Page 1

Operating and installation

Instructions

Washing machine

To avoid the risk of accidents or damage to the appliance, it is

essential to read these instructions before it is installed and used for

the first time.

en-AU, NZ M.-Nr. 11 213 010

Page 2

Contents

Caring for the environment .............................................................................. 6

Warning and Safety instructions...................................................................... 7

Operating the washing machine ...................................................................... 15

Control panel....................................................................................................... 15

Symbols on the control panel ............................................................................. 16

Symbols in the display ........................................................................................ 17

Sensor controls and touch display with sensor controls .................................... 18

Main menu........................................................................................................... 18

Examples on how to operate the appliance........................................................ 19

Using for the first time ...................................................................................... 20

1. Preparing the laundry.................................................................................... 24

2. Loading the washing machine ..................................................................... 25

3. Selecting a programme ................................................................................ 26

4. Selecting programme settings..................................................................... 27

5. Adding detergent........................................................................................... 29

Adding fabric softener or liquid starch separately.......................................... 30

6. Starting the programme - the end of the programme ............................... 31

Delay start .......................................................................................................... 32

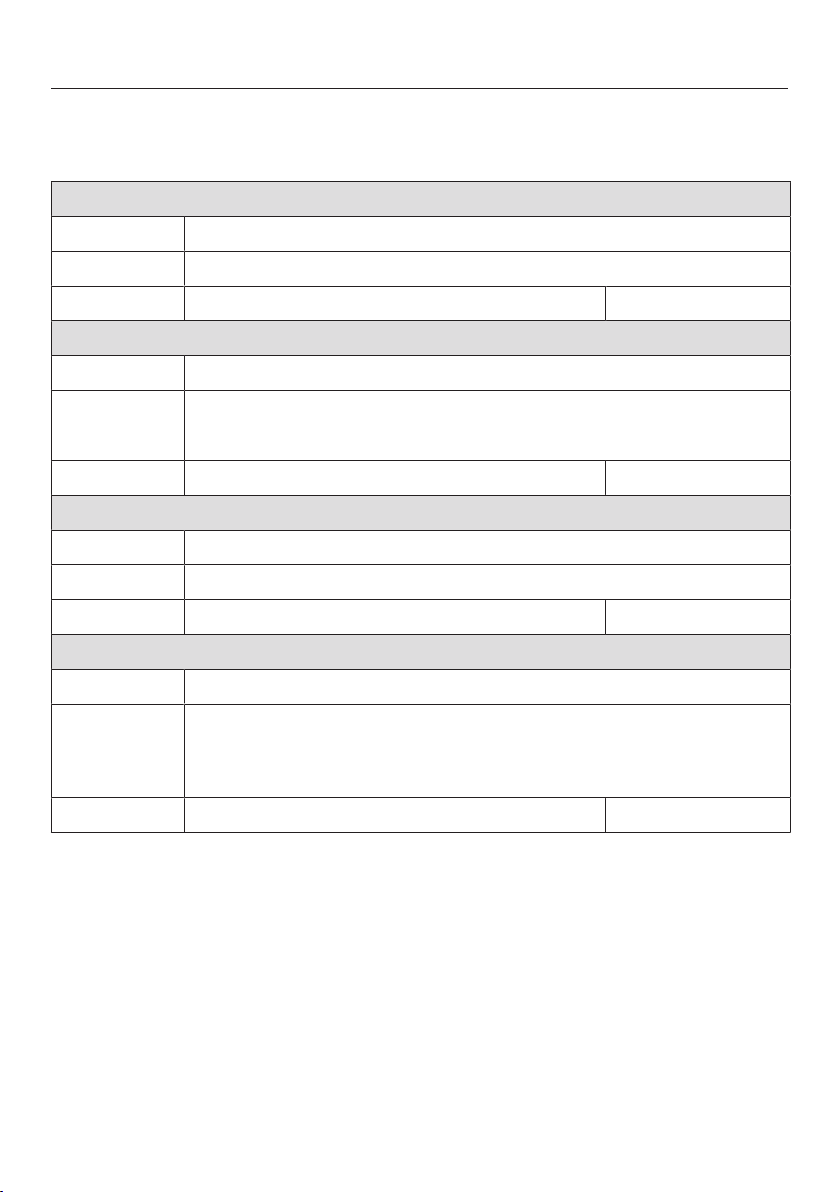

Programme chart .............................................................................................. 33

Mop programmes................................................................................................ 33

Programme packages ......................................................................................... 35

Standard programmes ................................................................................... 41

Extra options...................................................................................................... 42

Pre-wash....................................................................................................... 42

Pre-rinse........................................................................................................ 42

Rinse plus ..................................................................................................... 42

Microfibre....................................................................................................... 42

Special features in the programme sequence................................................ 43

Spinning .............................................................................................................. 43

Anti-crease .......................................................................................................... 43

Changing the programme sequence............................................................... 44

Changing a programme....................................................................................... 44

2

Page 3

Contents

Cancelling a programme ..................................................................................... 44

Switching on the washing machine after an interruption to the power supply ... 44

Adding or removing laundry ................................................................................ 45

Cleaning and care ............................................................................................. 46

Cleaning the external casing and fascia panel.................................................... 46

Cleaning the detergent dispenser drawer ........................................................... 46

Cleaning the drum, suds container and drainage system................................... 48

Cleaning the filters in the water inlet ................................................................... 48

Problem solving guide ...................................................................................... 50

The programme does not start............................................................................ 50

Programme cancellations and fault messages ................................................... 51

A fault message appears in the display .............................................................. 52

An unsatisfactory wash result ............................................................................. 53

General problems with the washing machine ..................................................... 54

The door will not open......................................................................................... 55

Opening the door in the event of a blocked drain outlet and/or power cut ........ 56

After sales service............................................................................................. 58

Contact in case of fault ....................................................................................... 58

Optional accessories........................................................................................... 58

Installation.......................................................................................................... 59

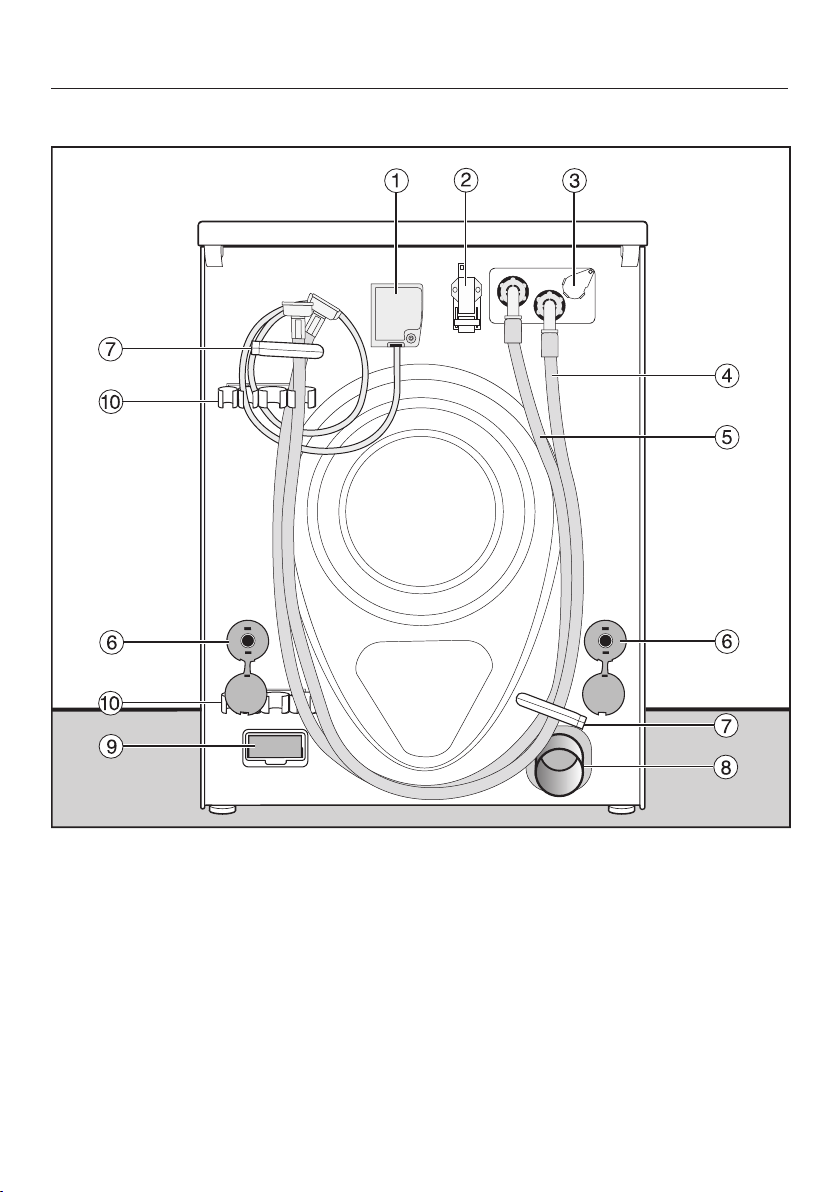

Front view............................................................................................................ 59

Rear view............................................................................................................. 60

Installation locations............................................................................................ 61

Installation notes ................................................................................................. 61

Transporting the washing machine to its installation site.................................... 62

Installation surface .............................................................................................. 63

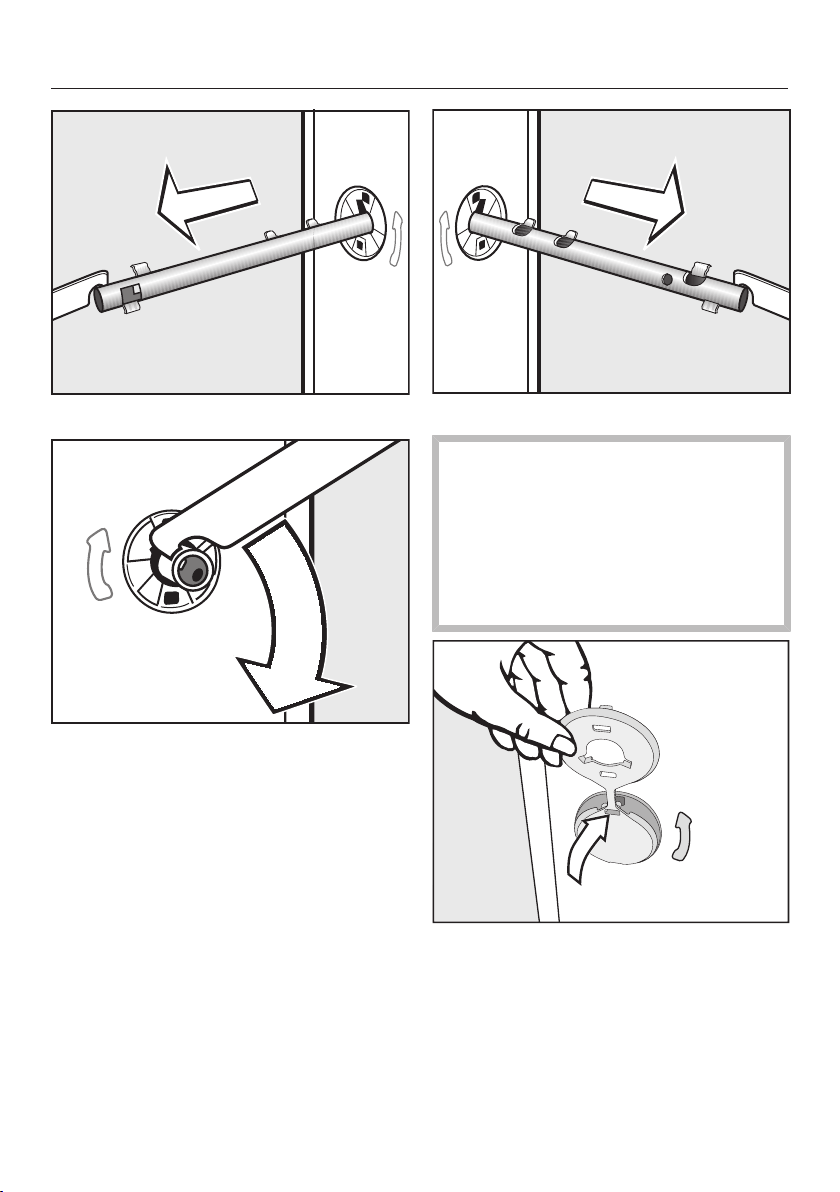

Removing the transit bars ................................................................................... 63

Refitting the transit bars ...................................................................................... 65

