Nikon AF-S DX NIKKOR 55-200mm Repair manual

作成承認印 配布許可印

M

サービス

計画課

INC

AF-S DX Nikkor

ED 55-200/4-5.6G

JAA79351-R.3670.A

JAA79351

JAA79301

REPAIR MANUAL

Black

Silver

Printed in Japan May 2005

Copyrighc2005 by Nikon Corporation.

All Rights Reserved.

無断転載を禁ず

!!

JAA79351-R.3670.A

INC

Specications

Type of lens: G-type AF-S DX Zoom-Nikkor lens with built-in CPU and Nikon bayonet

mount (Specially designed for use with Nikon digital SLR – Nikon DX

format – cameras)

Focal length: 55mm–200mm

Maximum aperture: f/4–5.6

Lens construction: 13 elements in 9 groups (2 ED lens elements)

Picture angle: 28°50’–8°

Focal length scale: 55, 70, 85, 105, 135, 200mm

Distance information: Output to camera body

Zoom control: Manually via separate zoom ring

Focusing: Autofocus using a Silent Wave Motor; manually via separate focus ring

Closest focus distance: 0.95m (3.1 ft.) at all zoom settings

Diaphragm: Fully automatic

Aperture range: f/4 to f/22 (at 55mm), f/5.6 to f/32 (at 200mm)

Exposure measurement:Via full-aperture method

Attachment size: 52mm (P = 0.75mm)

Dimensions: Approx. 68mm dia. x 79mm extension from the camera’s lens-mount ange

Weight: Approx. 255g (9 oz)

・Specications and designs are subject to change without any notice or obligation on the part

- M1

・ AF-S DX 55-200/4-5.6G

-

JAA79351-R.3670.A

INC

Before Disassembly / Assembly / Adjustment ...

Note:

① When disassembling, make sure to memorize the processing state of wires and FPC.

② Because prototypes are used for "Disassembly/(Re)assembly/Adjustment", they may differ from the actual

products in forms, etc.

③ Because pictures are processed by a special method, they may differ from the actual ones in texture.

Points to notice for Lead-free solder products

・Lead-free solder is used for this product.

・For soldering work, the special solder and soldering iron are required.

・Do NOT mix up lead-free solder with traditional solder.

・Use the special soldering iron respectively for lead-free solder and lead solder.

They cannot be used in common.

