Page 1

Terra™ 5200B

INSTRUCTIONS FOR USE

Advance model: 908 4508 010

INSTRUCCIONES DE USO

Modelo Advance: 908 4508 010

MODE D’EMPLOI ET D’ENTRETIEN

Modèle Advance: 908 4508 010

INSTRUÇÕES DE USO

Modelo Advance: 908 4508 010

146 1996 000(2)2004-08

Page 2

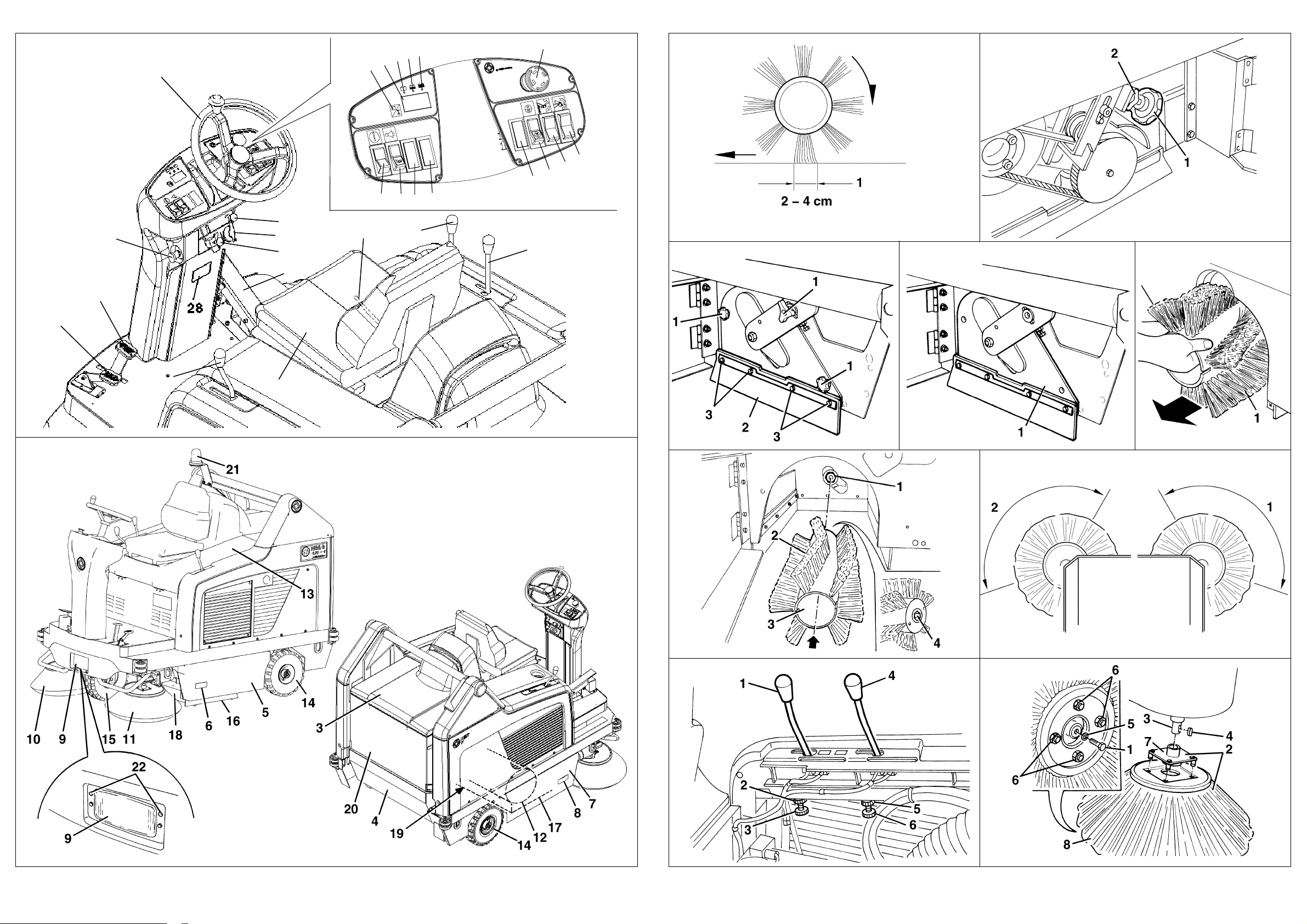

B

25

26

11

10

17

18

19

20

23

13

12

14

15

16

9

8

7

5

6

4

23

1

21

22

D

F

G

S310027

E

S310114

H

C

24

27

S310208

I

K

S310180

S310117

J

L

S310181

S310133

S300210

S310209

Terra™ 5200B – 146 1996 000(2)2004-08

S310119

S310211

Page 3

INSTRUCTIONS FOR USE

INTRODUCTION....................................................................................................................... 2

MANUAL PURPOSE AND CONTENTS ............................................................................................................ 2

TARGET ............................................................................................................................................................ 2

HOW TO KEEP THIS MANUAL ........................................................................................................................ 2

IDENTIFICATION DATA.................................................................................................................................... 2

OTHER REFERENCE MANUALS..................................................................................................................... 2

SPARE PARTS AND MAINTENANCE .............................................................................................................. 2

CHANGES AND IMPROVEMENTS .................................................................................................................. 2

SAFETY ............................................................................................................................................................. 2

SYMBOLS.......................................................................................................................................................... 2

GENERAL INSTRUCTIONS.............................................................................................................................. 3

UNPACKING...................................................................................................................................................... 3

MACHINE DESCRIPTION ........................................................................................................ 4

TERRA™ 5200B SWEEPER OPERATION....................................................................................................... 4

CONVENTIONS................................................................................................................................................. 4

DESCRIPTION .................................................................................................................................................. 4

TECHNICAL DATA ............................................................................................................................................ 5

FUSES ............................................................................................................................................................... 6

ACCESSORIES/OPTIONS................................................................................................................................ 6

USE ........................................................................................................................................... 6

BATTERY CHECK/SETTING ON A NEW MACHINE ....................................................................................... 6

BATTERY INSTALLATION AND WET OR GEL BATTERY SETTING ............................................................. 7

BEFORE MACHINE START-UP........................................................................................................................ 7

STARTING AND STOPPING THE MACHINE ................................................................................................... 8

MACHINE OPERATION .................................................................................................................................... 8

HOPPER DUMPING.......................................................................................................................................... 9

AFTER USING THE MACHINE ......................................................................................................................... 9

WORKING LIGHT ADJUSTMENT..................................................................................................................... 9

MACHINE LONG INACTIVITY .......................................................................................................................... 9

FIRST PERIOD OF USE ................................................................................................................................... 9

MAINTENANCE......................................................................................................................10

SCHEDULED MAINTENANCE TABLE ........................................................................................................... 10

MAIN BROOM HEIGHT CHECK AND ADJUSTMENT ................................................................................... 11

MAIN BROOM REPLACEMENT ..................................................................................................................... 11

SIDE BROOM HEIGHT CHECK AND ADJUSTMENT .................................................................................... 12

SIDE BROOM REPLACEMENT ...................................................................................................................... 12

FRAME DUST FILTER CLEANING AND INTEGRITY CHECK ...................................................................... 13

POCKET DUST FILTER CLEANING AND INTEGRITY CHECK .................................................................... 13

SKIRT HEIGHT AND OPERATION CHECK ................................................................................................... 14

HOPPER LIFTING SYSTEM HYDRAULIC OIL LEVEL CHECK..................................................................... 14

BATTERY CHARGING .................................................................................................................................... 14

SAFETY FUNCTIONS ............................................................................................................15

RUNNING CONSENT SWITCH ...................................................................................................................... 15

EMERGENCY PUSH-BUTTON....................................................................................................................... 15

HOPPER LIFTING/LOWERING CONSENT PUSH-BUTTON......................................................................... 15

HOPPER LIFTING CYLINDER SAFETY DEVICE VALVE.............................................................................. 15

TROUBLESHOOTING............................................................................................................15

SCRAPPING ........................................................................................................................... 16

146 1996 000(2)2004-08 – Terra™ 5200B 1

Page 4

INSTRUCTIONS FOR USE

INTRODUCTION

MANUAL PURPOSE AND CONTENTS

The purpose of this manual is to provide the Customer

with all necessary information to use the machine properly

in a safe and autonomous way. This includes information

about technical characteristics, operation, machine

inactivity, maintenance, spare parts and safety conditions.

Before carrying out any procedure on the machine, the

Operators and qualified Technicians must read this

manual carefully. Contact the Manufacturer in case of

doubts regarding the interpretation of the instructions and

for any further information.

TARGET

This manual is intended for the Operator and the

Technicians qualified for the machine maintenance.

The Operators must not carry out operations reserved for

qualified Technicians. The Manufacturer will not be

answerable for damages coming from the

non-observance of this prohibition.

HOW TO KEEP THIS MANUAL

The Instructions for Use must be kept near the machine,

inside an adequate case, far from liquids and other

substances that can cause damage to it.

IDENTIFICATION DATA

The machine model and serial number can be found on a

plate (28, Fig. B) affixed to the machine steering column

and readable from outside. The machine production year

is shown after the date Code on the serial plate (A04

means January 2004).

This information is useful when requiring machine

replacement parts. Use the following table to write down

the machine identification data for any further reference.

SPARE PARTS AND MAINTENANCE

All necessary operating, maintenance and repair

procedures must be carried out by qualified personnel or

by Nilfisk-Advance Service Centers. Only original spare

parts and accessories must be used.

Call Nilfisk-Advance for service or to order spare parts and

accessories, specifying the machine model and serial

number.

CHANGES AND IMPROVEMENTS

Our Company constantly improves its products and

reserves the right to make changes and improvements at

its discretion without being obliged to apply such benefits

to the machines that were sold previously.

Any modifications and/or addition of accessory must be

approved and performed by the Manufacturer.

