Nissan Micra 2003 User Manual

POWER STEERING SYSTEM

G STEERING

A

B

SECTION

POWER STEERING SYSTEM

CONTENTS

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 2

Caution: .................................................................... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Trouble Shooting Chart .................................... 4

STEERING WHEEL .................................................... 5

On Board Inspection and Service ............................ 5

PLAY INSPECTION .............................................. 5

NEUTRAL POSITION INSPECTION .................... 5

STEERING TORQUE INSPECTION .................... 5

STEERING ANGLE INSPECTION ........................ 5

Removal and Installation .......................................... 6

STEERING COLUMN ................................................. 7

Removal and Installation .......................................... 7

REMOVAL OF STEERING COLUMN ASSEM-

BLY ........................................................................ 7

INSPECTION AFTER REMOVAL OF STEER-

ING COLUMN ASSEMBLY ................................... 8

INSTALLATION OF STEERING COLUMN

ASSEMBLY ...........................................................8

CHECK AFTER STEERING COLUMN ASSEM-

BLYINSTALLATION ..............................................8

POWER STEERING GEAR AND LINKAGE ..............9

Removal and Installation ..........................................9

REMOVAL .............................................................9

INSTALLATION .....................................................9

Disassembly and Assembly .................................... 10

COMPONENTPARTSLOCATION(R24TTYPE)...10

DISASSEMBLY ...................................................10

INSPECTION AFTER DISASSEMBLY ................10

ASSEMBLY ......................................................... 11

SERVICE DATA AND SPECIFICATIONS (SDS) ......13

Wheel .....................................................................13

Steering Angle ........................................................13

Steering Column .....................................................13

Steering Linkage ..................................................... 13

Tightening Torque ...................................................14

C

D

E

F

PS

H

I

J

K

L

PS-1

M

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

● To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed by an authorized NISSAN/INFINITI dealer.

● Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

● Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or

harness connectors.

Caution:

● Always follow the warnings and the cautions below in disassembly procedures:

– Work in a clean, dust-free place. No dustproof device is necessary.

– Clean the outside of the unit before disassembly.

– Clean the parts to be disassembled. Care must be taken not to allow any dirt or other foreign materials to

enter or come in contact with the parts.

– Assemble the disassembled parts properly, following the order shown in the manual. If work has been

suspended in the middle of assembly, place a clean cover over the parts to prevent them from being contaminated.

– Use paper towels when removing dirt and other foreign materials. Cloth shop towels can leave lint on the

cleaned parts that might affect the operation of the parts.

– Clean disassembled parts with kerosene (except rubber parts), and then dry them thoroughly with an air

blower or paper towels.

