NAVMAN IN-HULL, THROUGH HULL User Manual

NAVMAN

www.navman.com

Installation Manual

THROUGH HULL AND

IN-HULL TRANSDUCERS

English..............3

Français.......... 10

Español...........18

Português....... 26

2 Through hull & In-hull transducer installation manual

NAVMAN

FCC Statement

Note: This equipment has been tested and found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference in a normal installation.

This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off

and on, the user is encouraged to try to correct the interference by one or more of the

following measures:

Reorient or relocate the receiving antenna

Increase the separation between the equipment and receiver

Connect the equipment into an output on a circuit different from that to which the

receiver is connected

Consult the dealer or an experienced technician for help

A shielded cable must be used when connecting a peripheral to the serial ports.

Important

It is the owner’s sole responsibility to install and use Navman’s transducers in a manner that

will not cause accidents, personal injury or property damage. The user of this product is solely

responsible for observing safe boating practices.

Transducer installation: The choice, location, angle and installation of the transducer is the most

critical part of installation. If installation is not correct, the unit can not perform at its designed

potential. If in doubt, consult your Navman dealer. Ensure that any holes that cut are in a safe

position and will not weaken the boat’s structure. If in doubt, consult a qualifi ed boat builder.

Disclaimer: The information in this manual is provided as a guide only. The transducer’s

performance is infl uenced by the boat’s material, hull design and engine installation and these

are beyond the control of Navman NZ Limited.

NAVMAN NZ LIMITED DISCLAIMS ALL LIABILITY FOR ANY USE OF THIS PRODUCT IN A

WAY THAT MAY CAUSE ACCIDENTS, DAMAGE OR THAT MAY VIOLATE THE LAW.

Governing language: This statement, any instruction manuals, user guides and other information

relating to the product (Documentation) may be translated to, or has been translated from,

another language (Translation). In the event of any confl ict between any Translation of the

Documentation, the English language version of the Documentation will be the offi cial version

of the Documentation.

This manual represents the transducer installation procedures as at the time of printing. Navman

NZ Limited reserves the right to make changes to specifi cations without notice.

Copyright © 2003 Navman NZ Limited, New Zealand, all rights reserved. Navman is a registered

trademark of Navman NZ Limited.

3Through hull & In-hull transducer installation manual

NAVMAN

1-1 Wiring

Each transducer has a cable to connect it to the

navigation instrument. When fi tting this cable:

Keep the cable away from other cables

and equipment (for example fl uorescent

lights, power inverters and VHF

transmitters.)

Do not cut the cable on any depth

transducer

If necessary, extend the cable by adding

a Navman 4 m (13 ft) extension cable (a

1 Introduction

1-2 Cleaning and maintenance

Clean a transducer with a damp cloth or mild

detergent. Avoid abrasive cleaners and petrol

or other solvents.

When repainting the hull, cover or remove any

speed transducers. Do not paint the transducer.

This manual describes how to install:

Navman’s range of through hull depth and

speed/temperature transducers

Navman’s in-hull depth transducer.

Accessories

These accessories are available from your

Navman dealer:

4 m (13 ft) speed/temperature transducer

extension cable

4 m (13 ft) depth transducer extension

cable for both single and dual frequency

units

Replacement speed/temperature

transducer hull fi tting

Replacement speed/temperature

transducer paddlewheel

20 m (65 ft) dual frequency depth

transducer extension cable.

maximum of one cable can be used). For

dual frequency transducers, a 20 m (65 ft)

extension cable is available.

Ensure no cable connectors lie

in the bilge

Secure the cable at regular intervals

Refer to the navigation instrument’s

installation manual for instructions on how

to connect the cable to the instrument.

Do not use a high pressure water blast on

the speed transducer paddlewheel as it may

damage the bearings.

