查询XPC850供应商

Networking Communication Microprocessors

XPC850 (Rev 0.3)

XPC860

Reliability Report

for

XPC860T

0.42m Single Poly Wafer Fabrication Process

Revision: 5/99

1.0 Purpose and Description

This report summarizes the reliability data for Motorola communication

microprocessors fabricated on the 0.42m single polysilicon process in our wafer

fabrication facility, Mos 11, in Austin, Texas. The current devices fabricated using this

process are given in the table below.

Device Mask Set Design

Revision

XPC850 F98S 0.3 309 x 335 0.42m

XPC860 J24A

H96G

XPC860T J21M 0.2 338 x 347 0.42m

Table 1. Device properties.

All of these devices are currently in their XC phase of product life, which is the

time when design errata are discovered and corrected. Although the 850 and 860 are still

classified as XC devices, they are built using production equipment and processes, and

have completed their reliability qualifications. There are some functional errata on these

devices, which may impact some customers. These errata are expected to be corrected in

revision D of the 860, which we expect to grant MC status to. For a list of current design

errata on these devices, please contact your local Motorola sales person. To locate the

nearest sales office, you can find them on our website at http://mot-sps.com/sales/

sales_web.html

2.0 Assembly / Package Information

B.1

C

Die Size

(mils)

338 x 329

338 x 329

Process

Geometry

0.42m

The XPC850 is assembled in a 256 leaded plastic ball grid array. The XPC860 is

assembled in a 357 lead plastic ball grid array (PBGA). Both packages have been shown

to meet level 3 moisture sensitivity as classified by JEDEC A113. Our volume

production is manufactured in MotorolaÕs Kuala Lumpur, Malaysia facility, however we

have also qualified Citizen Watch Co, in Japan as an alternate assembly site.

2

3.0 Family Qualification Strategy

Motorola uses a ÒfamilyÓ qualification strategy which allows sharing of certain

reliability data across a common design rule / fabrication geometries and packaging types.

Reliability data from other Motorola devices which are designed using the same design

rules and wafer fabrication processes are included with this report.

All of the devices in this report have been in production manufacturing for at least 3

years. The data presented in this report is both data from current production material

and historical data used to qualify devices, processes, and wafer fab and assembly sites.

This report will be updated periodically (typically twice/year) with new reliability data

from subsequent qualifications and reliability monitors.

3

4.0 Qualification Data

Motorola .42m Process Qualification Summary

The following data shows results of our .42m qualifications:

Life Test (+125°C, 4.5V)

