Page 1

SW900

Service Manual

Advance SW900 Battery – 9084112010

Nilsk SW900 Battery - 9084110010

Nilsk SW900 Petrol - 9084111010

English

2013-11 Form No. 1465376000

Page 2

Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Machine General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Service Manual Purpose and Field of Application . . . . . . . . . . . . . . . . . . . . . 5

Other Reference Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Service and Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Serial Number Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Visible Symbols on the Machine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Machine Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Machine Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Machine Nomenclature (SW900 B) (know your machine) . . . . . . . . . . . . . . . . . 12

Machine Nomenclature (SW900 P) (know your machine) . . . . . . . . . . . . . . . . .16

Service and Diagnostic Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Machine Material Composition and Recyclability . . . . . . . . . . . . . . . . . . . . . 22

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Scheduled Maintenance Table (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . 24

Scheduled Maintenance Table (SW900 P) . . . . . . . . . . . . . . . . . . . . . . . . . 25

Contents iiService Manual – SW900

Frame System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Frame (main parts) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Dust Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Wiring Diagram (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Wiring Diagram (SW900 P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Panel dust lter, cleaning and integrity check/replacement. . . . . . . . . . . . . .30

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Electrical lter shaker motor amperage check . . . . . . . . . . . . . . . . . . . . .33

Electrical Filter Shaker Motor Disassembly/Assembly . . . . . . . . . . . . . . . . 35

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Electrical and Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Functional Description (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Electrical Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Functional Description (SW900 P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Electrical Protections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Relays / Electromagnetic Switches / Diodes . . . . . . . . . . . . . . . . . . . . . . 40

Wiring Diagram (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Wiring Diagram (SW900 P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Component Locations (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Component Locations (SW900 P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Charging the batteries (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Page 3

Fuse Check/Replacement/Reset (SW900 B). . . . . . . . . . . . . . . . . . . . . . .51

Fuse Check/Replacement/Reset (SW900 P). . . . . . . . . . . . . . . . . . . . . . .53

Troubleshooting (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Battery Installation and Battery Type Setting (WET or GEL) (SW900 B) . . . . . . 55

Machine Check/Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Main motor amperage check (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . 59

Dynamotor Voltage Check (SW900 P) . . . . . . . . . . . . . . . . . . . . . . . . . 61

Main motor carbon brush replacement (SW900 B). . . . . . . . . . . . . . . . . . .63

Dynamotor Carbon Brush Replacement (SW900 P) . . . . . . . . . . . . . . . . . . 64

Main Motor or Fan Removal/Installation (SW900 B) . . . . . . . . . . . . . . . . . 65

Dynamotor Removal/Installation (SW900 P) . . . . . . . . . . . . . . . . . . . . . .69

Reduction Unit Removal/Installation . . . . . . . . . . . . . . . . . . . . . . . . . .73

Main Broom Shaft (Small) Gear Removal/Installation . . . . . . . . . . . . . . . .74

Drive Shaft (Big) Gear Removal/Installation . . . . . . . . . . . . . . . . . . . . . .77

Battery Charger Removal/Installation (SW900 B) . . . . . . . . . . . . . . . . . . .80

Hopper Position Switch Operation Check, Removal/Installation . . . . . . . . . . .82

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

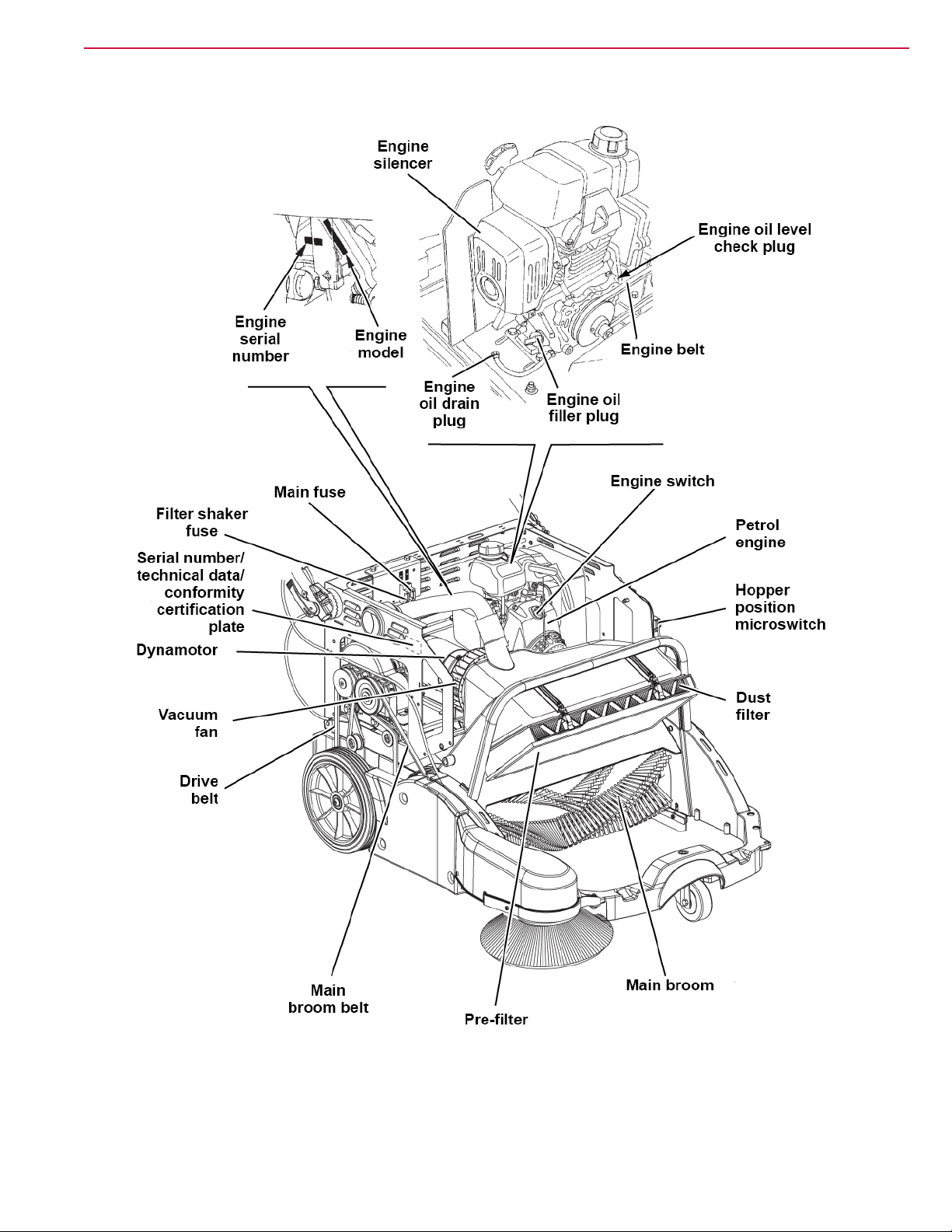

Petrol Engine System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

Engine RPM Check and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Engine Belt Check/Adjustment/Replacement . . . . . . . . . . . . . . . . . . . . . 90

Petrol Engine Assembly Removal/Installation . . . . . . . . . . . . . . . . . . . . . 93

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Contents iiiService Manual – SW900

Hopper System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Main Broom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .101

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Main Broom Height Check and Adjustment . . . . . . . . . . . . . . . . . . . . . 103

Skirt Height Check and Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 104

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Main Broom Removal/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Main Broom Belt Check/Replacement . . . . . . . . . . . . . . . . . . . . . . . . 111

Main Broom Pulley and Hexagonal Drive Hub Replacement . . . . . . . . . . . . 113

Skirt Removal/Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Side Broom System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Battery Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

Petrol Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Wiring Diagram (SW900 B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Wiring Diagram (SW900 P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Page 4

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Side Broom Height Check and Adjustment. . . . . . . . . . . . . . . . . . . . . . 121

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Side Broom Disassembly/Assembly . . . . . . . . . . . . . . . . . . . . . . . . . .123

Side Broom Motor Amperage Check . . . . . . . . . . . . . . . . . . . . . . . . . 124

Side Broom Reduction Unit Removal/Installation . . . . . . . . . . . . . . . . . . 125

Right Side Broom Control Cable Removal/Installation . . . . . . . . . . . . . . . 126

Side Broom Microswitch Adjustment and Removal/Installation . . . . . . . . . . 128

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Wheel System, Traction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Functional Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .131

Component Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Maintenance and Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Drive system control cable, disassembly/assembly. . . . . . . . . . . . . . . . . . 135

Drive belt, check/replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Contents ivService Manual – SW900

Page 5

Service Manual – SW900

General Information

General Information

Machine General Description

The SW900 is a “man-down” industrial machine designed to clean/sweep oors, in civil or industrial environments, in one pass. The machine can be supplied in one of the following version:

• with a rechargeable battery, installed on the machine (SW900 B)

• with a dynamotor driven by a petrol engine, both installed on the machine (SW900 Petrol)

The machine is equipped with one main cylindrical broom, and one or two side disc brooms.

The front hopper and a vacuum system allow for dust and dirt collection.

Service Manual Purpose and Field of Application

The Service Manual is a technical resource intended to help service technicians when carrying out mainte-

nance and repairs on the SW900, to guarantee the best cleaning performance and a long working life for the

machine.

Please read this manual carefully before performing any maintenance and repair procedure on the machine.

5

Other Reference Manuals

Model Product Code User Manual Spare Parts List

SW900 B - Advance 9084112010 1465374000 1465375000

SW900 B - Nilsk 9084110010 1465366000 1465367000

SW900 P - Nilsk 9084111010 1465371000 1465372000

Assembly Instructions Instruction Code Machines concerned

LEFT SIDE BROOM KIT 1465407000

MANUAL FILTER SHAKER KIT 1465626000

ELECTRICAL FILTER SHAKER KIT 1465627000

These manuals are available at:

• Local Nilsk-Advance Retailer

• Nilsk-Advance website: www.Nilsk-Advance.com

9084112010 – 9084110010 - 9084111010

9084110010 - 9084111010

ONLY FOR N-ALTO VERSIONS (NOT FOR THIS VERSION)

Page 6

Service Manual – SW900

General Information

Conventions

Forward, backward, front, rear, left or right are intended with reference to the operator’s position when driving.

Service and Spare Parts

Service and repairs must be performed only by authorised personnel or Nilsk Service Centers. The authorised

personnel is trained directly at the manufacturer’s premises and has original spare parts and accessories.

Contact Nilsk Retailer indicated below for service or to order spare parts and accessories, specifying the ma-

chine model and serial number.

(Apply Retailer label here)

6

Serial Number Label

The machine serial number and model name are

marked on the plate (see the example to the side).

Product number and year of production are marked

on the same plate.

This information is useful when requiring machine

spare parts.

Use the following table to write down the machine

identication data.

MACHINE model .............................................................................................

PRODUCT code ..............................................................................................

MACHINE serial number .................................................................................

P200249

ENGINE model ................................................................................................

ENGINE serial number ....................................................................................

Page 7

Service Manual – SW900

General Information

Safety

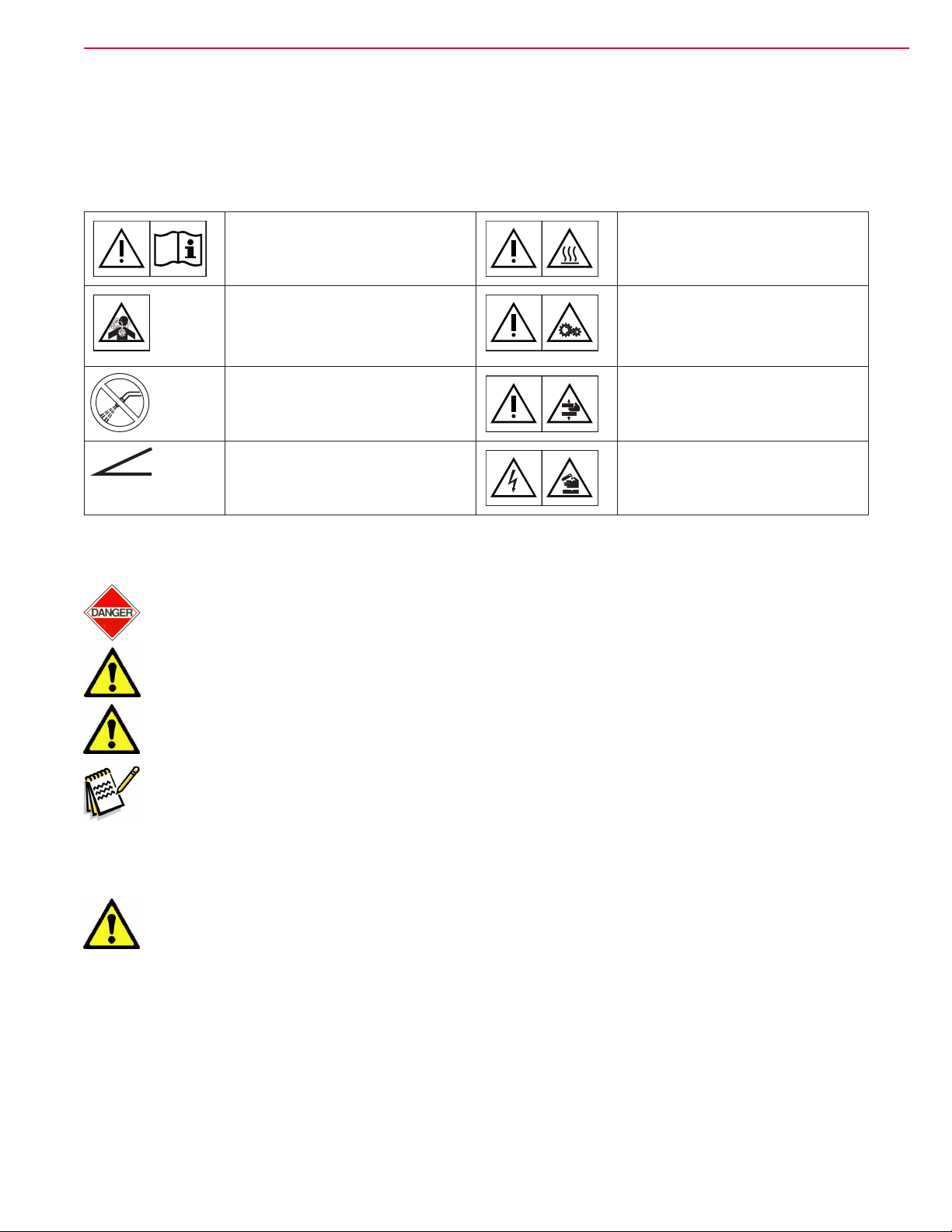

The following symbols indicate potentially dangerous situations. Always read this information carefully and

take all necessary precautions to safeguard people and property.

Visible Symbols on the Machine

WARNING!

Carefully read all the instructions before

performing any operation on the machine.

WARNING!

Hot parts, danger of burns.

7

X %

Symbols

Danger! It indicates a dangerous situation with risk of death for the operator.

Warning! It indicates a potential risk of injury for people or damage to objects.

Caution! It indicates a caution related to important or useful functions.

DANGER!

Internal combustion engine.

Do not inhale exhaust gas fumes.

