Page 1

DIGITAL COLOR PRINTER

MODEL

CP-K60DW-S

OPERATION MANUAL

THIS OPERATION MANUAL IS IMPORTANT

TO YOU.

PLEASE READ IT BEFORE USING YOUR

DIGITAL COLOR PRINTER.

Hereby, Mitsubishi Electric Corporation, declares that this digital color printer is in

compliance with the essential requirements and other relevant provisions of Directive

1999/5/EC.

Page 2

INFORMATION

This Class A digital apparatus complies with Canadian ICES-003.

WARNING :

TO PREVENT FIRE OR SHOCK HAZARD, DO NOT EXPOSE THIS APPLIANCE TO RAIN

OR MOISTURE.

WARNING:

Use the included AC power cord so as not to interfere with radio and television reception.

If you use other cables, it may cause interference with radio and television reception.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION :

SHOCK,

DO NOT REMOVE COVER (OR BACK)

TO REDUCE THE RISK OF ELECTRIC

NO USER-SERVICEABLE PARTS INSIDE

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

The lightning ash with arrowhead symbol, within an equilateral triangle, is intended

to alert the user to the presence of uninsulated “dangerous voltage” within the

product’s enclosure that may be of sufcient magnitude to constitute the risk of

electric shock.

The exclamation point within an equilateral triangle is intended to alert the user to

the presence of important operating and maintenance (servicing) instructions in the

literature accompanying the appliance.

The “Caution, hot surface” symbol indicates that the marked item may be hot and

should not be touched.

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

The “Electro Static Discharge (ESD) warning” symbol indicates that trouble (including

equipment malfunction) due to static electricity may occur in certain conditions.

The “OFF/ON” symbol indicates connection to or disconnection from the mains, at

least for mains switches.

The “Alternating current” symbol indicates that the equipment is suitable for

alternating current only.

Page 3

CAUTION:

Changes or modications not expressly approved by the party responsible for compliance could void

the user’s authority to operate the equipment.

NOTE:

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his or her own expense.

Operation is subject to the following two conditions;

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired

operation of the device.

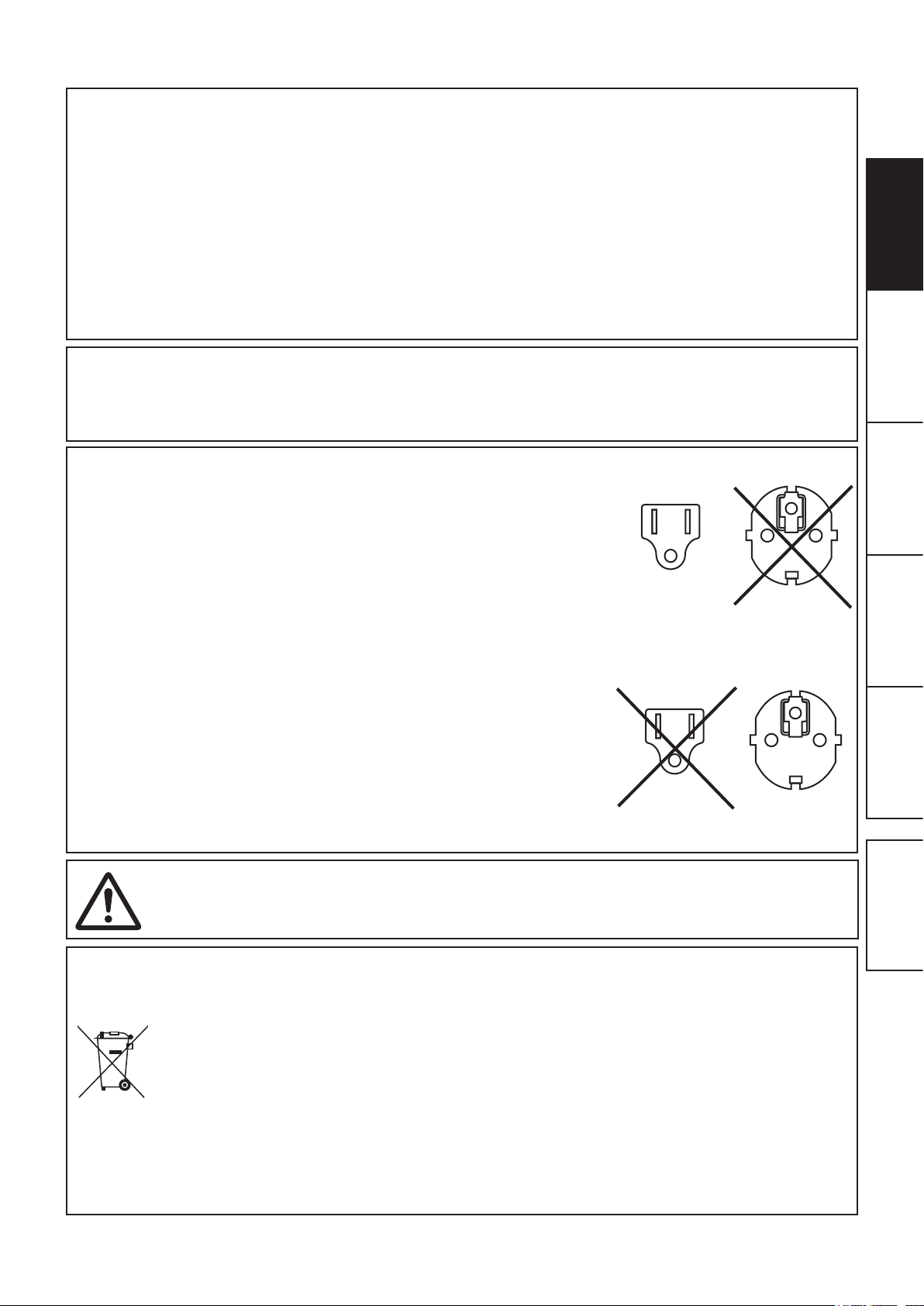

WARNING:

In the USA or Canada, use the AC power cord according to the recommendations as

below, in order to comply with UL60950-1 and CAN/CSA C22.2 No. 60950-1-03.

Connect to the 120 V receptacle of the room or the host equipment.

The AC power cord should be UL or CSA approved and consist of type SVT, size

16 or 18AWG, length 2 m or shorter cord with IEC60320-1/C13 type, 125 V 10 A or

higher rating connector and NEMA 5-15 type, 125 V 10 A or higher rating plug.

Use the AC power cord as specied above, so as not to interfere with radio and

television reception.

If you use other cables, it may cause interference with radio and television reception.

SHOOTING

TROUBLE-

WARNING:

In Europe, use the AC power cord according to the recommendations as below, in

order to comply with EN60950-1.

Connect to the 230 V receptacle of the room or the host equipment.

The AC power cord should be VDE approved and consist of core size 0.75 mm

bigger, length 2 m or shorter cord with IEC60320-1/C13 type, 250 V 10 A or higher

rating connector and CEE(7)VII type, 250 V 10 A or higher rating plug.

Use the AC power cord as specied above, so as not to interfere with radio and

television reception.

If you use other cables, it may cause interference with radio and television reception.

2

or

WARNING:

The socket outlet shall be installed near the equipment and shall be easily accessible.

Note: This symbol mark is for EU countries only.

This symbol mark is according to the directive 2002/96/EC Article 10 Information for users and Annex IV, and/or

to the directive 2006/66/EC Article 20 Information for end-users and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that electrical and electronic equipment, batteries and accumulators, at their end-of-life,

should be disposed of separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the battery

or accumulator contains a heavy metal at a certain concentration. This will be indicated as follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used electrical and electronic products,

batteries and accumulators.

Please, dispose of this equipment, batteries and accumulators correctly at your local community waste

collection/recycling centre.

Please, help us to conserve the environment we live in!