SAFETY

The following symbols indicate potentially dangerous

situations. Always read this information carefully and take

the necessary precautions to protect people and objects.

The machine Operator's cooperation is essential in order

to prevent injury. No accident prevention program is

effective without the total cooperation of the person

responsible for the machine operation. Most of the

accidents that may occur in a factory, while working or

moving around, are caused by failure to comply with the

simplest rules for exercising prudence. A careful and

prudent Operator is the best guarantee against accidents

and is essential for successful completion of any

prevention program.

SYMBOLS

DANGER!

It indicates a dangerous situation (risk of

death) for the Operator.

MACHINE model .........................................................

MACHINE serial number .............................................

OTHER REFERENCE MANUALS

– Spare Parts List (supplied with the machine).

– Service Manual (that can be consulted at any

Nilfisk-Advance Service Center).

WARNING!

It indicates a potential risk of injury for

people.

CAUTION!

It indicates a caution or a remark related to

important or useful functions. Pay

particular attention to the paragraphs

marked by this symbol.

CONSULTATION

Consult the Instructions for Use before

performing any operation.

2 Terra™ 5200B – 146 1996 000(2)2004-08

Page 5

INSTRUCTIONS FOR USE

GENERAL INSTRUCTIONS

Specific warnings and cautions to inform about potential

damages to people and machine are shown below.

DANGER!

– To perform maintenance/repair procedures turn the

machine ignition key to OFF position and disconnect

the battery.

– This machine must be used by qualified and

authorized personnel only. Children or disabled

people cannot use this machine.

– Keep the battery far from sparks, flames and smoke.

During the normal operation explosive gases are

delivered.

– Do not wear jewelry when working near electrical

components.

– Do not work under the lifted machine, if it is not

securely fixed.

– Each time you work under the open hood, ensure that

the hood cannot close by accident.

– Do not operate the machine near dangerous,

inflammable and/or explosive powders, liquids or

vapors.

– Battery charging produces explosive hydrogen gas.

Keep the hood open during battery charging and

perform this operation only in well-ventilated areas

and far from naked flames.

WARNING!

– Carefully read all the instructions before performing

any maintenance/repair procedure.

– Take all necessary precautions to prevent hair,

jewelry and loose clothes from being caught by the

machine moving parts.

– Do not smoke during battery charging.

– Do not leave the machine unattended with the ignition

key inserted and the parking brake disengaged.

– Do not use the machine on surfaces with a gradient

greater than the one indicated on the machine.

– Do not wash the machine with direct or pressurized

water jets or corrosive substances. Do not use

compressed air to clean this type of machine except

for filters (see related paragraph).

– While using this machine, take care not to cause

damage to people and children especially.

– Do not put any can containing liquids on the machine.

– The storage temperature must be between +32°F

and +104°F (0°C and +40°C).

– The machine must be used at a temperature between

+32°F and +104°F (0°C and +40°C).

– The humidity range should be between 30% and

95%.

– Always protect the machine against the sun, rain and

bad weather, both under operation or inactivity

condition.

– The machine cannot be used for towing or pushing

objects and/or loads. Do not use the machine as a

means of transport; the machine maximum capacity

is 242.5 lb (110 kg), besides the weight of the

operator.

– Do not allow the brooms to operate while the machine

is stationary to avoid damaging the floor.

– In case of fire, use a powder extinguisher. Do not use

water.

– Do not bump into shelves or scaffoldings, in particular

where there is a risk of falling objects.

– Adjust the operation speed to suit the floor conditions.

– This machine cannot be used on public roads.

– Do not tamper with the machine safety guards; follow

the routine maintenance instructions scrupulously.

– Do not remove or modify the plates affixed on the

machine.

– In case of machine malfunctions ensure that these

are not caused by a lack of maintenance.

Otherwise, request assistance from the authorized

personnel or the Service Center.

– If parts must be replaced, require ORIGINAL spare

parts from a Dealer or Authorized Retailer.

– To ensure the machine proper operation and safety

conditions, the authorized personnel or the Service

Center must carry out the scheduled maintenance

detailed in the related chapter of this manual.

– The machine must be disposed of properly, because

of the presence of toxic-harmful materials (batteries,

oils, plastics etc.), which are subject to standards that

require disposal in special centers (see the Scrapping

chapter).

– If the machine is used according to the instructions,

the vibrations do not cause dangerous situations. The

machine vibration level is under 2.7 yd/s

(EN 1032-96/A1-98).

– Do not tilt the machine more than 30° from its

horizontal position, or the highly corrosive acid could

leak out of the batteries. When it is necessary to tilt

the machine for maintenance, remove the batteries.

2

(2.5 m/s2)

UNPACKING

On delivery, carefully check that the machine and its

packing were not damaged during transportation. If the

damages are evident, keep the packing and have it

checked by the Parcel Service that delivered it. Call the

Parcel Service immediately to fill in a request for a

compensation for damages.

Please check that the following items have been supplied

with the machine:

Technical documents:

– Instructions for Use

– Spare Parts List

– No.1 150 A (FO) main fuse

– Battery connector

146 1996 000(2)2004-08 – Terra™ 5200B 3

Page 6

INSTRUCTIONS FOR USE

MACHINE DESCRIPTION

TERRA™ 5200B SWEEPER OPERATION

The Terra™ 5200B Sweeper is used to sweep dust or light

debris on smooth and solid floor, in civil or industrial

environment, under safe operation conditions by a

qualified Operator.

CONVENTIONS

Forward, backward, front, right, left or rear indications in

this manual, are intended with reference to the Operator's

position, that is to say on the driver's seat (23, Fig. B).

DESCRIPTION

Control area

(See Fig. B)

1. Hopper lifting/lowering consent push-button

2. Horn push-button

3. Working light push-button (optional)

4. Position for optional push-button (pivoting light)

5. Display

6. Display selection push-button for the following

operations, in sequence:

– Working hours

– Last digit of the hours - (dot) - minutes

– Battery voltage (V)

7. Discharged battery warning light (red)

8. Semi-discharged battery warning light (yellow)

9. Charged battery warning light (green)

10. Steering wheel

11. Steering wheel inclination adjusting knob

12. Emergency stop button

13. Position for optional push-button

14. Filter shaker push-button

15. Hopper lifting/lowering push-button

16. Hopper overturning push-button

17. Vacuum activation/deactivation lever

18. Ignition switch

19. Parking brake lock control lever (in combination with

position pedal 26)

20. Forward and reverse gear pedal

21. Right broom lifting/lowering lever

22. Left broom lifting/lowering lever

23. Seat longitudinal position adjusting lever

24. Main broom lifting/lowering lever

25. Front skirt lifting pedal

26. Servo brake pedal (parking brake when combined

with position lever 19)

27. Driver seat with safety microswitch

28. Serial number plate/technical data

Outside view

(See Fig. C)

3. Dust filter cover

4. Hopper

5. Left opening door

6. Left door lock retainer with screws

7. Right opening door

8. Right door lock retainer

9. Working light (optional)

10. Right side broom

11. Left side broom

12. Main broom

13. Battery compartment hood

14. Rear drive wheels on fixed axle

15. Front wheel, steering

16. Left side skirt

17. Right side skirt

18. Front skirt

19. Rear skirt

20. Dust filter container

21. Pivoting light (always on when the ignition switch is

turned to “I” position)

22. Working light aiming adjusting screws

Under-hood compartment

(See Fig. V)

