Page 1

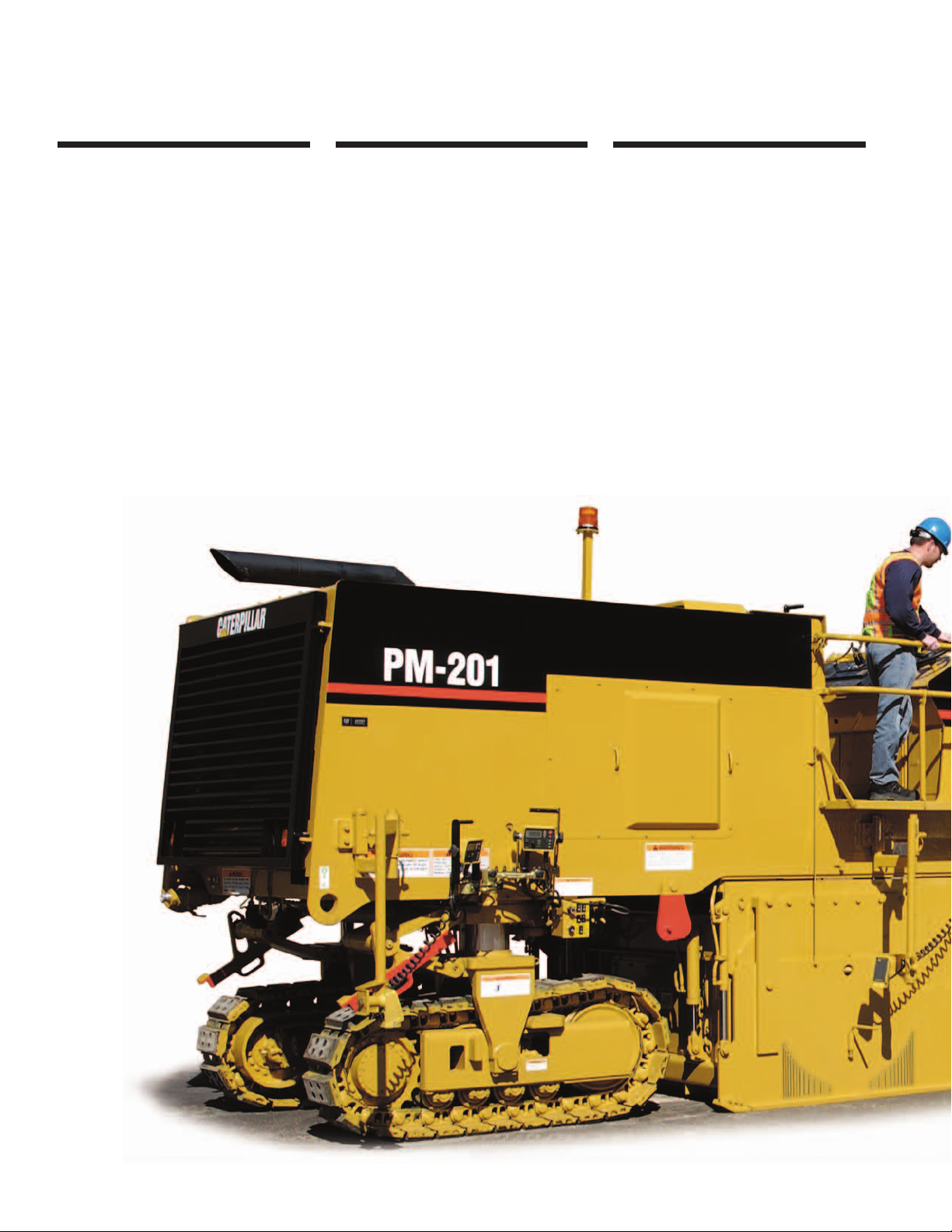

PM-201

Cold Planer

Cat®C18 Engine with ACERT®Technology

Gross Power 485 kW 650 hp

Rotor Width 2100 mm 83"

Rotor Depth (maximum) 305 mm 12"

Operating Weight

with conical rotor 39 165 kg 86,360 lb

eakaway rotor 38 145 kg 84,105 lb

with br

with weld-on rotor 38 050 kg 83,905 lb

Page 2

PM-201 Cold Planer

The new PM-201 combines enhanced production capabilities, optimized performance and

simplified service to complete tough milling applications with productive results.

C18 Engine with ACERT®Technology

ACERT®Technology works at the point

of combustion to optimize engine

performance and provide low exhaust

emissions. The C18 engine with

ACERT®Technology provides clean

burning power.

Page 4

Propel System

Propel pump provides balanced flow to

dual displacement drive motors on each

track. Provides superior tractive ef

on all surfaces. Load sensing system

controlled by the ECM, matches propel

speed to load on engine for maximum

production.

Page 5

fort

Rotor Drive

A Caterpillar wet clutch with automatic

belt tension adjustment delivers

ficient and reliable power to the

ef

pavement. The rotor drive consists of

field-proven Cat D8 Track-type Tractor

components for Caterpillar machine

commonality and long service life.

Page 5

2

Page 3

Rotor Options

With a choice of three rotor options, the

PM-201 can be configured for different

applications and production

requirements.

Page 6

Operator’s Station

Ergonomic design emphasizes comfort,

visibility and easy operation. Left and

right side machine controls are grouped

and conveniently located to enhance

operator visibility, productivity and

reduce fatigue.

Page 8

Maneuverability

Four steering modes: front, rear, crab

and coordinated enable the operator to

have complete control of the machine

position in tight milling applications.

The four-track drive provides

productive operation.

