Page 1

35mm Film Scanner

COOLSCAN II

Standard Model and Internal-Mount Model

Contents

1. Overview

1.1 Features

1.2 Operating Environment for Standard Model

2. Before Operation

2.1 Inspection

2.2 Components

2.3 Notes on Use

2.4 Cleaning the Unit

3. Parts Identification

3.1 Main Unit

3.2 Status Display LED

3.3 Strip Film Holder FH-2

4. Setting Up the Standard Model

4.1 Before Connection

4.2 Connecting the Power Cord

4.3 Connecting the SCSI Cable

4.4 Setting the SCSI ID

User’s Manual

- 1 -

Page 2

5. Setting Up the Internal-mount Model

5.1 Before Installing

5.2 Installing the Internal-mount Model

5.3 Setting the SCSI ID

5.4 Terminating the SCSI Chain

5.5 SCSI Cables Used with Internal Scanners

5.6 Connecting to the Computer SCSI

5.7 Setting Up a SCSI Chain with the Scanner

6. Operation

6.1 Turning on the Power

6.2 Film Insertion

7. Troubleshooting

Appendix: Specifications

Index

- 2 -

Page 3

Cautions

• The reproduction of all or part of this manual without our

permission is prohibited.

• The information contained in this manual is subject to change

without notice.

• We have made every effort to produce a perfect manual,

but should you find any mistakes, we would be grateful if you

would kindly let us know.

• We shall take no responsibility for consequences resulting

from the operation of this product, despite the terms

mentioned above.

Indication

The indications in this manual signify important safety

precautions. In order to use this product safely, please read

every section where these indications are placed before

beginning operation, this product. These indications are also

placed in the table of contents so users can find them easily.

Indication

The indications in this manual signify the need for caution

when using the products. These indications are placed in

sections that should be read by users before beginning

operation, in order to avoid damage to the product.

Trademark Information

Macintosh is a registered trademark of Apple Computer, Inc.

Microsoft is a registered trademark and Windows is a trademark of Microsoft

Corporation.

IBM PC/AT is a trademark of International Business Machines Corporation.

Other brand or product names are the trademarks or registered trademarks of

their respective holders.

- 3 -

Page 4

Federal Communications Commission (FCC)

Radio Frequency Interference Statement

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable

protection against harmful interference in a residential

installation. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful

interference to radio communications. However, there is no

guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference

to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following

measures:

CAUTIONS

Modifications

The FCC requires the user to be notified that any changes or

modifications made to this device that are not expressly

approved by Nikon Corporation may void the user's authority

to operate the equipment.

SCSI Cable

Please use the SCSI cable listed on page 5 in the user's Manual

supplied with the scanner. Using other interface cables may

exceed the limits of the class B Part 15 of FCC rules.

Notice for customers in Canada

CAUTION

This class B digital apparatus meets all requirements of the

Canadian interference Causing Equipment Regulations.

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for

help.

ATTENTION

Cet appareil numérique de la classe B respecte toutes les

exigences du Règlement sur le matériel brouilleur du Canada.

Notice for customers in European countries

ACHTUNG

Dieses Gerät entspricht den Bestimmungen der EG-Direktive

87/308/EEC zur Störungsunterdrückung. Lärmemission kleiner

70 dBA

- 4 -

Page 5

Cautions for Safety

In order to use the COOLSCAN II safely and correctly, and to

prevent problems, pay careful attention to the following points:

• Use an AC power supply of 50/60Hz and a voltage of from

100V–240V. Be sure to use a power cord rated for the

appropriate voltage.

At voltages of more than AC 125V:

use a power cord that complies with the safety standards of

the country in which it is used, which has a plug rated for AC

250V, 15A (NEMA 6P-15) and insulation of SVT type or

better, and which is more than AWG18 in thickness.

At voltages of AC 125V or less:

use a power cord that complies with the safety standards of

the country in which it is used, which has a plug rated for AC

125V, 10A and insulation of SVT type or better, and which is

more than AWG18 in thickness.

• Be sure that the electrical outlet of the power supply is

grounded. Conduct the grounding in common to the other

machines it is being connected with. Unless common

grounding is conducted, ground loop will occur, which will

cause electric shock and noise static.

* The shape of the plug depends

on the country of use.

• Do not conduct the grounding to a gas pipe or a water pipe.

- 5 -

Page 6

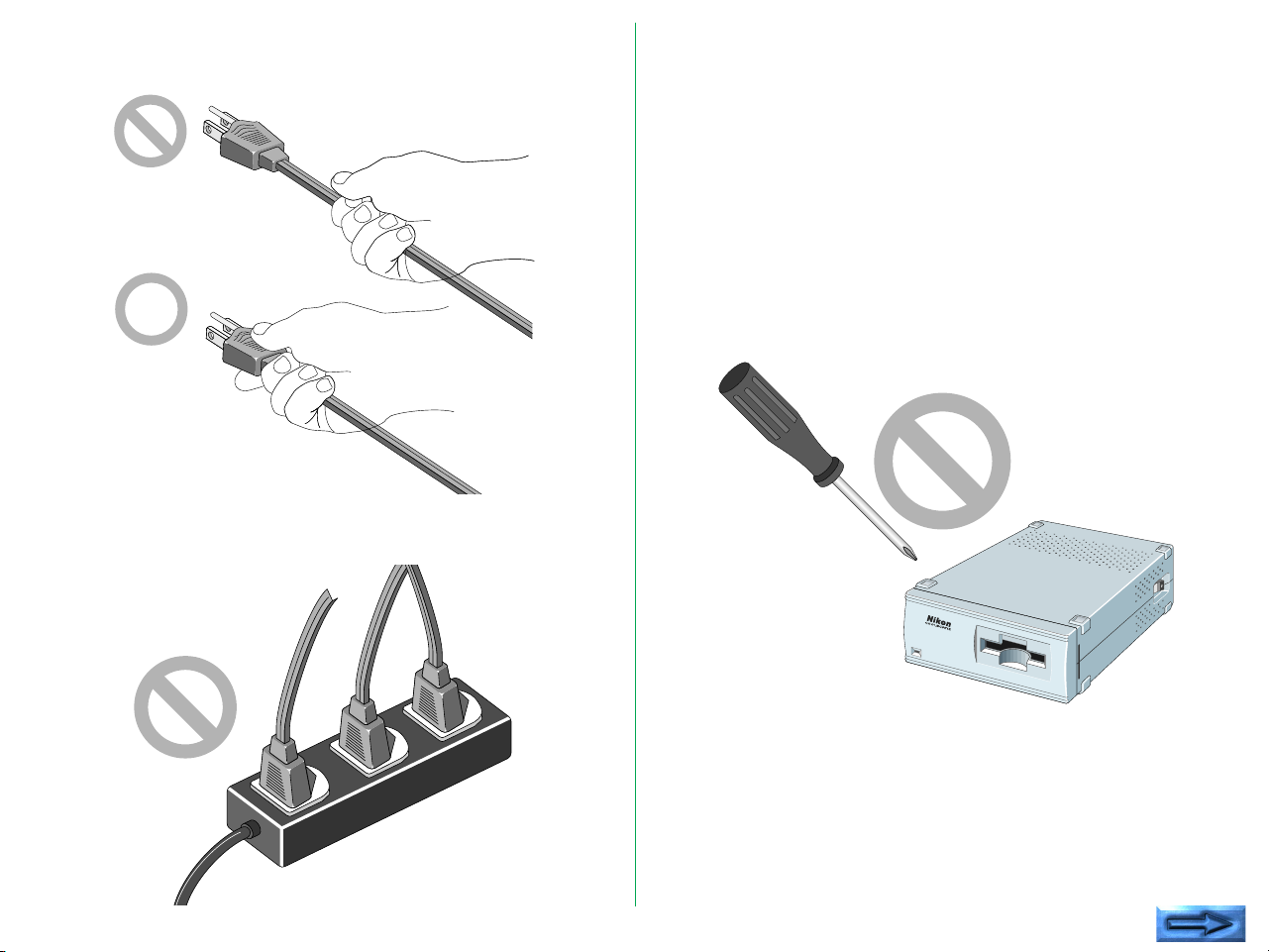

• When plugging in or unplugging the power cord, be sure to

touch only the plug.

• Do not extend the power cord of the product, as this may

cause malfunction. This can cause breakage and failure.

• Do not connect or remove peripheral equipment while the

power switch is on. This can cause breakage and failure.

• Do not unplug the power cord while the power switch is on.

This can cause breakage and failure.

• Do not move the Unit while the power switch is on. This

can cause breakage and failure.

• Once the power switch has been turned off, wait at least five

seconds before turning the power switch on.

• On no account disassemble the Unit. The high voltage parts

inside the unit can cause electric shock.

• Do not insert any foreign objects inside the unit. If

flammable objects, metal, or water come in contact with the

interior of the unit, failure, fire, and/or an electrical shock may

result.

- 6 -

Page 7

• Avoid harsh substances such as alcohol, benzine, thinner, or

pesticides, as failure, fire, and/or an electrical shock may

result.

• Do not subject the unit to any strong shocks. This can cause

breakage and failure.

• Do not place heavy objects on the unit.

- 7 -

Page 8

• Do not pull or bend the SCSI cable. This can cause the

cable to malfunction.

5

If You Notice Anything Abnormal

If unusual noise, odor or smoke occurs, switch the Unit off

immediately and disconnect the power cord and the SCSI cable.

Contact your retailer or Nikon sales representative in your

country.

