Page 1

PS-150C

Pneumatic

Compactor

Cat®3054C Turbocharged Diesel Engine

Gross Power 75 kW 100 hp

Operating W

Heavy Weight 17 273 kg 38,000 lb

Rolling Width 1743 mm 69"

eight 12 940 kg 28,535 lb

Page 2

Productivity and Reliability in a Durable Package

The PS-150C Compactor offers high compaction performance, speed

and gradeability to maximize productivity while providing exceptional reliability and durability.

Propel System

Hydrostatic propel system combines

smooth starts and stops with plenty of

torque. The “High Drive” concept does

not use any chains. The drive motors,

secondary brake and hoses are all

protected within the machine frame.

The heavy weight option incorporates

load compensating valves for each

4

propel motor to increase torque.

Page 4

4 New feature

Engine

Cat 3054C turbocharged diesel engine

4

delivers 75 kW (100 hp) and is built for

performance and reliability without

sacrificing fuel economy.

Page 4

4

Heavy Weight Option

The PS-150C offers an optional heavy

weight package that is able to increase

the maximum operating weight to

17 137 kg (38,000 lb). The propel

system includes load compensating

valves that provide increased torque to

the propel motors for working on

grades and on tough underfoot

conditions.

Page 6

Performance and reliability you can depend on.

Based upon the industry-proven reputation of the

Caterpillar

Compactors, the new PS-150C establishes new

standards for productivity and reliability in the

asphalt compaction industry.

Durable Cat powertrain, field-proven hydraulic

systems and the world’s largest and most dedicated

dealer support system ensure the PS-150C Asphalt

Compactors will provide maximum utilization.

2

®

PS-150B and the PS-200B Asphalt

Page 3

Visibility

The one-piece sloped hood design

provides exceptional operator visibility

to the rear of the machine. The sloped

water tank also provides good visibility

to the front of the machine.

Operator’s Station

The new PS-150C Pneumatic

Compactor features excellent operator

comfort and visibility

grouped control gauges and

conveniently located control switches

enhance operator productivity and

reduce fatigue. An optional MVP

control console rotates to three different

positions, left, right or center and

allows the operator to view the front

tire contact points.

Page 5

. The propel lever,

ersatility

V

The oscillating front and rear wheels

seek out and compact soft spots. The

oscillating wheels also provide even

wheel loads and uniform compaction

across the rolling width.

Page 5

Serviceability

The one-piece fiberglass hood tilts

upward to allow access to the engine

and daily maintenance points. Daily

check points are accessible from ground

The rear mounted cooling system

level.

4

allows easy access for cleaning.

standard oil change interval of 500

hours reduces downtime and

maintenance costs.