Page 9

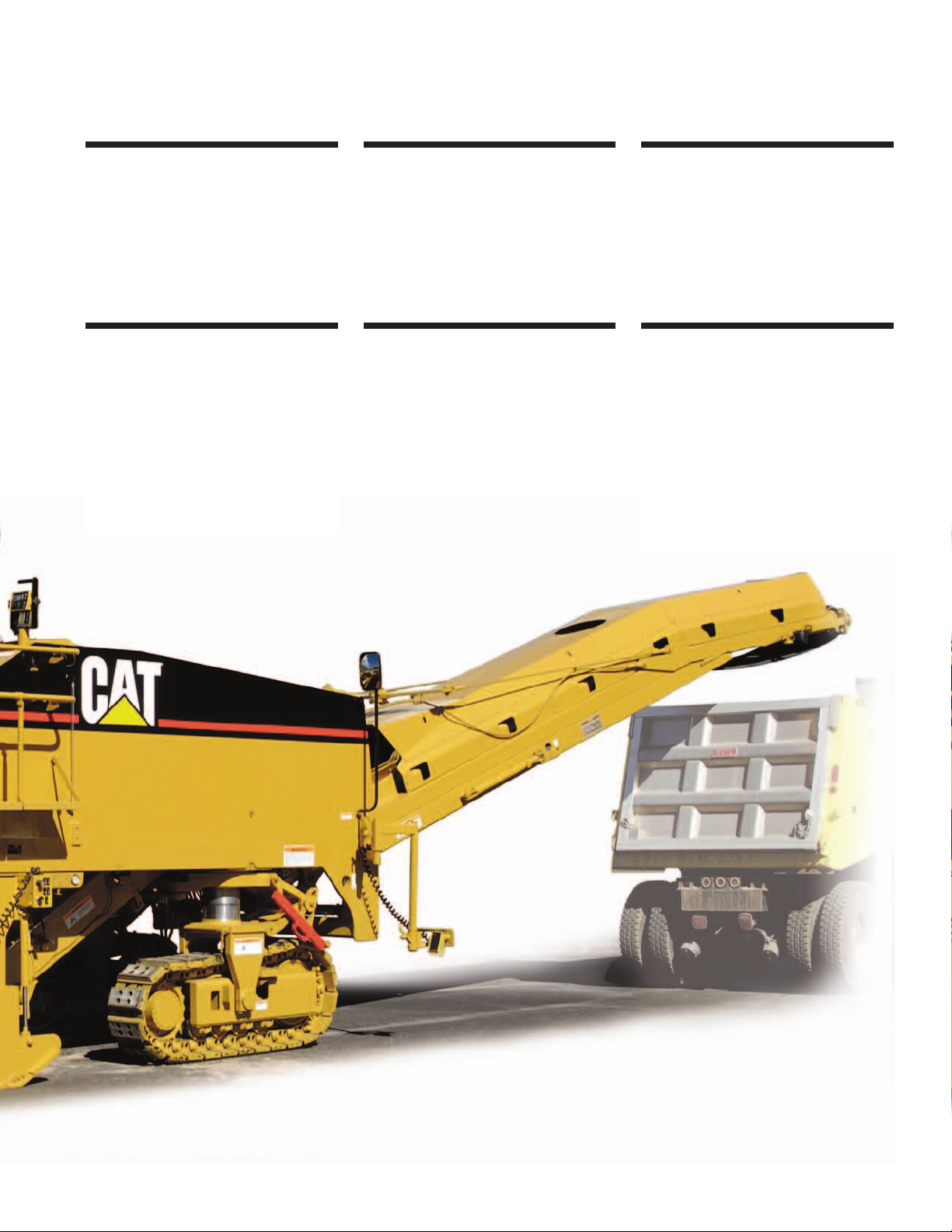

Front Loading Conveyor

The PM-201 features a front loading

conveyor for greater productivity. The

conveyor swings 45 degrees to the left

or right to meet your job requirements.

Conveyor functions can be controlled

from the operator’s station or at ground

level. Conveyor features a boost

function to cast material farther for

loading long haul trucks.

Page 7

Automatic Grade and Slope Controls

The optional grade and slope system

provides precise control of the machine

to a preset cutting depth and cross

slope. Remote mounted control boxes

allow simple operation from either the

operator’s station or ground level.

Page 9

Serviceability

The power-assisted engine hood opens

wide and provides exceptional walk-in

access to the engine, hydraulic pumps

and daily service points. Hydraulic

rotor service door provides convenient

access to the rotor for easy cutting tool

removal and replacement. Water spray

nozzles are easily removed for

inspection and replacement without the

need for tools.

