Operating and Installation Instructions

PT 8257 WP

PT 8337 WP

To prevent accidents

and machine damage

read these instructions

before installing or use.

en-US

M.-Nr. 09 390 530

2

Contents

IMPORTANT SAFETY INSTRUCTIONS ..........................................................4

Caring for the environment ...................................................................7

General description of the appliance ...........................................................8

Operating panel .............................................................................9

Drying....................................................................................11

Before first use .............................................................................11

Preparing the laundry ........................................................................11

1. Turn on the dryer .........................................................................12

2. Load the laundry..........................................................................12

3. Select a program .........................................................................13

4. Select [ "Blockplus" (if desired) ............................................................13

5. Adjust the program (if desired)...............................................................14

6. Select Delay Start (if desired) ................................................................15

7. Start a program...........................................................................16

8. End of program...........................................................................16

Extra features .............................................................................17

Skip or repeat program sequences .............................................................17

Program stop ..............................................................................17

Canceling a program ........................................................................17

K Information ...............................................................................18

Program ..................................................................................19

Estates ...................................................................................19

Program guide.............................................................................21

Basic programs ............................................................................21

Comforters ................................................................................23

Cleaning Contractors ........................................................................23

Fire Department ............................................................................24

Professional cleaners ........................................................................24

Chip card use / Coin mechanism .............................................................26

Drying using the coin mechanism C 4060 / C 4065 / C 4070 .........................................26

Cleaning and care ..........................................................................27

Cleaning the lint filter ........................................................................27

Dryer .....................................................................................27

Heat exchangers ...........................................................................28

Frequently asked questions .................................................................29

Fault messages.............................................................................29

IMPORTANT SAFETY INSTRUCTIONS .........................................................32

Installation ................................................................................33

Install dryer and heat pump ...................................................................34

Leveling the dryer ...........................................................................35

Installation on an elevated base ................................................................35

Coin mechanism ............................................................................35

Communication module XKM RS232 ............................................................35

Electrical connection ........................................................................36

Intake air, ambient air ........................................................................36

Condensate drain ...........................................................................36

Technical Data.............................................................................37

Quick Guide...............................................................................39

3

IMPORTANT SAFETY INSTRUCTIONS

Explanation of safety instructions and

warnings on the machine

Read the operating instructions.

Read all the instructions, e.g. the installation

instructions.

Caution, hot surfaces.

Caution, voltage up to 1000 volts.

Grounding

READ AND SAVE THESE INSTRUCTIONS

,

Proper use of the dryer

The dryer is only intended for drying fabrics that were

~

washed in water. Check fabric care labels to verify that the

articles can be machine dried.

To prevent fire, do not dry the following (with the

~

exception of the textiles permitted in the special programs):

Articles containing foam rubber, rubber or rubber-like

–

materials.

Articles that have been treated with flammable cleaning

–

agents.

Articles that have been contaminated with styling

–

creams, hair spray, nail polish remover, etc.

Articles that may be greasy, oily or that may contain

–

other residues, e.g. kitchen or salon laundry.

Mops, floor cloths, etc. if they contain substances such

–

as wax or chemical cleaning agents.

Damaged padded or filled fabrics such as jackets or

–

cushions.

Articles that are not sufficiently clean and are soiled with

–

grease or oil. Wash very dirty articles (e.g. work clothing)

with a special detergent. For information in this regard,

consult a cleaning agent retailer.

Keep these operating instructions in a safe place and

pass them on to any future user.

Read all instructions before installation or use of the

dryer to prevent injury and machine damage.

Installation, repair and maintenance work should be

performed by a Miele authorized service technician.

Work by unqualified persons could be dangerous

Improper use of the appliance can lead to personal

injury and material damage.

All personnel working with this machine must be fully

trained in all aspects of its use and safety.

– With these critical fabrics the laundry may

spontaneously combust. Immediately remove the

laundry at the end of the drying program and after a

power failure.

Keep a fire extinguisher near the dryer.

The laundry must not be removed from the dryer until

~

the cooling down phase has been completed.

If hot laundry items are stacked or packed they could

spontaneously combust.

Empty all pockets so that no flammable items such as

~

lighters, matches, candles and cosmetics end up in the

dryer.

If the dryer is operated in an area accessible to the

~

public, the operator must ensure that the appliance can be

used safely.

This dyer is not intended for outdoor use.

~

4

IMPORTANT SAFETY INSTRUCTIONS

Technical and electrical safety

The dryer must be installed and tested by Miele's

~

Technical Service Department or an authorized dealer.

The electrical safety of this appliance is only assured if it

~

is connected to a grounding system. Is is very important to

make sure that this essential safety requirement is met. If in

doubt have the house wiring system checked by a qualified

electrician. The manufacturer will not be held liable for

damage caused by a missing or improperly connected

ground wire.

The dryer is disconnected from the power supply only

~

when it is unplugged or when the main breaker or the

dryer's breaker at the building's electrical service panel is

switched off.

Unprofessional repairs may create unforeseeable risks

~

for the user, for which Miele assumes no liability. Repairs

should be carried out only by authorized Miele technicians

- otherwise, associated damage will not be covered by the

warranty.

Defective components must be replaced with genuine

~

Miele spare parts only. Only with these parts can we

guarantee that the safety requirements of our appliances

are met.

Do not operate the dryer in a room where cleaning

~

machines operate with solvents containing CFC. Vapors

from combustion turn into hydrochloric acid which

damages laundry and dryer. When operated in a separate

room, there must be no air exchange.

Make sure the dryer is supplied with clean fresh air only,

~

not air containing chlorine, fluorine or other solvent vapors.

The cool air intake opening is located on the back of the

~

dryer, while the exhaust air opening is located on the

cover. Never block these openings. Therefore, do not cover

the top of the dryer with any type of blankets, sheets or

boxes (see installation instructions).

Never use or store gasoline, petroleum-based

~

substances or other easily flammable substances near the

machine. Fire and explosion hazard!

The dryer needs timely and professional maintenance to

~

prevent performance loss, malfunctions and the risk of fire.

Use of the appliance

The dryer is only intended for drying fabrics that

,

were washed with water as a cleaning agent.

Operate the dryer only if an exhaust air duct is

~

connected and the room is adequately ventilated.

The dryer may be operated only if the heat pump

~

module is hooked up and connected to the dryer.

Sufficient ventilation must be ensured (see the installation

instructions).

Make sure that the heat pump is correctly connected to

~

the dryer without any gaps. It must not be possible to reach

between the two machines - risk of injury!

Persons who lack physical, sensory or mental abilities,

~

or experience with the appliance should not use it without

supervision or instruction by a responsible person.

Do not let children play in, on or near the dryer. Do not

~

let them play with the controls or operate the unit.

Make sure that no unattended children can access the

~

machine. There is a potential danger that children can be

trapped in the drum. This may cause major injuries or the

death of the child.

Do not operate the appliance if the control panel, wires

~

or cables are damaged.

Do not damage, remove, or bypass any of the safety

~

features and controls of the dryer.

Do not operate the dryer when housing parts have been

~

removed and the moving or electrical parts are exposed

and accessible.

High temperatures occur at the window and frame of

~

the drum door, and the laundry is extremely hot if it is

removed too soon.

Always make sure the drum is stationary before

~

reaching in to remove laundry. Never put your hand into a

drum that is still moving.

Take care not to pinch or cut your fingers on the hinges

~

of the drum door or lint flap and on the maintenance cover

on the back of the dryer. Use the handles and quick

release fasteners. Beware of any potential hazardous areas

when installing the dryer and heat pump.

The area necessary to open the drum door completely

~

must not be obstructed by doors or other structures.

5

IMPORTANT SAFETY INSTRUCTIONS

Do not use the dryer without the built-in lint filter in

~

place. Fire hazard!

If the lint filter is damaged it must be replaced immediately.

A build-up of lint will block the airflow and heating,

which will impair the efficiency of the dryer.

Disinfection and cleaning agents often contain chlorine

~

compounds. If these agents dry on stainless steel, the

chlorides may attack the stainless steel and cause it to rust.

To protect the dryer from rusting, use only chlorine-free

disinfection and cleaning agents for laundering and

disinfecting, and for cleaning the stainless steel surfaces. If

in doubt about a cleaning agent, contact the manufacturer.

If an agent containing chlorine is spilled, wash it off with

water and dry with a soft cloth.

Do not use a power washer or water jet to clean the

~

dryer. Only the heat exchangers and the space between

the maintenance flap (access via quick release fasteners

on the back of the dryer) may be rinsed out with a jet of

water (max. 4 bar).

Following operation, refrigerant lines and the

~

neighboring components may pose hazards in the form of

hot or cold surfaces and pressurized parts. Do not open

any cover parts until the system has had sufficient time to

cool down.

Using accessories

Only accessories expressly allowed by Miele may be

~

installed. Adding or installing other parts will void any

warranty and/or product liability claims.

Disposing of the appliance

If you are disposing of an old dryer (scrap metal

~

collection), destroy the door latch. This will prevent children

from accidentally locking themselves in, which would place

them at risk of death.

SAVE THESE

INSTRUCTIONS

Precautionary measures for dealing with a loss of

refrigerant

The heat pump refrigeration circuit contains a non-toxic,

~

odorless refrigerant (R134a) that quickly evaporates when

released. In vapor form it is heavier and air and poses a

suffocation hazard in unventilated rooms!

If you notice any damage to the copper lines on the

~

heat pump, do not operate the machine and exit the room.

–

Notify any other persons present of the danger.

–

Please refer to the safety data sheet for further

information on handling refrigerant.

6

Caring for the environment

Disposal of packing materials

The packing materials are intended to protect the

machine from damage during shipping. They have

been selected for environmental compatibility and

efficient disposal and can therefore be recycled.

Returning packaging to the materials cycle saves raw

material and reduces waste. The packing materials

can be returned to your dealer.

Keep packing materials such as shrink wrap

,

and plastic bags away from children

because of the danger of suffocation.

Disposal of the appliance

Appliances may contain materials that can be

recycled. Please contact your local recycling

authority about the possibility of recycling these

materials.

Please make sure that you dispose of your old

appliance in accordance with regional disposal

regulations and prevent an uncontrolled release of

refrigerant into the environment.

Ensure that the appliance presents no danger to

children while being stored for disposal. Before

discarding an old appliance, unplug it from the outlet,

cut off its power cord, remove any doors to prevent

hazards. and store appliance on side to prevent

tipping. For more information see the "IMPORTANT

SAFETY INSTRUCTIONS".

Information on saving energy

You have purchased a heat pump dryer featuring the

latest technology. This dryer uses 50% less energy

than conventional dryers with electric heating. The

following tips will help you further lower your energy

consumption:

Wash your laundry on maximum spin cycle speed.

This will reduce drying time and energy consumption.

If the washing machine's last rinse cycle is with warm

water, a shorter drying time will be required due to

the lower residual moisture and the residual heat in

the laundry, which in turn saves energy.

