Page 1

GROUP 00

CONTENTS

00-1

HOW TO USE THIS MANUAL. . . . . . 00-2

TARGETS OF DEVELOPMENT . . . . 00-2

PRODUCT FEATURES . . . . . . . . . . . 00-2

TECHNICAL FEATURES. . . . . . . . . . 00-3

EXTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . 00-3

INTERIOR . . . . . . . . . . . . . . . . . . . . . . . . . . 00-4

SPACIOUS CABIN . . . . . . . . . . . . . . . . . . . 00-4

ENGINE . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-5

TRANSMISSION. . . . . . . . . . . . . . . . . . . . . 00-5

SUSPENSION. . . . . . . . . . . . . . . . . . . . . . . 00-8

BRAKE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-10

STEERING . . . . . . . . . . . . . . . . . . . . . . . . . 00-11

LOCAL INTERCONNECT NETWORK (LIN)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-12

ACTIVE SAFETY. . . . . . . . . . . . . . . . . . . . . 00-13

PASSIVE SAFETY . . . . . . . . . . . . . . . . . . . 00-17

EQUIPMENTS. . . . . . . . . . . . . . . . . . . . . . . 00-20

ENVIRONMENTAL PROTECTION. . . . . . . 00-21

SERVICEABILITY AND RELIABILITY . . . . 00-21

VEHICLE IDENTIFICATION . . . . . . . . 00-22

MAJOR SPECIFICATIONS . . . . . . . . 00-23

Page 2

00-2

HOW TO USE THIS MANUAL

HOW TO USE THIS MANUAL

MODEL INDICATIONS

The following abbreviations are used in this manual

for identification of model types.

1100: Ind ica tes mode ls equip ped with the 1,1 24 mL

<134910> petrol engine.

1300: Indicates models equipped with the 1,332 mL

<135930> petrol engine.

TARGETS OF DEVELOPMENT

COLT has been developed as entry model of Mitsubishi model line-up, as compact passenger car

with space MPV versatility.

GENERAL

M2000029000242

1500: Indicates models equipped with the 1,499 mL

<13590> petrol engine.

DOHC: Indicates an engine with the double over-

head camshaft.

MIVEC: Indicates Mitsubishi innovative valve timing

electronic control system.

MPI: Indicates the multipoint injection.

M/T: Indicates the manual transmission.

A/C: Indicates the air conditioner.

M2000004000342

PRODUCT FEATURES

ADVANCED AND FASHIONABLE STYLING

The one motion silhouette which consists of roominess and stylish appearance.

NEWLY DEVELOPED ENGINE WITH

GOOD FUEL EFFICIENCY AND EXCELLENT POWER-DRIVEN PERFORMANCE

• 134910-DOHC MIVEC* engine with 3-cylinder

• 135930-DOHC MIVEC engine and

135950-DOHC MIVEC engine with 4-cylinder

NOTE: *MIVEC: Mitsubishi Innovative Valve timing

Electronic Control system is a generic term for the

engine with variable valve timing mechanism.

M2000005000174

HIGH LEVEL OF SAFETY

• Reinforced Impact Safety Evolution (RISE) chassis adopted

• Driver's SRS airbag equipped as standard

• Front passenger's SRS airbag, SRS side airbag,

and SRS curtain airbag adopted <Optional>

• ISO FIX child seat fixing bar equipped as standard

EXCELLENT PRACTICABILITY AND

SPACE UTILITY

• Multi function box storage as cup holder, ashtray,

small item holder, etc.

• 6:4 separate sliding, tumbling and removable rear

seat.

Page 3

GENERAL

TECHNICAL FEATURES

TECHNICAL FEATURES

00-3

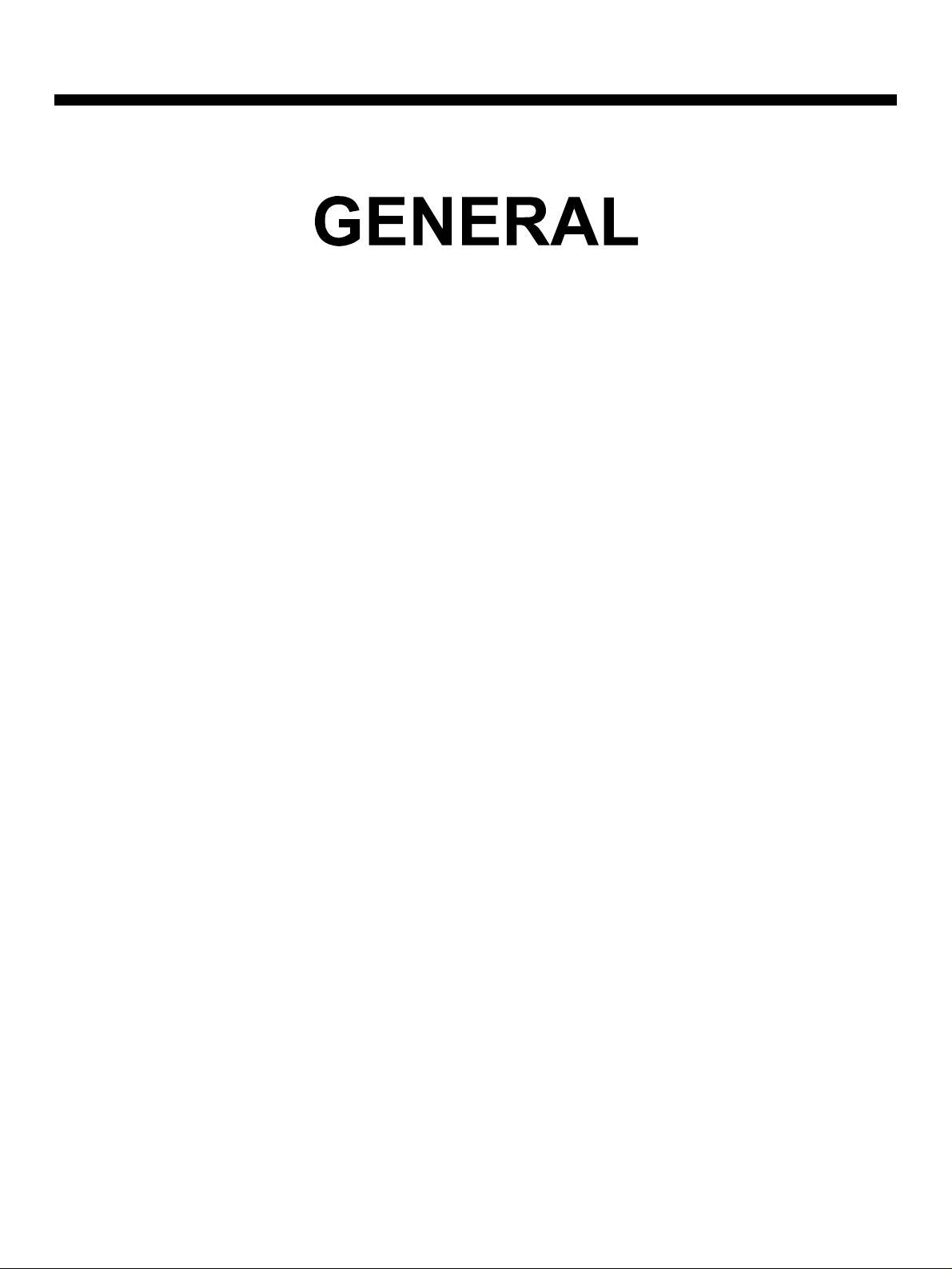

EXTERIOR

DESIGN FEATURES

3

M2000017000331

1

5

2

1

4

OVERALL

• Dynamic one motion line connects chamfered

front end.

• Simple body side section emphasis the wheel

arches.

• Dynamic DLO (day light opening) creates car is

motion even when car is stop.

• Front lights on the chamfered surface follows one

of the Mitsubishi identity.

• Inside of the light reflectors given high-tech

image of Japanese product.

• Simple exterior design emprises car’s functionality.

• Door cut’s matching the lines of the DLO and rear

light.

6

AC311182

AC

1. SIDE SILHOUETTE

Simple and dynamic one motion curve from the front

nose to the roof end.

2. BODY SIDE SURFACE

Take si mple and cl ean s urface to e mphasi ze wh eel

arches.

3. MITSUBISHI MARK

New Mitsubishi front face which designed every elements connects from three diamonds.

4. FRONT END CORNER

Apply the chamfer shape for easy handling.

5. HEAD LAMP

Create the high-tech image of Japanese product.

Page 4

00-4

GENERAL

TECHNICAL FEATURES

6. TAIL LAMP

Apply long vertical type to easy to recognize from

outside.

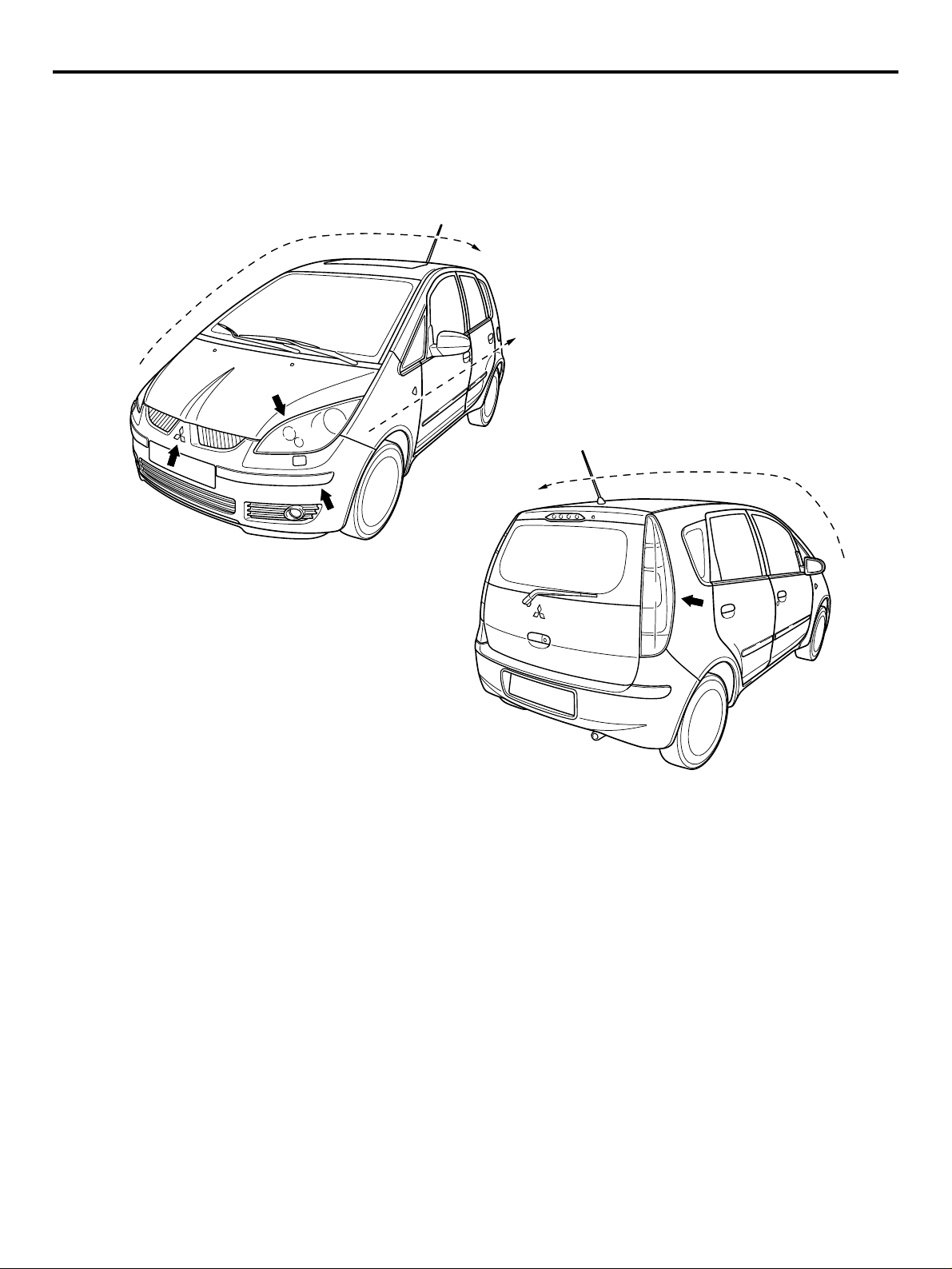

Combination meter

INTERIOR

M2000018000312

DESIGN FEATURES

Instrument panel

Translucent

parts

Cup holder and ashtray

OVERALL

• Sporty elegance feeling with comfortable space.

• The maximum roominess in the limited package.

Glove box

FLOOR CONSOLE AND DOOR TRIM

• Multi cup holder.

• Removable ashtray (This ashtray can be set in all

cup holders).

INSTRUMENT PANEL

• Illumination systems presented by translucent

parts of audio and A/C control panel

• Searchlight system from translucent parts.

• Useful glove box (card holder, pen holder, coin

holders and bottle holder).

By the adoption of the long wheelbase, it realizes the interior length of the top-class.

COMBINATION METER

• Easy to recognize, independent function meters.

SPACIOUS CABIN

AC312521

AB

M2000000400025

Page 5

GENERAL

TECHNICAL FEATURES

00-5

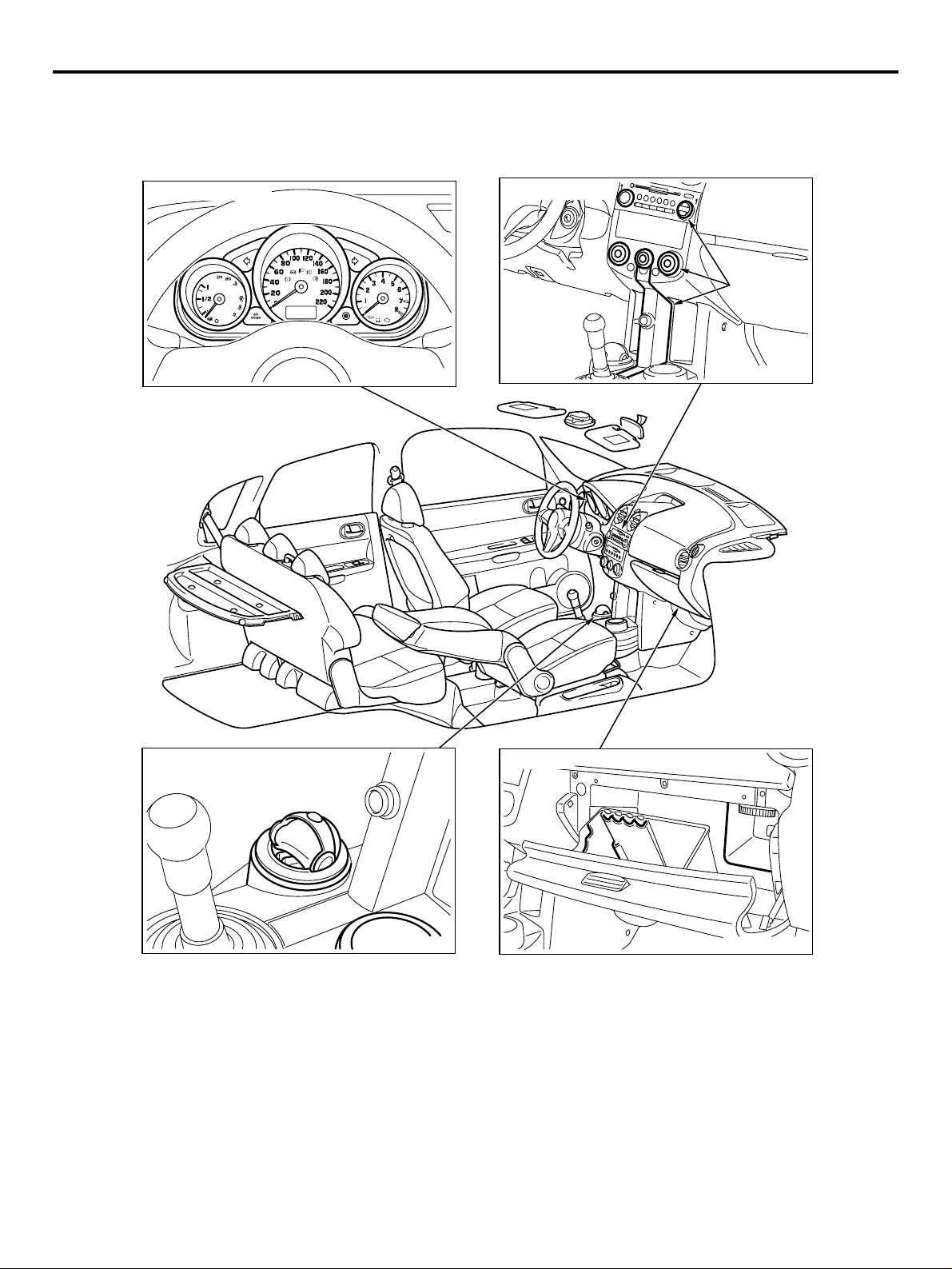

4

1

3

5

2

AC311954

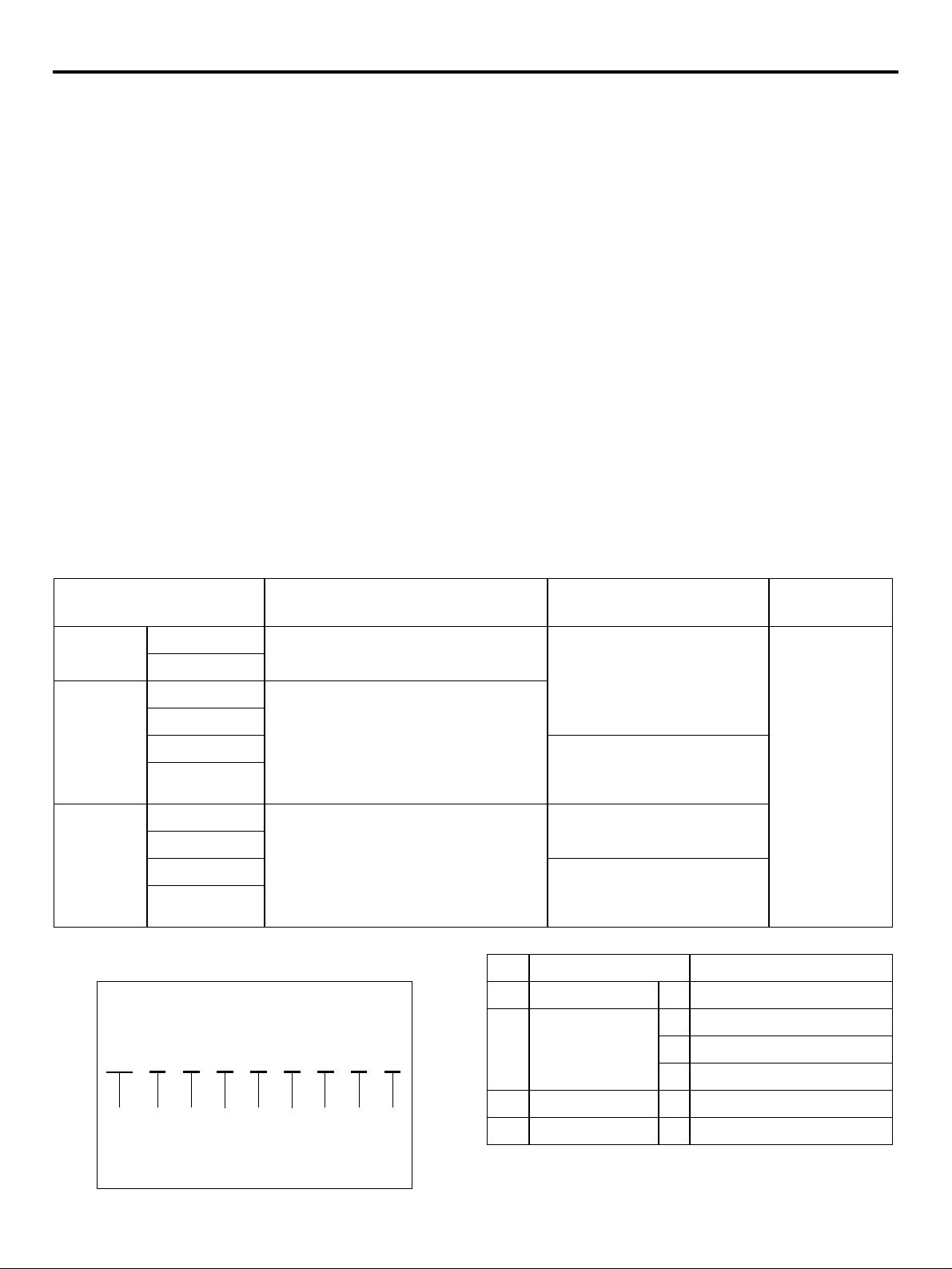

No. Item Dimension mm No. Item Dimension mm

1 Brake pedal room880 4Front head room 931

2 Hip point couple 825 5Rear head room 862

3Total leg room 1,705

NOTE: Refer to P.00-23 for the body dimensions.