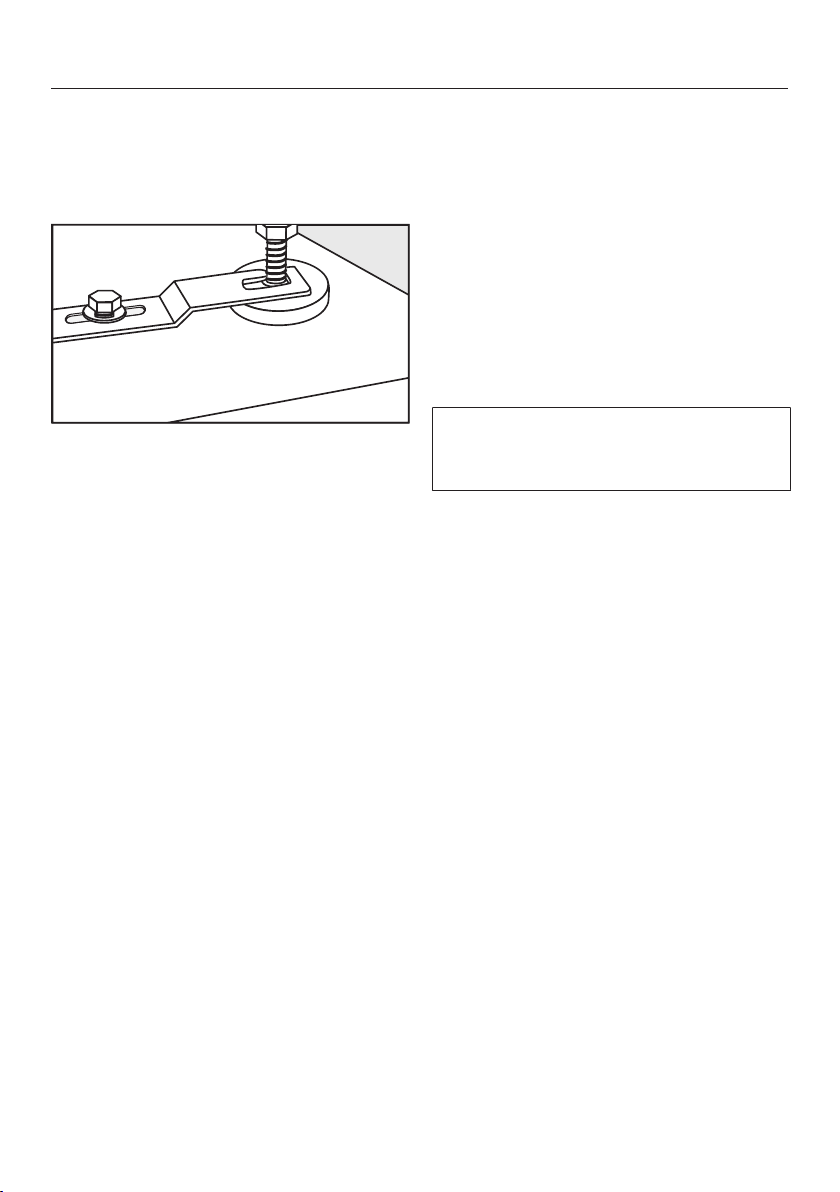

Aligning the washing machine............................................................................. 65

Fixing bracket for plinth ...................................................................................... 66

Positioning the fixing bracket ......................................................................... 66

Installing the fixing bracket............................................................................. 67

Securing the washing machine with the fixing bracket.................................. 68

External control equipment ................................................................................. 68

Payment system............................................................................................. 68

Water connection ................................................................................................ 69

Cold water connection .................................................................................. 69

Hot water connection*.................................................................................... 70

Drainage .............................................................................................................. 70

Drain valve...................................................................................................... 70

Electrical connection ........................................................................................... 71

3

Page 4

Contents

Technical data.................................................................................................... 72

Supervisor level ................................................................................................. 73

Code-based access ............................................................................................ 73

Changing the code.............................................................................................. 73

Opening the Supervisor level .............................................................................. 73

Exiting the Supervisor level ................................................................................. 73

Language............................................................................................................. 74

Brightness ........................................................................................................... 74

Clock display....................................................................................................... 74

Finish tone volume .............................................................................................. 74

Keypad tone ........................................................................................................ 74

Welcome tone volume......................................................................................... 74

Fault alarm........................................................................................................... 74

Memory ............................................................................................................... 74

Anti-crease .......................................................................................................... 75

Suds cooling........................................................................................................ 75

"Display" switch-off status.................................................................................. 75

"Machine" switch-off status ................................................................................ 76

Delay start ........................................................................................................... 76

Programme name................................................................................................ 76

Pre-wash water ................................................................................................... 76

Main wash water ................................................................................................. 77

First rinse water................................................................................................... 77

Final rinse water .................................................................................................. 77

Low water pressure............................................................................................. 77

Pre-spin mops..................................................................................................... 77

Mops temp. Std plus........................................................................................... 78

Mops Ch.-th. dis.................................................................................................. 78

Mops Th.-disin. ................................................................................................... 78

Microfibre mops .................................................................................................. 78

Mops, pre-treat rpm ............................................................................................ 78

Cl. cloths temp. Standard plus............................................................................ 78

Clean. cloths Ch.-th. dis...................................................................................... 79

Pre-treat cl. cloths rpm........................................................................................ 79

Empty sensor ...................................................................................................... 79

Early warning counter.......................................................................................... 79

Water level Cottons ............................................................................................. 79

Water level Minimum iron.................................................................................... 79

Pre-wash temp. Cottons ..................................................................................... 80

4

Page 5

Contents

Wash time pre-wash............................................................................................ 80

Wash time Cottons.............................................................................................. 80

Wash time Minimum iron..................................................................................... 80

Pre-rinse Cottons ................................................................................................ 80

Pre-rinse Minimum iron ....................................................................................... 80

Pre-wash Cottons/Min. iron ................................................................................ 80

Cottons rinses ..................................................................................................... 81

Minimum iron rinses ............................................................................................ 81

Disinfection rinse................................................................................................. 81

Temperature reduction ........................................................................................ 81

Programme packages ......................................................................................... 82

Disinfection prog. code ....................................................................................... 82

Auto load control................................................................................................. 82

Automatic dispensing.......................................................................................... 82

Peak load signal .................................................................................................. 82

Peak load prevention........................................................................................... 83

Alternating current............................................................................................... 83

Heater.................................................................................................................. 83

Payment system.................................................................................................. 83

Settings for payment systems........................................................................ 83

Feedback signal to pay system ...................................................................... 84

Clear paid signal............................................................................................. 84

FOC programmes........................................................................................... 84

Payment system lock ..................................................................................... 84

5

Page 6

Caring for the environment

Disposal of the packing material

The transport and protective packaging

has been selected from materials which

are environmentally friendly for

disposal, and can normally be recycled.

Recycling the packaging reduces the

use of raw materials in the

manufacturing process and also

reduces the amount of waste in landfill

sites. Ensure that any plastic

wrappings, bags etc. are disposed of

safely and kept out of the reach of

babies and young children. Danger of

suffocation.

Disposing of your old appliance

Electrical and electronic appliances

often contain valuable materials. They

also contain specific materials,

compounds and components, which

were essential for their correct function

and safety. These could be hazardous

to human health and to the environment

if disposed of with your domestic waste

or if handled incorrectly. Please do not,

therefore, dispose of your old appliance

with your household waste.

Please dispose of it at your local

community waste collection / recycling

centre for electrical and electronic

appliances. You are also responsible for

deleting any personal data that may be

stored on the appliance prior to

disposal. Please ensure that your old

appliance poses no risk to children

while being stored prior to disposal.

6

Page 7

Warning and Safety instructions

This washing machine complies with all current local and national

safety requirements. However, inappropriate use can lead to

personal injury and damage to property.

Read the operating instructions carefully before using the washing

machine. They contain important information on safety,

installation, use and maintenance of the appliance. This prevents

both personal injury and damage to the washing machine.

In accordance with standard IEC60335-1, Miele expressly and

strongly advises that you read and follow the instructions in

“Installation”, as well as in the “Warning and Safety instructions”.

Miele cannot be held liable for injury or damage caused by noncompliance with these instructions.

Keep these operating instructions in a safe place and pass them

on to any future owner.

When instructing other people how to use the washing machine,

they must be made aware of these Warning and Safety

instructions.

Correct application

The washing machine is only suitable for washing fabrics with a

care label stating that they are suitable for machine washing. Any

other applications may be dangerous. The manufacturer cannot be

held liable for damage resulting from incorrect or improper use or

operation of the machine.

This washing machine must be used as described in the operating

instructions and must be checked on a regular basis to make sure it

is functioning correctly. Maintenance must be carried out when

necessary.

The washing machine is not suitable for outdoor use.

7

Page 8

Warning and Safety instructions

This washing machine is intended for commercial use in small

businesses, care homes, sports clubs, hospitals and other similar

commercial environments. This machine may also be operated by

lay persons in public areas such as laundrettes, communal laundry

rooms or similar commercial environment.

This washing machine is not intended for use by persons

(including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have

been given supervision or instruction concerning its use by a person

responsible for their safety.

Young children must not be allowed to use this appliance.

Older children may only use the appliance when its operation has

been clearly explained to them and they are able to use it safely.

They must be able to understand and recognise the possible

dangers caused by incorrect operation.

Cleaning or maintenance on the washing machine may only be

carried out by older children under the supervision of an adult.

Always supervise any children in the vicinity of the washing

machine. Never allow children to play with the washing machine.

Disinfection programmes must not be interrupted, as this can

have a limiting effect on the disinfection result. It is the operator's

responsibility to ensure that the standard of disinfection in thermal as

well as chemo-thermal procedures is maintained by carrying out

suitable validation tests.

8

Page 9

Warning and Safety instructions

Technical safety

Before installing and operating the washing machine, check it for

any visible exterior damage. Do not set up or use a damaged

washing machine.

The electrical safety of this washing machine can only be

guaranteed when continuity is complete between it and an effective

earthing system which complies with current local and national

safety regulations.

It is most important that this basic safety requirement is present and

regularly tested and, when there is any doubt, the on-site wiring

system should be inspected by a qualified electrician.

Miele cannot be held liable for the consequences of an inadequate

earthing system (e.g. electric shock).

Unauthorised repairs could result in unforeseen dangers for the

user, for which the manufacturer cannot accept liability. Repairs

must only be carried out by a Miele authorised service technician,

otherwise any subsequent damage will not be covered by the

warranty.

Do not make any alterations to the machine, unless authorised to

do so by Miele.

In the event of a fault or for cleaning purposes, the washing

machine must be isolated from the electricity supply. It is only

completely isolated if:

- it is switched off at the wall socket and the plug is withdrawn, or

- the mains fuse is disconnected, or

- it is switched off at the mains circuit breaker.

For further information see “Installation - Electrical connection”.

9

Page 10

Warning and Safety instructions

If the electrical connection cable is faulty, it must only be replaced

by a Miele authorised service technician to protect the user from

danger.

The washing machine must be connected to the water supply

using the new hose set supplied with the appliance. Old hose sets

should not be re-used. Check the hose regularly for signs of wear.

Replace it in good time to avoid the risk of leaks and water damage.

Faulty components must only be replaced by genuine Miele

original spare parts. Miele can only guarantee the safety standards of

the machine when Miele replacement parts are used.

Do not connect the machine to the mains electricity supply by a

multi-socket adapter, extension lead or similar. These do not

guarantee the required safety of the machine (fire hazard due to the

risk of overheating).

The machine must not be installed and operated in mobile

locations (e.g. on a ship).

Please observe the instructions in “Installation” and “Technical

data”.

If the washing machine is equipped with a mains plug, it must be

easily accessible after installation so that the machine can be

disconnected from the electricity supply if necessary.

10

Page 11

Warning and Safety instructions

If the appliance is hard wired, an on-site dual circuit breaker must

be accessible at all times in order to disconnect the washing

machine from the mains supply. The means of disconnection must

be incorporated in the fixed wiring in accordance with the wiring

rules.

Reliable and safe operation of this washing machine is only

ensured if it has been connected to the mains electricity supply.

Correct use

The maximum load is 8.0kg (dry laundry). See the “Programme

chart” for the maximum recommended loads for individual

programmes.

Do not install your washing machine in a room where there is a

risk of frost. Frozen hoses may burst or split, and the reliability of the

electronic control unit may be impaired at temperatures below

freezing point.

Before using the machine for the first time, check that the transit

bars at the rear of the washing machine have been removed (see

“Installation and connection – Removing the transit bars”). During

spinning, transit bars which are still in place can cause damage to

both the machine and adjacent furniture or appliances.

Turn off the tap if the machine is to be left for any length of time

(e.g. while on holiday), especially if there is no floor drain (gully) in the

immediate vicinity.

If the ventilation openings are in the base of the washing

machine, ensure that they are not obstructed by deep-pile carpet or

similar.

11

Page 12

Warning and Safety instructions

Make sure that no foreign objects (e.g. nails, pins, coins, paper

clips) find their way into the machine with the laundry. In particular,

shake out any metal shavings which could be in the cleaning cloths

before washing. These can damage components of the machine

(e.g. suds container, drum). Damaged components can, in turn,

result in damage to the laundry.

If the correct amount of detergent is dispensed, the machine

should not need to be descaled. If, however, you do wish to descale

it, only use special non-corrosive descaling agents and strictly

observe the instructions on the packaging. Special descaling agent

is available from your Miele dealer or from Miele. Strictly observe the

instructions for the packaging.

For textiles that have been treated with solvent-based cleaning

agents, always check whether they can be washed in a washing

machine. To check whether this is possible, refer to safety notes,

information concerning the product's environmental compatibility,

and other information.

Never use solvent-based detergents, e.g. those containing

benzine, in this washing machine. This may result in damage to

component parts and create toxic fumes. Risk of fire and explosion!

Gasoline, petroleum, kerosene, paraffin, or any easily flammable

liquid must not be stored or used near the washing machine. Risk of

fire and explosion!

12

Page 13

Warning and Safety instructions

Only use dyes suitable for use in a washing machine. Always

observe the manufacturer's instructions carefully.

Dye removers contain sulphur compounds which can cause

damage such as corrosion. Dye removers must not be used in the

washing machine.

Avoid contact between stainless steel surfaces (front, lid, casing)

and liquid detergents or disinfecting agents which contain chlorine or

sodium hypochlorite. These agents can cause corrosion on stainless

steel. Aggressive vapours containing chlorine can also be corrosive.

Do not store open containers of these agents near the machine.

Do not use a high-pressure cleaner or water jet to clean the

washing machine.

It is particularly important to observe the manufacturer's

instructions when using a combination of cleaning agents and

special application products. Products must only be used for

applications approved by the manufacturer to avoid any material

damage or the occurrence of strong chemical reactions.

If detergent has come into contact with the eyes, rinse out

immediately with plenty of lukewarm water. If detergent has

accidentally been ingested, seek medical advice immediately. People

with damaged or sensitive skin should avoid contact with detergent.

When adding or removing laundry during the main wash, your skin

may come into contact with detergent, particularly if the detergent is

dispensed externally. Take care when placing your hands inside the

drum. If suds have come into contact with the skin, rinse off

immediately with lukewarm water.

13

Page 14

Warning and Safety instructions

Accessories

Only use genuine Miele spare parts and accessories with this

machine. Using spare parts or accessories from other manufacturers

will invalidate the warranty, and Miele cannot accept liability.