Sort fabrics:

- by fiber/weave,

- by desired drying level,

- by residual moisture.

Only dry full loads, if possible. Under-loading is not

cost efficient. Overloading provides poor drying

results and has an adverse effect on fabrics. Optimal

energy consumption is relative to the total amount of

laundry.

A free lint filter and clean heat exchangers increase

the efficiency of the system and the drying process,

thereby reducing runtime and energy required.

Ensure sufficient room ventilation.

7

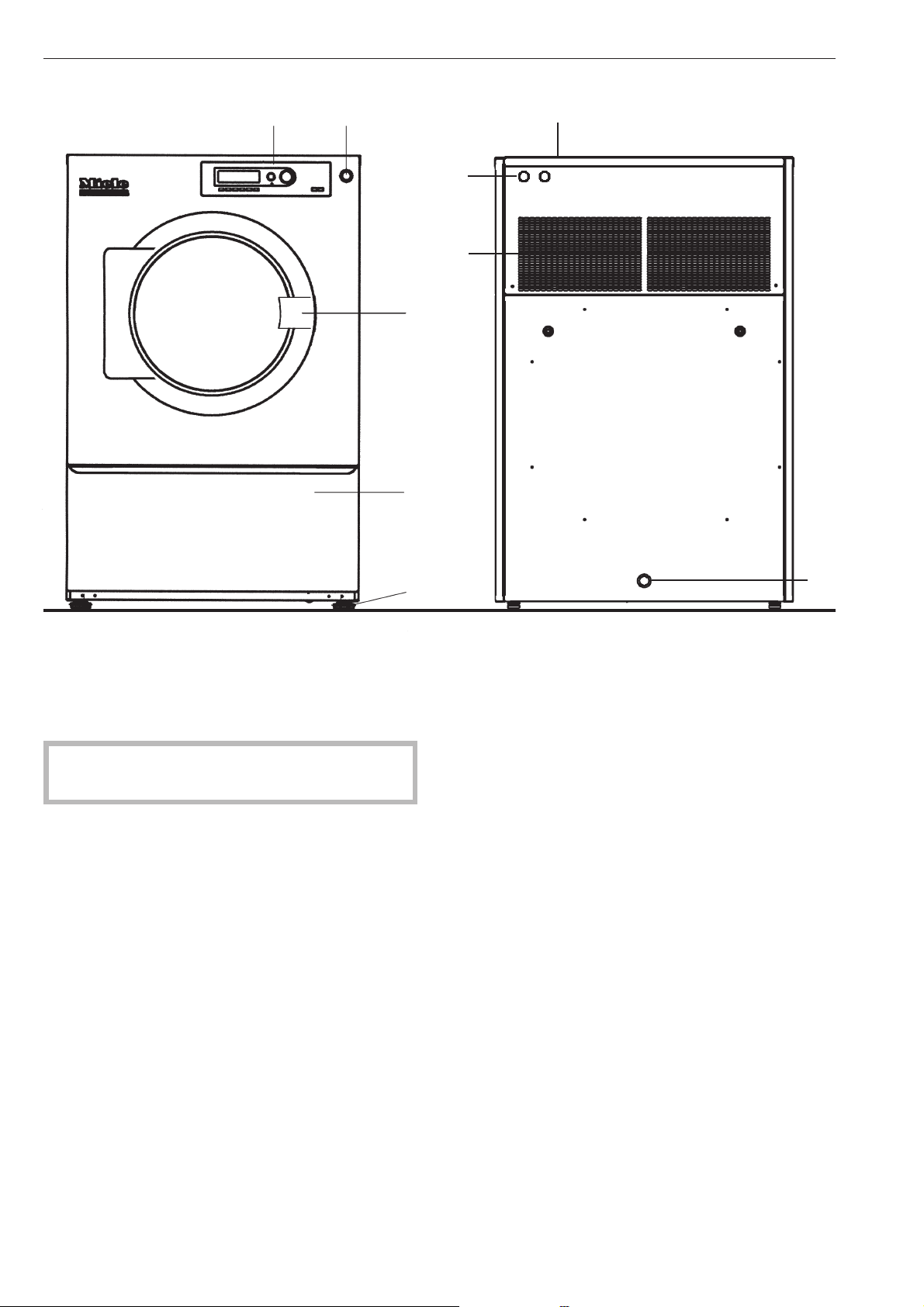

General description of the appliance

ab

g

f

h

c

d

a Emergency Stop button

Use only in case of an emergency.

After the problem has been eliminated, unlock the the

switch by turning the dial to the right.

Do not use the Emergency Stop switch to switch

off the dryer during normal operation!

b Control panel

c Drum door

Pull the door handle to open the drum door.

d Lint filter flap

Pull the handle to open the lint filter flap.

e 4 adjustable feet

e

i

f Electrical connection

g Exhaust air opening

h Air intake opening

i Condensation drain

8

General description of the appliance

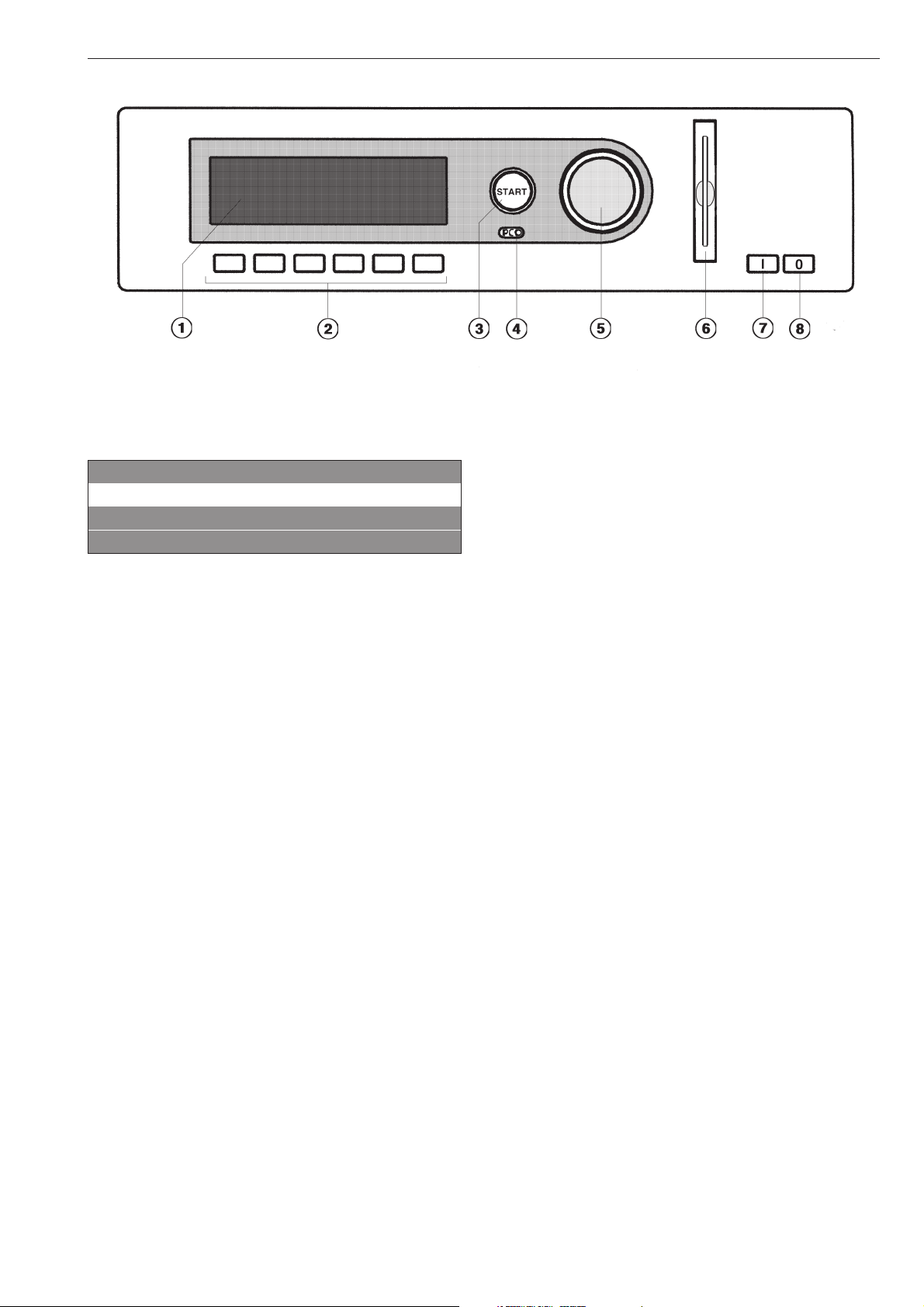

Operating panel

a Display*

1 White Cottons 0%

2 Cottons 0%

3 Cottons Hot Wash 0%

FC A

After turning on, the "Welcome" display will appear for

a short time followed by the program list. The most

recently used program is highlighted.

b Function keys

The keys have different functions depending on the

appliance status. The functions are shown in the

display above the buttons.

c Start button

The light ring flashes if a selected program can be

started or a selection can be made.

Once a program has started the Start button can be

pressed to show the original display.

d Optical PC interface

For data transfer between the machine’s controls and

a PC.

e Jog shuttle

Turn the jog shuttle for display selections and input

fields.

Press the jog shuttle to confirm display selections or

changes.

f Card reader

If the machine has been programmed for card

operation, you can only use those programs stored

on the card to dry laundry.

g I On button

h 0 Off button

* Contents in the display will vary with program

offering.

9

General description of the appliance

Control keys

f Stop / End

Press to stop a selected program or end an already

stopped program.

[ Block plus

The respective program block (e.g. pre-drying) will

be added to the program.

FC Functions

Press this key to temporarily select another language

and/or access the Supervisor level.

mDelay start

Press this key to select a start time in the display.

K Information

To show program information

ü Skip

Cycles of a program in progress can be skipped or

repeated.

A Back to the previous display

e/- Next or previous line

S Save

See the Programming Manual

Operator card

No programs are saved on this card. To transfer the

data from the control to the card and vice versa see

the Programming Manual.

30 programs with 6 blocks each can be saved on the

card.

The back of the card can be labeled.

Insert the card, arrow first.

$ Program locked

If a program has a "locked" status it cannot be

stopped or ended with the Off-button after one

minute.

% Program unlocked

\ Operating data

Data transfer

10

Drying

Before first use

Wipe the interior of the drum with a soft dry cloth

^

Preparing the laundry

Not all fabrics are suitable for drying in a

,

tumble dryer. Check the manufacturer’s

instructions on the fabric care label.

q = Dry at normal temperature

r = Dry at low temperature

s = Do not tumble dry

Sort the laundry by fabric type and color. This will

^

ensure even drying results and will prevent

damage to fabrics.

To prevent fire, do not dry the following

,

(with the exception of the textiles permitted in the

special programs):

Articles containing foam rubber, rubber or

rubber-like materials.

Articles that have been treated with flammable

cleaning agents.

