DATA SHEET

MOS INTEGRATED CIRCUIT

m

PD78P368A

16/8 BIT SINGLE-CHIP MICROCOMPUTER

The mPD78P368A is produced by replacing the internal mask ROM of the mPD78366A with a one-time PROM

or EPROM. One-time PROM products, in which data can be written once are effective for manufacture of small

quantities of multiple products and early stage start-up of application. EPROM products, to which programs can

be re-written after previously written programs have been erased, are suited for system evaluation.

The following user's manual describes the details of functions. Be sure to read it before design.

m

PD78366A User's Manual, Hardware: U10205E

m

PD78356 User's Manual, Instructions: IEU-1395

FEATURES

• Compatible with the

• Can be replaced with the

• Internal PROM: 48K bytes

• Data can be written once (one-time PROM product without an erasure window)

• Written data can be erased by exposure to ultraviolet light and re-written electrically (EPROM product with an

erasure window)

• PROM programming characteristics: Compatible with the

• QTOP

ORDERING INFORMATION

TM

microcomputer

Remark The QTOP microcomputer is a single-chip microcomputer with a built-in one-time PROM that is totally

supported by NEC. The support includes writing application programs, marking, screening, and

verification.

Part number Package Internal ROM

m

PD78P368AGF-3B9 80-pin plastic QFP (14 ¥ 20 mm) One-time PROM

m

PD78P368AKL-S

Note Under development

m

PD78366A

Note

m

PD78366A containing mask ROM on a full-production basis.

m

PD27C1001A

80-pin ceramic WQFN EPROM

In this manual, the description of the PROM is for both a one-time PROM and EPROM.

(Previous No. IP-3680)

Date Published June 1996 P

Printed in Japan

The information in this document is subject to change without notice.

The mark H shows major revised points.Document No. U11373EJ1V0DS00 (1st edition)

1996

©

1990

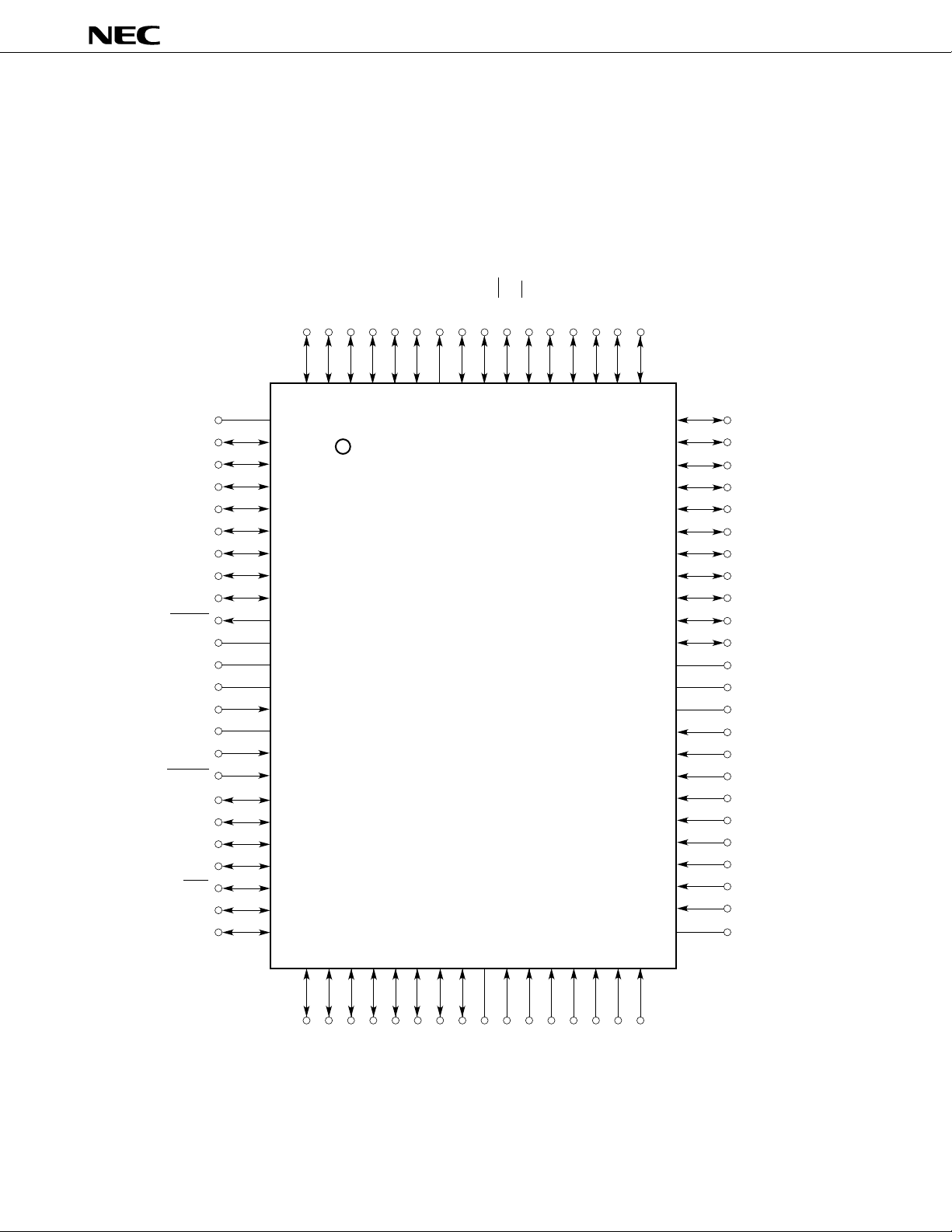

PIN CONFIGURATION (TOP VIEW)

(1) Normal operation mode (MODE0 = L, MODE1 = L)

• 80-pin plastic QFP (14 ¥ 20 mm)

m

PD78P368AGF-3B9

• 80-pin ceramic WQFN

m

PD78P368AKL-S

m

PD78P368A

V

P00/RTP0

P01/RTP1

P02/RTP2

P03/RTP3

P04/PWM0

P05/ TCUD/PWM1

P06/ TIUD/TO40

P07/ TCLRUD

WDTO

IC

V

V

X1

X2

MODE1

RESET

X

D0

P30/ T

P31/RXD0

P32/SO/SB0

P33/SI/SBI

P34/SCK

X

D1

P35/ T

X

D1

P36/R

P84/ TO04

P83/ TO03

P82/TO02

P81/ TO01

P80/ TO00

ASTB

P93

P92

P91/ WR

P90/RD

P57/A15

P56/A14

P55/A13

P54/A12

P53/A11

P85/ TO05

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65

SS

DD

SS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

P52/A10

P51/A9

P50/A8

P47/AD7

P46/AD6

P45/AD5

P44/AD4

P43/AD3

P42/AD2

P41/AD1

P40/AD0

SS

V

V

DD

AV

DD

AV

REF

P77/ANI7

P76/ANI6

P75/ANI5

P74/ANI4

P73/ANI3

P72/ANI2

P71/ANI1

P70/ANI0

SS

AV

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

P10

P11

P12

Caution Directly connect the IC pin to V

Remark Pin compatible with the mPD78366AGF

2

P13

SS.