Page 10

3

Page 4

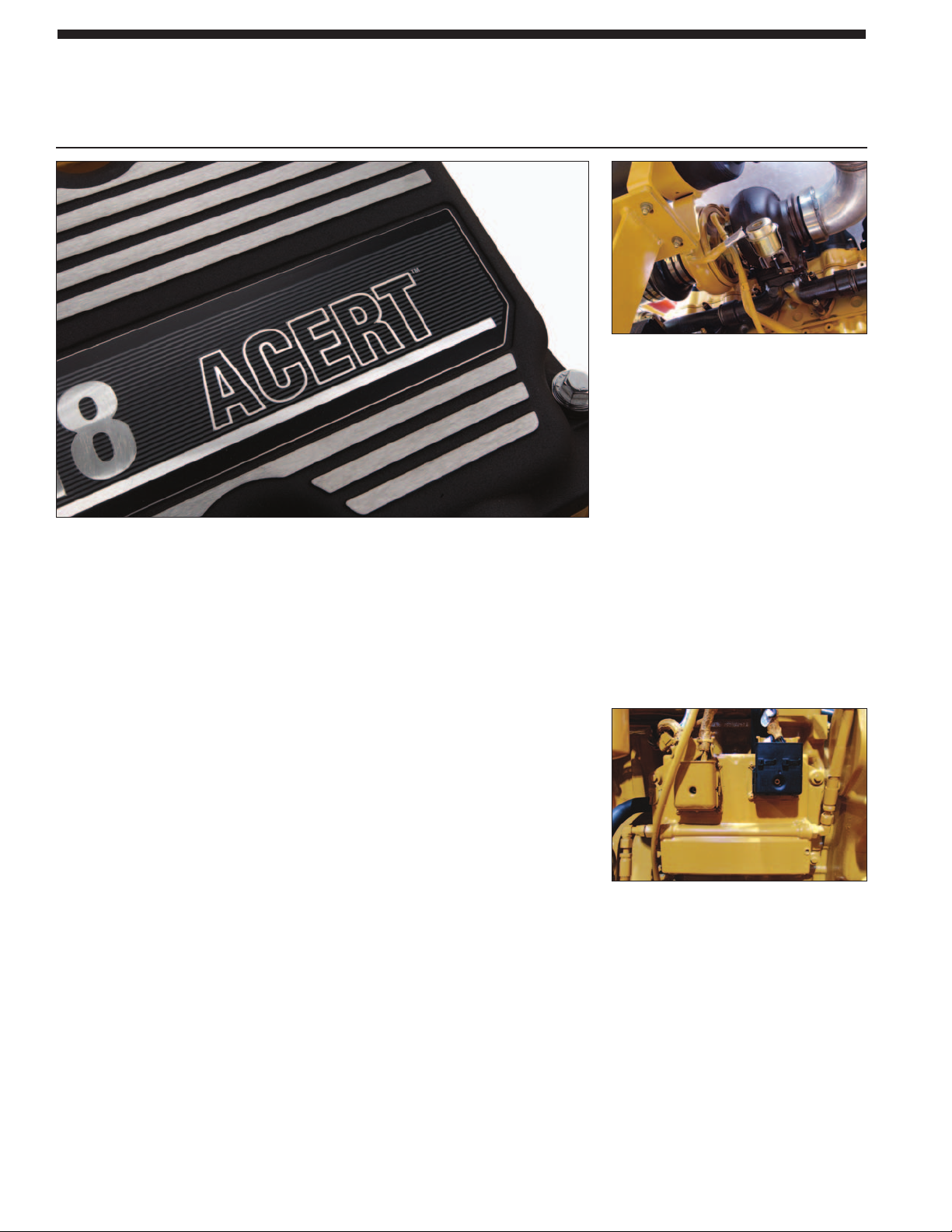

C18 Engine with ACERT®Technology

A combination of innovations working at the point of combustion, ACERT®Technology

optimizes engine performance while meeting U.S. EPA Tier 3 and European EU Stage IIIa

emission regulations for off-road applications.

Turbocharged and Air-to-Air

Aftercooling (ATAAC)

High horsepower with increased

response time is assured while keeping

exhaust temperatures low for long

hours of continuous operation.

Air-to-Air Aftercooling

Air-to-air aftercooling keeps air intake

temperatures down and in concert with

Optimum Power

The C18 engine performs at a full-rated

gross power of 485 kW (650 hp) at

2100 rpm. The combination of large

displacement and high torque allow the

PM-201 to achieve maximum

production. Engine power curve is

optimized for milling applications

providing optimum power while

keeping the engine operating at peak

efficiency.

C18 Cylinder Block

The cylinder block is a one-piece, grey

iron block that features generous ribbing

for stiffness and heavy bearing

bulkheads for rigidity and strength as

the crankshaft turns. This new design

supports the engine’s higher

compression ratios and increases its

power density. The incorporation of

straight-thread, o-ring connection points

reduces the loss of engine oil and fluids.

the tight tolerance combustion chamber

components, maximizes fuel efficiency

and minimizes emissions. New

turbocharger, unique cross-flow head

design, single front driven overhead

cam and a more efficient intake

manifold generate significant

improvements in air flow, maximizing

efficiency and reduced emissions.

Mechanically-Actuated Electronically

Controlled Unit Injection (MEUI)

The MEUI

system that combines the technical

advancement of an electronic control

system with the simplicity of direct

mechanically controlled unit fuel

injection. The MEUI system excels in

its ability to control injection pressure

over the entire engine operating speed

range. These features allow the C18 to

have complete control over injection

timing, duration and pressure.

Precise Multiple Injection Fuel Delivery

Combustion chamber temperatures are

lowered by precisely shaping the

combustion cycle generating fewer

emissions and optimizing fuel

combustion; translating into more work

output for your fuel cost.

4

fuel system is a unique

High Cylinder Pressures

High cylinder pressures combined with

tightly controlled tolerances promote

extremely efficient fuel burn, less blow

by and lower emissions.

Service, Maintenance and Repair

Easier service, maintenance and repair is

accomplished by monitoring key

functions and logging critical indicators.

Advanced electronic diagnostic

capabilities are possible using Cat

Electronic Technician.

ADEM™ A4 Electronic Control Module

The module manages fuel delivery

valve timing and airflow to get the most

performance per liter (gallon) of fuel

The control module provides

used.

flexible fuel mapping, allowing the

engine to respond quickly to varying

application needs. It keeps track of

engine and machine conditions while

keeping the engine operating at peak

ficiency.

