Page 1

G-PILOT 3100

AUTOPILOT

Installation Manual

English..............3

Español...........32

Português.......61

www.navman.com

NAV MAN

Page 2

.

Page 3

Contents

Important................................................................................................4

1 In tro duc tion.........................................................................................5

1-1 A typical in stal la tion....................................................................................5

1-2 Using the G-PILOT 3100 with other in stru ments..........................6

1-2-1 Using other instruments..........................................................................6

1-2-2 NavBus ...................................................................................................6

1-2-3 NMEA......................................................................................................6

2 G-PILOT 3100 hardware.....................................................................7

2-1 What comes with your G-PILOT 3100 .......................................................7

2-2 Other parts required...................................................................................8

3 Installation...........................................................................................8

3-1 Installation sequence .................................................................................8

3-2 Installation guide........................................................................................9

3-2-1 Location guide.....................................................................................9

3-2-2 Wiring guide........................................................................................9

3-3 Installing the main unit .............................................................................10

3-4 Installing the power supplies and steer ing drive ...................................... 11

3-4-1 Installing the power supplies.............................................................11

3-4-2 Installing the steering drive ...............................................................12

3-5 Installing the rudder feedback unit...........................................................16

3-6 Installing the compass..............................................................................19

3-7 Installing the gyro.....................................................................................21

3-8 Installing the display unit and other instruments......................................23

4 Dockside setup.................................................................................25

4-1 Start dockside setup.................................................................................25

4-2 Calibrating the rudder feedback unit........................................................26

5 Sea trials ...........................................................................................27

5-1 Calibrating the compass...........................................................................27

6 Aligning the compass and the rudder............................................28

6-1 Aligning the compass...............................................................................28

6-2 Aligning the rudder...................................................................................28

Appendix A - Specifi cations...............................................................29

Appendix B - Alarm and warning messages.....................................29

Appendix C - Troubleshooting...........................................................31

Appendix D - How to contact us ........................................................90

G-PILOT 3100 Installation Manual

NAVMAN

3

Page 4

Important

It is the owner’s sole responsibility to install and use the instrument and transducer/s in a manner

that will not cause accidents, personal injury or property damage. The user of this product is

solely responsible for observing safe boating practices.

The choice, location, and installation of all components in any autopilot system is critical. If

installation is not correct, the unit can not perform at its designed potential. If in doubt, consult

your Navman dealer. Ensure that any holes that cut are in a safe position and will not weaken

the boat's structure. If in doubt, consult a qualifi ed boat builder.

Using the G-PILOT 3100:

The G-PILOT 3100 is intended as an aid to save a helmsman from having to steer for long

periods of time, not as the main means of steering the boat.

The G-PILOT 3100 is not intended for use in extreme weather, in adverse conditions or in

water near other boats, dangerous waters or land.

The G-PILOT 3100 can not control the boat better than a helmsman. In adverse conditions

steer the boat manually.

Never leave the helm unattended. Keep a watch at all times. The helmsman should always

monitor the course of the boat and the G-PILOT 3100 and be ready to resume steering the

boat manually.

The performance of the G-PILOT 3100 can be affected by the failure of a part,

environmental conditions, improper installation and use.

NAVMAN NZ LIMITED DISCLAIMS ALL LIABILITY FOR ANY USE OF THIS PRODUCT IN A

WAY THAT MAY CAUSE ACCIDENTS, DAMAGE OR THAT MAY VIOLATE THE LAW.

As Navman is continuously improving this product we retain the right to make changes to the

product at any time which may not be refl ected in this version of manual. Please contact your

nearest Navman offi ce if you require any further assistance.

Governing Language: This statement, any instruction manuals, user guides and other information

relating to the product (Documentation) may be translated to, or has been translated from,

another language (Translation). In the event of any confl ict between any Translation of the

Documentation, the English language version of the Documentation will be the offi cial version

of the Documentation.

Copyright © 2003 Navman NZ Limited, New Zealand. All rights reserved. Navman is a registered

trademark of Navman NZ Limited.

FCC Statement

Note: This equipment has been tested and found to comply with the limits for a Class B

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a normal installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to

try to correct the interference by one or more of the following measures:

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an output on a circuit different from that to which the

receiver is connected.

Consult the dealer or an experienced technician for help.

A shielded cable must be used when connecting a peripheral to the serial ports.

4

NAVMAN

G-PILOT 3100 Installation Manual

Page 5

1 Introduction

Using this manual

This manual describes how to install and set

up the G-PILOT 3100. Refer to the separate

G-PILOT 3100 Operation Manual for information on how to use the G-PILOT 3100.

To install a G-PILOT 3100, you must perform

installation, dockside setup and sea trials (see

sections 3, 4 and 5).

T o fully set up a G-PILOT 3100 after a part has

been changed or if a problem is suspected,

perform dockside setup and sea trials (see

sections 4 and 5).

To verify that the G-PILOT 3100 is operating

correctly, perform sea trials (see section 5).

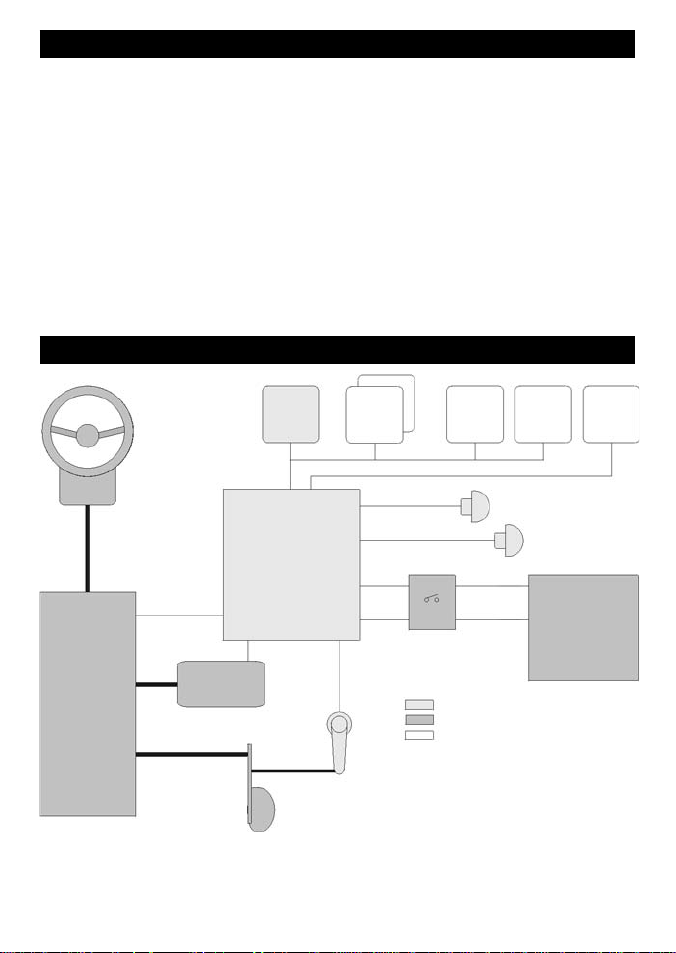

1-1 A typical installation

Display

unit

Manual helm

NavBus

Main

unit

Cleaning and maintenance

Clean the parts of the G-PILOT 3100 with a

damp cloth or mild detergent. Avoid abrasive

cleaners, petrol or other solvents.

Do not paint any part of the G-PILOT 3100

except for the cables.

Optional instruments

More

display

units

NMEA

WIND

3100

SPEED

3100

Compass

Gyro

GPS

NMEA

Light duty

Clutch drive

(optional)

Rudder control

G-PILOT 3100 Installation Manual

Steering

drive

Rudder

Rudder

feedback unit

NAVMAN

Power switch or switches

and power protection

Key

Parts supplied with G-PILOT

Other parts required

Optional parts

Note: Above shows typical

installation only. Please refer

to the information supplied with

your drive for further information.

Heavy duty

12 V DC

Power supply

5

Page 6

1-2 Using the G-PILOT 3100 with other instruments

1-2-1 Using other instruments

The G-PILOT 3100 can use data from these

instruments:

GPS: A GPS or chartplotter, such as a

Navman TRACKER 5000 series chartplotter

must be connected to the G-PILOT 3100 for

the G-PILOT 3100 to operate in GPS mode

(see the G-PILOT 3100 Operation Manual).