Contents

1 Introduction.............................................................................................3

1-2 Cleaning and maintenance ............................................................................ 3

1-1 Wiring ............................................................................................................. 3

2 Through hull transducers......................................................................4

2-1 Positioning a through hull transducer............................................................. 6

2-2 Installing a through hull transducer ................................................................ 6

3 In-hull depth transducer ........................................................................8

3-1 Positioning an in-hull transducer.................................................................... 8

3-2 Installing an in-hull depth transducer ............................................................. 9

4 Through hull & In-hull transducer installation manual

NAVMAN

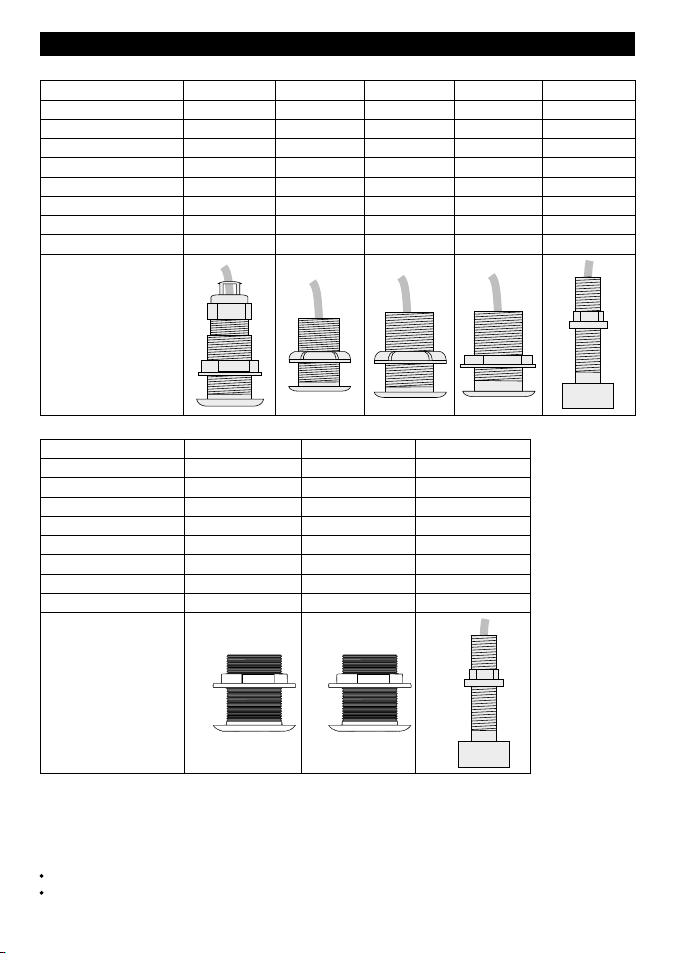

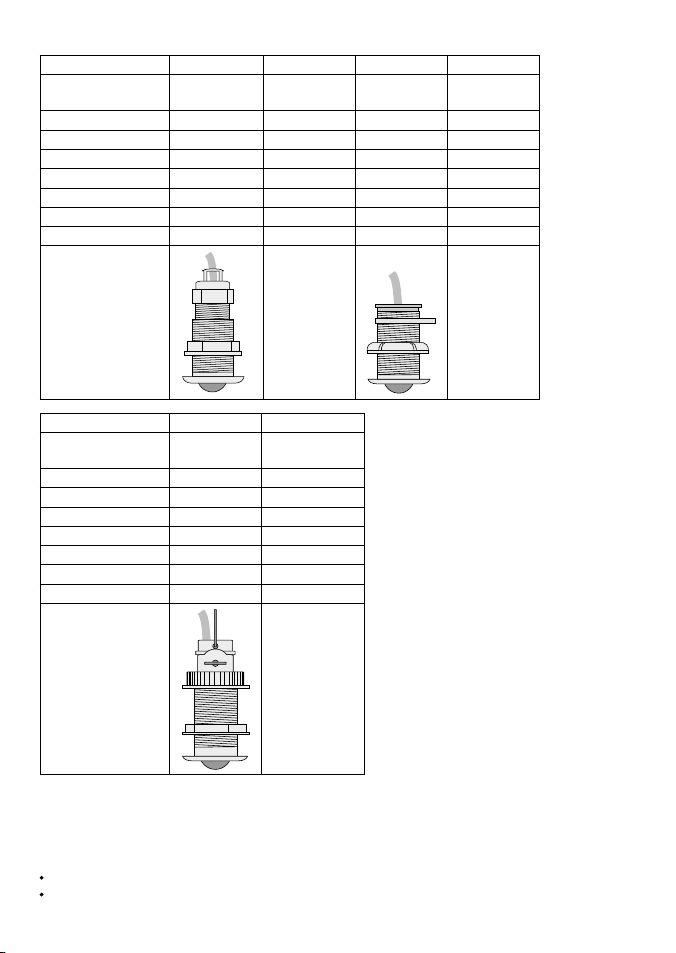

Part # - Europe 47535 47512 Not available

Part # - Rest of World AA002108 AA002107 AA002109

Material Bronze Plastic Bronze

Type (1) Fixed (Dual freq.) Fixed (Dual freq.) Fixed (Dual freq.)