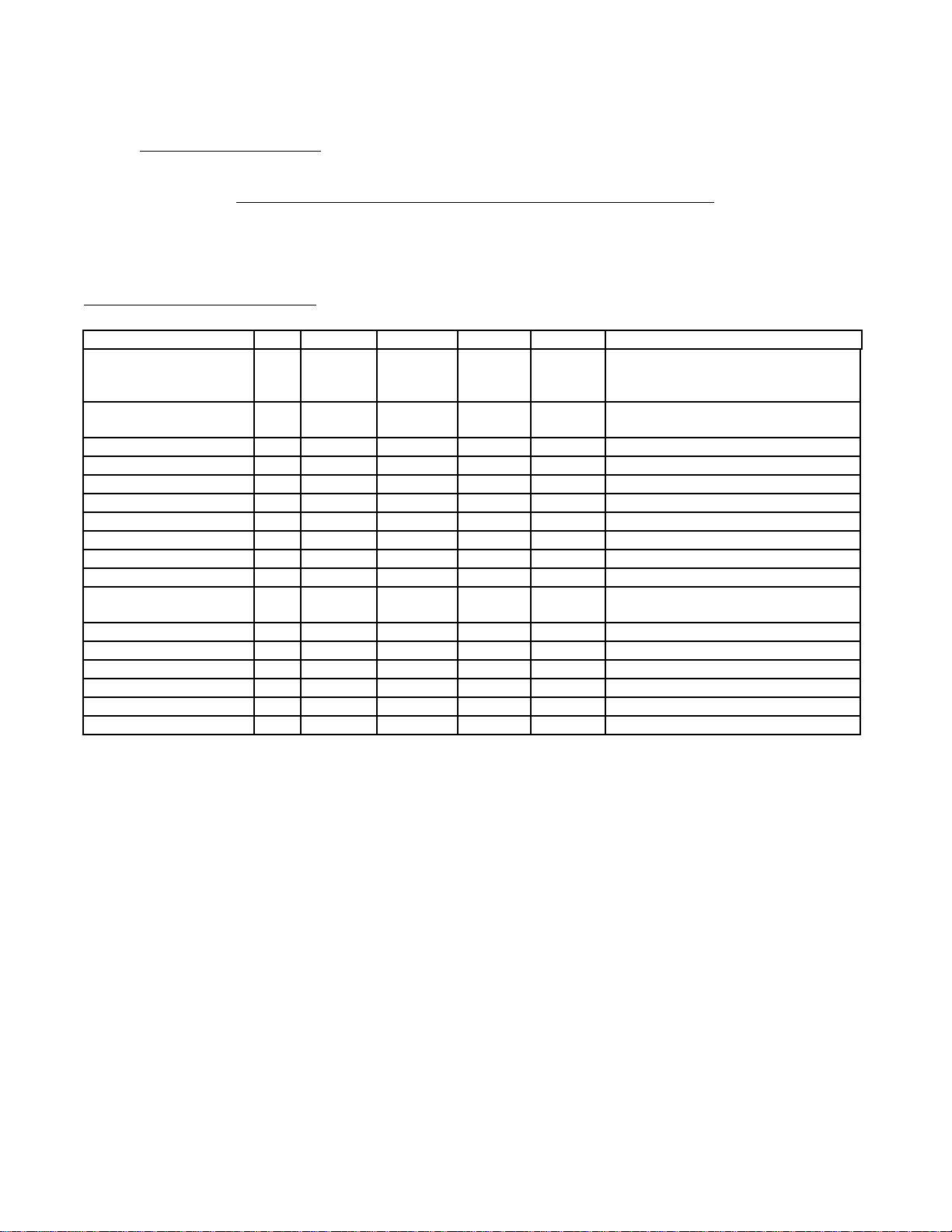

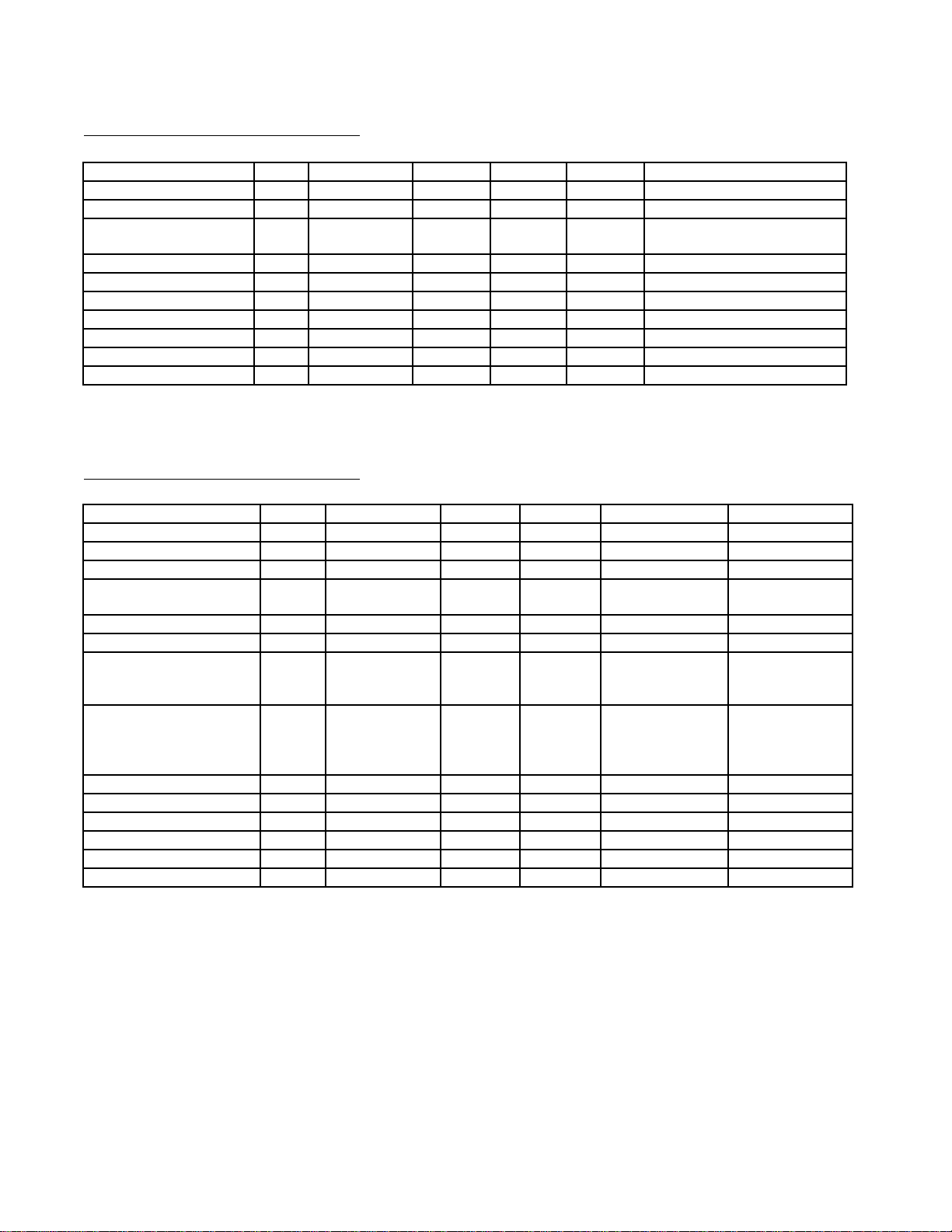

Device/Mask Set SS 168 Hrs. 504 Hrs. 1008 Hrs. 2016 Hrs. Failure Details

XPC850 (F98S) rev 0.3 77 1/77 0/76 0/71 --- 168 Hr : Speed degradation failure

1008 Hr: 4 parts missing balls, 1 part

damaged -discounted

XPC850 (F98S) rev 0.3 77 0/77 0/75 0/74 --- 504 /1008 Hr: Damaged part -

discounted

XPC850 (F98S) rev 0.3 77 0/77 0/77 0/72 --- 1008 Hr: Units discounted

XPC850 (F98S) rev 0.3 77 0/77 0/75 0/69 --- 168/504 Hr: Units discounted

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 ---

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (H96G) rev C.1 77 0/77 0/77 0/77 --XPC860 (H96G) rev C.1 77 0/77 1/77 0/77 --- Functional Failure Ð destroyed in FA

XPC860 (H96G) rev C.1 77 0/77 0/77 0/77 ---

XPC860T (J21M) 77 1/77 0/76 0/75 --- 168 hr: Funct fail, 1008 hr: 1 unit

damaged at test-discounted

68LC060 (G59Y) 77 0/76 0/76 0/63 --- 168/1008 Hr: Parts discounted

68LC060 (G59Y) 77 0/77 0/77 0/77 --- --68LC060 (G59Y) 77 0/77 0/77 0/77 --- --68LC060 (G59Y) 77 0/77 0/77 --- --- --68LC060 (G59Y) 77 1/77 0/76 --- --- 168 Hr: 1 functional fail

Total 1232 3/1231 1/1224 0/1040 0/231 ---

Table 1. Life Test Data.