P14

P15

P16

P17

SS

V

MODE0

P20/NMI

P21/INTP0

P22/INTP1

P23/INTP2

P25/INTP4

P24/INTP3/ TI

m

PD78P368A

P00-P07: Port 0

P10-P17: Port 1

P20-P25: Port 2

P30-P36: Port 3

P40-P47: Port 4

P50-P57: Port 5

P70-P77: Port 7

P80-P85: Port 8

P90-P93: Port 9

RTP0-RTP3: Real-time port

NMI: Nonmaskable interrupt

INTP0-INTP4: Interrupt from peripherals

TO00-TO05, TO40: Timer output

TI: Timer input

TIUD: Timer input for up/down

counter

TCUD: Timer control for up/down

counter

TCLRUD: Timer clear for up/down

counter

ANI0-ANI7: Analog input

TxD0, TxD1: Transmit data

RxD0, RxD1: Receive data

SI: Serial input

SO: Serial output

SB0, SB1: Serial bus

SCK: Serial clock

PWM0, PWM1: Pulse width modulation output

WDTO: Watchdog timer output

MODE0, MODE1: Mode

AD0-AD7: Address/data bus

A8-A15: Address bus

ASTB: Address strobe

RD: Read strobe

WR: Write strobe

RESET: Reset

X1, X2: Crystal

DD: Analog VDD

AV

AVSS: Analog VSS

AVREF: Analog reference voltage

DD: Power supply

V

SS: Ground

V

IC: Internally connected

3

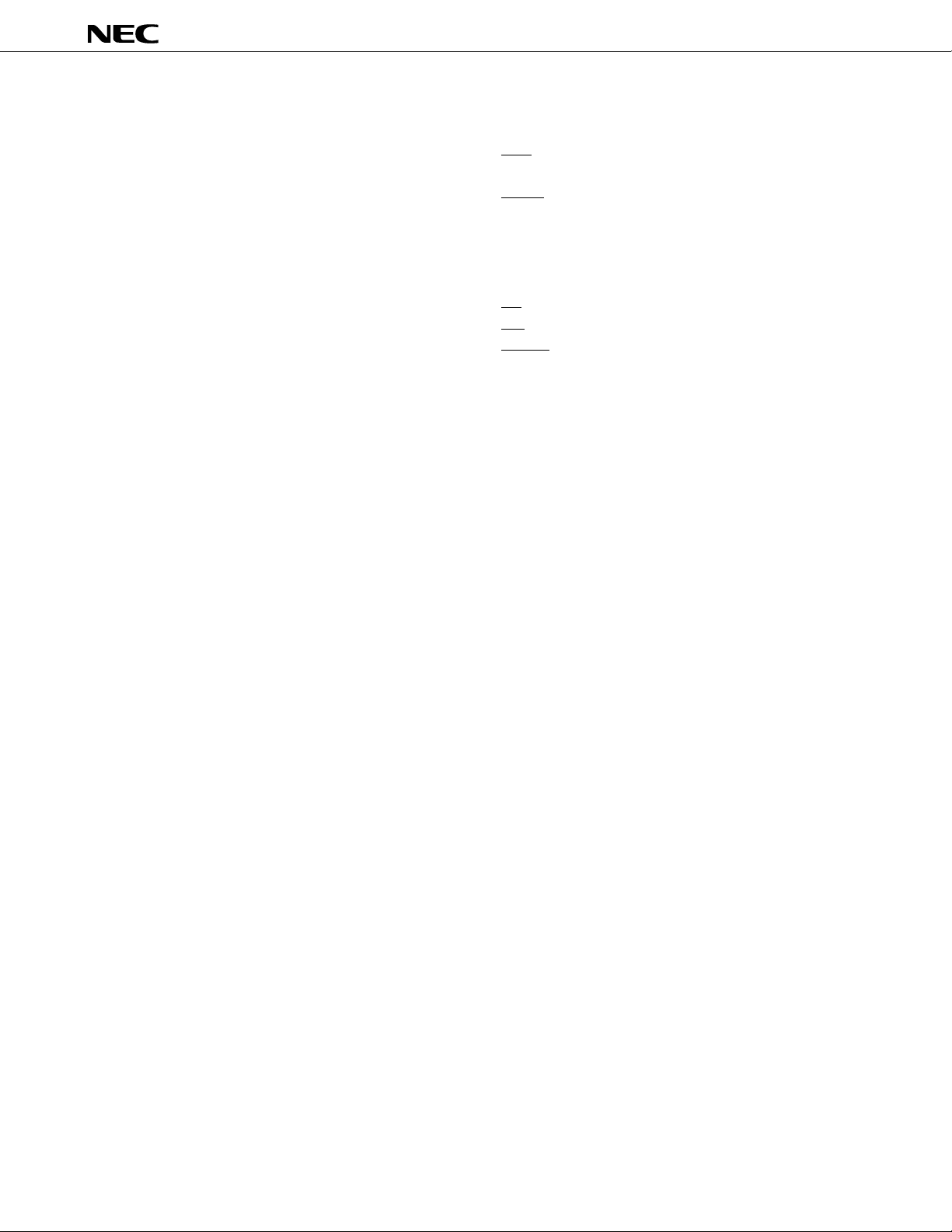

(2) PROM programming mode (MODE0/VPP = H, MODE1 = L)

• 80-pin plastic QFP (14 ¥ 20 mm)

m

PD78P368AGF-3B9

• 80-pin ceramic WQFN

m

PD78P368AKL-S

m

PD78P368A

VSS

A0

A1

A2

A3

A4

A5

A6

A7

(Open)

(G)

VDD

VSS

(G)

(Open)

MODE1

(G)

A16

(L)

(L)

A15

A14

A13

A11

A10

A12

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

PGM

CE

OE

(L)

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

D7

D6

D5

D4

D3

D2

D1

D0

V

VDD

VDD

(L)

SS

(G)

A9

VSS

(L)

A8

(G)

MODE0/ VPP

Caution Symbols in parentheses denote how the pins not used in the PROM programming mode should

be treated.

L: Connect these pins to the V

G: Connect these pins to the V

SS pins through separate resistors.

SS pins.

Open: Do not connect these pins to anything.