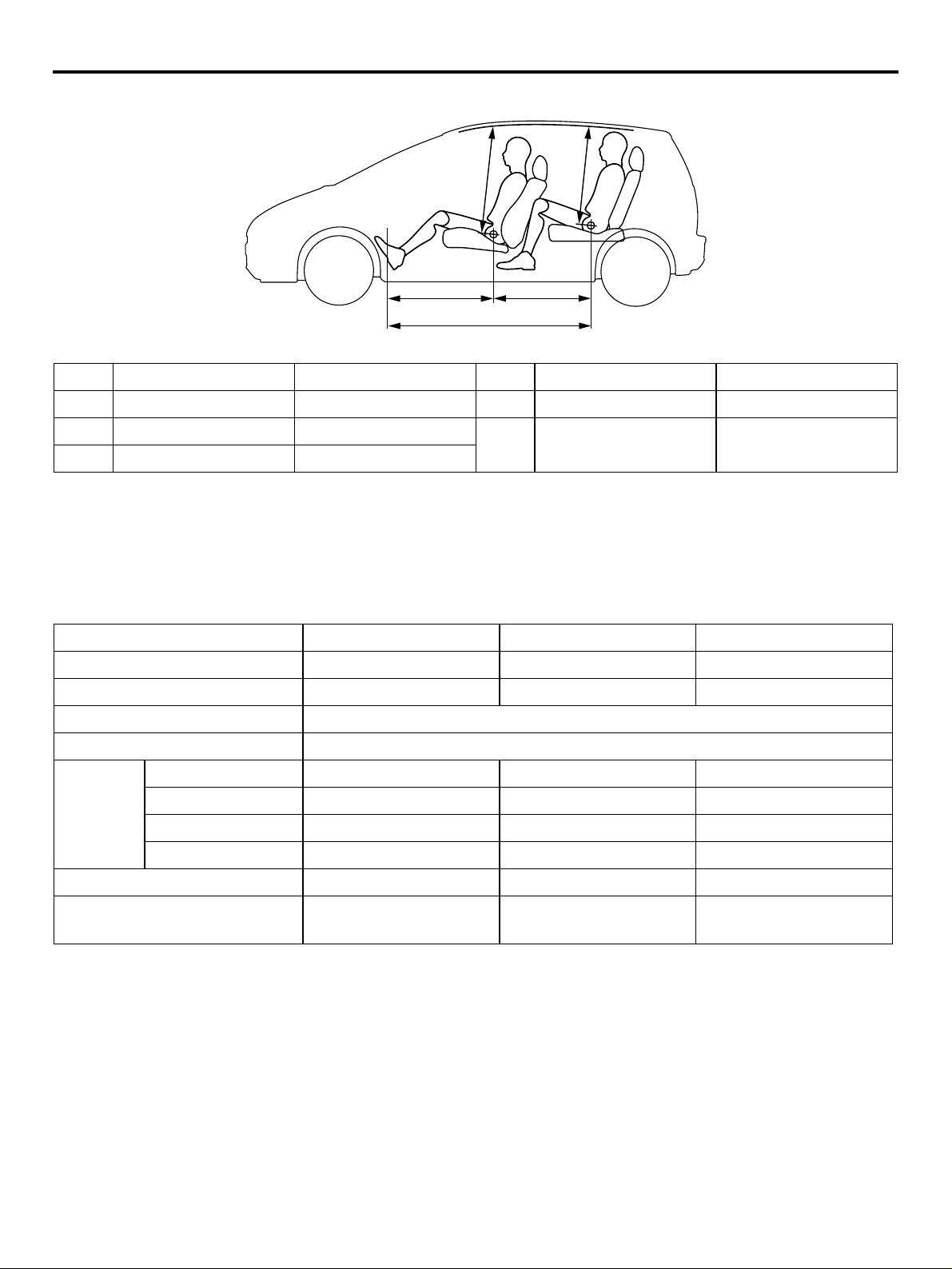

ENGINE

M2000020000223

The following three types of newly developed

engines have been adopted to realize light weight,

small size, and good fuel efficiency. Those engines

are complied with Step 4 in European emissions regulations.

AB

Item 134910 135930 135950

Total displa cemen t mL 1,124 1,332 1,499

Bore × stroke mm 75 × 84.8 75 × 75.4 75 × 84.8

Compression ratio 10.5

Combustion chamber Pentroof-type

Valve

timing

Intake opening BTDC 41° − ATDC 9° BTDC 41° − ATDC 9° BTDC 41° − ATDC 9°

Intake closing ABDC 19° − ABDC 69° ABDC 3° − ABDC 53° ABDC 11° − ABDC 61°

Exhaust opening BBDC 35° BBDC 35° BBDC 39°

Exhaust closing ATDC 5° ATDC 5° ATDC 5°

Maximum output kW(PS)/rpm 55(75)/6,000 70(95)/6,000 80(109)/6,000

Maximum torque

100(10.2)/3,500 125(12.7)/4,000 145(14.8)/4,000

N⋅m(kg-m)/rpm

TRANSMISSION

M2000021000226

• F5MGA 5-speed manual transmission

• F6SGA 6-speed automated manual transmission

The following two types of newly developed transmissions with light weight and small-size design

have been adopted to realize good fuel efficiency.

Page 6

00-6

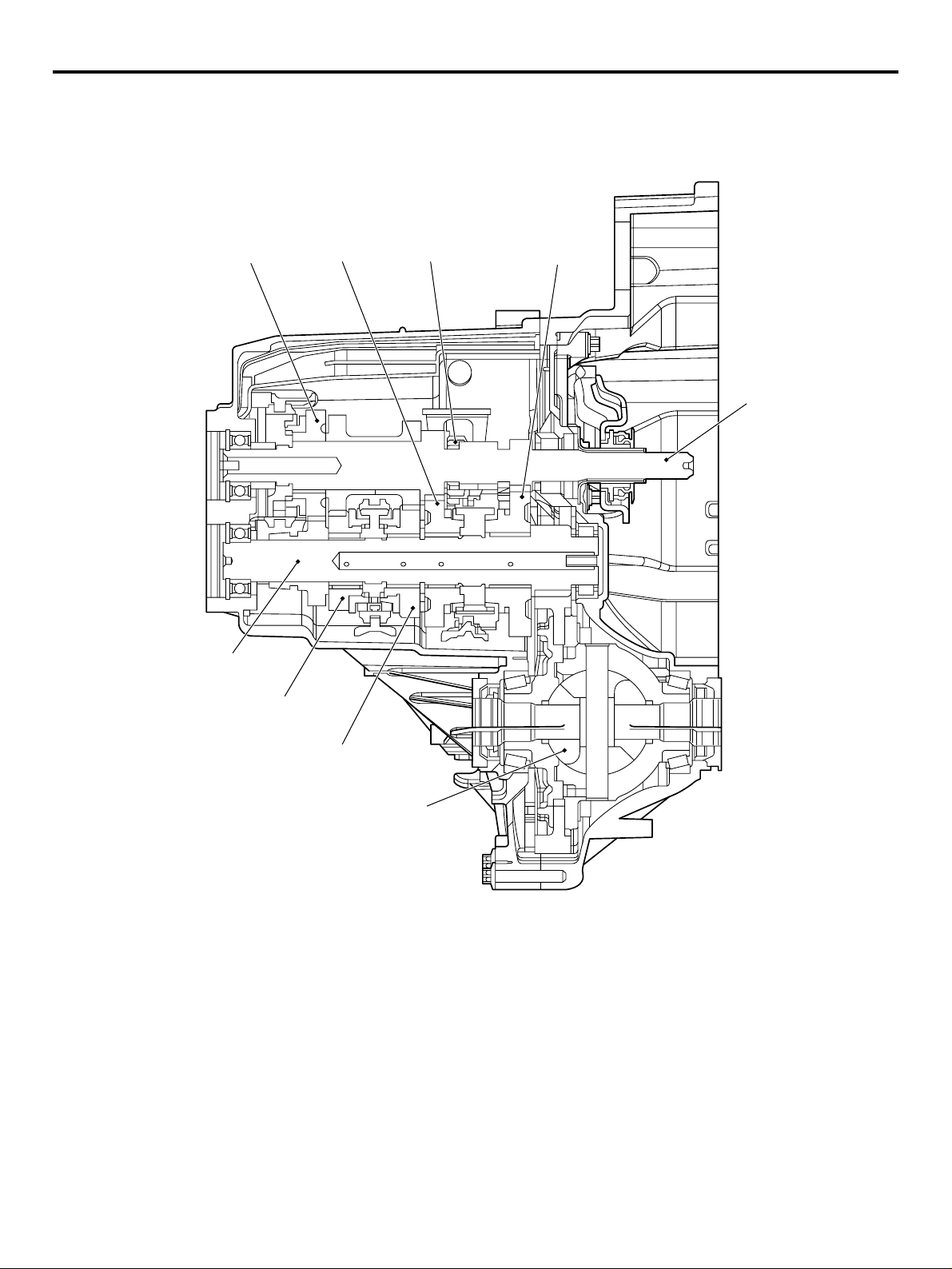

MANUAL TRANSMISSION

SECTIONAL VIEW

GENERAL

TECHNICAL FEATURES

5th gear

Output shaft

4th gear

2nd gear

Reverse gear

1st gear

Input shaft

3rd gear

Differential

AC311790

AC

Page 7

GENERAL

TECHNICAL FEATURES

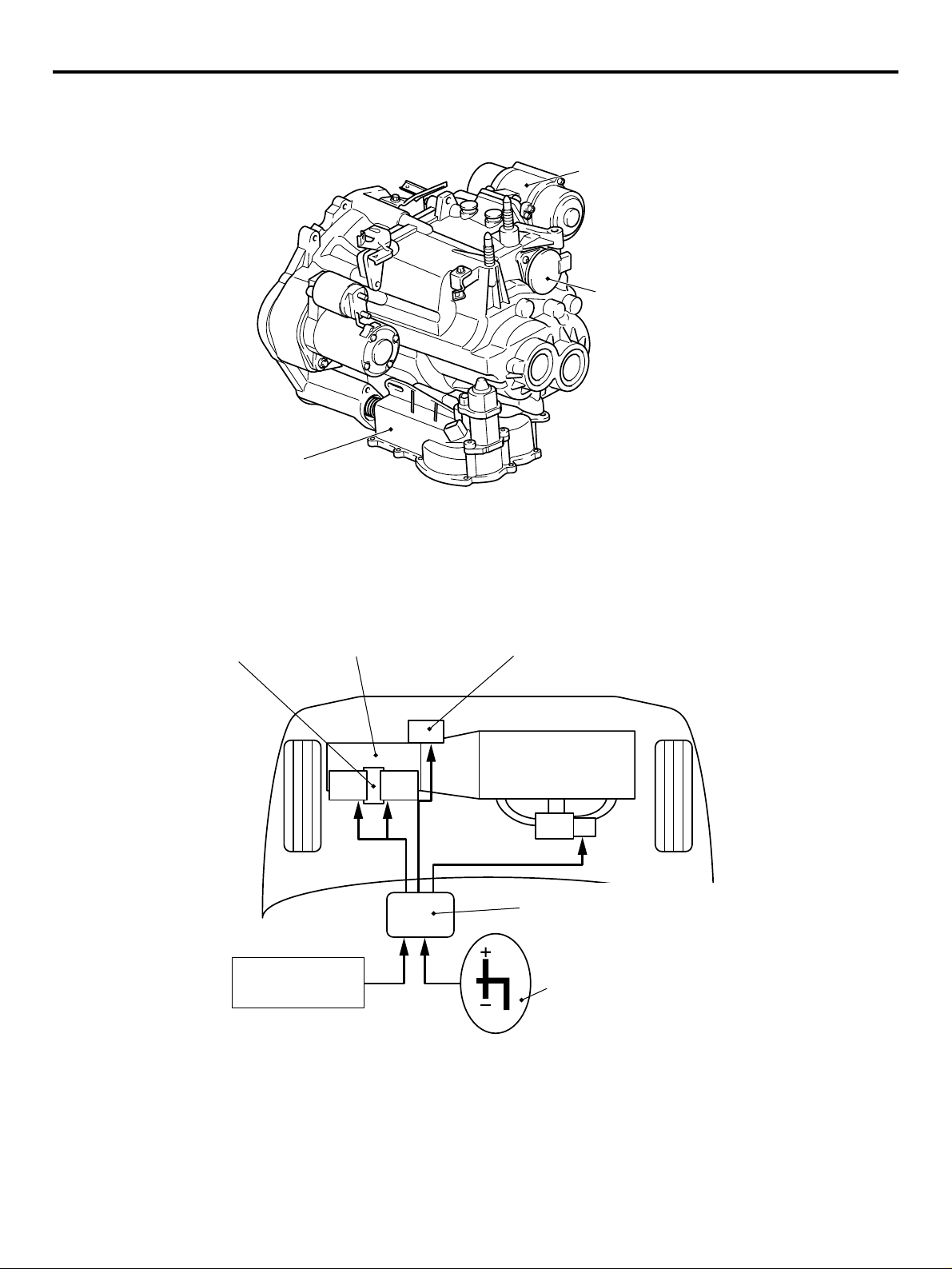

AUTOMATED MANUAL TRANSMISSION

OUTSIDE VIEW

Clutch actuator

Shift actuator assembly

Drum position sensor

AC311791

00-7

AB

As automated manual transmission is designed

based on 6-speed manual gearbox and driven by

electric actuators (motors) via sophisticated

twin-drum shift mechanism, it gives our customers

"easy to drive as A/T", "fun to drive and high fuel efficiency as M/T".

Shift actuator

assembly

Automated manual transmission

Accelerator pedal

Brake pedal

SCHEMATIC DIAGRAM

Clutch actuator

Engine

Engine automated manual

transmission electronic control unit

(Engine-A-M/T-ECU)

A

N

Allshift lever

R

AC311704

AB

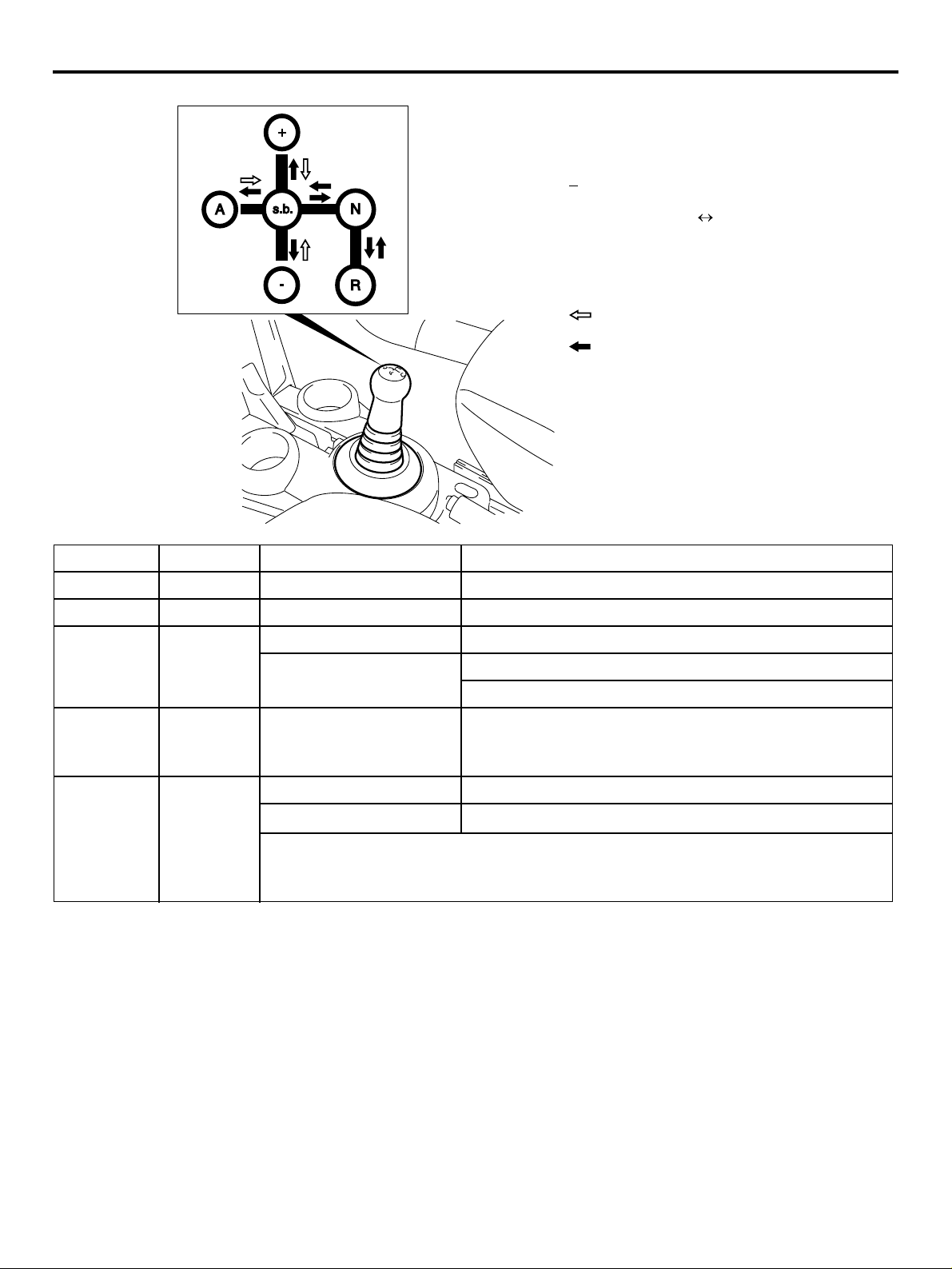

DRIVING MODE

Driving mode provides either manual mode (like

sequential M/T) or automatic mode (like conventional

A/T), by tipping shift lever toward "A" or "+" or "−"

from "s.b." position.

Page 8

00-8

GENERAL

TECHNICAL FEATURES

+: Up shifting

s.b.: Stand by (manual selection of gear)

: Down shifting

A: Switch automatic manual mode

N: Neutral

R: Reverse gear

: Automatic resume

: Manual operation

Position Operation Function Further explanation

"N" In "N" Neutral Engine start possible only at "N".

"R" "N" → "R" Reverse drive No creeping.

s.b. (stand

by)

"A" s.b. → "A"

"N" → s.b. Forward drive Creeping starts (with brake pedal depress).

Auto mode or Manual

mode

Starts from auto mode. <135950>

Starts from manual mode. <135930>

Mode change Auto mode or Manual mode comes alternatively.

(tip)

(Auto mode → Manual mode → Auto mode → Manual

mode)

"+", "−"s.b. → "+"

(tip)

s.b. → "−"

(tip)

+: Manual up shifting Higher gear will be selected. *1, *2

−: Manual down shifting

Lower gear will be selected. *1, *3

*1: After "+" or "−" tip action, mode becomes manual mode.

*2: If vehicle speed is too low, some up shifts neglected.

*3: If engine speed is too high, down shifting neglected.