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

Page 4

CONTENTS

CONTENTS

Contents .................................................................................................1

Safety precautions ..................................................................................2-4

Special features ......................................................................................5

Unpacking...............................................................................................6

Features and functions ...........................................................................7-8

Front panel ..............................................................................................7

Rear panel ...............................................................................................8

Before operation .....................................................................................9-16

Printer setup procedure ...........................................................................9

Positioning of adjustable paper guide .....................................................10

Print paper installation .............................................................................11-12

Ink ribbon installation ..............................................................................13-14

Handling of paper / ink ribbon set ...........................................................15

Connection with USB data signal equipment ..........................................16

Error messages and countermeasures ..................................................17-20

Indications on the front panel and countermeasures ..............................17

Overcoming paper jams ..........................................................................18

Repairing a torn ink ribbon ......................................................................19

Before calling for service .........................................................................20

Instructions for transportation ..................................................................20

Cleaning .................................................................................................21-22

Specications .........................................................................................23

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

1

Page 5

SAFETY PRECAUTIONS

In the interest of safety, please observe the following precautions:

POWER REQUIREMENT

This Digital Color Printer is designed to operate on 120 V AC 50/60 Hz in the U.S.A. and Canada, and 220 V - 240 V AC 50/60

Hz in Europe. Never connect to any outlet or power supply having a different voltage or frequency.

WARNING : THIS APPARATUS MUST BE EARTHED.

PROTECTIVE MEASURES

IF ABNORMALITIES ARISE, .....

Use of the unit during emission of smoke or abnormal sounds (without adopting countermeasures) is dangerous. In such a case,

unplug the power cord from the source outlet immediately, and request maintenance service from the sales dealer.

NEVER INSERT ANY OBJECT INTO THE UNIT

Foreign objects of any kind inserted into this unit constitute a safety hazard and can cause extensive damage.

DO NOT PLACE ANYTHING ON THE DIGITAL COLOR PRINTER

Heavy objects placed on the Digital Color Printer can cause damage or obstruct proper ventilation.

PROTECT THE POWER CORD

Damage to the power cord may cause re or shock hazard. When unplugging, hold by the plug only and remove carefully.

DO NOT PLACE WATER CONTAINERS ON THE UNIT

Do not place ower vases, and other water-holding containers on the device. If, for some reason, water seeps to the inside of

the unit, unplug the power cord from the source outlet, and contact the sales dealer. If used without corrective measures, the

unit may be damaged.

“In the interest of safety, avoid handling of liquids near the unit.”

DO NOT REMOVE THE CABINET

Touching internal parts is dangerous, besides, it may lead to malfunction. Contact the sales dealer to carry out internal checks

and adjustments. Before opening the cover for eliminating a jammed paper, etc., be sure to disconnect the power cord plug.

UNPLUG THE POWER CORD DURING A LONG ABSENCE

Turn off the main power switch and unplug the power cord during a long absence.

WHEN TRANSPORTING THE UNIT

When transporting the unit, remove the ink ribbon and print paper from the unit. See “INSTRUCTIONS FOR

TRANSPORTATION” on page 20.

WHEN MOVING THE UNIT

Check that the printing unit is closed rmly. And pay attention not to press the OPEN button accidentally. When the printing unit

is not closed rmly or you press the OPEN button accidentally, the printing unit may open. It can cause injury or damage.

BE CAREFUL AROUND PRINT PAPER EXIT SLOT

Don’t insert your hand or any material into the paper exit slot during printing.

Do not touch the cutter blade inside the paper exit slot.

Otherwise, your nger will be injured.

DO NOT TOUCH THE THERMAL HEAD EXCEPT WHEN CLEANING

Do not touch the thermal head (located inside the unit) except when cleaning.

They are heated to high temperature and may cause burns or injury when touched.

Also, malfunction caused by static electricity may occur.

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

WHEN PLACING THE PRINT PAPER, KEEP THE PRINT PAPER UPRIGHT

When you put the print paper sideways on a table, etc., it may roll and fall. This may cause injury.

CONNECTION CABLES

Use the provided power cord.

2

Page 6

SAFETY PRECAUTIONS

REMOVE THE PAPER STRIP BIN WHEN OPENING OR CLOSING THE DOOR

When you open or close the door with the paper strip bin installed, the bin may be removed and fall. This may cause injury or

damage. Also, the chips generated by margin cut may jam at the paper exit slot.

DO NOT LEAVE THE PRINTING UNIT OPEN

When the printer is moved with the printing unit open, it may cause injury or damage.

CLOSE THE PRINTING UNIT FIRMLY

Take care not to pinch your hand when closing the printing unit. When the printing unit is not closed rmly, it may open during

transportation and it may cause injury or damage.

DO NOT PUSH DOWN ON THE PRINTING UNIT OR THE DOOR

If you push down on the printing unit or the door when they are open, this unit may fall and it can cause damage or injury.

INSTALLATION LOCATIONS

MAINTAIN GOOD VENTILATION

Ventilation slots and holes are provided on the rear and both sides of this unit. Place the unit on a hard and level surface and

keep a space between the unit and the walls to ensure proper ventilation. When putting the unit on the system rack, take a

space between the unit and the back and sides of the rack.

SUITABLE LOCATIONS

Avoid shaky places or hot-springs areas where hydrogen sulde and acidic ions are likely to be generated.

AVOID PLACES WITH HIGH HUMIDITY AND DUST

Do not place the unit at a high humidity and dusty locations. They can cause extensive damage to this unit. Avoid places where

the unit is likely to be exposed to oily fumes and vapors.

AVOID PLACES LIKELY TO BE EXTREMELY HOT

Places exposed to direct sunlight, or near heating appliances can attain extremely high temperatures, which may deform the

cabinet, or can become a prime cause of damage.

PLACES THE UNIT ON A HORIZONTAL LEVEL

The unit is likely to be affected if it is placed in slanted conditions or in an unstable places.

PROTECT AGAINST DEW FORMATION

In extremely cold regions, if the unit is moved quickly from an extremely cold place to warmer one, dew is likely to be formed. If

dew is formed, printing is not possible.

OPERATING AMBIENT TEMPERATURE RANGE

The operating ambient temperature range is 15°C - 30°C (59°F - 86°F) and the humidity of 30% - 80% RH. When using the unit

on the system rack, be sure to keep this ambient temperature inside the rack.

Depending on the internal temperature, it may take some time to start printing.

FOR LONG OPERATING LIFE

UNSUITABLE MATERIALS FOR THE DIGITAL COLOR PRINTER

Coat aking and deformation are likely to occur if the unit is wiped with chemical dusters, benzine, thinner or any other solvent, if

rubber or PVC items are left in contact with the unit for extended duration, or if the unit is sprayed with insecticide.

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

CARE OF THE CABINET

Unplug and clean with a soft cloth slightly moistened with a mild soap and water solution. Allow to dry completely before

operating. Never use petroleum base solutions or abrasive cleaners.

HEAD ABRASION

The thermal head, like the video head, wears out. When it is abraded, it becomes hard to print out ne details of the picture. In

such a case, it is necessary to replace the thermal head. Consult with the sales dealer for replacing the head.

CONNECTING DEVICES

Read thoroughly “Operating Precautions” of the instruction booklets for the devices connected with the Digital Color Printer. The

power cord must be disconnected after printing is over.

CAUTION ON RELOCATING

When transporting this unit, make sure it is not likely to be subjected to impacts. They can be a prime cause for damage.

Further, make sure to disconnect the power cord from the power outlet, and the cables from the connected devices.

3

Page 7

SAFETY PRECAUTIONS

OTHER CAUTIONS

• Do not pull out nor touch the print paper until printing is completed. It may degrade the print quality or cause an error.

• Dust or other foreign matter adhering to the print paper or the ink cassette, or deformation resulting from exposure to

extremely low or high temperatures could cause loss of color, uneven color or lines, or wrinkles in the print images.

• Clean the thermal head and platen roller to keep good print quality whenever you replace the print paper and ink ribbon.

• Depending on the internal temperature, the printer may stop printing temporarily during printing. (The POWER indicator

blinks green.) Please wait for the printer to resume printing.

Do not touch the print paper.

• Each time printing is completed, remove the prints. If the prints are not removed, a paper jam may occur.