- D1・AF-S DX55-200/4-5.6G

1. Disassembly

INC

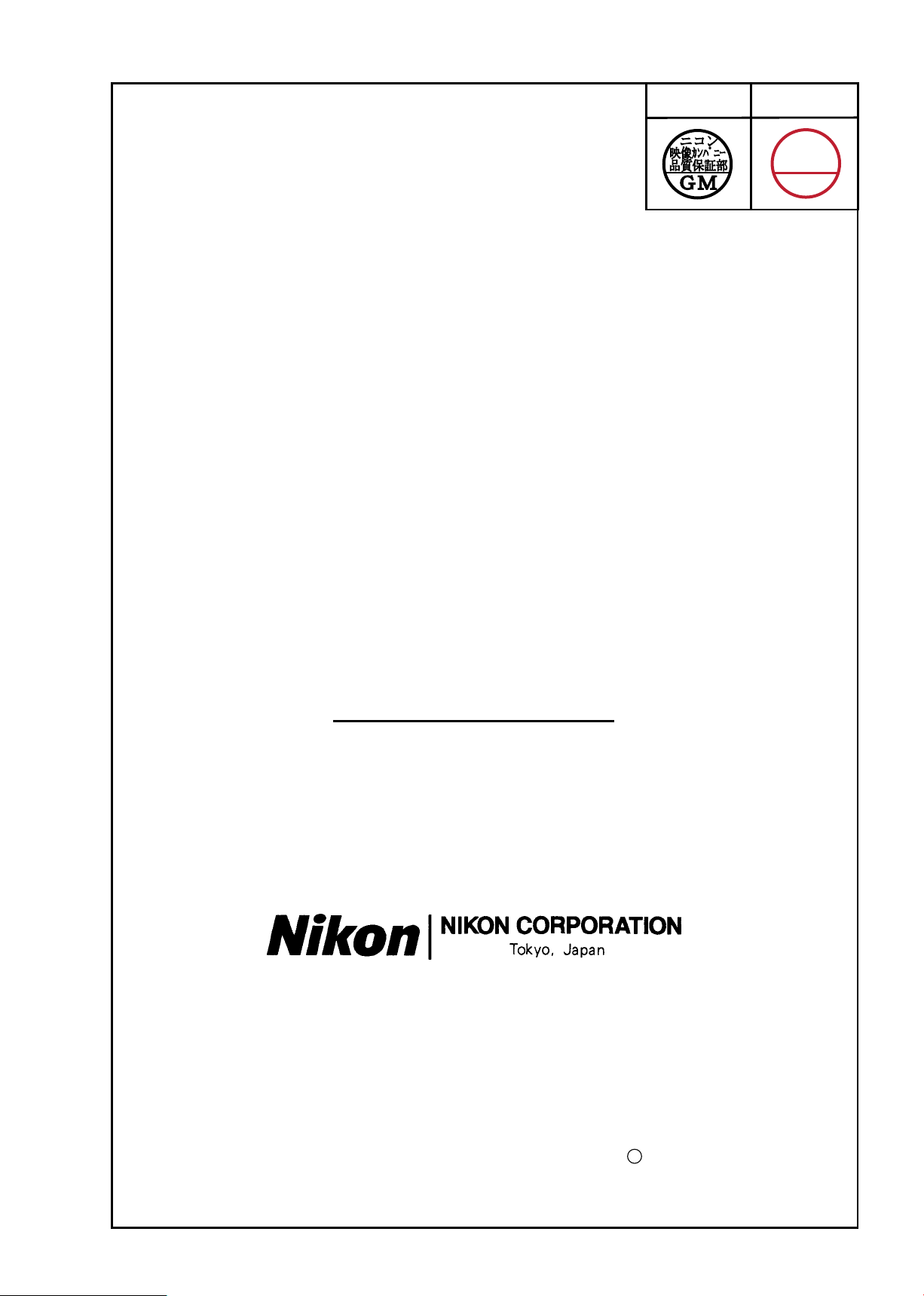

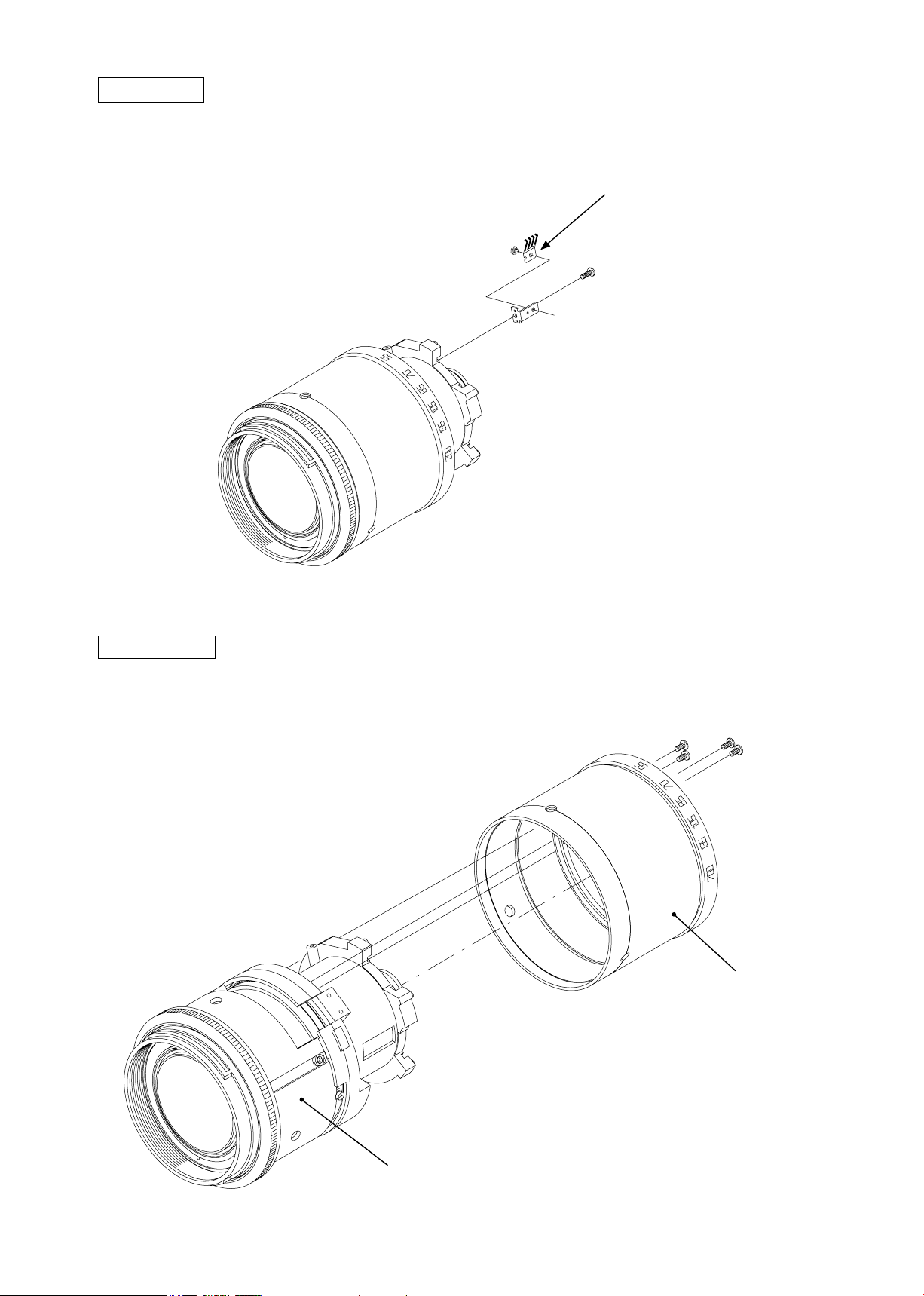

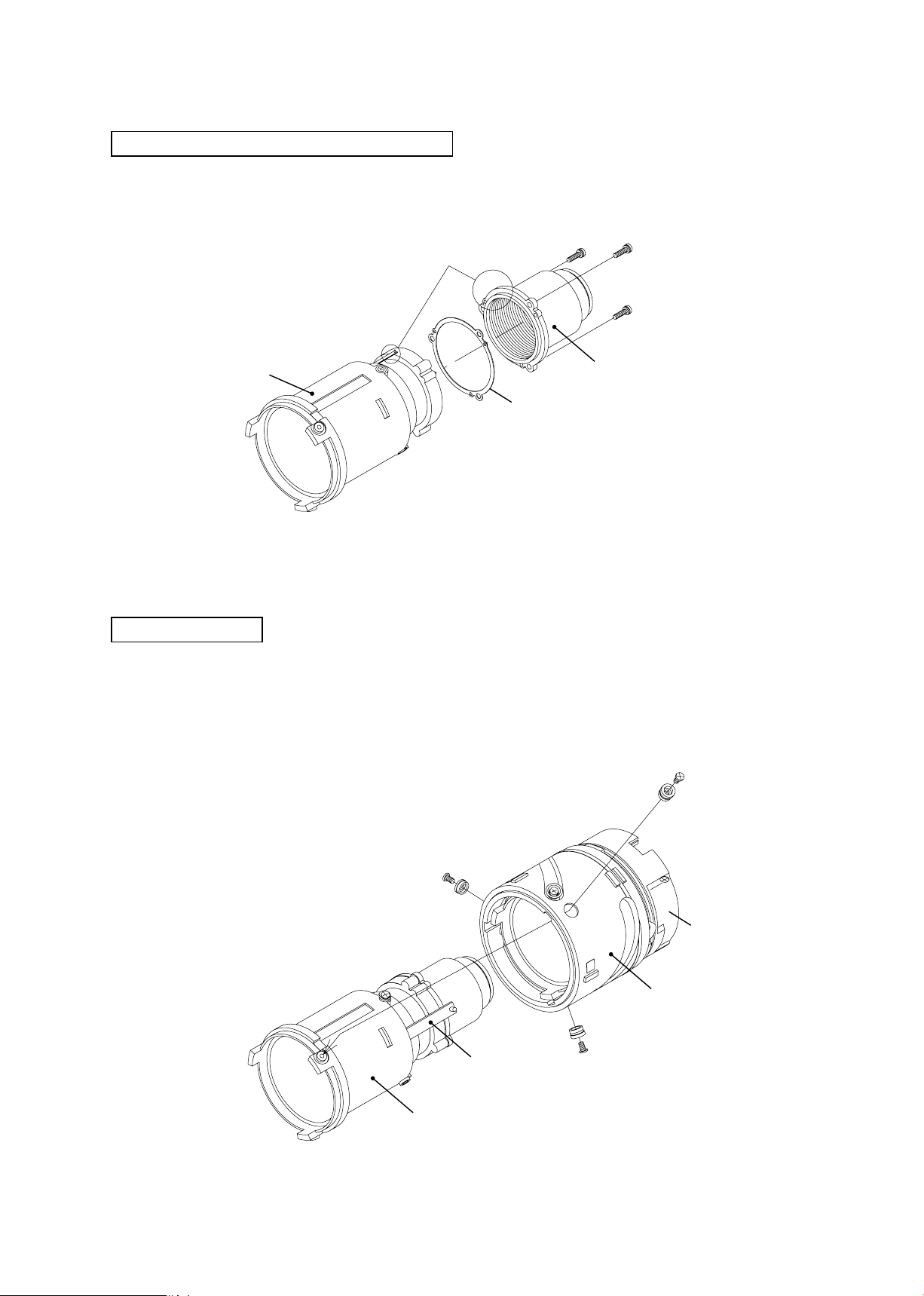

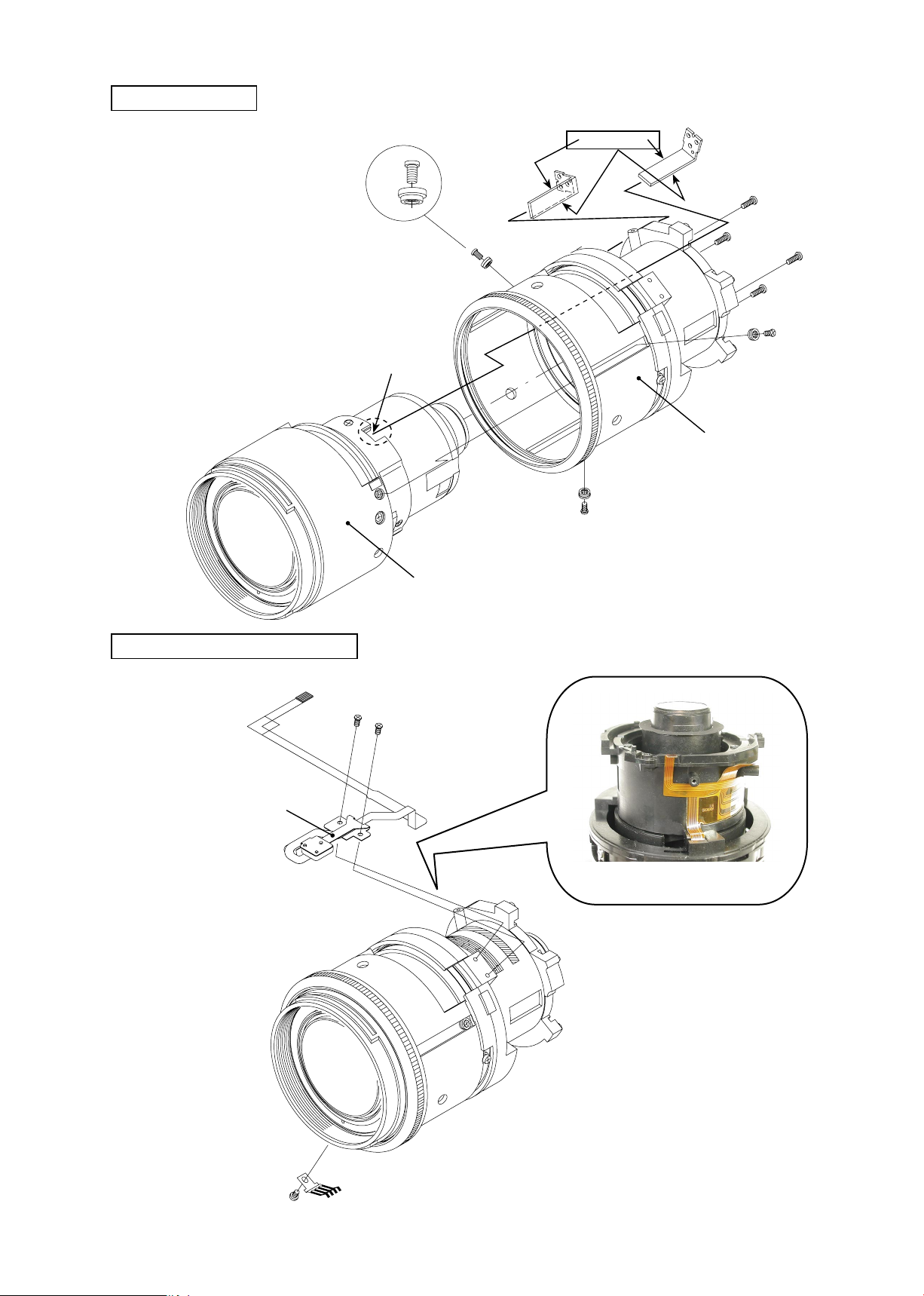

Rear cover ring

Take out 3 screws (#66) of the rear cover ring.

・

Take out 2 screws (#65) of AF contact unit.