- 8 -

Page 9

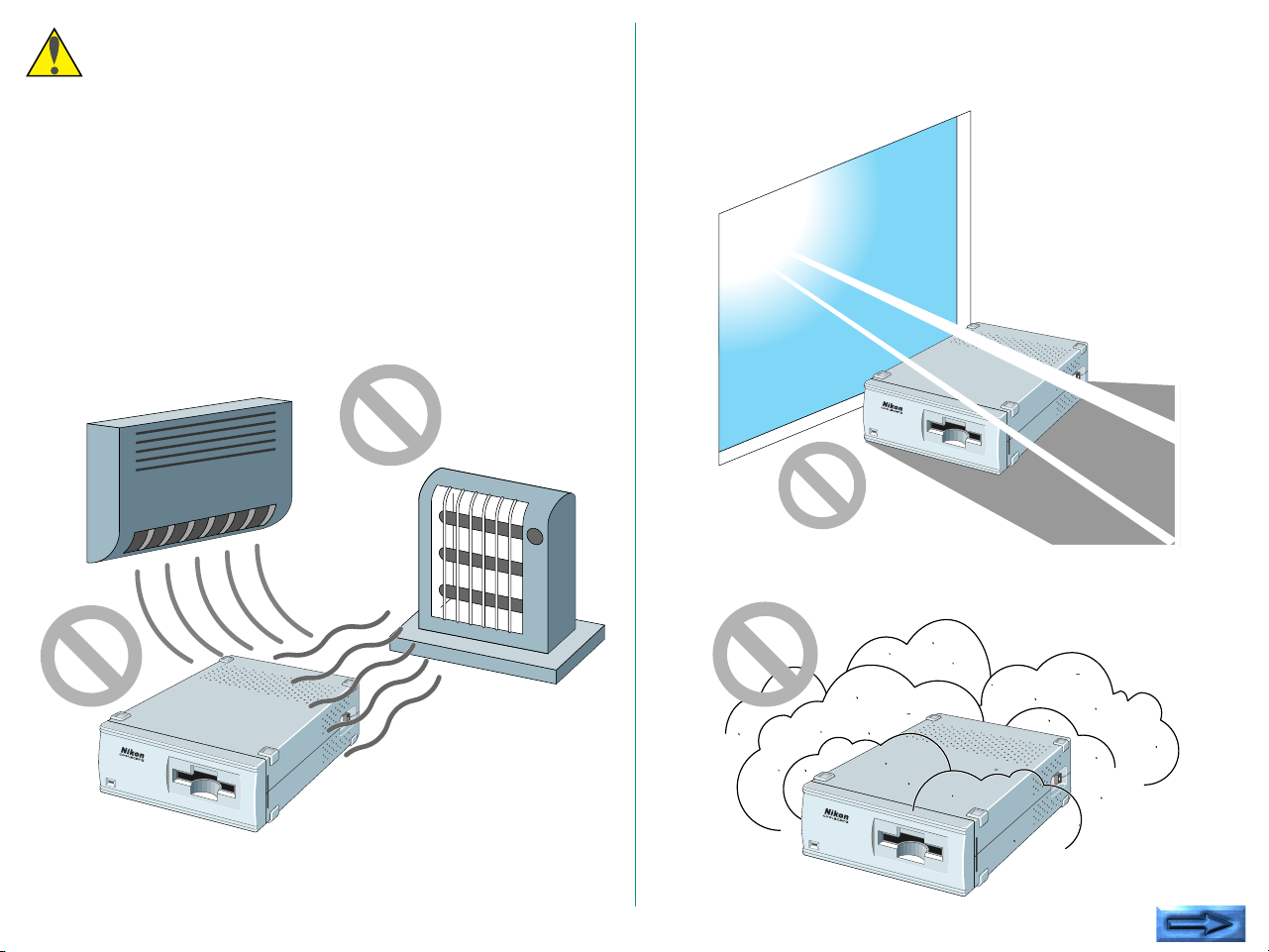

Storage and Operating Locations

Proper storage will ensure the long life of the Unit. In order to

avoid internal dust while being stored, it is recommended that

an appropriate cover be used on the Unit.

Do not store or use where:

• The temperature is above 95°F (35°C) or below 50°F

(10°C), the temperature changes drastically, or condensation

occurs.

• The humidity exceeds 80%.

• The Unit is exposed to direct sunlight.

• The atmosphere is excessively dusty.

- 9 -

Page 10

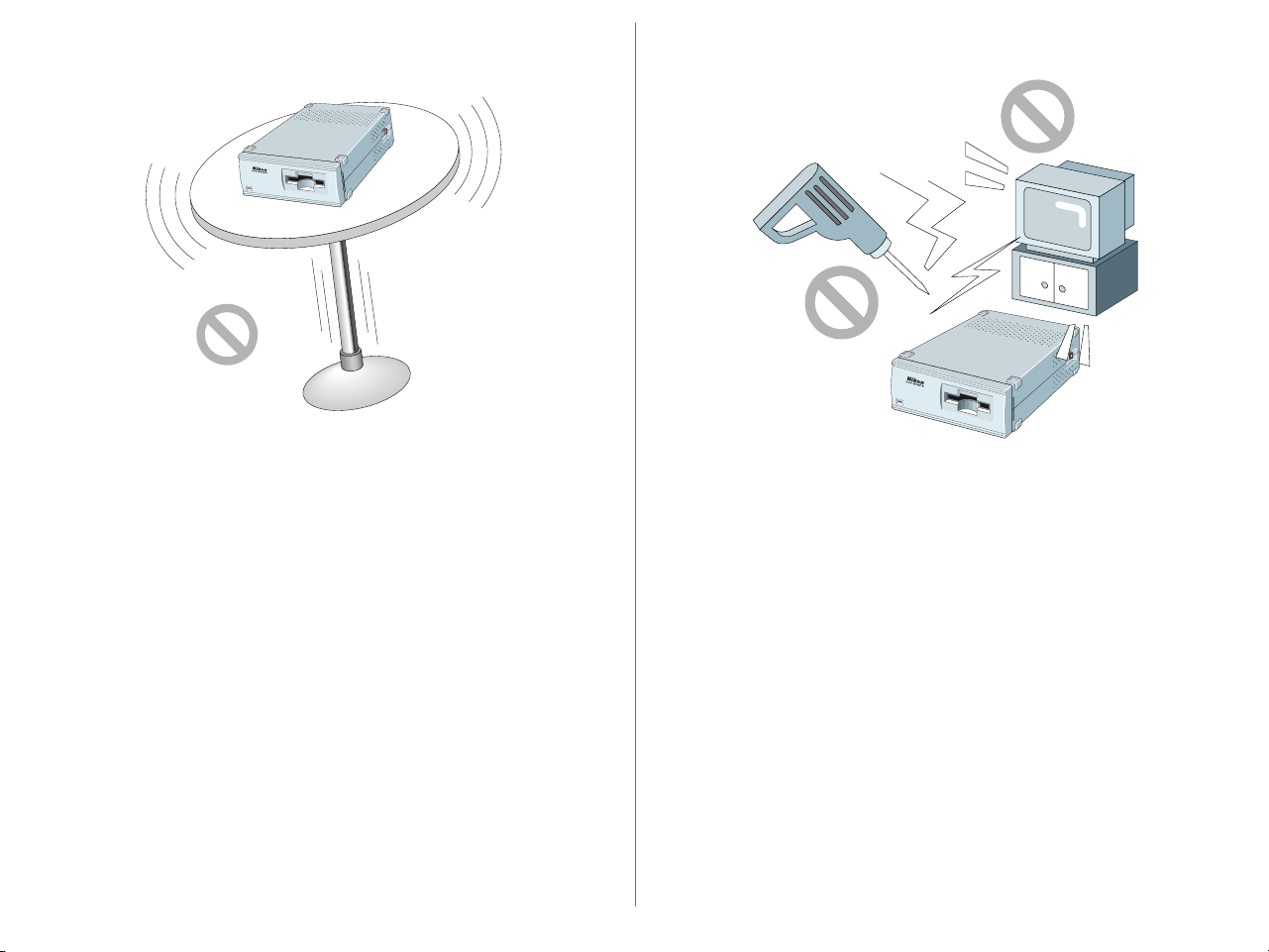

• The Unit may be subjected to excessive vibration.

• The Unit is placed on tilted surface.

• The Unit is exposed to electrical noise and interference from

other equipment nearby.

Leave sufficient space around the unit to ensure that the

ventilation slots are not blocked. Blocking these slots may cause

an internal heat build-up.

Place the unit on a level and stable surface for operation. If

operated in any other way, problems will occur.

- 10 -

Page 11

Cautions for Operation

When Taking the Unit Out of The Country

• Don't carry the Unit or film while scanning. This can cause

breakage and failure.

• When moving the scanning stage, don't touch or unmount

the film holder. This can cause breakage and failure.

• Don't use a slide mount more than 3mm thick. If the slide

mount surface is not smooth, you may feel some resistance

when mounting or unmounting the slide.

• Don't force the slide mount or strip film holder into or out

of the scanner if it does not move smoothly. This can cause

breakage and failure.

Transportation Precautions

When transporting the Unit, pack the unit with the original

package box and packing material provided by Nikon.

The use of this product may violate local laws and restrictions in

some countries. If this is the case, we cannot bear any

responsibility for any violations resulting from the use of this

product.

- 11 -

Page 12

Notice concerning prohibition of copying or

reproduction

Note that simply being in possession of material which has been

copied or reproduced by means of a scanner may be

punishable by law.

• Items prohibited by law from being copied or reproduced

Do not copy or reproduce paper money, coins, securities,

government bonds, or local government bonds, even if such

copies or reproductions are stamped “Sample”.

The copying or reproduction of paper money, coins, or

securities which are circulated in a foreign country is

prohibited.

The copying or reproduction of unused postage stamps or

post cards issued by the government without obtaining

approval from the government is prohibited.

The copying or reproduction of stamps issued by the

government and certified documents stipulated by law is

prohibited.

• Cautions on certain copies and reproductions

The government has issued cautions on copies or

reproductions of securities issued by private companies

(shares, bills, checks, gift certificates, etc.), commuter passes,

or coupon tickets, except when a minimum of necessary

copies are to be provided for business use by a company.

Also, do not copy or reproduce passports issued by the

government, licenses issued by public agencies and private

groups, ID cards, and tickets, such as passes and meal

coupons.

• Comply with copyright notices

The copying or reproduction of works such as books, music,

paintings, woodcut prints, maps, drawings, movies, and

photographs which are copyrighted creative works is

prohibited except when it is done for personal use at home

or for similar restricted and non-commercial use.

- 12 -

Page 13

1. Overview

1.1 Features

Thank you for purchasing the Nikon 35mm Film Scanner

COOLSCAN II. This manual describes the procedures for

unpacking, setting up, and connecting the scanner, with

emphasis on hardware use and precautions.

Please read the sections appropriate for the scanner you are

using, to ensure proper operation.

For an explanation of how to scan and reproduce images with

COOLSCAN II, please refer to the software manual.

We hope that you will find this manual helpful.

The COOLSCAN II is capable of scanning 35mm film (color/

monochrome, negative/positive) at high speed and high

resolution.

