Page 1

HT750 MTX850 MTX8250

HT1250 MTX850•LS MTX8250•LS

HT1250•LS HT1250•LS+ MTX950

HT1550•XLS MTX9250

Portable Radios

Professional Radio

Basic Service Manual

Motorola, Inc.

8000 West Sunrise Boulevard

Fort Lauderdale, Florida 33322

68P80906Z54-D

Page 2

ii

C

n

Foreword

This manual provides sufficient information to enable qualified service technicians to troubleshoot and repair

CDM Series mobile radios to the component level.

Product Safety and RF Exposure Compliance

Before using this product, read the operating instructions

!

a u t i o

This radio is restricted to occupational use only to satisfy FCC RF energy exposure requirements.

Before using this product, read the RF energy awareness information and operating instructions in

the Product Safety and RF Exposure booklet (Motorola Publication part number 68P81095C98) to

ensure compliance with RF energy exposure limits.

For a list of Motorola-approved antennas, batteries, and other accessories, visit the following web site

which lists approved accessories: http://www.motorola.com/cgiss/index.shtml.

for safe usage contained in the Product Safety and RF

Exposure booklet.

ATTENTION!

Computer Software Copyrights

The Motorola products described in this manual may include copyrighted Motorola computer pr ograms stored

in semiconductor memories or other media. Laws in the United States and other countries preserve for

Motorola certain exclusive rights for copyrighted computer programs, including, but not limited to, the

exclusive right to copy or reproduce in any form the copyrighted computer program. Accordingly, any

copyrighted Motorola computer programs contained in the Motorola products described in this manual may

not be copied, reproduced, modified, reverse- engineered, or distributed in any manner without the express

written permission of Motorola. Furthermore, the purchase of Motorola p roducts shall not be deemed to grant

either directly or by implication, estoppel, or otherwise, any license under the copyrights, patents or patent

applications of Motorola, except for the normal non-exclusive license to use that arises by operation of law in

the sale of a product.

Document Copyrights

No duplication or distribution of this document or any portion thereof shall take place without the express

written permission of Motorola. No part of this manual may be reproduced, distributed, or transmitted in any

form or by any means, electronic or mechanical, for any purpose without the express written permission of

Motorola.

Disclaimer

The information in this document is carefully examined, and is believed to be entirely reliable. However, no

responsibility is assumed for inaccuracies. Furthermore, Motorola reserves the right to make changes to any

products herein to improve readability, function, or design. Motorola does not assume any liability arising out

of the applications or use of any product or circuit described herein; nor does it cover any license under its

patent rights nor the rights of others.

Trademarks

MOTOROLA and the Stylized M logo are registered in the US Patent & Trademark Office. All other products

or service names are the property of their respective owners.

© Motorola, Inc. 2002.

Page 3

Table of Contents

Foreword.........................................................................................................ii

Product Safety and RF Exposure Compliance ............................................................... ii

Computer Software Copyrights....................................................................................... ii

Document Copyrights..................................................................................................... ii

Disclaimer....................................................................................................................... ii

Trademarks..................................................................................................................... ii

List of Figures ...............................................................................................ix

List of Tables.................................................................................................xi

Chapter 1

Introduction ................................................................................................ 1-1

1.1 Scope of Manual................................................................................................. 1-1

iii

1.2 Warranty and Service Support............................................................................ 1-1

1.2.1 Warranty Period and Return Instructions................................................. 1-1

1.2.2 After Warranty Period .............................................................................. 1-1

1.2.3 Piece Parts Availability............................................................................. 1-2

1.2.4 Technical Support.................................................................................... 1-3

1.3 Radio Model Information..................................................................................... 1-4

Chapter 2

Intrinsically Safe Radio Information......................................................... 2-1

2.1 FMRC Approved Equipment............................................................................... 2-1

2.2 Repair of FMRC Approved Products.................................................................. 2-2

2.2.1 Repair ...................................................................................................... 2-2

2.2.2 Relabeling................................................................................................ 2-2

2.2.3 Do Not Substitute Options or Accessories............................................... 2-3

Chapter 3

Maintenance ............................................................................................... 3-1

3.1 Introduction......................................................................................................... 3-1

3.2 Preventive Maintenance. .................................................................................... 3-1

3.2.1 Inspection................................................................................................. 3-1

Page 4

iv

3.2.2 Cleaning Procedures................................................................................ 3-1

3.3 Safe Handling of CMOS and LDMOS Devices ................................................... 3-2

3.4 Repair Procedures and Techniques — General ................................................. 3-2

3.5 Disassembling and Reassembling the Radio — General ................................... 3-3

3.6 Detailed Radio Disassembly ............................................................................... 3-4

3.6.1 Front Cover from Chassis Disassembly................................................... 3-4

3.6.2 Chassis Assembly/Disassembly............................................................... 3-6

3.6.3 Keypad, Display, and Keypad/PassPort/Option Board Disassembly....... 3-6

3.6.4 Speaker, Microphone, and Universal Connector Flex Disassembly ........ 3-8

3.6.5 PTT Disassembly..................................................................................... 3-9

3.6.6 Control Top Disassembly......................................................................... 3-9

3.7 Detailed Radio Reassembly.............................................................................. 3-10

3.7.1 Control Top Reassembly........................................................................ 3-10

3.7.2 PTT Reassembly.................................................................................... 3-10

3.7.3 Speaker, Microphone, and Universal Connector Flex Reassembly....... 3-10

3.7.4 Keypad, Display, and Keypad/PassPort/Option Board Reassembly...... 3-10

3.7.5 Chassis Assembly Reassembly............................................................. 3-11

3.7.6 Chassis and Front Cover Reassembly................................................... 3-11

3.7.7 DTMF Retrofit Kit Procedure (Optional Upgrade Procedure)................. 3-12

3.7.8 Option Board Installation........................................................................ 3-13

3.8 HT750 Radio Exploded Mechanical View and Parts List................................. 3-15

3.8.1 HT750 Exploded View........................................................................... 3-15

3.8.2 HT750 Exploded View Parts List............................................................ 3-16

3.8.3 HT1250 and HT1250•LS Exploded View ............................................... 3-17

3.8.4 HT1250 and HT1250•LS Parts List........................................................ 3-18

3.8.5 HT1250•LS+ Exploded View.................................................................. 3-19

3.8.6 HT1250•LS+ Exploded View Parts List.................................................. 3-20

3.8.7 MTX850 Exploded View......................................................................... 3-21

3.8.8 MTX850 Exploded View Parts List......................................................... 3-22

3.8.9 MTX850•LS Exploded View ................................................................... 3-23

3.8.10 MTX850•LS Exploded View Parts List ................................................... 3-24

3.8.11 MTX8250 Exploded View....................................................................... 3-25

3.8.12 MTX8250 Exploded View Parts List....................................................... 3-26

3.8.13 MTX8250•LS Exploded View ................................................................. 3-27

3.8.14 MTX8250•LS Exploded View Parts List ................................................. 3-28

3.8.15 HT1550•XLS Exploded View.................................................................. 3-29

Page 5

3.8.16 HT1550•XLS Exploded View Parts List ................................................. 3-30

3.8.17 MTX950 Exploded View......................................................................... 3-31

3.8.18 MTX950 Exploded View Parts List......................................................... 3-32

3.8.19 MTX9250 Exploded View....................................................................... 3-33

3.8.20 MTX9250 Exploded View Parts List....................................................... 3-34

3.9 Service Aids...................................................................................................... 3-35

3.10 Test Equipment................................................................................................. 3-36

3.11 Configuring and Wiring the Programming/Test Cable...................................... 3-37

Chapter 4

Transceiver Performance Testing ............................................................ 4-1

4.1 General............................................................................................................... 4-1

4.2 RF Test Mode..................................................................................................... 4-1

4.3 Test Frequencies for Display and Non-Display Radios...................................... 4-6

4.4 Receiver Performance Tests.............................................................................. 4-7

v

Chapter 5

Radio Tuning, Programming, Cloning, Lowband Antenna Cutting

Procedure, PassPort Tone Options, and Diagnostic Functions............ 5-1

5.1 Introduction......................................................................................................... 5-1

5.2 Global Radio Tuning Setup................................................................................. 5-2

5.2.1 Initial Test Equipment Setup.................................................................... 5-2

5.3 CPS Programming Setup ................................................................................... 5-3

5.4 Cloning (Conventional and LTR) ........................................................................ 5-3

5.4.1 Error Codes (Display Radios Only).......................................................... 5-4

5.5 Cloning (Privacy Plus) ........................................................................................ 5-4

5.6 Cloning (PassPort).............................................................................................. 5-5

5.7 Lowband Molded Antenna Cut Chart.................................................................. 5-6

5.8 HT1250•LS+ PassPort Tone Options................................................................. 5-7

5.9 HT1250•LS+ Special Diagnostic Functions........................................................ 5-7

Chapter 6

Power Up Self-Test..................................................................................... 6-1

6.1 Error Codes - Conventional and LTR Radios..................................................... 6-1

6.2 Error Codes - Privacy Plus ................................................................................. 6-2

Page 6

vi

6.3 Error Codes - PassPort....................................................................................... 6-3

6.4 Operation Display Codes .................................................................................... 6-3

Chapter 7

Accessories................................................................................................7-1

7.1 HT750/HT1250/HT1250•LS/HT1250•LS+/HT1550•XLS/MTX850/MTX950/

MTX850•LS/MTX8250/MTX9250/MTX8250•LS Accessories............................. 7-1

7.1.1 Antennas.................................................................................................. 7-1

7.1.2 Carrying Accessories ............................................................................... 7-2

7.1.3 Carry Cases ............................................................................................. 7-2

7.1.4 Chargers .................................................................................................. 7-3

7.1.5 Vehicular Accessories.............................................................................. 7-3

7.1.6 Batteries .................................................................................................. 7-3

7.1.7 Adapters................................................................................................... 7-3

7.1.8 Miscellaneous........................................................................................... 7-3

7.1.9 Service Aids ............................................................................................. 7-4

7.1.10 Audio Accessories ................................................................................... 7-4

7.1.11 Option Boards* (All option boards below are not compatible with

HT1550•XLS) ........................................................................................... 7-5

7.1.12 Remote Speaker Microphones................................................................. 7-5

7.1.13 Manuals ................................................................................................... 7-5

7.1.14 Retrofit Front Cover Kits .......................................................................... 7-5

Chapter 8

Model Chart and Test Specifications ....................................................... 8-1

8.1 UHF 403–470 MHz (Conventional)..................................................................... 8-1

8.2 UHF 450–512 MHz (Conventional)..................................................................... 8-2

8.3 UHF 403–470 MHz (LTR and PassPort)............................................................. 8-3

8.4 UHF 450–512 MHz (LTR and PassPort)............................................................. 8-4

8.5 UHF 403–470 MHz (Conventional/LTR) ............................................................. 8-5

8.6 UHF 450–512 MHz (Conventional/LTR) ............................................................. 8-6

8.7 VHF 136–174 MHz.............................................................................................. 8-7

8.8 VHF 136–174 MHz (Conventional/LTR) ............................................................. 8-8

8.9 VHF, 136–174 MHz (LTR & PassPort) ............................................................... 8-9

8.10 LowBand 29.7–42/35–50 MHz.......................................................................... 8-10

8.11 800 MHz (LTR).................................................................................................. 8-11

Page 7

vii

8.12 800 MHz (Privacy Plus).................................................................................... 8-11

8.13 900 MHz (Privacy Plus).................................................................................... 8-12

8.14 Specifications, HT750 Radio ............................................................................ 8-13

8.15 Specifications, HT1250 Radio .......................................................................... 8-15

8.16 Specifications, HT1250•LS+ Radio................................................................... 8-17

8.17 Specifications, HT1550•XLS Radio .................................................................. 8-19

8.18 Specifications, MTX850/MTX8250 (800 MHz),

MTX950/MTX9250 (900 MHz) Radios.............................................................. 8-21

8.19 Specifications, MTX850•LS and MTX8250•LS (800 MHz) Radios................... 8-23

Glossary.........................................................................................Glossary-1