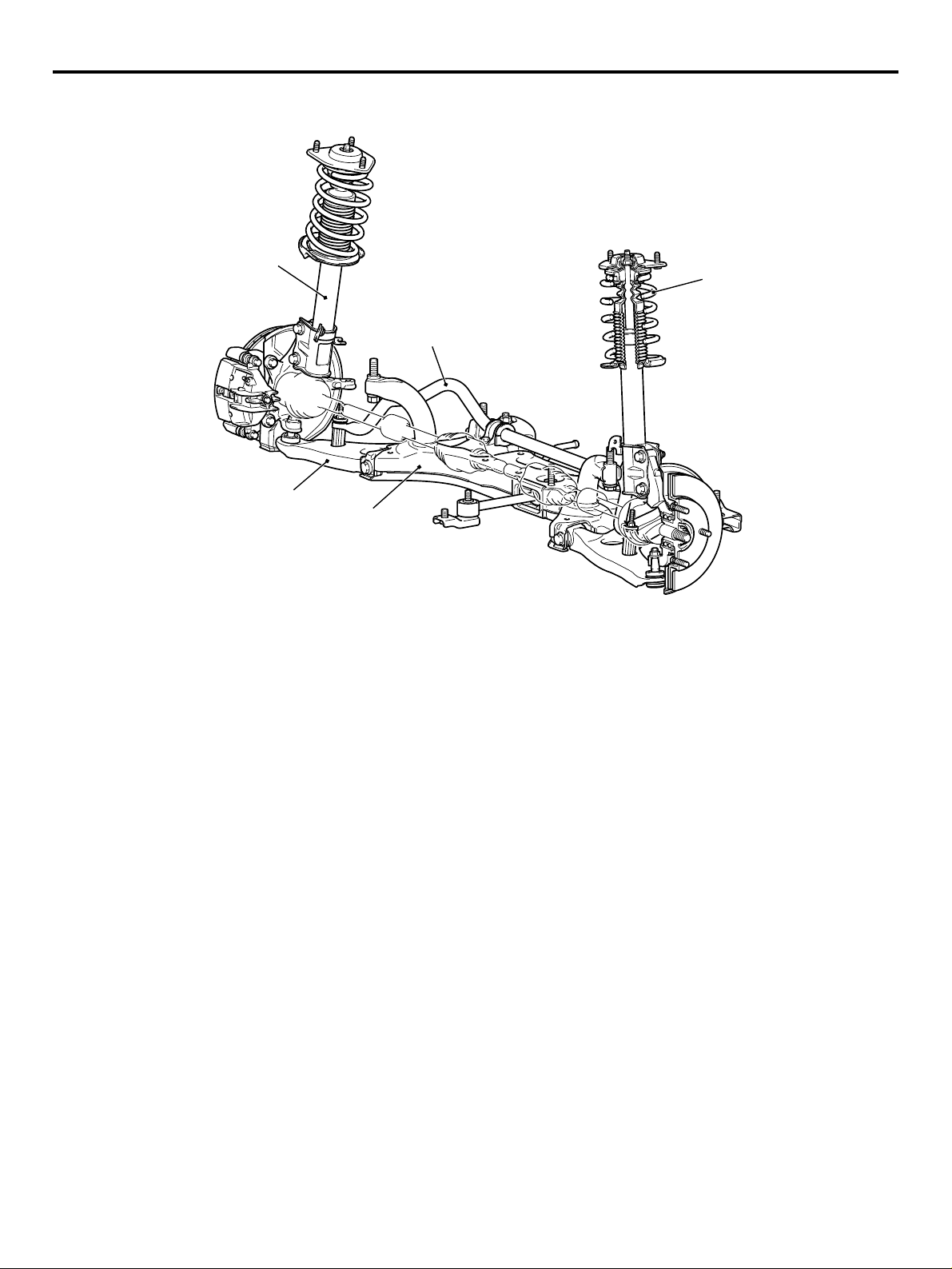

SUSPENSION

M2000023000211

FRONT SUSPENSION

The newly developed MacPherson Strut suspension

with compatible characteristics of high rigidity and

light weight has been adopted for the front suspension to realize sufficient driving comfort and driving

stability.

AC312516

AB

Page 9

GENERAL

TECHNICAL FEATURES

00-9

Strut assembly

Stabilizer bar

Lower arm

Crossmember

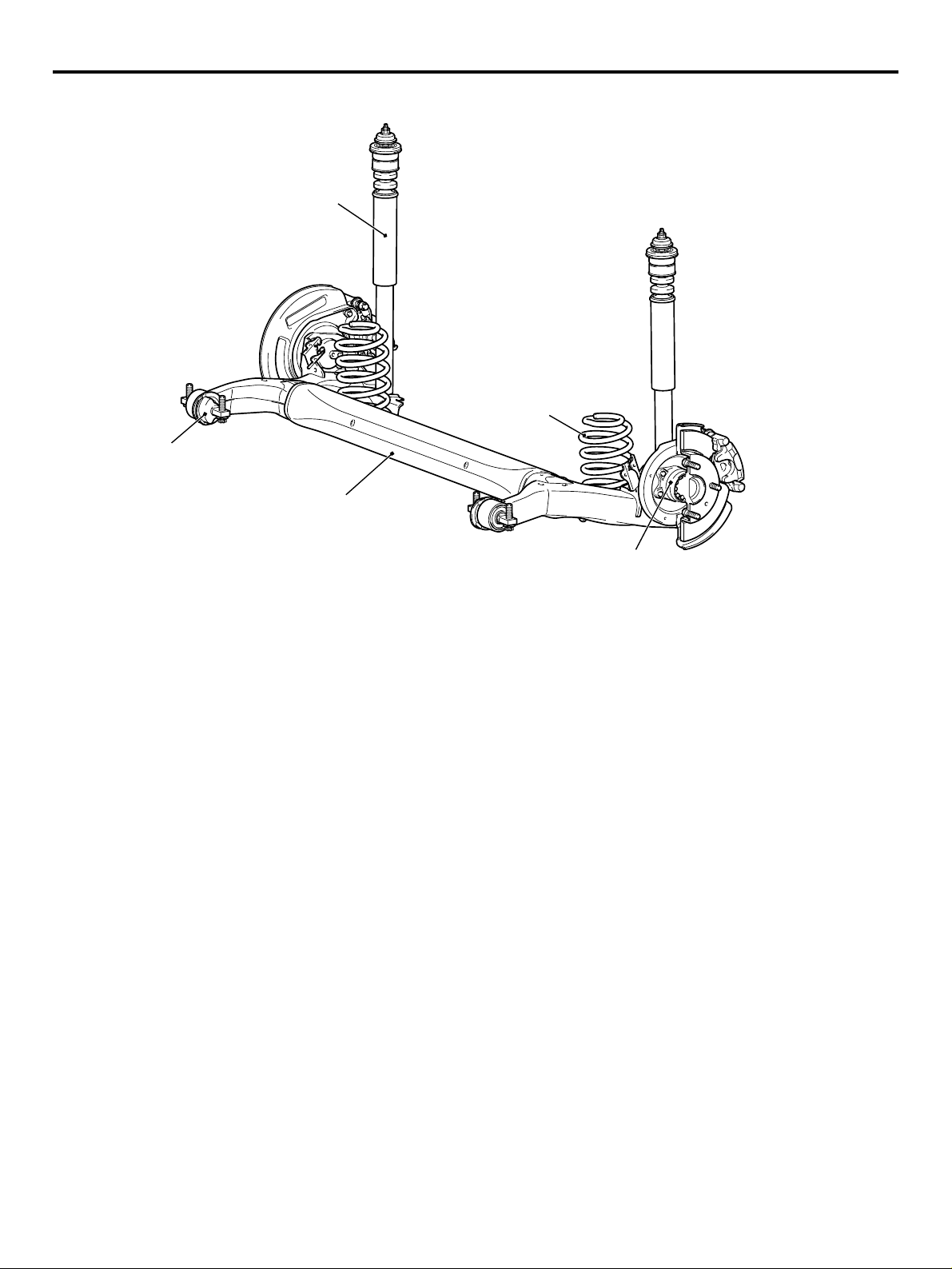

REAR SUSPENSION

The torsion beam suspension has been adopted for

the rear suspension to realize a large suspension

stroke and excellent driving comfort. The suspension

with small-size design has provided ample interior

space.

Coil spring

AC310151

AB

Page 10

00-10

GENERAL

TECHNICAL FEATURES

Shock absorber

Coil spring

Arm bushing

Torsion beam and arm assembly

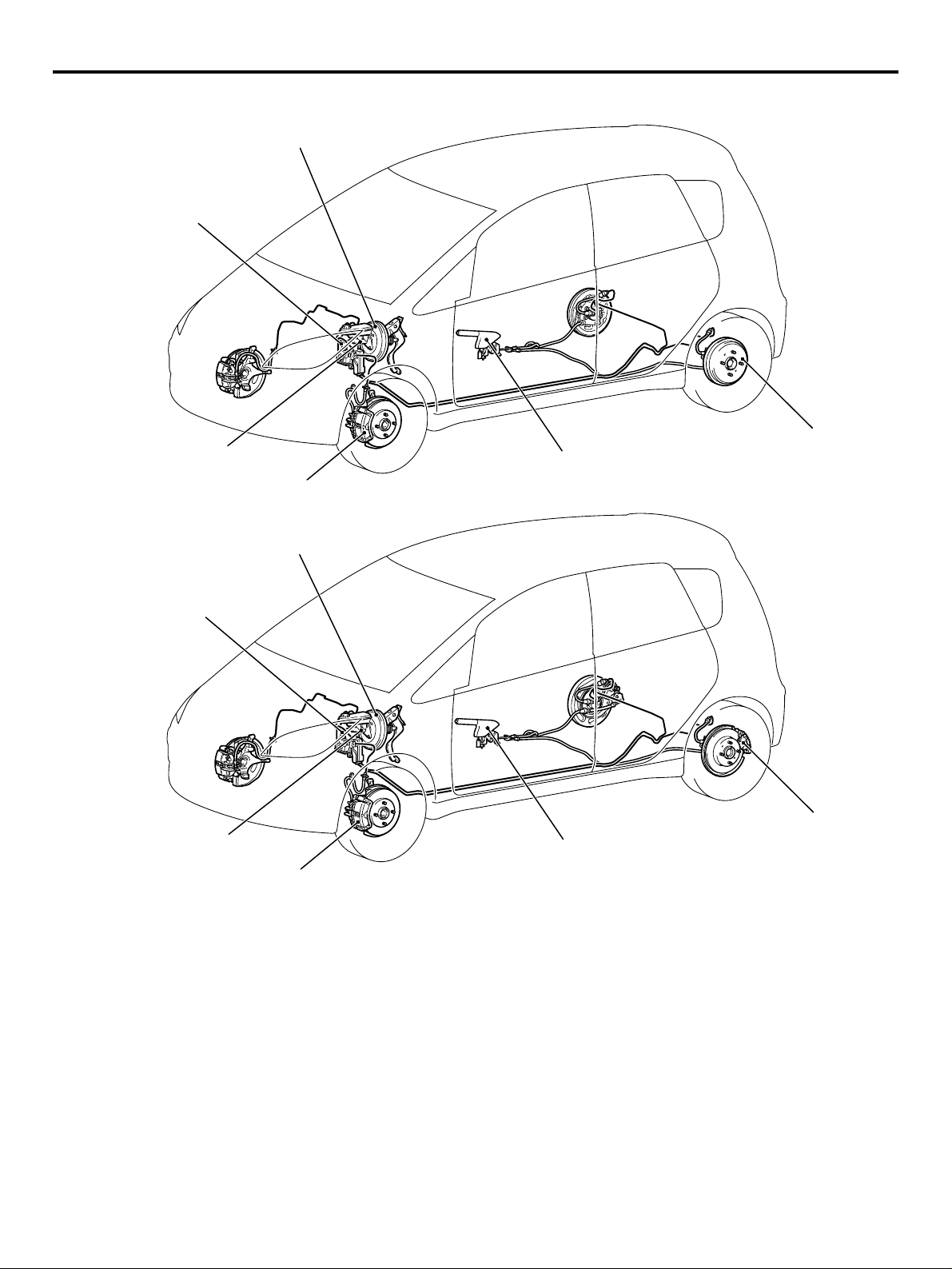

BRAKE

M2000024000043

14-inch ventilated disk brake for the front, 8-inch

leading trailing drum brake or 14-inch solid disk

brake for the rear have been installed to realize high

reliability and durability along with excellent braking

performance.

Unit type bearing

AC310152

AB

Page 11

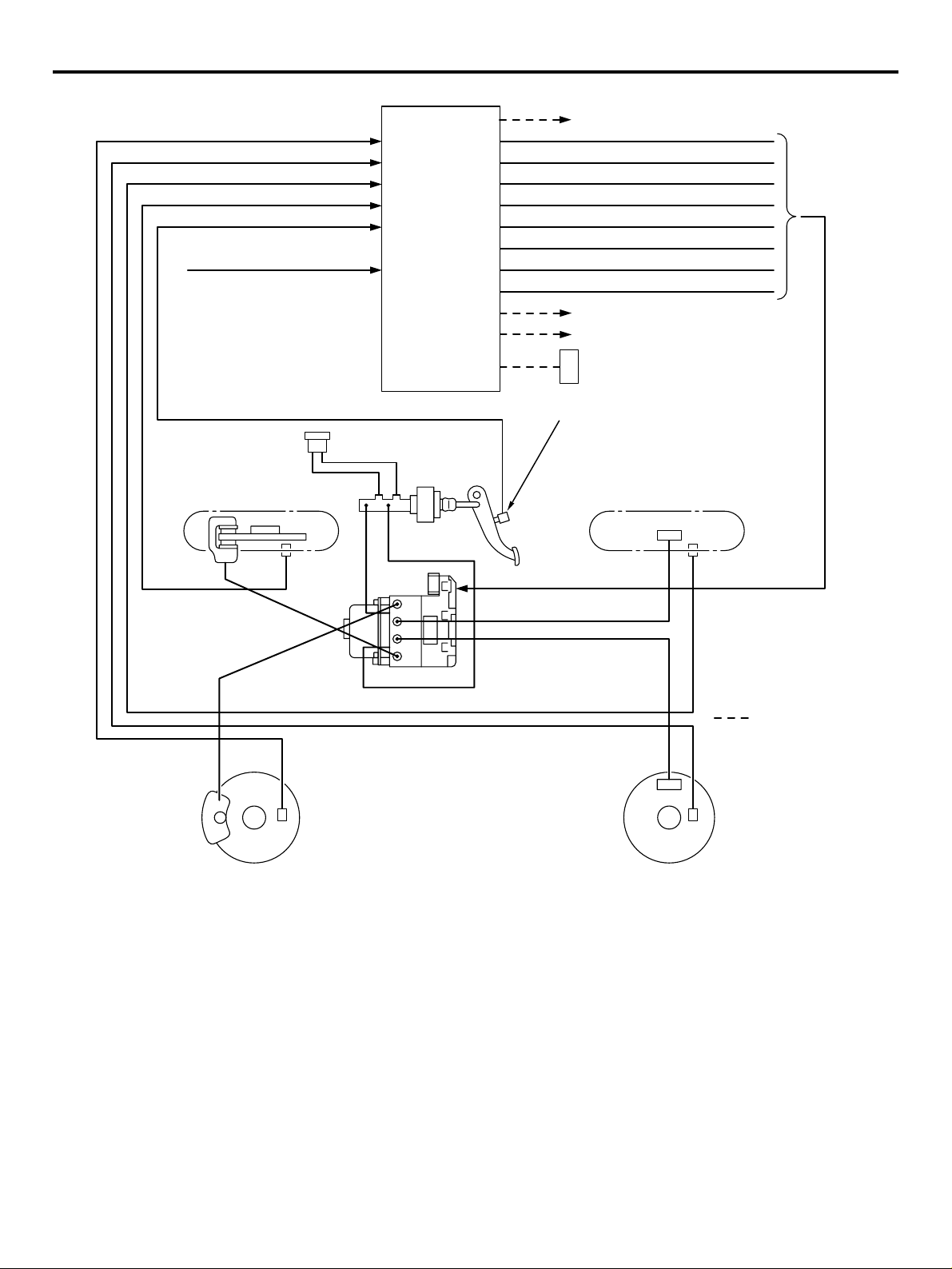

<Vehicle with rear drum brake>

Brake booster

Hydraulic unit

(Integrated with ABS-ECU/Active

Stability Control System-ECU)

GENERAL

TECHNICAL FEATURES

00-11

Master cylinder

Front disc brake

<Vehicle with rear disc brake>

Brake booster

Hydraulic unit

(Integrated with ABS-ECU/Active

Stability Control System-ECU)

Master cylinder

Front disc brake

Parking brake lever

Parking brake lever

Rear drum brake

AC311564

Rear disc brake

AC311651

AC311650

AB

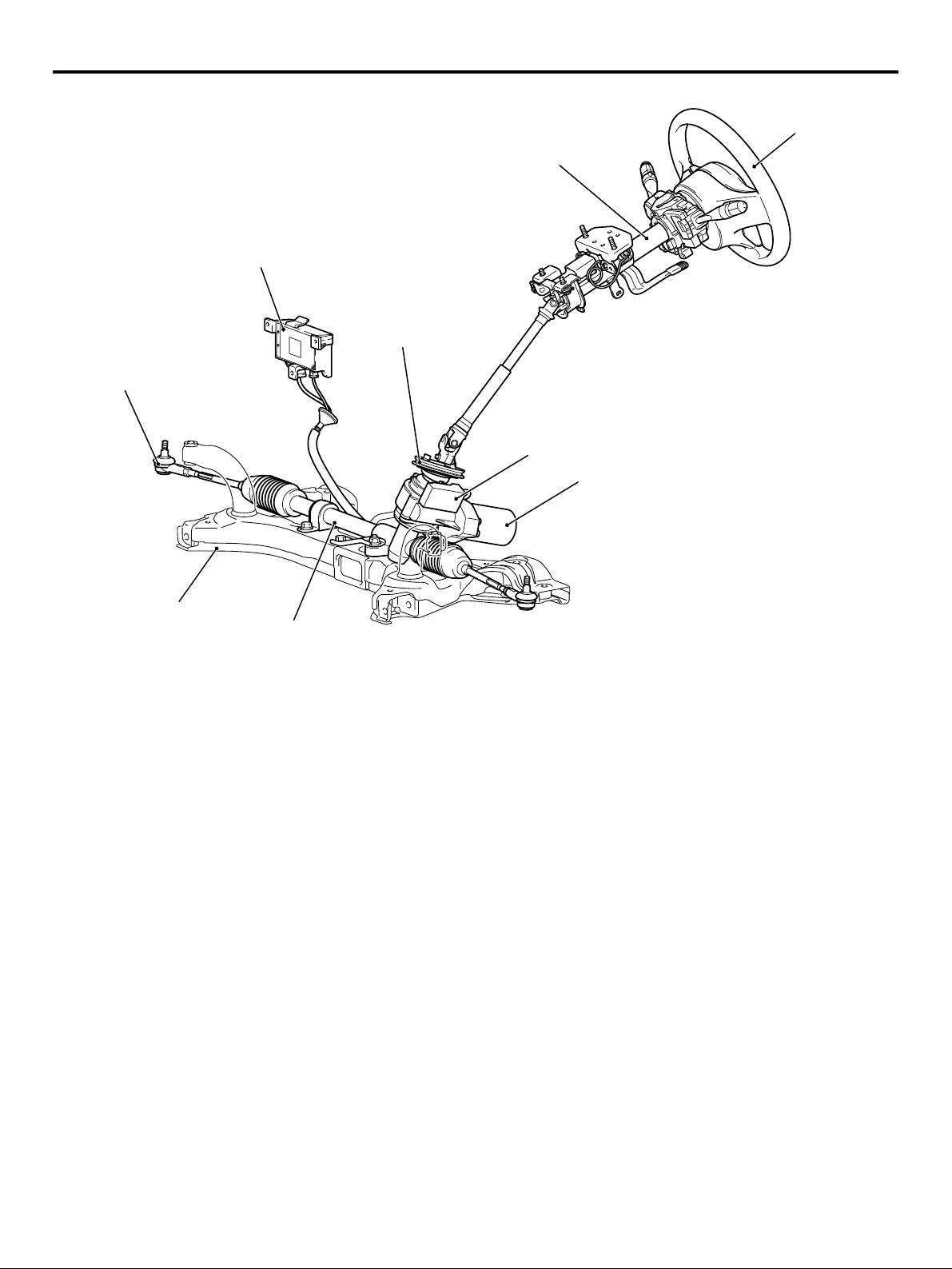

STEERING

M2000040000010

Due to the adoption of electric power steering driven

by newly developed pinion shaft, effortless steering

wheel manoeuvring at the low speed as well as stable steering wheel manoeuvring at the mid to high

speed has been achieved.

Page 12

00-12

Tie rod end

GENERAL

TECHNICAL FEATURES

Steering wheel

Steering column assembly

Electric power steering-ECU

Dash panel cover

Torque sensor

Motor

Crossmember

Steering gear

LOCAL INTERCONNECT NETWORK (LIN)

M2000041000013

LIN refers to "Local Interconnect Network", a global

standard of serial multiplex communication protocol

administrated by LIN consortium. A communication

circuit employing the LIN protocol connects each

ECU, and switch data can be shared among ECUs,

which enables more reduction in wiring. Transmission speed is 19.2 kbps.

*2

For COLT, ETACS

signals through CAN*

-ECU can receive some input

3

communication in addition to

the LIN communication.

*1

AC310150

NOTE:

*1

: The regulations have been decided in

detail, from software matters such as the necessary

transmission rate for communication, the system,

data format, and communication timing control

method to hardware matters such as the harness

type and length and the resistance values.

