Page 1

Jupiter 20

GPS receiver module

Development kit guide

Applies only to older models:

TU10-D007-400

TU10-D007-401

TU10-D007-402

Related products

• Jupiter 20 (standard)

TU20-D411-001

• Jupiter 20 S (high sensitivity)

TU20-D411-101

• Jupiter 20 D (dead reckoning)

TU20-D421-201

Related documents

• Jupiter 20 Product brief LA000509

• Jupiter 20 Data sheet LA000507

• Jupiter 20 DR Application note LA000433

• Jupiter 30 / 20 Integrator’s manual LA000577

• SiRF Binary Protocol reference manual

MN000314

• NMEA reference manual MN000315

• SiRFDemo and SiRFash user guides

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

Page 2

Contents

1.0 Introduction ....................................................................................................... 4

2.0 Equipment.......................................................................................................... 4

2.1 Equipment supplied ...................................................................................................... 4

2.2 Equipment required ...................................................................................................... 5

3.0 Technical conguration .................................................................................... 6

3.1 Overview ....................................................................................................................... 6

3.1.1 Power switch (ON/OFF) ........................................................................................ 6

3.1.2 Conguration DIP switch ...................................................................................... 6

3.1.3 Function LEDs ...................................................................................................... 6

3.1.4 Reset switch ......................................................................................................... 6

3.1.5 Clock out connector .............................................................................................. 6

3.1.6 Serial port 1 .......................................................................................................... 6

3.1.7 Serial port 2 .......................................................................................................... 7

3.1.8 DR connector ........................................................................................................ 7

3.1.9 Antenna connector ............................................................................................... 7

3.1.10 DC power input ................................................................................................... 7

3.2 Conguration DIP switch .............................................................................................. 7

3.2.1 DIP switch 1 – GPIO3 /GYROIN input ................................................................. 7

3.2.2 DIP switch 2 – GPIO15 /FR input ......................................................................... 7

3.2.3 DIP switch 3 – BOOT from serial mode ............................................................... 7

3.2.4 DIP switch 4 – GPIO1/W_TICKS input ................................................................. 8

3.2.5 DIP switch 5 – RTC backup power enable ........................................................... 8

3.2.6 DIP switch 6 – Antenna preamp power select (3.3 V or 5/12 V) .......................... 8

3.2.7 DIP switch 7 – Antenna preamp power select (5 V or 12 V) ................................ 8

3.2.8 DIP switch 8 – Antenna preamp power enable .................................................... 8

3.3 Function LEDs .............................................................................................................. 8

3.3.1 1PPS ..................................................................................................................... 8

3.3.2 Power ................................................................................................................... 8

3.3.3 AUX ...................................................................................................................... 8

3.3.4 GPIO .................................................................................................................... 8

3.4 Clock out connector ..................................................................................................... 9

3.5 Internal conguration .................................................................................................... 9

3.6 Jupiter 20 module on adapter board ...........................................................................11

4.0 Operating instructions ................................................................................... 12

4.1 Initial connection and operation ..................................................................................12

4.1.1 Install the supplied SiRFdemo on your PC: .........................................................12

4.1.2 Set up the hardware: ...........................................................................................12

4.2 Positioning the GPS antenna ......................................................................................12

4.3 Connecting an RTCM differential source ....................................................................12

4.4 Operating the GPS Analyser software ........................................................................13

4.4.1 VisualGPS ...........................................................................................................13

4.4.2 SiRFDemo ...........................................................................................................13

5.0 Jupiter 20 DR (Dead Reckoning) conguration ........................................... 14

5.1 DR connector pin conguration ...................................................................................14

5.1.1 Pin 1 – DC power supply......................................................................................14

5.1.2 Pin 2 – Heading rate gyro input ...........................................................................14

5.1.3 Pin 3 – Direction F/R sensor ................................................................................15

5.1.4 Pin 4 – Reserved .................................................................................................15

5.1.5 Pin 5 – Speed pulses ...........................................................................................15

5.1.6 Pin 6 – Ground .....................................................................................................15

6.0 Acronyms used in this document ................................................................. 15

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

Page 3

Figures

Figure 2-1 Equipment supplied in the Jupiter 20 GPS Development kit ............................. 4

Figure 3-1 Front and back panels of the Jupiter 20 development unit ............................... 6

Figure 3-2 Conguration DIP switch .................................................................................. 7

Figure 3-3 Function LEDs on front panel ........................................................................... 8

Figure 3-4 Pin layout of the clock out connector ................................................................ 9

Figure 3-5 Internal layout of the Development Unit ........................................................... 9

Figure 3-6 Jupiter 20 adapter board..................................................................................11