Page 8

viii

Page 9

LIST OF FIGURES

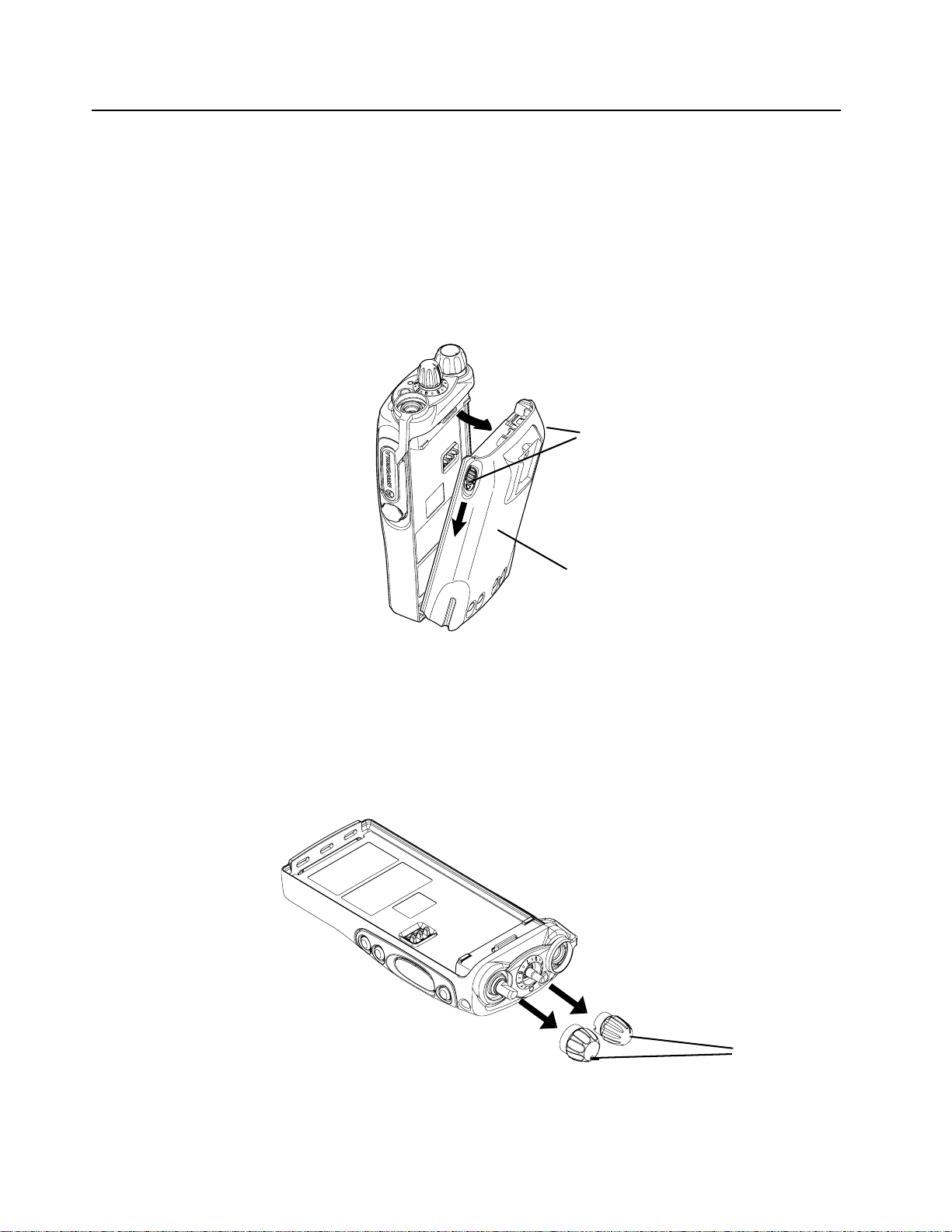

Figure 3-1: Battery Removal..................................................................................... 3-4

Figure 3-2: Knob Removal........................................................................................ 3-4

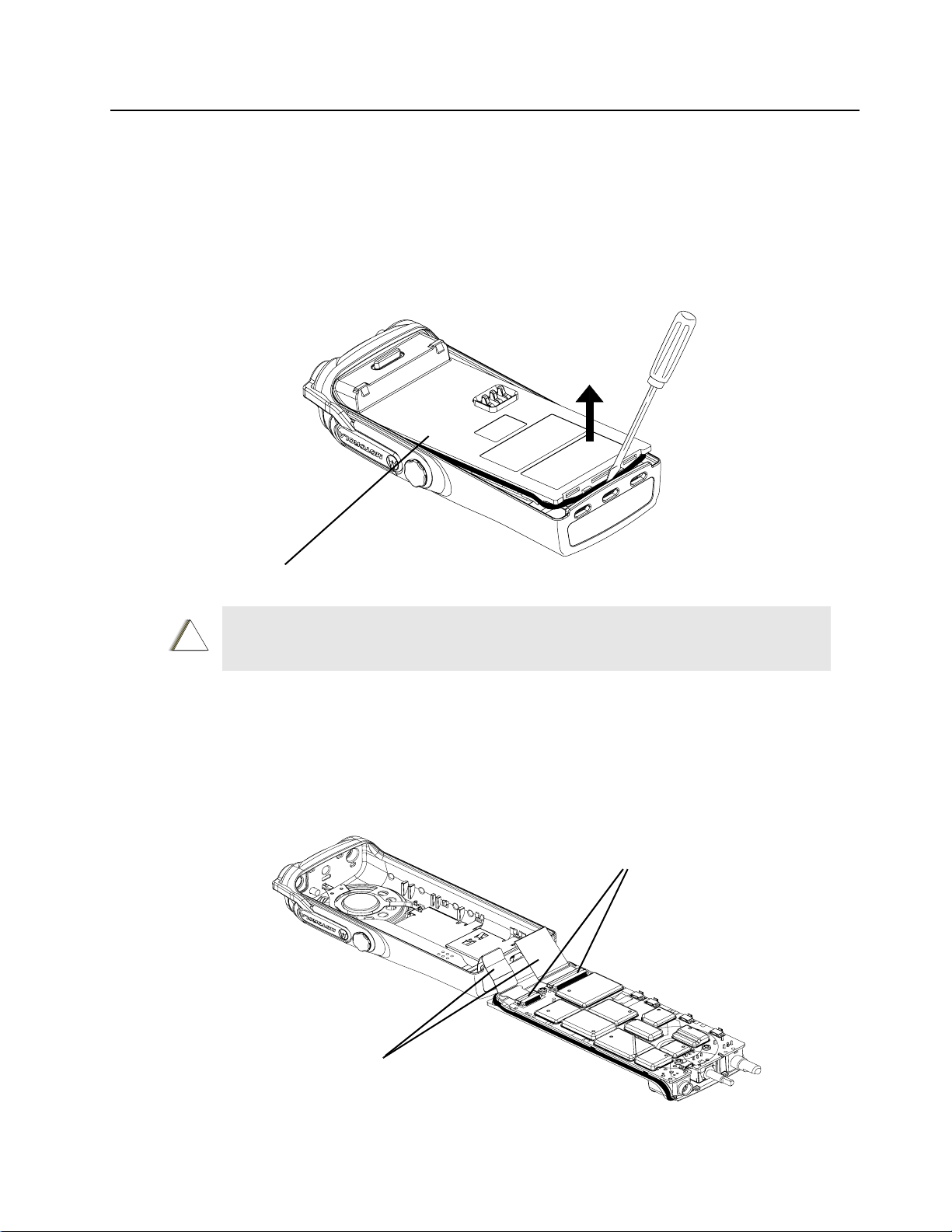

Figure 3-3: Chassis Removal ................................................................................... 3-5

Figure 3-4: Unlatch Flex Connectors ........................................................................ 3-5

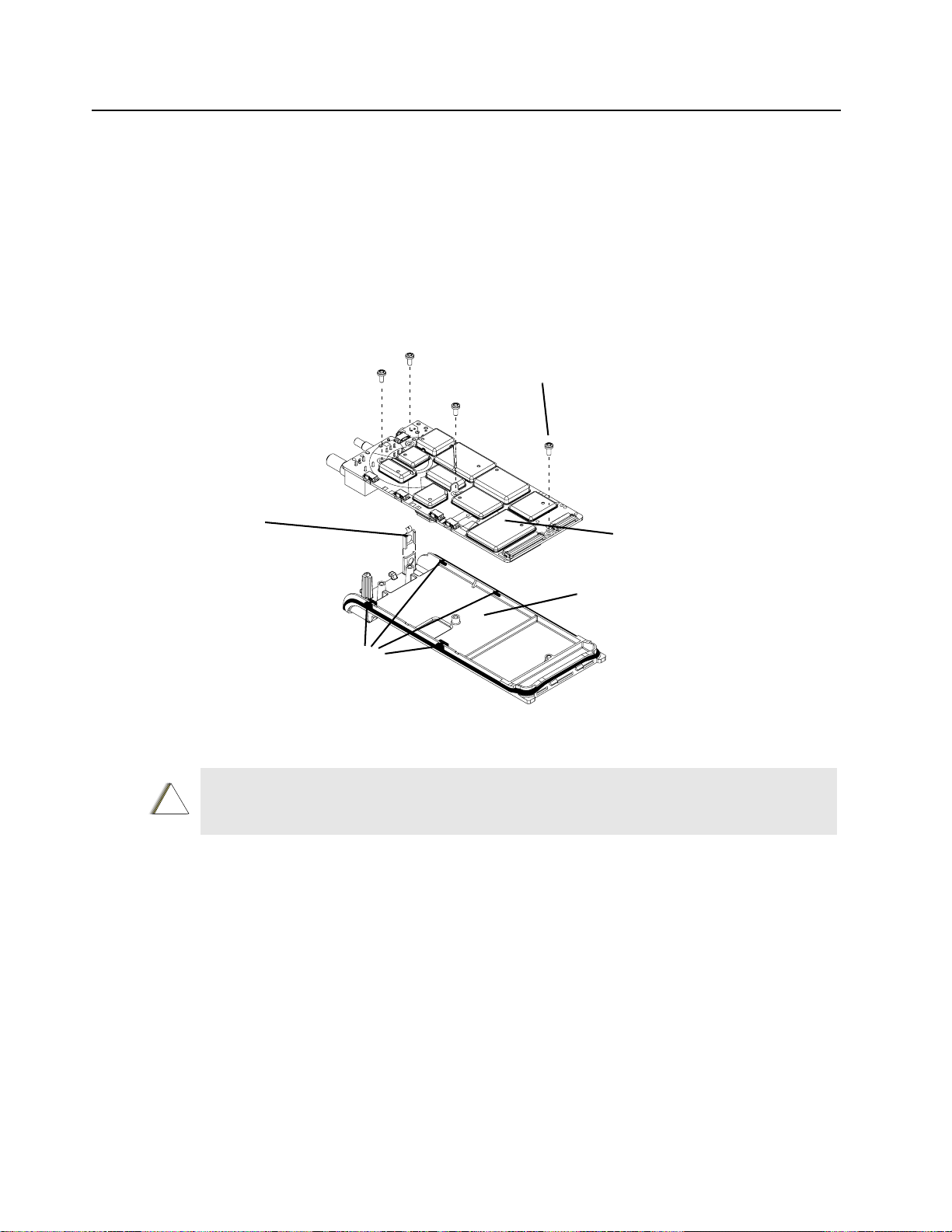

Figure 3-5: Remove Main Board from Chassis......................................................... 3-6

Figure 3-6: Remove Retainer.................................................................................... 3-7

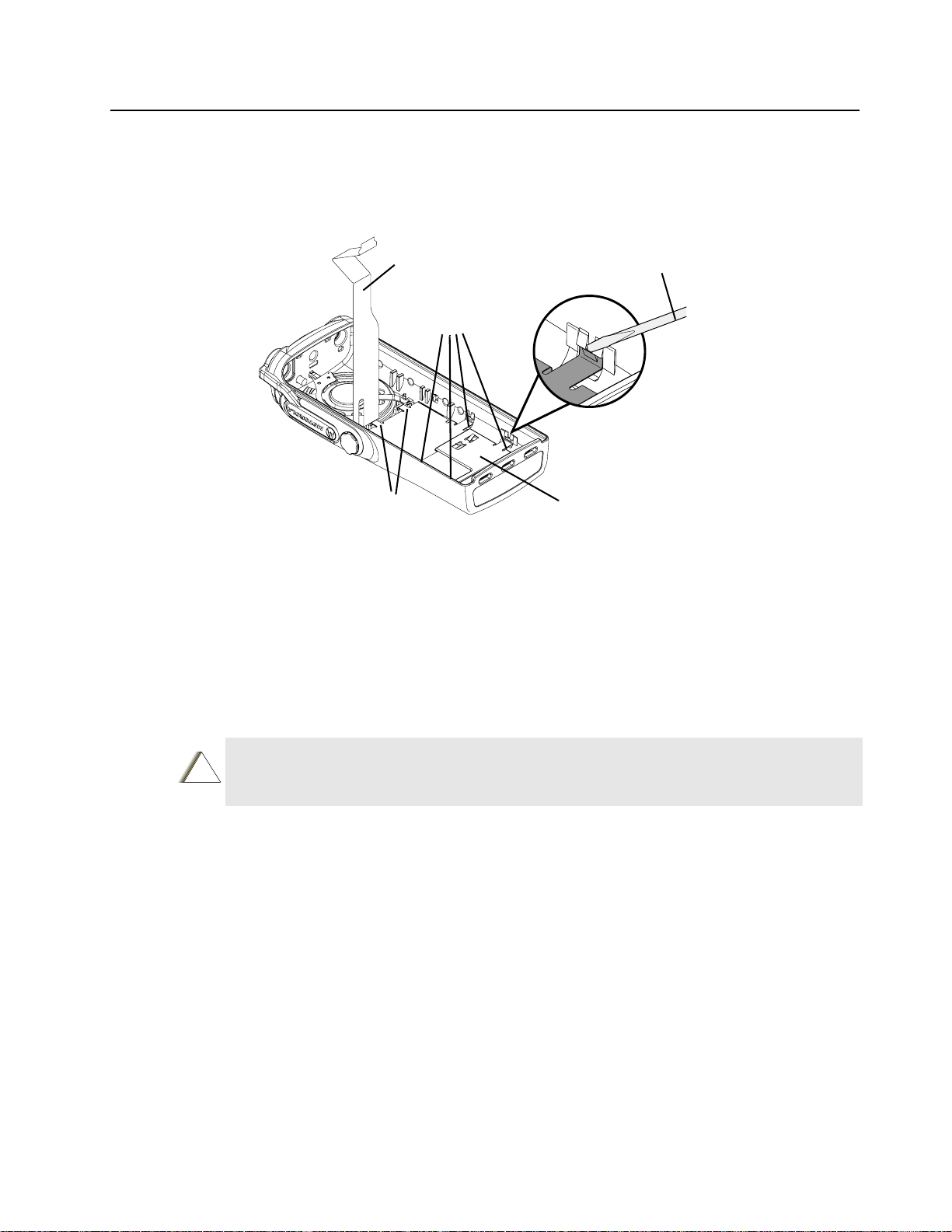

Figure 3-5: Removing the Keypad Retainer and Other Boards from the Radio........ 3-8

Figure 3-6: Removal Speaker-Microphone Assembly .............................................. 3-9

Figure 3-7: PTT Removal.......................................................................................... 3-9

Figure 3-8: Lock Retainer Catches to the Radio’s Body......................................... 3-11

Figure 3-9: Fastening the Chassis.......................................................................... 3-12

ix

Figure 3-10: Activating the Retrofit ........................................................................... 3-12

Figure 3-11: Changing Keypad/PassPort Board /Option Boards.............................. 3-13