Connector 6-pin LT 6-pin LT 6-pin LT

Hull hole diam. 2½" (63.5 mm) 2½" (63.5 mm) 1

1

/

6

" (27 mm)

Max. hull thickness 3

1

/

8

" (80 mm) 2¼" (56 mm) 4

7

/

8

" (110 mm)

Cable length 33 ft (10 m) 33 ft (10 m) 33 ft (10 m)

Flush or long stem Flush Flush Long stem

2 Through hull transducers

Depth transducers:

Part # - Europe 25983 26032 31357 31358 Not available

Part # - Rest of World Not available AA002155 Not available AA002106 AA000043

Material Plastic Plastic Plastic Bronze Bronze

Type (1) Insertable Fixed Fixed Fixed Fixed

Connector RCA phono RCA phono RCA phono RCA phono RCA phono

Hull hole diam. 1

7

/

8

" (48 mm) 1

5

/

8

" (42 mm) 2" (51 mm) 2" (51 mm)

7

/

8

" (22 mm)

Max. hull thickness 2

3

/

8

" (60 mm) 1

5

/

8

" (42 mm)

7

/

8

" (22 mm) 2

3

/

8

" (60 mm) 2

5

/

8

" (92 mm)

Cable length 26.2 ft (8 m) 26.2 ft (8 m) 26.2 ft (8 m) 26.2 ft (8 m) 29.5 ft (9 m)

Flush or long stem Flush Flush Flush Flush Long stem

Notes

1 With an insertable transducer, the transducer element can be removed, leaving the hull

fi tting in place in the hull. With a fi xed transducer, the transducer element and hull fi tting can

not be separated.

Caution

Plastic through hull transducers are not suitable for wooden hulls.

Bronze transducers are usually unsuitable for metal hulls.

5Through hull & In-hull transducer installation manual

NAVMAN

Speed/temperature transducers:

Part # - Europe 25982 40640 26017 40641

Part # - Rest of

World

Not available Not available AA002150 AA002082

Material Plastic Plastic Plastic Bronze

Type (1) Insertable Insertable Insertable Insertable

Connector 4-pin Fuji 8-pin LT 4-pin Fuji 8-pin LT

Hull hole diam. 1

7

/

8

" (48 mm) 1

7

/

8

" (48 mm) 1

5

/

8

" (42 mm) 1

5

/

8

" (42 mm)

Max. hull thickness 2

3

/

8

" (60 mm) 2

3

/

8

" (60 mm) 1

5

/

8

" (42 mm) 1

5

/

8

" (42 mm)

Cable length 26.2 ft (8 m) 26.2 ft (8 m) 26.2 ft (8 m) 26.2 ft (8 m)

Flush or long stem Flush Flush Flush Flush

Same as

25982, but

with 8-pin LT

connector

Same as

AA002150 /

26017, but

with 8-pin LT

connector

Part # - Europe 31359 47552

Part # - Rest of

World

AA000055 AA002151

Material Bronze Bronze

Type (1) Insertable Insertable

Connector 4-pin Fuji 8-pin LT

Hull hole diam. 2" (51 mm) 2" (51 mm)

Max. hull thickness 2

1

/

8

" (55 mm) 2

1

/

8

" (55 mm)

Cable length 29.5 ft (9 m) 29.5 ft (9 m)

Flush or long stem Flush Flush

Same as

AA000055 /

31359, but

with 8-pin LT

connector

Notes

1 With an insertable transducer, the transducer element can be removed, leaving the hull

fi tting in place in the hull. With a fi xed transducer, the transducer element and hull fi tting

can not be separated.

Caution

Plastic through hull transducers are not suitable for wooden hulls.

Bronze transducers are usually unsuitable for metal hulls.