ef

,

Page 5

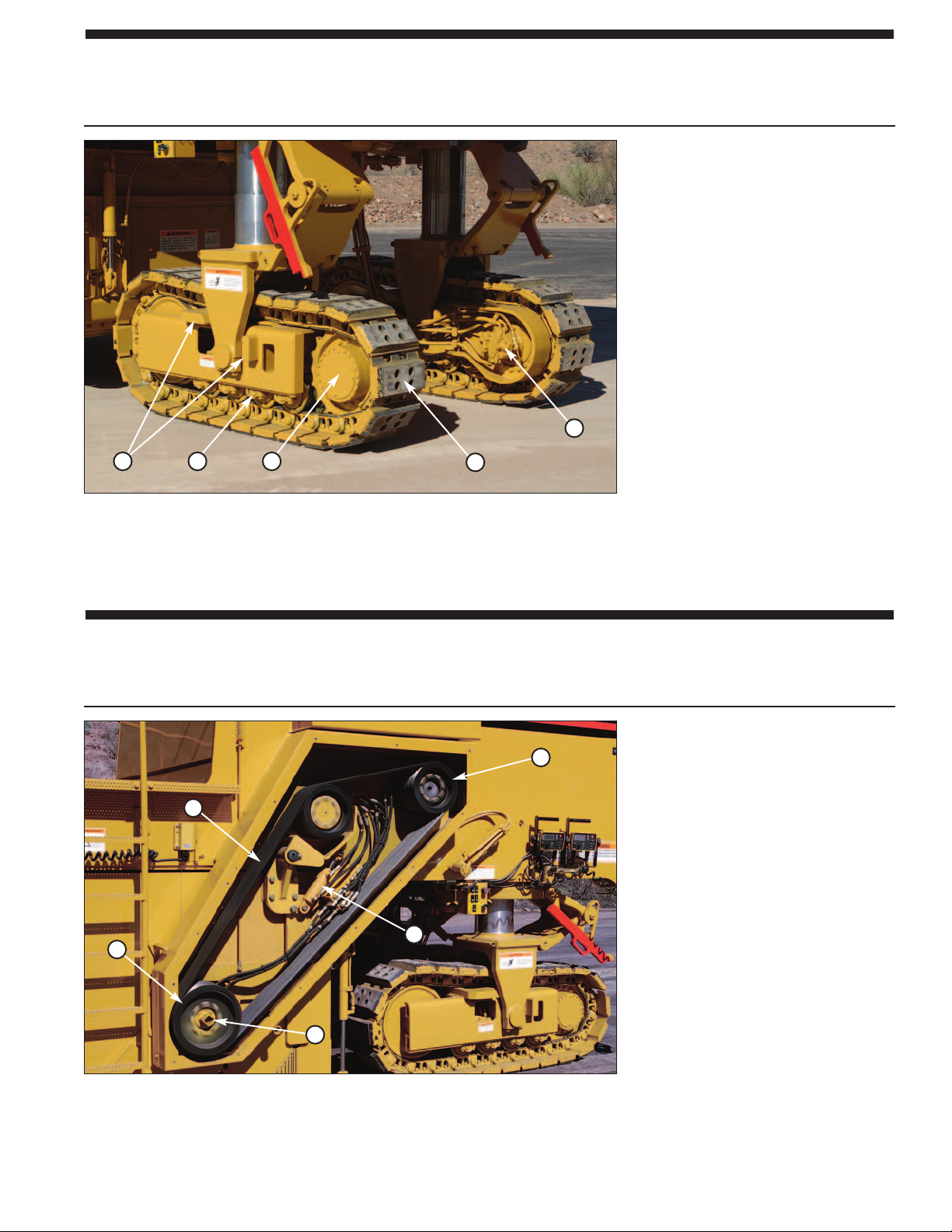

Propel System

Hydrostatic drive with hydraulic flow provided by a variable displacement piston-type

pump. Drive motors on each track provides balanced tractive effort.

Propel pump provides balanced flow to

the dual displacement drive motors on

each track. Provides superior tractive

effort on all surfaces.

Load sensing system controlled by the

ECM, matches propel speed to load on

engine for maximum production.

Two speed ranges allow the machine to

operate at either maximum torque to

propel the machine through the

toughest materials or a greater speed for

moving around the job site.

Infinitely variable machine speeds

1

345

2

1 Two Speed Drive Motor

2 Polyurethane Track Pads

3 Planetary w/Secondary Brake

4 Heavy-duty Cat Rollers

5 Track Frame Stops

determined by the propel lever.

Positive traction control provides equal

hydraulic oil flow to each drive motor

to increase tractive effort in hard cutting

applications.

Polyurethane track pads provide long

service life and positive traction on all

pavement surfaces.

Rotor Drive

Caterpillar wet clutch delivers maximum available horsepower to each ground engaging

tool while providing long service life and reliability.

Caterpillar wet clutch is the most

1

5

2

4

3

efficient and reliable system of applying

rotor power to the pavement. The rotor

clutch system has a separate oil sump,

pump, filter, clutch control valve and

oil cooler to provide continuous cooling

and lubrication.

Upper and lower sheave bearings are

continuously lubricated with oil from

the rotor drive clutch sump to provide

long life and reduced maintenance.

Caterpillar drum drive gear reducer

provides reliability and long service

life. An input shear shaft is provided to

protect the rotor and final drive from

overload conditions. Rotor mandrel is

liquid-filled to dissipate heat and cools

gear reducer.

1 Upper Sheave

ension Cylinder

T

2

Input Shear Shaft

3

4 Lower Sheave

5 Molded Drive Belt

Molded eleven-rib high tensile belt

provides long service life.

Automatic belt tension adjustment

prevents slipping and reduces

maintenance.

5

Page 6

Rotor Selection

Choice of three rotor designs for different applications and production requirements. Tools

are mounted in drive-in, knock-out holders for quick and easy replacement.

Conical Tool Holder Rotor

190 point-attack carbide-tipped tools are mounted

in durable three-piece, patented quick release tool

holders and arranged in a triple-wrap

configuration for maximum breakout force.

Quick release conical tool holder features a

tapered fit maintaining tightness in holder base.

Large replaceable carbide-faced loading paddles

effectively moves milled material onto collecting

conveyor resulting in higher production and less

wear on inside of rotor chamber and cutting tools.

Triple-tree tool placement on rotor ends provides

optimum tool spacing to clean up loose material and

reduces wear on drum when maneuvering in the cut.

Quick release three-piece tool holder.

Breakaway Tool Holder Rotor

Triple-tree tool placement.

Weld-on Tool Holder Rotor

147 point-attack carbide-tipped tools are mounted

in drive-in, knock-out tool holders and arranged in

a triple-wrap configuration for maximum breakout

force.

Triple-wrap design provides optimum tool impact

spacing allows higher working speeds and high

production.

170 point-attack carbide-tipped tools are mounted

in drive-in, knock-out tool holders and arranged in

a triple-wrap configuration for maximum breakout

force.

Bolt-on breakaway design tool holders allow for

fast replacement without welding.

Triple-wrap design provides optimum tool impact

spacing for high production.

Segmented flighting is designed to help protect

base blocks and effectively move milled material

onto collecting conveyor.

Triple-tree tool placement on rotor ends provides

optimum tool spacing to clean up loose material and

reduces wear on drum when maneuvering in the cut.

One-piece flighting has a thickness of 51 mm (2")

to provide optimum material movement onto

collecting conveyor and minimum wear.

Large loading paddles welded to the drum helps

move material onto the collecting conveyor.

6

Weld-on tool holder.

Page 7

Primary Collecting Conveyor

A large discharge opening and wide collecting conveyor belt clears out the cutter box fast

for increased production. Water spray system provides lubrication and controls dust.

Large discharge opening clears out the

1

cutter box fast for increased production.