Figure 3-12: HT750 Exploded View.......................................................................... 3-15

Figure 3-22: Programming/Test Cable AARKN4074 ................................................ 3-37

Figure 3-23: Pin Configuration of the Cable Side Connector.................................... 3-37

Figure 3-24: Programming/Test Cable Schematic.................................................... 3-38

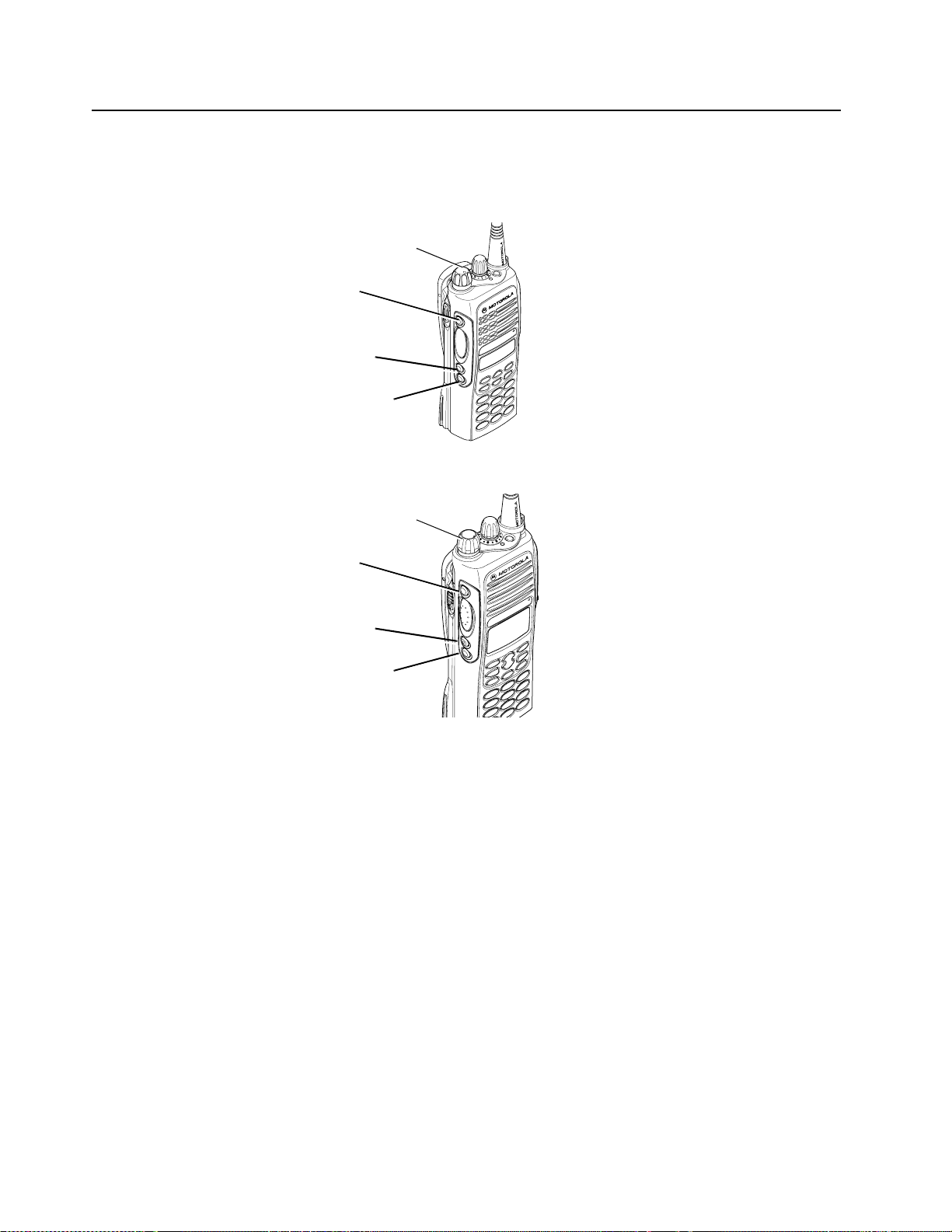

Figure 4-1: Radio Side Button Location.................................................................... 4-3

Figure 4-2: HT1550•XLS Radio Side Button Location.............................................. 4-3

Figure 4-3: Two-Line Display.................................................................................... 4-4

Figure 4-4: Four-Line Display (HT1550•XLS)........................................................... 4-4

Figure 5-1: Radio Tuning Test Equipment Setup...................................................... 5-2

Figure 5-2: CPS Programming Setup ....................................................................... 5-3

Figure 5-3: Radio Side Button Locations .................................................................. 5-4

Figure 5-4: HT1550•XLS Radio Side Button Locations ............................................ 5-4

Page 10

x

Notes

Page 11

LIST OF TABLES

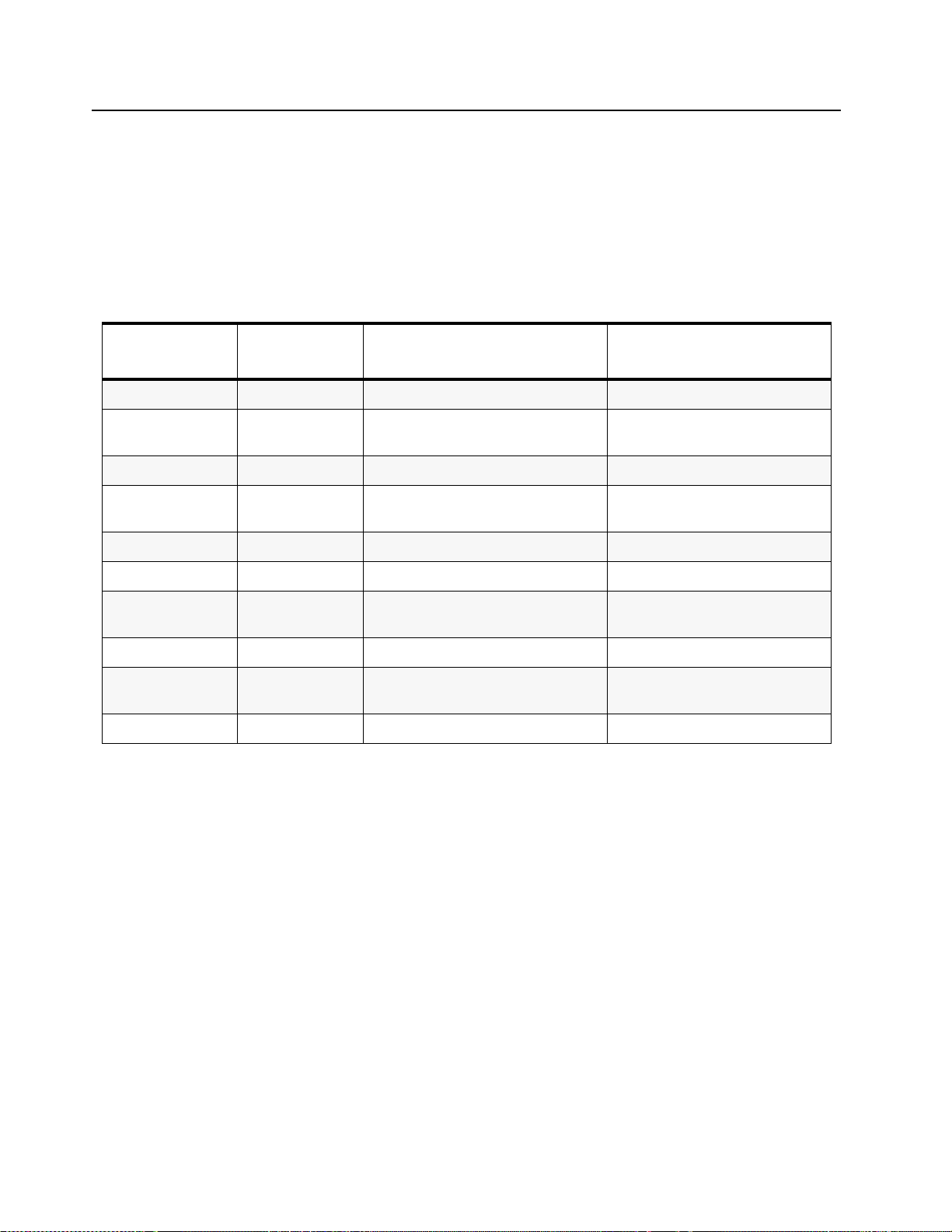

Table 1-1: Radio Model Number (Example: AAH25KDC9AA3AN)........................... 1-4

Table 3-11:Service Aids........................................................................................... 3-35

Table 3-12:Recommended Test Equipment ............................................................ 3-36

Table 4-1: Test Environments (Side Button 1).......................................................... 4-4

Table 4-2: Test Environments (Models with “G” in location 10 of model number EX:

AAH25RCH6GB6AN) .............................................................................. 4-5

Table 4-3: Test Channel Spacing (Side Button 2)..................................................... 4-5

Table 4-4: Test Frequencies (Using the Channel Selector Switch) .......................... 4-6

Table 4-5: Receiver Performance Checks................................................................ 4-7

Table 4-6: Transmitter Performance Checks............................................................ 4-8

Table 5-1: Software Installation Kits Radio Tuning Setup......................................... 5-1

xi

Table 5-2: Initial Equipment Control Settings............................................................ 5-2

Table 6-1: Power-up Display Codes - (Conventional Radios)................................... 6-1

Table 6-2: Power-up Display Codes ......................................................................... 6-2

Table 6-3: Power-up Display Codes (PassPort Trunking Controller Board)............. 6-3

Table 6-4: Operational Display Codes...................................................................... 6-3

Page 12

xii

Notes

Page 13

Chapter 1

Introduction

1.1 Scope of Manual

This manual is intended for use by service technicians familiar with similar types of equipment. It

contains service information required for the equipment described and is current as of the printing

date. Changes which occur after the printing date may be incorporated by a complete Manual revision

or alternatively as additions.

1.2 Warranty and Service Support

Motorola offers support which includes: full exchange and/or rep air of the product during the warranty

period; and service/repair or spare parts support out of warranty. Any “return for exchange” or “return

for repair” to an authorized Motorola Dealer must be accompanied by a Warranty Claim Form.

Warranty Claim Forms are obtained by contacting an Authorized Motorola Dealer. (See section 1.2.4

on page 1-3.)

1.2.1 Warranty Period and Return Instructions

1-1

The terms and conditions of warranty are defined fully in the Motorola Dealer or Distributor or Reseller

contract. These conditions may change from time to time, and the following subsections are for

guidance purposes only.

In instances where the product is covered under a “return for replacement” or “return for repair”

warranty , a chec k of the product should be performed prior to shipping the unit ba ck to Motorola. This

is to ensure that the product has been correctly programmed or has not been subjected to damage

outside the terms of the warranty.

Prior to shipping any radio back to the appropriate Motorola warranty depot, please co ntact Customer

Resources (Please see page 2 and page 3 in this chapter.). All returns must be accompanied by a

Warranty Claim Form, available from your Customer Resources representative. Products should be

shipped back in the

in transit.

original packaging, or correctly packag ed to ensure that no damage occurs

1.2.2 After Warranty Period

After the Warranty period, Motorola continues to support its products in two ways:

1. Motorola's Radio Parts and Service Group offers repair service to users and dealers at competitive prices.

2. The Motorola Customer Care and Services Division (CCSD) supplies individual parts and modules that can be purchased by dealers who are capable of performing fault analysis and repair.

Page 14

1-2 Introduction

1.2.3 Piece Parts Availability

Some replacement parts, spare parts, and/or product information can be ordered directly.

If... It Means That...

A complete Motorola part number is

assigned to the part, and it is not identified

as Depot ONLY

No part number is assigned The part is not normally available from

The part number is appended with an

asterisk

A parts list is not included Generally, no us er-serviceable parts are

The part is available from the Customer Care

and Services Division (CCSD).*

Motorola.

The part is serviceable by a Motorola Depot

only.

available for that kit or assembly.

*The Customer Care and Services Division

(CCSD) was formerly known as the Accessories and Aftermarket Division (AAD).

Motorola Online:

Motorola Online users can access our online catalog at

https://www.motorola.com/businessonline

To register for online access, please call 800-814-0601.

Mail Orders:

Send written orders to the following addresses:

Replacement Parts/

Test Equipment/Manuals/

Crystal Service Items:

Federal Government Orders:

International Orders:

Motorola Inc.

Customer Care and Services

Division*

(United States and Canada)

Attention: Order Processing

1307 E. Algonquin Road

Schaumburg, IL 60196

Motorola Inc.

U.S. Federal Government

Markets Division

Attention: Order Processing

7230 Parkway Drive

Landover, MD 21076

Telephone Orders

Customer Care and Services Division*

7:00 AM to 7:00 PM (Central Standard Time)

Monday through Friday (Chicago, U.S.A.)

1-800-422-4210

1-847-538-8023 (International Orders)

U.S. Federal Government Markets Division (USFGMD)

1-800-826-1913 Federal Government Parts - Credit Cards Only

8:30 AM to 5:00 PM (Eastern Standard Time)

Motorola Inc.

Customer Care and Services

Division*

(United States and Canada)

Attention: Order Processing

1307 E. Algonquin Road

Schaumburg, IL 60196

Page 15

Introduction 1-3

Fax Orders

Customer Care and Services Division*

1-800-622-6210

847-576-3023 (International)

USFGMD

(Federal Government Orders)

1-800-526-8641 (For Parts and Equipment Purchase Orders)

Parts Identification

Customer Care and Services Division*

(United States and Canada)

1-800-422-4210, menu 3

Product Customer Service

Customer Response Center

(Non-technical Issues)

1-800-247-2346

FAX:1-800-247-2347

*The Customer Care and Services Division (CCSD) was formerly known as the Accessories and

Aftermarket Division (AAD).