6 Through hull & In-hull transducer installation manual

NAVMAN

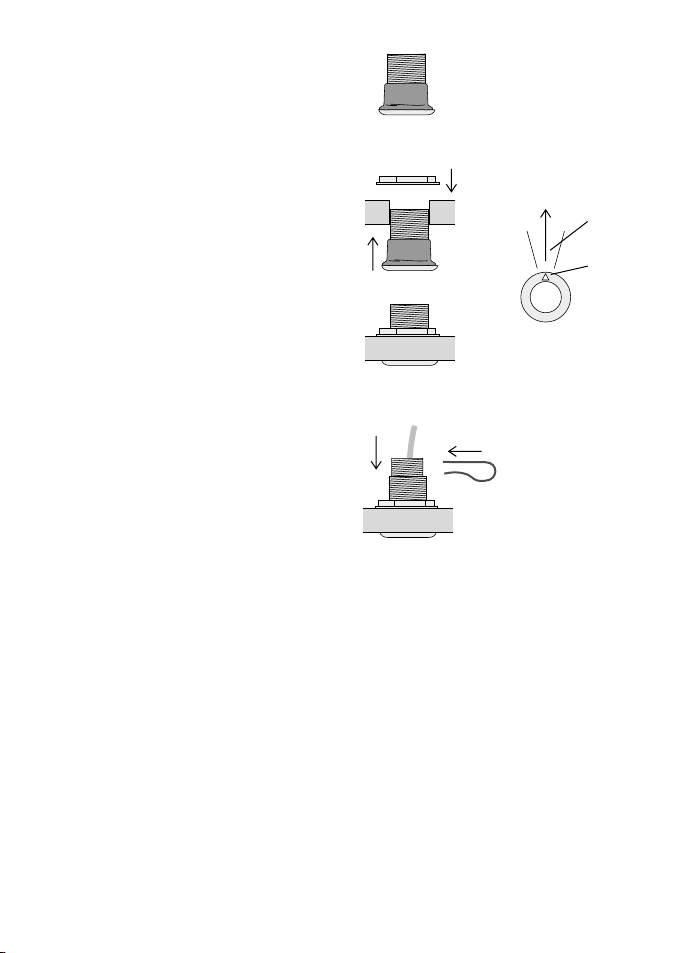

2-2 Installing a through hull transducer

1 Select a suitable position for the

transducer (see section 2-1).

If the hull panel is too thin or the panel

might not be strong enough, consider

fi tting a reinforcing pad on the inside of

the hull.

2 Find the hole size required for the

transducer from the table above. Drill or

cut the hole in the hull. The hole must be

perpendicular to the hull surface.

3 For an insertable transducer:

i remove the locking nut or pin

rom the fi tting

ii pull the transducer out from the

hull fi tting

iii unscrew the nut from the hull fi tting.

For a fi xed transducer:

i unscrew the nut from the hull fi tting

ii hold the nut just inside the hole

in the hull

iii feed most of the transducer cable

through the hole in the hull (from the

outside) and through the nut.

