Page 1

CLEANING

Cleaning as indicated below will help maintain stable printer operation and extend the printer’s life.

Wearing gloves at cleaning is recommended to prevent injury.

Make sure to turn off the power before cleaning.

VENTILATION INLET CLEANING

Clean the ventilation inlets on the front and both sides of the printer with a vacuum as

shown right.

THERMAL HEAD CLEANING

Press the OPEN button to open the printing unit.

Take the ink cassette out of the printer.

Preparations

Alcohol (ethyl alcohol, etc.)

Soft and clean cloth

Other : Cleaning ribbon (option)*

* Please ask the dealer about options.

When lines appear on the printed images, clean the thermal head.

Wipe the head cleaning part (as shown right) carefully with cloth dampened with a

small amount of alcohol.

NOTE

• Do not damage the thermal head.

• When the poor print quality is not corrected even if the head has been

cleaned, replacement of the thermal head may be required. Contact your

dealer.

Ventilation inlets

Ventilation inlet

152 mm

Lines

Printing

surface

About 12 mm About 12 mm

Thermal head

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

CAUTION

Thermal head is hot right after printing. Wait until the head cools before

cleaning the thermal head.

NOTE

The thermal head may be damaged if you touch it while static electricity builds

up on your body.

NOTE

• When you clean the thermal head, make sure not to apply excessive force

to the peeling roller on the bottom of the thermal head. When the excessive

force is applied to the roller, the roller may be deformed, resulting in

deterioration of the printing quality.

WHEN USING THE CLEANING RIBBON (CR-D70)

When you use print paper of 152 mm (6”) width after using that of 127 mm (5”),

thermal head cleaning with a cleaning ribbon may be required.

If one or two lines appear on the printing surface as shown in the illustration when

printing on the print paper of 152 mm (6”) width, clean the thermal head using the

optional cleaning ribbon.

Print paper of 127 mm(5”) width : 9x13 (3.5x5”), 13x18 (5x7”)

Print paper of 152 mm (6”) width : 10x15 (4x6”), 15x20 (6x8”), 15x23 (6x9”)

NOTE

• When the symptom of poor print quality is not corrected even after the head is

cleaned, replace the thermal head. Contact your dealer.

Cleaning part of

thermal head

Peeling roller

21

Page 2

CLEANING

PLATEN ROLLER CLEANING

Preparations

Alcohol (ethyl alcohol, etc.)

Soft and clean cloth

Clean the black part of the roller.

Wipe the black part carefully with cloth dampened with a small amount of alcohol.

Wipe the whole roller by turning it.

