MURATA OKY-T-3, OKY-T-5 Technical data

www.murata-ps.com

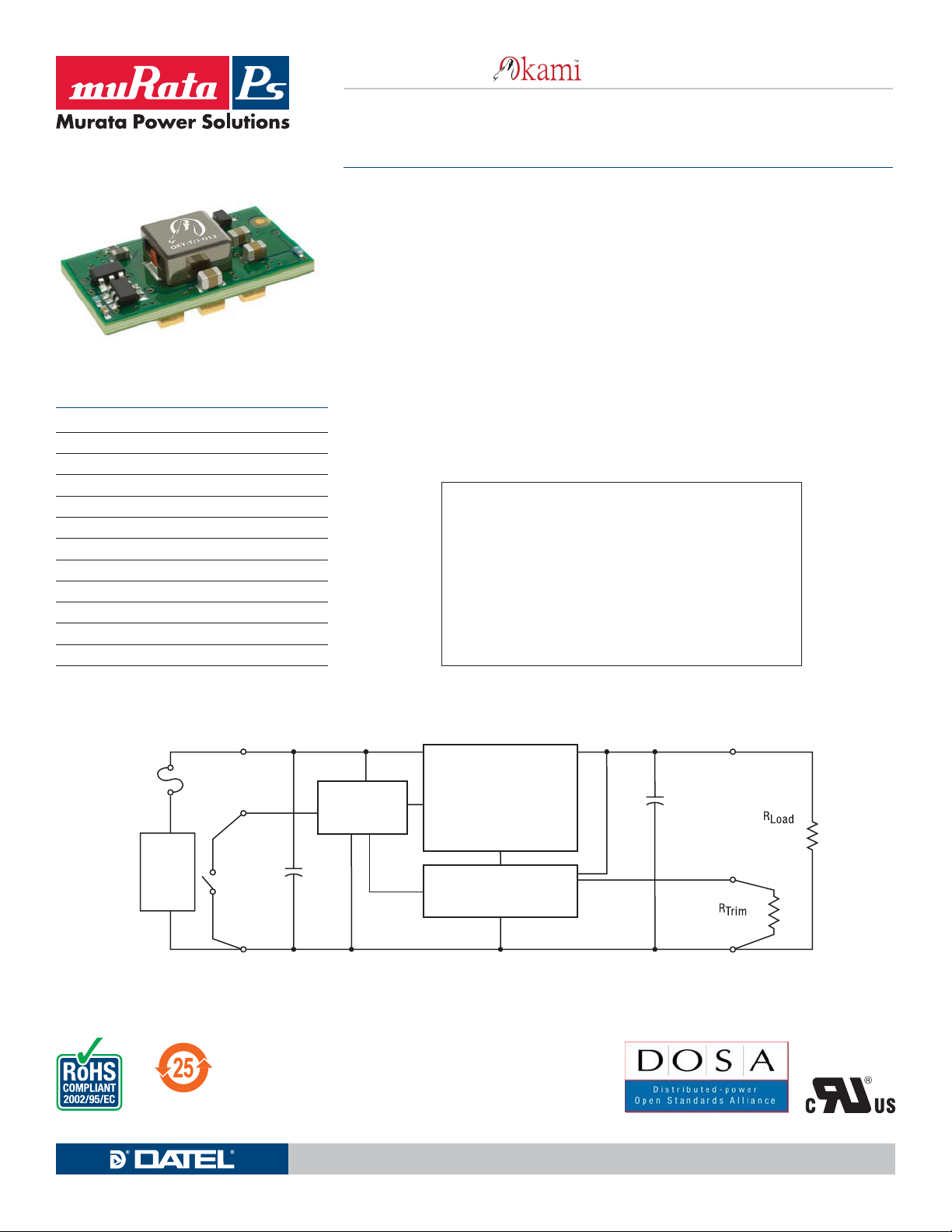

Typical unit

FEATURES

■ Non-isolated SMT POL DC/DC power module

■ 8.3-14Vdc input voltage range

■ Programmable output voltage from 0.75-5.5Vdc

■ 3 Amp (T/3) or 5 Amp (T/5) output current models

■ Drives 1000 µF capacitive loads

■ High power conversion effi ciency 93% at 3.3 Vout

■ Outstanding thermal derating performance

■ Over temperature and over current protection

■ On/Off control

■ UL/EN/IEC 60950-1 safety

■ Industry-standard (DOSA) surface-mount package

■ RoHS6 hazardous substance compliance

OKY-T/3,T/5-D12 Series

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

PRODUCT OVERVIEW

The OKY-T/3 and -T/5 series are miniature nonisolated Point-of-Load (POL) switch mode DC/DC

power converters for embedded applications. The

module is fully compatible with Distributed-power

Open Standards Alliance (DOSA) industry-standard

specifi cations (www.dosapower.com). Applications

include powering CPU’s, datacom/telecom systems,

distributed bus architectures (DBA), programmable

logic and mixed voltage systems.

The wide input range is 8.3 to 14 Volts DC. Two

maximum output currents are offered, 3 Amps (T/3

models) or 5 Amps (T/5 models). Based on fi xed-

Contents Page

Description, Connection Diagram, Photograph 1

Ordering Guide, Model Numbering 2

Mechanical Specifi cations, Input/Output Pinout 3

Detailed Electrical Specifi cations 4

Output Voltage Adjustment, Soldering Guidelines 5

Application Notes 6

OKY-T/3-D12 Performance Data and Oscillograms 9

OKY-T/5-D12 Performance Data and Oscillograms 15

Tape and Reel Information 21

frequency synchronous buck converter switching

topology, the high power conversion effi cient Point

of Load (POL) module features programmable

output voltage and On/Off control. These converters

also include under voltage lock out (UVLO), output

short circuit protection, over-current and over

temperature protections.

