Page 1

GROUP 13

FUEL

CONTENTS

MULTIPOINT FUEL INJECTION (MPI). . . . . . . . . . . . . . . . . . . . 13A

MULTIPOINT FUEL INJECTION (MPI) <4G1>. . . . . . . . . . . . . . 13B

FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13C

Page 2

GROUP 15

INTAKE AND

EXHAUST

CONTENTS

AIR INTAKE SYSTEM . . . . . . . . . . . . 15-2

AIR DUCT AND AIR CLEANER . . . . . . . . . 15-2

INTERCOOLER <4G1> . . . . . . . . . . . . . . . 15-3

INLET MANIFOLD <4A9>. . . . . . . . . . . . . . 15-4

INLET MANIFOLD <4G1> . . . . . . . . . . . . . 15-4

EXHAUST SYSTEM . . . . . . . . . . . . . . 15-5

EXHAUST MANIFOLD <4A9> . . . . . . . . . . 15-5

TURBOCHARGER <4G1> . . . . . . . . . . . . . 15-6

EXHAUST PIPE AND MUFFLER <4A9> . . 15-7

EXHAUST PIPE AND MUFFLER <4G1> . . 15-8

Page 3

15-2

INTAKE AND EXHAUST

AIR INTAKE SYSTEM

AIR INTAKE SYSTEM

AIR DUCT AND AIR CLEANER

CONSTRUCTION DIAGRAM

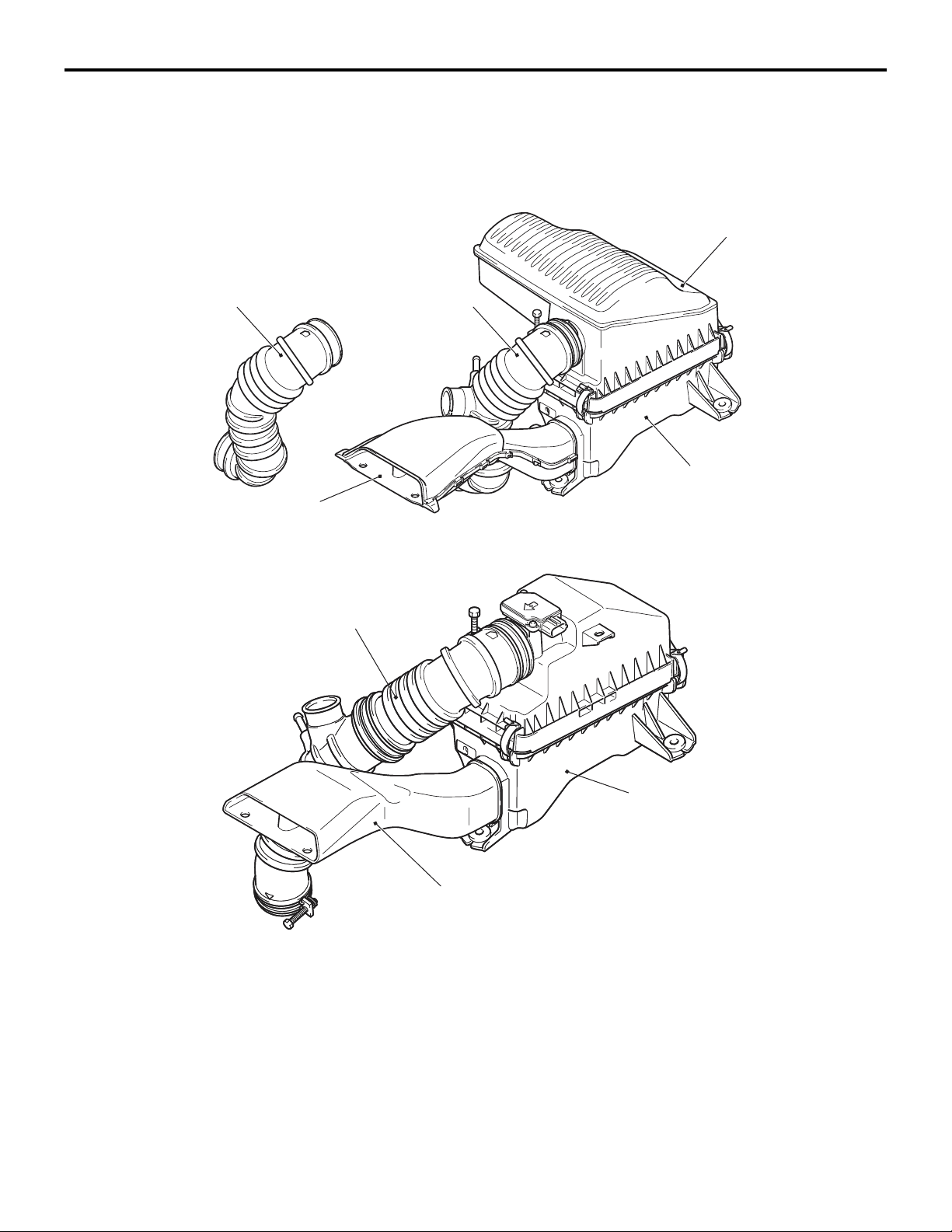

<4A9>

Engine

air intake hose

<M/T>

Air cleaner intake duct

<4G1>

M2150004000504

Engine

air intake hose

<CVT>

Air cleaner resonator

Air cleaner assembly

AC601193

AB

Engine air intake hose

Air cleaner intake duct

• An air cleaner resonator has been adopted to

improve engine performance and reduce air

intake noise <4A9>.

• A front air intake system that actively sucks cooling air from the front through the top of the radiator has been adopted in order to improve engine

performance and reduce air intake noise.

Air cleaner assembly

AC402138

AC402138

AB

• For the air cleaner intake duct, a venturi duct with

a diaphragm on its path has been adopted to sup

press rise in air resistance and reduce air intake

noise.

• In consideration of industrial waste reduction and

global environment, recycled materials made

from eating utensils and the scraps have been

adopted for the air cleaner body and cover of the

air cleaner assembly.

-

Page 4

INTAKE AND EXHAUST

AIR INTAKE SYSTEM

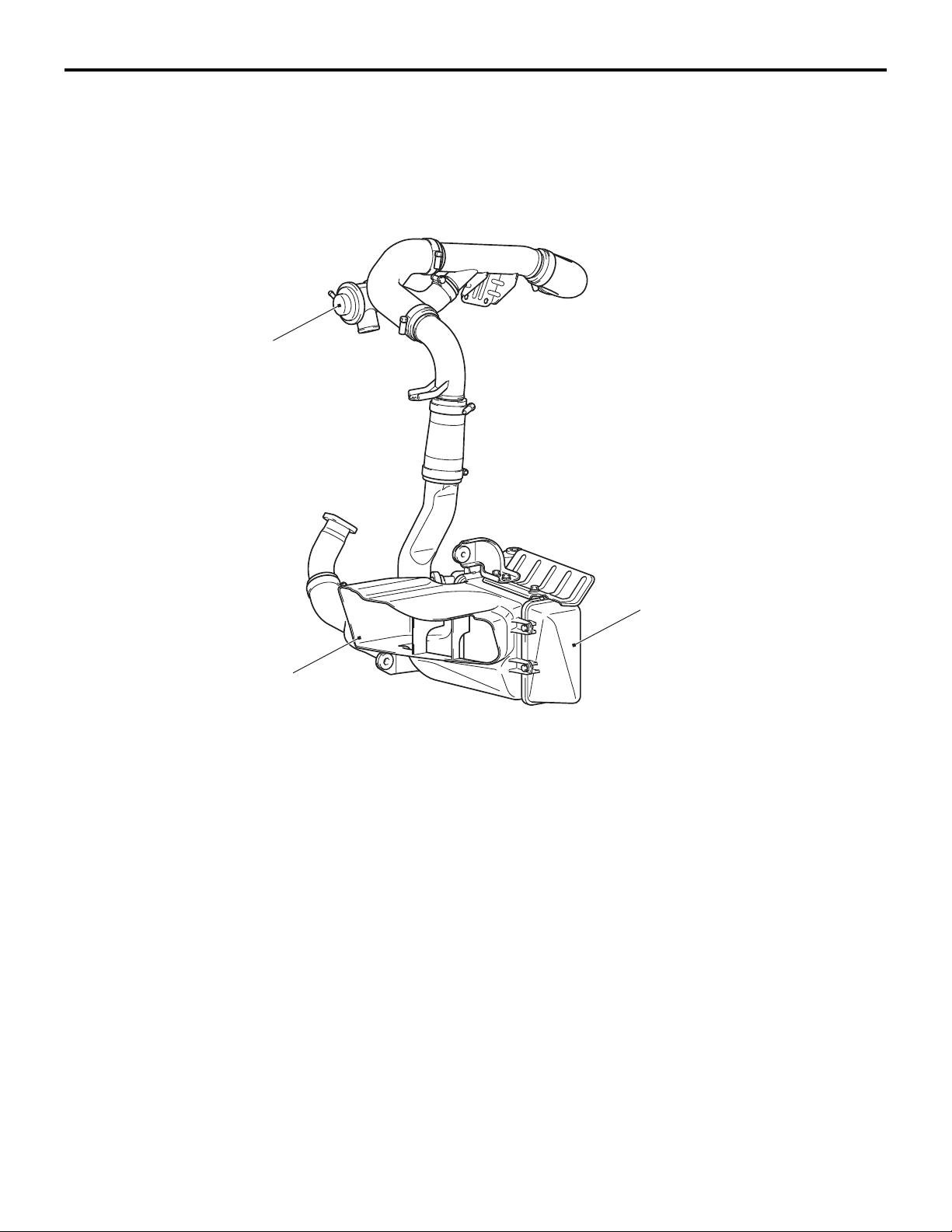

INTERCOOLER <4G1>

M2150007000246

An air cooled intercooler has been adopted to lower

the intake air temperature drastically and improve

engine performance.

CONSTRUCTION DIAGRAM

Air by-pass valve

15-3

Intercooler inlet air duct

Intercooler assembly

AC600080

AB

Page 5

15-4

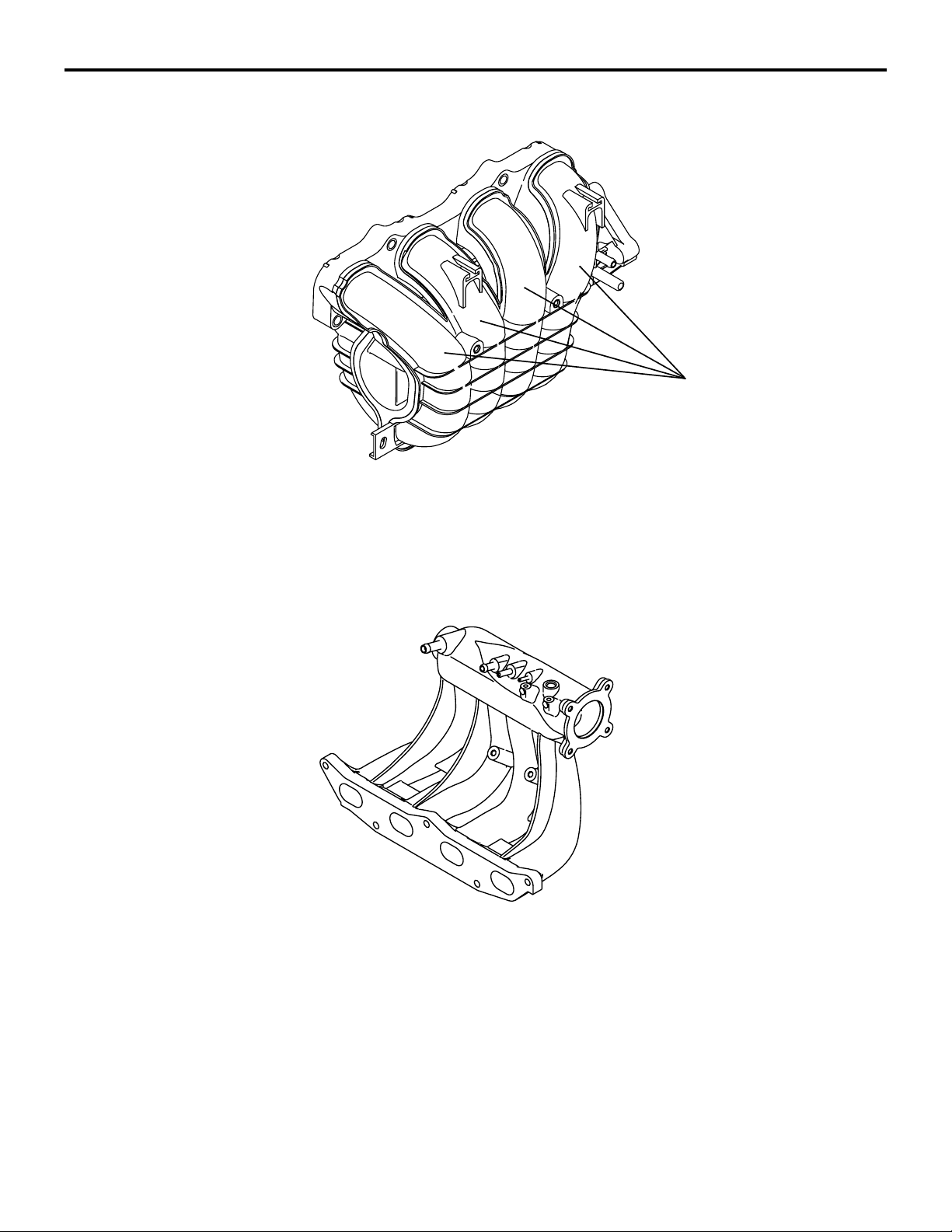

INLET MANIFOLD <4A9>

INTAKE AND EXHAUST

AIR INTAKE SYSTEM

M2150010000105

Inlet port

The inlet manifold is made of resin. The inlet ports

are curled for size and weight reduction.

INLET MANIFOLD <4G1>

AK305379

M2150010000116

AB

The port shape is changed to be optimum for the

vehicle with the turbocharger.

AK403235

Page 6

INTAKE AND EXHAUST

EXHAUST SYSTEM

EXHAUST SYSTEM

15-5

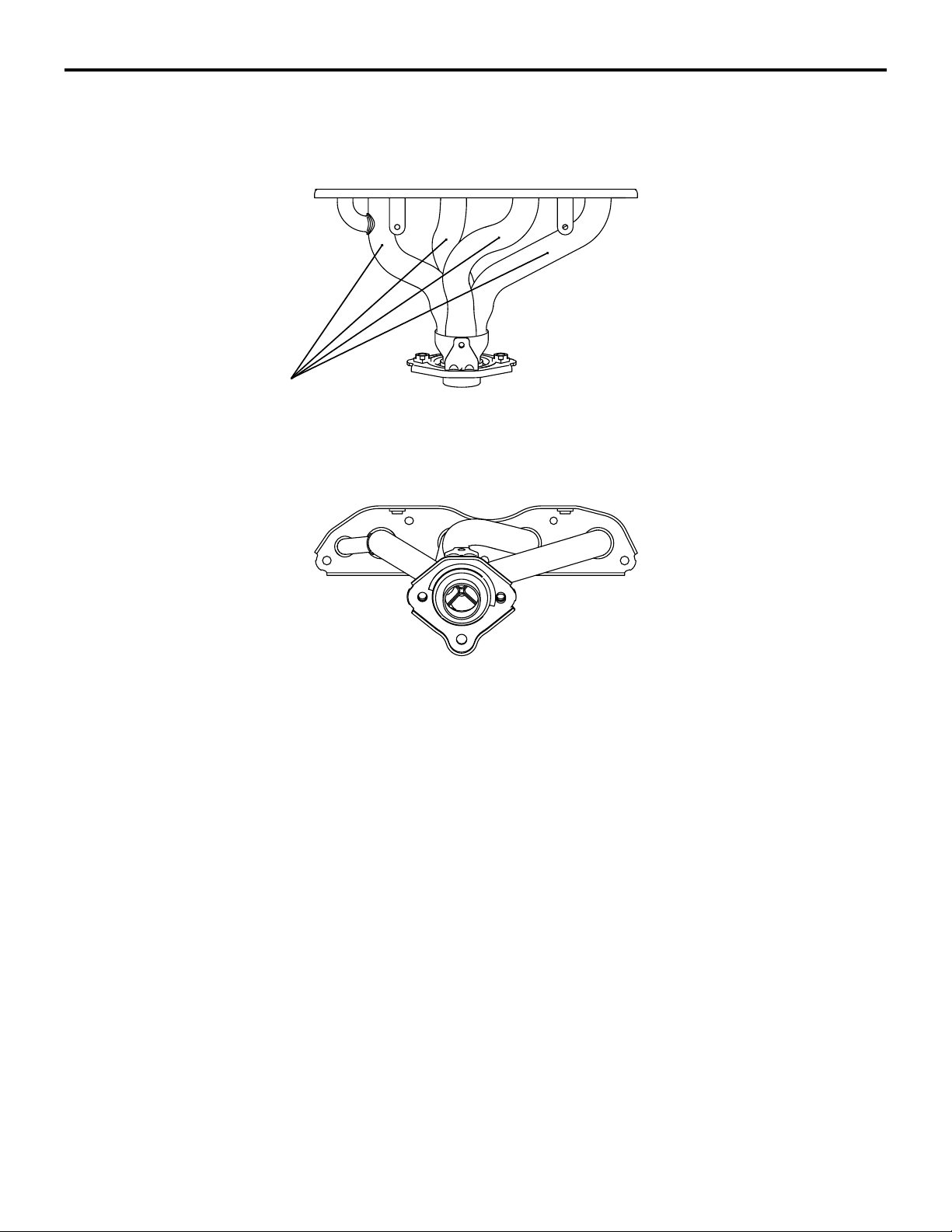

EXHAUST MANIFOLD <4A9>

Pipes

M2150006000317

The exhaust manifold consists of stainless steel

pipes, with all the ports being equal in length, to

achieve robust mid-range torque and weight reduc

tion.