4

MM

MM

1000.00

100.00

10.00

1.00

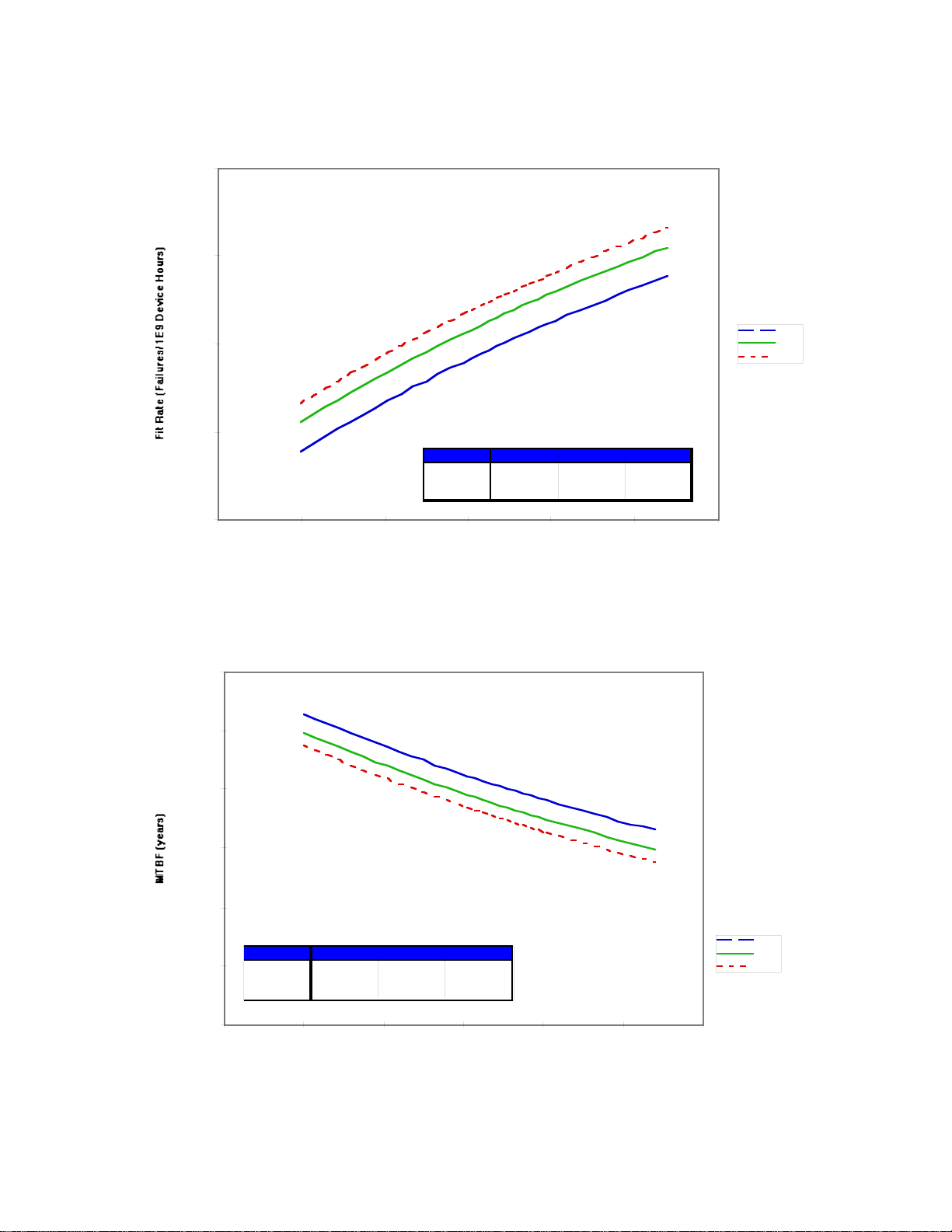

Fit Rate (Failures/1E9 Device Hours)

0.10

0 2 0 40 60 80 100 120

FITs vs Junction Temperature: .42u FIT/MTBF Data

Thermal and Voltage Acceleration

eA = 0.5 eV, Beta = 2.5, 90% Confidence

Tj 3 V 3.3 V 3.5 V

40 °C247

60 °C 6 13 22

80 °C 173659

Junction Temperature (°C)

3 V

3.3 V

3.5 V

1.00E+06

1.00E+05

1.00E+04

1.00E+03

MTBF (years)

1.00E+02

1.00E+01

1.00E+00

0 20 40 60 80 100 120

MTBF vs Junction Temperature: .42u FIT/MTBF Data

mm

mm

Tj 3 V 3.3 V 3.5 V

40 °C 5.4E+4 2.6E+4 1.6E+4

60 °C 1.8E+4 8.4E+3 5.1E+3

80 °C 6.6E+3 3.1E+3 1.9E+3

eA = 0.5 eV, Beta = 2.5, 90% Confidence

Junction Temperature (°C)