4 Apply a thick layer of fl exible bedding

compound (such as Sikafl ex) to the

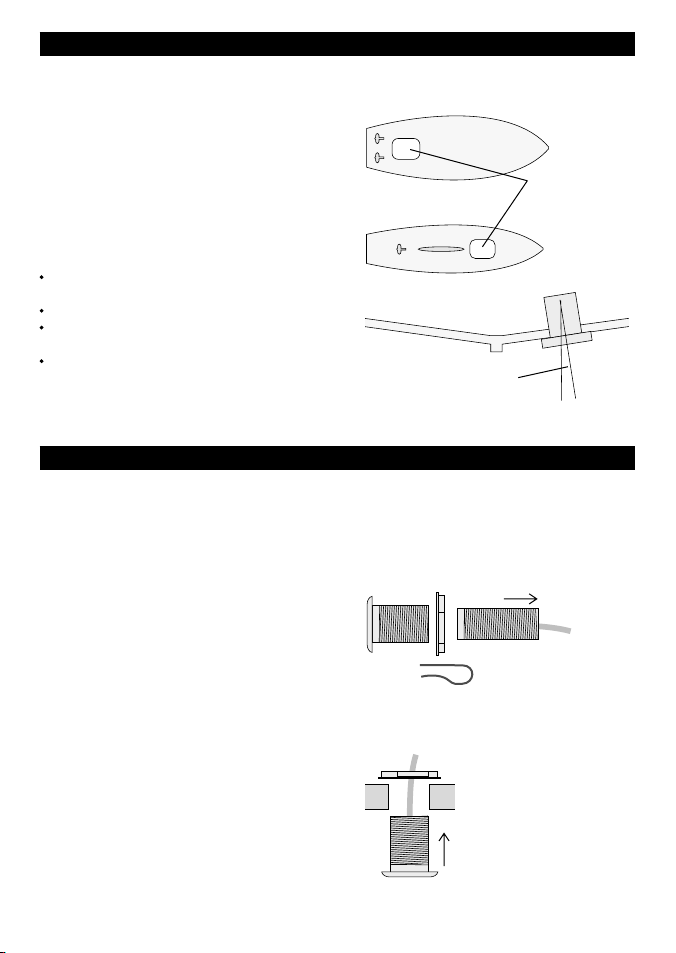

2-1 Positioning a through hull transducer

This transducer will be fi tted in a hole drilled

in the bottom of the boat. Select a position

for the transducer that has a smooth fl ow of

clear water over the transducer surface at all

times. This means that the transducer should

be ahead of any keel, hull projections, hull

openings, paddle wheel transducers, propellers

or propeller wash. If the bottom of the boat is

painted and the boat has been used, do not

mount the transducer where the paint is eroded

(an indication of turbulence).

In addition, position the transducer:

as close to the middle line of the hull as

possible and as deep as possible

where the deadrise angle is small

with suffi cient space inside the hull for

access and wiring

so that it will not interfere with launching

or retrieving the boat

Ideally a depth transducer should be fi tted so

that its axis is vertical, however it can be up to

15° off vertical.

Planing or displacement boat

Sailing boat

Suitable

locations for

transducer

Remove

transducer

Insertable transducer

Fixed transducer

Remove locking

nut or pin

Up to 15°

7Through hull & In-hull transducer installation manual

NAVMAN

Bedding

compound

Arrow faces forward

to within 5°

Arrow

5°

hull fi tting on the inside face of the fl ange

and on the exterior threads where they

pass through the hull.

5 Insert the hull fi tting into the hull from

outside. For a speed/temperature

transducer, rotate the fi tting until the arrow

on the outside lip points forward to within 5°.

6 Fit and tighten the nut on the hull fi tting.

For a plastic fi tting, hand-tighten the nut

and do not over tighten. For a bronze

fi tting, tighten with slip-joint pliers.

Tighten the nut until excess bedding

compound is squeezed out from under

the nut and the face of the hull fi tting.

Remove the excess bedding compound.

7 For a speed/temperature transducer,

check that the arrow on the hull fi tting still

points forward.

8 For an insertable transducer:

i ensure there is a thin layer of silicone

grease or O-ring lubricant on the

transducer O-rings

ii insert the transducer back into the hull

fi tting, rotating the transducer so that

the arrow on the transducer mates

with the notch on the fi tting

iii replace the locking nut or pin.

9 Wait for the bedding compound to dry.

10 Before leaving the boat unattended,

check that there is no water ingress

from around the transducer.