Page 6

The

3

Page 4

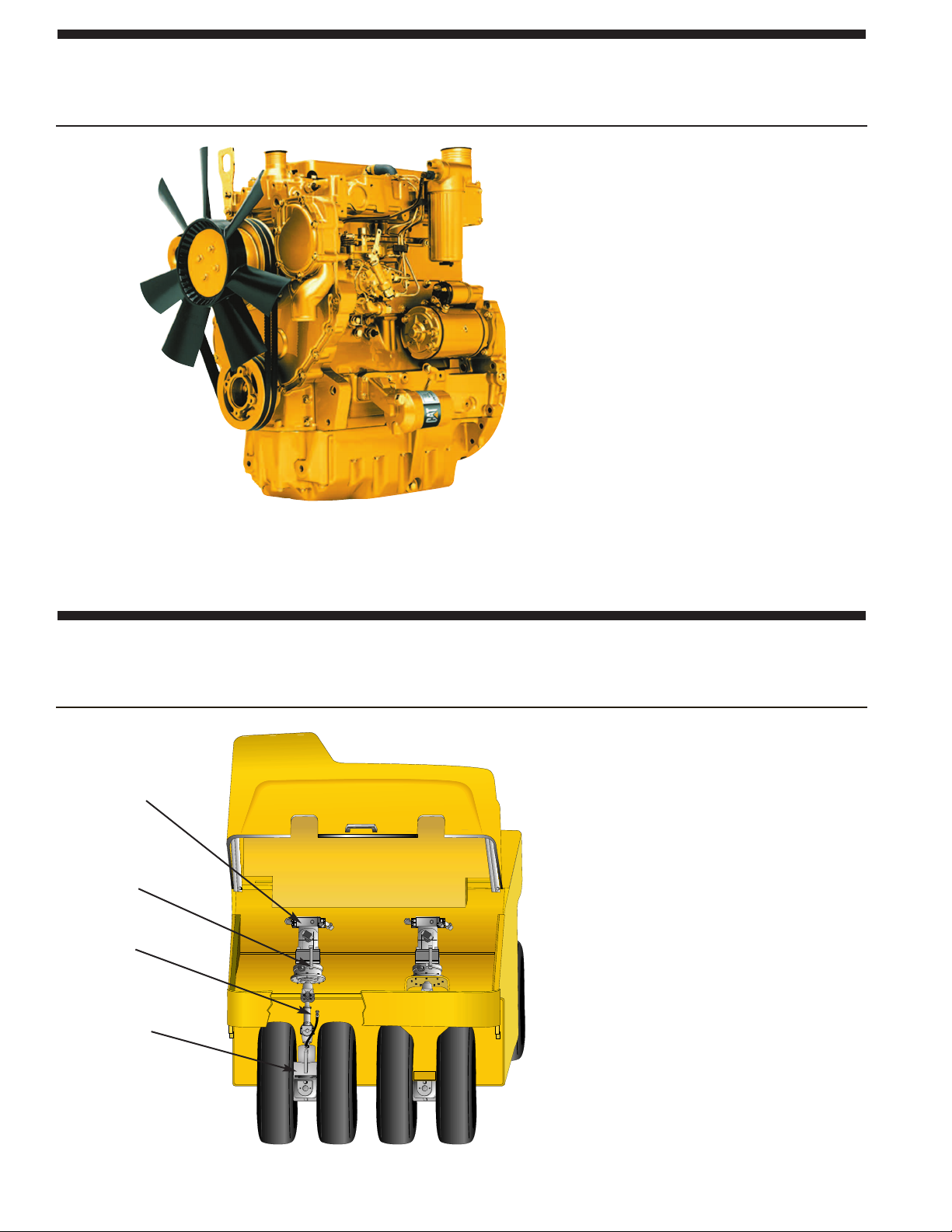

Caterpillar 3054C Turbocharged Diesel Engine

Industry-proven Caterpillar technology designed to provide unmatched performance,

reliability and fuel economy with ample power for the most demanding jobs.

Turbocharged engine provides 75 kW

(100 hp) of gross power

controlled direct injection provides

excellent fuel ef

Highly-ef

increases power while lowering fuel

consumption, engine emissions and

noise.

The engine meets

standards.

High displacement-to-power ratio

ensures long life and provides

outstanding reliability and durability.

Large oil cooler reduces oil

deterioration and varnishing of internal

components.

Combination fuel filter and water

separator offers superior protection for

the fuel injection system.

ficiency.

ficient combustion chamber

. Mechanically

U.S. Tier 2 emission

500 hour oil change interval is standard.

Propel System

Hydrostatic propel system combines smooth stops and starts with plenty of torque.

Power transmission with drive line

provides smooth starts and stops – no

chains are used.

q

w

e

r

1 Hydraulic motor

2 Secondary brake

3 Drive line

4 Axle/Planetary drive

Hydrostatic transmission provides

primary braking – no brake shoes or

pads to service.

Easy serviceability to all drive

components.

Hydraulic motors, secondary brakes

and drive lines are positioned high

inside the machine frame, limiting

contamination and damage.

Two speed ranges provide job site

mobility and traction capability to suit

working conditions.