• 3-color, high-brightness LED illuminant, eliminates the need

for illuminant maintenance

• High-speed single-pass scanning capability

• High quality images produced using an 8-bit A/D converter

• Maximum pixel count of 2,592 x 3,888 and high resolution

of 2,700dpi (on film surface)

• Auto-focus function, eliminating the need for manual focusing

• Compact, lightweight design, with low power consumption

- 13 -

Page 14

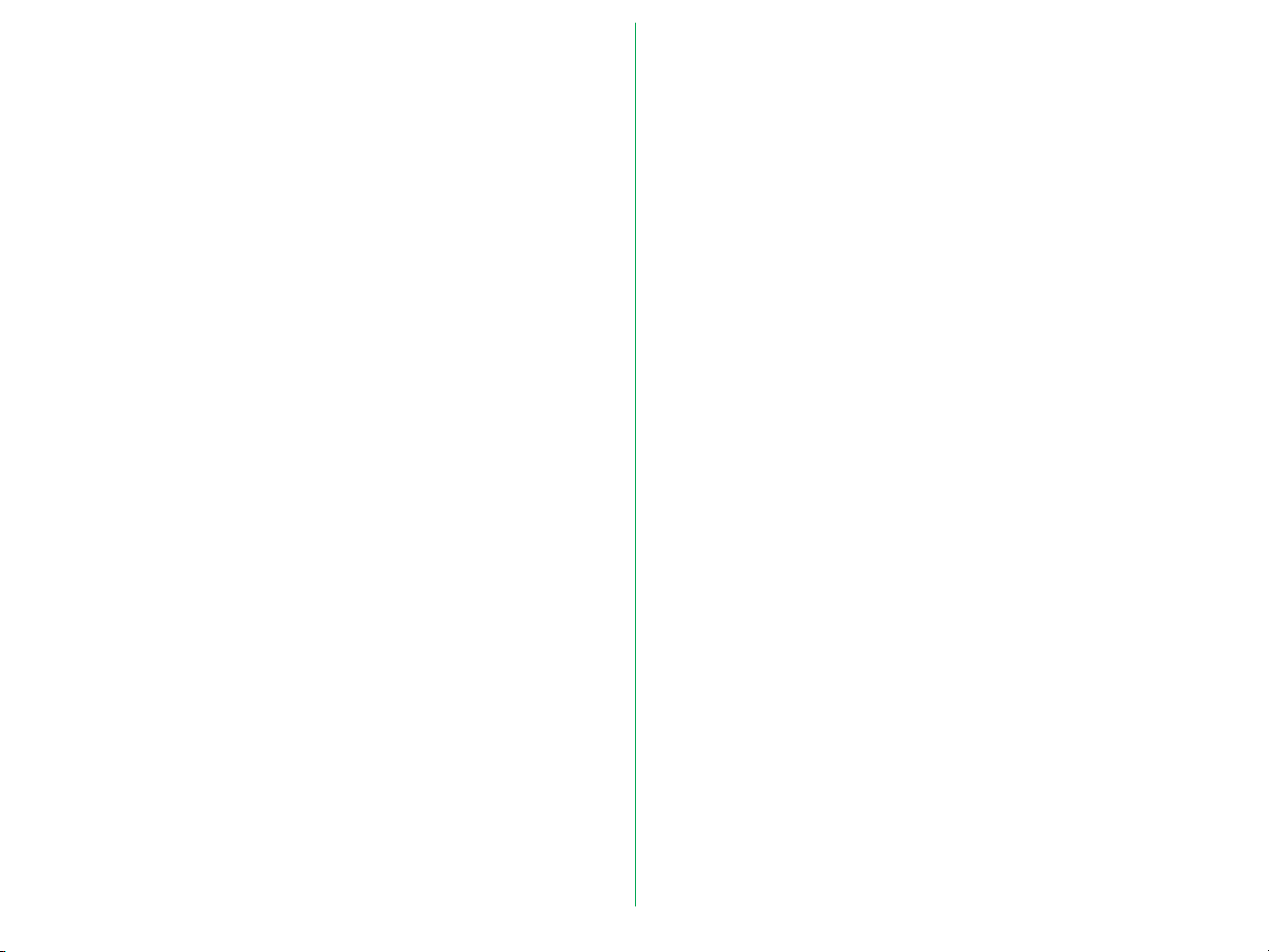

1.2 Operating Environment for Standard Model

Leave extra space around and above the unit to ensure smooth

operation. Please refer to the drawings below for the amount

of space to be provided.

If possible, place a suitable cover over the unit to avoid dust

accumulating when it is not being used.

For vertical installation

For horizontal installation

- 14 -

Page 15

2. Before Operation

2.1 Inspection

Inspect the package to see whether any damage has occurred

during shipment. If there is any damage to the package, please

contact your retailer directly and do not unpack the unit.

2.2 Components

When you open the package, check whether all the items are

present. If there are any missing items, please contact your

retailer immediately.

Standard Model

The following items are included with your COOLSCAN II

standard model package.

Power cord (1)

* The shape of the plug depends

on the country of use.

SCSI cable (1)

(50pin full pitch Dsub 25pin)

Terminator (1)

Main Body (1)

FH-2 Strip Film Holder (1)

User’s manual(s)

Software disk(s)

- 15 -

Page 16

Internal-mount Model

The following items are included with your COOLSCAN II

Internal-mount model package.

Main Body (1)

Guide rail (1)

SCSI 50-pin flat cable (1)

FH-2 Strip Film Holder (1)

Terminator (1)

User’s manual(s)

Software disk(s)

- 16 -

Internal Power Cable (1)

Page 17

2.3 Notes on Use

2.4 Cleaning the Unit

• Don’t use a slide mount neither less than 1.1mm nor more

than 3.0mm thick. If the slide mount is not flat on its surface,

you may feel some roughness when mounting or

unmounting the slide.

• Don’t force the slide-mount or strip film holder into or out

of the unit if it does not move smoothly.

• When scanning film, don’t touch or unmount the slide-

mount or film strip holder.

When carrying out routine maintenance and cleaning, ensure

that no volatile liquids such as alcohol, benzine, or thinner come

into contact with the COOLSCAN II as this may cause a failure,

fire, or electric shock.

Please observe the following points:

• Before cleaning, always turn the power off, and pull out the

power plug.

• Since the front cover is made from plastic material, remove

dust with a blower or a dry cloth.

Use a soft, dry cloth to remove dust from the metal panel at

the rear.

• If the unit has become badly soiled, clean with a cloth

moistened with a mild liquid detergent, then dry with a soft

cloth.

Avoid harsh substances such as alcohol, benzine, thinner, or

pesticides, as they may damage the surface, or remove the

exterior finish.

- 17 -

Page 18

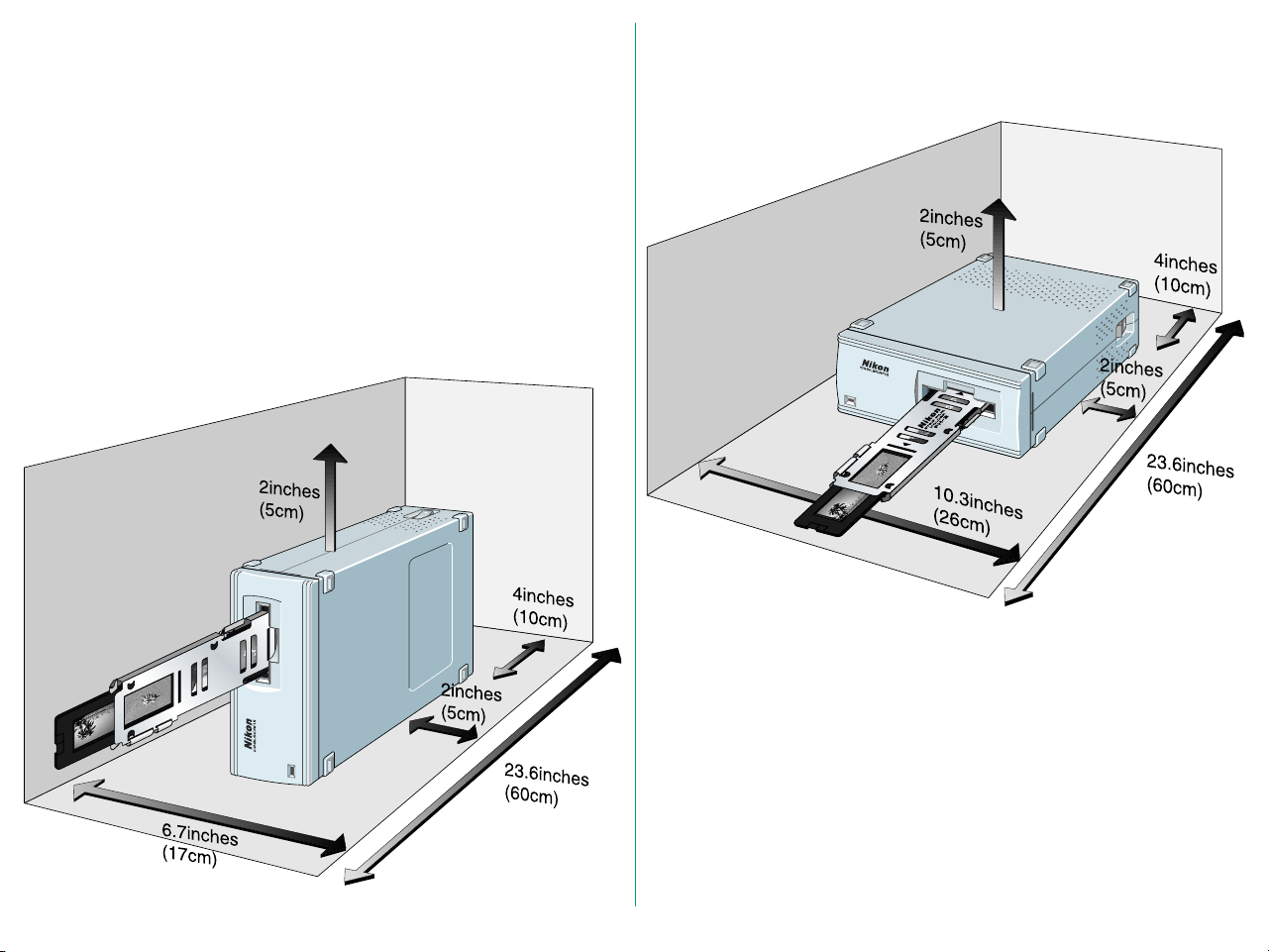

3. Parts Identification

3.1 Main Unit

Standard Model

Ventilation Holes

Status display LED

Film Slot

Film Slot: The film holder is inserted here.

Status display LED:

Shows the scanner status.

Power

Switch

AC Inlet

SCSI Connectors

5

SCSI Connectors:

For SCSI cable connection. No difference

between IN and OUT.

SCSI ID switch: Sets the SCSI ID number. Numbers 0 to 7

are shown and valid.

AC Inlet: Connect to the AC power source with the

power cord provided.

SCSI ID switch

Power Switch: Directly turns the AC power ON/OFF.

Ventilation Holes:

Since air is drawn in through these holes,

make sure that they are not blocked by other

equipment.

- 18 -

Page 19

Internal-mount Model

Film SlotStatus display

LED

Film Slot: The film holder is inserted here.

Status display LED:

Shows the scanner status.

Configuration

DIP switch

SCSI Connector:

For SCSI connection.

Configuration DIP switch:

Sets the SCSI ID number.

Power Connector:

Connect to the power source.

SCSI

Connector

Power

Connector

- 19 -

Page 20

3.2 Status Display LED

3.3 Strip Film Holder FH-2

The display LED is located on the front panel and shows the

scanner status.

Status Display

LED

Steady illumination:

Lights when power is supplied (READY

status).

Blinking (about once every 1.5 seconds):

Blinks slowly during operation (BUSY status).

Also blinks when the power is switched on

and during initialization.

Fast blinking (about 5 times a second):

Blinks fast when an error occurs either in the

scanner or in communication (ERROR status).

Note: The blinking cycle may sometimes be irregular, but this does

not necessarily signify a product malfunction.

This strip film holder can be used with a strip of film containing

up to six images.

Film holder latch

Film holder latch

Aperture

Adaptor cover

Cover latch

Adaptor snap

Upper holder

Lower holder

Lower holder

concave section

(Film sits here)

- 20 -

Page 21

4. Setting Up the Standard Model

For an IBM PC/AT or compatible in which a SCSI board has not

been installed, install a SCSI board as explained in the manual

supplied with the board.

4.1 Before Connection

Before connecting the cables, confirm that all devices, including

the computer system and the COOLSCAN II, are turned off.

POWER OFF

POWER ON

Note: Make sure that the PC is powered off before installing the

SCSI board.