1020 mm (40") wide collecting conveyor

is driven by two high torque hydraulic

motors provides maximum efficiency.

5

2

4

3

1 Water Spray Nozzles

2 Seamless Belt

3 Anti-Slab Device

4 Anti-Kickback Device

5 Hydraulic Front Door

Seamless belt features 25 mm (1")

high cleats to clear out the cutter box

effectively and provides better control

of fine particles.

Standard water spray lubricates and

controls dust on collecting belt. Water

spray nozzles are easily removed for

inspection and replacement without the

need for tools.

The optional hydraulically operated

front door provides an adjustable down

pressure to prevent slabbing of the road

surface resulting in optimum sizing and

gradation.

Anti-kickback device automatically

deactivates the rotor drive and propel

systems if a kickback is detected.

Front Loading Conveyor

High capacity and versatility adds to productivity. Momentary boost function increases

material handling to load long tractor trailers from the rear.

915 mm (36") wide upper conveyor with

hydraulically controlled height

adjustment and two cylinders for a 45

degree swing to the left and right.

Seamless belt features 25 mm (1")

high cleats, offers long service life and

provides better control of fine particles.

Variable belt speed controls upper belt

loading to match milled material type

and amount.

Conveyor boost function increases

material handling to load long tractor

trailers from the rear

Conveyor raise, lower and swing

controlled from the operator

and at two ground level control stations.

.

s station

’

7

Page 8

Operator’s Station

Designed for efficiency, productivity and simple operation from either side of the console.

Easy to reach controls minimize operator fatigue.

Dual operating controls including

steering wheels, propel levers, upper

conveyor, machine elevation and rear

track steering functions.

Computerized Monitoring System (CMS)

constantly monitors system pressures

and engine condition with six modes of

operation. Alerts the operator if a

problem does occur with three levels

of warning.

Clear control and instrumentation

layout designed for ease of use. All

gauges and displays are easily visible in

direct sunlight or low light conditions.

Isolated platform with four heavy-duty

rubber mounts to reduce machine

vibration transmitted to the operator.

Low sound levels help the operator and

ground crew communicate effectively.

Warning horns and shut down buttons

located on the operator’s station and at

five ground level control stations.

Electronic Control Module

Reliable Caterpillar technology that makes machine operation simple and self-diagnostics

simplifies troubleshooting.

Reliable Caterpillar technology

achieves maximum productivity and

simplifies troubleshooting.

Electronic Control Module (ECM)

receives input signals from sensors in

the engine, propel, steering and rotor

drive systems which monitor current

operating conditions.

Self-diagnostics provides information

for troubleshooting and alerts the

operator of potential system problems.

Automatic load controladjusts propel

speed so that engine speed is

maintained at no less than 1900 rpm.

Machine always works at peak

ficiency for maximum production.

ef

Steering control provides four steering

modes for maneuvering in tight

quarters: front steer only, crab steer,

coordinated steer and rear steer only.

8

Page 9

Automatic Grade and Slope Control

The optional contacting or non-contacting grade controls provide precise control of the

machine to a preset cutting depth. System can be configured to control grade or cross slope.

Contact or non-contact grade sensors

can be positioned on each side are easy

to position and provides a consistent

accuracy to ± 3 mm (1/8"). Cross slope

sensor adds to system versatility.

Contacting wire rope grade sensor

measures side plate movement that

enables the entire length of the side

plate to become an averaging device for

extremely accurate grade matching.

Remote mounted control boxes allow

manual or automatic operation from

either the operator’s station or at ground

Non-contacting grade sensor.

Contacting grade sensor.

Remote mounted control boxes.

level. Constant read-out for rotor depth

and cross slope are easily visible in

direct sunlight or low light conditions.

Sonic Averaging System features three

non-contacting grade sensors or a

combination of one contacting and two

non-contacting sensors that mount on

the side of the machine. Enables the

entire length of the machine to become

an averaging device.

Maneuverability

Four steering modes provide excellent handling for precise control and production.

Steering control provides four steering

modes for maneuvering in tight

quarters: front steer only

coordinated steer and rear steer only.

Standard reinforced polyurethane track

pads provides good traction, added

stability and improved durability

against track pad separation.

Visibility to the cutter box side plates is

exceptional. Excellent visibility

increases productivity and allows the

operator to precisely place the rotor

against gutter pans or when working

near obstructions.

Dual propel levers provide infinitely

variable machine speeds for moving

around the job site quickly.

, crab steer

,

9

Page 10

Reliability and Serviceability

Reliability and serviceability are integrated into every Caterpillar machine. These

important features keep your machine investment profitable.

The power-assist engine hood opens

wide to provide walk-in access to the

engine, air filter, hydraulic components

and daily ser

Electronically controlled on-demand

variable speed cooling fan provides the

lowest overall noise levels and high

ambient operation capability.

vice points.

Hydraulic rotor service door opens wide

for convenient access to rotor for

inspection and tool maintenance.

Engine mounted air compressor and

cutting bit removal tools makes

changing cutting tools quick and easy.

Chrome leg cylinders slide through leg

barrel equipped with a lip seal and a

replaceable nylon sleeve-type bearing.

Electronic Control Module (ECM)

monitors machine systems and provides

self-diagnostics for operator or service

personnel.

Three warning levels alert operator to

conditions on the machine that require

attention. Encourages repair before

major failure.

Level One – a flashing gauge indicator

and a flashing alert indicator light.

Level Two – level one warning plus the

warning action lamp flashing.

Level Three – level two warning plus

the warning action horn sounds.

Visual indicators allow easy check of

radiator coolant, water spray tank level,

hydraulic oil tank level and air

restriction indicator.

Quick-connect hydraulic test ports

simplify system diagnostics.

Ecology drains provide an

environmental method to drain fluids.

They are included on the radiator,

engine oil pan and hydraulic tank.

S•O•SSMports allow for simple fluid

collection of engine oil, engine coolant

and hydraulic oil.

Secure hose routing with polyethylene

routing blocks to reduce rubbing and

increase service life.