AK402037

AD

-

Page 7

15-6

INTAKE AND EXHAUST

EXHAUST SYSTEM

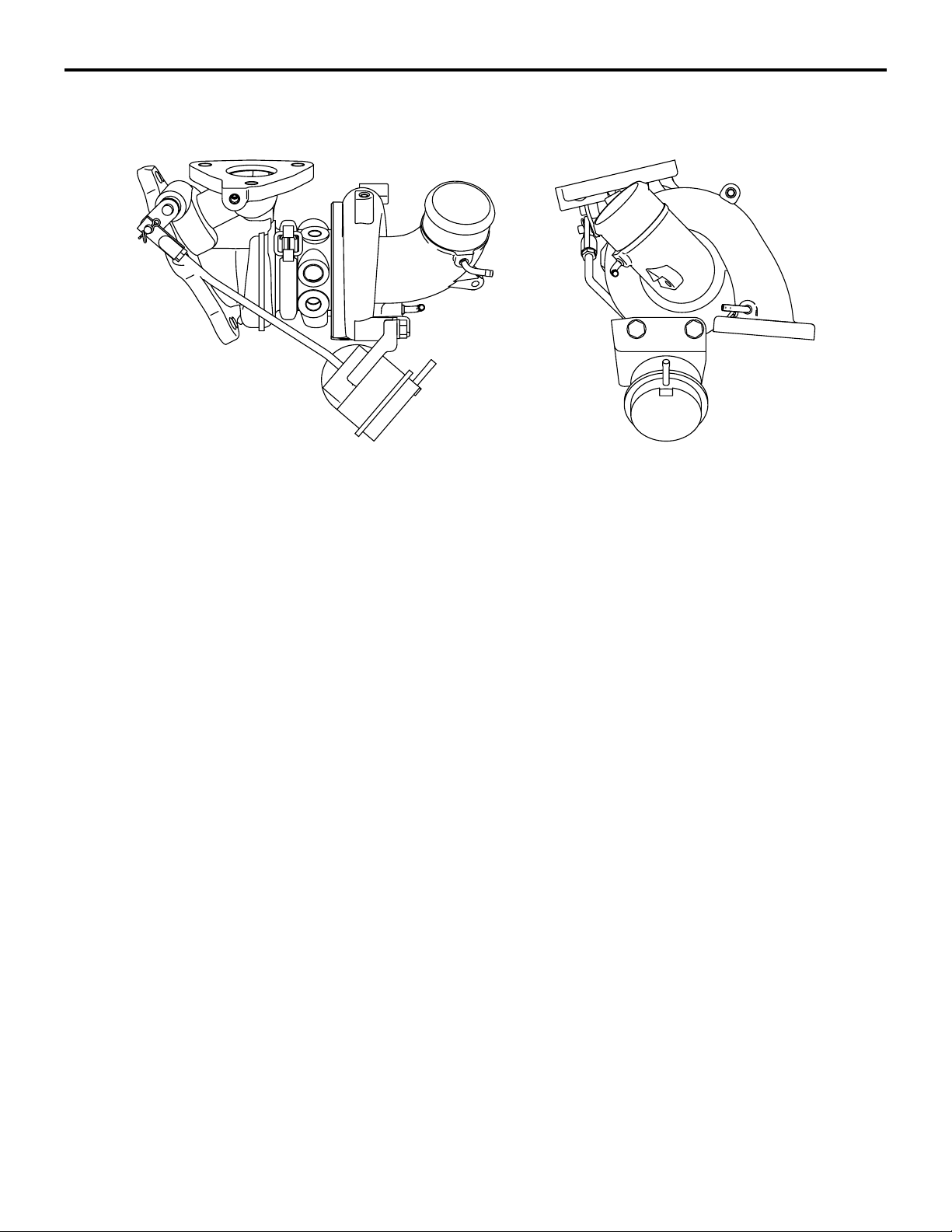

TURBOCHARGER <4G1>

Considering the balance among the engine output,

the response and the amount of the exhaust gases,

the optimized size is used .

M2150009000123

AK402141

Page 8

INTAKE AND EXHAUST

EXHAUST SYSTEM

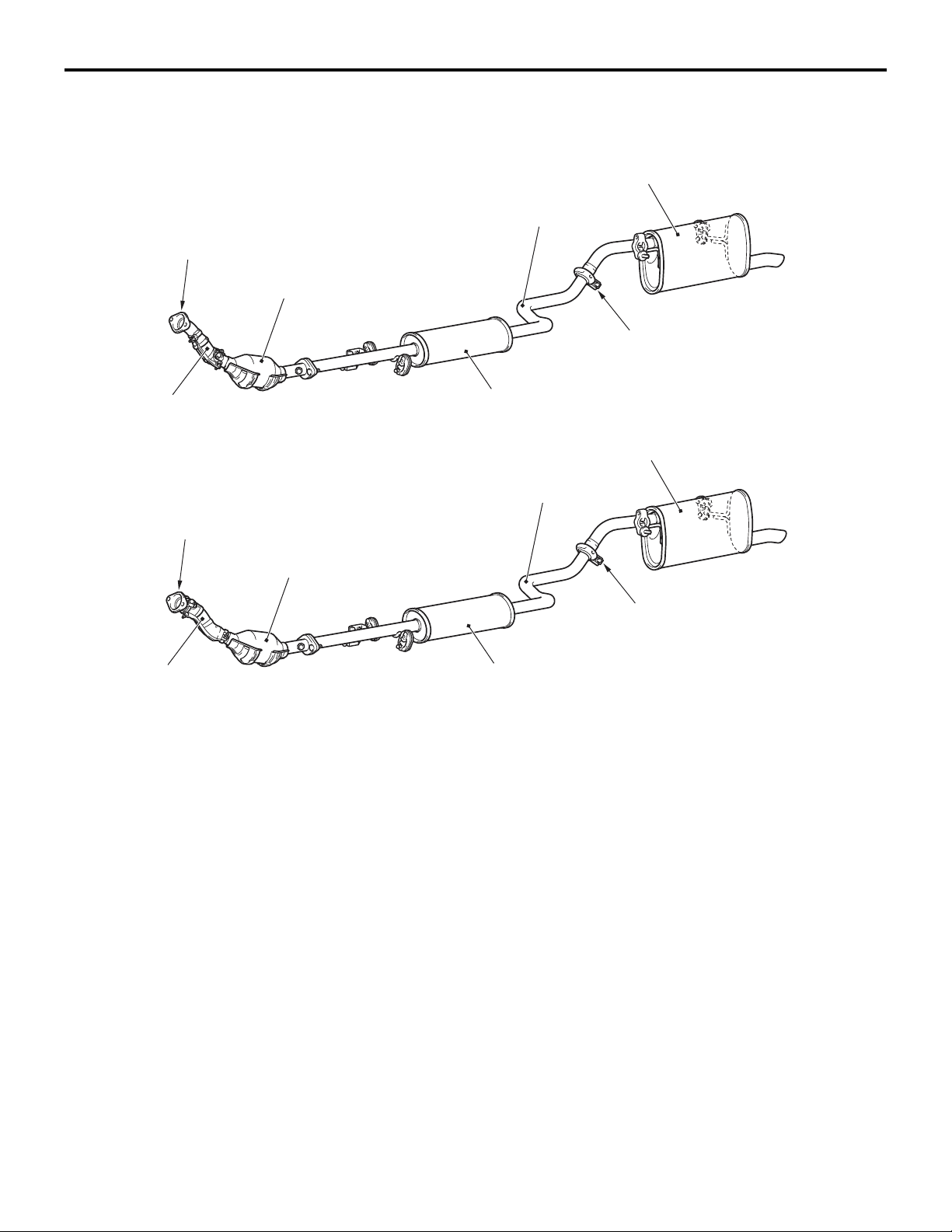

EXHAUST PIPE AND MUFFLER <4A9>

M2150003000642

CONSTRUCTION DIAGRAM

15-7

<M/T>

Annular joint

Front exhaust pipe

<CVT>

Annular joint

Under floor catalytic converter

Under floor catalytic converter

Centre exhaust pipe

Exhaust pre-muffler

Centre exhaust pipe

Exhaust main muffler

Insertion joint

Exhaust main muffler

Insertion joint

AC601362

AB

Front exhaust pipe

Exhaust pre-muffler

Exhaust pipe consisting of three separation system:

front exhaust pipe, centre exhaust pipe, and exhaust

main muffler, has the following features:

• An exhaust pre-muffler has been installed to the

centre exhaust pipe in order to reduce exhaust

noise.

• An insertion joint has been adopted for the connection between the centre exhaust pipe and the

exhaust main muffler to save the weight of the

exhaust system.

AC601363

• The under floor catalytic converter has been

moved closer to the engine side to improve

exhaust gas performance.

• An annular joint has been adopted for the connection between the exhaust manifold and the

front exhaust pipe to reduce the exhaust pipe's

vibration from the engine side.

AB

Page 9

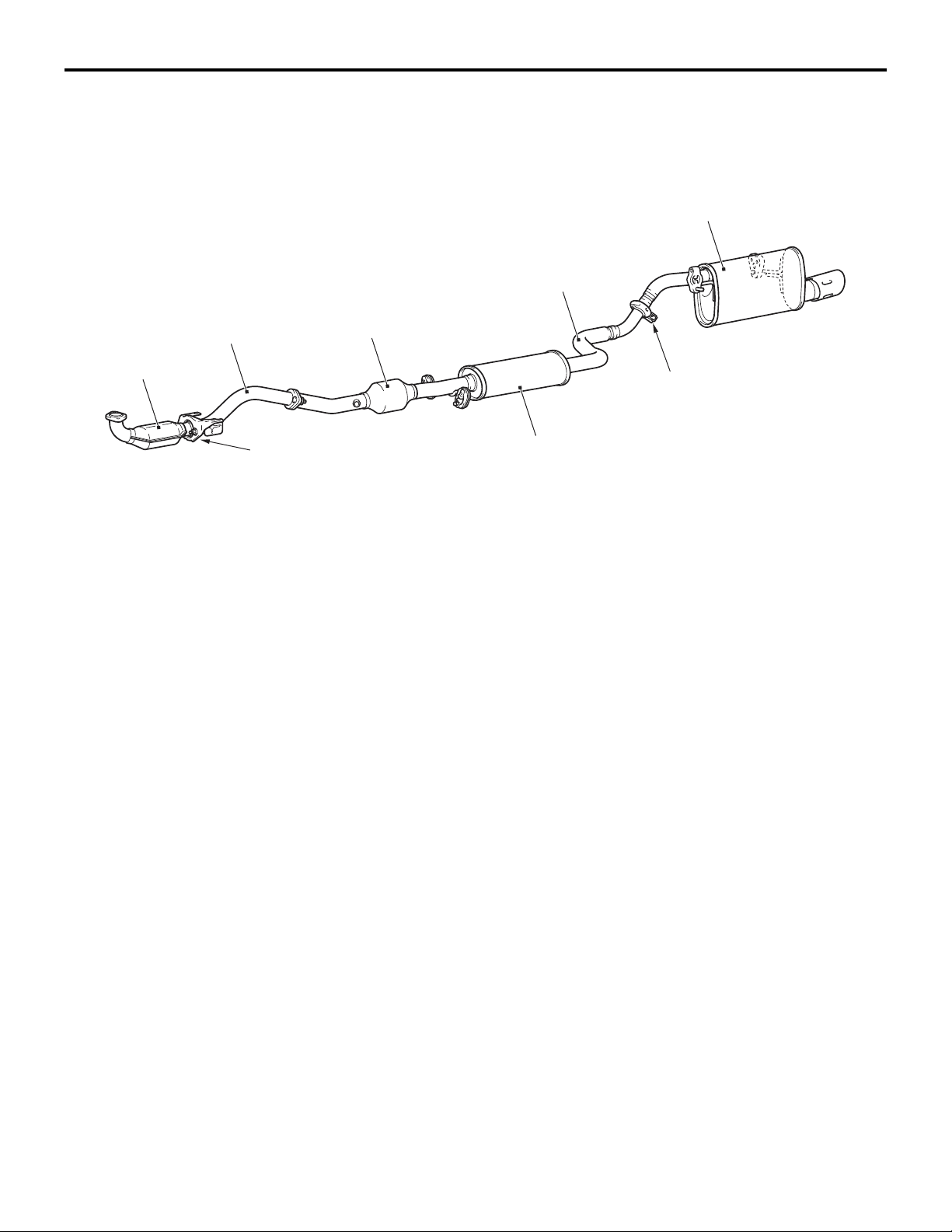

15-8

INTAKE AND EXHAUST

EXHAUST PIPE AND MUFFLER <4G1>

M2150003000653

CONSTRUCTION DIAGRAM

Under floor

Front

catalytic

converter

Front exhaust pipe

catalytic converter

EXHAUST SYSTEM

Exhaust main muffler

Centre exhaust pipe

Insertion joint

Annular joint

Exhaust pipe consisting of three separation system:

front exhaust pipe, centre exhaust pipe, and exhaust

main muffler, has the following features:

• An exhaust pre-muffler has been installed to the

centre exhaust pipe in order to reduce exhaust

noise.

• An insertion joint has been adopted for the connection between the centre exhaust pipe and the

exhaust main muffler to save the weight of the

exhaust system.

Exhaust pre-muffler

AC601366

• An annular joint has been adopted for the connection between the front exhaust pipe and the

front catalytic converter has been adopted to

reduce vibration from the engine side.

• A front catalytic converter and an under floor catalytic converter have been adopted to improve

exhaust gas performance.

AB

Page 10

GROUP 17

ENGINE AND

EMISSION

CONTROL

CONTENTS

ENGINE CONTROL . . . . . . . . . . . . . . 17-2

ACCELERATOR SYSTEM . . . . . . . . . . . . . 17-2

EMISSION CONTROL . . . . . . . . . . . . 17-3

GENERAL INFORMATION <4A9> . . . . . . . 17-3

GENERAL INFORMATION <4G1> . . . . . . . 17-4

Page 11

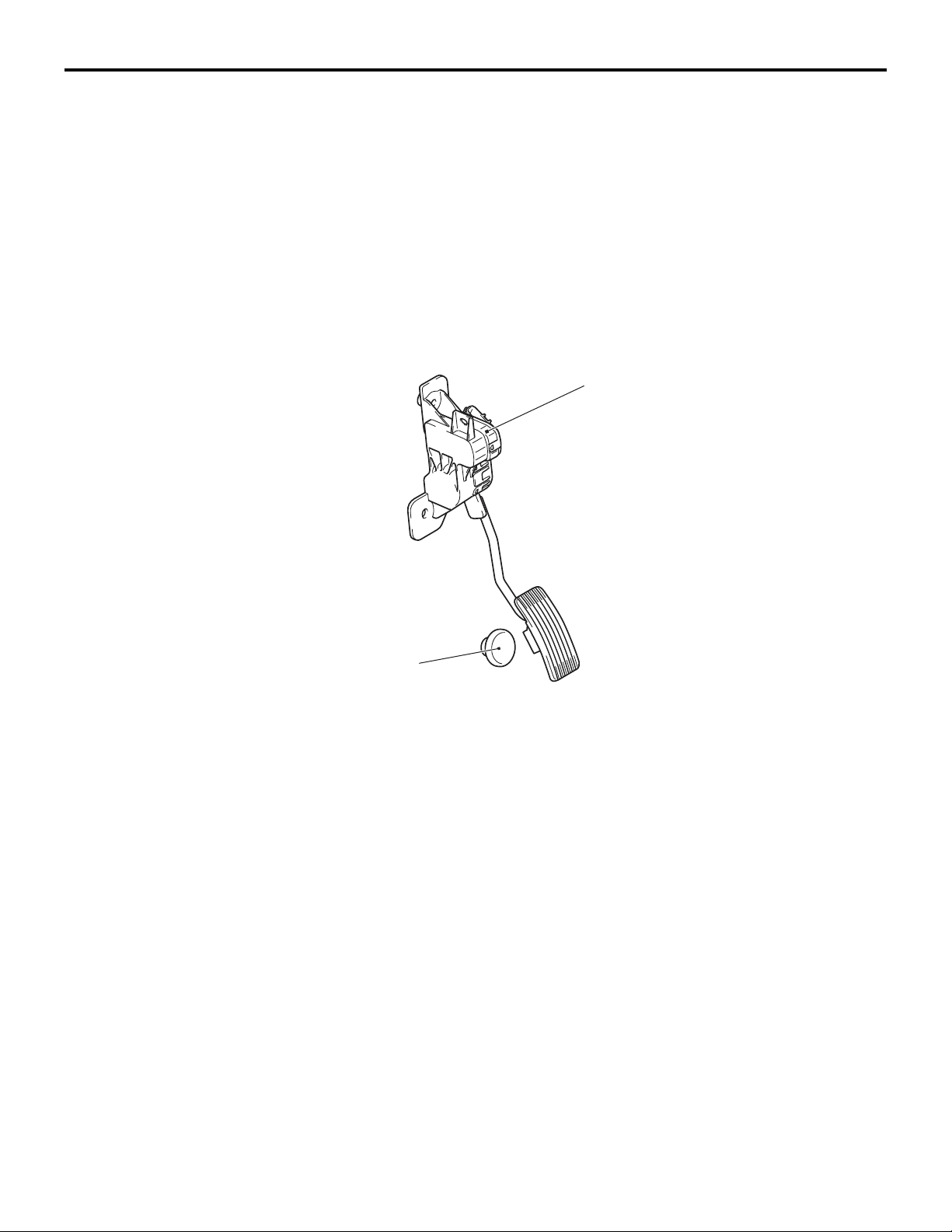

17-2

ENGINE AND EMISSION CONTROL

ENGINE CONTROL

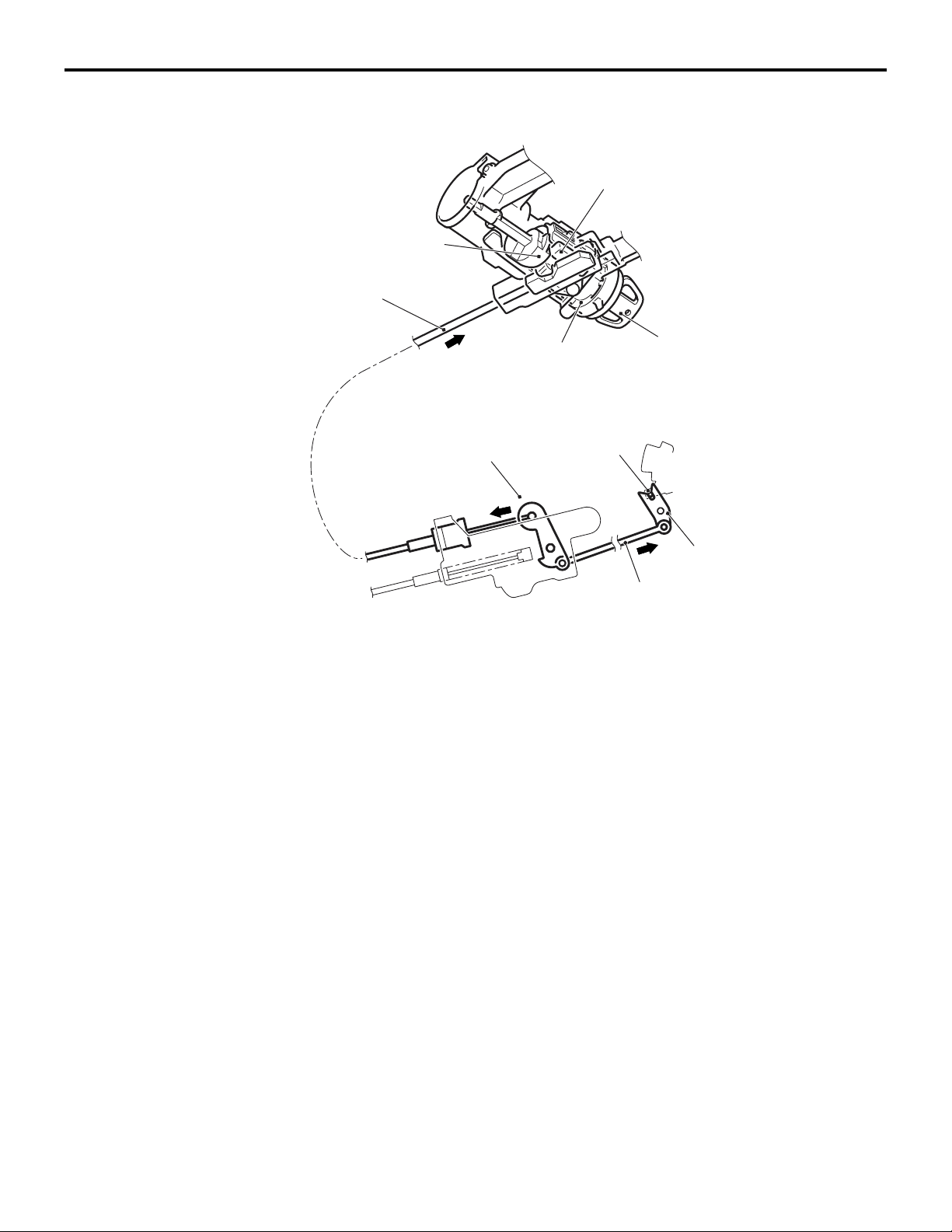

ENGINE CONTROL

ACCELERATOR SYSTEM

M2170003000310

For the accelerator system, an electronic throttle

valve control system has been adopted, eliminating

of an accelerator cable. This system detects the

amount of the accelerator pedal movement by using

a accelerator pedal-position sensor in the accelerator

pedal assembly for electronic control of the throttle

valve angle.