Figure 4-1 Development Unit test equipment ....................................................................13

Figure 5-1 DR interface connector (rear of unit) ................................................................14

Tables

Table 3-1 DIP switch settings ............................................................................................. 7

Table 3-2 Pin functions of the clock out connector ............................................................ 9

Table 3-3 Mating connector part description ...................................................................... 9

Table 3-4 Pin functionality .................................................................................................10

Table 3-5 Signals available on the test points ...................................................................10

Table 3-6 Connections J1 (2 mm pitch header) and J2 (2.54 mm pitch header) ..............11

Table 5-1 Gyro input specications ....................................................................................................15

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

Page 4

(1)

(2)

(3)

(4)

(5)

(6)

software and documentation

Serial Port 1

Antenna

DR

Clock

Out

Serial Port 2

-

+

DC Power

9-16Volts

1.0 Introduction

The TU10-D007-400 series of Development kits assist in the integration of either the standard

or DR version of the Jupiter 20 into a customer’s application, offering an easy to use platform

for evaluation purposes. This document provides detailed guidelines for the operation and

conguration of the Jupiter 20 GPS reciever module Development kit.

Note: before supplying power to the Development Unit, carefully review the conguration

settings outlined in section 3.0. Also, familiarise yourself with the main functional switches

and connectors on the Development Unit’s front and rear panels and with the operating

instructions described in this document for optimum receiver performance.

2.0 Equipment

This section provides a brief overview of the equipment included in the Development kit.