Carbon monoxide (CO) can cause brain

damage or death.

WARNING!

Do not wash the machine with direct or

pressurized water jets.

WARNING!

Do not use the machine on slopes with a

gradient exceeding the specications.

WARNING!

Moving parts.

WARNING!

Moving parts. Danger of crushing.

WARNING!

Parts under voltage. Presence of corrosive

uids.

Note: It indicates a remark related to important or useful functions.

General Instructions

Specic warnings and cautions to inform about potential damages to people and machine are shown below.

Warning! Make sure to follow the safety precautions to avoid situations that may lead to

serious injuries.

(For SW900 B/Petrol)

– Before performing any maintenance, repair, cleaning or replacement procedure disconnect the

battery connector, remove the ignition key and engage the parking brake; for SW900 B also dis-

connect the batteries. Make sure that the machine cannot move independently.

– This machine must be used by properly trained operators only.

– Keep the batteries away from sparks, ames and incandescent material. Explosive gases are

released when charging the batteries.

Page 8

Service Manual – SW900

– Do not wear jewels when working near electrical components.

– Do not work under the lifted machine without supporting it with safety stands.

– When working under the open hood, ensure that it cannot be closed by accident.

– Do not operate the machine near toxic, dangerous, ammable and/or explosive powders, liquids

or vapors: This machine is not suitable for collecting dangerous powders.

(For SW900 P)

– Carbon monoxide (CO) can cause brain damage or death.

– The internal combustion engine of this machine can emit carbon monoxide.

– Do not inhale exhaust gas fumes.

– Only use indoors when adequate ventilation is provided, and with the help of an assistant.

– Be careful: fuel is highly ammable.

– Do not smoke or bring naked ames in the area where the machine is refuelled or where the fuel

is stored.

– Refuel outdoors or in a well-ventilated area, with the engine off.

– Turn off the engine and let it cool down for a few minutes, then remove the fuel tank plug.

– To allow the fuel to expand, do not ll the fuel tank beyond the upper limit mark (A) shown in

the gure.

General Information

8

P200250

– After refuelling, check that the fuel tank cap is rmly closed.

– If any fuel is spilled while refuelling, clean the tank area and allow the vapors to evaporate be-

fore starting the engine.

– Do not let fuel come into contact with the skin; do not breathe fuel vapors. Keep out of reach of

children.

– Do not tilt the engine or the machine too much to avoid fuel spillage.

– Do not lay any object on the engine.

– Stop the engine before performing any procedure on it. To avoid any accidental start, disconnect

the spark plug cap.

– See also the SAFETY RULES in the Engine Manual, which is to be considered an integral part of

this Manual.

(For SW900 B)

– If the machine is equipped with lead (WET) batteries, battery charging produces highly explosive

hydrogen gas. Charge the batteries in well-ventilated areas and away from naked ames.

– When lead batteries (WET) are installed, do not tilt the machine for more than 30° from the

horizontal plane to prevent the highly corrosive acid from leaking out of the batteries. When the

machine is to be tilted to perform maintenance procedures, remove the batteries.

Warning! Make sure to follow the safety precautions to avoid situations that may lead to

serious injuries, damages to materials or equipments.

Page 9

Service Manual – SW900

(For SW900 B/Petrol)

– Carefully read all the instructions before performing any maintenance/repair procedure.

– This machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the machine by a person responsible for they safety.

Children should be supervised to ensure that they do not play with the machine.

– Close attention is necessary when used near children.

– Use only as shown in this Manual. Only Nilsk-Advance recommended accessories must be used.

– Check the machine carefully before each use, always check that all the components have been as-

sembled before use. If the machine is not perfectly assembled it can cause damages to people and

properties.

– Take all necessary precautions to prevent hair, jewels and loose clothes from being caught by the

machine moving parts.

– To avoid any unauthorized use of the machine, remove the ignition key.

– Do not leave the machine unattended without being sure that it cannot move independently.

– Do not use the machine on incline.

– Do not tilt the machine more than the angle indicated on the machine itself, in order to prevent

instability.

– Use only brooms supplied with the machine or those specied in the User Manual. Using other

brooms could reduce safety.

– Before using the machine, close all doors and/or covers as shown in the User Manual.

– Do not wash the machine with direct or pressurised water jets, or with corrosive substances.

– Use the machine only where a proper lighting is provided.

– While using this machine, take care not to cause damage to people or objects.

– Do not bump into shelves or scaffoldings, especially where there is a risk of falling objects.

– Do not lean liquid containers on the machine, use the relevant can holder.

– The storage temperature must be between 0°C and +40°C.

– The machine working temperature must be between 0°C and +40°C.

– The humidity must be between 30% and 95%.

– Always protect the machine against the rain and bad weather, both under operation and inactiv-

ity condition. Store the machine indoors, in a dry place. This machine must be used in dry conditions, it must not be used or kept outdoors in wet conditions.

– Do not use the machine as a means of transport, or for pushing/towing.

– Do not allow the brooms to operate while the machine is stationary to avoid damaging the oor.

– The machine maximum capacity is 30 kg (the maximum weight of waste).

– In case of re, use a powder re extinguisher, not a water one.

– This machine cannot be used on roads or public streets.

– Do not tamper with the machine safety guards.

– Follow the routine maintenance procedures scrupulously.

– Do not allow any object to enter into the openings. Do not use the machine if the openings are

clogged. Always keep the openings free from dust, hairs and any other foreign material which

could reduce the air ow.

– Do not remove or modify the plates afxed to the machine.

– In case of machine malfunctions, ensure that these are not due to lack of maintenance. If neces-

sary, request assistance from the authorised personnel or from an authorised Service Center.

– If parts must be replaced, require ORIGINAL spare parts from an Authorised Dealer or Retailer.

– To ensure machine proper and safe operation, the scheduled maintenance shown in the relevant

chapter of this Manual, must be performed by the authorised personnel or by an authorised Service Center.

– The machine must be disposed of properly, because of the presence of toxic-harmful materials

(batteries, oils, etc.), which are subject to standards that require disposal in special centres (see

the User Manual).

General Information

9

Page 10

Service Manual – SW900

(For SW900 P)

– While the engine is running, the silencer warms up; do not touch the silencer when it is hot to

avoid burns or res.

– Running the engine with an insufcient quantity of oil can seriously damage the engine. Check

the oil level with the engine off and the machine on a level surface.

– Never run the engine if the air lter is not installed, because the engine could be damaged.

– Technical service procedures on the engine must be performed by an authorised Dealer.

– Only use original spare parts or parts of matching quality for the engine. Using spare parts of

lower quality can seriously damage the engine.

– See also the SAFETY RULES in the Engine Manual, which is to be considered an integral part of

this Manual.

– Pay attention to hot parts when working near the engine and the mufer.

(For SW900 B)

– Before using the battery charger, ensure that frequency and voltage values, indicated on the

machine serial number plate, match the electrical mains voltage.

– Do not pull or carry the machine by the battery charger cable and never use the battery charger

cable as a handle. Do not close a door on the battery charger cable, or pull the battery charger

cable around sharp edges or corners. Do not run the machine on the battery charger cable.

– Keep the battery charger cable away from heated surfaces.

– Do not use the machine if the battery charger cable or plug is damaged. If the machine is not

working as it should, has been damaged, left outdoors or dropped into water, return it to the

Service Center.

– Before performing any maintenance procedure, disconnect the battery charger cable from the

electrical mains to avoid any risk of re, electric shock or injuries.

– Do not smoke while charging the batteries.

General Information

10

Page 11

Service Manual – SW900

Machine Lifting

Warning! Donotworkundertheliftedmachine,ifitisnotsecurelyxed.

Machine Transportation

Warning! Before transporting the machine, make sure that:

All covers are closed.

(For SW900 B) The battery connector is disconnected.

The machine is securely fastened to the means of transport.

General Information

11

Page 12

Service Manual – SW900

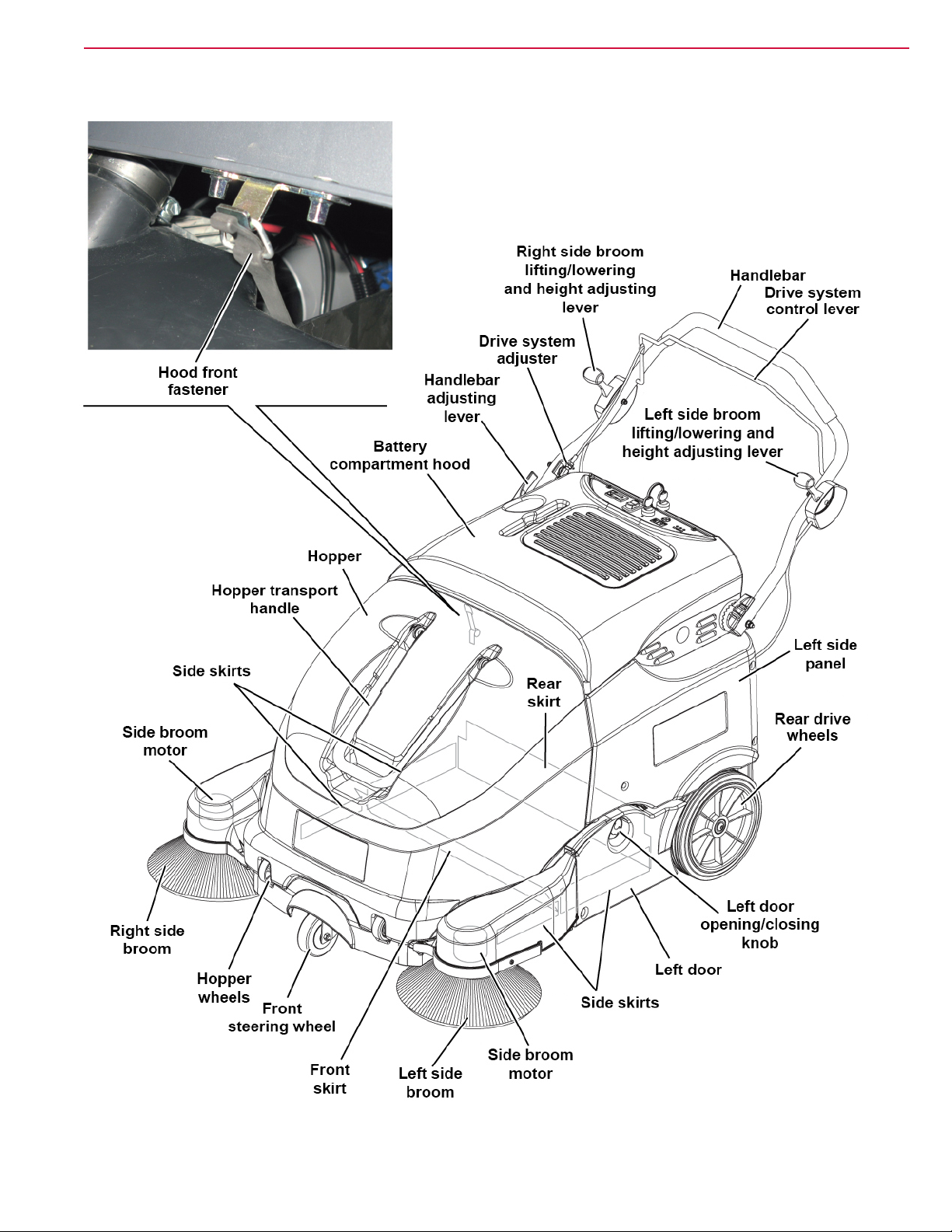

Machine Nomenclature (SW900 B) (know your machine)

General Information

12

P200251

Page 13

Service Manual – SW900

Machine Nomenclature (SW900 B) (Continues)

General Information

13

P200252

Page 14

Service Manual – SW900

Machine Nomenclature (SW900 B) (Continues)

General Information

14

P200253

Page 15

Service Manual – SW900

Machine Nomenclature (SW900 B) (Continues)

General Information

15

P200254

Page 16

Service Manual – SW900

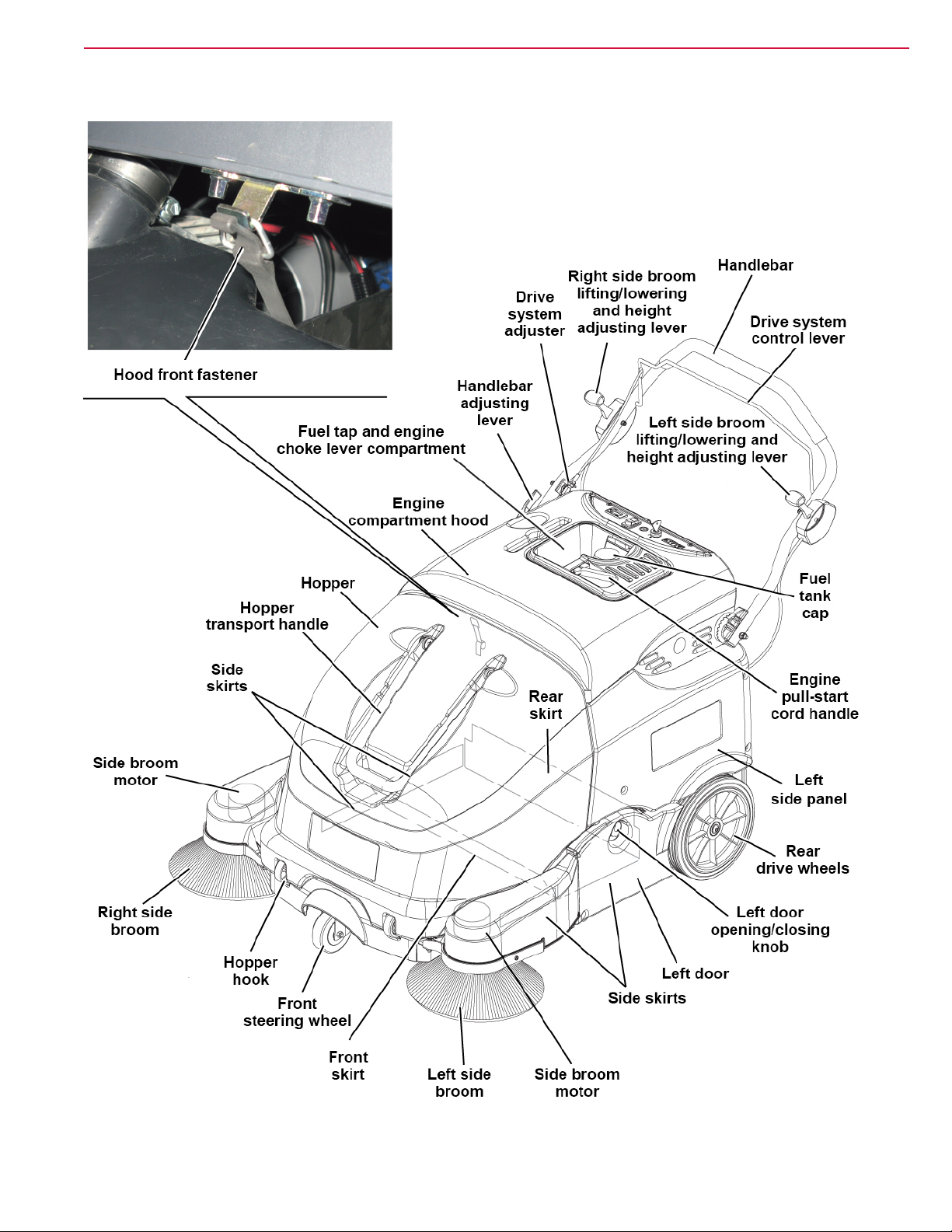

Machine Nomenclature (SW900 P) (know your machine)

General Information

16

P200255

Page 17

Service Manual – SW900

Machine Nomenclature (SW900 P) (Continues)

General Information

17

P200256

Page 18

Service Manual – SW900

Machine Nomenclature (SW900 P) (Continues)

General Information

18

P200257

Page 19

Service Manual – SW900

Machine Nomenclature (SW900 P) (Continues)

General Information

19

P200258

Page 20

Service Manual – SW900

General Information

Service and Diagnostic Equipment

Besides a complete set of standard meters, the following instruments are necessary to perform fast checks and

repairs on Nilsk-Advance machines:

• Digital Volt Meter (DVM)

• Amp clamp with possibility of making DC measurements

• Battery charge tester to check 12V batteries

• Static control wrist strap

• Dynamometric wrench set

• A copy of the User Manual and Spare Parts List of the machine to be serviced (provided with the machine

or available at www.advance-us.com or other Nilsk-Advance websites).