Note: GPS must be via NMEA input.

WIND: A wind instrument, such as a Navman

WIND 3100 series, must be connected to

the G-PILOT 3100 for the G-PILOT 3100 to

operate in WIND mode (see the G-PILOT

3100 Operation Manual).

SPEED: A speed instrument, such as:

Navman’s SPEED 3100 with a

paddlewheel speed sensor

or a GPS or chartplotter, such as

Navman’s TRACKER 5000 series

chartplotter can be connected to the

G-PILOT 3100 to increase steering

accuracy.

Note: The speed from a paddlewheel

sensor is the speed that the boat is moving

through the water. The speed from a GPS

is the speed over the ground. If there is a

water current then these two speeds will be

different. If the G-PILOT 3100 is connected

to an instrument with a paddlewheel sensor

and to a GPS, then the G-PILOT 3100 will

automatically use the speed from the

paddlewheel sensor instrument.

1-2-2 NavBus

NavBus is a Navman proprietary system that

allows systems of multiple instruments to be

built using a single set of transducers. When

instruments are connected by NavBus:

If you change the units, alarms or

calibration in one instrument, then the

values will automatically change in all

other instruments of the same type.

Each instrument can be assigned to a

group of instruments, called a backlight

group (see BKL GROUP in the FACTORY

menu, in the G-PILOT 3100 Operation

Manual). If you change the backlight in an

instrument in group 1, 2, 3 or 4 then the

backlight will automatically change in the

other instruments in the same group. If

6

NAVMAN

you change the backlight in an instrument

in group 0 then no other instruments are

affected.

If an alarm sounds, mute it on any

instrument which can display that alarm.

For more information, refer to the NavBus

Installation and Operation Manual. Note: GPS

must be via NMEA input.

NavBus and the G-PILOT 3100

The G-PILOT 3100 will automatically

work with additional display units.

The G-PILOT 3100 can receive wind data

from Navman’s WIND 3100 over NavBus.

The G-PILOT 3100 can receive speed

data from Navman’s SPEED 3100 over

NavBus.

1-2-3 NMEA

NMEA is an industry standard, but is not as

fl exible as NavBus as it requires dedicated

connections between instruments. The GPILOT has one NMEA input port and one

port that can be configured to be an input

or an output (See G-PILOT 3100 Operation

Manual).

G-PILOT 3100 NMEA inputs

GPS: The G-PILOT 3100 can receive

NMEA GPS data from a compatible GPS or

chartplotter, such as Navman’s TRACKER 5000

series chartplotter:

XTE (from APA, APB or XTE sentences)

is required for the G-PILOT to use GPS

mode

BRG (from APA sentences) and BOD

(from APA or APB sentences) are optional

and improve performance

COG (from VTG sentences) is optional

and can be displayed.

WIND: The G-PILOT 3100 can receive NMEA

wind data from a compatible wind instrument:

True or apparent wind direction (from

MWV sentences) is required for the

G-PILOT to use Wind mode.

SPEED: The G-PILOT 3100 can receive NMEA

speed data from a compatible paddlewheel or

GPS instrument:

SOG (from VTG sentences) is optional

and improves performance.

Note: If the G-PILOT 3100 is connected to a

G-PILOT 3100 Installation Manual

Page 7

Navman 3100 series wind or speed instrument

using NavBus, then the G-PILOT 3100 will

automatically receive and use the wind or

speed data, and the NMEA connection need

not be wired.

(see NMEA 2 DA T in the F ACTOR Y menu, See

G-PILOT 3100 Operation Manual).

G-PILOT 3100 NMEA outputs

The NMEA 2 port can be confi gured to be an

input or to be output:

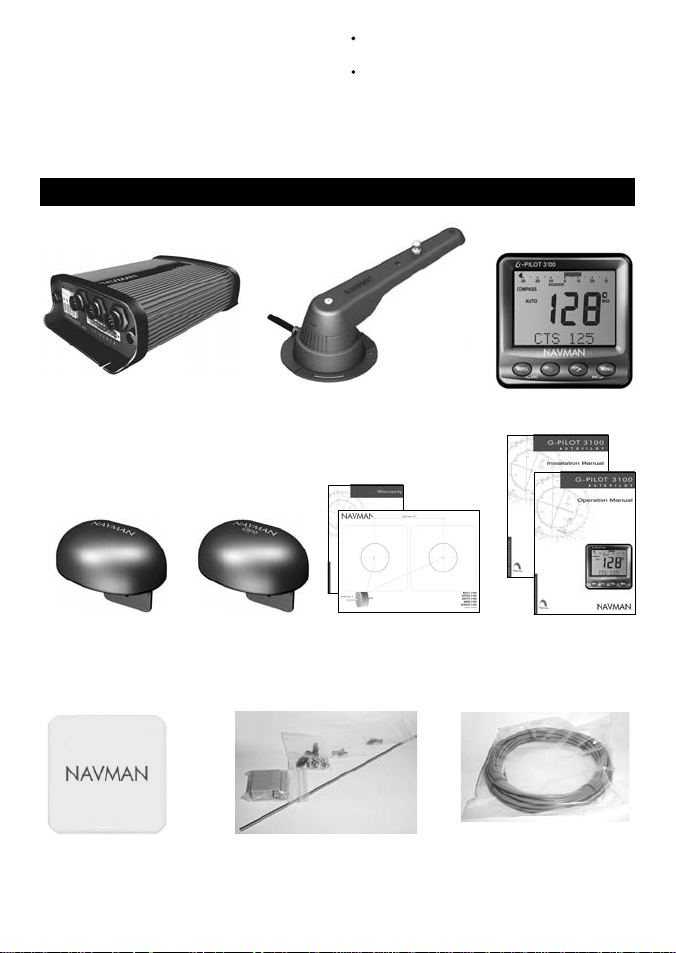

2 G-PILOT 3100 hardware

2-1 What comes with your G-PILOT 3100

either heading (HDG & HDT) and rudder

angle (RSA) once per second

or heading (HDG) ten times per second

Main unit

Compass, with 10

m (33 ft) attached

cable

Protective cover for

display unit

G-PILOT 3100 Installation Manual

Rudder feedback unit

Gyro, with 10 m

(33 ft) attached

cable

Mounting hardware, cable cover,

strain relief, spare fuses

Warranty and dis-

play unit mounting

NAVMAN

template

Display unit

This Installation

manual,

Operation manual.

2 mm (#14) twin stranded

cable for high current wiring

7

Page 8

2-2 Other parts required

Power supply: The G-PILOT 3100 requires

two power supplies, both nominally 12 V DC:

A heavy duty supply for the steering drive

A light duty supply for the G-PILOT 3100

electronics and display unit; this supply

also powers any additional display units

and other instruments.

The power supplies require one or two

switches and fuses or circuit breakers (see

section 3-4).

Steering drive: The G-PILOT 3100 can power

a hydraulic pump, constantly running pump set,

hydraulic linear drive or mechanical drive rated

at 12 V DC and up to 20 A.

Rudder linkage: To link rudder to rudder

feedback unit (see section 3-5).

For wiring, see Select Wire Table in section

3-4-2.

3 Installation

Warning Correct installation is critical to the

performance of the unit. It is vital to read this

manual and the documentation that comes with

the other parts before starting installation.

Warning

The G-PILOT main unit is not waterproof.

Mount the unit in a dry place.

The G-PILOT display unit is waterproof

from the front. Protect the rear of the unit

3-1 Installation sequence

The recommended installation sequence is:

1 Read this manual and the documentation

that comes with the other parts.

2 Plan the installation: select where the

equipment and wiring will be installed

(see section 3-2).

3 Install the main unit (see section 3-3).

4 Install the steering drive and wire the heavy

duty and light duty power supplies (see

section 3-4).

5 Install the rudder feedback unit (see

section 3-5).

6 Install the compass (see section 3-6).

External beepers or lights (optional ): The

external output is switched to ground, 30 V DC

and 250 mA maximum. If the beepers and lights

require more than 250 mA total, fi t a relay.

Other marine instruments (optional): Wind,

speed or GPS instruments can be connected

(see section 1-2).

Other parts: For systems of several

instruments, wiring and connectors are

required. Navman junction boxes can simplify

wiring several Navman instruments together

(see section 1-2 or the NavBus Installation

and Operation Manual).