2.1 Equipment supplied

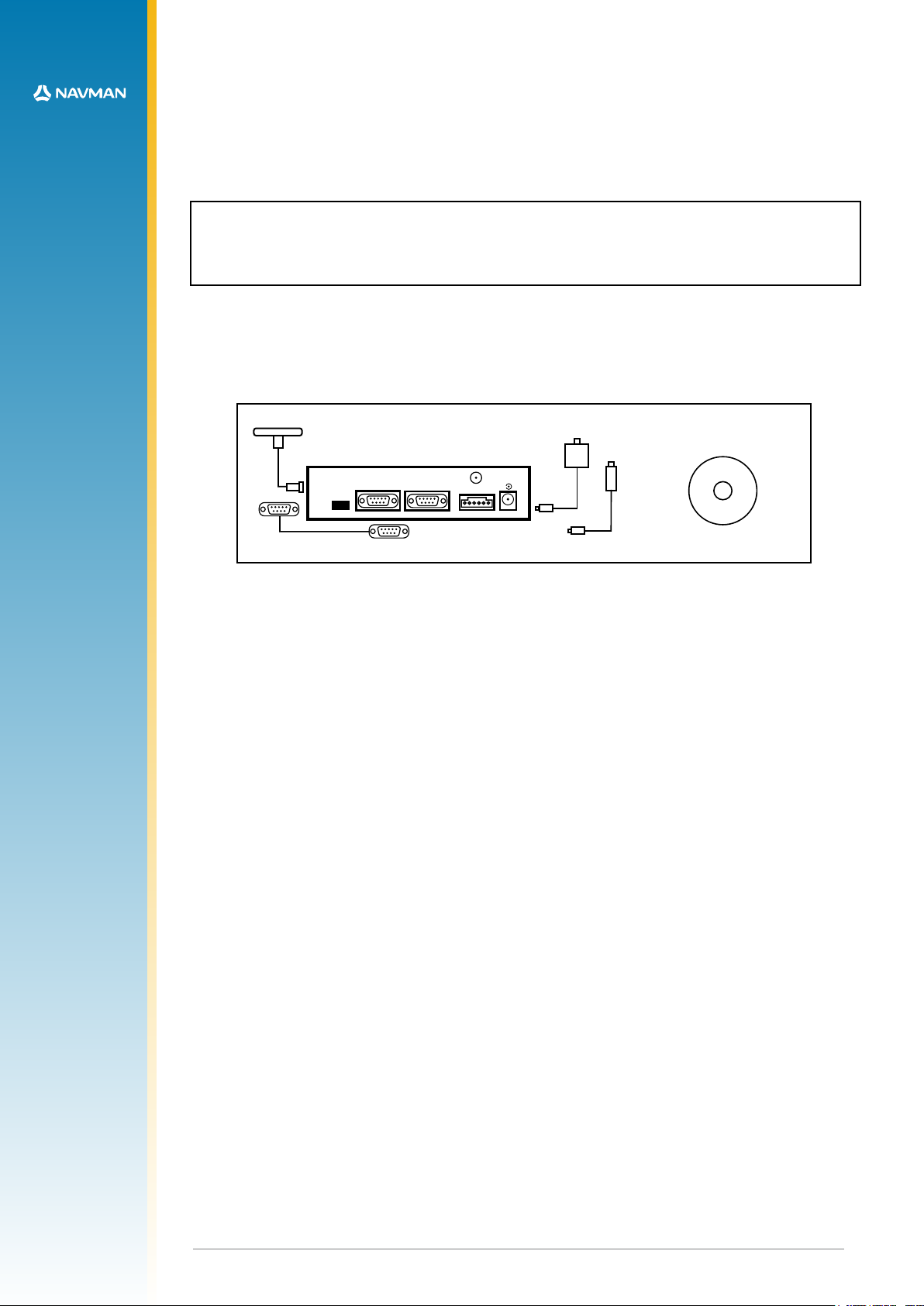

This kit should contain the items illustrated in Figure 2-1.

Figure 2-1 Equipment supplied in the Jupiter 20 GPS Development kit

1. Jupiter 20 GPS Development Unit

The Jupiter 20 GPS receiver Development Unit includes all of the following hardware to allow

thorough evaluation:

• Dual RS232 level serial data I/O ports

• Selectable bias voltages for active GPS antennas

• Backup power source for SRAM and RTC

• Provision to insert a current measuring device to monitor both primary and backup power

usage under various conditions

• Regulated DC power supply to the Jupiter 20 module

• Status indication through four LEDs on front panel

• Congurable functionality using a DIP switch accessed through the front panel

2. GPS antenna with pre-amp, magnetic base and SMA connector

A magnetic-mount active antenna is supplied along with an RF cable (RG-316) already

terminated with the proper connector for the Development Unit. The nominal measured

attenuation of the cable with connectors is approximately 5 dB. The supplied active antenna

should be biased at +3 VDC, but a different active antenna with a bias of either +3, +5 or

+12 VDC may be used. Refer to section 3.2 to ensure that the conguration switches on the front

panel of the Development Unit are set to select the appropriate bias voltage.

Caution: ensure antenna power switches are properly set before connecting the antenna. An

antenna designed for +3 VDC operation will be damaged if connected to a +12 VDC

source.

3. Serial interface cable

A serial cable is provided to interface between the Development Unit and a PC, or between

the Development Unit and a DGPS receiver. This cable is terminated at both ends with female

connectors to match the male connectors on the Development Unit and the PC. If the PC only

supports a USB port, an RS232/USB converter could be used.

4. Power adapter for 240/120 VAC operation

DC power for the Development Unit is provided by an AC/DC converter or automobile adapter.

The AC/DC converter operates from nominal 120/240 VAC input and gives 12 VDC at 500 mA out.

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

4

Page 5

5. Power adapter for 12 VDC vehicle operation

For mobile operation, an automotive adapter intended for use in 12 VDC vehicles is provided.

6. Software and documentation CD

The CD contains Jupiter 20 GPS receiver documentation and other information on how to

use GPS receivers. SiRFDemo and SiRFash analysis software are also provided to allow

communication with the Jupiter 20 GPS receiver through a serial port. This Windows based

software presents the receiver’s raw data in a geographical form, allowing both detailed analysis

and evaluation for both NMEA and SiRF Binary formats.

2.2 Equipment required

The following equipment is also required to evaluate the Jupiter 20 receiver.

• IBM compatible PC

• Minimum one serial port (If your PC only has USB, a USB/RS232 converter can be

employed)

• Windows 95/98, WinNT4.0 or higher

• 486 100MHz or higher

• SVGA at least 800x600 resolution

• 16 Megabytes of RAM

• 6 Megabytes (min) of disk space

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

5

Page 6

3.0 Technical conguration

1 2 3 4 5 6 7 8

CTS 206-8 T 114

'03$EVELOPMENT5NIT

#/.&)'52!4)/.

0/7%2

2%3%4

4)-%

-!2+

0/7%2 $'03

!#4)6%

.-%!

!3352%$

Serial Port 1

Antenna

DR

Clock

Out

Serial Port 2

-

+

DC Power

9-16Volts

This section provides a detailed description of all the technical aspects and congurable

functionality of the Jupiter 20 GPS Development Unit.

3.1 Overview

Figure 3-1 illustrates the connectors, switches and LEDs available on the Development Unit.

power switch

‘U’ slot for antenna

1PPS output

conguration switch

cable (custom)

comm 1

NMEA & binary

function LEDs

SMA antenna

connector

dead reckoning

input signals

comm 2

(RTCM)

reset switch

DC input J1

Figure 3-1 Front and back panels of the Jupiter 20 development unit

3.1.1 Power switch (ON/OFF)

The switch on the front panel controls primary power to the Jupiter 20 receiver module inside.