1. Hood (open position)

2. Battery

3. Battery caps

4. Battery connector

5. Main broom motor thermal circuit breaker

6. Right side broom motor thermal circuit breaker

7. Left side broom motor thermal circuit breaker

8. Lamellar fuse box

9. Vacuum/main broom motor

10. Vacuum fan

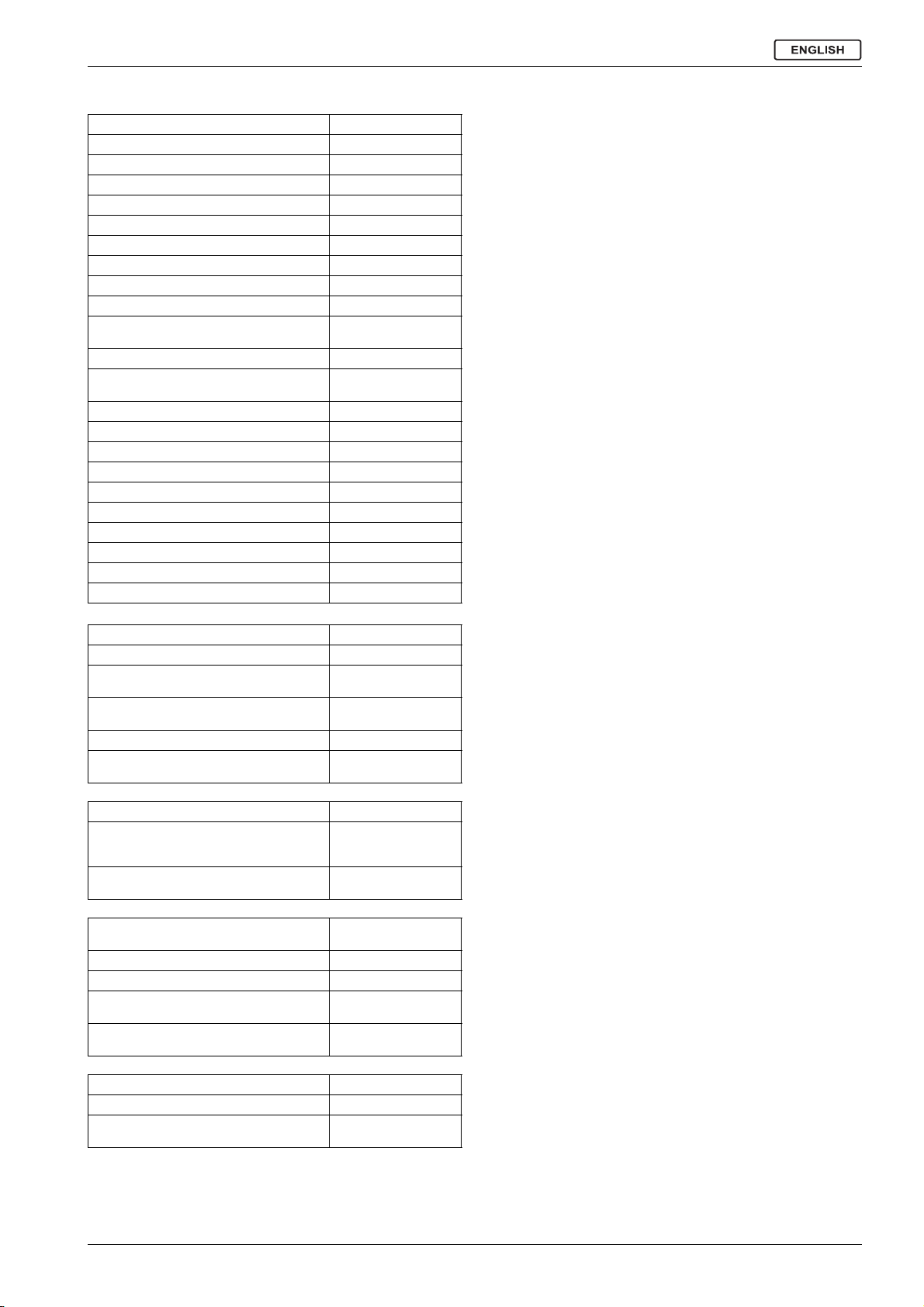

11. Drive motor

12. Electrical box

13. Drive electronic board

14. Hopper lifting system hydraulic oil tank

15. Battery assembly diagram

16. Hood lock rod

17. Bonnet holder bracket

4 Terra™ 5200B – 146 1996 000(2)2004-08

Page 7

INSTRUCTIONS FOR USE

TECHNICAL DATA

General Values

Cleaning width (with one side broom) 41.3 in (1,049 mm)

Cleaning width (with two side brooms) 51.6 in (1,310 mm)

Machine length 69.0 in (1,752 mm)

Machine width (with one side broom) 47.5 in (1,206 mm)

Machine width (with two side brooms) 51.6 in (1,310 mm)

Maximum height at the steering wheel 53.2 in (1,351 mm)

Minimum ground clearance (skirts not included) 2.3 in (58.42 mm)

Hopper maximum lifting height 65.0 in (1,651 mm)

Maximum weight liftable by the hopper 242.5 lb (110 kg)

Minimum/maximum dumping height

Minimum turning radius 66.5 in (1,690 mm)

Main broom dimensions

Side broom dimensions Ø 19.7 in (Ø 500 mm)

Maximum forward speed 4.3 mph (7 km/h)

Maximum reverse speed 2.2 mph (3.5 km/h)

Maximum slope 16%

Front axle weight in running conditions 617.3 lb (280 kg)

Rear axle weight in running conditions 948.0 lb (430 kg)

Machine total weight in running conditions 1,565.3 lb (710 kg)

Front steering wheel 4.00 – 4

Rear drive wheels 4.00 – 4

Sound level (A L

Electric motors Values

Electrical system voltage 24 V

Vacuum/main broom motor

Drive motor

Side broom reduction unit 24 V; 90 W; 85 RPM

Filter shaker motor

Batteries Values

Standard batteries

Optional batteries

Optional batteries (wet or gel, available at

Nilfisk retailers)

Battery total voltage 24V

Usable battery capacity 330 Ah

Battery container dimensions

Battery compartment max. size

Dust vacuuming and filtering Values

5-10 µm paper dust filter 10,850.0 in

Main broom compartment vacuum

) 66.9 dB(A)

pa

(Ø 300 mm x 800 mm)

No. 4 6V lead batteries

with acid electrolyte, in

No. 1 24V lead battery

10.6/54.3 in

(270 mm/1,380 mm)

Ø 11.8 in x 31.5 in

24 V; 1,000 W;

2,800 RPM

24 V; 750 W;

5,000 RPM

24 V; 90 W;

5,700 RPM

serial connection

with acid electrolyte

Values

12x31.5 in

(304x800 mm)

14.2x31.5x15.0 in

(360x800x380 mm)

2

(7 m2)

0.24 in H

(6 mm H

Wiring diagram

(See Fig. AF)

BE1: Beacon (OPT)

BZ1: Buzzer

C1: Batteries connector

EB1: Drive electronic board

EB2: Display board

ES1: Line electromagnetic switch

ES2: Main broom electromagnetic switch

ES3: Pump electromagnetic switch (up)

ES4: Pump electromagnetic switch (down)

ES5: Seat electromagnetic switch

F0: Main fuse (150A)

F1: Key fuse (15A)

F2: Hydraulic pump fuse (20A)

F3: Hopper actuator fuse (10A)

F4: Filter shaker fuse (15A)

F5: Service fuse (10A)

F6: Working light fuse (10A) (OPT)

F7: Right broom circuit breaker (10A)

F8: Left broom circuit breaker (10A)

F9: Main broom circuit breaker (50A)

HN: Horn

K1: Ignition switch

L1: Working light (OPT)

M1: Drive motor

M2: Main broom motor

M3: Hydraulic pump

M4: Actuator

M5: Filter shaker motor

M7: Right broom motor

M8: Left broom motor

R1: Drive potentiometer

SW0: Emergency stop switch

SW1: Drive forward/reverse mode switch

SW2: Main broom switch

SW3: Hopper safety switch

SW4: Hopper up-down switch

SW5: Hopper open-close switch

SW7: Right broom switch

SW8: Left broom switch

SW9: Horizontal hopper microswitch

SW10: Up hopper microswitch

SW11: Open hopper microswitch

SW12: Close hopper microswitch

SW13: Filter shaker microswitch

SW14: Working light switch (OPT)

SW15: Horn switch

SW16: Safety switch

Color codes

BK: Black

BU: Blue

BN: Brown

GN: Green

GY: Grey

OG: Orange

PK: Pink

RD: Red

O

2

O)

2

VT: Violet

WH: White

146 1996 000(2)2004-08 – Terra™ 5200B 5

Page 8

INSTRUCTIONS FOR USE

Hydraulic diagram

(See Fig. AG)

1. Hydraulic oil tank

2. Hydraulic oil filter

3. Hydraulic pump

4. Motor

5. Safety valve

6. Hopper lifting cylinder

FUSES

Under the hood, outside the electrical box, there are the

following fuses:

– Thermal circuit breakers, which can be reset by

pressing the related key:

– Main broom motor (5, Fig. V)

– Right side broom motor (6, Fig. V)

– Left side broom motor (7, Fig. V)

– Lamellar fuses, protected by a transparent plastic

lid, protect the indicated circuits:

– F1 (15 A) (the first starting from above): Ignition

switch

– F2 (20 A): Hydraulic pump

– F3 (10 A): Hopper actuator

– F4 (15 A): Filter shaker

– F5 (10 A): Services

– F6 (10 A): Working lights (optional)

– Spare 1 (20 A)

– Spare 2 (15 A)

Inside the electrical box (12, Fig. V), there is the following

fuse:

– F0 (150 A): Main (2, Fig. Z)

ACCESSORIES/OPTIONS

In addition to the standard components, the machine can

be equipped with the following accessories/options,

according to the machine specific use:

– Main and side brooms with harder and softer bristles;

– Antistatic polyester or polyester BIA C dust filter;

– Pocket filter;

– Pivoting light;

– Working light;

– Non marking skirt;

– Non marking wheels;

– Over head guard.

For further information concerning the optional

accessories apply to an Authorized Retailer.

USE

WARNING!

On some points of the machine there are

some adhesive plates indicating:

–DANGER

–WARNING

–CAUTION

– CONSULTATION

While reading this manual, the Operator must pay

particular attention to these symbols.

Do not cover these plates for any reason, in case of

damage replace them immediately.

BATTERY CHECK/SETTING ON A NEW

MACHINE

The machine requires one 24 V battery, or four 6 V

batteries connected according to the diagram (15, Fig. V).

The machine can be set in one of the following modes:

a) Battery already installed and ready to be used.

1. Open the hood (13, Fig. C) and hold it by using the

related rod (16, Fig. V).

Check that the battery is connected to the

machine through the appropriate connector (4,

Fig. V).

2. Disengage the lock rod and lower the hood, and

ensure that it is correctly closed.

3. Insert the ignition key in the switch (18, Fig. B) in

the control panel and turn it to “I” position (without

activating the pedal 20, Fig. B). If the green

warning light (9, Fig. B) turns on, the battery is

ready to be used.

If the yellow or red warning lights (8 or 7, Fig. B)

turn on, it is necessary to charge the batteries

(see the procedure in the Maintenance chapter).

b) Battery installed on the machine but without

electrolyte

1. Open the hood (13, Fig. C) and hold it by using the

related rod (16, Fig. V).

2. Remove the battery caps (3, Fig. V).

WARNING!

Be extremely careful when working with

sulfuric acid, as it is corrosive. If it comes in

contact with the skin or the eyes, wash

abundantly with water and call a doctor.

Batteries have to be filled up in a properly

ventilated area. Wear protective gloves.

6 Terra™ 5200B – 146 1996 000(2)2004-08

Page 9

INSTRUCTIONS FOR USE

3. Fill up each battery element with sulfuric acid for

batteries (density from 2.80 to 2.84 lb at 77 °F

(1.27 to 1.29 Kg at 25°C)) in accordance with the

instructions specified in the Battery Instruction

Manual.

The correct quantity of sulfuric acid is indicated in

the Battery Instruction Manual.

Let the battery rest and fill in with sulfuric acid in

accordance with the instructions specified in the

Battery Instruction Manual.

4. Charge the battery (see the procedure in the

Maintenance chapter).

c) Without batteries

1. Buy appropriate batteries (see the Technical Data

paragraph and the installation diagram (15, Fig.