These units are designed to meet all standard

UL/EN/IEC 60950-1 safety and FCC EMI/RFI

emissions certifi cations and RoHS6 hazardous

substance compliance.

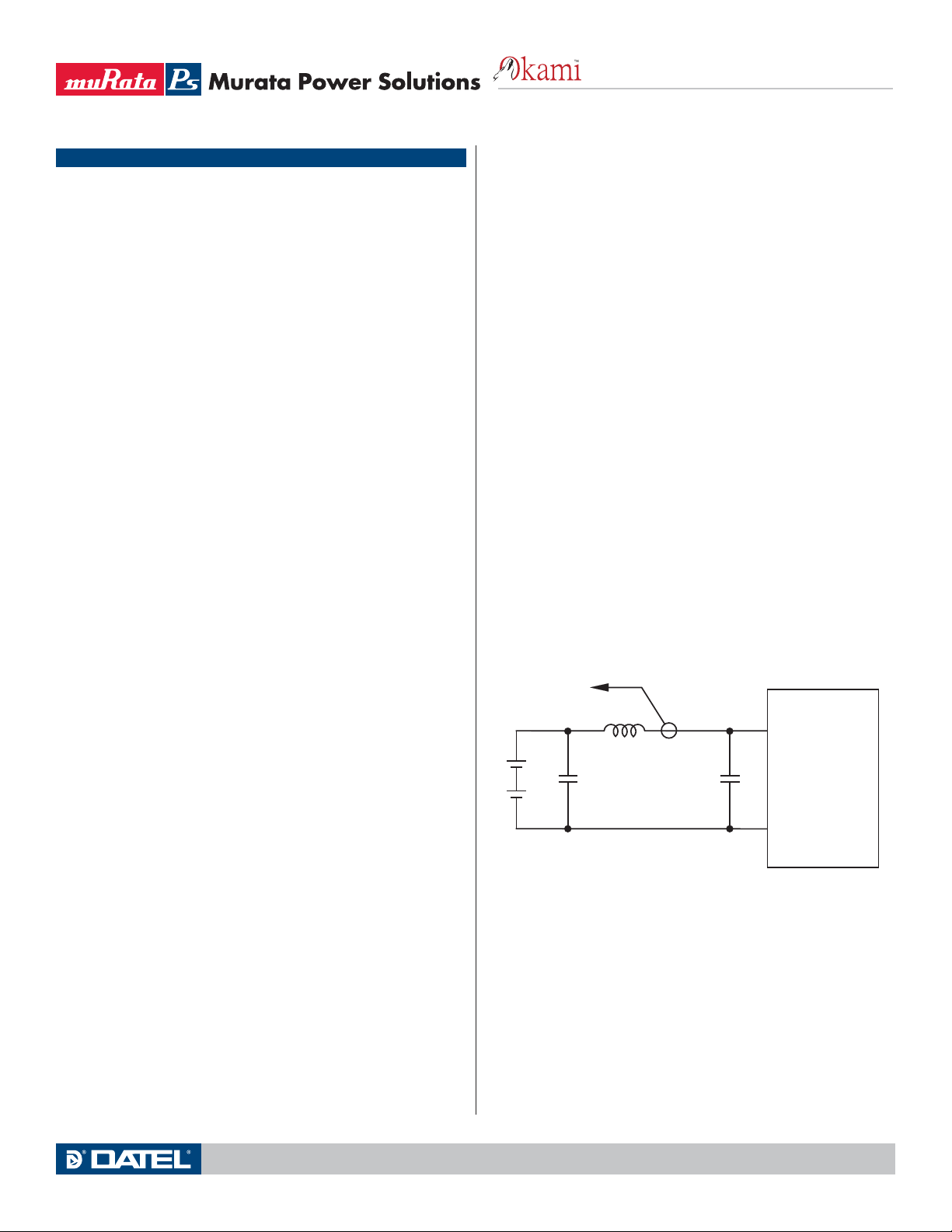

F1

External

DC

Power

Source

For full details go to

www.murata-ps.com/rohs

+Vin +Vout

Connection Diagram

On/Off

Control

Open = On

Closed = Off

Controller

Note: Murata Power Solutions strongly recommends an external input fuse, F1.

See specifi cations.