When installing a SCSI board for the first time, be careful not to

set conflicting I/O addresses, interrupt numbers, or graphic

board DMA channels.

- 21 -

Page 22

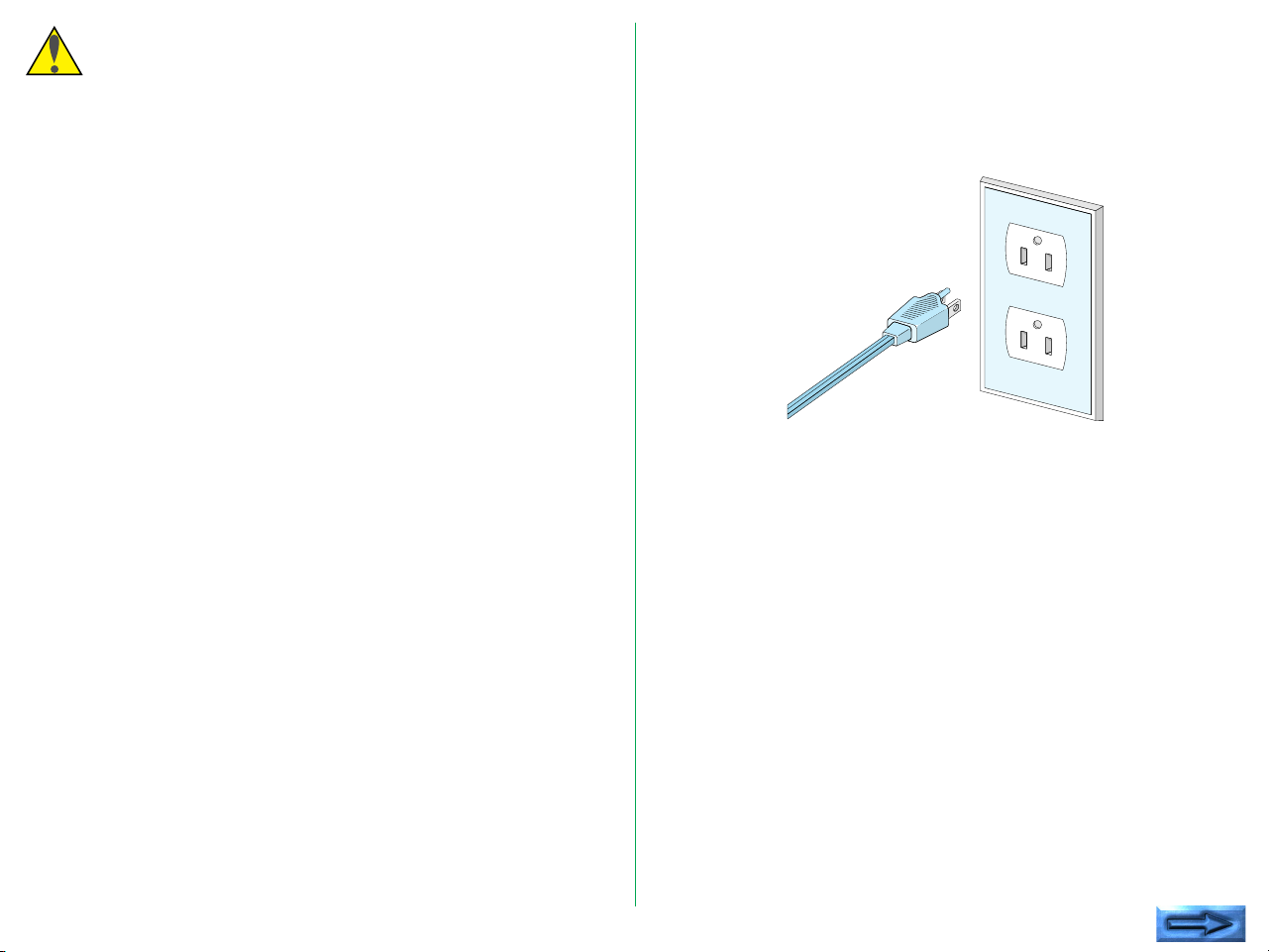

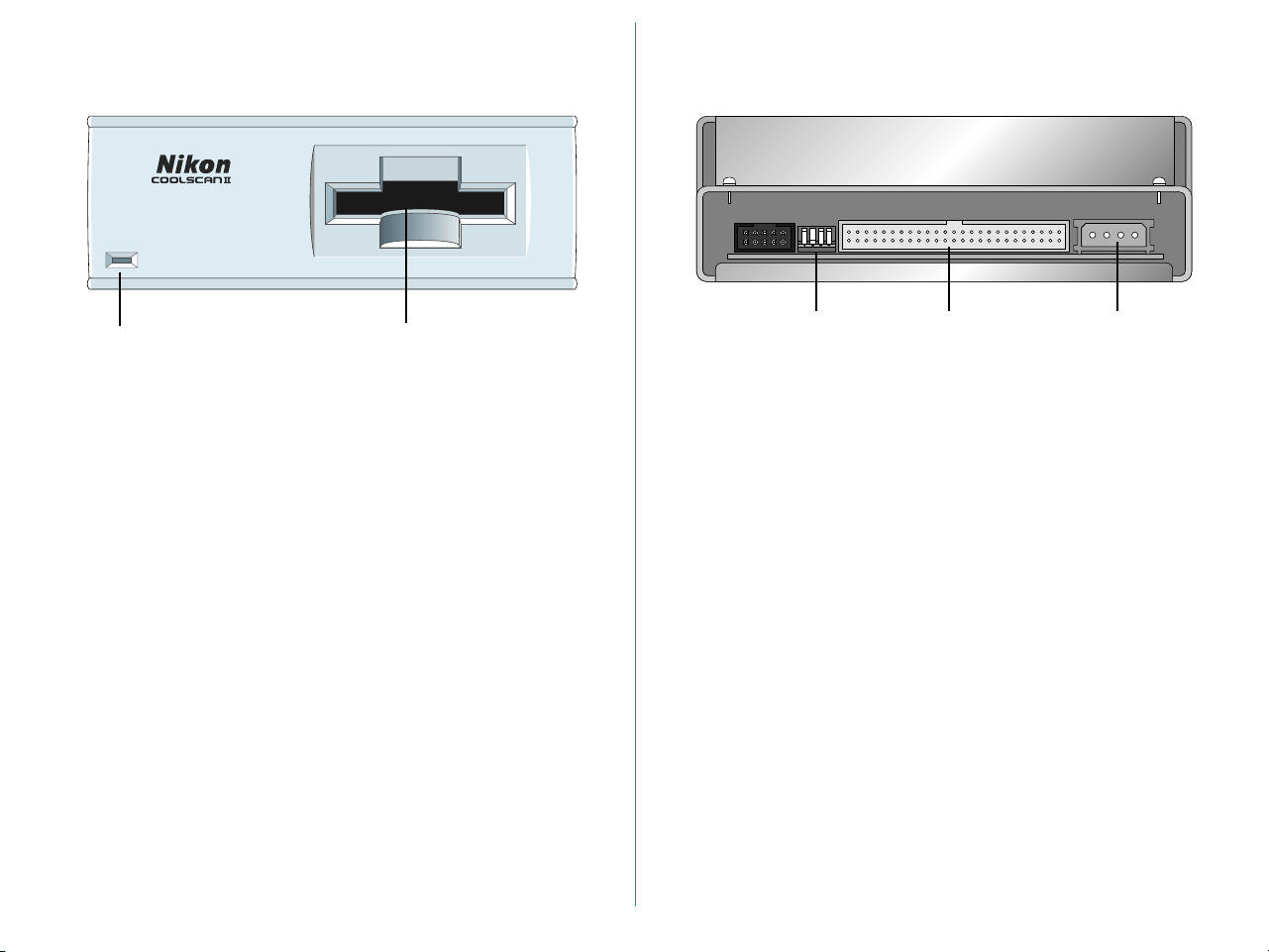

4.2 Connecting the Power Cord

Before connecting the power cord, confirm that the unit’s

power switch is in the off position.

Insert the female end of the supplied power cord into the AC

inlet located on the rear panel, then insert the plug into the AC

power outlet.

5

Remarks

• The power source must be grounded.

• If possible, try to use an independent electric outlet. If the

unit is connected to an outlet to which an electric household

appliance, such as a vacuum cleaner or air-conditioner, is

connected, the product may experience power source noise

interference.

• Do not extend the power cord of the product, as this may

cause malfunction.

* The shape of the plug depends

on the country of use.

* The shape of the plug depends

on the country of use.

- 22 -

Page 23

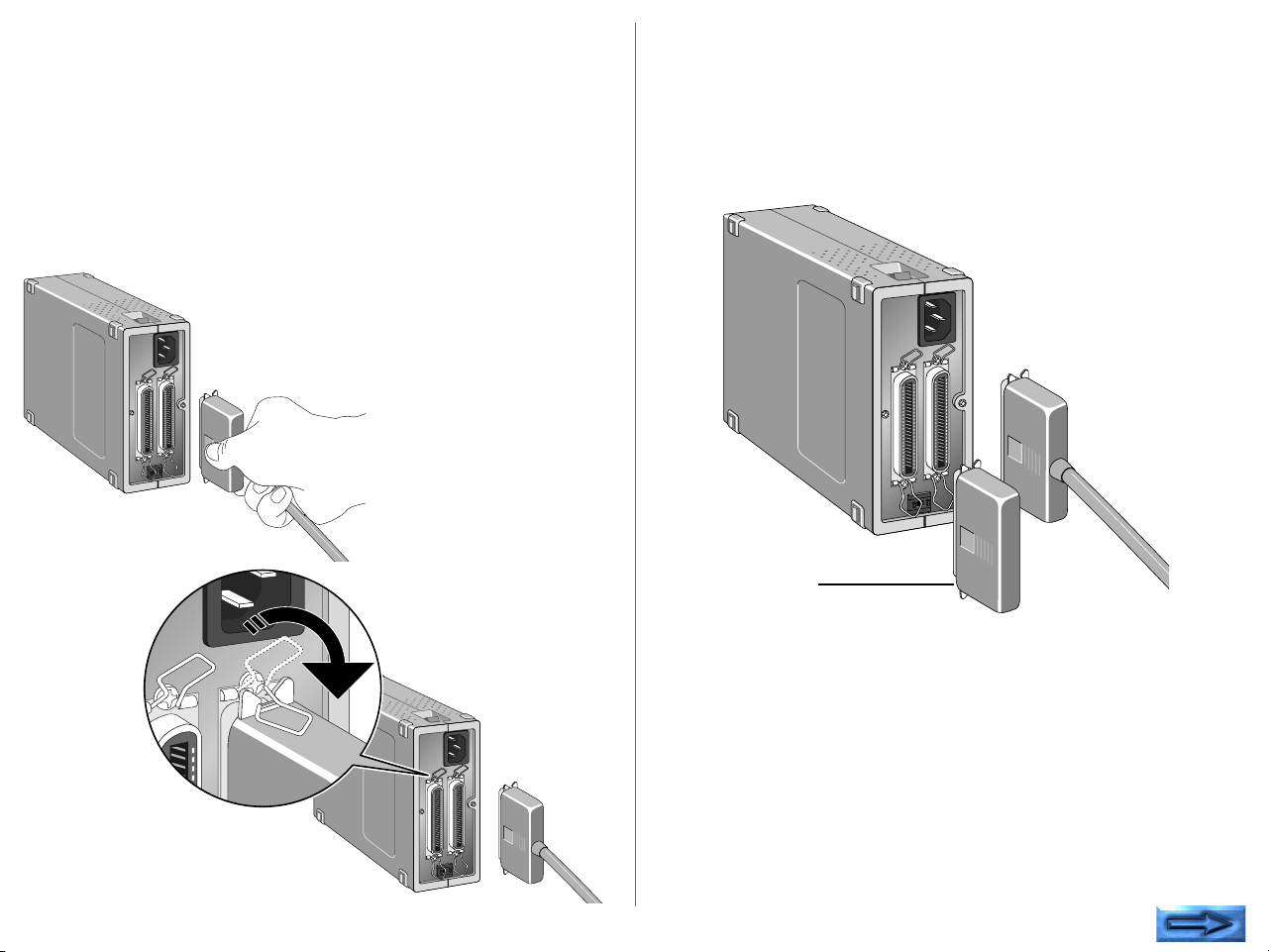

4.3 Connecting the SCSI Cable

5

Before connecting the SCSI cable, confirm that all SCSI devices,

including the computer system, have been turned off.