Articles that have been contaminated with hair

spray, nail polish remover, etc.

Articles that may be greasy, oily or saturated with

other residues, e.g. kitchen or salon laundry.

Important drying information:

Articles made from pure wool and wool mixtures

–

may become matted. Dry these with the Woolens

program only.

Pure linen may become rough with tumble drying.

–

Consult the manufacturer’s instructions before

drying.

Items with metal buckles, hooks, snaps, zippers,

–

etc. should be put into the dryer in a cloth bag

(e.g. pillow case) to protect the drum from

scratches and dents.

Articles with closed metal zippers may cause a

–

short at the sensor electrodes on the drum ribs, so

that the drying process ends too late or does not

end at all. These items should be dried with the

zippers open.

Loop knit materials tend to shrink. Over-drying

–

increases this effect. Do not use the highest dry

program for such fabrics.

Starched laundry can be tumble dried. Select a

–

program with a suitable residual moisture for

ironing by hand or machine.

Sort the laundry according to the level of dryness

required. It is not necessary to sort according to

size.

– Pillow cases and duvet covers should be buttoned

to prevent smaller items from getting caught inside

them.

– For cost efficiency, only dry full loads. Overloading

provides poor drying results and has an adverse

effect on fabrics.

Mops, floor cloths, etc. if they contain substances

such as wax or chemical cleaning agents.

Damaged padded or filled fabrics, like jackets or

cushions.

Articles that are not sufficiently clean and are

soiled with grease or oil. Wash very dirty articles

(e.g. work clothing) with a special detergent.

–

If the washing machine's last rinse cycle is with

warm water, a shorter drying time will be required

due to the lower residual moisture and the residual

heat in the laundry.

11

Drying

1. Turn on the dryer

Turn on the power main (on site).

^

Press the l "On" button to turn the dryer on.

^

The Welcome screen shows.

PROFESSIONAL

PT 8xx7

Welcome

The program list is displayed. The program last

started is highlighted.

1 White Cottons 0%

2 Cottons 0%

3 Colors 0%

FC A

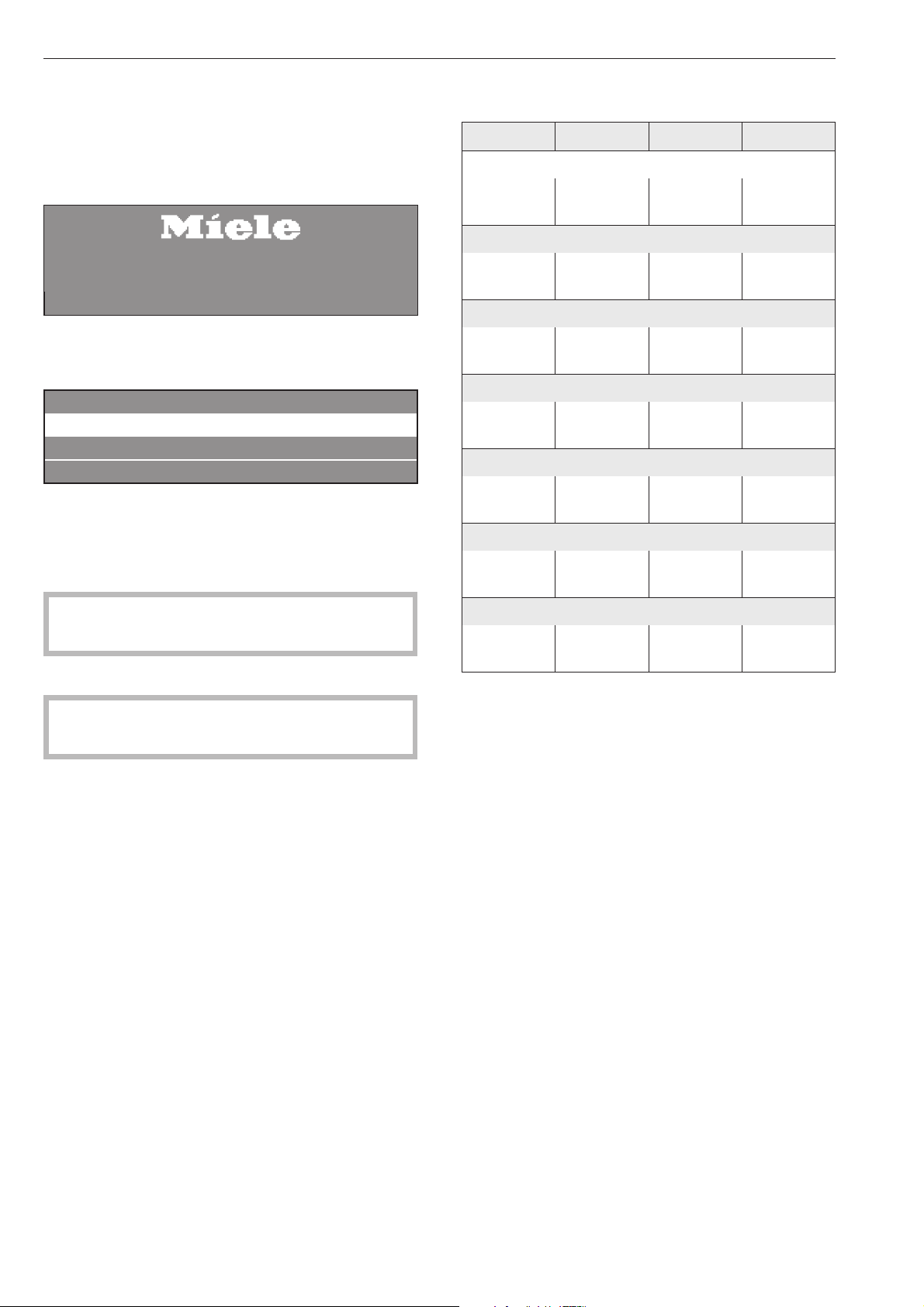

2. Load the laundry

Open the drum door.

^

^ Load the laundry loosely into the drum.

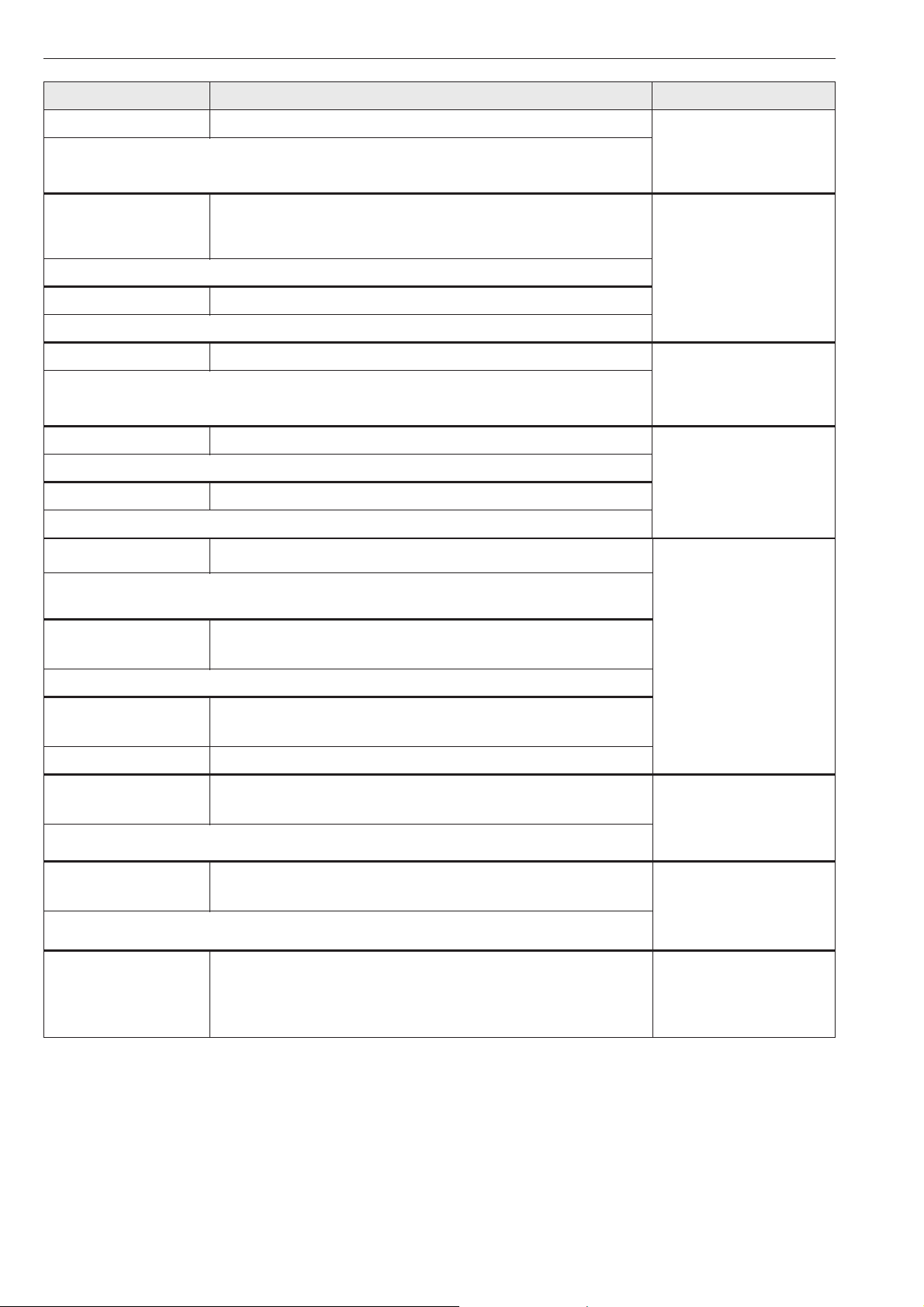

Maximum laundry weight

PT 8257 PT 8337 PT 8407 PT 8507

Drum volume

66 gal

(250 l)

86 gal

(325 l)

106 gal

(400 l)

132 gal

(500 l)

Cottons

22-29 lb

(10-13 kg)

29-35 lb

(13-16 kg)

35-44 lb

(16-20 kg)

44-55 lb

(20-25 kg)

Wrinkle-free

11 lb

(5 kg)

14.6 lb

(6.6 kg)

17.6 lb

(8 kg)

22 lb

(10 kg)

Woolens

8.8 lb

(4 kg)

11.5 lb

(5.2 kg)

14 lb

(6.4 kg)

17.6 lb

(8 kg)

Delicates/Synthetics

4.4 lb

(2 kg)

5.7 lb

(2.6 kg)

7lb

(3.2 kg)

8.8 lb

(4 kg)

Hot/Cool air

22-29 lb

(10-13 kg)

29-35 lb

(13-16 kg)

35-44 lb

(16-20 kg)

44-55 lb

(20-25 kg)

Check that there are no foreign objects in the

drum, e.g. wash dosage containers, coins, etc.

^ Close the drum door.