www.murata-ps.com

t4XJUDIJOH

t'JMUFST

t$VSSFOU4FOTF

Reference and

Error Amplifier

CommonCommon

Figure 1. OKY-T/3, -T/5

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000

MDC_MDC_OKY-T/3,T/5-D12 Series.B03 Page 1 of 22

Trim

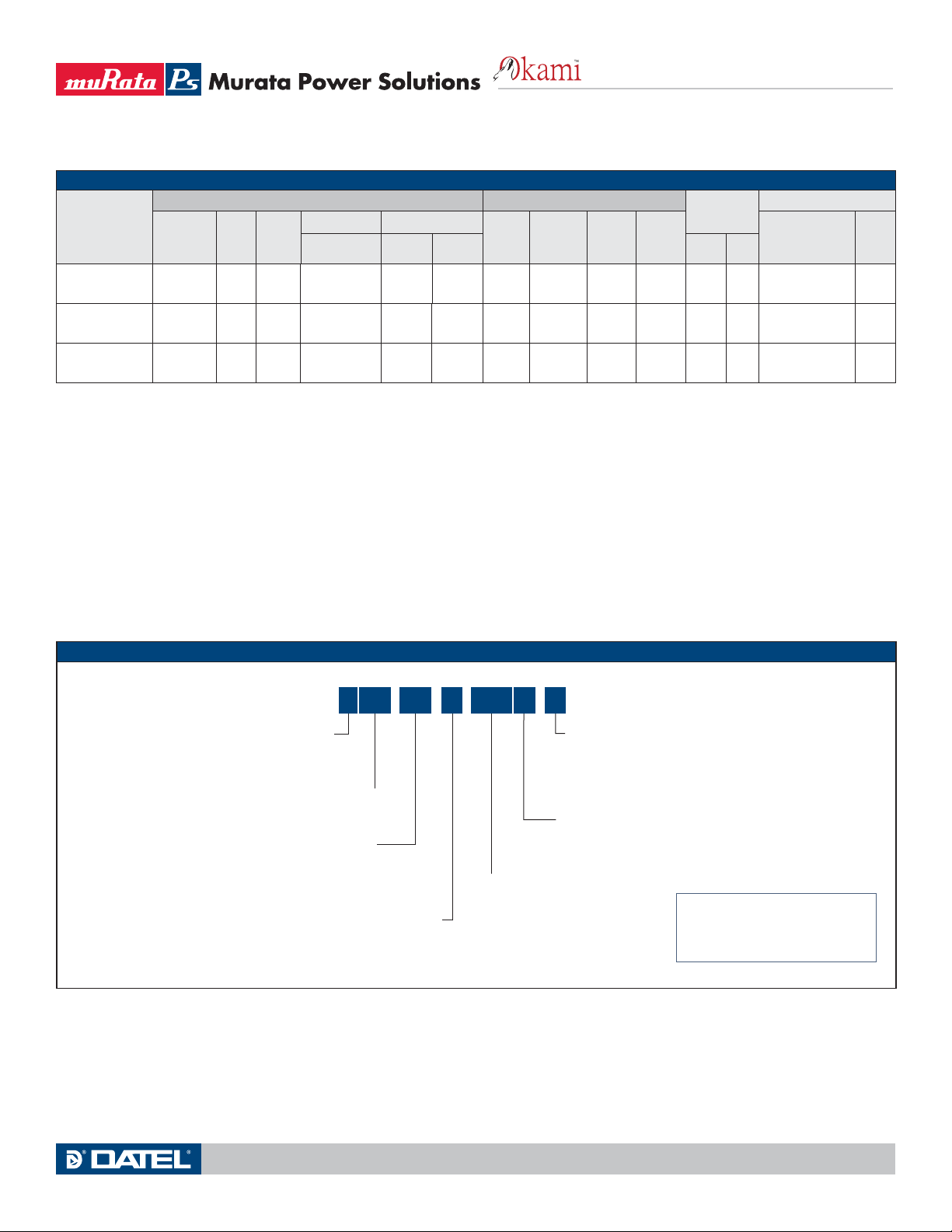

Performance Specifi cations and Ordering Guide

ORDERING GUIDE

Output Input

R/N (mVp-p)

Power

(Watts)

Root Model ➁

OKY-T/3-D12N-C

OKY-T/3-D12P-C

OKY-T/5-D12N-C

OUT

V

(Volts)

0.75-5.5

0.75-5.5 ➆

0.75-5.5

IOUT

(Amps

max)

3 15.3 25 ±0.1% ±0.2% 12 8.3-14 80 1.34 91.5% 93%

➆

3 15.3 25 ±0.1% ±0.2% 12 8.3-14 80 1.34 91.5% 93%

5 25.5 25 ±0.2% ±0.5% 12 8.3-14 80 2.24 91.5% 93%

➅

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

➄ Regulation (Max.)➂

VIN Nom.

(Volts)

OKY-T/3,T/5-D12 Series

Range

(Volts)

IIN,

no load

(mA)

full load

(Amps) Case C72 ➀ PinoutMax. Line Load Min. Typ.

IIN,

Effi ciency

0.47 x 0.82 x 0.28

(11.9 x 20.8 x 7.1)

0.47 x 0.82 x 0.28

(11.9 x 20.8 x 7.1)

0.47 x 0.82 x 0.28

(11.9 x 20.8 x 7.1)

Package

P78

P78

P78

➀ Dimensions are in inches (mm).

➁ These are partial model numbers. Please refer to the part number structure for complete ordering part numbers.

➂ All specifications are at nominal line voltage, Vout=nominal (5V for D12 models) and full load, +25 ˚C. unless

otherwise noted.

Output capacitors are 1 µF ceramic and 10 µF electrolytic in parallel. Input cap is 22 µF. See detailed specifica-

tions.

I/O caps are necessary for our test equipment and may not be needed for your application.

PART NUMBER STRUCTURE

O KY -/ D12-T 5 C-

Output

Confi guration:

Single Output,

Unipolar, Low Voltage

Non-Isolated Surface Mount

Trimmable Output

Voltage Range

0.75-5.5V

Maximum Rated Output

Current in Amps

fVin must be 2V or higher than Vout for 3.3 to 5V outputs.

gRipple and Noise is shown at Vout=1V. See specs for details.

OUT = 5.1V at IOUT = 5A.

➅Max. V

➆Max. VOUT = 5.1V at IOUT = 3A.

N

RoHS Hazardous

Substance Compliance

C = RoHS6 (does not claim EU RoHS exemption

7b–lead in solder)

On/Off Polarity

P = Positive Polarity

N = Negative Polarity

Input Voltage Range

8.3-14V

Note: Some model number combinations

may not be available. Contact Murata

Power Solutions for availability.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_MDC_OKY-T/3,T/5-D12 Series.B03 Page 2 of 22