Remote drive train flushing system

provides cool hydraulic oil to the brakes

and axles to provide extended drive

train life.

4

Page 5

Operator’s Station

Operating ease and comfort promote all-day productivity.

Exceptional all-around visibility

provides easy maneuvering.

Adjustable, cushioned seat provides

lasting comfort.

Flat platform enhances operator’s

mobility and visibility.

Streamlined gauges keep operator

informed of engine systems and

machine status.

Single lever propel control simplifies

operation.

Standard equipment includes Roll Over

Protective Structure (ROPS) and a 75

mm (3") wide retractable seat belt.

Optional rotating operator’s station

allows operator to swivel control

console from left side to right side.

Tire Overlap/Wheel Oscillation

Tires overlap and wheels oscillate for maximum compactive effort with each pass.

Front and rear wheels paths overlap

13 mm (0.5") to provide full-width

coverage of 1743 mm (69") and 2134

mm (84") with 11-wheel option.

Front and rear wheel bolsters oscillate

±4.4 degrees to allow uniform

compaction across entire rolling width.

(Note: With the 11-wheel option,

oscillation angle on outside rear wheels

is zero degrees up and 4.4 degrees

down.)

Wheel oscillation helps ensure

excellent bonding of longitudinal

asphalt joints.

Tire Overlap

5

Page 6

Serviceability

Easy, ground-level access provides convenient and quick service.

Large engine enclosure pivots upward

for access to engine, cooling package

and filters.

Single-point access to all engine

service points and filters is through the

engine enclosure.

Engine access at rear provides oneside, ground level, walk-up service.

Nylon braided wrap and all weather

connectors ensure electrical system

integrity.

Quick-connect hydraulic test ports

simplify system diagnosis.

Remote mounted drains for fuel,

hydraulic and cooling systems allow

collection of fluids.

500 hour oil change interval is standard.

Heavy Weight Option

Provides maximum machine versatility and utilization, while enhancing productivity.

Maximum operating weight of

17 137 kg (38,000 lb) increases

versatility for working on thick lifts.

Maximum weight per wheel of 1920 kg

(4,220 lb) provides increased ground

contact pressures for thick lifts and

harsh mixes.

Ballast (optional) provides an additional

6168 kg (13,600 lb) of steel ballast for

increased versatility.

Load compensating valves provide

increased torque to the propel motors

for working on grades and on tough

underfoot conditions.

Maximum travel speed of 25.6 km/h

(15.9 mph) provides quick

maneuverability around the job site.

12-ply tir

weight option.

6

es

are standard with the heavy

Page 7

Engine

Four-stroke, four cylinder 3054C

turbocharged diesel engine. The engine

meets U.S. EPA Tier 2 emissions

regulations.

Ratings at RPM kW hp

Gross power 2200 75 100

Ratings of Caterpillar machine engines

are based on standard air conditions of

25°C (77°F) and 100 kPa (29.61" Hg)

dry barometer. Power is based on using

API gravity of 35 at 15°C (60°F), fuel

having a LHV of 42 780 kJ/kg (18,390

Btu/lb) used at 30°C (86°F) [ref. a fuel

density of 838.9 g/L (7.001 lb/U.S.

gal)]. Net power advertised is the power

available at the flywheel when the

engine is equipped with fan, air cleaner,

muffler and alternator.

The following ratings apply at 2200

RPM when tested under the specified

standard conditions:

Net Power kW hp

ISO 9249 72 96

SAE J1349 72 96

EEC 80/1269 72 96

Dimensions

Bore 105 mm 4.13"

Stroke 127 mm 5"

Displacement 4.4 liters 269 cu. in.

Transmission

Two-speed hydrostatic propel system.

Hydrostatic pump provides oil to two

hydrostatic motors mounted above the

drive axles. Drive shafts connect the

motors to the rear axles.

single propel lever located on the

A

control console provides smooth

hydrostatic control of the infinitely

variable speeds in both forward and

reverse.

