Page 1

QM-Height

High-Precision Digital

Height Gauge

QMH-600A

QMH-600B

QMH-350A

QMH-350B

QMH-24"A

QMH-24"B

QMH-14"A

QMH-14"B

User's Manual

- Instructions for use -

Read this User's Manual thoroughly before operating

the instrument. After reading, retain it close at hand for

future reference.

No. 99MAF029B2

Date of publication: February 1, 2017

Page 2

Applicable product names and model numbers

QMH-600A

z

518-232

QMH-600B

z

518-236

QMH-350A

z

518-230

QMH-350B

z

518-234

QMH-24"A

z

518-233

QMH-24"B

z

518-237

QMH-14"A

z

518-231

QMH-14"B

z

518-235

Notice Regarding This Guide

yMitutoyo Corporation assumes no responsibilities for any damage to the instrument, caused by its

use not conforming to the procedure described in this User's Manual.

yUpon loan or transfer of this instrument, be sure to attach this User's Manual to the instrument.

yIn the event of loss or damage to this manual, immediately contact a Mitutoyo sales office or your

dealer.

yBefore operation of the instrument, thoroughly read this manual to comprehend its contents.

yParticularly, for full understanding of information, carefully read "Safety Precautions" and

"Precautions for Use" at the outset of this manual before using the instrument.

yThe contents in this manual are based on the information current as of February, 2017.

yNo part or whole of this manual may be transmitted or reproduced by any means without prior

written permission of Mitutoyo Corporation.

ySome screen displays in this manual may be highlighted, simplified or partially omitted for

convenience of explanation. In addition, some of them may differ from actual ones to the extent that

no user will misunderstand the functions and operations.

yThe corporation, organization and product names that appear in this manual are their trademarks

or registered trademarks.

© 2017 Mitutoyo Corporation. All rights reserved.

No. 99MAF029B

Page 3

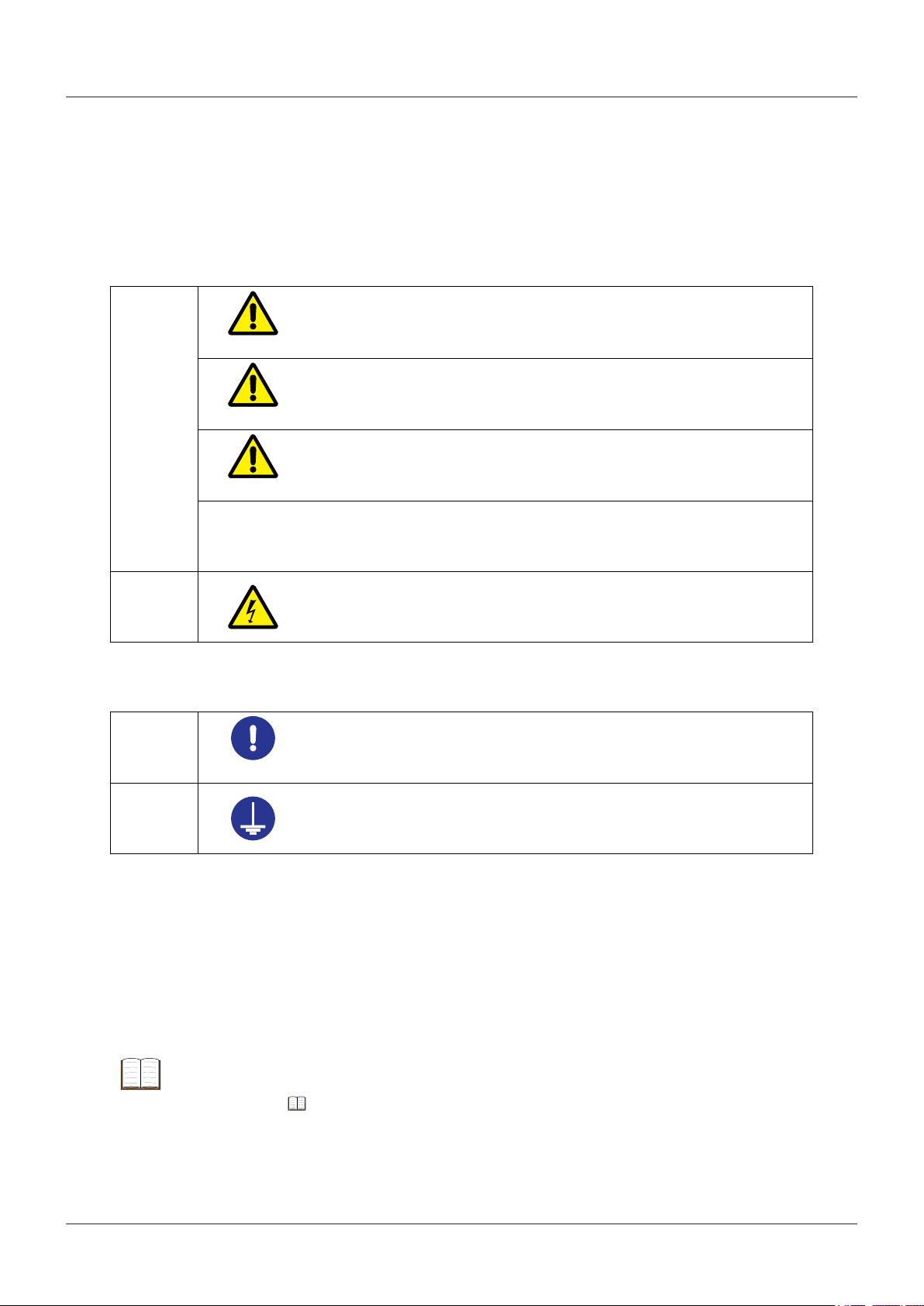

CONVENTIONS USED IN THIS MANUAL

Conventions used in this User's Manual are roughly divided into two types (safety reminders and

mandatory actions). Moreover, these safety symbols include general warnings and specific warnings.

Specific warning symbols are provided with concrete pictograms inside of them.

Safety reminder conventions and wording warning against potential hazards

Indicates an immediately hazardous situation which, if not avoided, will result

in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could result in

serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor injury.

General

DANGER

WARNING

CAUTION

NOTE

Specific

Conventions and wording indicating mandatory actions

General

Mandator y

Specific

Conventions and wording indicating referential information or referential

Indicates a potentially hazardous situation which, if not avoided, may result in

property damage.

Alerts the user to a specific hazardous situation that means "Caution, risk of

electric shock".

Indicates concrete information about mandatory actions.

Indicates that grounding needs to be implemented.

locations

Tips

Indicates referential information such as that for when the operating methods and procedures which

are printed in these sentences are to be applied to specific conditions.

Indicates referential locations if there is information that should be referred to in this guide or an

extraneous manual.

E.g.: For details,

"2.1 Measuring the Height" (page 17)

i

No. 99MAF029B

Page 4

Safety Precautions

Read these Safety Precautions thoroughly before operating the system to use it properly.

These safety precautions include such information as to prevent an injury to the operator and other

persons or damage to property. Be sure to observe the precautions.

• Do not disassemble or modify this product. Doing so can result in fire or electric shock.

• Do not place the product on an unstable surface. It may fall or topple over, causing an injury.

WARNING

CAUTION

• Do not place containers with water, such as flower pots, near this product. If water gets into the

device, a fire or electric shock may occur. If water does get into the device, turn off the power, and

contact us. Continuing to use the device may result in a fire or electric shock.

• Do not use the device in areas where volatile gases may be released. Doing so can result in a fire.

• Do not apply an external voltage to the product with a device such as an electric engraver. Doing so

may lead to damage or malfunction.

• If the device will not be used for an extended period of time, remove the batteries. Battery leakage

can damage the device.

• Only use LR6 (AA alkaline) or Ni-MH (nickel metal hydride) batteries. Handle the batteries

according to their instructions.

• Do not charge or disassemble the accompanying batteries. They may short circuit.

ii

No. 99MAF029B

Page 5

Precautions for Use

Product applications and handling

This product is a measuring instrument.

z

Do not use it for any purposes other than measuring.

This product is precision equipment.

z

It must be carefully handled. Be careful not to apply excessive shock or force to any of the parts during

operation.

Installation environment

Only use this product in the following environments.

yAreas free of dirt and dust

yAreas free of vibrations

yAreas with an ambient temperature between 0 C and 40 C (For precision measurements, the

temperature should be consistently around 20 C.)

yAreas with low humidity

yOn a surface plate

Avoid using the product in the following environments.

yIn locations where it may directly exposed to cutting fluids, water, etc.

yIn locations where it may be exposed directly to sunlight or hot or cold wind

yIn locations near machines that generate electromagnetic noise, such as welders or electrical

discharge machines

Maintenance

yClean the main unit, base, or probe by wiping it with a lint-free cloth or paper towel dampened with

a neutral detergent. Do not use an organic solvent such as a thinner.

yIn order to prevent dirt and dust accumulation, we recommend covering the main unit with the

included product cover.

Power Supply

yTurn off the power after use.

yDo not connect the AC adapter (optional accessory) to a high-current power supply used by

machine tools or large CNC measuring instrument.

iii

No. 99MAF029B

Page 6

Electromagnetic Compatibility (EMC)

This product complies with the EMC Directive. Note that, in environments where electromagnetic

interference exceeds the EMC requirements defined in this directive, appropriate countermeasures are

required to ensure product performance.

This is an industrial product. Not intended for use in a residential environment. Use of this product in a

residential environment may cause an electromagnetic interference with other instruments. In such a

case, appropriate measures against electromagnetic interference are required.

Export Control Compliance

This product falls into the Catch-All-Controlled Goods and/or Catch-All-Controlled Technologies

(including Programs) under Category 16 of Appended Table 1 of the Export Trade Control Order or

under Category 16 of the Appended Table of Foreign Exchange Control Order, based on the Foreign

Exchange and Foreign Trade Act of Japan.

If you intend re-export of the product from a country other than Japan, re-sale of the product in a

country other than Japan, or re-provision of the technology (including program), you are obligated to

observe the regulations of your country.

Also, if an option is added or modified to add a function to this product, this product may fall under the

category of List-Control Goods and/or List-Control Technology (including Programs) under Category 1

- 15 of Appended Table 1 of the Export Trade Control Order or under Category 1 - 15 of the Appended

Table of Foreign Exchange Control Order, based on Foreign Exchange and Foreign Trade Act of

Japan. In that case, if you intend re-export of the product from a country other than Japan, re-sale of

the product in a country other than Japan, or re-provision of the technology (including program), you

are obligated to observe the regulations of your country. Please contact Mitutoyo in advance.

Notes on Export to EU Member Countries

When you intend export of this product to any of the EU member countries, you may be required

to provide User's Manual(s) in English and EU Declaration of Conformity in English (under certain

circumstances, User's Manual(s) in the destination country's official language and EU Declaration

of Conformity in the destination country's official language). For detailed information, please contact

Mitutoyo in advance.

Disposal of Old Electrical & Electronic Equipment (Applicable in the European Union and other European countries with separate collection systems)

This symbol on the product or on its packaging is based on the WEEE Directive (Directive on

Waste Electrical and Electronic Equipment), which is a regulation in EU member countries, and

indicates that this product shall not be treated as household waste.

To reduce environmental impact and minimize the volume of landfill, please cooperate in reuse

and recycling.

For information on how to dispose of the product, please contact your dealer or the nearest

Mitutoyo sales office.

iv

No. 99MAF029B

Page 7

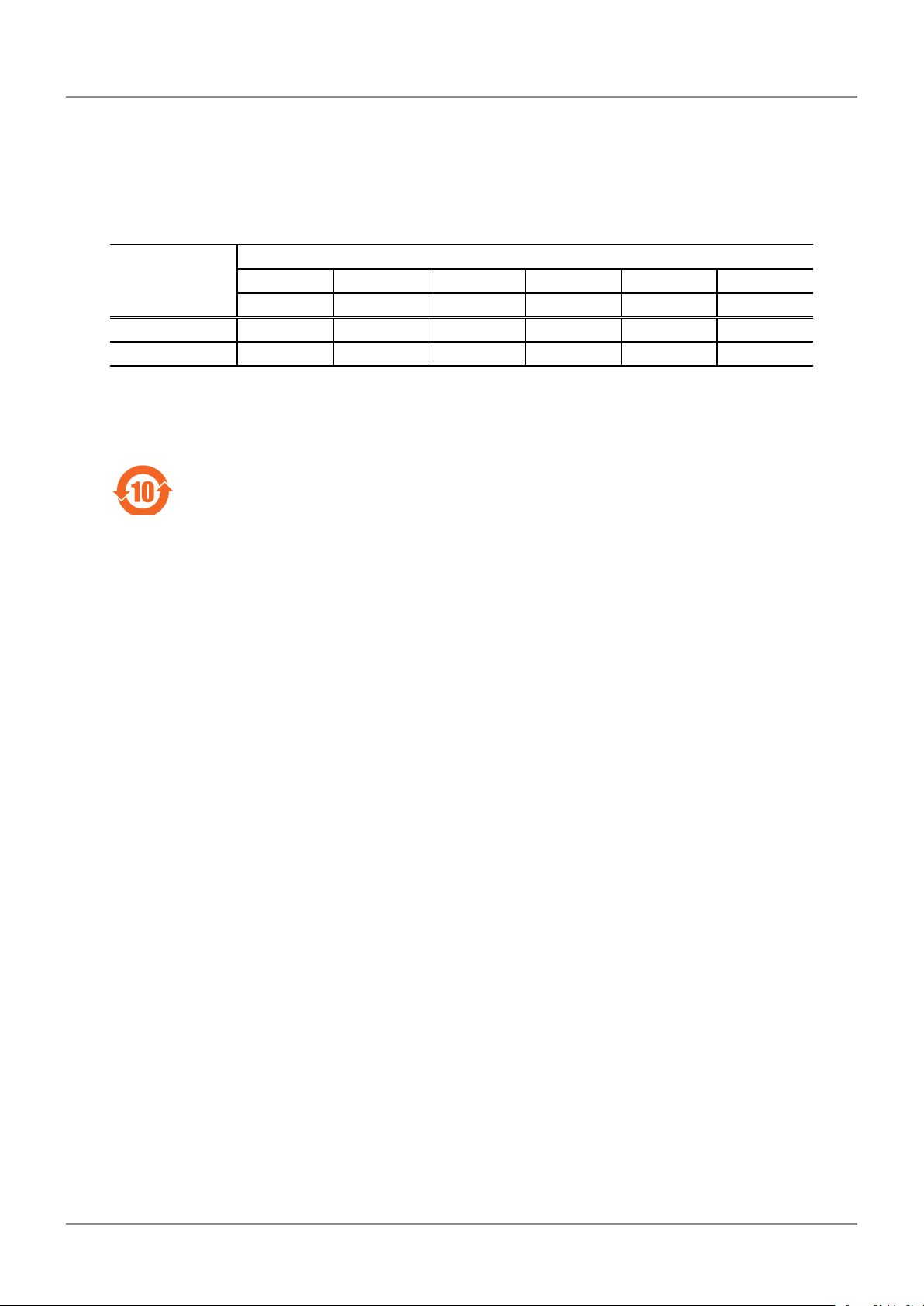

China RoHS Compliance Information

This product meets China RoHS requirements. See the table below.

产品中有害物质的名称及含量

有害物质

部件名称

本体 × ○ ○ ○ ○ ○

配件 ○ ○ ○ ○ ○ ○

本表格依据 SJ/T 11364 的规定编制。

○ :表示该有害物质在该部件所有均质材料中的含量均在 GB/T 26572 规定的限量要求以下。

× :表示该有害物质至少在该部件的某一均质材料中的含量超出 GB/T 26572 规定的限量要求。

环保使用期限标识,是根据电器电子产品有害物质限制使用管理办法以及,电子电气产品有害物

质限制使用标识要求 (SJ/T11364-2014),制定的适用于中国境内销售电子电气产品的标识。

电子电气产品只要按照安全及使用说明内容,正常使用情况下,从生产月期算起,在此期限内,

产品中含有的有毒有害物质不致发生外泄或突变,不致对环境造成严重污染或对其人身、财产造

成严重损害。

产品正常使用后,要废弃在环保使用年限内或者刚到年限的产品时,请根据国家标准采取适当的

方法进行处置。

另外,此期限不同于质量 / 功能的保证期限。

铅 汞 镉 六价铬 多溴联苯 多溴二苯醚

(Pb) (Hg) (Cd) (Cr(VI)) (PBB) (PBDE)

v

No. 99MAF029B

Page 8

Warranty

In the event that this product should prove defective in workmanship or material, within one year from

the date of original purchase for use, it will be repaired or replaced free of charge. Please contact your

dealer or the nearest Mitutoyo sales office.

If this product fails or is damaged for any of the following reasons, it will be subject to a repair charge

even if it is still under warranty.

yFailure or damage owing to fair wear and tear.

yFailure or damage owing to inappropriate handling, maintenance, or repair, or to unauthorized

modification.

yFailure or damage owing to transport, dropping, or relocation of the product after purchase.

yFailure or damage owing to fire, salt, gas, abnormal voltage, lightning surge, or natural disaster.

yFailure or damage owing to use in combination with hardware or software other than that

designated or permitted by Mitutoyo.

yFailure or damage owing to use in ultra-hazardous activities.

This warranty is effective only where the instrument is properly installed and operated in conformance

with the instructions in this manual within the original country of the installation.

EXCEPT AS SPECIFIED IN THIS WARRANTY, ALL EXPRESS OR IMPLIED CONDITIONS,

REPRESENTATIONS, AND WARRANTIES OF ANY NATURE WHATSOEVER INCLUDING,

WITHOUT LIMITATION, ANY IMPLIED WARRANTY OF MERCHANTABILITY, FITNESS FOR A

PARTICULAR PURPOSE, NONINFRINGEMENT OR WARRANTY ARISING FROM A COURSE OF

DEALING, USAGE, OR TRADE PRACTICE, ARE HEREBY EXCLUDED TO THE MAXIMUM EXTENT

ALLOWED BY APPLICABLE LAW.

You assume all responsibility for all results arising out of the selection of this product to achieve its

intended results.

Disclaimer

IN NO EVENT WILL MITUTOYO, ITS AFFILIATED AND RELATED COMPANIES AND SUPPLIERS

BE LIABLE FOR ANY LOST REVENUE, PROFIT, OR DATA, OR FOR SPECIAL, DIRECT,

INDIRECT, CONSEQUENTIAL, INCIDENTAL, OR PUNITIVE DAMAGES HOWEVER CAUSED AND

REGARDLESS OF THE THEORY OF LIABILITY ARISING OUT OF THE USE OF OR INABILITY TO

USE THIS PRODUCT EVEN IF MITUTOYO OR ITS AFFILIATED AND RELATED COMPANIES AND/

OR SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES.

If, notwithstanding the foregoing, Mitutoyo is found to be liable to you for any damage or loss which

arises out of or is in any way connected with use of this product by you, in no event shall Mitutoyo's

and/or its affiliated and related companies' and suppliers' liability to you, whether in contract, tort

(including negligence), or otherwise, exceed the price paid by you for the product only.

BECAUSE SOME COUNTRIES, STATES OR JURISDICTIONS DO NOT ALLOW THE EXCLUSION

OR THE LIMITATION OF LIABILITY FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES, IN SUCH

COUNTRIES, STATES OR JURISDICTIONS, MITUTOYO'S LIABILITY SHALL BE LIMITED TO THE

EXTENT PERMITTED BY LAW.

vi

No. 99MAF029B

Page 9

About This Document

Positioning of This Document in Document Map

This document explains how to use the product and provides troubleshooting information.

In addition to this document, a setup guide and a quick reference chart are available.

Operation

z

User's Manual (This Document)

Setup

z

Setup Manual

Quick reference chart

z

Quick Reference Manual

Intended Readers and Purpose of This Document

Intended Readers

z

This document is intended for beginners of the High-Precision Digital Height Gauge.

The readers are assumed to have been familiar with basic operations of a PC and Windows.

They are also assumed to be able to understand individual instructions by reading screen displays.

Purpose

z

To use this product safely and correctly, read this document thoroughly. After reading, keep it in a safe

place close to the product.

This document is aimed at understanding how to use the High-Precision Digital Height Gauge to

perform basic measurements and specific usage applications.

vii

No. 99MAF029B

Page 10

Contents

CONVENTIONS USED IN THIS MANUAL ………………………………………………… i

Safety Precautions …………………………………………………………………………… ii

Precautions for Use …………………………………………………………………………… iii

Electromagnetic Compatibility (EMC) …………………………………………………… iv

Export Control Compliance ………………………………………………………………… iv

Notes on Export to EU Member Countries ……………………………………………… iv

Disposal of Old Electrical & Electronic Equipment (Applicable in the European

Union and other European countries with separate collection systems) ………… iv

China RoHS Compliance Information ……………………………………………………… v

Warranty ………………………………………………………………………………………… vi

Disclaimer ……………………………………………………………………………………… vi

About This Document …………………………………………………………………………vii

1 Before Using This Product …………………………………………………………… 1

1.1 Product Capabilities ………………………………………………………………… 1

1.2 Part Names and Functions ………………………………………………………… 2

1.2.1 Main Unit……………………………………………………………………………………… 2

1.2.2 Display Unit ………………………………………………………………………………… 4

1.3 Basic Operations …………………………………………………………………… 7

1.3.1 Turning On the Power ……………………………………………………………………… 7

1.3.2 Moving the Probe …………………………………………………………………………… 7

1.3.3 Moving the Main Unit ……………………………………………………………………… 8

1.4 Preparing Measurements …………………………………………………………10

1.4.1 Origin Setup …………………………………………………………………………………10

1.4.2 Setting the Probe Diameter …………………………………………………………………14

2 Basic Measuring Methods ………………………………………………………………17

2.1 Measuring the Height ………………………………………………………………17

2.2 Measuring the Width ………………………………………………………………19

2.3 Measuring the Inner Diameter ……………………………………………………21

2.4 Measuring the Outer Diameter ……………………………………………………25

2.5 Measuring the Plane Displacement (Plane Scanning Measurement) …………29

3 Specific Usage Applications ……………………………………………………………31

3.1 Calculating the Difference Between 2 Measurements …………………………31

3.1.1 Determining the Difference Between the Most Recently Measured Value ……………32

viii

No. 99MAF029B

Page 11

3.1.2

3.1.3 Calculating the Difference Between Values Stored in the Memory ……………………35

Continuously Measuring the Distance from One Specific Point to Multiple Other Points

…33

3.2 Judging the Tolerance ………………………………………………………………38

3.2.1 Setting the Upper and Lower Limits ………………………………………………………38

3.2.2 Enabling/Disabling the Judgment Function ………………………………………………39

3.3 Simplifying Measurement Procedures ……………………………………………40

3.3.1 Registering a Measurement Procedure ……………………………………………………40

3.3.2 Measuring Using a Registered Measurement Procedure ………………………………42

3.4 Setting the Terminating Method for Scanning Measurements …………………43

3.5 Holding the Displayed Measurement Results ……………………………………44

3.6 Setting the Resolution for Measurements ………………………………………44

3.7 Setting the Time Until the Power Turns Off (Auto-Off) …………………………45

3.8 Setting the LED Lighting Time ……………………………………………………46

3.9 Outputting Measurement Results to an External Device ………………………47

3.9.1 Outputting to a Mini Printer (Optional Accessory) ………………………………………47

3.9.2 Outputting to a PC (Windows Only) ………………………………………………………48

4 Troubleshooting …………………………………………………………………………51

4.1 If the Following Problem Occurs …………………………………………………51

4.2 If Error Messages Are Displayed …………………………………………………53

5 Specifications ……………………………………………………………………………55

5.1 Basic Specifications …………………………………………………………………55

5.2 Digimatic Data Output Specification ………………………………………………57

5.2.1 Data Format …………………………………………………………………………………57

5.2.2 Connector Specification ……………………………………………………………………57

5.2.3 Timing Chart …………………………………………………………………………………58

5.3 USB Data Output Specification ……………………………………………………59

5.3.1 Communication Specification ……………………………………………………………… 59

5.3.2 Data Format …………………………………………………………………………………59

5.3.3 Connector Specification ……………………………………………………………………59

5.3.4 Data Format Examples………………………………………………………………………59

5.4 Accessories …………………………………………………………………………60

5.5 Optional Accessories ………………………………………………………………61

SERVICE NETWORK

Revision History

ix

No. 99MAF029B

Page 12

x

No. 99MAF029B

Page 13

1 Before Using This Product

1

This chapter explains the product's characteristics, part names and functions, basic operations, and

the settings that must be configured prior to measurement.

1.1

This product is a measuring instrument that makes measurements by vertically moving a part called

a probe into contact with a specific point, and calculating the height of that point. Because the

measurements are obtained from the probe's position, this product can measure the inner diameter of

holes and the outer diameter of cylinders as well.

Before Using This Product

Product Capabilities

(2)

(1)

Measurement

point

Bring the probe into contact with the point you want to measure (1), and read the displayed measurement (2).

1

No. 99MAF029B

Page 14

1 Before Using This Product

1.2

Part Names and Functions

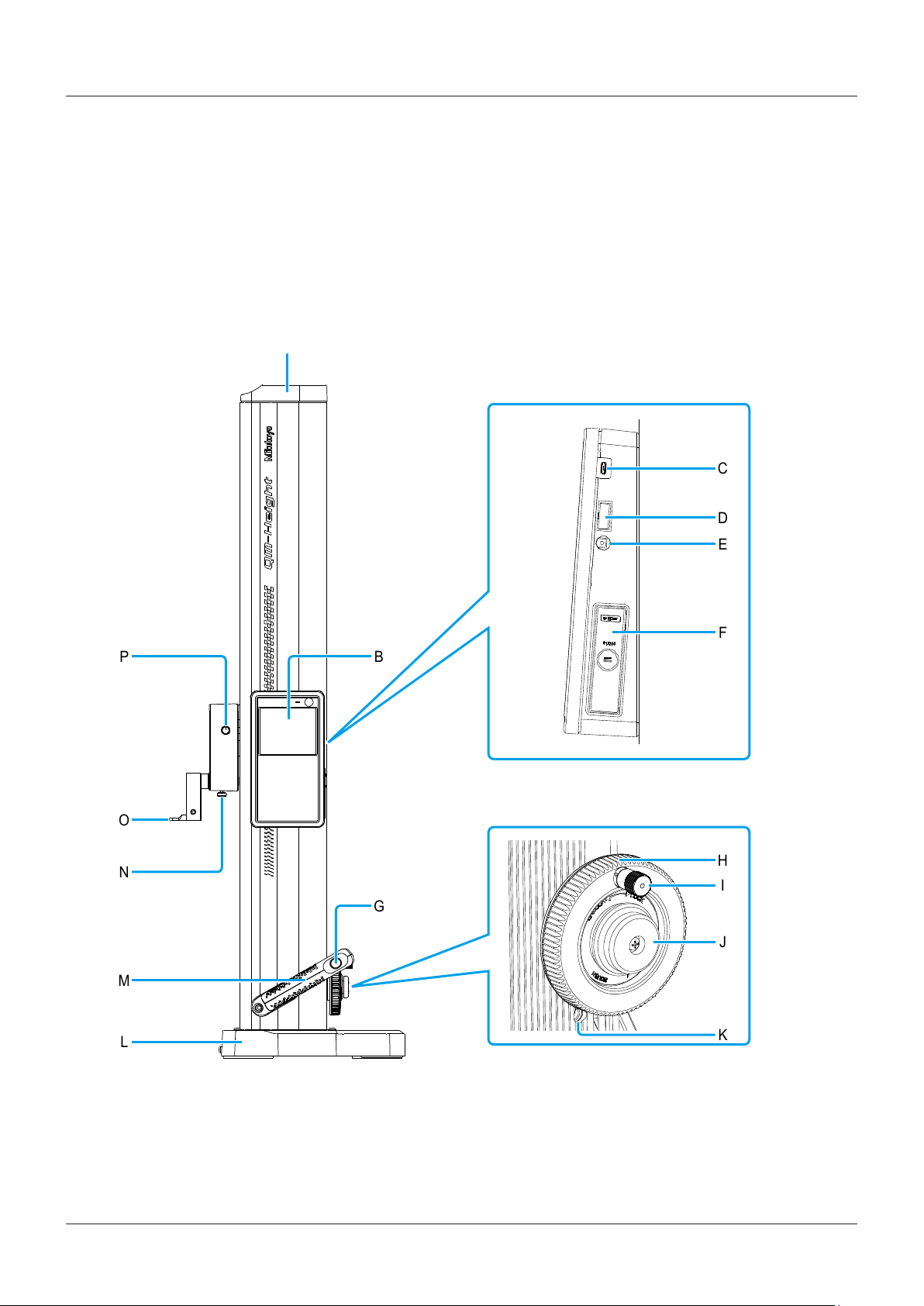

1.2.1 Main Unit

A

C

D

E

P B

O

N

M

L

F

H

I

G

J

K

2

No. 99MAF029B

Page 15

1 Before Using This Product

A Head cover B Display unit

C Micro USB connector (AB receptacle)

D Digimatic output connector*1

*1

This port is for connecting your PC with a

micro USB cable.

E DC jack

F Battery case

*1

This jack is for connecting the optional AC

adapter.

Displays measurements and any messages.

This port is for connecting the optional

Digimatic mini-processor (DP-1VR, etc.).

A case for inserting the batteries.

G Air-float switch (QMH-600B/QMH-350B/

QMH-24"B/QMH-14"B only)

This switch uses the air-float function to

make the main unit float.

NOTE

Measuring with the air-float function

active can cause measurement errors.

I Probe fine adjustment knob

Pulling the knob and turning it moves the

probe slowly.

K Float amount adjustment screw (QMH-600B/

QMH-350B/QMH-24"B/QMH-14"B only)

Adjusts the amount of airflow used in the

air-float function. Turning the screw right

increases airflow, and turning it left reduces

airflow.

M Carrier grip

Hold the carrier grip when moving the main

unit along the surface plate.

O Probe

Used for obtaining measurements. Touch

the sphere on the tip of the probe to the

workpiece to obtain the measurements.

H Probe up/down wheel

The probe moves up and down as the wheel

is turned left and right.

J Clamp screw

Fixes the rotational movement of the probe

up/down wheel.

L Base

Contact surface used when installing the

main unit on the surface plate. Grip the base

when moving the main unit along the surface

plate.

N Probe clamp knob

Clamps the probe so that it does not come

out.

P Clamp knob

Fixes the movement of the probe.

*1

During use, we recommend securing the cable with the included cable clamp.

3

No. 99MAF029B

Page 16

1 Before Using This Product

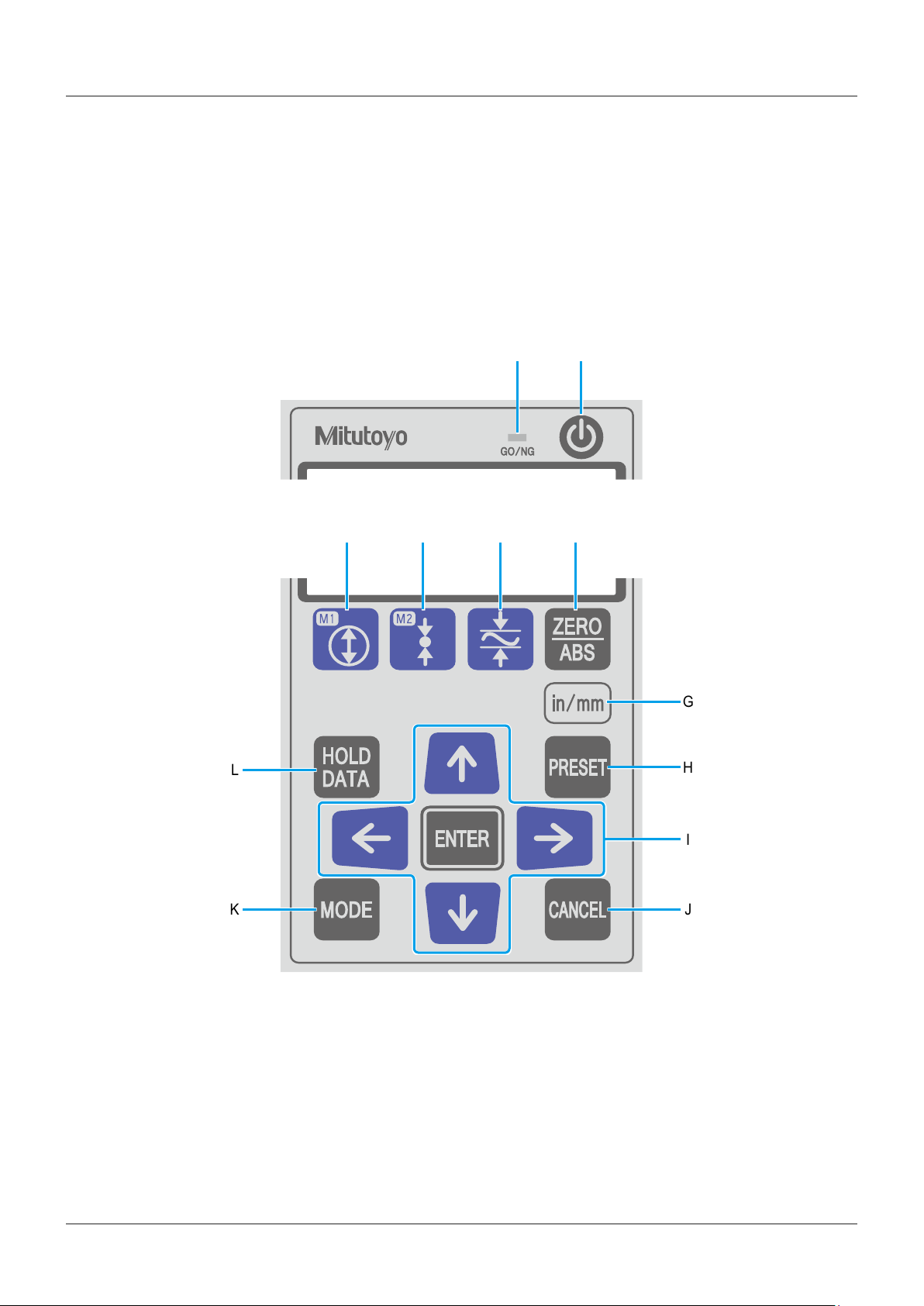

1.2.2 Display Unit

Operation panel

A

C D E F

L

B

G

H

I

K

4

J

No. 99MAF029B

Page 17

1 Before Using This Product

A Shows the result of the tolerance judgment.

Tips

C Measures the inner diameter.

Tips

E Measures the maximum, minimum, and

displacement values (maximum – minimum =

displacement) of a horizontal plane.

Tips

G Changes the setting for units between inches

and millimeters (only on models that support

inches).

For details, "3.2 Judging the

Tolerance" (page 38)

For details, "2.3 Measuring the

Inner Diameter" (page 21)

For details, "2.5 Measuring the

Plane Displacement (Plane Scanning

Measurement)" (page 29)

B Turns the power on or off.

D Measures the outer diameter.

Tips

F Changes the origin between ABS and INC

settings.

H Sets a value for the origin.

For details, "2.4 Measuring the

Outer Diameter" (page 25)

I

Changes numbers and settings. Press

to confirm an operation.

Tips

K Used to change settings for a specific

application, such as changing the

measurement resolution.

Tips

• Press and hold to reverse

the counting direction: Moving

the probe upwards decreases

the value, and moving the probe

downwards increases the value.

Press and hold the button again to

return to normal.

• If you reversed the counting

direction, follow the procedure in

"1.4.1 Origin Setup" (page

10) to reset the origin.

For details, "3 Specific Usage

Applications" (page 31)

J Cancels an operation.

L Holds a measurement in the display and

outputs the measurement results to external

devices.

Tips

For details, "3.5 Holding the

Displayed Measurement Results"

(page 44) and "3.9 Outputting

Measurement Results to an External

Device" (page 47)

5

No. 99MAF029B

Page 18

1 Before Using This Product

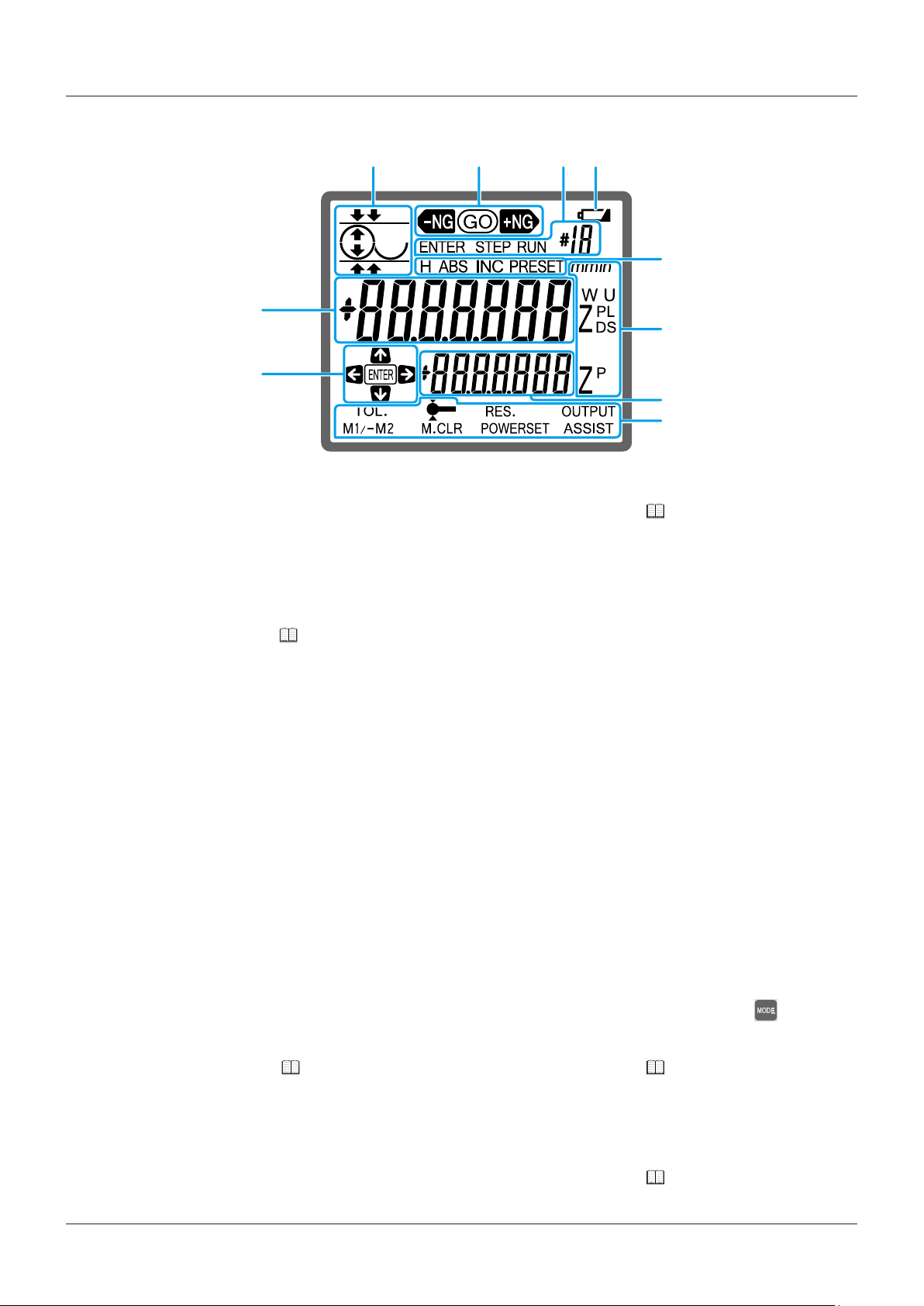

LCD screen

J

I

A B C D

E

F

G

H

A Displays an icon which represents an

operation.

C Displayed when registering measurement

steps or executing steps that have been

registered.

Tips

E Displayed during the following operations.

y[H]

When a measurement is being held in the

display.

y[ABS]/[INC]

When the origin has been changed

between ABS and INC settings.

y[PRESET]

When setting a value for the origin.

For details, "3.3 Simplifying

Measurement Procedures" (page 40)

B Shows the result of the tolerance judgment.

Tips

D Displayed when the battery is empty.

F The meanings of the following letters,

which are displayed during measuring, are

explained below.

y[ZP]

The difference between 2 measurements

y[U]/[L]

Upper/Lower tolerances

y[ZD]

Diameter

y[ZL]/[ZS]/[W]

Maximum/Minimum/Displacement

y[mm]

Millimeters (unit)

y[in]

Inches (unit)

For details, "3.2 Judging the

Tolerance" (page 38)

G Displays the difference with the previous

measurement.

Tips

I Shows which keys can be used during an

operation.

For details, "3.1 Calculating the

Difference Between 2 Measurements"

(page 31)

H Displays the available settings when is

pressed.

Tips

J Displays the measurement.

Tips

For details, "3 Specific Usage

Applications" (page 31)

For details, "2 Basic Measuring

Methods" (page 17)

6

No. 99MAF029B

Page 19

1 Before Using This Product

1.3

This section explains how to turn on the power, as well as how to move the probe and the main unit.

Basic Operations

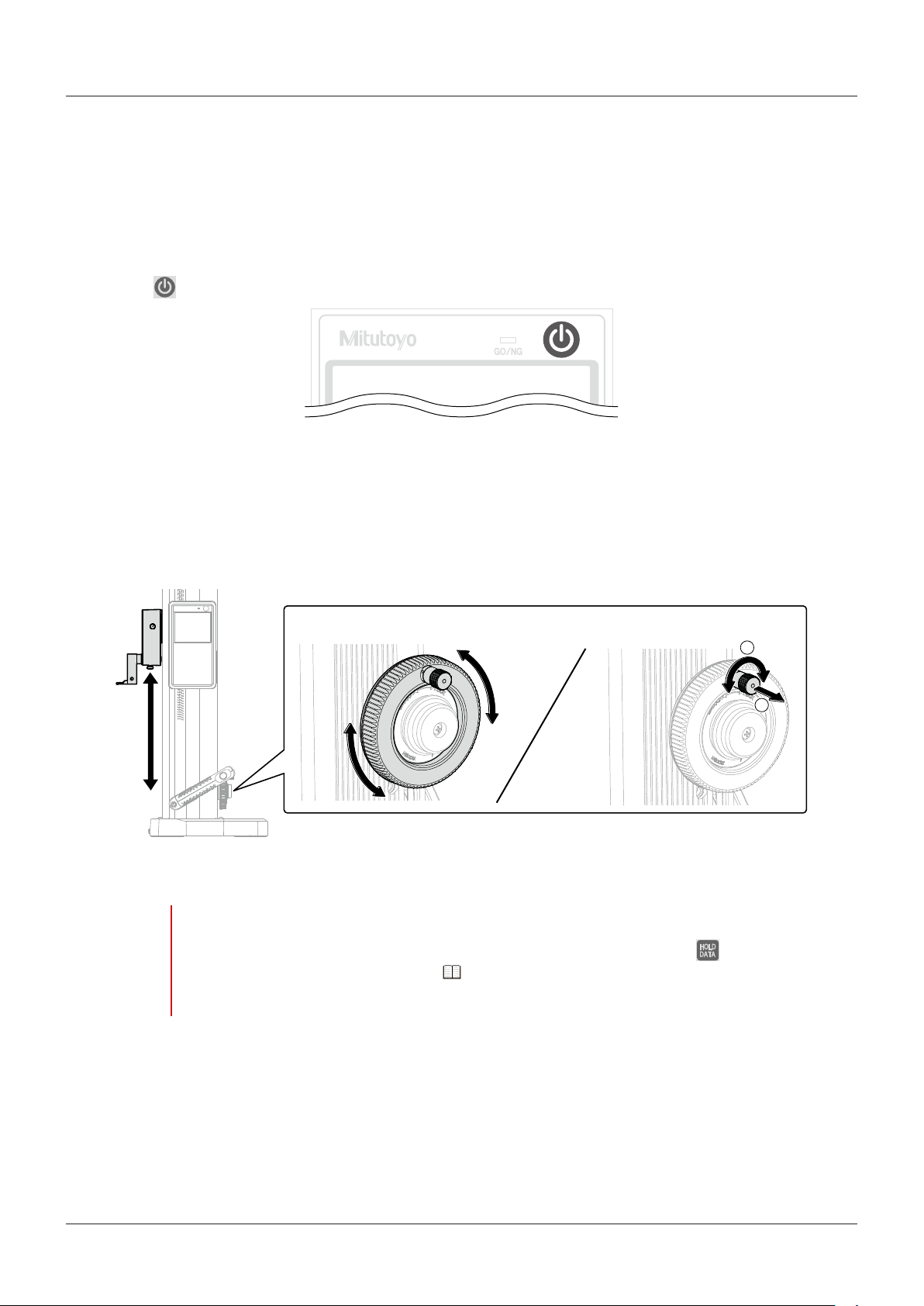

1.3.1 Turning On the Power

Press on the upper right of the LCD screen to turn on the power.

1.3.2 Moving the Probe

Turn the probe up/down wheel right and left to move the probe up and down, respectively. When

bringing the probe into contact with the workpiece or surface plate, be sure to move the probe slowly.

The probe can be moved slowly by pulling out and turning the probe fine adjustment knob.

"Quick Movement (Coarse adjustment)" "Slow Movement (Fine adjustment)"

2

1

When the probe contacts the measurement surface with a consistent force, a beep sound is made, and

the height position is measured.

NOTE

• In order to prevent a reduction in the product's performance, do not move the probe by grabbing it.

• If the display value remains held even when you move the probe vertically, press

not release the hold, follow the steps in "When the displayed value is held, and the workpiece

cannot be measured" (page 52) to release the hold.

. If this does

7

No. 99MAF029B

Page 20

1 Before Using This Product

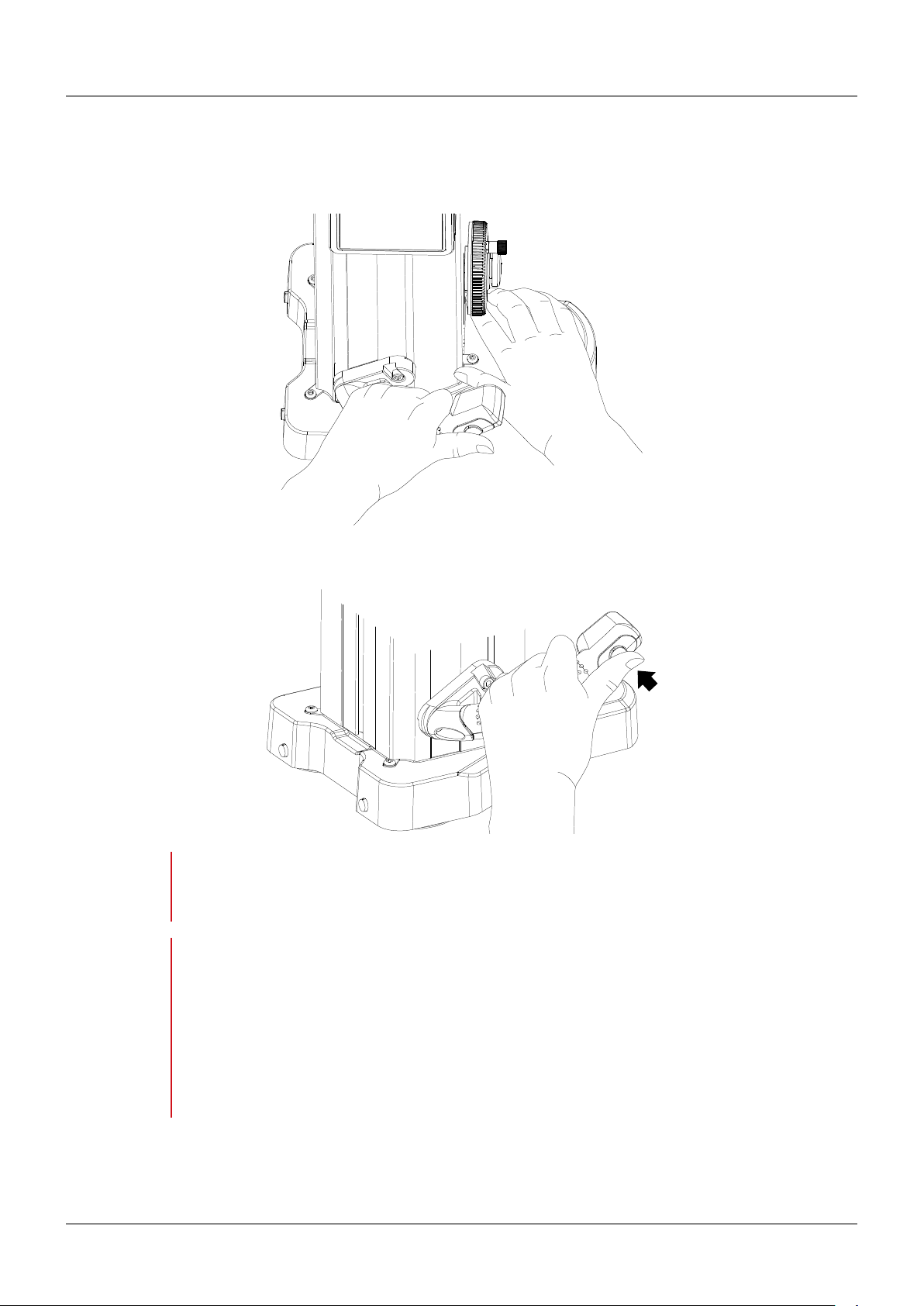

1.3.3 Moving the Main Unit

When moving the main unit on the surface plate, grab the base with your right hand and the carrier

grip with your left hand.

For QMH-600B/QMH-350B/QMH-24"B/QMH-14"B, pressing the air-float switch on the tip of the carrier

grip causes air to make the main unit float, allowing you to move it smoothly above the surface plate.

NOTE

NOTE

Do not move the product by grabbing parts other than the base or carrier grip. Doing so can negatively

affect measurement accuracy and the product itself.

If using the air-float function:

• Measuring with the air-float function active can cause measurement errors.

• Clean the surface plate in advance.

• Use a surface plate of Class JIS1 or higher. If the surface plate is scratched or uneven, the specified

performance may not be achieved.

• Use a rigid surface plate. If the surface plate warps under the weight of the product, the product

may not float.

8

No. 99MAF029B

Page 21

1 Before Using This Product

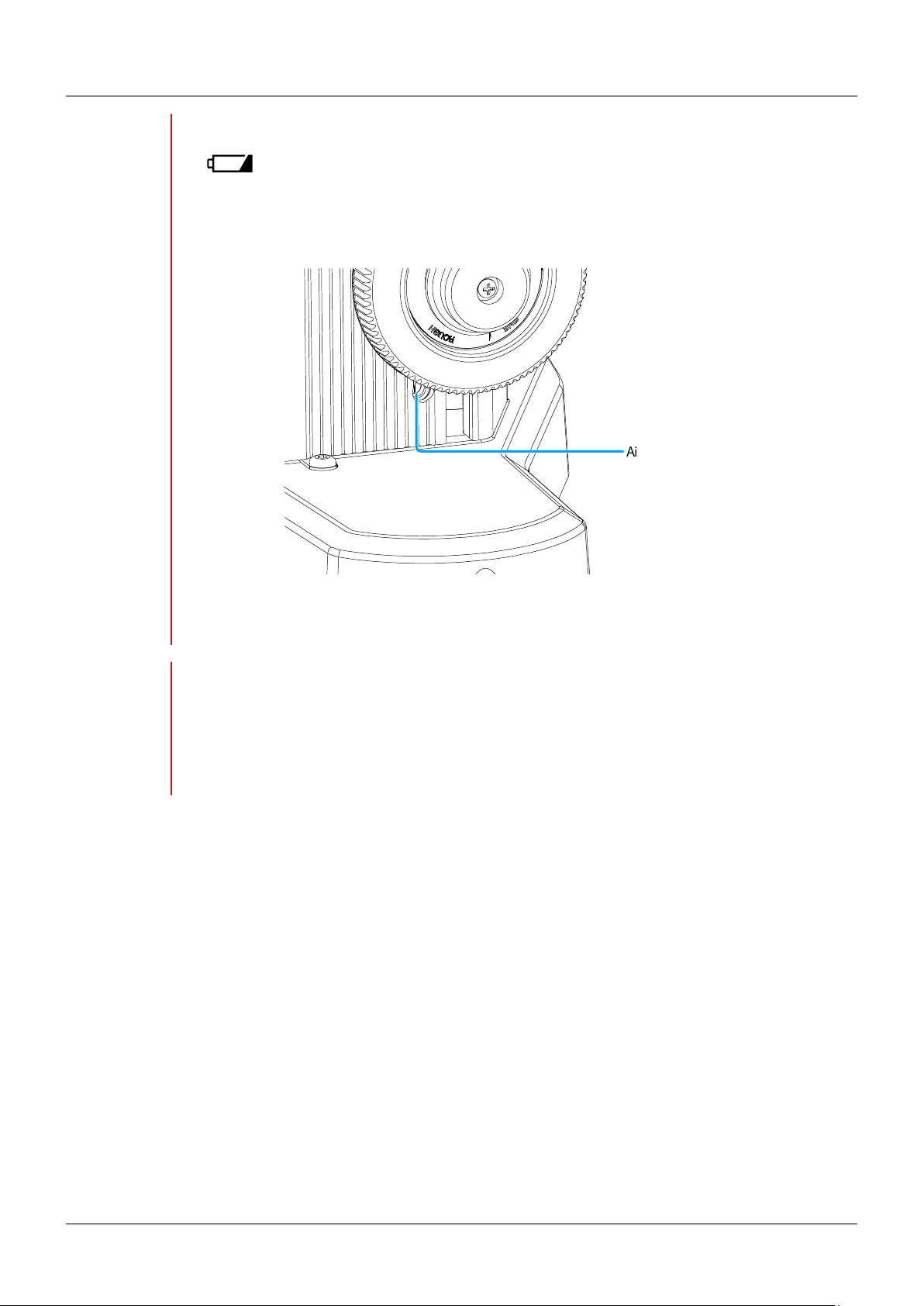

NOTE

If air-float does not work:

• If

with new ones.

• Use a flathead screwdriver to turn the air-float adjustment screw, and adjust the airflow. Turning the

screw right increases airflow, and turning it left reduces airflow. Adjust the amount relative to the

installation location.

is shown on the LCD screen, the air-float function cannot be used. Replace the batteries

Air-float

adjustment screw

NOTE

The airflow has been adjusted to provide optimal performance before shipment. We recommend

using the default settings as much as possible.

When adjusting the air-float flow:

• Due to the characteristics of the air-float mechanism, variations in airflow may cause the main unit

to vibrate. In this case, reduce the airflow.

• If you adjust the airflow, make sure that the friction between the surface plate and the main unit is

reduced before use.

9

No. 99MAF029B

Page 22

1 Before Using This Product

1.4

Complete the following setup before measuring.

yOrigin setup

yProbe diameter setup

Preparing Measurements

1.4.1 Origin Setup

Set the origin to use when measuring height. The dimensions measured from this origin will become

the height measurements. This product is compatible with both ABS and INC origins. Use one or the

other based on the application.

yABS origin

This method uses a user-defined value as the origin. When measuring the height from the surface

plate, set the surface plate as the origin point with a value of 0 mm.

Example: The surface plate is set as the origin at 0 mm.

Obtain the

measurement relative

to the surface plate

Surface plate

To use a datum other than the surface plate, assign that value as the origin point.

Example: Surface a1 is set as the origin at 50 mm.

Obtain the measurement relative to a1

Tips

a1

50 mm

For details about setting the ABS origin, "Setting the ABS origin" (page 11)

70 mm

10

No. 99MAF029B

Page 23

1 Before Using This Product

yINC origin

This method uses an arbitrary point on the workpiece as the origin. The specified point acts as the

datum for the measurements and is assigned a value of 0 mm.

Example: Surface a1 is set as the origin (normally 0 mm).

Obtain the measurement relative to a1

a1

Tips

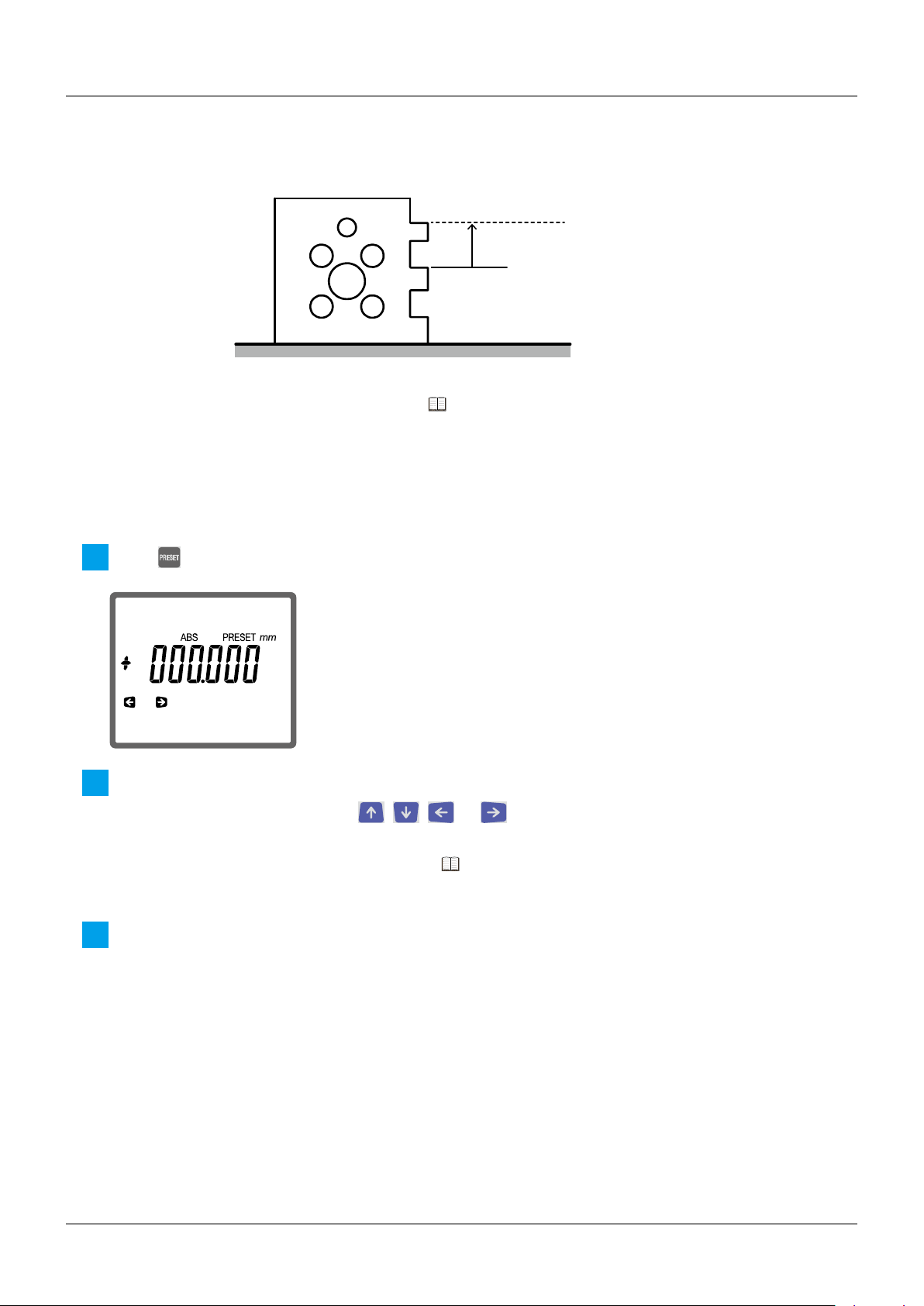

Setting the ABS origin

Setting the surface plate as the origin

z

Press .

1

Confirm that [+000.000] is displayed on the LCD screen.

2

If a different value is displayed, use , , , or to change the value to [+000.000].

For details about setting the INC origin, "Setting the INC origin" (page 13)

Tips

Slowly bring the probe into contact with the surface plate until a beep sound is made.

3

»The origin setup is complete.

For details about configuring the settings, "Setting a point other than the surface plate as the

origin" (page 12)

11

No. 99MAF029B

Page 24

1 Before Using This Product

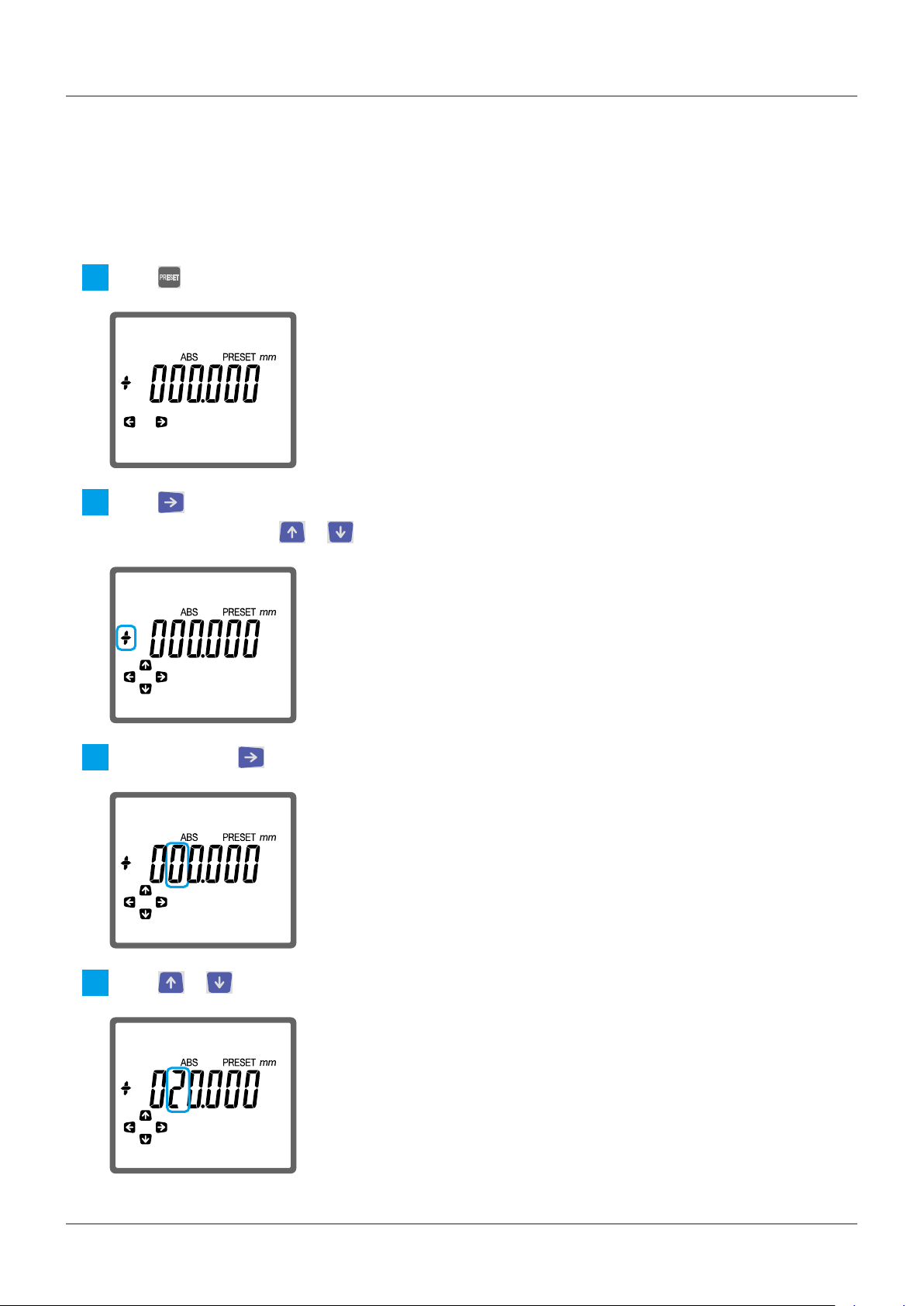

Setting a point other than the surface plate as the origin

z

As an example, the procedure for setting the origin point to [+25.000 mm] using a 25 mm gauge block

is explained below.

Tips

Press .

1

Press to make [+] flash.

2

If [–] is displayed, press or to change it to [+].

You can perform the settings using the dial test indicator or the dial indicator instead of the probe.

Repeatedly press until the value in the 10s place flashes.

3

Press or to display [2].

4

12

No. 99MAF029B

Page 25

1 Before Using This Product

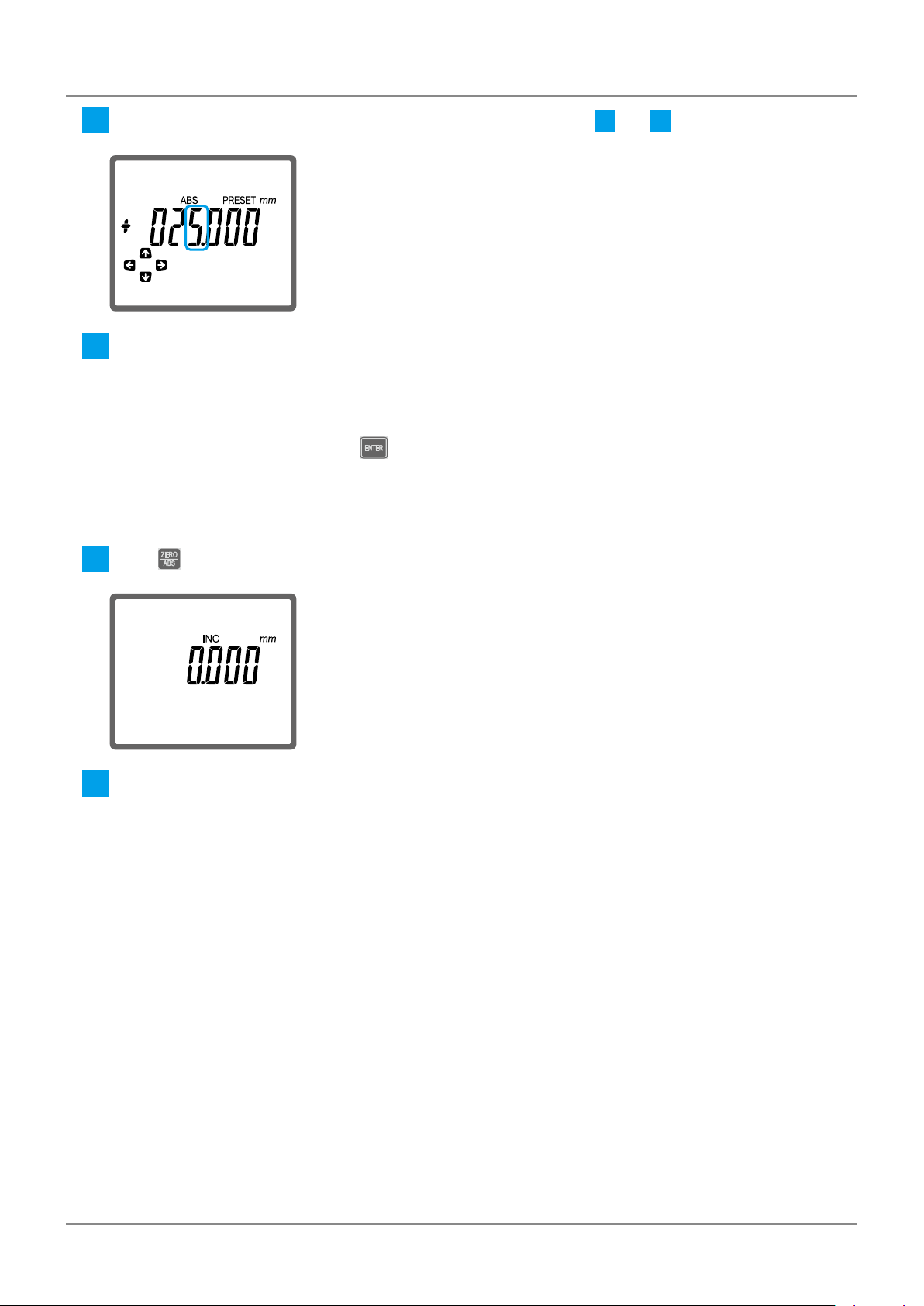

Display [5] in ones place using the same procedure described in steps

5

Slowly bring the probe into contact with the 25 mm gauge block until a beep sound is made.

6

»The origin setup is complete.

Tips

Setting the INC origin

Press .

1

For measurements using a dial test indicator or dial indicator, bring the stylus into contact with the

gauge block, and then press to finish the setup.

3

and 4.

Slowly bring the probe into contact with the desired origin point until a beep sound is made.

2

»The origin setup is complete.

13

No. 99MAF029B

Page 26

1 Before Using This Product

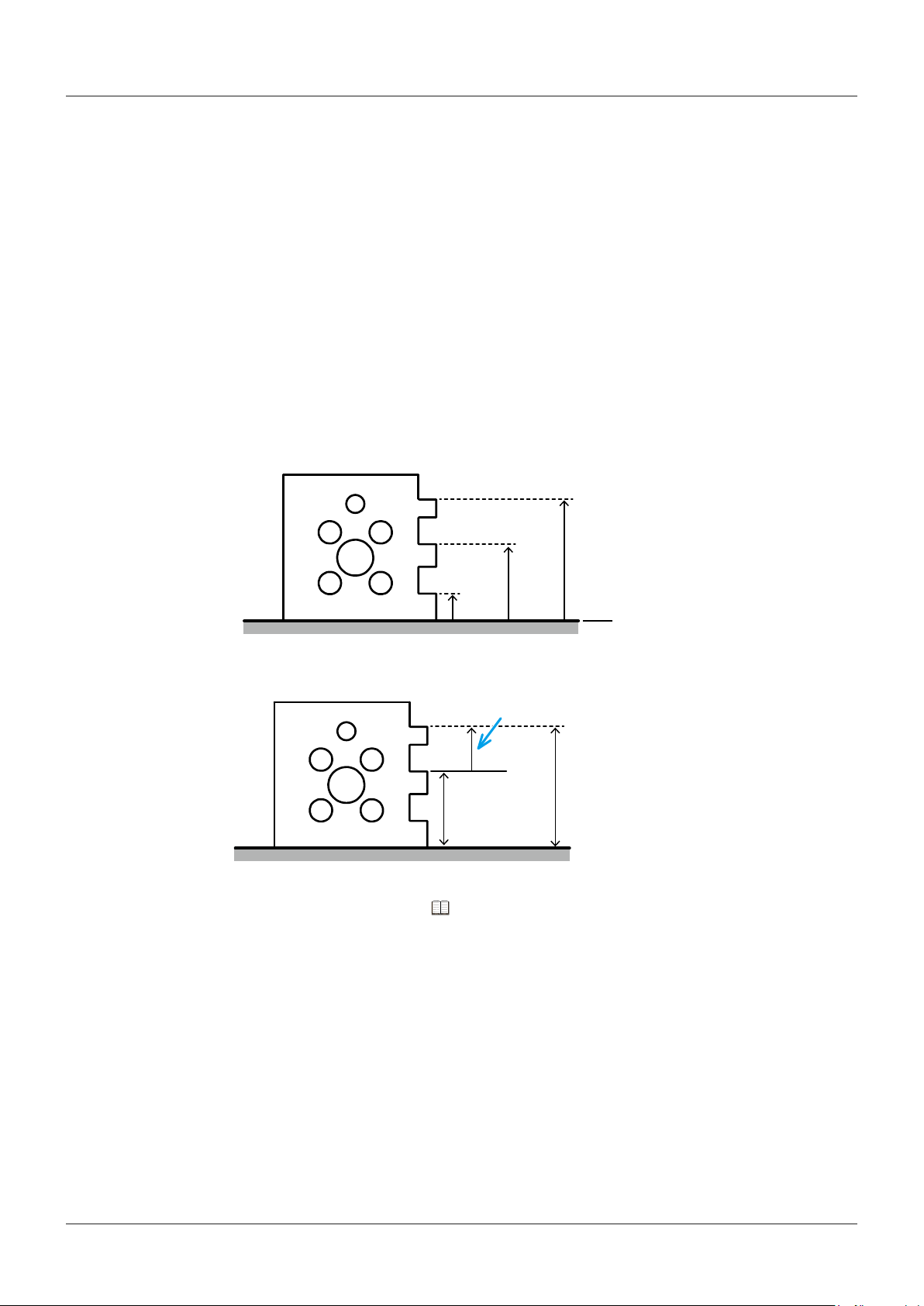

1.4.2 Setting the Probe Diameter

The height is calculated using the distance moved by the bottom surface of the sphere attached to the

tip of the probe. (See the left figure below.)

However, when measuring by making contact with the top surface of the sphere, the height will be

measured by adding the diameter of the sphere to the distance moved by the bottom surface of the

sphere. (See the right figure below.)

Top surface measurement

a1

Bottom surface measurement

a1

Surface a1 height = Distance moved by the bottom

surface of the sphere

The diameter of the sphere must be set in advance. The following procedure explains how to measure

the diameter of the sphere using the provided ball diameter calibration block. This procedure is

necessary if you are using the product for the first time or if you are replacing the probe.

Tips

Press .

1

»Characters and icons will be displayed in the bottom row of the LCD screen.

Press to select (probe settings).

2

Press .

3

»

Slowly bring the probe into contact with the following position on the ball diameter calibration block until

4

If using a gauge block, use one with a height of 20 mm or more.

will be displayed on the upper left of the LCD screen.

Origin

Surface a1 height = Distance moved by the bottom

surface of the sphere + diameter of the sphere

Origin

a beep sound is made.

»

will be displayed on the upper left of the LCD screen.

14

No. 99MAF029B

Page 27

1 Before Using This Product

Slowly bring the probe into contact with the following position on the ball diameter calibration block until

5

a beep sound is made.

Press .

6

»The probe diameter setting is complete.

NOTE

• The actual dimensions of the sphere diameter and the measured value may not match.

• When measuring, calculates the diameter of the sphere and displays the result. The moment the

probe is brought into contact with the workpiece, a beep will sound, and the displayed value may

appear to jump, but this is not a malfunction.

15

No. 99MAF029B

Page 28

1 Before Using This Product

16

No. 99MAF029B

Page 29

2 Basic Measuring Methods

2

Using the following workpiece as an example, the height, width, inner diameter, outer diameter, and

plane displacement measuring methods will be explained. Before measuring, prepare by setting the

origin, etc.

Tips

Basic Measuring Methods

For details about preparing measurements, "1.4 Preparing Measurements" (page 10)

2.1

There are 2 types of height measurement: One where the probe is brought into contact with the top

surface of the workpiece, and one where the probe is brought into contact with the bottom surface of

the workpiece. As an example, the procedure for measuring top surface height A (85 mm) and bottom

surface height B (115 mm), shown below, using the surface plate as the ABS origin is explained.

Tips

Press and hold to change to the ABS origin setting.

1

»[ABS] will be displayed on the LCD screen.

Measuring the Height

Top surface measurement

a1

A (85 mm)

For details about ABS origin, "1.4.1 Origin Setup" (page 10)

ABS origin ABS origin

Bottom surface measurement

a1

B (115 mm)

17

No. 99MAF029B

Page 30

2 Basic Measuring Methods

a1

Bring the probe into contact with surface a1 until a beep sound is made.

2

Maintain contact between the probe and the surface a1.

Top surface measurement Bottom surface measurement

a1

»When the measurement is complete, [H] and the measured value are displayed on the LCD screen.

Tips

Confirm the measurement.

3

Top surface measurement Bottom surface measurement

If the product is connected to any external devices, the measurement results will be automatically

output. For details, "3.9 Outputting Measurement Results to an External Device" (page 47)

18

No. 99MAF029B

Page 31

2 Basic Measuring Methods

a2

2.2

Measure the steps and the width of the grooves. As an example, the procedure for measuring the step

of A (10 mm) and the groove width of B (30 mm), shown below, using a1 as the INC origin is explained.

Tips

Press to change to the INC origin setting.

1

»[INC] will be displayed on the LCD screen.

Bring the probe into contact with surface a1 until a beep sound is made.

2

Measuring the Width

Step measurement

A (10 mm)

For details about INC origin, "1.4.1 Origin Setup" (page 10)

a2

a1

INC origin

Groove width measurement

B (30 mm)

a2

a1

INC origin

Step measurement Groove width measurement

a1

»[0.000] will be displayed on the LCD screen.

Bring the probe into contact with surface a2 until a beep sound is made.

3

Maintain contact between the probe and the surface a2.

Step measurement Groove width measurement

a2

a1

»When the measurement is complete, [H] and the measured value are displayed on the LCD screen.

19

No. 99MAF029B

Page 32

2 Basic Measuring Methods

Tips

Confirm the measurement.

4

Step measurement Groove width measurement

If the product is connected to any external devices, the measurement results will be automatically

output. For details, "3.9 Outputting Measurement Results to an External Device" (page 47)

20

No. 99MAF029B

Page 33

2 Basic Measuring Methods

2.3

Measure the diameter (inner diameter) of a hole. For the inner diameter measurement, obtain the

lowest and highest points of the hole to measure the distance. As an example, the procedure for

measuring the inner diameter of A (40 mm), shown below, is explained.

Tips

Press .

1

Measuring the Inner Diameter

Highest point

A (40 mm)

Lowest point

Depending on the method set for terminating the scanning measurement, the operating procedures

vary slightly. First, confirm the method set for terminating the scanning measurement. For details

about changing the settings, "3.4 Setting the Terminating Method for Scanning Measurements"

(page 43)

ABS origin

»

will be displayed on the upper left of the LCD screen.

Obtain the lowest point of the hole.

2

If the scanning measurement termination method is set to [Auto] (automatic termination)

Face the probe towards the left or right

1

of the center bottom surface of the hole,

and slowly bring it into contact with the

surface until a beep sound is made.

Maintain contact between the probe and

the surface.

»[0.000] will be displayed on the LCD

screen.

NOTE

2

Bring the probe into contact

within 0.5 mm of the lowest point.

Measuring with a wider range may

increase measurement errors.

Secure the probe up/down wheel with

your hand or the clamp screw in order to

prevent it from moving.

21

No. 99MAF029B

Page 34

2 Basic Measuring Methods

Move the probe left or right so that it

3

passes the center of the bottom surface

of the hole. Perform this action until a

beep sound is made.

»The measurement of the

lowest point is complete, and

will be displayed on the

upper left of the LCD screen.

If you have tightened the clamp screw,

4

loosen it.

If the scanning measurement termination method is set to [ENTER] (manual termination)

Face the probe towards the center of the

1

bottom surface of the hole, and slowly

bring it into contact with the surface until

a beep sound is made.

Maintain contact between the probe and

the surface.

»[0.000] will be displayed on the

LCD screen.

Secure the probe up/down wheel with

2

your hand or the clamp screw in order to

prevent it from moving.

Repeatedly move the probe left and

3

right.

»The value displayed on the

LCD screen will change based

on the vertical movement of

the probe.

When the displayed value stops

4

changing, press .

»The measurement of the

lowest point is complete, and

will be displayed on the

upper left of the LCD screen.

22

No. 99MAF029B

Page 35

2 Basic Measuring Methods

If you have tightened the clamp screw,

5

loosen it.

Obtain the highest point of the hole.

3

If the scanning measurement termination method is set to [Auto] (automatic termination)

Face the probe towards the left or right

1

of the center top surface of the hole,

and slowly bring it into contact with the

surface until a beep sound is made.

Maintain contact between the probe and

the surface.

»[0.000] will be displayed on the LCD

screen.

NOTE

2

3

4

If the scanning measurement termination method is set to [ENTER] (manual termination)

1

Bring the probe into contact within

0.5 mm of the highest point.

Measuring with a wider range may

increase measurement errors.

Secure the probe up/down wheel with

your hand or the clamp screw in order to

prevent it from moving.

Move the probe left or right so that it

passes the center of the top surface of

the hole. Perform this action until a beep

sound is made.

»The measurement of the

highest point is complete.

If you have tightened the clamp screw,

loosen it.

Face the probe towards the center of the

top surface of the hole, and slowly bring

it into contact with the surface until a

beep sound is made.

Maintain contact between the probe and

the surface.

Secure the probe up/down wheel with

2

your hand or the clamp screw in order to

prevent it from moving.

23

No. 99MAF029B

Page 36

2 Basic Measuring Methods

Repeatedly move the probe left and

3

right.

»The value displayed on the

LCD screen will change based

on the vertical movement of

the probe.

When the displayed value stops

4

changing, press .

»The measurement of the

highest point is complete.

If you have tightened the clamp screw,

5

loosen it.

Confirm the measurement.

4

Tips

To continue measuring press ; to finish measuring press .

5

If the product is connected to any external devices, the measurement results will be automatically

output. For details, "3.9 Outputting Measurement Results to an External Device" (page 47)

24

No. 99MAF029B

Page 37

2 Basic Measuring Methods

2.4

Measure the diameter (outer diameter) of a cylinder. For the outer diameter measurement, obtain the

lowest and highest point of the cylinder to measure the distance. As an example, the procedure for

measuring the outer diameter of A (20 mm), shown below, is explained.

Tips

Press .

1

Measuring the Outer Diameter

A (20 mm)

Depending on the method set for terminating the scanning measurement, the operating procedures

vary slightly. First, confirm the method set for terminating the scanning measurement. For details

about changing the settings, "3.4 Setting the Terminating Method for Scanning Measurements"

(page 43)

Highest point

Lowest point

ABS origin

» will be displayed on the upper left of the LCD screen.

Obtain the lowest point of the cylinder.

2

If the scanning measurement termination method is set to [Auto] (automatic termination)

Face the probe towards the left or right of

1

the center bottom surface of the cylinder,

and slowly bring it into contact with the

surface until a beep sound is made.

Maintain contact between the probe and

the surface.

»[0.000] will be displayed on the LCD

screen.

NOTE

2

Bring the probe into contact

within 0.5 mm of the lowest point.

Measuring with a wider range may

increase measurement errors.

Secure the probe up/down wheel with

your hand or the clamp screw in order to

prevent it from moving.

25

No. 99MAF029B

Page 38

2 Basic Measuring Methods

Move the probe left or right so that it

3

passes the center of the bottom surface

of the cylinder. Perform this action until a

beep sound is made.

»The measurement of the

lowest point is complete, and

will be displayed on the

upper left of the LCD screen.

If you have tightened the clamp screw,

4

loosen it.

If the scanning measurement termination method is set to [ENTER] (manual termination)

Face the probe towards the center of the

1

bottom surface of the cylinder, and slowly

bring it into contact with the surface until

a beep sound is made.

Maintain contact between the probe and

the surface.

»[0.000] will be displayed on the LCD

screen.

Secure the probe up/down wheel with

2

your hand or the clamp screw in order to

prevent it from moving.

Repeatedly move the probe left and

3

right.

»The value displayed on the

LCD screen will change based

on the vertical movement of

the probe.

When the displayed value stops

4

changing, press .

»The measurement of the

lowest point is complete, and

will be displayed on the

upper left of the LCD screen.

26

No. 99MAF029B

Page 39

2 Basic Measuring Methods

If you have tightened the clamp screw,

5

loosen it.

Obtain the highest point of the cylinder.

3

If the scanning measurement termination method is set to [Auto] (automatic termination)

Face the probe towards the left or right

1

of the center top surface of the cylinder,

and slowly bring it into contact with the

surface until a beep sound is made.

Maintain contact between the probe and

the surface.

»[0.000] will be displayed on the LCD

screen.

NOTE

2

3

4

If the scanning measurement termination method is set to [ENTER] (manual termination)

1

Bring the probe into contact within

0.5 mm of the highest point.

Measuring with a wider range may

increase measurement errors.

Secure the probe up/down wheel with

your hand or the clamp screw in order to

prevent it from moving.

Move the probe left or right so that it

passes the center of the top surface of

the cylinder. Perform this action until a

beep sound is made.

»The measurement of the

highest point is complete.

If you have tightened the clamp screw,

loosen it.

Face the probe towards the center of the

top surface of the cylinder, and slowly

bring it into contact with the surface until

a beep sound is made.

Maintain contact between the probe and

the surface.

Secure the probe up/down wheel with

2

your hand or the clamp screw in order to

prevent it from moving.

27

No. 99MAF029B

Page 40

2 Basic Measuring Methods

Repeatedly move the probe left and

3

right.

»The value displayed on the

LCD screen will change based

on the vertical movement of

the probe.

When the displayed value stops

4

changing, press .

»The measurement of the

highest point is complete.

If you have tightened the clamp screw,

5

loosen it.

Confirm the measurement.

4

Tips

To continue measuring press ; to finish measuring press .

5

If the product is connected to any external devices, the measurement results will be automatically

output. For details, "3.9 Outputting Measurement Results to an External Device" (page 47)

28

No. 99MAF029B

Page 41

2 Basic Measuring Methods

2.5

Measuring the Plane Displacement (Plane Scanning Measurement)

Moving the probe while maintaining contact with the surface of the workpiece obtains multiple

measurements. Based on the acquired data, the maximum, minimum, and displacement values

(maximum – minimum = displacement) can be measured.

As an example, the procedure for measuring the displacement of a1 (maximum value), a2 (minimum

value), and A (1 mm), shown below, is explained.

a1

a2

ABS origin

NOTE

A (1 mm)

Measure within a range of about 1 mm from the starting point. Measuring with a wider range may

increase measurement errors.

Press .

1

»

will be displayed on the upper left of the LCD screen.

Begin measuring.

2

Slowly bring the probe into contact with

1

the measuring surface until a beep

sound is made.

Maintain contact between the probe and

the surface.

»[0.000] will be displayed on the

LCD screen.

Secure the probe up/down wheel with

2

your hand or the clamp screw in order to

prevent it from moving.

1 mm

29

No. 99MAF029B

Page 42

2 Basic Measuring Methods

Move the probe while maintaining

3

contact with the surface of the workpiece.

»The value displayed on the

LCD screen will change based

on the unevenness of the

workpiece.

When the displayed value stops

4

changing, press .

»The measurement is complete.

Tips

Check the measurement result.

3

1

Tips

2

If the product is connected

to any external devices, the

measurement results will be

automatically output. For details,

"3.9 Outputting Measurement

Results to an External Device"

(page 47)

Press or .

»With each key press, the value

displayed on the LCD screen will

change among displacement (W),

minimum (ZS), maximum (ZL).

The difference between the

median displacement value and

the previous measurement will be

displayed in the bottom row of the

LCD screen.

If you have tightened the clamp screw,

loosen it.

To continue measuring press ; to finish measuring press .

4

30

No. 99MAF029B

Page 43

3 Specific Usage Applications

3

3.1

Specific Usage Applications

Calculating the Difference Between 2 Measurements

There are multiple methods for determining the measurement difference. Use the method that matches

your application.

yDifference with the previous measurement

The difference between the current and immediately prior measurements will automatically be

displayed in the bottom row of the LCD screen. For example, if the previous measurement was 25

mm and the current measurement is 45 mm, [20.000] will be displayed.

The difference with the previous measurement can be checked simply by reading the value

displayed in the bottom row.

Tips

yDifference with a user-defined point

A user-defined point can be set as the comparison point for measurements. For example, set the

surface plate as the origin, and then while continually making measurements, the distance relative

to the surface plate will be displayed each time in the bottom row of the LCD screen.

Tips

yDifference between two measurements stored in memory

The two measurements are stored in the product's internal memory, and the difference between

the two values is calculated. This memory storage method is useful for when you cannot calculate

the measurement difference using the 2 previously described methods, such as obtaining a

measurement difference with a value obtained 2 measurements ago.

Tips

For details, "3.1.1 Determining the Difference Between the Most Recently Measured Value"

(page 32)

For details, "3.1.2 Continuously Measuring the Distance from One Specific Point to Multiple

Other Points" (page 33)

For details, "3.1.3 Calculating the Difference Between Values Stored in the Memory" (page

35)

31

No. 99MAF029B

Page 44

3 Specific Usage Applications

3.1.1 Determining the Difference Between the Most Recently Measured Value

Check the difference between the current and previous measurement by observing the value in

the bottom row of the LCD screen. As an example, with the surface plate set as the ABS origin, the

heights of a1, a2, and a3 are measured in that order, and the difference for each measurement can be

checked.

a3

Tips

Press and hold to change to the ABS origin setting.

1

»[ABS] will be displayed on the LCD screen.

Measure the height of a1.

2

• For details about ABS origin, "1.4.1 Origin Setup" (page 10)

• For details about measuring height,

• If an inner diameter, outer diameter, or plane scanning measurement is made, the median

measurement will be used for comparisons. For example, if the inner diameter is measured

sequentially for circles s1 and s2, the difference displayed in the bottom row of the LCD screen will

be calculated using the median values (centers) of circle s1 and s2.

"2.1 Measuring the Height" (page 17)

a1

25 mm

a2

45 mm

67 mm

ABS origin

Measure the height of a2.

3

»The difference with a1 is displayed in the bottom row.

32

No. 99MAF029B

Page 45

3 Specific Usage Applications

Measure the height of a3.

4

»The difference with a2 is displayed in the bottom row.

3.1.2 Continuously Measuring the Distance from One Specific Point to Multiple Other Points

Set an arbitrary point as the origin, and proceed to measure the distance continuously from that point.

As an example, the procedure for continuously obtaining the distance between a1 (center height of

circle s1) and a2 (center height of circle s2) shown below with the surface plate set as the origin is

explained.

NOTE

Set the origin point.

1

1

Tips

The following values can be set as the origin point.

• Height measurement

• Median value of an inner or outer diameter measurement

• Median, minimum, or maximum value of a plane scanning measurement

Slowly bring the probe into contact with the surface plate until a beep sound is made.

Maintain contact with the probe.

• Perform the same operation even if a point other than the height of the surface plate is set as the

origin point. (Bring the probe into contact with the point to set as the origin.)

• To set an inner diameter, outer diameter, or plane scanning measurement as the origin point, make

the appropriate measurement. For details,

"2.4 Measuring the Outer Diameter" (page 25), "2.5 Measuring the Plane Displacement (Plane

Scanning Measurement)" (page 29)

s2

s1

a2

a1

10 mm

"2.3 Measuring the Inner Diameter" (page 21),

30 mm

ABS origin

33

No. 99MAF029B

Page 46

3 Specific Usage Applications

With the measurement displayed, press and hold until a beep sound is made.

2

»The surface plate is set as the origin.

Tips

Measure the inner diameter of s1.

2

»The distance between the surface plate and a1 is displayed in the bottom row.

Tips

• If you measured an inner or outer diameter in step 1, the median of that diameter will be set as the

origin point. If you made a plane scanning measurement, display the value that you want to set as

the origin point (median, minimum, maximum), and then press and hold .

• If you reversed the counting direction, follow the procedure in

to reset the origin.

• If following the procedure in

hold until a beep sound is made, and then perform the procedure.

• Removing the batteries or the AC adapter (optional accessory) cable will erase the origin setting.

• For details about measuring inner diameters, "2.3 Measuring the Inner Diameter" (page 21)

• If inner diameter, outer diameter, or plane scanning measurements are made, the median

measurement will be set as the target value for determining distance.

"1.4.1 Origin Setup" (page 10) to reset the origin, first press and

"1.4.1 Origin Setup" (page 10)

Measure the inner diameter of s2.

3

»The distance between the surface plate and a2 is displayed in the bottom row.

Press and hold until a beep sound is made.

4

»The origin setting is canceled, and the product returns to normal measuring mode.

34

No. 99MAF029B

Page 47

3 Specific Usage Applications

3.1.3 Calculating the Difference Between Values Stored in the Memory

Store 2 measurements in the internal memory of the product, and then calculate the difference

between them. Any measurements that are stored in the memory and are no longer needed can be

erased as needed.

Tips

Calculating the difference between 2 values stored in the memory

As an example, the procedure for calculating the distance between a1 and a3 (42 mm), with the

surface plate set as the ABS origin and heights measured at a1, a2, and a3, is explained.

Tips

Press and hold to change to the ABS origin setting.

1

Removing the batteries or the AC adapter (optional accessory) cable will erase any values stored in

the memory.

a1

42 mm

a3

25 mm

For details about ABS origin, "1.4.1 Origin Setup" (page 10)

a2

45 mm

67 mm

ABS origin

»[ABS] will be displayed on the LCD screen.

Measure the height of a1.

2

Tips

With the measurement for a1 displayed, press and hold until a beep sound is made.

3

»The a1 measurement is stored in memory, and [M1] (memory 1), which shows the location of storage in the

Measure the height of a2.

4

Measure the height of a3.

5

For details about measuring height, "2.1 Measuring the Height" (page 17)

memory, is displayed on the bottom left of the LCD screen.

35

No. 99MAF029B

Page 48

3 Specific Usage Applications

With the measurement for a3 displayed, press and hold until a beep sound is made.

6

»Measurement a3 is stored in the memory, and [M2] (memory 2), which indicates the location of storage in the

memory, is displayed on the bottom left of the LCD screen.

Press .

7

Proceed to the next step, and determine the difference between the two values stored in memory.

Press 2 times.

8

»Characters will be displayed in the bottom row of the LCD screen.

Press to select [M1/-M2] (memory calculation).

9

»The difference between [M1] and [M2] will be displayed.

Tips

Press 2 times.

10

Erasing the measurement from memory

Press 2 times.

1

If you want to check the proportional difference between 2 measurements, press . The value of [M1]

divided by [M2] will be displayed.

»Characters will be displayed in the bottom row of the LCD screen.

Press to select [M.CLR] (memory clear).

2

»[M1] and [M2] will be displayed on the lower left of the LCD screen.

Tips

If measurements are not stored in memory, [M1], [M2], and [M.CLR] will not be displayed.

36

No. 99MAF029B

Page 49

3 Specific Usage Applications

Erase the measurements stored in the memory.

3

Erasing both [M1] and [M2] from memory

Press .

1

Erasing only either [M1] or [M2] from memory

Press or to select the target for deletion, and then press .

1

Press .

4

37

No. 99MAF029B

Page 50

3 Specific Usage Applications

3.2

By setting the upper and lower tolerance limits in advance, the acceptability judgment can be

automatically performed. The acceptability judgment will be displayed on the LED and the LCD screen,

meaning it can be easily determined whether the value falls within the tolerance range.

Operation panel

Red: Upper tolerance limit exceeded.

Orange: Lower tolerance limit exceeded.

Green: Within the tolerance range.

To perform the acceptability judgment automatically, register the upper and lower tolerance limits, and

then enable the acceptability judgment function.

Tips

Judging the Tolerance

LCD screen

You can change the length of time that the LED is lit. For details about changing the settings, "3.8

Setting the LED Lighting Time" (page 46)

[+NG]: Upper tolerance limit exceeded.

[-NG]: Lower tolerance limit exceeded.

[GO]: Within the tolerance range.

3.2.1 Setting the Upper and Lower Limits

For example, the procedure for setting the upper [+0.010 mm] and lower [–0.005 mm] tolerance limits

is explained below.

Tips

Press .

1

»Characters and icons will be displayed in the bottom row of the LCD screen.

Press to select [TOL.] (tolerance setting).

2

»[U] and the current upper limit will be displayed on the LCD screen.

Press to make [+] flash.

3

If [–] is displayed, press or to change it to [+].

• The set values are retained in memory even if the power is turned off.

• Be sure to set the upper limit value to a numeric value larger than the lower limit value. If a smaller

value is set, there will be an error.

38

No. 99MAF029B

Page 51

3 Specific Usage Applications

Repeatedly press until the 2nd value from the right flashes.

4

Press or to display [1], and then press .

5

»[L] and the current lower limit will be displayed on the LCD screen.

Press to make [–] flash.

6

If [+] is displayed, press or to change the display to [–].

Display [5] in the thousandths place using the same procedure described in steps

7

press

»Setup is complete.

.

3.2.2 Enabling/Disabling the Judgment Function

Press .

1

»Characters and icons will be displayed in the bottom row of the LCD screen.

Press to select [TOL.] (tolerance setting).

2

»[U] and the current upper limit will be displayed on the LCD screen.

Press .

3

4

and 5, and

Press or , to select [toL.on] (enabled) or [toL.oFF] (disabled), and then press .

4

Press .

5

39

No. 99MAF029B

Page 52

3 Specific Usage Applications

3.3

For example, if you want to make measurements in the following order: height at 4 points, inner

diameter at 4 points, and outer diameter at 2 points. When performing multiple measurements in a

set order, it is beneficial to register the procedure. Because the measurements are automatically

performed following the order of the registered procedure, the overall operation is simplified.

The following measurement functions can be registered.

yInner diameter measurement

yOuter diameter measurement

yPlane scanning measurement

yBottom surface measurement

yTop surface measurement

Tips

Simplifying Measurement Procedures

For details about each measurement function, "2 Basic Measuring Methods" (page 17)

3.3.1 Registering a Measurement Procedure

Select the measurement functions, such as height and inner diameter, in the order they will be used,

and register them. Up to 10 steps can be registered.

Press 2 times.

1

»Characters will be displayed in the bottom row of the LCD screen.

Press to select [ASSIST] (assist function).

2

Press or to select [ENTER STEP], and then press .

3

40

No. 99MAF029B

Page 53

3 Specific Usage Applications

Register a measurement procedure.

4

Refer to the following table. Press the key for the first measurement to be performed.

1

Measurement

function

Inner diameter

measurement

Outer diameter

measurement

Plane scanning

measurement

Bottom surface

measurement

Top surface

measurement

For example, to register an top surface measurement, press . In this case, [5] will be displayed for the

measurement function number.

Setting key

Measurement

function number

1

2

3

4

5

»Registering the first measurement is complete, and the flashing cursor moves to the right.

Register the subsequent steps using the same method.

2

»Setting the 10th step completes the registration. The measurement function registered to the 1st step will

then automatically run.

Tips

Proceed to step 4 in "3.3.2 Measuring Using a Registered Measurement Procedure" (page 42) to

5

make the measurements.

To register 9 or fewer steps, press to complete the registration process. The measurement

function registered to the 1st step will then automatically run.

Press to terminate the operation.

41

No. 99MAF029B

Page 54

3 Specific Usage Applications

3.3.2 Measuring Using a Registered Measurement Procedure

Press 2 times.

1

»Characters will be displayed in the bottom row of the LCD screen.

Press to select [ASSIST] (assist function).

2

Press or to select [RUN], and then press .

3

»The first registered measurement will be automatically performed.

Make the measurements.

4

Make the first measurement.

1

»The first registered measurement will finish, and then the second registered measurement will be

performed.

Tips

2

• For inner diameter, outer diameter, or plane scanning measurements, press to proceed to the

next registered measurement.

• For details about making measurements,

Make the subsequent measurements.

»When the 10th measurement is made, all measurements will be finished.

"2 Basic Measuring Methods" (page 17)

To continue measuring press ; to finish measuring press .

5

42

No. 99MAF029B

Page 55

3 Specific Usage Applications

3.4

Setting the Terminating Method for Scanning Measurements

A scanning measurement obtains multiple measurements by moving the probe while maintaining

contact with the workpiece and calculates values such as the maximum and minimum values from

among the measurements. This section explains how to specify the termination method for scanning

measurements. This setting is applicable to inner and outer diameter measurements.

Tips

Press .

1

»Characters and icons will be displayed in the bottom row of the LCD screen.

Press to select (probe settings).

2

Press or to display the following screen.

3

[Auto] (automatic termination) is the default setting.

Press or to select the setting, and then press .

4

Setting Details

[ENTER]

[Auto] The scanning measurement automatically terminates when the probe elevates

»Setup is complete.

NOTE

If [Auto] (automatic termination) is set, ensure that the probe is set to pass through the lowest and

highest points of the hole or cylinder. An accurate measurement result cannot be obtained if the probe

does not pass through the lowest and highest points.

Press

about 0.5 mm from the lowest point or lowers about 0.5 mm from the highest

point of the hole or cylinder. When the measurement is complete, a beep sound is

made.

to manually terminate the scanning measurement.

43

No. 99MAF029B

Page 56

3 Specific Usage Applications

3.5

You can hold a measurement on the display. Even if the probe moves away from the workpiece, the

displayed value will not change until you release the hold function. This function is applicable to height

and width measurements.

Measure the height or width.

1

»[H] and the measurement will be displayed on the LCD screen.

Tips

Press while [H] and the current measurement are displayed.

2

»The displayed value is held.

Tips

Holding the Displayed Measurement Results

For details about measuring height and width, "2.1 Measuring the Height" (page 17) and

"2.2 Measuring the Width" (page 19)

• Press again to release the display.

• Even if you output measurement results to this product from externally connected devices, the

display will not be released.

3.6

You can change the smallest reading (resolution) that the measuring instrument will display on the

LCD screen.

Tips

Press .

1

»Characters and icons will be displayed in the bottom row of the LCD screen.

Press to select [RES.] (resolution setting).

2

Press or to select the setting, and then press .

3

Setting the Resolution for Measurements

The default setting is [0.001 mm] for models that support millimeters and [0.00005 in] for models that

support inches.

»Setup is complete.

44

No. 99MAF029B

Page 57

3 Specific Usage Applications

3.7

Setting the Time Until the Power Turns Off (AutoOff)

Auto-off is a function that automatically turns off the product if it is not used for a specified period of

time. This section explains how to set the length of time that must pass before the auto-off function is

activated.

Tips

Press 2 times.

1

»Characters will be displayed in the bottom row of the LCD screen.

Press to select [POWER SET] (power setting).

2

Press or to select the setting, and then press .

3

[2min] The power is turned off if there is no operation for 2 minutes.

[5min] The power is turned off if there is no operation for 5 minutes.

[oFF] Disables the auto-off function.

[2min] (2 minutes) is the default setting.

Setting Details

»Setup is complete.

45

No. 99MAF029B

Page 58

3 Specific Usage Applications

3.8

Sets the time that the LED lights for tolerance judgment. If the battery is quickly depleted, we

recommend changing the setting so that the LED is off.

Tips

Press 2 times.

1

»Characters will be displayed in the bottom row of the LCD screen.

Press to select [POWER SET] (power setting).

2

Press or to display [LEd].

3

Press or to select the setting, and then press .

4

[3 SEc] Lights for 3 seconds.

[ALL] Stays continuously lit.

[oFF] Turns off the light.

Setting the LED Lighting Time

[3 SEc] (3 seconds) is the default setting.

Setting Details

»Setup is complete.

46

No. 99MAF029B

Page 59

3 Specific Usage Applications

3.9

Outputting Measurement Results to an External Device

Depending on the application of the measurement results data can be output to the optional mini

printer or sent to the PC.

3.9.1 Outputting to a Mini Printer (Optional Accessory)

Connecting the optional Digimatic mini-processor (DP-1VR, etc.) to the Digimatic output connector of

this product will allow you to output measurement results. The measurement results will automatically

be output upon completion of measuring. However, you can also output data by pressing .

NOTE

Tips

You can output measurement results when they are displayed. There is no output during a scanning

measurement.

• You can also output measurement results by using optional external devices. For details, see the

accompanying manual for the Digimatic mini-processor.

• By default, the product is set to output the value displayed in the top row of the LCD screen. Use

the following procedure to change the setting to the bottom row.

Press .

1

»Characters and icons will be displayed in the bottom row of the LCD screen.

Press to select [OUTPUT] (output setting).

2

Press or to select the bottom row, and then press .

3

»Setup is complete.

• If the resolution for models that support inches is set to [0.00005 in], you can change which digits

in the measurement are output. By default, the lowest 6 digits are set to be output. For example, in

[22.12345 in], [2.12345 in] will be output. Use the following procedure to change the output to the

highest 6 digits.

Press .

1

»Characters and icons will be displayed in the bottom row of the LCD screen.

Press to select [OUTPUT] (output setting).

2

Press or .

3

Press or to select [88.8888] (the first 6 digits), and then press .

4

»Setup is complete.

47

No. 99MAF029B

Page 60

3 Specific Usage Applications

3.9.2 Outputting to a PC (Windows Only)

By connecting this product to your Windows PC using a micro USB cable, you can send measurement

results to the PC. Results can be output to commercially-available communication software.

Before sending the data, the communication driver must be installed on the PC. The system

requirements for the communication driver are provided below.

Items Operating environment

OS Windows 8/Windows 7/Windows Vista/Windows XP SP3

HDD capacity 500 KB or more

Display 800 x 600 resolution or higher, 256 colors or more

Other yCommunication software such as Hyper Terminal is required.

yWe recommend using the standard USB port on the main unit (the usage of

other USB ports are not officially supported).

yInternet access is required.

Tips

Installing the communication driver on your PC

Download the communication driver from our website.

1

http://www.mitutoyo.co.jp/global.html

Install the downloaded driver on the PC.

2

Sending can also be done using the optional USB input tool, U-WAVE, etc. For details, see the

accompanying manual for each product.

48

No. 99MAF029B

Page 61

3 Specific Usage Applications

Sending the measurement results to your PC

Connect the product to your PC using a commercially available micro USB cable.

1

Tips

Start up communication software such as Hyper Terminal on the PC.

2

Tips

Make a measurement.

3

»The measurement results will be automatically sent to the PC.

Tips

When the cable is plugged in, the product is in the USB communication state, which depletes the

battery. Remove the cable when not in use.

The communication setups for the communication software should be subject to "5.3.1

Communication Specification" (page 59).

• For details about measurement methods, "2 Basic Measuring Methods" (page 17)

• You can also send the measurement results by pressing

.

49

No. 99MAF029B

Page 62

3 Specific Usage Applications

50

No. 99MAF029B

Page 63

4 Troubleshooting

4

If a problem occurs while using this product, please try one of the solutions provided below. If the

solution does not work, contact our service department via your dealer for repair.

4.1

Based on the problem, determine the cause and the solution.

The power does not turn

on when

The battery quickly

depletes.

Troubleshooting

If the Following Problem Occurs

Problem Cause Solution

is pressed.

yThe batteries are not

inserted correctly.

yThe AC adapter

(optional accessory) is

not properly connected.

The LED is set for

continuous use.

yReinsert the batteries.

yReconnect the AC adapter (optional

accessory).