Grease

Insert

Replace locking nut or pin

Forward

View from bottom

Insertable transducer

8 Through hull & In-hull transducer installation manual

NAVMAN

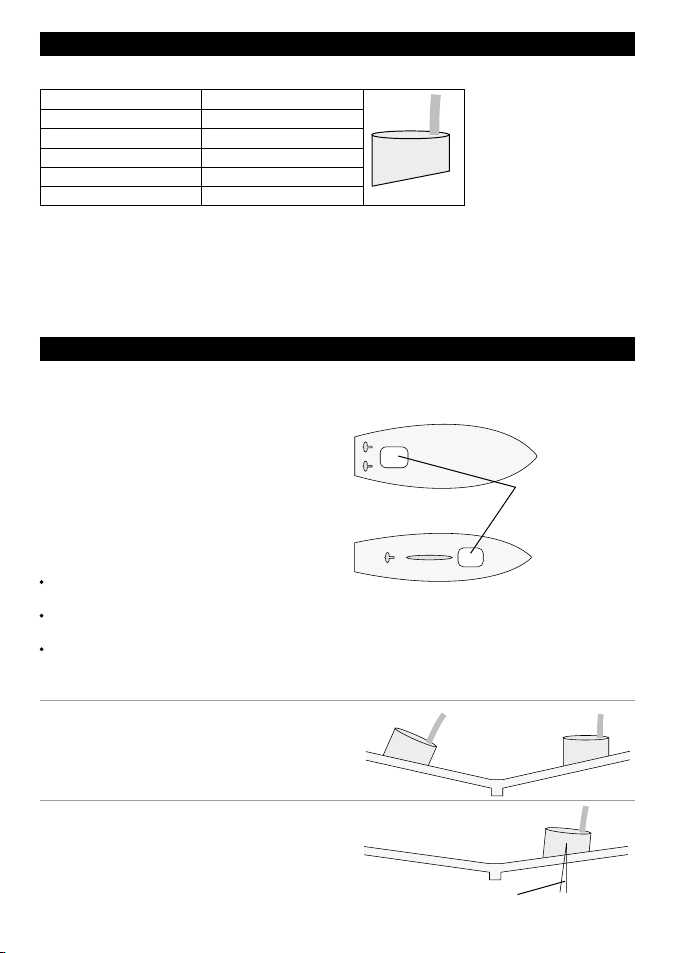

3 In-hull depth transducer

3-1 Positioning an in-hull transducer

This transducer will be glued to the inside of

the bottom of the boat. Select a position for the

transducer that has a smooth fl ow of clear water

under the transducer at all times. This means

that the transducer should be ahead of any keel,

hull projections, hull openings, paddle wheel

transducers, propellers or propeller wash. If

the bottom of the boat is painted and the boat

has been used, do not mount the transducer

where the paint is eroded (an indication of

turbulence).

In addition, position the transducer:

as close to the middle line of the hull as

possible and as deep as possible

with suffi cient space inside the hull for

access and wiring

where the inside surface of the hull is fl at and

smooth and there will be no gaps between

the face of the transducer and the hull.

Planing or displacement boat

Sailing boat

Suitable locations

for transducer

Up to 15°

Part # - Europe 27948

Part # - Rest of World AA002161

Material Plastic

Connector RCA phono

Max. hull thickness ¾" (20 mm)

Cable length 26.2 ft (8 m)

One in-hull transducer is available, a depth transducer.

Caution

In-hull depth transducers are only suitable for solid GRP hulls up to ¾" (20 mm) thick, without air

pockets, beads or voids. They are not suitable for wooden, metal or sandwich hulls. Compared to

other types of transducer, in-hull depth transducers generally have lower performance because

power is absorbed in the hull.

No Yes

Ideally the transducer should be rotated so

that its axis is vertical, however it can be up

to 15° off vertical.

The face of the transducer is angled. When

fi tting the transducer, rotate the transducer so

that the axis of the transducer is as close to

vertical as possible.

9Through hull & In-hull transducer installation manual

NAVMAN

1 Select a suitable position for the

transducer and establish how the

transducer should be rotated so that the

axis is as vertical as possible (see section

2-1).

2 Test the transducer at this position

with the boat in the water before

mounting it permanently:

i Partially fi ll a thin plastic bag with

water, place the transducer inside and

close it tightly around the cable

with a tie-wrap.

ii Install the depth instrument as

described in the instrument’s

Installation and Operation manual.

iii Wet the surface of the hull and press

the transducer against the inside of

the hull where you plan to mount the

transducer.

iv Check that the instrument measures

depth correctly and consistently, up

to the maximum depth specifi ed for

the instrument. If necessary, move the

bag around the hull to fi nd the best

position.

3 Choose an adhesive or sealant to glue

the transducer to the hull. Hard epoxies

transmit the transducer signals best but

temperature changes and hull fl exing can

cause delamination. As a compromise,

use a viscous slow cure, fairly rigid epoxy

or Sikafl ex 252 sealant.

3-2 Installing an in-hull depth transducer

4 Ensure the inside of the hull where the

transducer will be mounted is fl at.

Clean, degrease and dry:

the inside of the hull where the

transducer will be mounted

the sloping face of the transducer

5 Fit the transducer:

i Apply the epoxy or sealant to the

middle of the transducer face.

ii Press the transducer into place

on the hull.

iii Twist the transducer back and forth to

expel any trapped air and to expel as

much glue as possible from the joint.

The fi nished joint should be as thin as

possible and not contain any

air bubbles.

Leave the transducer rotated to the

correct angle.

iv Temporarily secure the transducer in

place with tape and wait for the glue

to cure for 24 hours.

Glue

10 Guide d’installation des capteurs traversants et des

sondes à montage interne

NAVMAN

Important

Il incombe au propriétaire de veiller à ce que l’instrument et le capteur soient installés et utilisés

de telle sorte qu’ils ne causent pas d’accidents, de blessures ou de dommages matériels.