Max. speeds (forward and reverse):

Low 0 - 11 km/h (6.8 mph)

High 0 - 25.6 km/h (15.9 mph)

Wheels and Tires

6-Ply: 8.50/90 x 15

5 wheels front, 4 wheels rear

11-wheel option

6-Ply: 8.50/90 x 15

Heavy weight option

12-Ply: 7.50 x 15

Electrical System

24-volt electrical system includes two

maintenance-free Cat batteries, colorcoded and numbered wiring wrapped in

nylon braid. A 55-amp alternator

powers the electrical system.

Brakes

vice brake features

Ser

Closed-loop hydrostatic drive system

provides dynamic braking during

machine operation.

Secondary brake features*

Spring-applied/hydraulically released

disc brakes are actuated by a switch on

the control console. They are also

activated automatically if pressure is

lost in the brake circuit or when the

engine is shut off.

*Brake systems meet SAE standar

d J1472 and EN500-4.

Axles

Tractive effort is delivered to the four

rear drive wheels by standard, heavyduty axles.

Dual-element, dry-type air cleaner with

visual restriction indicator, glow plug

starting aid and fuel/water separator are

standard.

PS-150C specifications

7

Page 8

Water System

The gravity water system is efficient

and reliable. System includes

galvanized distribution bars over the

front and rear tires and retractable

nylon tire scrapers for each tire.

polyethylene water tank is located at

A

the front of the machine on the

operator’s platform. A water level

gauge is on the tank within easy sight

of the operator.

Pressurized water system is optional.

Steering

Steering is hydraulic power-assist for

responsive, low-ef

Minimum turning radius:

Inside 4648 mm (15' 3")

Outside

Steering angle (each direction) 37.5°.

Hydraulic system – one 75 mm (3")

bore, double-acting cylinder powered

by a gear pump.

fort machine handling.

6453 mm (21' 2")

Instrumentation and Gauges

The start switch, engine throttle switch,

alternator indicator light, coolant

temperature gauge, engine oil pressure

gauge, hydraulic oil temperature gauge

and hour meter are located on the

instrument panel in front of the

operator.

Machine instrumentation and most

controls are located at the operator’s

right on the control console. This

includes the propel lever, speed selector

switch, water system control, horn and

secondary brake switch.

Service Refill Capacities

U.S.

Liters Gallons

Fuel tank* 173 45.6

Cooling system 16.1 4.2

Engine oil (w/filter) 7.3 1.9

Brake 0.3 0.08

Axle 2.7 0.71

Hydraulic tank 54.9 14.5

Water spray tank 394 104

*Note: Actual fuel tank capacity is 162 L (42.8 gal).

Frame

Frame is fabricated from welded heavygauge steel plates. Integral baffle plates

prevent water surge when water

ballasted. Ballast compartments have

cover plates.

The clean, unitized design provides a

flat deck for excellent operator

mobility. The frame is designed for

easy access to all major components.

Operator and Machine Protective Equipment

The Roll Over Protective Structure

(ROPS) is a two-post structure that

bolts directly onto flanges welded to the

machine frame. The structure meets

SAE J231, SAE J1040, ISO 3449 and

ISO 3471.

Backup alarm emits a 107 dB(A) alarm

whenever the machine is in reverse.

The backup alarm is standard

equipment.

Retractable seat belt is 76 mm (3")

wide and is standard equipment.