Coupling connectors and 10 m (33 ft)

extension cables are available to extend the

rudder feedback unit, compass or gyro cables.

Do not fi t more than one extension cable to

each unit.

from water, or else water might enter the

breathing hole and damage the unit. The

warranty does not cover damage caused

by moisture or water entering the back of

the unit.

The compass, gyro and rudder feedback

unit are completely waterproof.

Warning Ensure that any holes that you cut

will not weaken the boat’s structure. If in doubt,

consult a qualifi ed boat builder.

7 Install the gyro (see section 3-7).

8 Install the display unit and any other

marine instruments that will be used with

the G-PILOT 3100 (see section 3-8).

9 Carry out the dockside setup (see

section 4).

10 Carry out the sea trials (see section 5).

If you are unsure where a part should be

installed, mount and wire the part temporarily,

without cutting holes in the boat. After the sea

trials have been completed, install and wire

the part permanently.

8

NAVMAN

G-PILOT 3100 Installation Manual

Page 9

3-2 Installation guide

This is a general guide for locating and wiring the parts of the G-PILOT 3100. The instructions for

a particular part may have additional requirements.

3-2-1 Location guide

Do not mount any part where it can be used

as a handhold, where it will interfere with

the operation of the boat or where it might

be submerged.

Do not mount any part where it will interfere

with launching or retrieving the boat.

Do not mount any part within 0.5 m (20")

of the plane of a radar antenna.

Mount the compass and gyro:

At least 1 m (3 ft) away from sources

of electrical signals or noise, such as

the batteries, high-current cables,

other boat cables, engines, fl uorescent

lights, power inverters, radio or radar

transmitters and antennas.

At least 1 m (3 ft) away from equipment

containing a magnet, such as a

compass.

3-2-2 Wiring guide

The G-PILOT 3100 has two kinds of cables:

The heavy-duty power supply and steering

drive usually require high-current cables:

Select the wire gauge from the wire size

table (see section 3-4-2).

Fit high-current cables at least 1 m (3

ft) away from other electronic devices in

the boat.

Keep the cables as short as possible.

Twin 2 mm (#14) cable is supplied with the

G-PILOT 3100 and can be used for the high

current cable if its gauge is suitable.

All the other cables are low-current:

Fit low-current cables at least 1 m (3 ft)

away from sources of electrical signals

or noise, such as the high-current cables,

other boat cables, engines, fluorescent

lights, power inverters and radio or radar

transmitters and antennas.

If the cable for the rudder feedback unit,

compass or gyro is too long, do not shorten

the cable; instead coil the cable up near the

main control unit.

The cable for the rudder feedback unit,

compass or gyro can be extended by

adding a 10 m (33 ft) extension cable and

coupling connector. Do not fi t more than

one extension cable to each unit.

When fi tting any type of cable:

Do not crush, pinch or strain the cable.

Secure the cable at regular intervals.

Ensure no connectors or exposed terminals

are in the bilge.

G-PILOT 3100 Installation Manual

NAVMAN

9

Page 10

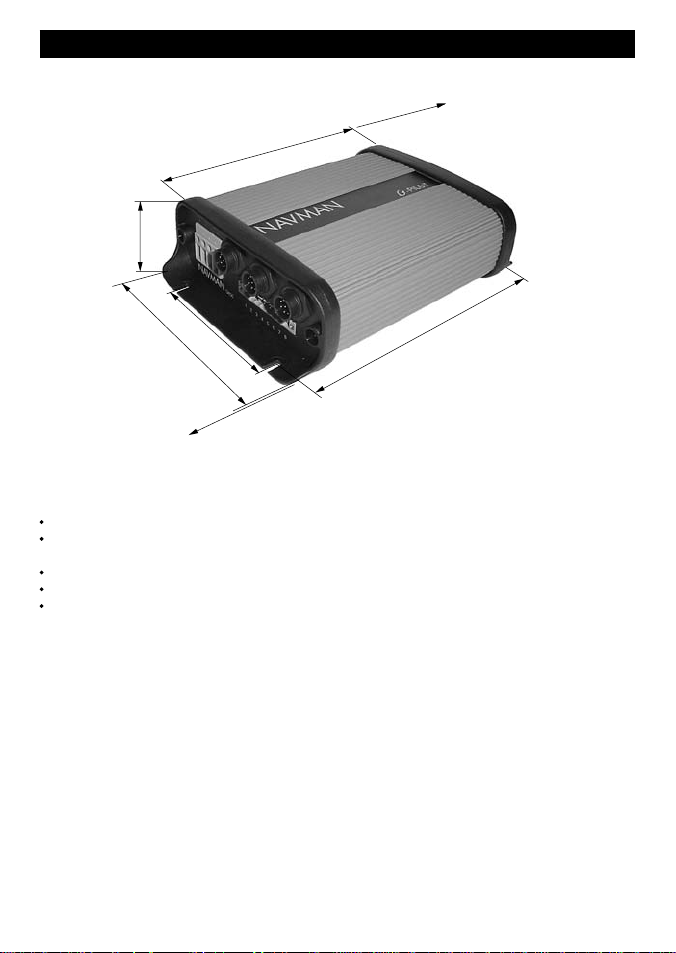

3-3 Installing the main unit

Physical

200 mm (7.87")

IMPORTANT: 200 mm (7.87")

clearance required for cover

removal

(2.16")

55 mm

Screws 90 mm (3.54") apart

200 mm (7.87")

140 mm (5.10")

Screw holes 184 mm (7.24") apart

IMPORTANT: 60 mm (2.36")

60 mm (2.36")

clearance required for cables

Installation

Find a suitable location for the unit:

In a dry, cool place; if possible not the engine room.

Close to the high-current power supply and the steering drive, to reduce the length of the

high current wiring.

Accessible for installation and service.

If possible on a vertical panel which does not vibrate.

Follow the location guide (see section 3-2-1).

Mount the unit with the cable connectors at the bottom or to one side, using the screws provided.

Do not mount the unit with the connectors at the top, because dust or moisture might enter

the unit.

10

NAVMAN

G-PILOT 3100 Installation Manual

Page 11

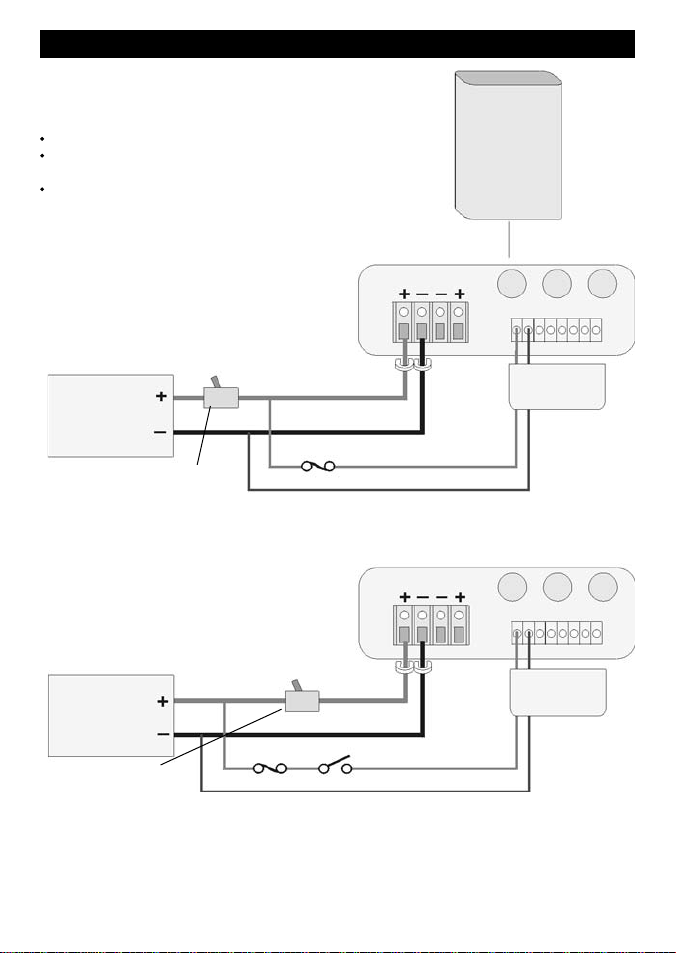

3-4 Installing the power supplies and steering drive

3-4-1 Installing the power supplies

The G-PILOT 3100 requires a light and a heavy duty

power supply, both 12 V DC (10.5 to 16.5 V DC).