V)).

Apply to battery qualified retailers to choose and

install the battery.

2. Install and set the machine batteries according to

WET or GEL batteries (see the procedure in the

following paragraph).

3. Recharge the batteries (see the procedure in the

Maintenance chapter).

BATTERY INSTALLATION AND WET OR

GEL BATTERY SETTING

Battery installation

1. Install the batteries on the machine according to the

diagram (15, Fig. V).

According to the battery dimensions, check if it is

possible to put them inside the related plastic

container, supplied with the machine.

If the batteries dimensions are larger than the

container capacity, use the square guides, supplied

with the machine, to ensure the stability inside the

battery compartment.

WET or GEL battery setting

NOTE

The machine factory setting is for lead

(WET) batteries. If this setting corresponds

to the type of battery installed on your

machine, do not set the batteries.

Otherwise, perform the following operations:

2. It is necessary to set the electronic board of the

machine according to the type of batteries installed

(WET or GEL). Proceed as follows:

– Turn the ignition switch (18, Fig. B) to “0” position;

– Open the hood (13, Fig. C) and hold it by using the

related rod (16, Fig. V);

– Disconnect the battery connector (4, Fig. V);

– Remove the screws (1, Fig. AD) and carefully pull

out the right control panel (2);

– Install a jumper wire (1, Fig. AE) on the WET

connectors (2) for lead batteries or on the GEL

connectors (3) for gel batteries;

– Carefully reassemble the control panel (2, Fig.

AD) and fix it by using the related screws (1);

– Reconnect the battery connector (4, Fig. V);

– Disengage the lock rod (16, Fig. V) and close the

hood (13, Fig. C).

BEFORE MACHINE START-UP

1. Check that there are no open doors/hoods and that

the machine is in normal operating conditions.

2. If the machine has not been used after being

transported, check that all the blocks used for the

transportation have been removed.

WARNING!

Non-sealed lead/acid batteries always need

an appropriate container to prevent the acid

form leaking.

Do not install the non-sealed lead/acid

batteries without an appropriate container.

146 1996 000(2)2004-08 – Terra™ 5200B 7

Page 10

INSTRUCTIONS FOR USE

STARTING AND STOPPING THE MACHINE

Starting the machine

1. Sit in the driver's seat (27, Fig. B) and, by operating

the lever (23) adjust the seat longitudinally, to a

comfortable position.

2. Unlock the steering wheel (10, Fig. B) by using the

knob (11) and adjust its tilting according to one's

comfort; after the adjustment, release the knob (11)

and lightly move the steering wheel to hook it on the

internal retainer.

3. Insert the ignition key in the switch (18, Fig. B); turn it

to “I” position, without activating the pedal (20), then

wait (for a few seconds) for the display (5, Fig. B) to

turn on and the working hours to appear.

Check that the green warning light turns on (9, Fig.

B).

4. If the warning light becomes red or yellow (7 or 8, Fig.

B) turn the ignition switch to “0” position and remove

the key. Charge the batteries (see the procedure in

the Maintenance chapter).

NOTE

The seat (27, Fig. B) is equipped with a

safety sensor, which allows the machine

operation only if the operator is seated on

the driver's seat.

5. Disengage the parking brake by pressing the related

pedal (26, Fig. B) and unlocking the lever (19).

6. Drive the machine to the working area, with the hands

upon the steering wheel (10, Fig. B); press the pedal

(20) on the front side to move forward and on the rear

side to move backward.

According to the pressure on the pedal, the speed

increases form zero to the maximum value.

7. Lower the main broom by operating the lever (24, Fig.

B), then activate the vacuum system by operating the

lever (17, Fig. B).

8. Lower the right side broom by operating the lever (21,

Fig. B).

9. Lower the left side broom by operating the lever (22,

Fig. B).

NOTE

All brooms (10, 11, 12, Fig. C) can be lifted

or lowered when the machine is moving.

When the brooms are lifted, they do not

turn.

When the main broom is lifted, the vacuum

system is not operating.

10. To sweep, start the machine with the hands upon the

steering wheel (10, Fig. B) and press the pedal (20)

accordingly.

Stopping the machine

1. To stop the machine, release the pedal (20, Fig. B).

To stop the machine quickly, press also the servo

brake pedal (26, Fig. B).

In case of emergency, press the emergency

push-button (12, Fig. B) to immediately stop the

machine. To deactivate the emergency push-button

(12) after pressing it, rotate it in the direction indicated

by the arrow on the push-button.

2. Turn the ignition switch (18, Fig. B) to “0” position,

and remove the key.

3. Engage the parking brake by pressing the brake

pedal (26, Fig. B) and by operating the brake lock

control lever (19).

MACHINE OPERATION

1. Avoid stopping for a long time with the machine in the

same position and the brooms rotating: this could

create unwanted marks on the floor.

2. To collect light and bulky waste materials, lift the front

skirt by activating the pedal (25, Fig. B); consider that

the vacuum capability of the machine is reduced

when the front skirt is lifted.

WARNING!

When operating on wet grounds, it is

essential to deactivate the vacuum system

by operating the lever (17, Fig. B) to prevent

the dust filter from being damaged.

3. For the machine proper operation, the dust filter must

be as clean as possible. To clean it while sweeping,

proceed as follows:

– Lift the main broom by operating the lever (24, Fig.

B) to deactivate the vacuum system;

– Press the filter shaker push-button (14, Fig. B) at

short intervals;

– Then, lower the main broom to activate the

vacuum system again, and resume operation.

Repeat the operation at least every ten minutes

while working (according to the area dusty

conditions).

NOTE

This operation can be performed also when

the machine is moving.

NOTE

When the dust filter is obstructed and/or

the hopper is full, the machine cannot

collect dust and debris anymore.

4. The hopper (4, Fig. C) should be dumped after each

working period and whenever it is full.

8 Terra™ 5200B – 146 1996 000(2)2004-08

Page 11

INSTRUCTIONS FOR USE

HOPPER DUMPING

1. The maximum dumping height is 54.3 in (1,380 mm)

(see Fig. U).

2. To dump the hopper, drive the machine near the

dustbin and proceed as follows:

– Lift the side and main brooms;

– Deactivate the vacuum system by operating the

lever (17, Fig. B);

– Press the filter shaker button (14, Fig. B).

WARNING!

Always carry out this operation on a level

ground to avoid machine unbalance.

WARNING!

When lifting and dumping the hopper (4,

Fig. C), keep the parking brake engaged by

pressing the pedal and operating the lever

(26 and 19, Fig. B).

3. Keep people far from the machine and especially

from the hopper (4, Fig. C).

4. Press both the consent push-button (1, Fig. B) and

the hopper lifting push-button (15) to lift the hopper (1,

Fig. T) up to the desired position.

5. Press both the consent push-button (1, Fig. B) and

the hopper (2, Fig. U) overturning push-button (16,

Fig. B) and discharge all the debris in the dustbin (1,

Fig. U).

CAUTION!

The hopper (2, Fig. U) can be overturned

only after having lifted it at a minimum

height of 10.6 in (270 mm).

AFTER USING THE MACHINE

At the end of the work, before leaving the machine:

– Lift the main broom by operating the lever (24, Fig. B).

– Lift the side brooms by operating the levers (21 and

22, Fig. B).

– Deactivate the vacuum system by operating the lever

(17, Fig. B), then press the filter shaker push-button

(14, Fig. B) for a short interval, and activate the

vacuum system again.

– Dump the hopper (4, Fig. C) (see the previous

paragraph).

– Remove the key from the ignition switch (18, Fig. B).

– Engage the parking brake by pressing the brake

pedal (26, Fig. B) and by operating the brake lock

control lever (19).

WORKING LIGHT ADJUSTMENT

If it is necessary to adjust the working light beam aiming

(9, Fig. C), operate on the screws (22).

MACHINE LONG INACTIVITY

If you foresee that the machine will not be used for more

than 30 days, proceed as follows:

– Check that the machine storage area is dry and

clean.

– Disconnect the battery connector (4, Fig. V).

FIRST PERIOD OF USE

After the first period of use (first 8 hours) it is necessary to

check that the fixing and connecting elements are

correctly tightened, that the visible parts are integral and

that there are no tears.

6. To overturn the hopper back to the horizontal

position, press the consent push-button (1, Fig. B)

while pressing the hopper overturning push-button

(16. Fig. B).

7. To lower the hopper, press both the consent

push-button (1, Fig. B) and the hopper lowering

push-button (15).

CAUTION!

The hopper can be overturned only if it is

not in its original position (horizontal

position).