・

#65×2

JAA79351-R.3670.A

Rear cover ring

Light-shielding plate / Rubber ring

#66×3

Light-shielding plate

Lens body

- D2・AF-S DX55-200/4-5.6G

JAA79351-R.3670.A

INC

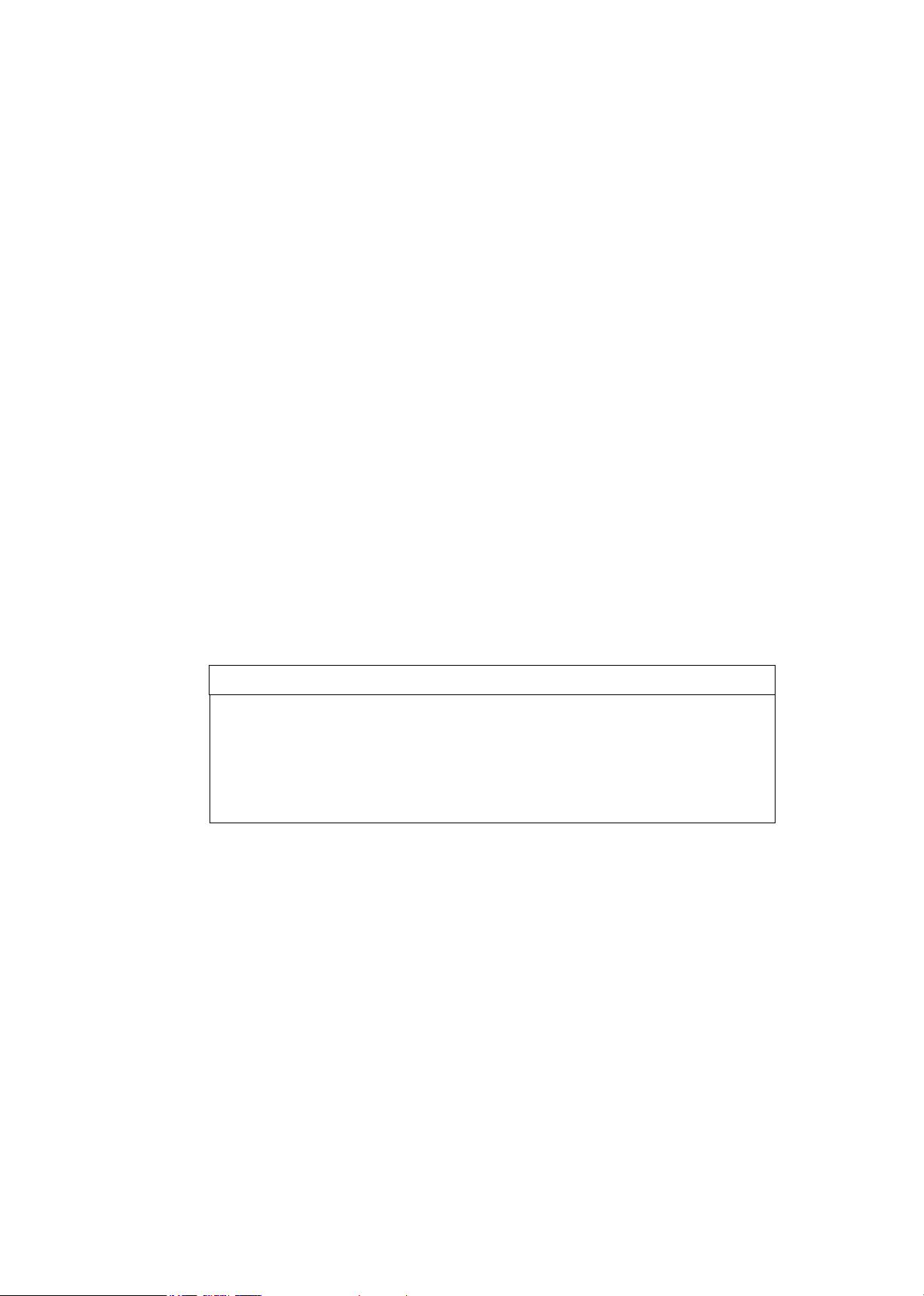

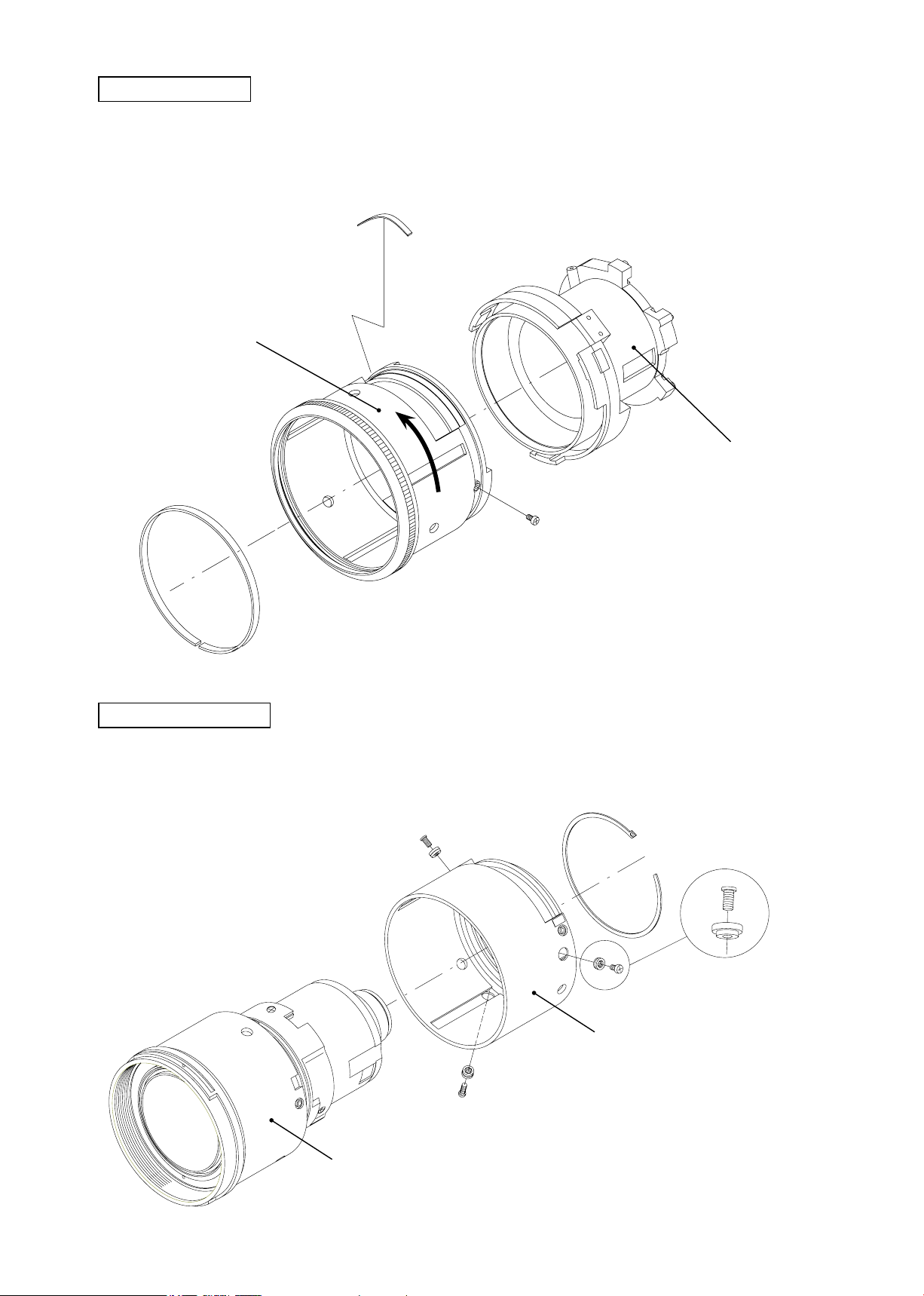

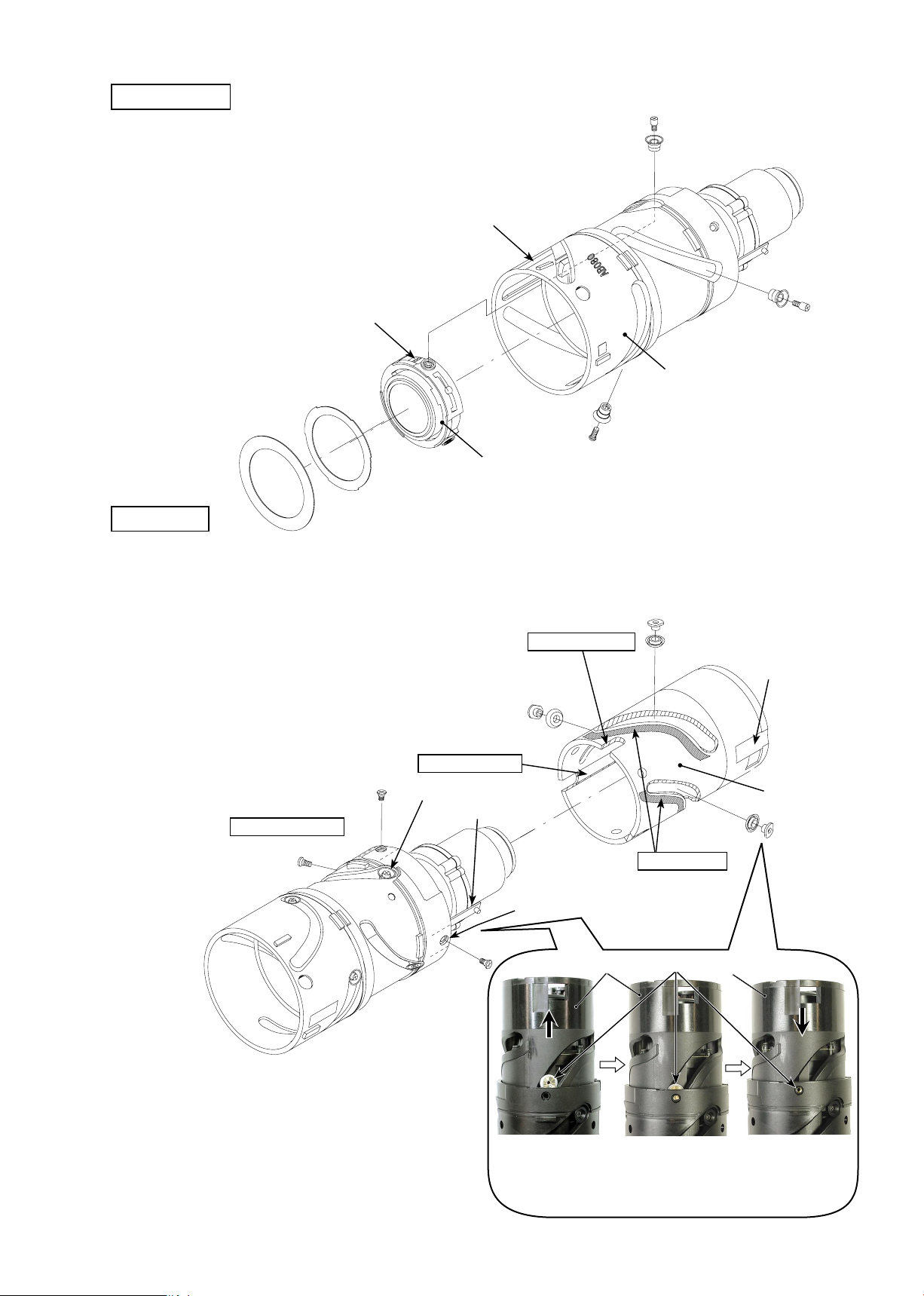

Index ring / Mount unit

Take out 3 screws (#64).

・

Slacken the mount unit a little. Then remove the GND wire (of the main PCB) from the GND terminal (of the

・

mount unit).

Remove the mount and washer (#62) from the lens body.

・

Set the change-SW to A mode.

・

Take out the screw (#59) and the A/M change SW comes off by sliding it slightly in the direction of the arrow.

・

Pass the change SW unit through the hole of the index ring, and remove the index ring.

