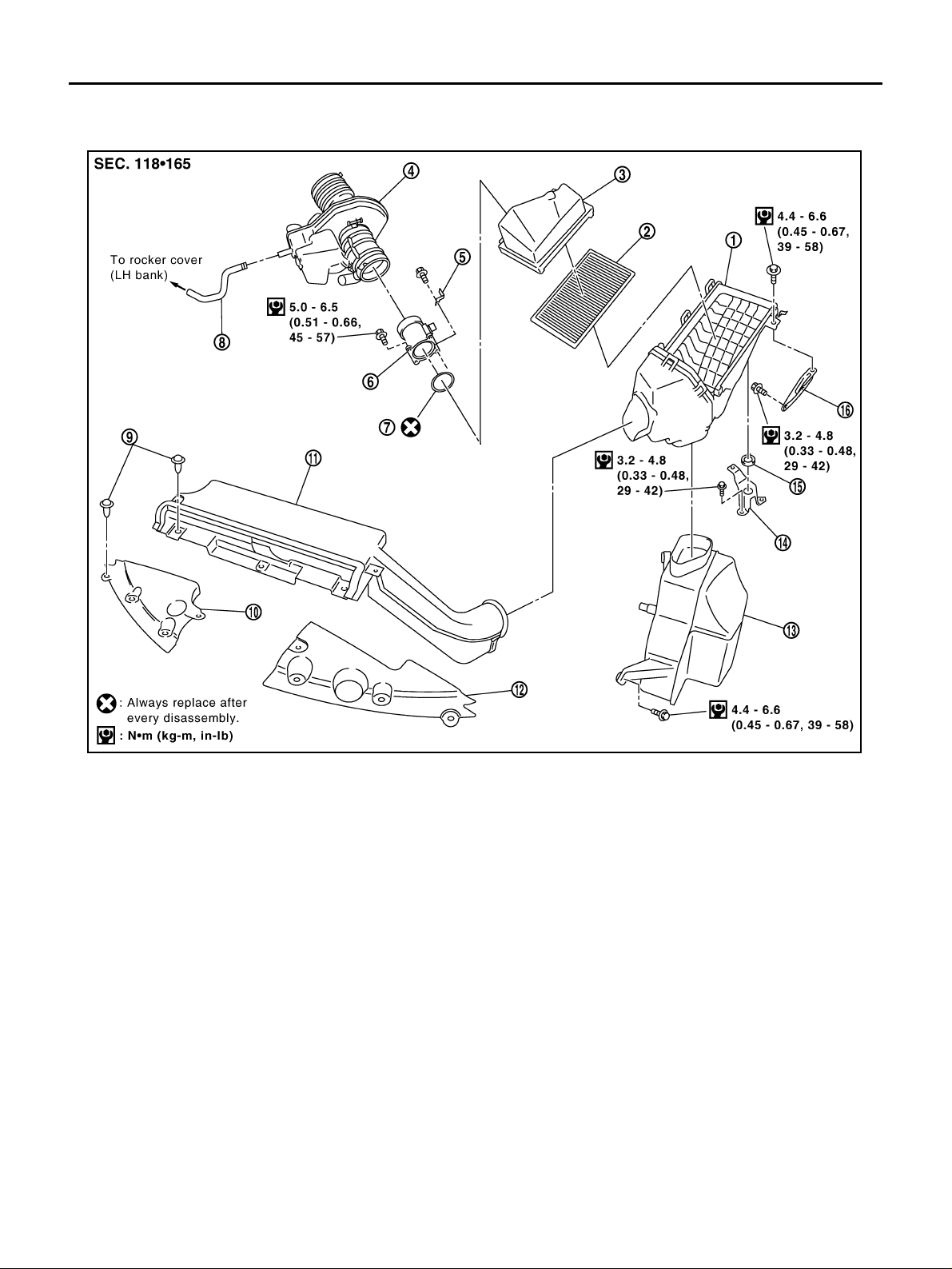

AIR CLEANER AND AIR DUCT PFP:16500 Removal and Installation ABS0033C

PBIC1806E

1. Air cleaner case (lower) 2. Air cleaner filter 3. Air cleaner case (upper)

4. Air duct assem bl y 5. Harness brac ket 6. Mass air flow sensor

7. O-ring 8. PCV hose 9. Clip

10. Radiator cover grill (right side) 11. Air duct (inlet) 12. Radiator cover grill (left side)

13. Resonator 14. Bracket 15. Grommet

16. Bracket

REMOVAL

1. Remove radiator cover grills (right and left side).

2. Remove air duct (inlet).

3. Disconnect harness connector from ma ss air flow sensor.

4. Disconnect PC V hose.

5. Remove air cleaner cases (upper and lower) with mass air flow sensor and air duct assembly disconnecting their joints.

● Add mating marks as nece s sa ry for easier installation.

6. Remove mass air flow sensor from air cleaner case (upper), as necessary.

CAUTION:

Handle mass air flow sensor with following cares.

● Do not shock it.

● Do not disassemble it.

● Do not touch its sensor.

Revision: 2004 November 2004 Murano

EM-14

AIR CLEANER AND AIR DUCT

7. Remove resonator, removing left side fender protector (front), as necessary.

INSPECTION AFTER REMOVAL

Inspect air duct assembly for crack or tear.

● If anything found, replace air duct assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

● Align marks. Attach each joint. Screw clamps firmly.

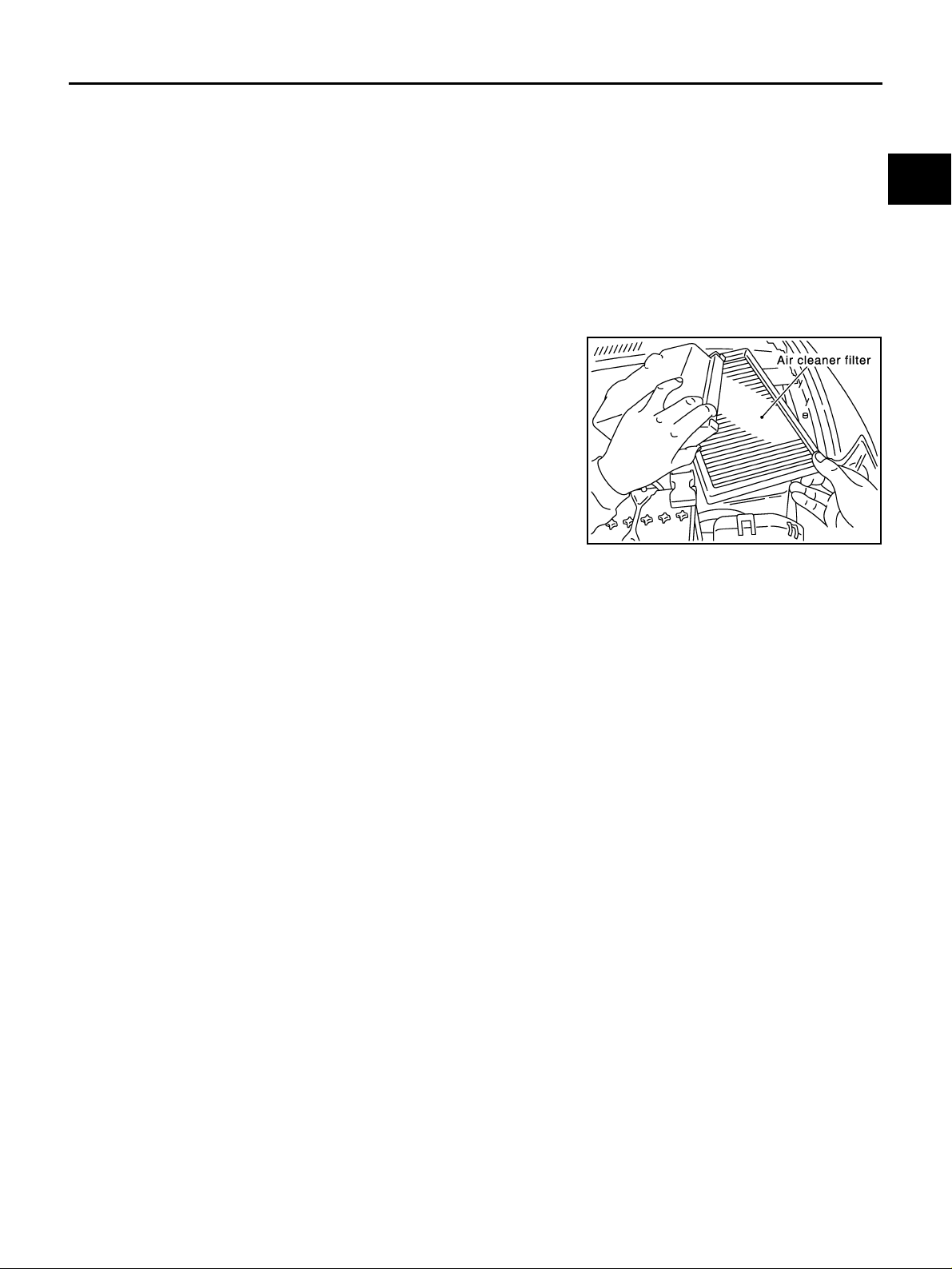

Changing Air Cleaner Filter ABS00BYS

REMOVAL

1. Unhook air cleaner case (lower) side clips and lift up air cleaner case (upper).

2. Remove air cleaner filter.

A

EM

C

D

E

F

G

INSTALLATION

Install in the reverse order of removal.