Miele tumble dryers and Miele washing machines can be installed

as a washer-dryer stack. This requires a Miele washer-dryer stacking

kit which can be purchased separately. Please ensure that the

washer-dryer stacking kit is suitable for your Miele tumble dryer and

your Miele washing machine.

If installing the machine on a Miele plinth (available as an optional

accessory), please make sure you order the correct one for this

washing machine.

Miele cannot be held liable for damage caused by non-compliance

with these Warning and Safety instructions.

14

Page 15

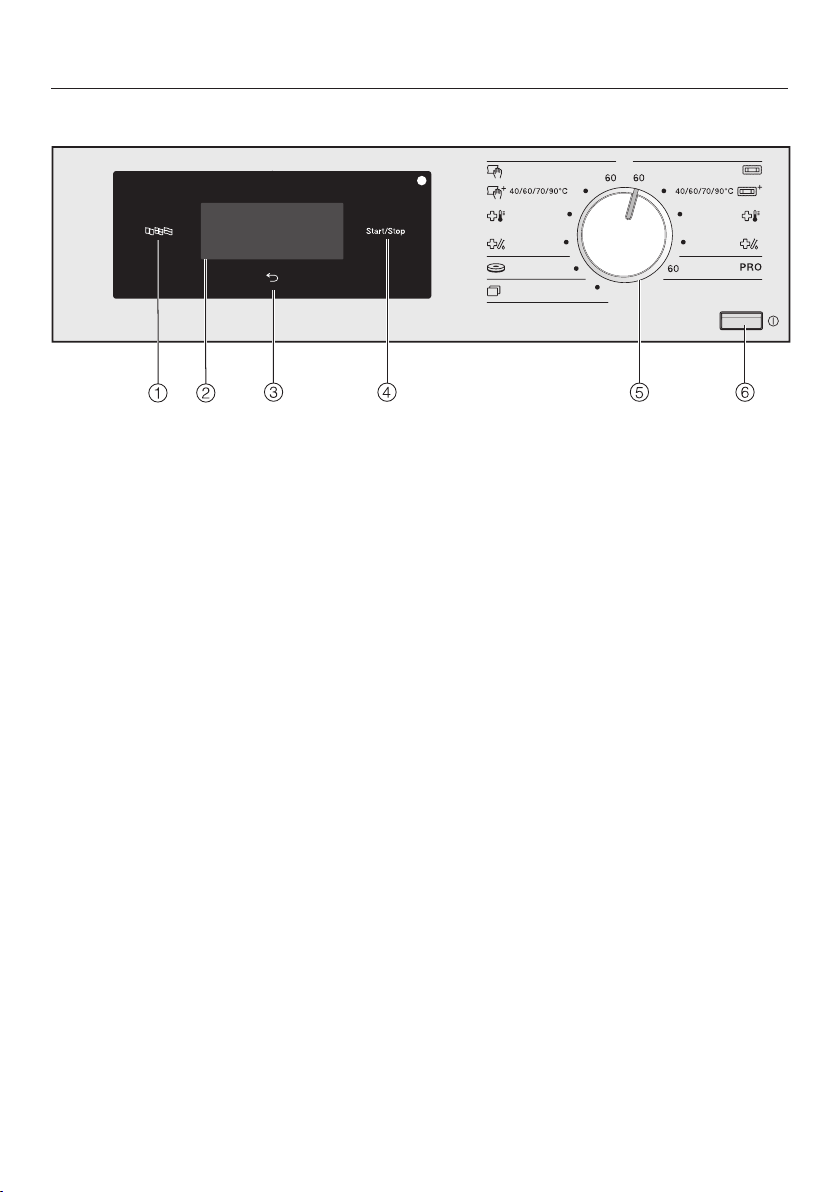

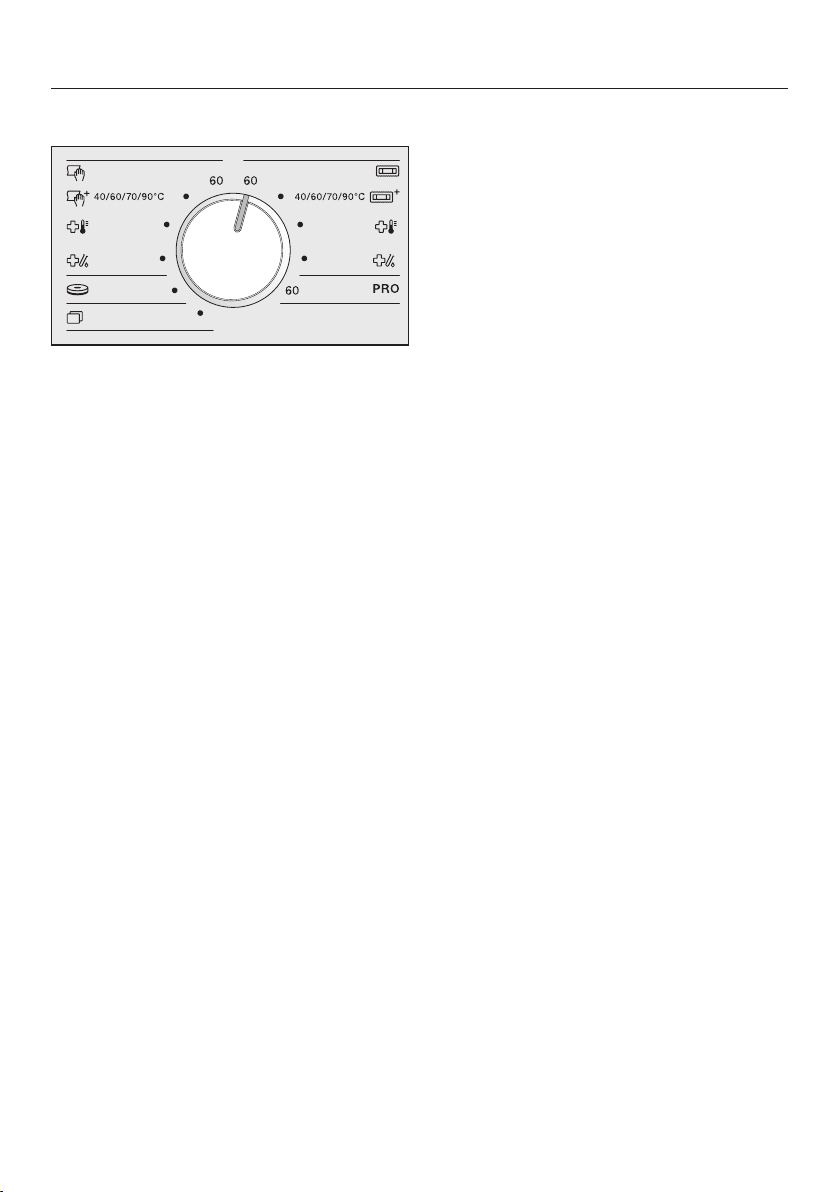

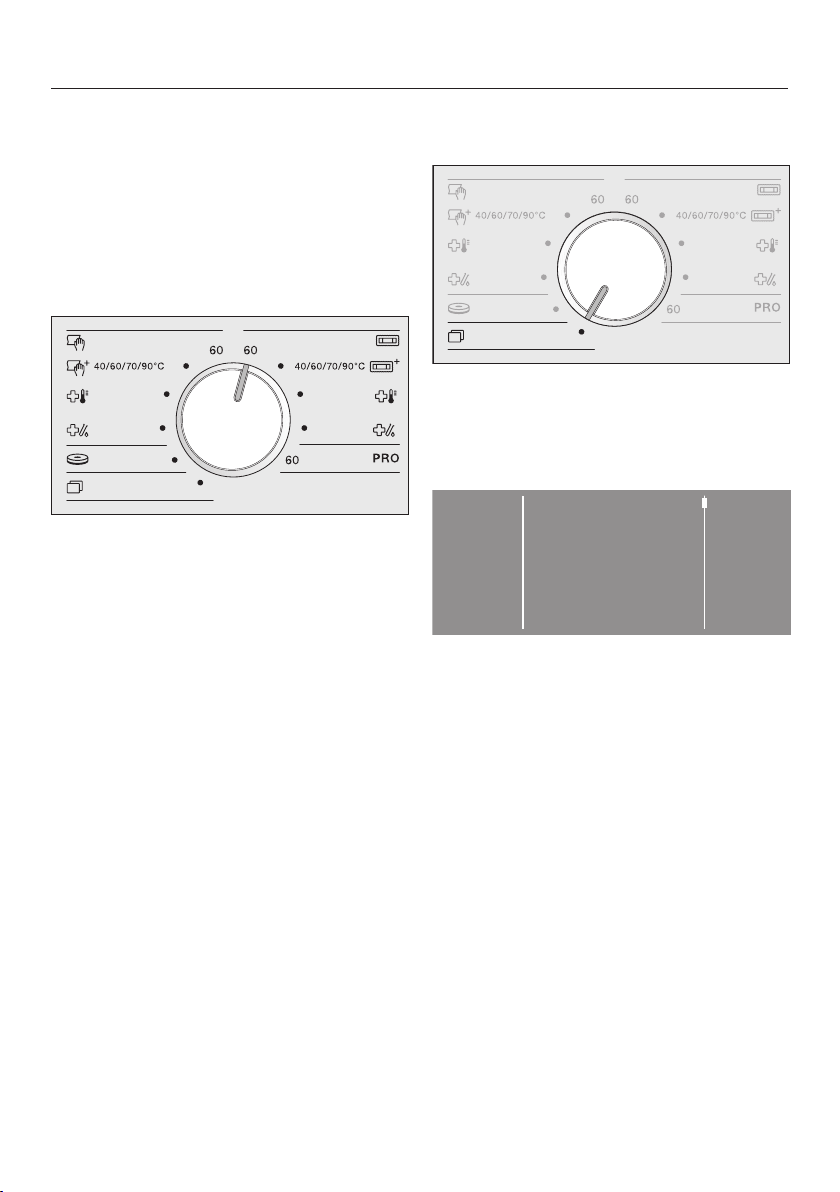

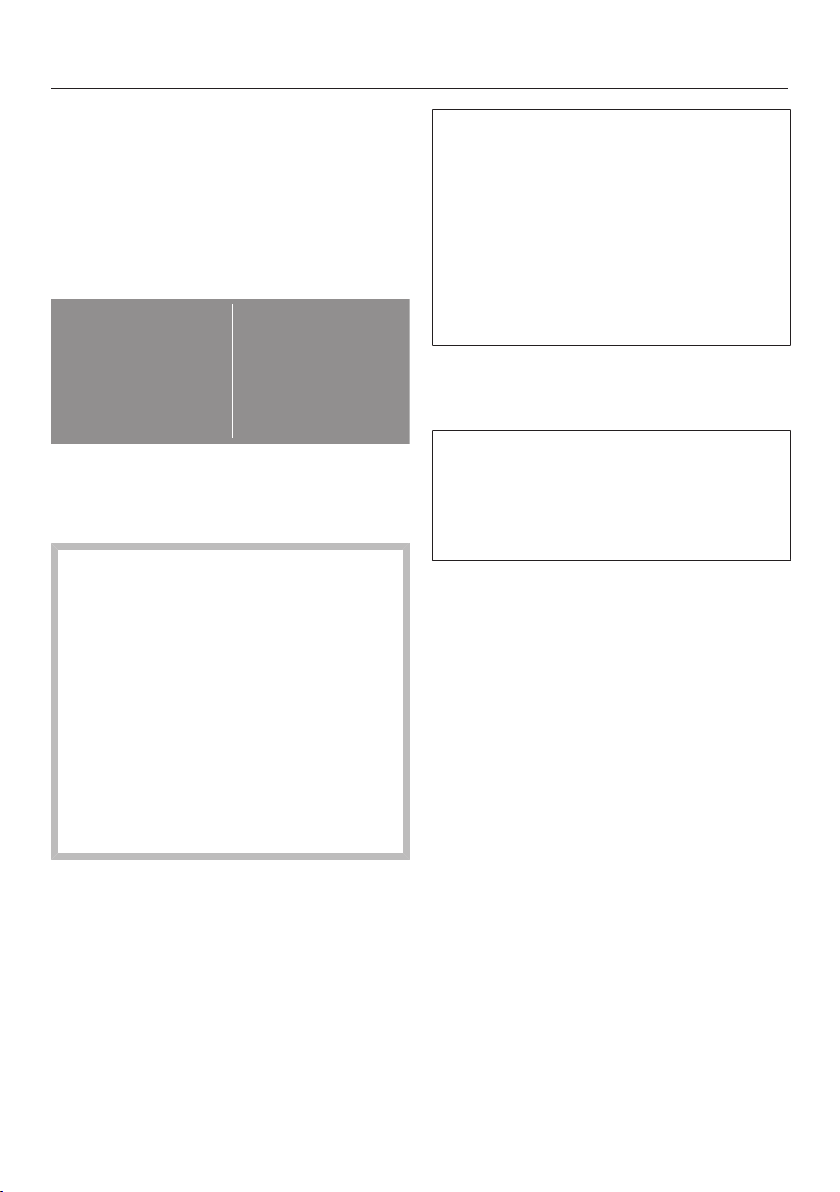

Control panel

Operating the washing machine

a

Language sensor control

For selecting the current user

language.

The operating language is displayed

again at the end of the programme.

b

Touch display with sensor controls

Displays the selected programme.

The programme settings are selected

using the sensor controls in the touch

display.

c

Back sensor control

Takes you back one level in the

menu.

d

Start/Stop sensor control

For starting the selected programme

and cancelling a programme that has

already started.

e

Programme selector

For selecting the wash programme.

The programme selector can be

turned clockwise or anti-clockwise.

f

Button

For switching the washing machine

on and off.

The washing machine switches itself

off automatically to save energy. This

occurs 15 minutes after the end of

the programme/anti-crease phase, or

after being switched on if no further

selection is made.