CONSTRUCTION DIAGRAM

Accelerator pedal assembly

(Built-in accelerator pedal

position sensor)

Accelerator pedal

arm stopper

AC206106

AD

Page 12

ENGINE AND EMISSION CONTROL

EMISSION CONTROL

EMISSION CONTROL

17-3

GENERAL INFORMATION <4A9>

Although the emission control systems are basically

the same as those of the 4G1-Non-Turbo engine

used in the COLT, the following improvements have

been added.

System Remarks

Crank case ventilaton system Closed type

Evaporative emission control system Electronic control type with duty signal

Exhaust gas recirculation (EGR) system <CVT> Electronic control (stepper motor) type

Air/fuel ratio closed loop control Oxygen sensor signal used

Catalytic converter Three-way catalytic converter

• The adoption of the catalytic converter just

beneath exhaust manifold realizes the earlier

activation.

• The adoption of the dual oxygen sensor has

increased reliability air/fuel ratio control.

•

The abolition of the EGR system <M/T>.

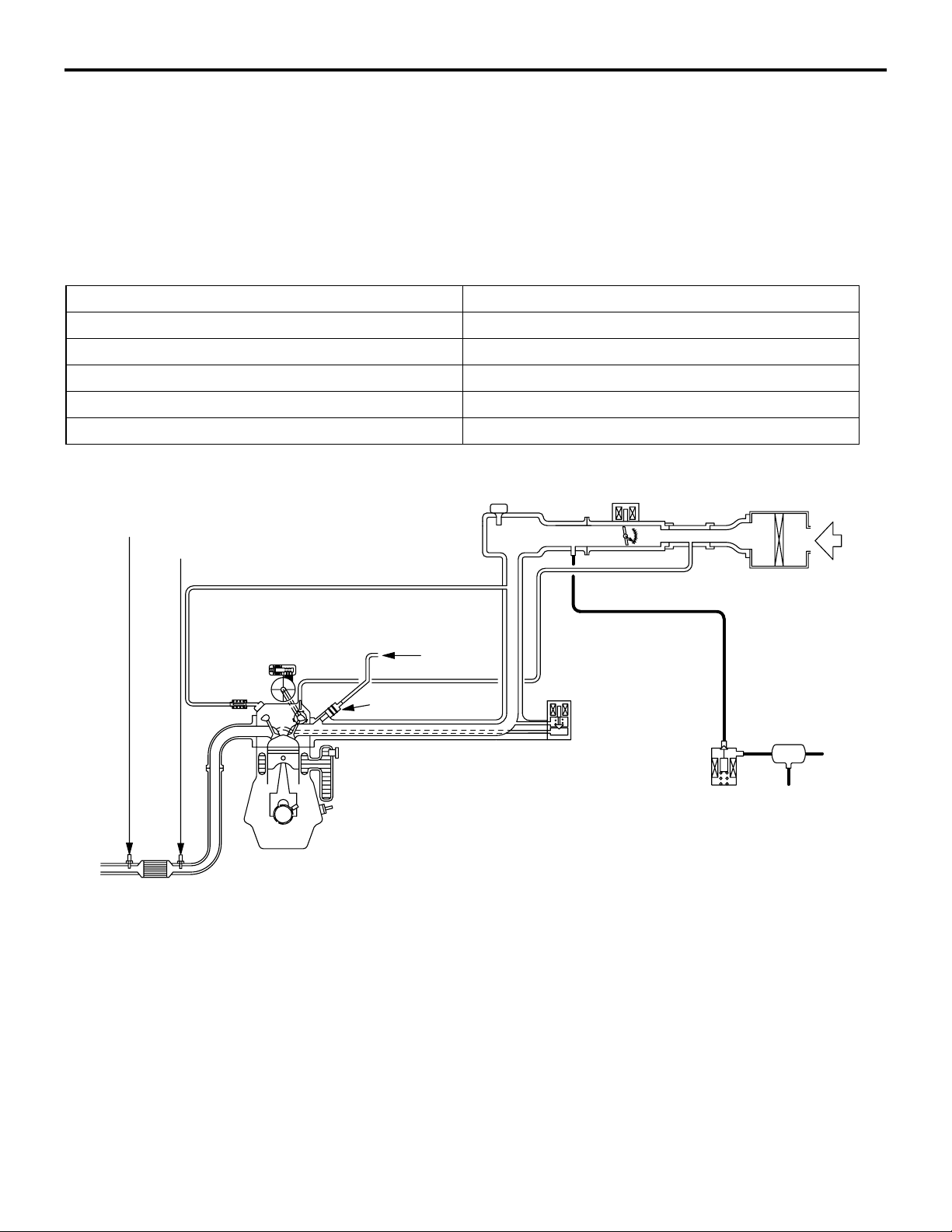

EMISSION CONTROL SYSTEM DIAGRAM

Oxygen sensor (rear)

Oxygen sensor (front)

M2171000100838

Air

inlet

PCV valve

Catalytic converter

Injector

From

fuel pump

EGR valve

(stepper motor)

<CVT>

Purge control

solenoid valve

Canister

AK402829

AC

Page 13

17-4

ENGINE AND EMISSION CONTROL

EMISSION CONTROL

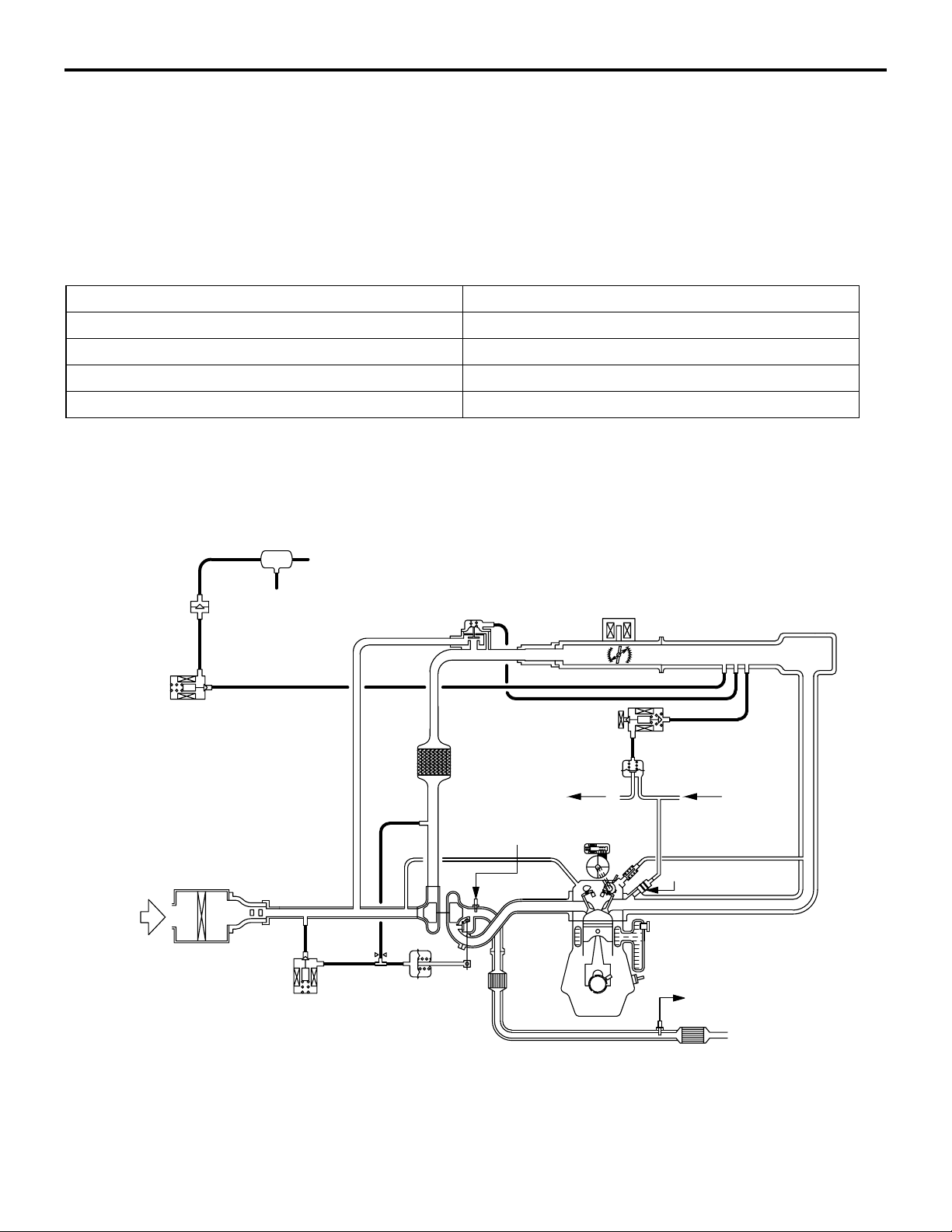

GENERAL INFORMATION <4G1>

Although the emission control systems are basically

the same as those of the 4G1-Non-Turbo engine

used in the COLT, the following improvements have

been added.

• The adoption of the catalytic converter just

beneath turbo charger and under the floor

increased the performance of the emission con

-

trols.

System Remarks

Crank case ventilaton system Closed type

Evaporative emission control system Electronic control type with duty signal

Air/fuel ratio closed loop control Oxygen sensor signal used

Catalytic converter Three-way catalytic converter

• The adoption of the check valve between the

purge control solenoid valve and the canister pro

tects the regurgitation as turbocharging.

•

The abolition of the EGR system

EMISSION CONTROL SYSTEM DIAGRAM

M2171000100849

-

Air

inlet

Check valve

Purge control

solenoid valve

Canister

Waste gate

solenoid valve

Waste gate

actuator

Fuel pressure control

solenoid valve

To

fuel tank

Oxygen sensor

(front)

Catalytic

converter

Fuel pressure

regulator

From

fuel pump

Injector

Oxygen sensor

(rear)

Catalytic

converter

AK600530AB

Page 14

GROUP 23

CONTINUOUSLY

VARIABLE

TRANSMISSION

(CVT)

CONTENTS

CVT. . . . . . . . . . . . . . . . . . . . . . . . . . . 23-2

GENERAL INFORMATION. . . . . . . . . . . . . 23-2

ELECTRONIC CONTROL SYSTEM. . . . . . 23-3

EEPROM. . . . . . . . . . . . . . . . . . . . . . . . . . . 23-3

CONTROLLER AREA NETWORK (CAN)

COMMUNICATION . . . . . . . . . . . . . . . . . . . 23-3

RATIO PATTERN . . . . . . . . . . . . . . . . . . . . 23-3

DIAGNOSIS CLASSIFICATION TABLE . . . 23-4

ATF WARMER (ATF COOLER) . . . . . . . . . 23-5

TRANSMISSION CONTROL . . . . . . . 23-6

GENERAL INFORMATION . . . . . . . . . . . . . 23-6

SELECTOR LEVER ASSEMBLY . . . . . . . . 23-7

CVT ERRONEOUS OPERATION

PREVENTION MECHANISMS . . . . . . . . . . 23-8

Page 15

23-2

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

CVT

CVT

GENERAL INFORMATION

M2231000100165

The F1C1A transmission is adopted for the CVT.

This transmission is basically the same as conven

tional transmission.

The ATF warmer (ATF cooler) is adopted.

-

SPECIFICATIONS

Item Specification

Transmission model F1C1A

Engine model 4A91

Tor qu e co nv er te r Type 3-element, 1-stage, 2-phase type

Lock-up Provided

Stall torque ratio 2.0

Transmission type Forward automatic continuously variable (steel belt type),

1st in reverse

Gear ratio Forward 2.319 − 0.445

Reverse 2.588

Clutch A pair of multi-plate system

Brake A pair of multi-plate system

Manual control system P-R-N-D-Ds-L (smart shift)

Function Variable speed control Yes

Line pressure control Yes

Direct engagement control Yes

N-D/N-R control Ye s

Shift pattern control Yes

Self-diagnosis Yes

Failsafe Ye s

Oil pump Type External gear pump

Configuration Built-in (chain drive)

Control method Electronic control (INVECS-III)

Transmission oil Specified lubricants DIA QUEEN ATF SP III

Quantity L 8.1

Page 16

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

ELECTRONIC CONTROL SYSTEM

CVT

23-3

EEPROM

M2231012000024

Because EEPROM has been used, even if the battery terminals or control unit connectors are disconnected, the necessary learned values are stored in

the engine-CVT-ECU to prevent a loss of shift qual

ity. (Initialisation is available by M.U.T.-III).

CONTROLLER AREA NETWORK (CAN)

COMMUNICATION

CAN* communication has been adopted for communication with other ECUs in order to decrease the

number of wires and ensure information transmis

sion. For CVT control, the engine-CVT-ECU receives

the following signals.

CAN COMMUNICATION INPUT SIGNAL TABLE

Input signal Transmitter ECU

Average vehicle speed signal from drive wheels ABS-ECU

Motor current signal EPS-ECU

EPS warning lamp illumination request signal

Compressor signal Meter and A/C-ECU

NOTE: *: For more information about CAN (Controller Area Network), refer to GROUP 54C P.54C-2.

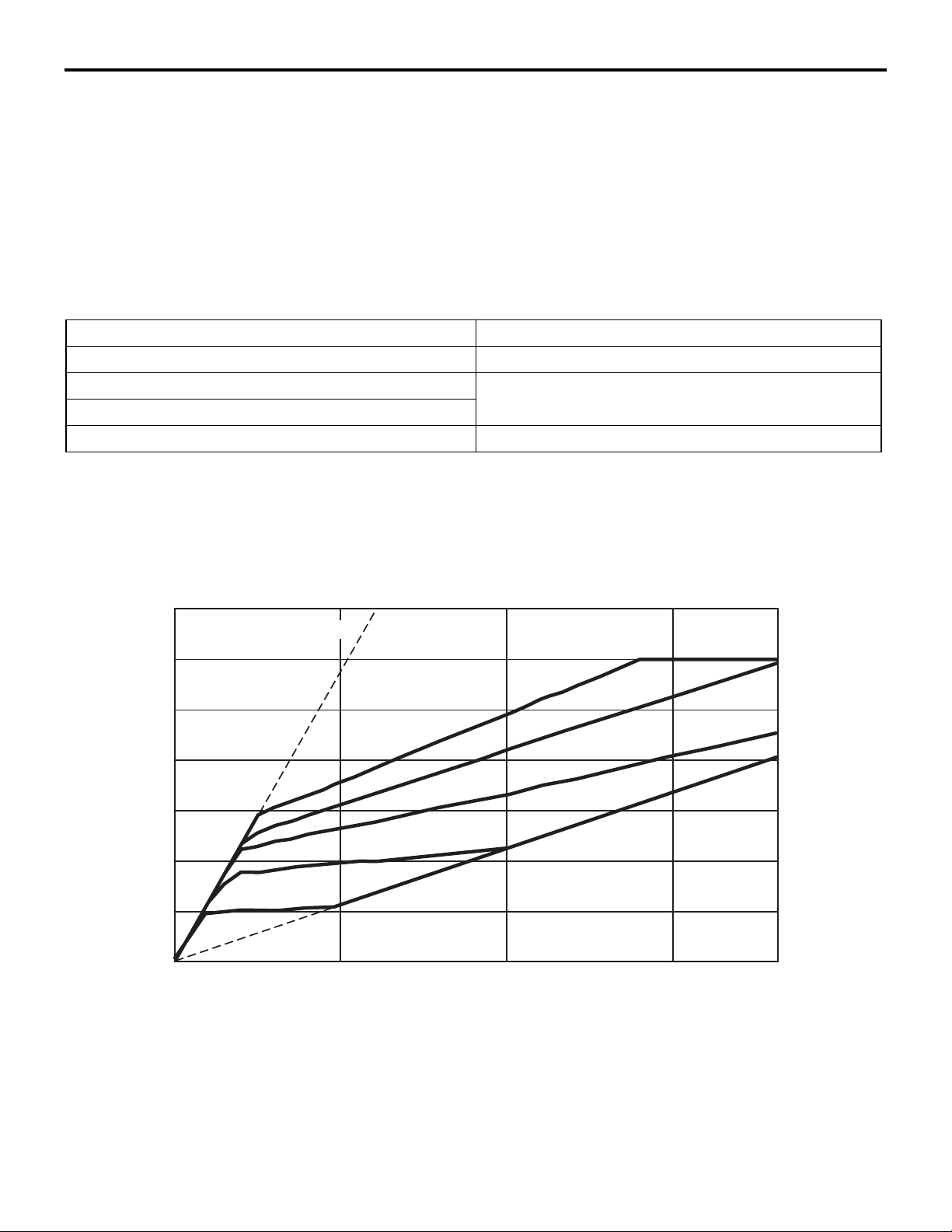

RATIO PATTERN

M2231013000061

Engine speed

(r/min)

7,000

LOW

M2231017000018

-

6,000

5,000

4,000

3,000

2,000

1,000

Accelerator

fully open

40%

Accelerator

fully closed, 20%

0

Vehicle speed (km/h)