4

m

PD78P368A

A0-A16: Address bus

D0-D7: Data bus

CE: Chip enable

OE: Output enable

PGM: Programming mode

MODE0, MODE1: Programming mode set

PP: Programming power supply

V

DD: Power supply

V

SS: Ground

V

5

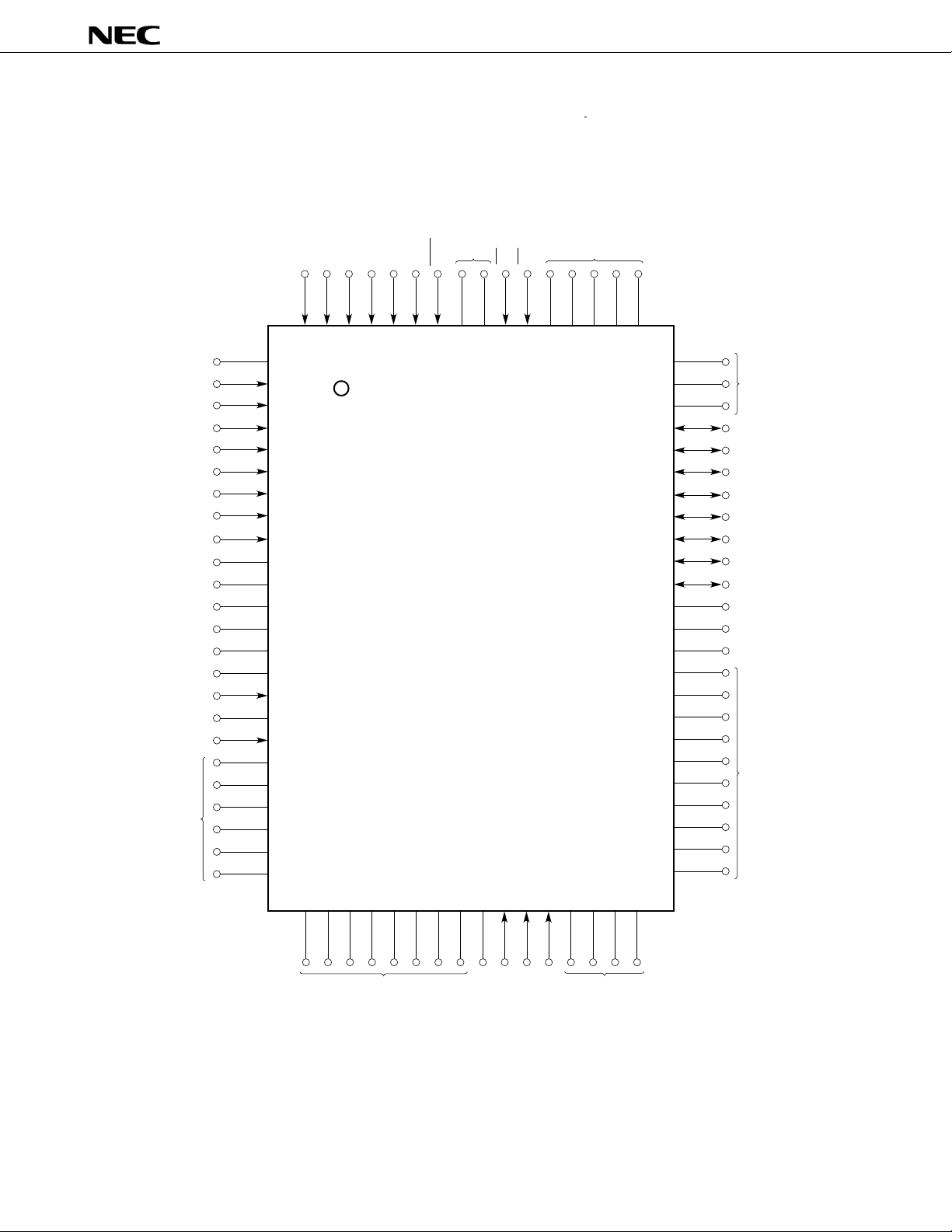

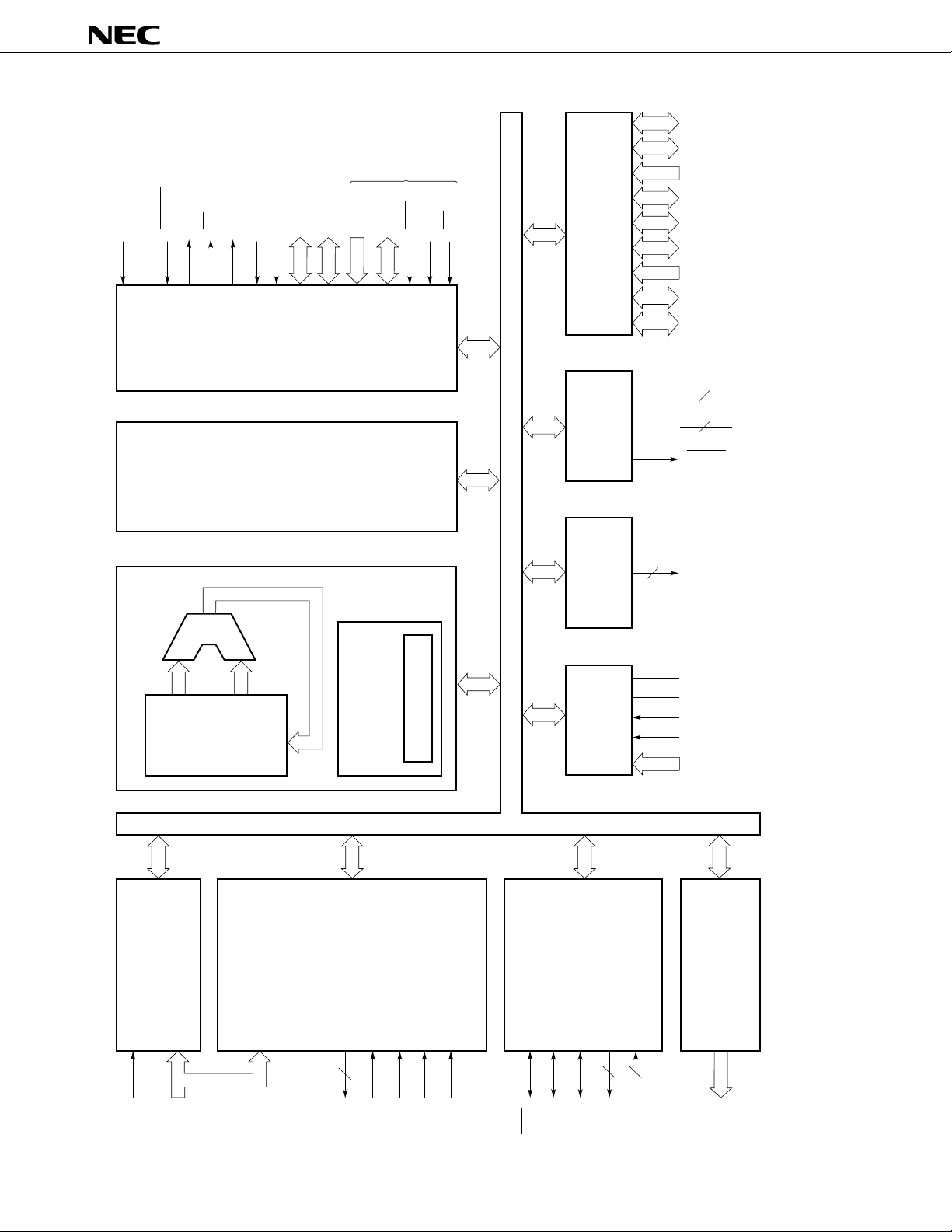

BLOCK DIAGRAM

X1X2RESET

BCU

ASTBRDWR

MODE1

System

control

Note

PP

MODE0/V

&

Bus

A8-A15

8

control

&

A0-A16

AD0-AD7

8

17

Prefetch

control

Note

D0-D7

8

PGM

CE

OE

Port

Watchdog

timer

m

PD78P368A

P0

8

8

P1

6

P2

7

P3

8

P4

P5

8

8

P7

6

P8

4

P9

2

DD

V

4

V

SS

WDTO

PROM/RAM

EXU

Main RAM

128 × 8

General

registers

ALU

&

PROM

Data

memory

Periph-

&

eral RAM

1792 × 8

Micro

sequence

control

Micro ROM

PWM

A/D

converter

2

PWM

DD

AV

AV

SS

AV

REF

INTP2

8

ANI

48K × 8

128 × 8

Note Shading indicates the pins used in the PROM programming mode.

(SBI)

(UART)

Serial

interface

Programmable

interrupt

NMI

controller

5

5

INTP

(Real-time pulse unit)

Timer/counter unit

4

7

TI

TO

TIUD

TCUD

TCLRUD

SCK

SO/SB0

2

SI/SB1

TxD

2

RxD

Real-time output

port

4

RTP

6

m

PD78P368A

CONTENTS

1. PIN FUNCTIONS........................................................................................................................ 8

1.1 NORMAL OPERATION MODE (MODE0 = L, MODE1 = L) ......................................................... 8

1.2 PROM PROGRAMMING MODE (MODE0/V

1.3 INPUT/OUTPUT CIRCUIT TYPE FOR EACH PIN AND HANDLING OF UNUSED PINS .......... 1 1

PP = H, MODE1 = L) ................................................ 10

2. MEMORY CONFIGURATION................................................................................................... 13

3. DIFFERENCES BETWEEN THE mPD78P368A AND mPD78366A ......................................... 1 4

4. PROM PROGRAMMING ............................................................................................................ 15

4.1 OPERATION MODE........................................................................................................................ 15

4.2 PROCEDURE FOR WRITING ON PROM (PAGE PROGRAM MODE)............................... 16

4.3 PROCEDURE FOR WRITING ON PROM (BYTE PROGRAM MODE) ................................ 18

4.4 PROCEDURE FOR READING FROM PROM ........................................................................... 21

5. ERASURE CHARACTERISTICS (mPD78P368AKL-S ONLY) ................................................ 22

6. PROTECTIVE FILM COVERING THE ERASURE WINDOW (mPD78P368AKL-S ONLY)........ 22

7. SCREENING ONE-TIME PROM PRODUCTS.......................................................................... 22

8. ELECTRICAL SPECIFICATIONS ............................................................................................. 23

9. PACKAGE DRAWINGS ............................................................................................................. 39

10. RECOMMENDED SOLDERING CONDITIONS...................................................................... 41

APPENDIX A TOOLS...................................................................................................................... 42

A.1 DEVELOPMENT TOOLS ................................................................................................................ 42

A.2 EMBEDDED SOFTWARE............................................................................................................... 47