• Empty the paper strip bin frequently to prevent jamming the strips at the print outlet.

NOTE:

YOUR UNDERSTANDING IS REQUESTED FOR THE LOSS OF IMAGES IN MEMORY DUE TO THE SUDDEN

OCCURRENCE OF A MALFUNCTION.

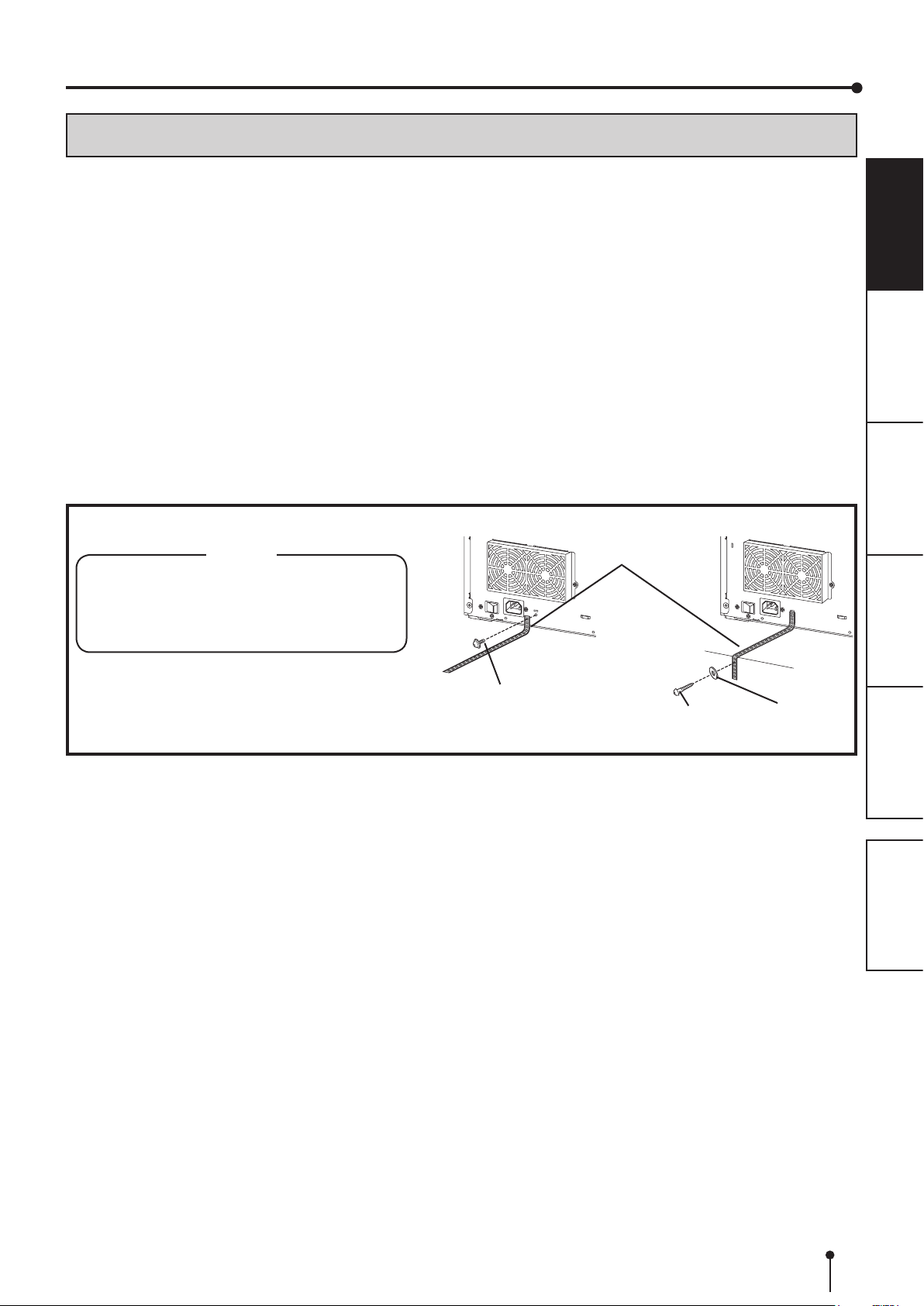

Cautions to prevent the printer from falling

Securing band

CAUTION

Falling this printer due to shock or other reasons

may cause injury.

For your safety, make sure to secure the printer

by the following procedure when you decide the

location of installation of the printer.

(supplied)

SHOOTING

TROUBLE-

1. Secure the securing band (supplied) to the printer

with the screw (supplied).

2. Secure the other side of the securing band to the

installation location with the round head wood

screw (supplied).

Screw (supplied)

Round head wood screw

(supplied)

Washer

(supplied)

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

4

Page 8

SPECIAL FEATURES

SPECIAL FEATURES

AVAILABLE 3 PRINT SIZES

3 printing sizes, 10x15 (4x6”) (max. 102 x 152 mm), 13x18 (5x7”) (max. 127 x 178 mm), and 15x20 (6x8”) (max. 152 x 203 mm),

are selectable.

300 DPI HIGH RESOLUTION

CP-K60DW-S has a high resolution of 300 dpi for precise illustrations and sharp photographic images.

LARGE CAPACITY PRINTING

Maximum of 320 prints per roll for 10x15 (4x6”) is offered. Large economical print capacity per roll reduces frequency of

exchanging paper and ink ribbon.

HIGH QUALITY PRINTS

CP-K60DW-S is a dye sublimation thermal transfer color printer, which produces superior high quality images. It also produces a

continuous tone at 256 gradient for each of Y, M, and C.