80%

60%

100 15050

OD

AC403740

AE

Page 17

23-4

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

CVT

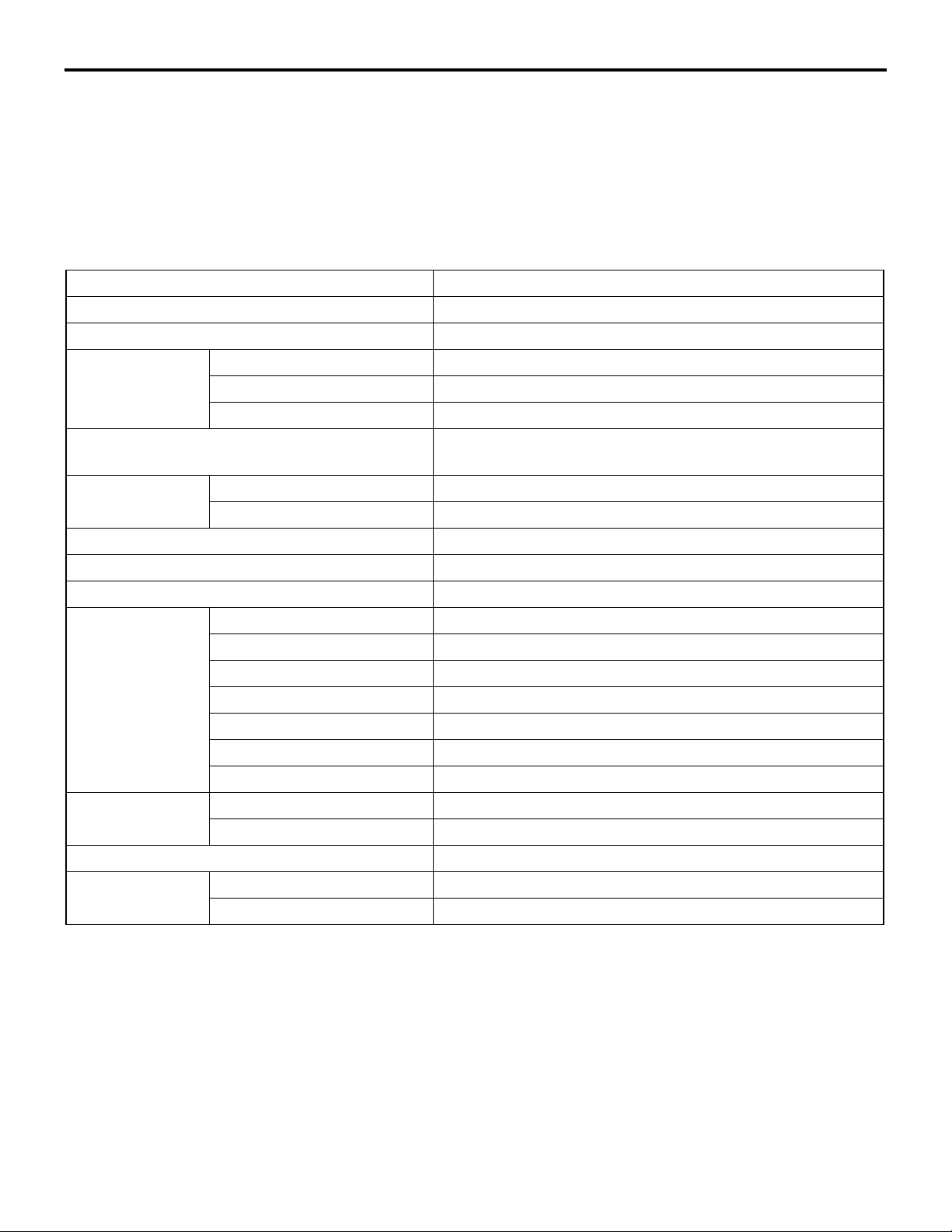

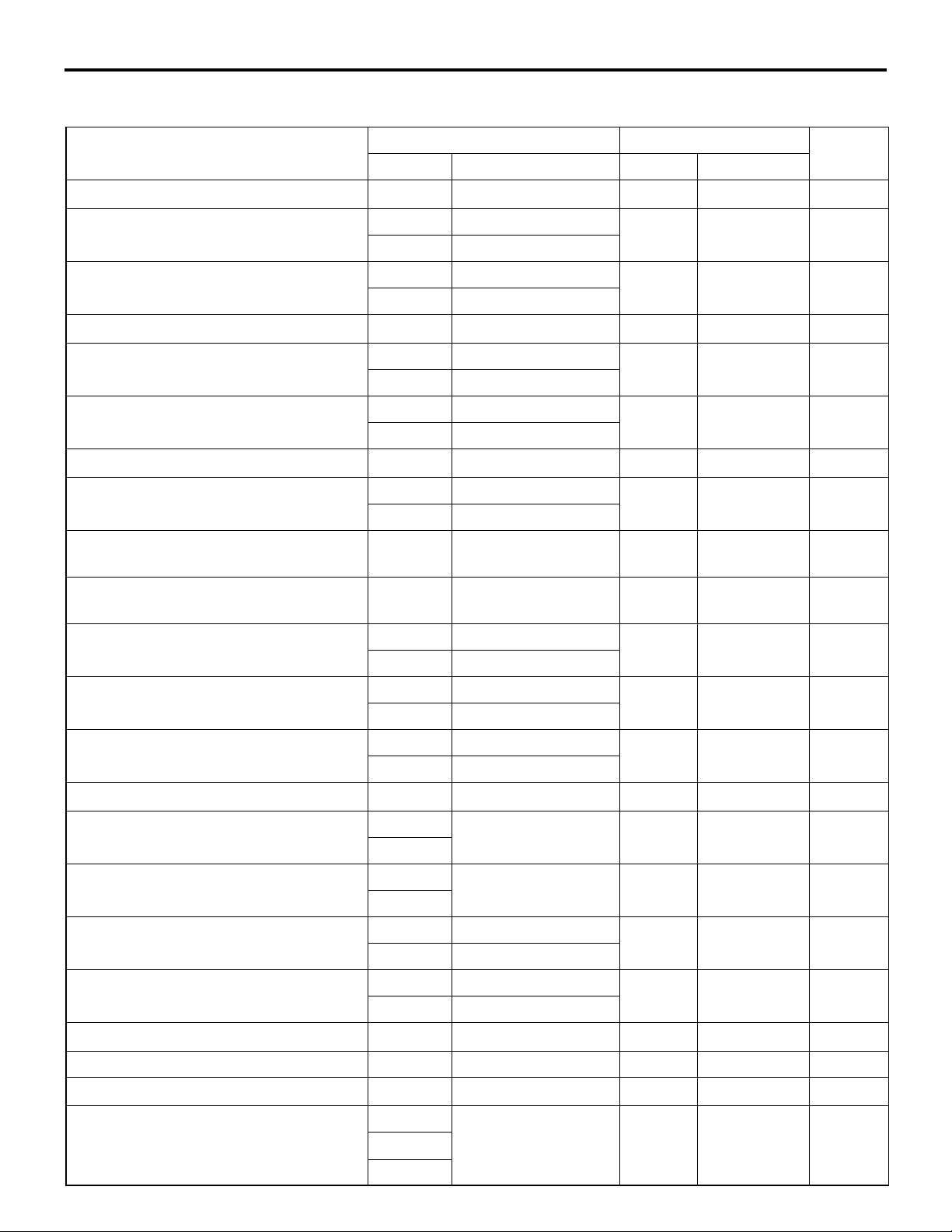

DIAGNOSIS CLASSIFICATION TABLE

M2231015000056

Item Diagnosis Data list Actuator

Code No. Trouble symptoms Item No. Display

Crank angle sensor

CVT fluid temperature sensor 15 Open circuit 08

− −

16 Short circuit

01 r/min

°C −

test

−

Line pressure sensor 18 Open circuit 09 MPa

19 Short circuit

Turbine speed sensor 22 Open circuit 02 r/min

Primary speed sensor 23 Open circuit 03 r/min

26 System failure

Secondary speed sensor 24 Open circuit 04 r/min

25 System failure

Accelerator pedal position sensor (APS)

Primary pressure sensor 27 Open circuit 11 MPa

Gear ratio

Line pressure control solenoid valve 31 Open circuit/short

Shift control solenoid valve 32 Open circuit 15 % 02

Damper clutch control solenoid valve 33 Open circuit 14 % 03

Clutch pressure control solenoid valve 34 Open circuit 17 % 04

− −

28 Short circuit

− −

circuit

36 Short circuit

37 Short circuit

06 mV

12 Displays the

gear ratio.

16 % 01

−

−

−

−

−

−

−

38 Short circuit

Shift system 42 System failure

Damper clutch system 44 System failure 10 r/min

45

Clutch system 46 System failure

48

Inhibitor switch 51 Open circuit 26 P/R/N/D/Ds/L

52 Short circuit

Stop lamp switch 53 Open circuit 33 ON/OFF

54 Short circuit

Battery voltage

CVT control relay 56 Open circuit 25 V 11

Steel belt system 59 System failure

Line pressure system 57 System failure

− −

71

72

− − −

− − −

24 V

− − −

− − −

−

−

−

−

Page 18

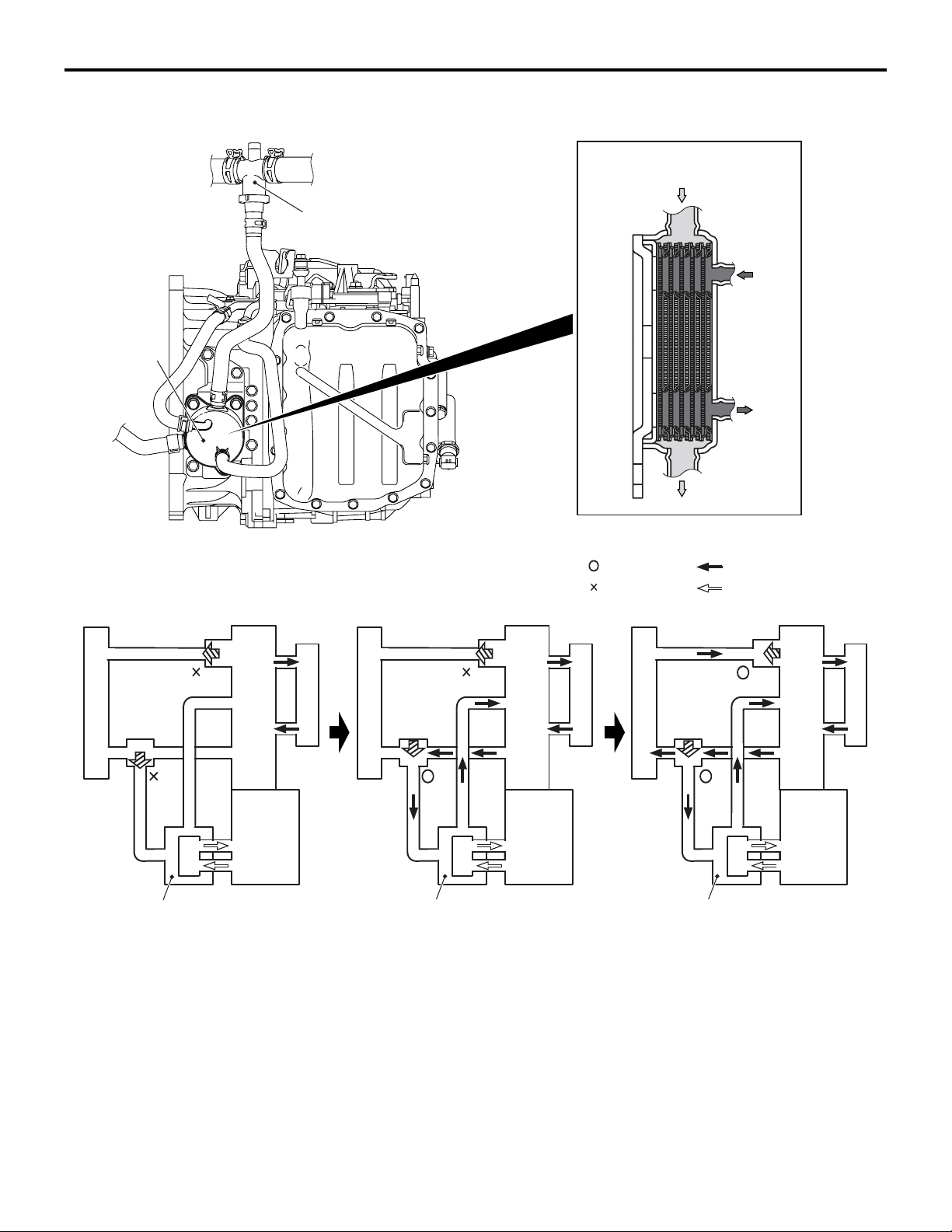

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

ATF WARMER (ATF C OOL ER)

Thermo valve

ATF Warmer

(ATF Cooler)

M2230000600082

CVT

23-5

Sectional view

Engine coolant

ATF

Thermostat

Thermo

Radiator

valve

ATF warmer (ATF cooler)

Engine

CVT CVT CVT

<Engine coolant temperature:

75˚C or less>

Engine coolant flows through

the heater only.

Heater

Radiator

ATF warmer (ATF cooler)

<Engine coolant temperature:

75 - 85˚C>

Engine coolant flows through

the heater and the ATF warmer.

Thermostat

Thermo

valve

The ATF warmer (ATF cooler) is adopted. (the ATF

cooler incorporating the radiator is not adopted)

At the start of running, the temperature of the engine

coolant rises earlier than that of the ATF. The ATF

warmer utilizes this characteristic to raise the ATF

temperature as early as possible to an appropriate

level (70 - 80

°C). It also controls fluid temperature

Engine

: Valve open

: Valve closed

Heater

: Engine coolant

: ATF

Thermostat

Thermo

Radiator

valve

ATF warmer (ATF cooler)

AC403052

Engine

AC

Heater

<Engine coolant temperature:

85˚C or more>

Engine coolant flows through

AC403006

all the sections.

AC

stably and reduces ATF agitation resistance to

improve fuel consumption ratio.

In addition, a thermo-valve has been adopted to

restrict the engine coolant supply to the ATF warmer

(ATF cooler) until the engine coolant temperature

reaches the appropriate temperature when low tem

perature start in winter, giving the priority to the heating performance.

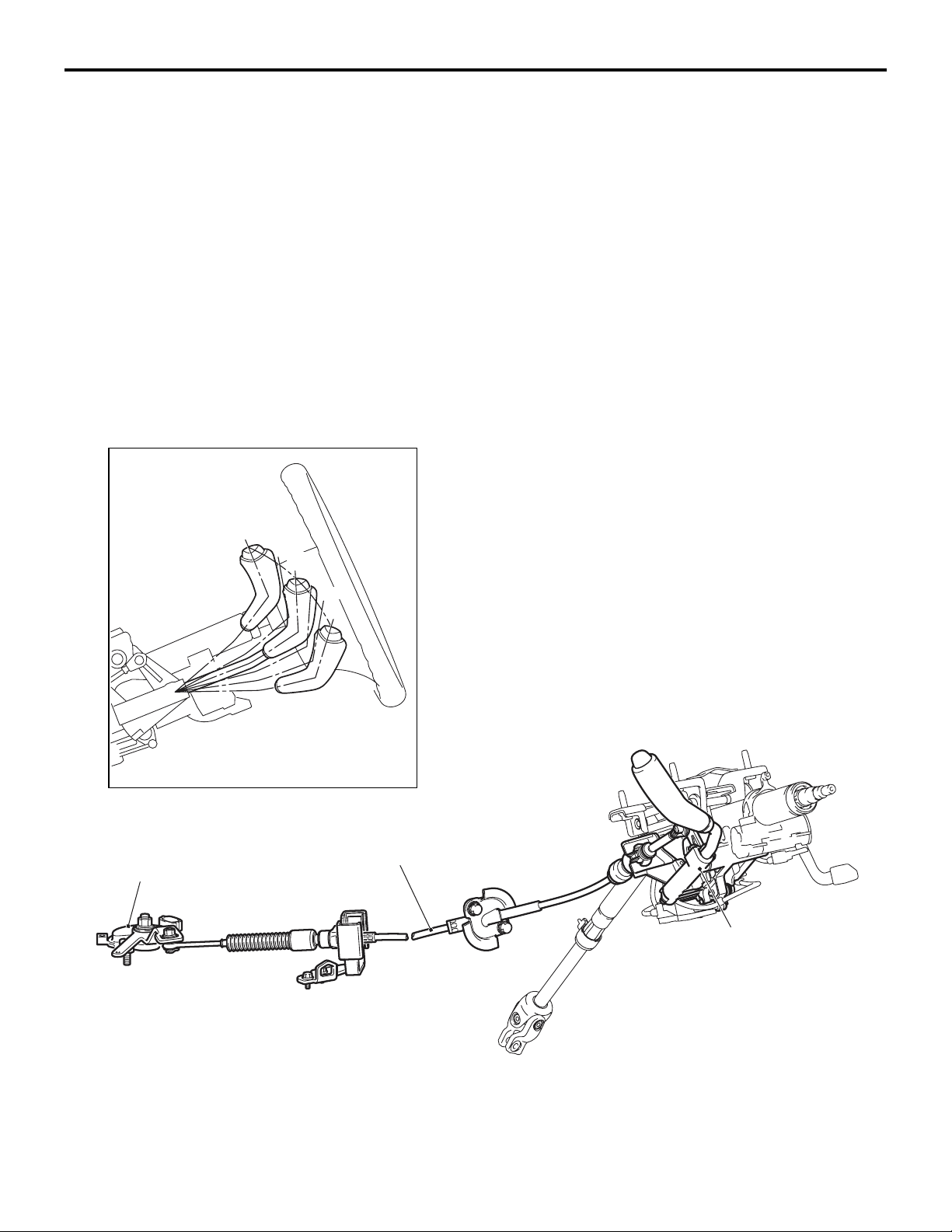

Page 19

23-6

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

TRANSMISSION CONTROL

TRANSMISSION CONTROL

GENERAL INFORMATION

M2232000100447

• A smart shift type selector lever has been

adopted in order to facilitate walkthrough

between the seats.

• A gun grip type selector lever knob has been

adopted for better operation and easier visual

recognition of the switches arranged in the centre

panel.

• The selector lever assembly has been a single

unit made by aluminium die casting for better

accuracy and fewer parts, resulting in the light

weight and compact structure.

COMPONENT VIEW

P

R

N

D

Ds

L

• The selector lever has been designed to be compact and appropriately configured not to interfere

with the energy absorbing mechanism on the

steering column upon impact of the vehicle.

• In order to prevent abrupt start by erroneous

operation of selector lever, a CVT erroneous

operation prevention mechanism (the shiftlock

mechanism and key interlock mechanism) has

been adopted.