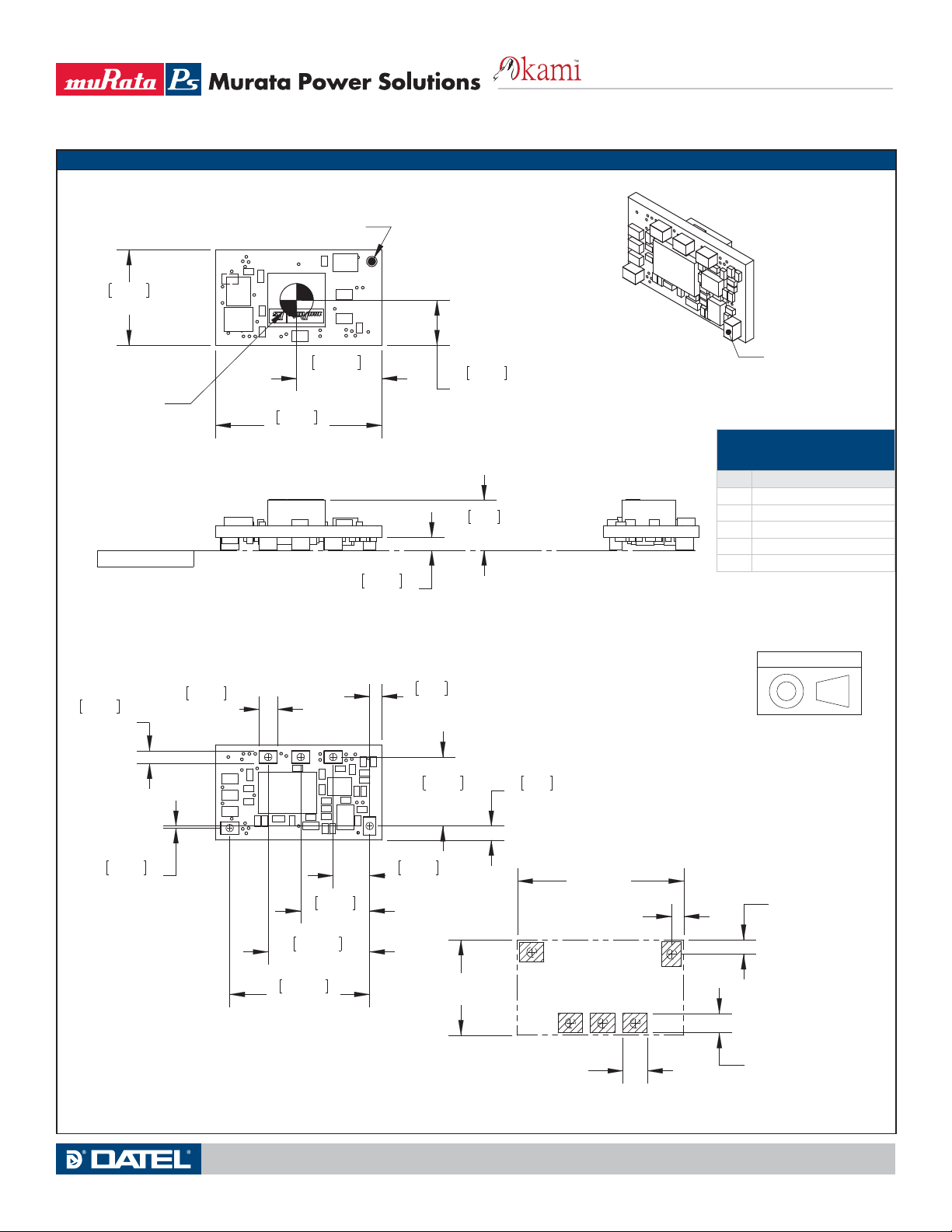

MECHANICAL SPECIFICATIONS

TOP VIEW

CORNER (FARSIDE)

11.9

0.47

NOZZLE

PICKUP

POINT

PIN #1 THIS

20.8

0.82

SIDE VIEW

MTG PLANE

10.67

0.420

REF

1.59

0.063

OKY-T/3,T/5-D12 Series

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

ISOMETRIC

VIEW

5.64

0.222

REF

END VIEW

6.2

0.25

PIN #1

INPUT/OUTPUT CONNECTIONS

OKY-T/3, -T/5

Pin Function

1 On/Off Control*

2+VIN

3 Ground (Common)

4 Trim

5+V

*The Remote On/Off can be provided with

either positive (P suffi x) or negative (N

suffi x) polarity

OUT

BOTTOM VIEW

1.59

0.063

TYP

2.29

0.090

TYP

3

4 5

2

0.25

0.010

8.63

0.340

12.69

0.500

17.52

0.690

MATERIAL:

SMT PINS: COPPER ALLOY

FINISH: (ALL PINS)

GOLD (5u"MIN) OVER NICKEL (50u" MIN)

1

4.57

0.180

1.5

0.06

8.63

0.340

0.47

REF

1.8

0.07

Figure 2. OKY-T/3, -T/5 Mechanical Outline

0.82 REF

0.060

REF

21

35

4

MIN0.120

0.135 MAX

RECOMMENDED PAD LAYOUT

Dimensions are in inches (mm shown for ref. only).

Third Angle Projection

Tolerances (unless otherwise specified):

.XX ± 0.02 (0.5)

.XXX ± 0.010 (0.25)

Angles ± 1˚

Components are shown for reference only.

0.070

REF

0.095 MIN

0.110 MAX

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_MDC_OKY-T/3,T/5-D12 Series.B03 Page 3 of 22

Performance and Functional Specifi cations

See Note 1

Input

Input Voltage Range See Ordering Guide and Note 7.

Isolation Not isolated

Start-Up Voltage 7.5 V. min, 8.25 V. max

Undervoltage Shutdown (see Note 15) 7.3 V. min, 8.05 V. max

Overvoltage Shutdown None

Refl ected (Back) Ripple Current (Note 2) 20 mA pk-pk

Internal Input Filter Type Capacitive

Recommended External Fuse 6A

Reverse Polarity Protection N/A. See fuse information.

Input Current:

Full Load Conditions See Ordering Guide

Inrush Transient 0.4 A2Sec.

Shutdown Mode (Off, UV, OT) 5 mA

Output in Short Circuit 60 mA

No Load 80 mA

Low Line (Vin=Vmin, 5Vout) 1.93 A. (OKY-T/3-D12)

3.24 A. (OKY-T/5-D12)

Remote On/Off Control (Note 5)

Negative Logic (“N” model suffi x) ON = Open pin or ground to +0.4V. max.