8. The machine is ready to start working again.

146 1996 000(2)2004-08 – Terra™ 5200B 9

Page 12

INSTRUCTIONS FOR USE

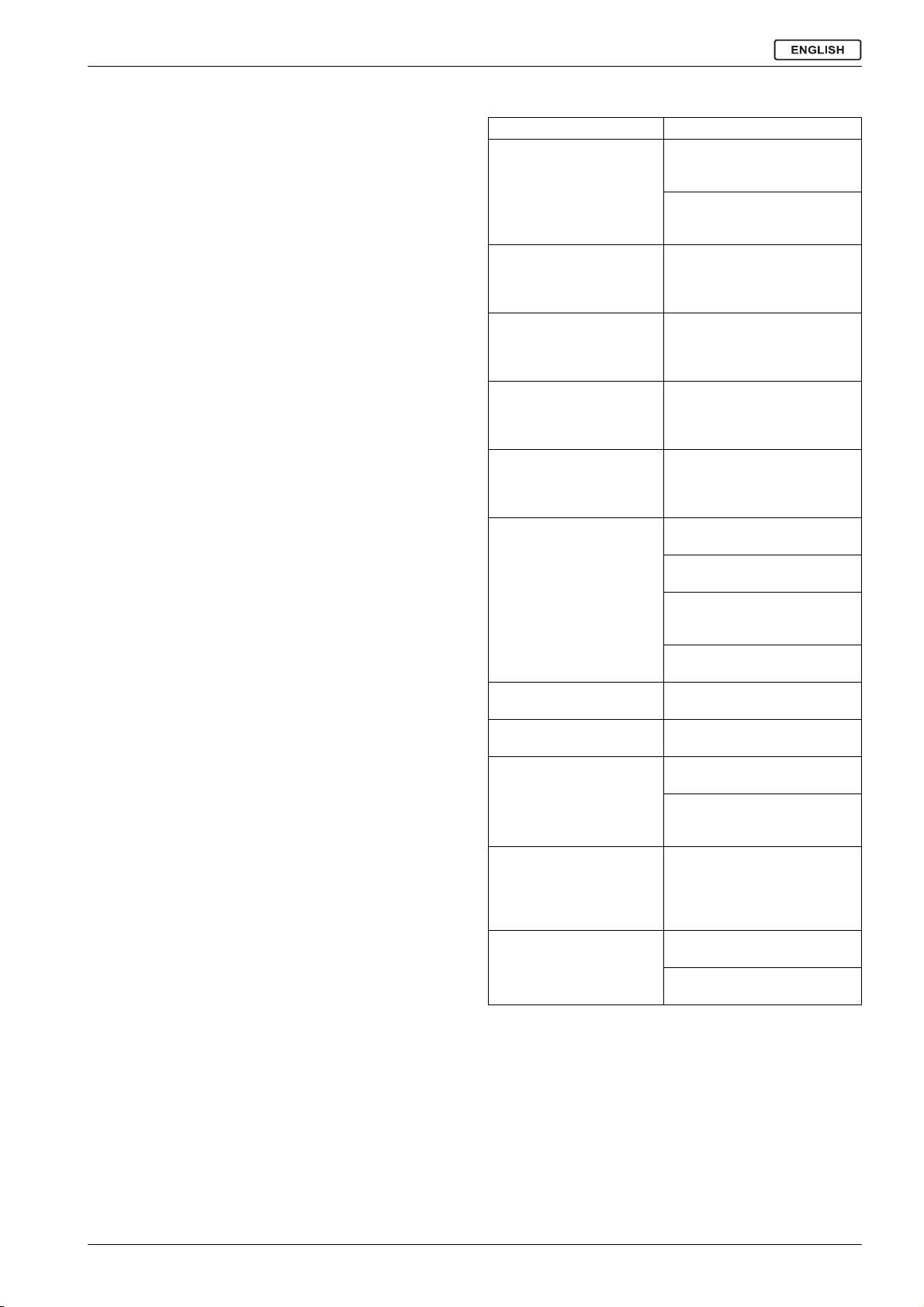

MAINTENANCE

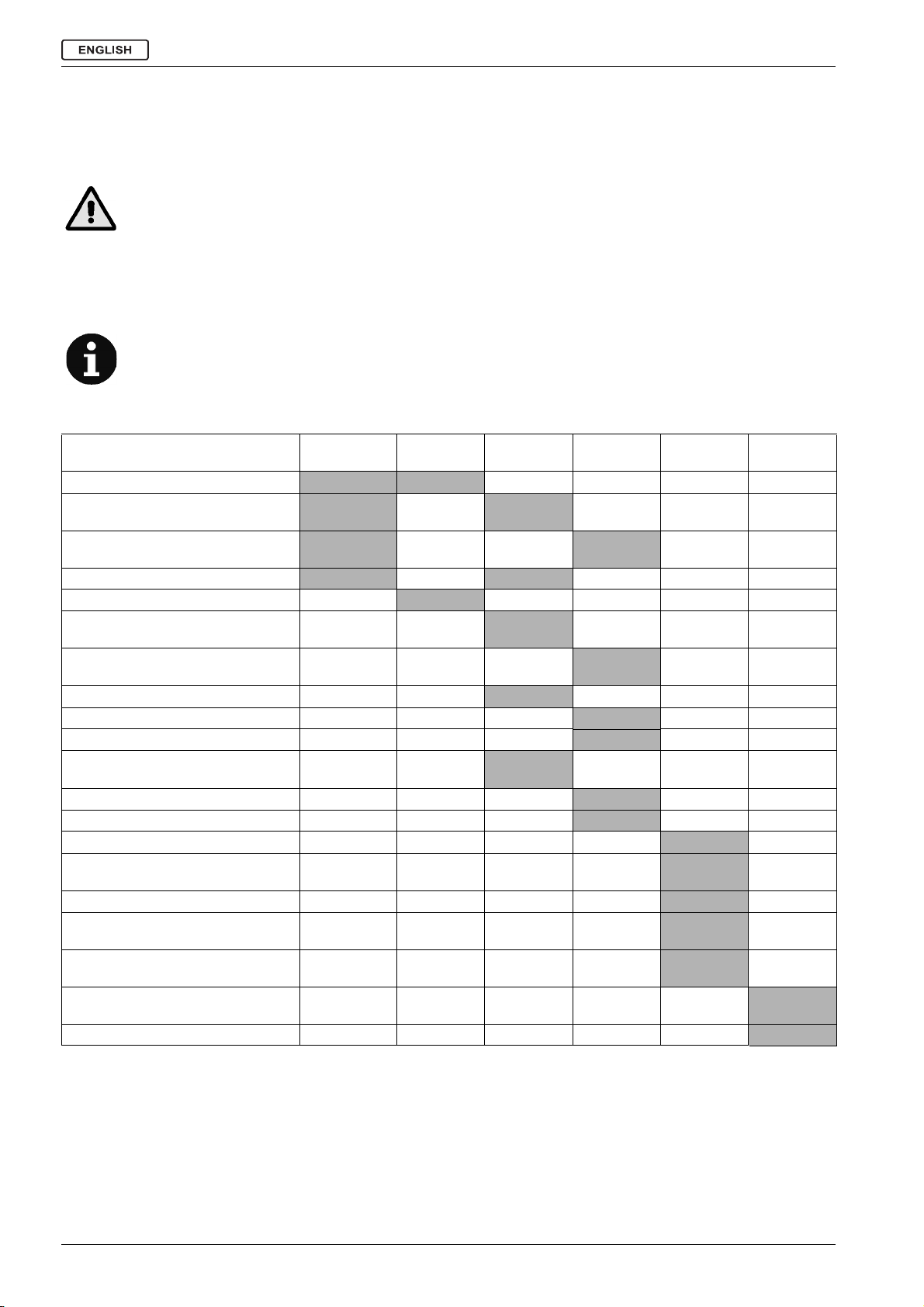

The lifespan of the machine and maximum operating safety are ensured by correct and regular maintenance.

The following table summarizes the routine maintenance required. The intervals indicated can be changed to suit working

conditions. These must be defined by the person in charge of the maintenance.

WARNING!

These operations must be carried out with the machine off, the ignition key not inserted and (if

required) the battery disconnected.

Moreover, carefully read the instructions in the Safety chapter.

All scheduled or extraordinary maintenance operations must be performed by skilled personnel, or by an Authorized

Service Center.

This manual describes only the easiest and most common maintenance procedures.

NOTE

For other maintenance procedures contained in the Scheduled Maintenance Table, refer to the

specific Service Manual that can be consulted at any Service Center.

SCHEDULED MAINTENANCE TABLE

Maintenance operation On delivery

Battery fluid level check (1)

Hopper lifting system hydraulic oil level

check

Motor-to-main broom belt visual

inspection and tension check

Skirt height and operation check

Side and main broom height check

Frame dust filter cleaning and integrity

check

Pocket dust filter cleaning and integrity

check

Filter shaker operation check (*)

Brake adjustment (*)

Nut and screw tightening check (*) (2)

Drive wheel chain tension check and

cleaning

Steering chain cleaning (*)

Vacuum hose integrity check (*)

Pulley-to-main broom belt replacement (*)

Motor-to-main broom pulley V-belt

replacement

Hopper gasket integrity check (*)

Hopper lifted position control microswitch

adjustment check

Hopper horizontal position control

microswitch adjustment check

Motor carbon brush check and

replacement

Hydraulic oil replacement (*) (3)

Every 10

hours

Every 50

hours

(1)

(*)

Every 100

hours

(*)

Every 200

hours

(*)

(*)

(*)

Every 400

hours

(*)

(*): for the related procedure, refer to the Service Manual.

(1): or before each start.

(2): and after the first 8 running-in hours

(3): replace hydraulic oil for the first time after 500 hours, then after 2,000 hours or every year

10 Terra™ 5200B – 146 1996 000(2)2004-08

Page 13

INSTRUCTIONS FOR USE

MAIN BROOM HEIGHT CHECK AND

ADJUSTMENT

NOTE

Brooms of various hardness are available.

This procedure is applicable to all types of

brooms.

1. Check that the main broom is at the correct height

from the ground, proceeding as follows:

– Drive the machine on a level ground;

– Keep the machine stationary and rotate the main

broom for a few seconds;

– Stop and lift the main broom, then move the

machine;

– Check that the main broom print (1, Fig. D), along

its width, is from 0.79 to 1.57 in (20 to 40 mm)

wide.

If the print (1) is different, it is necessary to adjust

the broom height, proceeding as described in the

following steps.

2. Stop the machine by turning the ignition switch (18,

Fig. B) to “0” position.

WARNING!

Before opening the left door (5, Fig. C), it is

always necessary to stop the machine to

prevent belt and pulley operation.

3. Release the retainer (6, Fig. C) after removing the

related screw by using a screwdriver.

4. Open the left door (5, Fig. C).

5. Loosen the locknut (2, Fig. E).

6. Turn the knob (1, Fig E) and remind that:

– To decrease the pressure of the broom on the

ground, it must be screwed;

– To increase the pressure of the broom on the

ground, it must be unscrewed.

NOTE

When the knob is completely unscrewed,

you have reached the maximum pressure of

the broom on the ground.