8

PS-150C specifications

Page 9

Dimensions

R

PS-150C

H

EAVY-WEIGHT

R

PS-150C

A Length 4.29 m 14' 1" 4.29 m 14' 1"

B Compaction width 1.74 m 5' 8" 2.13 m 6' 11"

Height at steering wheel 2.32 m 7' 7" 2.32 m 7' 7"

C

D Height at ROPS 3.0 m 9' 10" 3.0 m 9' 10"

E Wheelbase 3.34 m 10' 11" 3.34 m 10' 11"

F Ground clearance 267 mm 10.5" 267 mm 10.5"

G Tire overlap 13 mm 0.5" 13 mm 0.5"

Outside turning radius 6.45 m 21' 2" 6.45 m 21' 2"

Inside turning radius 4.64 m 15' 3" 4.44 m 14' 7"

Oscillation angle ±4.4 degrees ±4.4 degrees*

* Oscillation angle for outside rear wheels is zero degrees up and 4.4 degrees down.

w/11-wheel option

D

C

F

G

B

E

A

PS-150C specifications

9

Page 10

Weights (approximate)

Operating weights include lubricants, coolant, 80 kg (175 lb) operator

and ROPS.

Operating Weights

Model Condition Weight of Ballast Total Weight Average Weight per Wheel

PS-150C

Standard machine empty — — 4885 kg 10,775 lb 545 kg 1,200 lb

Maximum water ballast 3825 kg 8,430 lb 8710 kg 19,205 lb 970 kg 2,145 lb

Maximum wet sand ballast 8055 kg 17,760 lb 12 940 kg 28,535 lb 1440 kg 3,180 lb

PS-150C w/11-Wheel Option

Standard machine empty — — 4955 kg 10,925 lb 450 kg 993 lb

Maximum water ballast

Maximum wet sand ballast 8055 kg 17,760 lb 13 010 kg 28,685 lb 1183 kg 2,608 lb

PS-150C w/Heavy

Standard machine empty — — 4955 kg 10,925 lb 551 kg 1,214 lb

Maximum water ballast 3825 kg 8,430 lb 8780 kg 19,355 lb 970 kg 2,145 lb

Maximum wet sand ballast 8055 kg 17,760 lb 13 010 kg 28,685 lb 1440 kg 3,180 lb

With 12 307 kg (27,075 lb) 12 307 kg 27,075 lb 17 273 kg 38,000 lb 1920 kg 4,222 lb

of iron and wet sand ballast

PS-150C w/Heavy Weight Option and 11-Wheel Option

Standard machine empty — — 5025 kg 11,078 lb 457 kg 1,008 lb

Maximum water ballast 3825 kg 8,430 lb 8850 kg 19,511 lb 805 kg 1,775 lb

Maximum wet sand ballast 8055 kg 17,760 lb 13 080 kg 28,836 lb 1189 kg 2,621 lb

Weight Option

3825 kg 8,430 lb 8780 kg 19,355 lb 798 kg 1,760 lb

, full fuel tank, full hydraulic system, half-full water tank

Ballast Compartments

Ballast compartments are positioned with

a calculated balance of wheel to weight

ratio. Internal-frame baffles help prevent

surges when water ballasted.

Sand and steel ballast can be added

through large cover plates on the

operation deck and water can be added

through a fill port.

When adding water, it is recommended

that only the primary ballast chamber be

used because it is sealed.

Sand and steel ballast can be removed

through a bolt-on side cover and water

ballast can be emptied through a drain

port.

Ballast Considerations and Ground Contact Pressures

The most common method of changing

ground contact pressure is to vary the

tire pressure.

Another means to change

ground contact pressure is to alter the

ballast.

with sand, water

of each.

The PS-150C can be ballasted

, steel or a combination

Ballast capacities

Primary 3.9 m3(139 ft3)

Secondary 0.4 m3(11 ft3)

Total 4.3 m3(150 ft3)

Ballast materials

0.028 m3(1 ft3) of wet sand weighs 57 kg (125

lb)

0.028 m3(1

3

ft

) of water weighs 28 kg (62.4 lb)

These three components provide varying

weight capacities, allowing the machines

to be tailored to specific requirements.

10

PS-150C specifications

Page 11

Average Ground Contact Pressures

Actual Ground Contact Pressures are measured across the width of the tire. The charts include wheel path overlap.