-

Inhibitor switch

AC206842

Transmission

control cable

Selector lever

assembly

AC207638

AC206864

AB

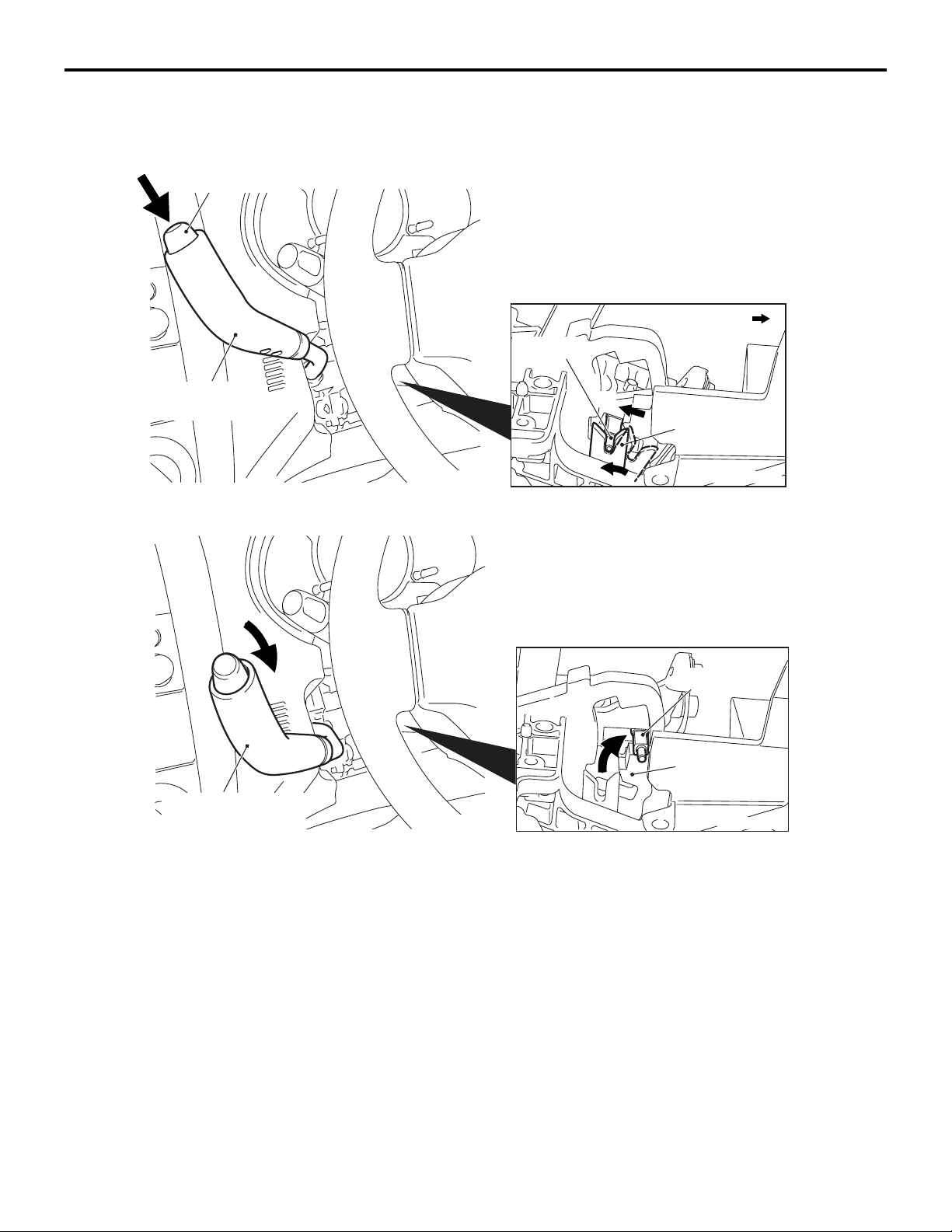

Page 20

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

SELECTOR LEVER ASSEMBLY

Push button

TRANSMISSION CONTROL

M2232002000190

Detent pin

23-7

Front of vehicles

Selector lever

(P position)

Selector lever

(except for P position)

AC206896

AC206897

A

Lock cam

AC206898

Detent pin

Detent block

AC206899

Operation

1. When the selector lever is in the P position, the

detent pin is engaged with the lock cam. When

the pushbutton on the selector lever is pressed,

the detent pin moves in the direction A as illustrated in the figure to rotate the lock cam.

2. When the detent pin rotates the lock cam to disengage, the selector lever can go over the protruding part of the detent block. This enables

shifting the selector lever.

AC207644

AB

Page 21

23-8

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

TRANSMISSION CONTROL

CVT ERRONEOUS OPERATION PREVENTION MECHANISMS

SHIFT LOCK MECHANISM

Only when the following two conditions are satisfied,

the selector lever can be shifted from the P position

to another position:

• When the brake pedal is depressed

• When the ignition key is in other than the LOCK

(OFF) position

When the brake pedal is not depressed

Detent pin

Lever

Shiftlock cable

Stopper

Brake pedal

M2232003000104

Lock cam

Rod

When the selector lever is in the P position with the

brake pedal not depressed, the shiftlock cable stop

per keeps the lever locked so that the rod and lock

cam do not move.

When the brake pedal is depressed

Shiftlock cable

Brake pedal

When the brake pedal is depressed, the stopper is

pulled by the shiftlock cable so that the lever

becomes unlocked.

Then the lock cam linked to the rod can also rotate

so that the selector lever can be shifted from the P

position to another position by pressing the pushbut

ton.

As a result of this, the pushbutton of the selector

-

lever linked to the detent pin cannot be pressed and

the selector lever cannot be shifted from the P posi

tion to another position.

Detent pin

Lever

Lock cam

Rod

Stopper

NOTE: When the brake pedal is depressed with the

ignition key in the LOCK (OFF) position, the selector

lever cannot be shifted from the P position to another

position.

-

AC206902

AC206903

AB

-

AB

Page 22

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

TRANSMISSION CONTROL

23-9

When the ignition key is in the LOCK (OFF) position or pulled out (With the selector

lever in the P position)

Slider

Projection of rotor

Key interlock cable

Ignition key

Engine starting

switch assembly

LOCK (OFF) position

In the engine starting switch assembly, the slider is

engaged with the groove of the key interlock cable,

and the slider is locked by the projection of the rotor

so that the key interlock cable as well as the lever,

rod, and lock cam does not move.

Lever

Lock cam

Rod

AC206911

As a result of this, any attempt to shift the selector

lever is prevented. The pushbutton on the selector

lever cannot be pressed because the lock cam does

not rotate, then the selector lever cannot be shifted

from the P position to another position.

AB

Page 23

23-10

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

TRANSMISSION CONTROL

When the ignition key is in other than the LOCK (OFF) position (With the selector

lever in the P position)

Slider

A

Projection of rotor

Key interlock cable

The rotor in the engine starting switch assembly has

a notch between ACC and START so that the slider

becomes unlocked.

Then the slider can move in the direction A as illustrated in the figure to allow the lock cam to rotate so

that the selector lever can be shifted from the P posi

tion to another position by pressing the pushbutton.

KEY INTERLOCK MECHANISM

When the selector lever is not in the P position, the

ignition key cannot be turned to the LOCK (OFF)

position and pulled out.

Engine starting

switch assembly

Lever

Ignition key

ACC to START

position

Lock cam

Rod

AC206912

NOTE: When the ignition key is in other than the

LOCK (OFF) position with the brake pedal not

depressed, the selector lever cannot be shifted from

the P position to another position.

-

AB

Page 24

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

TRANSMISSION CONTROL

When pulling out the key with the selector lever in other than the P position

Slider

B

Projection of rotor

Key interlock cable

23-11

A

The lock cam is kept in a rotated condition, and the

key interlock cable is kept pulled in direction A as

illustrated in the figure. In this state, the slider in the

engine starting switch assembly is moved and locked

in direction B as illustrated in the figure.

Engine starting

switch assembly

Lever

A

Ignition key

ACC to START

position

Rod

Lock cam

AC206912

AC

As a result of this, any attempt to turn the ignition key

to the LOCK (OFF) position is prevented because

the slider prevents the rotor from rotating, and the

ignition key can only turn up to the ACC position and

cannot be pulled out.

Page 25

23-12

CONTINUOUSLY VARIABLE TRANSMISSION (CVT)

TRANSMISSION CONTROL

When pulling out the key with the selector lever in the P position

Slider

Projection of rotor

Key interlock cable

When releasing the pushbutton on the selector lever

with the selector lever in the P position, the lock cam

is rotated by the detent pin. Then the key interlock

cable is moved by the lock cam in direction A as illustrated in the figure.

A

Engine starting

switch assembly

Lever

A

Detent pin

Ignition key

ACC to START

position

Lock cam

Rod

AC206911

As a result of this, the slider in the engine starting

switch assembly is unlocked. The rotor can then turn,

and the ignition key can be pulled out by turning it to

the LOCK (OFF) position.

AC

Page 26

GROUP 26

FRONT AXLE

CONTENTS

GENERAL INFORMATION . . . . . . . . 26-2

Page 27

26-2

FRONT AXLE

GENERAL INFORMATION

GENERAL INFORMATION

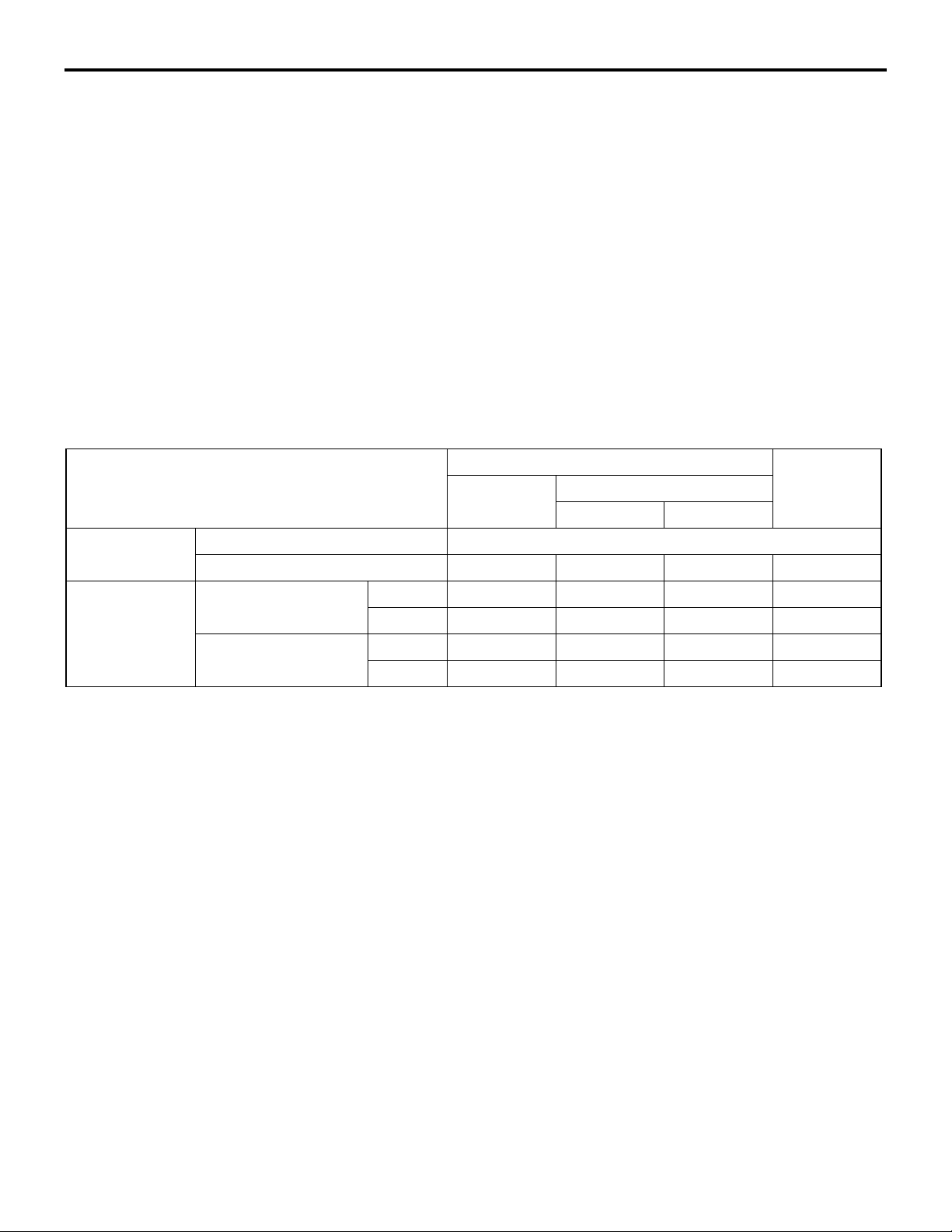

The front axle consists of front hub, wheel bearing,

knuckles and driveshafts, and has the following fea

tures:

• The wheel bearing incorporates magnetic

encoder for wheel speed sensing.

• The driveshaft incorporates EBJ-TJ type constant

velocity joint <4A9-CVT, 4A9-M/T (LS)>,

EBJ-ETJ type constant velocity joint <4A9-M/T

(VR)>, BJ-TJ type constant velocity joint <4G1>.

• The dynamic damper is mounted to reduce differential gear noise.

• The bracket assembly is mounted to reduce

torque steer. < 4G1>

SPECIFICATIONS

Item 4A9 4G1

• For environmental protection, a lead-free grease

-

CVT M/T

is used on the joints.

EBJ(Eight Ball Fixed Joint):The use of the

smaller-sized eight balls inside the joint achieves

weight saving and compact size compared with a

BJ(Birfield Joint).

ETJ(Eco type Tripod Joint):This joint achieves

weight saving and compact size compared with a

TJ(Tripod Joint).

BJ:Birfield Joint

TJ: Tripod Joint

LS VR

M2260000100701

Wheel bearing Type Double-row angular contact ball bearing

Bearing (OD x ID) mm 76 × 40 76 × 40 76 × 40 76 × 40

Driveshaft Joint type Outer EBJ EBJ EBJ BJ

Inner TJ TJ ETJ TJ

Length (joint to joint)

× diameter mm

LH 377 × 21.2 377 × 21.2 379 × 23 352 × 24.9

RH 688 × 21.2 688 × 21.2 664.3 × 23 378.2 × 24.9

Page 28

CONSTRUCTION DIAGRAM

FRONT AXLE

GENERAL INFORMATION

26-3

<4A9>

Front hub

<4G1>

Strut assembly

Knuckle

Strut assembly

EBJ

Wheel bearing

TJ (LH) <CVT, M/T (LS)>

ETJ (LH) <M/T (VR)>

Dynamic damper

Driveshaft (LH)

Driveshaft (RH)

TJ (RH) <CVT, M/T (LS)>

ETJ (RH) <M/T (VR)>

Dynamic damper

AC402000

AC403318

AG

Front hub

Knuckle

BJ

Wheel bearing

Driveshaft (LH)

TJ

Bracket assembly

TJ

Driveshaft (RH)

Dynamic damper

AC511705

AC

Page 29

26-4

FRONT AXLE

GENERAL INFORMATION

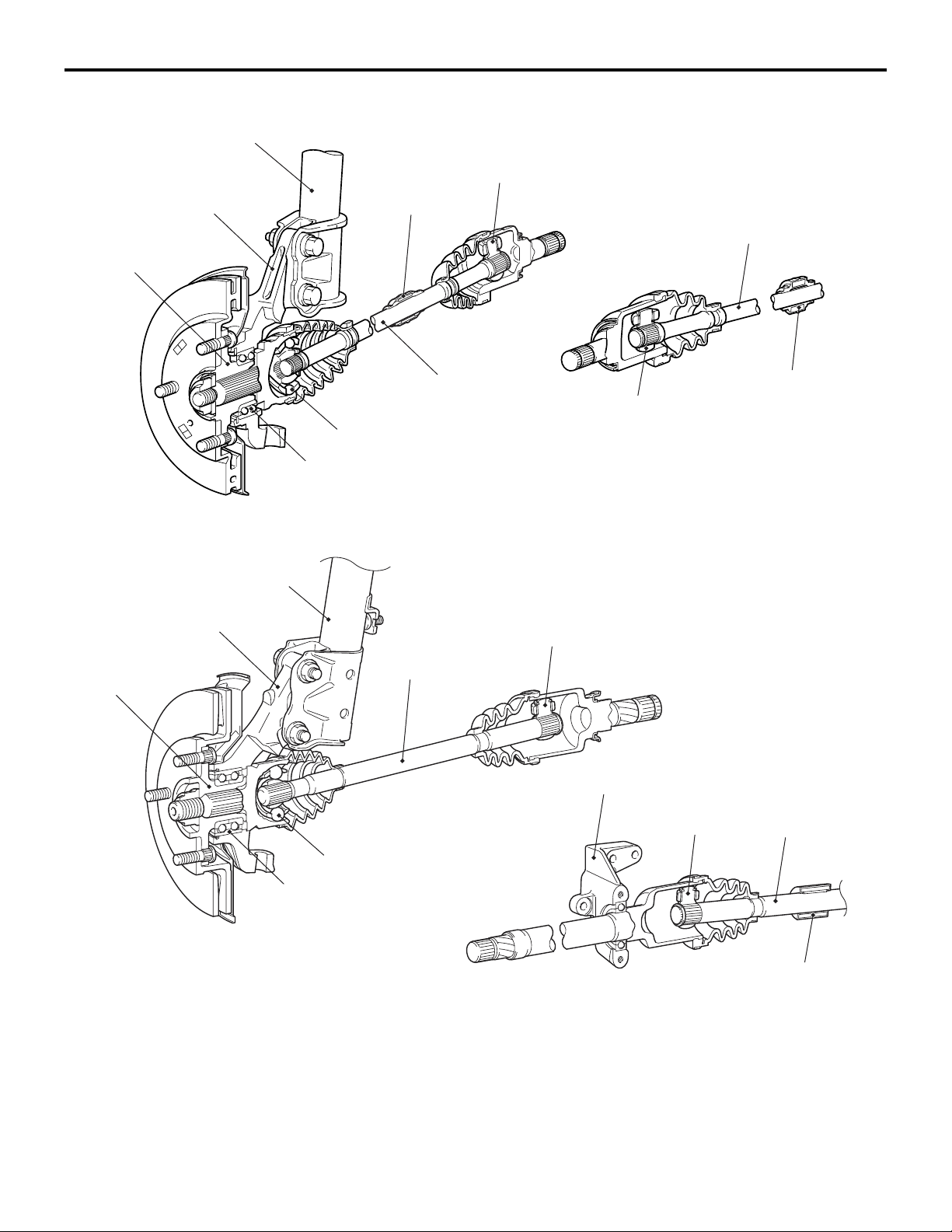

BJ

Comparison between BJ and EBJ

EBJ

Comparison between TJ and ETJ

TJ

ETJ

AC306013AE

Page 30

GROUP 27

REAR AXLE

CONTENTS

GENERAL INFORMATION . . . . . . . . 27-2

Page 31

27-2

REAR AXLE

GENERAL INFORMATION

GENERAL INFORMATION

M2270000100382

The rear axle has the following features:

• The wheel bearing is a unit ball bearing (double-row angular contact ball bearing) for reduced

friction.

• The wheel bearing incorporates magnetic

encoder for wheel speed sensing.

SPECIFICATION

Item Specification

Wheel bearing Type Unit ball bearing (double-row angular

NOTE: The wheel bearing is part of the hub, therefore its size is not listed here.

CONSTRUCTION DIAGRAM

• The rear wheel hub assembly combines the hub,

wheel bearing and oil seal in a single unit for

fewer parts, better durability, improved assembly

precision, and better structural organization.

contact ball bearing)

Rear hub

<4G1> <4A9>

Oil seal

Magnetic encoder

Wheel bearing

Rear hub

Wheel bearing

Oil seal

Magnetic encoder

AC402053AC600026

AC600074

AD

Page 32

GROUP 31

WHEEL AND TYRE

CONTENTS

GENERAL INFORMATION . . . . . . . . 31-2

Page 33

31-2

WHEEL AND TYRE

GENERAL INFORMATION

GENERAL INFORMATION

M2310000100800

The wheels and tyres of the following specifications

have been established.

SPECIFICATIONS

ROAD WHEEL AND TYRE

Item LS VR, VR-X RALLIART

Wheel Type Steel type Aluminium type Aluminium type

Size 14 × 5.5JJ 15 × 6JJ 16 × 6.5JJ

Amount of wheel offset mm46 46 43

PCD mm 100 100 11 4 . 3

Tyre Size 175/65R14 82S 185/55R15 81V 205/45R16 83W

NOTE: PCD indicates the pitch circle diameter of the wheel installation holes.