・

Index ring

Mount unit

#64×3

#62

Aperture coupling lever

Contact socket

#59

Change-SW

Lens body

- D3・AF-S DX55-200/4-5.6G

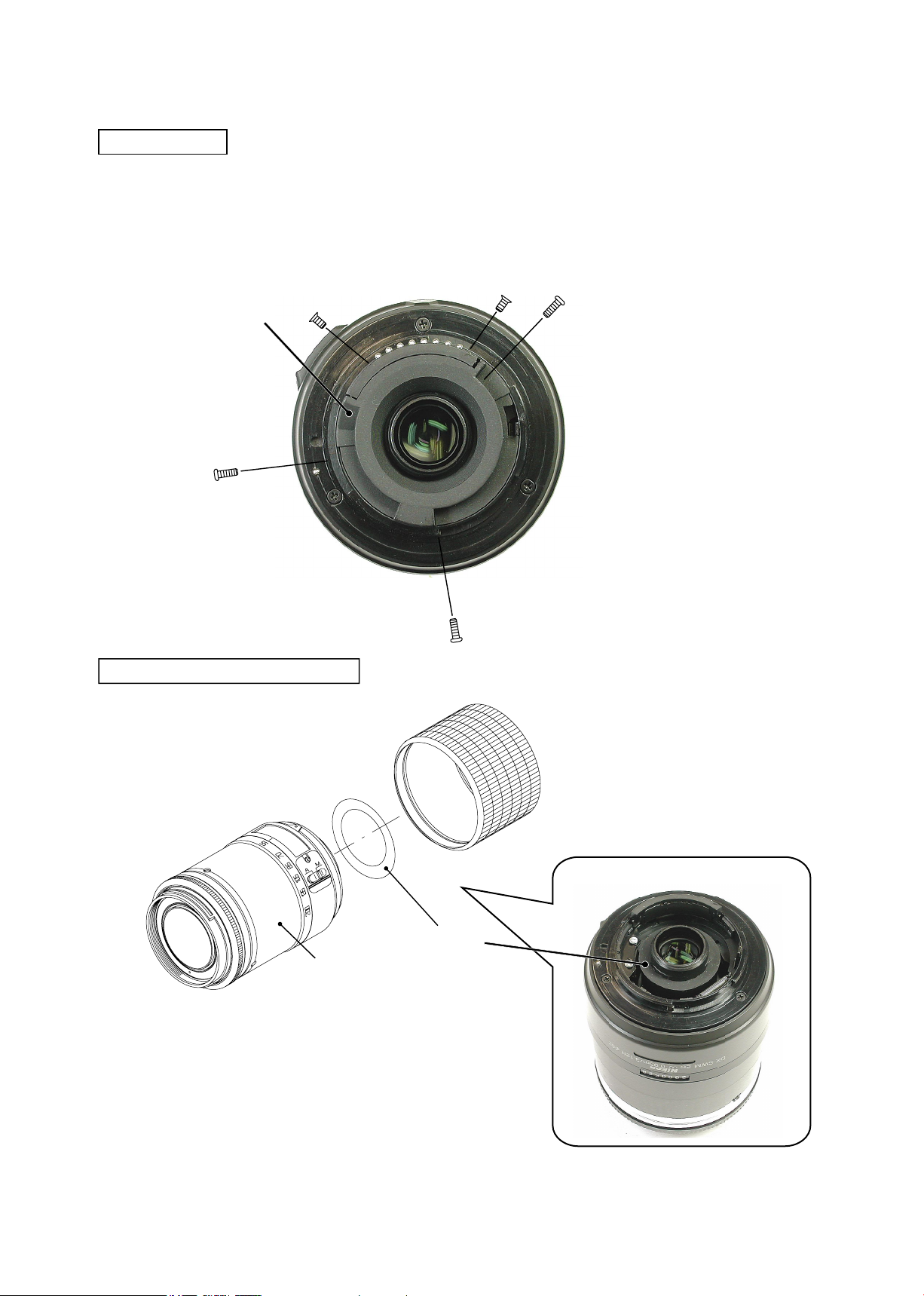

Main PCB

INC

Remove the FPC of the SWM motor from the connector.

・

Disconnect each FPC of the MR sensor, AF contact, and zoom encoder from each connector.

・

Take out 3 screws (#73).

・

Remove the main PCB from the lens body.

・

JAA79351-R.3670.A

MR sensor FPC

SWM unit

AF contact FPC

Screw (#73)×2

Zoom encoder FPC

Red

White

Change SW

SWM FPC

Screw (#73)

Take out the screws (#47-1 and #47-2), and remove the SWM unit.

・

Note: Do NOT touch A part directly with hand.

- D4・AF-S DX55-200/4-5.6G

SWM unit

#47-1

A part

#46-2

#47-2

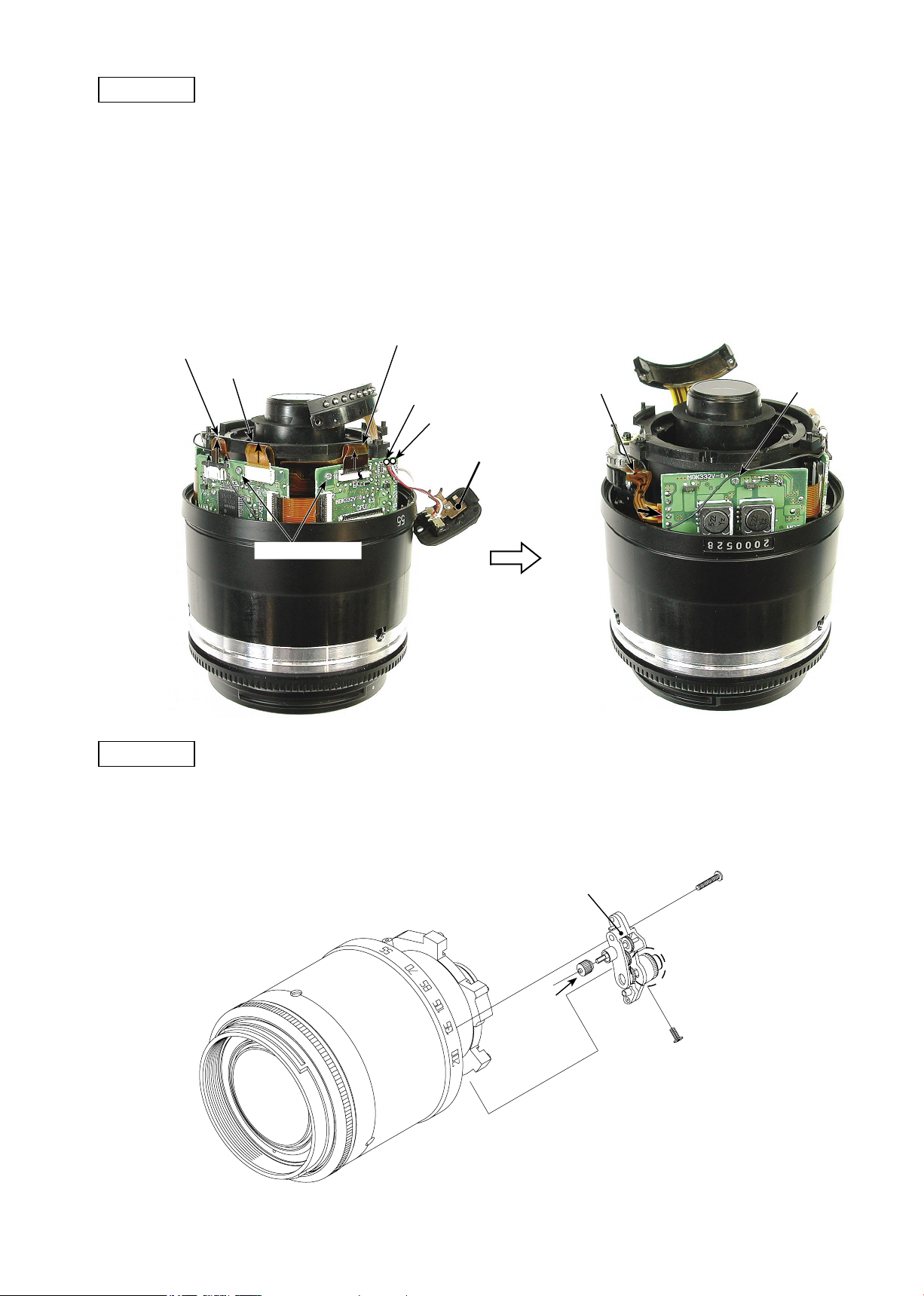

Zoom brush

INC

Take out the screw (#53) to remove the zoom brush.

・

JAA79351-R.3670.A

Zoom brush

#55

#53

#52

Zoom ring

Take out 4 screws (#51) to remove the zoom ring unit.

・

#51×4

Zoom ring unit

Lens body

- D5・AF-S DX55-200/4-5.6G

AF contact unit

INC

Remove the AF contact unit, which is attached with the both-sided adhesive tape.

・

AF contact unit

JAA79351-R.3670.A

MR sensor unit

Take out 2 screws (#75) to remove the MR sensor unit.

・

Take out the screw (#39) to remove the focus brush.