The following equipment is also available at Nilsk-Advance Centers.

20

Page 21

Service Manual – SW900

Technical Data

General Information

21

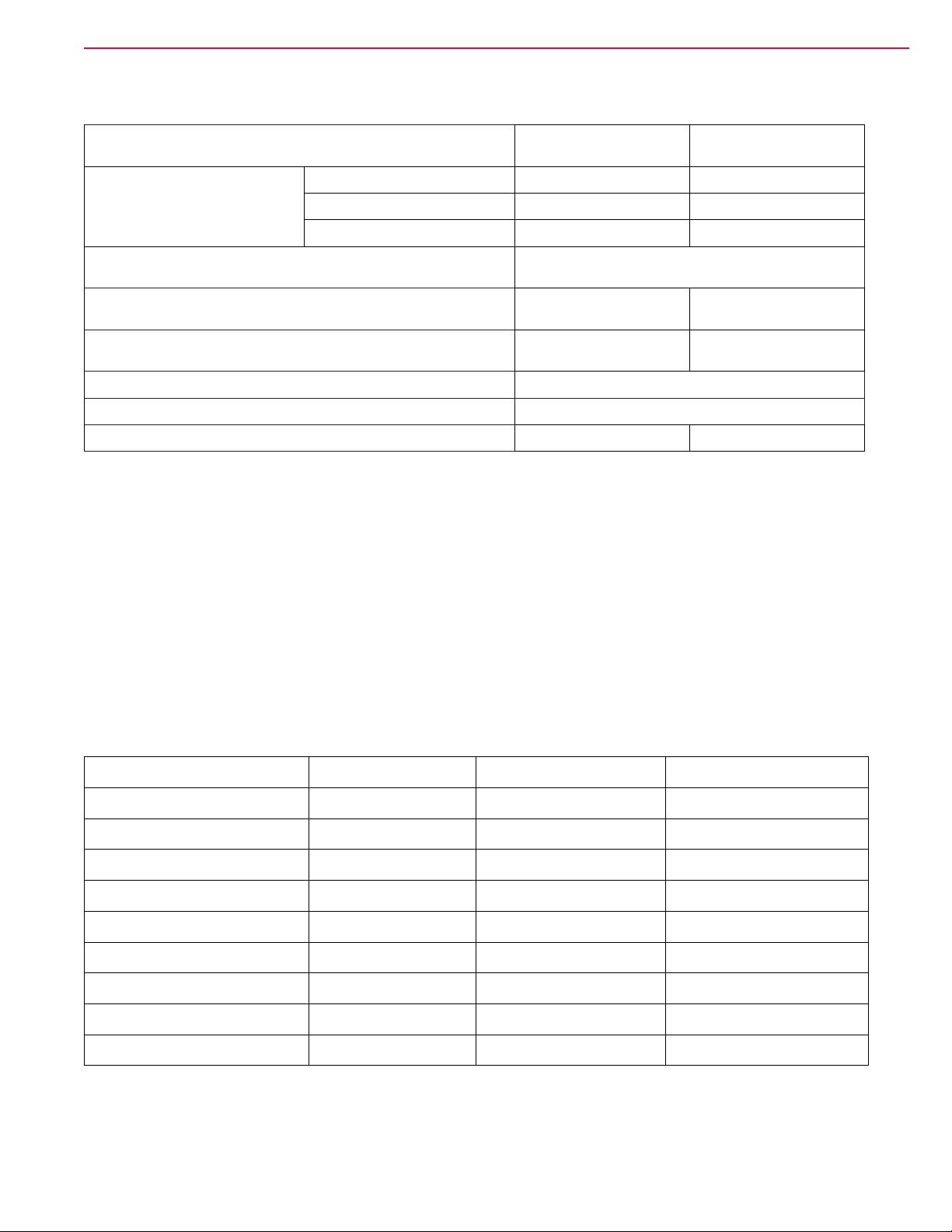

Model

Cleaning width

Main broom size (length x diameter) 23.6 x 10.4 in (600 x 265 mm)

Side broom diameter 12.4 in (315 mm)

Theoretical working capacity

Hopper

Filter

Power 12V batteries -

Power - 2.1 kW @ 3,600 rpm

Engine model - Honda GX-100

Fuel tank capacity 0.77 liters

with one side broom 32.5 in (825 mm)

with two side brooms 41.3 in (1,050 mm)

with one side broom 39.987 ft2/h (3.715 m2/h)

with two side brooms 50.859 ft2/h (4.725 m2/h)

capacity 2.1 ft3 (60 Liters)

maximum transportable weight 66 lb (30 kg)

cleaning system

area 20.5 ft2 (1.9 m2)

ltering capacity 5-10 µm

Advance / Nilsk

SW900 B

Electrical lter shaker

(manual on Advance version)

Nilsk

SW900 P

Main motor

Dynamotor

Main broom speed 420 rpm

Side broom

Drive forward speed 2.8 mi/h (4.5 km/h)

Maximum gradient when working 2 %

Filter shaker motor 12 W

Total absorbed power 67A (0.8 kW) -

Working autonomy 3 h 1.5 h

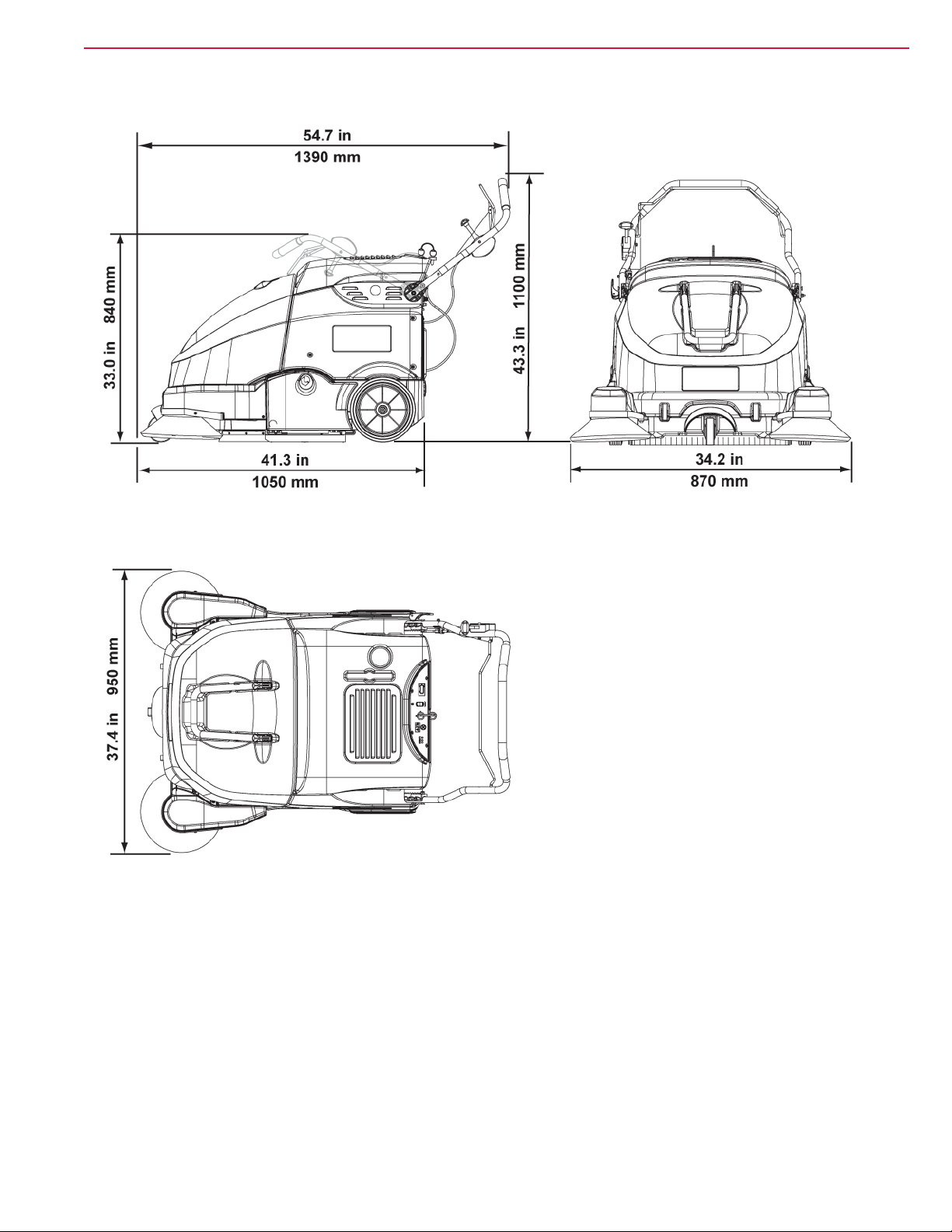

Dimensions

(length x width x height)

power (drive/main broom/vacuum

system)

power (drive/main broom/vacuum

system)

motor power 0.05 hp (40 W)

speed 100 rpm

machine running 54.7 x 34.2 x 43.3 in (1,390 x 870 x 1,100 mm)

machine with folded handlebar 41.3 x 34.2 x 33 in (1,050 x 870 x 840 mm)

machine with two side brooms 54.7 x 37.4 x 43.3 in (1,390 x 950 x 1,100 mm)

battery compartment 12.9 x 9 x 15 in (327 x 230 x 380 mm)

0.9 hp (680 W) -

- 0.26 hp (198 W)

Page 22

Service Manual – SW900

Technical Data (Continues)

General Information

22

Model

kerb weight without batteries 181 lb (82 Kg) 194 lb (88 Kg)

Weight

Wheel specic pressure on the oor (front - rear wheels, in running

conditions)

Sound pressure level at workstation

(ISO 11201, ISO 4871, EN 60335-2-72) (LpA)

Machine sound pressure level

(ISO 3744, ISO 4871, EN 60335-2-72) (LwA)

IP protection class X3

U-turn space 61 in (1,550 mm)

Vibration level at the operator’s arms (ISO 5349-1) (**) < 98 in/s2 (< 2.5 m/s2) 157 in/s2 (4 m/s2)

total kerb weight 315 lb (143 Kg) 195 lb (88.5 Kg)

gross vehicle weight (GVW) 388 lb (176 Kg) 269 lb (122 Kg)

Advance / Nilsk

SW900 B

301 - 72 psi (2.1 - 0.5 N/mm2)

70 ± 3 dB(A) 78 ± 3 dB(A)

84 dB(A) 93 dB(A)

Nilsk

SW900 P

(*) Machines have been tested under the following conditions:

• Battery maximum size

• Brooms of maximum size

• Full hopper

• Optional components installed

• Weight on wheels checked

• Print on the oor checked on cement for each single wheel

Result expressed as maximum value for both front and rear wheels

(**) Under normal working conditions, on a level asphalt surface.

Machine Material Composition and Recyclability

Type Recyclable percentage SW900 B weight percentage SW900 P weight percentage

Aluminium 100 % 2.4 % 2.2 %

Electric motors - various 29 % 11.8 % 18.8 %

Ferrous materials 100 % 39.4 % 35.5 %

Wiring harnesses 80 % 1.8 % 1.6 %

Liquids 100 % 0.0 % 1.1 %

Plastic - non-recyclable material 0 % 9.4 % 8.6 %

Plastic - recyclable material 100 % 27.1 % 24.7 %

Polyethylene 92 % 5.9 % 5.4 %

Rubber 20 % 2.4 % 2.2 %

Page 23

Service Manual – SW900

Dimensions

General Information

23

P200259

Page 24

Service Manual – SW900

General Information

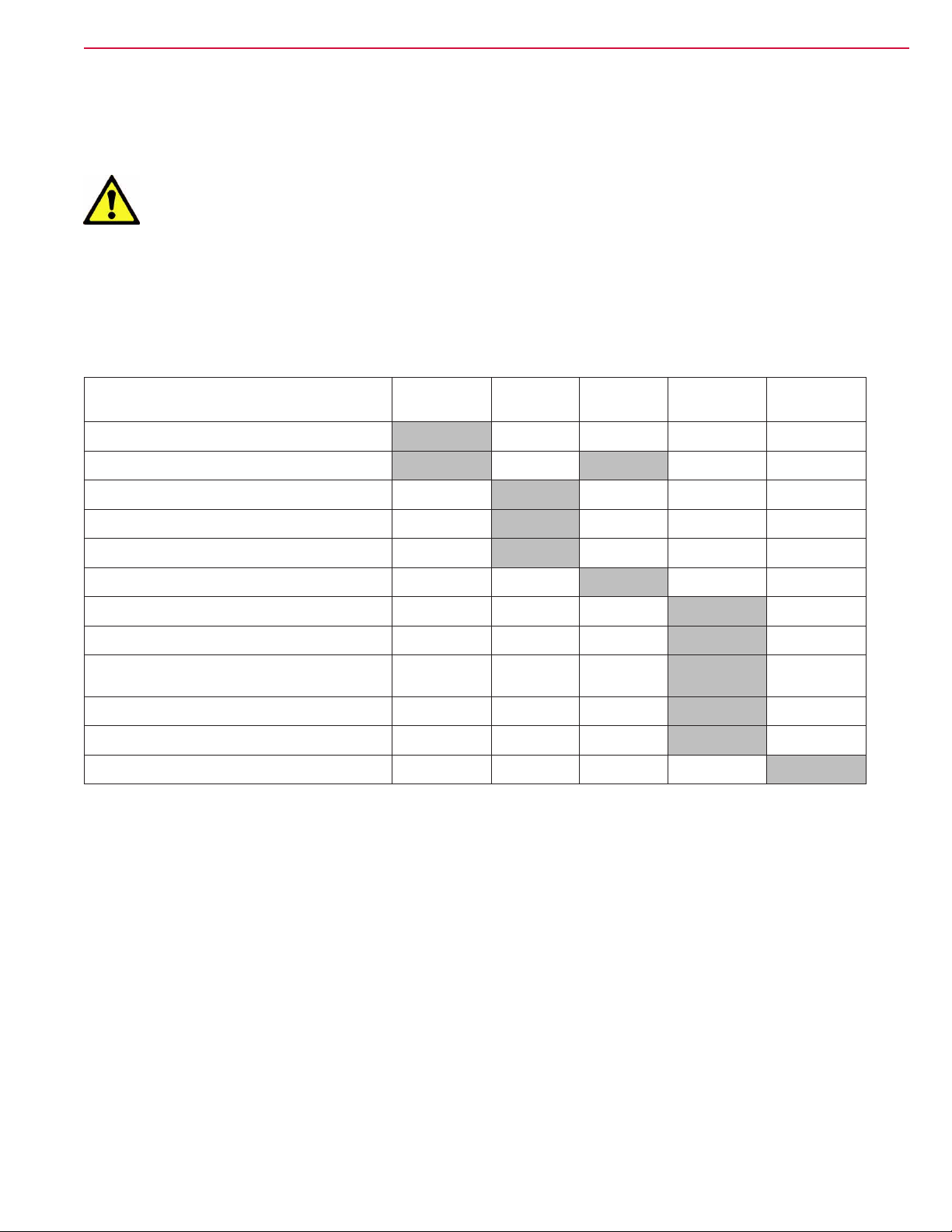

Maintenance

The lifespan of the machine and its maximum operating safety are ensured by correct and regular maintenance.