Connect the unit to the computer using the SCSI cable. After

attaching the connector, be sure to lock it in place. You can

connect the SCSI cable to either of the SCSI connectors on the

rear panel of the unit.

5

If the unit is the only connected SCSI device, or if the unit is

connected at the end of the SCSI chain, attach a terminator

(terminal resistance) to the other SCSI connector. At this point,

remove the terminator of the other SCSI device that has been

placed between them. The terminator is not needed when the

unit is connected between other SCSI devices.

Terminator

Connect SCSI devices in a chain, and attach terminators to both

ends of the chain. Since the terminator is built into the host

computer in most cases, the host computer should be at the

end of the SCSI chain. The operation manuals of some

notebook computers require a terminator to be attached

outside the computer; please refer to the operation manual for

the computer to which the unit is connected.

5

Note: The SCSI cable used for SCSI connection should be of highimpedance type.

- 23 -

Page 24

SCSI Chain Connection with Other Devices

If Scanner is connected at the end of the SCSI chain:

• Connect the 50-pin full pitch connector of the SCSI cable to

the SCSI connector located on the rear panel of the unit,

and insert the other end to the SCSI connector of other

SCSI device.

• Connect the supplied terminator (terminal resistance) to the

other SCSI connector on the rear panel of the unit.

Terminator

If Scanner is connected between the other SCSI devices:

• Connect the 50-pin full pitch connector of the SCSI cable to

the SCSI connector located on the rear of the unit, and

insert the other end to the SCSI connector of other SCSI

device.

• Connect the other SCSI device by using the other SCSI

connector on the rear panel of the unit.

• Connect the supplied terminator (terminal resistance) to the

SCSI device connected at the end of SCSI chain.

- 24 -

Terminator

Page 25

Remarks

• The maximum number of SCSI devices that can be

connected to one computer is eight including the CPU.

When using with a host computer with a built-in SCSI hard

disk or built-in CD-ROM, note that SCSI ID numbers have

been pre-assigned for the host CPU and the SCSI devices.

• The SCSI cable must not be extended beyond a total length

of 19 feet (6 meters), or else failure may result.

• If you use the type of terminator that is inserted between

the SCSI cable and SCSI interface connector, install a

terminator independent of the other SCSI connector of the

COOLSCAN II.

• Terminators must be attached to the devices located at both

ends of the SCSI chain.

If the host computer is a Macintosh, the Macintosh itself will

provide termination at one end of the chain.

If the host computer is an IBM PC/AT or compatible,

equipped with a SCSI board, the SCSI board itself will

present termination at one end of the chain.

Note that when a SCSI chain connection is made inside a

computer, the end of the SCSI device inside the computer

will become the end terminal.

• Before installing a SCSI board, be sure to read the user’s

manual provided with the board. The numbers for the I/O

address, interrupt level (INT) and DMA channel might

conflict with other interface boards and peripheral devices. If

so, change them as explained in the manual.

- 25 -

Page 26

4.4 Setting the SCSI ID

The SCSI ID for the COOLSCAN II is set at “5” when the unit

is shipped. If other SCSI devices are connected to your

computer, make sure that the SCSI ID for the COOLSCAN II is

different from those assigned to other SCSI devices.

Note that in the case of a host computer which has a built-in

SCSI hard disk or built-in CD-ROM, the ID numbers of the host

CPU and each SCSI device have already been assigned.

If the IDs are the same, you must change the ID number of the

other SCSI device or the ID of the COOLSCAN II to avoid any

conflict.

Remarks

• To change the ID, confirm that the COOLSCAN II power is

off. The ID cannot be changed when the power is on.

• As 7 has been assigned for the CPU and 0 has been assigned

to the built-in hard disk for a Macintosh, and 0 and 7 have

also been assigned to other personal computer systems, any

number from 1 to 6 is recommended for the ID number.

• If conflicting ID numbers are assigned, the system might not

function, or important data on the hard disk might be

destroyed. It is therefore essential to check the ID numbers

carefully before connecting the COOLSCAN II.

- 26 -

Page 27

5. Setting Up the Internal-mount Model

The internal-mount scanner is easy to install, following the

procedure described below.

5.1 Before Installing

The internal-mount scanner is shown below. Note that the

front of the internal-mount model is identical to that of the

standard model.

Rear panel

The rear panel of the internal-mount scanner is shown below.

The rear panel contains the DC power connector, SCSI

connector, and configuration DIP switch block.

Front panel

The front of the scanner includes the film slot and the status

display LED.

Film SlotStatus display LED

Configuration

DIP switch

The default DIP switch configuration is shown in Table 5.1. The

meaning of the SCSI ID DIP switch is explained later. The

internal-mount scanner is set at the factory to SCSI ID #5.

DIP Switch Default Usage

1 Closed SCSI ID bit 0 = 1

2 Open SCSI ID bit 1 = 0

3 Closed SCSI ID bit 2 = 1

4 – (Not used)

Table 5.1 Factory set default DIP switch configuration

- 27 -

SCSI

Connector

Power

Connector

Page 28

Both sides of the internal-mount scanner are identical as shown

below. Note the set of two tapped holes on each side. One

set of holes on each side of the scanner will be used for the rails

as shown in this figure.

Locking tab

Top

panel

Front panel Tapped holes

Mounting holes

Guide rail

5.2 Installing the Internal-mount Model

To install the internal-mount scanner, first screw the guide rails

provided with the scanner to the two sides of the scanner, then

insert the scanner into the drive bay using the computer drive

bay slots. Connections to the back of the scanner include the

computer power and the SCSI flat cable.

Due to the tight space constraints inside the computer, it is not

possible to connect the cables to the scanner after it has been

installed. The SCSI cable and terminating networks are easier

to connect to the scanner before it is mounted in the drive bay.

The computer power connector is easily connected to the

scanner when the scanner is partially inserted into the drive bay.

- 28 -

Page 29

Installing the guide rails

Different computers have their own special requirements for

mounting devices in an internal drive bay. In most cases, a pair

of guide rails are screwed to the sides of the scanner to enable

it to be slid into the drive bay. These guide rails are also used

to lock the scanner in place.

The computer drive bays

The scanner will slide into a 5 1/4" half-height drive bay as

shown below. To enable film to be inserted into the scanner,

the computer must have a cutout for this drive bay, so that the

drive bay is externally accessible. The scanner will be powered

from the computer using the standard computer drive power

supply connector. The computer mother board needs to have

an available single short connector slot for the SCSI interface

board.

In order for a scanner to be mounted inside the computer, the

computer must have the following:

1. An externally accessible 5 1/4" half-height bay

2. A standard power supply connector

3. A card slot available on the motherboard

Rail stop

(open)

Rail stop screw

Insert the scanner

here

Rail stop screw

Rail slots

Film slot

Rail stop

(closed)

- 29 -

Page 30

The computer drive bay has one or two metal stops screwed

into the tapped holes on the sides of each half-height drive slot.

These should be loosened to allow them to either be removed

or to hang freely so they do not block the drive bay receptacles

for the guide rails. These will be repositioned after the scanner

is installed to lock the scanner in place.

The scanner side mounting holes

Two sets of vertical holes are provided on the sides of the

scanner. These are the top and bottom rail mounting holes.

One set must be chosen according to where the computer

allows the scanner to be positioned in the drive bay. Most

computers require that the bottom set of mounting holes be

used. Position the rails at the bottom of the scanner and, while

holding the scanner, see if the scanner will slide into the bay rail

slots.

The guide rail mounting holes

The guide rails have a tapered end and a non-tapered end. The

tapered end is mounted at the rear of the scanner to facilitate

the scanner’s insertion into the drive bay slot. The non-tapered

end is mounted at the front of the scanner. This flat end allows

the scanner to be locked into position once the scanner is

installed. Certain holes on the rails are elongated vertically,

allowing precise adjustment of the position of the rails with

respect to the scanner. The rails have a set of horizontal holes

that can be used to position the rails forward or backward with

respect to the scanner.

Attaching the guide rails to the scanner

Depending on the type of computer, it may take several tries to

find the best combination of holes on the scanner and rails for

optimal mounting. The face of the scanner has to fit flush with

other peripherals in the drive bays as well as the face of the

computer. In addition, the scanner must slide into the drive bay

without touching any other devices, or the drive bay itself. It

should sit so that the cutout in the computer front panel aligns

with the front of the scanner.

Several attempts may be required to align the scanner in the

computer drive bay. It is often easiest to identify the best holes

while holding the scanner and rails in front of the drive bay.

Choose the position that looks best, then screw the rails into

the side of the scanner loosely and attempt to push the scanner

into the bay. If it fits, remove the scanner, tighten the screws

and continue with the installation. If not, move the rails with

respect to the scanner and try again until it fits.

Sliding the scanner into the drive bay

Before the scanner is inserted into the drive bay, insure that the

DIP switch block is set correctly. In rare cases, it may be

necessary to change the configuration of the DIP switch block.

On no account force the scanner into the drive bay. It

should have a snug fit, yet it should not be necessary to

apply excessive force when pushing in the scanner. If it

does not slide in easily, reposition the guide rails or

visually check the drive bay to see what might be blocking

the path of the scanner.

- 30 -

Page 31

Installing the internal-mount scanner in the

drive bay

Step 1—Connect the SCSI cable to the scanner

Connect one end of the flat 50-pin SCSI cable to the 50-pin

SCSI connector on the rear of the internal-mount scanner as

shown below. Insure that Pin 1 of the cable is aligned with Pin

1 of the scanner.