Note:

Keep all wiring as short as possible.

For the heavy duty supply, use the wire size

given in the table (see section 3-4-2).

Follow the wiring guide (see section 3-2-2).

Power supply: one switch confi guration

Choose this confi guration to have one switch to turn the

G-PILOT 3100 and any other instruments on and off.

Main unit

1 2 3 4 5 6 7 8

Fit strain relief

12 V DC power

supply, current to

suit drive

Circuit breaker or fuse

and switch, current rating

to suit steering drive

Power supply: two switch confi guration

Choose this confi guration to be able to turn the

drive power off and leave other instruments

powered.

12 V DC power

supply, current to

suit drive

Circuit breaker or

fuse and switch,

current rating to

suit steering drive

Note: If powering more than three extra display units or other 3100 series instruments, fi t

another switch and fuse for the light duty power supply for these extra instruments

G-PILOT 3100 Installation Manual

Fuse 1 A

Fuse 1 A

Fit strain relief

Switch

NAVMAN

Heavy

duty

Heavy

duty power

Connector

cover

Light duty

power

1 2 3 4 5 6 7 8

Connector

cover

Light duty

power

11

Page 12

3-4-2 Installing the steering drive

Install the steering drive according to one of the

diagrams on the following pages.

Note

Keep all wiring as short as possible.

Use the wire size given in the table below.

Follow the wiring guide (see section

3-2-2).

Wire less than #10 gauge will not fi t

directly into the four way terminal block.

Fit ferrules or reterminate the wire with

#10 gauge wire.

If more than one wire is to be fi tted to a

terminal of the four way terminal block,

join the wires together in a suitable way.

Wire size table

To choose a wire gauge for an installation:

1 Measure the length of twin cable required, i.e. the distance from the main control unit to the

heavy duty power supply or to the drive.

2 Choose the column with the cable length and the row with the circuit current. The intersection

of the row and column gives the preferred (minimum) cable wire gauge for less than 3% voltage

drop in a 12 V system.

Cable length (from main control unit to power supply or to drive)

0.7 m 1.5 m 2.2 m 3 m 3.7 m 4.5 m 5.2 m 6 m

Current 2.5 ft 5 ft 7.5 ft 10 ft 12.5 ft 15 ft 17.5 ft 20 ft

1 amp #18 #18 #18 #18 #18 #18 #18 #18

2 amp #18 #18 #18 #18 #18 #16 #16 #16

3 amp #18 #18 #18 #16 #16 #16 #14 #14

4 amp #18 #18 #16 #16 #14 #14 #14 #12

5 amp #18 #18 #16 #14 #14 #12 #12 #12

6 amp #18 #16 #16 #14 #12 #12 #12 #10

7 amp #18 #16 #14 #14 #12 #12 #10 #10

8 amp #18 #16 #14 #12 #12 #10 #10 #10

9 amp #18 #16 #14 #12 #12 #10 #10 #10

10 amp #18 #14 #12 #12 #10 #10 #10 #8

15 amp #16 #12 #12 #10 #10 #8 #8 #6

20 amp #14 #12 #10 #8 #8 #6 #6 #6

12

NAVMAN

G-PILOT 3100 Installation Manual

Page 13

Example of hydraulic steering with hydraulic help pump.

In the VESSEL menu (See G-PILOT 3100 Operation Manual), set DRVE TYPE to MTR.

Main unit

1 2 3 4 5 6 7 8

Fit strain relief

Heavy duty power

No connection

(see section 3-4-1)

Wiring polarity

does not matter.

Motor

Example of mechanical steered power vessels with hydraulic linear drive for sailing boat

In the VESSEL menu (See G-PILOT 3100 Operation Manual), set DRVE TYPE to MTR.

Main unit

Note: Clutch relay coil must

draw less than 300 mA

(see section 3-4-1)

G-PILOT 3100 Installation Manual

Heavy duty power

Motor

Clutch

relay

coil

Fit strain relief

Wiring polarity

does not matter.

1N4002 diode or equivalent

Fit close to relay coil

NAVMAN

Connector

cover

13

Page 14

Installing a electric drive motor with clutch relay

In the VESSEL menu (See G-PILOT 3100

Operation Manual), set DRVE TYPE to MTR.

Main unit

1 2 3 4 5 6 7 8

Fit strain relief

Heavy duty power (see section 3-4-1)

1N4002 diode or equivalent

Fit close to relay coil

Relay contacts

Clutch

coil

Wiring polarity

does not matter.

Motor

1N4002 diode or equivalent. Fit close to relay coil

Note: Relay is required if the

clutch circuit is greater than 300 mA.

Installing a continuous running pump and solenoid valves.

In the VESSEL menu (See G-PILOT 3100

Operation Manual), set DRVE TYPE to SPL -.

Fit strain relief

Heavy duty power (see section 3-4-1)

Relay contacts

Note: Motor is not

required for engine

PTO systems.

Motor

Wiring polarity

does not matter.

Starboard

Port

14

NAVMAN

Main unit

1N4002 diode or equivalent

Fit close to relay coil

Note: Relay is required

if the clutch circuit is

greater than 300 mA.

Connector

cover

Relay coil

1 2 3 4 5 6 7 8

Connector

cover

Relay coil

G-PILOT 3100 Installation Manual

Page 15

Installing solenoid valves or relays with jog or electric steering

In the VESSEL menu (See G-PILOT 3100 Operation Manual), set DRVE TYPE to SPL -.

Main unit

1 2 3 4 5 6 7 8

Fit strain relief

Heavy duty power

(see section 3-4-1)

No connection

Starboard

Port

Jog/steer controls

G-PILOT 3100 Installation Manual

NAVMAN

15

Page 16

3-5 Installing the rudder feedback unit

Physical

Rudder

90 mm

(3.5")

220 mm

(8.7")

Linkage

to rudder

shaft

Connecting rod, with

quick release fi ttings

and lock nuts each end

Base

LT8 connector

10 m (33 ft) cable

Arm rotates freely

Arm

around base.

End of connecting

rod snaps into one of

the holes on the arm.

Mounting requirements

These two

distances to

be equal.

Adjust position of rod on

arm if required.

Base to be adjacent

to rudder shaft so that

this angle is 90°

Cut connecting

rod if required.

Note

The unit is completely waterproof but should not be immersed.

Mount the unit on a panel which does not vibrate.

Follow the location guide (see section 3-2-1).

16

NAVMAN

Thread = M5

These two

distances

to be equal.

Rudder shaft to

be parallel to

shaft in base.

Rudder linkage

and arm to move

in the same

plane

G-PILOT 3100 Installation Manual

Page 17

Alignment

The arm can rotate freely around the base. When the rudder is amidships, the arrow on the arm

must point to one of the centre lines on the base.

Centre line

Base

Centre line

Therefore in an installation, the base can be rotated to two positions. We recommend the position

that has the cable on the opposite side to the connecting rod.

Sets of lines

show the two

linear ranges of

the unit.

Recommended

(rudder amidships).

Not recommended, cable

can foul rudder linkage.

Arrangements

Recommended: U-shaped arrangement with the arm parallel to the length of boat:

Bow of

boat

Satisfactory: U-shaped arrangement

with arm not parallel to length of boat,

for example:

Bow of

boat

G-PILOT 3100 Installation Manual

Not recommended: Z-shaped arrangement,

for example:

If rudder turns too far, the unit might not return to

the Z shape.

NAVMAN

17

Page 18

Installation

1 Find a suitable location and arrangement for the unit as described above.

2 Choose, assemble and fi t a suitable rudder linkage.

3 Fit the unit as shown below:

Set rudder

amidships.

If necessary,

mount base on

block to set height.

Rotate base so arrow on arm

points near centre line on

base. Fit two screws provided

loosely in middle of slots.

Rotate base so arrow on

arm points to centre line

on base. Fit third screw

provided, tighten all screws.

Ensure rudder

is amidships.

Join coupling to

rudder linkage.

If necessary, cut connecting

rod at this end, then replace

Snap end into

correct hole in

arm.

coupling and lock nut.

4 Wire the cable back to the main unit, following the wiring guide (see section 3-2-2).

Holes in the bulkheads

Main unit

must be at least 18.5 mm

(0.73") diameter.