MAIN BROOM REPLACEMENT

NOTE

Brooms of various hardness are available.

This procedure is applicable to all types of

brooms.

CAUTION!

It is advisable to use protective gloves

when replacing the main broom because

there can be cutting debris between the

bristles.

1. Drive the machine on a level ground and engage the

parking brake by means of the pedal and the lever (26

and 19, Fig. B).

2. Turn the ignition switch (18, Fig. B) to “0” position.

3. Open the hood (1, Fig. V) and disconnect the battery

connector (4, Fig. V).

4. Disengage the retainer (8) and open the right door (7,

Fig. C)

5. Unscrew and remove the knobs (1, Fig. F).

6. Remove the broom compartment cover (1, Fig. G).

7. Remove the broom (1, Fig. H).

8. Check that the drive hub (1, Fig. I) is free from dirt or

foreign materials (cords, clothes, etc.) accidentally

rolled up.

9. The new broom must be installed with the bristles

rows positioned as shown in the figure (2, Fig. I).

10. Install the new broom (3, Fig. I) on the machine and

ensure that its flange (4) correctly fits on the related

drive hub (1).

11. Reinstall the broom compartment cover (1, Fig. G)

and screw down the knobs (1, Fig. F).

12. Engage the retainer (8) and close the right door (7,

Fig. C)

13. Carry out the main broom height check and

adjustment, as described in the previous paragraph.

7. Tighten the locknut (2, Fig. E).

8. Perform step 1 again to check the proper adjustment

of the main broom height from the ground.

9. When the broom is too worn and can no longer be

adjusted, replace it according to the instructions in the

following paragraph.

10. Engage the retainer (6) and close the left door (5, Fig.

C).

NOTE

If it is not possible to properly adjust the

print (1, Fig. D), since the broom pressure

differs from one end to another, refer to the

Service Manual for the related adjustment

procedure.

146 1996 000(2)2004-08 – Terra™ 5200B 11

Page 14

INSTRUCTIONS FOR USE

SIDE BROOM HEIGHT CHECK AND

ADJUSTMENT

NOTE

Brooms of various hardness are available.

This procedure is applicable to all types of

brooms.

1. Check the side broom height from the ground,

proceeding as follows:

– Drive the machine on a level ground;

– Keep the machine stationary, lower the side

brooms and rotate them for few seconds;

– Stop and lift the side brooms, then move the

machine;

– Check that the side broom print are, in extension

and orientation, as shown in the figure (1 and 2,

Fig. J).

In case one or both prints are not within the

specifications, it is necessary to adjust the broom

height, proceeding as described in the following

steps.

2. Engage the parking brake by means of the pedal and

the lever (26 and 19, Fig. B).

3. Turn the ignition switch (18, Fig. B) to “0” position.

4. Open the hood (13, Fig. C) and hold it by using the

related rod (16, Fig. V).

5. For the right side broom, actuate the driving gear of

the lever (1, Fig. K): Loosen the ring nut (2) and adjust

the register (3) until the correct print is achieved (1,

Fig. J). Install the register and fit it on the lever with

the ring nut (2, Fig. K).

For the left side broom, actuate the driving gear of

the lever (4, Fig. K): Loosen the ring nut (5) and adjust

the register (6) until the correct print is achieved (2,

Fig. J). Install the register and fit it on the lever with

the ring nut (5, Fig. K).

6. Perform step 1 again to check the proper adjustment

of the side broom height from the ground.

7. When the broom is too worn out and can no longer be

adjusted, replace it according to the instructions in the

following paragraph.

SIDE BROOM REPLACEMENT

NOTE

Brooms of various hardness are available.

This procedure is applicable to all types of

brooms.

CAUTION!

It is advisable to use protective gloves when

replacing the side brooms because there

can be cutting debris between the bristles.

1. Drive the machine on a level ground and engage the

parking brake by means of the pedal and the lever (26

and 19, Fig. B).

2. Turn the ignition switch (18, Fig. B) to “0” position.

3. Operate the lever (21 or 22, Fig. B) to lower the

related side broom.

4. Remove the screw (1, Fig. L) inside the side broom,

then remove the broom and the hub (2) by

disengaging it from the shaft (3).

Recover the key (4) and the washer (5).

5. At the workbench, remove the four screws and nuts

(6) and separate the broom (8) from the hub (7).

6. Install the new broom (8) on the hub (7) and tighten

the screws and the nuts (6).

7. Reinstall the new broom and the hub (2) on the

machine after seating the key (4). Reinstall the

washer (5) and tighten the screw (1).

8. Carry out the side broom height check and

adjustment as described in the previous paragraph.

NOTE

If necessary, it is possible to adjust also the

side broom inclination. Please, refer to the

Service Manual for the related procedure.

12 Terra™ 5200B – 146 1996 000(2)2004-08

Page 15

INSTRUCTIONS FOR USE

FRAME DUST FILTER CLEANING AND

INTEGRITY CHECK

NOTE

Besides the standard paper filter, optional

polyester filters are also available. The

following procedure is applicable to each

type.

1. Drive the machine on a level ground and engage the

parking brake by means of the pedal and the lever (26

and 19, Fig. B).

2. Turn the ignition switch (18, Fig. B) to “0” position.

3. Open the hood (13, Fig. C) and hold it by using the

related rod (16, Fig V).

4. Disconnect the battery connector (4, Fig. V).

Remove the filter cover (2, Fig. M) by disengaging it

from the retainers (1).

5. Disconnect the electric connector (1, Fig. N) from the

filter shaker.

6. Remove the filter shaker support frame fixing knobs

(2, Fig. N).

7. Remove the filter support frame (3, Fig. N).

8. Pull out the dust filter (4, Fig. N).

9. In an appropriate outdoor area, clean the filter

shaking it on a level and clean surface, tapping the

side (1, Fig. O), opposite the wire gauze (2).

Complete the cleaning by using compressed air (3) at

max. 6 bars, blowing only from the side protected by

the wire gauze (2), at a minimum distance of 30 cm.

According to the filter type, take care of the following

cautions:

– Paper filter (standard): do not use water or

detergents to clean it; the filter can be damaged;

– Polyester filter (optional): to clean it, see the

above-mentioned instructions. If necessary, for a

better cleaning, it is allowed to wash the filter with

water and non-lathering detergents. This provides

better quality cleaning but reduces the life of the

filter, which will have to be replaced more

frequently. The use of inadequate detergents can

damage the filter.

Check the filter body for lacerations.

10. Clean the filter compartment rubber seal (1, Fig. P)

along its perimeter and check its integrity. If

necessary, replace it.

11. Install in the reverse order of removal (steps from 8 to

1).

WARNING!

When reinstalling the filter, the wire gauze

(2, Fig. O) must be facing upward.

POCKET DUST FILTER CLEANING AND

INTEGRITY CHECK

NOTE

The polyester pocket filters are normally

kept clean by activating the electric filter

shaker supplied with the machine.

If necessary, they can be cleaned using the

procedure indicated below.

When the filtration surfaces are no longer

suitable, the filter must be replaced.

1. Drive the machine on a level ground and engage the

parking brake by means of the pedal and the lever (26

and 19, Fig. B).

2. Turn the ignition switch (18, Fig. B) to “0” position.

3. Open the hood (13, Fig. C) and hold it by using the

related rod (16, Fig. V).

4. Remove the filter cover (2, Fig. M) by disengaging it

from the retainers (1).

5. Unscrew the knobs (1, Fig. AA) and remove the

brackets (2).

6. Pull out the dust filter (1, Fig. AB), and remove it after

disconnecting the electrical connector (2) from the

filter shaker.

7. Disassemble the polyester filtering surface, as

indicated by the following steps; these procedures

must be carried out in a suitable outdoor area and the

Operator must be suitably equipped (gloves, mask,

glasses).

8. Remove the filter shaker motor (1, Fig. AC) by

unscrewing the two fixing screws.

9. Open the filter shaker motor support unit (2, Fig. AC)

completely and release the filtering pocket tension

rods (3).

10. Remove all the filtering pocket tension rods (4, Fig.

AC).

11. Open the upper retaining cord (5, Fig. AC) of the

closed pocket filter to remove it from the upper frame

(6).

12. Remove the internal pocket separator (7, Fig. AC).

13. Clean the polyester fibre surface (8, Fig. AC) from the

dirty side, using an external vacuum cleaner,

spreading it out completely or cleaning pocket by

pocket. At the same time, clean both the surfaces of

the pocket separator (7, Fig. AC) removing anything

deposited on them. Check that the filtering surface is

not cut, if it is, replace it. It is also possible to use

compressed air (max. 6 bars), blowing the air from

the clean side towards the dirty side.

WARNING!

It is not advisable to wash the filter with

water. The polyester fibre can shrink and

become unusable.

146 1996 000(2)2004-08 – Terra™ 5200B 13

Page 16

INSTRUCTIONS FOR USE

14. Reassemble all the components of the filter in the

reverse order of disassembly.

15. If necessary, clean the filter compartment rubber seal

(3, Fig. AB) along its perimeter and check its integrity.

If necessary, replace it.

16. Reassemble all the components in the reverse order

of disassembly.

SKIRT HEIGHT AND OPERATION CHECK

Side skirt

1. Drive the machine on a level ground that is suitable

for checking the skirt height.

2. Engage the parking brake by means of the pedal and

the lever (26 and 19, Fig. B).

3. Turn the ignition switch (18, Fig. B) to “0” position.

4. Disengage the retainers (8 and 6) and open the right

and left doors (7 and 5, Fig. C).

5. Check the side skirt (2, Fig. F) integrity.

Replace the skirts when they have cuts (1, Fig. Q)

larger than 0.79 in (20 mm) or cracks/tears (2) larger

than 0.39 in (10 mm) (for skirt replacement, refer to

the Service Manual).