15

Page 16

Operating the washing machine

Symbols on the control panel

Right side:

Mops

Mops plus

Mops thermal disinfection

Mops chemo-thermal disinfection

PRO Cottons PRO

Left side:

Cloths

Cloths plus

Cleaning cloths thermal disinfection

Cleaning cloths chemo-thermal disinfection

Pads

Further programmes

16

Page 17

Symbols in the display

Temperature: Use the Temperaturesensor control to set the temperature

of the wash programme.

Spin speed: Use the Spin speedsensor control to set the spin speed of

the wash programme.

Extras: Use the Extrassensor control to add Extras to a wash

programme.

Pre-wash: Use the Pre-washsensor control to select the Pre-washExtra

for a wash programme.

Pre-rinse: Use the Pre-rinsesensor control to rinse the laundry before

the start of the wash programme.

Rinse plus: Use the Rinse plussensor control to add an additional rinse

cycle to a wash programme.

Microfibre: Use the Microfibresensor control to gently cool microfibre

mops at the end of the main wash cycle.

Residual moisture: Use the Residual moisturesensor control to set the

residual moisture after spinning.

Operating the washing machine

Spin duration: Use the Spin durationsensor control to set the residual

moisture after spinning.

Further selections: Use the Further selectionssensor control to select

further options.

Supervisor level: Use the Supervisor levelsensor control to alter the

washing machine's settings.

Delay start: Use the Delay startsensor control to set the start time of a

wash programme...

...or the finish time

...or the time until the programme starts.

17

Page 18

Operating the washing machine

1400

Mops

60°C

h

0:47

1400

New mops

0:42

h

60°C

Sensor controls and touch display with sensor controls

The, andStart/Stopsensors

and the sensor controls in the display

react to finger contact. Every touch of a

sensor is confirmed by an audible tone.

You can adjust the volume of the

keypad tone or switch it off (see

“Supervisor level”).

The control panel with the sensor

controls and the touch display can

be scratched by pointed or sharp

objects, e.g. pens.

Only touch the display with your

fingers.

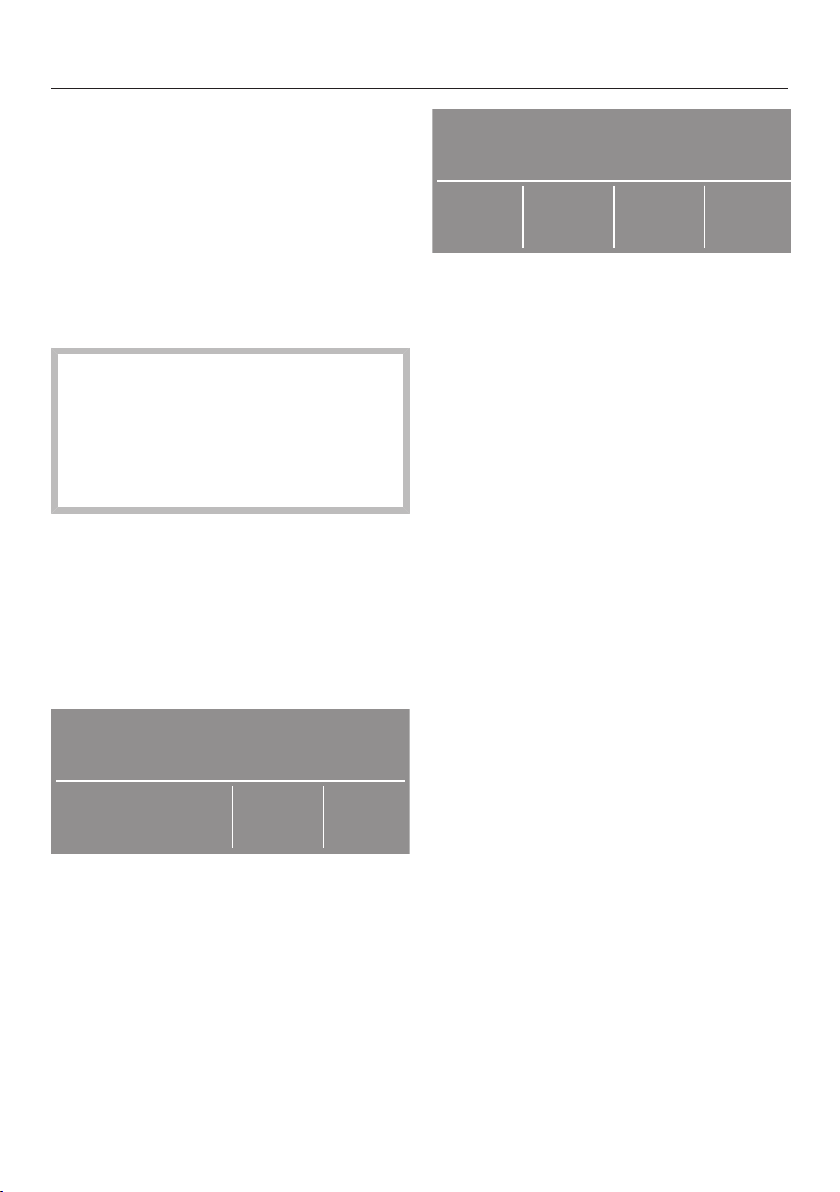

Main menu

The main menu of a wash programme

displays different values depending on

the programme.

- the selected programme

- the programme duration

- the temperature set

- the spin speed set

- the selectable Extras

- Further selections: Delay start and

the settings in the Supervisor level

For programmes with a fixed

temperature setting:

- the selected programme with the set

temperature

- the programme duration

- the spin speed set

- the selectable Extras

- Further selections: Delay start and

the settings in the Supervisor level

For programmes with a variable

temperature setting:

18

Page 19

Operating the washing machine

Language

deutsch

čeština

english

(AU)

dansk

Spin speed

800

1000

400

0

1200

1400

Finish

(today)

10

OK

25:

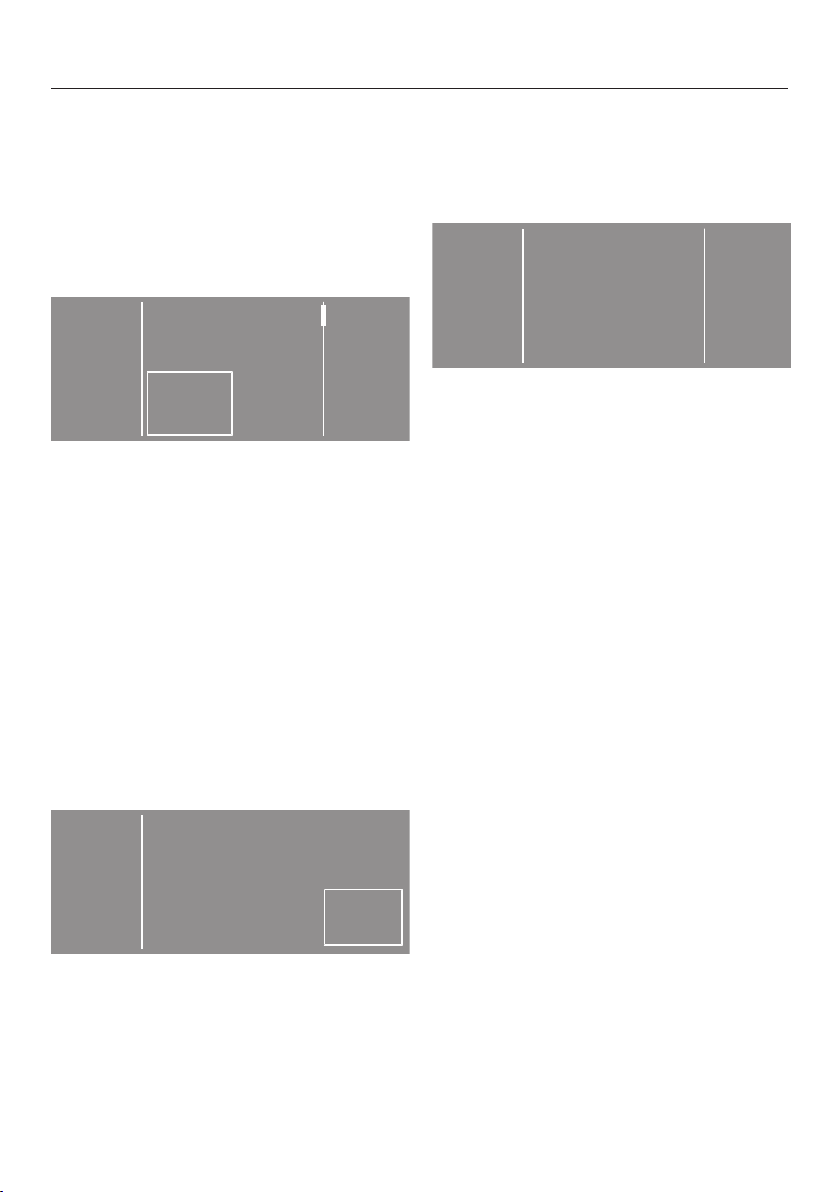

Examples on how to operate the appliance

Selection lists

The andarrows on the right of the

display indicate that further choices are

available.

The list scrolls down when the

sensor control is touched. The list

scrolls up when the sensor control is

touched.

The scroll bar indicates that further

options follow.

The currently selected value is marked

with a frame.

Touch the required value to select it.

Setting numerical values

To change a numerical value, use the

andarrows above or below the

numbers you want to change.

Touch theandarrows and confirm

with the OK sensor.

Exiting a submenu

Select the backsensor to exit a

submenu.

If a value is selected in a submenu but

not confirmed with OK, this value is

discarded by selecting the sensor

control.

Single selection

If there are no arrows, the selection is

limited to the displayed values.

The currently selected value is marked

with a frame.

Touch the required value to select it.

19

Page 20

Using for the first time

Language

deutsch

čeština

english

(AU)

dansk

Damage resulting from incorrect

installation and connection.

Installing and connecting the

washing machine incorrectly will

cause serious damage to property.

Please observe the instructions in

“Installation and connection”.

Emptying the drum

A swivel elbow for the drain hose and/

or assembly material may be stored in

the drum.

When commissioning the washing

machine for the first time, you will

have to define the settings for the

daily use of the appliance. Some

settings can only be configured

during the initial commissioning

process. After that, they must be

changed by Miele.

Complete the initial commissioning

process.

These settings are also described in

“Supervisor level”.

Setting the display language

You will be asked to select the language

for the display. You can change the

language at any time (see “Supervisor

level - Language”).

Pull open the door.

Remove the swivel elbow and

assembly material.

Shut the door with a gentle swing.

Switching on the washing machine

Press the button.

The welcome screen will light up.

20

Touch the orsensor until the

language you want appears in the

display.

Touch the sensor for the required

language.

The selected language is marked with a

frame and the display will change to the

next setting.

Page 21

Using for the first time

Brightness

–

70

OK

+

%

Yes No

Should the clock display not

be shown?

Time

12

OK

05:

Programme

packages

Standard

Pre-treat

mops

Standard

Separate rinse

OK

Confirm selection

Setting the display brightness

Set the desired brightness with the –

and + sensors and confirm your

selection with the OKsensor.

The display will change to the next

setting.

Confirming the time query

Touch the Yes or No sensor.

If you select Yes, the system will skip

the Clock displaysetting.

If you select No, the display will switch

to the Clock displaysetting.

Setting the time of day

Use the andsensor controls to

enter the time and confirm your entry

with the OK sensor.

The display will change to the next

setting.

Selecting programme packages

Touch the orsensor control until

the programme package you want

appears in the display.

Touch the sensor control of the

programme package.

The display shows the associated

programmes.

The activated programmes are marked

with a frame.

Touch the sensors for the

programmes.

21

Page 22

Using for the first time

Programme

packages

Disinfection

Continue

Payment

system

No payment

system

Programme

control

Pre-wash

water

Cold Hot

Main wash

water

Cold Hot

The programmes are activated (framed)

or deactivated (no frame).

Confirm with the OK sensor.

The display switches back to the

programme packages.

Select other programme packages or

confirm your selection with the

Nextsensor control.

The display will change to the Pre-wash

watersetting.

Setting up a payment system

If you wish to set up a payment system,

read the chapter “Supervisor level Payment system”.

If you do not wish to set up a payment

system, you can skip this step.

Selecting pre-wash water

Touch the Coldsensor if the washing

machine is only connected to the

cold water supply, or touch Hotif the

washing machine is connected to

both cold and hot water.

The display will change to the next

setting.

Selecting main wash water

Touch the Coldsensor if the washing

machine is only connected to the

cold water supply, or touch Hotif the

washing machine is connected to

both cold and hot water.

Touch the No payment system sensor.

The display will change to the next

setting.

22

Further information will appear in the

display.

Page 23

Using for the first time

1400

Disin. clean. cloths

85 °C

h

1:05

min

I 15

Removing the transit bars

The display will remind you to remove

the transit bars.

Damage resulting from failure to

remove the transit bars.

Failure to remove the transit bars can

result in damage to the washing

machine and to adjacent cabinetry or

appliances.

Remove the transit bars as described

in “Installation and connection”.

Confirm that the transit bars have

been removed with the OKsensor.

The following appears in the display:

Continue setting up as described in the

Operating instructions

Confirm the message with the OK

sensor.

Completing the commissioning process

To complete commissioning, the

Cleaning cloths thermal

disinfectionprogramme must be run

without laundry and without detergent.

If the power is interrupted prior to the

start of the first wash programme (e.g.

if the machine is switched off with the

button), the initial commissioning

process can be completed again.

Once a wash programme has been

running for over 20minutes, the initial

commissioning process does not need

to be performed again.

Turn on the water taps.

Turn the programme selector

toCleaning cloths thermal

disinfection.

Touch the Start/Stop sensor.

When the programme has finished, your

machine is ready for use for the first

time.

23

Page 24

1. Preparing the laundry

Damage due to foreign objects.

Foreign objects (e.g. nails, coins,

paper clips etc.) can cause damage

to garments and to components in

the machine.

Check the mops or the laundry

before washing and remove any

foreign objects.