HIGH SPEED PRINTING

HI-SPEED USB (VER. 2.0) INTERFACE SUPPORTING

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

5

Page 9

UNPACKING

UNPACKING

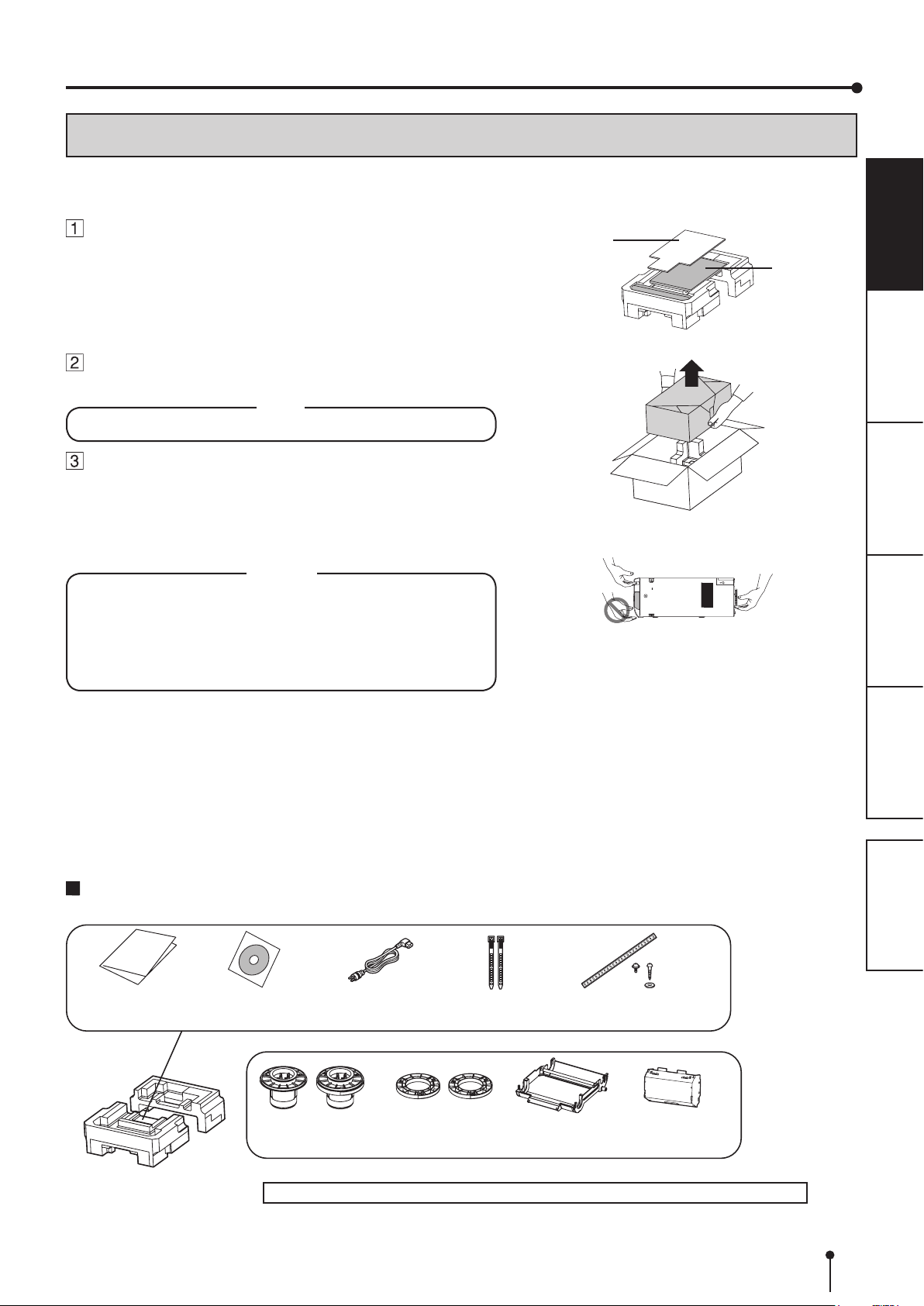

Take the printer out of the box by the following procedures. Make sure to check the accessories.

Open the printer box from the top and remove

the top cushion containing the accessories out

of the box.

Remove the protective cardboard and then take the accessories

out of the cushion.

Carefully pull the printer up and out of the box.

Pull the printer straight up as shown in the gure.

NOTE

Printer weighs about 12 kg. Handle it with care.

Unwrap the packing.

Remove the protective materials for transportation such as

protective sheet.

Remove the paper strip bin before carrying the printer.

Hold the printer by the front and rear handle as illustrated in the

drawing.

CAUTION

• Do not carry the printer with the paper strip bin attached and

by holding the part under the paper strip bin. The paper strip

bin may be removed and fall. It may cause injury or damage.

• When the printing unit is not closed rmly or you press the

OPEN button accidentally, the printing unit may open. It can

cause injury or damage.

Protective

cardboard

Accessories

SHOOTING

TROUBLE-

CONTENTS

The accessories items are placed in the top cushion. Check all items are included.

Quick setup

guide

CD-ROM

Paper anges Spacers

Power cord

Cable ties

Ink cassette

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

Securing band

Screws, Washer

Paper strip bin

These are contained in the printing unit.

Make sure to remove the protective materials from the ink cassette and paper anges.

6

Page 10

FEATURES AND FUNCTIONS

1

5

3

4

2

6

7

8

8

9

FRONT PANEL

PAPER STRIP BIN

Holds the paper strips generated by margin cut. Empty

the bin frequently to prevent jamming the strips at the

print outlet.

NOTE

Remove the bin before opening the door. If the door

is opened with this bin attached, the printer or this

bin may be damaged. Do not remove the bin during

printing. It may cause a malfunction.

CONNECTOR COVER

Do not open the cover during normal use.

ALARM INDICATOR ( )

This indicator illuminates or blinks when a paper jam

occurs or the door is open. See page 17.

PAPER RIBBON INDICATOR ( )

When an error concerning the ink ribbon or print paper

occurs, this indicator illuminates or blinks. See page

17.

OPENING THE DOOR

Pull out the printing unit by pressing the OPEN button

and then pull the knob to open the door.

Knob

POWER INDICATOR ( )

When the power is turned on, the indicator illuminates.

It normally illuminates green, however, blinks or

illuminates orange depending on the printer status. See

page 17.

PRINT OUTLET

The printed paper comes out here.

OPEN BUTTON ( )

Press to release the printing unit out.

PRINTING UNIT

Open to load print paper or ink ribbon. Press the

OPEN button to release the printing unit.

DOOR

Open the door to mount print paper.

PAPER STRIP BIN

Hook and pull up the paper strip bin to attach it rmly.

Hold and pull the handle on the lower part of paper strip

bin to remove.

1 2

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

Printing unit Door

7

Page 11

FEATURES AND FUNCTIONS

4

2

1

3

5

REAR PANEL

POWER SWITCH

Use to switch the power ON and OFF.

POWER SOCKET (AC LINE)

Use to connect the provided power cord. Insert the

cord rmly.

FAN COVER /

HANDLE FOR TRANSPORTING

When carrying the printer, hold this handle and the

front upper part of the printer.

USB TERMINAL

Use to connect the USB cable.

See page 16.

SECURING HOLES FOR THE CABLE TIE

Use to secure the power cord or USB cable by using

the cable ties (supplied).

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

SECURING THE POWER CORD AND USB CABLE

1. Wrap a cable tie (supplied) around the power cord or the

USB cable.

2. Draw the tie through the securing hole on the rear panel

and secure it.

(Example)

Securing hole for the cable tie

8

Page 12

BEFORE OPERATION

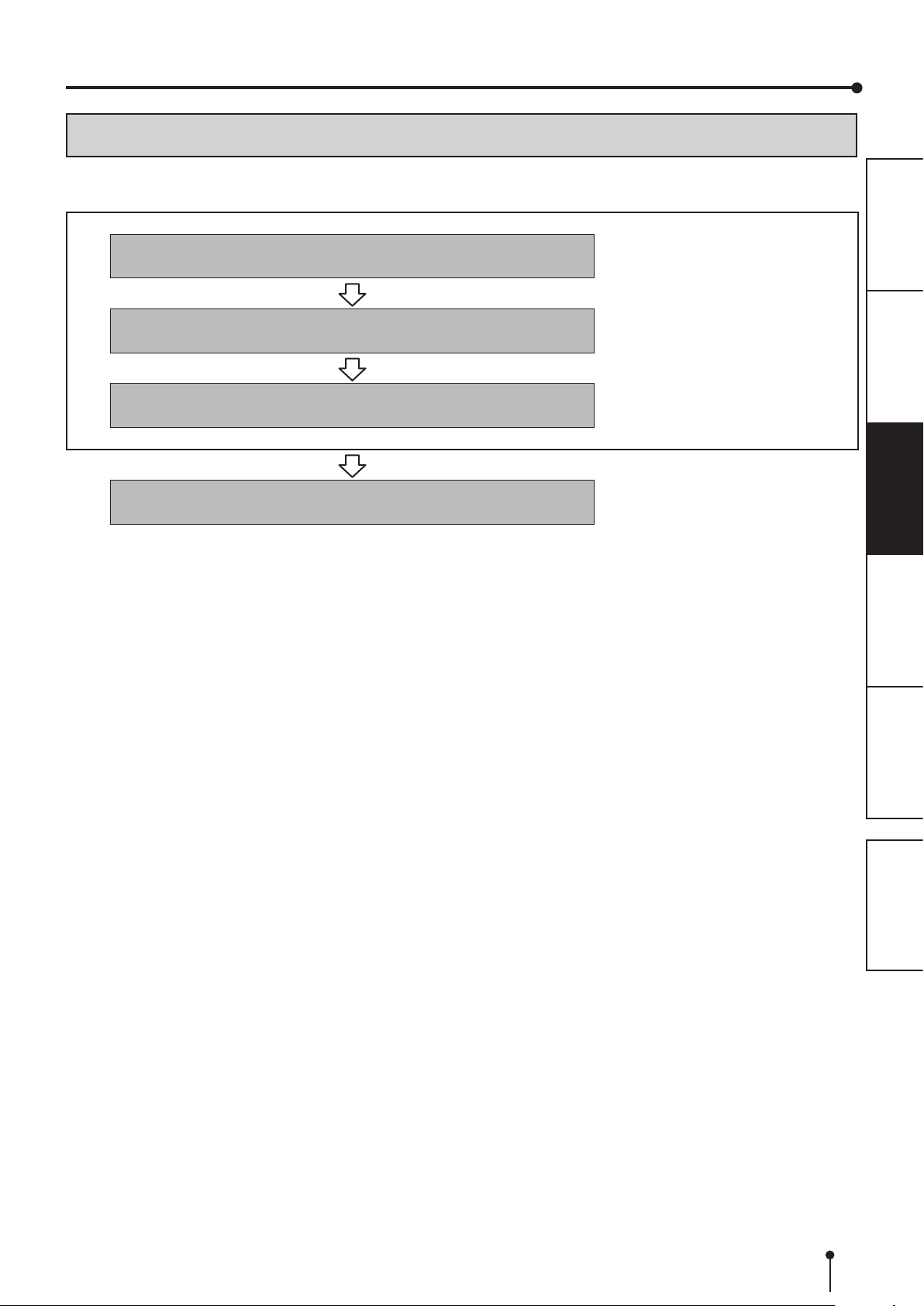

PRINTER SETUP PROCEDURE

Before printing, follow the printer setup listed below.