・

#75×2

MR sensor unit

#39

Focus brush

- D6・AF-S DX55-200/4-5.6G

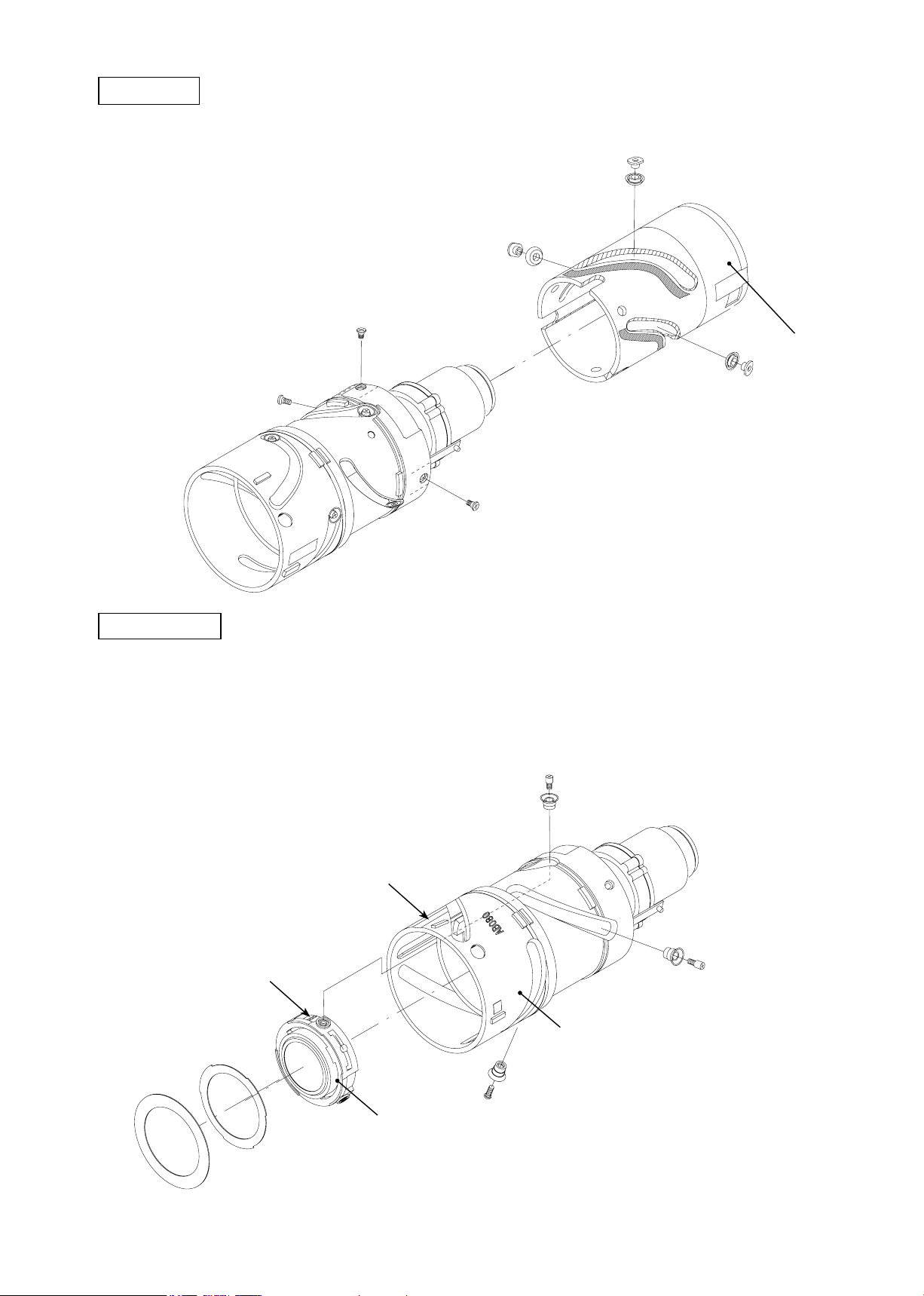

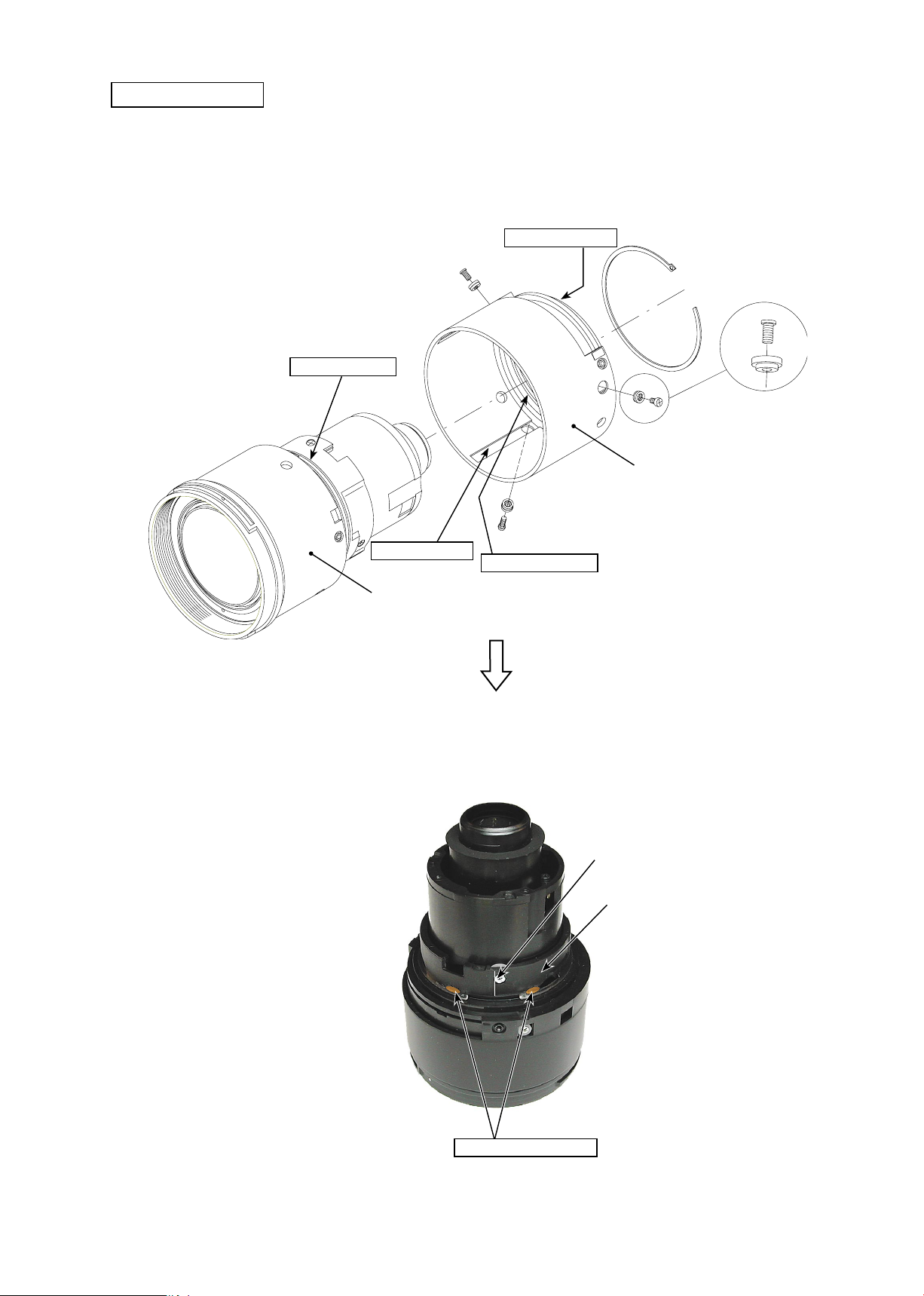

Mid-lens barrel unit

INC

Take out 3 screws (#41) and 3 collars (#40).

・

Take out 4 screws (#45) to remove the mid-lens barrel unit from the lens body.

・

2 keys (#48) come off at the same time.

・

#41

#40

JAA79351-R.3670.A

#48×2

#45×4

Lens body

Mid-lens barrel unit

#40×3

#41×3

- D7・AF-S DX55-200/4-5.6G

Focus gear ring unit

INC

Remove the stopper screw (#42).

・

Viewed from the object, turn the focus gear ring counterclockwise a little to remove it.

・

The friction spring (#70) comes off.

・

#70

Focus gear ring

JAA79351-R.3670.A

Mid-lens barrel unit

Object side

Focus coupling ring

Take out 3 screws (#34) and 3 collars (#33).

・

Remove the stopper ring (#35) to detach the focus coupling ring.

・

#34×3

#33×3

#42

#35

#34

#33

Focus coupling ring

Lens body

- D8・AF-S DX55-200/4-5.6G

JAA79351-R.3670.A

INC

1st lens group

Turning the 1st lens-group sliding ring and focus ring each in the direction of the arrow, and remove them

・

from the lens body.

1st lens-group sliding

ring

Focus ring

- D9・AF-S DX55-200/4-5.6G

Lens body

Fixed tube

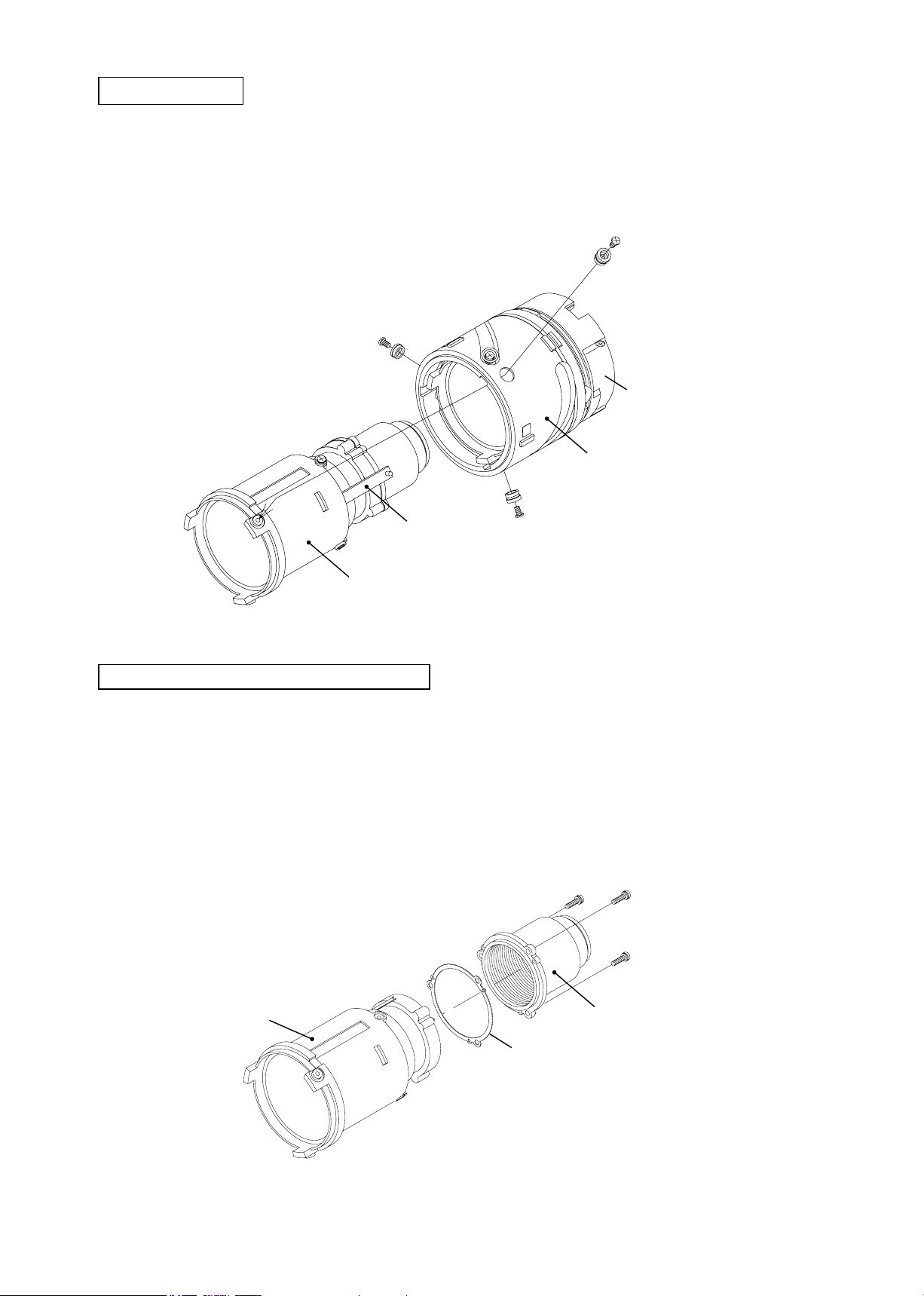

INC

Take out 3 screws (#28).