Warning! Read carefully the instructions in the Safety chapter before performing any

maintenance procedure.

The following tables provides the scheduled maintenance. The intervals shown may vary according to particu-

lar working conditions, which are to be dened by the person in charge of the maintenance.

For instructions on maintenance procedures, see the following paragraphs.

Scheduled Maintenance Table (SW900 B)

24

Procedure

Battery charging

Battery (WET) uid level check

Battery charger cable check

Dust lter cleaning and integrity check (2)

Side and main broom height check and adjustment

Skirt height and operation check

Dust lter holder gasket check

Electrical lter shaker operation check

Drive belt check/adjustment: drive system, main

broom.

Hopper position microswitch operation check

Drive belt replacement: drive system, main broom.

Main motor carbon brush check and replacement

(1) Daily or after using the machine.

(2) Or before use.

Upon

delivery

(1)

Every 10

hours

Every 50

hours

Every 200

hours

Every 400

hours

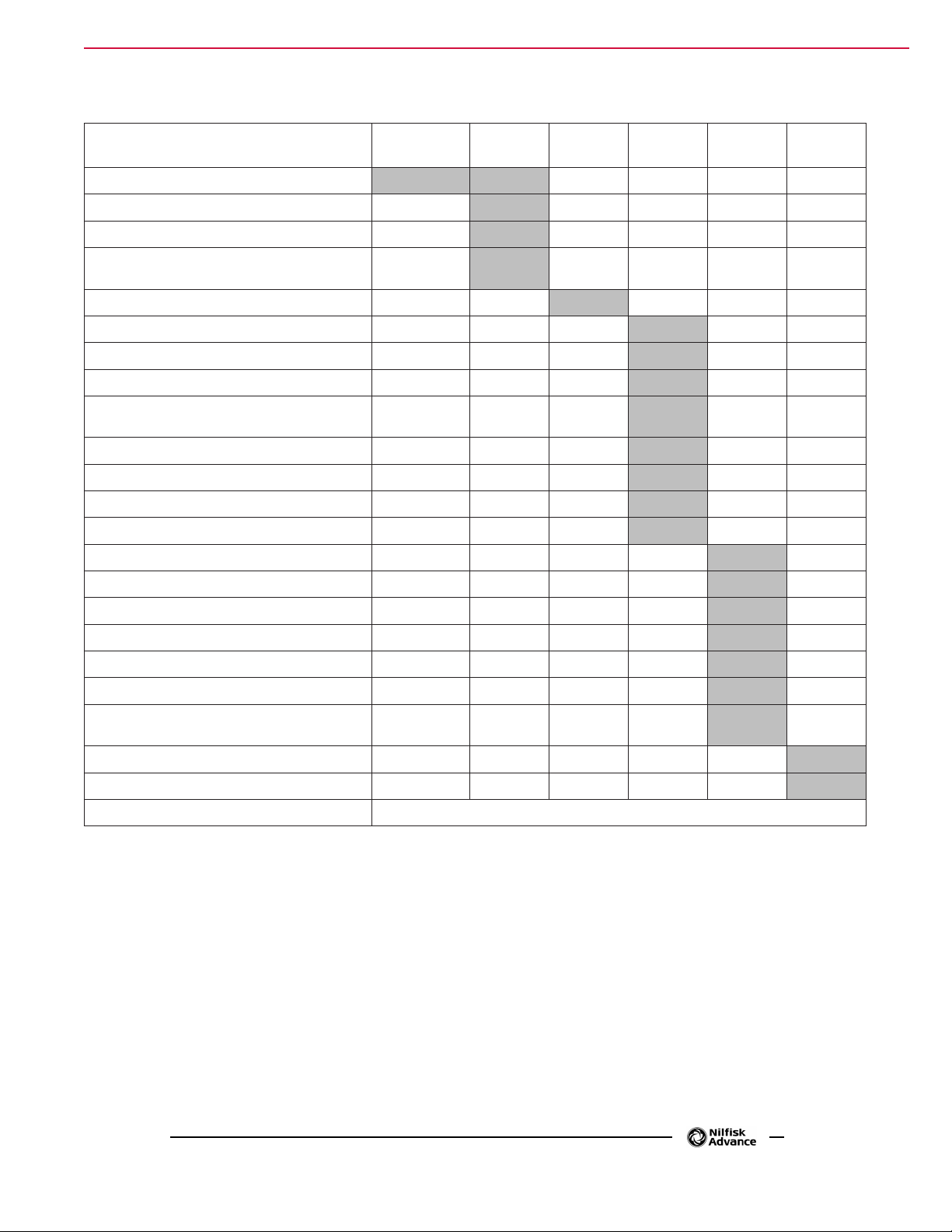

Page 25

Service Manual – SW900

Scheduled Maintenance Table (SW900 P)

General Information

25

Procedure

Engine oil level check (1) (5)

Engine air lter check (1) (5)

Dust lter cleaning and integrity check (1)

Side and main broom height check and

adjustment

Skirt height and operation check

Electrical lter shaker operation check

Engine air lter cleaning (3) (5)

Drive belt tensioner adjustment (1)

Drive belt check/adjustment: engine, drive system,

main broom

Engine Oil Change (2) (5) (6)

Spark plug check/cleaning (5)

Fuel tank and lter cleaning (4) (5)

Engine speed check

Dust lter holder gasket check

Engine air lter replacement (3) (5)

Upon

delivery

Every 10

hours

Every 50

hours

Every 100

hours

Every 200

hours

Every 300

hours

Spark plug replacement (2) (5)

Valve clearance check/adjustment (4) (5)

Hopper gasket integrity check

Hopper position microswitch operation check

Drive belt replacement: engine, drive system,

main broom

Dynamotor carbon brush check and replacement

Engine combustion chamber cleaning (4) (5)

Fuel hose check (4) (5) Every two years

(1) Or before use.

(2) Or every year.

(3) Or more often in dusty areas.

(4) Maintenance procedures to be performed by an authorised Honda Dealer, unless the operator has the service equipment

and data, and is qualied to perform such procedures.

(5) For the relevant procedure, see the Petrol Engine Manual.

(6) The rst time after 20 hours or after one month.

Page 26

Service Manual – SW900

Frame System

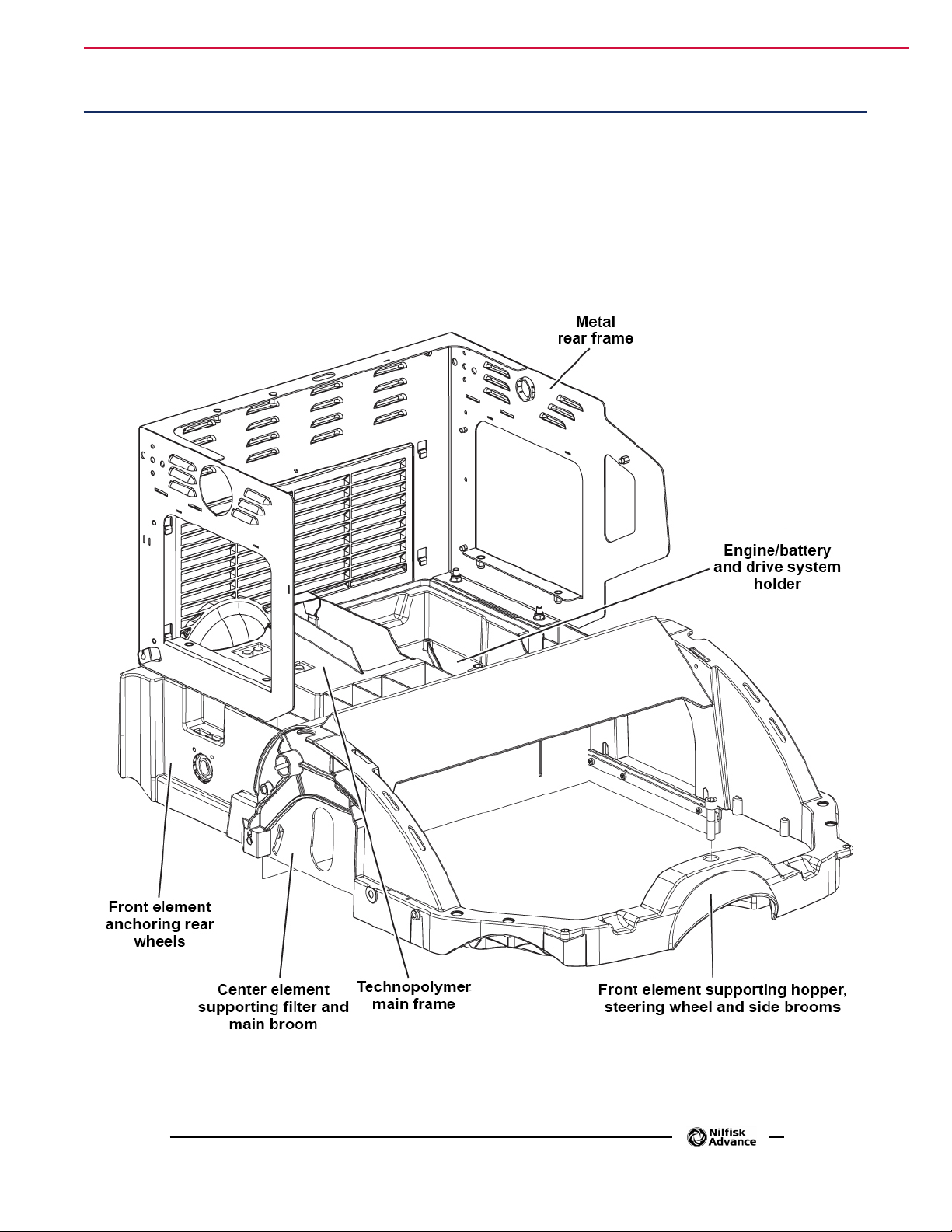

Frame (main parts)

• Technopolymer main frame

• Front element anchoring rear wheels

• Rear metal frame

• Engine/battery and drive system holder

Frame System

• Center element supporting lter and main broom

• Front element supporting hopper, steering wheel

and side brooms

26

P200260

Page 27

Dust Control System

Functional Description

The dust generated in the compartment of the main

broom is drawn toward the lter from a air ow generated by the fan on main motor (Battery version) or

dynamotor (Petrol version).

The lter located between the vacuum system and the

hopper, retain dirt which is then discharged into the

hopper itself.

The operation of the system depends on the activation

of the machine and the main broom.

The vacuum system consists of a fan installed on the

main motor / dynamotor which is powered by the relay (K0) (see Electrical and Control System chapter).

Dust Control System 27Service Manual – SW900

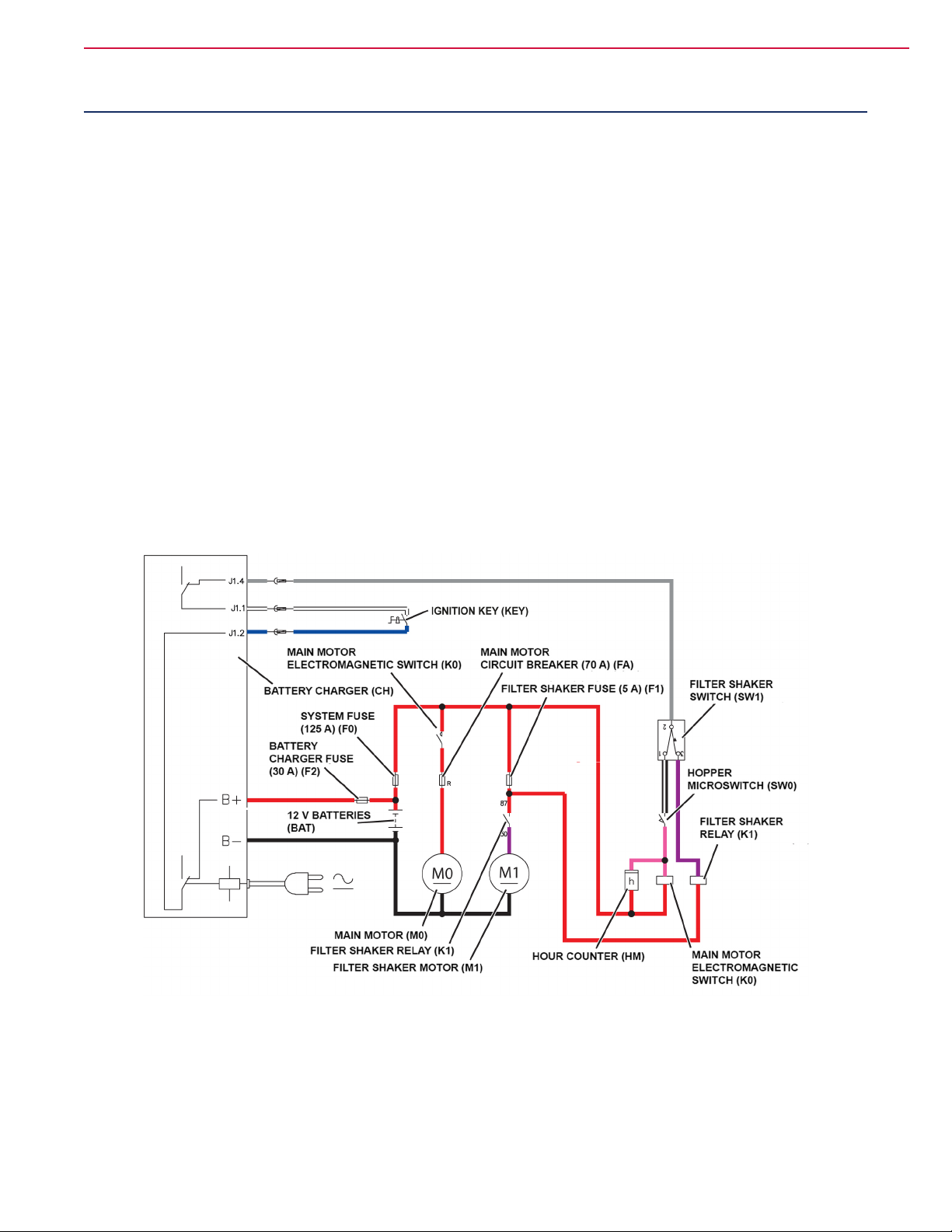

VERSION WITH ELECTRICAL FILTER SHAKER

The electric lter shaker system consists of a motor

(M1) which is powered by the relay (K1) and protected

by the fuse (F1) (see Electrical and Control System

chapter).