Damage due to solvent-based

cleaning agents.

Cleaning agents containing benzine,

stain remover, etc., can damage

plastic parts.

When pre-treating garments, make

sure that any plastic parts (e.g.

buttons) do not come into contact

with cleaning agent.

Risk of explosion due to solvent-

based cleaning agents.

When using solvent-based

detergents, an explosive mixture may

develop.

Never use solvent-based cleaning

agents in the washing machine.

Sorting the washing items

Separate the mops, cleaning cloths

and pads.

Shake mops, cleaning cloths and

pads out well to get rid of coarse

soiling before placing them in the

drum.

Sorting the laundry

Empty all pockets.

Clean badly soiled areas and stains

on the textiles before washing.

Spillages should be carefully dabbed

off using a soft, colourfast cloth.

Sort the laundry by colour and by

care label. Most garments have a

textile care label in the collar or side

seam.

Useful tip: Do not wash items which

are specified by the manufacturer as

not washable on the care label

(symbol).

24

Page 25

2. Loading the washing machine

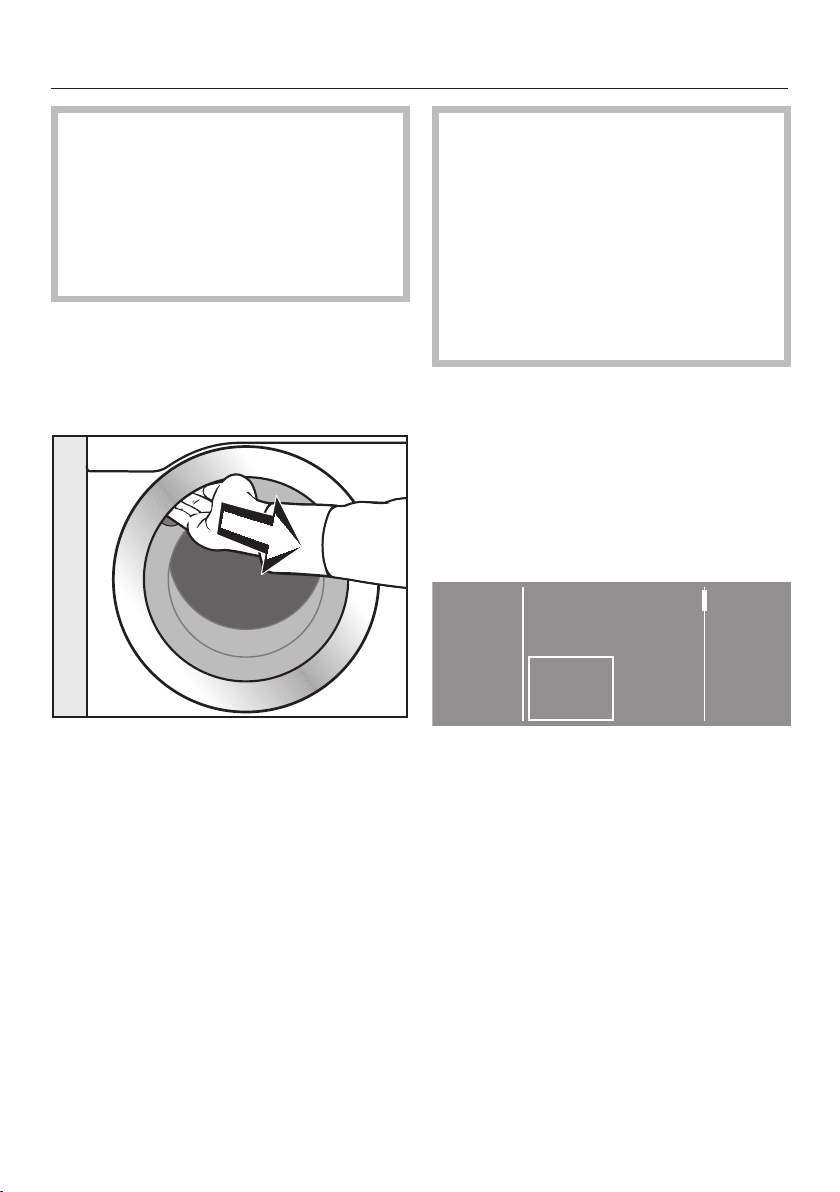

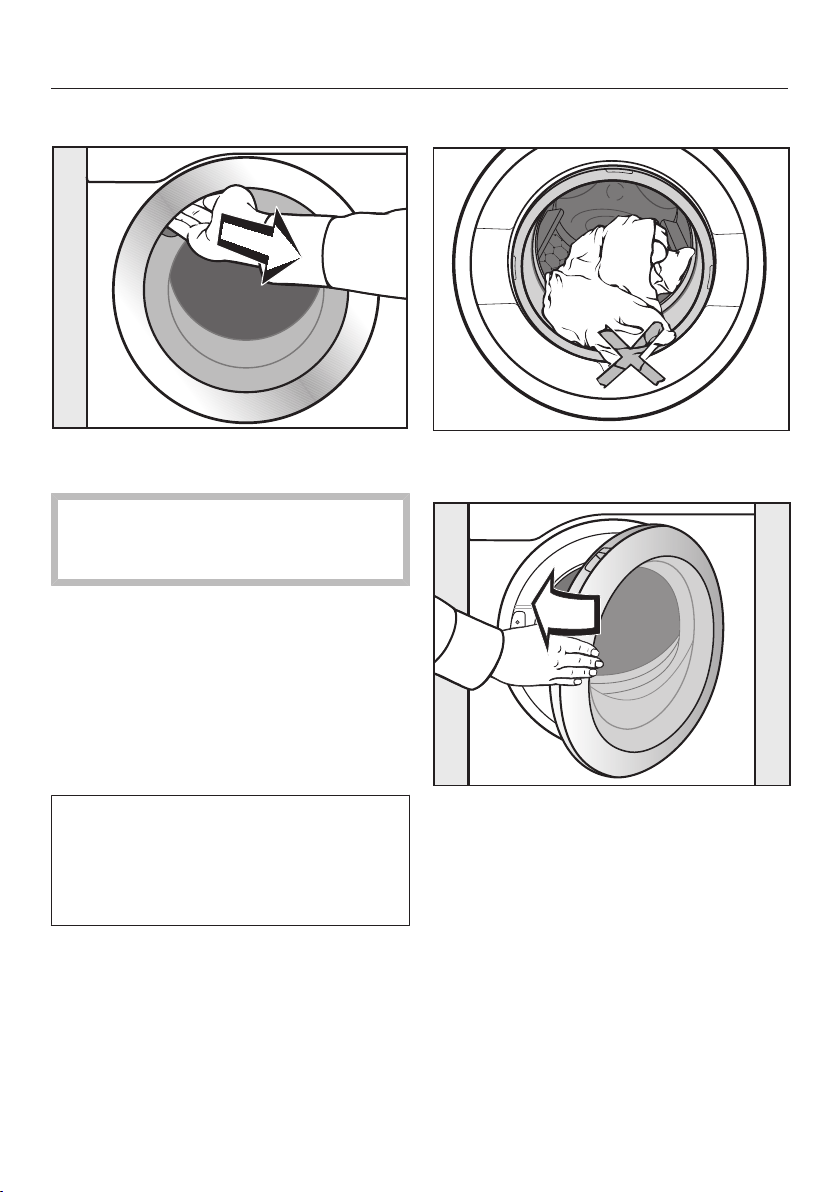

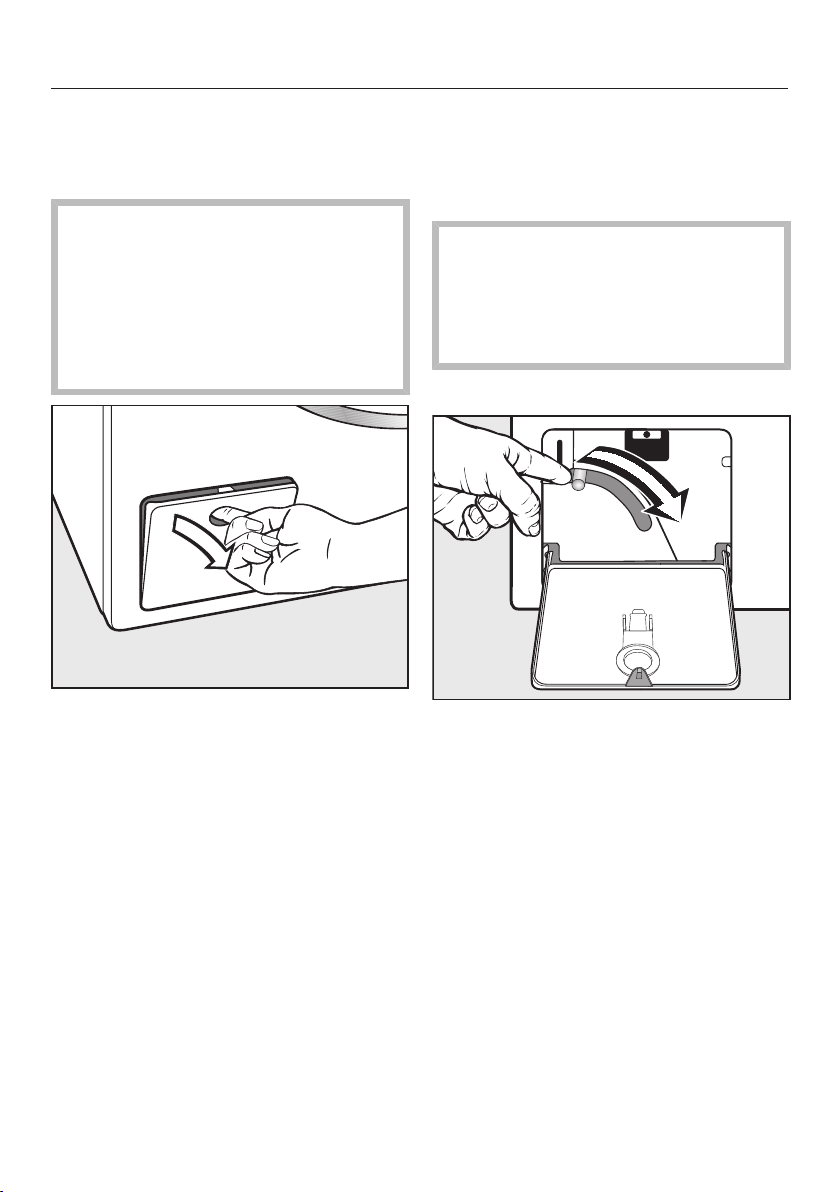

Opening the door

Reach under the door grip and pull

the door open.

Check the drum for pets or foreign

objects before loading it with

laundry.

Load the mops, cleaning cloths or

pads loosely in the drum.

Unfold the laundry and load loosely

into the drum.

Closing the door

Make sure that no items are caught

between the door and the seal.

Mixing both large and small items gives

better wash results and helps distribute

the load evenly during spinning.

The most efficient use of energy and

water is achieved when a full load is

washed. However, do not overload as

this reduces cleaning efficiency and

causes creasing.

Shut the door with a gentle swing.

25

Page 26

3. Selecting a programme

Further

progs

New mops

Curtains

Switching on the washing machine

Press the button.

Selecting a programme

Selecting standard programmes with the programme selector

Turn the programme selector to the

required programme.

The selected programme will be shown

in the display. The display will then

change to the main menu for that

programme.

Selecting further programmes with

the programme selector turned to

Turn the programme selector to the

position.

You can select the required programme

via the display.

Touch the orsensor control until

the programme you want appears in

the display.

26

Touch the sensor for that programme.

The display will change to the main

menu for that programme.

Page 27

4. Selecting programme settings

Temp.

40°C 60°C30°C

Spin speed

800

1000

400

0

1200

1400

Selecting the temperature

You can alter the preset temperature of

certain programmes.

Touch the Temperaturesensor.

The following will appear in the display:

Select the desired temperature.

The selected temperature is marked

with a frame.

Selecting the spin speed

You can alter the preset spin speed.

Touch the Spin speedsensor.

The following will appear in the display:

Select the desired spin speed.

The selected spin speed is marked with

a frame.

27

Page 28

4. Selecting programme settings

Extras

Pre-wash

Rinse plus

Further

selections

Finish at

Supervisor level

Selecting Extras

You can select Extras for the wash

programmes.

For some programmes, an Extra is

offered directly in the main menu.

Touch the sensor of the Extra to

activate it.

For some programmes, you select

Extras in the Extrassubmenu.

Touch the Extrassensor.

Select one or two of the available

Extras in succession.

Not all Extras can be selected with

every programme. If an Extra is not

listed, it is not permitted for use with

this wash programme.

Selecting further options

You can select a delay start time or

change the settings of the washing

machine.

Touch the Further selections

sensor.

The following will appear in the display:

Select the desired option.

The display will change to the submenu

for that option.

Delay start is not possible for some

programmes.

28

Page 29

5. Adding detergent

There are several options for adding

detergent.

Detergent dispenser drawer

Any detergent suitable for automatic

front loading washing machines can be

used with this appliance.

Detergent dispensing

Please follow the detergent

manufacturer's instructions in relation

to dosage.

Adding too much detergent will lead

to excessive foaming.

Avoid adding excess detergent.

The amount to dispense will depend on:

- the amount of laundry

- the degree of soiling of the laundry

- the water hardness

Water

hardness

range

soft (I) 0-1.5 0-8.4

medium (II) 1.5-2.5 8.4-14

hard (III) above 2.5 above 14

Check with your local water supplier if

you do not know the water hardness in

your area.

Hardness in

mmol/l

German scale

°dH

Adding detergent

Pull out the detergent dispenser

drawer and add detergent to the

compartments.

Detergent for the pre-wash

(divide the total recommended

amount as follows: ⅓ to

compartment and ⅔ to

compartment )

Detergent for the main wash

Fabric softener or liquid starch

For disinfection programmes, the

andcompartments can be

filled with detergent for the main wash

if you have not selected Pre-wash.