PBIC1165E

H

I

J

K

L

M

Revision: 2004 November 2004 Murano

EM-15

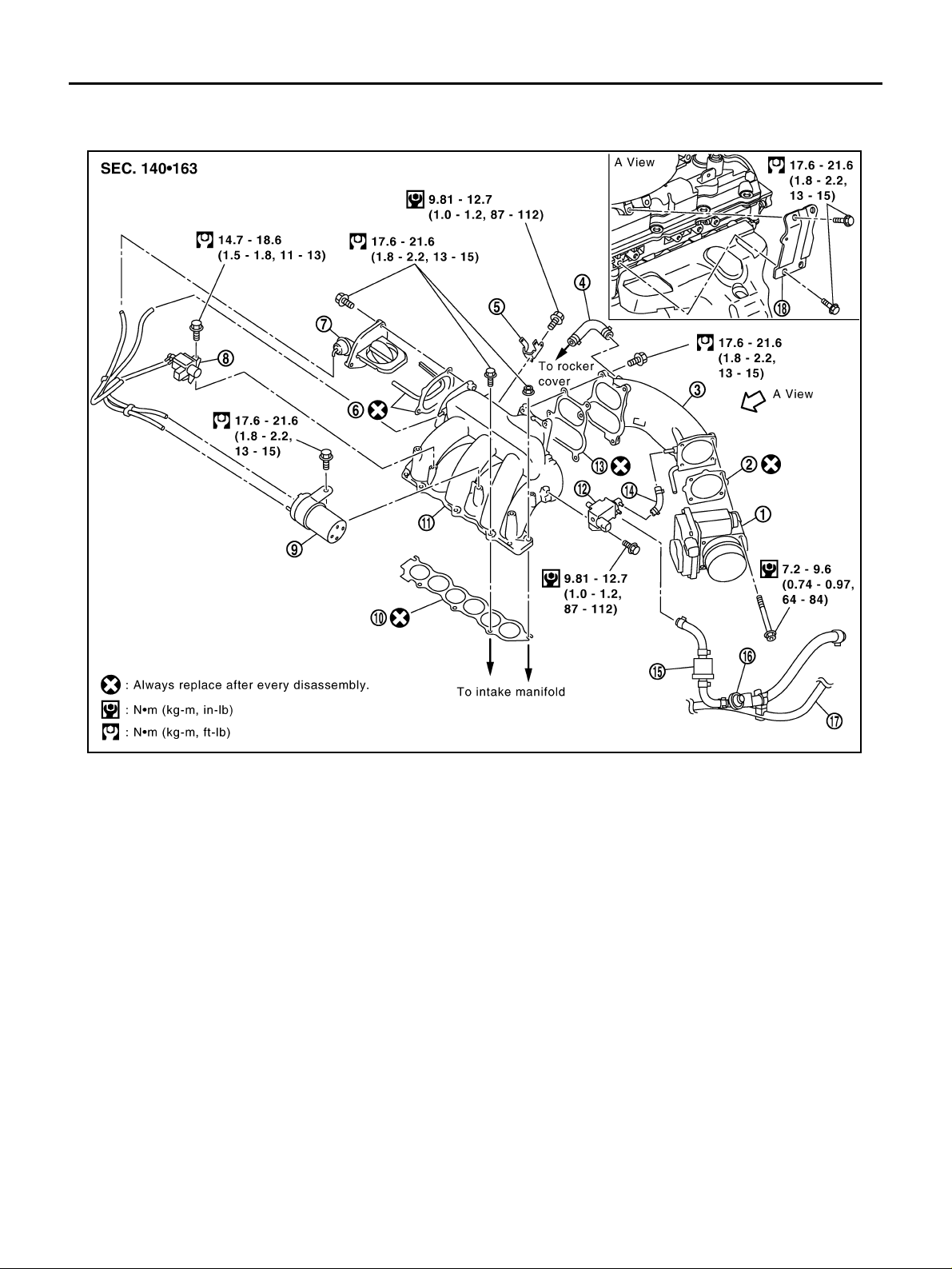

INTAKE MANIFOLD COLLECTOR

INTAKE MANIFOLD COLLECTOR PFP:14003 Removal and Installation ABS00FPR

PBIC1906E

1. Electric th rott le cont rol act uat or 2. Gasket 3. Intake manifold collector (upp er)

4. PCV hose 5. Harness bracket 6. Gasket

7. Power valve 8. VIAS control solenoid valve 9. V acuum tank

10. Gasket 11. Intake manifold collector (lower) 12.

13. Gasket 14. EVAP hose 15. Purge resonator

16. Service port 17. Fuel hose 18. Intake manifold collector support

EVAP canister purge volume control

solenoid valve

Revision: 2004 November 2004 Murano

EM-16

INTAKE MANIFOLD COLLECTOR

REMOVAL

WARNING:

To avoid the da nge r of being scalde d, nev er drai n engi ne coo lan t whe n engi ne is hot.

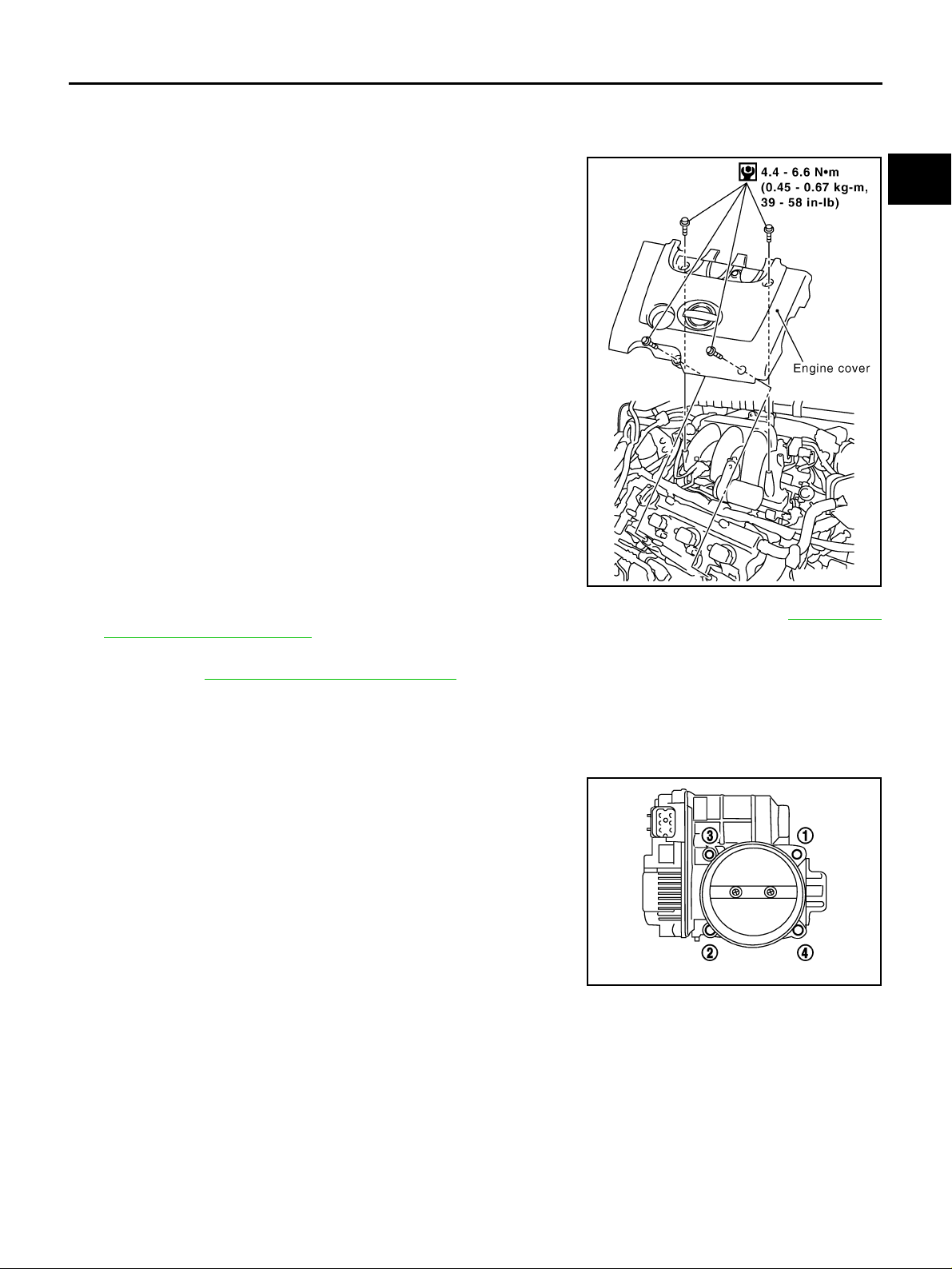

1. Remove engine cover.

CAUTION:

Be careful not to damage or scratch engine cover.

A

EM

C

D

E

F

G

PBIC1910E

2. Remov e air cleaner case (upper) with ma ss air flow sens or and air duct as sembly. Refer to EM-14, "

AIR

CLEANER AND AIR DUCT" .

3. Drain engine coolant, or when water hoses are disconnected, attach plug to prevent engine coolant leakage. Refer to CO-9, "

Changing Engine Coolant" .

CAUTION:

Perform when engine is cold.

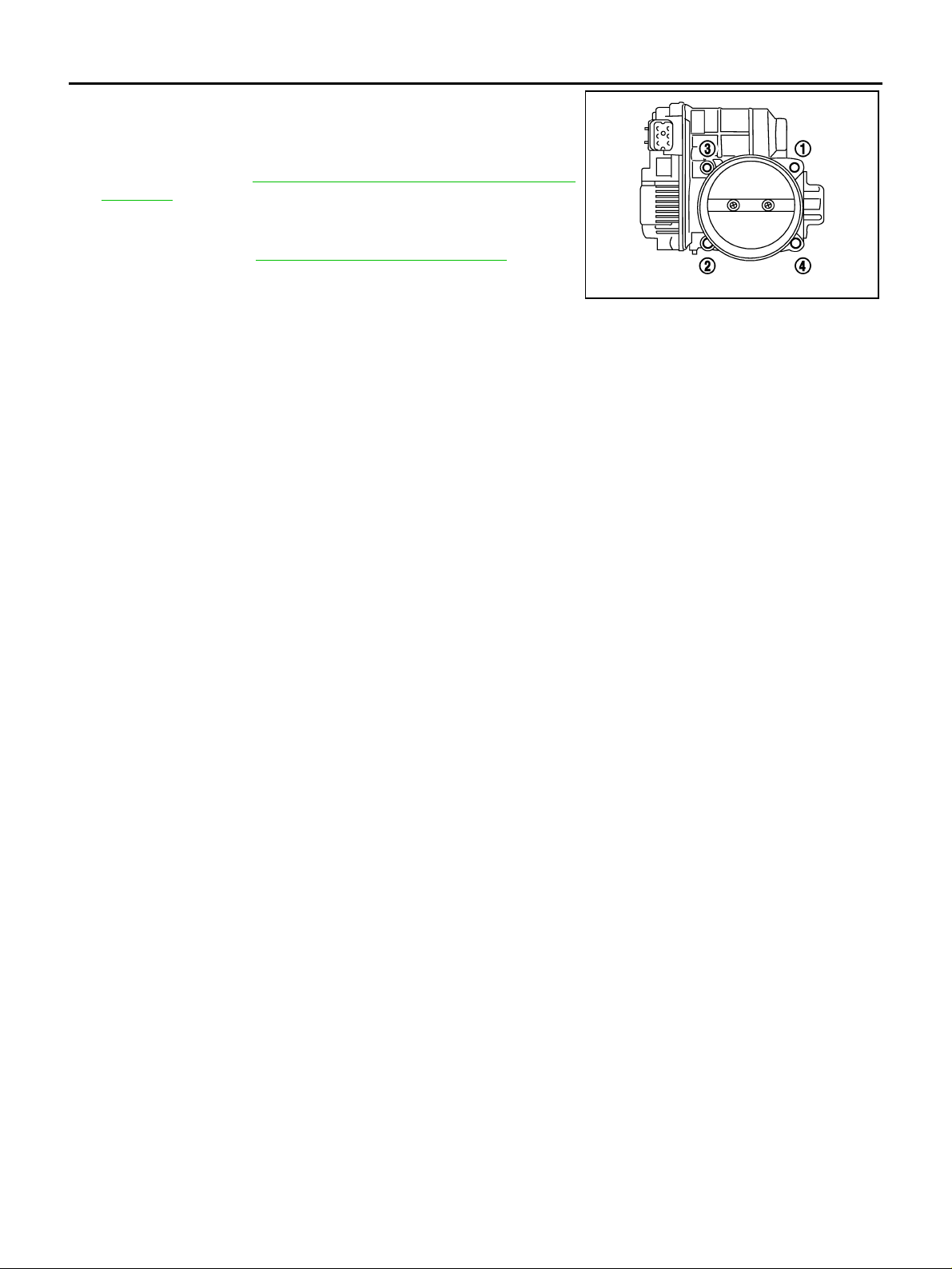

4. Remove electric throttle control actuator as follows:

a. Disconnect harness connector.