・

Remove 3 cam-tube guide axles (#31) and 3 cam-tube guide

・

collars (#30).

Remove the xed tube (#29) from the lens body.

・

JAA79351-R.3670.A

#30×3

#31×3

#28×3

2nd lens group

Peel off the sheet (#8).

・

Remove 3 2nd lens-group collars (#20-6) and 3 screws (#20-7).

・

Remove the 2nd lens unit.

・

#29

Reference line

#8

#20-7×3

#20-6×3

Concave portion

Straight tube unit

2nd lens group

#9

- D10・AF-S DX55-200/4-5.6G

Straight tube unit

INC

Remove 3 3rd lens-group collars (#20-4) and 3 screws (#20-5).

・

The 3rd lens group and straight tube unit come off.

・

JAA79351-R.3670.A

#20-5×3

#20-4×3

Concave portion

Straight tube unit

3rd lens group

Removal of 3rd lens group and 4th lens group

Take out 3 screws (#19).

・

#17 and 4th lens group come off.

・

Aperture lever

The washer and spring-

・

washer are assembled in the

screw (#19).

#19×3

3rd lens group

4th lens group

#17

#15×3

#16×3

- D11・AF-S DX55-200/4-5.6G

2. Assembly / Adjustment

AB08

INC

Mounting of 4th lens group on 3rd lens group

JAA79351-R.3670.A

3rd lens group

Straight tube unit

Align the letter of the 4th lens group

with the position of the aperture lever.

#17

#19×3

4th lens group

The washer and spring-

・

washer are assembled in the

screw (#19).

Align the concave portion of the straight tube unit with the position of the aperture lever of the 3rd lens group,

・

and assemble them. Then attach 3 3rd lens-group collars (#20-4) with 3 screws (#20-5).

#20-5×3

#20-4×3

Convex portion

Straight tube unit

Aperture lever

3rd lens group

- A1・ AF-S DX55-200/4-5.6G -

2nd lens group

INC

Align the reference line of the 2nd lens group with the

・

concave portion of the straight tube unit, and assemble

them. Then x with 3 collars (#20-6) and 3 screws

(#20-7).

Reference line

#9

Concave portion

JAA79351-R.3670.A

#20-7×3

#20-6×3

Straight tube unit

2nd lens group

Fixed tube

#8

Align the concave portion of the xed tube (#29) with the position of the aperture lever of the

①

lens body. Then assemble them so that 2nd lens G collars enter into the 3 U-grooves.

Put 3 cam-tube guide axles (#30) and 3 guide collars

②

(#31) through 3 grooves of the xed tube (#29), and

-groove× 3 locations

U

Grease: MZ-800S

#30×3

#31×3

insert them into the concave portions inside of the

lens body. (ref. Pic. 1)

Fix the 3 cam-tube guide collars (#30)

③

with 3 screws (#28).

Apply a little to upper half

around the tube.

Adhesive: EDB0011

#28×3

Vertical groove in the

inner diameter surface

×3 locations

Grease: MZ-800S

2nd lens G collar

Aperture lever

Concave portion inside

of the lens body

Grease: G92KA

Fitting 3 locations

Concave portion

#29

A

As shown "A", lift up #29 a little and insert #30. Then when it

is seated at "B" position, push #29 down into "C" position.

- A2・ AF-S DX55-200/4-5.6G -

#29

#30

Pic. 1

#29

B

C

JAA79351-R.3670.A

INC

1st lens group

Put the 1st lens-G adjusting washer (#3) and the 1st lens-group into the 1st lens-G sliding ring.

①

Attach 3 1st lens-G collars (#6) and 3 screws (#7) to the 1st lens-G sliding ring.

②

Set the straight tube of the lens body to WIDE side.

③

Viewed from the 1st lens group side, place the “PC-30” letters of the focus ring at the position of 10 o'clock,

④

: Newly prepared as RJ

★

by counting the index position of the 1st lens-G sliding ring as 12 o'clock.

Put the focus ring and 1st lens-G sliding ring in the place of Fig.1. Then align the convex portion of the lens

⑤

body with the concave portion of the focus ring to assemble them.

Turn the lens body, which was assembled in⑤ in the direction of the arrow until its convex portion enters in

⑥

the inner groove of the 1st lens-G sliding ring. Then push the lens body and focus ring all the way into the

1st lens-G sliding ring.

Apply to convex portion × locations

and entire circumference surface.

★

Grease:6308/10K

#7

#6

“PC-30”10-o'clock position

Convex portion

Concave portion

Concave portion

Inner groove

1st lens G sliding

ring

Index

1st lens group

#7×3

#6×3

Grease: MZ-800S

Apply to tting part and vertical groove.

Grease: MZ-800S

Apply to cam groove

Focus ring

Lens body

Grease: MZ-800S

2 kinds of convex portions

× 6 locations

Approx. 10 mm

Fig.1

#3

- A3・ AF-S DX55-200/4-5.6G -

JAA79351-R.3670.A

- A4・ AF-S DX55-200/4-5.6G -

Focus coupling ring

Note:

Do NOT pull out the 1st lens group from the lens body while assmbling to keep it from becoming detached from the

grooves, etc of the lens body.

Grease: MZ-800S

Apply to sliding surface with #35.

#35

#34×3

#33×3

#34

#33

Focus coupling ring

Lens body

Grease: MZ-800S

Apply to tting part.

Grease:MZ-800S

Apply to vertical

groove.

Grease: MZ-800S

Apply to tting part.

Adhesive: EDZ4113

Concave portion

Boundary line of concave portion

・

Fix the focus coupling ring retainer (#35) at the below position, and apply the adhesive (EDZ4113) at

2 locations of the below.

INC

JAA79351-R.3670.A

- A5・ AF-S DX55-200/4-5.6G -

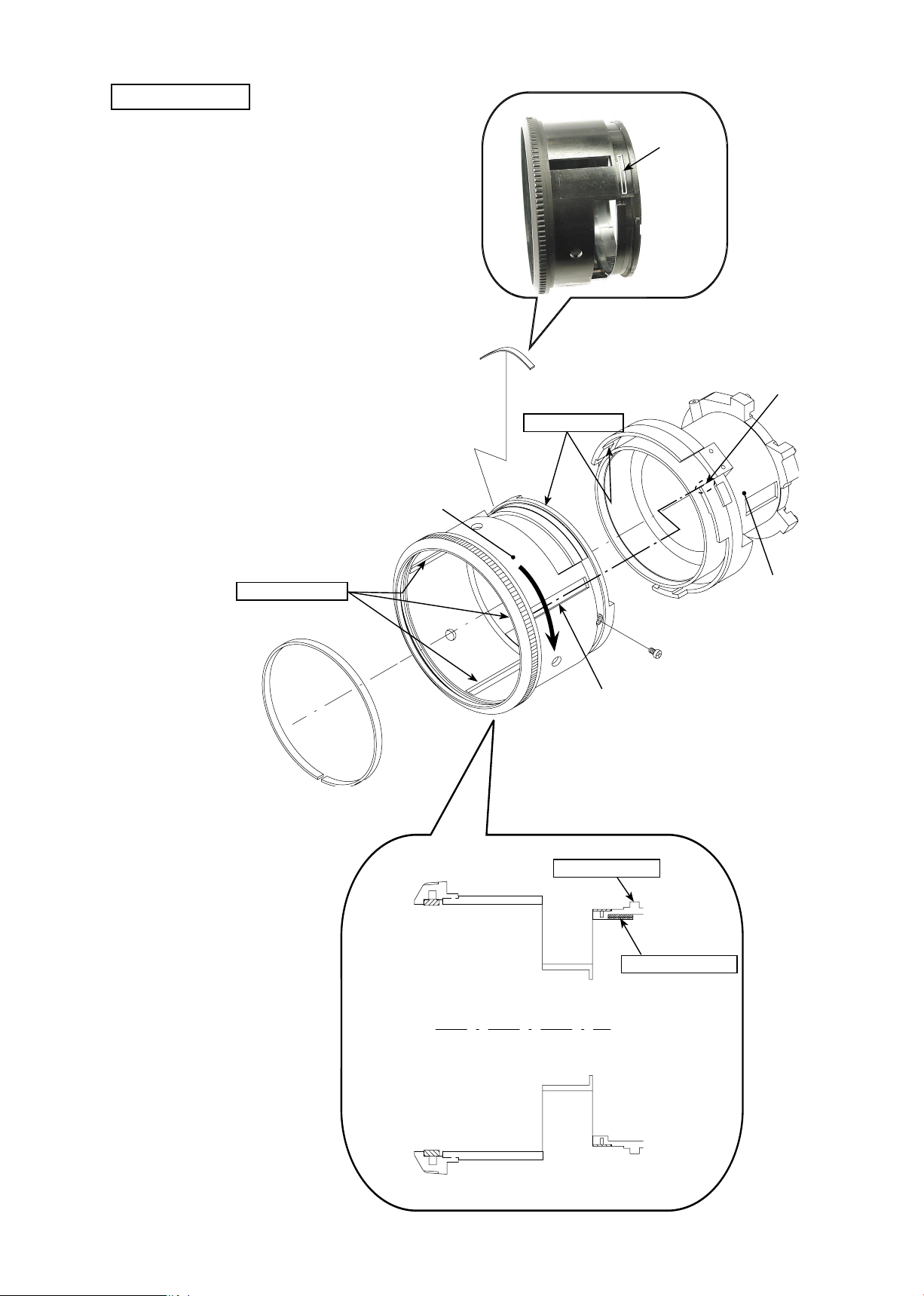

Focus gear ring

①

Attach the friction cloth (#36) to the focus gear

ring.