NOTE: *

2

: ETACS (Electronic Time and Alarm Con-

trol System)

NOTE: *

3

: CAN (Controller Area Network)

AB

Page 13

GENERAL

TECHNICAL FEATURES

00-13

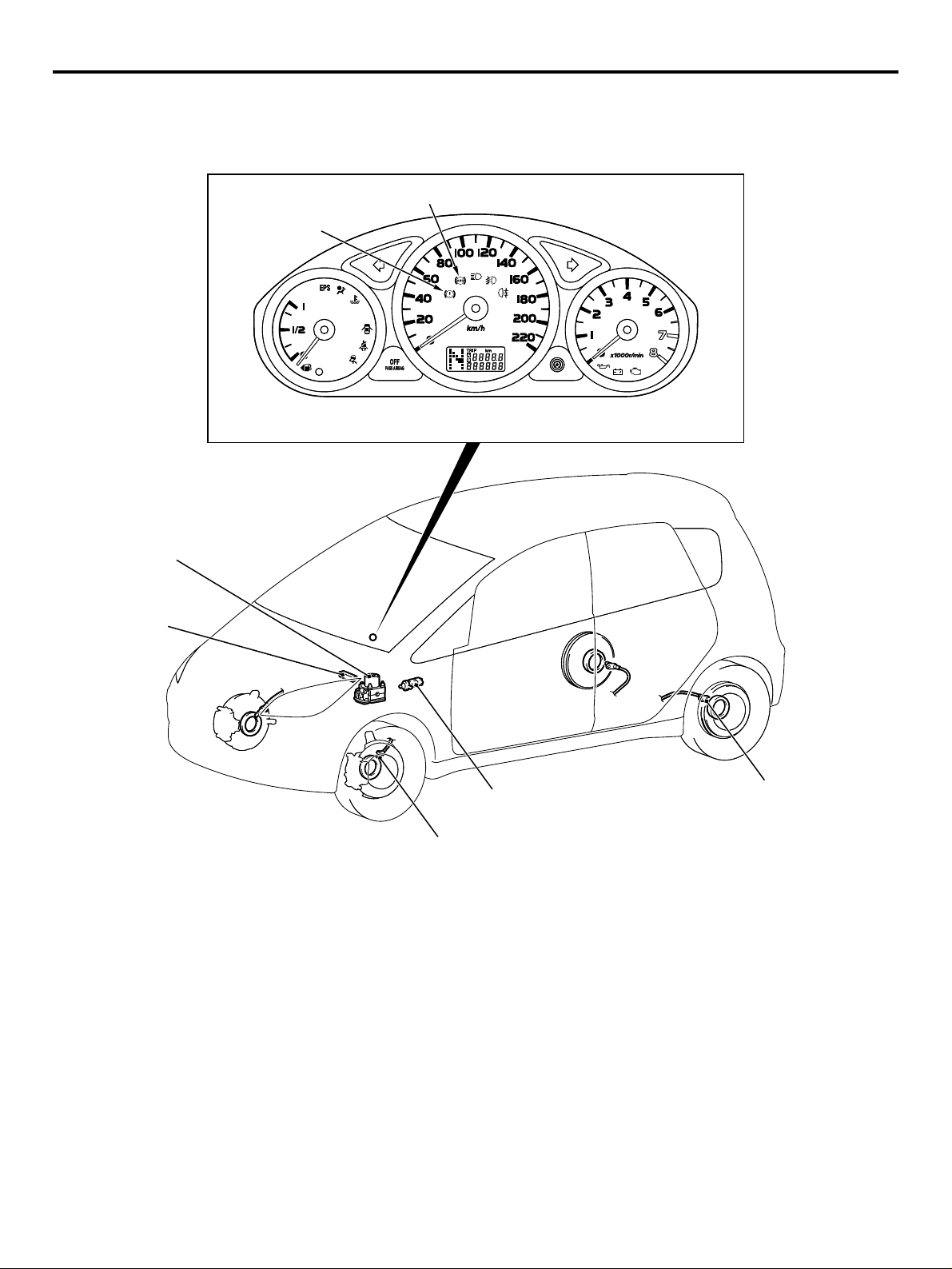

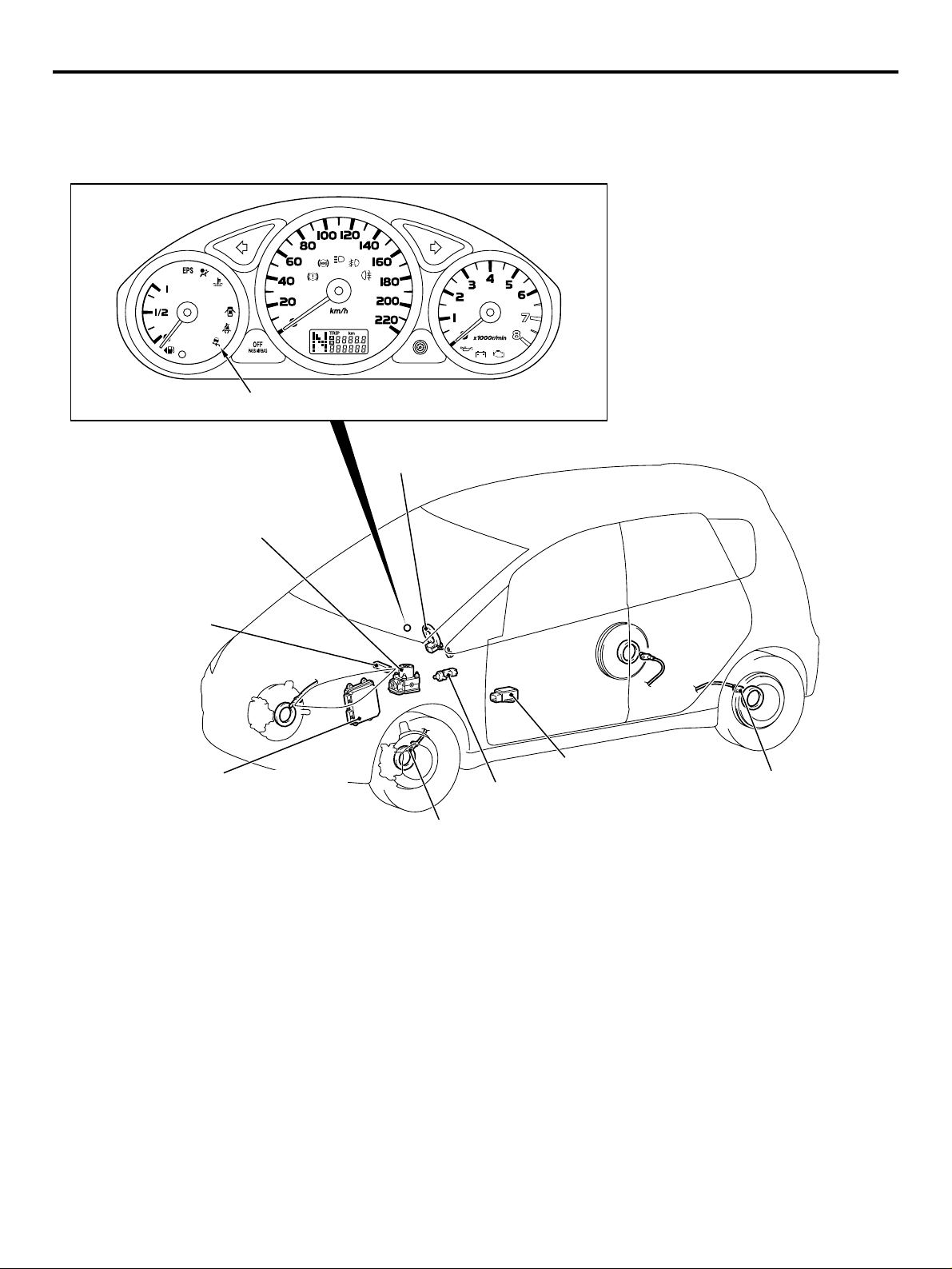

ACTIVE SAFETY

BRAKING SYSTEM

Brake warning lamp

Hydraulic unit and

ABS-ECU

M2000031000216

ABS warning lamp

AC311642

AC311642

Diagnosis

connector

Wheel speed sensor

Stop lamp switch

Wheel speed sensor

AC311643

AC311643

AC311644

AC311644

AC

Page 14

00-14

Front-left wheel speed sensor

Rear-left wheel speed sensor

Rear-right wheel speed sensor

Front-right wheel speed sensor

Stop lamp switch

ABS-ECU power supply

GENERAL

TECHNICAL FEATURES

Front right solenoid valve (out)

Front right solenoid valve (in)

Front left solenoid valve (out)

Front left solenoid valve (in)

Rear right solenoid valve (out)

ABS-ECU

Rear right solenoid valve (in)

Rear left solenoid valve (out)

Rear left solenoid valve (in)

ABS warning lamp

Stop lamp switch

Engine-ECU <M/T> or Engine-A-M/T-ECU*

<Automated manual transmission>

Brake warning lamp

Diagnosis connector

Front-right wheel (FR)

Front-right

wheel

speed

sensor

Hydraulic

unit (HU)

Front-left wheel

speed sensor

Front-left wheel (FL)

4-WHEEL ANTI-SKID BRAKING SYSTEM

(4ABS)

A 4-wheel anti-skid braking system (4ABS) has been

adopted to prevent slipping caused by the vehicle

wheels locking up, in order to minimize braking distance, and also to maintain a stable vehicle posture

and steering performance.

Rear-right wheel (RR)

Rear-right wheel

speed sensor

Note

*Engine-A-M/T-ECU:

Engine automated manual

transmission electronic

control unit

: CAN-bus line

Rear-left wheel

speed sensor

Rear-left wheel (RL)

AC311645

AC

ELECTRONIC BRAKE-FORCE

DISTRIBUTION (EBD)

An electronic brake-force distribution (EBD) which

makes it possible to maintain the maximum amount

of braking force even when the vehicle's load is varied has been adopted.

Page 15

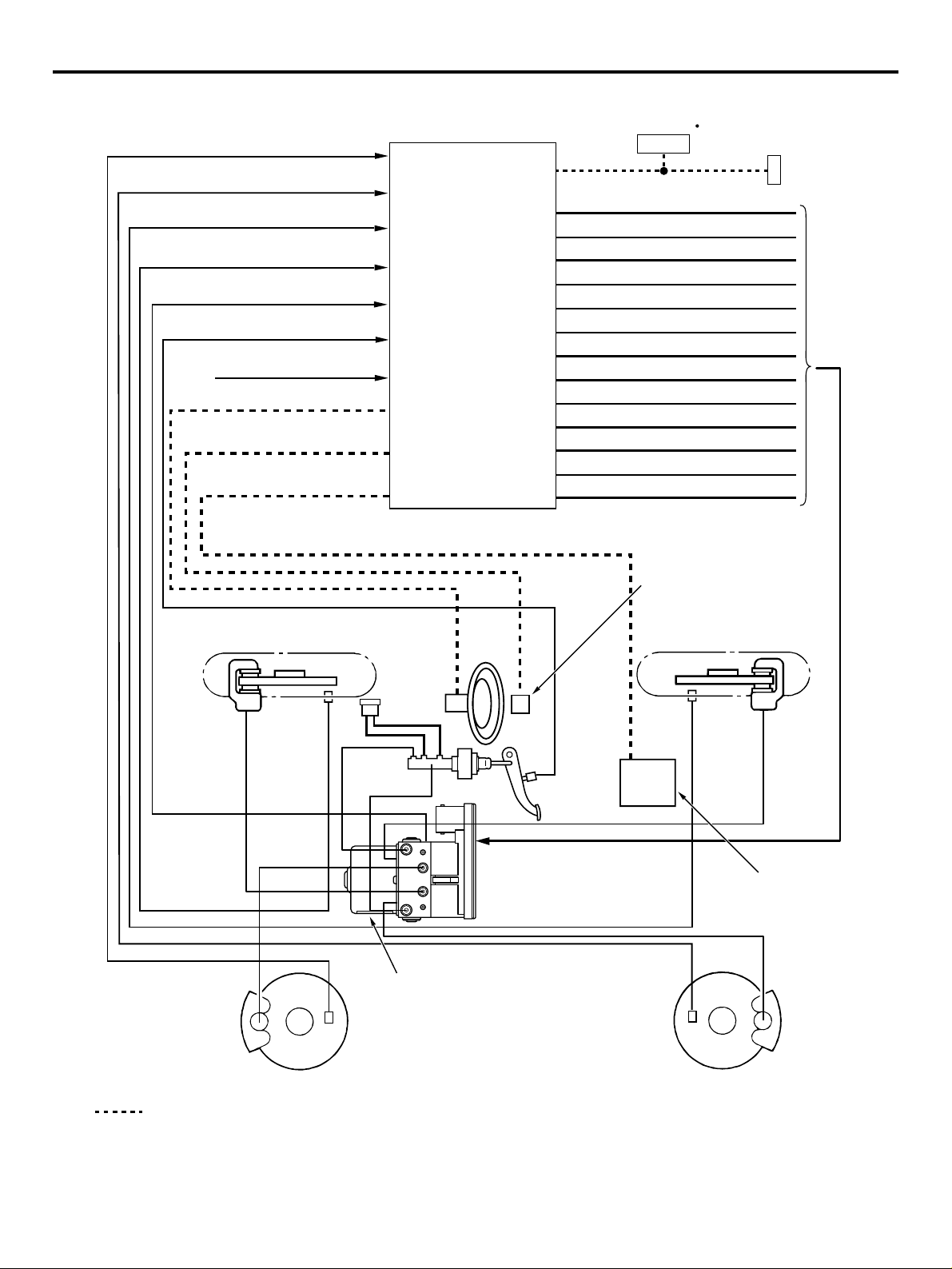

TECHNICAL FEATURES

ANTI-SKID BRAKE SYSTEM

(ABS)/ACTIVE STABILITY CONTROL

SYSTEM

Anti-skid Brake/Active stability control indicator lamp

Steering wheel

sensor

Pressure sensor, Hydraulic unit and

Anti-skid Brake/Active stability

control system control unit

(ABS/Active stability control

system-ECU)

GENERAL

00-15

Diagnosis

connector

Engine-ECU <M/T> or Engine-A-M/T-ECU

(Engine automated manual transmission

electronic control unit)

<Automated manual transmission>

Stop lamp switch

Wheel speed sensor

G and yaw rate sensor

Wheel speed sensor

AC311649

AC

Page 16

00-16

Front-left wheel speed sensor

Rear-left wheel speed sensor

Rear-right wheel speed sensor

Front-right wheel speed sensor

Master cylinder pressure sensor

Stop lamp switch

Power supply to ABS/Active stability

control system-ECU

Steering wheel sensor

G and yaw rate sensor

Engine-ECU <M/T> or engine-AM/T-ECU <Automated manual

transmission>

GENERAL

TECHNICAL FEATURES

Suction valve (FR)

Suction valve (FL)

Cut valve (FR)

Cut valve (FL)

Control solenoid valve (FR) IN

ABS/Active stability

control system-ECU

Control solenoid valve (FR) OUT

Control solenoid valve (FL) IN

Control solenoid valve (FL) OUT

Control solenoid valve (RR) IN

Control solenoid valve (RR) OUT

Control solenoid valve (RL) IN

Control solenoid valve (RL) OUT

Pamp motor

Combination meter

ABS/Active stability control

indicator lamp

Diagnosis

Connector

Front-right wheel (FR)

Wheel

speed

sensor

Steering

wheel

sensor

Hydraulic

unit

Wheel speed

sensor

G and yaw rate sensor

Rear-right wheel (RR)

Wheel

speed

sensor

Stop lamp

switch

Engine-ECU <M/T> or engineA-M/T-ECU <Automated manual

transmission>

Wheel speed

sensor

Note

: CAN-bus line

Front-left wheel (FL)

Rear-left wheel (RL)

AC311782

AC

Page 17

GENERAL

TECHNICAL FEATURES

00-17

The Anti-skid Brake System (ABS)/Active stability

control system is a combination system of active stability control system and anti-skid brake control system. The active stability control system avoids a

dangerous vehicle attitude by limiting the engine output and braking a set of wheels (left front and right

rear, or right front and left rear) according to driving

conditions. The anti-skid brake control system prevents wheel spinning at vehicle start.

ABS/Active stability control system is available for all

models as optional equipment.

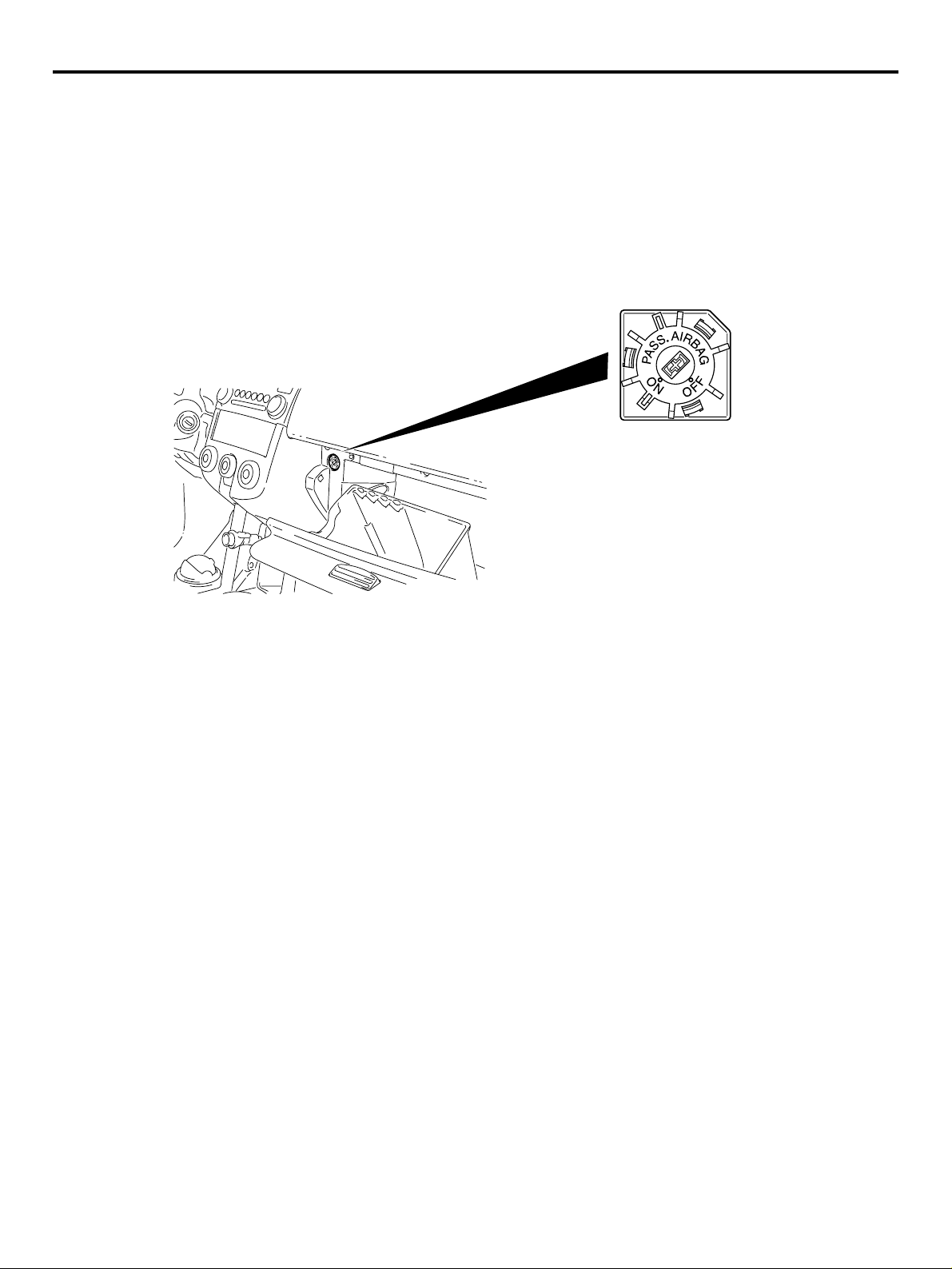

PASSENGER’S AIR BAG CUT OFF

SWITCH

AC311721

AC311720

Passenger’s air bag cut off switch is located in the

glove box.

The passenger’s air bag cut off switch can be used to

disable the passenger's (front) air bag.