The power status LED (see section 3.3) indicates status: if lit, the module has primary power

supplied. If the conguration DIP switch 5 is on and Jumper JB5/6 linked, the module’s

secondary supply SRAM and RTC will continue to be powered when the power switch is off.

Only removal of the DC power input at the rear of the unit will stop secondary power being

applied (assuming Jumper JB5/6 and switch 5 are correctly set). Having this secondary power

supply applied means that the Jupiter 20 will have a ‘hot start’ capability when primary power is

re-applied within 4 hours, and a ‘warm start’ thereafter, by maintaining last position, current time

and satellite ephemerides.

3.1.2 Conguration DIP switch

The conguration DIP switch on the front panel provides the ability to congure the Jupiter

20 module, offering exibility depending on the specic application. Refer to section 3.2 for

a description of the functionality of each individual switch, including the typical settings when

using the Jupiter 20 module.

3.1.3 Function LEDs

The four LEDs on the front panel indicate the current status of basic features associated with

the Development Unit. Refer to section 3.3 for a description of the function of each LED.

3.1.4 Reset switch

A reset push button is provided on the front panel to generate a receiver system hardware reset.

3.1.5 Clock out connector

The Clock out connector, located on the rear panel of the Development Unit, can be used to

provide module generated timing signals. Refer to section 3.4 for more detailed information.

3.1.6 Serial port 1

This host serial port is used to send and receive serial data. This port is used as the default, with

transmission in NMEA format at the rate of 9600 Baud. Use 9-pin D-subminiature connectors

with these serial ports.

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

6

Page 7

3.1.7 Serial port 2

This is the auxiliary serial port, primarily used for the reception of RTCM SC-104 DGPS

(Differential GPS) correction messages.

3.1.8 DR connector

The DR connector is used to interface with a gyroscope, wheel tick pulses and forward/reverse

indicator when using a Jupiter 20 DR module. Refer to section 3.5 for more information.

3.1.9 Antenna connector

The antenna provided with this Development kit should be connected to the SMA connector

located on the rear panel of the Development Unit.

3.1.10 DC power input

The supplied DC power adapter should be plugged into the DC connector on the rear panel of

Development Unit. The Development Unit will accept voltages from 9 to 16 VDC. The middle pin

on J1 is negative polarity, while the outer shell is positive.

3.2 Conguration DIP switch

A typical setting of the Conguration DIP switch is shown in Figure 3-2.

1 2 3 4 5 6 7 8

ON

OFF

Figure 3-2 Conguration DIP switch

Table 3-1 outlines the available functionality and corresponding switch position for the

Conguration DIP switch.

Switch Description Typical setting

1 GPIO3/GYROIN* OFF (high)

2 GPIO15/FR* OFF (high)

3 Serial BOOT OFF (normal run)

4 GPIO1/W_TICKS* OFF (high)

5 RTC BACKUP POWER ON (enabled)

6 PREAMP power select OFF (3 V)

7 PREAMP power select OFF (12 V)

8 PREAMP power enable ON (enabled)

* These functions have been disabled by internal switch SW3 to allow correct operation of

the antenna current sense circuits on the Jupiter 20 adapter board.

Table 3-1 DIP switch settings

A brief description of the functionality of each switch is specied below. Refer to the Jupiter 20

Data sheet for more information about the functionality of specic pads. The receiver

operating settings will not change after moving the position of a conguration switch while the

Development Unit is operating. Pressing the reset switch, or turning the unit OFF and ON will

enable the settings to take effect in the receiver. The recommended method for reconguration

is to switch the unit OFF, modify the switch positions, then re-apply the power.

3.2.1 DIP switch 1 – GPIO3 /GYROIN input

DIP switch 1 interfaces with the GPIO3 /GYROIN pad of the module. The switch is typically

OFF, but has no effect with the standard module’s software. This switch can be enabled by the

internal switch SW3.1.

3.2.2 DIP switch 2 – GPIO15 /FR input

DIP switch 2 interfaces with the GPIO15 /FR pad of the module. The switch is typically OFF, but

has no effect with the standard module’s software. This switch can be enabled by the internal

switch SW3.2.

3.2.3 DIP switch 3 – BOOT from serial mode

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

7

Page 8

DIP switch 3 interfaces with the BOOT pad of the module and allows the user to upgrade the

Flash memory. For normal operation the switch should be set to OFF. To boot from the serial

port the switch should be set to ON. This switch is enabled by the internal switch SW3.3.

3.2.4 DIP switch 4 – GPIO1/W_TICKS input

DIP switch 4 interfaces to the GPIO1/W_TICKS pad of the module. The switch is typically

OFF, but has no effect with the standard module’s software. This switch can be enabled by the

internal switch SW3.4.