To prevent fabric damage, check that laundry will

not be caught in the closed door.

Proofing, Outerwear

11-14.5 lb

(5-6.6 kg)

13.2-19.8 lb

(6-9 kg)

17.6-24.3 lb

(8-11 kg)

22-28.7 lb

(10-13 kg)

See "Adjust the program - Laundry weight" for more

information.

12

Drying

3. Select a program

The dryer uses an electronic sensor system which

monitors the residual moisture in the laundry and a

timer for extra safety.

Once the required level of dryness has been reached

the laundry is cooled and the drying program will

end.

1 White Cottons 0%

2 Cottons 0%

3 Colors 0%

FC A

Select a program by turning the jog shuttle (e.g.

^

Program 2 Hot Wash / Cottons dry).

See the "Program Guide" for more information on

the standard programs.

4. Select [ "Blockplus" (if desired)

(Not available for standard programs)

Confirm the selected program by pressing the jog

^

shuttle.

22 Hot Wash / Cottons dry 22.0 / 22.0 lb

15 % Drying 176 °F

Cool down e

[ m A

Press the [ "Blockplus" button to select a

^

program block, e.g. pre-drying if desired.

22 Hot Wash / Cottons dry 22.0 / 22.0 lb

24 % Pre-drying

0 % Drying e

[ m A

The field [ is highlighted.

The function can be deselected by pressing the

button again.

If you do not need to make any other changes to the

program:

^ Press the "START" button and the drying program

will begin.

13

Drying

5. Adjust the program (if desired)

To change program settings before starting the

program:

Confirm the selected program by pressing the jog

^

shuttle.

2 Cottons 22.0 / 22.0 lb

0 % Drying 176°F

Cool down e

m A

The maximum laundry weight is shown on the right

side in the display.

Laundry weight

The laundry weight can be manually selected.

2 Cottons 22.0 22 lb

0 % Drying 176°F

Cool down e

m A

Residual moisture

In 1 % steps from -4 to 40 %.

Turn the jog shuttle to "Residual moisture" (0 %)

^

and press to confirm the selection.

2 Cottons 22.0 lb

0% Drying 176°F

Cool down

m A

Turn the jog shuttle to the desired percentage and

^

press it to confirm the selection.

Press the "Start" button to begin the program.

^

The program sequence is shown in the display after

the start of the program.

2 Cottons

0 % Drying >40 %{

Cool down Finish at 12:35

mKf

^ Turn the jog shuttle until "Laundry weight" is

highlighted and press to confirm the selection. Turn

the jog shuttle to the desired laundry weight and

press to confirm the selection.

Temperature

In 1 °F or °C steps from 86 °F / 30 °C to max. 203 °F /

95 °C.

^ Turn the jog shuttle to "Temperature" and press to

confirm the selection.

2 Cottons 22.0 lb

0 % Drying 176°F

Cool down e

m A

^

Turn the jog shuttle to the desired temperature and

press it to confirm the selection.

In the second display line, next to "Drying", the actual

residual moisture is shown (>40%) and if the heating

{ is active. The third line shows the following program

block.

The "Finish at 12:35" on the right side shows the end

time of the program.

The "Finish at" display has a self learn function.

Several program cycles are necessary for an exact

display.

14

Drying

6. Select Delay Start (if desired)

Use the m "Delay start" button to start a program at a

later time.

Setting the delay start

Select a program.

^

Press m "Delay Start".

^

2 Cottons 22.0 lb

Start time: 2 :10 pm Start date: 2.13.2006

After setting the delay start press Start.

m A

The display shows the current time of day and date.

The hour entry field is highlighted.

Turn the jog shuttle to the "Hours" entry field. Press

^

the jog shuttle to select the hour. Turn the jog

shuttle to the desired hour and press it to confirm

the selection.

Turn the jog shuttle to the "Minutes" entry field.

^

Press the jog shuttle to select the minutes. Turn the

jog shuttle to the desired minutes and press it to

confirm the selection.

The program will start at the selected time.

2 Cottons 22.0 lb

0 % Drying

2:07pm -2.13.2006 Start: 2:10pm-2.13.2006

m A

The display shows the current time of day, date and

the start time.

If the door is opened before the delay start time

^

has elapsed, press the "Start" button again.

Canceling the Delay Start

Press the m "Delay Start" or A "Back" button to

^

cancel the delay start function.

^ Turn the jog shuttle to the "Start date" entry field.

Press the jog shuttle to select the start date. Turn

the jog shuttle to the desired date and press it to

confirm the selection.

^ Press the "Start" button.

15

Drying

7. Start a program

Press the "Start" button to begin the program.

^

8. End of program

2 Cottons

Program end

Anti-crease Finish at 12:35

m FC Kf

The program end is shown in the display and the

buzzer sounds.

Open the drum door.

^

Remove the laundry.

^

If the laundry is not removed from the machine at the

end of the program an anti-crease cycle will

automatically start. The drum turns in intervals to

minimize creasing in the laundry.

The laundry must not be removed from the

,

dryer before the drying program has finished. The

cooling down phase must be completed.

If hot laundry items are stacked or packed they

could spontaneously combust.

^ Check the lint filter and clean if necessary.

Close lint filter flap, trip hazard.

2 Cottons

Program end

Caution: Lint filter is clogged

A

A reminder will appear in the display when the filter

needs to be cleaned.

^

Clean the lint filter immediately after the program

ends.

^

Close the drum door.

^

Press the 0 "Off" button to turn off the machine.

^

Turn off power at the power mains (on site).

16

Extra features

Skip or repeat program sequences

Sequences of a program in progress can be skipped

or repeated.

Press the f "End" button to stop the program.

^

2 Cottons

Program stop

Press Start.

ü f

Press the ü "Skip/Repeat" button.

^

The display shows the current program segment. See

"Program structure" in the Programming Manual.

Skip/Repeat -> 2 Cottons

Program stop

Area 1: Drying e

S A

Area 1: Drying

Block 1: Pre-drying

-

S A

Program stop

Press the f "End" button to stop the program.

^

2 Cottons

Program stop

Press Start.

ü f

Press the "Start" button to continue the program.

^

Canceling a program

To cancel a program, press the f "End" button twice.

^ Turn the jog shuttle to "Area" and press it to confirm

the selection.

Area: Select 1 Drying or 2 Cooling and confirm.

^ Turn the jog shuttle to "Block" and press it to

confirm the selection.

Block: Select Drying 1-10 or Cooling 1-10 and

confirm.

^

Press the S "Save" and "Start" button to skip the

program cycles.

^

To go back without skipping program cycles:

Press the A "Back" to go back to the program

stop.

17

Extra features

K Information

Press the K "Information" button during the program

^

to see program information.

Examples:

2 Cottons

Delay start: 10.7.2003

Start time: 9:47 e

m K f

Time after Start:0h23min

Time left:0h11min

Program end time: 10:21 pm e

Area 1: Drying

Block 1: Pre-drying

Actual exhaust air temp.: 138 °F e

Peak load: No

Anti-crease: 3s./87s./60min

Recirculation/vent flap: Recirculation e

Language

The display language can be temporarily changed

with the flag symbol.

1 White Cottons 0%

2 Cottons 0%

3 Colors 20%

FC A

Press the FC function button.

^

Settings Back <Main menu Language

Programming level

FC A

Press the jog shuttle to select "Language".

^

Settings svenska

Language english (USA)

Back <-

FC A

2 Cottons

Block end signal: Yes -

^ Press the A "Back" button to get back to the

program sequence.

A

^ Turn the jog shuttle to select the desired language

and press to confirm the selection.

When the selection is confirmed the display switches

to the selected language.

The language is set back to its original setting:

– if no activity was carried out for 5 minutes.

– 5 minutes after the program has ended.

when the door is opened.

18

Estates

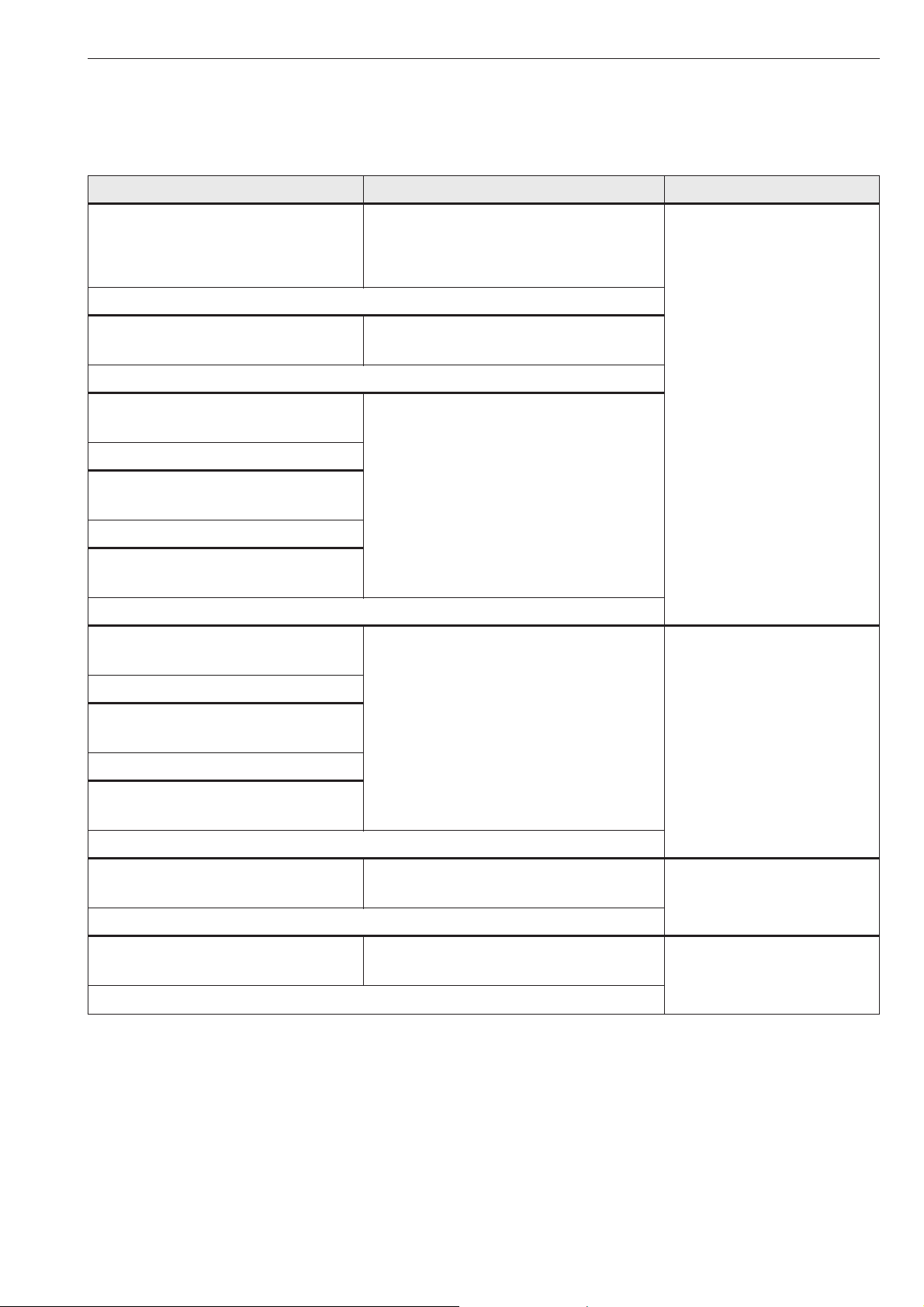

Program Fabric Type max. load

White Cottons White items made of cottons, linens

Program

Cottons White or colored items made of cottons, linens or mixed fabrics

Colors Colored items made of cottons, linens or mixed fabrics

Darks Dark items made of cottons, linens or mixed fabrics

Wrinkle Free Items made of synthetic fabrics, mixed fabrics PT 8257 11 lb

Delicates Items made of synthetic fabrics, mixed fabrics PT 8257 4.4 lb

Dry to 20% residual moisture

600+TC Sheets Hot Bed linens high thread count sheet

made of cottons, mixed fabrics

600+TC Sheets

Warm

Silk and Rayon

Bed Linens

Bed linens high thread count sheet

made of cottons, mixed fabrics PT 8257 11 lb

Bed linens made of silk, rayon, satin

PT 8257 22-29 lb

(10-13 kg)