Position the adjustable paper guides.

Install the print paper to this printer.

Install the ink ribbon to this printer.

Connect the printer to a personal computer.

Make sure to close the printing unit when the setup procedure is completed.

(See page 10.)

(See pages 11 to 12.)

(See pages 13 to 14.)

(See page 16.)

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

9

Page 13

BEFORE OPERATION

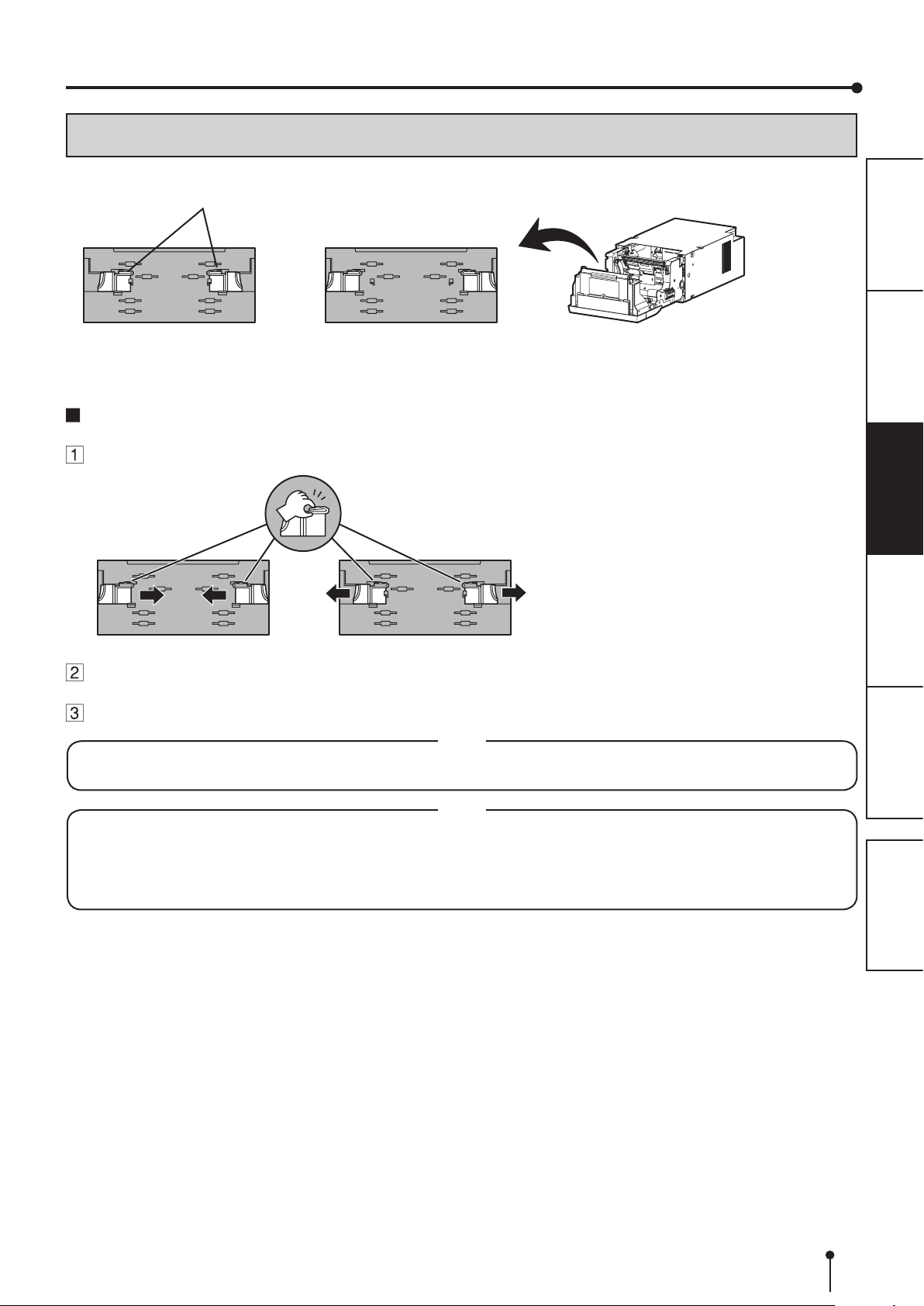

POSITIONING OF ADJUSTABLE PAPER GUIDE

Adjust the paper guides according to the paper width.

Adjustable paper guides

For 13x18(5x7”) size paper

(5”-width)

For 10x15(4x6”) or 15x20(6x8”)

size paper (6”-width)

HOW TO SET THE ADJUSTABLE PAPER GUIDES

Pinch the tab on the adjustable paper guide and slide it right or left.

Tab

Slide the paper guide until it stops. The paper guide will snap into place.

Slide other paper guide in the similar way.

NOTE

Make sure to set the adjustable paper guides to the size of the paper width. When they are not positioned properly, a

malfunction such as paper jam and misaligned printing position may occur.

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

NOTE

When you use 10x15 (4x6”) or 15x20 (6x8”) size paper (having width of 152 mm) after using 13x18 (5x7”) size paper

(having width of 127 mm) for a long time or printing such paper in large quantities, thermal head cleaning may be required.

For cleaning of the thermal head, see page 21.

In some cases, the print quality is not improved though thermal head cleaning is carried out. In this case, replacement of

the thermal head is required. For detail, consult your dealer.

CONTENTS

10

Page 14

BEFORE OPERATION

PRINT PAPER INSTALLATION

Spacers

See the Quick Setup Guide on how to use the spacers.

How to attach the spacers

1. Insert the spacer with the paper ange’s stoppers retracted.

2. Turn the spacer until the latches are locked.

When you remove the spacers from the paper anges, follow the above procedure

in reverse.

Attachthesuppliedpaperangestobothsidesoftheprint

paper.

When you pinch the latches on the paper ange, the stoppers retract into the shaft.

Attach the anges to the print paper with the stoppers retracted.

Make sure that the anges are attached to the print paper securely, and release the

latches.

NOTE

• Take care not to pinch your ngers.

• Do not remove the sticker on the print paper roll yet.

• Do not loosen the paper roll. Any slack in the print paper may degrade the print

quality.

Spacer

Latch

Paper

ange

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CAUTION

• When placing the print paper, keep the print paper upright.

•

When you put the print paper sideways, it may roll and fall. This may cause injury.

NOTE

• Fingerprints or dust on the paper’s surface may degrade print quality and cause

paper jams.

Sticker

CONTENTS

INCORRECT CORRECT

11

Page 15

BEFORE OPERATION

Press the POWER switch on the rear panel to turn on the

power.

After the POWER indicator’s color has changed from orange to

green, press the OPEN button to release the printing unit out.

POWER switch

OPEN button

Remove the paper strip bin and then pull the knob to open the

door.

Install the print paper into the unit.

Place the printing paper in the correct orientation.

Make sure the paper roll is rmly installed.

CAUTION

Do not push down on the printing unit or the door.