3.2.5 DIP switch 5 – RTC backup power enable

DIP switch 5 provides control of the RTC backup power to the module. When set to the ON

position, the RTC backup power is applied to the module, allowing the RTC and SRAM to

continue being powered when the primary source is removed. The jumper JB5/6 must also be

in place for the backup power to be supplied. This power supply will be supplied to the module

even with the main power switch in the OFFposition.

3.2.6 DIP switch 6 – Antenna preamp power select (3.3 V or 5/12 V)

DIP switch 6 provides control of the antenna preamp voltage applied to the module. The

position of the switch determines the supply voltage (OFF = 3.3 V, ON = 5/12 V). The positions

of switches 7 and 8 also need to be considered when using the preamp function.

Note: the supplied antenna is a 3.3 V type.

3.2.7 DIP switch 7 – Antenna preamp power select (5 V or 12 V)

DIP switch 7 also controls the antenna preamp voltage applied to the module. If switch 6 is ON,

then switch 7 will determine the supply voltage to the active antenna (OFF = 12 V, ON = 5 V).

3.2.8 DIP switch 8 – Antenna preamp power enable

DIP switch 8 provides the ability to enable/disable the antenna preamp voltage to the module

depending on the antenna being used. Typically this switch is ON, enabling 3 V to be applied to

the active antenna supplied with the kit.

3.3 Function LEDs

There are four LEDs on the front panel of the Development Unit, indicating the status of a

selection of basic functions. The functions of the LEDs are described in the sections that follow.

1PPS Power AUX GPIO

Figure 3-3 Function LEDs on front panel

Note that some early versions of the Development unit have different LED legends.

3.3.1 1PPS

This LED will ash ON with each transition of the 1 PPS (Pulse Per Second) output of the GPS

receiver. The 1PPS LED will begin ashing when the receiver is tracking a satellite.

3.3.2 Power

This LED indicates presence of primary DC power to the module.

3.3.3 AUX

This LED shows activity on the auxiliary serial RS232 port (DGPS).

3.3.4 GPIO

This LED indicates the state of GPIO15 , which can be set via DIP switch 2. This LED is lit

when switch 2 is set to ON. (Note that switch 2 has no effect when using standard Jupiter 20

software.)

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

8

Page 9

3.4 Clock out connector

The Clock out connector provides an interface for all associated timing signals with the module.

It provides the user access to the Time Mark (1PPS) signal. The pinout connections are

described in Table 3-2, and illustrated in Figure 3-4.

Pin number Function

1 not used

2 inverted 1PPS signal

3 normal 1PPS signal

4 ground

Table 3-2 Pin functions of the clock out connector

4

3

2

1

Figure 3-4 Pin layout of the clock out connector

A mating connector for the clock out connector is supplied with the Development kit. The part

number is shown in Table 3-3.

Manufacturer Part number

Molex 70400 series ‘G’

Table 3-3 Mating connector part description

3.5 Internal conguration

It should not be necessary to open the Development Unit unless changing the internal switches

for DR operation or accessing the internal test pins. Most combinations of I/O can be made from

the front panel conguration switch. In the event that it is necessary to open the unit, Figure 3-5

illustrates the internal layout of the Development Unit board.

serial p ort 1

timing c onnec tor

JB13/14/15

test points E1 to E9

JB16/17

SW3

all off exc ept SW3. 3

JB10/11/12

voltage select ion

switch (3.3V or 5V )

JB1/2

JB3/4

DC power

DR connector

serial p ort 2

ON/OF F switch cong uratio n DIP

switch

function LEDS JB5/6 reset switch

Figure 3-5 Internal layout of the Development Unit

As shown in Figure 3-5, there is a selection of links that can be congured to provide

functionality depending on the application. Table 3-4 lists the functions available.

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

9

Page 10

Pins Function when linked

Current link for 5 V supply. Can be used to

JB1/2

JB3/4

JB5/6

JB10/11 5 V supplied to Pin 1 of the DR connector

JB11/12 3.3 V supplied to Pin 1 of the DR connector

JB13/14 not used

JB14/15 not used

JB16/17 Internal interface enable (normally tted)

determine current on 5 V rail. Not used for the

Jupiter 20 module.

Current link for the primary power 3.3 V

supply. Can be used to determine supply

current for 3.3 V rail.

Current link for the secondary power RTC

supply. Can be used to determine supply

current for RTC rail.

Table 3-4 Pin functionality

In addition to the congurable jumpers, there is a selection of test points on the board. The

signals available on the test points are shown in Table 3-5.

Test point Function

E1 TXA

E2 RXA

E3 TXB

E4 RXB

E6 1PPS

E7 not used

E8 ground

E9 ground

Table 3-5 Signals available on the test points

There are some settings that should not be changed when using the standard Jupiter 20 module

in conjunction with the Development Unit. These are as follows:

• SW2 must remain selected on 3.3 VDC

• Link for JB3/4 must be tted

• Link for JB16/17 must be tted

• SW3 DIP switch must be all off except SW3.3

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

10

Page 11

3.6 Jupiter 20 module on adapter board

Figure 3-6 shows the adapter board with the positions of the connectors and indicators.

power LED GPS x LED

Jupiter 20 module

antenna

Figure 3-6 Jupiter 20 adapter board

Table 3-6 lists the pin congurations for the J1 and J2 connectors.

Jupiter function J2 (2.54 mm pitch header)

pin no.

V_ANT 1 1

VCC_RF 2

V_BATT 3 3

VDD 4 4

M_RST 5 5

GPIO3/GYRO IN 6 6

GPIO15/FR 7 7

BOOT 8 8

GPIO1/W TICKS 9 9

RFON 10

GND 10

TXA 11 11

RXA 12 12

GPIO5/SDI 13

GND 13

TXB 14 14

RXB 15 15

GPIO7/SCK 16

GND 17 16

GPIO6/SDO 18

GND 17

GND 18

1PPS 19 19

GPS_FIX/GPIO10 20

J1 (2 mm pitch header)

Table 3-6 Connections J1 (2 mm pitch header) and J2 (2.54 mm pitch header)

RTC backup bat tery

(not normally tted)

(not normally tted)

pin no.

J1

J2

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

11

Page 12

4.0 Operating instructions

This section provides important information for the evaluation of the Jupiter 20 GPS module.

Step-by-step instructions for connecting and operating the GPS development kit are included for

rst time setup.

4.1 Initial connection and operation

The following steps describe how to connect and operate the GPS Development Kit.

4.1.1 Install the supplied SiRFdemo on your PC:

1. Insert the supplied CD into the CDROM drive

2. Double click on the SiRFDemo software icon and follow the installation process.

4.1.2 Set up the hardware:

1. Connect the DC power adapter to the power input J1.

2. Connect the antenna cable to the SMA coaxial antenna connector on the rear panel of the

Development unit.

3. Connect the DB9 serial data cable between the PC serial communication port and the

Development Unit’s Serial Port 1.

4. Place the antenna in a site where a good view of the sky can be seen (refer to section 4.2 for

more detail).

5. Run the GPS analyser software on the PC. (Refer to section 4.4 for more details.)

6. Connect the power supply to a suitable AC outlet.

7. Turn the unit on using the power switch on the front panel to provide primary power to the

Jupiter 20 receiver. Once power is applied, the Power LED should be lit.

4.2 Positioning the GPS antenna

The GPS antenna should be located with a clear view of the sky for optimal reception of the

satellite signals. The 1PPS LED should begin ashing at 1 Hz once the receiver is powered

and has started receiving at least one satellite. This provides an indication of whether or not the

receiver is running.

Note: GPS signals may be severely attenuated or totally obscured by roofs, solid walls, dense

foliage, or even coated glass (found in many ofce structures and car windows). The

Development Unit should be outside, or on the roof of a building to effectively evaluate

receiver performance. With stationary developments, care should be taken to keep the

antenna away from the side of a building as GPS signals can reect off metal or coated

glass. These reections have a longer path than direct signals and can cause multi-path

errors.

4.3 Connecting an RTCM differential source

For debugging purposes, it is suggested that users log both the GPS and RTCM data

simultaneously. To allow the provision to do this, Navman can supply a software program called

Labmon.

The Development Unit, PC and the RTCM SC-104 differential correction source are connected

as shown in Figure 4.1. If RTCM SC-104 data needs to be logged at the same time it is sent

to the receiver, the OEM must supply a cable with three connectors to connect the RTCM

correction source to the Development Unit’s auxiliary port and to an unused serial port on the

PC. In this case, data is only logged when Labmon is invoked with le names as command line

arguments (refer to the Labmon application note LA010103). Logging and subsequent review of

the RTCM correction data often resolves performance or compatibility issues.

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

12

Page 13

optional antenna

or pre-amplier

antenna

power

development unit

RTCM DGPS

data source

monitor

PC

optional connection for logging RTCM data

Figure 4-1 Development Unit test equipment

The Development Unit should be set up as shown in Figure 4-1 with only the RTCM correction

source connected to the receiver. If the RTCM cable is not connected to the receiver’s auxiliary

port, DGPS operation will not be possible. When RTCM data is being received the AUX LED will

be lit.

Note: the Development Unit may be connected to either the COM1, COM2, COM3, or COM4

serial ports and the RTCM differential correction data source connected either directly to

the receiver’s auxiliary I/O port, to one of the remaining serial ports of the PC, or to both

using an OEM-supplied three-connector serial cable.

4.4 Operating the GPS Analyser software

There are two software packages supplied with the GPS Development kit: SiRFDemo and

SiRFFlash. The VisualGPS program can be obtained free of charge from the VisualGPS website

(www.visualgps.net/VisualGPS/ ).

4.4.1 VisualGPS

VisualGPS graphically presents the serial data transmitted by the receiver. The receiver output

must be enabled in the NMEA protocol for this software to be used.

To enable the receiver output

1. Open the VisualGPS software installed on the PC.

2. Select the Settings>Communications tab.

3. When the Communications Settings window is displayed, select the correct COM Port and set

the Baud rate to 9600 Baud.

When this has been carried out, and the Development Unit is powered, raw NMEA data should

appear in the NMEA Monitor Window. For more detailed information on any of the analysis

windows, use the Help function in the top toolbar.

4.4.2 SiRFDemo

SiRFDemo software can provide analysis of receiver output in either SiRF binary or NMEA

protocols. When enabled in NMEA format, the only analysis provided is raw data being

transmitted by the receiver. While the module is transmitting serial data in NMEA format, it is

suggested that VisualGPS is used for analysis, rather than SiRFDemo.

To provide graphical presentation of the data, the receiver can be set to output in SiRF binary

format.

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

13

Page 14

To set the receiver output to SiRF binary

1. Open the SiRFDemo software.

2. When the Data Source setup is displayed, select the appropriate COM port and 9600 Baud

from the drop down menu.

3. Select the Action menu and click on Open Data Source. If the Development Unit is powered,

and the serial port is connected to the PC, NMEA data should appear in the Debug View

window.

To change to SiRF binary, select the Action menu and click on the Switch to SiRF Protocol. This

should now present information in each window, similar to that of VisualGPS. Whilst enabled in

SiRF binary protocol, more of the analysis software’s functionality can be accessed. To switch

back into NMEA mode, select the Action menu and click on Switch to NMEA Protocol. Select

9600 for the baud rate and click on the Send button.

Note: settings, including the current output protocol, are reset if all power is removed from the

unit. For more information, refer to the SiRFDemo and SiRFFlash User Guides.

5.0 Jupiter 20 DR (Dead Reckoning) conguration

The DR connector on the rear panel of the Development Unit provides an interface with the

external inputs under DR operation. This functionality is only to be used when evaluating Jupiter

20 DR modules.

The connector is used for signals transmitted by:

• An angular rate sensor (gyro)

• A wheel ticks source

• A forward/reverse indicator

These signals are present on many late model vehicles and may be used to assist the DR

receiver in determining position accuracy during the loss of signal conditions. Direct connection

to the vehicle is not normally possible as the inputs need to be 3 V logic level signals.

Note: when using the Jupiter 20 DR version in a Development Unit, the front panel switches 1,

2, 3 and 4 should be isolated by turning the internal switches SW3 OFF. If the front panel

DIP switch 3 is still required, leave the internal switch SW3.3 ON.

5.1 DR connector pin conguration

The following sections describe the functions of the DR connector pins. Refer to Figure 5-1.

J5

+3.3 VDC,

or +5 VDC

2

1

gyro ground

direction

F/R

3

reserved

4 5 6

wheel

ticks

Figure 5-1 DR interface connector (rear of unit)

5.1.1 Pin 1 – DC power supply

This pin can be used to power at either 3.3 or 5 VDC for external devices used in the DR

operation. To modify the supply voltage, refer to section 3.5 for details of the jumper positioning.

5.1.2 Pin 2 – Heading rate gyro input

Table 5-1 details the gyro requirements. It is important to ensure that the rate gyro signals have

the following characteristics:

• Range: 0 to 5 V

• Output (no gyro rotation): 2.5 V

• Clockwise rotation of the gyro causes the output voltage to rise

• Maximum voltage deviation due to rotation should occur with a turning rate of 90º per

second or less

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

14

Page 15

The gyro should be mounted so that its sensitive axis is as near vertical as practical. Deviations

from the vertical will reduce sensitivity for heading changes in the horizontal direction.

Experiments have shown that acceptable performance can be achieved with mounting

deviations of several degrees, but a better performance is achieved when the gyro is mounted

closer to vertical.