Plug connector into socket

18

NAVMAN

G-PILOT 3100 Installation Manual

Page 19

3-6 Installing the compass

Physical

Mounting holes

for screws

101 mm, (4")

71 mm, (2.8")

97 mm,

(3.8")

LT8 connector

Location

Mount the compass:

At least 1 m (3 ft) away from any steel or

iron boat part, such as:

a steel hull, deck, cabin or steel

reinforcing in ferro-cement hulls

steel equipment such as motors and

cooking equipment

places where steel objects are stored,

such as the anchor locker and storage

lockers

At least 2 m (6 ft) away from equipment

with a magnet and equipment which

generates electromagnetic fi elds, such as

a compass, a battery, high current wiring,

Fibreglass or wood hull and cabin: mount compass at the centre of movement (for planing hulls,

the centre of movement is usually close to the stern):

Steel hull, non-steel cabin: mount compass

1 m, (3 ft) above hull:

1 m (3 ft)

10 m (32.8 ft)

an electric motor and a radio or radar

transmitter or antenna.

As close as possible to the centre of

movement of the boat, to minimise how

much the compass moves when the boat

rocks and pitches. If the compass can not

be mounted at the centre of movement, it

is usually best to mount the compass as

low as possible.

On a vertical panel which does not

vibrate.

The unit is completely waterproof but should

not be immersed. The compass is not

affected by other metals, such as stainless

steel, copper or brass. Follow the location

guide (see section 3-2-1).

Steel hull and steel cabin: mount compass

on a pole 1 m (3 ft) above the hull and at

least 1 m (3 ft) from the cabin:

At least 1 m (3 ft)

1 m (3 ft)

G-PILOT 3100 Installation Manual

NAVMAN

19

Page 20

Installation

1 Find a suitable location for the unit as described above.

2 Mount the unit with the three screws provided. Use a level to ensure the unit is vertical to

within 10°.

Less than

10° 10°

Less than

10° 10°

3 Wire the cable back to the main unit, following the wiring guide (see section 3-2-2).

Main unit

Holes in the bulkheads must be at least

18.5 mm (0.73 in)

diameter.

Plug connector into socket

Note

If you move the compass with respect to the gyro while the power is on, wait for the heading

to stabilize.

20

NAVMAN

G-PILOT 3100 Installation Manual

Page 21

3-7 Installing the gyro

Physical

Mounting holes

for screws

101 mm, (4")

71 mm, (2.8")

97 mm,

(3.8")

LT8 connector

10 m (32.8 ft)

Location

Mount the gyro as close as possible to the cen tre of movement of the boat, to minimize how much

the gyro moves when the boat rocks and pitches.

Mount the gyro on a panel which does not vi brate.

The unit is completely waterproof but should not be immersed. Follow the location guide (see

sec tion 3-2-1).

The Ideal location is at the centre of movement (for planing hulls, the centre of movement is

usually close to the stern).

G-PILOT 3100 Installation Manual

NAVMAN

21

Page 22

Installation

1 Find a suitable location for the unit as described above.

2 Mount the unit with the three screws provided. Use a level to ensure the unit is vertical to

within 10°.

Less than

10° 10°

3 Wire the cable back to the main unit, following the wiring guide (see section 3-2-2).

Less than

10° 10°

Holes in the bulkheads

Main unit

must be at least 18.5 mm

(0.73") diameter.

Plug connector into socket

Note

If you move the gyro with respect to the compass while the power is on, wait for the heading

to stabilise.

22

NAVMAN

G-PILOT 3100 Installation Manual

Page 23

3-8 Installing the display unit and other instruments

Installing the display unit

1 Choose a location for the display unit that is:

Easily seen and close to the manual

helm.

Accessible from behind; the minimum

clearance required at the back is

50 mm (2") (see mounting diagram).

With the back of the unit protected

from moisture.

Follow the location guide (see section 3-2-1).

2 The unit must mount on a fl at panel which

is less than 20 mm (0.75") thick. Stick the

mounting template in place. Drill a 50 mm

(2") fi xing hole through the centre hole in

the template. Note that the template allows

space around the unit for the protective

cover.

3 Remove the fi xing nut from the back of

the unit. Insert the stud at the back of the

unit through the mounting hole. Hand

tighten the fi xing nut.

Wiring the display unit

Display

unit

Main unit

Clutch relay out, 8

NMEA 2, 7

NMEA in 1, 6

NMEA common, 5

NavBus -, Blue 4

NavBus +, Orange 3

Ground, Black 2

12 V power +, Red 1

Note

Wire the display unit power wires (red and black wires) to the eight way connector terminals 1 and

2 to ensure the display unit and main control unit have the same light duty power supply.

Connector cover

8-way connector

Green

Side view of display unit mounting

20 mm (0.75")

maximum thickness

Fixing hole

50 mm (2")

Display unit

Clearance 50 mm (2") minimum

Follow the wiring guide (see

section 3-2-2).

Display unit cable, Requires 6 mm (1/4 in) hole

through bulkhead.

Yellow (isolate, do not cut)

White (isolate, do not cut)

Light duty power

(see section 3-4-1)

Optional external beepers and

lamps for the external alarm. If

the beepers and lights require

more than 250 mA, fi t an external

relay.

Fixing

nut

Cables

G-PILOT 3100 Installation Manual

NAVMAN

23

Page 24

Wiring other instruments

More G-PILOT

display units

Follow the wiring guide (see section 3-2-2).

Other 3100 series

instruments

A GPS, such as a

Navman TRACKER

5000 series chartplotter

Display

units

3100

units

GPS

Main unit

NMEA

in & out

Power,

NMEA in

Clutch, optional

Clutch relay out, 8

NMEA 2, 7

NMEA in 1, 6

NMEA common, 5

NavBus -, Blue 4

NavBus +, Orange 3

Ground, Black 2

Connector cover

(see section 3-4-2)

NMEA in/out

GPS NMEA out

GPS NMEA common

Light duty power

(see section 3-4-1)

12 V power +, Red 1

Green (from one

display unit only)

GreenGreen

Beepers and lights

(see previous page)

Note:

Refer to the instrument’s installation manual for more wiring information.

If adding more than three display units or other 3100 series instruments, fi t a separate light-duty

power supply for the extra instruments (see section 3-4 or the instrument’s installation manual)

The external alarm outputs (green wire) of Navman 3100 series instruments and 5000 series

chartplotters can be connected together to drive the external beepers and lights.

In systems with several other instruments, we recommend using NavBus junction boxes to

simplify wiring (see the NavBus Installation and Operation Manual).

24

NAVMAN

G-PILOT 3100 Installation Manual

Page 25

4 Dockside setup

Perform the dockside setup:

after installing a G-PILOT 3100 system (see section 3)

after a part has been changed or if a problem is suspected

After dockside setup, perform the sea trials (see section 5 ).

4-1 Start dockside setup

1 Turn the G-PILOT 3100 on (See G-PILOT

3100 Operation Manual). If the rudder

moves, immediately turn the power off (See

G-PILOT 3100 Operation Manual) and check

for incorrect wiring. Check that the display

unit shows AP3100 on the bottom line for a

couple of seconds, then the version number,

then displays the normal heading display.

If you try to enter AUTO and the rudder

feedback unit or compass have not yet

been calibrated, then the G-PILOT will

display CAL ERROR.

2 If the G-PILOT 3100 has been used before,

reset all user data to the factory defaults:

i Go to NVM RESET in the FACTORY

menu (See G-PILOT 3100 Operation

Manual).

ii Press > to turn the function on.

iii Press MENU to reset the data.

iv Hold AUTO to exit the menus.

3 Enter the user data listed in the User Data table

below (See G-PILOT 3100 Operation Manual

to fi nd what each data item means and how

to enter the data). Beside each item, write

the value of the user data that you enter.

4 After entering the data, hold AUTO to exit

the menus.

User Data table (to record installation setup data)

VESSEL menu

Item Data value

VSL TYPE . . . . . . . . . . . . . .

DRVE TYPE . . . . . . . . . . . . . .

WIND TYPE . . . . . . . . . . . . . .

HDG TYPE . . . . . . . . . . . . . .

MAG VAR . . . . . . . . . . . . . .

OPTIONS menu

Menu Data value

DODGE ANG . . . . . . . . . . . . . .

TACK ANG . . . . . . . . . . . . . .

GYBE ANGLE . . . . . . . . . . . . . .

TACK DELY . . . . . . . . . . . . . .