②

Put the friction spring (#70) into the concave

portion of the focus gear ring.

③

Align the center of the vertical groove of the fo-

cus gear ring with the "A" part of the mid-lens

barrel unit, and assemble them. Then turn the

focus gear ring a little in the direction of the ar-

row.

④

Fix the stopper screw (#42).

#42

#36

Object side

#70

Grease: 6308/10K

Ap ply to tt ing

part

A part

Vertical groove

Focus gear ring

Mid-lens barrel unit

Grease: MZ-800S

Vertical groove× 3 locations

★

: Newly prepared as RJ

★

Focus gear ring

Concave

portion

Cross-section view of Focus gear ring

Grease: MZ-800S

Apply to gear

Grease: 6308/10K

Apply to tting part

INC

Mid-lens barrel unit

INC

Note) Pass 2 zoom coupling plates

(#48) through the groove of

the mid-lens barrel unit, then

in t o the g r oove of the len s

body. Fix the mid-lens barrel

unit with 4 screws (#45).

Groove of the lens body

#41

#40

Apply to tting part.

Grease: G92KA

#40×3

#41×3

JAA79351-R.3670.A

#48×2

#45×4

Mid-lens barrel unit

MR sensor unit / Focus brush

MR sensor unit

Lens body

#75×2

FPC attaching position

#39

Focus brush

- A6・ AF-S DX55-200/4-5.6G -

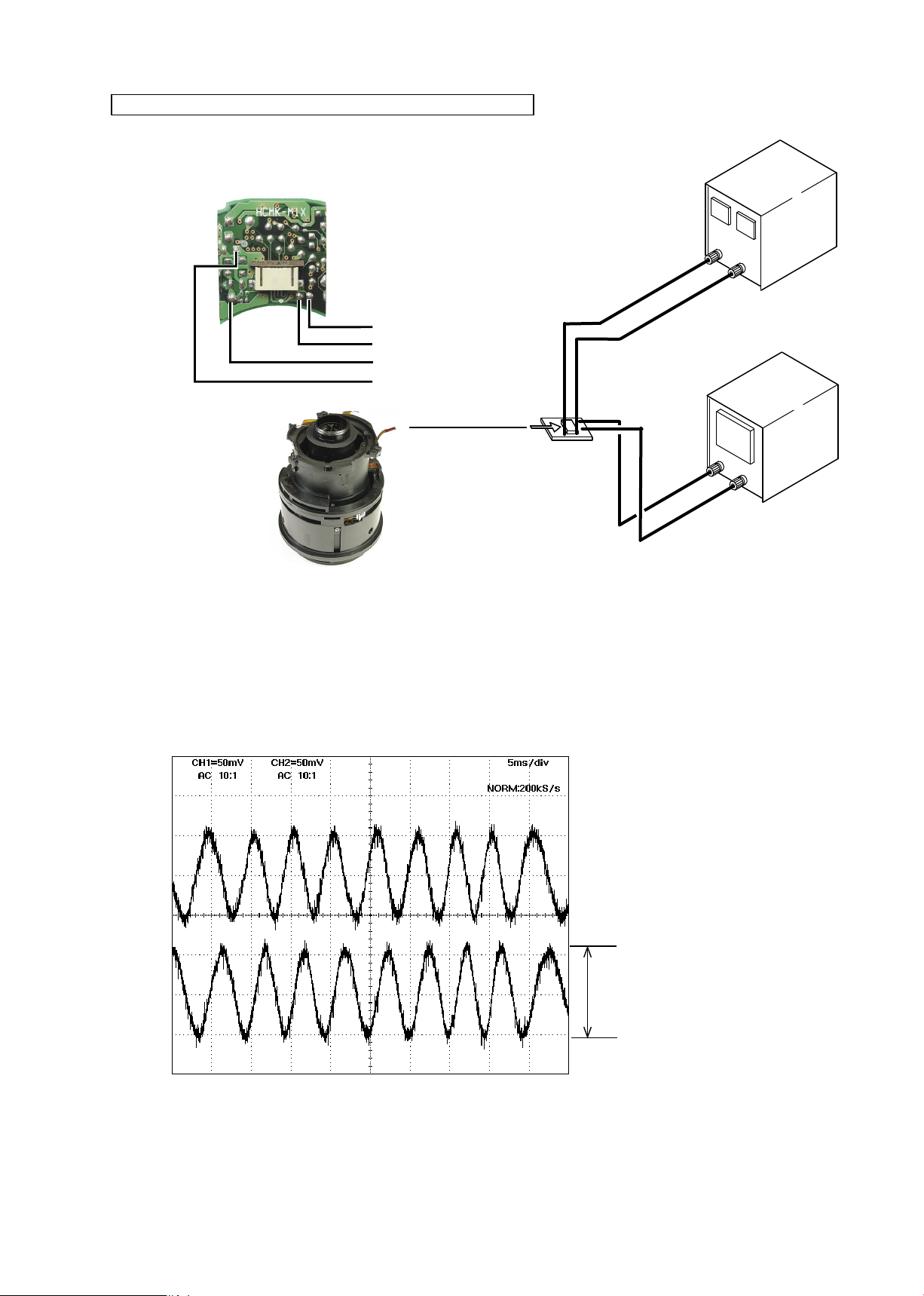

Inspection and adjustment of MR encoder output waveform

INC

Attachment diagram

・

【

】

Self-made tool that is created with

the main PCB of AF-S 24-85

JAA79351-R.3670.A

Rated voltage power-supply

(GND)

( + )

Oscilloscope

Oscilloscope

Rated voltage power-supply

Rated voltage power-supply

How to inspect and adjust:

・

Conrm that the electric current and voltage of the connected rated voltage power-supply are set values, then

①

turn it ON.

Set the oscilloscope, and turn the focus ring manually.

②

(2ch)

(1ch)

(+)

(-)

Self-made tool

Set value

5.0 V

100 mA

Oscilloscope

(2ch type)

Note: The waveform varies according to the rotational speed of the focus ring. So change "Time/Div” setting

accordingly.

CH1

CH2

Fig.1

● Oscilloscope setting

V/Div (ch1) : 50 mV

V/Div (ch2) : 50 mV

Coupling : AC

Time/Div : 5 m Sec

Trigger Mode : NORMAL

Trigger Coupling : AC

Amplitude

Standard:

Note:

Amplitude of all pulses/

waveforms is 70mV or more.

Check the waveform by moving the

focus ring back and forth from the

innity-end to the close-end positions

entirely.

- A7・ AF-S DX55-200/4-5.6G -

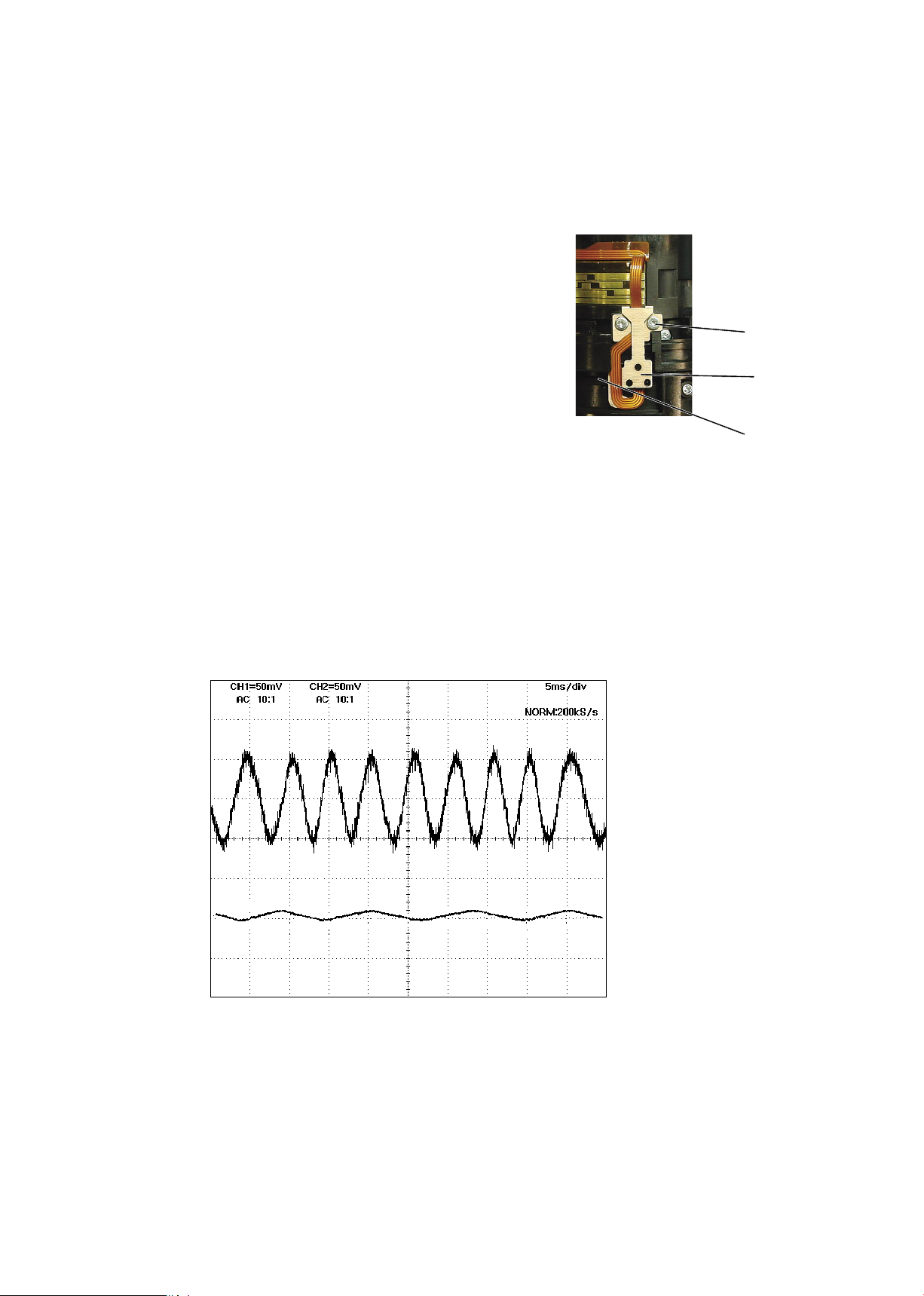

In case large waveform-noise (as shown in Fig. 1) is detected, use the FILTER function.