SPARE WHEEL AND TYRE

Item LS, VR VR-X RALLIART

Spare

wheel

Type Steel type Steel type Steel type

Size 14 × 4T 15 × 4T 15 × 3.5B

Amount of wheel offset mm38 46 40

PCD mm 100 100 11 4 . 3

Spare tyre Size T115/70D14 88M T125/70D15 95M T125/70D15 95M

NOTE: PCD indicates the pitch circle diameter of the wheel installation holes.

Page 34

GROUP 33

FRONT

SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . . 33-2

Page 35

33-2

FRONT SUSPENSION

GENERAL INFORMATION

GENERAL INFORMATION

Newly developed MacPherson strut suspension has

been adopted.

• The steering gear box is installed in the lower

position for better cornering performance.

• The roll centre and the kingpin axle are installed

appropriately for better cornering performance.

• The long stroke strut is adopted for sufficient road

holding quality.

M2330000100824

• High-rigid and light-weight flat crossmember is

adopted for sufficient suspension rigidity.

• The strut coil spring is installed appropriately for

friction reduction and comfortable ride.

• The coil spring of high tension material is adopted

for weight reduction.

• The open-section lower arm is adopted for weight

reduction.

Page 36

CONSTRUCTION DIAGRAM

<4A9>

Coil spring

FRONT SUSPENSION

GENERAL INFORMATION

Strut assembly

Stabilizer bar

33-3

Lower arm

close

section

Lower arm

<4G1>

Ball joint

Coil spring

Front axle No.1 crossmember

(Flat crossmember)

A-point bushing

Lower arm

Strut assembly

Stabilizer bar

AC402422

Lower arm

close

section

AF

AC207732

Lower arm

Ball joint

Front axle No.1 crossmember

(Flat crossmember)

A-point bushing

Lower arm

AC402422

AE

Page 37

33-4

FRONT SUSPENSION

GENERAL INFORMATION

SPECIFICATIONS

SUSPENSION SYSTEM

Item Specification

Suspension type MacPherson strut with coil spring

WHEEL ALIGNMENT

Item Specification

Camber

Caster 4A9 2°35'

4G1 2°40'

Kingpin inclination 13°20'

Toe -i n At the centre of tyre tread mm 0

To e- an gle ( pe r wh ee l) 0°

− 0 °30'

COIL SPRING

<4A9>

Item Specification

Wire diameter mm 12

Average outside diameter mm 133 − 149 − 154

Free length mm CVT 331

5MT 301

<4G1>

Item Specification

Wire diameter mm 13

Average outside diameter mm 133 − 150 − 154

Free length mm 300

Page 38

GROUP 34

REAR SUSPENSION

CONTENTS

GENERAL INFORMATION . . . . . . . . 34-2

Page 39

34-2

REAR SUSPENSION

GENERAL INFORMATION

GENERAL INFORMATION

Newly developed H-shaped torsion beam type suspension has been introduced.

• The coil spring is installed under the rear floor,

the torsion beam and arm assembly is installed in

front of the spare tyre house, and the shock

absorber is installed outside, so that the large

cabin space is achieved.

• The arm bushing with the toe control function is

adopted to optimise the tyre steering angle using

the bushing deflection caused by lateral force

and longitudinal force generated at cornering, so

that the good cornering performance is secured.

CONSTRUCTION DIAGRAM

M2340000100825

• The layout of shock absorber is optimised for

smooth riding.

• Long wheel stroke secures sufficient road holding

quality.

• The hub-integrated unit bearing is adopted for the

wheel bearing for sufficient suspension rigidity

(Refer to GROUP 27, Rear Axle

P.27-2).

• The dumping characteristic of shock absorber

has been changed. <4G1>

• The urethane bump stopper has been adopted to

improve the linearity. <4G1>

• To rs io n b ea m r ig id it y h as b ee n i mp ro v ed < 4G 1>

Shock absorber

Arm bushing

Section A – A

<4G9>

Torsion bar

Torsion beam and arm assembly

Torsion beam and arm assembly

A

A

Coil spring

Section A – A

<4G1>

Torsion beam and arm assembly

AC405533

AD

Page 40

REAR SUSPENSION

GENERAL INFORMATION

SPECIFICATIONS

SUSPENSION SYSTEM

Item Specification

Suspension type To rs ion b ea m sus pe ns io n

WHEEL ALIGNMENT

Item Specification

Camber

Toe -i n At the centre of tyre tread mm 3

To e- an g le ( per w he el ) 0°09'

−1°

COIL SPRING

Item 4A9 4G1

Wire diameter mm 10 11

Average outside diameter mm 75 − 107 − 75 111

34-3

Free length mm 301 283

Page 41

GROUP 35

SERVICE BRAKE

CONTENTS

BASIC BRAKE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35A

ANTI-SKID BRAKE SYSTEM (ABS) . . . . . . . . . . . . . . . . . . . . . 35B

ACTIVE STABILITY CONTROL SYSTEM (ASC). . . . . . . . . . . . 35C

Page 42

GROUP 35A

BASIC BRAKE

SYSTEM

CONTENTS

GENERAL INFORMATION . . . . . . . . 35A-2

CONSTRUCTION DESCRIPTION . . . 35A-5

MASTER CYLINDER . . . . . . . . . . . . . . . . . 35A-5

BRAKE BOOSTER . . . . . . . . . . . . . . . . . . . 35A-5

BRAKE PEDAL . . . . . . . . . . . . . . . . . . . . . . 35A-6

FRONT BRAKE . . . . . . . . . . . . . . . . . . . . . . 35A-7

REAR BRAKE . . . . . . . . . . . . . . . . . . . . . . . 35A-8

Page 43

35A-2

BASIC BRAKE SYSTEM

GENERAL INFORMATION

GENERAL INFORMATION

FEATURES

Brake system with high reliability and durability have

achieved distinguished braking performance.

BRAKING PERFORMANCE

• Brake booster with 9-inch variable amplification

ratio mechanism by which greater braking force

can be obtained with a less pedal pressure has

been installed (with brake assist function).

• 14-inch disc brake is installed on the front

wheels. <LS, VR>

• 15-inch disc brake is installed on the front

wheels. <VR-X, RALLIART Version-R>

• 8-inch leading trailing type drum brake is installed

on the rear wheels. <LS, VR>

• 14-inch disc brake is installed on the rear wheels.

<VR-X, RALLIART Version-R>

STABILITY

• 4-wheel anti-lock braking system (4ABS) is

adopted to prevent slipping caused by the vehicle

wheels locking up, in order to maintain appropri

ate braking distance, and also to maintain vehicle

stability and steering function.

-

M2350000100848

• Electronic brake-force distribution (EBD) is

adopted to maintain the maximum amount of rear

braking force even when the vehicle's load is var

ied.

• Diagonal split (X-type) brake fluid line is adopted.

• Ventilated discs have been adopted to front

brakes to improve anti-fading performance.

• A brake pedal retraction suppression structure

that restrains the retraction of the brake pedal

and reduces the shock to the feet of the driver in

the event of a frontal collision has been adopted.

SERVICEABILITY

• Diagnosis function is adopted for the ABS system

in order to make inspection easier.

• For the front disc brakes, brake disc separated

front hub is adapted to make removal and instal

lation easier.

• ABS-ECU and hydraulic unit have been integrated to make them more compact and lighter.

-

-

Page 44

CONFIGURATION DIAGRAM

<LS, VR>

Brake booster (with variable

boosting mechanism)

Master cylinder

Front disc brake

BASIC BRAKE SYSTEM

GENERAL INFORMATION

Hydraulic unit

(Integrated with ABS-ECU)

35A-3

Rear drum brake

<VR-X, RALLIART Version-R>

Brake booster (with variable

boosting mechanism)

Master cylinder

Front disc brake

Hydraulic unit

(Integrated with ABS-ECU)

Rear disc brake

AC601653

AB

Page 45

35A-4

BASIC BRAKE SYSTEM

GENERAL INFORMATION

SPECIFICATIONS

Item Specifications

Master cylinder Ty pe Ta nd em ty pe

I.D. mm LS, VR 20.6

VR-X 22.2

RALLIART Version-R 23.8

Brake booster Type Vacuum t y p e , s i n g le

Effective dia. of power cylinder mm 230

Boosting ratio LS, VR, VR-X 6.0 (pedal pressure: 116 N)

7.0 (pedal pressure: 159 N)

RALLIART Version-R 6.0 (pedal pressure: 87 N)

7.0 (pedal pressure: 125 N)

Rear wheel hydraulic control method Electronic brake-force

distribution (EBD)

Front brakes Type LS, VR Floating caliper, 1 piston,

ventilated disc (V4-S51)

VR-X, RALLIART Version-R Floating caliper, 1 piston,

ventilated disc (V5-S54)

Disc effective dia. ×

thickness mm

LS, VR 206 × 20

VR-X 226 × 24

Rear disc brakes

<VR-X, RALLIART

Version-R>

Rear drum brakes

<LS, VR>

RALLIART Version-R 232 × 25.8

Cylinder I.D. mm LS, VR 50.8

VR-X, RALLIART Version-R 54.0

Pad thickness mm LS, VR, VR-X 10

RALLIART Version-R 10.5

Clearance adjustment Automatic

Type VR-X Floating caliper, 1 piston,

solid disc (S4-S30P)

RALLIART Version-R Floating caliper, 1 piston,

solid disc (S4-S34P)

Disc effective dia. ×

thickness mm

Cylinder I.D. mm VR-X 30.2

Pad thickness mm VR-X 9.5

Clearance adjustment Automatic

Type Leading trailing drum

Drum I.D. mm 203

Cylinder I.D. mm 19.0

Lining thickness mm 4.0

VR-X 224 × 10

RALLIART Version-R 200.6 × 10

RALLIART Version-R 34.0

RALLIART Version-R 10.0

Clearance adjustment Automatic

Brake fluid DOT3 or DOT4

Page 46

BASIC BRAKE SYSTEM

CONSTRUCTION DESCRIPTION

CONSTRUCTION DESCRIPTION

35A-5

MASTER CYLINDER

M2350001000509

Reserve tank

Master cylinder

The master cylinder is a tandem-type, with a structure that emphasizes safety.

Secondary piston

BRAKE BOOSTER

Diaphragm

Primary piston

AC505737

M2350002000632

AB

Push rod

Booster return spring

9-inch brake booster has been installed. The brake

booster employs a variable amplification ratio mech

anism that varies amplifications ratios so that even

small pedal force can provide great breaking force.

Reaction disc

Operating rod

AC505736

AB

-

Page 47

35A-6

n

BRAKE PEDAL

BASIC BRAKE SYSTEM

CONSTRUCTION DESCRIPTION

M2350007000154

Collision load

Reinforced bracket

After collision

Fixed bolt

Reinforced bracket

Retreat locus of brake pedal during collision

Before collision

AC207292

Deck crossmember

Stopper plate

Brake booster

The brake pedal rearward displacement prevention

mechanism has been adopted in order to reduce the

driverís leg and foot injury during frontal collision.

Brake pedal position before collision

Brake pedal position after collision

(Conventional)

Brake pedal position after collision

(Brake pedal rearward displacement preventio

mechanism operated)

AC207291

AC207749

AE

The brake booster is forced to move backward

according to retreating engine body during frontal

collision and then the reinforced bracket is released

from the stopper plate. After released, the reinforced

bracket is forced to move backward and downward

by guiding the rear end of the reinforced bracket

along the stopper plate slope and it prevent the back

ward and upward displacement of the brake pedal.

-

Page 48

FRONT BRAKE

14-inch disc brake

<LS, VR>

BASIC BRAKE SYSTEM

CONSTRUCTION DESCRIPTION

M2350003000538

Conventional structure

Caliper support

bracket

35A-7

15-inch disc brake

<VR-X, RALLIART Version-R>

• Ventilated disc brake (V4−S51 or V5−S54) is

installed.

• The calliper support bracket integrated with the

knuckle has been installed, achieving weight

reduction and optimising it for brake perform

ance.

• Audible wear indicator that informs the driver of

wear limit is installed to the inner brake pad.

(Only left side)

DISC BRAKE DESIGNATION

Knuckle

When new When worn

Pad

Wear indicator

Brake disk

AC403189

AE

No. Item Content

1 Brake disc type V: Ventilated

2 Brake size

-

(Minimum applicable

4: 14-inch

5: 15-inch

disc wheel)

3 No. of piston S: 1piston (floating type)

4 Piston size (rounded

to nearest integer)

30: φ 30 mm

34: φ 34 mm

51: φ 51 mm

54: φ 54 mm

S 4 - S 30 P

1 2 3 4 5

AC403539

5 Parking brake

mechanism

P: Set

Page 49

35A-8

REAR BRAKE

<8-inch leading trailing type drum brake> <14-inch disc brake>

BASIC BRAKE SYSTEM

CONSTRUCTION DESCRIPTION

M2350004000531

• 8-inch leading trailing type drum brake, which

assures stable braking force during forward or

rearward movement, has been installed. <LS,

VR>

• Disc brake (S4-S30P) has been installed. <VR-X,

RALLIART Version-R>

AC403060

AD

• An audible wear indicator that informs the driver

of application limit has been installed to the left

brake pad. <VR-X, RALLIART Version-R>

NOTE: For disc brake designation, refer to P.35A-7.

Page 50

GROUP 35B

ANTI-SKID BRAKE

SYSTEM (ABS)

CONTENTS

GENERAL INFORMATION . . . . . . . . 35B-2 CONSTRUCTION DESCRIPTION . . . 35B-6

SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . 35B-6

ABS-ECU. . . . . . . . . . . . . . . . . . . . . . . . . . . 35B-6

Page 51

35B-2

ANTI-SKID BRAKE SYSTEM (ABS)

GENERAL INFORMATION

GENERAL INFORMATION

FEATURES

The ABS ensures directional stability and controllability during hard braking.

For vehicles with this type of ABS, 4 sensors (4

channels) are installed on front and rear wheels

allowing independent left and right control.

The system has the following features:

• EBD (Electronic Brake-force Distribution system)

control has been added to provide the ideal brak

ing force for the rear wheels.

• Magnetic encoder for wheel speed detection has

been installed as a sensing device instead of the

rotor.

• For wiring harness saving and secure data communication, CAN* bus has been adopted as a

tool of communication with another ECU.

NOTE: *: For more information about CAN (Controller Area Network), refer to Group 54C, General Information P.54C-2.

M2351000100409

EBD CONTROL

In ABS, electronic control is used so the rear wheel

brake hydraulic pressure during braking is regulated

by rear wheel control solenoid valves in accordance

with the vehicle's rate of deceleration, and the front

and rear wheel slippage which are calculated from

the signals received from the various wheel speed

sensors. EBD control provides a high level of control

-

for both vehicle braking force and vehicle stability.

The system has the following features:

• Because the system provides the optimum rear

wheel braking force regardless of vehicle load

condition and the condition of the road surface,

the system reduces the required pedal depres

sion force, particularly when the vehicle is heavily

loaded or driven on road surfaces with high fric

tional coefficients.

• Because the duty placed on the front brakes is

reduced, the increase in pad temperature can be

controlled during brakes application to improve

the wear resistance characteristics of the pad.

• Control valves such as the proportioning valve

are not required.

-

-

SPECIFICATIONS

Item Specification

ABS control method 4-sensor, 4-channel

Wheel speed

sensor

Magnetic encoder Front 86 (N pole:43 S pole:43)

Rear 86 (N pole:43 S pole:43)

Type Semiconductor

Page 52

CONSTRUCTION DIAGRAM

ANTI-SKID BRAKE SYSTEM (ABS)

GENERAL INFORMATION

35B-3

6

3, 7

4

5

2

1

1

AC400129

AB

Name of part Number Outline of function

Sensor Wheel speed sensor 1 Sends alternating current signals at frequencies which are

proportional to the rotation speeds of each wheel to the

ABS-ECU.

Stop lamp switch 2 Sends a signal to the ABS-ECU to indicate whether the

brake pedal is depressed or not.

Actuator Hydraulic unit 3 Drives the solenoid valves according to signals from the

ABS-ECU in order to control the brake hydraulic pressure

for each wheel.

ABS warning lamp 4 Illuminates in response to signals from the ABS-ECU

when a problem develops in the system.

Brake warning lamp 5 Illuminates in response to signals from the ABS-ECU

when a problem develops in the EBD system.

Diagnosis connector 6 Outputs the diagnosis codes and allows communication

with the M.U.T.-III.

ABS-ECU 7 Controls actuators (described above) based on the signals

coming from each sensor.

Controls the self-diagnosis and fail-safe functions.

Controls the diagnostic function (M.U.T.-III compatible).

Page 53

35B-4

ANTI-SKID BRAKE SYSTEM (ABS)

GENERAL INFORMATION

SYSTEM CONFIGURATION DIAGRAM

Front-left wheel speed sensor

Rear-left wheel speed sensor

Rear-right wheel speed sensor

Front-right wheel speed sensor

Stop lamp switch

ABS-ECU power supply

Front-right wheel (FR)

ABS-ECU

Engine-CVT-ECU

Front-right solenoid valve (out)

Front-right solenoid valve (in)

Front-left solenoid valve (out)

Front-left solenoid valve (in)

Rear-right solenoid valve (out)

Rear-right solenoid valve (in)

Rear-left solenoid valve (out)

Rear-left solenoid valve (in)

Brake warning lamp

ABS warning lamp

Diagnosis connector

Stop lamp switch

Rear-right wheel (RR)

Rear-right

wheel speed

sensor

Front right

wheel speed

sensor

Hydraulic

unit

Front-left

wheel speed

sensor

Front-left wheel (FL)

NOTE: Broken lines show CAN-bus line.

Rear-left

wheel speed

sensor

Rear-left wheel (RL)

AC314168

AB

Page 54

ANTI-SKID BRAKE SYSTEM (ABS)

GENERAL INFORMATION

ABS ELECTRICAL CIRCUIT DIAGRAM

35B-5

Fusible

link No.1

J/B

(Fuse)

No.42

15A

Stop lamp

switch

Off

On

Ignition

switch (IG1)

No.40

7.5A

Fusible

link No.5

ABS-ECU

Motor power

supply

Fusible

link No.3

Solenoid valve

power supply

Fusible

link No.6

J/B

(Fuse)

No.33

15A

Hydraulic unit

Solenoid valve

Motor power

supply

Front wheel speed

sensor

(rear, left)

Rear wheel speed

sensor

(rear, right)(front, right)(front, left)

Engine-CVT-ECU

J/C

(CAN2)

J/C

(CAN1)

Combination meter

(ABS warning lamp and

brake warning lamp)

Diagnosis connector

AC314169

AB

Page 55

35B-6

ANTI-SKID BRAKE SYSTEM (ABS)

CONSTRUCTION DESCRIPTION

CONSTRUCTION DESCRIPTION

SENSORS

M2351001000427

WHEEL SPEED SENSORS AND MAGNETIC ENCODER FOR WHEEL SPEED

DETECTION

Front Rear <Drum> Rear <Disc>

Front wheel speed sensor

Encoder for wheel

speed detection

Wheel speed sensor is a kind of a pulse generator

consisted of a magnetic encoder (a plate on which

north and south pole sides of the magnet are

arranged alternately) for wheel speed detection

which rotates at the same speed of the wheels, and a

speed sensor (semiconductor sensor), sends fre

quency pulse signals in proportion to wheel speed.