b. Loosen mounting b olts in reverse order as shown in the figure.

CAUTION:

● Handle carefully to avoid any shock to electric throttle

control actuator.

● Do not disassemble.

KBIA2007J

5. Disconnect water hoses from intake manifold collector (upper).

● When engine coola nt is not drained fr om rad iator, attach plug to water hoses to pre vent engine coolant

leakage.

H

I

J

K

L

M

Revision: 2004 November 2004 Murano

EM-17

INTAKE MANIFOLD COLLECTOR

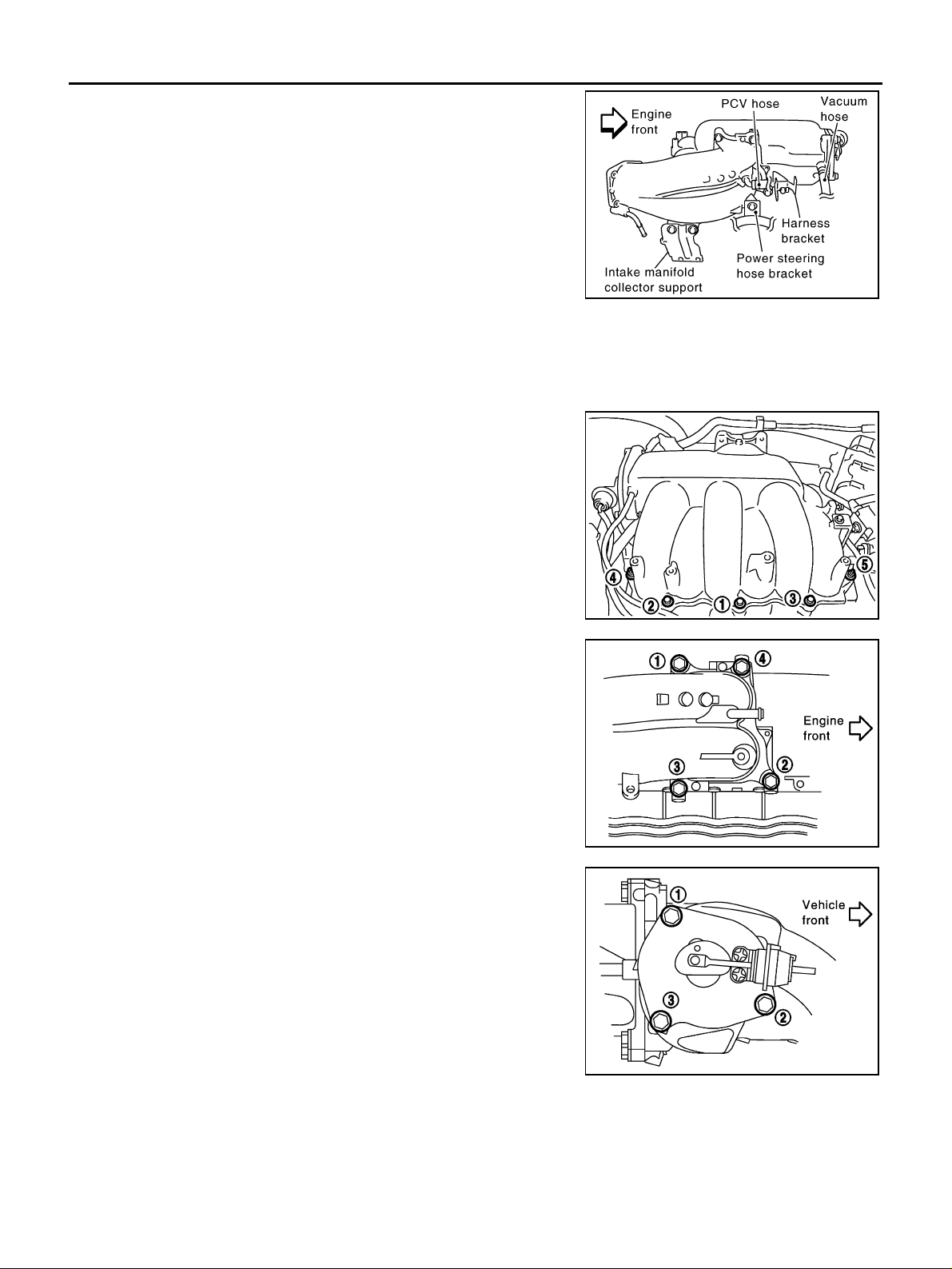

6. Remove the following parts:

● Vacuum hose

● PCV hose

● Power steering hose bracket

● Intake manifold collector support

● Harness bracket

PBIC2455E

7. Disconnect EVAP hoses and harness connector from EVAP canister purge volume control solenoid valve.

8. Remove EVAP canister purge volume control solenoid valve.

9. Remove VIAS control solenoid valve and vacuum tank.

● Add mating marks as nece s sa ry for easier installation.

10. Loosen mounting nuts and bolts in reverse order as shown in

the figure with power tool , and remove intake manifold col lector

(upper and lower) assembly and gasket.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

11. Loosen mounting bolt s in rev er se or d er as sh own in th e fig ur e to

remove intake manifold collector (upper) from intake manifold

collector (lower) with power tool.

12. Loosen mount ing bo l ts in reverse order as shown in th e fig ur e to

remove power valve from intake manifold collector (lower).

SEM713G

SEM712G

SEM714G

Revision: 2004 November 2004 Murano

EM-18

INTAKE MANIFOLD COLLECTOR

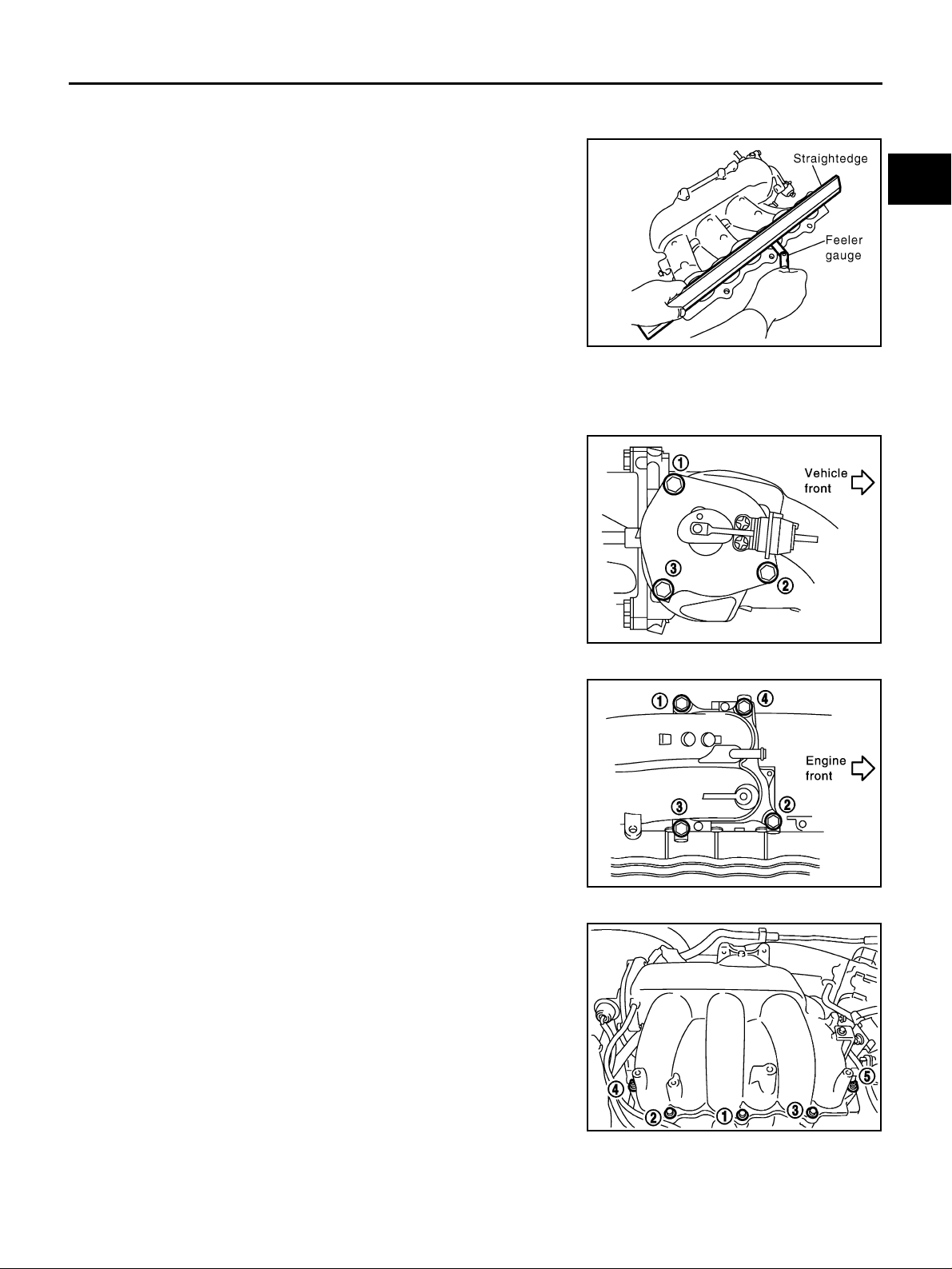

INSPECTION AFTER REMOVAL

Surface Distortion

● Check the surface distortion of intake manifold collector (lower)

with straight edge and feeler gauge.