Tire Ply

Tire Pressure kPa

psi

Wheel Load

GCP kPa

545 kg psi

1,200 lb CA cm

in

GCP kPa

970 kg psi

2,145 lb CA cm

in

GCP kPa

1440 kg psi

3,180 lb CA cm

in

GCP kPa

1920 kg psi

4,220 lb CA cm

in

6-Ply 12-Ply 14-Ply

8.50/90 x 15

7.50 x 15 7.50 x 15

Smooth Tires Smooth Tires Smooth Tires

275 344 344 413 482 550 619 688 757 344 413 482 550 619 688 757 826 862

40 50 50 60 70 80 90 100 110 50 60 70 80 90 100 110 120 125

ound Contact Pressures (GCP) and Contact Areas (CA)

Gr

162 183 236 266 284 306 317 317 344 243 266 284 295 317 330 344 359 367

24 27 34 39 41 44 46 46 50 35 39 41 43 46 48 50 52 53

2

329 291 226 200 187 174 168 168 155 220 200 187 181 168 162 155 149 145

2

2

2

2

2

2

2

45 35 31 29 27 26 26 24 34 31 29 28 26 25 24 23 22

51

197 214 250 284 314 343 369 378 410 259 295 321 343 369 388 410 421 427

29 31 36 41 46 50 54 55 60 38 43 47 50 54 56 60 61 62

485 446 381 336 304 278 258 252 233 368 323 297 278 258 245 233 226 223

75 69 59 52 47 43 40 39 36 57 50 46 43 40 38 36 35 34

235 254 280 304 331 358 390 405 607 273 312 336 364 390 413 437 465 475

34 37 41 44 48 52 57 59 88 40 45 49 53 57 60 64 68 69

601 556 504 465 426 394 362 349 233 517 452 420 388 362 342 323 304 297

93 86 78 72 66 61 56 54 36 80 70 65 60 56 53 50 47 46

— — 296 319 346 368 387 403 440 309 319 341 354 372 387 403 414 417

— — 43 47 50 53 56 59 64 45 47 49 51 54 56 59 60 61

— — 601 559 516 485 461 442 405 577 559 522 504 479 461 442 429 427

— — 93 86 80 75 71 68 63 89 86 81 78 74 71 68 67 66

PS-150C specifications

11

Page 12

Actual Ground Contact Pressures for 6-Ply: 8.50/90 x 15 Tires

Tire Inflation

Pressures

0

10

20

30

40

50

110

120

130

140

150

60

70

80

90

100

0

69

0 0

69

0 0

69

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

545 kg (1,200 lb) Wheel Load – Standard machine empty

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

10

20

30

40

50

110

120

130

140

150

60

70

80

90

100

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

970 kg (2,145 lb) Wheel Load – Maximum water ballast

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

10

20

30

40

50

110

120

130

140

150

60

70

80

90

100

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

1440 kg (3,180 lb) Wheel Load – Maximum wet sand ballast

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

275 kPa (40 psi)

344 kPa (50 psi)

Actual Ground Contact Pressures are measured across the width of the tire. The charts include wheel path overlap.

12

PS-150C specifications

Page 13

Actual Ground Contact Pressures for 12-Ply: 7.50 x 15 Tires

276 kPa (40 psi)

345 kPa (50 psi)

414 kPa (60 psi)

344 kPa (50 psi)

482 kPa (70 psi)

619 kPa (90 psi)

757 kPa (110 psi)

Tire Inflation

Pressures

0 0

69

10

20

30

40

50

110

120

130

140

150

60

70

80

90

100

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

970 kg (2,145 lb) Wheel Load – Maximum water ballast

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

0

10

20

30

40

50

110

120

130

140

150

60

70

80

90

100

0

69

0 0

69

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

1440 kg (3,180 lb) Wheel Load – Maximum wet sand ballast

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

10

20

30

40

50

110

120

130

140

150

60

70

80

90

100

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

1920 kg (4,220 lb) Wheel Load – Maximum iron and wet sand ballast, PS-150C w/Heavy Weight

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

Actual Ground Contact Pressures are measured across the width of the tire. The charts include wheel path overlap.