PT 8337 29-35 lb

(13-16 kg)

(5.0 kg)

PT 8337 14.6 lb

(6.6 kg)

(2 kg)

PT 8337 5.7 lb

(2.6 kg)

PT 8257 22-29 lb

(10-13 kg)

PT 8337 29-35 lb

(13-16 kg)

(5.0 kg)

PT 8337 14.6 lb

(6.6 kg)

Down Comforters &

Pillows

See load size in "Covers" section

Washable

Bedspreads

See load size in "Covers" section

Linen Tablecloths Tablecloths, napkins made of cottons, linens PT 8257 22-29 lb

Mixed Fiber

Tablecloths

Down comforters, duvet covers made of down

Blankets, covers made of synthetic fabrics

Tablecloths, napkins

made of synthetic fabrics, mixed fabrics

PT 8257 22 lb

(10 kg)

PT 8337 28.7 lb

(13 kg)

(10-13 kg)

PT 8337 29-35 lb

(13-16 kg)

PT 8257 11 lb

(5.0 kg)

PT 8337 14.6 lb

(6.6 kg)

19

Program

Program Fabric Type max. load

Outerwear Coats and jackets made of mixed fabrics PT 8257 11-14.6 lb

(5-6,6 kg)

PT 8337 14.6-19.8 lb

(6,6-9 kg)

Hand wash Silks Blouses, dresses, pants, skirts, coats, evening gowns,

wedding gown, faux furs made of silk, rayon, satin, acetate,

viscose

Hand wash Woolens Woolens and mixed woolens

Waterproofing Drying of waterproofed outdoor items PT 8257 11-14.6 lb

Hot air Drying small loads or finish drying single items PT 8257 22-29 lb

Cool air Airing/Fluffing items

PT 8257 8.8 lb

(4 kg)

PT 8337 11.5 lb

(5.2 lb)

(5-6,6 kg)

PT 8337 14.6-19.8 lb

(6,6-9 kg)

(10-13 kg)

PT 8337 29-35 lb

(13-16 kg)

Smoothing

Reduces wrinkles after the being washed. Remove items immediately after program

end and allow to air dry.

Denim / Jeans

(Machine iron)

Dress Shirts

(Machine iron)

Towels Multi-layer fabrics and towels.

Outerwear Plus Outdoor clothing suitable for drying in a tumble dryer.

Automatic Mixed loads of fabrics for the Cottons and Wrinkle-free

Cotton and linen fabrics

Items made of denim

Shirts and blouses

Towels, wash cloths, bath robes, etc.

The fibers are straightened, improving water-repellency.

programs.

PT 8257 11 lb

(5.0 kg)

PT 8337 14.6 lb

(6.6 kg)

PT 8257 22-29 lb

(10-13 kg)

PT 8337 29-35 lb

(13-16 kg)

PT 8257 11-14.6 lb

(5-6,6 kg)

PT 8337 14.6-19.8 lb

(6,6-9 kg)

PT 8257 11 lb

(5.0 kg)

PT 8337 14.6 lb

(6.6 kg)

20

Program guide

The following programs are available upon request. Please contact Miele for more

information.

Basic programs

Program Fabric Type max. load

1 Hot Wash / Cottons extra dry 0%

(Normal+)

2 Hot Wash / Cottons - dry 0%

(Normal)

3 Hot Wash / Cottons - damp 20 %

(Machine iron)

4 Hot Wash / Cottons - damp 25%

(Machine iron)

5 Hot Wash / Cottons - damp 40 %

(Machine iron)

6 Wrinkle Free dry 0 %

(Normal)

Multilayered or very thick fabrics made of

cotton and linen which do not completely

dry when using the "Hot wash / Cottons

dry" program.

Single and multilayered cotton and linen

laundry

PT 8257 22-29 lb (10-13 kg)

PT 8337 29-35 lb (13-16 kg)

Cotton and linen fabrics which are to be

machine ironed

7 Wrinkle Free moist 10 %

(Machine iron)

8 Wrinkle Free moist 20 %

(Machine iron)

9 Woolens 5 min. To fluff pre-dried woolens PT 8257 8.8 lb (4 kg)

10 Delicates 20 % Sensitive items made of synthetic, cotton

Synthetic, cotton or mixed fabrics PT 8257 11 lb (5.0 kg)

PT 8337 14.6 lb (6.6 kg)

PT 8337 11.5 lb (5.2 lb)

PT 8257 4.4 lb (2 kg)

or mixed fabrics

PT 8337 5.7 lb (2.6 kg)

21

Program guide

Program Fabric Type max. load

11 Timed drying - cool air 15 min. To air fluff items

12 Timed drying - warm air 20 min. Drying small loads or finish drying single items

PT 8257 22-29 lb

(10-13 kg)

PT 8337 29-35 lb

(13-16 kg)

13 Waterproofing

(Normal)

This program includes an additional step for water-proofing. Water-proofed items must

only be treated with a water repellent that is "Suitable for membrane textiles". These

products are fluoride compound based. Fire hazard! Do not dry fabrics which were

treated with agents containing paraffin!

14 Outerwear Outdoor clothing suitable for drying in a tumble

For drying fabrics that can be machine-dried,

e.g. micro fibers, ski and outdoor clothing, thin

dense cottons (poplin), table cloths.

dryer.

PT 8257 11-14.6 lb

(5-6,6 kg)

PT 8337 14.6-19.8 lb

(6,6-9 kg)

22

Program guide

Comforters

Program Fabric Type max. load

Down Comforters Feather or down comforters and pillows PT 8257 1 cover or 2 pillows

Drying to 0% residual moisture, Additional drying, Cooling

Synthetic Comforters Synthetic covers and pillows

Drying to 0% residual moisture, Additional drying, Cooling

Wool Comforters Natural fiber covers and blankets

Drying 3 minutes, Cooling

Natural fiber covers should not be completely dried in the dryer or it will

felt. A brief drying is recommended.

PT 8337 3 pillows or

These values are approximate and

may vary depending on size and

thickness of the items.

Cleaning Contractors

Laundry that has not been adequately cleaned and contains residues (wax or chemicals) is a fire hazard!

,

Wash particularly dirty laundry thoroughly: Use sufficient detergent and wash at a high temperature. If in doubt,

wash these items several times.

22 lb (10 kg)

1 pillow + 1 cover

28.7 lb (13 kg)

Program Fabric Type max. load

Mops Cotton mops

Drying to 0% residual moisture, Cooling

Microfiber mops Micro fiber mops

Drying to 0% residual moisture, Cooling

Cleaning cloths Micro fiber cloths, dust cloths PT 8257 12.3 lb (5.6 kg)

Drying to 0% residual moisture, Cooling

PT 8257 22 lb (10 kg)

PT 8337 28.7 lb (13 kg)

PT 8337 15.4 lb (7 kg)

23

Program guide

Fire Department

Program Fabric Type max. load

Face masks Protective mask with head harness max. Fasteners / Masks

Dry 45 min., Cooling.

Protective masks may only be dried is they are locked with special

mounting plates (optional accessory) in the drum.

Protective clothing Fire department uniforms e.g. Nomex

jackets, pants

Drying to 0% residual moisture, Additional drying, Cooling

For optimum drying results turn the garments inside out.

Fire gear waterproofing Items treated with a proofing agent

®

,

PT 8257 4 8

PT 8337 4 12

PT 8257 approx.1-2Uniforms

(1 Jacket + 2 Pants or 2 Jackets)

PT 8337 approx. 2 Uniforms

(or 3 Jackets)

Drying to 0% residual moisture, Additional drying, Cooling

Water-proofed items must only be treated with a water repellant that is

"Suitable for membrane textiles". These products are fluoride compound

based.

Fire hazard! Do not dry fabrics which were treated with agents containing

paraffin!

PT 8257 11-14.6 lb (5-6.6 kg)

PT 8337 14.6-19.8 lb (6.6-9 kg)

Professional cleaners

Program Fabric Type max. load

WetCare Sensitive Non-washable items PT 8257 approx. 8.8-11 lb (4-5 kg)

Fluffing 3 minutes, Cooling

WetCare Silk Non-washable items which crease easily PT 8257 approx. 8.8-11 lb (4-5 kg)

Drying to 15% residual moisture, Cooling

WetCare Intensive Washable items PT 8257 approx. 11-14.6 lb (5-6.6 kg)

Drying to 0% residual moisture, Cooling

PT 8337 approx. 11-14.6 lb (5-6.6 kg)

PT 8337 approx. 11-14.6 lb (5-6.6 kg)

PT 8337 approx. 14.6-19.8 lb (6.6-9 lb)

24

Equestrian

To protect the drum from damage, metal buckles, hooks and eyes must be covered.

,

Program Fabric Type max. load

Horse blankets Horse blankets, saddle cloths, tendon boots, bandages, cloth

halter

Drying to 0% residual moisture, Additional drying, Cooling

Wool horse blankets Horse blankets with a high wool content

Drying 5 min., Cooling

Type

PT 8257 7 2 1

Saddle

cloths

Program guide

PT 8257 22 lb (10 kg)

PT 8337 28.7 lb (13 kg)

Load size

Summer

blankets

Winter

blankets

PT 8337 9 2 - 3 1 - 2

11 2-3 1-2

12 3 2

25

Chip card use / Coin mechanism

If the machine is programmed for card operation,

only the drying programs on the card can be used.

Cards containing a program are programmed for a

machine type. Empty cards can be programmed for

any machine type.

Press l "On" to turn the dryer on.

^

The Welcome screen appears.