VERSION WITH MANUAL FILTER SHAKER

By operating on the lever on the right side of the machine, a rake acts mechanically on the lter ns allowing dirt trapped in the folds of the same to fall by

gravity into the hopper.

WiringDiagram(SW900Bwithelectricltershaker)

P200261

Page 28

WiringDiagram(SW900Bwithmanualltershaker)

Dust Control System 28Service Manual – SW900

Wiring Diagram (SW900 P)

P200261

P200262

Page 29

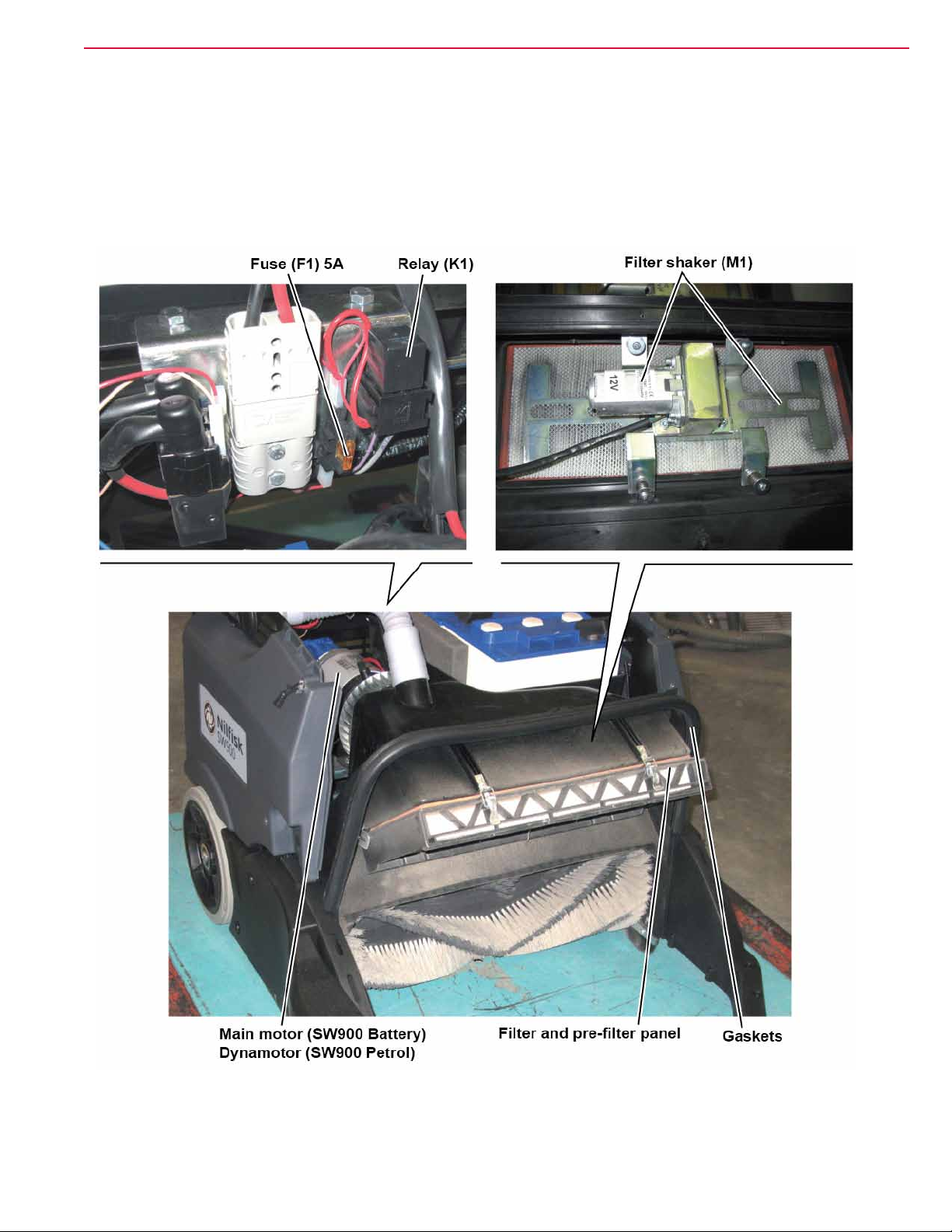

Component Locations

Dust Control System 29Service Manual – SW900

• Main motor (SW900 B)

• Dynamotor (SW900 P)

• Filter and pre-lter panel

• Gaskets

• Filter shaker (M1)

• Fuse (F1) 5A

• Relay (K1)

P200264

Page 30

Maintenance and Adjustments

Paneldustlter,cleaningandintegritycheck/replacement

Dust Control System 30Service Manual – SW900

Caution! Thedustltermustbe

regularly cleaned to

maintaintheefciencyofthe

vacuum system. Follow the

recommendedlterservice

intervalsforthelongestlter

life.

Warning! Tocleanthelter,alwayswear

safety guards (such as safety

glasses, dust mask, gloves,

etc.)andcleanthelterina

well-ventilated area. Take care

nottopiercethelter.

Note: Besides the standard polyester

lter, paper lters are also

available.

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

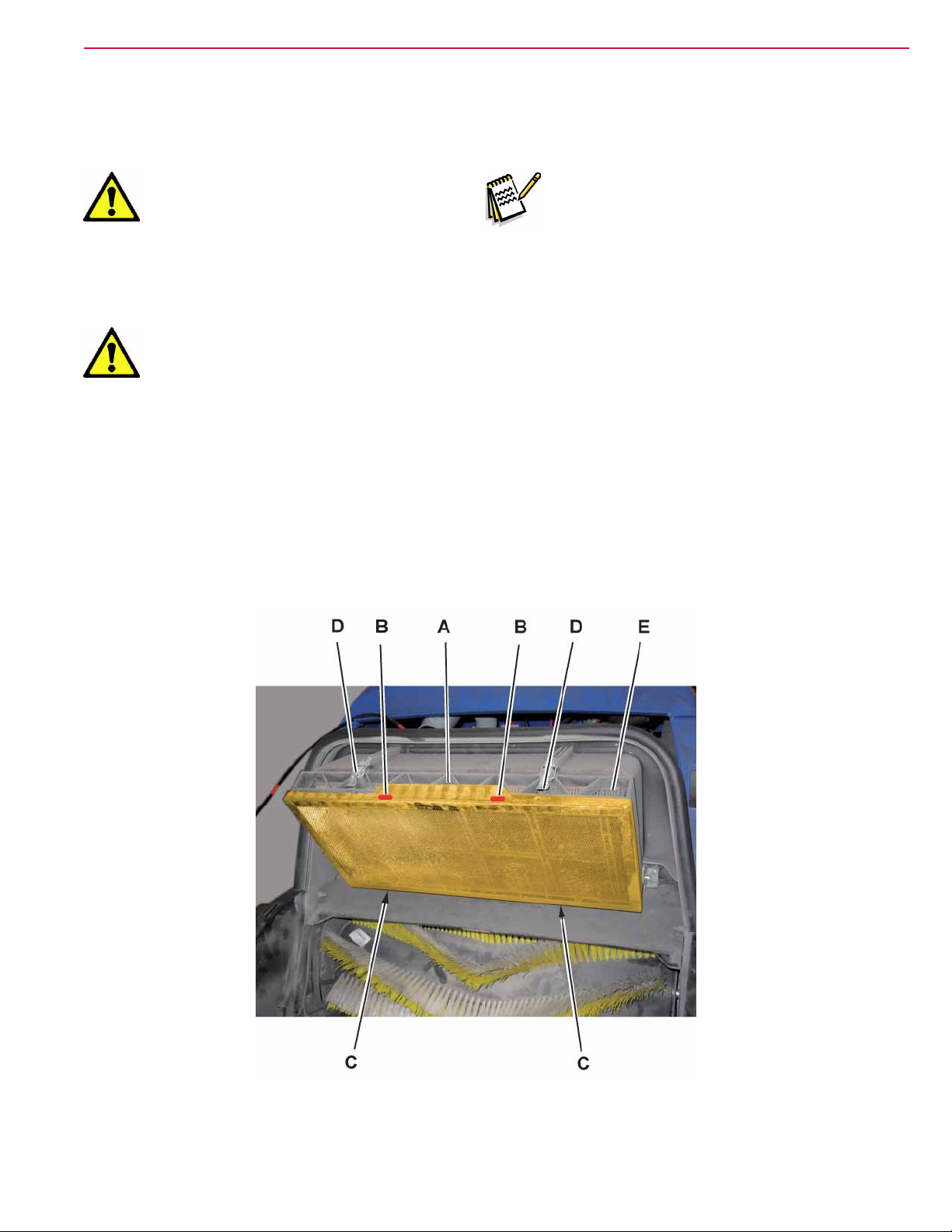

4. If equipped, remove the pre-lter (A) after

releasing the upper fasteners (B) and then the

lower fasteners (C).

5. Disengage the lever fasteners (D) and turn down

the lter holder assembly (E) to the end-of-

stroke (F).

P200265

Page 31

Paneldustlter,cleaningandintegritycheck/replacement(Continues)

Dust Control System 31Service Manual – SW900

6. Remove the dust lter (G).

7. In an outdoor area, clean the dust lter by

shaking it on a level and clean surface, tapping

the side (H), opposite to the wire gauze (I).

8. Complete the cleaning with compressed air (J)

(maximum pressure 6 bar) blowing only from the

side of the wire gauze (I) and in perpendicular

position as to the gauze itself.

According to the type of lter, observe the

following cautions:

• Polyester lter (standard): For a better clean-

ing, it is allowed to wash the lter with water

and non-lathering detergents. This provides

better quality cleaning but reduces the life of

the lter, which will have to be replaced more

frequently. The use of inadequate detergents

can damage the lter.

• Paper lter (optional): Do not use water or

detergents to clean it; the lter can be dam-

aged.

9. Check the lter body for tears.

10. Clean the gasket (K) along its perimeter and

check it for integrity. If necessary, replace the

lter.

11. Clean the gasket (L) along its perimeter and

check it for integrity; if necessary replace it.

12. If equipped, clean also the pre-lter with

compressed air (maximum pressure 6 bar)

13. Assemble the components in the reverse order of

disassembly.

P200266

Page 32

Troubleshooting

Trouble Possible causes Remedy

Dust Control System 32Service Manual – SW900

Dust/debris vacuuming is insufcient.

No vacuuming.

The electrical lter shaker does not work.

Dust/debris vacuuming is insufcient.

The lter is clogged.

The vacuum system compartment gasket is

damaged

The hopper is full. Empty the hopper.

The main motor circuit breaker (FA) is open.

The fuse (F2) is open. Replace the fuse.

The relay (K1) is broken. Replace.

The switch (SW1) is not efcient. Replace.

The lter shaker is broken. Repair/replace.

The lter is clogged.

The vacuum system compartment gasket is

damaged

Clean the dust lter by using the lter shaker

or by disassembling it.

Repair/replace

Wait for the main motor to cool down, then

reset the fuse by pressing the relevant pushbutton.

Clean the dust lter by using the lter shaker

or by disassembling it.

Repair/replace

Page 33

Removal and Installation

Electricalltershakermotoramperagecheck

Dust Control System 33Service Manual – SW900

Warning! This procedure must be

performedbyqualied

personnel only.

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Disengage the front fastener and open the

battery/engine hood.

5. Apply the amp clamps (A) on one cable (B) of the

lter shaker motor connection wiring harness.

6. Carefully operate and keep operated, the

hopper position microswitch (C) (to simulate the

presence of the hopper).

7. (For SW900 B) Turn the ignition key to “I”.

(For SW900 P) Turn the ignition key to “I” and

start the petrol engine.

8. Carefully activate the electrical lter shaker

switch (D) and check that the electrical lter

shaker motor amperage is between 3 and 4A at

12V.

9. Release the electrical lter shaker switch (D).

10. Turn the ignition key to “0”.

11. Remove the amp clamps (A).

P200267

Page 34

Electricalltershakermotoramperagecheck(Continues)

Dust Control System 34Service Manual – SW900

12. If the amperage is higher, perform the following

procedures to detect and correct it:

• Check that the relevant fuse (F1) 5A is prop-

erly positioned.

• Remove the electric lter shaker motor (see

the procedure in the next paragraph), and

check the condition of all its components.

Before removing the lter shaker motor (E),

check that the lter shaker frame (F) can

slide on the spacer bushes of the springs (G),

overcoming the resistance of the springs and

that it is not locked.

• If the above-mentioned procedures do not

produce the correct readings for the electrical

lter shaker motor amperage, the motor must

be replaced (see the procedure in the relevant

paragraph).

13. Close the battery/engine compartment hood and

engage the front fastener.

14. Reinstall the hopper.

15. Turn the ignition key to “0”.

P200268

Page 35

Electrical Filter Shaker Motor Disassembly/Assembly

Disassembly

Dust Control System 35Service Manual – SW900

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Disengage the front fastener and open the

battery/engine hood.

5. (For SW900 B) Remove the batteries and their

container (see the procedure in the relevant

paragraph).

6. Disconnect the “wet by-pass” hoses (A) from the

deector (B).

7. Remove all the mounting screws (C) of the

deector (B).

8. Move aside the conveyor (B).

P200269

Page 36

Electrical Filter Shaker Motor Disassembly/Assembly (Continues)

Dust Control System 36Service Manual – SW900

9. Disconnect the lter shaker connector (N).

10. For disassembling the lter shaker motor (E)

only, remove the four screws (F), then remove

it from its housing by disengaging the inner

eccentric (F).

The eccentric (F) must be rmly locked on the

shaft of the lter shaker motor.

For the complete removal of the motor (E), it is

necessary to disconnect the semiconnector out of

its wiring harness (L).

11. For disassembling the motor (E) with the holder

(O), remove the four screws (P).

12. For disassembly of the motor (E) with its of

the frame (G) electrical lter shaker, remove

the screws (H) and recover the springs (I), the

washers (J) and the spacer bushes (K).

Check the integrity of the disassembled parts.

Assembly

13. Assemble the components in the reverse order of

disassembly, and note the following:

- When reinstalling of the spacer bushes (K)

make sure that the same should are ushed

with the machine frame and that the slots

(M) of the frame (G) slide on spacers (K).

After assembling of the frame (G), check that

the frame can slide on the spacer bushes (K)

of the springs (I), overcoming the resistance

of the springs.