OFF = +1.5V min. to +Vin

Current 1 mA max.

Positive Logic (“P” model suffi x) ON = Open pin (internally pulled up) or

+7.8Vdc to +Vin max.

OFF = Ground pin to +0.4V. max.

Current 1 mA max.

Output

Output Power 15.3W max. (OKY-T/3)

25.5W max. (OKY-T/5)

Output Voltage Range See Ordering Guide

Minimum Loading No minimum load

Accuracy (50% load, untrimmed) ±2 % of Vnominal

Voltage Output Range (Note 13) See Ordering Guide

Overvoltage Protection (Note 16) None

Temperature Coeffi cient ±0.02% per °C of Vout range

Ripple/Noise (20 MHz bandwidth) See Ordering Guide and note 8

Line/Load Regulation See Ordering Guide and note 10

Effi ciency See Ordering Guide

Maximum Capacitive Loading (Note 14)

Cap-ESR=0.001 to 0.01 Ohms 1,000 F

Cap-ESR >0.01 Ohms 3,000 F

Current Limit Inception (Note 6)

(98% of Vout setting, after warm up) 7.5 Amps max.

Short Circuit Mode

Short Circuit Current Output 2 A

Protection Method Hiccup autorecovery upon overload

removal. (Note 17)

Short Circuit Duration Continuous, no damage

(output shorted to ground)

Prebias Startup Converter will start up if the external

output voltage is less than Vnominal.

Dynamic Characteristics

Dynamic Load Response 90Sec max. to within ±2% of fi nal value

(50-100-50% load step, di/dt=2.5A/μSec)

Start-Up Time 8 mSec for Vout=nominal

(Vin on or On/Off to Vout regulated)

Switching Frequency 320 KHz

± 30

KHz

OKY-T/3,T/5-D12 Series

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

Environmental

Calculated MTBF

Telecordia method (4a) OKY-T/3-D12N-C: 10,155,200 hours

Calculated MTBF

MIL-HDBK-217N2 method (4b) OKY-T/3-D12N-C: 6,309,035 hours

Operating Temperature Range (Ambient, vertical mount)

See derating curves -40 to +85 ˚C. with derating (Note 9)

Operating PC Board Temperature -40 to +100 ˚Celsius max., no derating (12)

Storage Temperature Range -55 to +125 deg. C.

Thermal Protection/Shutdown +130 ˚Celsius

Relative Humidity to 85%/+85 ˚C., non-condensing

Physical

Outline Dimensions See Mechanical Specifi cations

Weight 0.1 ounces (2.8 grams)

Electromagnetic Interference Designed to meet FCC part 15, class B,

EN55022 and CISPR22 class B conducted

and radiated (may need external fi lter)

Safety Designed to meet UL/cUL 60950-1, CSA C22.2 No. 60950-1, IEC/EN 60950-1

Restriction of Hazardous Substances RoHS6 (

7b–lead in solder

MSL Rating 2

Absolute Maximum Ratings

Input Voltage (Continuous or transient) 0 V.to +15 Volts max.

On/Off Control 0 V. min. to +Vin max.

Input Reverse Polarity Protection See Fuse section

Output Current (Note 7) Current-limited. Devices can withstand a

sustained short circuit without damage.

The outputs are not intended to accept

appreciable reverse current.

Storage Temperature -55 to +125 ˚C.

Lead Temperature See soldering specifi cations

Absolute maximums are stress ratings. Exposure of devices to greater than any of

any of these conditions may adversely affect long-term reliability. Proper operation

under conditions other than those listed in the Performance/Functional Specifi cations

Table is not implied or recommended.

Specifi cation Notes:

(1) Specifi cations are typical at +25 °C, Vin=nominal (+12V.), Vout=nominal (+5V), full load, external caps and

natural convection unless otherwise indicated. Extended tests at full power must supply substantial forced

airfl ow.

All models are tested and specifi ed with external 1 F paralleled with 10F ceramic/tantalum output

capacitors and a 22 F external input capacitor. All capacitors are low ESR types. These capacitors are

necessary to accommodate our test equipment and may not be required to achieve specifi ed performance

in your applications. However, Murata Power Solutions recommends installation of these capacitors. All

models are stable and regulate within spec under no-load conditions.

(2) Input Back Ripple Current is tested and specifi ed over a 5 Hz to 20 MHz bandwidth. Input fi ltering is Cin=2 x

100 F tantalum, Cbus=1000 F electrolytic, Lbus=1 H.

(3) Note that Maximum Power Derating curves indicate an average current at nominal input voltage. At higher

temperatures and/or lower airfl ow, the DC/DC converter will tolerate brief full current outputs if the total

RMS current over time does not exceed the Derating curve.

(4a) Mean Time Before Failure is calculated using the Telcordia (Belcore) SR-332 Method 1, Case 3, ground fi xed

conditions, Tpcboard=+25 ˚C, full output load, natural air convection.

(4b) Mean Time Before Failure is calculated using the MIL-HDBK-217N2 method, ground benign, +25ºC., full

output load, natural convection.

(5) The On/Off Control Input should use either a switch or an open collector/open drain transistor referenced

to -Input Common. A logic gate may also be used by applying appropriate external voltages which do not

exceed +Vin.

(6) Short circuit shutdown begins when the output voltage degrades approximately 2% from the selected

setting.

does not claim EU RoHS exemption

)

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_MDC_OKY-T/3,T/5-D12 Series.B03 Page 4 of 22

OKY-T/3,T/5-D12 Series

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

Specifi cation Notes, Cont.:

(7) For W5 models, the Input Voltage must exceed the Output Voltage at all times by the ratio of Vin >= (1.15 x

Vout). Please see the separate W5 data sheet.