If the card was inserted the wrong way

Card fault

§

Insert the card properly into the card reader.

^

If the card is not suitable for this type of machine

Card operation

Card programs are only applicable

for machine type PT 7251.

Insert a card suitable for this machine type.

^

Reinsert card correctly in card reader.

Continue: Press Start.

ü f

A

Drying using the coin mechanism C 4060 /

C 4065 / C 4070

Follow the instructions strictly or the money / token

will be lost.

^ Insert the card, arrow first.

The display shows the list of programs on the card.

Card operation

17 Drying Protect. Clothing 113 °F

18 Wrinkle-free 140 °F

FC A

^

Turn the jog shuttle to select a program. Press it to

confirm the selection.

^

Press the "Start" button.

^

Remove the card from the card reader. When the

program is finished it will be erased from the

machines memory.

,

Do not insert any other items into the card

reader.

1. Load the laundry and close the drum door.

2. Press the l "On" button.

3. Select a program.

4. Insert money or tokens.

5. Press the "Start" button.

26

Cleaning and care

Cleaning the lint filter

Clean the lint filter at least once a day and

,

when the "Clean lint filter" display shows. A

clogged filter is a fire hazard!

Dryer

Before cleaning or servicing, disconnect the dryer

from the power supply by shutting off the power main

or tripping the circuit breaker.

Do not use a high pressure cleaner or water jet

,

to clean the machine.

Use a mild solution of warm water and liquid dish

^

soap applied with a soft cloth to clean the housing,

the control panel and the plastic parts, then dry

with a soft cloth.

After drying starched laundry, clean the drum with

^

a soft, moist cloth.

Never use abrasive cleaners, scouring pads, steel

wool or caustic cleaners. They will damage the

surface.

Check the gasket and lock of the drum door and the

lint filter flap.

The air intake opening is located on the back of the

dryer. Never block this opening. Do not cover the

dryer top with any blankets or cloths.

^ Open the lint filter flap.

^ Do not remove the lint filter.

^ Wipe the lint off the filter with your hand (do not use

any sharp objects). Scoop out the lint and be

careful not to damage the filter.

,

Do not use the machine without the built-in

filter in place.

This is a fire hazard.

If the lint filter is damaged it must be replaced

immediately.

A build-up of lint could block the airflow, heating

and ventilation, and may impair the efficiency of

the machine.

Keep the area surrounding the dryer, especially

around the air intake opening, clear of lint to ensure

clean air intake. Lint will settle in the dryer and cause

malfunctions.

Have Miele Technical Service check for lint deposits

and clean the following once a year:

– The entire interior of the dryer

–

The exhaust air blower wheel

27

Cleaning and care

Heat exchangers

Regular and professional maintenance preserves the

high efficiency of the system and helps increase

component life.

During operation, lint as well as detergent residues

and other substances contained in water vapor

collect on the heat exchangers. Soiling of the heat

exchangers decreases the transfer of heat to air,

thereby reducing system efficiency. Heat exchangers

should therefore be cleaned annually, or more

frequently in the case of heavy lint soiling or high

volume of use, by Miele Technical service.

Turn off the system and disconnect from power

–

supply!

Open the maintenance cover on the rear side of

–

the heat pump. Put the maintenance cover in a

safe place (trip and injury hazard).

Before the start of the rinsing process, remove the

–

collecting basin and rid it of coarse particles. This

prevents the drain from becoming clogged. Then

put back the collecting basin before starting the

rinsing process.

Seal off the heat exchangers by closing the

–

maintenance cover before returning the system to

operation.

Before turning on the power supply, make sure that

–

no electrical parts have come into contact with

rinsing water.

To protect the fins, avoid direct contact and wear

–

gloves to prevent cuts.

Only the heat exchangers (area behind the

,

maintenance cover) may be cleaned with water.

Water must not be used to clean the dryer and

other parts. Danger of fatal electric shock!

The dryer needs timely and professional

,

maintenance to prevent performance loss,

malfunctions and the risk of fire.

–

Thoroughly rinse out the heat exchangers with a

water jet (max. 4 bar) for several minutes. Using

pressure washers as well as detergents containing

chlorine, sand, soda or acid is prohibited. As an

alternative cleaning method, the heat exchangers

can be vacuumed or brushed off. Make sure not to

bend or damage the fins. Water must enter only

the described area of the heat exchangers.

–

To prevent flooding the dryer or the room in which

it is located, ensure that the cleaning water drains

sufficiently.

–

Remove all soiling that is not rinsed out.

–

Clean the collection basin and check the water

drain for possible clogs.

28

Frequently asked questions

Fault messages

Repairs to electrical, gas or steam appliances

,

should only be carried out by a Miele authorized

technician in accordance with local and national

safety regulations. Unauthorized repairs could

cause injury or machine damage. The

manufacturer cannot be held responsible for

unauthorized work.

After turning the machine on at the mains or if the

program list was selected the control carries out a

system analysis. All modules and their sensors, data

from the operating system, drying programs and

languages are checked.

If an error occurred in a program or language, they

are marked with § and can not be selected (here "3

Cottons Hot Wash 0%" and "English").

1 White Cottons 0%

2 Cottons 0%

3 Colors 0% §

f

Faults that occur before or after the start of a program

will flash in the display.

If the following error messages cannot be fixed with

five restarts, a general message will show:

System fault

§

Contact Technical Service

if restart w/o success.

f

If the display remains off, the dryer has no power.

Check the plug, the main switch and the fuses

^

on-site.

Settings Back <Language Deutsch

English §

FC A

If an error occurs in an already selected language the

following will show:

Data fault

§

Limited function.

Language defect.

f

Fan fault

§

Program stop. Press Start.

Motor temperature too high.

^ Allow motor to cool.

Machine fault

§

Contact Technical Service

if restart does not work.

^

Contact Technical Service.

Drive motor fault

m

Program stopped. Press Start. Motor

overheated due to overloading.

f

f

f

Allow motor to cool.

29

Frequently asked questions

Power failure

y

Program stop.

Press Start.

Press "START" to continue the program.

^

Card fault

§

Reinsert card correctly in card

reader.

Insert the card properly into the card reader.

^

f

A

Escaping condensation

If condensation escapes from an undesired place in

the system, check if the collection basin is resting

correctly in the drain and the drain is free of soiling.

These parts are accessible via the rear maintenance

cover in the floor area.

Decreasing system efficiency

This system is designed to operate at a room

temperature of up to 113°F (45 °C). Occasional

operation above this temperature should not cause

any problems. However, if temperatures continuously

exceed 113°F (45 °C), an external cool air supply

must be ensured. You can additionally reduce strain

on the system by keeping the heat exchangers free of

lint accumulation and other soiling. This reduces wear

and tear, thereby increasing the life of your system.

Check the system for the following should it lose

efficiency over time and require clearly longer drying

times:

Soiling of the dryer lint filter

–

Soiling of the heat exchangers in the heat pump

–

– Tightness of the connection between the dryer and

heat pump

– Heat pump air intake and and exhaust vent

– External fresh air and ventilation ducting is

recommended if room temperature frequently

exceeds 113°F (45 °C)..

After-sales service

^

In the event of a fault which you cannot correct

yourself, please contact Technical Service.

^

When contacting Technical Service please quote

the model, serial number (SN) and part number

(M.-Nr.) of the machine.

They can be found on the data plate located at the

top of the door opening (when drum door is open) or

on the back of the machine at the top.

30

^

When contacting Technical Service report the fault

in the display.

Only use original Miele spare parts when performing

maintenance or repairs on this machine. When

ordering please quote the model, serial number (SN)

and part number (M.-Nr.) of the machine.

Installation instructions

IMPORTANT SAFETY INSTRUCTIONS

WARNING - Risk of Fire

Any installation, service or repair work is to be done by

~

a Miele Service Technician. Any work done by an

unauthorized person could be dangerous.

Installation must conform with all local and national

~

codes and regulations.

Before installation, disconnect the dryer from the

~

electrical supply by shutting off the power, unplugging the

power cord or tripping the circuit breaker. Do not restore

power until installation is complete.

Be certain your appliance is properly installed and

~

grounded by a qualified technician.

For electrical safety this appliance must be grounded

~

z in accordance with local codes. It is imperative that this

basic safety requirement be met. If there is any doubt, have

the electrical system of the house checked by a qualified

electrician.

Do not damage, remove or bypass the safety

~

components, fixtures and control elements of this machine.

CAUTION: Label all wires prior to disconnection when

~

servicing controls. Wiring errors can cause improper

operation.

Ensure that there is adequate ventilation for operation in

~

the room where it is installed.

Do not operate the dryer in a room where cleaning

~

machines operate with solvents containing CFC. Vapors

turn into salt acid which may damage the laundry and

machine. When operated in adjoining rooms, there should

be no air exchange possible.

CAUTION: An unvented dryer produces combustible

~

lint. Exhaust outdoors!

No filters or louvers should be built into the exhaust

~

duct.

The connection between the exhaust ducting and the

~

dryer must be airtight.

Protect exhausts ducted into the open air against the

~

weather by a 90° downward angle.

To facilitate cleaning of the duct, cleaning flaps or

~

covers should be fitted on the bends wherever possible.

With upward sloping exhaust ducting a condensate

~

drain must be made at the lowest point.

Use only genuine Miele spare parts to replace faulty

~

components.

The minimum dimensions and distance required from

~

the wall, as shown in the installation diagram, must be

observed to allow service to be performed and the data

plate to be viewed.

Do not install the dryer where it is exposed to water

~

and/or the weather.

Install the dryer with adequate clearances for servicing

~

and proper operation.

See the "Installation - Exhaust, Air intake, Ventilation

~

cross sections and Steam" manual for more information.

SAVE THESE

INSTRUCTIONS

The exhaust must not be led into a chimney used by

~

another gas, coal or oil heated appliance. It must not be

connected to any gas vent, chimney, wall, ceiling, or

concealed space of a building. It should be directed by the

shortest route into the open air or into a suitable venting

duct. The duct must be designed and installed to

accommodate the high air throughput (as few bends and

as short a duct as possible and well shaped, leakproof

joints).

32

The dryer must be installed and tested by Miele's

Technical Service Department or an authorized

dealer.

This appliance must be installed in accordance with

the applicable regulations and may be used only in

rooms with adequate ventilation.

Read the instructions prior to installation and use of

this appliance.

Do not put the dryer in rooms where the temperature

may drop below freezing.