6. Check that side skirt (2, Fig. F) height from ground is

within 0 – 0.12 in (0 – 3 mm) (Fig. R).

After loosening the screws (3, Fig. F), if necessary,

adjust the skirt position. Then tighten the screws (3).

Front and rear skirt

7. Remove the main broom, as described in the related

paragraph.

8. Check the front and rear skirts (1 and 2, Fig. W) for

integrity.

Replace the skirts when they have cuts (1, Fig. Q)

larger than 0.79 in (20 mm) or cracks/tears (2) larger

than 0.39 in (10 mm) (for skirt replacement, refer to

the Service Manual).

9. Check that the front and rear skirts (1 and 2, Fig. W)

rub lightly on the floor but are not completely lifted

from the ground (see figure S).

After loosening the screws (3, Fig. W), if necessary,

adjust the skirt position. Then tighten the screws (3).

10. Press the front (25, Fig. B) skirt lifting pedal

completely, and check that the front skirt lifts 1.97 in

(50 mm) approximately.

Release the pedal and check that the skirt returns to

the initial position and not in an intermediate position.

If necessary, adjust the skirt lifting cable (1, Fig. X) by

using the adjuster (2) on the left front side of the skirt

(for the front skirt control cable replacement, refer to

the Service Manual).

11. Reassemble all the components in the reverse order

of disassembly.

HOPPER LIFTING SYSTEM HYDRAULIC

OIL LEVEL CHECK

CAUTION!

These operations must be performed with

the hopper (4, Fig. C) in its original position

(as shown in the figure).

1. Engage the parking brake by means of the pedal and

the lever (26 and 19, Fig. B).

2. Open the hood (1, Fig. V) and hold it by using the

related rod (16, Fig. V).

3. Check that the hydraulic oil level in the tank (14, Fig.

V) is between the MIN and MAX indicators (as shown

in Fig. Y).

4. If necessary add hydraulic oil - viscosity grade 32 cSt

- through the plug (1, Fig. Y).

5. Disengage to lock rod (16, Fig. V) and close the hood

(1, Fig. V).

BATTERY CHARGING

WARNING!

Battery charging produces explosive

hydrogen gas. Charge the batteries only in

well-ventilated areas and far from naked

flames.

Do not smoke during battery charging.

Keep the hood open while recharging the

battery.

WARNING!

Be extremely careful when charging the

batteries as there may be battery fluid

leakages. The battery fluid is corrosive. If it

comes in contact with the skin or the eyes,

rinse thoroughly with water and consult a

doctor.

1. Drive the machine on a level ground and engage the

parking brake by means of the pedal and the lever (26

and 19, Fig. B).

2. Turn the ignition switch (18, Fig. B) to “0” position.

3. Open the hood (13, Fig. C) and hold it by using the

related rod (16, Fig. V).

4. Check the correct level of electrolyte inside the

batteries; if necessary, top up through the caps (3,

Fig. V).

Leave the caps (3) open for the next recharging.

Clean, if necessary, the upper surface of the

batteries.

5. Check that the battery charger is appropriate,

referring to the Battery Charger Operating Manual.

The battery charger voltage rating is 24 V.

The battery charger must be appropriate for the

battery installed on the machine.

14 Terra™ 5200B – 146 1996 000(2)2004-08

Page 17

INSTRUCTIONS FOR USE

6. Disconnect the battery connector (4, Fig. V) and

connect it to the external battery charger.

7. Connect the battery charger to the electrical mains

and charge the batteries.

8. When the recharging is complete, disconnect the

battery charger from the electrical mains and from the

battery connector (4, Fig. V).

9. Check the correct level of electrolyte inside the

batteries and close the caps (3, Fig. V).

10. Reconnect the battery connector (4, Fig. V) to the

machine.

11. Disengage the lock rod (16, Fig. V) and close the

hood (13, Fig. C); the machine is ready to be used.

SAFETY FUNCTIONS

The machine is equipped with the following safety

functions.

RUNNING CONSENT SWITCH

It allows the machine to run only if the operator is on the

driver's seat (27, Fig. B).

EMERGENCY PUSH-BUTTON

It is in the position 12, Fig. B, easily accessible for the

operator; it must be pressed when it necessary to stop the

machine operation immediately.

HOPPER LIFTING/LOWERING CONSENT

PUSH-BUTTON

It is in the position 1, Fig. B and must be pressed and held

to activate the hopper lifting/lowering and overturning

push-buttons.

HOPPER LIFTING CYLINDER SAFETY

DEVICE VALVE

It is located on the hopper lifting cylinder.

It stops the hopper in the position it has reached (without

possibility for it to lower accidentally) if the hydraulic

system piping, feeding the lifting cylinder, should break.

TROUBLESHOOTING

TROUBLE REMEDY

After having turned the ignition

switch (18, Fig. B) to “I”

position, the display does not

illuminate and the machine

does not work

The machine does not move

when pressing the accelerator

pedal

The main broom does not work

The side brooms do not work

The machine operates only

when stationary, otherwise it

switches off and the red

warning light turns on

The machine collects few

debris/dust

The battery autonomy is low

The hopper does not lift

The hopper does not overturn

The hopper does not lower

The filter shaker does not work

Check that the battery connector

(4, Fig. V) is correctly connected to

the machine

Check the integrity of the following

fuses: F1 (1, Fig. Z) and F0 (2, Fig.

Z)

Turn the ignition switch to “0”

position, then to “I” position, being

careful not to press the accelerator

pedal during this operation

Check that the related thermal

circuit breaker (5, Fig. V) is not

deactivated; otherwise reactivate it

by pressing the related key

Check that the related thermal

circuit breaker (6 or 7, Fig. V) is not

deactivated; otherwise reactivate it

by pressing the related key

Re-charge the battery.

If the problem persists, replace the

batteries

Check that the dust filter (4, Fig. N)

is not obstructed

Check that the hopper (4, Fig. C) is

not full

Check that the skirts (16, 17, 18,

19, Fig. C) are not broken or

incorrectly adjusted

Check the correct height of the

brooms (10, 11, 12, Fig. C)

Install a battery with greater

capacity: (240 Ah)

Check the fuse (F2, Fig. Z)

integrity

Check the fuse (F3, Fig. Z)

integrity

Check that the hopper is lifted from

the ground at an height greater

than 10.6 in (270 mm)

Before lowering the hopper by

pressing the push-button (15, Fig.

B), check that the hopper is in its

horizontal position by pressing the

push-button (16, Fig. B)

Operate the lever (24, Fig. B) to

check that the main broom is lifted

Check the fuse (F4, Fig. Z)

integrity

For further information consult the Service Manual at any

Nilfisk Service Center.

146 1996 000(2)2004-08 – Terra™ 5200B 15

Page 18

INSTRUCTIONS FOR USE

SCRAPPING

Have the machine scrapped by a qualified scrapper.

Before scrapping the machine, always remove the

following materials:

– Battery

– Polyester dust filter

– Main and side brooms

– Hydraulic oil

– Hydraulic oil filter

– Electronic boards

– Plastic components and pipes

CAUTION!

The removed components must be

disposed of properly according to the Law

in force.

16 Terra™ 5200B – 146 1996 000(2)2004-08

Page 19

INSTRUCCIONES DE USO

INTRODUCCIÓN ...................................................................................................................... 2

FINALIDAD Y OBJETO DE ESTE MANUAL .................................................................................................... 2

DESTINATARIOS ............................................................................................................................................. 2

CONSERVACIÓN DEL MANUAL ..................................................................................................................... 2

DATOS DE IDENTIFICACIÓN .......................................................................................................................... 2

OTROS MANUALES DE REFERENCIA .......................................................................................................... 2

PIEZAS DE REPUESTO Y MANTENIMIENTO ................................................................................................ 2

MODIFICACIONES Y MEJORAS ..................................................................................................................... 2

SEGURIDAD ..................................................................................................................................................... 2

SÍMBOLOS ....................................................................................................................................................... 2

INSTRUCCIONES GENERALES ..................................................................................................................... 3

DESEMBALAJE ................................................................................................................................................ 3

DESCRIPCIÓN DE LA MÁQUINA ...........................................................................................4

CARACTERÍSTICAS DE FUNCIONAMIENTO DE LA BARREDERA TERRA™ 5200B ................................. 4

CONVENCIONES ............................................................................................................................................. 4

DESCRIPCIÓN ................................................................................................................................................. 4

DATOS TÉCNICOS .......................................................................................................................................... 5

FUSIBLES ......................................................................................................................................................... 6

ACCESORIOS/OPCIONES .............................................................................................................................. 6

USO ..........................................................................................................................................6

CONTROL/PREPARACIÓN BATERÍAS EN LA MÁQUINA NUEVA ................................................................ 6

INSTALACIÓN DE LAS BATERÍAS Y REGULACIÓN DEL TIPO DE BATERÍA (WET O GEL) ...................... 7

ANTES DE LA PUESTA EN MARCHA DE LA MÁQUINA ............................................................................... 7

PUESTA EN MARCHA Y PARADA DE LA MÁQUINA ..................................................................................... 8

MÁQUINA EN FUNCIÓN .................................................................................................................................. 8

VACIADO DEL CAJÓN DE RESIDUOS ........................................................................................................... 9

DESPUÉS DE LA UTILIZACIÓN DE LA MÁQUINA ......................................................................................... 9

AJUSTE DE LA LUZ DE TRABAJO ................................................................................................................. 9

PERIODO DE LARGA INACTIVIDAD DE LA MÁQUINA ................................................................................. 9

PRIMER PERIODO DE UTILIZACIÓN ............................................................................................................. 9

MANTENIMIENTO .................................................................................................................10

ESQUEMA DE MANTENIMIENTO PROGRAMADO ..................................................................................... 10

CONTROL Y AJUSTE DE LA ALTURA DEL CEPILLO PRINCIPAL ............................................................. 11

SUSTITUCIÓN DEL CEPILLO PRINCIPAL ................................................................................................... 11