Limit : 0.1 mm (0.004 i n)

● If it exceeds the limit, replace intake manifold collector (lower).

A

EM

C

D

PBIC1168E

INSTALLATION

Note the following, and install in the reverse order of removal.

Power V a lve

Tighten mounting bolts in nu merical order as shown in the figure.

Intake Manifold Collector (Upper)

Tighten mounting bolts in nu merical order as shown in the figure.

SEM714G

E

F

G

H

I

J

K

L

SEM712G

Intake Manifold Collector (Lower)

Tighten mounting nu ts and bolts in numerical order a s shown i n the

figure.

SEM713G

Electric Throttle Control Actuator

● Install gasket with positioning no-protrusion surface upward or downward.

Revision: 2004 November 2004 Murano

EM-19

M

INTAKE MANIFOLD COLLECTOR

● Tighten mounting bolts in numerical order as shown in the fig-

ure.

● Perform the “Throttle V alve Closed Position Learning” when har-

ness connector of electric throttle control actuator is disconnected. Refer to EC-43, "

Learning" .

● Perform the “Idle Air Volume Learning” and “Throttle Valve

Closed Position Learning” when electric throttle control actuator

is replaced. Refer to EC-43, "

Throttle Valve Closed Position

Idle Air Volume Learning" .

KBIA2007J

Revision: 2004 November 2004 Murano

EM-20

INTAKE MANIFOLD

INTAKE MANIFOLD PFP:14003

Removal and Installation ABS0033D

A

EM

C

D

E

F

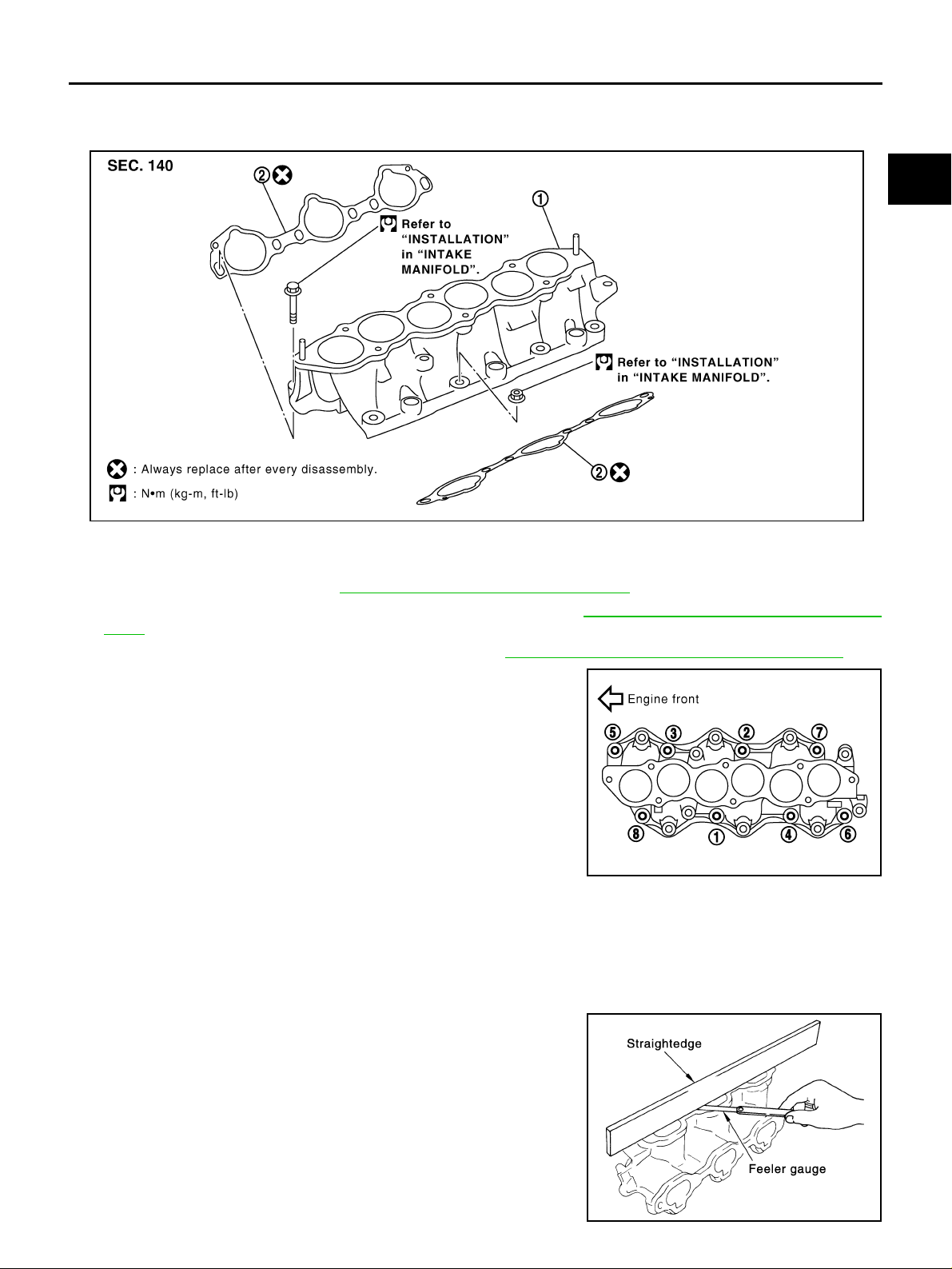

1. Intake manifold 2. Gasket

REMOVAL

1. Release fuel pre ssure . Refe r to EC-45, "FUEL PRESSURE RELEASE" .

2. Remove in take manifold collectors (upper and l ower). Refer to EM-16, "

TOR" .

3. Remove fuel tube and fuel injector assembly. Refer to EM-40, "

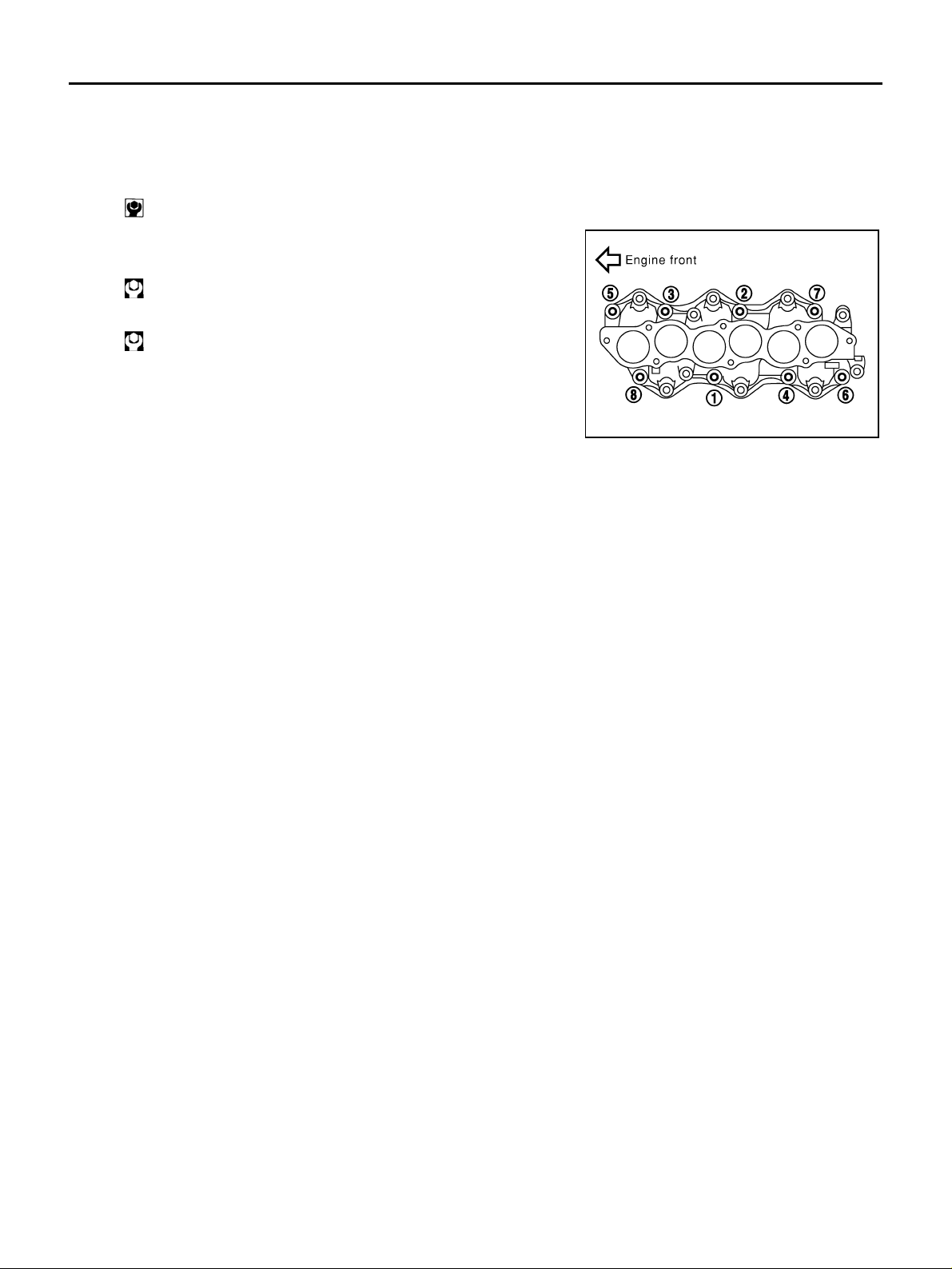

4. Loosen mounting nuts and bolts in reverse order as shown in

the figure to remove intake manifold with power tool.

5. Remove gaskets.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

FUEL INJECTOR AND FUEL TUBE" .

PBIC2458E

INTAKE MANIFOLD COL LEC-

PBIC0778E

G

H

I

J

K

L

M

INSPECTION AFTER REMOVAL

Surface Distortion

● Check the surface di stortion of the intake manifold mating sur-

faces with straightedge and feeler gauge.

Limit : 0.1 mm (0.0 04 in)

● If it exceeds the limit, replace intake manifold.