APPENDIX B DIMENSIONS OF THE CONVERSION SOCKET AND RECOMMENDED

PATTERN ON BOARDS ......................................................................................... 49

H

H

7

1. PIN FUNCTIONS

1.1 NORMAL OPERATION MODE (MODE0 = L, MODE1 = L)

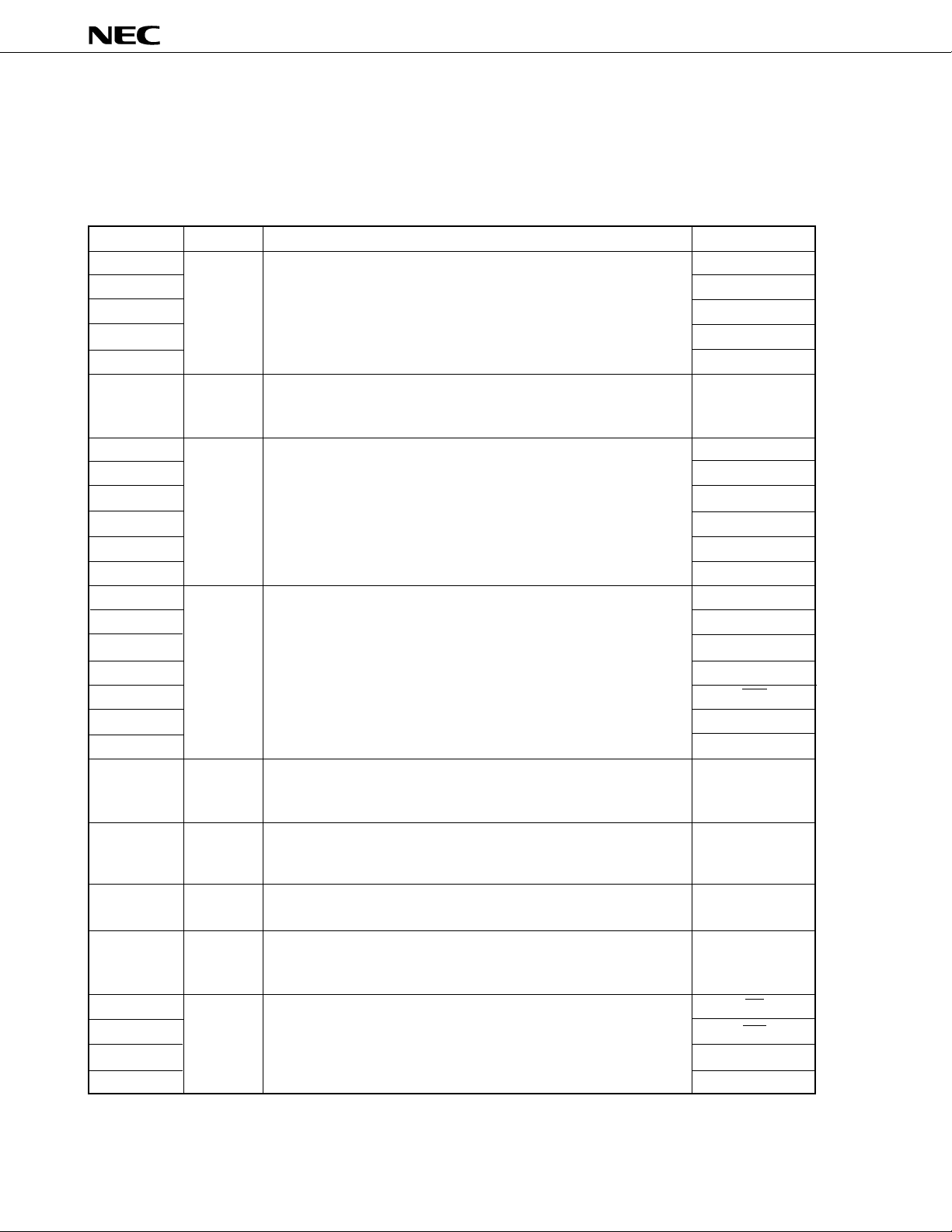

(1) Port pins

m

PD78P368A

P00-P03

P04

P05

P06

P07

P10-P17

P20

P21

P22

P23

P24

P25

P30

P31

P32

P33

P34

P35

P36

P40-P47

P50-P57

P70-P77

I/O Dual-function pinPin name

I/O

I/O

I/O

I/O

I/O

Function

Port 0.

8-bit I/O port.

Can be specified as input or output bit by bit.

Port 1.

8-bit I/O port.

Can be specified as input or output bit by bit.

I

I

Port 2.

Port used only for 6-bit input.

Port 3.

7-bit I/O port.

Can be specified as input or output bit by bit.

Port 4.

8-bit I/O port.

Can be specified as input or output in units of 8 bits.

Port 5.

8-bit I/O port.

Can be specified as input or output bit by bit.

Port 7.

Port used only for 8-bit input.

RTP0-RTP3

PWM0

TCUD/PWM1

TIUD/TO40

TCLRUD

–

NMI

INTP0

INTP1

INTP2

INTP3/TI

INTP4

TxD0

RxD0

SO/SB0

SI/SB1

SCK

TxD1

RxD1

AD0-AD7

A8-A15

ANI0-ANI7

8

P80-P85

P90

P91

P92

P93

I/O

I/O

Port 8.

6-bit I/O port.

Can be specified as input or output bit by bit.

Port 9.

4-bit I/O port.

Can be specified as input or output bit by bit.

TO00 - TO05

RD

WR

–

–

(2) Non-port pins (1/2)

m

PD78P368A

RTP0-RTP3

NMI

INTP0

INTP1

INTP2

INTP3

INTP4

TI

TCUD

TIUD

TCLRUD

TO00-TO05

TO40

ANI0-ANI7

TxD0

TxD1

RxD0

RxD1

SCK

SI

SO

SB0

SB1

PWM0

PWM1

WDTO

AD0-AD7

A8-A15

ASTB

RD

WR

I/O

I/O

I/O

I/O

Function

O

I

I

O

I

O

I

I

O

O

O

O

Outputs a pulse in real time as triggered by a trigger signal sent from the

real-time pulse unit.

Nonmaskable interrupt request input

External interrupt request input

External count clock input to timer 1

Input for the control signal to determine whether the up/down counter (timer

4) counts up or down.

External count clock input to the up/down counter (timer 4)

Clear signal input to the up/down counter (timer 4)

Pulse output from the real-time pulse unit

Analog input to the A/D converter

Serial data output from the asynchronous serial interface

Serial data input to the asynchronous serial interface

Serial clock I/O for the clock synchronous serial interface

Serial data input to the clock synchronous serial interface in the 3-wire mode

Serial data output from the clock synchronous serial interface in the 3-wire

mode

Serial data I/O for the clock synchronous serial interface in the SBI mode

PWM signal output

Output for the signal which indicates the watchdog timer overflowed. (A

nonmaskable interrupt is generated.)