If you push down on the printing unit or the door when they are open, this unit may

fall and it can cause damage or injury.

NOTE

• Make sure to turn on the power before installing the

print paper. Otherwise, a paper jam may occur.

• Load the paper roll slowly into the unit. If it is dropped

along the ditches, the unit or accessories may be

damaged.

Knob

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

Direction of paper insertion

Remove the sticker and insert the print paper between the roller

and guide as shown right to feed it. When the buzzer sounds,

stop the paper feeding.

Remove the sticker before inserting the print paper between roller and guide. Make

sure to insert the paper straight.

Buzzer continues to sound until the printing unit is closed.

NOTE

• Keep the rollers clean. Dirt on the rollers may produce poor print quality.

NOTE

• When taking the print paper out, pull it up toward you by holding the paper

anges.

• Make sure to turn on the power before replacing the print paper.

• Make sure to eliminate any slack from the print paper. If you carry out the

following steps without eliminating the slack, the print paper may be damaged.

Close the door.

CONTENTS

Print paper

Roller

Guide

Roller

12

Page 16

BEFORE OPERATION

3

4

1 2

3

4

1 2

INK RIBBON INSTALLATION

After installing the print paper, install the ink cassette into this unit.

Before installing the ink cassette into this unit, load the ink ribbon in the ink cassette.

It is recommended to clean the thermal head to keep good print quality when you replace

the print paper and ink ribbon.

NOTE

• Place the ink cassette on a at surface, when loading the ink ribbon.

• Select a place that is free of dust when loading the ink ribbon. Dust or dirt

settling on the ink ribbon results in poor print quality.

• Make sure that the shafts of the ink ribbon t into the ink cassette rmly.

Load the ink ribbon in the ink cassette as shown below.

Make sure to load it in the correct position.

Ditch

Shaft

Ink ribbon

Make sure to set the ink ribbon roller to the ditches rmly.

Turn the shaft to eliminate any slack.

Handle

Ink cassette

Place the ink cassette containing the ink ribbon in the

position as shown in the illustration.

To insert the ink cassette, align the protrusions on both sides of the

cassette with the right and left guides inside the printing unit and slide it in

a slanting direction.

Mount the ink cassette to the back rmly by holding the handle.

NOTE

Do not touch the thermal head.

Fingerprints or dust on the thermal head will degrade the print quality.

CAUTION

Do not touch the thermal head right after printing because it is

extremely hot. Otherwise you may get burned or injured.

NOTE

Note that the thermal head is quite sensitive to static electricity. When

you touch the thermal head while carrying static electricity on your

body, the thermal head may be damaged.

Handle

Guides

Protrusion

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

13

Page 17

BEFORE OPERATION

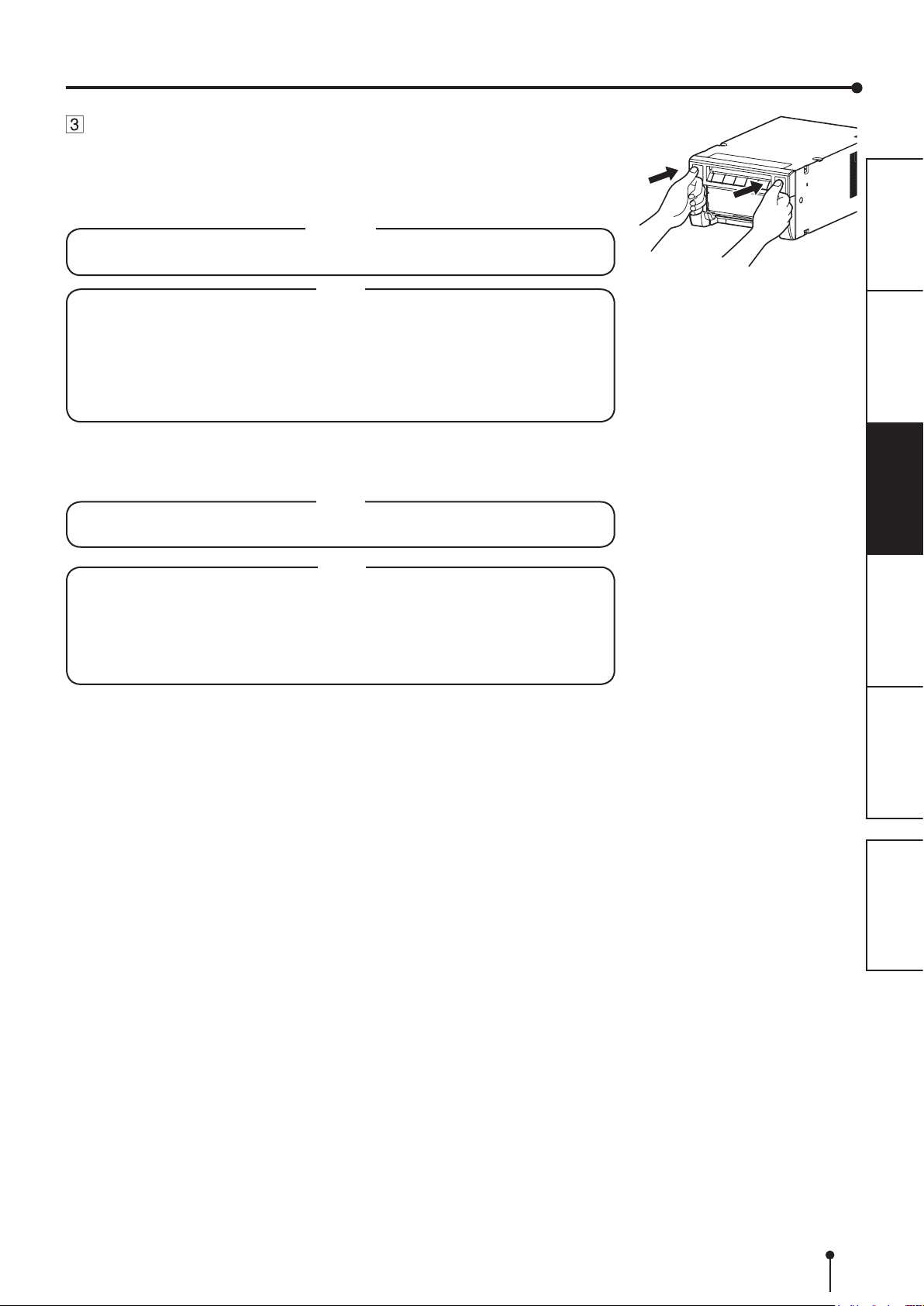

Push the printing unit to close.

Close the printing unit by pushing the right and left sides of the unit from the front

with both hands.

When a new paper is loaded and the printing unit is closed with the power turned

on, the paper will be automatically fed and cut.

CAUTION

When closing the printing unit, be careful not to get your hands caught

between the printer and the printing unit. Otherwise, you may get injured.

NOTE

• When closing the printing unit, push it until a click is heard.

• If the PAPER RIBBON indicator illuminates when the printing unit is closed, the

print paper may have not been installed correctly.

In this case, open the printing unit to make sure that the print paper has been

installed correctly. Then close the printing unit again.

• When the paper roll is reinstalled more than three times, the print paper may be

used up earlier than the ink ribbon.

Installation of the print paper and the ink ribbon is completed.

NOTE

• Make sure to replace the print paper and the ink ribbon simultaneously. A large

amount of print paper may remain depending on the used condition.

NOTE

• Empty the paper strip bin frequently to prevent jamming the strips at the print

outlet. Whenever you replace the paper and ink ribbon, make sure to throw

away the paper strips in the paper strip bin.

• Whenever you replace the print paper and the ink ribbon, clean the thermal

head and the platen roller. For the cleaning procedures, see “CLEANING” (on

pages 21 and 22).

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

14

Page 18

BEFORE OPERATION

HANDLING OF PAPER / INK RIBBON SET

BEFORE PRINTING

• Fingerprints or dust on the paper printing surface may produce poor print quality and cause paper jams.