P200270

Page 37

Specications

Dust Control System 37Service Manual – SW900

Model

cleaning system

Filter

Filter shaker motor 12 W

Paper lter ltering capacity 99% @ 0.8 µm

Air ow 11301 ft3/h (320 m3/h)

Broom compartment vacuum - new lter 0.13 inH2O (3.6 mmH2O)

area 20.5 ft2 (1.9 m2)

ltering capacity 5-10 µm

Advance / Nilsk

SW900 B

Electrical lter shaker

(manual on Advance version)

Nilsk

SW900 P

Page 38

Electrical and Control System

Functional Description (SW900 B)

Electrical and Control System 38Service Manual – SW900

The machine functionality check is mainly performed

by the battery charger (CH) that monitors the battery

voltage (BAT) (also) during machine operation (not

only during recharging).

The ignition key (KEY) provides to the battery charger information about the machine on and off condition.

When the ignition switch (KEY) is closed, the battery

charger checks the battery voltage and, if it is insufcient, it activates the electromagnetic switch (K0).

The activation of the electromagnetic switch (K0) is

cut off when the battery charger is connected to the

electrical mains.

On the same circuit of the electromagnetic switch(K0),

there is the hopper safety switch (SW0) which prevents the activation of the electromagnetic switch

(K0) if the hopper is not properly positioned, or if the

upper hood is open.

For the versions equipped with electrical lter shaker, on the same circuit of the electromagnetic switch

(K0) there is the lter shaker switch (SW1). When

pressed, it turns off the electromagnetic switch (K0)

and activates the relay (K1).

The electromagnetic switch (K0) directly drives the

main motor (M0) and the side broom motors (M2) and

(M3*), while the relay (K1) (if equipped) turns on the

lter shaker motor (M1).

On the circuit of the side broom motors (M2) and

(M3*) there are microswitches (SW2) and (SW3*)

respectively, which deactivate the relevant motors

when the brooms are lifted from the ground by means

of the manual levers on the handlebar.

The display on the control panel shows the battery

charge status and the battery charger by means of

the LED electronic board (EB1), which is directly connected to the battery charger.

The hour counter (HM) is connected in parallel to the

electromagnetic switch (K0) and it counts the operating time of the main motor (M0).

The machine system is connected to the battery with

the connector (C1). The battery charger is always connected to the batteries.

* : when the left broom is equipped

Electrical Protections

The main motor (M0) is protected by the 70A circuit

breaker (FA).

The side broom motors (M2) and (M3*) are protected

by 5A circuit breakers (FB) and (FC*) respectively.

The lter shaker motor circuit (M1) is protected by

the 5A fuse (F1).

The battery charger (CH) is protected by the 30A fuse

(F2).

The main battery wiring harness is protected by a

125A safety fuse (F0) (on the supported versions).

Page 39

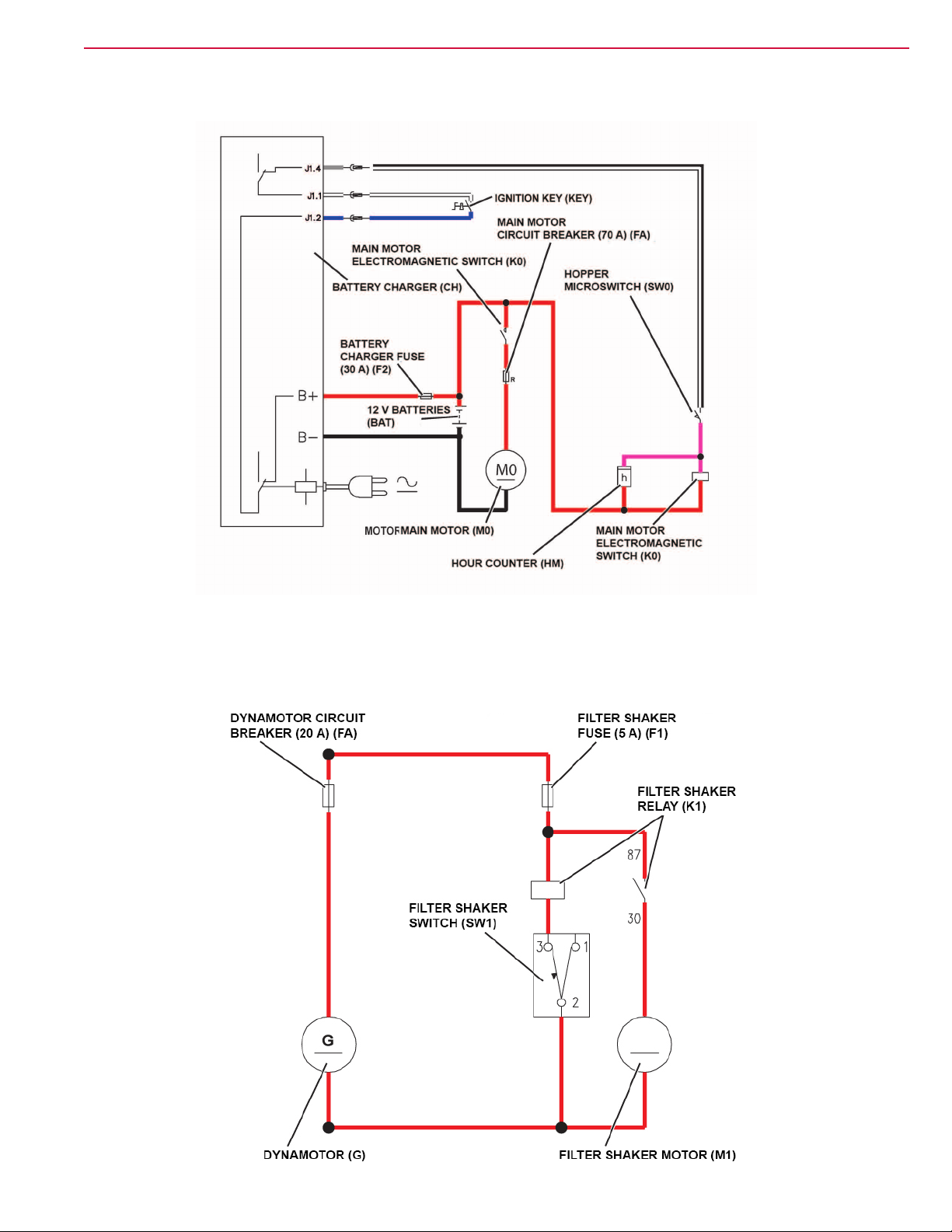

Functional Description (SW900 P)

Electrical and Control System 39Service Manual – SW900

The dynamotor (G) provides the current necessary

for the activation of the side broom motors (M2) and

(M3*), lter shaker circuit (M1) and hour counter

(HM).

The ignition key (KEY) turned to “0” inhibits the ac-

tivation of the engine, when turned to “1” it allows for

startup and operation.

When the engine is turned on, the current generated by the dynamotor (G) directly activates the side

broom motors (M2) and (M3*).

On the same circuit of the ignition switch (KEY), there

is the hopper safety switch (SW0) which prevents the

activation of the engine if the hopper is not properly

positioned, or if the upper hood is open.

On the versions equipped with electrical lter shaker,

the dynamotor (G) powers also the lter shaker switch

(SW1) which, when pressed, activates the relay (K1).

The relay (K1) turns on the lter shaker motor (M1).

On the circuit of the side broom motors (M2) and

(M3*) there are microswitches (SW2) and (SW3*)

respectively, which deactivate the relevant motors

when the brooms are lifted from the ground by means

of the manual levers on the handlebar.

The optional hour counter (HM) is connected to the

key circuit (KEY) and is powered by the dynamotor

(G) when the engine is running.

Electrical Protections

The dynamotor (G) is protected by the 20A fuse (FA).

The side broom motors (M2) and (M3*) are protected

by 5A circuit breakers (FB) and (FC*) respectively.

The lter shaker motor circuit (M1) is protected by

the 5A fuse (F1).

* : when the left broom is equipped

Page 40

Electrical and Control System 40Service Manual – SW900

Wiring Diagram

Fuses

SW900 B SW900 P

Acronym

F0 125A BATTERY (BATT) -

F1 5A FILTER SHAKER MOTOR (M1) 5A FILTER SHAKER MOTOR (M1)

F2 30A BATTERY CHARGER (CH) - -

FA 70A MAIN MOTOR (M0) 20A DYNAMOTOR (M0)

FB 5A RIGHT SIDE BROOM MOTOR (M2) 5A RIGHT SIDE BROOM MOTOR (M2)

FC 5A LEFT SIDE BROOM MOTOR (M3) 5A LEFT SIDE BROOM MOTOR (M3)

Relays / Electromagnetic Switches / Diodes

Nominal

Size

Protected Function Nominal Size Protected Function

Acronym

K0 MAIN MOTOR (M0) -

K1 FILTER SHAKER (M1) FILTER SHAKER (M1)

SW900 B SW900 P

Activated function Activated function

Page 41

WiringDiagram(SW900Bwithelectricltershaker)

LED ELECTRONIC BOARD (EB1)

Electrical and Control System 41Service Manual – SW900

LED ELECTRONIC BOARD (EB1)

IGNITION KEY (KEY)

MAIN MOTOR

ELECTROMAGNETIC SWITCH (K0)

BATTERY CHARGER (CH)

SYSTEM

FUSE (125 A) (F0)

BATTERY

CHARGER FUSE

(30 A) (F2)

12 V BATTERIES (BAT)

M0

RIGHT SIDE BROOM MICROSWITCH (SW2)

LEFT SIDE BROOM MICROSWITCH (SW3)

MAIN MOTOR (M0)

RIGHT SIDE BROOM MOTOR (M2)

LEFT SIDE BROOM MOTOR (M3)

FILTER SHAKER RELAY (K1)

FILTER SHAKER MOTOR (M1)

+ LDG

+ LDY

+ LDR

- COM

MAIN MOTOR CIRCUIT

BREAKER (70 A) (FA)

RIGHT SIDE BROOM

CIRCUIT BREAKER (5 A) (FB)

M3

M2

LEFT SIDE BROOM

CIRCUIT BREAKER (5 A) (FC)

FILTER SHAKER FUSE (5 A) (F1)

M1

HOUR COUNTER (HM)

FILTER SHAKER

SWITCH (SW1)

HOPPER

MICROSWITCH (SW0)

FILTER SHAKER

RELAY (K1)

MAIN MOTOR

ELECTROMAGNETIC

SWITCH (K0)

P200306

WiringDiagram(SW900Bwithmanualltershaker)

+ LDG

IGNITION KEY (KEY)

MAIN MOTOR

ELECTROMAGNETIC SWITCH (K0)

BATTERY CHARGER (CH)

BATTERY

CHARGER FUSE

(30 A) (F2)

12 V BATTERIES (BAT)

M0

RIGHT SIDE BROOM MICROSWITCH (SW2)

LEFT SIDE BROOM MICROSWITCH (SW3)

MAIN MOTOR (M0)

RIGHT SIDE BROOM MOTOR (M2)

LEFT SIDE BROOM MOTOR (M3)

+ LDY

+ LDR

- COM

MAIN MOTOR CIRCUIT

BREAKER (70 A) (FA)

RIGHT SIDE BROOM

CIRCUIT BREAKER (5 A) (FB)

M3

M2

LEFT SIDE BROOM

CIRCUIT BREAKER (5 A) (FC)

HOUR COUNTER (HM)

HOPPER

MICROSWITCH (SW0)

MAIN MOTOR

ELECTROMAGNETIC

SWITCH (K0)

P200306

Page 42

Wiring Diagram (SW900 P)

LEFT SIDE BROOM

CIRCUIT BREAKER (5 A) (FC)

RIGHT SIDE BROOM

CIRCUIT BREAKER (5 A) (FB)

FILTER SHAKER FUSE (5 A) (F1)

LEFT SIDE BROOM

MICROSWITCH (SW3)

FILTER SHAKER RELAY (K1)

Electrical and Control System 42Service Manual – SW900

DYNAMOTOR CIRCUIT

BREAKER (20 A) (FA)

IGNITION KEY (KEY)

HOPPER

MICROSWITCH (SW0)

ENGINE

SPARK PLUG (SPK)

G

RIGHT SIDE BROOM

MICROSWITCH (SW2)

LEFT SIDE BROOM

MOTOR (M3)

RIGHT SIDE BROOM

MOTOR (M2)

M3 M2

M1

FILTER SHAKER

SWITCH (SW1)

FILTER SHAKER MOTOR (M1)

DYNAMOTOR (G)

FRAME (FR)

HOUR COUNTER (HM)

P200307

Page 43

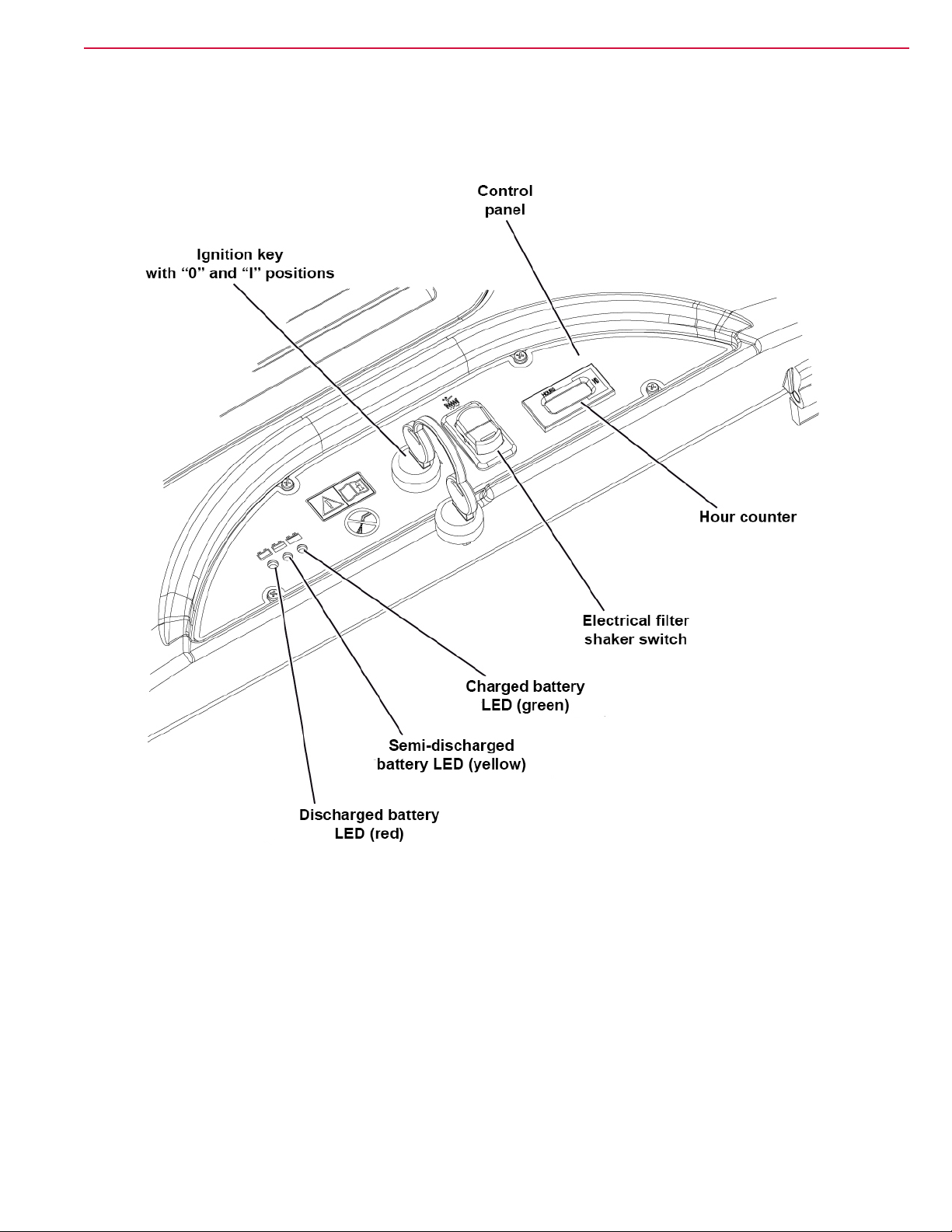

Component Locations (SW900 B)