Nylon braided wrap and all-weather

connectors ensure electrical system

integrity. Electrical wiring is colorcoded, numbered and labeled with

component identifiers to simplify

troubleshooting.

Maintenance-free Caterpillar batteries

are mounted on the top of the machine

and are accessible through a bolt-on

cover. Cat batteries are specifically

designed for maximum cranking power

and protection against vibration.

Cooling package is a multi-row modular

design, stacked in series for easy access

for cleaning and service. A modular

stacked cooling system provides more

efficient cooling of individual systems

and makes replacement and routine

cleaning easier.

10

Page 11

Engine

The Caterpillar®C18 engine with

ACERT®Technology is a six cylinder,

turbocharged air-to-air after-cooled

diesel engine. The engine meets U.S.

A Tier 3 and European EU Stage IIIa

EP

engine emission regulations.

Engine Cat®C18

Gross Power kW hp

485 650

SAE J1995 483 648

Net Power kW hp

ISO 9249 466 625

EEC 80/1269 466 625

SAE J1349 461 618

Specifications

Bore 145 mm 5.7"

Stroke 183 mm 7.2"

Displacement 18.1 liters 1105 in

n

The power ratings apply at a rated

speed of 2100 RPM when tested

under the reference conditions for the

specific standard.

n

The net power advertised is the

power available at the flywheel when

the engine is equipped with an

alternator, air cleaner, muffler and fan

at minimum speed.

n

The net power at the flywheel when

the fan is at maximum speed is 445

kW (597 hp) per the SAE J1349

reference standards.

n

Derating is not required up to an

altitude of 2134 m (7000').

n

Dual fuel filters with water separator

and air compressor are standard.

Propel System

Hydrostatic drive with hydraulic flow

provided by a variable displacement

piston-type pump. Drive motors with

planetary gear reduction on each track

provides balanced tractive ef

Features

n

A variable displacement, piston-type

pump with electronic displacement

control supplies pressurized flow.

n

Positive traction control valve

provides equal hydraulic oil flow to

each drive motor to increase tractive

effort in hard or deep cuts. Operator

can activate by a switch on the

operator’s console.

n

Drive motors have two swashplate

positions allowing operation at either

3

maximum torque for work or greater

speed for moving around the job site.

n

Gear selection controlled electrically

by a two-position switch on the

operator’s console.

n

Infinitely variable machine speed and

direction of travel controlled by

propel lever.

n

Load sensing system, controlled by

Electronic Control Module (ECM),

matches propel speed to load on the

engine.

n

Tracks are 2045 mm (80.5") long,

348 mm (14") wide and feature

replaceable, steel reinforced

polyurethane track pads for long life.

Max. Speeds (forward and reverse):

Operating 40 mpm - 132 fpm

Travel 6.0 km/h - 3.7 mph

fort.

Rotor Drive System

Operates direct through a hydraulically

actuated, Caterpillar wet clutch driving

a Caterpillar planetary gear reducer

located inside the rotor mandrel.

es

Featur

n

Heavy-duty wet clutch mounts

directly to the engine. Hydraulically

actuated by a ON/OFF switch on the

operator’s console.

n

The rotor clutch system has a separate

oil sump, pump, filter, clutch control

valve and oil cooler to provide

continuous cooling and lubrication.

n

Upper and lower sheave bearings are

continuously lubricated with oil from

the clutch sump to provide long life.

n

One eleven-rib high tensile strength

drive belt drives the rotor through a

drum drive gear reducer located

inside the rotor mandrel.

n

The Caterpillar D8 Track-type-Tractor

drum drive gear reducer provides

reliability and long service life.

n

The rotor mandrel is partially liquidfilled to dissipate heat and cools the

drum drive gear reducer.

n

Input shear shaft protects rotor drive

components from severe shock loads.

n

Hydraulically powered automatic

drive belt tensioner prevents slipping

and reduces maintenance.

n

Single caliper with dual disc brake

installed on PTO output drive shaft.

Rotor Speed:

@ 2100 engine rpm 98 rpm

Rotor Options

Three rotor styles are available. All mount to the standard rotor chamber.

Rotor Width Diameter Tools Max. Depth

Conical 2100 mm (83") 1168 mm (46") 190 305 mm (12")

Breakaway 2100 mm (83") 1168 mm (46") 170 305 mm (12")

Weld-on 2100 mm (83") 1168 mm (46") 147 305 mm (12")

Rotor Housing

n

Large discharge opening clears out

the rotor housing fast for increased

production and reduced tool wear.

n

Side plates have replaceable bolt-on

carbide wear strips front and rear and

features wear-resistant skis for

reduced wear and longer service life.

n

Floating moldboard with adjustable

down pressure is standard and

features a carbide replaceable cutting

edge.

n

A panel on the rear door can be

removed to windrow the milled

material directly behind the machine.

n

Height control for rotor door located

at operator’s station and at two

ground level control stations.

PM-201 specifications

11

Page 12

Steering

PM-201

Hydraulic power-assist steering with

two steering wheels on operator’s

console. Four steering modes with

automatic realignment of rear tracks

through ECM is standard.

Features

n

Double-acting steering cylinders

control the front and rear tracks and

are powered by a pressurecompensated, piston-type pump.

Constant pressure is assured in the

steering system.

n

Switch on operator’s console

provides four steering modes.

Steering Modes

n

Front steer only—controlled by a

hand metering unit, maintained by

closed-loop control.

automatically aligns rear tracks to the

center position for straight tracking.

n

Rear steer—controlled by a toggle

switch on operator’s console,

maintained by closed-loop control.

n

Crab—front and rear tracks turn

simultaneously in the same direction.

n

Coordinated—front and rear tracks

turn simultaneously in the opposite

direction.

The ECM

Dimensions

Operating

A Overall length (conveyor up) 15.1 m 49' 5"

Overall machine width 2.81 m 9' 2"

B

C Maximum height 5.04 m 16' 6"

D Minimum height 3.22 m 10' 7"

E Maximum truck clearance 4.75 m 15' 7"

Rotor ground clearance 305 mm 12"

Conveyor swing

Collecting conveyor width 1020 mm 40"

Upper conveyor width 915 mm 36"

Inside turning radius 4.66 m 15' 4"

Shipping

F Length of base machine 8.25 m 27'

Length (conveyor down) 15.7 m 51' 6"

G Maximum height 2.98 m 9' 9"

H Maximum width 2.58 m 8' 5"

G

D

F

45 degrees left or right of center

A

C

E

Turning Radius:

Minimum 4.66 m (15' 4")

Brakes

Primary Brake Features

n

Closed-loop hydrostatic drive

provides dynamic braking during

normal operation.