(8) Output noise may be further reduced by adding an external fi lter. At zero output current, the output may

contain low frequency components which exceed the ripple specifi cation. The output may be operated

indefi nitely with no load.

(9) All models are fully operational and meet published specifi cations, including “cold start” at –40˚ C.

(10) Regulation specifi cations describe the deviation as the line input voltage or output load current is varied

from a nominal midpoint value to either extreme.

(11) Other input or output voltage ranges will be reviewed under scheduled quantity special order.

(12) Maximum PC board temperature is measured with the sensor in the center of the converter.

(13) Do not exceed maximum power specifi cations when adjusting the output trim.

(14) The maximum output capacitive loads depend on the the Equivalent Series Resistance (ESR) of the external

output capacitor and, to a lesser extent, the distance and series impedance to the load. Larger caps will

reduce output noise but may change the transient response. Newer ceramic caps with very low ESR may

require lower capacitor values to avoid instability. Thoroughly test your capacitors in the application. Please

refer to the Output Capacitive Load Application Note.

(15) Do not allow the input voltage to degrade lower than the input undervoltage shutdown voltage at all times.

Otherwise, you risk having the converter turn off. The undervoltage shutdown is not latching and will

attempt to recover when the input is brought back into normal operating range.

(16) The outputs are not intended to sink appreciable reverse current.

(17) “Hiccup” overcurrent operation repeatedly attempts to restart the converter with a brief, full-current output.

If the overcurrent condition still exists, the restart current will be removed and then tried again. This short

current pulse prevents overheating and damaging the converter. Once the fault is removed, the converter

immediately recovers normal operation.

Output Voltage Adustment

The output voltage may be adjusted over a limited range by connecting an

external trim resistor (Rtrim) between the Trim pin and Ground. The Rtrim

resistor must be a 1/10 Watt precision metal fi lm type, ±1% accuracy or

better with low temperature coeffi cient, ±100 ppm/oC. or better. Mount the

resistor close to the converter with very short leads or use a surface mount

trim resistor.

Soldering Guidelines

Murata Power Solutions recommends the specifi cations below when installing these

converters. These specifi cations vary depending on the solder type. Exceeding these

specifi cations may cause damage to the product. Be cautious when there is high

atmospheric humidity. We strongly recommend a mild pre-bake (100 ºC. for 30

minutes). Your production environment may differ therefore please thoroughly review

these guidelines with your process engineers.

Reflow Solder Operations for surface-mount products (SMT)

For Sn/Ag/Cu based solders:

Preheat Temperature Less than 1 ºC. per second

Time over Liquidus 45 to 75 seconds

Maximum Peak Temperature 260 ºC.

Cooling Rate Less than 3 ºC. per second

For Sn/Pb based solders:

Preheat Temperature Less than 1 ºC. per second

Time over Liquidus 60 to 75 seconds

Maximum Peak Temperature 235 ºC.

Cooling Rate Less than 3 ºC. per second

In the tables below, the calculated resistance is given. Do not exceed the

specifi ed limits of the output voltage or the converter’s maximum power

rating when applying these resistors. Also, avoid high noise at the Trim

input. However, to prevent instability, you should never connect any capacitors to Trim.

OKY-T/3-D12, -T/5-D12

Output Voltage Calculated Rtrim (KΩ)

5.0 V. 1.472

3.3 V. 3.122

2.5 V. 5.009

2.0 V. 7.416

1.8 V. 9.024

1.5 V. 13.05

1.2 V. 22.46

1.0 V. 41.424

0.7525 V. ∞ (open)

Resistor Trim Equation, D12 models:

10500

RTRIM (:) =

_____________

VOUT – 0.7525V

–1000

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_MDC_OKY-T/3,T/5-D12 Series.B03 Page 5 of 22

OKY-T/3,T/5-D12 Series

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

APPLICATION NOTES

Input Fusing

Certain applications and/or safety agencies may require fuses at the inputs of

power conversion components. Fuses should also be used when there is the

possibility of sustained input voltage reversal which is not current-limited. We

recommend a time delay fuse installed in the ungrounded input supply line

with a value which is approximately twice the maximum line current, calculated at the lowest input voltage.

The installer must observe all relevant safety standards and regulations. For

safety agency approvals, install the converter in compliance with the end-user

safety standard, i.e. IEC/EN/UL 60950-1.

Input Under-Voltage Shutdown and Start-Up Threshold

Under normal start-up conditions, converters will not begin to regulate properly

until the ramping-up input voltage exceeds and remains at the Start-Up

Threshold Voltage (see Specifi cations). Once operating, converters will not

turn off until the input voltage drops below the Under-Voltage Shutdown Limit.

Subsequent restart will not occur until the input voltage rises again above the

Start-Up Threshold. This built-in hysteresis prevents any unstable on/off operation at a single input voltage.

Users should be aware however of input sources near the Under-Voltage

Shutdown whose voltage decays as input current is consumed (such as

capacitor inputs), the converter shuts off and then restarts as the external

capacitor recharges. Such situations could oscillate. To prevent this, make

sure the operating input voltage is well above the UV Shutdown voltage AT ALL

TIMES.

Start-Up Time

Assuming that the output current is set at the rated maximum, the Vin to Vout

Start-Up Time (see Specifi cations) is the time interval between the point when

the ramping input voltage crosses the Start-Up Threshold and the fully loaded

regulated output voltage enters and remains within its specifi ed accuracy band.

Actual measured times will vary with input source impedance, external input

capacitance, input voltage slew rate and fi nal value of the input voltage as it

appears at the converter.

These converters include a soft start circuit to moderate the duty cycle of its

PWM controller at power up, thereby limiting the input inrush current.