Electrical and Control System 43Service Manual – SW900

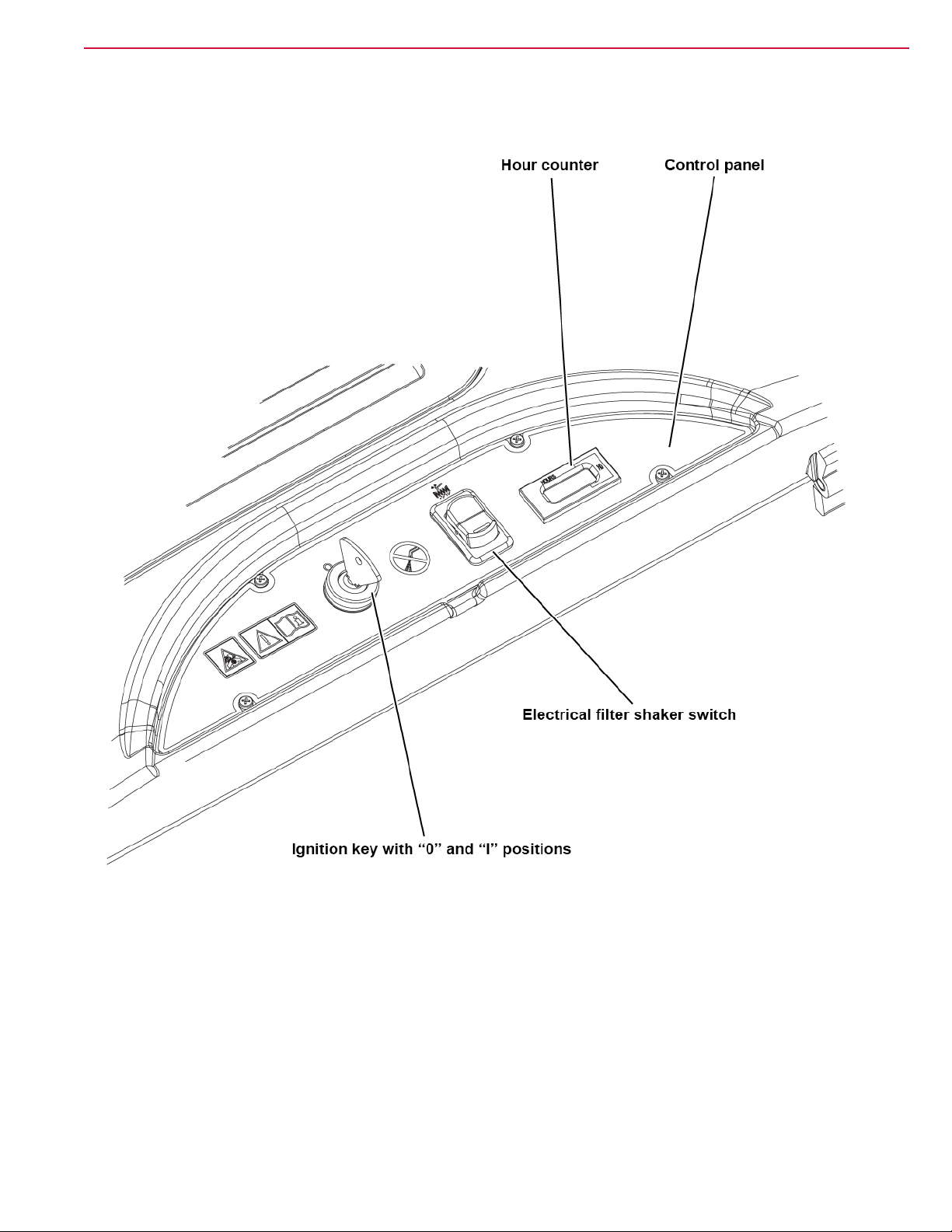

• Dashboard

• Ignition key (KEY)

• Filter shaker (SW1)

• Hour counter (HM)

• LED electronic board (EB1)

P200308

Page 44

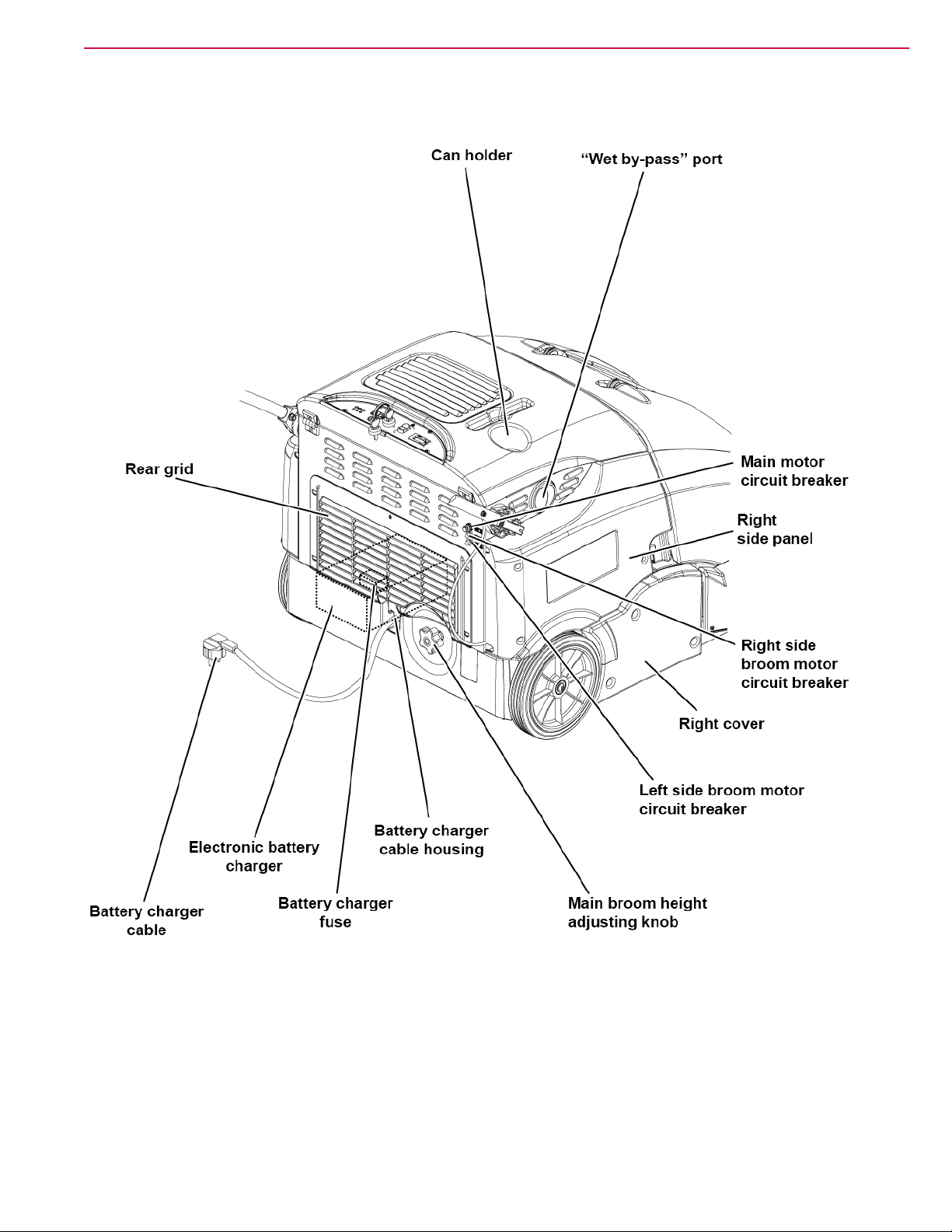

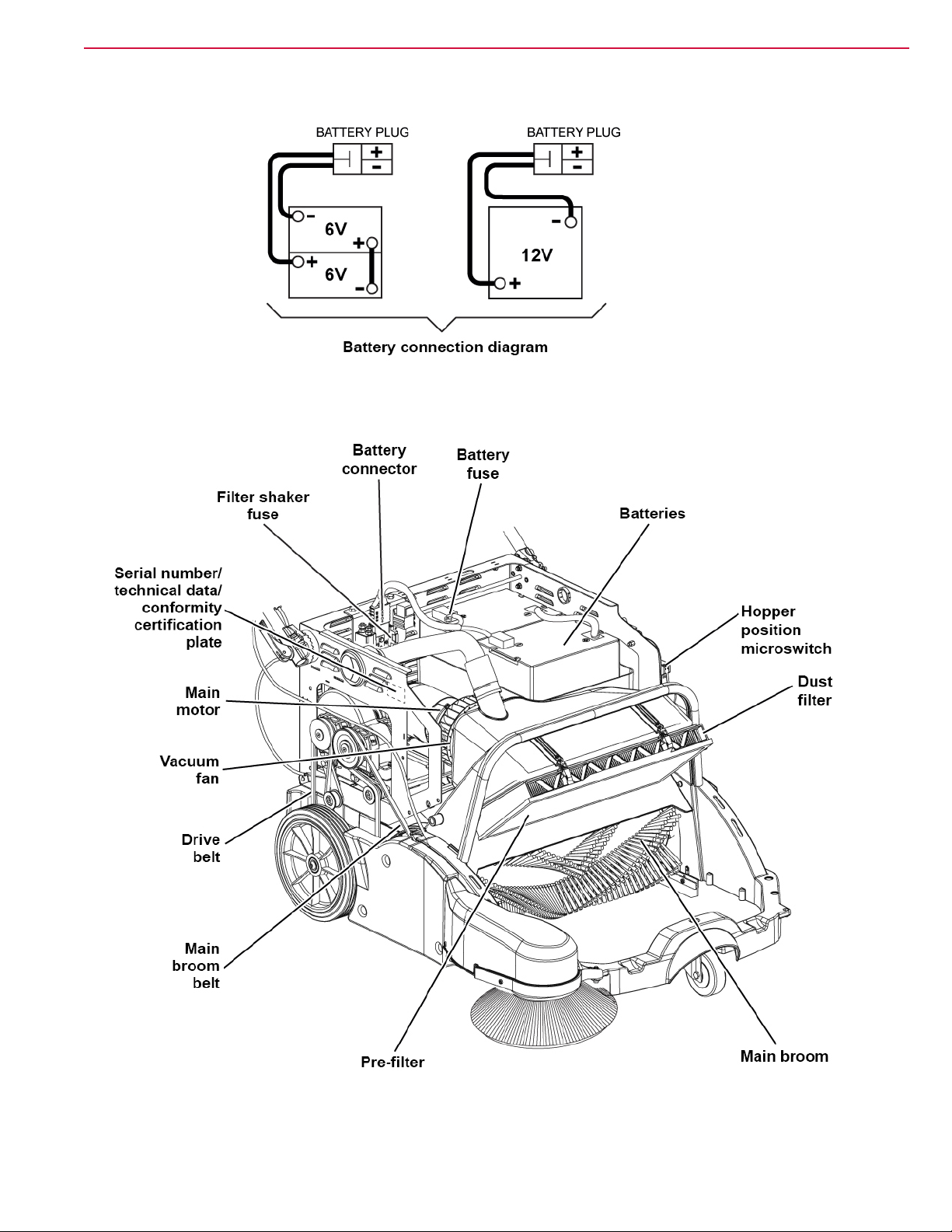

Component Locations (SW900 B) (Continues)

Electrical and Control System 44Service Manual – SW900

• Wiring harnesses

• Main motor (M0)

• Batteries (BAT)

• Battery connector

• Main motor relay (K0)

• 5A fuse, electrical lter shaker (F1)

• 125A fuse, battery (F0)

• Reduction unit

• Filter shaker relay (K1)

P200273

Page 45

Component Locations (SW900 B) (Continues)

• Battery charger (CH)

• Hopper position microswitch (SW0)

• 30A fuse, battery charge (F2)

• 70A circuit breaker, main motor (FA)

• 5A circuit breaker, right side broom motor (FB)

• 5A circuit breaker, left side broom motor (FC)

Electrical and Control System 45Service Manual – SW900

P200309

Page 46

Component Locations (SW900 P)

Electrical and Control System 46Service Manual – SW900

• Dashboard

• Ignition key (KEY)

• Filter shaker (SW1)

• Hour counter (HM)

P200310

Page 47

Component Locations (SW900 P) (Continues)

Electrical and Control System 47Service Manual – SW900

• Wiring harnesses

• Dynamotor (G)

• Filter shaker relay (K1)

• Electrical lter shaker (F1) fuse (5A)

• Dynamotor (FA) fuse (20A)

• Reduction unit

P200274

Page 48

Component Locations (SW900 P) (Continues)

• Hopper position microswitch (SW0)

• Right side broom motor (FB) circuit breaker (5A)

• Left side broom motor (FC) circuit breaker (5A)

Electrical and Control System 48Service Manual – SW900

P200311

Page 49

Maintenance and Adjustments

Charging the batteries (SW900 B)

Electrical and Control System 49Service Manual – SW900

Caution! Charge the batteries when

the yellow (A) or red (B) LED

turns on, or at the end of each

working cycle. Keeping the

batteries charged make their

life last longer.

Warning! When the batteries are

discharged, charge them as

soon as possible, as that

condition makes their life

shorter.

Warning! If the machine is equipped

with lead (WET) batteries,

battery charging produces

highlyexplosivehydrogen

gas. Charge the batteries in

well-ventilated areas and away

fromnakedames.

Do not smoke while charging

the batteries.

While charging the batteries

always keep the hood open.

Warning! Pay careful attention when

charging lead batteries (WET)

astheremaybebatteryuid

leakages.Thebatteryuid

is corrosive. If it comes in

contact with skin or eyes,

rinse thoroughly with water

and consult a physician.

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

P200275

Page 50

Charging the batteries (SW900 B) (Continues)

Electrical and Control System 50Service Manual – SW900

3. Remove from the housing (C) the electrical

cable (D) of the electronic battery charger, then

connect it to the electrical mains.

Warning! The mains voltage and

frequency must match the

electronic battery charger

values shown on the machine

serial number plate.

Note: When the electronic battery

charger is connected to the

electrical mains, all machine

functions are automatically

disabled.

4. When the green LED (E) turns on, the batteries

are charged.

For further information about the battery

charger operation, see the Battery Charger

Manual.

5. Disconnect the electronic battery charger

electrical cable (D) from the electrical mains,

then place it in the housing (C).

