Page 1

Page 2

English

2

Page 3

English

Contents

Components

Attachments Included Attachments.................................................................5

Accessories Included Accessories..................................................................6

Guidance Congratulations...........................................................................7

Getting the best results...............................................................7

Installation Assembly.....................................................................................8

Warnings.....................................................................................8

Operation Switching on the machine...........................................................9

Using the machine......................................................................10

During Use..................................................................................10

Maintenance Daily............................................................................................11

Weekly........................................................................................11

Precautions Do’s & Don’ts..............................................................................11

Service Guarantee...................................................................................12

Technical Technical Data............................................................................13

Troubleshooting Symptom, possible cause & action.............................................14

Modified January 2010

Symbols used to mark instructions.............................................4

3

Page 4

English

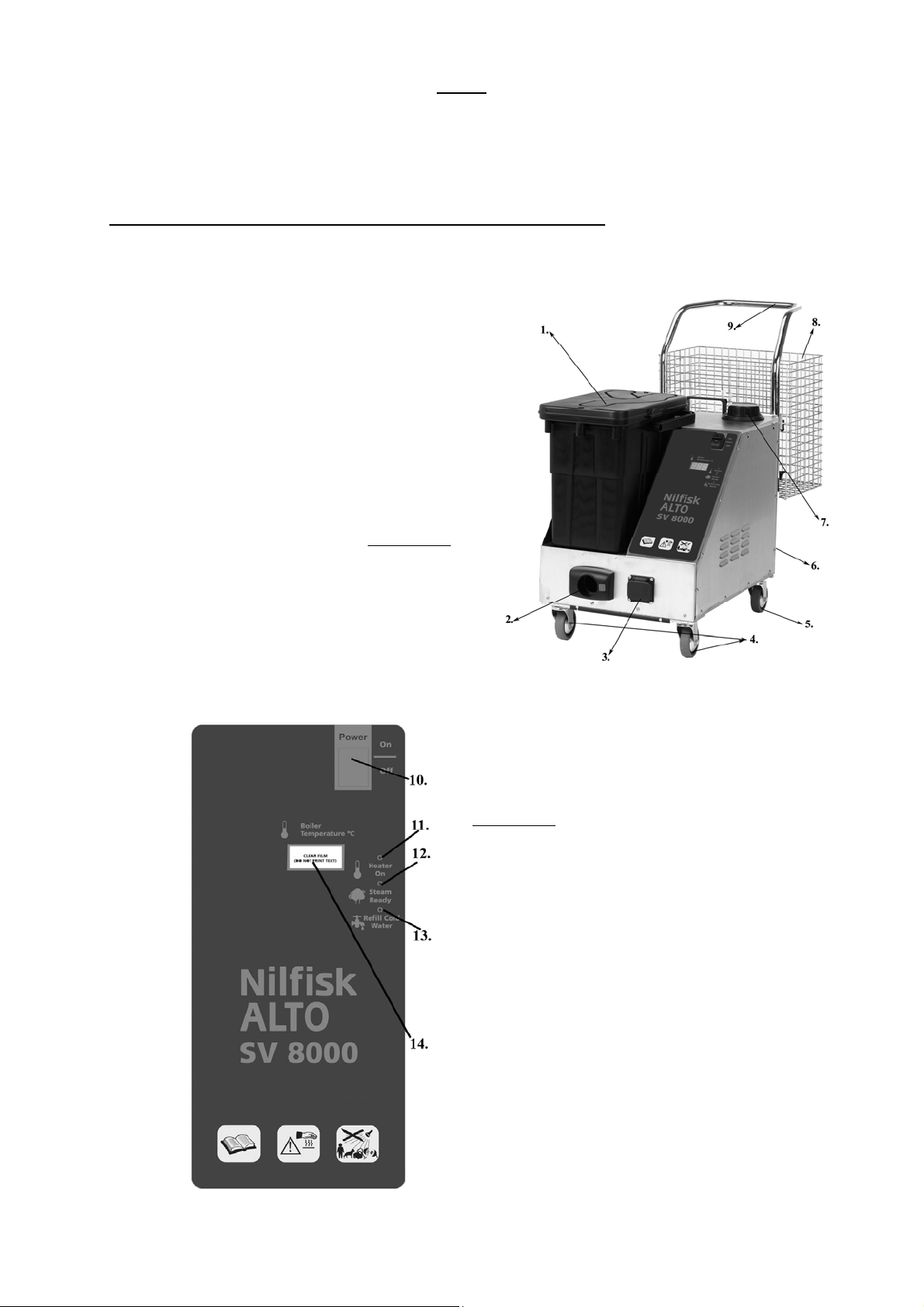

Diag

Diag

Components

1. Collection Tank

2. Vacuum Hose Socket

3. Steam Hose Socket

4. Castor with Brake

5. Caster with No Brake

6. Serial Number

7. Cold Water Tank

8. Wire Basket

9. Tubular Handle

ram A

ram B

10. On/Off Switch

11. Heater On LED

12. Steam Ready LED

13. Cold Water Refill LED

14. Temperature Display LED

4

Page 5

English

y

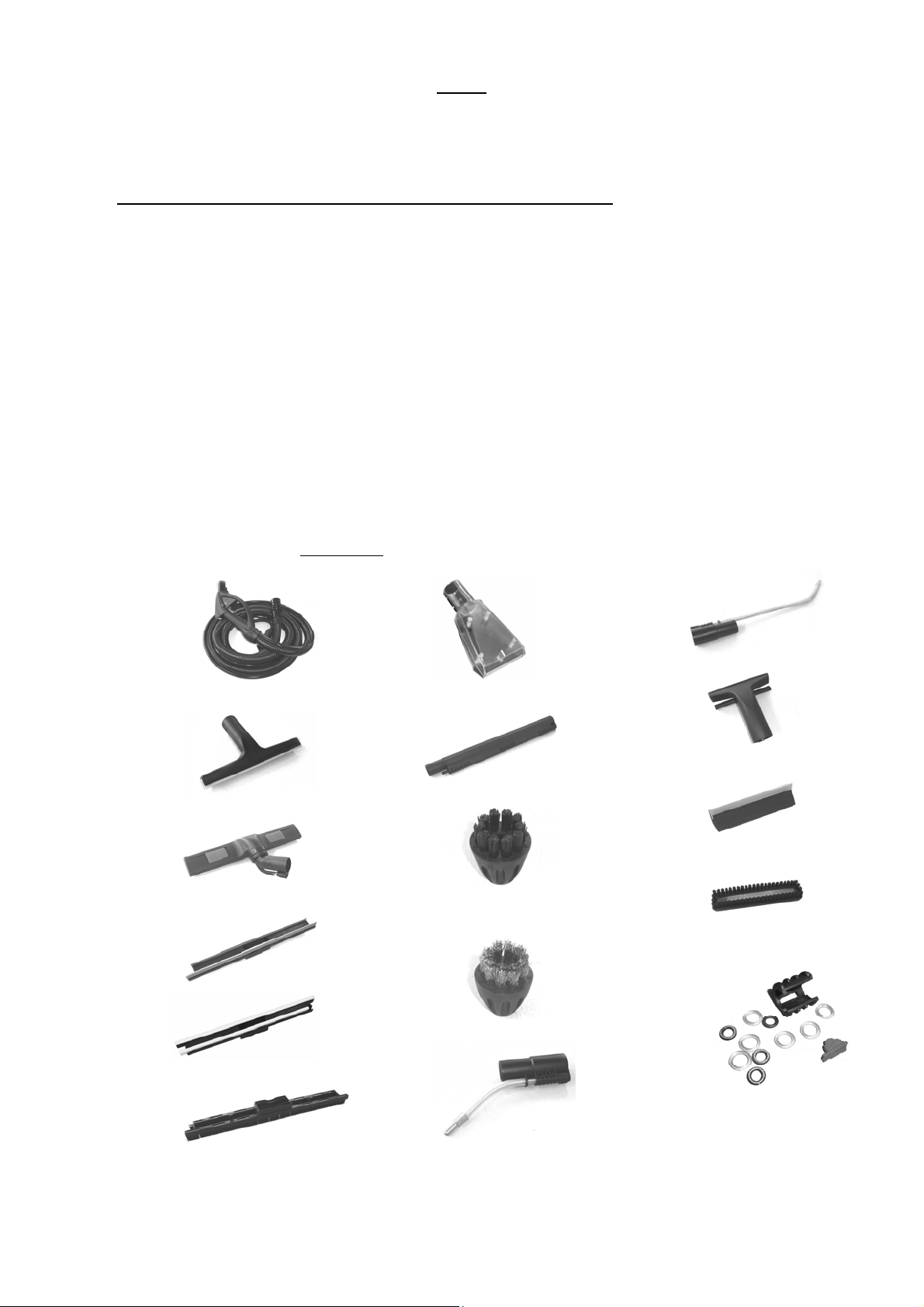

Diag

Attachments

These Parts were carefully packed at Nilfisk ALTO. Please check all accessories on receipt. If any