• When the print paper or ink ribbon is abruptly transferred from a cool place to a hot place, vapor or dew is generated

on the surface, which causes paper jams or degraded print quality. Leave the print paper in the room to stabilize its

temperature before use.

• If you repeat the PRINT PAPER INSTALLATION procedure more than the designated number of times, the indicated

number of prints may not be made. In addition, if you replace the print paper before it is used up, the indicated number of

prints may not be made.

AFTER PRINTING

• If the paper absorbs nonvolatile organic solvents (alcohol, ester, ketone, etc.) the print may be discolored.

• Discoloration of prints is accelerated if the print paper comes into contact with soft vinyl chloride such as transparent

tape.

• Avoid storing prints in direct sunlight or places with high humidity.

STORAGE OF PAPER / INK RIBBON SET

• Do not store the print paper and ink ribbon in the container made of soft polyvinyl chloride. They may be discolored

because of chemical reaction.

• Store the print paper and ink ribbon out of direct sunlight and away from heating appliances in a cool, dark place where

the temperature is 5˚C to 30˚C and the humidity is 20% to 60% RH.

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

15

Page 19

BEFORE OPERATION

To USB port

Personal computer Digital color printer

To USB port

CONNECTION WITH USB DATA SIGNAL EQUIPMENT

CONNECTING TO PERSONAL COMPUTER (EXAMPLE)

Check that the printer is turned on before connecting procedure.

Turn on the power of a personal computer.

Connect the printer and a personal computer with a USB cable.

NOTE

A USB cable is not supplied with this unit. Use the USB 2.0 certied cable of 2 m or less in length.

NOTE

Refer to the following website to check the printer information.

http://www.MitsubishiElectric.co.jp/vcp/

SHOOTING

TROUBLE-

OTHERSPRECAUTIONS FEATURES PREPARATION

CONTENTS

16

Page 20

ERROR MESSAGES AND COUNTERMEASURES

INDICATIONS ON THE FRONT PANEL AND COUNTERMEASURES

If, for some reason, printing is not possible or an error occurs during printing, the indicators on the front panel will

illuminate or blink. In this case, follow the procedure described below.

: Steady on : Off : Blinking

ALARM PAPER RIBBON POWER Causes and Countermeasures Page

This printer is in standby mode.

(Orange)

(Green)

(Green)

(Green)

(Green)

(Green)

(Green)

Connect a USB cable to the printer when not

connected.

It may take time that the printer is ready to print

images after the image data is sent.

The printing unit is open.

• Close the printing unit.

A paper jam or a problem concerning the ink

ribbon occurs.

• Refer to “Overcoming paper jams.”

The temperature of the thermal head is too high

or too low.

• Wait until the indication goes off. When the

indicator stops blinking, the printer resumes

printing automatically.

While the printer is working, do not open the door

or turn off the power.

The ink ribbon which is not available to this

printer is installed.

• Replace the ink ribbon with a new one.

The actual combination of ink ribbon and print

paper is inconsistent with the setting made by the

personal computer.

• Open the printing unit and conrm that the

actual combination of ink ribbon and print

paper is consistent with the setting made by the

personal computer. After checking, close the

printing unit.

The print paper or ink ribbon is not installed.

The print paper or ink ribbon is used up.

• Install new print paper or ink ribbon.

Other errors

7

16

7

18

7

13-14

11-14

20

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

When the ALARM or the PAPER RIBBON indicator illuminates or blinks, open the door and carry out the above

countermeasures.

17

Page 21

ERROR MESSAGES AND COUNTERMEASURES

OVERCOMING PAPER JAMS

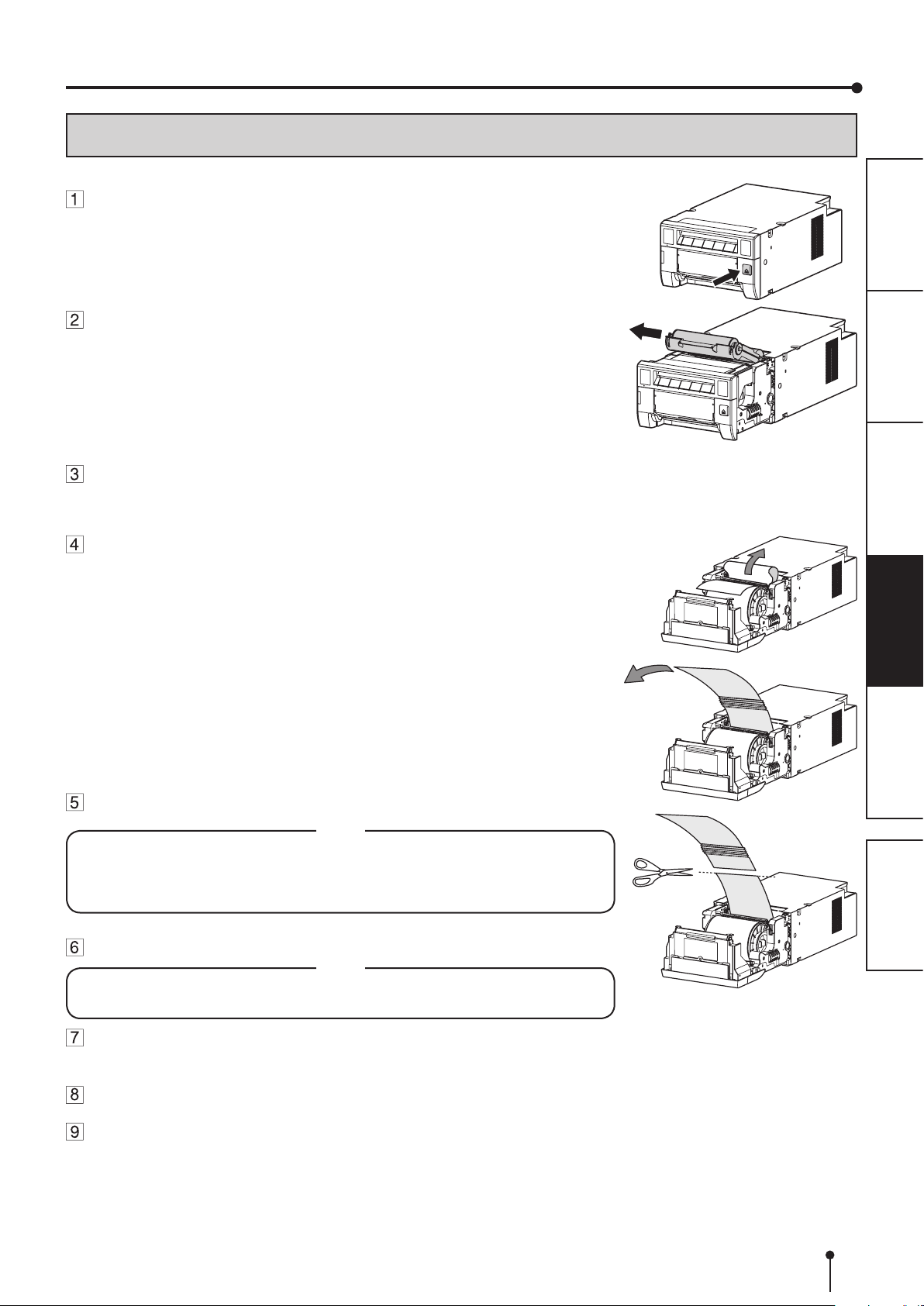

Press the OPEN button to open the printing unit.

Make sure that the power is turned on before opening the printing unit.

Remove the ink cassette.

Open the door.

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

Pull out the defective part of the print paper to the direction of

an arrow.

Cut off the defective part of the print paper with scissors.

NOTE

• Make sure to cut off the printed part of the print paper. Failure to do this may

result in the ink ribbon sticking to the print paper and being torn.

•

Make sure to clean the thermal head and the platen roller. Refer to “CLEANING”

(on pages 21 and 22).

Remove the print paper.

NOTE

• Remove the slack from the print paper completely. If the door is closed with the

print paper slacked, it may cause a paper jam.

SHOOTING

TROUBLE-

Install the print paper and the ink cassette with the ink ribbon.