TURN RATE . . . . . . . . . . . . . .

ALARMS menu

Item Data value

CE ALARM . . . . . . . . . . . . . .

XTE ALARM . . . . . . . . . . . . . .

WPT AKN . . . . . . . . . . . . . .

WND ALARM . . . . . . . . . . . . . .

(SAIL only)

BAT ALARM . . . . . . . . . . . . . .

CUR ALARM . . . . . . . . . . . . . .

FACTORY menu

Item Data value

BKL GROUP . . . . . . . . . . . . . .

KEY BEEPS . . . . . . . . . . . . . .

NMEA2 DAT . . . . . . . . . . . . . .

WARNING

Until the rudder feedback unit is calibrated (see section 4-2), there is no rudder limit. The user

must ensure that rudder is not driven onto an endstop when using the jog command (see G-PILOT

3100 Operation Manual).

G-PILOT 3100 Installation Manual

NAVMAN

25

Page 26

4-2 Calibrating the rudder feedback unit

This procedure matches the rudder feedback unit to the rudder.

Note

To exit the calibration at any time, press ESC.

If you do not move the rudder as prompted or the rudder feedback unit is not working then

the G-PILOT can not fi nish the calibration. The G-PILOT will display CALB FAIL. Press ESC,

fi x the problem and repeat the calibration.

In normal operation, the G-PILOT will not turn the rudder closer than 3° to an endstop.

RFU CAL

Go to RFU CAL in the DEVICES menu

(See G-PILOT 3100 Operation

ENT

CENTRE

Turn the manual helm until

the rudder is amidships

ENT

MAX PORT

Turn the manual helm

to turn the rudder to the

endstop which makes the

boat turn to port

ENT

MAX STBD

Turn the manual helm to

turn the rudder to the endstop which makes the boat

turn to starboard

ENT

ANGLE 25

With rudder at its starboard endstop, measure the rudder angle

from amidships

(30° in this example).

Press < or > to set the displayed

angle to the measured rudder

angle (30° in this example).

ANGLE 30

ENT

26

30°

CENTRE

Turn the manual helm until

the rudder is amidships

ENT

STAND CLR

Stand clear of rudder and linkage,

remove anything that will foul rudder’s

travel between endstops. The G-PILOT

is about to turn the rudder.

ENT

TEST LIMS

The G-PILOT turns the rudder to one

endstop, to the other endstop, then

back to amidships.

Press ESC at any time to stop the rudder.

ENT

Displayed rudder angle.

PILOT

ACPT CAL

Turn the manual helm to turn the rudder from one

endstop to another, checking that the displayed

rudder angle looks correct (7° in this example).

To cancel the calibration, press ESC

ENT

CALB DONE

The rudder feedback unit is calibrated.

ENT

End of calibration.

NAVMAN

G-PILOT 3100 Installation Manual

7°

Page 27

5 Sea trials

Perform the sea trials:

After performing the dockside setup (see

section 4).

To check the operation of the G-PILOT 3100.

For the sea trials, sail in an open area where

there are no other craft or obstructions. The

sea should be calm, the wind speed as low as

possible and there should be no currents.

5-1 Calibrating the compass

Note

To exit the calibration at any time, press ESC.

If the boat is not turned as prompted or the compass is not working then calibration can not be completed,

the G-PILOT displays CALB FAIL. Press ESC, fi x the problem and repeat the calibration.

Local disturbances in magnetic fi eld may affect the compass. Calibration must be preformed away

from large metal structures such as marinas, large ships etc.; this is the responsibility of the user.

Ensure that both sources are referencing the same north (true or magnetic). If your magnetic

compass has not been calibrated then you can use another source for heading. If using vessel’s

compass then ensure that the deviation tables are applied to check the autopilot’s compass.

Turn G-PILOT 3100 on (See G-PILOT 3100

Operation Manual). Use the manual helm to

sail a straight course at a slow speed.

CSU CAL

Go to CSU CAL in the DEVICES menu

(See G-PILOT 3100 Operation Manual).

TURN BOAT

Use the manual

helm to make 2.5

turns, steady turn to

port or starboard.

Turns should be

smooth and con-

tinuous in one direction.

Each rotation should take approximately

1 to 2 minutes to perform. The G-PILOT

detects when the boat has performed 2.5

rotations and automatically goes to the

Use the manual helm to sail a straight

course and ensure the boat heading does

not change during this step.

< ALIGN >

Press < or > to set the displayed heading

to the actual heading (20° in this example).

For example,

actual heading

is 20° and displayed heading

is 23°.

< ALIGN >

ENT

ACPT CAL

This step aligns the compass. If the

G-PILOT is connected to a GPS then press

MENU twice to skip this step and accept

the calibration. Then align the compass to

the GPS (see section 6-1-2).

Use an accurate compass or external GPS

to fi nd the actual boat heading. If using an

external GPS, sail as fast as convenient to

ensure the heading is accurate.

G-PILOT 3100 Installation Manual

Turn the manual helm to several headings,

checking that the displayed heading is close

to the actual heading.

To cancel the calibration, press ESC.

ENT

CALB DONE

The compass is calibrated.

NAVMAN

ENT

End of calibration.

27

Page 28

6 Aligning the compass and the rudder

The compass or rudder can be aligned separately.

6-1 Aligning the compass

This aligns the G-PILOT 3100 compass to

display the correct heading.

6-1-1 Aligning the G-PILOT 3100 compass

to a reference compass

Use an accurate compass or external GPS

to fi nd the actual boat heading. If using an

external GPS, sail as fast as convenient to

ensure the heading is accurate.

Use the manual helm to sail a

straight course and ensure the

boat heading does not change

during this procedure.

Go to ALIGN HDG in the DEVICES

menu (See G-PILOT 3100 Operation Manual)

The compass can be aligned either to a reference compass or to a GPS connected to the

G-PILOT 3100. Ensure there is no cross-wind

or current.

6-1-2 Aligning the G-PILOT 3100 compass to

a GPS connected to the G-PILOT

Sail as fast as convenient to ensure the

heading is accurate.

Use the manual helm to sail a

straight course and ensure the boat

heading does not change during this

procedure.

Go to ALIGN GPS in the DEVICES

menu (See G-PILOT 3100 Operation Manual).

ALIGN HDG

ENT

For example,

actual heading

is 20° and

displayed

< ALIGN >

Press < or > to set the displayed heading

to the actual heading (20° in this example).

heading is 23°.

< ALIGN >

ALIGN GPS

ENT

The G-PILOT 3100

records the GPS

heading.

Turn the manual helm to several head-

ENT

ings, checking that the displayed heading

is close to the actual heading.

End of calibration.

6-2 Aligning the rudder

This sets the rudder setting to sail a straight course. Ensure there is no cross-wind or current.

Use the manual helm to sail a

straight course at a normal cruising speed.

CENTR RFU

Go to CENTR RFU in the DEVICES menu

(G-PILOT 3100 Operation Manual).

28

NAVMAN

The G-PILOT 3100 records the

ENT

rudder position and sets the rudder

angle to zero.

End of calibration.

G-PILOT 3100 Installation Manual

Page 29

Appendix A - Specifi cations

Electrical

Heavy duty power supply 10.5 to 16.5 V

DC, 20 A maximum

Light duty power supply 10.5 to 16.5 V DC:

Main unit: 80 mA.

Each display unit, 30 mA without

backlighting, 110 mA with full

backlighting.

Other optional instruments: refer to the

instrument’s operation manual.

Interfaces

NavBus connection to other Navman

instruments.

NMEA 0183 outputs: HDG, HDT, RSA;

inputs APA, APB, BOD, BWC, MWD,

MWV, RMA, RMB, RMC, VHW, VTG,

XTE

NMEA 0183 ports:

NMEA 1: Input

NMEA 2: Can be programmed to be an

input or output

Standards compliance

EMC compliance

USA (FCC): Part 15 Class B.

Europe (CE): EN50081-1, EN50082-1

New Zealand and Australia (C Tick):

Environment:

Compass, gyro, rudder feedback unit:

completely waterproof.

Display unit: IP66 from front when

correctly mounted.

Main unit: requires a cool, dry, clean

environment.

AS-NZS 3548.