Multiplexed address/data bus used when external memory is expanded

Address bus used when external memory is expanded

Output for the timing signal used in externally latching address information

output from the AD0 to AD7 and A8 to A15 pins, in order to access the

external memory

Read strobe signal output to the external memory

Write strobe signal output to the external memory

Dual-function pinPin name

P00-P03

P20

P21

P22

P23

P24/TI

P25

P24/INTP3

P05/PWM1

P06/TO40

P07

P80-P85

P06/TIUD

P70-P77

P30

P35

P31

P36

P34

P33/SB1

P32/SB0

P32/SO

P33/SI

P04

P05/TCUD

–

P40-P47

P50-P57

–

P90

P91

9

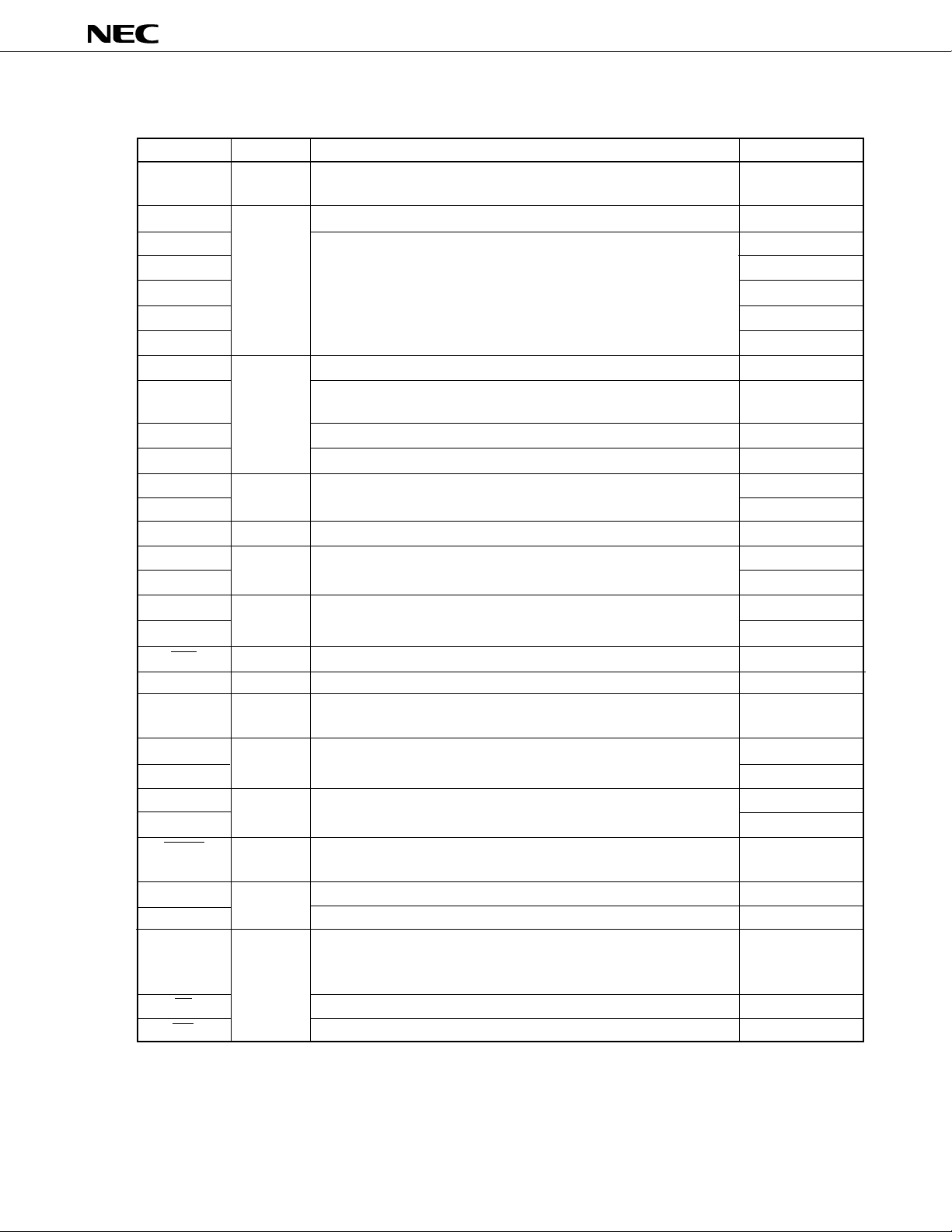

(2) Non-port pins (2/2)

m

PD78P368A

I/O Dual-function pinPin name

MODE0

MODE1

RESET

X1

X2

AVREF

AVDD

AVSS

VDD

VSS

IC

I

I

I

–

I

–

–

–

–

–

Input for the control signal which sets the operation mode. Normally, both

MODE0 and MODE1 are directly connected to the VSS pin.

System reset input

Crystal input pin for the system clock. A clock signal provided externally is

input to the X1 pin. The reversed signal of the clock signal is input to the

X2 pin.

A/D converter reference voltage input

Analog power supply for the A/D converter

Ground for the A/D converter

Positive power supply

Ground

Internally connected. Directly connect the IC pin to VSS.

1.2 PROM PROGRAMMING MODE (MODE0/V

Pin name

MODE0/VPP

MODE1

A0-A16

D0-D7

PGM

CE

OE

VDD

VSS

I/O

PROM programming mode set/programming supply voltage

I

PROM programming mode set

I

Address bus

I

Data bus

I/O

Program input

I

Enable PROM

I

Read strobe to PROM

I

Positive power supply

GND

Function

–

–

–

–

–

–

–

–

–

PP = H, MODE1 = L)

Function

10

m

PD78P368A

1.3 INPUT/OUTPUT CIRCUIT TYPE FOR EACH PIN AND HANDLING OF UNUSED PINS

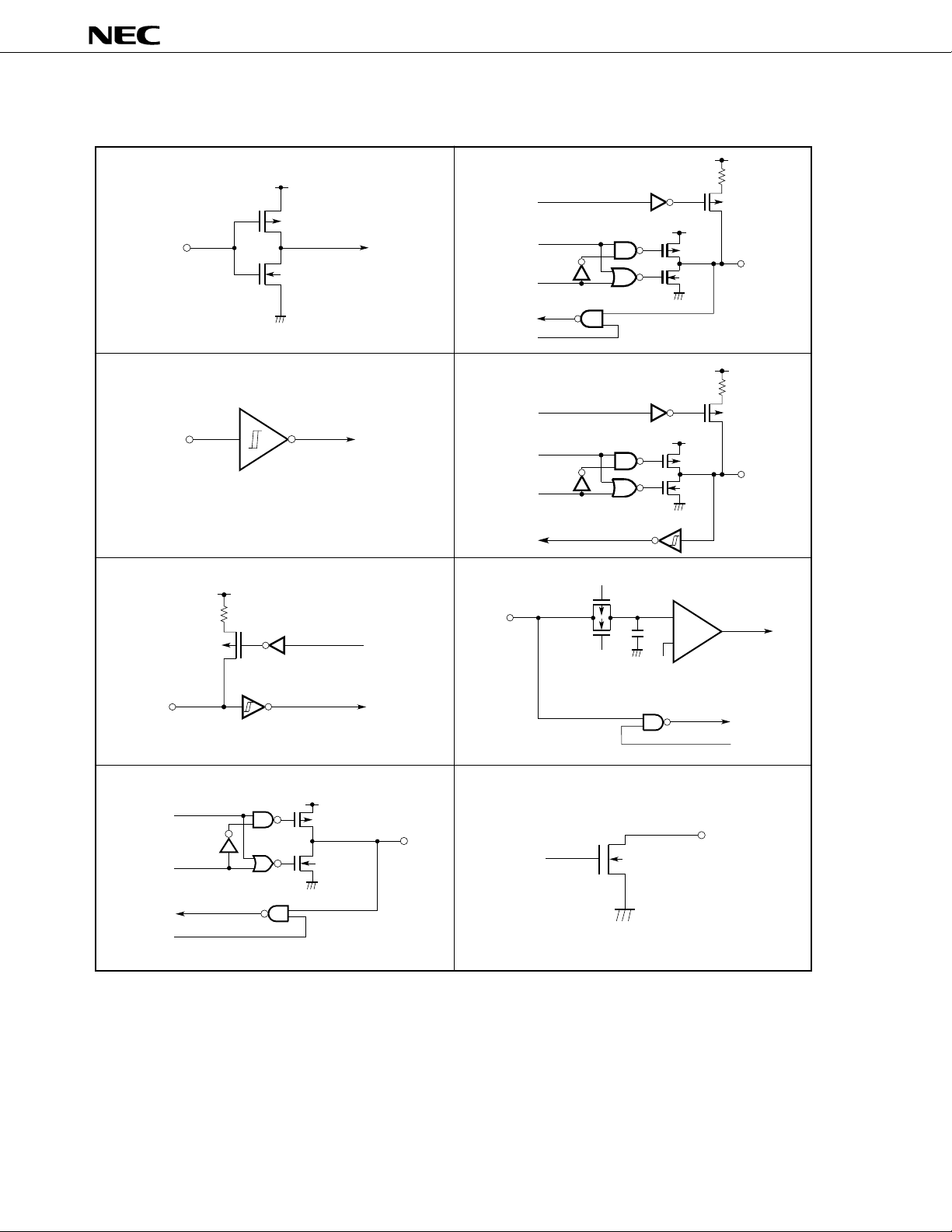

Table 1-1 lists the input and output circuit type for each pin and how to handle it when it is not used. Fig. 1-1 shows

the circuits.