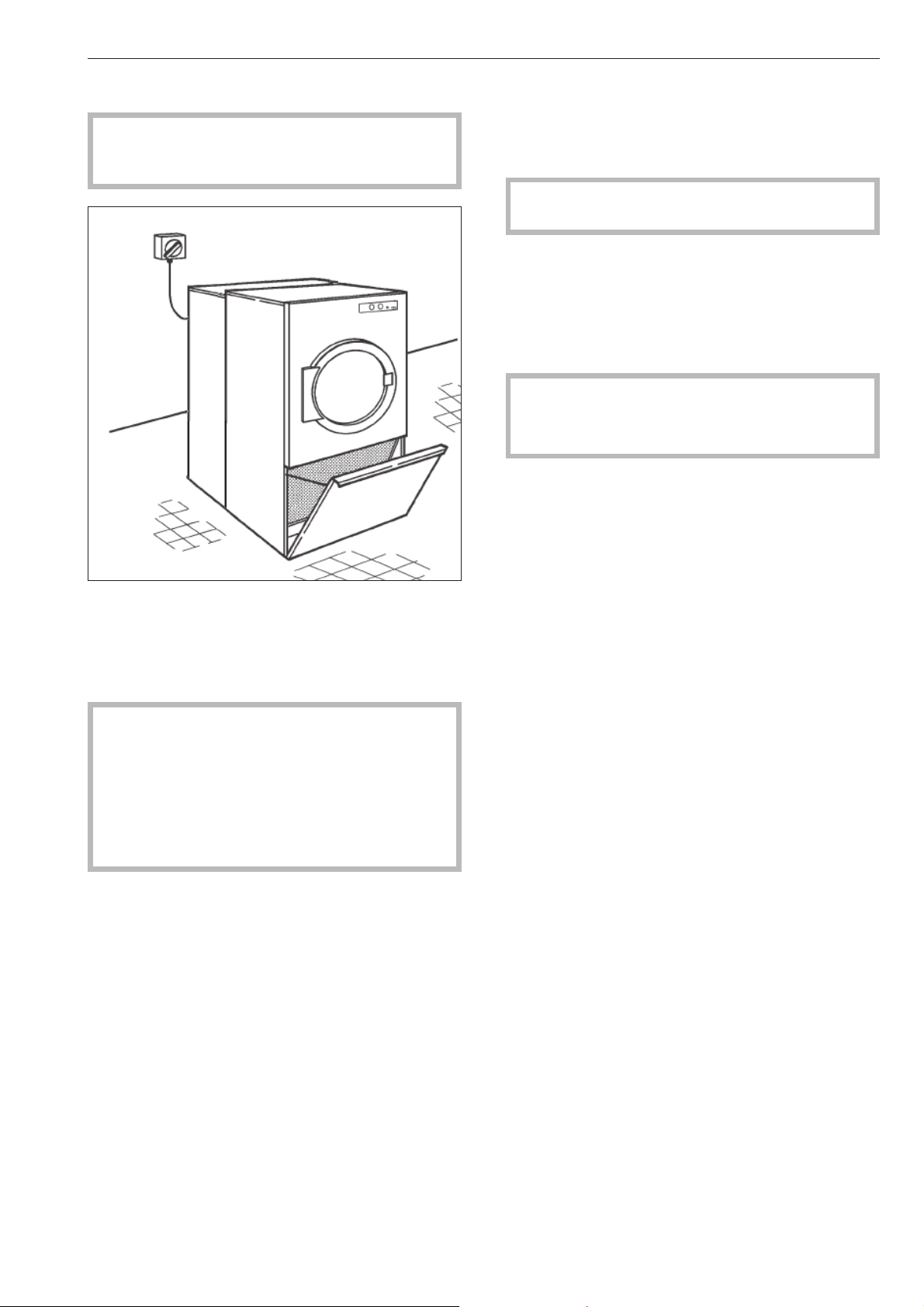

Installation

For ease of maintenance and servicing, the minimum

dimensions and distance to the wall with passage

must be observed.

The dryer and the heat pump must not be

,

transported without a shipping pallet.

The dryer and heat pump modules must be

separated when being transported even over short

distances. Transporting these modules as a single

unit is not permitted and may result in damage.

The system may be transported only using suitable

transport aids.

Avoid tilting the heat exchanger more than 30°.

Following transport, the heat pump should rest for

one hour before being activated. The resting phase

should be extended up to 24 hours following any

heavy shaking or tilting beyond 30°.

At the installation location, lift the dryer and the heat

pump from the shipping pallet using appropriate

lifting equipment.

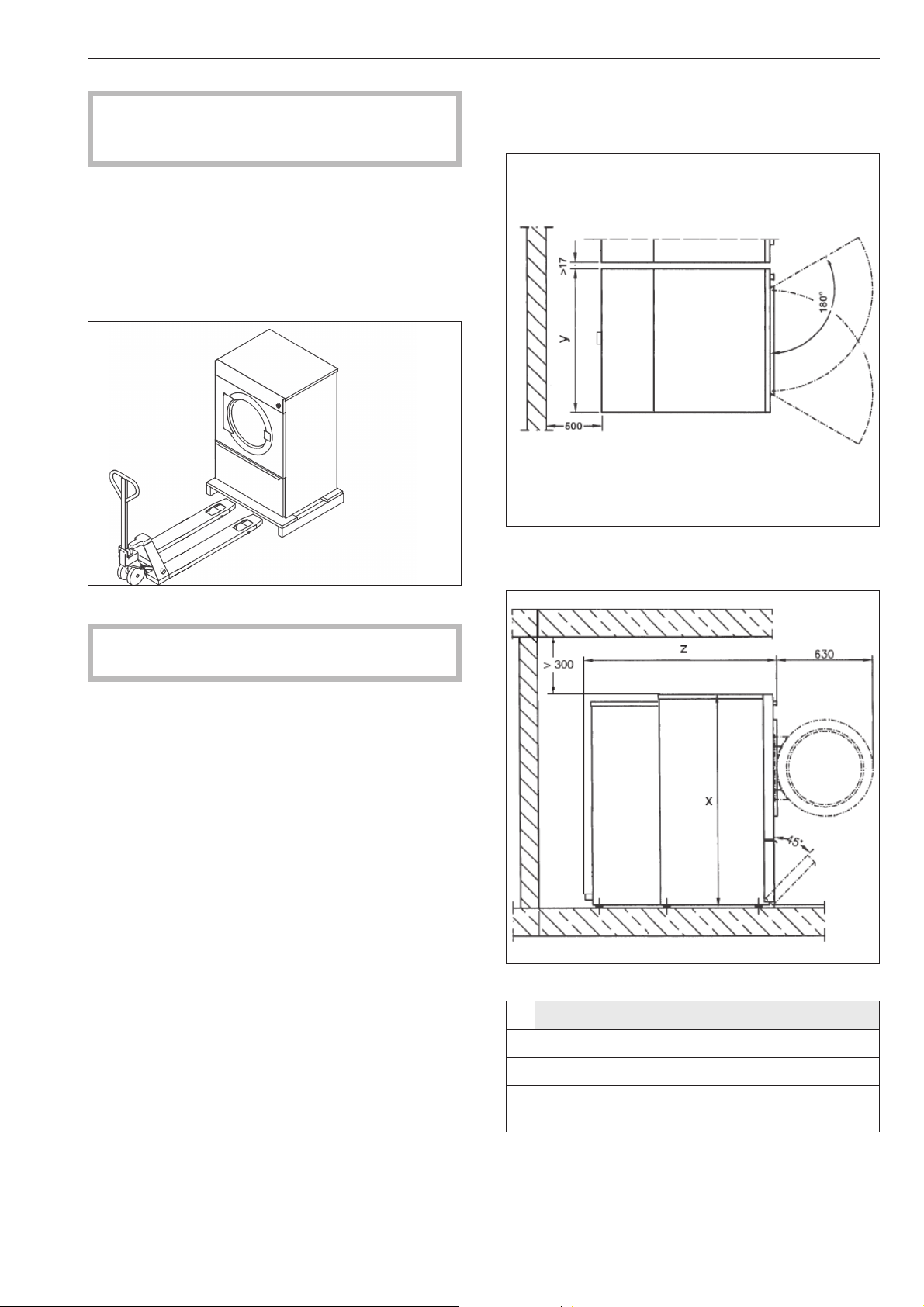

Minimum distance to the wall and accessibility of the

maintenance passage 19 11/16" (500 mm).

PT 8257 / 8337

x 55 1/8" (1400 mm)

y 35 11/16" (906 mm)

7

z 47

/16" (1205 mm) /

13

54

/16" (1393 mm)

33

Installation

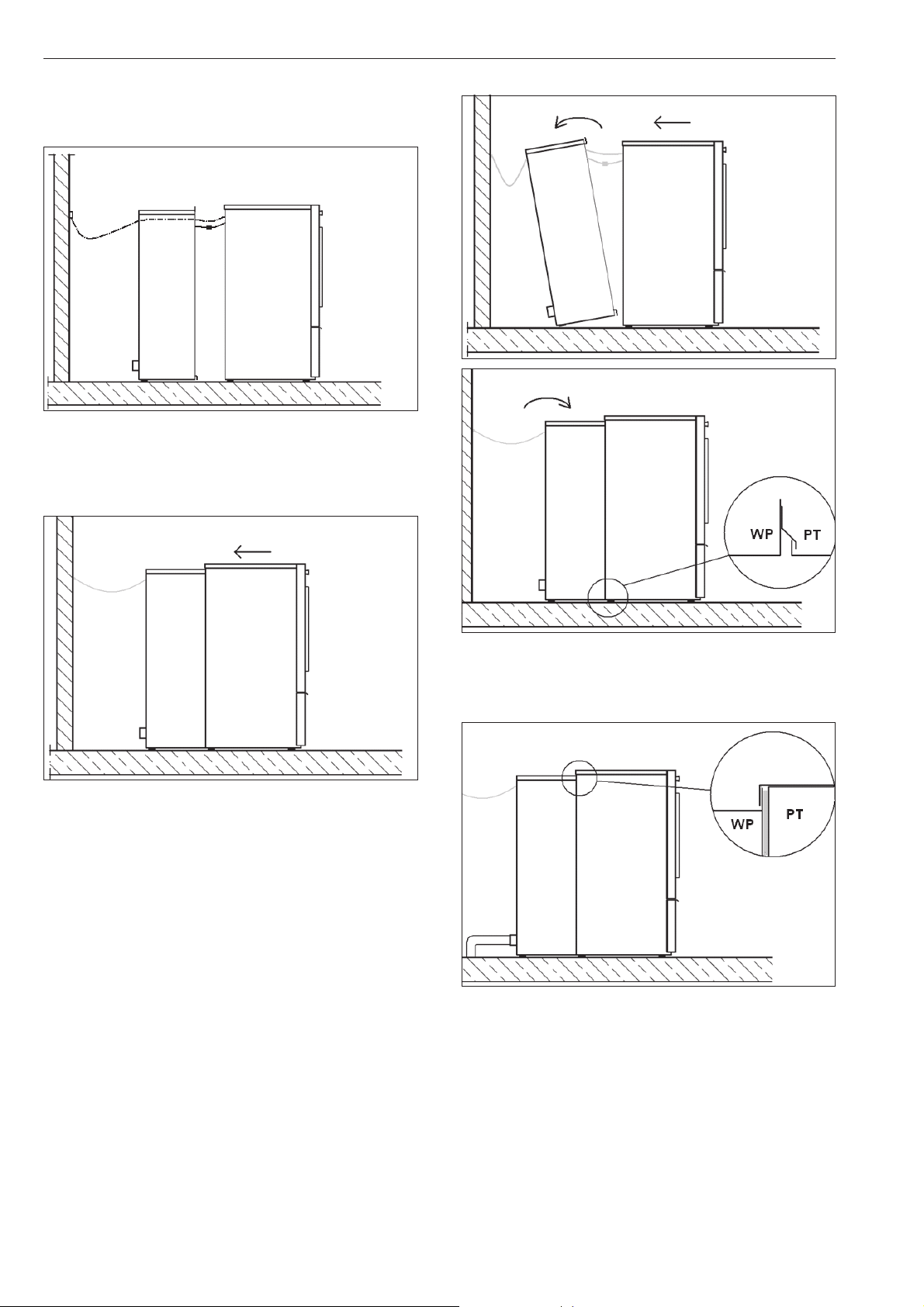

Install dryer and heat pump

Remove dryer cover.