Main unit terminal block connections:

Terminal Signal

1 Heavy duty power positive, 10.5 to

16.5 V DC, 20 A maximum

2 Heavy duty power negative

3 Steering drive negative output

4 Steering drive positive output

Main unit connector connections:

Terminal Signal

1 Light duty power positive, 10.5 to

16.5 V DC, 80 mA maximum

2 Light duty power supply common

3 NavBus +

4 NavBus 5 NMEA common

6 NMEA in 1

7 NMEA in 2

8 Steering clutch relay drive output,

switched ground to turn relay on,

30 V DC, 300 mA maximum

Display unit power/data cable wires:

Wire Signal

Red Power positive, 10.5 to 16.5 V DC,

30 mA without backlighting, 110

mA with full backlighting

Black Power negative

Orange NavBus +

Blue NavBus Yellow Factory use (isolate, do not cut)

White Factory use (isolate, do not cut)

Green External alarm, switched to

ground,

30 V DC and 250 mA max.

Appendix B - Alarm and warning messages

Alarm display Reason for message Recommended action by user Notes

BAT ALARM Battery voltage is less than the Check batteries a

minimum value set by the user Disengage G-PILOT if voltage too low

CAL ERROR

or compass unit is not calibrated (see sections 5-2 and 6-1)

CCH ERROR The clutch current is to high Check clutch connection a s

CE ALARM Course error has exceeded the Manually steer boat towards course a

maximum value set by the user

CSU ERROR Compass not sending data to Check compass is connected to a s

main unit main unit; Service compass

CUR ALARM The motor current exceeded the Check steering drive is not jammed a s

maximum value set by the user Increase the alarm value

G-PILOT 3100 Installation Manual

The G-PILOT rudder feedback unit

NAVMAN

Calibrate both the units a

29

Page 30

Alarm display Reason for message Recommended action by user Notes

DRV ERROR Rudder angle does not change Check drive power is turned on a s

when steering drive operates Check RFU is connected to rudder

Check fuses inside end of main

control unit

Check steering drive operation

GPS ERROR GPS has stopped sending data to Check GPS operation a c s

main unit Check GPS connection

GSU ERROR Gyro not sending data to main unit Check gyro is connected to a s

main unit; Service gyro

MCU ERROR Main unit not sending data to Check display unit is connected to a s

display unit main unit

Service main unit or display unit

NAV ERROR GPS is not navigating to a waypoint Start GPS navigating to a waypointm

when trying to engage G-PILOT or along a route

NEXT WPT? Boat has reached a waypoint Press any key to proceed to cancel alarm

(in GPS mode and WPT AKN is on) Then press ENT to start steering to the

next waypoint or press ESC to return to

STBY

NO DATA G-PILOT not receiving GPS data Check GPS operation m

when setting mode to GPS Check GPS connection

or G-PILOT not receiving wind instrument Check wind instrument operation m

data when setting mode to wind Check wind instrument connection

NVM ERROR Main unit memory has been corrupted Service main unit a s

PHA ERROR Rudder turns wrong way to rudder Check the rudder feedback unit a s

feedback unit Perform a rudder calibration

RFU ERROR Rudder feedback unit has stopped Check rudder feedback unit is a s

sending data to main unit connected to main unit

Service rudder feedback unit

ROUTE END Boat has reached the end of Press ESC to change to STBY or

a GPS route press ENT to change to compass

mode, sailing at current heading

TRK ERROR G-PILOT has changed to GPS mode Press ESC to return to STBY or press

but boat is too far off course ENT to have the G-PILOT steer the boat

to the correct course.

TAK ERROR In wind mode, attempt to tack in the Change angle to wind m

wrong way or boat will be in irons

WND ALARM The wind angle has changed by more Change SWA a

than the alarm value Change to Compass mode

WND ERROR Wind instrument has stopped Check wind instrument operation a c s

sending data to main unit Check wind instrument connection

XTE ALARM XTE has exceeded the maximum Manually steer boat towards course a

value set by the user

Notes a Alarm sounds the internal and external (optional) beepers; press any key to mute

alarm, then press ESC to cacel the alarm message

c The G-PILOT 3100 changes to Compass mode

m The G-PILOT 3100 mode does ot change

s The G-PILOT 3100 changes to STBY

30

NAVMAN

G-PILOT 3100 Installation Manual

Page 31

Appendix C - Troubleshooting

This troubleshooting guide assumes that you

have read and understood this manual.

It is possible in many cases to solve diffi culties

without having to send the unit back to the

manufacturer for repair. Please follow this

troubleshooting section before contacting the

nearest Navman dealer.

There are no user serviceable parts. Specialized

methods and testing equipment are required to

ensure that the unit is reassembled correctly.

Repairs to the unit must only be carried out by a

service centre approved by Navman NZ Limited.

Users who service the unit themselves will void

the warranty. More information can be found on

our Website: www.navman.com

1 Unit will not turn on:

a Fuse blown or circuit breaker tripped.

b Battery voltage is outside the range

10.5 to 16.5 V DC.

c Power/data cable damaged.

2 G-PILOT 3100 makes too frequent

course corrections:

The value of response is too low (see

G-PILOT 3100 Operation Manual).

3 When sailing a straight course, the boat

drifts from side to side of the course:

a The boat should drift from side to side

of the course when the G-PILOT 3100

steering is optimized.

b Change to a profi le suitable for

boat speed and sea conditions (see

G-PILOT 3100 Operation Manual).

c If the boat drifts too far from the

course, adjust response, ratio,

counter rudder gain, GPS gain (if

G-PILOT is in GPS mode) or wind

gain (if G-PILOT is in wind mode) (see

G-PILOT 3100 Operation Manual).

4 When sailing a straight course, the boat

drifts off course:

a Change to a profi le suitable for

boat speed and sea conditions (see

G-PILOT 3100 Operation Manual).

b Adjust response, ratio, counter rudder

gain, GPS gain (if G-PILOT is in GPS

mode) or wind gain (if G-PILOT is

in wind mode) (see G-PILOT 3100

Operation Manual).

G-PILOT 3100 Installation Manual

.

NAVMAN

5 When making a large course change,

boat does not follow the expected

course:

a Change to a profi le suitable for

boat speed and sea conditions (see

G-PILOT 3100 Operation Manual).

b Check turn rate is not too low (go

to TURN RATE in the OPTIONS

menu, see G-PILOT 3100 Operation

Manual).

c Adjust counter rudder gain (see

G-PILOT 3100 Operation Manual).

6 Boat turns too sharply:

Reduce turn rate (go to TURN RATE

in the OPTIONS menu, see G-PILOT

3100 Operation Manual).

7 The word SIMULATE flashes on

the display, values displayed are

unexpected:

Unit is in simulate mode (See

G-PILOT 3100 Operation Manual).

8 The display fogs:

a Moist air has entered the breathing

tube at the rear of the unit. Air the

boat or run unit with backlight fully on.

b Water has entered the breathing tube.

Return unit for service.

31

Page 32

Appendix D - How to contact us www.navman.com.

NORTH AMERICA

Navman USA Inc.

30 Sudbury Rd, Acton, MA 01720.

Toll Free: +1 866 628 6261

Fax: +1 978 897 8264

e-mail: sales@navmanusa.com

web:www.navman.com

AUSTRALIA

Navman Australia Pty. Limited

Unit 2 / 5-13 Parsons St.

Rozelle, NSW 2039, Australia.

Ph: +61 2 9818 8382

Fax: +61 2 9818 8386

e-mail: sales@navman.com.au

web: www.navman.com

OCEANIA

New Zealand

Absolute Marine Ltd.

Unit B, 138 Harris Road,

East Tamaki, Auckland.

Ph: +64 9 273 9273

Fax: +64 9 273 9099

e-mail: navman@absolutemarine.co.nz

Papua New Guinea

Lohberger Engineering,

Lawes Road, Konedobu.

PO Box 810, Port Moresby.

Ph: +675 321 2122

Fax: +675 321 2704

e-mail: loheng@online.net.pg

web: www.lohberger.com.pg

SOUTH AMERICA

Argentina

Costanera Uno S.A.

Av Pte Ramón S. Castillo y Calle 13

Zip 1425 Buenos Aires, Argentina.

Ph: +54 11 4312 4545

Fax +54 11 4312 5258

e-mail:

purchase@costanerauno.com.ar

web: www.costanerauno.ar

Brazil

Equinautic Com Imp Exp de Equip

Nauticos Ltda.