parts are missing or damaged please contact the company in which you purchased this machine,

within 7 da

1.

12.

7.

13.

2. 8.

14.

3.

9.

15.

4.

10.

5. 16.

11.

6.

s of purchase quoting your serial number on the back of the machine.

1. 4 Meter Steam, Detergent & Vacuum Hose 2. Glass Washer

3. Floor Nozzle 400mm 4. Squeegee Insert for Floor Nozzle

5. Carpet Insert for Floor Nozzle 6. Brush Insert for Floor Nozzle

7. Clear Upholstery Tool 8. Extension Tubes x 2

9. Nylon Details Brush x 5 10. Brass Details Brush x 5

11. Short Steam Lance 12. Long Steam Lance

13. Suction Nozzle 150mm 14. Clip on Squeegee 150mm

15. Clip On Brush 150mm 16. Accessory Service Kit

ram C

Also available is Stainless Steel detail brushes (Packs of 10)

5

Page 6

English

p

Diag

•

•

Accessories

These Parts were carefully packed at Nilfisk ALTO. You will find these items in your box with all the attachments.

Please check all accessories on receipt. If any parts are missing or damaged please contact the company in which you

urchased this machine, within 7 days of purchase quoting your serial number on the back of the machine.

ram D

• Wire Basket

• Plastic Wing Nuts x 4

• Caster with No Brake x 2

Tubular Handle

Castor with Brake x2

6

Page 7

English

p

•

Guidance

Congratulations

………………………………………………...

We would like to take this opportunity to thank you for your purchase of the Nilfisk ALTO

combined steam and vacuum cleaner.

This instruction manual contains all of the necessary information to operate and maintain

this machine. Please read this instruction manual carefully before you start using or

carrying out any maintenance on the machine.

If you use this machine correctly as stated in this instruction manual this machine will fulfil

all your steam cleaning needs.

• Operate the machine in accordance with

• Maintain the machine in accordance

Keep this manual in a safe place for future reference and ordering of spare parts

The SV 8000 is manufactured in the EU to the highest quality Standards

• This machine is intended for use in a commercial clea ning environment. If you do

not follow the instructions contained in this manual, situations may arise which may

be dangerous or harmful to the machine or the pers o n o perating the machine. Read

this manual carefully so that you know when such situations can arise.

• Ensure that all operators of this machin e are fully trained on how it works.

• Report any problems or damage to the machine immediately to the supplier or a

Nilfisk ALTO approved supplier for this product. Do not operate the machine until

roblem or damage has been resolved.

the

Getting the Best Results

………………………………………………...

Use only parts supplied by Nilfisk ALTO approved

the instruction manual

with instruction manual

distributors

• Use only detergents and cleaning products in the

solution tank which have been approved by Nilfisk

ALTO

7

Page 8

English

•

Installation

• Diagram D – Casters with No Brake x 2. Remove bolts from the machine and

position into place towards back of the machine. Tighten securely ensurin g no

movement on the brackets.

• Diagram D – Casters with Brake x 2. Remove bolts from the machine and position

into place towards front of the machine. Tighten securely ensuring no movement on

the brackets.

• Once all the wheels are fully assembled, resume the machine to its upright position.

• Place Tubular Handle (Diagram D) in position on the back of the machine and secure

using the 4 x Plastic Wing Nuts (Diagram D).

!! Do not screw them all the way in at this point.

• Place Wire Basket (Diagram D) over the Wing Nuts and tighten up to secure.

• Check all accessories are present in the box as shown in Diagram C & D.

Warnings

………………………………………………...

This machine has been designed with your safety in mind; however it is important that you

observe the following points for safe operation during the o per a ting procedure

• This is an electrical product – Do not use in wet weather or allow the machine to get wet.