6. Now the machine is ready to be used.

P200276

Page 51

Fuse Check/Replacement/Reset (SW900 B)

Electrical and Control System 51Service Manual – SW900

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

Fuse Check/Reset

3. Check one of the following fuses for deactivation:

- (A): 70A fuse (FA), main motor

- (B): 5A fuse (FB), right side broom motor

- (C): 5A fuse (FC), left side broom motor

4. Reset any deactivated fuse, when the component

that caused deactivation has fully cooled down.

Various Fuse Check/Replacement

5. Remove the hopper by using its transport handle

and wheels.

6. Disengage the front fastener and open the

battery compartment hood.

7. Disconnect the battery connector.

8. Remove the rear grid after removing the upper

mounting screw and disengaging the fasteners.

9. Disengage and open the cover (I), then check the

fuse:

- (J): 30A fuse (F2), battery charger

- If necessary, remove the nuts (D) and replace

the fuse (J). Screw down and tighten the

nuts.

P200277

Page 52

Fuse Check/Replacement/Reset (SW900 B) (Continues)

Electrical and Control System 52Service Manual – SW900

10. Check/replace the fuse:

- (E): 5A lamellar fuse (F1), electrical lter

shaker

11. Check/replace the fuse:

- (F): 125A fuse (F0), battery

When reinstalling the fuse (F), engage its

ange (G) on the electrical cable terminals

(H), as shown in the gure.

Reassembly

12. Install the rear grid by engaging the fasteners

and then tighten the upper mounting screw.

13. Connect the battery connector.

14. Close the battery compartment hood and engage

the front fastener.

15. Install the hopper by using its transport handle

and wheels.

P200278

Page 53

Fuse Check/Replacement/Reset (SW900 P)

Electrical and Control System 53Service Manual – SW900

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

Fuse check/reset

3. Check one of the following fuses for deactivation:

- (A): 5A fuse (FB), right side broom motor

- (B): 5A fuse (FC), left side broom motor

4. Reset any deactivated fuse, when the component

that caused deactivation has fully cooled down.

Lamellar Fuse Check/Replacement

5. Remove the hopper by using its transport handle

and wheels.

6. Disengage the front fastener and open the

engine compartment hood.

7. On the right side of the engine (C), check/replace

the fuses:

- (D): 20A fuse (F0), main

- (E): 5A fuse (F1), electrical lter shaker

Reassembly

8. Close the engine compartment hood and engage

the front fastener.

9. Install the hopper by using its transport handle

and wheels.

P200279

Page 54

Troubleshooting (SW900 B)

Trouble Possible causes Remedy

The battery connector is disconnected Connect

The batteries are discharged Charge

Electrical and Control System 54Service Manual – SW900

The main motor does not start

The right/left broom motor does not run

The hopper is not in the correct position

The upper hood is open

The circuit breaker (FA) is open

The lever is not activated correctly

The circuit breaker (FB) or (FC) is open

Adjust

Check the operation of the microswitch

Close it properly

Check the operation of the microswitch

Press the push-button on the fuse, if the

trouble persists remove the overload cause

Use the lever up to the end-of-stroke

Check the operation of the microswitch

Press the push-button on the fuse, if the

trouble persists remove the overload cause

Page 55

Electrical and Control System 55Service Manual – SW900

Removal and Installation

Battery Installation and Battery Type Setting (WET or GEL) (SW900 B)

Warning! The electric components of

the machine can be seriously

damaged if the batteries are

either improperly installed

or connected. The batteries

mustbeinstalledbyqualied

personnel only.

According to the type of

batteries (WET or GEL-AGM),

set the machine battery

charger.

Check the batteries for

damage before installation.

Disconnect the battery

connector and the battery

charger plug.

Handle the batteries with great

care.

Install the battery terminal

protection caps supplied with

the machine.

Warning! Do not tilt the lead batteries

(WET) to prevent the highly

corrosive acid from leaking

out of the batteries. Do not

connect, not even accidentally,

the battery positive and

negative terminals by using

tools, keys, etc. This could

cause dangerous shortcircuits.

The machine requires one 12V battery, or two 6V batteries connected according to the diagram below.

The machine can be supplied in one of the following

congurations:

• WET or GEL batteries already installed on the

machine

• Without batteries

Note: The machine is supplied with

the battery charger set for using

generic GEL-AGM batteries.

P200312

Page 56

Electrical and Control System 56Service Manual – SW900

Battery Installation and Battery Type Setting (WET or GEL) (SW900 B) (Continues)

Battery Removal

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Disengage the front fastener and open the

battery compartment hood.

5. Disconnect the battery connector.

6. Disengage the guards (A) from the battery

terminals.

7. Disconnect the battery terminals.

8. Carefully remove the batteries (B).

Battery installation

1. Install on the machine the type of batteries

which is compatible with the setting of the

machine; for checking the setting of the machine

or to change it, refer to the procedure described

below.

2. Route and install the battery cables, then

carefully tighten the nut on each battery

terminal.

3. Engage the guards (A) on the battery terminals.

4. Connect the battery connector.

5. Close the battery compartment hood and engage

the front fastener.

6. Install the hopper on the machine, by using its

transport handle and wheels.

P200313

Page 57

Machine Check/Setting

Electrical and Control System 57Service Manual – SW900

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Disengage the front fastener and open the

battery compartment hood.

5. Disconnect the battery connector.

6. Check the battery cables for insulation.

7. Remove the battery charger cable (A) from the

housing; connect it temporarily to the electrical

mains and, during the connection, check the

number and color of the LED ashings (B),

then compare them with the indications in the

following table, to determine the battery setting

of the machine.

Type of battery set on

the machine

EXIDE™ Two ashes of the yellow LED

OPTIMA™

DISCOVER™

GEL/AGM (generic) Two ashes of the green LED

WET (all makes) Two ashes of the red LED

Two ashes of the green and yellow

LEDs together

Two ashes of the red and green LEDs

together

Flashes

8. If it is necessary to install batteries which are

different from the machine setting, it is possible

to change the machine settings according to the

following procedure.

9. If equipped, remove the batteries from the

machine and also remove the battery case.

P200314

Page 58

Machine Check/Setting (Continues)

Electrical and Control System 58Service Manual – SW900

10. In the battery compartment, lift the rubber mat

(C).

12. Carefully set the switches (E, F, G) as shown in

the following table to set machine according to

the type of batteries to be installed.

11. Lift the battery charger plate (D).

Type of battery set on the machine E switch F switch G switch

EXIDE™ OFF OFF OFF

OPTIMA™ OFF ON OFF

DISCOVER™ ON OFF OFF

GEL/AGM (generic) ON ON OFF

WET (all makes) Any Any ON

Set the switch (H) as shown below:

13. Repeat steps 6. and 7. to check that the machine

has been set correctly.

- For batteries having capacity of 150Ah

or higher (discharge in 5 hours) leave the

14. Reinstall the plate (D) and the oor mat (C).

default setting to OFF (nominal charge

current 25A).

- For batteries having capacity lower than

15. Install the battery case.

16. Install the batteries.

150Ah (discharge in 5 hours) set H switch to

ON (nominal charge current 15A).

P200315

Page 59

Main motor amperage check (SW900 B)

Electrical and Control System 59Service Manual – SW900

Warning! This procedure must be

performedbyqualied

personnel only.

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Check that the side brooms are lifted.

5. Disengage the front fastener and open the

battery compartment hood.

6. Remove the screws (A) and the right side panel

(B) from the machine.

7. Turn the tensioner (C) in the direction shown by

the arrow and disengage the belt (D) from the

pulley (E).

8. Turn the tensioner (F) in the direction shown by

the arrow and disengage the belt (G) from the

pulley (H).

9. Apply amp clamps on a cable (I) of the main

motor (J).

10. Carefully operate and keep operated, the

hopper position microswitch (K) (to simulate the

presence of the hopper).

11. Turn the ignition key to “I” thus turning on the

main motor; check that the amperage of the

motor (J) is between 30 and 35A at 24V.

12. Turn the ignition key to “0”.

13. Remove the amp clamp.

P200280

Page 60

Main motor amperage check (SW900 B) (Continues)

Electrical and Control System 60Service Manual – SW900

14. If the amperage is higher, perform the following

procedures to detect and correct it:

• Check that there are no obstacles to the

rotation of the pulleys (E) and (H) and the

reduction unit (L).

• Check the main motor carbon brushes (see

the procedure in the relevant paragraph).

• If necessary, disassemble the main motor

(see the procedure in the relevant para-

graph), and check the condition of all its

components.

If the above-mentioned procedures do not lead

to a correct amperage, the main motor must

be replaced (see the procedure in the relevant

paragraph).

Reassembly

15. Release the hopper position microswitch (K)

from the forced operation, and check that the

microswitch operates properly.

16. Turn the tensioner (F) in the direction shown by

the arrow and engage the belt (G) to the pulley

(H) and to the tensioner (F); check the proper

operation of the tensioner (F).

17. Turn the tensioner (C) in the direction shown by

the arrow and engage the belt (D) to the pulley

(E) and to the tensioner (C); check the proper

operation of the tensioner (C).

18. Perform steps 3. 5. and 6. in the reverse order.

P200281

Page 61

Dynamotor Voltage Check (SW900 P)

Electrical and Control System 61Service Manual – SW900

Warning! This procedure must be

performedbyqualied

personnel only.

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Carefully operate and keep operated, the hopper

position microswitch (to simulate the presence of

the hopper).

5. Check that the main and side brooms(s) are

lifted.

6. Turn the ignition key to “I” and start the petrol

engine (as shown in the User Manual); wait

at least 5 minutes that the engine reaches the

target speed.

7. Disengage the front fastener and open the

engine compartment hood.

8. Move aside the guards (A) of the terminals (B)

and (C) of the dynamotor (D).

9. Apply the detectors (E) and (F) of the tester

on the terminals (B) and (C) and measure the

voltage produced by the dynamotor, which must

be between the 12V and 14V.

Stop the petrol engine (as shown in the User

Manual).

Turn the ignition key to “0”.

P200282

Page 62

Dynamotor Voltage Check (SW900 P) (Continues)

Electrical and Control System 62Service Manual – SW900

If the voltage is lower than the specied value,

perform the following procedures to detect the

cause and correct it:

• Check that the drive belt between the

engine and reduction unit is properly tensioned (see the procedure in the relevant

paragraph) and that the pulleys are efcient

and not loose.

• Check that the reduction unit is correctly

closed.

• Check the dynamotor carbon brushes (see

the procedure in the relevant paragraph).

• If necessary, disassemble the dynamotor

(see the procedure in the relevant para-

graph), and check the condition of all its

components.

If the above-mentioned procedures do not lead

to a correct voltage, the dynamotor must be

replaced (see the procedure in the relevant

paragraph).

Reassembly

10. Close the engine compartment hood and engage

the front fastener.

11. Release the hopper position microswitch

from the forced operation, and check that the

microswitch operates properly.

12. Install the hopper by using its transport handle

and wheels.

Page 63

Main motor carbon brush replacement (SW900 B)

Disassembly

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Disengage the front fastener and open the

battery compartment hood.

5. Disconnect the battery connector.

6. Remove the batteries and their container (see

the procedure in the relevant paragraph).

7. Remove the screws (A) and the right side panel

(B) from the machine; then remove also the left

side panel.

Electrical and Control System 63Service Manual – SW900

8. On the main motor, release the fastener (C) and

remove the protection band (D) of the carbon

brushes.

9. Remove the fastening screws (E) of the electrical

connections of the four carbon brushes (F).

10. Remove the four carbon brushes (F) from

their housings, by disengaging them from the

retaining springs (G).

11. Check the two carbon brushes (F) for wear.

Replace the carbon brushes when: the contact

with the motor armature is insufcient, the

carbon brushes are worn, the carbon brush

contact surface is not integral, the thrust spring

is broken, etc. If the length of the carbon brushes

is insufcient, these must be replaced.

In this cases, replace all motor carbon brushes.

Assembly

12. Assemble the components in the reverse order of

disassembly.

P200316

Page 64

Dynamotor Carbon Brush Replacement (SW900 P)

Disassembly

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Disengage the front fastener and open the

engine compartment hood.

5. Remove the screws (A) and the right side panel

(B) from the machine; then remove also the left

side panel.

6. On the dynamotor, release the fastener (C) and

remove the protection band (D) of the carbon

brushes.

Electrical and Control System 64Service Manual – SW900

7. Remove the fastening screws (E) of the electrical

connections of the four carbon brushes (F).

8. Remove the four carbon brushes (F) from

their housings, by disengaging them from the

retaining springs (G).

9. Check the two carbon brushes (F) for wear.

Replace the carbon brushes when: the contact

with the dynamotor armature is insufcient,

the carbon brushes are worn, the carbon brush

contact surface is not integral, the thrust spring

is broken, etc. If the length of the carbon brushes

is insufcient, these must be replaced.

In this cases, replace all motor carbon brushes.

Assembly

10. Assemble the components in the reverse order of

disassembly.

P200316

Page 65

Main Motor or Fan Removal/Installation (SW900 B)

Disassembly

1. Drive the machine on a level oor and ensure

that it cannot move.

2. Turn the ignition key to “0”.

3. Remove the hopper by using its transport handle

and wheels.

4. Disengage the front fastener and open the

battery compartment hood.

5. Remove the batteries and their container (see

the procedure in the relevant paragraph).

6. Remove the screws (A) and the right side panel

(B) from the machine; then remove also the left

side panel.

7. Remove the rear grid (C) after removing the

upper mounting screw (D) and disengaging the

fasteners.

Electrical and Control System 65Service Manual – SW900

8. Turn the tensioner (E) in the direction shown by

the arrow and disengage the belt (F) from the

pulley (G).

9. Turn the tensioner (H) in the direction shown

by the arrow and disengage the belt (I) from the

pulley (J).

P200317

Page 66

Main Motor or Fan Removal/Installation (SW900 B) (Continues)

10. On the rear side of the machine, cut the clamps

(K) fastening the wiring harness (L); cut also the

inner clamp (M).

11. Disengage the protection caps (N) and

disconnect the electrical connections (O) of the

main motor.

12. Loosen the clamp (P) and disconnect the “wet by

pass” hose (Q).

13. Remove the screws (R) with nut (S).

14. On the inner side of the main motor (T), remove

the screws (U).

15. Carefully remove the main motor assembly with

the reduction unit (V).

Electrical and Control System 66Service Manual – SW900

P200318

Page 67

Main Motor or Fan Removal/Installation (SW900 B) (Continues)

Electrical and Control System 67Service Manual – SW900

16. At the workbench, remove the screws with the

nut (W).

17. Remove the four screws (X) and disconnect

the motor (Y) from the reduction unit (Z),

by disengaging the shaft with key (AH); if

necessary use a plastic mallet.

18. If necessary, remove the fan (AA) as shown

below.

19. Remove the screw (AB) and the dowel (AC).

P200319

Page 68

Main Motor or Fan Removal/Installation (SW900 B) (Continues)

Electrical and Control System 68Service Manual – SW900

20. With a puller applied to the head (AD) of the

shaft and on the groove (AE), remove the fan

(AA) from the shaft.

21. If necessary, remove the four screws (AG) and

remove the ange (AF).

Assembly

22. Assemble the components in the reverse order of

disassembly, and note the following: