Page 1

Distribution Pipe

䋩

MSDD-50TR-E

* model change from MSDD-50SR-E

Photo

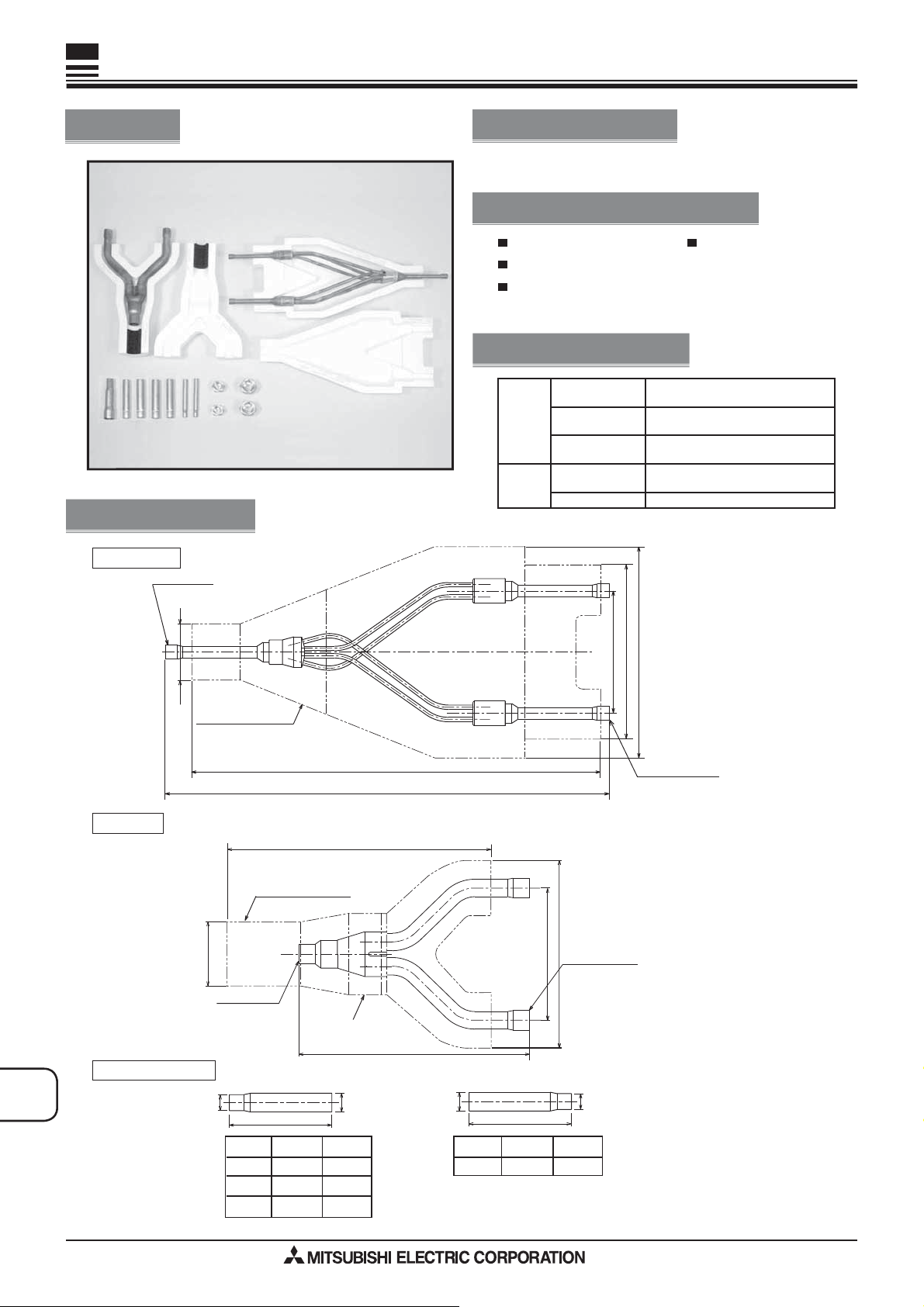

Dimensions

㪣㪠㪨㪬㪠㪛㩷㪧㪠㪧㪜

㱢㪐㪅㪌㪉㩿㪠㪛㪀

Unit : mm

Descriptions

Branch pipe for Multi-System Twin type Twin use. (50:50)

Applicable Models

PU-P71/100/125/140

PUH-P71/100/125/140

PUHZ-RP71/100/125/140

for Twin 50:50 use

PUHZ-HRP71/100/125

Specifications

Main body

Accessory

Distribution ratio

Number of

distribution pipes

Pipe material

Pipe cover

Joint

Outdoor unit capacity is divided into

two (50:50)

1 each for liquid pipe and gas pipe

Phosphate deoxidized copper

C1220T-OL (JIS H3300)

Styrofoam molding (1 each for liquid

pipe and gas pipe)

7 joints (4 types)

OPTIONAL

PAR TS

㪦㪬㪫㪛㪦㪦㪩

㪬㪥㪠㪫

㪪㪠㪛㪜

㱢㪋㪍

㪞㪘㪪㩷㪧㪠㪧㪜

㪦㪬㪫㪛㪦㪦㪩

㪬㪥㪠㪫

㪪㪠㪛㪜

㪡㪦㪠㪥㪫㩿㪘㪺㪺㪼㫊㫊㫆㫉㫐㪀

㪧㪠㪧㪜㩷㪚㪦㪭㪜㪩

䋨㪈㪎㪉㬍㪊㪊㪌㬍㪎㪉䋩

㪧㪠㪧㪜㩷㪚㪦㪭㪜㪩

䋨㪈㪎㪇㬍㪉㪋㪇㬍㪎㪋䋩

㱢㪌㪏

㱢㪈㪌㪅㪏㪏䋨㪠㪛䋩

㪊㪊㪌

㪋㪊㪌

㪉㪋㪇

㪧㪠㪧㪜㩷㪚㪦㪭㪜㪩

㪉㪈㪇

㪈㪉㪇

㪈㪎㪇

㪉㪄㱢㪈㪌㪅㪏㪏䋨㪠㪛䋩

㪈㪇㪇

㪈㪋㪉

㪈㪎㪉

㪠㪥㪛㪦㪦㪩

㪬㪥㪠㪫

㪪㪠㪛㪜

㪉㪄㱢㪐㪅㪌㪉䋨㪠㪛

㪠㪥㪛㪦㪦㪩

㪬㪥㪠㪫

㪪㪠㪛㪜

E-148

㱢䌁

㪏㪇

ΦA(ID)

ΦB(OD)

6.35

9.52 15.88 2

12.7 15.88 2

9.52

㱢䌂

Amount

2

㱢䌃

ΦC(ID)

19.05

㪏㪇

ΦD(OD)

15.88

㱢䌄

Amount

1

Page 2

Distribution Pipe MSDD-50TR-E

How to Use / How to Install

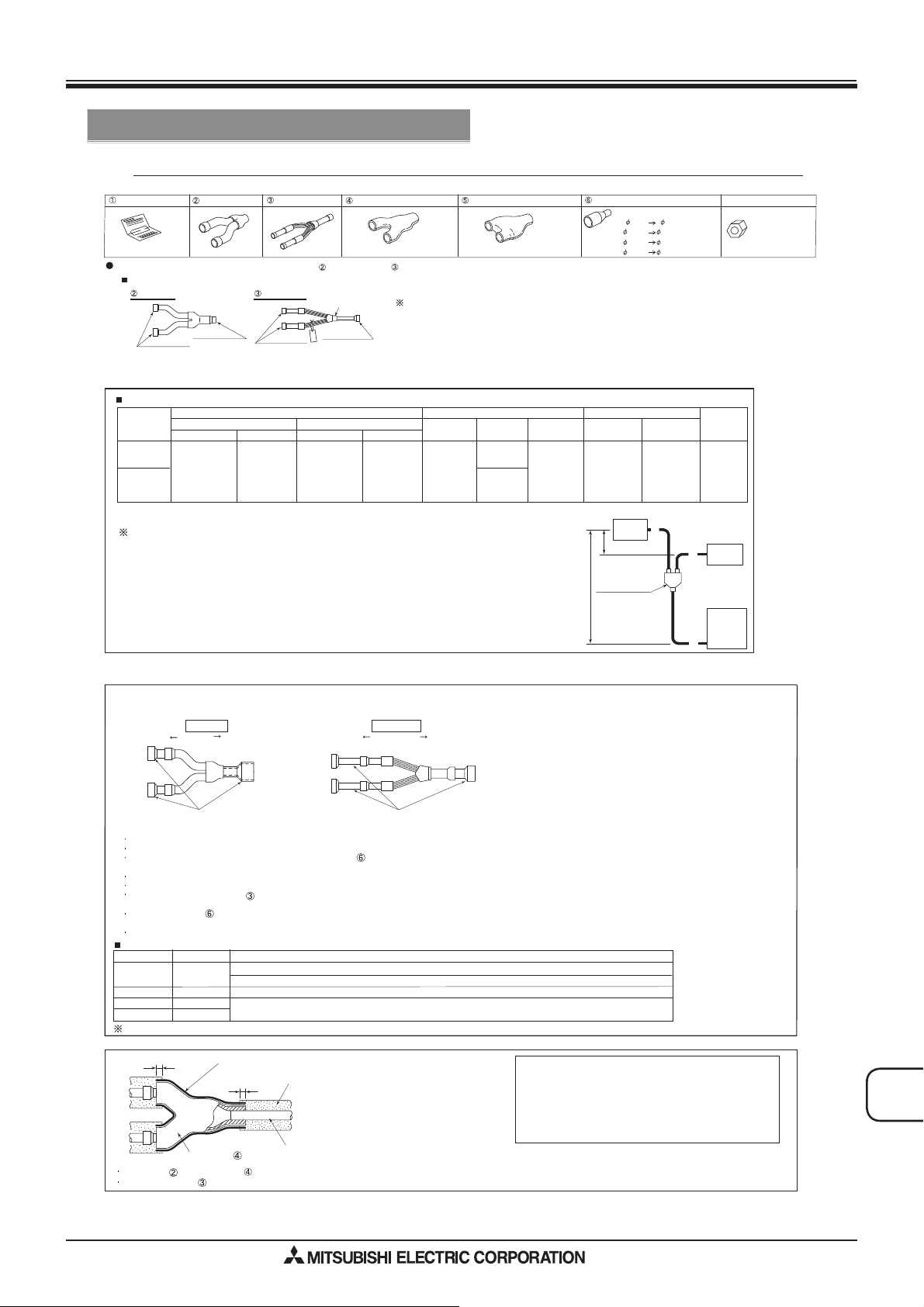

Package Air-conditioner Optional Parts Instruction Sheet for Simultaneous Twin Distributing Pipe

Make sure that you have all the following parts before installation.

Instruction sheet

This sheet 1 sheet

See the following for the specifications of gas pipe,and liquid pipe

MSDD-50TR

Gas pipe

ID Ǟ15.88

㧔to indoor unit㧕

Pipe size and limit to refrigerant pipe

For R410A (Table 1-2)

Outdoor

unit capacity

71(3Hp)

100

㨪

140

(4

㨪

6Hp)

Note 1: Limit the number of bends for refrigerant pipes to 8 in each of the ޛA㧗Bޜ and ޛA㧗Cޜ ranges.

See the installation manual provided with the main unit for details on chargeless pipe length and refrig erant additional charge amount.

Gas pipe

ID Ǟ15.88

㧔to outdoor unit㧕

Gas pipe side

Outdoor unit side Indoor unit side Outdoor unit side

Ǟ15.88

(5/8)

Liquid pipe

1pc

Liguid pipe

ID Ǟ9.52

㧔to indoor unit㧕

Pipe size (mm) Actual pipe length (m)

RP35, 50

Ǟ9.52(3/8)

Ǟ12.7(1/2)

RP60 125

~

Ǟ15.88(5/8)

Pipe cover (for gas pipe)

1pc

㧔Model name indication㧕

Tag

ID Ǟ9.52

㧔to outdoor unit㧕

Liquid pipe side

Ǟ9.52

3/8

Pipe cover (for liquid pipe) Joint pipe

1pc 1pc

,

Procure the following at local site in addition to the above

Tape for heat insulator sealing

Extended pipe for refrigerant pipe

Indoor unit side

RP35, 50

Ǟ6.35(1/4)

RP60

㨪

125

Ǟ9.52(3/8)

Indoor-Outdoor

A㧗B㧗C㧩

50m or less

㧙

75m or less

Indoor-Indoor

֥B㧙C֥㧩

8m or less

Height Difference (m)

Indoor-Outdoor

H =

30m or less

Indoor unit

(Fig. 1)ޓ

h

9.52 6.35···· 2pcs

15.88 12.7······ 2pcs

15.88 19.05···· 1pc

15.88 9.52······ 2pcs

Indoor-Indoor

h =

1m or less

B

C

Flare nut

For R410A indoor unit.

Note 1

Number

of bends

15 or less

Indoor unit

....

1/4F 2pcs

....

1/2F 2pcs

H

Distributing pipe

Pipe connections

Combination pattern of indoor and outdoor units and

joints to be used:

(Fig. 2)

Indoor side Outdoor side Indoor side Outdoor side

1. Perform work, taking care with the followings:

Be sure to check the combination pattern of indoor and outdoor units and joints to be used (Table 2).

Be sure to observe the limits to refrigerant pipe length and number of bends (Table 1).

Insert the refrigerant pipe (procured at local site) and joint into the expanded pipe portions of distributing pipe

(this product) until they stop, and then connect them using anti-oxidization soldering.

There is no restriction on the orientation of distributing pipe (this product)during installation.

Take care that no foreign object, such as dust, enters during pipe connecting work.

Remove the tag of liquid pipe after checking it.

2. Pipe connections

The provided joints will be necessary depending on the capability of model used: See (Table 2), and connect

ޓthe joints as shown in (Fig. 2).

Do not bend or widen the distributing pipe (liquid pipe).

For R410A

Outdoor unit

71(3Hp)

100(4Hp) 50+50 (2+2)

125(5Hp)

140(6Hp) 71+71 (3+3)

Installation positions in brackets ( ).

Gas pipe

Joints Joints

Indoor unit Joint to be used

35+35 (1.6+1.6)

60+60 (2.5+2.5)

Outer Ǟ15.88㧙inner Ǟ12.7 [indoor gas pipe side], Outer Ǟ9.52㧙inner Ǟ6.35 [indoor liquid pipe side]

Outer Ǟ15.88㧙inner Ǟ9.52 [indoor gas pipe side], Outer Ǟ9.52㧙inner Ǟ6.35 [indoor liquid pipe side]

Outer Ǟ15.88㧙inner Ǟ12.7 [indoor gas pipe side], Outer Ǟ9.52㧙inner Ǟ6.35 [indoor liquid pipe side]

No joint is necessary.

Liquid pipe

(Table 2-2)

Heat insulation work

Wrap margin (Note 2)

Fit gas pipe into pipe covers , and then seal the mated portion of pipe covers ԛ using heat insulation seal tape (procured at local site).

Process liquid pipe in the same way.

Tape (procured at local site)

(Note 1)

Wrap margin

Pipe cover

Please install contents other than this description on the main part of a product with an attached installation description, and use them as it.

Insulation material

(procured at local site) (Note 1)

Pipe from local site

Notes:

1.

Cover the entire refrigerant pipe (procured at local site)

with heat insulation material. When using generally available

heat insulation material, heat-resistant insulation material

(at least 12 mm thick).

2.

Pipe covers

Provide wrap margins with insulation material.

and will shrink slightly at high temperatures:

Outdoor unit

A

OPTIONAL

PAR TS

E-149

Loading...

Loading...