29

Page 30

5. Adding detergent

Adding fabric softener or liquid starch separately

Select the Separate rinseprogramme.

Change the spin speed if necessary.

Add the fabric softener or the liquid

starch to the compartment. Do not

exceed the maximum level mark.

Touch the Start/Stopsensor.

This will be automatically dispensed in

the final rinse. At the end of the wash

programme a small amount of water

remains in the compartment.

Dye removers and dyes

Damage due to colour run/dye

removers.

Colour run and dye removers can

cause corrosion in the washing

machine.

Do not use colour run or dye

removers in this washing machine.

Only use dyes suitable for use in a

washing machine. The manufacturer's

instructions on the packaging must be

observed.

External dispensing

The washing machine is pre-equipped

for connection to an external detergent

dispensing system. A separate

conversion kit for external dispensing

systems is required. This must be fitted

by a Miele authorised service

technician.

30

Page 31

6. Starting the programme - the end of the programme

Starting a programme

The programme can be started once

the Start/Stop sensor is flashing on and

off.

Touch the Start/Stop sensor.

The door will lock ( symbol) and the

wash programme will start.

If a delay start time has been selected,

this will count down in the display until

the programme starts.

At the end of the delay start time or

immediately after the programme has

started, the programme duration will

appear in the display. The programme

sequence is also shown in the display.

Useful tip: Touch the sensor control

to display the set temperature, spin

speed and any set Extras.

At the end of the programme

The door remains locked during the

anti-crease phase. However, the door

can be unlocked at any time by

touching the Start/Stop sensor.

Removing the laundry

Pull open the door.

Remove the laundry.

Items left in the drum could discolour

other items in the next wash or

become discoloured themselves.

Remove all items from the drum.

Check the folds in the door seal for

any small articles, e.g. buttons, which

might be lodged there.

Useful tip: For safety reasons, close the

door when the washing machine is not

in use. Otherwise there is a danger of

objects being placed inadvertently in

the drum. If these remain unnoticed and

were washed in the next load, they

could damage the laundry. An open

door is also a danger to pets and

children.

Switch the washing machine off with

the button.

Useful tip: Leave the detergent

dispenser drawer slightly open to allow

it to dry.

31

Page 32

Delay start

Add laundry

Cancel

programme

Start programme

immediately

The Delay start function can be used to

set the time until the programme starts

or the programme finish time (see

“Supervisor level - Delay start”).

Selecting Delay start

Touch the Further

selectionssensor.

Select the Finish at, Start at or

Start inoption.

Use the andsensors to enter the

hours and minutes and confirm your

entry with the OKsensor.

The minutes entry moves to the next

“full quarter of an hour” and can then

be adjusted in 15-minute increments.

Starting Delay start

Touch the Start/Stopsensor.

The door will lock and the time

remaining until the programme starts

will appear in the display.

Cancelling or changing Delay start

Touch the Start/Stop sensor.

The following will appear in the display:

Touch the Start programme immediately

sensor.

The wash programmes starts

immediately.

or

Touch the Cancel programme sensor.

The programme start is cancelled and

the Start/Stopbutton flashes on and

off.

32

Page 33

Programme chart

Mop programmes

- A pre-spin* and a pre-rinse cycle are carried out before the main wash.

Mops 60°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes Use specialist detergents.

1400 rpm Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 2-5*

Mops plus 40°C to 90°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - Use specialist detergents.

- The pre-set temperature can be altered.*

1400 rpm Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 2-5*

Thermal disinfection 85°C/15min Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - Further disinfection methods can be selected.*

- Use powder detergent containing a bleaching agent.

1400 rpm Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 3-6*

Chemo-therm. disinfection 60°C/20min Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - Further disinfection methods can be selected.*

- Use specialist detergents. Observe the country-specific

guidelines for disinfection.

1400 rpm Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 3-6*

* Settings can be altered in the Supervisor level.

33

Page 34

Programme chart

Cloths programmes

- A pre-rinse cycle is carried out before the main wash.

Cloths 60°C Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes Use specialist detergents.

1400 rpm Extras: Pre-wash Rinse cycles: 2-5*

Cloths plus 40°C to 90°C Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes - Use specialist detergents.

- The pre-set temperature can be altered.*

1400 rpm Extras: Pre-wash Rinse cycles: 2-5*

Thermal disinfection 85°C/15min Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes Use specialist detergents.

1400 rpm Extras: Pre-wash Rinse cycles: 3-6*

Chemo-therm. disinfection 70°C/10min Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes - Further disinfection methods can be selected.*

- Use specialist detergents. Observe the country-specific

guidelines for disinfection.

1400 rpm Extras: Pre-wash Rinse cycles: 3-6*

* Settings can be altered in the Supervisor level.

34

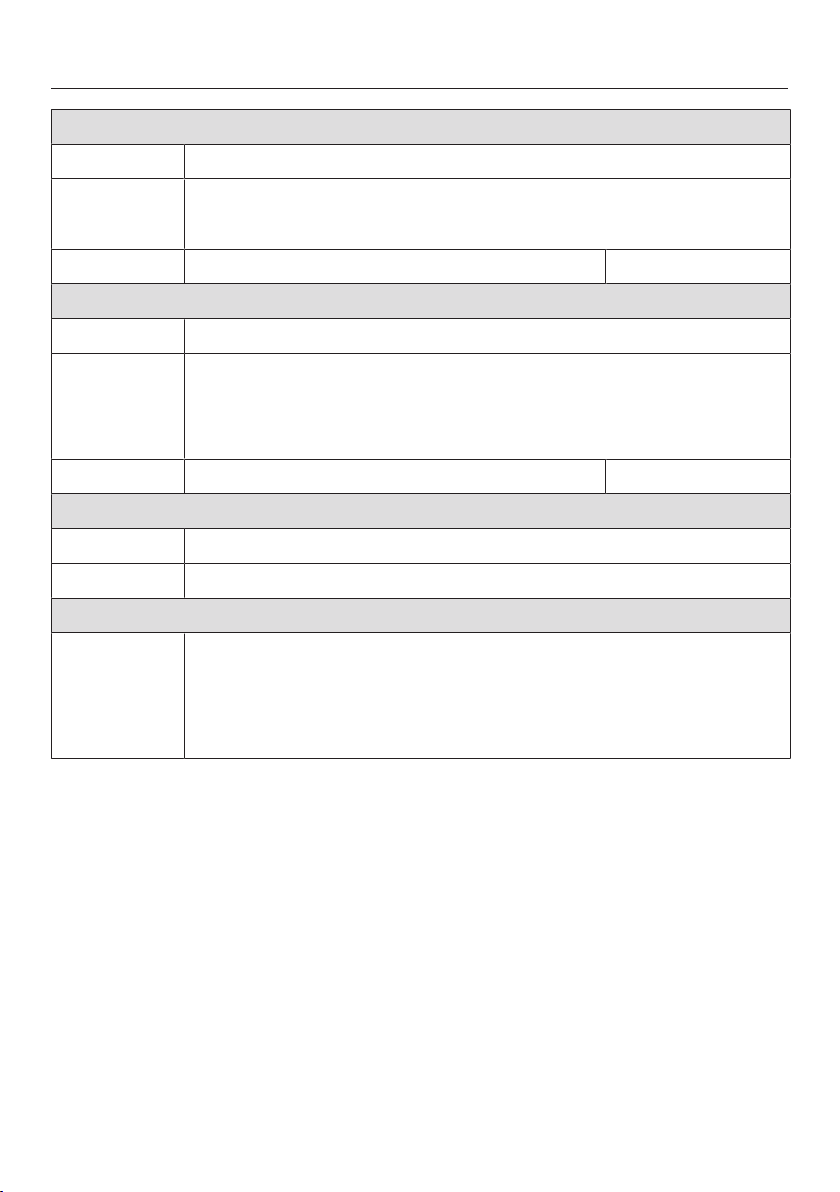

Page 35

Programme chart

CottonsPRO60°C Max. load 8.0 kg

Items Mixed fibre textiles (50% cotton and 50% polyester)

Notes - Extra energy-efficient wash programme for commercial cotton

or cotton/synthetic blend textiles with moderate levels of soiling,

e.g. workwear.

1400 rpm Extras: Pre-wash Rinse cycles: 2

Pads 40°C Max. load 1.5 kg

Items Microfibre polishing pads and buffers

Notes - A pre-rinse cycle is carried out before the main wash.

- Use specialist detergents.

1400 rpm Extras: 2nd Pre-rinse Rinse cycles: 3

Programme packages

You can select various programmes packages. The programmes selected from the

programme packages are displayed under the Further programmeslist.

Standard

New mops 60°C to 90°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - For washing new mops before first use. Manufacturing residues

are washed out of the fibres. This increases the amount of water

absorbed by the fibres when mopping.

- Use universal or colour detergents.

- Do not use fabric softener.

1400 rpm Extras: Microfibre Rinse cycles: 2

35

Page 36

Programme chart

Curtains cold to 40°C Max. load 3.0 kg

Items Curtains specified as machine-washable by the manufacturer

Notes - A pre-rinse cycle is carried out before the main wash.

- For curtains which crease easily, deselect the spin speed.

600 rpm Extras: Pre-wash Rinse cycles: 3

Separate rinse Max. load 8.0 kg

Items Fabrics that only need to be rinsed and spun

Notes - For rinsing residual detergent.

- For removing coarse soiling before the main wash.

- Make sure you select the appropriate spin speed.

1400 rpm Rinse cycles: 2

Drain/Spin Max. load 8.0 kg

Notes Make sure you select the appropriate spin speed.

1400 rpm

Clean machine 70°C No load

36

For cleaning the suds container and the drainage system.

- Add universal detergent to the compartment.

- Use the Clean machineprogramme regularly if you frequently

use disinfection programmes.

Page 37

Programme chart

Pre-treat mops programmes (ready to use - rtu)

- Mops are washed and pre-treated in one cycle.

- A pre-spin* and a pre-rinse cycle are carried out before the main wash.

- There is no water intake via the fabric softener compartment during the

disinfection process.

Mops +rtu 60°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes Add the pre-treating agent via the fabric softener compartment or

the external dispensing system.

0–60 sec Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 2-5*

Mops plus + rtu 40°C to 90°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes Add the pre-treating agent via the fabric softener compartment or

the external dispensing system.

0–60 sec Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 2-5*

Disinfect mops + rtu 85°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - Further disinfection methods can be selected.*

- Use powder detergent containing a bleaching agent.

0–60 sec Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 3-6*

Disinfect mops + rtu 70°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - Further disinfection methods can be selected.*

- Use specialist detergents. Observe the country-specific

guidelines for disinfection.

0–60 sec Extras: 2nd Pre-rinse , Microfibre Rinse cycles: 3-6*

Mops rtu Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - For pre-treating clean mops.

- Add the pre-treating agent via the fabric softener compartment

or the external dispensing system.

0–60 sec Rinse cycles: 1

* Settings can be altered in the Supervisor level.

37

Page 38

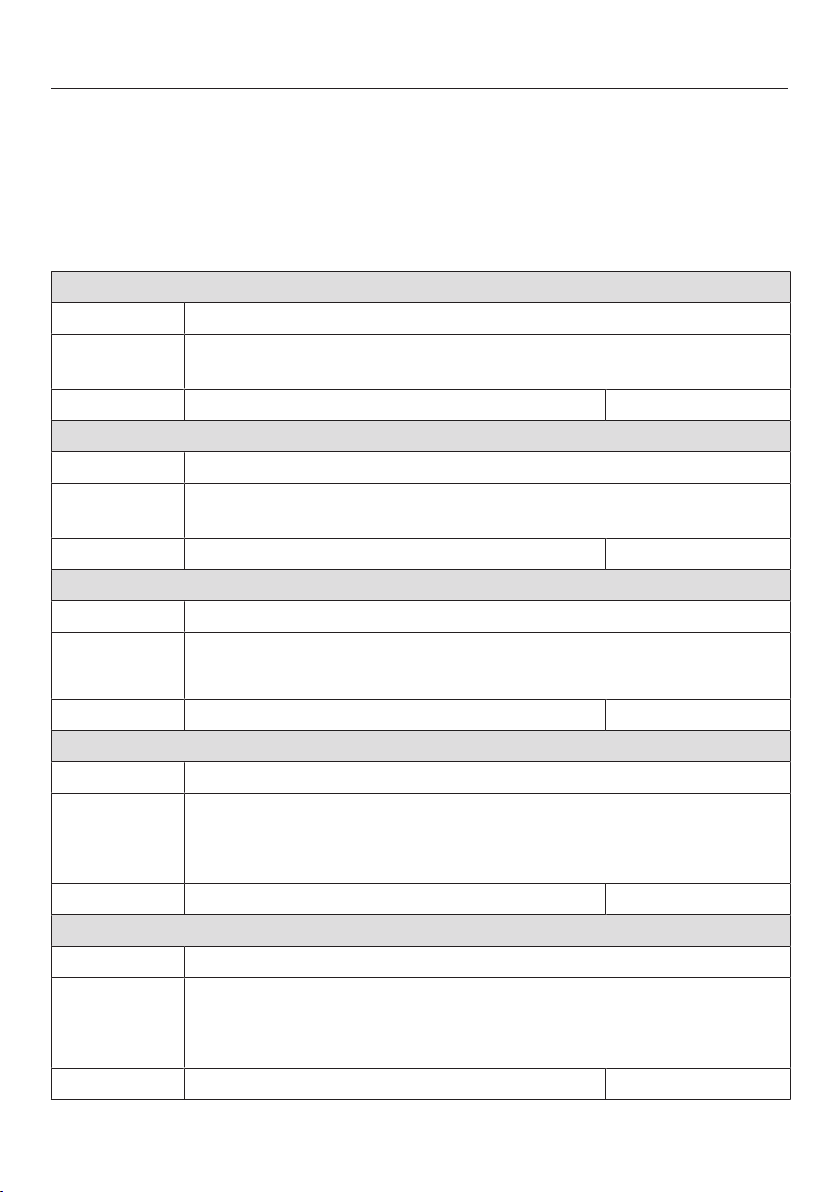

Programme chart

Pre-treat cloths programmes (ready to use - rtu)

- Cleaning cloths are washed and pre-treated in one cycle.