CONTROL Y AJUSTE DE LA ALTURA DEL CEPILLO LATERAL ................................................................ 12

SUSTITUCIÓN DE LOS CEPILLOS LATERALES ......................................................................................... 12

LIMPIEZA DEL FILTRO DE POLVO DE BASTIDOR Y CONTROL DE LA INTEGRIDAD ............................ 13

LIMPIEZA DEL FILTRO DE BOLSAS Y CONTROL DE LA INTEGRIDAD .................................................... 13

CONTROL ALTURA Y FUNCIONAMIENTO DE LAS PUERTAS ABATIBLES .............................................. 14

CONTROL NIVEL ACEITE HIDRÁULICO SISTEMA DE SUBIDA CAJÓN DE RESIDUOS .......................... 14

CARGA DE LAS BATERÍAS ........................................................................................................................... 14

FUNCIONES DE SEGURIDAD .............................................................................................. 15

INTERRUPTOR DE ASENSO MARCHA ....................................................................................................... 15

PULSADOR DE EMERGENCIA ..................................................................................................................... 15

PULSADOR DE ASENSO SUBIDA/BAJADA DEL CAJÓN DE RESIDUOS .................................................. 15

VÁLVULA DE SEGURIDAD DEL CILINDRO DE SUBIDA DEL CAJÓN DE RESIDUOS .............................. 15

BÚSQUEDA AVERÍAS ..........................................................................................................15

ELIMINACIÓN ........................................................................................................................ 16

146 1996 000(2)2004-08 – Terra™ 5200B 1

Page 20

INSTRUCCIONES DE USO

INTRODUCCIÓN

FINALIDAD Y OBJETO DE ESTE MANUAL

Este manual contiene todas las informaciones necesarias

para que el Cliente utilice la máquina de forma adecuada,

autónoma y segura. Incluye informaciones técnicas, sobre

el funcionamiento, el período de inactividad, el

mantenimiento, las piezas de repuesto y la seguridad.

Antes de efectuar cualquier operación de mantenimiento,

los Operadores y los Técnicos calificados para el

mantenimiento tienen que leer cuidadosamente las

instrucciones incluidas en este Manual. En caso de dudas

sobre la correcta interpretación de las instrucciones,

consulte el fabricante para obtener explicaciones.

DESTINATARIOS

Este Manual es para los Operadores y los Técnicos

calificados para el mantenimiento de la máquina.

Los operadores no deben efectuar operaciones que sólo

los técnicos calificados pueden efectuar. El Fabricante no

es responsable para los daños causados a la máquina por

falta de observación de esta prohibición.

CONSERVACIÓN DEL MANUAL

Este manual de instrucciones debe conservarse junto a la

máquina, dentro de su contenedor, lejos de líquidos y

otras substancias que podrían dañarlo.

DATOS DE IDENTIFICACIÓN

El número de serie y el modelo de la máquina están

marcados en la placa (28, Fig. B) aplicada a la columna de

la dirección, legible desde el exterior. El año de

fabricación de la máquina está indicado después del

Código fecha en la placa serial (A04 significa Enero 2004).

Esta información es necesaria cuando se pidan piezas de

repuesto para la máquina. Utilizar el espacio siguiente

para escribir los datos de identificación de la máquina

para todas referencias futuras.

Modelo MÁQUINA ......................................................

Número de serie MÁQUINA .......................................

OTROS MANUALES DE REFERENCIA

– Catálogo piezas de repuestos (en dotación a la

máquina).

– Manual de taller (que se puede consultar cerca de los

Centros de asistencia Nilfisk-Advance).

PIEZAS DE REPUESTO Y

MANTENIMIENTO

Para cualquier necesidad que se refiere a la utilización, al

mantenimiento y a las reparaciones, consultar el personal

calificado o los Centros de asistencia Nilfisk-Advance. Se

recomienda utilizar sólo piezas de repuesto y accesorios

originales.

Para la asistencia o para ordenar piezas de repuesto o

accesorios, acuda a un Centro Nilfisk-Advance,

especificando siempre el modelo y el número de serie de

la máquina.

MODIFICACIONES Y MEJORAS

Nuestra Empresa está constantemente mejorando sus

productos y se reserva el derecho de realizar

modificaciones y mejoras a su discreción, sin verse

obligada a aplicar dichas ventajas a las máquinas

vendidas previamente.

Sólo el Fabricante puede aprobar y efectuar cualquier

modificación y/o instalación de accesorios.

SEGURIDAD

La siguiente simbología sirve para señalar situaciones de

potencial. Leer siempre cuidadosamente estas

peligro

informaciones y tomar las precauciones necesarias para

proteger personas y cosas.

Para evitar desgracias, la cooperación del Operador de la

máquina es fundamental. Ningún programa de prevención

de accidentes resulta eficaz sin la total cooperación de la

persona directamente responsable del funcionamiento de

la máquina. La mayoría de los accidentes que pueden

producirse en una empresa, durante el trabajo o los

traslados, son provocados por no observar las reglas de

seguridad fundamentales. Un operador cuidadoso y cauto

es la mejor garantía para evitar posibles accidentes y

resulta más eficaz que cualquier programa de prevención.

SÍMBOLOS

¡PELIGRO!

Indica un peligro con riesgo, incluso

mortal, para el operador.

¡ATENCIÓN!

Indica el riesgo potencial de infortunios

para las personas.

¡ADVERTENCIA!

Indica una advertencia o una nota sobre

una función importante o útil. Tener mucho

cuidado de las partes del texto marcadas

con este símbolo.

CONSULTAS

2 Terra™ 5200B – 146 1996 000(2)2004-08

Antes de efectuar cualquier operación

consulte las Instrucciones de uso.

Page 21

INSTRUCCIONES DE USO

INSTRUCCIONES GENERALES

Se describen a continuación las advertencias y

precauciones específicas por lo que se refiere a los

potenciales riesgos de daños a la máquina o a las

personas.

¡PELIGRO!

– Antes de efectuar cualquier operación de

mantenimiento/reparación, poner el conmutador de

arranque en posición OFF y desconectar la batería.

– Sólo el personal calificado y autorizado puede utilizar

esta máquina. Los niños y los minusválidos no

pueden utilizar esta máquina.

– Tener chispas, llamas y humo lejos de las baterías.

Durante el uso normal pueden salir gases explosivos.

– Quitarse las joyas cuando se trabaja cerca de los

componentes eléctricos.

– No trabajar bajo la máquina levantada si ésta no está

fijada con los soportes adecuados.

– Cada vez que se trabaja bajo del capó abierto,

asegurarse que el capó mismo no pueda cerrarse de

forma accidental.

– No utilizar esta máquina en un ambiente donde haya

polvo, líquidos o vapores nocivos, peligrosos,

inflamables y/o explosivos.

– Cargando las baterías se produce gas hidrógeno

explosivo. Tener el capó abierto durante las

operaciones de carga de la batería y efectuar la

carga solo en áreas muy bien ventiladas y lejos de

llamas libres.

¡ATENCIÓN!

– Antes de efectuar cualquier operación de

mantenimiento/reparación, leer cuidadosamente

todas las instrucciones relacionadas.

– Tomar todas las precauciones necesarias para que

el pelo, las joyas y las ropas no sean capturados por

las partes móviles de la máquina.

– No fumar cuando se cargan las baterías.

– No dejar la máquina sin custodia sin haber sacado la

llave de encendido y activado el freno de

estacionamiento.

– No utilizar sobre suelos con inclinación mayor a la

indicada en la máquina.

– No lavar la máquina con chorros de agua directa o

presurizada, o con sustancias corrosivas. No utilizar

aire comprimido para la limpieza general de este tipo

de máquina, excepto para los filtros (véase el párrafo

relacionado).

– Cuando se utiliza esta máquina, tener cuidado de

salvaguardar la incolumidad de las personas,

especialmente los niños.

– No apoyar contenedores de líquidos sobre la

máquina.

– La temperatura de almacenamiento debe estar entre

0°C y +40°C (+32°F y +104°F).

– La temperatura de funcionamiento la máquina debe

estar entre 0°C y +40°C (+32°F y +104°F).

– La humedad debe estar entre el 30% y el 95%.

– Proteger siempre la máquina del sol, lluvia y otras

intemperie, tanto durante el funcionamiento como

durante los períodos de inactividad.

– No se puede utilizar la máquina para remolcar o

empujar objetos y/o cargas. No utilizar la máquina

como medio de transporte; la capacidad máxima de

la máquina, además del peso del Operador, es de

110 kg (242,5 lb).

– No permitir que los cepillos funcionen mientras la

máquina esta parada en un punto para evitar

posibles daños al suelo.

– En caso de incendio utilizar un extintor de polvo. No

utilizar agua.

– No chocar contra estanterías o andamios de los que

puedan caer objetos.

– Ajustar la velocidad de funcionamiento según la

adherencia al suelo.

– Esta máquina no tiene aprobación para la utilización

en carreteras o vías públicas.

– No adulterar por ninguna razón la máquina, respetar

escrupulosamente las instrucciones previstas para el

mantenimiento ordinario.

– No quitar ni modificar las placas que el Fabricante ha

colocado en la máquina.

– Cuando la máquina no funciona correctamente,

asegurarse de que ésto no sea causado por falta de

mantenimiento.

En caso contrario pedir la intervención del personal

autorizado o del Centro de asistencia.

– Si deben sustituirse piezas, solicitar piezas de

repuesto ORIGINALES a un Concesionario o

Revendedor autorizado.

– Para asegurar condiciones de funcionamiento

correcto y seguro, el personal autorizado o el Centro

de asistencia autorizado debe llevar a cabo el

mantenimiento programado según las

especificaciones en el capítulo relacionado de este

manual.

– La máquina nunca debe dejarse desentendida

durante la fase de eliminación, por la presencia de

materiales tóxicos y dañinos (baterías, aceites,