Parking Brake Features

n

Spring-applied/hydraulically-released

multiple disc type brake mounted on

each gear reducer. Secondary brakes

are activated by a button on the

operator’s console, loss of hydraulic

pressure in the brake circuit or when

the engine is shut down.

n

Propel pump is destroked when

parking brake is engaged. Propel

lever must be returned to neutral after

brake is released before machine will

propel.

12

PM-201 specifications

H

B

Weights

Operating Weights*

Machine 35 110 kg 77,420 lb

on front tracks 19 310 kg 42,580 lb

on rear tracks 15 800 kg 34,840 lb

Weights shown are approximate and include coolant, lubricants, full fuel tank, full

water tank and a 75 kg (165 lb) operator.

Shipping Weights*

Machine 30 840 kg 68,000 lb

on front tracks 16 655 kg 36,720 lb

on rear tracks 14 185 kg 31,280 lb

Weights shown are approximate and include coolant, lubricants, 50% fuel level and

empty water tank.

*Weights do not include rotor. Include the appropriate rotor below to get the total weight required.

Rotor Configurations (add to above figur

Conical 4055 kg 8942 lb

Breakaway 3035 kg 6687 lb

eld-on

W

Rotor weights include cutting tools.

es)

2945 kg

6488 lb

Page 13

Grade and Slope Control

Machine elevation – rotor depth and

cross slope controlled manually by

operator is standard. Automatic rotor

depth and slope control is optional and

features electronic over hydraulic

control. System can be configured with

contacting or non-contacting grade

sensors. Slope sensor adds versatility.

Features

n

Machine elevation controls located on

the operator’s console and at ground

level allows rotor depth and cross slope

to be controlled manually. Visual depth

gauge displays depth of cut.

n

The optional AUTOMATIC grade

and slope control automatically

controls rotor depth and cross slope to

a preset cutting depth. Setting cutting

depth is easily accomplished first in

manual mode by using the adjustment

knob on the controller.

n

Remote mounted control boxes allow

manual or automatic operation from

either the operator’s station or at

ground level. A cross communication

function allows the operator to view

and change settings of control boxes

located on the opposite side of the

machine. This allows operators a

means to control both sides of a job

from a single location. Constant readout for rotor depth and cross slope

are easily visible in direct sunlight.

n

Sonic grade control sensors can be

positioned on each side are easy to

position and provides a consistent

accuracy to ± 3 mm (1/8").

n

Wire rope contacting grade sensor

measures side plate movement that

enables the entire length of the side

plate to become a mini averaging ski

for optimum grade matching.

n

Sonic Averaging System features

three non-contacting grade sensors or

a combination of one contacting and

two non-contacting sensors that

mount on the side of the machine.

Enables the entire length of the

machine to become an averaging

device. Eliminates the need for a

contact type ski for greater machine

maneuverability

n

Remote mounted control boxes and

sonic grade sensors can be easily

removed and securely stowed to

prevent damage or theft.

.

Conveyor System

n

Collecting conveyor is driven by two

high torque hydraulic motors to

ensure even belt tracking and clears

out the rotor housing effectively.

n

ariable belt speed for front loading

V

conveyor controls loading of milled

materials to closely match material

type and amount.

n

Boost function increases material

handling to load long tractor trailers.

n

Raise, lower and swing controlled

from the operator’s station and at two

ground level control stations.

Collecting Conveyor

Length 3.74 m 12' 3"

Width 1020 mm 40"

Speed 189 mpm 620 fpm

Upper Conveyor

Length 8.31 m 27' 3"

Width 915 mm 36"

Max. speed 231 mpm 760 fpm

Speed w/boost 293 mpm 960 fpm

Swing (from center) 45 degrees

Hydraulic System

n

Pumps for propel, rotor drive,

collecting and upper conveyors,

auxiliary hydraulics and cooling fan

are installed on the engine mounting

pad.

n

Hydraulic oil cooler located at the

rear of the machine and arranged in a

modular stacked design for ef

ficient

cooling and easy access for cleaning.

n

Three-micron filtration on pressure

side of auxiliary flow, seven-micron

filtration on return side.

n

Quick-connect hydraulic test ports

simplify system diagnostics.

Service Refill Capacities

Liters Gallons

Fuel tank (useable)

Cooling system

946

80

Engine oil w/filter 64 17

Propel planetary

gear reducer (each)

4.2

Rotor planetary

gear reducer

Rotor mandrel coolant

14

307

Hydraulic tank 180 47.5

Rotor clutch sump

ater spray system

W

45

3787

250

21.1

1.1

3.7

81

11.9

1000

Water Spray System

n

Hydraulically-driven centrifugal

pump supplies water to spray nozzles

for dust control and collecting belt

lubrication.

n

Centrifugal pump is rated at 206

L/min (55 gpm) at 276 kPa (40 psi).

n

ater spray nozzles focuses the

W

water spray in a flat fan pattern to the

rotor for better cooling of cutting

tools.

n

Nozzles are easily removed for

inspection and replacement without

the need for tools.

n

Automatic water spray system

operates only when the rotor is

engaged and machine is moving

forward to conserve water.

n

System includes gauges to monitor

water pressure, replaceable filters, a

low water level indicator and water

control valves to conserve water

usage.

n

Water tank can be filled from the top

of the machine or at ground level.

Electrical

The 24-volt electrical system consists

of two maintenance-free Cat batteries.

Electrical wiring is color-coded,

numbered, wrapped in vinyl-coated

nylon braid and labeled with

component identifiers. The starting

system provides 1365 cold cranking

amps (cca).

The system includes a

100-amp alternator.