EGS001B3

EGS000J1

PS-2

PREPARATION

PREPARATION PFP:00002

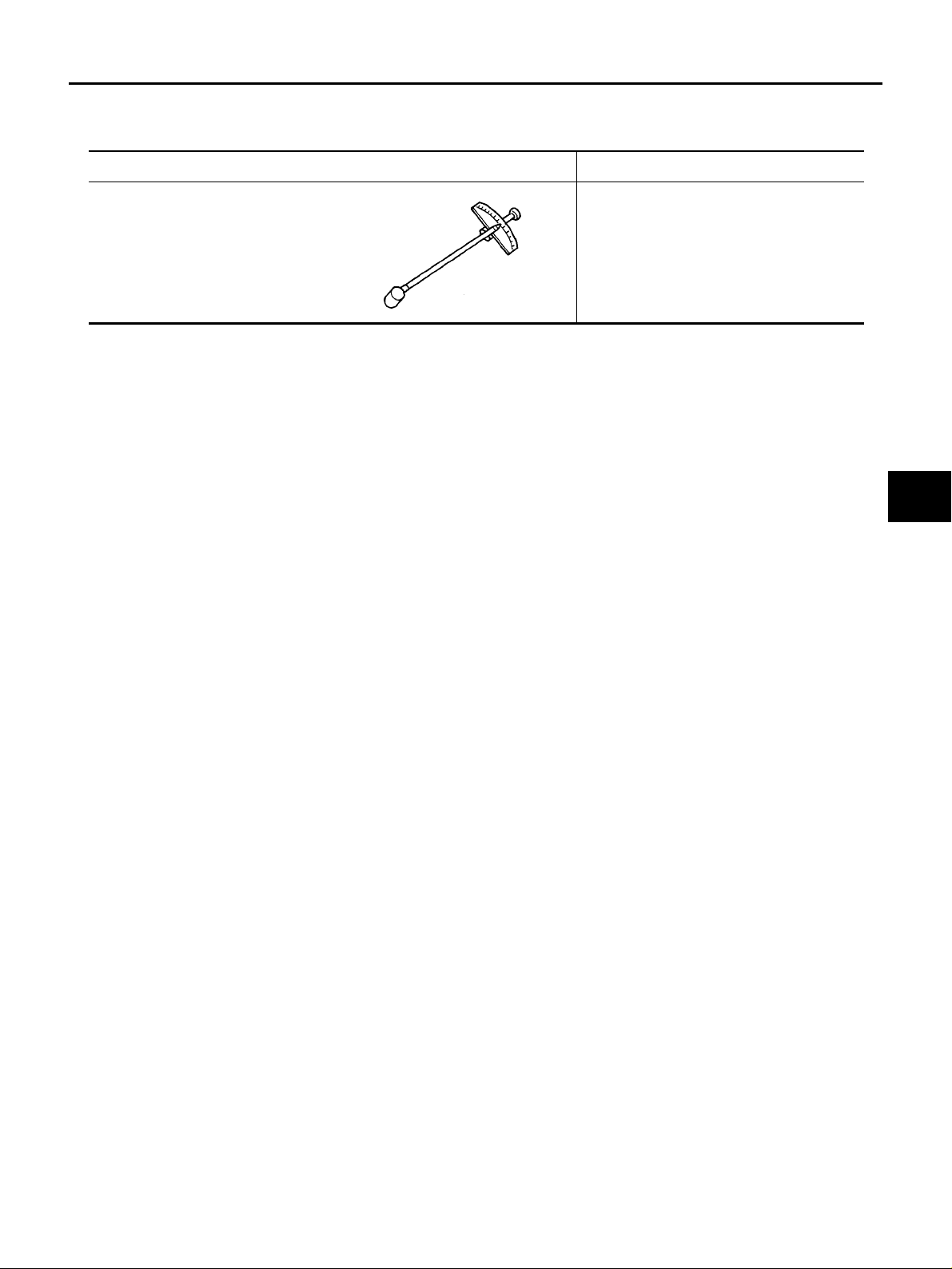

Special Service Tools

EGS000J2

A

Preload gauge

ST3127S000

Description Application

● Checking steering torque

● Pinion gear rotating torque measurement

for steering gear

ZZA0806D

B

C

D

E

F

PS

H

I

K

M

J

L

PS-3

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

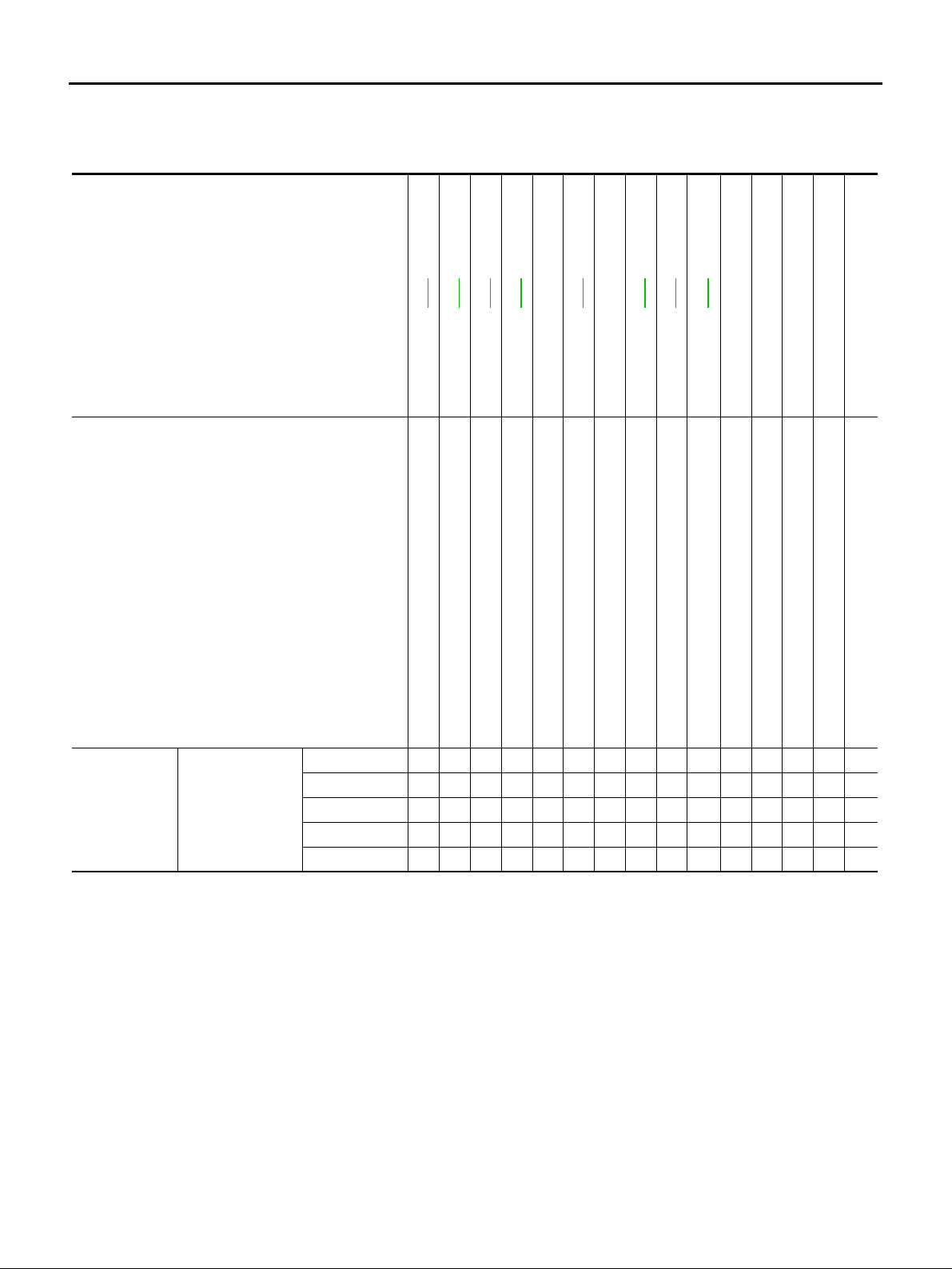

NVH Trouble Shooting Chart

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

PS-9

PS-9

PS-9

–

PS-5

–

PS-7

PS-7

PS-7

PS-9

NVH in WT section

NVH in WT section

NVH in FAX section

NVH in FAX, RAX, FSU, RSU section

EGS000J3

NVHinBRsection

Possible cause and SUSPECTED PARTS

Symptom STEERING

×: Applicable

Tie-rod ball joint tensile force

Tie-rod ball joint sliding torque

Tie-rod ball joint end play

Steering wheel play

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

Noise ×××× ×××× ×

Shake ××× ×××× ×

Vibration ЧЧЧЧЧ ×× ×

Shimmy ××× ×××× ×

Judder ××××××

PS-4

STEERING WHEEL

STEERING WHEEL PFP:48430

On Board Inspection and Service

PLAY INSPECTION

1. Turn steering wheel to the straight-ahead position. Start engine and lightly turn steering wheel clockwise

and counterclockwise until the front wheels start moving. Measure the travel to the starting point on the

circumference of steering wheel. If play is outside the specified range, check steering gear assembly ,front

suspension, axles, and steering column for proper installation.

Steering wheel play inspection standard : 0 - 35 mm (0 - 1.38 in)

2. Check steering wheel for vertical, horizontal, or axial play.

Steering wheel axial end play : 0 mm (0 in)

● Lift vehicle and check steering gear nuts and bolts for looseness.

Tightening torque : 85 - 103 N·m (8.7 - 10.5 kg-m, 63 - 75 ft-lb)

NEUTRAL POSITION INSPECTION

● After wheel alignment inspection, perform neutral position inspection. Refer to FSU-6, "Wheel Alignment"

.

● Set vehicle to the straight-ahead position and confirm steering wheel is in the neutral position.

● If it is not in the neutral position, loosen lock nut on tie-rod. Then adjust until the amount of left and right

becomes equal.