Thermal and Voltage Acceleration

3 V

3.3 V

3.5 V

5

Temp Cycle (-65°C / +150°C)

Die Rev/Mask Set SS PC-MSL3 100 Cyc 500 Cyc 1000 Cyc Failure Details

XPC860 77 0/77 0/77 0/77 1/77 1000 Cyc: 1 fail

XPC860 77 0/77 0/77 0/77 0/77 ---

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 *0/76 1000 Cyc: missing ball-

discounted

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 ---

Total 693 0/693 0/693 0/693 1/693 ---

Table 2. Temperature Cycle Data (MSL3).

Autoclave (+121°C / 15PSIG)

Die Rev/Mask Set S S PC-MSL3 48 Hrs 96 Hrs 144 Hrs Failure Details

XPC860 77 0/77 0/77 0/77 0/77 ---

XPC860 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 --- --- --- Terminated-die

attach problem

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77 --XPC860 (J23A) rev A.3 77 0/77 0/77 0/76 0/76 48 hr:

Mishandled-

discounted

XPC860 (J23A) rev A.3 77 0/77 2/77 8/75 1/67 48 Hr: 2 functional

96 Hr: 8 functional

144 Hr: 1

functional

XPC860 (J23A) rev A.3 60 0/60 0/60 0/60 0/60

XPC860 (J23A) rev A.3 36 0/36 0/36 0/36 0/36

XPC860 (J23A) rev A.3 76 0/76 0/76 0/76 0/76

XPC860 (J23A) rev A.3 77 0/77 0/77 0/77 0/77

XPC860 (J23A) rev A.3 77 1/77 0/76 0/76 0/76 MSL3: functional

Total 942 1/942 2/864 8/861 1/853 ---

Table 3. Autoclave Data (MSL3).

6

THB (+85°C / 85%RH)

Die Rev/Mask Set SS PC-MSL3 168 Hrs 504 Hrs 1008 Hrs Failure Details

XPC860 (J23A)

rev A.3

XPC860 (J23A)

rev A.3

XPC860 (J23A)

rev A.3

XPC860 (J23A)

rev A.3

Total 308 0/307 0/230 0/230 0/229 ---

77 0/77 0/77 0/77 0/76 1008 Hr: Unit discounted

77 0/77 --- --- --- Terminated - die attach problem

77 0/76 0/76 0/76 0/76 PC: Substrate damage-

discounted

77 0/77 0/77 0/77 0/77 ---

Table 4. THB Data (MSL3).