PBIC0870E

Revision: 2004 November 2004 Murano

EM-21

INTAKE MANIFOLD

INSTALLATION

Note the following, and install in the reverse order or removal.

Intake Manifold

● If stud bolts were removed, install them and tighten to the specified torque below.

: 9.8 - 11.8 N·m (1.0 - 1.2 kg-m, 87 - 104 in-lb)

● Tighten all mounting nuts and bolts to the specified torque in two

or more steps in numerical order shown in figure.

1st step

: 4.9 - 9.8 N·m (0.5 - 1.0 kg-m, 4 - 7 ft-lb)

2nd step and after

: 26.5 - 31.4 N·m (2.7 - 3.2 kg-m, 20 - 23 ft-lb)

PBIC0778E

Revision: 2004 November 2004 Murano

EM-22

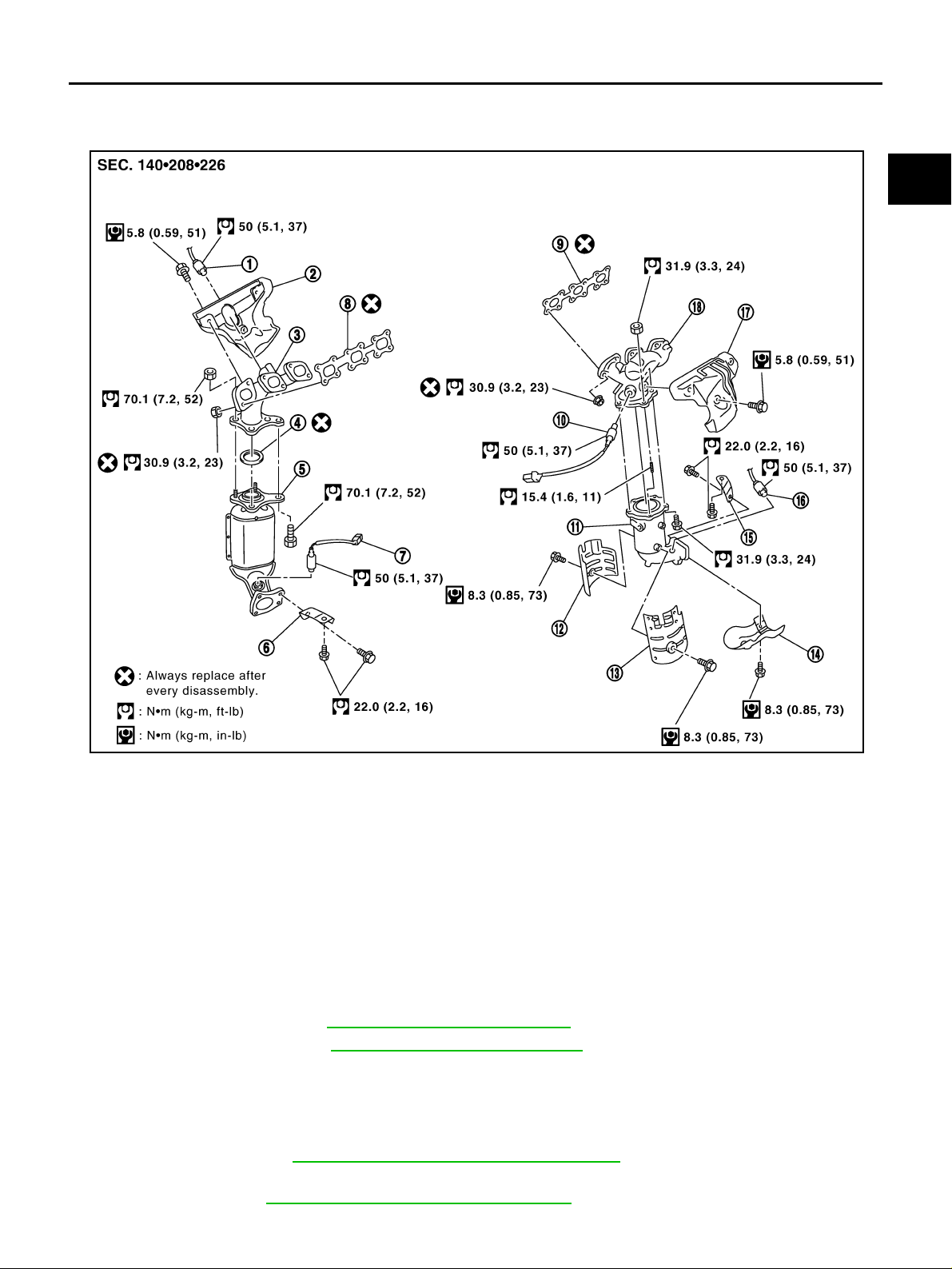

EXHAUST MANIFOLD AND THREE WAY CATALYST

EXHAUST MANIFOLD AND THREE WAY CA TALYST PFP:14004

Removal and Installation ABS0032G

A

EM

C

D

E

F

G

PBIC2461E

1. Air fuel ratio sensor 1 (bank 1) 2. Exhaust manifold cover (right bank) 3. Exhaust manifo ld (right bank)

4. Ring gasket 5. Three way catalyst (right bank) 6.

7. Heated oxygen sensor 2 (bank 1) 8. Gasket 9. G as ket

10. Air fuel ratio sensor 1 (bank 2) 11. Three way catalyst (left bank) 12. Three way catalyst cover

13. Three way catalyst cover 14. Three way catalyst cover 15.

16. Heated oxygen sensor 2 (bank 2) 17. Exhaust manifold cover (left bank) 18. Ex haust manifold (left bank)

Three way catalyst support (right

bank)

Three way catalyst support (left

bank)

REMOVAL

WARNING:

● Perform the work when the exhaust and cooling system have comple tely cooled down.

● When removing engine m ounti ng th roug h bolts and nuts, lift the engine up slightly for sa fety w ith

transmissi on jack. Refer to EM-105, "

1. Drain engine coolant. Refer to CO-9, "

CAUTION:

● Perform this step when engine is cold.

● Do not spill engine coolant on drive belts.

2. Remove following parts:

● Engine cover; Refer to EM-16, "INTAKE MANIFOLD COLLECTOR" .

● Radiator cover gri lles, air duct (inl et), air cl eaner cases (upper) wit h mass air flow se nsor and air duct

assembly; Refer to EM-14, "

AIR CLEANER AND AIR DUCT" .

ENGINE ASSEMBLY" .

Changing Engine Coolant" .

H

I

J

K

L

M

Revision: 2004 November 2004 Murano

EM-23

EXHAUST MANIFOLD AND THREE WAY CATALYST

● Undercover

● Radiator and r adiator cooling fan assembly; Refer to CO-13, "RADIATOR" .

3. Remove exhaust front tube mounting bracket and then remove exhaust front tube.Refer to EX-3,

"EXHAUST SYSTEM" .

4. Remove front w iper ar m (RH) a nd cow l top cov er (righ t) (when RH exh aust ma nifold and th ree way catalyst is removed). Refer to WW-4, "

5. Remove heat insulator.

6. Support the tr an sa xle b ot t om wi th jac k. ( AWD models) (when RH exha us t ma ni fol d an d th re e way ca talyst

is removed)

CAUTION:

Put a peace of wood or so mething similar as the supporting surfac e, be careful not to damage

transaxle.

7. Remove rear en gine mounting insulator. (AWD models) Refer to EM-105, "

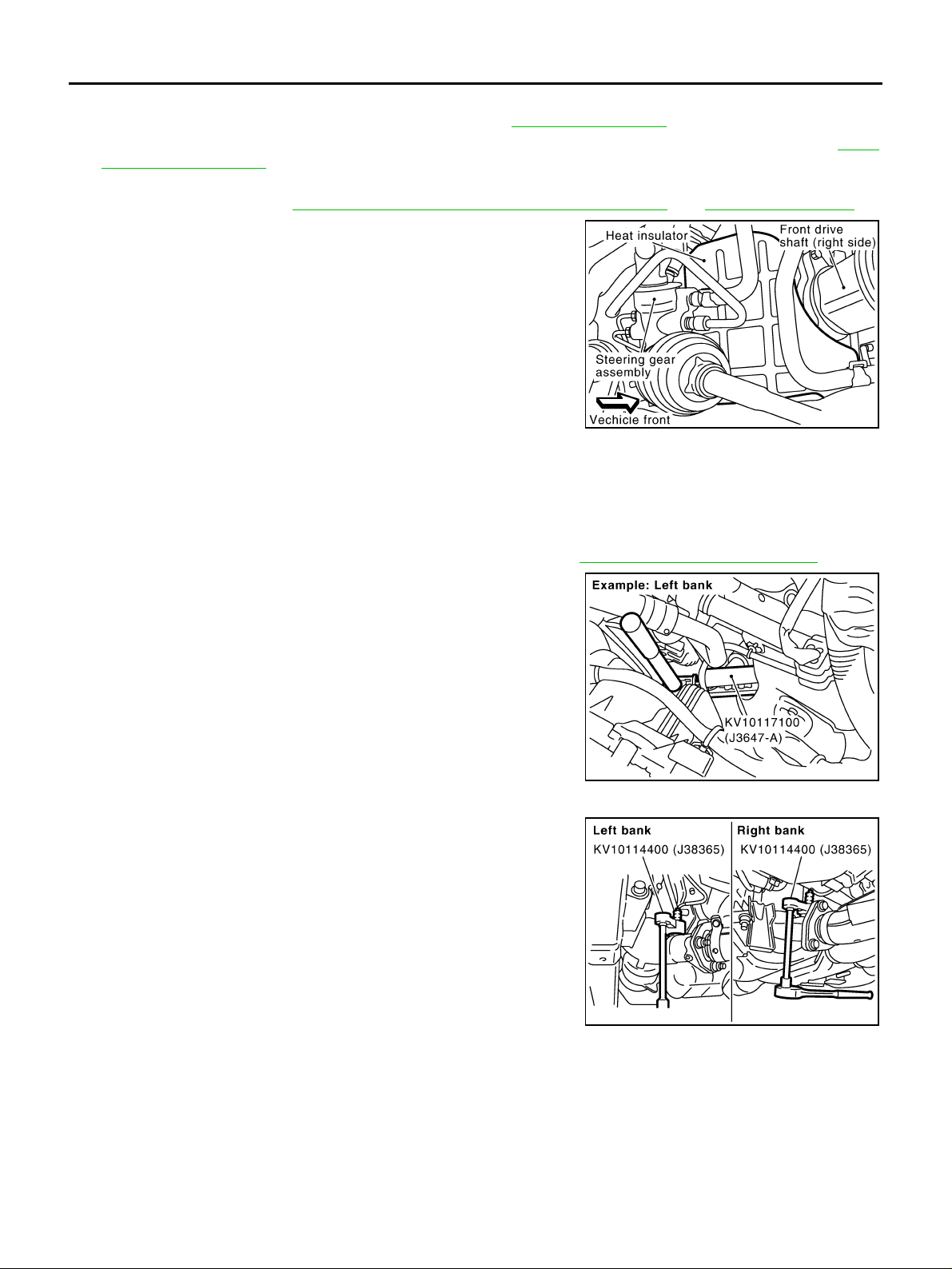

8. Disconnect harness connector and remove air fuel ratio sensor

1 on both banks with heated oxygen sensor wrench [SST].