Rout the connection line through the heat pump and

connect to dryer (see electrical connection).

Insert the heat pump-dryer connection line, plug into

the socket on the dryer.

The dryer is placed in front of the air openings of the

heat pump. Using the adjustable feet, level the dryer

and heat pump and align them parallel to one

another .

Tilt the heat pump slightly so that the bottom lug fits

over the bottom profile edge on the dryer. Return the

heat pump to level position so that it is not possible to

shift the dryer forward.

The clamping lug of the heat pump must clamp

beneath the dryer cover. Screw on dryer cover.

Ensure that there is no air leakage between the dryer

and heat pump.

34

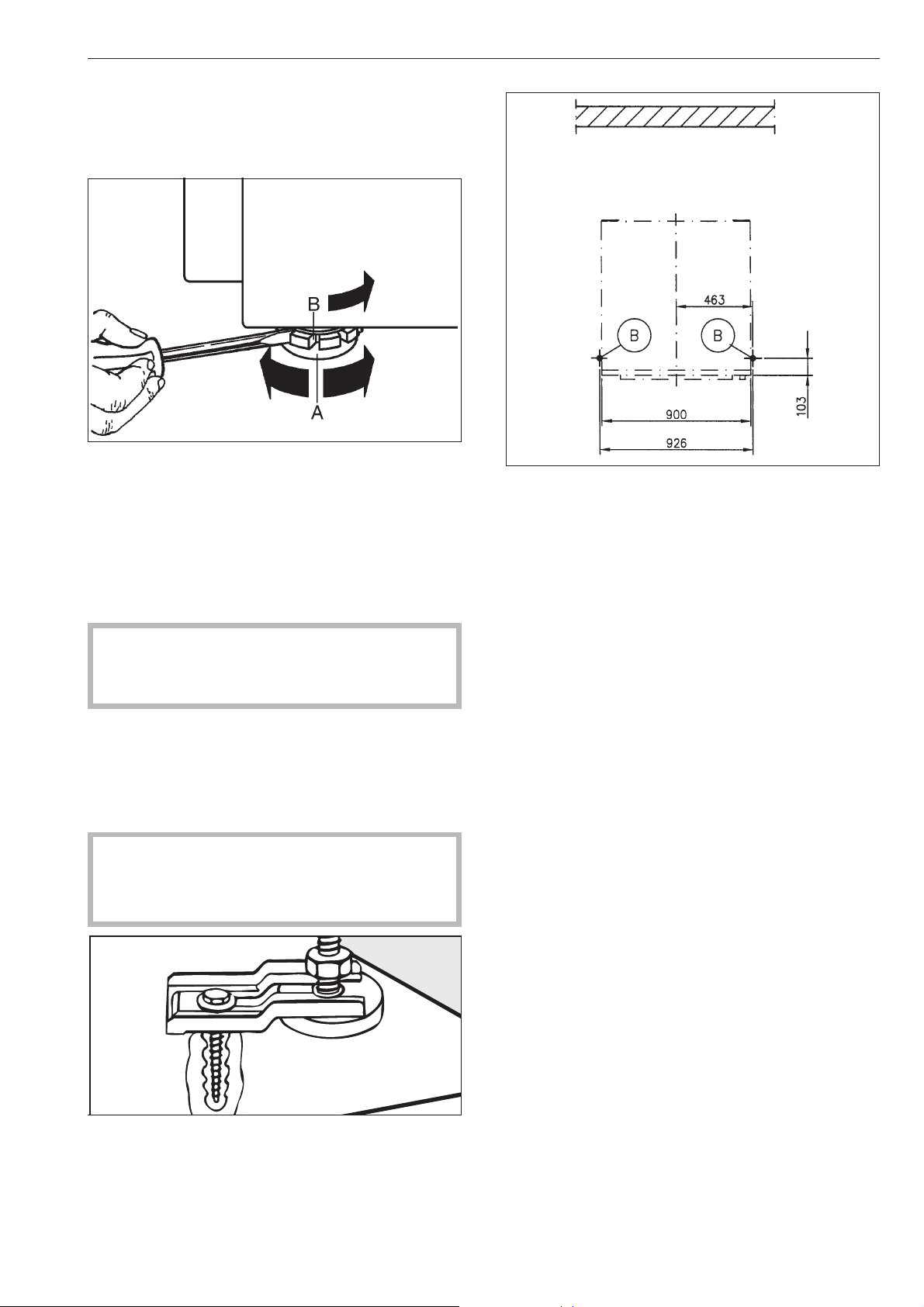

Leveling the dryer

The dryer and the heat pump do not need to be

installed on a base. However, adjustments must be

made to compensate for any unevenness in the floor.

The dryer and the heat pump must be level for proper

operation.

Level the dryer and the heat pump by adjusting the

dryer’s four adjustable feet (A).

Once leveled, the discs (B) must be screwed tight to

the dryer’s base plate.

Installation

b Drill holes for retaining clips

Coin mechanism

The dryer can be equipped with a coin mechanism*.

This requires an adapter*. The necessary

reprogramming of the dryer must be performed by a

Miele Service Technician.

Prior to initial startup, the system must be adapted

to ambient temperature and remain still for at least

one hour.

Installation on an elevated base

The dryer can be installed on an elevated concrete

base.

,

If installing the heat pump dryer on an existing

concrete base, it must be secured with retaining

clips. Otherwise, the heat pump dryer may fall off

the base.

Empty the coin box on a daily basis. This prevents

the coins and tokens from accumulating and causing

a malfunction.

* can be ordered from Miele.

Communication module XKM RS232

(where available)

The communication module makes it possible to

connect the dryer to a PC (personal computer) via a

serial interface.

The outlet for the module is located on the back of the

dryer.

This requires a special Editor Program which is

available from the Miele Professional Department.

^

Secure the front feet of the dryer with the retaining

clips provided.

35

Installation

Electrical connection

The electrical connections must be carried out by a

certified electrician in accordance with all the national

regulations.

Observe the enclosed wiring diagram.

Before installation, make sure that the voltage and

frequency listed on the data plate correspond with

the site’s electrical supply.

Intake air, ambient air

(EA) exhaust air, (IA) intake air, (CD) condensate

drain

(EL) Electrical connection, (SLA) Peak load cutout

If the appliance is hard wired, a multiple-pole

separator must be installed. Separators with a

contact gap of more than 1/8" (3 mm) are valid as

separators. All components have to bear CSA or UL

approval.

The plug connection or the separator must be

accessible at all times.

You must be able to lock the separator or monitor it at

all times in case the appliance has to be

disconnected from the power supply.

When the dryer has been connected, check the

rotation direction of the compressor.

,

An incorrect phase connection will result in a

loud, chattering noise. Incorrect compressor

rotation direction will damage the system and must

be stopped immediately.

The dryer may be operated only if there is a supply of

adequately cool fresh air. If ambient temperature

frequently exceeds 113°F (45°C), the cooling circuit

of the heat pump must be connected to an external

intake and exhaust air line.

Condensate drain

The dryer with heat pump operates according to the

principle of condensation. The appearing

condensation water must be drained separately via a

floor drain.

The C 1 3/16" (30 mm) condensation water drain is

located on the rear of the water pump and can be

routed to the floor drain via a hose or downward

sloping pipe.

,

Once the system has been installed, replace

all the outer housing parts that were removed.

36

Technical Data

PT 8257 WP PT 8337 WP

Height 4' 7 1/8" (1400 mm) 4' 7 1/8" (1400 mm)

Width 2' 11 11/16" (906 mm) 2' 11 11/16" (906 mm)

Depth 3' 11 7/16" (1205 mm) 4' 6 13/16" (1393 mm)

Depth with door open 6" 1/4" (1835 mm) 6" 7 5/8" (2023 mm)

Weight 696 lb (315.5 kg) 724 lb (328.5 kg)

Drum volume 66 gal (250 l) 86 gal (325 l)

Max. dry laundry weight 28.7 lb (13 kg) 35.3 lb (16 kg)

Connected voltage see data plate

Rated load see data plate

Fuse rating see data plate

Certificates see data plate

Max. installed floor load in N

Noise pressure level < 70 dB (A)

Noise power level < 80 dB (A)

PT 8257 WP PT 8337 WP

37

38

Quick Guide

1.Sort the laundry

Not all fabrics are suitable for drying in a tumble dryer. Pay attention to the manufacturer’s

instructions on the wash care label.

q = Dry at normal temperature

r = Dry at low temperature

s = Do not tumble dry

Sort the laundry by fabric and color

^

2.Turn on the dryer and load the laundry

Press the l "On" button to turn the dryer on.

^

Open the drum door and load the laundry loosely into the drum.

^

3.Turn the jog shuttle to select a program

Programs may vary depending on the offerings of your machine.

1 White Cottons 0% 14 Outerwear 0%

2 Cottons 0% 15 Hand wash Silks 16%

3 Colors 0 % 16 Hand wash Woolens

4 Darks 0% 17 Waterproofing 0%

5 Wrinkle Free 0% 18 Hot air 20 Min.

6 Delicates 20% 19 Cool air 15 Min.

7 600+TC Sheets Hot 0% 20 Smoothing

8 600+TC Sheets Warm 0% 21 Denim / Jeans 2%

9 Silk and Rayon Bed Linens 16% 22 Dress Shirts 2%

10 Down Comforters & Pillows 0% 23 Towels 0%

11 Washable Bedspreads 0% 24 Outerwear Plus 0%

12 Linen Tablecloths 25% 25 Automatic 0%

13 Mixed Fiber Tablecloths 25%

4.Press the "Start" button to start the program

5.The buzzer sounds when the program is finished

^

Open the drum door and remove the laundry.

2 Cottons

Program end

Anti-crease Finished 12:35

m FC A

6.After drying

^

Close the drum door.

^

If necessary, clean the lint filter.

39

40

41

Alteration rights reserved / 1612

M.-Nr. 09 390 530 / 00

Loading...

Loading...