1.2.4 Technical Support

Technical support is available to ass ist th e de ale r/distributor in resolving any malfunction which may

be encountered. For service, contact the Service Depot in your area. If your area does not have a

depot, please contact your Business Development Manager, Distributor, or contact Motorola

Technical Support. When contacting Motorola Technical Support, keep the product model number

and the unit’s serial number handy.

For service, contact one of the following Depots. Pl ease call and confirm your return before sending

the unit to the depot for service.

Motorola Radio Support Center

2200 Galvin Dr.

Elgin, IL 60123

1-800-227-6772

Motorola Toronto Service Center

3900 Victoria Avenue

North York, Ontario, Canada M2H 3H7

1-800-543-3222

1-416-756-5841

1-888-331-9872 (Fax)

Motorola U.S. Federal Government Depot

4395 Nicole Drive

Lanham, MD 20706

1-800-969-6680

1-301-731-6676

Page 16

1-4 Introduction

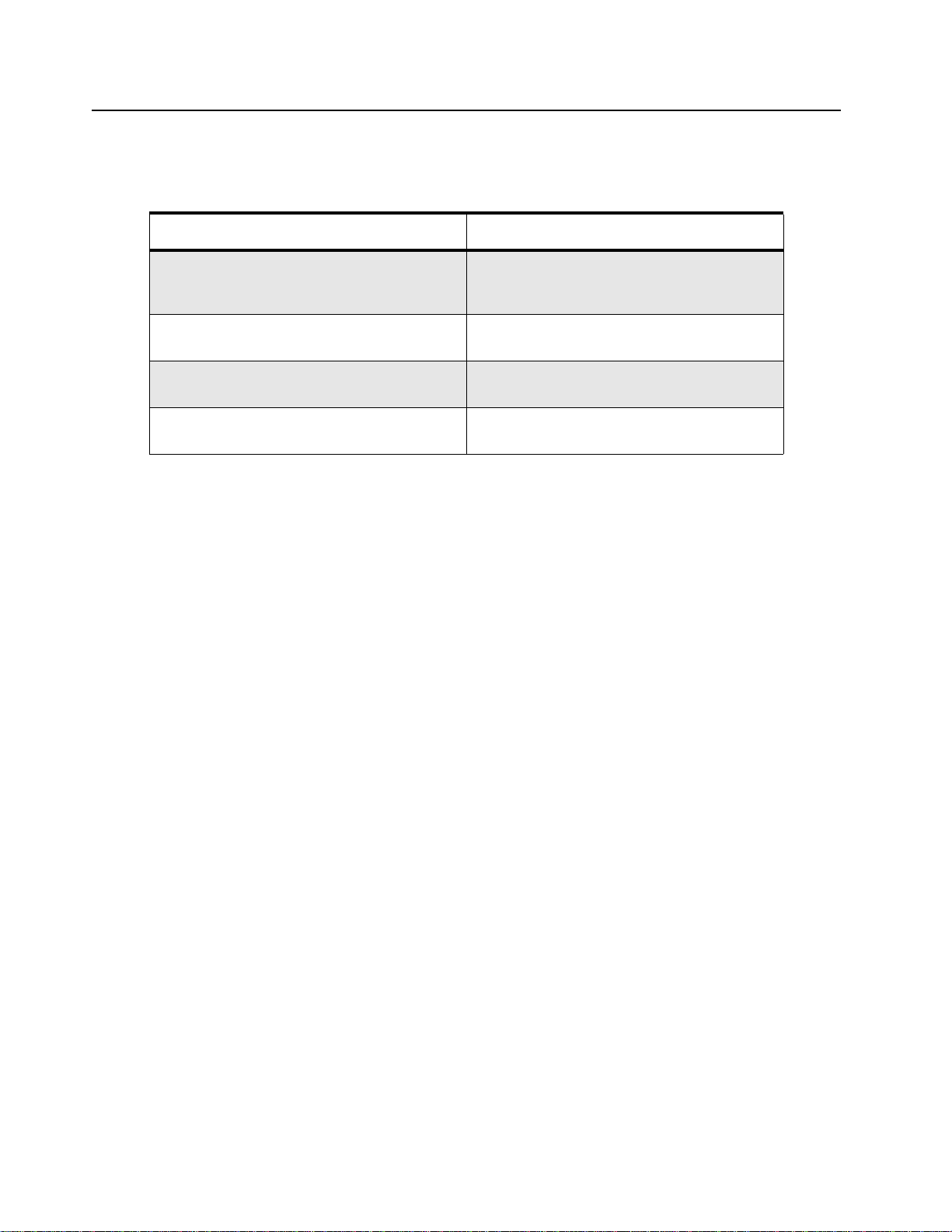

1.3 Radio Model Information

The model number and serial number are located on a label attached to the back of your radio. You

can determine the RF output power, frequency band, protocols, and physical packages. The example

below shows one portable radio model number and its specific characteristics.

Table 1-1:Radio Model Number (Example: AAH25KDC9AA3AN)

T ype of

Unit

AA orLAH25 K

Model

Series

Freq.

Band

VHF

(136-174

MHz)

H = Portable

A or LA = Motorola Internal Use

R

UHF1

(403-470

MHz)

S

UHF2

(450-512

MHz)

B

Low Band,

R1 (29.7-

42.0 MHz)

C

Low Band,

R2 (35.0-

50.0 MHz)

U

800 MHz

(806-821)

(851-866)

W

900 MHz

(896-902)

(935-941)

Power

Level

C

1-3.9W

D

4-5W

E

5.1-6WNHT1550•XLS

Physical

Packages

C

HT750

MTX850

MTX850•LS

MTX950

(no display)

H

HT1250

HT1250•LS

MTX8250

MTX8250•LS

MTX9250

(1-Line Display)

(4-Line Display)

Channel

Spacing

9

Programma-

ble

6

25 kHz

4

12.5 kHz

Protocol

AA

Conventional

DU

LTR

DP

PassPort

CK

MPT

GB

Privacy Plus8HT1550•XLS

Feature

Level

3

HT750

MTX850

MTX850•LS

MTX950

(non-keypad)

5

HT1250

HT1250•LS

Limited

Keypad

6

HT1250

HT1250•LS

MTX8250

MTX8250•LS

MTX9250

Full Keypad

7

HT1250•LS

Limited

Keypad

MDC on Conv.

9

HT1250•LS

Full Keypad

MDC on Conv.

Revision

+

+

+

+

Model

Model

Package

AN

Page 17

Chapter 2

W

G

Intrinsically Safe Radio Information

2.1 FMRC Approved Equipment

Anyone intending to use a radio in a location where hazardous concentrations of flammable

materials exist (hazardous atmosphere) is advised to become familiar with the subject of intrinsic

safety and with the National Electric Code NFP A 70 (National Fire Protection Association) Article 500

(hazardous [classified] locations).

An Approval Guide, issued by Factory Mutual Research Corporation (FMRC), lists manufacturers

and the products approved by FMRC for use in such locations. FMRC has also issued a voluntary

approval standard for repair service (“Class Number 3605”).

FMRC Approval labels are attached to the radio to identify the unit as being FM Approved for

specified hazardous atmospheres. This label specifies the hazardous Class/Division/Group along

with the part number of the battery that must be used. Depending on the design of the portable unit,

this FM label can be found on the back or the bottom of the radio housing. The FM Approval mark is

shown below.

2-1

FM

APPROVED

• Do not operate radio communications equipment in a hazardous

!

!

A R N I N

Radios must ship from the Motorola manufacturing facility with the Intrinsically Safe, hazardous

atmosphere capability and FM Approval labeling. Radios will not be “upgraded” or converted to

Intrinsically safe, and or labeled in the field, after it has been shipped from the manufactu ring

location.

atmosphere unless it is a type especially qualified (for example,

FMRC Approved) for such use. An explosion or fire may result.

• Do not operate an FMRC Approved Product in a hazardous

atmosphere if it has been physically damaged (for example,

cracked housing). An explosion or fire may result.

• Do not replace or charge batteries in a hazardous atmosphere.

Contact sparking may occur while installing or removing batteries

and cause an explosion or fire.

• Do not replace or change accessories in a hazardous atmosphere.

Contact sparking may occur while installing or removing

accessories and cause an explosion or fire.

• Turn a radio off before removing or installing a battery or

accessory.

• Do not disassemble an FMRC Approved Product unit in any way

that exposes the internal electrical circuits of the unit.

Page 18

2-2 Intrinsically Safe Radio Information

W

G

W

G

Modifications can only be made by the original product manufacturer (Motorola) at one of its FM

audited manufacturing facilities.

• Failure to use an FMRC Approved portable radio unit with an

!

!

A R N I N

FMRC Approved battery or FMRC Approved accessories

specifically Agency approved for that product may result in the

dangerously unsafe condition of an unapproved radio

combination being used in a hazardous location.

• Unauthorized or incorrect modification of an FMRC Approved

Product unit will negate the Approval rating of the product.

2.2 Repair of FMRC Approved Products

REPAIRS FOR MOTOROLA PRODUCTS WITH FMRC APPROVAL ARE THE RESPONSIBILITY

OF THE USER.

You should not repair or relabel any Motorola- manufactured communication equipment bearing the

FMRC Approval label (“FMRC Approved Product”) unless you are familiar with the current FMRC

Approval standard for repairs and service (“Class Number 3605”). Repairs and service to be done

FM audited locations.

!

!

A R N I N

The following are key definitions, from the FMRC’s Approval Standard Class Number 3605, 1994.

2.2.1 Repair

A repair constitutes something done internally to the unit that would bring it back to its original

condition-Approved by FMRC. A repair should be done in an FMRC audited facility. Items not

considered as repairs are those in which an a ction is perform ed on a unit which do es not require the

outer casing of the unit to be opened in a manner which exposes the internal electrical. You do not

have to be an FMRC audited Repair Facility to perform these actions.

2.2.2 Relabeling

The repair facility shall have a method by which the replacement of FMRC Approval labels are

controlled to ensure that any relabeling is limited to units that were originally shipped from the

Manufacturer with an FM Approval label in place. F MRC Ap pr oval labe ls sh all not be stocked by the

repair facility. An FMRC Approval label shall be ordered from the original manufacturer, as needed,

to repair a specific unit. Replacement labels may be obtained and applied by the repair facility,

provided there is satisfactory evidence that the unit being relabeled was originally an FMRC

Approved unit. Verification may include, but is not limited to: a unit with a damaged Approval label, a

unit with a defective housing displaying an Approval labe l, or a customer invoice indicating the serial

number of the unit and purchase of an FMRC Approved model.

• Incorrect repair or relabeling of any FMRC Approved Product unit

could adversely affect the Approval rating of the unit.

• Use of a radio that is not intrinsically safe in a hazardous

atmosphere could result in serious injury or death.

Page 19

Intrinsically Safe Radio Information 2-3

2.2.3 Do Not Substitute Options or Accessories

The Motorola communications equipment certified by Factory Mutual is tested as a system and

consists of the FM Approved portable, FM Approved battery, and FM Approved accessories or

options, or both. This FM Approved portable and battery combination must be strictly observed. The re

must be no substitution of items, even if the substitute has been previously Approved with a different

Motorola communications equipment unit. Approved configurations are listed in the FM Approval

Guide published by FMRC, or in the product FM product listing. This FM product listing is shipped

from the manufacturer with the FM Approved radio and battery combination.

Page 20

2-4 Intrinsically Safe Radio Information

Notes

Page 21

Chapter 3

C a u t i o n

Maintenance

3.1 Introduction

This chapter provides details about the following:

l Preventive maintenance (inspection and cleaning)

l Safe handling of CMOS and LDMOS devices

l Disassembly and reassembly of the radio

l Installation of Optional Retrofit Kit

l Installation of Option Boards

3.2 Preventive Maintenance

The radios do not require a scheduled preventive maintenance program; however, periodic visual

inspection and cleaning is recommended.

3-1

3.2.1 Inspection

Check that the external surfaces of the radio are clean, and that all external controls and switches are

functional. It is not recommended to inspect the interior electronic circuitry.

3.2.2 Cleaning Procedures

The following procedures describe the recommended cleaning agents and the methods to be used

when cleaning the external and internal surfaces of the radio. External surfaces include the front

cover, housing assembly, and battery case. These surfaces should be cleaned whenever a periodic

visual inspection reveals the presence of smudges, grease, and/or grime.

NOTE: Internal surfaces should be cleaned only when the radio is disassembled for service

or repair.

The only recommended agent for cleaning the external radio surfaces is a 0.5% solution of a mild

dishwashing detergent in water. The only factory recommended liquid for cleaning the printed circuit

boards and their components is isopropyl alcohol (70% by volume).

CAUTION: Certain chemicals and their vapors can have harmful effects on certain

!

plastics. Avoid using aerosol sprays, tuner cleaners, and other chemicals.

Cleaning External Plastic Surface

Apply the 0.5% detergent-water solution sparingly with a stiff, non-metallic, short-bristled brush to

work all loose dirt away from the radio. Use a soft, absorbent, lintless cloth or tissue to remove the

solution and dry the radio. Make sure that no water remains entrapped near the connectors, cracks,

or crevices

Cleaning Internal Circuit Boards and Components

Isopropyl alcohol (70%) may be applied with a stiff, non-metallic, short-bristled brush to dislodge

embedded or caked materials located in hard-to-reach areas. The brush stroke sh ould direct the

Page 22

3-2 Maintenance

C

n

dislodged material out and away from the inside of the radio. Make sure that controls or tunable

components are not soaked with alcohol. Do not use high-pressure air to hasten the drying process

since this could cause the liquid to collect in unwanted places. Afte r completing of the cleaning

process, use a soft, absorbent, lintless cloth to dry the area. Do not brush or apply any isopropyl

alcohol to the frame, front cover, or back cover.

NOTE: Always use a fresh supply of alcohol and a clean container to prevent contamination

by dissolved material (from previous usage).

3.3 Safe Handling of CMOS and LDMOS Devices

Complementary metal-oxide semico nductor (CMOS) devices are used in this family of radios, and are

susceptible to damage by electrostatic or high voltage charges. Damage can be latent, resulting in

failures occurring weeks or months later. Therefore, special precautions must be taken to prevent

device damage during disassembly , troubleshooting, and repair.

Handling precautions are mandatory for CMOS circuits and are especially important in low humidity

conditions. DO NOT attempt to disassemble the radio without fir st referring to th e following CAUTION

statement.

CAUTION: This radio contains static-sensitive devices. Do not open the radio unless

you are properly grounded. Take the following precautions when working on this

!

a u t i o

unit:

l Store and transport all CMOS devices in conductive material so that all exposed

leads are shorted together. Do not insert CMOS devices into conventional plastic

“snow” trays used for storage and transportation of other semiconductor devices.

l Ground the working surface of the service bench to protect the CMOS d evice. W e

recommend using the Motorola Static Protection Assembly (part number

0180386A82), which includes a wrist strap, two ground cords, a table mat, and a

floor mat.

l Wear a conductive wrist strap in series with a 100k resistor to ground.

(Replacement wrist straps that connect to the bench top covering are Motorola

part number RSX-4015.)

l Do not wear nylon clothing while handling CMOS devices.

l Do not insert or remove CMOS devices with power applied. Check all power

supplies used for testing CMOS devices to be certain that ther e ar e no voltage

transients present.

l When straightening CMOS pins, provide ground straps for the apparatus used.

l When soldering, use a grounded soldering iron.

l If at all possible, handle CMOS devices by the package and not by the leads. Prior

to touching the unit, touch an electrical ground to remove any static charge that

you may have accumulated. The package and substrate may be electrically

common. If so, the reaction of a discharge to the case would cause the same

damage as touching the leads.

3.4 Repair Procedures and Techniques — General

Parts Replacement and Substitution

When damaged parts are r eplaced, identica l p art s sh ould be used. If the ide ntical replacement p art is

not locally available, check the parts list for the proper Motorola part number and order the part from

the nearest Motorola Communications parts center listed in the “Piece Parts” section of this manual

(See page 1-2).

Page 23

Maintenance 3-3

Rigid Circuit Boards

This family of radios uses bonded, multi-layer, printed circuit boards. Since the inner layers are not

accessible, some special considerations are required when soldering and unsoldering components.

The printed-through holes may interconnect multiple layers of the printed circuit. Therefore, exercise

care to avoid pulling the plated circuit out of the hole.

When soldering near the 20-pin and 40-pin connectors:

l Avoid accidentally getting solder in the connector.

l Be careful not to form solder bridges between the connector pins.

l Examine your work closely for shorts due to solder bridges.

Flexible Circuits

The flexible circuits are made from a different material than the rigid boards, and require different

soldering techniques. Excessive prolonged heat on a flexible circuit can damage the mater ial.

Therefore, avoid excessive heat and excessive bending.

For parts replacement, use the ST-1087 Temperature-Controlled Solder Station with a 600-700

degree tip, and use small diameter solder such as ST-633. The smaller size solder will melt faster and

require less heat to be applied to the circuit.

To replace a component on a flexible circuit:

1. Grasp with seizers (hemostats) the edge of the flexible circuit near the part to be removed.

2. Pull gently.

3. Apply the tip of the soldering iron to the component connections while pulling with the seizers.

NOTE: Do not attempt to puddle-out components. Prolonged application of heat may

damage the flexible circuit.

3.5 Disassembling and Reassembling the Radio — General

Since these radios may be disassembled and reassembled with the use of only four (board to casting)

screws, it is important to pay particular attention to the snaps and tab s, and how parts align with each

other.

The following tools are required for disassemb ling the radi o :

l 3/16” flat blade screwdriver

l Penknife-size screwdriver

l TORX™ T6 screwdriver

If a unit requires more complete testing or serv ic e than is customarily performed at the basic level,

send this unit to a Motorola Authorized Service Center. (See Chapter, section 1.2.4 Technical Support

on page 1-3 for a list of authorized service centers.)

The following disassembly procedures should be performed only if necessary:

section 3.6.2 Chassis Assembly/Disassembly on page 3-6

section 3.6.3 Keypad, Display, and Keypad/PassPort/Option Board Disassembly on page 3-6

section 3.6.4 Speaker, Microphone, and Universal Connector Flex Disassembly on page 3-8

section 3.6.5 PTT Disassembly on page 3-9

section 3.6.6 Control Top Disassembly on page 3-9

section 3.7.7 DTMF Retrofit Kit Procedure (Optional Upgrade Procedure) on page 3-12

section 3.7.8 Option Board Installation on page 3-13

Page 24

3-4 Maintenance

3.6 Detailed Radio Disassembly

3.6.1 Front Cover from Chassis Disassembly

1. Turn off the radio.

2. Remove the battery:

a. Pull down on the two battery-release buttons.

b. With the buttons pulled down, the top of the battery will fall from the radio.

c. Remove the battery completely from the radio.

Battery

Release

Buttons

Battery

Figure 3-1: Battery Removal

3. Remove the ante nn a.

3. Pull the volume and channel selector knobs off their shafts .

NOTE: Both knobs slide on and off. However, they are supposed to fit very tightly on their

shafts.

Figure 3-2: Knob Removal

Knobs

Page 25

Maintenance 3-5

C

n

4. Separate the chassis from the internal electronics front cover assembly as follows:

a. Insert a small, 3/16” flat-blade screwdriver, or similar instrument, in between the thin

remaining wall and the chassis at the bottom of the radio. Do not mar the O-ring se aling area

on the housing.

b. Slowly pry the bottom of the chassis from the cover by pushing the 3/16” flat-blade

screwdriver down, and rotating the handle of the tool over and behind the base of the rad io.

This prying action forces the thin inner plastic wall toward the base of the radio, releasing the

two chassis base tabs.

Radio

Figure 3-3: Chassis Removal

CAUTION: Marring the front cover O-ring sealing area will preve nt the r adio f rom

!

a u t i o

sealing properly.

6. Lay the chassis down. Rotate the front cover backward and slightly away from the chassis.

NOTE: Flexible ribbon circuits (flexes) connecting the front cover assembly and the

chassis prevent you from completely sep arating t he two unit s. Display radios an d

radios with option boards have two flexes.

5. Lift the latches on the main circuit board to release the flexes from their connectors.

Latches

Flex Connector

Figure 3-4: Unlatch Flex Connectors

Page 26

3-6 Maintenance

C

n

NOTE: At this point, if necessary, the DTMF Retrofit Kit Procedure can be performed.

(See section 3.7.7 DTMF Retrofit Kit Procedure ( Optional Upgrade Procedure) on page

3-12).

3.6.2 Chassis Assembly/Disassembly

1. If disassembly of the chassis or the main board is required, then use a TORX™ screwdriver with

a T6 head to remove the four screws holding the main board to the chassis.

Screws (4)

Compliant

Ground

Contact

Main

Board

Radio

Chassis

O-Ring

Retaining

Features

Figure 3-5: Remove Main Board from Chassis

CAUTION: Refer to the CMOS CAUTION in paragraph on page 3-2 before removing

the main board. Be sure to use electrost atic discharge (ESD) protection when

!

a u t i o

handling circuit boards.

2. Lift the main board from the chassis (refer to Figure 3-5).

3. Remove the small O-ring retainers from their slots in the chassis. Note the alignment of the

retainers for reassembly.

4. Remove the O-ring.

5. If required in disassembly, slide off the ground contact from the top corner boss of the radio

chassis.

3.6.3 Keypad, Display, and Keypad/PassPort/Option Board Disassembly

1. If the disassembly of the keypad or the keypad printed circuit board, is required, lift the

microphone flex circuit up, and carefully remove the microphone and its boot from the front cover

pocket. (See Figure 3-6 on page 3-7).

2. Lay this flex circuit to one side.

Page 27

Maintenance 3-7

C

n

3. To remove the keypad retainer shield:

a. Insert the tip of a “penknife size,” flat blade screwdriver in the opening at the end of the

keypad retainer arm tab.

b. Pry the tab away from the side of the front cover until it moves past the ledges on the side

wall. Repeat this procedure for the four remaining retainer arm tabs.

Speaker-Microphone

Flex Circuit Tail

Keypad Retainer

Arm Tabs (4)

Flat Blade

Screwdriver

Retainer

Top Hooks

Retainer

Figure 3-6: Remove Retainer

4. Note that the two “top hooks” are still held underneath the front cover—right below the speaker.

Lift the keypad retainer out of the front cover, then lift and pivot the two hooks out of the front

cover.

5. If disassembly involves the removal of the display module, disconnect the display flex from the

keypad option board connector by lif ting the latch on the con nector. (This is similar to the process

for releasing the flexes.) (see page 3-5.)

6. The display module is attached to the front cover with a doub le-sided adhesive p ad. Carefully pull

up on the display module, using a small screwdriver, if necessary, and remove it from the front

cover. Use a new piece of double-sided adhesive to re-mount the display to the cover.

CAUTION Take care not to damage the display. Do not cut, bend, or pinch the heat

!

seal. Display modules contain CMOS devices. Be sure to use ESD protection.

a u t i o

7. The keypad/PassPort/option board can be removed without the use of tools.

Page 28

3-8 Maintenance

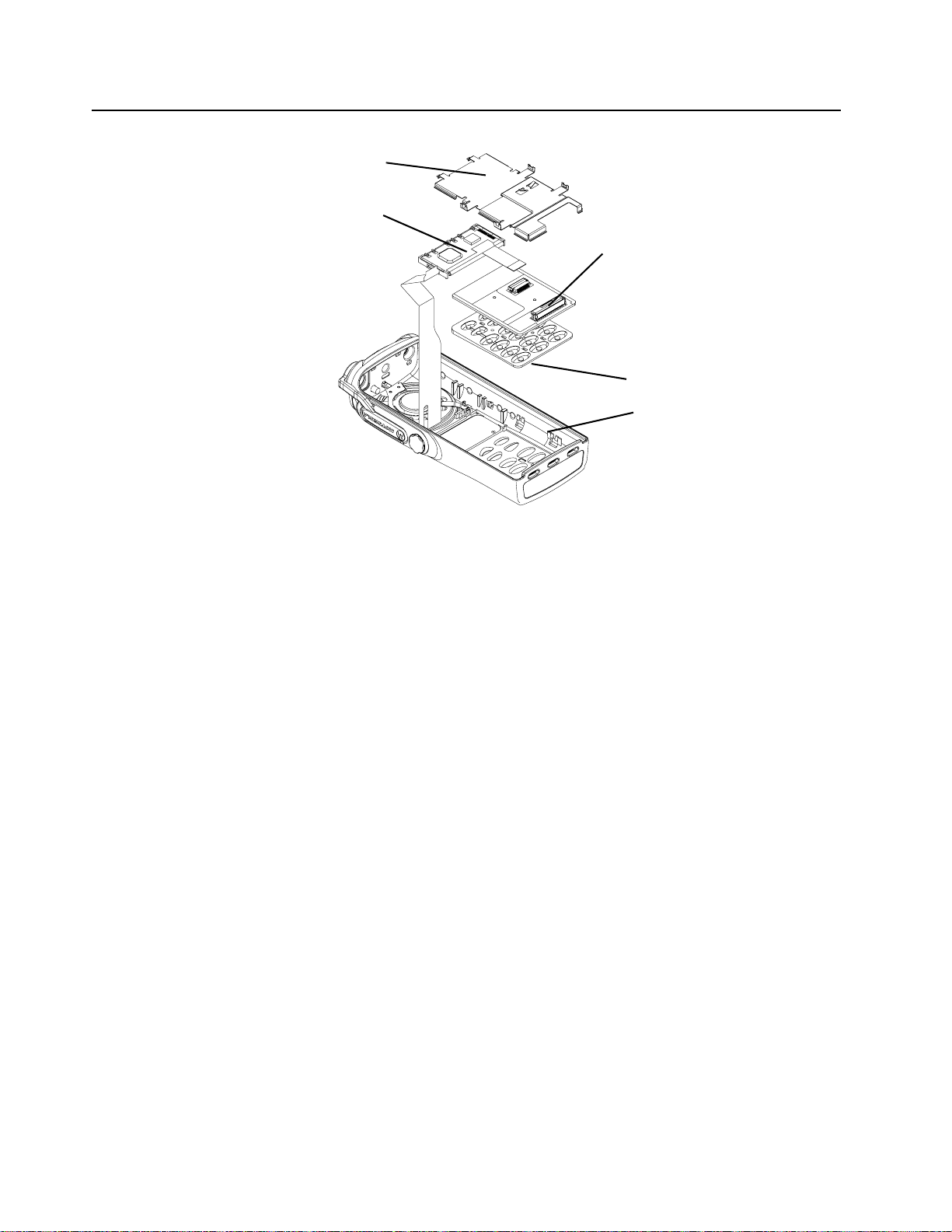

Retainer

Display

Module

Keypad

Option

Board

Keypad

Radio

Body

Figure 3-5: Removing the Keypad Retainer and Other Boards from the Radio

NOTE: At this point, the Option Board Installation Procedure should be performed, if

necessary. (See page 3-13)

3.6.4 Speaker, Microphone, and Universal Connector Flex Disassembly

1. If disassembly of the speaker-microphone assembly is necessary, remove the dustcover by

turning the screw at the bottom of the dustcov e r counterclockwise with your fingers. Lift the

dustcover out of its pocket.

NOTE: The dustcover must be removed to remove the speaker-microphone assembly flex

circuit. The speaker is held in place with a two-legged retainer bracket. The bracket

legs are secured by the front cover slots. Be careful not to damage the speaker when

removing the retainer bracket.

2. Using a screwdriver, push down on the portion of the speaker retainer bracket pointing toward the

bottom of the radio. Then, remove the retainer by slightly pushing it toward the top of the radio

until you slide it past the front cover slot.

3. Pull the rubber microphone boot from its seated position. Unless you are replacing the

microphone, leave it in the boot.

NOTE: The speaker-microphone assembly flex circuit goes through the front cover wall to

the outside wall. To replace this assembly, you must peel-off the universal connector

escutcheon label. The existing escutcheon cannot be reassembled; a new part must

be used. (See item number 10 on the exploded view drawing on page 3-15).

4. Peel-off the universal connector flex circuit escutcheon (label).

5. Pry the flex circuit (adhesive held) backer board away from the front cover, and remove the

universal connector tail of the speaker-microphone assembly through its opening in the front

cover.

Page 29

Maintenance 3-9

6. After the universal connector tail of the speaker-microphone assembly is removed, the assembly

can be completely removed. If it is necessary to replace the speaker or micr ophone, or bo th, do it

while the flex circuit is removed from the front cover. When reassembling the microphone in its

boot, make sure the microphone port faces the round hole in the bottom of the boot.

Speaker

Universal

Connector

Tail

Microphone

Boot

Microphone

Speaker Microphone

Flex Circuit Assembly

Speaker Orientation

Tab (12:00 Position)

Figure 3-6: Removal Speaker-Microphone Assembly

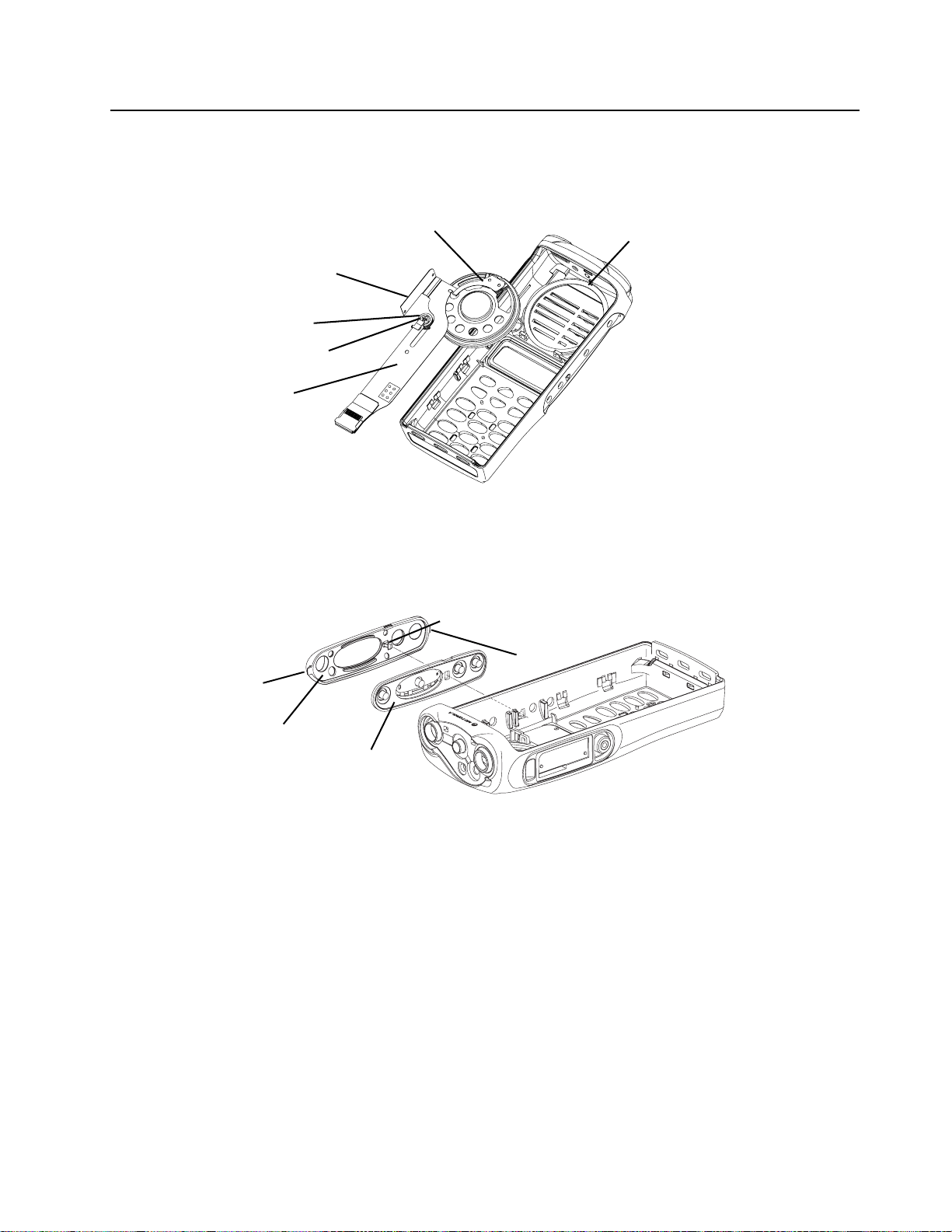

3.6.5 PTT Disassembly

If required, the PTT bezel and the PTT seal assembly can be d isassembled using a small screwdriver

as follows:

Tab

PTT

Bezel

PTT

Seal

1. Pry back the T-tab found inside the front cover (in between the four buttons on the PTT

assembly).

2. Remove the PTT bezel by slightly bowing it until the top and bottom tabs are released from the

slots in the front cover.

3. The PTT seal can be easily lifted from the bezel without the use of tools.

3.6.6 Control Top Disassembly

1. To remove the control top assembly, place a screwdriver next to the antenna boss, then pry it

against the control top escutcheon. This lifts the control top escutcheon away from its

double-sided adhesive. Grab the double-sided a dhesive near the volu me potentiometer , then lift it

away.

2. Remove the integrated control top seal, emergency button, and transmit light pipe.

T-Shaped

Retainer Tab

Tab

Figure 3-7: PTT Removal

Page 30

3-10 Maintenance

3.7 Detailed Radio Reassembly

3.7.1 Control Top Reassembly

1. Replace transmit light pipe and control top seal.

2. Peel off the liners from a new control top escutcheon and place it in the recess in the front cover.

Press the control top escutcheon firmly against the adhesive.

3.7.2 PTT Reassembly

1. Put the PTT seal in the PTT bezel.

2. Place the bezel top tab in the top slot inside the front cover PTT opening. Slightly bow the bezel

so that the bottom tab can fall inside the bottom slot.

3. Press the PTT assembly against the front cover opening.

NOTE: Look inside the front cover to make sure the T-tab is fully engaged with the front

cover. If necessary, press the T-tab toward the top of the radio until it becomes fully

engaged.

3.7.3 Speaker, Microphone, and Universal Connector Flex Reassembly

1. Feed the universal connector tail of the speaker-microphone flex assembly th rough the opening in

the side wall of the front cover.

2. Peel-off the adhesive liner on the back of the universal connector t ail of the flex circuit. Att ach the

flex tail to the front cover using the guide pins for correct alignment.

3. Replace the universal connector escutcheon. Make sure that all the connector openings align

with the gold pads on the flex circuit.

4. Align the notch in the speaker at the twelve o’clock position with the tab on the front cover as

shown in Figure 3-8.

5. Place the speaker retainer bracket into the hole on the top of the front cover, and bend the

retainer down to fit underneath the boss below the speaker.

6. If display, keyp ad, o r keyp ad option boar d are not in volved, reinser t the mi crophone a nd boot into

the pocket in the front cover

3.7.4 Keypad, Display, and Keypad/PassPort/Option Board Reassembly

1. If you are replacing the display, use a new double-sided adhesive displa y pad (item nu mber 17 on

the exploded view diagram in paragraph 3-8).

2. Replace the keypad, and the keypad/option board. Make sure the display module flex tail is

connected to the connector on the keypad/option board.

3. Insert the “top hooks” of the keypad retainer into the slots below the speaker (above the display)

in the front cover. Snap all four of the retainer arm tabs in place in the front cover.

NOTE: Pull the speaker-microphone flex circuit out of the way during reassembly.

4. Reinsert the microphone and boot into the pocket in the front cover.

5. Lay the speaker-microphone flex on top of keypad/PassPort/option board retainer.

Page 31

Maintenance 3-11

Catches

Retainer

Figure 3-8: Lock Retainer Catches to the Radio’s Body

3.7.5 Chassis Assembly Reassembly

1. Slide on the ground contact (if it was removed) on the top corner boss of the chassis.

2. Replace the O-ring. The tabs on the O-ring should reach into the chassis and point down.

3. Stretch the O-ring to place it into the retaining pocket at the bottom end of the chassis.

NOTE: When properly assembled, the retainers on the O-ring should align with the slots on

the chassis. If this is not the case, remove and replace the O-ring until it is aligned

with the chassis and completely seated in place around the perimete r.

4. Ensure that the antenna nut insulator is correctly replaced by pushing it all the way to the top of

the antenna nut.

5. Replace the battery contact seal (if necessary) surrounding the battery contact.

6. Place the main circuit board straight down on top of the chassis.

NOTE: Be sure the battery contact seal protrudes through the chassis and is not pinched

under the chassis.

7. Use the T6 TORX screwdriver to fasten the screws holding the main board to the chassis.

3.7.6 Chassis and Front Cover Reassembly

1. Align the chassis assembly end-to-end with the front cover assembly.

2. Insert the tails of the flex circuits into their respective connectors at the bottom of the front cover.

3. Push down the latches on the connectors to hold the flex circuits to the main board.

4. Slide the volume potentiometer and frequency switch shafts into their respe ctive holes in the front

cover.

5. Push the chassis assembly completely into the top of the front cover until it settles in place.

6. Be sure the O-ring is properly seated.

7. Snap the bottom of the chassis into the front cover.

Page 32

3-12 Maintenance

8. Reassemble the knobs, dust cover, antenna, and battery.

Radio

Chassis

Figure 3-9: Fastening the Chassis

3.7.7 DTMF Retrofit Kit Procedure (Optional Upgrade Procedure)

If you are performing an upgrade from a basic model to a DTMF model, replace the existing front

cover kit with kit number HLN9984 and follow the reassembly steps to reassemble the upgraded

radio. (See paragraph 3.7 for details about reassembly.)

To activate the retrofit using the radio software, follow these steps:

1. Start the Customer Programming Software (CPS).

2. Read the codeplug data by clicking on the READ icon in the menu bar, or by selecting READ

DEVICE in the pulldown menu.

3. Open the Radio Configuration dialog box. (See Figure 3-10.)

Figure 3-10: Activating the Retrofit

4. Change the Keypad Configuration from “No Keypad” to “Programmable/Numeric”.

(See Figure 3-10.)

5. Write the codeplug back to the radio by clicking on the WRITE icon in the menu bar, or by

selecting WRITE DEVICE in the pulldown menu.

Page 33

Maintenance 3-13

NOTE: The CPS may display a warning dialog box when you attempt to write the codeplug

back to the radio. It is safe to ignore this warning. Press the OK button.

3.7.8 Option Board Installation

1. With the keypad retainer removed the keypad backer board can be removed without the use of

tools.

2. Remove the jumper flex from the connector on the keypad board. Notice the orient ation of the flex

to the connector. Arrows on the jumper flex point to the correct way of inserting the flex into the

connector.

3. Discard the keypad backer board.

4. The “breakaway” tab at the top of all option boards contains an extra row of keys and is used to

accommodate other radio models.

5. Break-off and discard the option board tab, taking care not to damage the option board. Trim any

tab fragments that may remain on the option board.

Retainer

Keypad/

Option

Board

Jumper

Flex

TO KP

Display

Flex

Figure 3-11: Changing Keypad/PassPort Board /Option Boards

6. Reassemble the option board to the front cover assembly.

7. Insert the display flex circuit into the connector on the option board.

8. Insert the jumper flex circuit into the connector on the option board. Notice the orientation of the

flex circuit. Arrows on the jumper flex point to the correct way of inserting the flex into the

connector.

9. Replace the retainer by placing the two top hooks into the slots below the speaker in the front

cover; then, pivot the retainer into the front cover. Ensure that all four tab arms snap correctly into

the front cover.

10. With the keypad option board, display, and retainer correctly in place, the front cover assembly

can now be reassembled per paragraph 3.7.6.

Page 34

3-14 Maintenance

Notes

.

Page 35

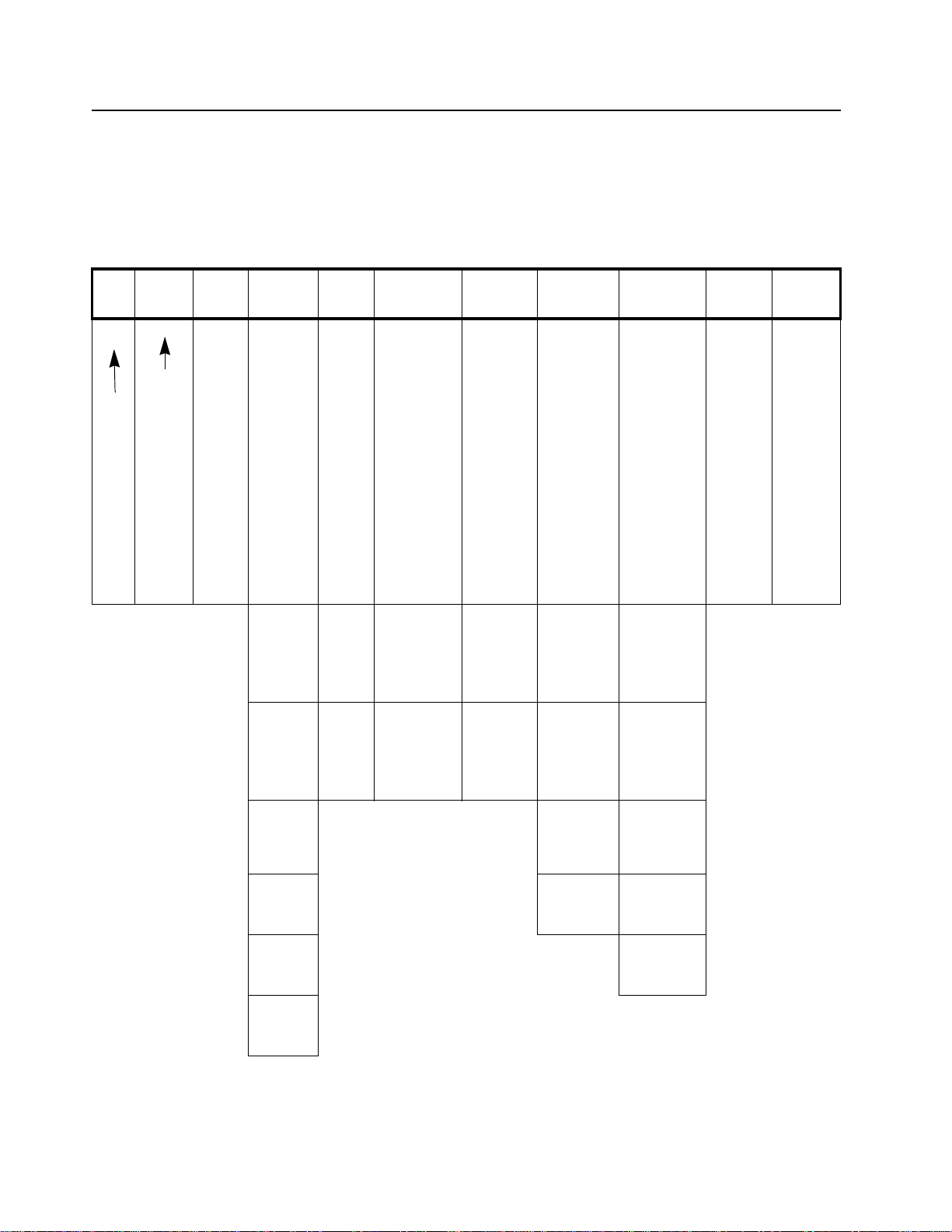

3.8.15 HT1550•XLS Exploded View

3-29

1

2

3

4

5

6

7

8

14

13

17

15

16

18

19

20

21

24

26

28

29

32

35

37

39

40

41

42

43

10

11

22

23

25

44

9

12

27

30

31

33

34

36

38

Figure 3-19: HT1550•XLS Exploded View

Page 36

3-30

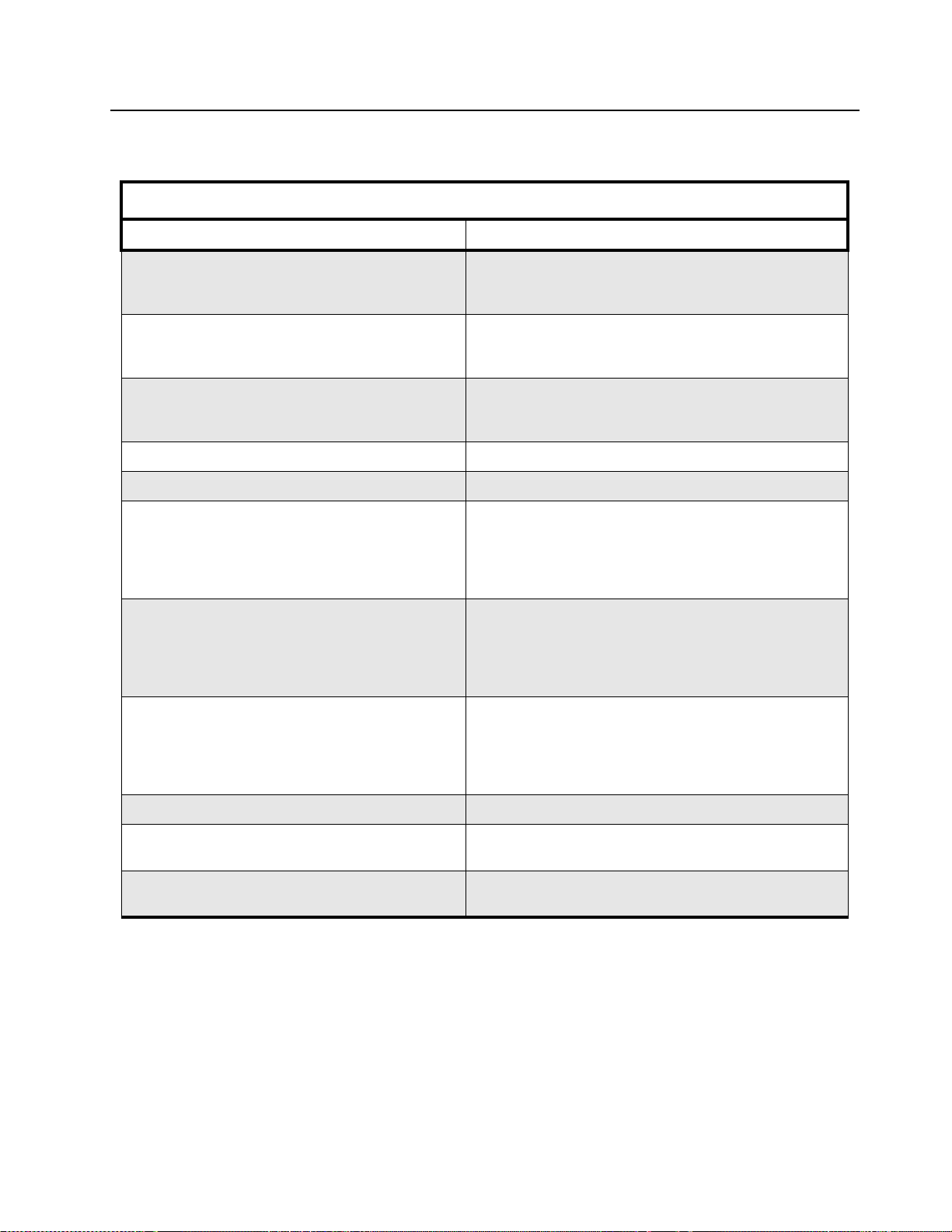

3.8.16 HT1550•XLS Exploded View Parts List

Table 3-8. HT1550•XLS Parts List

Item

1 See Section 7 in

2 3280529Z01 Knob, Volume

3 3280530Z01 Knob, Frequency

4 1380525Z03 Escutcheon, Top (Dotted)

5 3380644Z01 Escutcheon, Adhesive

6 3280533Z01 Seal, Control Top

7 6180527Z01 Litepipe, Tx

8 HKLN4011A Nameplate, HT1550•XLS

9 1586059A01 Dust Cover, Univ Conn

10 1386058A01 Escutcheon, Univ Flex

11 1580666Z02 Front Cover DTMF

12 Not Field

13 7580532Z01 Keypad, Side Control

14 1380528Z01 Bezel, Side Control

Motorola Part

Number

manual

Replaceable

Description

Antenna

Escutcheon, FM

Table 3-8. HT1550•XLS Parts List (Continued)

Item

30 6062884K01 Backup Battery

31 0304726J04 Screw

32 3980667Z01 Contact, Finger (For UHF)

33 Typical Ctrl/RF Board Assembly

34 8485615Z01 Flex, Keypad/Controller

35 1480652Z01 Insulator, Antenna

36 7580556Z01 Pad, Thermal

37 3280534Z01 Seal, Contact

38 3380564Z01 Label, Warning

39 3280536Z02 Gasket, O-Ring

40 3980698Z01 Contact, Ground (For VHF)

41 2780518Z02 Chassis

42 1586178A01 Shroud, Chassis

43 See Section 7 in

44 HLN9714 Beltclip

Motorola Part

Number

manual

Description

Battery

15 7585745Z03 Keypad

16 0104008J38 Keypad Board Assembly

17 5105385Y57 LCD Module

18 7585659Z01 Pad, Retainer Front

19 4285660Z01 Retainer, Keypad Board

20 7585659Z02 Pad, Retainer Back

21 3586057A01 Felt, Speaker

22 3586170A01 Felt, Mic

23 1405368W01 Boot, Mic

24 5085738Z03 Speaker

25 5005227J08 Microphone

26 8480549Z01 Flex, Univ Conn

27 2113740A41 Cap, 33pF

28 4280504Z01 Retainer, Speaker

29 1480503Z01 Boot, Backup Battery

Page 37

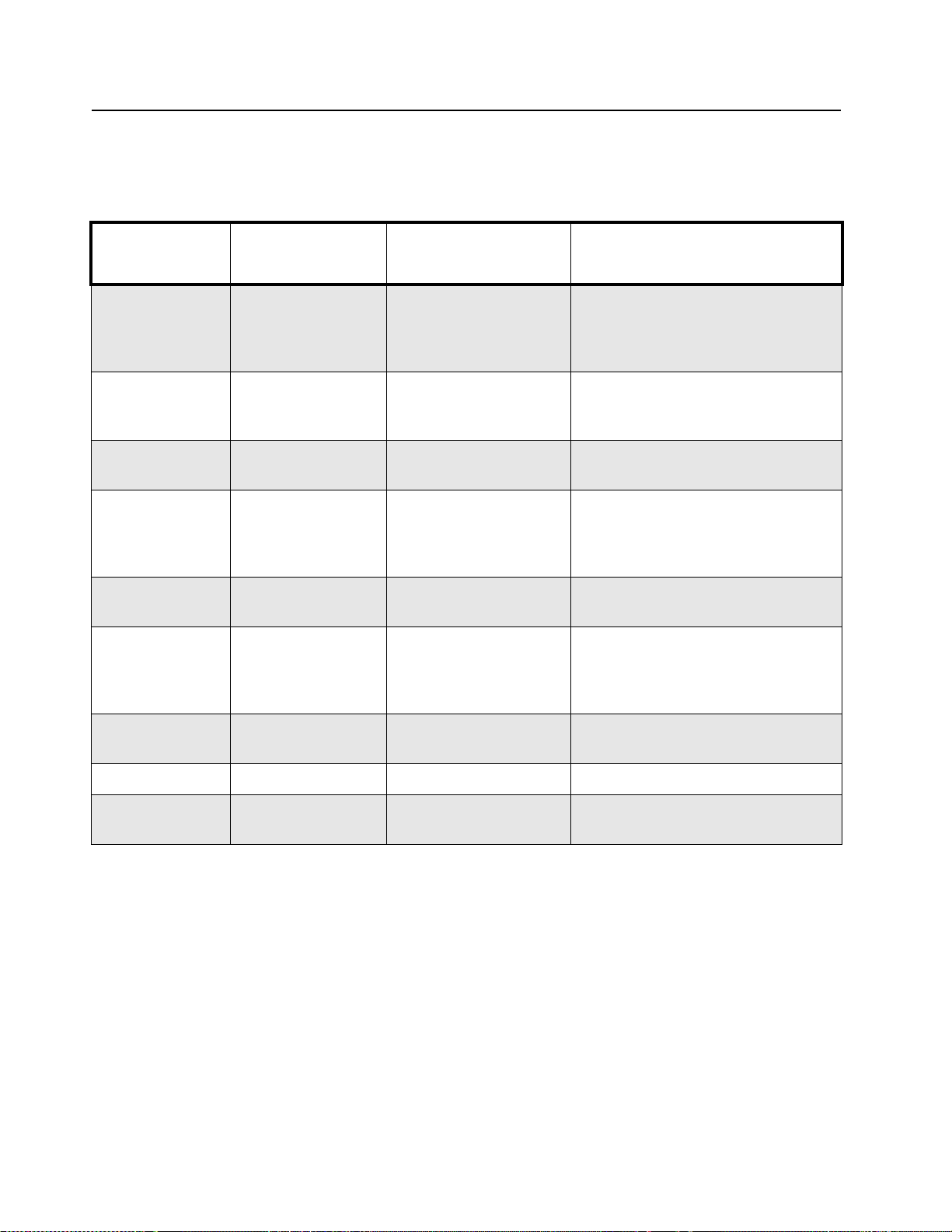

Service Aids 3-35

3.9 Service Aids

Table 3-11 lists service aids recommended for working on the HT750/HT1250/HT1250•LS/

HT1250•LS

NOTE: While all of these items are available from Motorola, most are standard shop

+

/HT1550•XLS/MTX850/MTX950/MTX850•LS/MTX8250/MTX9250/MTX8250•LS radios.

equipment items, and any equivalent item capable of the same performance may be

substituted for the item listed.

Table 3-11:Service Aids

Motorola

Part No.

RLN4460 Portable Test Set Enables connection to audio/accessory jack. Allows

HVN9025 Customer Programming Soft-

ware (CPS Plus) CD ROM.

Includes PPCPS (PassPort Customer Programming Software,

Global tuner, Reflashing tool,

tutorial, frequency finder and frequency table).

HVN9067 Customer Programming Soft-

ware (CPS).

AARKN4075 Programming Cable Includes radio interface box (RIB) capability.

AARKN4074 Programming Cable/Test Cable Connects radio to RIB (RLN4008B).

AARKN4073 Radio to Radio Cloning Cable Allows

RLN4008 Radio Interface Box Enables communications between radio and com-

Description Application

switching for radio testing.

Programs customer option and channel data. Tunes

hardware parameters, front end, power, deviation,

etc. Conventional, LTR, and PassPort products.

Same as above (Privacy Plus protocol products).

radio to be duplicated from a master radio by

transferring programmed data from the master radi o

to the other.

puter’s serial communications adapter.

HHLN4134 BNC Adaptor Adapts radio antenna port to BNC cabling of equip-

ment (VHF and UHF, B1 only).

5880313B69 SMA to BNC adapter Adapts radio antenna port to BNC cabling of equip-

ment (800 MHz radios).