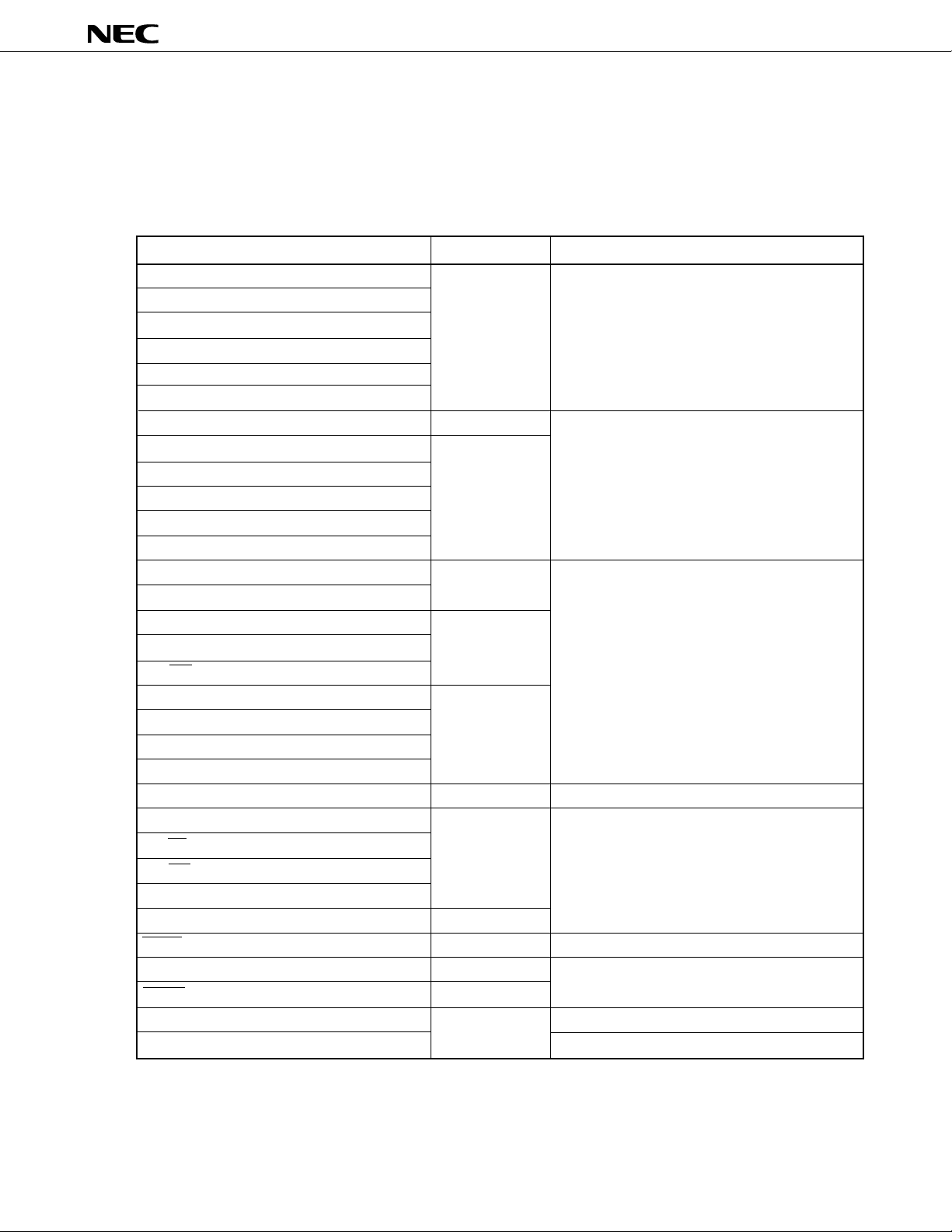

Table 1-1 Input/Output Circuit Type for Each Pin and Recommended Connection Methods for Unused

Pins

P00/RTP0-P03/RTP3

P04/PWM0

P05/TCUD/PWM1

P06/TIUD/TO40

P07/TCLRUD

P10-P17

P20/NMI

P21/INTP0

P22/INTP1

P23/INTP2

P24/INTP3/TI

P25/INTP4

P30/TxD0

P31/RxD0

P32/SO/SB0

P33/SI/SB1

P34/SCK

P35/TxD1

P36/RxD1

P40/AD0-P47/AD7

P50/A8-P57/A15

P70/ANI0-P77/ANI7

P80/TO00-P85/TO05

P90/RD

P91/WR

P92, P93

ASTB

WDTO

MODE0, MODE1

RESET

AVREF, AVSS

AVDD

Pin

I/O circuit type

5-A

2

2-A

5-A

8-A

5-A

9

5-A

5

19

1

2

–

Recommended connection method

Input state: Each pin is connected to the V DD or

VSS pin via a separate resistor.

Output state: Open

Connected to the VSS pin.

Input state: Each pin is connected to the V DD or

VSS pin via a separate resistor.

Output state: Open

Connected to the VSS pin.

Input state: Each pin is connected to the V DD or

VSS pin via a separate resistor.

Output state: Open

Connected to the VSS pin.

–

Connected to the VSS pin.

Connected to the VDD pin.

11

Fig. 1-1 Input/Output Circuits of Each Pin

Input

enable

Output

disable

Pull-up

enable

Data

IN/OUT

N-ch

V

DD

P-ch

V

DD

P-ch

N-ch

OUT

m

PD78P368A

Type 1 Type 5-A

DD

V

P-ch

IN

N-ch

Type 2 Type 8-A

Pull-up

IN

enable

Data

Output

disable

Schmitt trigger input with hysteresis characteristics

Type 2-A Type 9

V

DD

IN

P-ch

Pull-up

enable

IN

Schmitt trigger input with hysterisis characteristics

P-ch

N-ch

V

DD

P-ch

N-ch

Comparator

+

–

V

ref

(Threshold voltage)