AC312760

AB

PASSIVE SAFE TY

M2000032000208

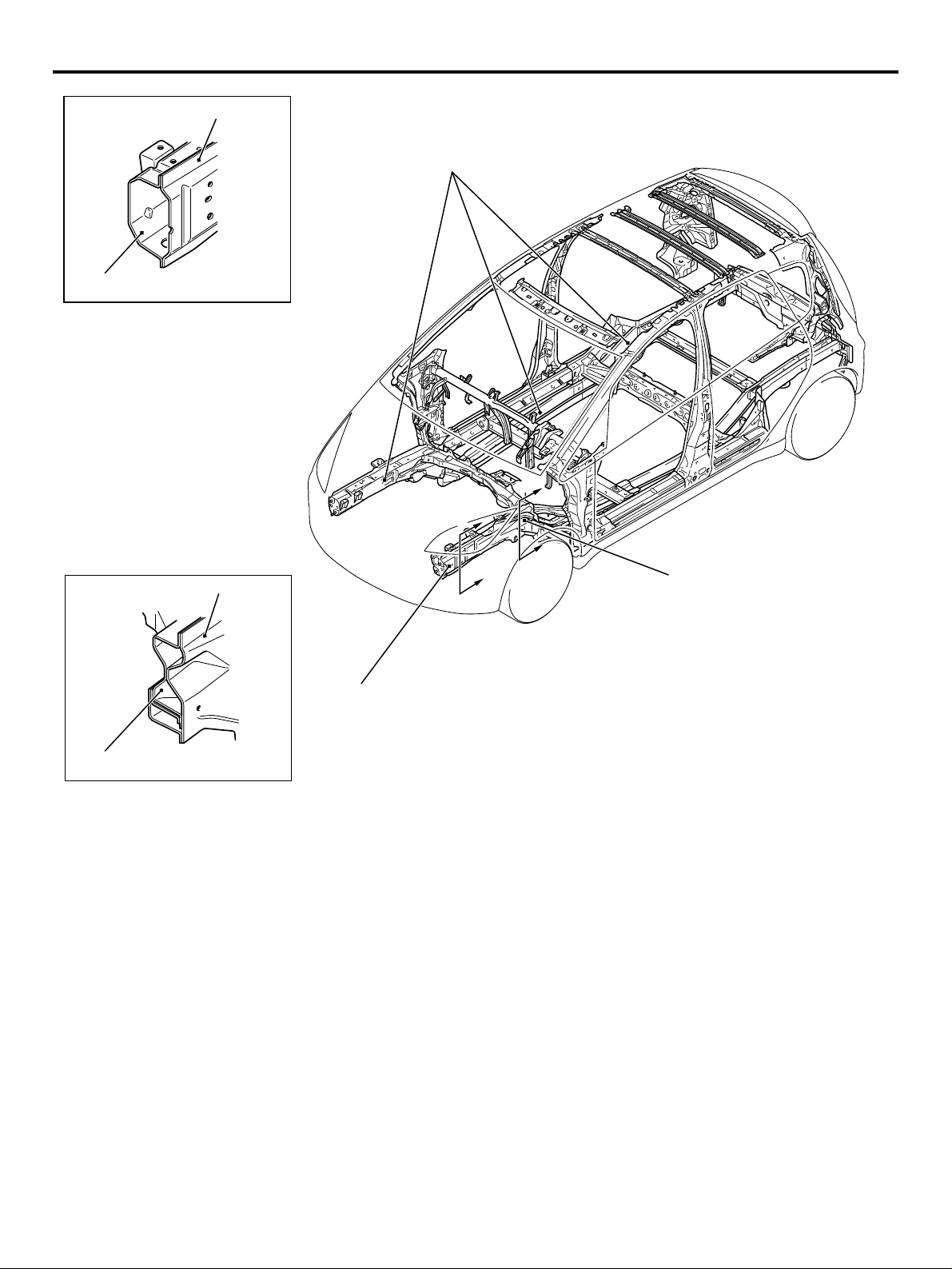

IMPACT SAFETY BODY

The front and rear structures to absorb high energy,

and the highly tough cabin structure reduce the risk

of passenger injuries at front-, rear-, and side-impact

collisions, secure the space for life protection, and

facilitate rescuing passengers.

Page 18

00-18

GENERAL

TECHNICAL FEATURES

Section A - A

Front side member

inner

Section B - B

Front side member

outer

AB301790

Front side member

outer

2

B

A

B

AB301783

1

A

1

Front side member

inner

1. The octagonal cross section for the front of the

front sidemember and 8-shaped cross section for

the rear of the front sidemember have been

adopted for enlargement so that the applied

structures can effectively absorb energy from the

impact at the time of collision.

AB301791

AB301835

2. Due to the adoption of straightened front sidemember and the rear floor sidemember, the

structure can effectively absorb energy from the

impact at the time of collision.

AB

Page 19

TECHNICAL FEATURES

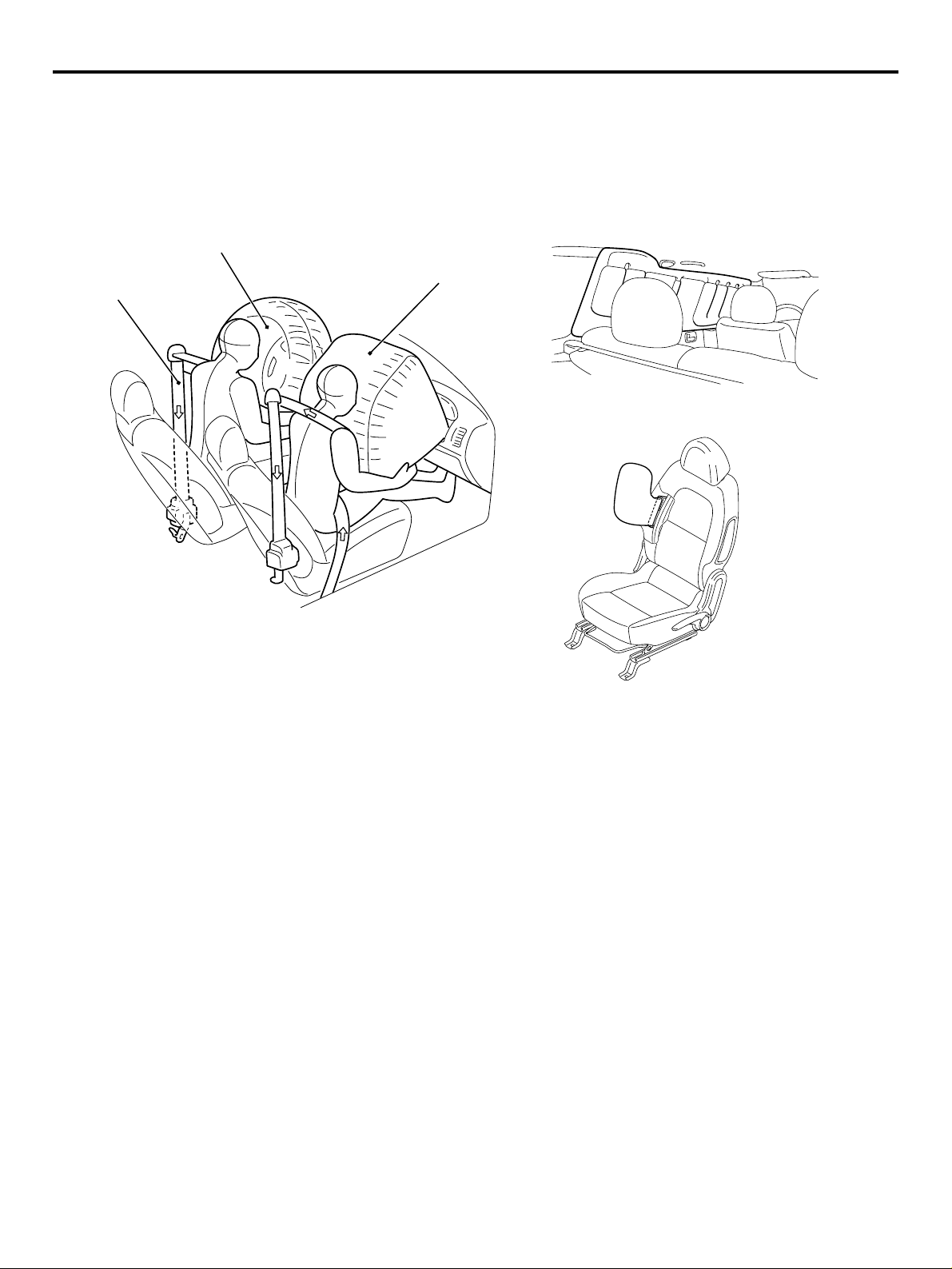

SUPPLEMENTAL RESTRAINT SYSTEM

(SRS) AND FRONT SEAT BELTS WITH

PRE-TENSIONER

GENERAL

00-19

Seat belt with

pre-tensioner

Driver's air bag

module

Curtain air bag modules

Passenger's (front)

air bag module

Side air bag modules

SUPPLEMENTAL RESTRAINT SYSTEM

(SRS)

The SRS is designed to supplement the front seat

belts. It eliminates or reduces injury to the front passenger(s) by deploying air bag(s) in case of a

head-on collision.

SRS SIDE AIR BAG

Side air bag systems in the front seats are activated

when sideward impacts applied to the vehicle exceed

a threshold to protect the occupants’ upper bodies.

SRS CURTAIN AIR BAG

The curtain air bag systems are activated when sideward impacts applied to the vehicle exceed a threshold, to protect the heads of the occupants in the front

and rear seats.

AC313299

AB

SEAT BELT WITH PRE-TENSIONER

The seat belts with pre-tensioner work simultaneously with the SRS. The pre-tensioner takes up seat

belt slack immediately when a collision takes place,

restraining the front passengers sooner than the

SRS. This prevents the passengers from moving forward.

STEERING SHAFT AND STEERING

COLUMN

The impact absorption mechanism in combination of

retractable steering shaft and steering column disengagement mechanism has been adopted to alleviate

the impact from the steering wheel to the driver.

BRAKE PEDAL

The brake pedal backward movement restraint

mechanism to restrain the backward movement of

the brake pedal to the minimum at the time of frontal

collision has been adopted so that the impact to the

lower limbs of the driver can be alleviated.

Page 20

00-20

GENERAL

TECHNICAL FEATURES

CHILD SEAT FIXING BAR COMPATIBLE

WITH ISO FIX*

The anchor bar has been equipped as standard for

easily and securely fixing the child seat compatible

with ISO FIX.

NOTE: *ISO: International Organisation for Standardisation

REAR SEAT BELT WITH CHILD SEAT

FIXING MECHANISM (ALR*)

The child seat fixing mechanism has been adopted

to easily and securely fix the child seat that is not

compatible with ISO FIX.

NOTE: *ALR: Automatic Locking Retractor

POWER WINDOW WITH SAFETY

MECHANISM

The power window with safety mechanism has been

adopted to automatically roll down and stop the door

window glass as soon as the occurrence of jamming

is detected at the time of rolling up the door window

glass.

SUNROOF WITH SAFETY MECHANISM

The sunroof with safety mechanism has been

adopted so that the roof lid glass can move in the

reverse direction and stop when application of external force hinders the movement during the sliding to

close or tilt down operation.

TRIMS AND HEADLINING

The head impact absorption structure has been

adopted for the pillar trim, quarter trim, and headlining so that impact towards the head of a passenger

can be reduced.

OTHER SAFETY FEATURES

• 3-point ELR seat belts

• Child-protection rear door locks

• Front fog lamps <Optional>

• Rear fog lamp (Driver’s side)

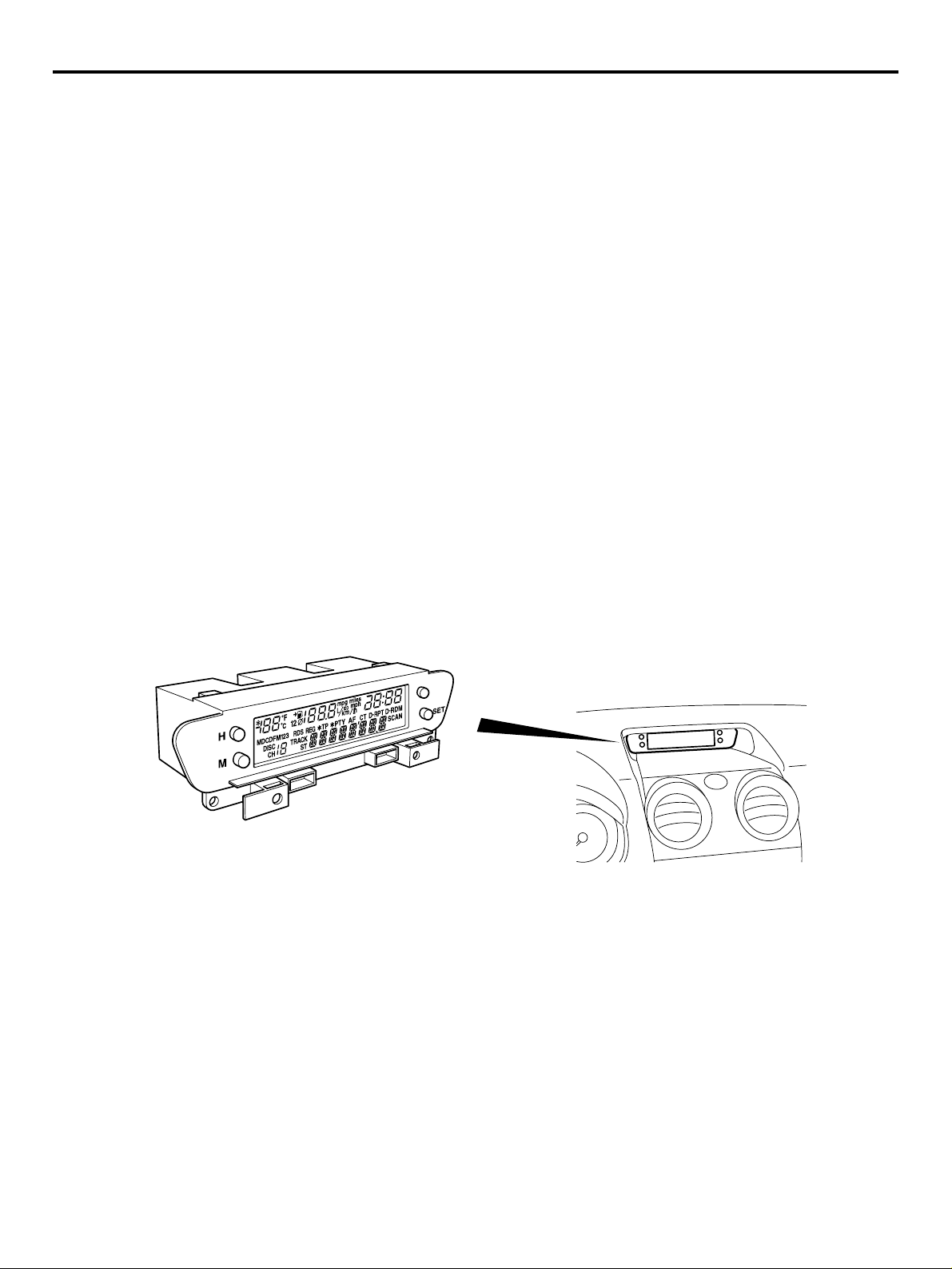

EQUIPMENTS

M2000026000191

MULTI-CENTRE DISPLAY

Multi-centre display

The multi-centre display to provide vehicle information in the text form has been equipped on the centre

console as standard. The multi-centre display has

the following functions:

• Clock

AC311613

• Outside temperature

• Vehicle information (average speed, instant fuel

consumption, remaining distance)

• Audio information

AB

Page 21

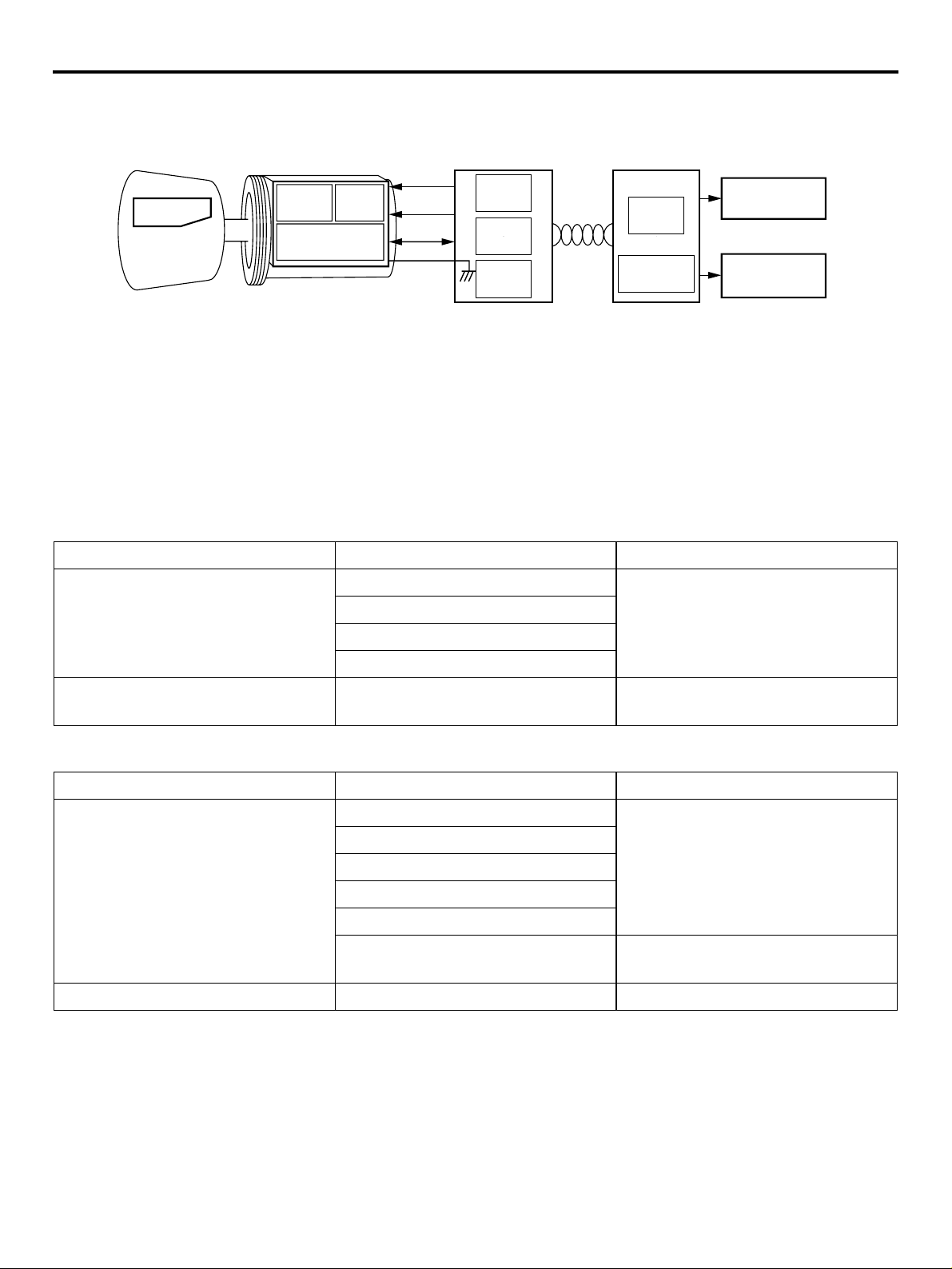

IMMOBILIZER SYSTEM

GENERAL

TECHNICAL FEATURES

00-21

Ignition key Key ring antenna

Encrypted

code

Transponder

Note

*Engine-A-M/T-ECU: Engine automated manual transmission electronic control unit

AMP SCI

RF circuit

Steering lock

All models are equipped with the immobilizer system

as standard. The immobilizer system is the theft prevention system designed for prohibiting the engine

from fuel injection so that the vehicle cannot be

started if someone tries to start the engine with

something other than the ignition key encrypted for

ETACS-ECU

(immobilizer-ECU)

Power

Clock

Data

Engine-ECU <M/T> or Engine-A-M/T-ECU*

<Automated manual transmission>

SCI

CPU

CANI/F

CANBus

CPU

CAN-I/F

Ignition

Injection

AC312166

ENVIRONMENTAL PROTECTION

M2000027000257

Mitsubishi has given careful consideration to protection of natural resources and the environment in the

vehicle. Environmentally friendly features are shown

below.

that vehicle.