- A pre-rinse cycle is carried out before the main wash.

- There is no water intake via the fabric softener compartment during the

disinfection process.

Cloths + rtu 60°C Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes Add the pre-treating agent via the fabric softener compartment or

the external dispensing system.

0–60 sec Extras: Pre-wash Rinse cycles: 2-5*

Cloths plus + rtu 40°C to 90°C Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes Add the pre-treating agent via the fabric softener compartment or

the external dispensing system.

0–60 sec Extras: Pre-wash Rinse cycles: 2-5*

Disinfect cleaning cloths + rtu 85°C Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes - Further disinfection methods can be selected.*

- Use specialist detergents.

0–60 sec Extras: Pre-wash Rinse cycles: 3-6*

Disinfect cleaning cloths+ rtu 70°C Max. load 4.0 kg

Items Cotton, mixed fibre and microfibre cloths

Notes - Further disinfection methods can be selected.*

- Use specialist detergents. Observe the country-specific

guidelines for disinfection.

0–60 sec Extras: Pre-wash Rinse cycles: 3-6*

Cloths rtu Max. load 4.0 kg

Items Cotton, mixed fibre or microfibre cloths

Notes - For pre-treating clean cleaning cloths.

- Add the pre-treating agent via the fabric softener compartment

or the external dispensing system.

0–60 sec Extras: Pre-wash Rinse cycles: 1

* Settings can be altered in the Supervisor level.

38

Page 39

Programme chart

Ready to use (rtu)

- The residual moisture after pre-treatment is selected with the sensor control.

Mops + rtu 40°C to 90°C Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - Mops are washed and finished in one cycle.

- A pre-spin* and a pre-rinse cycle are carried out before the main

wash.

- Add the pre-treating agent via the fabric softener compartment

or the external dispensing system.

– Extras: Pre-rinse, Microfibre Rinse cycles: 2-5*

Mops rtu cold Max. load 8.0 kg

Items Cotton, mixed fibre or microfibre mops

Notes - For finishing clean mops.

- Add the pre-treating agent via the fabric softener compartment

or the external dispensing system.

– Rinse cycles: 1

* Settings can be altered in the Supervisor level.

39

Page 40

Programme chart

Workwear

Oil/fat special 60°C to 90°C Max. load 8.0 kg

Items Work coats, work jackets, hats, cleaning cloths made from cotton

or mixed fibres

Notes - Activate Pre-wash for heavy soiling.

- Use liquid detergent.

1400 rpm Extras: Pre-wash Rinse cycles: 3

Dust/flour special 40°C to 90°C Max. load 8.0 kg

Items Cotton or mixed fibre workwear, table cloths, or cleaning cloths

soiled with dust or flour

Notes - The automatic pre-rinse removes any coarse soiling. Add a

second pre-rinse for very heavy levels of soiling.

- Select Pre-wash for stubborn stains.

1400 rpm Extras: Pre-wash , Pre-rinse Rinse cycles: 3

Intensive wash 60°C to 90°C Max. load 8.0 kg

Items Heavily soiled workwear made from cotton, linen, and mixed fibres

Notes A particularly good wash and rinse result is achieved by a high

water level.

1400 rpm Extras: Pre-wash Rinse cycles: 2

40

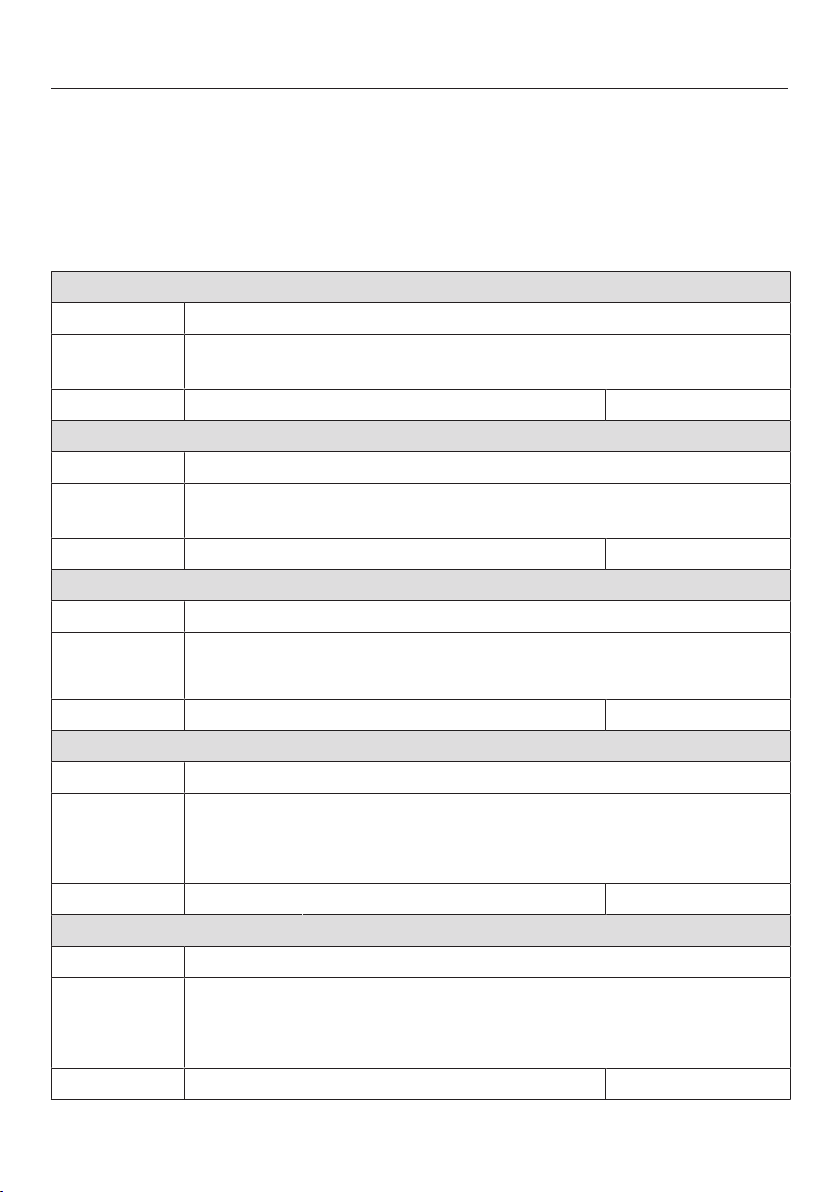

Page 41

Programme chart

Standard programmes

White items 90°C Max. load 8.0 kg

Items Cotton, linen, and mixed fibre textiles

Notes An additional pre-rinse can be programmed.*

1400 rpm Extras: Pre-wash Rinse cycles: 2-5*

Coloured items 30°C to 60°C Max. load 8.0 kg

Items Cotton, linen, and mixed fibre textiles

Notes - For dark coloured fabrics use a colour detergent or liquid

detergent.

- An additional pre-rinse can be programmed.*

1400 rpm Extras: Pre-wash Rinse cycles: 2-5*

Minimum iron 30°C to 60°C Max. load 4.0 kg

Items Synthetic, mixed fibre and easy care cotton fabrics

Notes - Reduce the final spin speed for fabrics which crease easily.

- An additional pre-rinse can be programmed.*

1200 rpm Extras: Pre-wash Rinse cycles: 2-4*

Express 20°C to 60°C Max. load 4.0 kg

Items Cotton garments that have hardly been worn or are only very

lightly soiled

1400 rpm Extras: Rinse plus Rinse cycles: 1

Lightweight curtains cold to 40°C Max. load 3.0 kg

Items Curtains specified as machine-washable by the manufacturer

Notes For curtains which crease easily, deselect the spin speed.

600 rpm Extras: Pre-wash, Rinse plus Rinse cycles: 2

* Settings can be altered in the Supervisor level.

41

Page 42

Extra options

You can supplement the wash

programmes with Extras.

Not all Extras can be selected with

every programme. If an Extra is not

listed, it is not permitted for use with

this wash programme.

Selecting Extras

For some programmes, an Extra is

offered directly in the main menu.

Touch the sensor of the Extra to

activate it.

For some programmes, Extras are

selected in the Extrassubmenu.

Touch the Extrassensor.

Select one or two of the Extras

available.

Pre-wash

A pre-wash can be added for heavily

soiled laundry. Coarse soiling is

loosened and removed before the main

wash.

Pre-rinse

The laundry is rinsed before the main

wash to remove larger quantities of

soiling, e.g. dust, sand.

Rinse plus

An additional rinse cycle can be

activated to achieve a particularly good

wash result.

Microfibre

Microfibre mops are gently cooled at

the end of the main wash cycle.

42

Page 43

Special features in the programme sequence

Spinning

Final spin speed

When a programme is selected, the

maximum spin speed for this wash

programme is shown in the display.

You can reduce the final spin speed.

However, you cannot select a final spin

speed higher than that shown in the

chart.

Interim spin

There is a spin cycle after the main

wash and between the rinses. A

reduction in the final spin speed will

also reduce the interim spin speed

accordingly.

Deselecting the interim spin and the final spin

Select the programme setting Spin

speed 0.

After the last rinse cycle, the water will

be pumped away and the anti-crease

phase will switch on.

Spinning for mop and cleaning cloth programmes

In pre-treat programmes for mops and

cleaning cloths, the residual moisture of

the load can be set using either the

Spin duration or the Residual

moisture sensor control. The stored

spin speeds can be altered (see

“Supervisor level”).

Anti-crease

At the end of the programme, the drum

continues to turn at intervals for up to

30minutes to help prevent creasing.

The door can be opened at any time

during the anti-crease phase.

There is no anti-crease phase at the

end of some programmes.

43

Page 44

Changing the programme sequence

Changing a programme

After the start of a programme, it is no

longer possible to select a different

programme.

You will need to cancel the current

programme before you can select a

different one.

If the programme selector is changed,

Programme change not possible will

appear in the display. The text

disappears when the programme

selector is set to the original

programme.

Cancelling a programme

You can cancel a programme at any

time after it has started.

Disinfection programmes can only be

cancelled with a PIN code.

Touch the Start/Stopsensor.

Select Cancel programme.

The suds will be pumped away. The

programme is cancelled. The door lock

is released.

If you want to select a different

programme:

Close the door.

Select the required programme.

Add detergent to the detergent

dispenser drawer, if necessary.

Touch the Start/Stopsensor.

The new programme will start.

Switching on the washing machine after an interruption to the power supply

If the washing machine is switched off

with the button during a wash

programme, the programme will be

interrupted.

Switch it back on with the button.

Note the message in the display.

Touch the Start/Stopsensor.

The programme will also be interrupted

if power is interrupted by a power cut.

When power is restored, confirm the

message in the display with OK.

Pull open the door.

Remove the laundry.

44

Touch the Start/Stopsensor.

The programme will continue.

Page 45

Changing the programme sequence

Add laundry

Cancel

programme

Adding or removing laundry

You can add or remove items during the

first few minutes after the programme

has started.

Touch the Start/Stopsensor.

The following will appear in the display:

Touch the Add laundry sensor.

The programme will stop and the door

will unlock.

Risk of chemical burns from

detergent.

When adding or removing laundry

during the main wash, your skin may

come into contact with detergent,

particularly if the detergent is

dispensed externally.

Take care when placing your hands

inside the drum.

If suds have come into contact with

the skin, rinse off immediately with

lukewarm water.

Once a programme has started

successfully, the washing machine

cannot recognise any adjustment to

the load.

For this reason, if laundry is added or

removed after the start of a

programme, the machine will always

complete the programme cycle

assuming a full load.

The door cannot be opened, if:

- The suds temperature is above 55°C.

The safety lock will remain activated if

the temperature in the drum is above

55°C. The lock will not deactivate until

the temperature has dropped to below

55°C.

Pull open the door.

Add laundry or remove individual

items.

Close the door.

Touch the Start/Stopsensor.

The wash programme will continue.

45

Page 46

Cleaning and care

Risk of electric shock!

Only ever perform cleaning and

maintenance work when the

appliance is disconnected from the

power.

Disconnect the washing machine

from the mains electricity supply.

Cleaning the external casing and fascia panel

Damage caused by cleaning

agents.

Solvent based cleaning agents,

abrasive cleaners, glass cleaners or

multi-purpose cleaning agents can

cause damage to plastic surfaces

and other parts.

Do not use any of these cleaning

agents.

Risk of damage due to ingress of

water.

The pressure of a water jet can

cause water to get into the washing

machine, resulting in damage to

components.

Do not spray the washing machine

with a water jet.