V

DD

P-ch

Input

enable

IN/OUT

Type 5 Type 19

Data

Output

disable

V

DD

P-ch

IN/OUT

N-ch

Input

enable

12

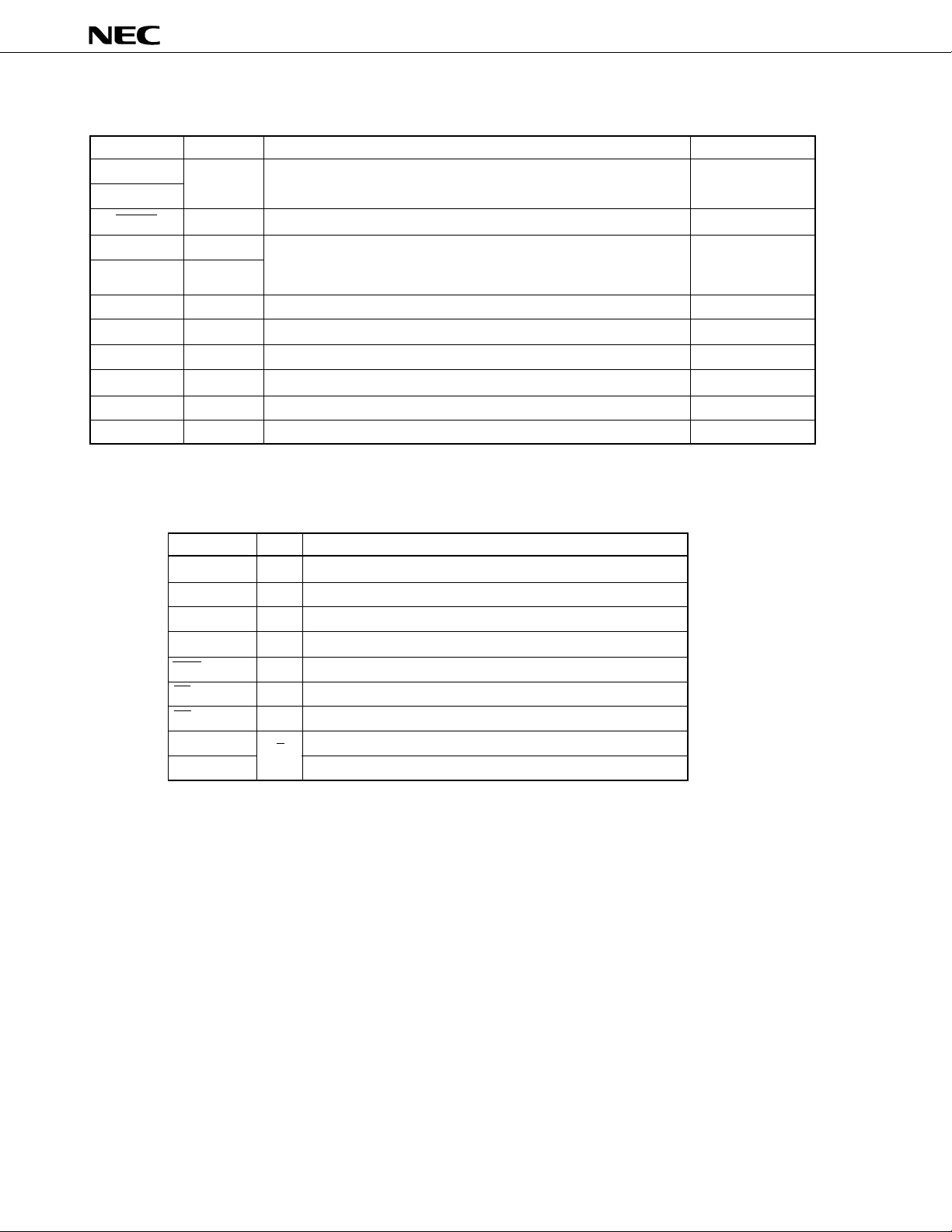

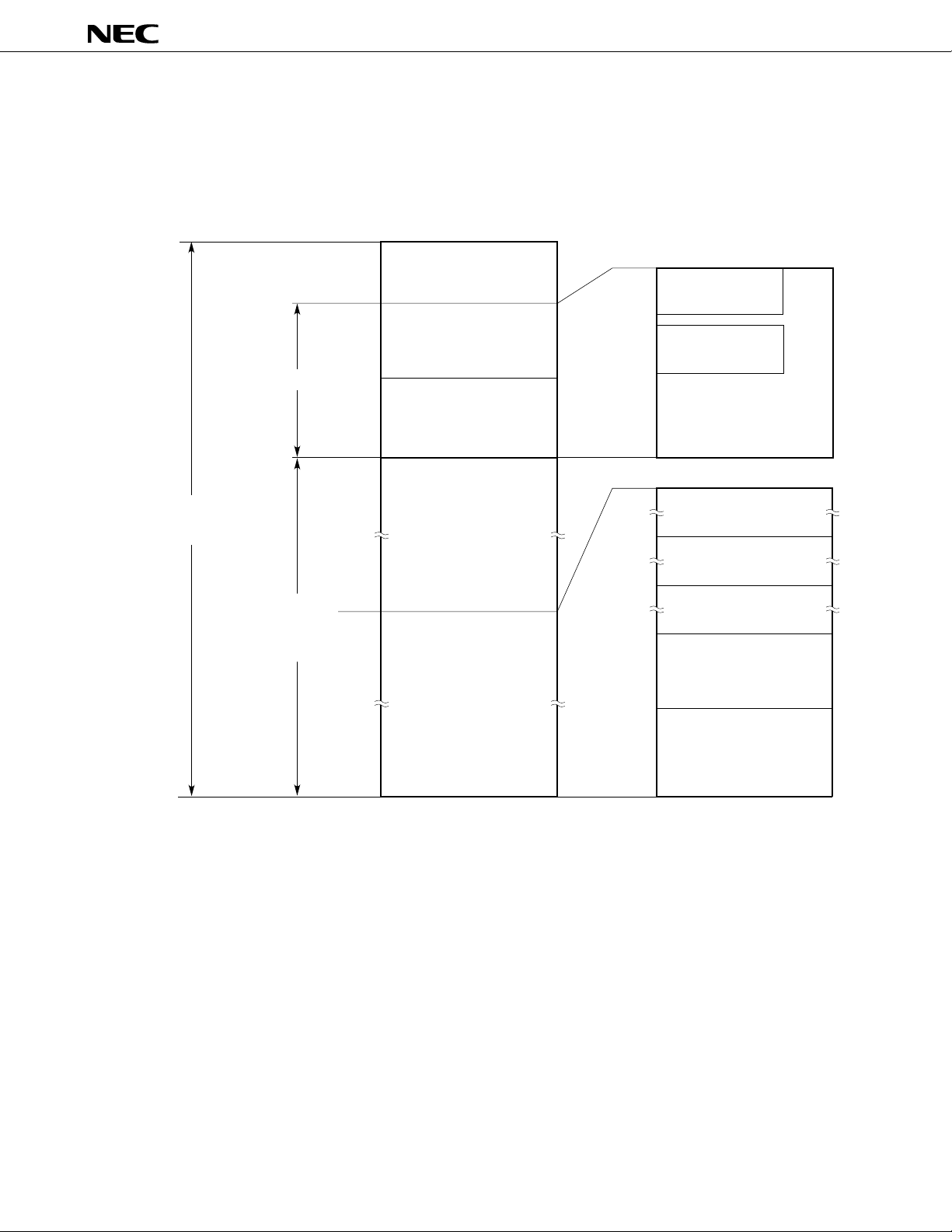

2. MEMORY CONFIGURATION

The mPD78P368A can access memory of up to 64K bytes. Fig. 2-1 shows the memory map.

Fig. 2-1 Memory Map

MODE 0, 1 = LL

Data memory

FFFFH

FF00H

FEFFH

FE00H

FDFFH

F700H

F6FFH

Special function

register (SFR)

(256 × 8)

Main RAM

(256 × 8)

Peripheral RAM

(1792 × 8)

FEFFH

FE80H

FE25H

FE06H

F700H

General register

(128 × 8)

Macro service control

(32 × 8)

m

PD78P368A

Data area

(2048 × 8)

Memory

space

(64K × 8)

Program

memory

Data

memory

C000H

BFFFH

0000H

External memory

(14080 × 8)

Internal PROM

(49152 × 8)

Note

BFFFH

1000H

0FFFH

0800H

07FFH

0080H

007FH

0040H

003FH

0000H

Program area

CALLF instruction

entry area

(2048 × 8)

Program area

CALLT instruction

table area

(64 × 8)

Vector table area

(64 × 8)

Note Access in the external memory expansion mode.

Caution When word access (including the stack operation) to the main RAM space (FE00H to FEFFH) is

executed, the addresses specified in the operand must be even numbers.

13

m

PD78P368A

3. DIFFERENCES BETWEEN THE

mm

m

PD78P368A AND

mm

mm

m

PD78366A

mm

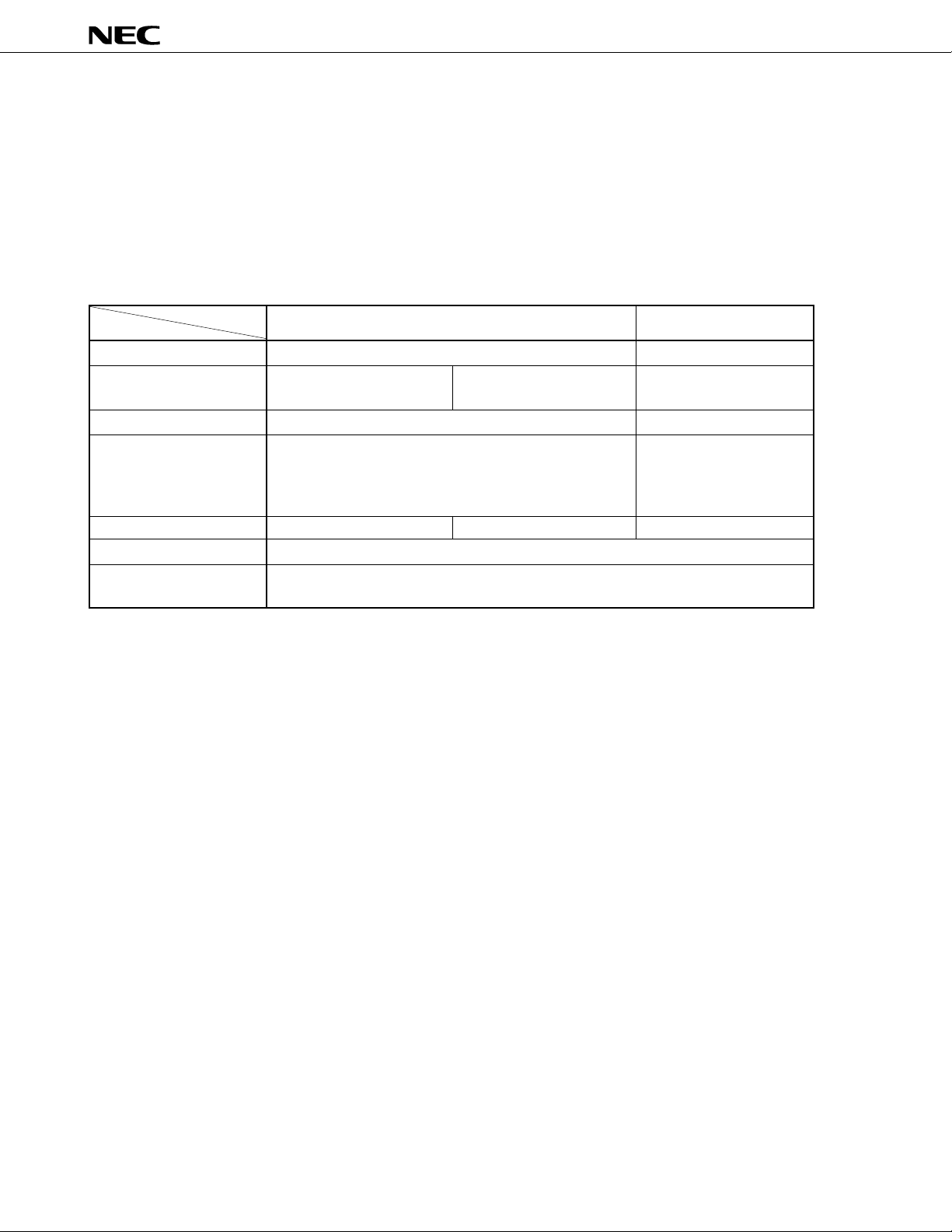

The mPD78P368A is produced by replacing the internal mask ROM of the mPD78366A with a 48K-byte PROM.