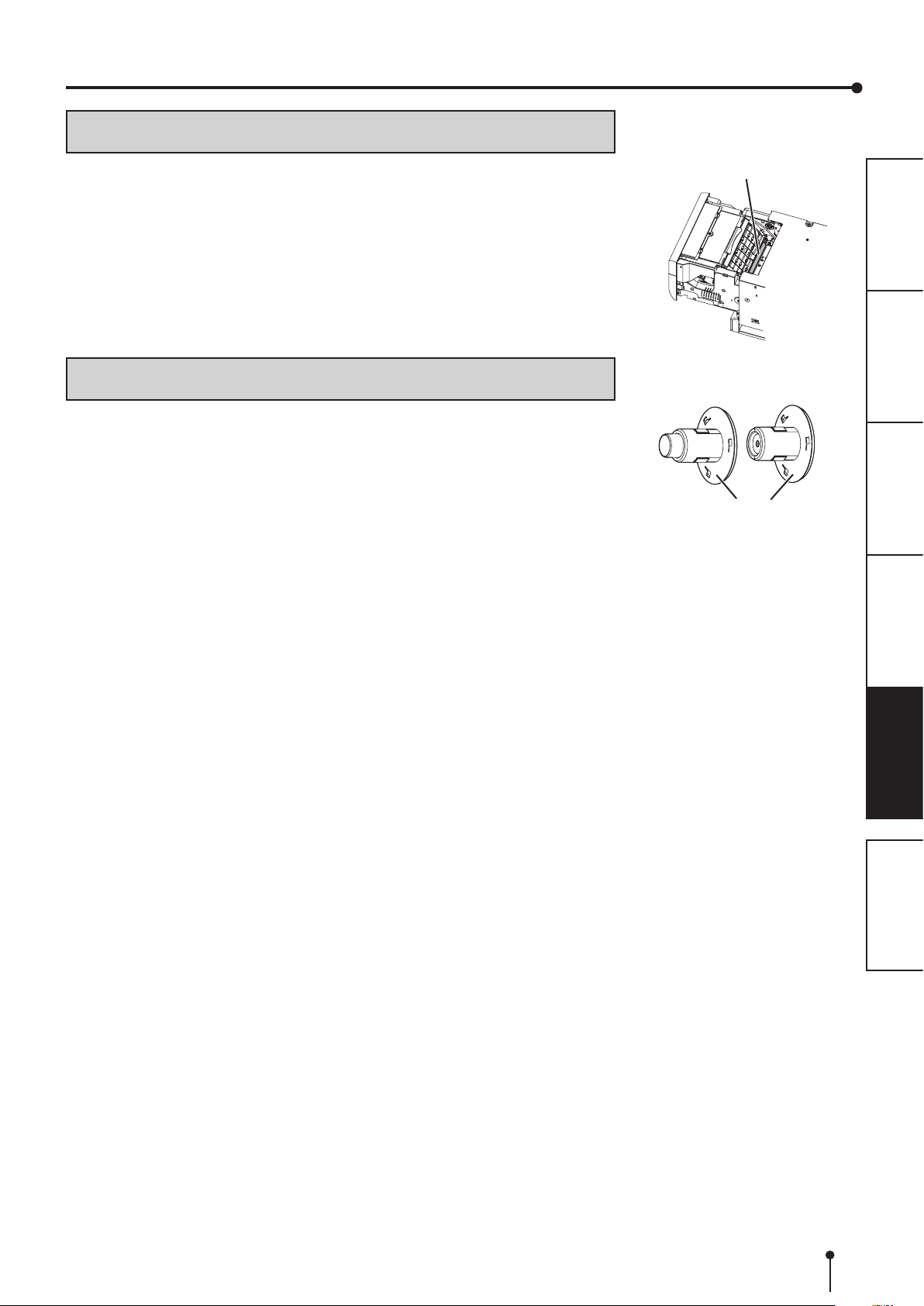

PAPER FLANGE CLEANING

Clean the parts that contact the print paper sides as shown right.

Wipe the parts carefully with cloth dampened with a small amount of alcohol.

Platen roller

Cleaning part

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

22

Page 3

SPECIFICATIONS

Class Digital Color Printer

Model CP-D90DW

Printing method Sublimation Dye Thermal Transfer line print

3-color faces progressive printing (yellow, magenta, and cyan) and surface lamination

Print’s resolution 300 x 300 dpi (dpi : dots per inch)

Print size 9x13 (3.5x5”)

10x15 (4x6”)

13x18 (5x7”)

15x20 (6x8”)

15x23 (6x9”)

Gradations 256 (8 bits) for each color

Supply method Automatic

Interface Hi-Speed USB (Ver.2.0)

DC output terminals 12 V / 2.0 A max. (high priority)

5 V / 2.0 A max. (low priority)

Power supply 100 - 240 V AC 50/60 Hz

Power consumption 5.5 A

Operating conditions Temperature : 5°C - 40°C

Humidity : 30% - 80% RH (no dewing)

Installation conditions Operating attitude : Horizontal ±5°

Outside dimensions 276 (W) x 367 (D) x 238 (H) mm

Weight Approx. 14 kg (excluding accessories)

Standard accessories Power cords (for 120 V and 230 V), Ink cassette (1), CD-ROM (1), Paper ange (1 set),

Spacers (2), Quick setup guide (1), Paper strip bin (1), Paper tray (1), Cable tie (2),

Securing band (1), Screw for securing band (2), Washer (1)

89 x 127mm (without frame)

102 x 152mm (without frame)

127 x 178mm (without frame)

152 x 203mm (without frame)

152 x 229mm (without frame)

FEATURESPRECAUTIONS OTHERS CONTENTS

PREPARATION

SHOOTING

TROUBLE-

Print size and outside dimensions show typical value.

Design and specications are subject to change without notice.

Contents of CD-ROM

• Operation manual

23

Page 4

MITSUBISHI ELECTRIC US. INC.

Visual and Imaging Systems

5900-A Katella Ave.

Cypress, CA 90630-5019, U.S.A.

Phone 888-307-0309

MITSUBISHI ELECTRIC EUROPE B.V.

UK Branch

Travellers Lane, Hateld, Herts. AL10 8XB, England, U.K.

Phone +44 (0) 1707 276100 FAX +44 (0) 1707 278755

German Branch

Gothaer Strasse 8, 40880 Ratingen ; Postfach 1548, 40835 Ratingen ; Germany

Phone +49 (2102) 486-9250 FAX +49 (2102) 486-7320

French Branch

25, Boulevard des Bouvets - 92741 NANTERRE cedex, France

Phone +33 (1) 55 68 55 00 FAX +33 (1) 55 68 57 31

Benelux Branch

Nijverheidsweg 23a,

3641 RP Mijdrecht, The Netherlands

Phone +31 (0) 297-282461 FAX +31 (0) 297-283936

Spanish Branch (Barcelona)

Ctra. de Rubí, 76-80 - Apdo. 420

08190-Sant Cugat del Vallés - (Barcelona) Spain

Phone +34 93 565 3154 FAX +34 93 589 4388

Please contact the nearest Mitsubishi sales branch to get DOC (Declaration of Conformity) of the EC Directive

1999/5/EC.

Manufactured by Mitsubishi Electric (Malaysia) Sdn. Bhd.

PLO 32, Kawasan Perindustrian Senai II, 81400 Senai, Johor Darul Takzim, Malaysia

WE919C194A2

Loading...

Loading...