• Do not discharge steam towards people, danger of scolding. Or towards equipment containing

electrical components

• Never allow children to play with this appliance.

• Do not use the machine for other purposes that it was built for.

• Please remember that the steam cleaner operates at temperatures in excess of 150°C. Never

use it on objects, which cannot resist the temperature (delicate materials, fabrics, plastics,

wood etc). Where any doubt exists check carefully on a part of the material where minor

marks will not matter.

• Do not operate the machine or carry out any maintenance out on it

Unless you are trained and authorised to do so

Unless you have read and thoroughly understand this instruction manual.

Lift the machine out of the box.

• Carefully place the machine on its side in

order to assemble the wheels securely.

!! A flat surface is required which will

not scratch or damage the surfaces of the

machine.

8

Page 9

English

Operating Procedure

………………………………………………...

1. Fill the cold water tank (Num ber 7 Diagram A) with clean cold water only.

!! Anything other than clean cold water used in the

2. Connect the Vacuum Hose to the front of the machine (Number 2 Diagram A) ensuring

3. Connect the Steam Hose to the front of the machine (Number 3 Diagram A) ensuri ng it

!! To release the steam hose, lift the flap and pull.

4. Plug the power cable into a 240 Volt supply.

8. Switch the On/Off switch (Number 10 Diagram B) to the ON position. The Heater On

9. Allow approximately 10 minutes for the boiler to heat the water

10. When the Steam Ready LED (Number 12 Diagram B) illuminates the machine is ready

water tank will void the manufacturers warranty.

it locks into position. To release the vacuum hose from the socket slide the red button

upwards at the same time as pulling the hose out.

!! If the Hose becomes damaged the complete hose must be replaced. Do not

attempt this task yourself, contact a Nilfisk ALTO approved supplier for

replacement.

is pushed in all the way and the pin on the flap locks into the hole on the hose.

!! Grease “O” rings on steam pin before connecting.

!! Inspect the electric cable before every use. If the cable becomes damaged at

anytime the complete cable must be replaced by a Nilfisk ALTO approved

distributor.

!! Never touch the power cable or plug with wet hands

!! Always unplug the machine when

i. The machine is not in use

ii. Cleaning the machine

iii. Any maintenance work is being carried out

light LED (Number 11 Diagram B) will illuminate.

to be used.

9

Page 10

English

Operating Procedure cont….

………………………………………………...

11. The handle controls are now active.

• The red trigger on the hose handle will release steam when pressed.

• The red button on the side of the handle will lock the steam trigger in the off

13. Choose and fit the required accessory (Diagram C) to the hose handle. Lock the

accessory in place by turning the accessory locking clip.

During Use

………………………………………………...

Cold Water Tank Empty(Number 7 Diagram A)

1. Refill the cold water tank when the refill cold water LED (Number 13 Diagram B) is

illuminated. A buzzer will sound and the steam will no longer come out of the nozzle

when the steam switch on the handle is pressed.

2. Always empty the collection tank each time the cold-water tank is refilled.

3. The pumps will not work when the cold-water tank is empty.

4. Once the cold water refill LED is illuminated the boiler heater will remain on for 30

minutes. If the cold-water tank is not refilled within 30 minutes and the machine is left

powered on the boiler heater will switch off.

Collection Tank Full (Number 1 Diagram A)

1. Always empty the collection tank each time the cold-water tank is ref illed

2. The pitch of the motor noise changes and there is no suction at the nozzle

3. Switch off the machine, empty the collection tank and rinse clean

position.

• Pressing the left hand switch on top of the handle will activate the vacuum.

• Pressing the right hand momentary switch loc ate d on the top of the handle is

inactive as there is no detergent facility on this machine.

!! When changing accessories during use please note these will be hot.

10

Page 11

English

y

Maintenance

DO

Warning: Disconnect the machine from the mains before

cleaning or carrying out any maintenance work.

Daily Maintenance

………………………………………………...

To be carried out every day or every 8 hours of operation.

1. Grease “O” rings on the steam pin in the steam hose.

2. Wash the hose by sucking one or two litres of water from a basin into the collection

tank.

3. Empty the collection tank, ri nse and wipe down.

4. Remove the foam filter, wash in water and re fit.

• Take care not to damage the filter mesh. If it becomes torn do not use

the machine and replace damaged pa rts immediately.