Rua Ernesto Paiva, 139

Clube dos Jangadeiros

Porto Alegre - RS - Brasil

CEP: 91900-200.

Ph: +55 51 3268 6675

+55 51 3269 2975

Fax: +55 51 3268 1034

e-mail:

equinautic@equinautic.com.br

web: www.equinautic.com.br

Realmarine

Estrada do Joa 3862,

Barra da Tijuca, Rio de Janeiro,

Brazil. CEP: 22611-020.

Ph: +55 21 2483 9700

Fax: +55 21 2495 6823

e-mail: tito@realmarine.com.br

web: www.realmarine.com.br

Chile

Equimar

Manuel Rodrigurez 27

Santiago, Chile.

Ph: +56 2 698 0055

Fax +56 2 698 3765

e-mail: mmontecinos@equimar.cl

Mera Vennik

Colon 1148, Talcahuano,

4262798, Chile.

Ph: +56 41 541 752

Fax +56 41 543 489

e-mail: meravennik@entel.chile.net

90

CENTRAL AMERICA

Mexico

Mercury Marine de Mexico

Anastacio Bustamente #76

Interior 6 Colonia Francisco Zarabia,

Zapapan, Jalisco, C.P. 45236 Mexico.

Ph: +52 33 3283 1030

Fax: +52 33 3283 1034

web: www.equinautic.com.br

ASIA

China

Peaceful Marine Electronics Co. Ltd.

Guangzhou, Hong Kong, Dalian,

Qingdao, Shanghai

1701 Yanjiang Building

195 Yan Jiang Zhong Rd. 510115

Guangzhou, China.

Ph: +86 20 3869 8839

Fax: +86 20 3869 8780

e-mail: sales@peaceful-marine.com

web: www.peaceful-marine.com

India

Access India Overseas Pvt. Ltd.

A-98, Sector 21,

Noida - 201 301, India.

Ph: +91 120 244 2697

TeleFax: +91 120 253 7881

Mobile: +91 98115 04557

e-mail: vkapil@del3.vsnl.net.in

Esmario Export Enterprises

Block No. F-1, 3rd Floor, Surya Towers

Sardar Patel Rd, Secunderbad 500 003.

Ph: +91 40 2784 5163

Fax: +91 40 2784 0595

e-mail: gjfeee@hd1.vsnl.net.in

web: www.esmario.com

Indonesia

Polytech Nusantara,

Graha Paramita 2nd Floor,

Jln Denpasar Raya Blok D2

Kav 8 Kuningan, Jakarta 12940.

Ph: +62 21 252 3249

Fax: +62 21 252 3250

e-mail: polytech@transavia.co.id

Korea

Kumhomarine Technology Co. Ltd.

#604-842, 2F, 1118-15, Janglim1-Dong,

Saha-Gu, Busan, Korea.

Ph: +82 51 293 8589

Fax: +82 51 265 8984

e-mail: info@kumhomarine.com

web: www.kumhomarine.com

Maldives

Maizan Electronics Pte. Ltd.

Henveyru, 08 Sosunmagu.

Male', Maldives.

Mobile: +960 78 24 44

Ph: +960 32 32 11

Fax: +960 32 57 07

e-mail: ahmed@maizan.com.mv

Singapore, Malaysia, Brunei,

Indonesia and Phillipines

RIQ PTE Ltd.

Blk 3007, 81 Ubi Road 1, #02-440,

Singapore 408701.

Ph: +65 6741 3723

Fax : +65 6741 3746

e-mail: riq@postone.com

Taiwan

Seafirst International Corporation

No. 281, Hou-An Road, Chien-Chen

Dist. Kaohsiung, Taiwan R.O.C.

Ph: +886 7 831 2688

Fax: +886 7 831 5001

e-mail: seafirst@seed.net.tw

web: www.seafirst.com.tw

NAVMAN

Thailand

Thong Electronics (Thailand) Co. Ltd.

923/588 Ta Prong Road, Mahachai,

Muang, Samutsakhon 74000, Thailand.

Ph: +66 34 411 919

Fax: +66 34 422 919

e-mail: sales@thongelectronics.com

admins@thongelectronics.com

web: www.thongelectronics.com

Vietnam

Haidang Co. Ltd.

1763 Le Hong Phong St. Ward 12

District 10, Ho Chi Minh City.

Ph: +84 8 863 2159

Fax: +84 8 863 2124

e-mail: sales@haidangvn.com

web: www.haidangvn.com

MIDDLE EAST

Lebanon and Syria

Balco Stores

Balco Building, Moutran Street,

Tripoli (via Beirut). - Lebanon

P.O. Box: 622.

Ph: +961 6 624 512

Fax: +961 6 628 211

e-mail: balco@cyberia.net.lb

United Arab Emirates

Kuwait, Oman, Iran, Saudi

Arabia, Bahrain & Qatar

Abdullah Moh’d Ibrahim Trading, opp

Creak Rd. Baniyas Road, Dubai.

Ph: +971 4 229 1195

Fax: +971 4 229 1198

e-mail: sales@amitdubai.com

AFRICA

South Africa

Pertec (Pty) Ltd (Coastal Division)

16 Paarden Eiland Road.

Paarden Eiland, 7405

PO Box 527,

Paarden Eiland, 7420

Cape Town, South Africa.

Ph: +27 21 508 4707

Fax: +27 21 508 4888

e-mail: info@kfa.co.za

web: www.pertec.co.za

EUROPE

France, Belgium and Switzerland

Plastimo SA

15, rue Ingénieur Verrière,

BP435,

56325 Lorient Cedex.

Ph: +33 2 97 87 36 36

Fax: +33 2 97 87 36 49

e-mail: plastimo@plastimo.fr

web: www.plastimo.fr

Germany

Navimo Deutschland

15, rue Ingénieur Verrière

BP435- 56325 Lorient Cedex.

Ph: +49 6105 92 10 09

+49 6105 92 10 10

+49 6105 92 10 12

Fax: +49 6105 92 10 11

e-mail:

plastimo.international@plastimo.fr

website: www.plastimo.de

Italy

Navimo Italia

Nuova Rade spa, Via del Pontasso 5

16015 Casella Scrivia (GE).

Ph: +39 1096 80162

Fax: +39 1096 80150

e-mail: info@nuovarade.com

web: www.plastimo.it

Holland

Navimo Holland

Industrieweg 4,

2871 JE Schoonhoven.

Ph: +31 182 320 522

Fax: +31 182 320 519

e-mail: info@plastimo.nl

web: www.plastimo.nl

United Kingdom

Navimo UK

Hamilton Business Park

Bailey Road, Hedge End

Southhampton, Hants S030 2HE.

Ph: +44 01489 778 850

Fax: +44 0870 751 1950

e-mail: sales@plastimo.co.uk

web: www.plastimo.co.uk

Sweden, Denmark, Finland and

Norway

Navimo Nordic

Lundenvägen 2,

473 21 Henån.

Ph: +46 304 360 60

Fax: +46 304 307 43

e-mail: info@plastimo.se

web: www.plastimo.se

Spain

Navimo España

Avenida Narcís Monturiol, 17

08339 Vilassar de Dalt,

Barcelona.

Ph: +34 93 750 75 04

Fax: +34 93 750 75 34

e-mail: plastimo@plastimo.es

web: www.plastimo.es

Portugal

Navimo Portugal

Avenida de India N°40

1300-299 Lisbon.

Ph: +351 21 362 04 57

Fax: +351 21 362 29 08

e-mail: plastimo@siroco-nautica.pt

web: www.plastimo.com

Other countries in Europe

Plastimo International

15, rue Ingénieur Verrière BP435

56325 Lorient Cedex, France.

Ph: +33 2 97 87 36 59

Fax: +33 2 97 87 36 29

e-mail:

plastimo.international@plastimo.fr

web: www.plastimo.com

REST OF WORLD/

MANUFACTURERS

Navman NZ Limited

13-17 Kawana St.

Northcote.

P.O. Box 68 155,

Newton,

Auckland,

New Zealand.

Ph: +64 9 481 0500

Fax: +64 9 481 0590

e-mail: marine.sales@navman.com

web: www.navman.com

G-PILOT 3100 manual de instalação

Page 33

.

Page 34

Made in New Zealand

MN000212E

G-PILOT 3100 Installation

Lon 174° 44.535'E

Lat 36° 48.404'S

NAVMAN

Loading...

Loading...