The On/Off Remote Control interval from On command to Vout regulated

assumes that the converter already has its input voltage stabilized above the

Start-Up Threshold before the On command. The interval is measured from the

On command until the output enters and remains within its specifi ed accuracy

band. The specifi cation assumes that the output is fully loaded at maximum

rated current. Similar conditions apply to the On to Vout regulated specifi cation

such as external load capacitance and soft start circuitry.

Input Source Impedance

These converters will operate to specifi cations without external components,

assuming that the source voltage has very low impedance and reasonable

input voltage regulation. Since real-world voltage sources have fi nite imped-

ance, performance is improved by adding external fi lter components. Sometimes only a small ceramic capacitor is suffi cient. Since it is diffi cult to totally

characterize all applications, some experimentation may be needed. Note that

external input capacitors must accept high speed switching currents.

Because of the switching nature of DC/DC converters, the input of these

converters must be driven from a source with both low AC impedance and

adequate DC input regulation. Performance will degrade with increasing input

inductance. Excessive input inductance may inhibit operation. The DC input

regulation specifi es that the input voltage, once operating, must never degrade

below the Shut-Down Threshold under all load conditions. Be sure to use

adequate trace sizes and mount components close to the converter.

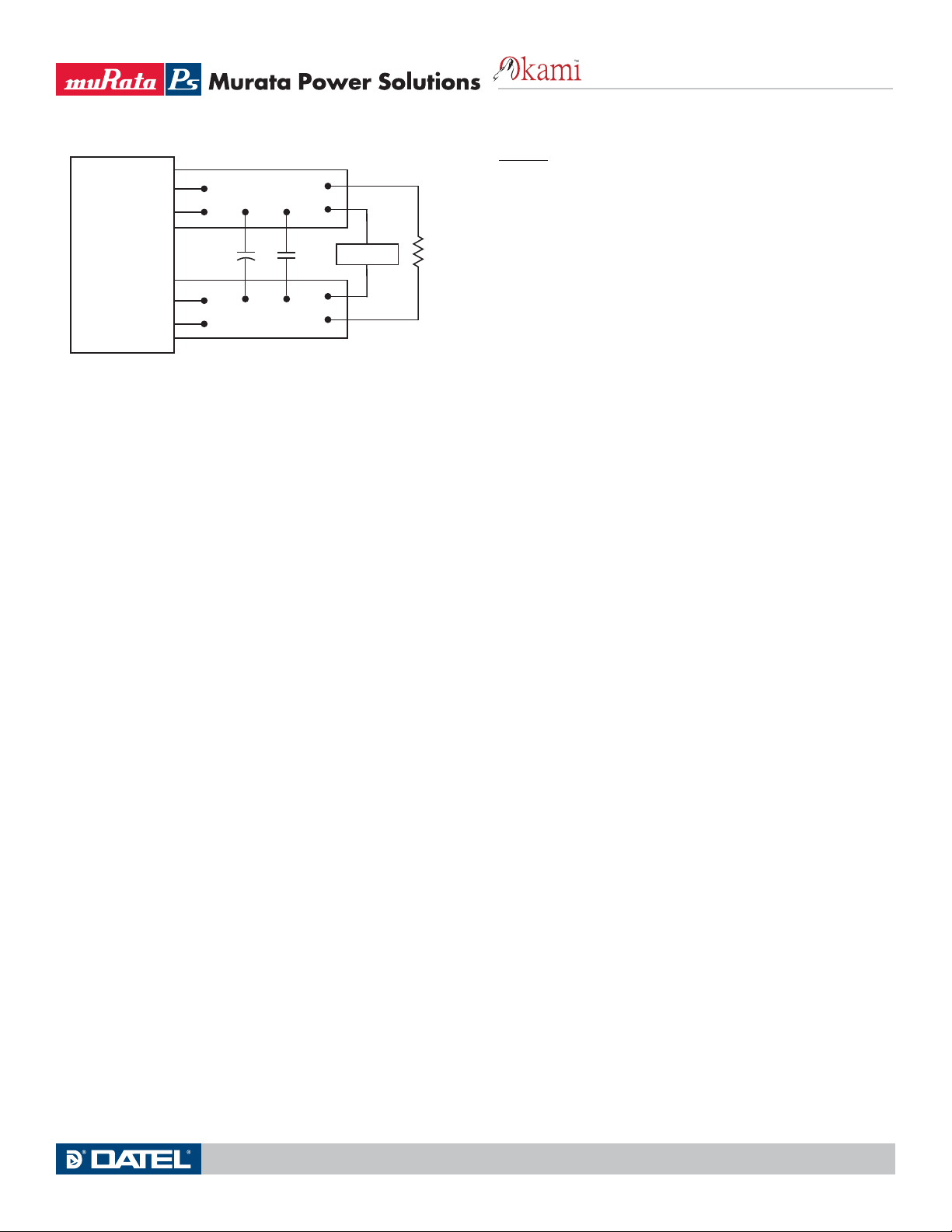

I/O Filtering, Input Ripple Current and Output Noise

All models in this converter series are tested and specifi ed for input refl ected

ripple current and output noise using designated external input/output components, circuits and layout as shown in the fi gures below. External input

capacitors (Cin in the fi gure) serve primarily as energy storage elements,

minimizing line voltage variations caused by transient IR drops in the input

conductors. Users should select input capacitors for bulk capacitance (at

appropriate frequencies), low ESR and high RMS ripple current ratings. In the

fi gure below, the Cbus and Lbus components simulate a typical DC voltage

bus. Your specifi c system confi guration may require additional considerations.

Please note that the values of Cin, Lbus and Cbus will vary according to the

specifi c converter model.

In critical applications, output ripple and noise (also referred to as periodic

and random deviations or PARD) may be reduced by adding fi lter elements

such as multiple external capacitors. Be sure to calculate component temperature rise from refl ected AC current dissipated inside capacitor ESR.