Front wheel speed sensor consists of a front wheel

speed sensor secured on the knuckle, and a mag

netic encoder for wheel speed detection fitted to the

inside of the front wheel bearing. Rear wheel speed

sensor consists of a rear wheel speed sensor

secured on the rear hub, and a magnetic encoder for

wheel speed detection press fitted to the rear hub

inner ring.

Rear wheel speed sensor

Encoder for wheel

speed detection

-

-

Rear wheel speed sensor

Encoder for wheel

speed detection

ABS-ECU

• By integrating ABS-ECU into the hydraulic unit,

no more wiring harnesses for sending signal that

operates the solenoid valve and pump motor is

required, assuring higher reliability.

• Self-diagnostic programs and memory functions

are integrated into ABS-ECU. If any malfunction

is detected by the self-diagnostic function,

ABS-ECU activates a fail-safe function and illuminates ABS warning lamp and brake warning

*

.

lamp

NOTE: *: ABS-ECU illuminates the brake warning

lamp as EBD control warning lamp.

• ABS-ECU detects vehicle speed from the wheel

speed sensor signal, recognizes the wheel rota

tion, estimates the wheel slip condition based on

the preprogrammed algorithm, and then controls

the solenoid valve in the hydraulic unit so that the

wheels do not lock.

AC601358

M2351003000252

AB

-

ABS FLUID PRESSURE CONTROL

FOUR-WHEEL CONTROL

ABS fluid pressure is controlled independently for

four wheels.

Page 56

ANTI-SKID BRAKE SYSTEM (ABS)

CONSTRUCTION DESCRIPTION

EBD FLUID PRESSURE CONTROL

Ideal distribution curve when

seated by fixed persons

Rear braking force

Ideal distribution curve when seated by one persons

EBD operating conceptual design

Braking force distribution

by EBD control

Braking force distribution curve

by the existing proportioning valve

Front braking force

35B-7

Braking Force

Improved

EBD control is activated within the lower slip ratio

area where ABS is disabled. ABS-ECU calculates

vehicle deceleration and slip amount of the four

wheels based on the wheel speed sensor signal. If

the rear wheel speed differs from the vehicle speed

by a certain level or more, ABS-ECU boost, holds,

and depressurises the rear wheel control solenoid

valve in the hydraulic unit, and then adjusts rear

wheel brake fluid pressure fairly close to an ideal dis

tribution curve.

INITIAL CHECK

ABS-ECU internally activates the self-diagnostic

function. ABS-ECU illuminates ABS warning lamp for

3 seconds (including the initial check)

*

after the ignition switch is turned ON. If any malfunction is

detected, ABS-ECU continues illuminating ABS

warning lamp and disables ABS control.

NOTE: *: ABS warning lamp may stay ON after the

ignition switch is turned ON until the startup vehicle

speed reaches approximately 10km/h. As far as

ABS-ECU memorizes any diagnosis code related to

the wheel speed sensor malfunction recorded during

previous ignition ON status, ABS-ECU continues illu

minating ABS warning lamp until it verifies that the

malfunction for that code is resolved (Startup check).

STARTUP CHECK

When the startup vehicle speed reaches approximately 10 km/h, ABS-ECU performs the following

checks.

• Motor, solenoid valve check (only in initial startup*)

AC208548

Operates the motor relay in ECU and checks the

pump motor operation. At the same time,

ABS-ECU sequentially energizes each solenoid

valve in a very short period and checks the valve

operation.

NOTE: *: Initial startup indicates a first startup after

the system has started.

• Wheel speed sensor check

-

ABS-ECU checks for any wheels that have not

received wheel speed sensor signal from the

startup.

CONSTANT CHECK

ABS-ECU constantly checks the following item.

• ABS-ECU

Performs self-diagnosis in ECU.

• ECU power supply

Checks if ECU power supply voltage reaches within

the operational range.

• Wheel speed sensor

• Monitors the output voltage of the sensor sig-

nal wiring harness and checks for abnormal

output voltage (open/short circuit).

-

• Checks for any wheels that do not send pulse

signal while the vehicle is in motion.

• Checks if wheel speed which is abnormally

higher or lower than the vehicle speed is

input.

• Pump motor and solenoid valve

Checks that ABS-ECU output signal and the operat-

ing condition of the pump motor and solenoid

valve agree with each other.

AB

Page 57

35B-8

ANTI-SKID BRAKE SYSTEM (ABS)

CONSTRUCTION DESCRIPTION

CAN COMMUNICATION

ABS-ECU outputs ABS warning lamp and EBD

*

warning lamp

combination meter through CAN communication.

NOTE: *: ABS-ECU illuminates the brake warning

lamp as EBD control warning lamp.

Diagnosis

code No.

C1200 Open or short

C1201 Wheel speed

C1205 Open or short

C1206 Wheel speed

C1210 Open or short

illumination request signals to the

Item Action during fail-safe operation

ABS control EBD control CAN output Brake

Prohibits

circuit in wheel

speed sensor (FR)

sensor (FR) system

circuit in wheel

speed sensor (FL)

sensor (FL) system

circuit in wheel

speed sensor (RR)

control of

malfunctioning

wheel.

Prohibits all

wheel control

after control is

completed.

FAIL - SAFE FUNCTION

If any malfunction is detected by the self-diagnostic

function, ABS-ECU illuminates ABS warning lamp

and brake warning lamp

EBD as shown in the following table.

NOTE: *: ABS-ECU illuminates the brake warning

lamp as EBD control warning lamp.

Two or less

wheel

Abnormal:

Enabled

Three or

more wheels

Abnormal:

Prohibits

Output

permitted

*

, and it controls ABS and

ABS

warning

lamp

Two or less

wheel

Abnormal:

OFF

Three or

more

wheels

Abnormal:

ON

warning

lamp

ON

C1211 Wheel speed

sensor (RR)

system

C1215 Open or short

circuit in wheel

speed sensor (RL)

C1216 Wheel speed

sensor (RL) system

C1225 Wheel speed

sensor malfunction

System

shut-down

System

shut-down

Output

permitted

ON ON

Page 58

ANTI-SKID BRAKE SYSTEM (ABS)

CONSTRUCTION DESCRIPTION

35B-9

Diagnosis

code No.

C1226 Control solenoid

C1231 Control solenoid

C1236 Control solenoid

C1241 Control solenoid

C1246 Control solenoid

Item Action during fail-safe operation

valve (FR) pressure

holding system

valve (FR)

decompressing

system

valve (FL) pressure

holding system

valve (FL) pressure

reducing system

valve (RR)

pressure holding

system

ABS control EBD control CAN output Brake

warning

lamp

Prohibited Prohibited Output

permitted

ON ON

ABS

warning

lamp

C1251 Control solenoid

valve (RR)

pressure reducing

system

C1256 Control solenoid

valve (RL) pressure

holding system

C1261 Control solenoid

valve (RL)

decompressing

system

C1266 Motor system

(stuck)

C1273 Motor relay stuck

off

C1274 Motor relay stuck

on

C1276 Valv e r elay system System

C1278 Valv e r elay system

stuck off

C1279 Valv e r elay system

stuck on

Prohibited Enabled Output

shut-down

System

shut-down

Prohibited Enabled Output

System

shut-down

System

shut-down

permitted

Output

permitted

Output

permitted

permitted

OFF ON

ON ON

ON ON

OFF ON

Page 59

35B-10

ANTI-SKID BRAKE SYSTEM (ABS)

CONSTRUCTION DESCRIPTION

Diagnosis

code No.

C1607 Trouble in

C1860 High voltage at

C1861 Low voltage at

U1073 Trouble in CAN bus

Item Action during fail-safe operation

ABS-ECU

Trouble in

ABS-ECU (CAN

Initialisation

malfunction)

ABS-ECU power

supply

ABS-ECU power

supply

system

ABS control EBD control CAN output Brake

warning

lamp

System

shut-down

Enabled Enabled Output

Wait Wait Output

Wait Wait Output

Enabled Enabled Output

System

shut-down

Output

permitted

(Output may

be

impossible).

impossible

permitted

permitted

impossible

ON ON

*

ON

ON ON

ON ON

*

ON

ABS

warning

lamp

*

ON

*

ON

NOTE: .

*

•

: If any trouble occurs in CAN communication,

the brake warning lamp and ABS warning lamp

on the combination meter turns ON.

•

Prohibit: Any controls are not performed until the

ignition switch is turned OFF.

•

System shut-down: Control will be disabled until

valve power supply is turned off, and then ignition

switch is turned to the OFF position.

•

Wait: ABS control is restarted when the normal

condition is resumed even though the ignition

switch is not turned OFF.

DIAGNOSTIC FUNCTION

ABS-ECU has the following functions for easier system checks. The following items can be diagnosed

using the M.U.T.-III (ABS warning lamp illuminates

and ABS control is prohibited while the ABS-ECU

communicates with the M.U.T.-III).

• Diagnosis code set

• Service data output

• Actuator test

DIAGNOSIS CODE SET

There are 28 diagnostic items. Since all the diagnostic results are recorded in volatile memory (EEPROM*), they are stored in the memory even though

the battery terminals are disconnected.

NOTE: .

•

*EEPROM (Electrical Erasable &;Programmable

ROM): Special type of memory that can be pro

grammed or erased electrically

•

For each diagnostic item, refer to Fail-safe Function.

-

Page 60

ANTI-SKID BRAKE SYSTEM (ABS)

CONSTRUCTION DESCRIPTION

35B-11

SERVICE DATA OUTPUT

The following items of the ECU input data can be

read using M.U.T.-III.

Item No. Check item Check condition Normal condition

01 FR wheel speed sensor Perform a test run of the vehicle. Speedometer display and

02 FL wheel speed sensor

03 RR wheel speed sensor

04 RL wheel speed sensor

05 Power supply voltage Always 10 V or more

06 Stop lamp switch The brake pedal is depressed ON

The brake pedal is released. OFF

07 Valve relay When ABS is operating ON

When ABS is not operating OFF

10 FL inlet valve When ABS is operating ON

When ABS is not operating OFF

11 FL outlet valve When ABS is operating ON

M.U.T.-III display almost agree

with each other.

When ABS is not operating OFF

12 FR inlet valve When ABS is operating ON

When ABS is not operating OFF

13 FR outlet valve When ABS is operating ON

When ABS is not operating OFF

14 RL inlet valve When ABS is operating ON

When ABS is not operating OFF

15 RL outlet valve When ABS is operating ON

When ABS is not operating OFF

16 RR inlet valve When ABS is operating ON

When ABS is not operating OFF

17 RR outlet valve When ABS is operating ON

When ABS is not operating OFF

20 Pump motor When ABS is operating ON

When ABS is not operating OFF

Page 61

35B-12

ANTI-SKID BRAKE SYSTEM (ABS)

CONSTRUCTION DESCRIPTION

ACTUATOR TEST

Activation Pattern

Solenoid

valve

Pump

motor

A

B

C

On

Off

Note

Hydraulic pressure increases

A:

Hydraulic pressure holds

B:

Hydraulic pressure decreases

C:

Start of

activation

1 s

2 s

End of

activation

AC300188

AD

NOTE: .

•

When ABS-ECU is disabled, the actuator test

cannot be performed.

•

The actuator test can be performed only when

the vehicle is stationary. When the vehicle speed

reaches 10km/h, the forcible actuator operation is

disabled.

•

During actuator test, the ABS warning lamp illuminates, and ABS control is prohibited.

Item No. Check item Drive Contents

01 Solenoid valve for

front-right wheel

02 Solenoid valve for

front-left wheel

Solenoid valves

and pump motor in

the hydraulic unit

(simple inspection

mode)

03 Solenoid valve for

rear-right wheel

04 Solenoid valve for

rear-left wheel

The M.U.T.-III can be used to force-drive all solenoid

valves and the pump motor.

Page 62

GROUP 36

PARKING BRAKES

CONTENTS

GENERAL INFORMATION . . . . . . . . 36-2

STRUCTURAL DESCRIPTION

<CVT> . . . . . . . . . . . . . . . . . . . . . . . . 36-4

OPERATIONAL DESCRIPTION

<CVT> . . . . . . . . . . . . . . . . . . . . . . . . . 36-5

Page 63

36-2

PARKI N G B R A K E S

GENERAL INFORMATION

GENERAL INFORMATION

<CVT>

Employment of the parking brake pedal clears front

centre space to allow a walk through design.

PUSH-ON/PUSH-RELEASE type pedal has been

installed for easier operation.

Parking brake pedal assembly

M2360000100656

The parking brake pedal retreat suppression mechanism that restraints the retraction of the brake pedal

during collision has been adopted in order to reduce

the shock to the driver's feet. The mechanism of the

parking brake pedal is basically the same as that of

the brake pedal.

NOTE: For more information about brake pedal

retreat suppression mechanism, refer to GROUP

35A, Brake Pedal

P.35A-6.

Parking brake cable cover

<LS>

<VR-X>

AC506311

AC

Page 64

PARKING BRAKES

GENERAL INFORMATION

36-3

<Parking brake pedal retreat suppression mechanism>

Parking brake pedal

bracket

Collision load

Brake pedal position

before collision

AC207360

After collision

Fixed bolt

Deck

crossmember

Retreat trajectory of brake pedal

during collision

Brake pedal surface position after collision

(Brake pedal retreat suppression

mechanism operated)

Parking brake pedal bracket

Before collision

AC207354

AC207757

AB

<M/T>

The parking brake is of a mechanical rear-wheel acting type, and its operation utilises a parking brake

lever.

<RALLIART Version-R>

Parking brake lever (Leather grip)

Parking brake cable

<LS, VR>

Parking brake lever

Parking brake cable

AC601652

AB

Page 65

36-4

Return spring

PARKI N G B R A K E S

STRUCTURAL DESCRIPTION <CVT>

STRUCTURAL DESCRIPTION <CVT>

M2360000200192

The parking brake pedal assembly consists of the

parking brake pedal, sector, release lever, pawl

return spring, pawl, and return spring. The sector is

secured to the parking brake pedal bracket body.

The pawl and release lever are fixed to the pin axle

by the section with an oblong hole. The pawl and

release lever are connected by the pawl returning

spring, and move together with the pedal.

Pawl

Sector

Release lever

Pawl return spring

AC207357

AB

Page 66

PARKI N G B R A K E S

OPERATIONAL DESCRIPTION <CVT>

OPERATIONAL DESCRIPTION <CVT>

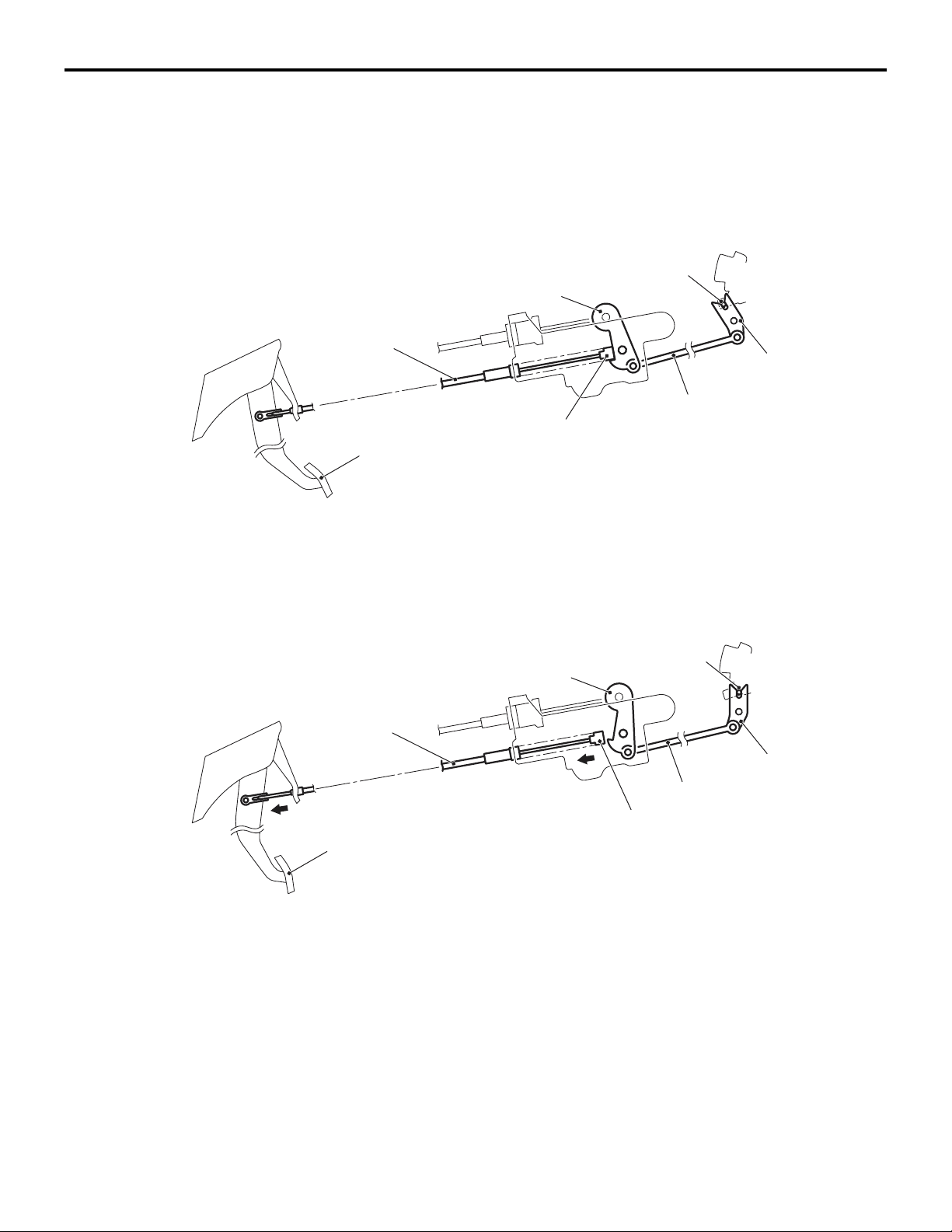

PARKI N G B RA K E P ED AL OP E RAT I ON

OPERATION WHEN PEDAL IS

DEPRESSED

Spring force

Sector

Pawl axle

Release lever

Pawl

Pawl return spring

AC405464

When the parking brake is released, the pawl

receives the left-rotation force (the direction of

engagement) around the pawl axis from the pawl

return spring. Then, depressing the pedal engages

the pawl and sector, releasing a clicking sound.