● Put marks to identify installation positions of each air fuel ratio

sensor 1.

CAUTION:

● Be careful not to damage air fuel ratio sensor 1.

● Discard any air fuel ratio sensor 1 which has been

dropped from a height of mo re tha n 0 .5 m (1 9.7 in) onto a

hard surface such as a concrete floor; replace with a new

sensor.

NOTE:

Figure is shown as an example of left bank.

9. Disconnect harness connector and remove heated oxygen sensor 2 on both ba nks with heated oxygen sensor wrench [SST].

● Put marks to ident if y in stallation positions of ea ch he ated ox y-

gen sensor 2.

CAUTION:

● Be careful not to damage heated oxygen sensor 2.

● Discard any heated oxygen sensor 2 which has been

dropped from a height of mo re tha n 0 .5 m (1 9.7 in) onto a

hard surface such as a concrete floor; replace with a new

sensor.

FRONT WIPER AND WASHER SYSTEM" and EI-21, "COWL TOP" .

PBIC2503E

ENGINE ASSEMBLY" .

PBIC2674E

PBIC2675E

10. Remove exhaust manifold covers (right and left banks) and three way catalyst covers.

Revision: 2004 November 2004 Murano

EM-24

EXHAUST MANIFOLD AND THREE WAY CATALYST

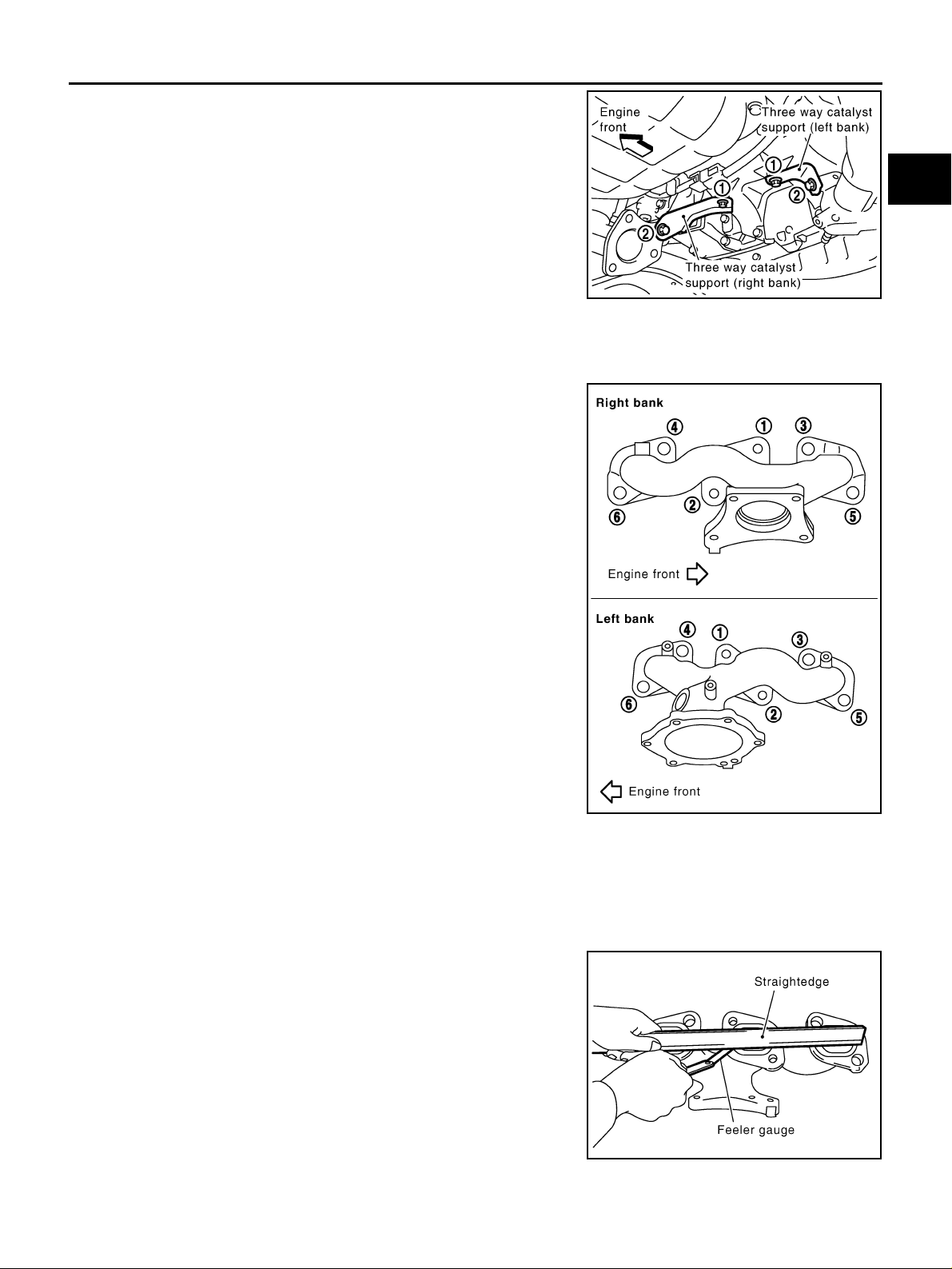

11. Remove mounting bolts in reverse o rder as shown in the figure

to remove three way catalyst supports (right and left banks).

12. Remove three way catalysts (right and left banks) by loosening bolts first and then removing nuts.

CAUTION:

Handle carefully to avoid any shock to th ree way catalyst.

13. Loos en mo un tin g n uts in rev ers e o rder as shown in the fi gu re to

remove exhaust manifolds (right and left banks).

A

EM

C

PBIC2463E

D

E

F

G

14. Remove gaskets.

CAUTION:

Cover engine openings to avoid entry of foreign materials.

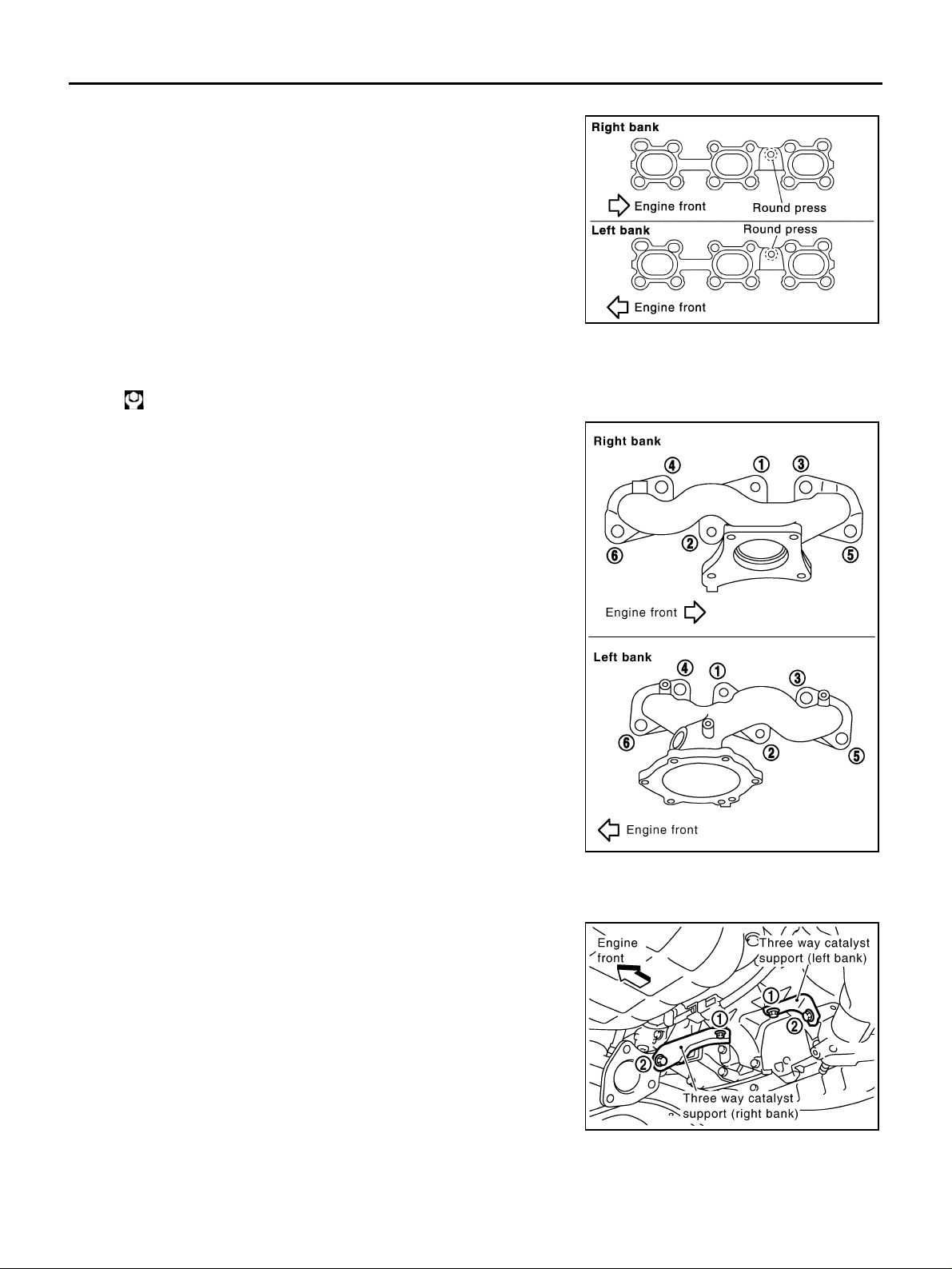

INSPECTION AFTER REMOVAL

Surface Distortion

● Check the surface distortion of the exhaust manifold mating sur-

faces with straightedge and feeler gauge.