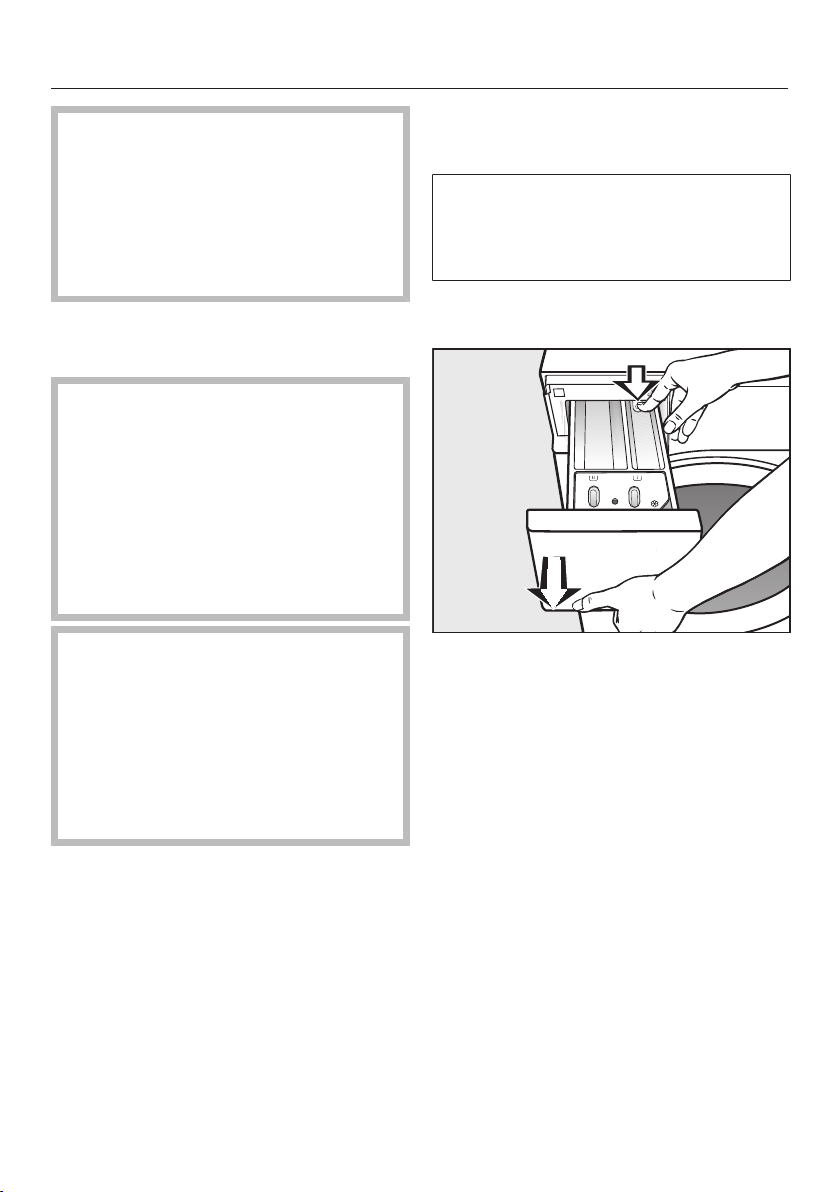

Cleaning the detergent dispenser drawer

Washing at low temperatures and the

use of liquid detergent can lead to a

build-up of mould and bacteria in the

detergent dispenser drawer.

For hygiene reasons, clean the entire

drawer at regular intervals.

Pull out the detergent dispenser

drawer until a resistance is felt. Press

down the release button and at the

same time pull the drawer right out of

the machine.

Clean the detergent dispenser drawer

with warm water.

Clean the casing and control panel

with a mild cleaning agent or soap

and water and dry both with a soft

cloth.

The drum and other stainless steel

parts can be cleaned using a suitable

stainless steel cleaning agent.

46

Page 47

Cleaning and care

Cleaning the siphon and the channel

Pull the siphon out of the

compartment.

Clean the siphon under warm running

water. Clean the siphon tube in the

same way.

Refit the siphon.

Cleaning the detergent dispenser drawer housing

Use a bottle brush to remove

detergent residues and limescale

from the jets inside the detergent

dispenser drawer housing.

Replace the detergent dispenser

drawer.

Useful tip: Leave the detergent

dispenser drawer slightly open to allow

it to dry.

Clean the fabric softener channel

using a brush and warm water.

47

Page 48

Cleaning and care

Cleaning the drum, suds container and drainage system

The drum, suds container, and drainage

system can be cleaned if necessary.

Start the Clean machine programme.

Add powder detergent to the

compartment in the detergent drawer.

At the end of the programme, check

the inner drum and remove any

coarse residues.

Use the Clean machineprogramme

regularly if you frequently use

disinfection programmes.

Cleaning the filters in the water inlet

The washing machine has filters to

protect the water inlet valves. Check

these filters about every 6 months or

more often if there are frequent

interruptions to the external water

supply.

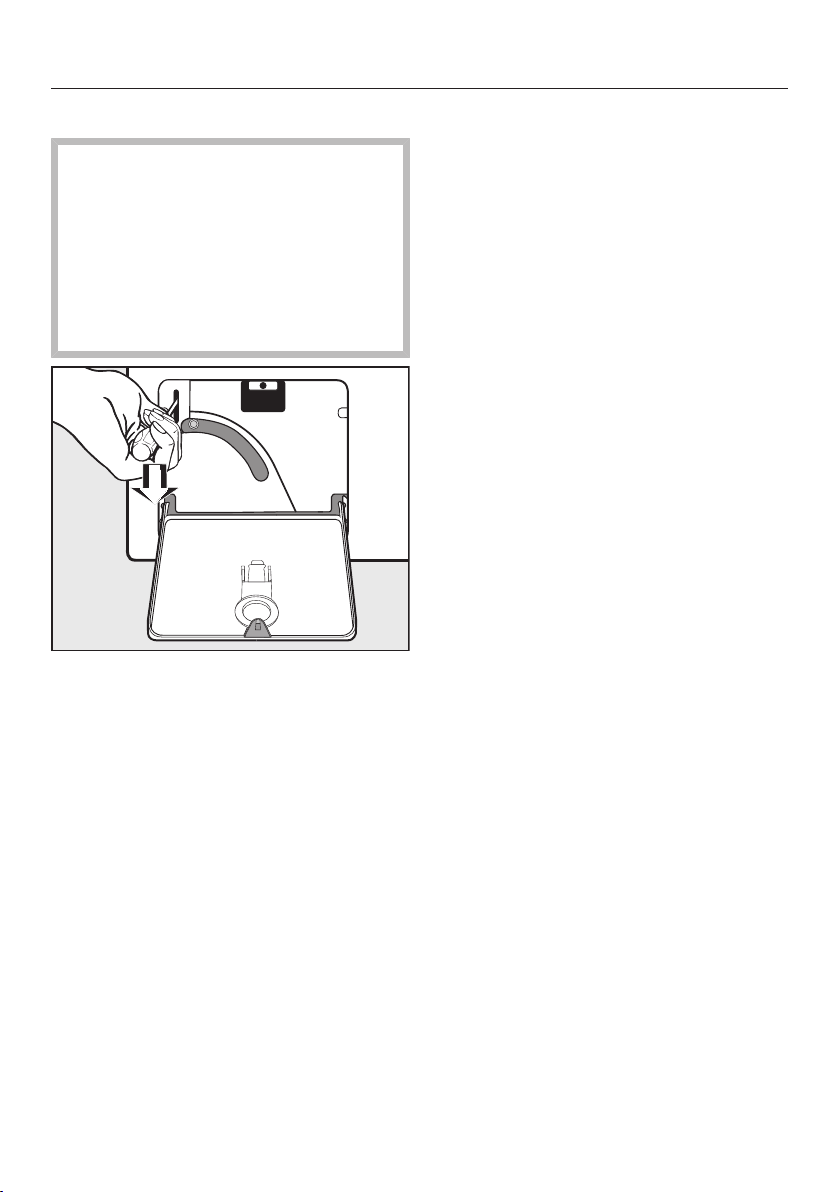

Cleaning the filters in the inlet hoses

First turn off the tap.

Unscrew the inlet hose.

Remove the rubber seal from the

recess.

Using combination or pointed pliers,

take hold of the plastic filter bar and

remove the filter.

Clean the plastic filter.

Reassemble the filter and seal in the

reverse order and reconnect the

hose.

48

Make sure there is no water leaking

from the threaded union.

Tighten the threaded union.

Cleaning the filters in the water inlet valves

Using pliers, carefully loosen the

ribbed plastic nut on the inlet valve

and unscrew.

Page 49

Withdraw the filter at the bar with

pointed pliers and rinse it clean under

running water. Reassemble the filter

and seal in the reverse order and

reconnect the hose.

Replace the filters after cleaning.

Cleaning and care

49

Page 50

Problem solving guide

With the help of the following guide, minor faults in the performance of the

appliance, some of which may result from incorrect operation, can be remedied

without contacting Miele. This will save you time and money because you will not

need a service call.

Please note, however, that a call-out charge will be applied to unnecessary service

visits where the problem could have been rectified as described in these operating

instructions.

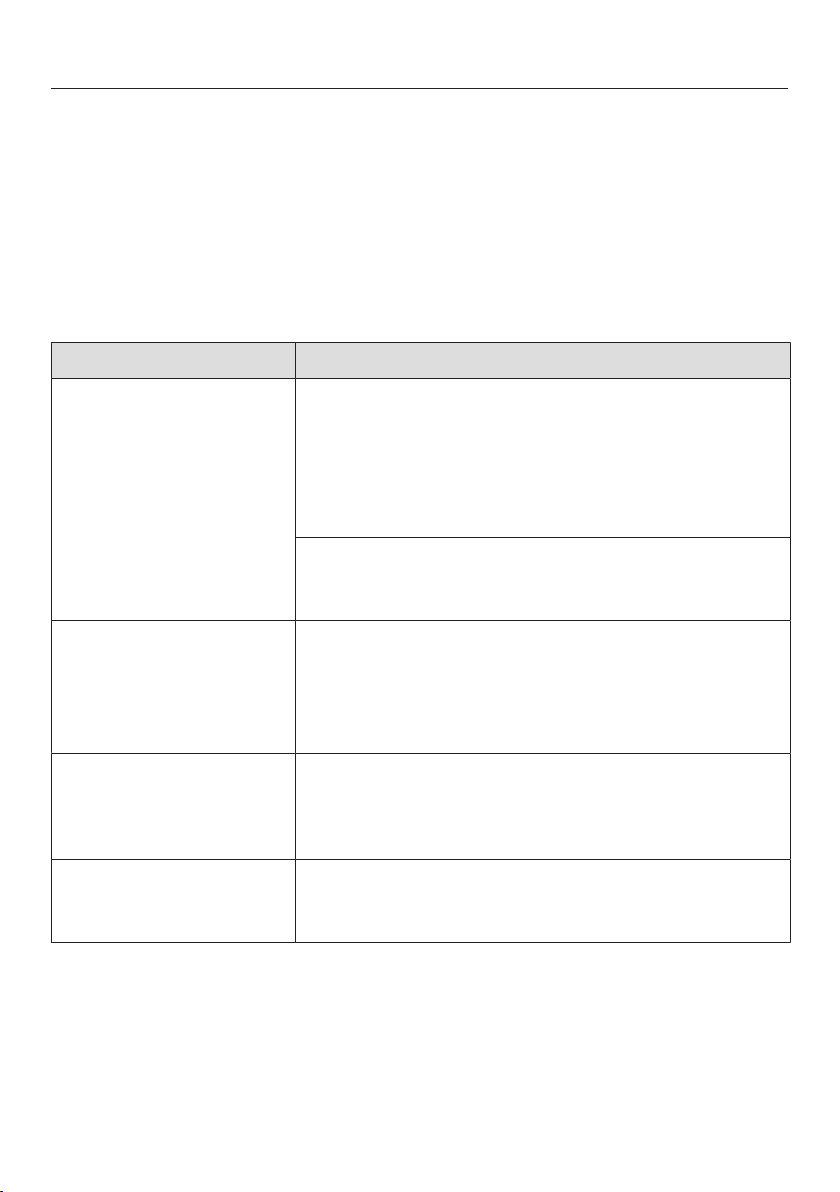

The programme does not start

Problem Possible cause and remedy

The display remains

dark and the Start/Stop

sensor does not light up

or flash.

The following appears

in the display:

Door will not lock. Call

Miele.

The programme does

not start when Spin is

selected.

The display is dark and

the Start/Stop sensor is

flashing slowly.

There is no power to the machine.

Check whether the washing machine is switched

on.

Check whether the washing machine is connected

to the electricity supply.

Check whether the circuit breaker has tripped.

The washing machine has switched off automatically

to save energy.

Switch it back on with the button.

The door is not closed properly. The door lock could

not engage.

Close the door again.

Start the programme again.

If the fault message appears again, contact Miele.

You have not yet completed the initial commissioning

process.

Follow the instructions in the section Completing

the commissioning process in these instructions.

The display has switched off automatically to save

energy.

Touch any sensor. The display will switch on again.

50

Page 51

Problem solving guide

Programme cancellations and fault messages

Problem Possible cause and remedy

Water drainage fault.

Water intake fault.

Turn on the tap.

Waterproof system

activated

Disinfection

temperature not

reached

Fault F. If restart

fails, call Miele.

The water outlet is blocked or restricted.

Call Miele.

The water inlet is blocked or restricted.

Check whether the tap is turned on properly.

Check whether the inlet hose is kinked.

The water pressure is too low.

Switch on the Low water pressuresetting (see

“Supervisor level - Low water pressure”).

The filters in the water inlet are blocked.

Clean the filters (see “Cleaning and care - Cleaning

the filters”).

The water protection system has reacted.

Turn off the tap.

Call Miele.

The required temperature was not reached during the

disinfection programme.

The washing machine has not carried out the

disinfection cycle correctly.

Start the programme again.

There is a fault.

Disconnect the washing machine from the mains

electricity supply.

Wait at least 2 minutes before reconnecting the

washing machine to the electricity.

Then switch the washing machine on again.

Start the programme again.

If the fault message appears again, contact Miele.

51

Page 52

Problem solving guide

A fault message appears in the display

1

Problem Possible cause and remedy

Dispenser container

empty

One of the detergent containers for external dosing is

empty.

Refill the detergent containers.

Container 1 empty

External detergent container 1 is almost empty.

The message can refer to containers 1 to 6.

Refill the detergent container.

Reset the container's early-warning counter (see

“Supervisor level - Early-warning counter”).

Check hot water

intake

The hot water supply is blocked or restricted.

Check whether the hot water tap is turned on

properly.

Check whether the inlet hose is kinked.

Align the machine.

Laundry not properly

spun.

The selected spin speed was not reached during the

final spin due to excessive imbalance.

Check that the washing machine is standing level.

Start the spin cycle again.

Machine is leaking

The washing machine or the drain valve is leaking.

Turn off the tap.

Call Miele.

1

The messages will appear at the end of the programme and when the washing

machine is switched on and need to be confirmed with the OKsensor.

52

Page 53

Problem solving guide

An unsatisfactory wash result

Problem Possible cause and remedy

Liquid detergent does

not give the required

result.

White residues which

look like powder