PS-150C specifications

13

Page 14

Actual Ground Contact Pressures for 14-Ply: 7.50 x 15 Tires

276 kPa (40 psi)

345 kPa (50 psi)

414 kPa (60 psi)

0

0

69

10

20

30

40

50

110

120

130

140

150

60

70

80

90

100

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

970 kg (2,145 lb) Wheel Load – Maximum water ballast

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

344 kPa (50 psi)

482 kPa (70 psi)

619 kPa (90 psi)

757 kPa (110 psi)

Tire Inflation

Pressures

862 kPa (125 psi)

0

20

30

40

50

110

120

130

140

150

60

70

80

90

100

0

69

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

1440 kg (3,180 lb) Wheel Load – Maximum wet sand ballast

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

10

0 0

6910

20

30

40

50

110

120

130

140

150

60

70

80

90

100

138

207

276

345

758

827

896

965

1034

414

483

552

621

689

1920 kg (4,220 lb) Wheel Load – Maximum iron and wet sand ballast, PS-150C w/Heavy Weight

Ground Contact

Pressures (psi)

Ground Contact

Pressures (kPa)

Actual Ground Contact Pressures are measured across the width of the tire. The charts include wheel path overlap.

14

PS-150C specifications

Page 15

Optional Equipment

Note: Standar

d and optional equipment may vary. Consult your Caterpillar dealer for specifics.

The Speedometer is calibrated in both

kilometers per hour and miles per hour

on an analog dial.

Pressure Water Spray System provides

constant water spray regardless of the

tank level or when working on grades.

12-Ply or 14-Ply Tires with higher tire

pressures and increased ground contact

pressure provide greater compactive

effort.

Radial Tires (7.50 x 15) ensure a flat

contact area, regardless of the tire load

or inflation pressure.

Heat Retention Shields (Tire Skirts)

trap heat and help prevent asphalt from

adhering to the tire surfaces.

11-Wheels Option add two wheels to

the rear axle.

intended for chip and seal applications

and cannot be used in conjunction with

the ballast option.

Roading Light Package consists of

front and rear floodlights, taillights and

parking lights with flashers.

Rotating Operator’s Station with

Maximum Visibility Position (MVP)

control console pivots to three locked

positions – left, center and right.

Suspension Seat is mechanical type

with vertical adjustment and armrests.

Sun Canopy is a sheet-metal structure

that blocks the operator’s station from

the sun. The structure is bolted to the

ROPS.

This option is only

Traction Control consists of a foot

activated control switch that activates a

hydraulic oil flow divider for increased

tractive effort.

Heavy Weight Option increases weight

capacity to 17 273 kg (38,000) and

includes load sensing valves for each

propel motor to increase torque for

braking and working on grades.

Ballast Option provides an additional

6168 kg (13,600 lb) of steel ballast for

use with the heavy weight option.

Total Customer Support System

Parts availability—most parts on dealer’s shelf when you need them. Computer-controlled, emergency search system backup.

Parts stock lists—dealer helps you plan on-site parts stock to minimize your parts investment while maximizing machine

availability.

Service capability—dealer’s shop or fast field service by trained technicians using latest tools and technology.

Machine management services—ef

operator and mechanic training.

Literature support—easy-to-use parts books, operation and maintenance manuals, and service manuals help you get maximum

value from equipment.

Flexible financing—your dealer can arrange attractive financing on the entire line of Caterpillar equipment. Terms structured to

meet cash flow requirements. See how easy it is to own, lease or rent Cat equipment.

fective preventive maintenance programs, cost-ef

fective repair options, customer meetings,

15

Page 16

© 2004 Caterpillar

All Rights Reserved.

www.CAT.com

QEHQ1075 (4/04)

Featured machines in photography may include optional equipment.

Materials and specifications ar

e subject to change without notice.

Loading...

Loading...