Limit : 0.3 mm (0.012 in)

PBIC2464E

H

I

J

K

L

M

● If it exceeds the limit, replace exhaust manifold.

PBIC1173E

INSTALLATION

Note the following, and install in the reverse order of removal.

Revision: 2004 November 2004 Murano

EM-25

EXHAUST MANIFOLD AND THREE WAY CATALYST

Exhaust Manifold Gasket

Install in the direction indicated in the figure.

Exhaust Manifold

● If stud bolts were removed, install them and tighten to the torque specified below.

: 14.2 - 16.6 N·m (1.5 - 1.6 kg-m, 11 - 12ft-lb)

● Ti ght en moun tin g nu t s i n nu meri ca l orde r as show n in the figu r e.

KBIA1051E

PBIC2464E

Three Way Catalyst Supports

1. Temporarily tighten three way catalyst support mounting bolts.

2. Tighten three way catalyst support mounting bolts to specified

torque in numerical order as shown in th e figure.

PBIC2463E

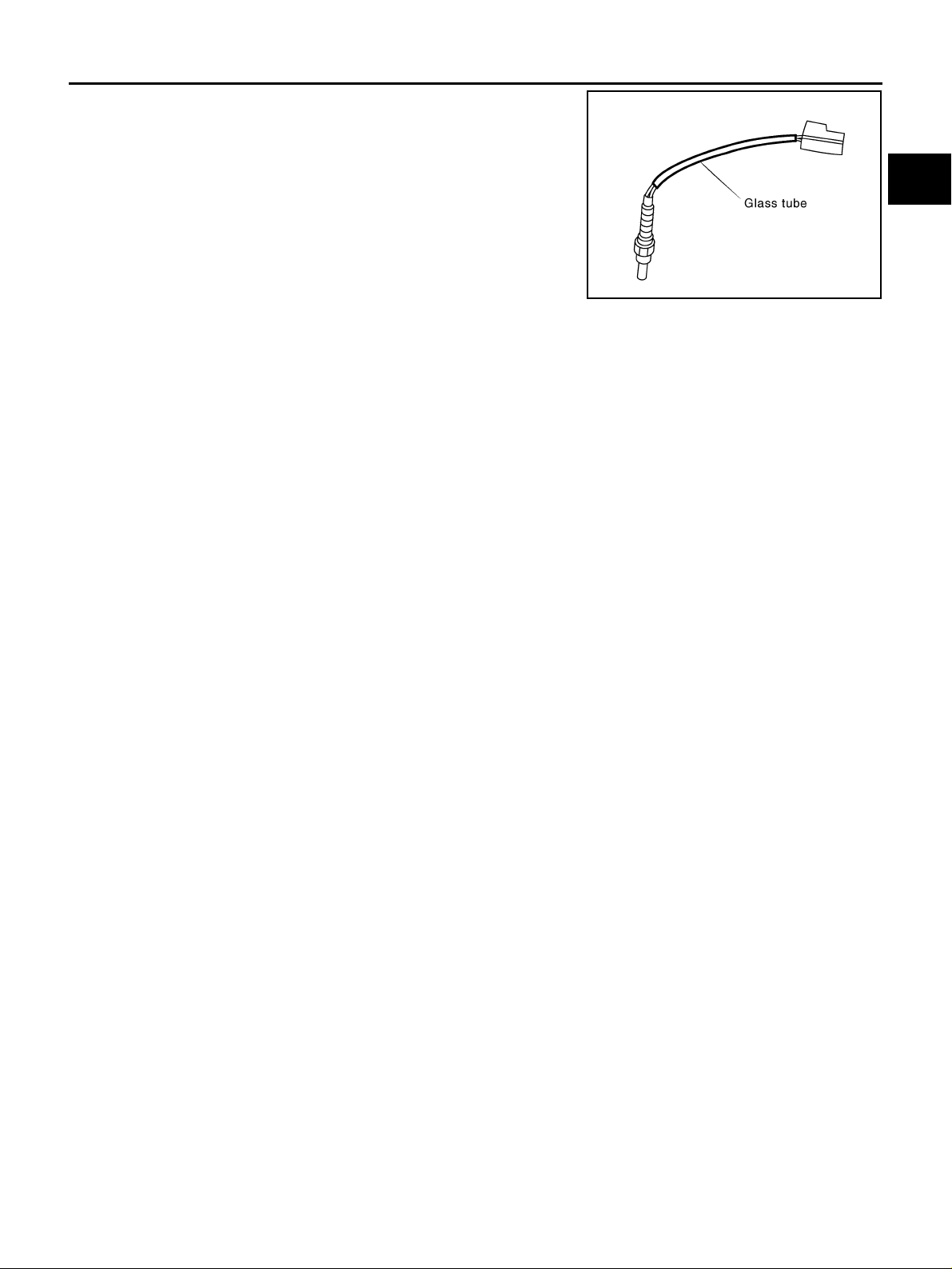

Air Fuel Ratio Sensor 1 and Heated Oxygen Sensor 2

● Install air fuel ratio sensor 1 and heated oxygen sensor 2 in the original position.

Revision: 2004 November 2004 Murano

EM-26

EXHAUST MANIFOLD AND THREE WAY CATALYST

● Install referring the following if the installation positions cannot

be identified.

Glass tube color

Air fuel ratio sensor 1 : Black

Heated oxygen sensor 2 : White

CAUTION:

● Before installing a new heated oxygen sensor, clean

exhaust system threads using oxygen sensor thread

cleaner (commercial service tool: J-43897-18 or J43897-12)

and apply anti-seize lubricant (commercial service tool).

● Do not over torque h ea ted ox yg en sensor. Doing so may cause dama ge to heated oxyg en se ns or,

resulting in “MIL” coming on.

PBIC2652E

A

EM

C

D

E

F

G

H

K

M

I

J

L

Revision: 2004 November 2004 Murano

EM-27

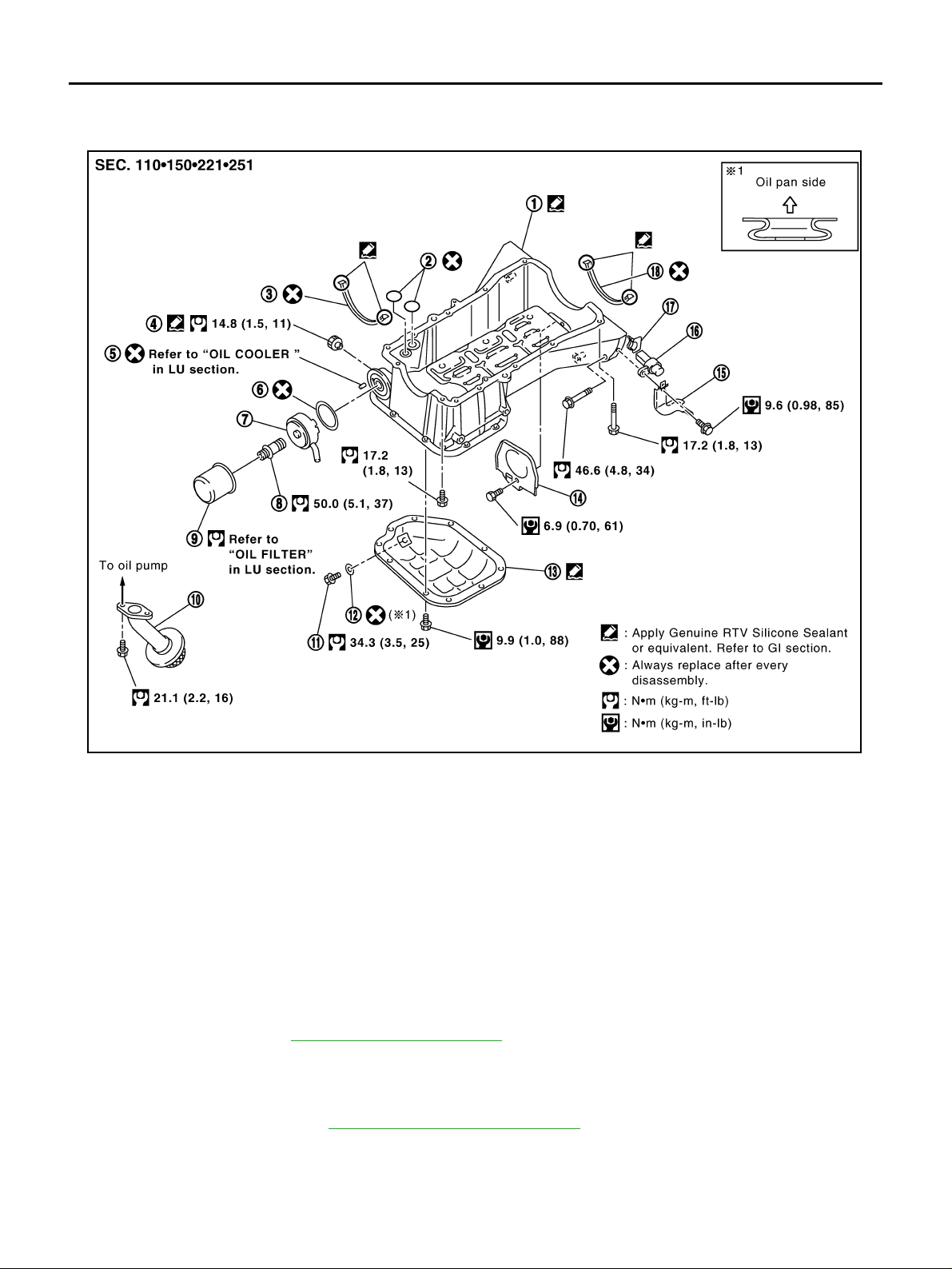

OIL PAN AND OIL STRAINER

OIL PAN AND OIL STRAINER PFP:11110 Removal and Installation ABS00FPS

1. Oil pan (upper) 2. O-ring 3. Oil pan gasket

4. Oil pressure switch 5. Relief valve 6. O-ring

7. Oil cooler 8. Connec tor bolt 9. Oil filter

10. Oil straine r 11. Drain plug 12. Drain plug washer

13. Oil pan (lower) 14. Rear plat e cover 15. Harness brack et

16. Cranksh af t pos ition sensor (POS) 17. Seal rubber 18. Oil pan gasket

REMOVAL

2WD Model

WARNING:

To avoid the danger of being scalded, do not drain engine oil when engine is hot.

NOTE:

When removing oil pan (lower) or oil strainer only, take step 1 then step 10 and 11.