Frame

Fabricated from heavy gauge steel

rack

plates and structural steel tubing.

assembly features track frame stops to

limit track angles to provide machine’s

ability to propel up inclines and out of

op of deck and steps

deep cuts.

T

features non-skid treads for sure

footing.

T

PM-201 specifications

13

Page 14

Optional Equipment

Note: Some options listed may be an option in some areas and standard in others. Consult your dealer for specifics.

Hydraulically Operated Front Door

provides an adjustable down pressure to

prevent slabbing of the road surface in

front of the machine resulting in

optimum sizing and gradation.

Hydraulically Operated Side Plates

allow ground personnel to raise/lower

side plates to precisely place the rotor

against gutter pans or when working

near obstructions. Side plate features

replaceable bolt-on carbide wear strips

front and rear and a wear-resistant ski

for reduced wear and long service life.

Upper Conveyer Cover helps avoid

material spillage and blowing of fine

materials.

Auxiliary Rotor Drive easily rotates

the rotor for easy tool inspection and

replacement. System includes a high

torque motor and hydraulic hoses with

quick-connect couplers. A ground level

control box equipped with a toggle

switch controls the direction of rotor

rotation.

Automatic Grade and Slope System

automatically controls rotor depth and

cross slope to a preset cutting depth.

System can be configured with

contacting or non-contacting grade

sensors. System also includes a cross

slope sensor to meet slope

applications/requirements in job

specifications.

Contacting wire rope grade sensor

measures side plate movement that

enables the entire length of the side

plate to become a mini averaging ski

for optimum grade matching.

Non-contacting sonic grade sensors can

be configured using one sensor per side

or the Sonic Averaging System (SAS).

The Sonic Averaging System features

three non-contacting grade sensors or a

combination of one contacting and two

non-contacting sensors that mount on

the side of the machine. Enables the

entire length of the machine to become

an averaging device.

High Pressure Washdown System uses

water from the water spray system tank

to help with machine clean-up at the end

of each day’

a spray wand and 15.2 m (50 ft) of hose

with a quick-connect coupler.

Conical Rotor features 190 point-attack

carbide-tipped tools mounted in durable

three-piece, patented quick release tool

holders. Quick release conical tool

holders have a tapered fit maintaining

tightness in holder base. Mandrel has

12 carbide-faced replaceable loading

paddles.

Breakaway Rotor features 170 pointattack carbide-tipped tools mounted in

drive-in, knock-out tool holders. Bolt-on

breakaway design tool holders allow for

fast replacement without welding.

Weld-on Rotor features 147 pointattack carbide-tipped tools mounted in

drive-in, knock-out tool holders. Onepiece flighting has a thickness of 51 mm

(2") to provide optimum material

movement onto collecting conveyor and

minimum wear.

s operation. System includes

14

PM-201 specifications

Page 15

PM-201 Specifications

Operating Weights (with conical rotor)

Machine 39 165 kg 86,360 lb

on front tracks 21 540 kg 47,500 lb

on rear tracks 17 625 kg 38,860 lb

Shipping Weights (with conical rotor)

Machine 34 900 kg 76,950 lb

on front tracks

on rear tracks 16 055 kg 35,400 lb

Machine Dimensions (operating)

Overall length (conveyor up) 15.1 m (49' 5")

Overall machine width 2.81 m (9' 2")

Maximum height 5.04 m (16' 6")

Minimum height 3.22 m (10' 7")

Maximum truck clearance 4.75 m (15' 7")

Rotor ground clearance 305 mm (12")

Conveyor swing 45 degrees left or right of center

Collecting conveyor width 1020 mm (40")

Upper conveyor width 915 mm (36")

Inside turning radius 4.66 m (15' 4")

Machine Dimensions (shipping)

Overall length of base machine 8.25 m (27')

Overall length (conveyor down) 15.7 m (51' 6")

Maximum height 2.98 m (9' 9")

Maximum width 2.58 m (8' 5")

18 845 kg 41,550 lb

Power Train

Engine C18 with ACERT®Technology

Gross power 485 kW 650 hp

Speeds

Operating 40 mpm 132 fpm

Travel 6.0 km/h 3.7 mph

Drive train (propel) Hydrostatic w/planetary

Track length 2045 mm (80.5")

Track width 348 mm (14")

Rotor Drive System

Rotor drive Eleven-rib high tensile belt

Transmission Mechanical

Clutch Hydraulic/wet multi-disc

Gear reduction Caterpillar D8

Speed 98 rpm

Rotor

Cutting width 2100 mm (83")

Cutting depth

Number of tools

Conical 190

Breakaway

eld-on

W

Tool spacing (tip) 15 mm (0.6")

305 mm

170

147

(12")

Miscellaneous

Electrical system 24 VDC

Steering system

Water tank capacity

Fuel capacity 946 liters 250 gal

Front/Rear

3787 liters

1000 gal

PM-201 specifications

15

Page 16

Caterpillar offers a comprehensive line of profilers.

The PM-102 and PM-200 are designed to have the best productivity, reliability, versatility,

visibility and ease of operation in their class.

Contact your local Caterpillar dealer to learn more about the complete line of Caterpillar Paving Products.

PM-102

Operating

Gross Power (SAE J1995) 168 kW 225 hp

Cutting Width 1000 mm 40"

Cutting Depth 305 mm 12"

Propel Speeds

Rotor Drive Six-rib high tensile belt

Weight 17 600 kg 38,810 lb

Operating 27 mpm 89 fpm

Travel 4.1 km/h 2.5 mph

Clutch Hydraulic/dry multi-disc

PM-200

Operating Weight 30 900 kg 68,135 lb

Gross Power (SAE J1995) 429 kW 575 hp

Cutting Width 2010 mm 79"

Cutting Depth 320 mm 12.6"

Propel Speeds

Operating 38 mpm 125 fpm

Travel 5.9 km/h 3.6 mph

Rotor Drive Two six-rib high tensile belts

Clutch Hydraulic/wet multi-disc

QEHQ1146 (06/05)

© 2005 Caterpillar

All Rights Reser

www

ed machines in photography may include optional equipment.

Featur

Materials and specifications are subject to change without notice.

ved.

.cat.com.

Loading...

Loading...