L’utilisateur de ce produit est seul responsable du respect des règles de sécurité en matière

de navigation.

Installation du capteur : une attention toute particulière doit être portée au choix, à

l’emplacement et à l’angle de montage du capteur. Si le capteur n’est pas correctement installé,

il ne pourra pas fonctionner de manière optimale. N’hésitez pas à consulter votre revendeur

Navman pour des informations complémentaires. Veillez à ce que les trous de montage soient

percés à des endroits adaptés et n’endommagent pas la structure du bateau. En cas de doute,

veuillez vous adresser à un chantier naval.

Avertissement : les informations contenues dans cette notice sont données à titre indicatif.

Certains facteurs indépendants de la volonté de Navman NZ Limited, tels que le matériau de

construction du bateau, la forme de la coque ou l’installation moteur, ont une infl uence sur les

performances du capteur.

NAVMAN NZ LIMITED DECLINE TOUTE RESPONSABILITE DANS LE CAS D’UNE

UTILISATION DU PRODUIT OCCASIONNANT DES ACCIDENTS, DES DOMMAGES MATE-

RIELS OU UN NON-RESPECT DE LA LOI.

Langue de référence : cette notice a été traduite de l’anglais. En cas de litige concernant

l’interprétation de la notice, la version anglaise de la notice prévaudra.

Cette notice présente les procédures d’installation des capteurs traversants et des sondes à

montage interne telles qu’elles sont à la date d’impression. Navman NZ Limited se réserve le

droit de modifi er les spécifi cations contenues dans cette notice sans préavis.

Copyright © 2003 Navman NZ Limited, Nouvelle-Zélande. Tous droits réservés. NAVMAN est

une marque déposée de Navman NZ Limited.

11Guide d’installation des capteurs traversants et des

sondes à montage interne

NAVMAN

1-1 Câblage

Chaque capteur est équipé d’un câble qui doit

être relié à l’instrument de navigation. Lors de

l’installation :

S’assurer que le câble passe le plus loin

possible des autres câbles et du reste de

l’équipement (lampes fl uo, convertisseurs

et émetteurs-récepteurs VHF).

Ne pas couper le câble d’une sonde.

Si nécessaire, utiliser un câble

d’extension 4 m (une seule rallonge

possible). Un câble d’extension 20 m est

1 Introduction

1-2 Nettoyage et entretien

Nettoyer le capteur à l’aide d’un chiffon humide

ou imprégné de détergent doux. Ne pas utiliser

de produits abrasifs, d’essence ou tout autre

solvant.

Si vous désirez repeindre la coque, recouvrir

ou retirer tout capteur de vitesse présent. Ne

pas peindre le capteur.

Ce guide explique comment installer :

les capteurs traversants Navman (vitesse/

température et profondeur).

la sonde à montage interne Navman.

Accessoires

Les accessoires suivants sont disponibles

chez votre revendeur local :

Câble d’extension 4 m pour capteur de

vitesse/température.

Câble d’extension 4 m pour sonde mono

ou bi-fréquence.

Passe-coque de rechange pour capteur

de vitesse/température.

Roue à aubes de rechange pour capteur

de vitesse/température.

Câble d’extension 20 m pour sonde bi-

fréquence.

également disponible pour les sondes

bi-fréquence.

S’assurer qu’aucun connecteur de câble

ne repose sur le fond de cale.

Attacher le câble à intervalles réguliers.

Pour la connexion du câble à l’instrument,

se référer au guide d’installation de

l’instrument de navigation.

Ne jamais utiliser de système de nettoyage

haute pression sur la roue à aubes du capteur

de vitesse afi n de ne pas endommager les

paliers.

Sommaire

1 Introduction.............................................................................................3

1-1 Câblage.......................................................................................................... 3

1-2 Nettoyage et entretien.................................................................................... 3

2 Capteurs traversants .............................................................................4

2-1 Choix de l’emplacement d’un capteur traversant........................................... 6

2-2 Installation d’un capteur traversant ................................................................ 6

3 Sonde à montage interne.......................................................................8

3-1 Choix de l’emplacement d’une sonde à montage interne .............................. 8

3-2 Installation d’une sonde à montage interne ................................................... 9

Loading...

Loading...