Both have the same functions except some differences in ROM specifications, such as write and verify modes. Table

3-1 shows the differences.

m

In this manual, the functions specific to the

m

to the

PD78366A document.

Table 3-1 Differences between the

Item

ROM

Internal program memory

(Electrical write)

PROM programming pin

Setting of MODE0 and

MODE1

Package

Electrical characteristics

Others

Part number

48K bytes

One-time PROM

(Data can be written once)

Provided

• Normal operation mode

MODE0, 1 = LL

• PROM programming mode

MODE0, 1 = HL

80-pin plastic QFP

They differ in supply current and other factors.

Since each product has a different circuit scale and mask layout, the noise immunity and

noise radiation of each product differ.

PD78P368A are explained. For details of the other functions, refer

mm

m

PD78P368A and mPD78366A

mm

m

m

PD78P368A

EPROM (Data can be

written multiple times)

80-pin ceramic WQFN

32K bytes

Mask ROM

Not provided

• Normal operation mode

• ROM-less mode

80-pin plastic QFP

PD78366A

MODE0, 1 = LL

MODE0, 1 = HH

Cautions1. The PROM and mask ROM products differ in noise immunity and noise radiation. Use not ES

products but CS products (mask ROM products) to evaluate them thoroughly when considering

the change from the PROM products to the mask ROM products during processes from

preproduction to volume production.

2. Connect the MODE0 and MODE1 pins directly to the V

DD or VSS pin.

14

m

PD78P368A

4. PROM PROGRAMMING

The mPD78P368A is provided with an electrically writable PROM of 48K ¥ 8 bits. When programming this PROM,

use the MODE0/V

The

m

PD78P368A provides programming characteristics compatibility with the mPD27C1001A.

PP and MODE1 pins to set the

Table 4-1 Pin Functions in Programming Mode

m

PD78P368A to the PROM programming mode.

Function

Address input

Data input

Program pulse

Chip enable

Output enable

Program voltage

Mode control

Normal operation mode

P00-P07, P21, P20, P80-P85, P30

P40-P47

ASTB

P91

P90

MODE0/VPP

MODE1

Programming mode

A0-A16

D0-D7

PGM

CE

OE

4.1 OPERATION MODE

To enter the program write/verify mode, set each pin as follows: MODE0/V

PP = H, MODE1 = L. In addition, any

of the operation modes listed in Table 4-2 can be selected by setting the CE, OE, and PGM pins in this mode.

m

Set the

PD78P368A to the read mode in order to read the contents of PROM.

Handle unused pins as described in PIN CONFIGURATION (2).

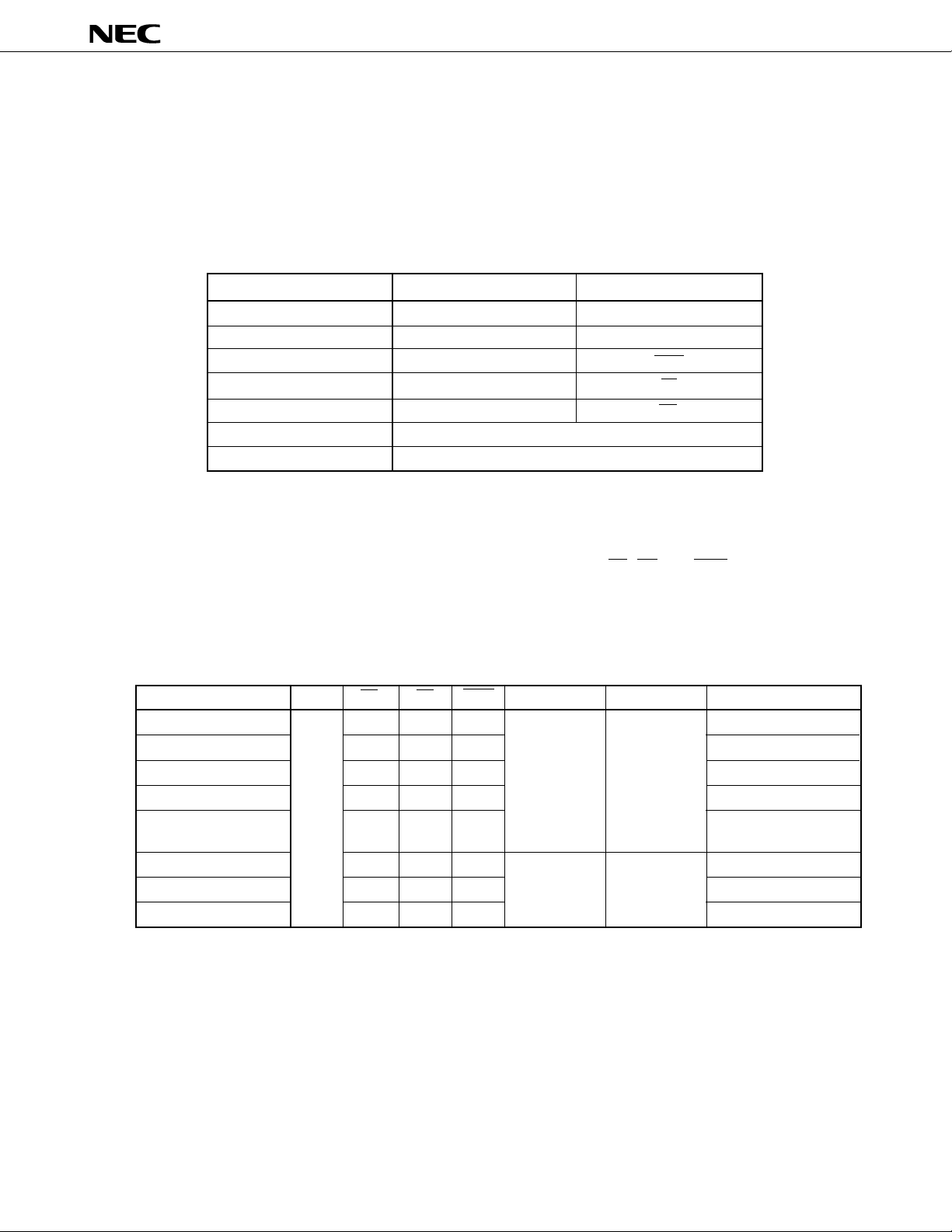

Table 4-2 Operation Modes for PROM Programming

Mode

Page data latch

Page program

Byte program

Program verify

Program inhibit

Read

Output disable

Standby

MODE1

L

CE

H

H

L

L

¥

¥

L

L

H

OE

L

H

H

L

L

H

L

H

¥

PGM

H

L

L

H

L

H

H

¥

¥

MODE0/VPP

+12.5 V

+5 V

VDD

+6.5 V

+5 V

D0-D7

Data input

High impedance

Data input

Data output

High impedance

Data output

High impedance

High impedance

Remark ¥: L or H

15

m

PD78P368A

4.2 PROCEDURE FOR WRITING ON PROM (PAGE PROGRAM MODE)

The following is a procedure for writing on PROM. (See Fig. 4-1.)

In the page program mode, data is written in units of pages (four bytes). When write data completes midway of

a page, latch FFH after the data so that the data fits into pages.

(1) Always set each pin as follows: MODE0/V

CONFIGURATION (2).

(2) Apply +6.5 V to the VDD pin and +12.5 V to the VPP pin.

(3) Input an initial address to the A0 to A16 pins.

(4) Clear the page counter.

(5) Data latch mode. Input write data to the D0 to D7 pins and input an active-low pulse to the OE pin. Increment

the address and the page counter.

(6) Repeat step (5) for a page (four bytes).

(7) Input a 0.1 ms program pulse (active low) to the PGM pin.

(8) Verify mode. Checks if data has been written in PROM.

Apply a low level to the CE pin, input an active-low pulse to the OE pin, and then read the write data from the

D0 to D7 pins. Repeat this for a page (four bytes). When verification completes, apply a high level to the CE

pin.

• If data has been written, go to step (10).

• If not, repeat steps (7) and (8). If no data is written yet after the steps have been repeated 10 times, go to

step (9).

(9) Assume the device to be defective and stop write operation.

(10) Increment the address.

(11) Repeat steps (4) to (10) until the address exceeds the last address.

Fig. 4-2 is a timing chart of these steps (2) to (9).

PP = H and MODE1 = L. Connect unused pins according to PIN

16

Loading...

Loading...