7

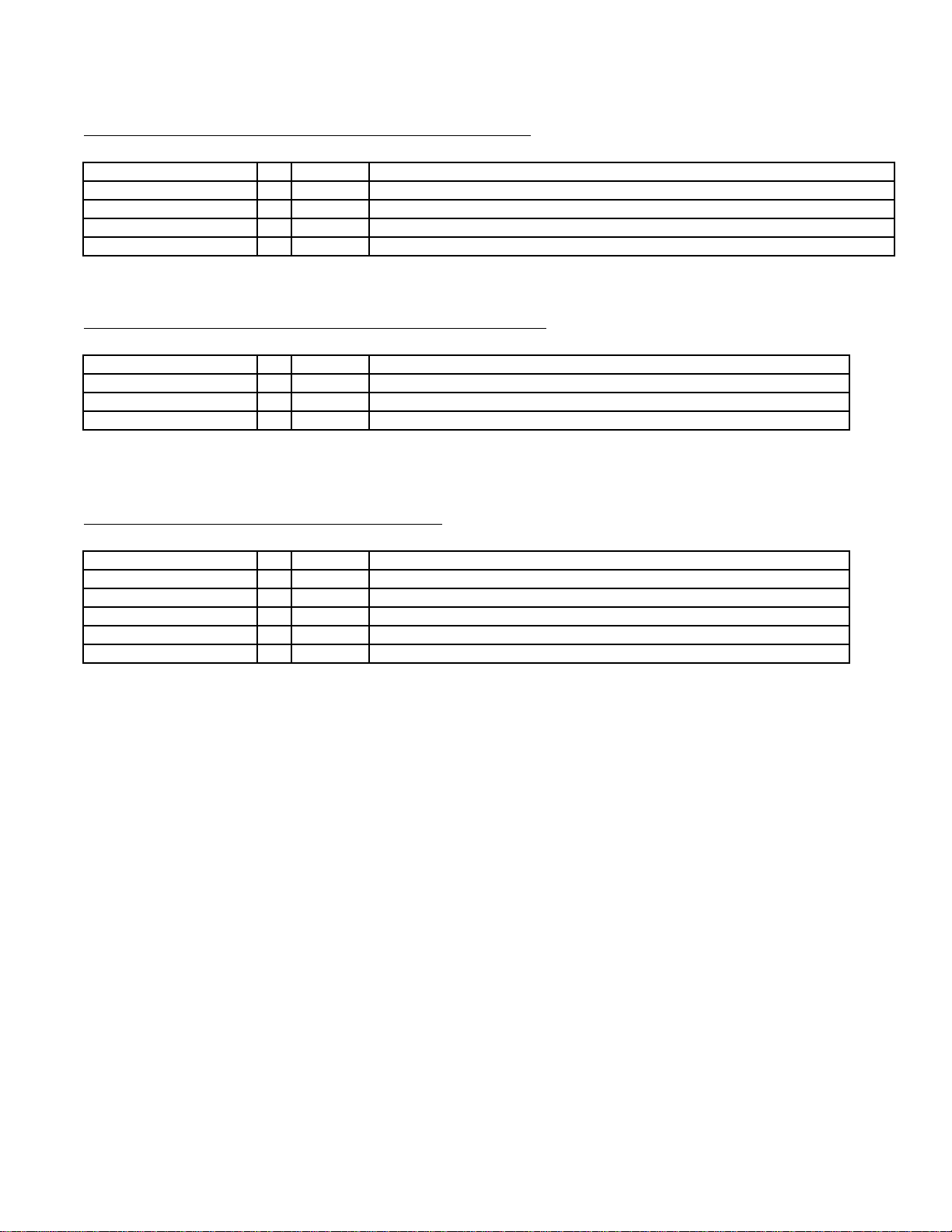

Electrostatic Discharge Data

The following ESD data is device specific:

860 ESD Human Body Model (I/O)

Mask Set SS 1 kV 1.5 kV 2.0 kV 2.5 kV Failure Details

J24A (860 rev B.1) 3 2/3 --- --- --- 2 functional, in analysis

H96G (860 rev C.1) 9 0/2 0/2 0/3 0/2 ---

J21M (860T) 3 0/3 --- --- --- ---

Total 15 2/8 0/2 0/3 0/2 ---

Table 5. Human Body Model (I/O) ESD data for the 860.

860 ESD Human Body Model (PWR)

Mask Set SS 1Kv 1.5Kv 2.0Kv 2.5Kv Failure Details

J24A (860 rev B.1) 3 0/3 --- -- --- 2 functional, in analysis

H96G (860 rev C.1) 2 --- --- --- 0/4 ---

Total 5 0/3 --- --- 0/4 ---

Table 6. Human Body Model (PWR) ESD data for the 860.

860 ESD Machine Model, Vmax=200 V

Mask Set SS 100v 200v Failure Details

J24A (860 rev B.1) 3 --- 0/3 --J24A (860 rev B.1) 3 --- 0/3 ---

J21M (860T) 3 0/3 --- ---

Total 9 0/3 0/6 ---

Table 7. Machine Model ESD data for the 860.

860 ESD CDM, Vmax=1000 V corner balls, 500V inner balls

Mask Set SS 500V/1000V Failure Details

H96G (860 Rev. C.1) 3 0/3 ---

Table 8. Charged device model ESD data for the 860.

8

850 ESD Human Body Model (I/O), Vmax=1kV

Mask Set SS #Fails Failure Details

(F98S) REV 0.3 6 3/6 Functional fails

(F98S) REV 0.3 3 0/3 --(F98S) REV 0.3 3 3/3 Functional fails

Total 12 6/12 ---

Table 9. Human Body Model (I/O) ESD data for the 850.