IMPROVEMENT ON RECYCLING EFFICIENCY

Category Part name Feature

Recyclable materials Door handle Thermo plastics-easy recyclable

Bumper

AC

Radiator grille

Instrument panel

Recycled materials Engine oil level gauge Recycled from other industries

scrap

REDUCTION OF MATERIAL BURDEN ON ENVIRONMENTt

Category Part name Feature

Elimination of hazardous

substances

Radiator core and heater core Lead free materials

Windshield ceramic print

Body electrodeposited coating

Battery cable connector

Wiring harness

Water proof film Polyvinyl chloride (PVC) free

material

Prevention of ozone depletion Air conditioner refrigerant HFC134a refrigerant

SERVICEABILITY AND RELIABILITY

M2000028000272

MUT-III (MULTI USE TESTER-III)

Comprehensive improvements have been made to

the MUT-II, a tester for diagnosing problems with the

electronic control system. For easier servicing, the

newly developed MUT-III has greatly improved functions and is much easier to use. The MUT-III

expands the functions of the MUT-II in the following

ways:

1. Interactive Error Diagnosis

• In response to the nature of the problem, the

corresponding troubleshooting page from the

maintenance manual is retrieved.

• Service data is displayed, and from the actuator test screen, the page of the maintenance

manual is retrieved for a list of inspection reference values.

Page 22

00-22

GENERAL

VEHICLE IDENTIFICATION

2. Service Manual Viewer

• The technical information manual and workshop manual can be displayed on a personal

computer monitor.

3. CAN* bus diagnosis

• Auto diagnosis function for the CAN communications bus line.

NOTE: *CAN: Controller Area Network (for further

details, refer to GROUP 54C P.54C-2).

IMPROVED SERVICEABILITY

• Since adoption of unvolatile memory (EEPROM*)

helps the learned value not to be initialised when

the battery terminal or connector of the control

unit is disconnected, maintainability can be

improved.

VEHICLE IDENTIFICATION

MODELS

NOTE: *EEPROM: Electrical Erasable Programma-

ble ROM (information to be memorised can be

electronically written into and erased from ROM)

• Since the adoption of service hole at the quarter

trim is designed for removal and installation of the

rear shock absorber assembly, maintainability

can be improved.

• Since the adoption of electric power steering

makes hydraulic pipes and oil pumps unnecessary, maintainability can be improved.

• Since adoption of service hole at the splash

shield helps for removal and installation of headlamp bulb (low beam) and front turn signal lamp

bulb, maintainability can be improved.

• The instrument lower panel can be removed or

installed without using tools at the time of fuse

replacement in the junction block.

M2000001000644

Model code Engine model Transmission model Fuel supply

system

Z32A XNLHL6 134910-DOHC MIVEC (1,124 mL) F5MGA <2WD, 5M/T> MPI

XNLHR6

Z34A XNLHL6 135930-DOHC MIVEC (1,332 mL)

XNLHR6

XJLHL6 F6SGA <2WD, 6-speed

XJLHR6

Z36A XNLHL6 135950-DOHC MIVEC (1,499 mL) F5MGA <2WD, 5M/T>

XNLHR6

XJLHL6 F6SGA <2WD, 6-speed

XJLHR6

MODEL CODE

2

Z3

1

2

A

N

X

4

3

5

H

L

L

6

7

6

8

9

No. Item Content

1DevelopmentZ3MITSUBISHI COLT

2Engine type 21,124 mL petrol engine

3Sort APassenger car

4Body style X4-door hatchback

automated manual

transmission>

automated manual

transmission>

41,332 mL petrol engine

61,499 mL petrol engine

AC311514

Page 23

No. Item Content

GENERAL

MAJOR SPECIFICATIONS

00-23

5Transmission

type

N5-speed manual

transmission

J6-speed automated

manual transmission

6Trim level LL-line

7Specification

HMPI-DOHC MIVEC

engine feature

8Steering wheel

location

LLeft hand drive

RRight hand drive

9Destination 6For Europe

MAJOR SPECIFICATIONS

M2000030000268

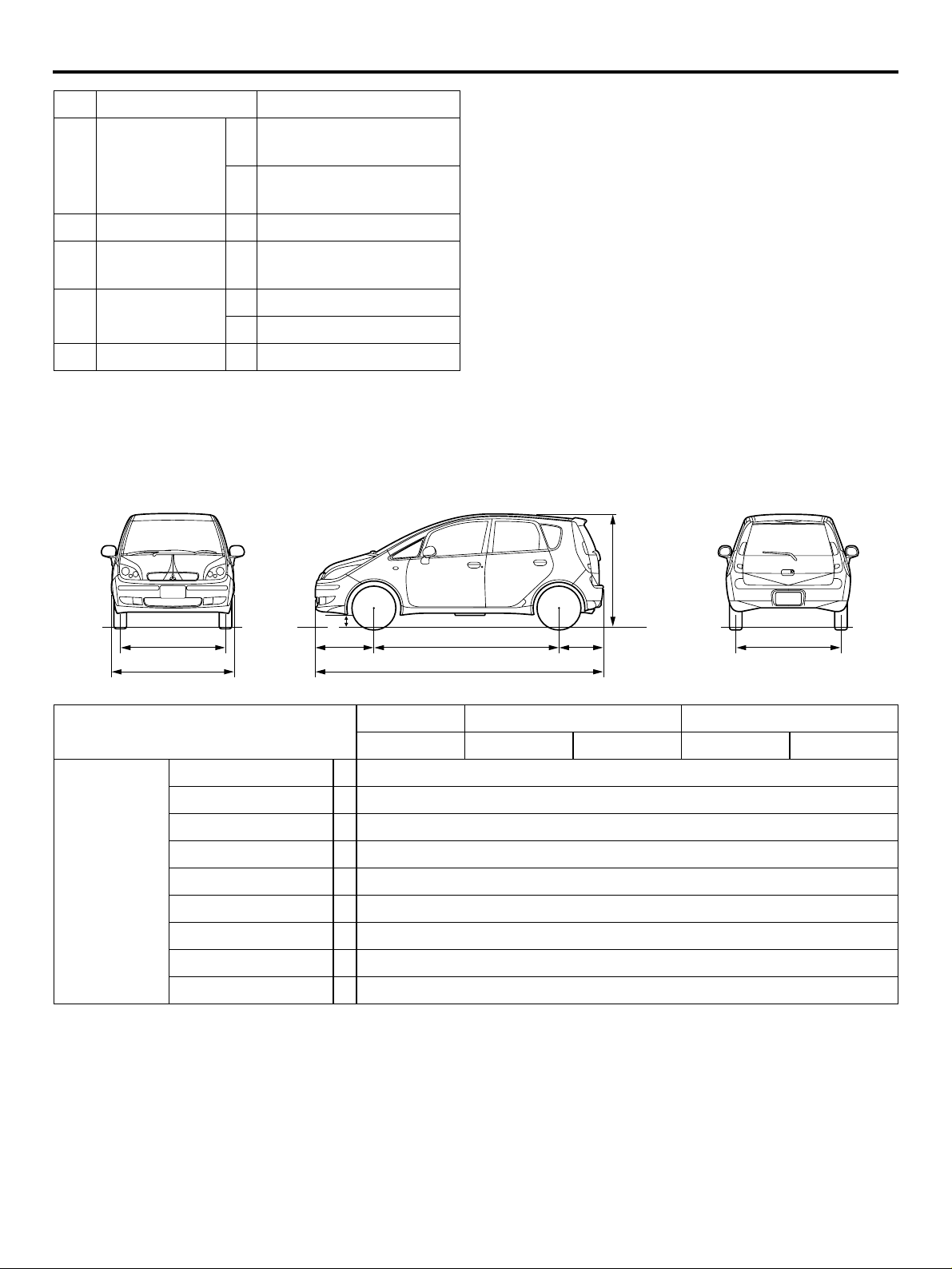

8

7

1

2

3

4

6

5

Item Z32A Z34A Z36A

XNLHL6/R6 XNLHL6/R6 XJLHL6/R6 XNLHL6/R6 XJLHL6/R6

Vehicle

dimensions

mm

Front track 1 1,460

Overall width 2 1,695

Front overhang 3 780

Wheel base 4 2,500

Rear overhang 5 590

Overall length 6 3,870

Ground clearance 7 154/169*

Overall height 8 1,550/1,565*

Rear track 9 1,445

9

AC313517

AB

Page 24

00-24

Item Z32A Z34A Z36A

Vehicle

weight kg

Kerb weight 965 970 975 990 995

Max. gross vehicle

weight

MAJOR SPECIFICATIONS

XNLHL6/R6 XNLHL6/R6 XJLHL6/R6 XNLHL6/R6 XJLHL6/R6

1,450 1,460 1,465

GENERAL

Max. axle weight

rating-front

Max. axle weight

rating-rear

Max.

trailer

weight

Max. trailer-nose

weight

Seating capacity 5

Engine Model code 134910 135930 135950

To tal d i splacement mL 1 , 124 1 , 332 1 ,499

Transmission Model code F5MGA F6SGA F5MGA F6SGA

Type 5-speed manual

Fuel system Fuel supply system MPI

NOTE: *: Vehicles with high ground suspension

With brake 1,000

Without

brake

735 745 750

745

500

50

transmission

6-speed

automated

manual

transmission

5-speed

manual

transmission

6-speed

automated

manual

transmission

Page 25

GROUP 11

CONTENTS

ENGINE MECHANICAL <134>. . . . . . . . . . . . . . . . . . . . . . . . . . 11A

ENGINE MECHANICAL <135>. . . . . . . . . . . . . . . . . . . . . . . . . . 11B

11-1

Page 26

11A-1

GROUP 11A

ENGINE

MECHANICAL <134>

CONTENTS

GENERAL INFORMATION . . . . . . . . 11A-2 BASE ENGINE . . . . . . . . . . . . . . . . . . 11A-3

Page 27

11A-2

ENGINE MECHANICAL <134>

GENERAL INFORMATION

GENERAL INFORMATION

The newly developed 1.1L 134910 engine features

3-cylinder, 12-valve, and double overhead camshafts

(DOHC).

The engine family has the following features.

• Aluminum cylinder block

• A counter balance shaft

MAJOR SPECIFICATIONS

Item Specification

Total displa cement mL 1 ,1 24

Bore × Stroke mm 75 × 84.8

Compression ratio 10.5

Compression chamber Pentroof-type

Valve timing Intake openi ng BT DC 41 ° − ATDC 9°

Intake closing ABDC 19° − ABDC 69°

Exhaust opening BBDC 35°

• MIVEC (Mitsubishi Innovative Valve timing Electronic Control system)

• Selective valve tappet of direct acting valve system for valve clearance adjustment

• Timing chain

M2112000100404

Exhaust closing ATDC 5°

Maximum output kW (PS)/rpm 55 (75)/6,000

Maximum torque Nm (kgm)rpm 100 (10.2)/3,500

Fuel system Electronically controlled multipoint fuel injection

Ignition system Electronic-controlled 3-coil

Page 28

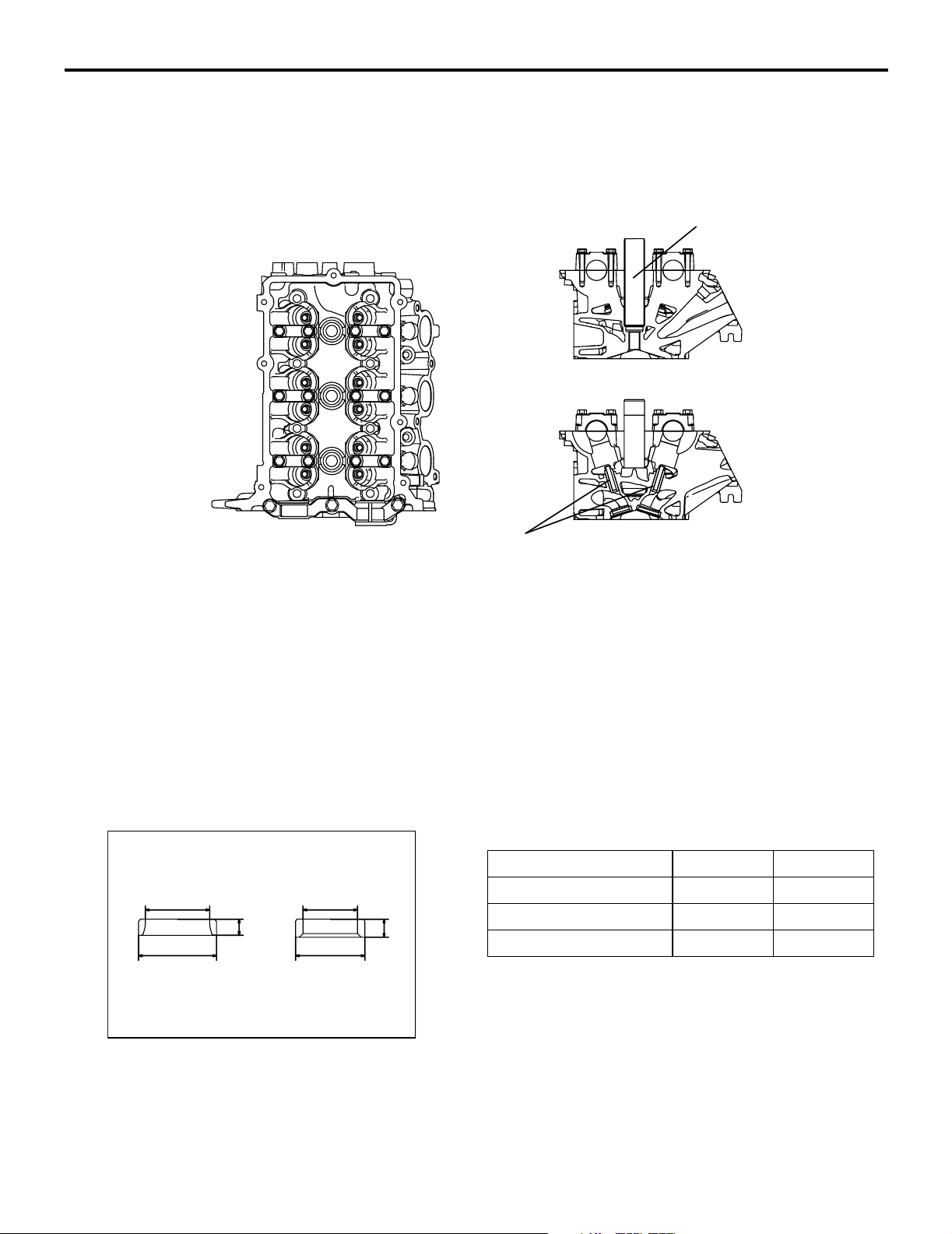

CYLINDER HEAD

ENGINE MECHANICAL <134>

BASE ENGINE

BASE ENGINE

11A-3

M2112001000325

Spark plug guide

Exhaust

side

Valve guide

The cylinder head is made of aluminum alloy, which

is lightweight and has an excellent cooling efficiency.

The pentroof type combustion chamber has a spark

plug in the center. The valve angle is relatively small,

contributing to size reduction.

The intake and exhaust ports are arranged in a

cross-flow construction. Each cylinder has a pair of

intake ports on one side and a pair of exhaust ports

on the other side.

VALVE SEAT

Intake

side

AK305051

Each of the intake and exhaust camshafts is supported by 4 bearings. On each camshaft, the thrust

load is supported by No. 1 bearing. The No. 1 bearings for the intake and exhaust camshafts have a

common bearing cap.

Sintered alloy valve seat

AB

Intake

d

h

DD

Exhaust

d

AK305052

h

AB

Item Intake Exhaust

D (Outer diameter) mm 31.5 28

d (Inner diameter) mm 26 22

h (height) mm 6.6 7.3

Page 29

11A-4

VALVE GUIDE

ENGINE MECHANICAL <134>

BASE ENGINE

The intake and exhaust valves use the same-design

d

valve guide.

Item Specification

D (Outer diameter) mm 10.5

h

d (Inner diameter) mm 4.5

h (height) mm 34.5

D

CYLINDER HEAD GASKET

AK305053

AB

Oil hole

Water hole

The metal gasket having the one layer of wave stopper is used for the cylinder head gasket.

AK305055

AB

Page 30

CYLINDER HEAD COVER

ENGINE MECHANICAL <134>

BASE ENGINE

11A-5

Cylinder head cover

Plate

Oil seal

Cylinder head

cover gasket

A resin cylinder head cover is used for the cylinder

head.

AK305057

AB

The oil plate and the oil seal are integrated with the

cylinder head cover assembly.

Page 31

11A-6

CYLINDER BLOCK

ENGINE MECHANICAL <134>

BASE ENGINE

Right side view

Top view

Front

Front view

Front

Nipple

Under view

Front

Left side view

Front

Thermostat case installation position

Oil filter installation position

The cylinder block is made of lightweight aluminum

alloy.

The crankshaft journal is supported by 4 bearings.

The crankshaft thrust load is supported by No. 3

bearing.

The water jacket is of a full-siamese design.

A nipple is provided at the front of the block to supply

engine oil onto the timing chain.

Rear view

AK305060

AB

Item Dimen

sion

Overall height mm 280

Overall length mm 292.1

Top fac e to c ranksh aft c enter mm 205

Crankshaft center to bottom face mm 75

Bore mm 75

Bore pitch mm 83

Stroke mm 84.8

Page 32

REAR OIL SEAL CASE

A

ENGINE MECHANICAL <134>

BASE ENGINE

The rear oil seal case is a sheet-metal work. The

A-A

case is installed with sealant applied onto the mounting face to prevent oil leakage.

11A-7

PISTON

A

AK305061

AB

The piston is made of special aluminum alloy. Weight

reduction is achieved by minimizing the overall

height while maximizing the recess on both ends of

the piston pin.

The center of the piston pin hole is offset by 0.5 mm

from the center of the piston towards the thrust side.

Front mark

The piston skirt has a streak finish to enhance oil

retention and anti-seizing property.

Item Dimension

Piston pin offset

Base diameter mm 75

Pin diameter mm 18

Overall height mm 46.04

PISTON PIN

AK305063

AC

The piston pin is of a semi-floating type, press-fitted

into the connecting rod small end while capable of

floating relative to the piston.

Item Dimension

d

D

Outer diameter mm 18

Inner diameter mm 11

h

AK305064

AB

Overall length mm 50

Page 33

11A-8

PISTON RING

ENGINE MECHANICAL <134>

BASE ENGINE

Spacer

Piston ring No.1

Piston ring No.2

Oil ring

Rail

Piston ring No.1

Maker mark

Oil ring

Piston ring No.2

AK305365

AB

Each piston is provided with No. 1 and No. 2 compression rings and an oil ring.

Item No. 1 piston ring No. 2 piston ring Oil ring

Shape Barrel Tapered 3-piece

Surface treatment (Contact

Nitride coated Parkerized Hard chrome plated

face with cylinder)

Maker mark R 2R No marking

Page 34

CONNECTING ROD

d

ENGINE MECHANICAL <134>

BASE ENGINE

11A-9

The connecting rod is made of highly rigid, forged

carbon steel. The rod portion has an H-shaped cross

section.

The connecting rod big end bearing is lubricated

through an oil passage running from the main journal

to the crankshaft pin.

Item Dimension

D

d (Small end inner

18

diameter) mm

D (Large end inner

43

diameter) mm

L (Center distance) mm 135.6

L

CONNECTING ROD BEARING

Identification

color

H

AK305066

A

AK305309

AB

AB

The upper and lower connecting rod bearing halves

are identical.

The connecting rod bearing is equipped with back

metal. While the bearing itself is made of aluminum

alloy, the back metal is normally made of steel sheet.

The connecting rod bearing is narrower than the

bearing cap, this is to minimize wear.

Item Dimension

H (Width) mm 13.5

A (Thickness) mm 1.5

Page 35

11A-10

CRANKSHAFT

Crankshaft sensing ring

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft

sprocket B

ENGINE MECHANICAL <134>

BASE ENGINE

Balance weight

Oil hole

Balance weight

Crankshaft

A casted crankshaft is used for the crankshaft.

The crankshaft consists of 4 main bearings and 4

balance weights.

The crankshaft pins are arranged at 120° intervals.

The oil hole supplies lubrication oil from the journal to

the crank pin.

CRANKSHAFT BEARING, THRUST BEARING

Front

Thrust bearing

Groove

AK305069

AB

A crankshaft sprocket, an oil pump drive gear shaft,

and crankshaft sprocket B are press-fitted onto the

front of the crankshaft.

The crankshaft is also fitted with a crankshaft sensing ring.

Upper bearing

Lower bearing

Oil groove

Oil hole

Identification

color

The upper crankshaft bearing (with oil groove) is

located on the cylinder block side while the lower

bearing (without oil groove) is held by the bearing

cap.

Identification

color

AK305071

AB

The crankshaft bearing is equipped with back metal.

While the bearing itself is made of aluminum alloy,

the back metal is made of steel sheet.