SCSI connector

SCSI flat cable

The connectors on both the scanner and the cable are

protected with a protruding tab to force the connector to

mount properly. Note that Pin 1 on the scanner connector and

the cable connector is marked with a triangle, and the wire

associated with Pin 1 has a red stripe on it. Do not force the

cable connector into the scanner. It should snap into place with

moderate force. Make sure that the connector on the cable is

positioned parallel to the connector on the scanner before

applying force. This will reduce the risk of bending any pins.

Warning! Make sure that Pin 1 marked on the scanner

connector mates with Pin 1 of the flat cable connector.

Step 2—Terminating the SCSI chain

The internal-mount scanner needs SCSI termination. Refer to

“5.4 Terminating the SCSI chain” in this chapter for more

information.

Step 3—Loosen the lock down screws

On one or both sides of the drive bay opening are locking

screws. These may be positioned so that they block the access

to the openings in the drive bay where the rails will slide in.

Loosen these screws so that the metal tab does not block

access to the openings. It may be necessary to remove these

tabs. Keep them handy because they will be repositioned in

Step 8 below.

- 31 -

Page 32

Step 4—Feed the computer power connector

Feed the computer power 4-pin connector, through the drive

bay from the inside as far as it will extend out through the drive

bay. Connect the cords with each 12V DC or 5V DC

connector.

Computer power connector

(Typical connector on four wire

cable)

Note: When you establish a ground, connect a grounding

cable (not provided) to the GND screw.

GND screw

Step 5—Slide the scanner part way into the drive bay

Thread the unconnected end of the 50-pin SCSI cable through

the drive bay and pull it through into the inside of the computer

while sliding the scanner rear-first into the drive bay. The

scanner should slide in easily if the rails are properly positioned.

Push the scanner in so that the rear of the scanner aligns with

the computer power connector.

Y-Adapter power connector

(Optional Y-type power connector)

Warning!

The top or bottom of the scanner should not touch anything

when sliding into the computer. Damage can occur to the

scanner or to other devices if the scanner scrapes during

installation.

- 32 -

Page 33

Step 6—Connect the power connector

Connect the 4-pin power connector of the computer to the 4pin power connector of the scanner. Note that both

connectors are keyed so that one side of the connector is

beveled. Be careful to insure that the beveled edges are

properly aligned. Under certain circumstances, it is possible to

force the connector in at an improper angle, thereby creating a

reversed connection. Extreme damage can occur to the

scanner should this happen. Make sure that the connection is

correct.

Note: An optional Y-adapter may be necessary if there are no

available power connectors in the computer.

Warning! Do not attempt to connect power to the scanner

with the computer power on.

5.3 Setting the SCSI ID

Up to eight devices can share a SCSI host. These are each

identified by SCSI ID numbers. Thus, a SCSI ID can have a

value between 0 and 7. There are no implicit regulations

regarding the use of these numbers. Typically, the computer

itself would be SCSI ID number 7, while the SCSI peripherals

would be 0 through 6.

A minimum of two devices must be connected to any SCSI bus.

In this case, one is designated as the initiator while the other is

the target. It is possible to have many configurations of initiators

and targets on a bus. More than one initiator can be present

on a SCSI bus. The typical configuration is one initiator and one

or more targets. The internal-mount scanner is always a target.

In the case we show below, the only initiator is the computer.

Step 7—Slide the scanner into the computer

Once the power connection is made, carefully slide the scanner

the rest of the way into the computer. Pull gently on the SCSI

cable with one hand to provide slight tension on the cable while

the scanner is being pushed in. Do not tug on the cable or

allow the cable to fold while pushing in the scanner.

Step 8—Screw down the rail stops

Once the scanner has been pushed into the computer,

reposition or reinsert the lock tabs mentioned in Step 3 above.

The tabs should slide in front of the scanner guide rails, thereby

locking the scanner in place.

The SCSI ID is typically set by a switch on the rear of the SCSI

peripherals. The default SCSI ID number set at the factory is ID

#5.

- 33 -

Page 34

Determining which ID to use

Remarks

If the scanner is the only SCSI device that will be connected to

the SCSI bus, there is no need to change the SCSI ID from the

preset value.

If the scanner must share the SCSI bus with one or more other

peripherals, it is necessary to insure that no two peripherals

have the same ID. Create a list of SCSI peripherals on the

desired bus, noting the device type and the SCSI ID of that

device. To determine the SCSI ID of the other peripherals,

check the rear of each peripheral for some indication of the

SCSI ID of that device. If there is no indication of the ID

number, consult the peripheral’s user’s manual or call the

peripheral manufacturer to determine the SCSI ID setting.

• To change the ID, confirm that the computer power is off.

The ID cannot be changed when the power is on.

• As 0 and 7 have been generally assigned to the computer

system, any number from 1 to 6 is recommended for the ID

number.

• If conflicting ID numbers are assigned, the system might not

function, or important data on the hard disk might be

destroyed. It is therefore essential to check the ID numbers

carefully before connecting the COOLSCAN II.

If another SCSI peripheral shares the same SCSI ID as the

COOLSCAN II, change the SCSI ID of the COOLSCAN II to

an unused SCSI ID as indicated in the following sections.

- 34 -

Page 35

Setting the SCSI ID on the Internal Scanner

The SCSI ID is set by a set of DIP switches on the back of the

internal-mount scanner as shown below. In most cases, these

DIP switches will not be changed.

Factory default for

COOLSCAN II

If it is necessary to change the default SCSI ID, change the

position of the DIP switches to the proper SCSI ID. Refer to

Table 5.2 for the proper DIP switch values. When changing the

position of the switches, use a pointed instrument to toggle the

switch. Use of a pen or pencil is not recommended, since these

will leave a mark on the switch and make it difficult to

differentiate between the “on” and “off” positions.

SCSI ID DIP #1 DIP #2 DIP #3

0 Open Open Open

1 Closed Open Open

2 Open Closed Open

3 Closed Closed Open

4 Open Open Closed

5 Closed Open Closed

6 Open Closed Closed

7 Closed Closed Closed

Table 5.2 SCSI ID DIP switch values

- 35 -

Page 36

5.4 Terminating the SCSI Chain

The SCSI chain is an electrical bus connecting two or more

devices. It is critical that this bus be correctly terminated for the

SCSI peripherals to work properly.

Termination is an electronics term that applies to the

impedance found at both ends of the bus. The electrical signals

on the SCSI bus are changing rapidly between their digital “on”

and “off” states. To minimize noise, a terminator is placed on

each end of the bus. The effects of this termination may be

subtle, but are critical to the correct operation of the scanner

on bus.

Typically, the computer is located at one end of the SCSI bus.

Assuming this is the case, the SCSI controller in the computer

has to be terminated.

Warning! Incorrect SCSI termination can cause unpredictable

errors.

If one other SCSI peripheral shares this SCSI bus, it also has to

be terminated. If additional SCSI devices are connected to the

bus between the two end SCSI devices, these devices can NOT

be terminated. Only two terminated devices can reside on the

SCSI bus, one at each end.

Improperly terminated SCSI peripherals can fail immediately or

may work correctly for a period of time before generating their

first errors.

Terminating the Internal-mount Scanner

If the LS-20 is at the end of the chain, attach the provided SCSI

terminator as described below.

The SCSI terminator is usually inserted between the SCSI

connector on the LS-20 and the provided SCSI flat cable, as

shown below.

Insert terminator

between these connectors

- 36 -

Page 37

Remarks

• When connecting the terminator to the scanner, insert it

straight, and correctly aligned with the locator key, taking

care not to bend the pins.

• When removing the terminator from the scanner, pull it

straight out, taking care not to bend the pins.

If there is not enough space to connect the terminator directory

to the LS-20, the SCSI connector on the LS-20 should be

attached to the connector stamped in the center of a daisychaining flat cable (not provided), and the provided SCSI

terminator should be attached to the unconnected stamped

connector at one end of this cable.

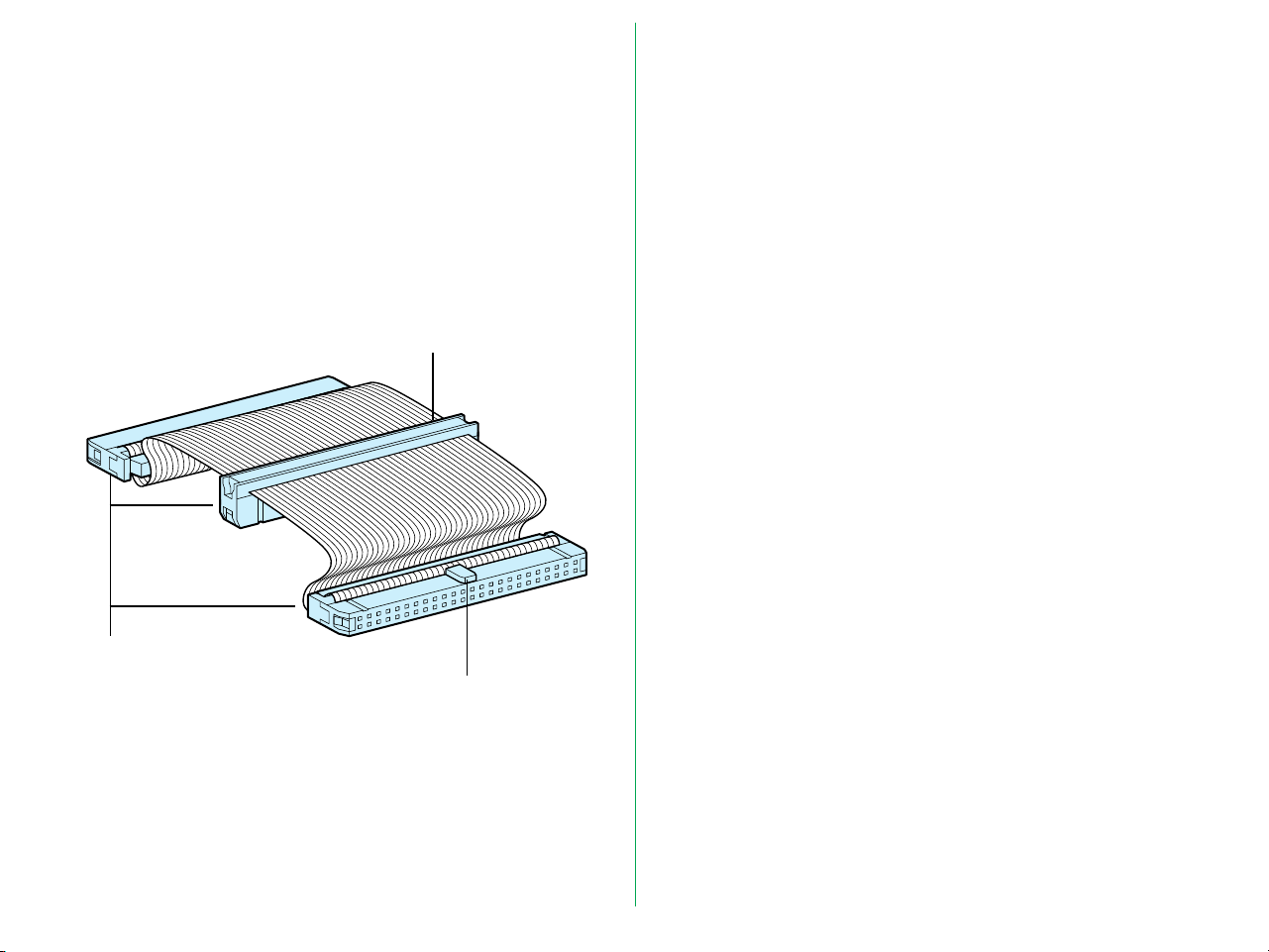

5.5 SCSI Cables Used with Internal Scanners

The internal SCSI cable is a 50-pin flat cable with two identical

molded connectors on each end. One end of this cable will

connect to the SCSI controller while the other end will connect

to the connector on the rear of the internal-mount scanner. A

typical SCSI internal cable is shown below.