850 ESD Human Body Model (PWR)_Vmax=1kV

Mask Set SS #Fails Failure Details

(F98S) REV 0.3 3 0/3 --(F98S) REV 0.3 3 0/3 ---

Total 6 0/6 ---

Table 10. Human Body (PWR) ESD data for the 850.

850 ESD Machine Model, Vmax=200V

Mask Set SS #Fails Failure Details

(F98S) REV 0.3 3 0/3 --(F98S) REV 0.3 3 0/3 --(F98S) REV 0.3 3 0/3 --(F98S) REV 0.3 3 0/3 ---

Total 12 0/12 ---

Table 11. Machine Model ESD data for the 850.

9

Latchup Data For .42 m Devices

The following latchup data is specific for each device type:

Device - XPC860 S S 150mA 200mA Failure Details

XPC860 (J23A) rev A.3 3 0/3 --XPC860 (J23A) rev A.3 3 0/3 --XPC860 (J23A) rev A.3 3 0/3 ---

(J24A) rev B.1 3 0/3 --(H96G) rev C.1 3 0/3 ---

Total 15 0/15 ---

Device - XPC860T

(J21M) 3 0/3 ---

Total 3 0/3 ---

Device - 850

(F98S) rev 0.3 3 0/3 ---

(F98S) rev 0.3 3 0/3 ---

Total 6 0/6 ---

Table 12. Latchup Data for each device type.

10

AVERAGE OUTGOING QUALITY

In Parts per Million

4th Quarter 3 r d

Quarter

Device Type Category 1998 1998 1998 1998

XPC850 Electrical 872.3 0 106 0

Vis/Mech 0 0 509.6 0

XPC 860, XPC860T Electrical 96.7 69.3 68.4 189.1

Vis/Mech 0 180.6 185.1 0

2nd Quarter 1st Quarter

Networking Microprocessors

100

90

80

70

60

Electrical

Vis/Mech

AOQ

50

40

30

20

10

0

1Q98 2Q98 3Q98 4Q98 1Q99

Quarter

11

5.0 Qualification Stress Descriptions

The following summary briefly describes the various reliability tests included in the

Motorola reliability monitor program.

DYNAMIC EARLY FAIL STUDY (EFR)

This stress is performed to accelerate infant mortality failure mechanisms, which are

defects that occur within the first year of normal device operation. The typical stress

condition is a temperature of 125°C, a voltage of 6V for 5V products and 4.5V for 3.3V

products, and a duration of 168 hours. Devices used in this test are sampled directly after

the standard production final test flow with no prescreening, unless called out in the

normal production flow.

HIGH TEMPERATURE OPERATING LIFE (HTOL) TEST

High Temperature Operating Life (HTOL) test is performed to accelerate failure

mechanism which are thermally activated through the application of extreme temperatures

and the use of dynamic operating conditions. All devices performing the HTOL test are

sampled directly after final electrical test with no prior burn-in or other pre-screening.

Testing is performed per Mil Std 883, Method 1005, with dynamic signaling applied to

the devices for a minimum duration of 168 hours. Some sample groups are extended to

2016 hours.

A device will be considered to have failed the life test if parametric limits are exceeded or

if functionality cannot be demonstrated under nominal and worst case conditions

specified in the data sheet. Forms of mechanical damage, such as cracking of the package,

will be considered as a reject. Device which recovers after baking will also be considered

as a reject. Verified ESD and EOS failures shall not be considered legitimate nor will

failures caused by handling, such as bent leads or cosmetic package defects.

12

TEMPERATURE CYCLE (T/C)

Temperature Cycle accelerates the effects of thermal expansion mismatch between

different components of the packaging system, a condition which can cause wire bond

problems and seal leakage. Temperature Cycle is typically performed per Mil Std 750 or

Mil Std 883, Method 1010, Condition D.