A thrust bearing is installed on both sides of the No.

3 crankshaft bearing.

Page 36

CRANKSHAFT PULLEY

ENGINE MECHANICAL <134>

BASE ENGINE

Item Dimensio

Crankshaft bearing Width mm 16

Crankshaft thrust bearing Thickness mm3.275

11A-11

n

Thickness mm20

Timing mark

The crankshaft pulley is made of steel plate. The pulley has grooves to engage with a V-ribbed belt (5

ribs), which drives an alternator and a water pump.

AK305073

AC

An ignition timing mark (notch) is stamped on the

flange of the pulley.

Page 37

11A-12

FLYWHEEL

ENGINE MECHANICAL <134>

BASE ENGINE

Flywheel

Ring gear

The flywheel is made of cast-iron. A separate ring

gear is mounted on it.

AK305074

AB

Page 38

TIMING CHAIN TRAIN

ENGINE MECHANICAL <134>

BASE ENGINE

11A-13

Timing chain mark

link plate (bule)

Camshaft sprocket

timing mark

Camshaft sprocket

Tensioner lever

Timing chain

tensioner

Timing mark

Crankshaft

sprocket

timing mark

Timing mark

Timing chain mark

link plate (bule)

V.V.T. sprocket

timing mark

V.V.T. sprocket

Chain guide

Timing chain mark

link plate (bule)

Crankshaft sprocket

The 2 camshafts are driven by the timing chain via

the respective sprockets.

The timing chain, consisting of 122 links, is an endless chain, connecting the crankshaft sprocket with

the camshaft and V.V.T. sprockets.

The timing chain is equipped with 3 mark link plates

(blue) to correctly time the 3 sprockets with each

other.

The timing chain is tensioned by the timing chain tensioner, which has a built-in plunger with plunger

springs.

Item No. of

teeth

Camshaft sprocket 36

V.V.T. sp ro cket 36

Crankshaft sprocket 18

AK305058

AB

TIMING CHAIN TENSIONER

Coil spring 1

Ball sheet

Ball

Retainer

The plunger in the timing chain tensioner directly

pushes the tension lever, and the pressure automatically adjusts the timing chain tension.

A cam is provided to lock the plunger in place after

the engine stops. This helps prevent the timing chain

from wobbling just after the engine starts.

With the timing chain tensioner installed, do not

crank the engine in the reverse direction. This will

force the plunger to overcome the cam, or even

cause other problems.

Plunger

Pin

Cam

Coil spring 2

AK305388

AB

Page 39

11A-14

VALVE ME CHANISM

Exhaust camshaft

ENGINE MECHANICAL <134>

BASE ENGINE

Spark plug guide

Intake camshaft

Valve tappet

Exhaust valve

The valve mechanism is based on a 4-valve DOHC

(Double Over Head Camshaft) design having the

camshaft on the upper valve. Each cylinder has 2

intake valves and 2 exhaust valves, arranged in a

V-shape pattern.

Intake valve

AK305077

AB

Camshaft rotation is transmitted via valve tappets to

the respective valves which open and close accordingly.

Page 40

VALVE

ENGINE MECHANICAL <134>

BASE ENGINE

11A-15

Intake

DD

L

The valves have heat-resistance. The entire valve

surface is treated with gas nitriding.

VALVE ST EM SEAL

Valve stem seal

Exhaust

d

L

d

Item Intake valve Exhaust valve

Head diameter mm30.5 25.5

Stem diameter mm5.0 5.0

Overall length mm89.61 90.94

The valve stem seal employs springs to enhance

sealing performance, minimizing oil passing down to

the port.

AK305078

AB

VALVE SPRING

AK305079

AB

The valve spring has a dual pitch spring to prevent

surging in the high speed range.

Item Specification

Free length mm 43.1

No. of spring turns 8.49

h

AK300721

AB

Page 41

11A-16

VALVE TAPPET

ENGINE MECHANICAL <134>

Thickness

Identification mark

BASE ENGINE

Valve tappets are available in 31 thicknesses, at 0.02

mm intervals between 2.70 mm and 3.30 mm, to

ensure correct valve clearance.

AK300722

AB

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

A

V.V.T.sprocket

bolt

A

Oil control valve

Oil control

valve filter

bolt

Cylinder head

Cylinder block

A-A

Oil control

valve filter

AK300856

AB

MIVEC (Mitsubishi Innovative Valve timing Electronic

Control system) consists of the components illustrated above.

The intake valve timing is optimally controlled (continuously variable) under the changing driving conditions to improve power in the entire speed range.

V.V.T. SPROCKET (VARIABLE VALVE TIMING S PROCKET)

Timing mark

Sprocket

Vane housing

Advance oil chamber

Vane roter

Vane bushing

V.V.T.sprocket

bolt

Retard oil chamber

Stopper pin

AK300857

AB

Page 42

ENGINE MECHANICAL <134>

BASE ENGINE

Oil from the oil control valve is sent to the V.V.T.

sprocket, moving the vane rotor and thus regulating

the valve timing.

CAMSHAFT

Intake camshaft

11A-17

Advance

Retard

oil channel

Exhaust camshaft

oil channel

Dowel pin

The lightweight camshaft is achieved by the hollow

design.

Oil channels run through the intake camshaft,

through which oil is sent from the oil control valve to

the V.V.T. sprocket.

A cam position sensing ring is press-fitted onto the

rear portion of the intake camshaft.

Hollow section

Sealing cap

Sensing bean

AK305000

AB

Item Dimensio

n

Overall length mm Intake 324.5

Exhaust 278.9

Journal mm 26

Valve lift mm Intake 8.5

Exhaust 7.6

OIL CONTROL VALVE (OCV)

Spool

Plunger spring

Valve sleeve

Spring guide

Insulation coilar

Pressure

chamber

Drain

Pump

Default

pressure

chamber

Drain

Bobbin

O-ring

Stator

Enameled copper wire

Tape

Bracket

Guide cap

Terminal

Shaft

Plunger

Seal cap

Yoke

AK302997

AB

Page 43

11A-18

ENGINE MECHANICAL <134>

The oil control valve is essentially a solenoid valve,

regulated by the engine-ECU or engine-A-M/T-ECU

signals to feed oil to the V.V.T. sprocket assembly to

move the vane rotor.

TIMING CHAIN CASE

BASE ENGINE

Engine support bracket

The engine support bracket, the oil pump and the

relief valve are integrated as well as water chamber

of the water pump.

AK305244

AB

Page 44

ENGINE MECHANICAL <134>

BASE ENGINE

BALANCER

The 3-cylinder engine has three throws distributed at

equal intervals. The motion of No. 1 and No. 3 pistons generates pitching moment around the No. 2

cylinder. This unbalancing moment is canceled out

by the following system.

The crank webs for No. 1 and No. 3 cylinders are fitted with overbalance weights.

A counterbalance shaft is provided in parallel with

the crankshaft that rotates at the same speed but in

the opposite direction from the crankshaft.

Balancer chain mark

link plate (yellow)

Counter

balance

shaft

A

A

11A-19

The counterbalance shaft is fitted with weights that

are balanced in mass with the overbalance weights

fitted on the No. 1 and No. 3 cylinder crank webs.

The inertia force generated by the pistons and overbalance weights are cancelled out by the counterbalance weights, minimizing the pitching moment.

NOTE: The numbers shown in the drawings indicate

the inertia forces expressed in ratio to "1."

Mark to match with

balancer sprocket

Balancer

shaft sprocket

Balancer

chain

Timing mark

Balance

shaft driven

gear

Counter

balance

shaft

Balance

shaft sprocket

A-A

Balance

shaft drive

gear

The counterbalance shaft is driven by the crankshaft

via crankshaft sprocket B, the balancer chain B, the

balance shaft sprocket, the balance shaft drive gear,

and the balance shaft driven gear.

The balancer chain B, made up of 48 links, is an endless chain, connecting the crankshaft sprocket B with

the balance shaft sprocket.

The balancer chain is provided with a mark link plate

(yellow) at two locations to ensure the sprockets are

timed correctly with each other.

Tensioner B

lever Assy

Crankshaft

sprocket B

Balancer chain mark

link plate (yellow)

Item No. of

Crankshaft sprocket B 22

Balance shaft sprocket 25

Balance shaft drive gear 25

Balance shaft driven gear 22

AK304445

teeth

AC

Page 45

11A-20

BALANCE SHAFT

ENGINE MECHANICAL <134>

BASE ENGINE

Rear view

The cast-iron counterbalance shaft and the integrated driven gear are driven together by the chain

B.

Front view

AK305245

AB

Page 46

11B-1

GROUP 11B

CONTENTS

GENERAL INFORMATION . . . . . . . . 11B-2 BASE ENGINE . . . . . . . . . . . . . . . . . . 11B-2

Page 47

11B-2

ENGINE MECHANICAL <135>

GENERAL INFORMATION

GENERAL INFORMATION

M2112000100415

The unit is powered by the newly developed 135930

/ 135950 engine. The total displacement is 1.3L for

the 135930, and 1.5L for the 135950. Both engines

are a 4-cylinder 16-valve DOHC (Double Over Head

Camshaft) design.

The engine family has the following features.

MAJOR SPECIFICATIONS

Item 135930 135950

Total displa cemen t mL 1,332 1 ,49 9

Bore × Stroke mm 75 × 75.4 75 × 84.8

Compression ratio 10.5

Compression chamber Pentroof-type

Valve tim ing Intake op eni ng BT DC 41° − ATDC 9° BTDC 41° − ATDC 9°

Intake closing ABDC 3° − ABDC 53° ABDC 11° − ABDC 61°

• Aluminum cylinder block

• MIVEC (Mitsubishi Innovative Valve timing Elec-

tronic Control system)

• Selective valve tappet of direct acting valve system for valve clearance adjustment

• Timing chain

Exhaust opening BBDC 35° BBDC 39°

Exhaust closing ATDC 5° ATDC 5°

Maximum output kW (PS)/rpm 70 (95)/6,000 80 (109)/6,000

Maximum torque Nm (kgm)/rpm 125 (12.7)/4,000 145 (14.8)/4,000

Fuel system Electronically controlled multipoint fuel injection

Ignition system Electronic-controlled 4-coil

BASE ENGINE

M2112001000336

CYLINDER HEAD

The cylinder head is made of aluminum alloy, which

is lightweight and has an excellent cooling efficiency.

The pentroof type combustion chamber has a spark

plug in the center. The valve angle is relatively small,

contributing to size reduction.

The intake and exhaust ports are arranged in a

cross-flow construction. Each cylinder has a pair of

intake ports on one side and a pair of exhaust ports

on the other side.

Each of the intake and exhaust camshafts is supported by 5 bearings. On each camshaft, the thrust

load is supported by No. 1 bearing. The No. 1 bearings for the intake and exhaust camshafts have a

common bearing cap.

Page 48

ENGINE MECHANICAL <135>

BASE ENGINE

Spark plug guide

11B-3

VALVE SEAT

Intake

DD

Exhaust

side

d

Intake

side

Valve guide

AK305050

AB

Sintered alloy valve seat

Item Intake Exhaust

Exhaust

d

h

h

D (Outer

diameter) mm

d (Inner

31.5 28

26 22

diameter) mm

h (height) mm 6.6 7.3

VALVE GUI DE

AK305052

AB

The intake and exhaust valves use the same-design

d

valve guide.

Item Intake

D (Outer diameter) mm 10.5

h

d (Inner diameter) mm 4.5

h (height) mm 34.5

D

AK305053

AB

Page 49

11B-4

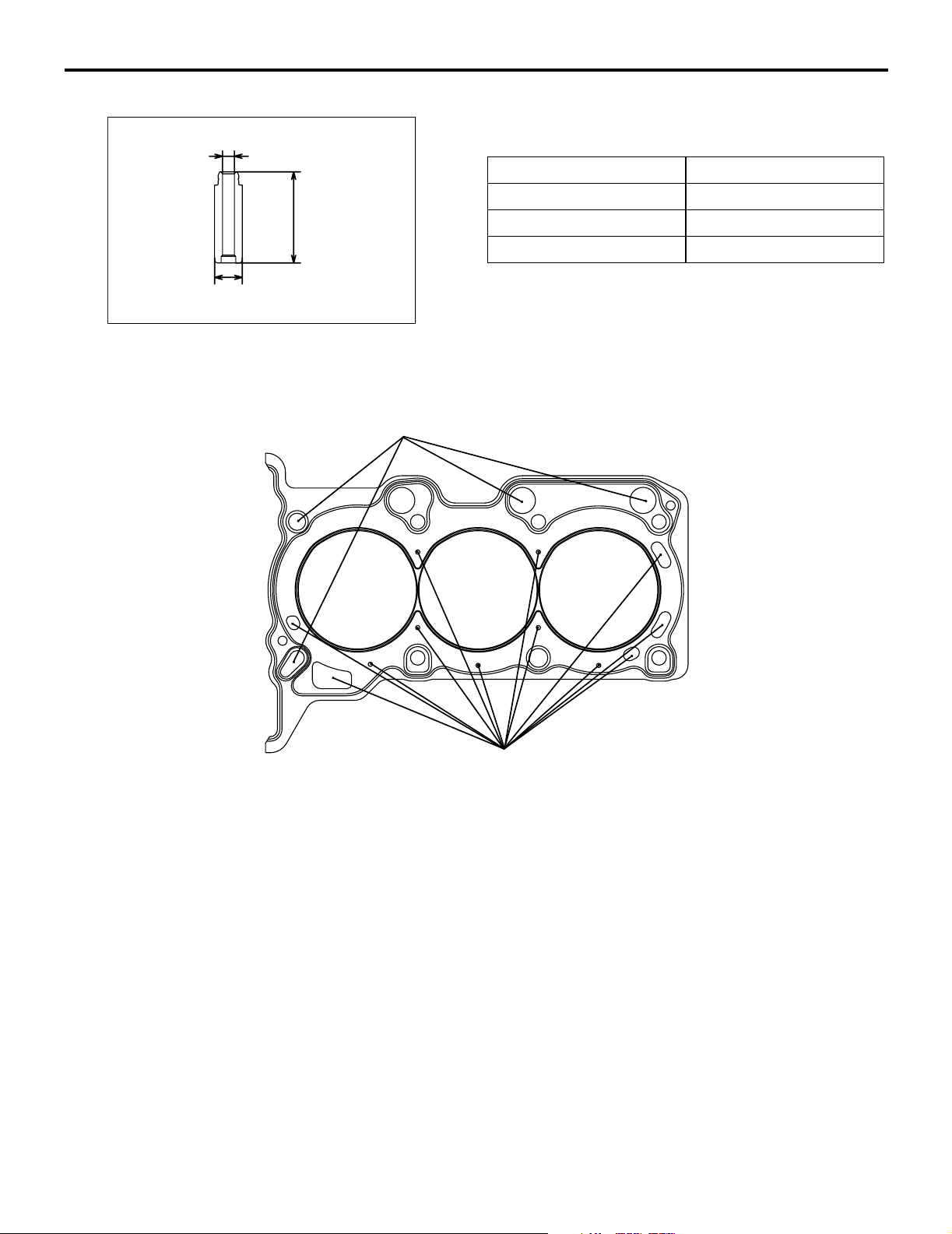

CYLINDER HEAD GASKET

ENGINE MECHANICAL <135>

BASE ENGINE

Oil hole

Water hole

The metal gasket having the one layer of wave stopper is used for the cylinder head gasket.

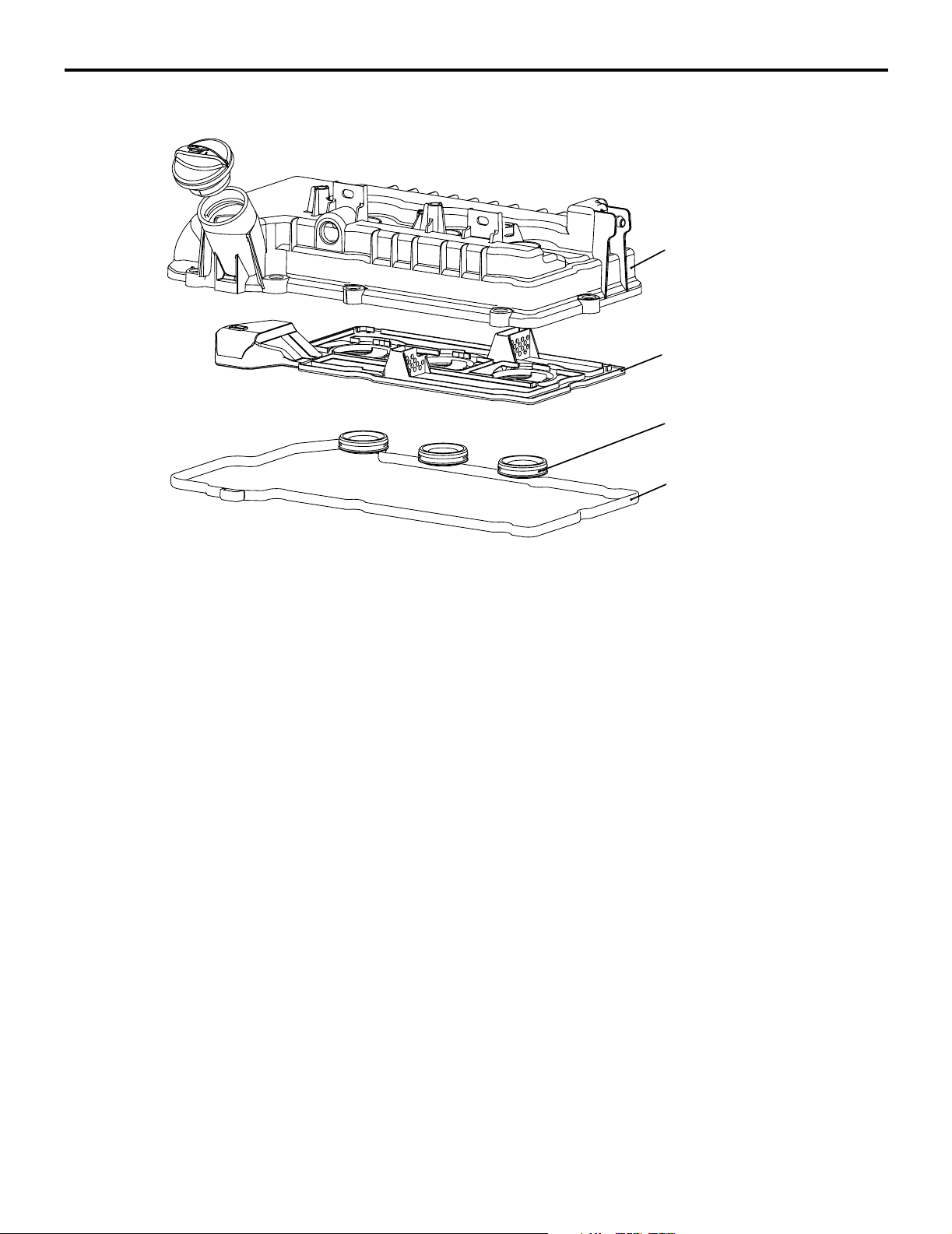

CYLINDER HEAD COVER

Water hole

AK305054

Cylinder head cover

Plate

Oil seal

AB

A resin cylinder head cover is used for the cylinder

head.

Cylinder head

cover gasket

AK305056

AB

The oil plate and the oil seal are integrated with the

cylinder head cover assembly.

Page 50

CYLINDER BLOCK

ENGINE MECHANICAL <135>

BASE ENGINE

11B-5

Right side view

Top view

Front

Front view

Front

Nipple

Under view

Front

Left side view

Front

Thermostat case installation position

Oil filter installation position

The cylinder block is made of lightweight aluminum

alloy.

The crankshaft journal is supported by 5 bearings.

The crankshaft thrust load is supported by No. 4

bearing.

The water jacket is of a full-siamese design.

A nipple is provided at the front of the block to supply

engine oil onto the timing chain.

Rear view

AK305059

AB

Item Dimen

sion

Overall height mm 280

Overall length mm 375.1

Top fac e to cranks haft cent er mm 2 05

Crankshaft center to bottom face mm 75

Bore mm 75

Page 51

11B-6

ENGINE MECHANICAL <135>

Item Dimen

sion

Bore pitch mm 83

Stroke mm 135930 75.4

135950 84.8

REAR OIL SEAL CASE

A

A-A

BASE ENGINE

The rear oil seal case is a sheet-metal work. The

case is installed with sealant applied onto the mounting face to prevent oil leakage.

PISTON

A

<135930>

AK305061

AB

Piston pin offset

<135950>

Front mark

Piston pin offset

The piston is made of special aluminum alloy. Weight

reduction is achieved by minimizing the overall

height while maximizing the recess on both ends of

the piston pin.