RLN4510 Battery Eliminator 7.5V Regula-

tor

AA0180305G54

AA8180384F68

0180357A57 Wall-Mounted Power Supply

0180358A56 Wall-Mounted Power Supply

3080369B72 Computer Interface Cable Connects computer’s serial communications adapter

Shop Battery Block

Bench Test Housing Eliminator

(120 VAC)

(220 VAC; 2-prong)

Works in combination with Shop Battery Block,

0180305G54.

Interconnects radio to power supply. Provides for

troubleshooting of radio when housing is removed.

Used to supply power to RIB.

Used to supply power to RIB.

to RIB (RLN4008B).

Page 38

3-36 Test Equipment

3.10 Test Equipment

Table 3-12 lists test equipment required to service the HT750/HT1250/HT 1250•LS/HT1250•LS+/

HT1550•XLS/MTX850/MTX950/MTX850•LS/MTX8250/MTX9250/M TX8250•LS radios.

Table 3-12:Recommended Test Equipment

Motorola Part

No.

R2000, R2600

R2400, or R2001

with trunking

option

*R1049 Digital Multimeter Two meters recommended for AC/

*S1100 Audio Oscillator 67 to 200Hz tones Used with service monitor for injec-

*S1053,

*SKN6009,

*SKN6001

R1053 Dual-trace Oscillo-

*S1350,

*ST1215 (VHF)

*ST1223 (UHF)

*T1013

Description Characteristics Application

Service Monitor This monitor will

substitute for items

listed below with an

asterisk *

AC Voltmeter,

Power Cable

for meter,

Test leads for meter

scope

Wattmeter,

Plug-in Elements

(VHF & UHF), RF

Dummy Load

• 1 mV to 300 V

• 10 MΩ input impedance

20 MHz bandwidth,

5 mV/cm - 20 V/cm

• 50 Ω

• ±5% accuracy

10 W, max. 0-1000

MHz, 300 W

Frequency/deviation meter and signal generator for wide-range troubleshooting and alignment

DC voltage and current measurements

tion of PL tones

Audio voltage measurements

Waveform measurements

Transmitter power output measurements

S1339 RF Millivolt Meter 100 µV to 3 VRF, 10

kHz to 1.2 GHz

*R1013 SINAD Meter Receiver sensitivity measurements

S1347 or

S1348 (prog)

DC Power Supply 0-20 Vdc, 0-5 Amps Bench supply for 7.5Vdc

RF level measurements

Page 39

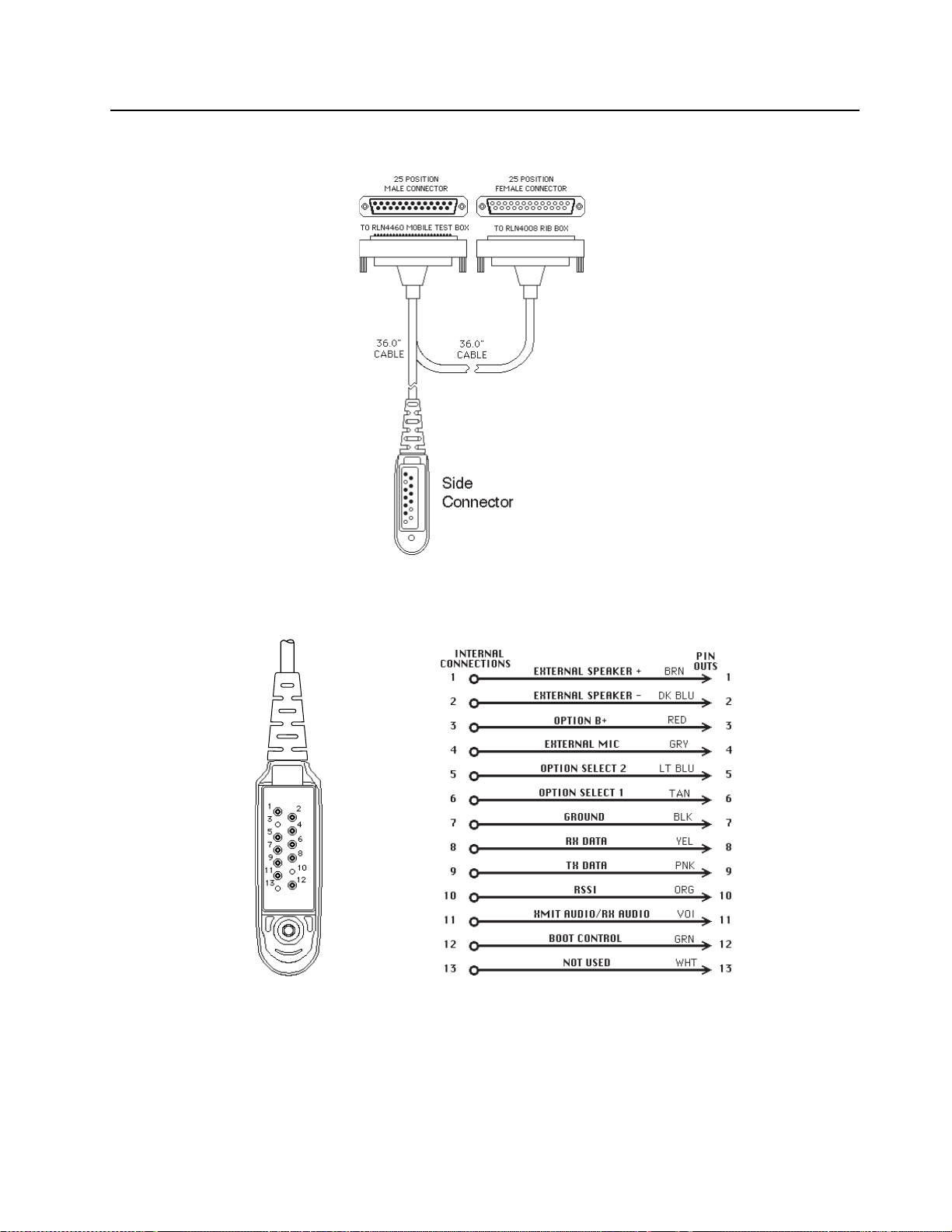

Configuring and Wiring the Programming/Test Cable 3-37

3.11 Configuring and Wiring the Programming/Test Cable

Block

Figure 3-22: Programming/Test Cable AARKN4074

Figure 3-23: Pin Configuration of the Cable Side Connector

Page 40

3-38 Configuring and Wiring the Programming/Test Cable

CONNECTOR

EXT SPKR +

EXT SPKR -

OPTION B+

EXT MIC

OPT SEL 2

OPT SEL 1

GND

RX DATA

TX DATA

RSSI

XMIT/RX AUDIO

BOOT CTRL

N/C

P1

TO RADIO

UNIVERSAL

1

2

3

4

5

6

7

8

9

10

11

12

13

10K

P2

TO RADIO

TEST SET

RLN4460

1

2

5

7

8

9

15

16

18

19

20

21

22

25

J1

TO RIB

RLN4008

1

4

11

15

25

AUDIO AUDIO +

MIC AUDIO

GND

VOL CTRL

DISC

PTT

OPT SEL INT/EXT

BOOT CTRL

GND

BIAS

BUS -

BUS +

BOOT CTRL

FL0830062O

Figure 3-24: Programming/Test Cable Schematic

Page 41

Chapter 4

Transceiver Performance Testing

4.1 General

These radios meet published specifications through their manufacturing process by utilizing high

accuracy laboratory-quality test equipment. The recommended field service equipment approaches

the accuracy of the manufacturing equipment with few exceptions. This accuracy must be maintained

in compliance with the manufacturer’s recommended calibration schedule.

4.2 RF Test Mode

When the radio is operating in its normal environment, the radio’s microcontroller controls the RF

channel selection, transmitter key-up, and receiver muting. However, when the unit is on the bench

for testing, alignment, or repair, it is removed from its normal environment and cannot receive

commands from its system. Therefore, the internal microcontroller does not key the transmitter or

unmute the receiver. This prevents the use of a normal tuning procedure. To solve this problem, a

special “test mode” is incorporated into the radio.

Note 1: On VHF/UHF, LTR models, the radio must be in either conventional or LTR mode.

Note 2: The test mode procedure that follows assumes that the Customer Programming Software

Front Panel Access screen has both the FPA and RF TEST boxes selected. Select from the

programming screen to enable or disable certain features of the radio RF test mode.

l FPA entry not selected blocks all test modes.

l FPA entry selected and RF TEST not selected blocks RF test mode.

l FPA entry selected and RF TEST selected enables all test modes.

4-1

To enter the test mode for a display radio:

1. Turn the radio on.

2. Within ten seconds after the self test is complete, press ‘side button 2’, shown in

Figure 4-1 on page 4-3, five times in succession.

3. After “CSQ CHXX SP25” appears on the display, the radio is on channel XX (see Note

on following page), carrier squelch mode, 25 kHz channel spacing. Each additional

press of ‘side button 2’ (see Table 4-3 on page 4-5) scrolls to the next channel spacing,

and a corresponding set of tones are sounded. Refer to Figure 4-4 on page 4-4 for test

mode information for a four-line display radio.

4. Press ‘side button 1’ to scroll through the test environments listed in Table 4-1 on

page 4-4.

5. Press ‘side button 2’ for 3 seconds to switch the radio to the control head test mode.

‘LCD Test’ appears on the display.

6. Press ‘side button 1’ to turn on all the dots of the first character. Another ‘side button 1’

press turns on all the dots of the next character, continuing until the last character is

reached.

7. Press ‘side button 1’ at the end of the LCD test to activate the ‘Icon Test’. The next ‘side

button 1’ press turns on the first icon.

Page 42

4-2 Transceiver Performance Testing

8. Press ‘side button 1’ at the end of the Icon T est to activate the button test. Pressing any

side button (except ‘side button 1’), or any keypad button during the LCD test or Icon

test immediately activates this test. A good button press is verified by a chirp.

9. Press ‘side button 2’ for 3 seconds in the control head test mode to return the radio to

the RF Test mode.

10. Turn radio off to exit test mode.

To enter the test mode for a non-display radio:

1. Turn the radio on.

2. Within ten seconds after the self test is complete, press ‘side button 2’ (Figure 4-1) five

times in succession.

3. Press ‘side button 1’ the number of times listed in Table 4-1 to get the number of corresponding beeps.

4. Turn radio off to exit test mode.

5. To access all 14 test modes on a 4-channel radio, the frequency knob and mechanical

stop sleeve must be removed (see paragraph 3-8 exploded view diagram).

Button Test (For models with ”G” in location 10 of model number Example: AAH25RCH6

1. Press the orange button; “3/1” appears which indicates that switch 3 is in the closed condition.

2. Release the orange button; “3/0” appears which indicates that switch 3 is in the open condition.

3. Rotate the mode selector knob; “4/0”through “4/15” appears which indicates that knob 4 is in

mode position 1 through 15.

4. Rotate the volume control; “2/0” through “2/255” appears.

5. Press SB1, view “96/1”; release, view “96/0”.

6. Press SB2, view “97/1”; release, view “97/0”.

7. Press SB3, view “98/1”; release view “98/0”.

8. Press PTT button, view “1/1”; release view “1/0”.

Keypad (For models with ”G” in location 10 of model number Example: AAH25RCH6

1. Press 0, view “48/1”; release, view “48/0”.

2. Press 1, view “49/1”; release, view “49/0”.

3. Press 2, view “50/1”; release, view “50/0”.

4. Press 3, view “51/1”; release, view “51/0”.

5. Press 4, view “52/1”; release, view “52/0”.

6. Press 5, view “53/1”; release, view “53/0”.

7. Press 6, view “54/1”; release, view “54/0”.

8. Press 7, view “55/1”; release, view “55/0”.

9. Press 8, view “56/1”; release, view “56/0”.

10. Press 9, view “57/1”; release, view “57/0”.

11. Press *, view “58/1”; release, view “58/0”.

12. Press #, view “59/1”; release, view “59/0”.

13. Press <, view “128/1”; release, view “128/0”.

GB6AN)

GB6AN)

Page 43

Transceiver Performance Testing 4-3

14. Press HOME, view “129/1”; release, view “129/0”.

15. Press >, view “130/1”; release, view “130/0”.

16. Press Option Select1, view “135/1”; release, view “135/0”.

17. Press Option Select2, view “136/1”; release, view “136/0”.

18. Press Option Select3, view “137/1”; release, view “137/0”.

19. Pressing SB2 for 3 seconds in the Control Head T est mode will cause the radio to return to the RF

Test mode.

Channel

Selector

Knob

On/Off

Knob

Side Button 1

(programmable)

Side Button 2

(programmable)

Side Button 3

(programmable)

Side Button 1

(programmable)

Side Button 2

(programmable)

Side Button 3

(programmable)

Figure 4-1: Radio Side Button Location

Channel, Talkgroup,

Zone or Menu Selector

Knob

On/Off

Knob

Figure 4-2: HT1550

•XLS Radio Side Button Location

Page 44

4-4 Transceiver Performance Testing

Annunciators

Figure 4-3: Two-Line Display

Annunciators

Test Mode

Information,

Line 2

Figure 4-4: Four-Line Display (HT1550

Table 4-1: Test Environments (Side Button 1)

Number of

Side

Button 1

No. of

Beeps

Display

Shows

Presses

Initial (No but-

ton presses

required)

1 1 TPL Tone Private-

2 2 DPL Digital Private-

3 3 DTMF Dual-Tone

0 CSQ Carrier

•XLS)

Description Function

RX: if carrier detected

Squelch

Line

Line

Multiple

Frequency

TX: mic audio

RX: unsquelch if carrier and tone

(192.8Hz) detected

TX: mic audio + tone (192.8Hz)

RX: unsquelch if carrier and digital code (131) detected

TX: mic audio + digital code (131)

RX: unsquelch if carrier detected

TX: selected DTMF tone pair

4 5 Open Unsquelch RX: constant unsquelch

TX: mic audio

5 9 HSS MDC1200 RX: unsquelch if carrier detected