Devices are inserted into cycling system and held at -65C for at least ten minutes, devices

are then transferred to a second chamber and held at +150C for at least 10 minutes. The

system employs a circulating air environment to assure rapid stabilization at the specified

temperature. The dwell at each extreme, plus two transition times of five minutes each,

constitute one cycle. The duration of this testing is typically 500 or 1000 cycles.

A device shall be considered as a reject, if hermeticity cannot be demonstrated, parametric

limits are exceeded, or if functionality cannot be demonstrated, as per the data sheet

limits. Mechanical damage, such as cracking, chipping, or breaking of package, will also be

considered as a reject provided such damage was not caused by fixturing or handling.

Verified EOS and ESD failures shall not be considered as legitimate rejects.

TEMPERATURE HUMIDITY BIAS (THB)

This is an environmental test performed at a temperature of 85°C and a relative humidity

of 85% (per JEDEC Standard 22 Method A101). The test is designed to measure the

moisture resistance of plastic encapsulated circuits. A nominal (5V) static bias is applied

to the device to create the electrolytic cells necessary to accelerate corrosion of the

metallization. Typical stress duration is 1008 hours.

A device will be considered to have failed the static temperature humidity bias test if

parametric limits are exceeded, or functionality cannot be demonstrated under normal and

worst case conditions as specified in the data sheet. Device which recovers after baking

shall be considered as a reject. Verified ESD or EOS failures shall not be considered

legitimate rejects.

13

AUTOCLAVE (AC)/PRESSURE TEMPERATURE HUMIDITY (PTH)

Autoclave is an environmental test that measures device resistance to moisture

penetration and the resultant effects of galvanic corrosion. It is a highly accelerated and

destructive test performed per JEDEC Standard 22B, Method A110 Code C). Conditions

employed during the test include 121°C, 100% relative humidity, and 15 psig. Corrosion

of the die is the expected failure mechanism. Typical test duration is 144 hours.

A device will be considered to have failed the autoclave test if parametric limits are

exceeded or if functionality cannot be demonstrated under normal and worst case

conditions specified in the data sheet. Verified EOS and ESD failures shall not be

considered as legitimate failures, nor will mechanical damage such as cracking of the

package. Cosmetic package defects and degradation of lead finish and solderability are not

considered as a reject criterion.

PRE-CONDITIONING - VAPOR PHASE (VPR) AND INFRARED REFLOW (IR)

Pre-conditioning is a process which simulates the manufacturing steps involved in

mounting and rework of a surface mount device on to the customer's application printed

circuit board. Different methodologies can be employed for this purpose. Infrared Reflow

uses heaters instead of hot fluorocarbon vapor for the reflow. Vapor Phase Reflow(VPR)

is known to be the most contingent stress to the surface mount devices (per JEDEC

Standard 22, Method A112/3). In vapor phase pre-conditioning, different presoak

conditions are defined such as 85C/85% Relative Humidity(RH)(Class I), 85C/60%RH

(Class II), 30C/60%RH (Class III, IV & V) to simulate different environmental

conditions. Devices are exposed to VPR within 4 hours after the completion of the presoaking process. Three cycles of VPR are performed to the parts, 8 to 10 minutes cool

down time is allowed between VPR immersions. Devices are visually inspected for

package cracks after the final immersion. The pre-conditioning test is conducted prior to

the normal reliability test.

SOLDERABILITY TEST

The purpose of this test is to determine the solderability of device package termination

that are intended to be joined to another surface using solder for the attachment. This test

provides optional conditions for aging and solder the purpose of allowing simulation of

the soldering process to use in the device application. It provides procedures for through

hole, axial and surface mount devices. Leads should be dipped at a solder temperature of

245±5C for a duration of 5-10 seconds (per JEDEC Standard 22, Method A102).

14

HIGH TEMPERATURE BAKE (HTB)

The purpose of High Temperature Bake (HTB) is to bake the device for a specified length

of time to determine the stability of the device transistors (per Mil Std 883, Method

1008).

ELECTROSTATIC DISCHARGE (ESD)

This series of stresses included Human Body Model (HBM), Machine Model (MM)

(per JEDEC Standard 22, Method 2007) to determine if the devices cab be handled in a

normal production environment without being damaged by the various sources of static

that are present.

15

Loading...

Loading...