SCSI flat cable

SCSI 50-pin connectors

- 37 -

Connector protection key

Page 38

5.6 Connecting to the Computer SCSI

The SCSI port on the computer is a connector located either

inside the computer or on the rear panel of the computer.

There are three basic types of SCSI connectors dealt with in

this manual: the 50-pin internal connector, standard 25-pin

DB25 type connector, and 50-pin external Centronics

connector.

Warning! The SCSI connector should never be connected or

disconnected while the computer is running.

Connecting inside the computer

The SCSI connector inside the computer will be a 50-pin flat

connector as shown below. Note the position of pin 1 and the

key. A wide variety of 50-pin flat connectors are used. Some

may have keys while others do not; some may have Pin 1

clearly marked while others will not; and some may have

mechanical levers to assist in inserting and removing the

connector.

To remove connector: Pry the flat cable

connector out gently with a small, flat- bladed

screwdriver

SCSI connector

- 38 -

Circuit card

SCSI flat cable

Page 39

Care must be exercised when inserting and removing these 50pin connectors. The connecting pins are rather fragile. Follow

the rules below when handling these connectors.

5.7 Setting Up a SCSI Chain with the Scanner

1. Never force the connector in and out.

2. Make sure that the connectors are properly aligned before

inserting.

3. Do not remove a connector from the socket by pulling on

the cable. Instead use a small screwdriver to pry each of

the sides out, a little at a time.

This connector is similar to the connector on the back of the

internal-mount scanner.

The internal-mount scanner is equipped with one SCSI 50-pin

connector. When the scanner is connected as the only other

device on the chain, or as the last device on the chain, the

connector of the 50-pin cable will end at the scanner. This case

is shown below.

Computer internal SCSI

termination set

Computer SCSI

controller

Computer SCSI

connector

- 39 -

Scanner

Insert terminator between

these connectors

SCSI cable

Page 40

Typically, the scanner will be the only peripheral on the internal

SCSI bus. If this is the case, the 50-pin cable provided will work.

In some cases, the scanner will not be the only peripheral on

the internal SCSI bus. When this occurs, the SCSI cable

provided will not work. A special cable with a connector

stamped in the center of the cable as well as a connector

stamped on both ends of the cable will be required. This

special cable is shown below.

SCSI flat cable (not provided)

SCSI 50-pin connectors

Connector orientation key

- 40 -

Page 41

6. Operation

6.1 Turning on the Power

Turn the COOLSCAN II on first, the other SCSI devices next,

and the host computer last. If your scanner is the internalmount model, you need not turn the COOLSCAN II on.

After turning the power on, the LED will begin to blink to

indicate scanner initialization.

POWER ON

The scanner is self-calibrating. A calibration procedure occurs

automatically during power-up. This procedure typically takes

about twenty seconds.

Remarks

• To turn the COOLSCAN II power off, turn the host

computer off first, the other SCSI devices next, and the

COOLSCAN II last (reverse order from switching on).

• Once the power is turned off, please wait five seconds or

more before turning the power on again.

• Do not turn the power off while the scanner is scanning.

• Make sure there is no strip film holder in the scanner during

power-up, or the scanner will not calibrate correctly.

Due to the patented light source, there is no warm up time

necessary for the scanner. Once the scanner has performed its

power-on calibration, it is ready to go.

- 41 -

Page 42

6.2 Film Insertion

The COOLSCAN II can scan different types of 35mm positive/

negative monochrome/color images. In addition, it can scan a

film strip of up to 6 frames or single film ‘chips’.

Insertion of Mounted slides

The COOLSCAN II can scan mounted slides as they are.

• Confirm that the thickness of the mounted slides to be

scanned is between 1.1mm and 3.0mm.

• Ensure that the emulsion surface is facing up.

When the scanner is installed vertically, insert the mounted

slide so that the emulsion surface is facing toward the right

(shiny surface facing left).

When the scanner is installed horizontally, insert the

mounted slide so that the emulsion surface is facing

downward (shiny surface facing upward).

* All film has an emulsion surface and a base surface. The

emulsion surface is slightly dull and concave. The base

surface is slightly convex and is shinier than the emulsion

surface.

Insert the mounted slide lengthways until it touches the back of

the scanning stage.

Note: Do not insert the mounted slide so that the width and

length of the mount are reversed. If you do so, the COOLSCAN II

will not be able to scan both sides of the mounted slide.

- 42 -

Page 43

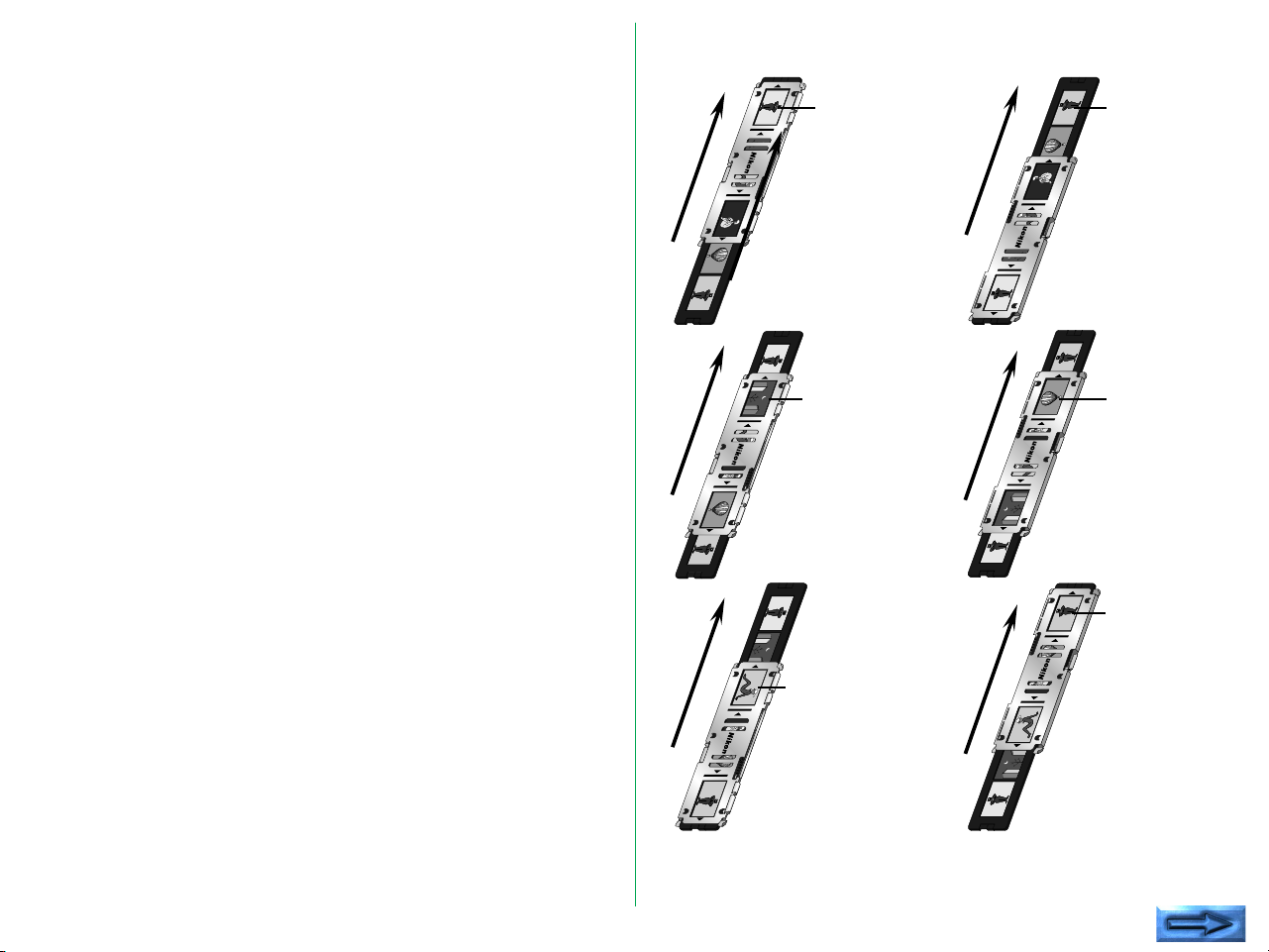

The standard orientation of a mounted portrait or landscape

slide is shown below. If the top and bottom are reversed, the

image can be flipped using software.

Orientation of a portrait slide

Orientation of a landscape slide

- 43 -

Page 44

Insertion of Film Strip

Step 2

Insert the film strip into the attached film holder FH-2, and then

insert the holder into the film slot of the front panel of the unit.

Step 1

Remove the cover latch and open the upper holder. Be sure

the word Nikon, printed on the adaptor cover of the upper

holder is facing upward.

Upper holder

Adaptor cover

Cover latch

Place the film strip on the concave section which is fixed in the

adaptor of the lower holder. Be sure to place the film strip on

the lower holder so that the emulsion surface will be facing

down (the shiny surface will be facing up). The orientation is

correct if the image edge numbers can be read.

Aperture

Film strip

- 44 -

Lower holder

Page 45

Step 3

Step 4

Align each image of the strip film with an aperture in the lower

holder.

Close the upper holder, aligning both ends of the upper holder

and the lower holder.

Fasten the latches at both ends of the holder after securing the

adaptor cover and fastening the cover latch.

Holder latch

Cover latch

Holder latch

- 45 -

Page 46

Step 5

Align the image to be read with either of the two apertures in

the silver-colored adaptor frame.

Insert the film holder in the film slot of the front panel in the

scanner , with placing the aperture through which the image is

to be read toward the slot.

The film holder can be inserted into the COOLSCAN II from

either end. Decide the insertion direction of the film holder

according to which image is to be read.

The first

image will be

read.

The fourth

image will be

read.

- 46 -

The second

image will be

read.

The third

image will be

read.

The fifth

image will be

read.

The sixth

image will be

read.