Characteristics Symbol Condition Minimum Standard Maximum Unit

Supply voltage Vcc +4.5 +5.0 +5.5 VDC

Max. angular velocity ω max –80 +80 deg/s

Output Vo angular velocity = 0 at –30

~ 80°C

Scale factor Sv at –30 ~ 80°C 19.3 22.2 25.1 mV/deg/s

Asymmetry CW & CCW 3 deg/s

Temp coefcient scale

factor

Temp coefcient drift reference temp:

Noise level 7kHz noise 20 mVrms

Linearity in the maximum angular

Operating temp range Topr –40 85 °C

reference temp:

–30 ~ 80°C

–30 ~ 80°C

velocity range

2.200 2.500 2.800 VDC

±10 %FS

9 deg/s

0.5 %FS

Table 5-1 Gyro input specications

5.1.3 Pin 3 – Direction F/R sensor

Input from a signal that is normally at +0 V, but rises to +3 V when the vehicle is in the reverse

gear. Use of this signal is optional; if it is not used, the effect of occasional reversing by the

vehicle will not signicantly degrade navigation performance. To ensure minimum current under

backup power, be sure that this input is not pulled up external to the board.

If this signal is not connected, switch SW3.2 should be left on, with DIP switch 2 also on to

select ‘forward’.

5.1.4 Pin 4 – Reserved

5.1.5 Pin 5 – Speed pulses

The input to this pin is a pulse train generated in the vehicle. If this signal is derived from the

vehicle’s electrical system, external level shifting for this signal is required. The pulse frequency

is proportional to the vehicle velocity. These pulses, or wheel ticks, are generated in most

vehicles by the ABS (Anti-lock Braking System), the transmission, or the drive shaft. System

design must restrict the pulses between 0 and 3 V.

Detection limits are as follows:

• Minimum detectable rate: 1 Hz

• Maximum detectable rate: 4 kHz

5.1.6 Pin 6 – Ground

6.0 Acronyms used in this document

1PPS: One Pulse Per Second

DGPS: Differential Global Positioning System

GPIO: General Purpose Input Output

GPS: Global Positioning System

NMEA: National Marine Electronics Association

RTC: Real Time Clock

RTCM: Radio Technical Commission for Maritime services

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

15

Page 16

Windows® is a trademark of Microsoft Corporation.

© 2004 Navman NZ Ltd. All Rights Reserved.

Information in this document is provided in connection with Navman NZ Ltd. (‘Navman’) products. These materials are

provided by Navman as a service to its customers and may be used for informational purposes only. Navman assumes

no responsibility for errors or omissions in these materials. Navman may make changes to specications and product

descriptions at any time, without notice. Navman makes no commitment to update the information and shall have no

responsibility whatsoever for conicts or incompatibilities arising from future changes to its specications and product

descriptions. No license, express or implied, by estoppel or otherwise, to any intellectual property rights is granted by

this document. Except as provided in Navman’s Terms and Conditions of Sale for such products, Navman assumes no

liability whatsoever.

THESE MATERIALS ARE PROVIDED “AS IS” WITHOUT WARR ANT Y OF ANY KIND, EITHER EXPRESSED OR

IMPLIED, RELATING TO SALE AND/OR USE OF NAVMAN PRODUCTS INCLUDING LIABILITY OR WARRANTIES

RELATING TO FITNESS FOR A PARTICULAR PURPOSE, CONSEQUENTIAL OR INCIDENTAL DAMAGES,

MERCHANTABILITY, OR INFRINGEMENT OF ANY PATENT, COPYRIGHT OR OTHER INTELLECTUAL

PROPERTY RIGHT. NAVMAN FURTHER DOES NOT WARRANT THE ACCURACY OR COMPLETENESS OF THE

INFORMATION, TEXT, GRAPHICS OR OTHER ITEMS CONTAINED WITHIN THESE MATERIALS. NAVMAN SHALL

NOT BE LIABLE FOR ANY SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, INCLUDING

WITHOUT LIMITATION, LOST REVENUES OR LOST PROFITS, WHICH MAY RESULT FROM THE USE OF THESE

MATERIALS.

Navman products are not intended for use in medical, lifesaving or life sustaining applications. Navman customers

using or selling Navman products for use in such applications do so at their own risk and agree to fully indemnify

Navman for any damages resulting from such improper use or sale. Product names or services listed in this publication

are for identication purposes only, and may be trademarks of third parties. Third-party brands and names are the

property of their respective owners. Additional information, posted at www.navman.com, is incorporated by reference.

Reader Response: Navman strives to produce quality documentation and welcomes your feedback. Please send

comments and suggestions to tech.pubs@navman.com. For technical questions, contact your local Navman sales

ofce or eld applications engineer.

LA000510C © 20 06 Navman NZ Ltd. A ll rights reser ved. Pr oprietary informa tion and s peci catio ns subje ct to chan ge with out notice.

16

Loading...

Loading...