5. Wipe down the body of the machine with a cl ean damp cloth

6. Always wash the accessories in hot soapy water

DO NOT IMMERSE THE MACHINE OR HOSE IN WATER

8. Wrap the power cable around the handle before storage.

Weekly Maintenance

………………………………………………...

To be carried out every week or every 50 hours of operation.

As for daily maintenance plus the following:

1. Inspect the power cable for any signs of damage. If damage d do not repair,

contact the supplier of this pr oduct. Do not use until repaired.

2. Inspect the hose assembly for any signs of damage. If damaged do not repair,

contact the supplier of this pr oduct. Do not use until repaired.

3. Inspect castors to ensure all securing bolts are fully tightened.

Safety Precautions

………………………………………………...

This machine is to be used by trained operatives onl

• Check the cable and plug are safe and intact

before plugging the machine in.

• Place cleaning in progress signs where

necessary

• Point the steam nozzle away from your body

during use

• Empty and clean machine after each use

DON’T

• Use the machine near people, children or

animals

• Point steam at electrical apparatus

• Use the machine to clean the machine

down

• Do not use on Velvet, satin or leather

• Leave the machine unattended

11

Page 12

English

Service & Guarantee

Service

………………………………………………...

If you require a service or advice on using or maintaining your machine

please contact your Nilfisk ALTO appr oved distributor.

Guarantee

………………………………………………...

Nilfisk ALTO guarantees that if within 12 months from the date of purchase this

appliance, or any parts the reof, is proved to be defective b y reason of faulty workmans h i p

or materials, we will at our option repair or replace the same free of charge for labour and

materials, provided that:

• The appliance has been installed and used in accordance with our operating and

servicing instructions.

• If the appliance has been serviced, maintai ne d, re paired, modified taken apart or

tampered with by any person not authorised by us, then we will not be liable under

this guarantee for any fault arising from their defective workmanship.

• We shall not be liable under this guarantee for any fault in the appliance arising

from the use of spare parts not supplied and recommended by us.

• Excluded from this guarantee are parts that need replacement due to normal wear

and tear such as hoses, nozzles and accessories.

12

Page 13

English

Technical

Technical Information

………………………………………………...

Boiler

Wattage: 3000W – (2000 +1000)

Type: Stainless Steel

Capacity: 3.3 Litres

Continuous Fill Yes

Steam Pressure 8 Bar

Steam at source: 165°C >

Vacuum

Type Integral

Motor 850 Watt

Electrical

Voltage 230V ~ single phase

Low Voltage Controls 5V

Cord length 10m

Capacities

Boiler 3.3 Litres

Cold Water Tank 5 Litres (easy fill)

Collection Tank 12 Litres

Weight 25kg

13

Page 14

English

Trouble Shooting

Symptom Possible cause Action

No power Not connected / Faulty socket Check connection to wall socket and

socket switch. Try in another wall

socket

On / Off switch not on Press On / Off switch which will

illuminate when on

Fuse blown Replace fuse with approved 13A fuse

Unknown Call for service

No steam Steam Control turned down fully

clockwise

Steamer not ready Wait for the “Ready to steam” light to

Clean water tank is low (beeping

sound& "refill" light is lit)

Turn the control to half way

illuminate

Pour water into the clean water tank

until the beeper stops. The steam

handle will work again.

Unknown Call for service

No steam, Just water Steamer not ready Wait for the "Ready to steam " light

to illuminate

Boiler at pressure and not heating

(temperature less than 110ºC)

Unknown Call for service

Steam Leaking from

front socket

“O” rings worn Change and re grease “O” Rings. To

Vacuum power low Vacuum operation has been

Unknown Call for service

“O” Rings split Change and re grease “O” Rings. To

selected on the machine

High pitch motor noise

Hold the steam switch on for

approximately one minute, ever if just

water is coming out. This will result

in the heater coming back on

avoid this happening ensure “o” rings

are grease before every use.

avoid this happening ensure “o” rings

are grease before every use.

Operate any of the handle controls,

which will reset the motor power to

full. Continue vacuuming

Switch the machine off and empty the

collection tank. Refill the collection

tank with clean water to the mark and

recommence work.

14

Page 15

Page 16

Loading...

Loading...