Page 47

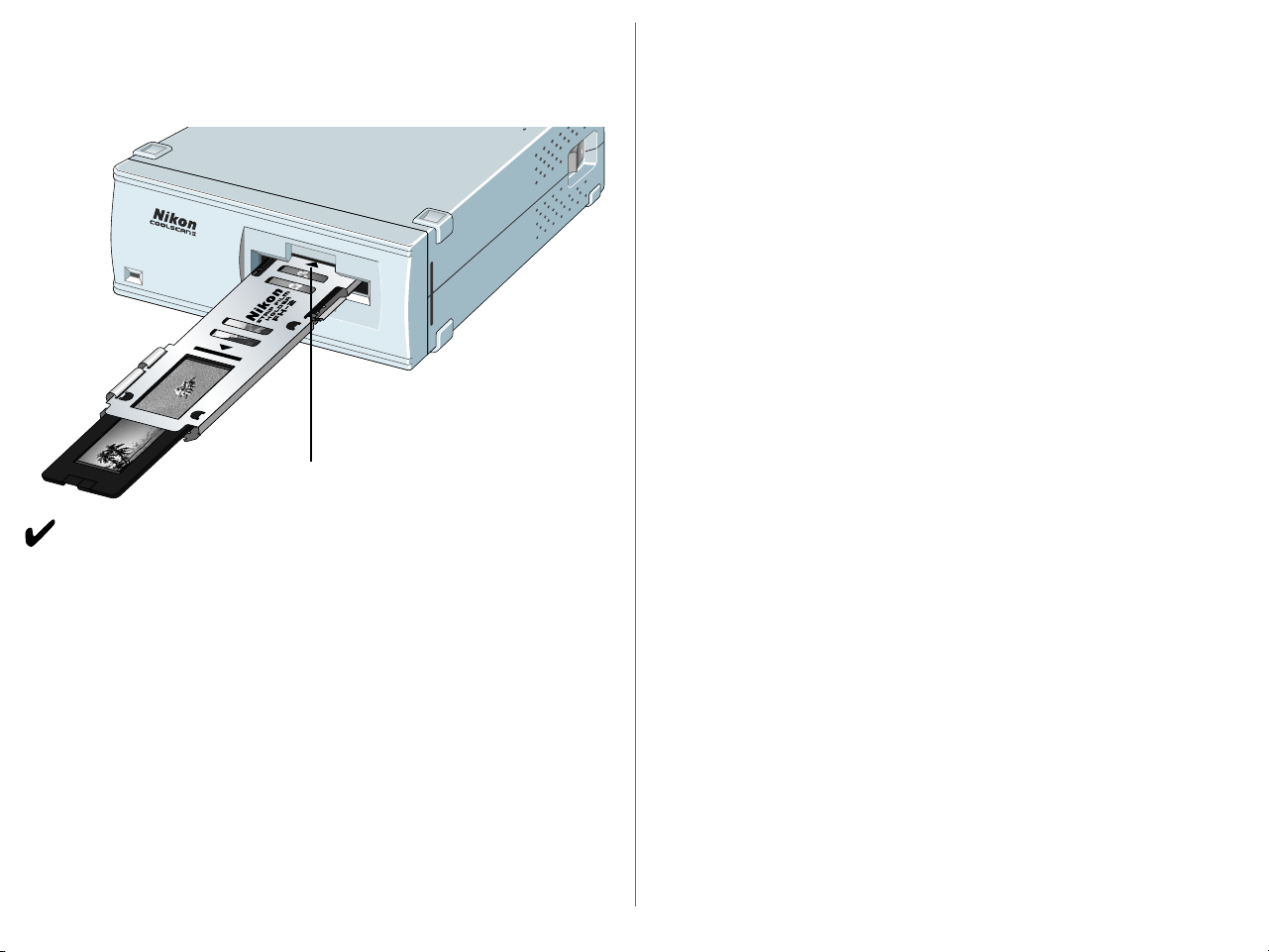

Step 6

Insert the film holder until it touches the back of the stage and

is aligned with the edge of film slot, as shown.

Mark

Remarks

• Do not force the film holder into the scanner.

• Though the film holder is made of plastic, it will be damaged

if film is forced into it.

• Remove dust on the film or film holder with a blower or

photographic brush.

• Insert the film holder slowly.

- 47 -

Page 48

7. Troubleshooting

If something unusual should occur, please check the following

items before you conclude that there is a unit failure. For more

details, refer to the Troubleshooting section of the software

manual.

Scanner cannot turned on.

• Is the Power cord connected?

Connect the Power cord.

• Is the power switch turned on?

Turn the power switch on.

Scanning cannot be performed.

• Is the SCSI cable connected?

Connect the SCSI cable.

• Are you using the supplied SCSI cable?

Use the supplied SCSI cable.

• Is the end of the connected SCSI cable terminated?

Connect the terminator.

• Are the numbers you have set for I/O, INT and DMA for

the SCSI board different from those for other boards? (For

Windows version)

Do not set the conflicting numbers.

• Does your system satisfy our recommended system

requirements?

Provide the recommended system described in the software

manual.

• Have you installed software?

For information on installing and operating software, refer to

the software manual provided with the unit.

• Have you properly set the configuration, such as

CONFIG.SYS ?

If you have installed applications for Windows, for instance,

note that the configuration may change automatically. (For

Windows version)

Poor image quality.

• Have you set the film properly?

Set the film properly.

• Is the SCSI ID number different from the SCSI ID of other

devices?

Change the ID number if it is duplicated.

• Are you using a recommended SCSI board ? (For Windows

version)

Use a recommended SCSI board.

• Can you see dust on the film?

Remove dust on the film with a blower or photographic

brush.

• Was the unit subjected to vibration during the scanning

operation?

Place the unit where it will not be subjected to vibration or

physical shocks.

• Are you using software properly?

For details, please refer to the manual for your software.

- 48 -

Page 49

Appendix: Specifications

Reading system/Optics

Film type: 35mm film (color or monochrome, negative

or positive)

Reading resolution:

2,592 x 3,888 pixels

Reading area: 24.3 x 36.5mm

Effective area: 23.4 x 35.4mm (with strip film holder)

Scanning/Signal processing

Image scanning (single pass):

Main scanning: 2,592-element CCD line

sensor

Sub-scanning: Moving film stage driven by

step motor

Scanning time: Prescan, Preview: Approx. 20 sec.

Actual scan: depends on the kind of interface,

resolution setting and film density (Approx.

80 sec. for 3-color within a 2,592 x 3,888pixel range with standard film)

Light source: RGB 3-color LED

Film holder: No holder needed for mounted slides.

Strip film holder FH-2 for strip film.

Image optics: High-resolution optics (Autofocus)

Focusing: Auto

Gradation: 256 gradations each for R, G and B

Resolution: 2,700 dpi

A/D conversion: 8 bit

Data Transmission

Interface: SCSI-2 compliant

Maximum transfer rate:

Approx. 2.66MB/sec with SCSI

- 49 -

Page 50

Others

Power requirements:

Standard model: AC 100 - 240V, 50/60Hz,

0.3 - 0.2A

Internal-mount model: DC 5V, 1.5A, DC

12V, 1.2A

Panel indicators:

READY, BUSY and ERROR states indicated

by LED

Temperature: 50˚F – 95˚F (10˚C – 35˚C)

Humidity: 20% – 85% (with no condensation)

Dimensions: Standard model: 6.0 (W) x 10.5 (D) x 2.5

(H) inches (151 x 267.5 x 63.3mm)

Internal-mount model: 6.0 (W) x 8.2 (D) x

1.7 (H) inches (148 x 210 x 42mm)

Weight: Standard model: Approx. 4.2lbs (1.9kg)

Internal-mount model: Approx. 2.0lbs (0.9kg)

- 50 -

Page 51

Index

A

AC inlet 18

Adaptor cover 44

Adaptor snap 20

B

Before use 15

C

Cleaning the unit 17

Components 15

Configuration DIP switch 19

Connecting the power cord

22

Connecting the SCSI cable

23

Connecting to external SCSI

38

Connecting to internal SCSI

38

D

Display LED 20

Drive bay 29

installing scanner in 30

F

Film, inserting 42

Film slot 18, 19

G

Guide rail mounting holes 30

Guide rails

attaching to scanner 30

installing 29

I

Internal-mount model 19

installing 28

SCSI cables for use with 37

M

Main unit 18

Mounting holes 30

N

Notes on use 17

O

Operating environment 14

P

Parts 18

Power connector 19

Power switch 18

S

SCSI

connecting scanner to an

SCSI chain 24, 39

determining which SCSI to

use 34

setting the internal

scanner's SCSI ID 35

setting the SCSI DIP switches

35

setting the SCSI ID 26, 33

terminating the internally

mounted model 36

termination 36

SCSI connector 18, 19

SCSI ID switch 18

Set up 21, 27

Slides

mounted, inserting 42

orientation of landscape

slides 43

orientation of portrait slides

43

Specifications 49

Standard model 18

Status display LED 18, 19

Strip Film Holder FH-2 20

upper holder 44

Strip film, inserting 44

T

Troubleshooting 48

Turning on 41

V

Ventilation holes 18

- 51 -

Page 52

EC DECLARATION OF CONFORMITY

We

Name: Nikon UK Limited

Address: Nikon House, 380 Richmond Road, Kingston, Surrey KT2

5PR, UK

declare that the product

Product Name: Nikon 35mm Film Scanner LS-20E/LS-20I

Manufacturer’s Name: Nikon Corporation

Manufacturer’s Address: Fuji Bldg., 2-3, Marunouchi 3-chome, Chiyoda-ku, Tokyo

100, Japan

is in conformity with the following Standards

EN55022 Class B

EN50082-1

IEC801-2: 1991 4kV

IEC801-3: 1984 3V/m

IEC801-4: 1988 1kV AC, 0.5kV I/O

following the provisions of the EMC Directive (89/336/EEC)

DECLARATION DE CONFORMITE DE LA CEE

Nous

Nom: Nikon UK Limited

Adresse: Nikon House, 380 Richmond Road, Kingston, Surrey KT2

5PR, UK

déclarons que ce produit

Nom du produit: Nikon 35mm Film Scanner LS-20E/LS-20I

Nom du fabricant: Nikon Corporation

Adresse du fabricant: Fuji Bldg., 2-3, Marunouchi 3-chome, Chiyoda-ku, Tokyo

100, Japan

est conforme aux normes suivantes

EN55022 Classe B

EN50082-1

IEC801-2: 1991 4kV

IEC801-3: 1984 3V/m

IEC801-4: 1988 1kV AC, 0.5kV I/O

selon les dispositions de la directive de la CEE (89/336/EEC)

ERKLÄRUNG ÜBER EG-NORMENGERECHTHEIT

Wir

Name: Nikon UK Limited

Anschrift: Nikon House, 380 Richmond Road, Kingston, Surrey KT2

5PR, UK

erklären hiermit, daß das folgende Produkt

Produktbezeichnung: Nikon 35mm Filmscanner LS-20E/LS-20I

Name des Herstellers: Nikon Corporation

Anschrift des Herstellers: Fuji Bldg., 2-3, Marunouchi 3-chome, Chiyoda-ku, Tokyo

100, Japan

den nachstehend aufgeführten Normen genügt:

EN55022 Klasse B

EN50082-1

IEC801-2: 1991 4kV

IEC801-3: 1984 3V/m

IEC801-4: 1988 1kV AC, 0.5kV I/O

und zwar gemäß den Bestimmungen der EMC-Richtlinie (89/336/EEC)

Kingston, UK September 30, 1995

Place Date Signature/Managing Director

Lieu Date Signature/Directeur général

Ort Datum Unterschrift/Geschäftsführer

- 52 -

Loading...

Loading...