(Refer to pages 11-15.)

Close the door.

Close the printing unit by pushing it.

18

Page 22

ERROR MESSAGES AND COUNTERMEASURES

REPAIRING A TORN INK RIBBON

Positiontheinkcassettewiththetorninkribbononaat,cleansurface.

Place a piece of transparent adhesive cellophane tape on the center of the ink ribbon.

Cellophane tape

Direction to turn

the shaft

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

Wind the shaft of the ink ribbon in the direction of the arrow so that the cellophane tape is not

seen.

Install the ink cassette in the printer.

SHOOTING

TROUBLE-

19

Page 23

ERROR MESSAGES AND COUNTERMEASURES

BEFORE CALLING FOR SERVICE

For the following symptoms, check the unit again before calling for service.

Symptom Check & Remedy

The power is not turned on. Is the power cord plug disconnected from the outlet?

→ Connect the power cord plug to the outlet rmly.

→ The protective circuit may be working. Turn off the power and wait for

about two minutes. Then turn on the power again.

The printing unit doesn’t open. Are you turning off the power during printing procedure?

→ Turn on the power and then open the printing unit.

The image is not printed. Is the PAPER RIBBON indicator or the ALARM indicator illuminating or

blinking?

→ Refer to “Overcoming paper jams.”

Is the appropriate size of data sent to this unit?

→ Make sure that the appropriate size of image data is sent to this unit.

Is the print paper or the ink ribbon used up?

→ Check them.

Is the printing unit set rmly?

→ Set the printing unit rmly.

→ When the indicators keep illuminating or blinking though the above

operations are performed, remove the ink ribbon and print paper and

reinstall them.

An error can not be resolved. → Turn off and on the power of the printer with the printing unit set rmly.

This printer starts initialization.

→ Press the switch inside of the hole of the front panel with a thin stick or

the like for 5 seconds or more.

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

Switch

INSTRUCTIONS FOR TRANSPORTATION

When transporting this unit for some reason such as repair, follow the instructions below.

1. Use the original packaging.

The genuine package unit may not endure more than one round trip. If the unit is transported with the package unit more

than one round trip, it may not be guaranteed.

Purchase another package unit when transporting this unit again.

Pack the unit with the accessories (ink ribbon and print paper) removed.

2. Closetheprintingunitrmly.

When closing the printing unit, push it until a click is heard.

CAUTION

When the printing unit is not closed rmly or you press the OPEN button accidentally, the printing unit may open. It can

cause injury or damage.

3. If the ink ribbon, print paper, or ink cassette can not be taken out, consult with your dealer.

20

Page 24

CLEANING

Cleaning as indicated below will help maintain stable printer operation and extend the printer’s life.

Wearing gloves at cleaning is recommended to prevent injury.

Make sure to turn off the power before cleaning.

FILTER CLEANING

Clean the lter part and the ventilation inlet with a vacuum as shown right.

THERMAL HEAD CLEANING

Press the OPEN button to open the printing unit.

Take the ink cassette out of the printer.

Preparations

Alcohol (ethyl alcohol, etc.)

Soft and clean cloth

When lines appear on the printed images, clean the thermal head.

Wipe the head cleaning part (as shown right) carefully with cloth dampened with a

small amount of alcohol.

NOTE

• Do not damage the thermal head.

• When the poor print quality is not corrected even if the head has been cleaned,

replacement of the thermal head may be required. Contact your dealer.

CAUTION

Thermal head is hot right after printing. Wait until the head cools before

cleaning the thermal head.

Ventilation inlet

about 12 mm

152 mm

lines

Printing

surface

Thermal head

Filter (inside)

about 12 mm

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

NOTE

The thermal head may be damaged if you touch it while static electricity builds

up on your body.

NOTE

When you clean the thermal head, make sure not to apply excessive force to the

peeling roller on the bottom of the thermal head. When the excessive force is

applied to the roller, the roller may be deformed, resulting in deterioration of the

printing quality.

Cleaning part of thermal head

Peeling roller

21

Page 25

CLEANING

PLATEN ROLLER CLEANING

Preparations

Alcohol (ethyl alcohol, etc.)

Soft and clean cloth

Clean the black part of the roller.

Wipe the black part carefully with cloth dampened with a small amount of alcohol.

Wipe the whole roller by turning it.

PAPER FLANGE CLEANING

Clean the parts that contact the print paper sides as shown right.

Wipe the parts carefully with cloth dampened with a small amount of alcohol.

Platen roller

Cleaning part

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

22

Page 26

SPECIFICATIONS

SPECIFICATIONS

Class Digital Color Printer

Model CP-K60DW-S

Printing method Sublimation Dye Thermal Transfer line print

3-color faces progressive printing (yellow, magenta, and cyan) and surface lamination

Print’s resolution 300 x 300 dpi (dpi : dots per inch)

Dot resolution 10x15 (4x6”)

13x18 (5x7”)

15x20 (6x8”)

Print size 10x15 (4x6”)

13x18 (5x7”)

15x20 (6x8”)

Gradations 256 (8 bits) for each color

Supply method Automatic

Interface Hi-Speed USB (Ver.2.0)

Power supply 220 - 240 V AC 50/60 Hz, 120 V AC 50/60 Hz

Power consumption 2.4 A (220 - 240 V AC, 50/60 Hz)

4.6 A (120 V AC, 50/60 Hz)

Operating conditions Temperature : 15°C - 30°C

Humidity : 30% - 80% RH (no dewing)

Installation conditions Operating attitude : Horizontal ±5°

Outside dimensions 275(W) x 446(D) x 170(H) mm

Weight Approx. 12 kg (excluding accessories)

Standard accessories

Power cord (for 230 V), Ink cassette (1), CD-ROM (1), Paper ange (1 set), Spacers (2), Quick

setup guide (1), Paper strip bin (1), Cable tie (2), Securing band (1), Screw for securing band (2),

Washer (1)

1218 x 1864 dots

1568 x 2128 dots

1864 x 2422 dots

102 x 152mm (without frame)

127 x 178mm (without frame)

152 x 203mm (without frame)

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

Print size and outside dimensions show typical value.

Design and specications are subject to change without notice.

Contents of CD-ROM

• Operation manual

23

Page 27

MITSUBISHI ELECTRIC EUROPE B.V.

Spanish Branch (Barcelona)

Ctra. de Rubí, 76-80 - Apdo. 420

08190-Sant Cugat del Vallés - (Barcelona) Spain

Phone +34 93 565 3154 FAX +34 93 589 4388

UK Branch

Travellers Lane, Hateld, Herts. AL10 8XB, England, U.K.

Phone +44 (0) 1707 276100 FAX +44 (0) 1707 278755

German Branch

Gothaer Strasse 8, 40880 Ratingen ; Postfach 1548, 40835 Ratingen ; Germany

Phone +49 (2102) 486-9250 FAX +49 (2102) 486-7320

French Branch

25, Boulevard des Bouvets - 92741 NANTERRE cedex, France

Phone +33 (1) 55 68 55 00 FAX +33 (1) 55 68 57 31

Italian Branch

Centro Direzionale Colleoni, Palazzo Sirio, ingresso n.1

Viale Colleoni, 7, 20041 Agrate Brianza, (Milano) Italy

Phone +39 03960531 FAX +39 0396053214

Benelux Branch

Nijverheidsweg 23a,

3641 RP Mijdrecht, The Netherlands

Phone +31 (0) 297-282461 FAX +31 (0) 297-283936

MITSUBISHI ELECTRIC VISUAL SOLUTIONS AMERICA, INC.

9351 Jeronimo Road, Irvine, CA 92618, U.S.A.

Phone 949-465-6000

Please contact the nearest Mitsubishi sales branch to get DOC (Declaration of Conformity) of the EC Directive

1999/5/EC.

Manufactured by Mitsubishi Electric (Malaysia) Sdn. Bhd.

PLO 32, Kawasan Perindustrian Senai II, 81400 Senai, Johor Darul Takzim, Malaysia

WE919C176A6

Loading...

Loading...