The center of the piston pin hole is offset by 0.5 mm

from the center of the piston towards the thrust side.

The piston skirt has a streak finish to enhance oil

retention and anti-seizing property.

AK305280

AB

Item Dimension

Base diameter mm 75

Pin diameter mm 18

Overall height mm135930 50.46

135950 46.04

Page 52

PISTON PIN

ENGINE MECHANICAL <135>

BASE ENGINE

The piston pin is of a semi-floating type, press-fitted

into the connecting rod small end while capable of

floating relative to the piston.

11B-7

PISTON RING

d

D

D (Outer diameter) mm 18

d (Inner diameter) mm 11

Item Dimension

h

AK305064

Piston ring No.1

Piston ring No.2

AB

h (Overall length) mm 50

Piston ring No.1

Maker mark

Oil ring

Piston ring No.2

Oil ring

Spacer

Rail

Each piston is provided with No. 1 and No. 2 compression rings and an oil ring.

Item No. 1 piston ring No. 2 piston ring Oil ring

Shape Barrel Tapered 3-piece

Surface treatment (Contact

Nitride coated Parkerized Hard chrome plated

face with cylinder)

Maker mark R 2R No marking

AK305365

AB

Page 53

11B-8

CONNECTING ROD

ENGINE MECHANICAL <135>

BASE ENGINE

The connecting rod is made of highly rigid, forged

carbon steel. The rod portion has an H-shaped cross

section.

The connecting rod big end bearing is lubricated

through an oil passage running from the main journal

to the crankshaft pin.

d

L

CONNECTING ROD BEARING

Identification

color

H

D

AK305065

A

AK305309

AB

AB

Item Dimension

d (Small end inner diameter) mm 18

D (Large end inner diameter) mm 43

L (Center

distance) mm

135930 140.3

135950 135.6

The upper and lower connecting rod bearing halves

are identical.

The connecting rod bearing is equipped with back

metal. While the bearing itself is made of aluminum

alloy, the back metal is normally made of steel sheet.

The connecting rod bearing is narrower than the

bearing cap, this is to minimize wear.

Item Dimension

H (Width) mm 13.5

A (Thickness) mm 1.5

Page 54

CRANKSHAFT

ENGINE MECHANICAL <135>

BASE ENGINE

11B-9

<135930>

<135950>

Crankshaft sensing ring

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft

Balance weight

Crankshaft sensing ring

Oil pump drive

gear shaft

Crankshaft

sprocket

Crankshaft

Balance weight

Oil hole

Balance weight

Oil hole

A casted crankshaft is used for the crankshaft.

The crankshaft consists of 5 main bearings and 4

balance weights for 135930 or consists of 5 main

bearings and 8 balance weights for 135950.

The crankshaft pins are arranged at 180° intervals.

Balance weight

The oil hole supply lubrication oil from the journal to

the crank pin.

A crankshaft sprocket and an oil pump drive gear

shaft are press-fitted onto the front of the crankshaft.

The crankshaft is also fitted with a crankshaft sensing ring.

Oil hole

Oil hole

Balance weight

Balance weight

AK305281

AB

Page 55

11B-10

ENGINE MECHANICAL <135>

BASE ENGINE

CRANKSHAFT BEARING, THRUST BEARING

Front

Thrust bearing

Groove

The upper crankshaft bearing (with oil groove) is

located on the cylinder block side while the lower

bearing (without oil groove) is held by the bearing

cap.

The crankshaft bearing is equipped with back metal.

While the bearing itself is made of aluminum alloy,

the back metal is made of steel sheet.

A thrust bearing is installed on both sides of the No.

4 crankshaft bearing.

Upper bearing

Lower bearing

Oil groove

Oil hole

Identification

color

Identification

color

AK305070

AB

Item Dimen

sion

Crankshaft bearing Width mm 16

Thickness mm20

Crankshaft thrust

bearing

Thickness mm135930 3.275

135950 3.275

CRANKSHAFT PULLEY

<135930>

Timing mark

A steel billet crankshaft pulley is used for 135930.

The pulley has grooves to engage with a V-ribbed

belt (5 ribs), which drives an alternator and a water

pump.

<135950>

Rubber

Timing mark

AK305282

AB

An ignition timing mark (notch) is stamped on the

flange of the pulley.

Page 56

ENGINE MECHANICAL <135>

BASE ENGINE

The crankshaft pulley for 135950 is equipped with a

torsional damper to minimize the torsional vibration

of the crankshaft as well as substantially reduce

noise and vibration at the high speed range.

FLYWHEEL

Flywheel

11B-11

Ring gear

The flywheel is made of cast-iron. A separate ring

gear is mounted on it.

AK305074

AB

Page 57

11B-12

TIMING CHAIN TRAIN

ENGINE MECHANICAL <135>

BASE ENGINE

Timing chain mark

link plate (bule)

Camshaft sprocket

timing mark

Camshaft sprocket

Tensioner lever

Timing chain

tensioner

Timing mark

Crankshaft

sprocket

timing mark

Timing mark

Timing chain mark

link plate (bule)

V.V.T. sprocket

timing mark

V.V.T. sprocket

Chain guide

Timing chain mark

link plate (bule)

Crankshaft sprocket

The 2 camshafts are driven by the timing chain via

the respective sprockets.

The timing chain, consisting of 122 links, is an endless chain, connecting the crankshaft sprocket with

the camshaft and V.V.T. sprockets.

The timing chain is equipped with 3 mark link plates

(blue) to correctly time the 3 sprockets with each

other.

The timing chain is tensioned by the timing chain tensioner, which has a built-in plunger with plunger

springs.

Item No. of

teeth

Camshaft sprocket 36

V.V.T. sp rocke t 36

Crankshaft sprocket 18

AK305075

AB

TIMING CHAIN TENSIONER

Coil spring 1

Ball sheet

Ball

Retainer

The plunger in the timing chain tensioner directly

pushes the tension lever, and the pressure automatically adjusts the timing chain tension.

A cam is provided to lock the plunger in place after

the engine stops. This helps prevent the timing chain

from wobbling just after the engine starts.

With the timing chain tensioner installed, do not

crank the engine in the reverse direction. This will

force the plunger to overcome the cam, or even

cause other problems.

Plunger

Pin

Cam

Coil spring 2

AK305388

AB

Page 58

VALVE MEC HANI SM

Exhaust camshaft

ENGINE MECHANICAL <135>

BASE ENGINE

Spark plug guide

11B-13

Intake camshaft

Valve tappet

Exhaust valve

The valve mechanism is based on a 4-valve DOHC

(Double Over Head Camshaft) design having the

camshaft on the upper valve. Each cylinder has 2

intake valves and 2 exhaust valves, arranged in a

V-shape pattern.

VALVE

Intake

DD

d

Intake valve

AK305076

AB

Camshaft rotation is transmitted via valve tappets to

the respective valves which open and close accordingly.

Exhaust

d

L

The valves have heat-resistance. The entire valve

surface is treated with gas nitriding.

L

AK305078

AB

Item Intake valve Exhaust valve

Head diameter mm30.5 25.5

Stem diameter mm5.0 5.0

Overall length mm89.61 90.94

Page 59

11B-14

VALVE STE M SE AL

Valve stem seal

ENGINE MECHANICAL <135>

BASE ENGINE

The valve stem seal employs springs to enhance

sealing performance, minimizing oil passing down to

the port.

VALVE SPR ING

VALVE TAPP ET

h

Thickness

AK305079

AK300721

AB

The valve spring has a dual pitch spring to prevent

surging in the high speed range.

Item Specification

Free length mm 43.1

No. of spring turns 8.49

AB

Valve tappets are a vaila ble in 31 t hickn esses , at 0.02

mm intervals between 2.70 mm and 3.30 mm, to

ensure correct valve clearance.

Identification mark

AK300722

AB

Page 60

ENGINE MECHANICAL <135>

BASE ENGINE

11B-15

MIVEC (MITSUBISHI INNOVATIVE VALVE TIMING ELECTRONIC CONTROL SYSTEM)

A

V.V.T.sprocket

bolt

A

MIVEC (Mitsubishi Innovative Valve timing Electronic

Control system) consists of the components illustrated above.

Oil control valve

Oil control

valve filter

bolt

Cylinder head

Cylinder block

The intake valve timing is optimally controlled (continuously variable) under the changing driving conditions to improve power in the entire speed range.

V.V.T. SPROCKET (VARIABLE VALVE TIMING SPROCKET)

A-A

Oil control

valve filter

AK300856

AB

Timing mark

Sprocket

Oil from the oil control valve is sent to the V.V.T.

sprocket, moving the vane rotor and thus regulating

the valve timing.

Vane housing

Advance oil chamber

Vane roter

Vane bushing

V.V.T.sprocket

bolt

Retard oil chamber

Stopper pin

AK300857

AB

Page 61

11B-16

CAMSHAFT

ENGINE MECHANICAL <135>

BASE ENGINE

Intake camshaft

Advance

Retard

oil channel

Exhaust camshaft

oil channel

Dowel pin

The lightweight camshaft is achieved by the hollow

design.

Oil channels run through the intake camshaft,

through which oil is sent from the oil control valve to

the V.V.T. sprocket.

A cam position sensing ring is press-fitted onto the

rear portion of the intake camshaft.

Cam positon sensing ring

Hollow section

Sealing cap

AK304999

AB

Item Dimen

sion

Overall length mm Intake 407.5

Exhaust 361.9

Journal mm 26

Valve lift mm I ntake 135930 7.9

OIL CONTROL VALVE (OCV)

Insulation coilar

Spool

Plunger spring

Valve sleeve

Spring guide

Pressure

chamber

Drain

The oil control valve is essentially a solenoid valve,

regulated by the engine-ECU or engine-A-M/T-ECU

Default

pressure

chamber

Pump

135950 8.4

Exhaust 135930 7.6

135950 7.9

Bobbin

Drain

O-ring

Stator

Enameled copper wire

Tape

Bracket

Guide cap

Terminal

Shaft

Plunger

Seal cap

Yoke

AK302997

signals to feed oil to the V.V.T. sprocket assembly to

move the vane rotor.

AB

Page 62

TIMING CHAIN CASE

ENGINE MECHANICAL <135>

BASE ENGINE

Engine support bracket

11B-17

The engine support bracket, the oil pump and the

relief valve are integrated as well as water chamber

of the water pump.

AK305243

AB

Page 63

GROUP 12

CONTENTS

12-1

GENERAL INFORMATION . . . . . . . . 12-2

OIL PUMP . . . . . . . . . . . . . . . . . . . . . 12-3

RELIEF VALVE . . . . . . . . . . . . . . . . . 12-3

OIL SCREEN . . . . . . . . . . . . . . . . . . . 12-4

OIL FILTER. . . . . . . . . . . . . . . . . . . . . 12-4

OIL PAN . . . . . . . . . . . . . . . . . . . . . . . 12-5

OIL LEVEL GAUGE, OIL FILLER CAP, OIL

DRAIN PLUG . . . . . . . . . . . . . . . . . . . 12-6

Page 64

12-2

GENERAL INFORMATION

LUBRICATION SYSTEM SCHEMATIC

ENGINE LUBRICATION

GENERAL INFORMATION

M2120000100034

Oil screen

Oil pump

Relief valve

Oil pressure switch

Cylinder head

oil passage

No.1 Camshaft

journal

Intake camshaft

journal

Timing chain case

oil passage

Cylinder block

oil passage(right side)

Oil filter

Cylinder block

oil passage

(main gallery)

Crankshaft

journal

Crankshaft

pin

Exhaust camshaft

journal

Counter balance shaft

rear journal

Oil pan

The lubrication system employs a full-flow filtering

and forced feeding. Oil in the oil pan is sucked by the

oil pump which then sends out oil at pressure regulated by the relief valve, through the oil filter and to

the cylinder block. From there, oil flow is divided into

the passage to the crankshaft journals and that to the

cylinder head.

AK305366

AB

From the crankshaft journals, oil flows to the crank

pins. From the cylinder head, oil flows to the camshaft journals.

Page 65

ENGINE LUBRICATION

OIL PUMP

OIL PUMP

12-3

M2120002000011

A

A

The oil pump is of a cycloid type, directly driven by

the crankshaft.

Specifically, oil is sucked into the expanding space

and is pushed out from the shrinking space.

Timing chain case

Machine screw

Cover

On the cycloid oil pump, as the inner rotor is rotated

by the crankshaft, the outer rotor also rotates. The

resultant change in spatial volumes between the

rotors generates pumping action.

Item Specification

Type Cycloid pump

No. of lobes Inner rotor 10

A-A

Oil seal

Oil pump

inner rotor

Oil pump

outer rotor

AK305367

AB

Outer rotor 11

Displacement L/min(6,000 r/min.) 35

RELIEF VALVE

A

A

The relief valve is of a plunger type. The valve regulates the maximum pressure of lubrication oil being

sent to the engine.

When the pressure of oil from the oil pump exceeds

the specified value, the valve opens to relieve the

excess flow.

The excess oil is returned to the suction side of the

oil pump.

A-A

Timing chain case

Relief plunger

Relief spring

Plug

AK305369

M2120003000014

AB

Page 66

12-4

OIL SCREEN

Timing chain case

ENGINE LUBRICATION

OIL SCREEN

M2120004000017

The oil screen is located in the position with the least

disturbance to the oil suction volume that results

from oil level variation in the oil pan while the vehicle

is driven.

Oil screen

Element

Oil filter

Oil pan

AK305372

AK305373

AB

OIL FILTER

The oil filter is mounted onto the cylinder block.

Item Specification

Filtering method Full-flow filtering, Paper

Filtration area cm

Rated flow L/min. 25

AB

M2120005000010

element

2

750

Page 67

<134>

<135>

ENGINE LUBRICATION

OIL PAN

OIL PAN

Oil drain plug

installation side

12-5

M2120006000013

Oil drain plug

installation side

The oil pan, located below the engine, is made of

sheet metal.

AK305283

AB

Page 68

12-6

OIL LEVEL GAUGE, OIL FILLER CAP, OIL DRAIN PLUG

ENGINE LUBRICATION

OIL LEVEL GAUGE, OIL FILLER CAP, OIL DRAIN PLUG

M2120007000016

<134>

<135>

Oil level gauge

Oil filler cap

Oil drain plug

Oil level gauge

Oil drain plug

The oil level gauge, oil filler cap, and oil drain plug

are all located in the front of the engine for excellent

serviceability.

Oil filler cap

AK305389

AB

Page 69

GROUP 13

CONTENTS

MULTIPOINT FUEL INJECTION (MPI). . . . . . . . . . . . . . . . . . . . 13A

FUEL SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13B

13-1

Page 70

GROUP 13A

CONTENTS

13A-1

GENERAL INFORMATION . . . . . . . . 13A-2

CONTROL SYSTEM . . . . . . . . . . . . . 13A-7

SENSOR. . . . . . . . . . . . . . . . . . . . . . . 13A-8

ACTUATOR . . . . . . . . . . . . . . . . . . . . 13A-14

FUEL INJECTION CONTROL . . . . . . 13A-15

THROTTLE VALVE OPENING ANGLE

CONTROL . . . . . . . . . . . . . . . . . . . . . 13A-23

IGNITION TIMING AND DISTRIBUTION

CONTROL . . . . . . . . . . . . . . . . . . . . . 13A-25

MIVEC (Mitsubishi Innovative Valve timing

Electronic Control system) . . . . . . . 13A-31

POWER SUPPLY CONTROL. . . . . . . 13A-39

FUEL PUMP RELAY CONTROL . . . . 13A-40

OXYGEN SENSOR HEATER CONTROL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13A-41

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A/C COMPRESSOR CONTROL. . . . . 13A-42

ALTERNATOR CONTROL . . . . . . . . . 13A-43

STARTER RELAY CONTROL . . . . . . 13A-44

CONTROLLER AREA NETWORK (CAN)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13A-44

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS SYSTEM. . . . . . . . . . . . . 13A-45

Page 71

13A-2

MULTIPOINT FUEL INJECTION (MPI)

GENERAL INFORMATION

GENERAL INFORMATION

The engine control system consists of sensors that

detect the conditions of the engine and the actuators

that operate under the control of the engine-ECU or

engine automated manual transmission electronic

control unit (engine-A-M/T-ECU), which calculates

and determines the engine control contents based

on the signals provided by the sensors. The

engine-ECU or engine-A-M/T-ECU effects fuel injec-

M2132000100428

tion control, idle speed control, ignition timing control,

and fuel pump control. In addition, the engine-ECU

or engine-A-M/T-ECU contains a self-diagnosis system to facilitate the diagnosis of malfunctions in the

major sensors and actuators.

Page 72

System Block Diagram

MULTIPOINT FUEL INJECTION (MPI)

GENERAL INFORMATION

13A-3

Manifold absolute pressure

sensor

Intake air temperature sensor

Engine coolant temperature

sensor

Accelerator pedal position

sensor (main)

Throttle position sensor (sub)

Crank angle sensor

Camshaft position sensor

Detonation sensor

Oxygen sensor (front)

Oxygen sensor (rear)

Engine-ECU or engine-A-M/T-ECU

[1] Fuel injection control

[2] Throttle valve opening control

and idle speed control

[3] Ignition timing control

[4] MIVEC (Mitsubushi Innovative

Valve timing Electronic Control

system)

[5] Power supply control

(Power supply to sensor,

actuator)

[6] Fuel pump relay control

[7] Oxygen sensor heater

control

No. 1 injector

No. 2 injector

No. 3 injector

No. 4 injector <135 engine>

No. 1 ignition coil

No. 2 ignition coil

No. 3 ignition coil

No. 4 ignition coil <135 engine>

Engine control relay

Starter relay

Fuel pump relay

Ignition switch-IG

Ignition switch-ST

Power supply

Alternator FR terminal

Throttle valve contorol servo

power supply

Throttle position sensor (main)

Accelerator pedal position

sensor (sub)

[8] A/C compressor control

[10] Alternator control

[11] Starter relay control

[12] Purge control

[11] Diagnostic output

[12] RAM data transmission

Throttle valve control servo

relay

Oxygen sensor heater (front)

Oxygen sensor heater (rear)

A/C compressor

Oil control valve (for MIVEC)

Purge control solenoid valve

Alternator G terminal

Throttle valve control servo

(DC motor)

AK304661

AB

Page 73

13A-4

Control System Diagram

MULTIPOINT FUEL INJECTION (MPI)

GENERAL INFORMATION

1 Oxygen sensor (rear)

2 Oxygen sensor (front)

3 Crank angle sensor

4 Camshaft position

sensor

5 Detonation sensor

6 Engine coolant

temperature sensor

7 Manifold absolute

pressure sensor

8 Intake air temperature

sensor

9 Throttle position

sensor (main)

10 Throttle position

sensor (sub)

Power supply

Ignition switch-IG

Ignition switch-ST

Oil pressure switch

Alternator FR

terminal

Accelerator pedal

position sensor

(main)

Accelerator pedal

position sensor

(sub)

8 Intake air temperature

sensor

7 Manifold absolute

pressure sensor

EngineECU

or engineA-M/TECU

1 Oil control valve

2 Injector

3 Throttle valve

control servo

4 Purge control

solenoid valve

9 Throttle position sensor (main)

10 Throttle position sensor (sub)

3 Throttle valve

control servo

Engine control relay

Fuel pump relay

Throttle valve

control servo relay

Starter relay

Ignition coil

Alternator G terminal

Oxygen sensor heater

A/C compressor

Air

From fuel

pump

3 Crank angle sensor

1 Oxygen sensor (rear)

Catalytic

converter

2 Oxygen sensor (front)

1 Oil control valve

List of Components and Functions

Name Function

ECU Engine-ECU or

engine-A-M/T-ECU

Effects control to actuate the actuators in accordance with the driving

conditions, based the signals input by the sensors.

4 Camshaft

position sensor

2 Injector

6 Engine coolant

temperature sensor

5 Detonation sensor

Canister

4 Purge control

solenoid valve

AK304662

AB

Page 74

MULTIPOINT FUEL INJECTION (MPI)

GENERAL INFORMATION

Name Function

Sensors Ignition switch-IG Detects the ignition switch-IG ON/OFF signals. The engine-ECU or

engine-A-M/T-ECU turns the engine control relay ON/OFF in

accordance with these signals.

Ignition switch-ST Detects that the engine is cranking. Based on this signal, the

engine-ECU or engine-A-M/T-ECU effects fuel injection and ignition

timing control that are suited for starting the engine.

Manifold absolute

pressure sensor

Contains a piezoelectric resistor semiconductor pressure sensor to