INC

③

How to set FILTER function (e.g. DL1540 manufactured by YOKOGAWA

1. Press the FILTER button.

2. Select “Smooth” of the menu on screen and turn it ON.

In case the amplitude is small, check if there is

⑥

deformation in the MR head. If there is, correct the

deform of the MR head. However, if such correction

is impossible or no deformation is detected, replace

the MR sensor unit. (Fig.2)

JAA79351-R.3670.A

)

#75×2

Note: When adjustments are made,

magnetic surface and MR head from touching the

magnetized driver bit. Otherwise, the magnetic

data may be damaged.

Ref.

<

● As shown in Fig. 3,

>

if the amplitude of only either CH1 or CH2 is small, one of the 2 screws (#75) may be

loosened, so check for it. If this is not the case, the MR head may malfunction, so replace the MR sensor

unit and make a readjustment.

prevent the

MR head

Magnetic

surface

Fig.2

CH1

CH2

Fig. 3

- A8・ AF-S DX55-200/4-5.6G -

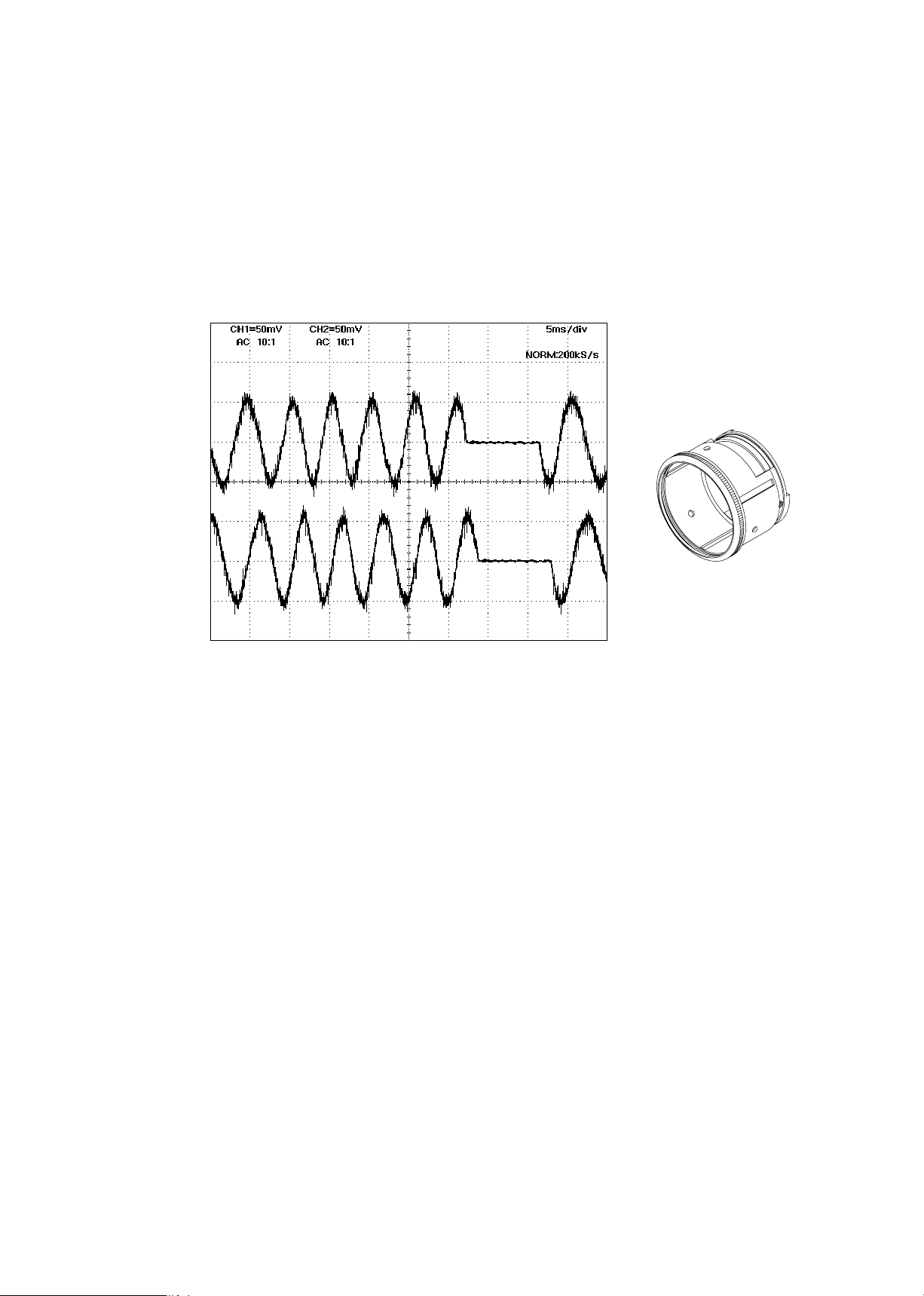

JAA79351-R.3670.A

INC

As shown in Fig. 4,

●

magnetic data of the tape may be damaged. So replace the focus gear ring unit and make a readjustment.

Replacing only the magnetic surface is impossible.

CH1

if the amplitude partially drops between the innity and the close-distance, the

Focus gear ring unit

CH2

⑤

Turn off the rated voltage power-supply.

Fig.4

- A9・ AF-S DX55-200/4-5.6G -

JAA79351-R.3670.A

- A10 ・ AF-S DX55-200/4-5.6G -

AF contact unit

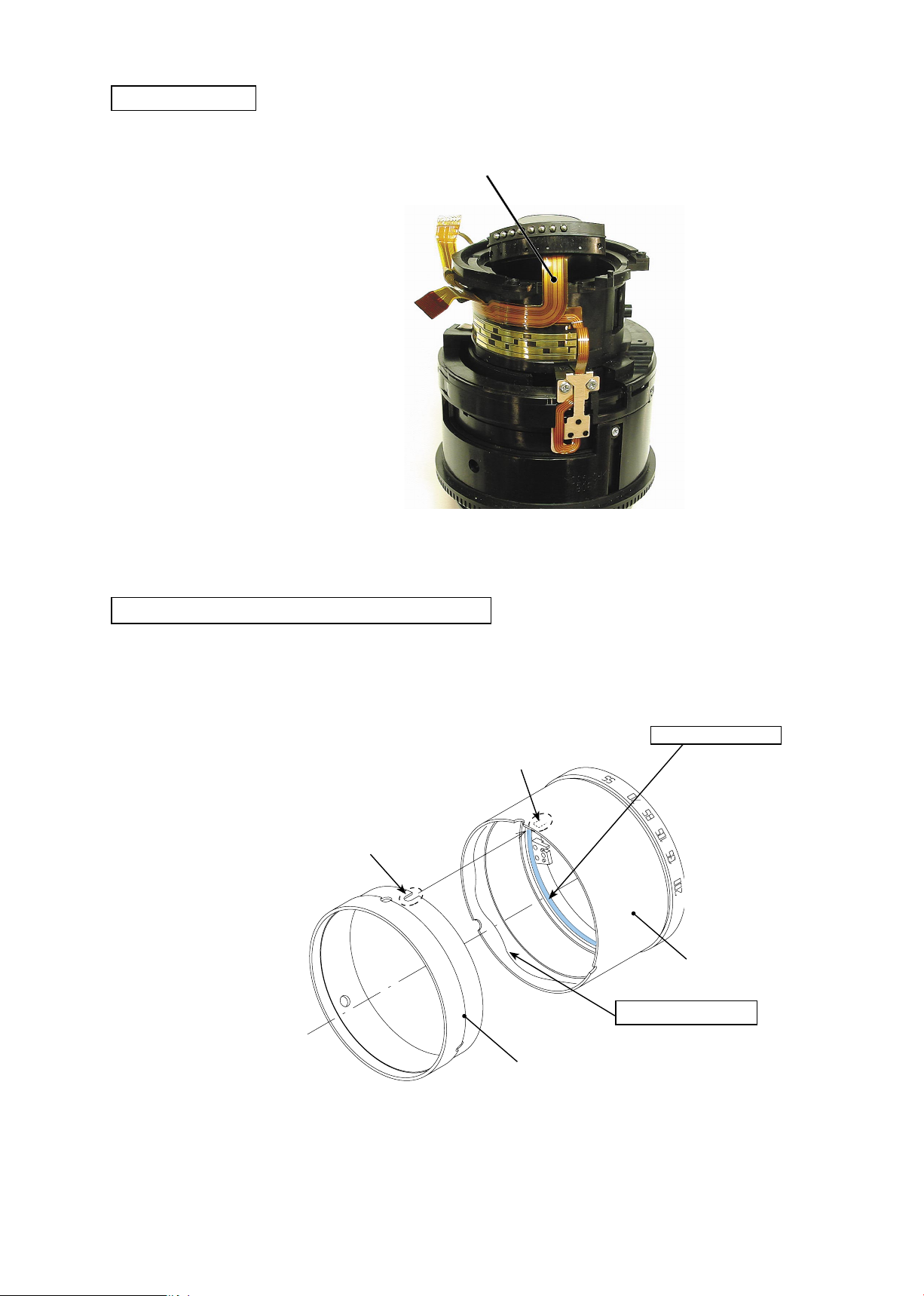

Adhesion of Zoom ring and Zoom reinforcement ring

AF contact unit

・

By using the both-sided adhesive

tape of the AF contact unit,

attach the AF contact unit to the

lens body.

Grease: G92KA

Apply to the overall circumferential

convex portion

Adhesive: C-8008B

Apply to the circumferential joining part with the

zoom reinforcement ring.

Zoom reinforcement ring

Zoom ring

・

Enter the inner convex portion of the zoom ring into

the U-groove of the

zoom reinforcement ring to assemble them. Then apply the adhesive.

Inner convex portion

U-groove

INC

Loading...

Loading...