EGS000J4

A

B

C

D

E

F

PS

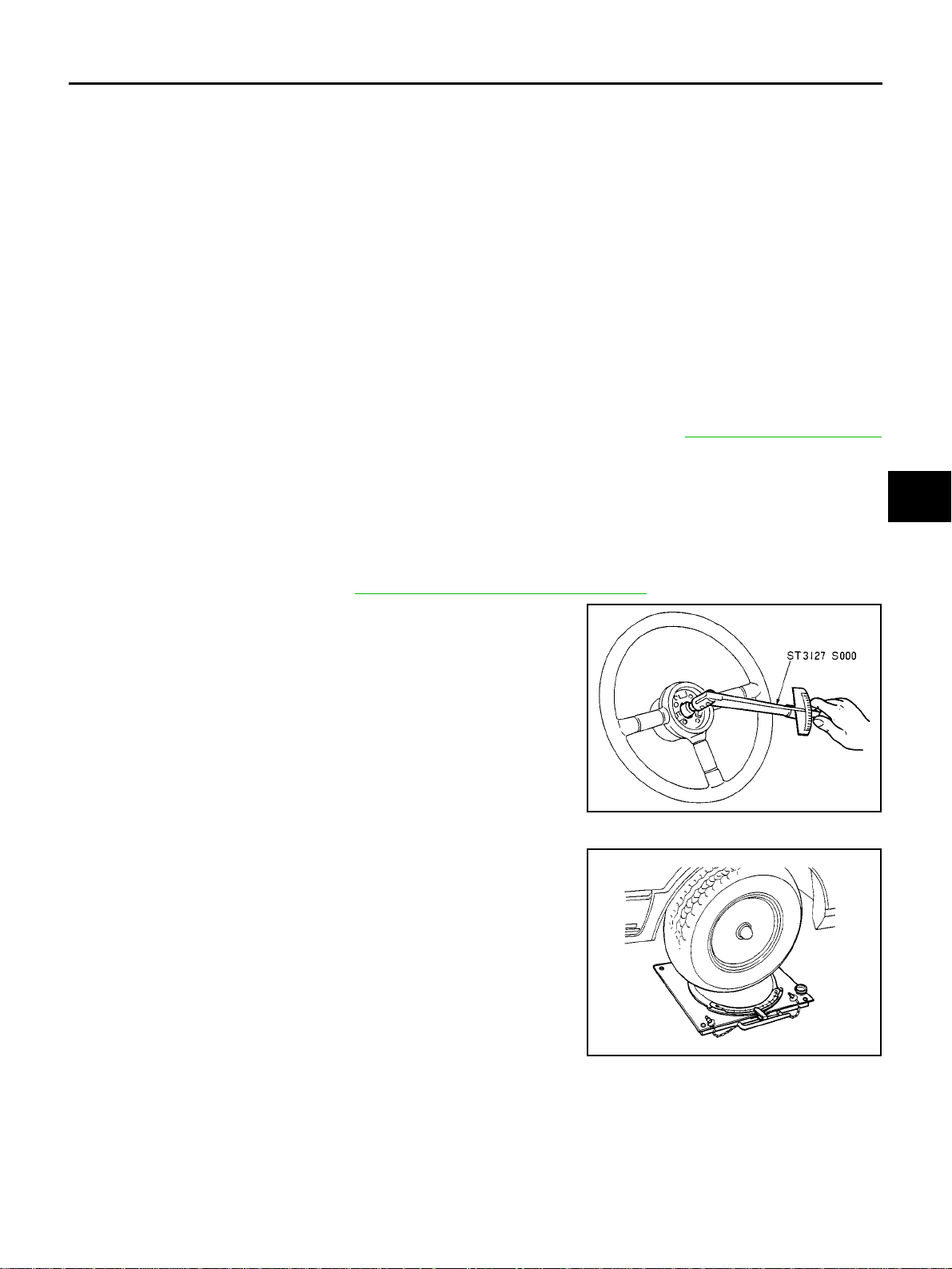

STEERING TORQUE INSPECTION

1. Stop vehicle on a dry flat paved road and apply parking brake.

2. Remove air bag module. Refer to SRS-36, "

DRIVER AIR BAG MODULE" .

3. Start engine and use a preload gauge (SST) to check steering

wheel torque.

Steering torque : 1.8 - 5.6 N·m (0.18 - 0.57 kg-m,

16 - 49 in-lb) or less

4. When torque is outsidethe standard, check steeringcolumn and

steering gear. If any non-standard condition is detected, replace

if necessary.

STEERING ANGLE INSPECTION

● After toe-in inspection, check the steering angle. Place the front

wheels on turning radius gauges and the rear wheels on stands

so that the vehicle can be level. Check the maximum inner and

outer wheel steering angles for LH and RH road wheels.

STA0005D

H

I

J

K

L

M

PS-5

FAA0016D

Loading...

Loading...