TO

OSCILLOSCOPE

L

+

–

V

IN

+

–

CIN = 2 x 100µF, ESR < 700mΩ @ 100kHz

BUS

= 1000µF, ESR < 100mΩ @ 100kHz

C

BUS

= 1µH

L

BUS

C

BUS

Figure 2: Measuring Input Ripple Current

CURRENT

PROBE

C

IN

+INPUT

-INPUT

In the fi gure, the two copper strips simulate real-world printed circuit

impedances between the power supply and its load. In order to minimize circuit

errors and standardize tests between units, scope measurements should be

made using BNC connectors or the probe ground should not exceed one half

inch and soldered directly to the fi xture.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_MDC_OKY-T/3,T/5-D12 Series.B03 Page 6 of 22

Adjustable Output 3 and 5-Amp DOSA-SMT DC/DC Converters

COPPER STRIP

+OUTPUT

R

C1

-OUTPUT

COPPER STRIP

C1 = 0.1µF CERAMIC

C2 = 10µF TANTALUM

LOAD 2-3 INCHES (51-76mm) FROM MODULE

Figure 3: Measuring Output Ripple and Noise (PARD)

C2

SCOPE

Minimum Output Loading Requirements

All models regulate within specifi cation and are stable under no load to full

load conditions. Operation under no load might however slightly increase

output ripple and noise.

Thermal Shutdown

To prevent many over temperature problems and damage, these converters

include thermal shutdown circuitry. If environmental conditions cause the

temperature of the DC/DC’s to rise above the Operating Temperature Range

up to the shutdown temperature, an on-board electronic temperature sensor

will power down the unit. When the temperature decreases below the turn-on

threshold, the converter will automatically restart. There is a small amount of

hysteresis to prevent rapid on/off cycling. The temperature sensor is typically

located adjacent to the switching controller, approximately in the center of the

unit. See the Performance and Functional Specifi cations.

CAUTION: If you operate too close to the thermal limits, the converter may

shut down suddenly without warning. Be sure to thoroughly test your application to avoid unplanned thermal shutdown.

Temperature Derating Curves

The graphs in the next section illustrate typical operation under a variety of

conditions. The Derating curves show the maximum continuous ambient air

temperature and decreasing maximum output current which is acceptable

under increasing forced airfl ow measured in Linear Feet per Minute (“LFM”).

Note that these are AVERAGE measurements. The converter will accept brief

increases in current or reduced airfl ow as long as the average is not exceeded.

Note that the temperatures are of the ambient airfl ow, not the converter

itself which is obviously running at higher temperature than the outside air.

Also note that very low fl ow rates (below about 25 LFM) are similar to “natural

convection”, that is, not using fan-forced airfl ow.

Murata Power Solutions makes Characterization measurements in a closed

cycle wind tunnel with calibrated airfl ow. We use both thermocouples and an

infrared camera system to observe thermal performance. As a practical matter,

it is quite diffi cult to insert an anemometer to precisely measure airfl ow in

most applications. Sometimes it is possible to estimate the effective airfl ow if

you thoroughly understand the enclosure geometry, entry/exit orifi ce areas and

the fan fl owrate specifi cations.

LOAD

OKY-T/3,T/5-D12 Series

CAUTION: If you routinely or accidentally exceed these Derating guidelines,

the converter may have an unplanned Over Temperature shut down. Also, these

graphs are all collected at slightly above Sea Level altitude. Be sure to reduce

the derating for higher density altitude.

Output Overvoltage Protection

This converter monitors its output voltage for an over-voltage condition. If

the output exceeds OVP limits, the sensing circuit will power down the unit,

and the output voltage will decrease. After a time-out period, the PWM will

automatically attempt to restart, causing the output voltage to ramp up to its

rated value. It is not necessary to power down and reset the converter for the

automatic OVP-recovery restart.

If the fault condition persists and the output voltage climbs to excessive

levels, the OVP circuitry will initiate another shutdown cycle. This on/off cycling

is referred to as “hiccup” mode. It safely tests full current rated output voltage

without damaging the converter.

Output Fusing

The converter is extensively protected against current, voltage and temperature

extremes. However your output application circuit may need additional protection. In the extremely unlikely event of output circuit failure, excessive voltage

could be applied to your circuit. Consider using an appropriate fuse in series

with the output.

Output Current Limiting

As soon as the output current increases to approximately 125% to 150% of

its maximum rated value, the DC/DC converter will enter a current-limiting

mode. The output voltage will decrease proportionally with increases in output

current, thereby maintaining a somewhat constant power output. This is also

commonly referred to as power limiting.

Current limiting inception is defi ned as the point at which full power falls

below the rated tolerance. See the Performance/Functional Specifi cations.

Note particularly that the output current may briefl y rise above its rated value

in normal operation as long as the average output power is not exceeded. This

enhances reliability and continued operation of your application. If the output

current is too high, the converter will enter the short circuit condition.

Output Short Circuit Condition

When a converter is in current-limit mode, the output voltage will drop as the

output current demand increases. If the output voltage drops too low (approximately 98% of nominal output voltage for most models), the magnetically

coupled voltage used to develop primary side voltages will also drop, thereby

shutting down the PWM controller. Following a time-out period, the PWM will

restart, causing the output voltage to begin ramping up to its appropriate value.

If the short-circuit condition persists, another shutdown cycle will initiate. This

rapid on/off cycling is called “hiccup mode”. The hiccup cycling reduces the

average output current, thereby preventing excessive internal temperatures

and/or component damage. A short circuit can be tolerated indefi nitely.

The “hiccup” system differs from older latching short circuit systems

because you do not have to power down the converter to make it restart. The

system will automatically restore operation as soon as the short circuit condition is removed.

Technical enquiries email: sales@murata-ps.com, tel: +1 508 339 3000www.murata-ps.com

MDC_MDC_OKY-T/3,T/5-D12 Series.B03 Page 7 of 22

Loading...

Loading...