1. Drain engine oil. Refer to LU-8, "

CAUTION:

● Perform this step when engine is cold.

● Do not spill engine oil on drive belts.

2. Drain engine coolant. Refer to CO-9, "

CAUTION:

● Perform this step when engine is cold.

● Do not spill engine coolant on drive belts.

3. Remove following parts:

Changing Engine Oil" .

Changing Engine Coolant" .

PBIC2676E

Revision: 2004 November 2004 Murano

EM-28

OIL PAN AND OIL STRAINER

● Engine cover; Refer to EM-16, "INTAKE MANIFOLD COLLECTOR" .

● Undercover

● Splash guard (RH)

● Exhaust front tube; Refer to EX-3, "EXHAUST SYSTE M" .

● Drive belts; Refer to EM -11, "DRIVE BELTS" .

4. Remove A/C compressor with piping connected, and temporarily secure it to aside. Refer to ATC-131,

"Components" .

5. Remove three way catalysts (right and left banks) from exhaust manifolds (right and left banks). Refer to

EM-23, "

6. Remove oil pressure switch. Refer to LU-7, "

7. Remove crankshaft position sensor (POS).

CAUTION:

● Handle carefully to avoid dropping and shocks.

● Do not disassemble.

● Do not allow metal powder to adhere to magnetic part at sensor tip.

● Do not place sensor in a location where it is exposed to magnetism.

8. Remove oil filter. Refer to LU-9, "OIL FILTER" .

9. Remove oil cooler and water pipes. Refer to LU-10, "

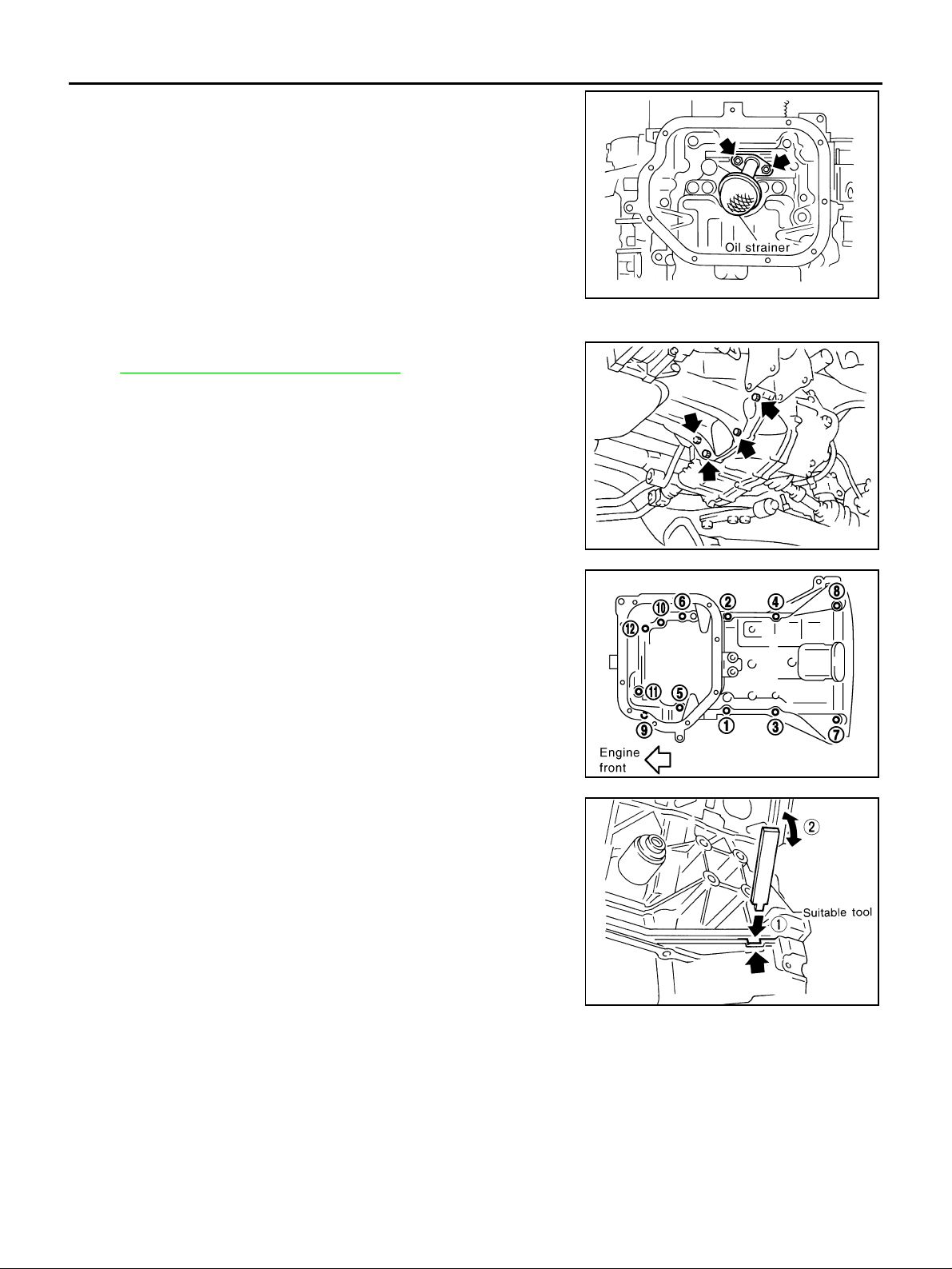

10. Remove oil pan (lower) as follows:

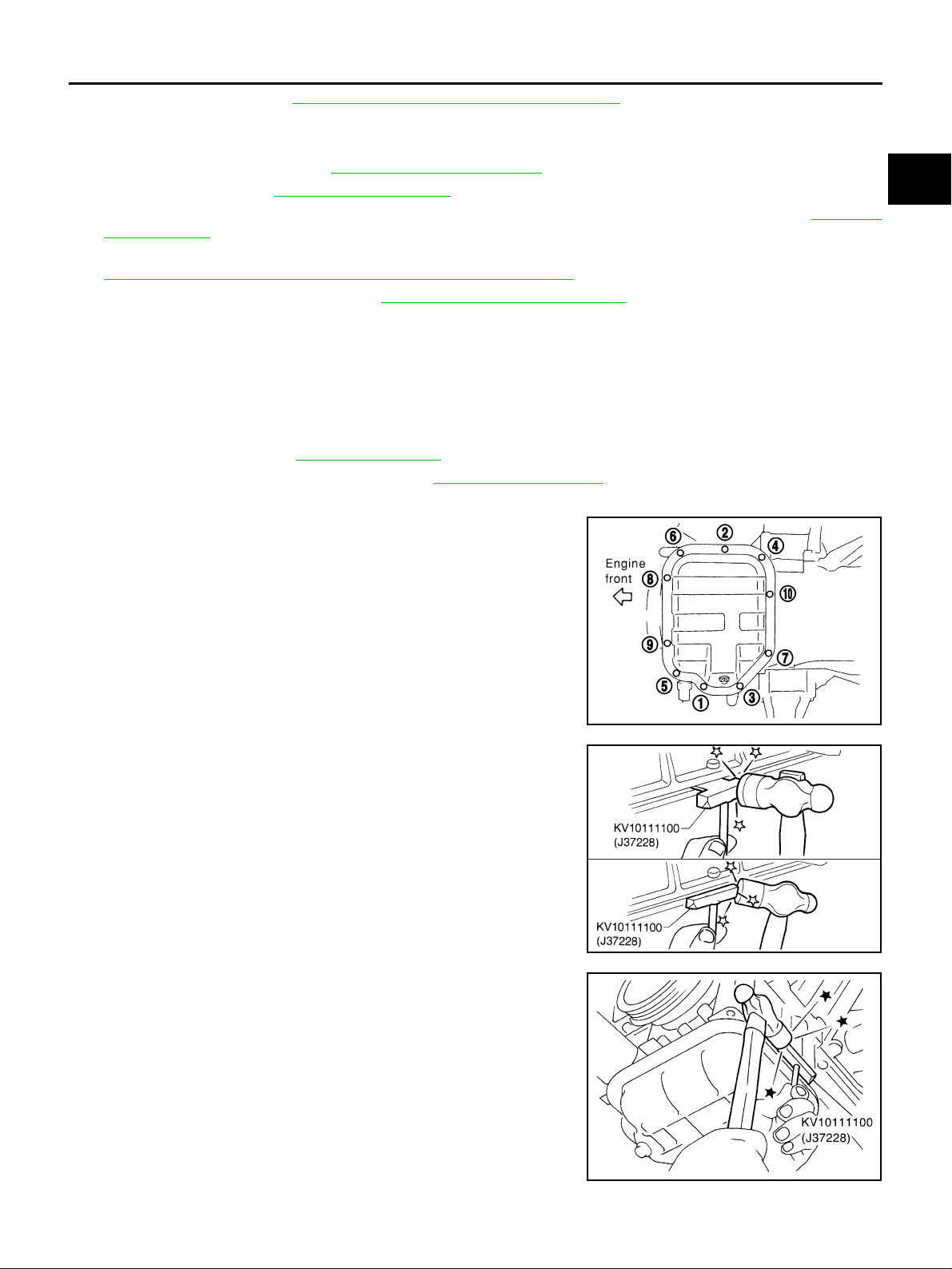

a. Loosen mounting b olts in reverse order as shown in the figure.

EXHAUST MANIFOLD AND THREE WAY CATALYST" .

OIL PRESSURE CHECK" .

OIL COOLER" .

A

EM

C

D

E

F

G

b. Insert seal cutter [SST] between oil pan (lower) and oil pan

(upper).

CAUTION:

● Be careful not to damage the mating surfaces.

● Do not insert screwdriver, this will damage the mating

surfaces.

c. Slide seal cu tter by tapping on th e sid e of t he too l wi th hamm er.

Remove oil pan (lower).

H

I

J

PBIC0782E

K

L

M

SEM365E

SEM960F

Revision: 2004 November 2004 Murano

EM-29

OIL PAN AND OIL STRAINER

11. Remove oil strainer.

12. Remove oil pan (upper) as follows:

a. Remove transaxle joint bolts which pierce oil pan (upper). Refer

to CVT-224, "

TRANSAXLE ASSEMBLY" .

PBIC1766E

b. Loosen mounting bolts in reverse order as shown in the figure.

c. Insert suitable tool into the notch of oil pan (upper) as shown (1).

Pry off oi l pan (upper) by moving tool up and down as shown (2)

to remove oil pan (upper).

SEM949G

PBIC1636E

SEM155F

Revision: 2004 November 2004 Murano

EM-30