AB

36-5

M2360000300207

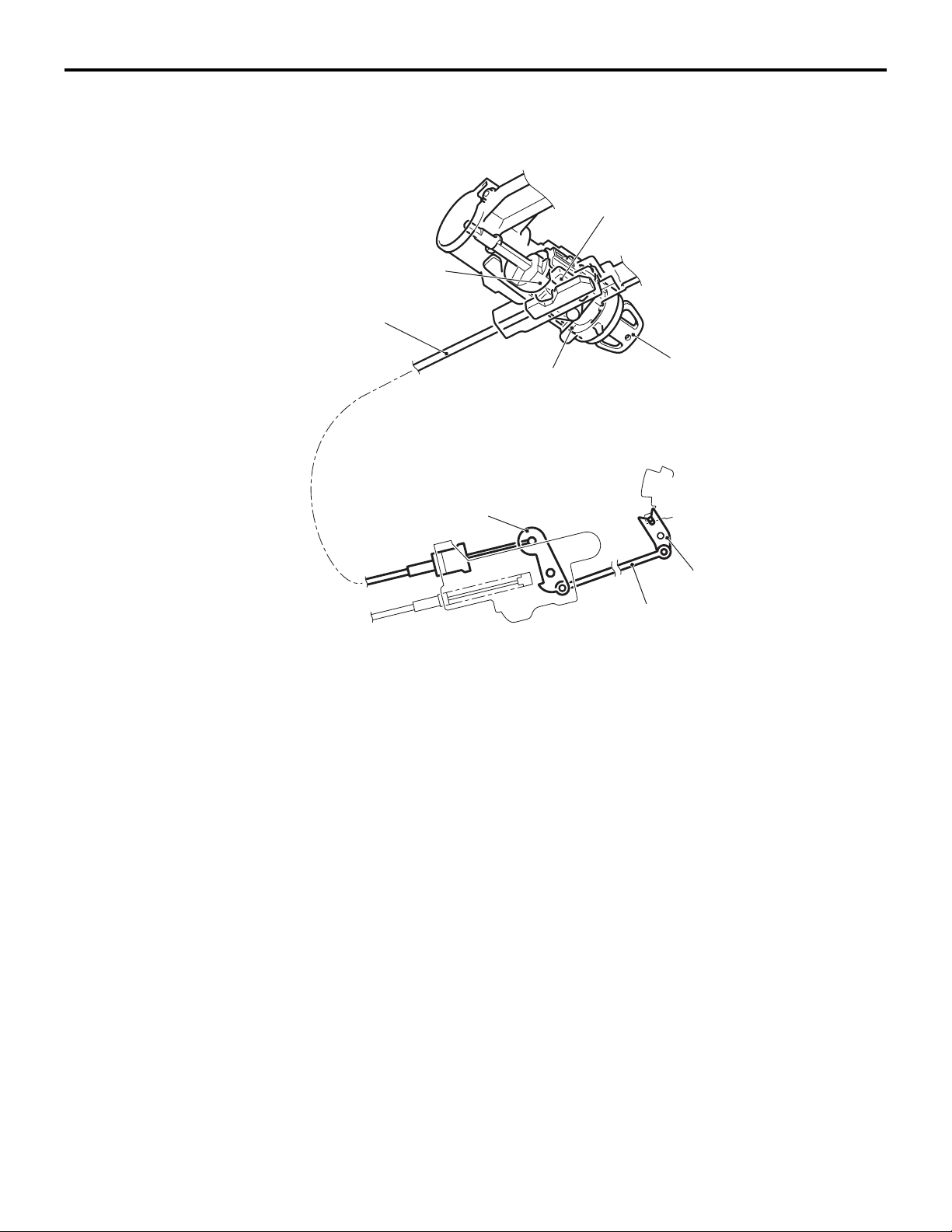

OPERATION AFTER PEDAL IS

DEPRESSED

Contact point

of release lever

and pawl

Release lever

rotates

AC405465

Depressing the pedal and removing one's foot

causes the pawl axis to slide the section with an

oblong hole from the repulsive force of the cable.

Then, the release lever affixed to the pawl axis is

pushed by the pawl and rotates, the pawl return

spring position is inverted, and right-rotation force (in

the release direction) is applied to the pawl. At this

time, the engagement force of the pawl and sector

prevents release.

AB

OPERATION WHEN PEDAL IS

DEPRESSED

Disengaged

AC405466

Depressing the pedal again for release disengages

it, rotating the pawl from the spring force and releas

ing the lock.

AB

-

Page 67

36-6

OPERATION WHEN PEDAL IS

RETURNED

PARKI N G B R A K E S

OPERATIONAL DESCRIPTION <CVT>

Lever

returning

part

AC405467

AB

When returning the pedal, the release lever returns

to the starting position from the lever returning sec

tion as the spring position is inverted, causing the

pawl to return to the position of release for the park

ing break.

-

-

Page 68

GROUP 12

ENGINE

LUBRICATION

CONTENTS

GENERAL INFORMATION . . . . . . . . 12-2

OIL PUMP<4A9> . . . . . . . . . . . . . . . . 12-4

RELIEF VALVE<4A9> . . . . . . . . . . . . 12-4

OIL SCREEN<4A9> . . . . . . . . . . . . . . 12-5

OIL FILTER<4A9> . . . . . . . . . . . . . . . 12-5

OIL PAN<4A9> . . . . . . . . . . . . . . . . . . 12-6

OIL LEVEL GAUGE, OIL FILLER CAP,

OIL DRAIN PLUG<4A9> . . . . . . . . . . 12-6

OIL COOLER<4G1> . . . . . . . . . . . . . . 12-7

Page 69

12-2

ENGINE LUBRICATION

GENERAL INFORMATION

GENERAL INFORMATION

LUBRICATION SYSTEM SCHEMATIC<4A9>

M2120000100175

Oil screen

Oil pump

Relief valve

Oil pressure switch

Cylinder head

oil passage

No.1 Camshaft

journal

Intake camshaft

journal

Timing chain case

oil passage

Cylinder block

oil passage(right side)

Oil filter

Cylinder block

oil passage

(main gallery)

Crankshaft

journal

Crankshaft

pin

Exhaust camshaft

journal

The lubrication system of the 4A9 engine has a full

pressure delivery system and a full flow oil filtering

system. The oil stored in the oil pan is pumped

up/out by the oil pump. After the relief valve regulates the oil pressure, the oil is delivered to the cylinder block through the oil filter, the oil passage of the

cylinder block and the each journal of the crankshaft.

AK402024

AC

The oil delivered to the each journal of the crankshaft

is supplied to the pin through the inner passage of

the crankshaft.

The oil delivered to the cylinder head is supplied to

the each journal of the camshaft through the cylinder

head.

Page 70

ENGINE LUBRICATION

GENERAL INFORMATION

LUBRICATION SYSTEM SCHEMATIC<4G1>

12-3

Oil screen

Oil pump

Lash adjuster

Cam

Relief valve

Turbo charger

Cylinder head

oil passage

No.1 Camshaft

journal

Intake camshaft

journal

Oil pan

Oil cooler

Oil filter

Cylinder block

oil passage

(main gallery)

Crankshaft

journal

Crankshaft pin

Exhaust camshaft

journal

Oil pressure switch

Oil jet

Piston

AK402151

AC

To correspond with the improved engine output performance by employing the turbocharger, the oil

cooler and the oil jet are used for 4GI engine.

Page 71

12-4

ENGINE LUBRICATION

OIL PUMP<4A9>

OIL PUMP<4A9>

M2120002000044

A

A

The oil pump is of a cycloid type, directly driven by

the crankshaft.

Specifically, oil is sucked into the expanding space

and is pushed out from the shrinking space.

Timing chain case

Machine screw

Cover

On the cycloid oil pump, as the inner rotor is rotated

by the crankshaft, the outer rotor also rotates. The

resultant change in spatial volumes between the

rotors generates pumping action.

Item Specification

Type Cycloid pump

No. of lobes Inner rotor 10

Outer rotor 11

A-A

Oil seal

Oil pump

inner rotor

Oil pump

outer rotor

AK305367

AB

Displacement L/min(6,000 r/min.) 35

RELIEF VALVE<4A9>

A

A

The relief valve is of a plunger type. The valve regulates the maximum pressure of lubrication oil being

sent to the engine.

When the pressure of oil from the oil pump exceeds

the specified value, the valve opens to relieve the

excess flow.

The excess oil is returned to the suction side of the

oil pump.

A-A

Timing chain case

Relief plunger

Relief spring

Plug

AK305369

M2120003000047

AB

Page 72

ENGINE LUBRICATION

OIL SCREEN<4A9>

Timing chain case

OIL SCREEN<4A9>

The oil screen is located in the position with the least

disturbance to the oil suction volume that results

from oil level variation in the oil pan while the vehicle

is driven.

12-5

M2120004000039

Oil screen

Oil filter

Oil pan

AK305372

Oil filter

bracket

Oil filter

AK401817

AB

OIL FILTER<4A9>

The oil filter is installed to the oil filter bracket

attached to the cylinder block.

Item Specification

Filtering method Full-flow filtering, Paper

Filtration area cm

Rated flow L/min. 25

AE

M2120005000032

element

2

750

Element

AK305373

AB

Page 73

12-6

ENGINE LUBRICATION

OIL PAN<4A9>

OIL PAN<4A9>

M2120006000035

Oil drain plug

installation side

The oil pan, located below the engine, is made of

sheet metal.

OIL LEVEL GAUGE, OIL FILLER CAP, OIL DRAIN

PLUG<4A9>

Oil level gauge

Oil filler cap

AK305374

AB

M2120007000038

Oil drain plug

The oil level gauge, oil filler cap, and oil drain plug

are all located in the front of the engine for excellent

serviceability.

AK402349

AC

Page 74

Coolant inlet

(from throttle body)

ENGINE LUBRICATION

OIL COOLER<4G1>

OIL COOLER<4G1>

Coolant outlet

(to water inlet pipe)

To cylinder block

Oil inlet

12-7

M2120008000020

Oil cooler bolt

From oil filter

An oil cooler is used for the vehicle with a turbocharger to improve the performance of cooling lubricant.

Oil cooler

Oil outlet

AK402142

AC

By circulating the coolant and the oil within the oil

cooler, heat is exchanged and the oil is cooled.

Page 75

GROUP 16

ENGINE

ELECTRICAL

CONTENTS

GENERAL INFORMATION . . . . . . . . 16-2

Page 76

16-2

ENGINE ELECTRICAL

GENERAL INFORMATION

GENERAL INFORMATION

The electronic device is basically the same as that in

the conventional 4G1 engine.

The employed alternator is a lightweight type in

which the electronic voltage regulator for detecting

the battery voltage is built.

M2160000100038

The employed starter motor is a small planetary gear

reduction drive type.

The employed spark plug is a long reach type with

iridium.

The employed ignition coil is a plug top type in which

the powertrain per cylinder is built.

Page 77

GROUP 00

GENERAL

CONTENTS

HOW TO USE THIS MANUAL. . . . . . 00-2

TARGETS OF DEVELOPMENT . . . . 00-2

PRODUCT FEATURES . . . . . . . . . . . 00-3

TECHNICAL FEATURES. . . . . . . . . . 00-4

EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . 00-4

INTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . 00-6

SPACIOUS CABIN . . . . . . . . . . . . . . . . . . . 00-8

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-9

TRANSMISSION. . . . . . . . . . . . . . . . . . . . . 00-10

SUSPENSION. . . . . . . . . . . . . . . . . . . . . . . 00-14

BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-15

STEERING . . . . . . . . . . . . . . . . . . . . . . . . . 00-18

ACTIVE SAFETY. . . . . . . . . . . . . . . . . . . . . 00-19

PASSIVE SAFETY . . . . . . . . . . . . . . . . . . . 00-24

EQUIPMENTS. . . . . . . . . . . . . . . . . . . . . . . 00-27

ENVIRONMENTAL PROTECTION . . . . . . . 00-28

SERVICEABILITY AND RELIABILITY . . . . 00-28

VEHICLE IDENTIFICATION . . . . . . . . 00-30

MAJOR SPECIFICATIONS . . . . . . . . 00-31

<CVT> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-31

<M/T> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-32

Page 78

00-2

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

MODEL INDICATIONS

The following abbreviations are used in this manual

for identification of model types.

DOHC. Indicates an engine with the double over-

head camshaft.

MIVEC. Indicates Mitsubishi innovative valve timing

electronic control system.

MPI. Indicates the multipoint injection.

M/T. Indicates the manual transmission.

CVT. Indicates the continuously variable transmis-

sion.

A/C. Indicates the air conditioner.

TARGETS OF DEVELOPMENT

EXCEPT RALLIART Version-R

The New COLT featuring "exciting feeling and freedom" has been developed for realising "safety, running, quality" and "free-to-select enjoyment" as well

as "true convenience and economical efficiency."

That makes NEW COLT a new generation compact

car.

GENERAL

M2000029000628

M2000004001066

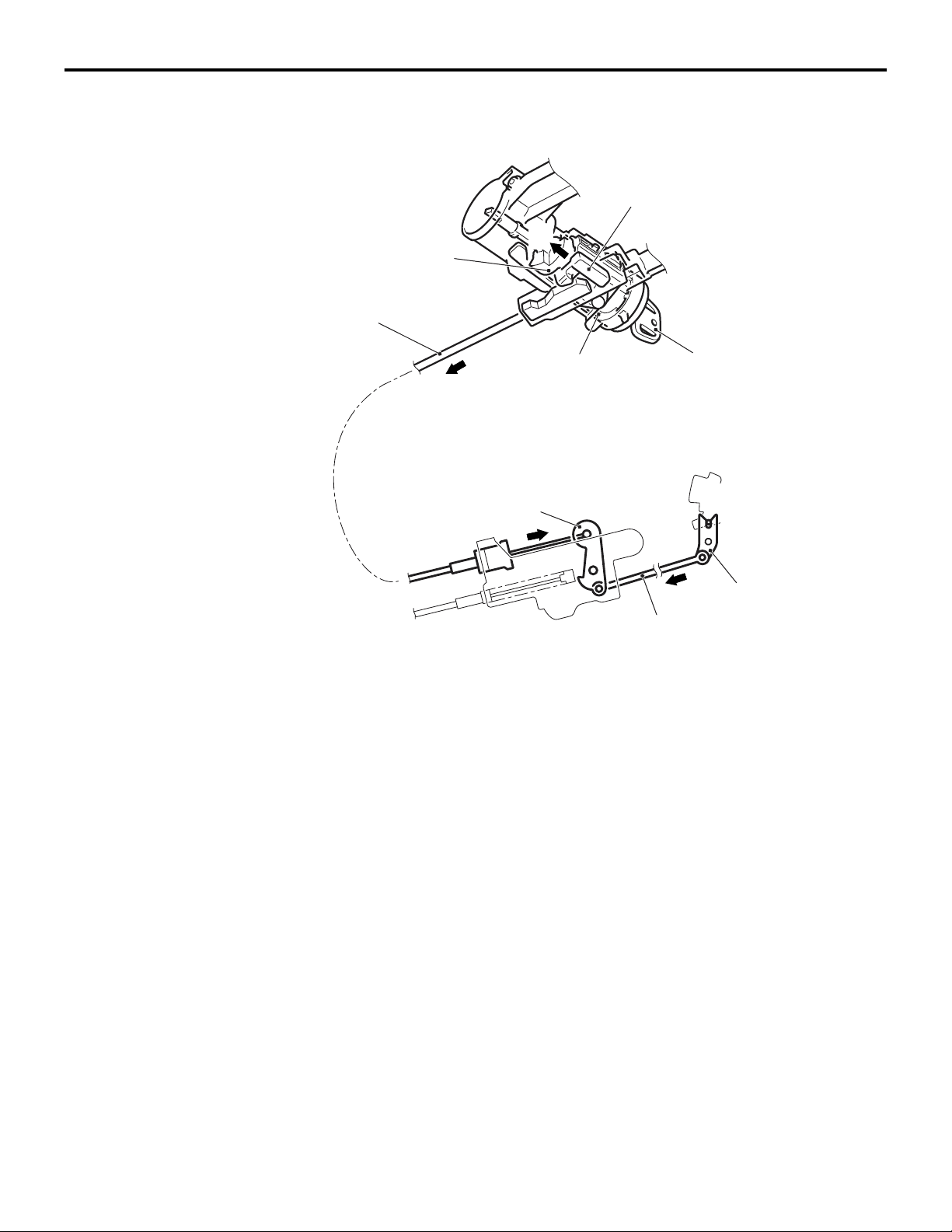

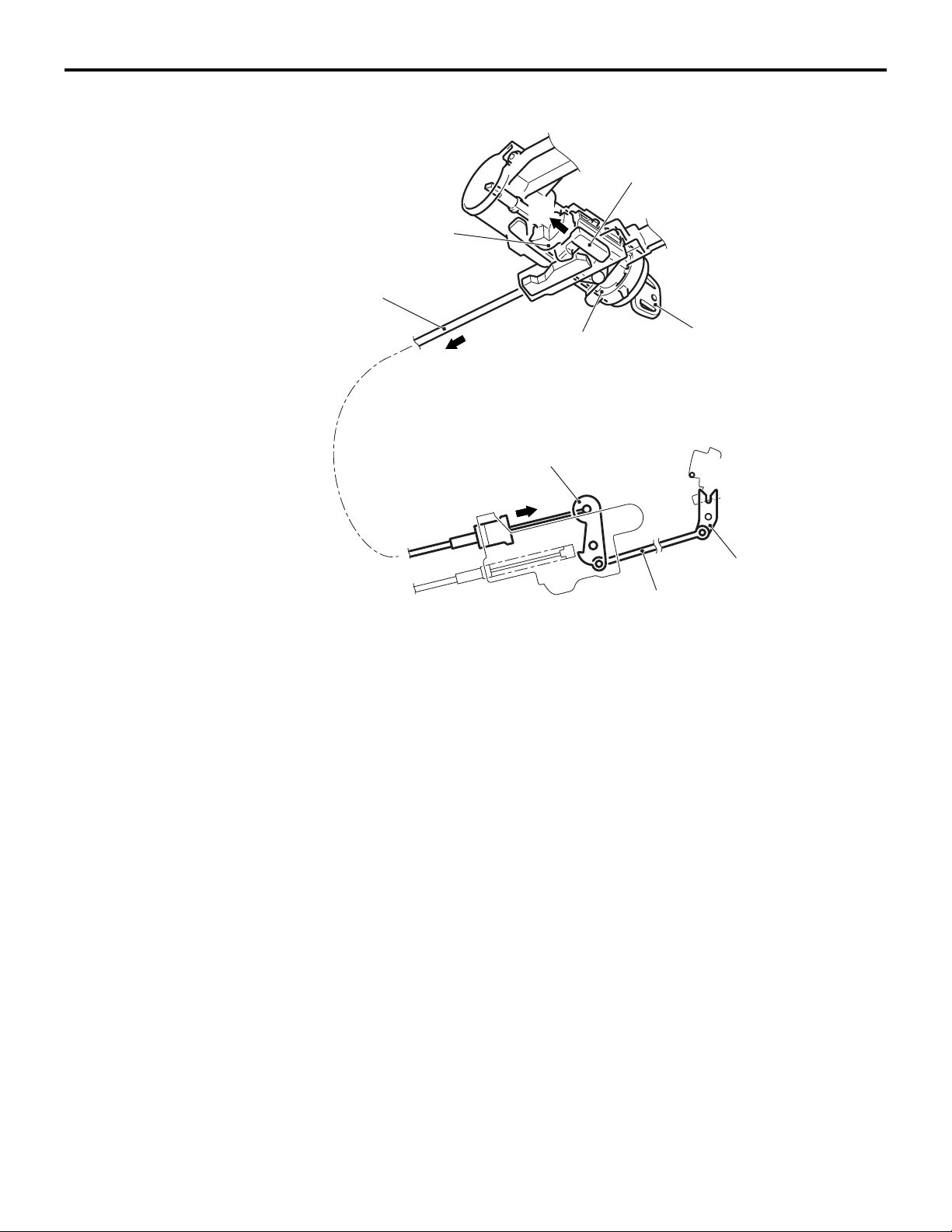

RALLIART Version-R