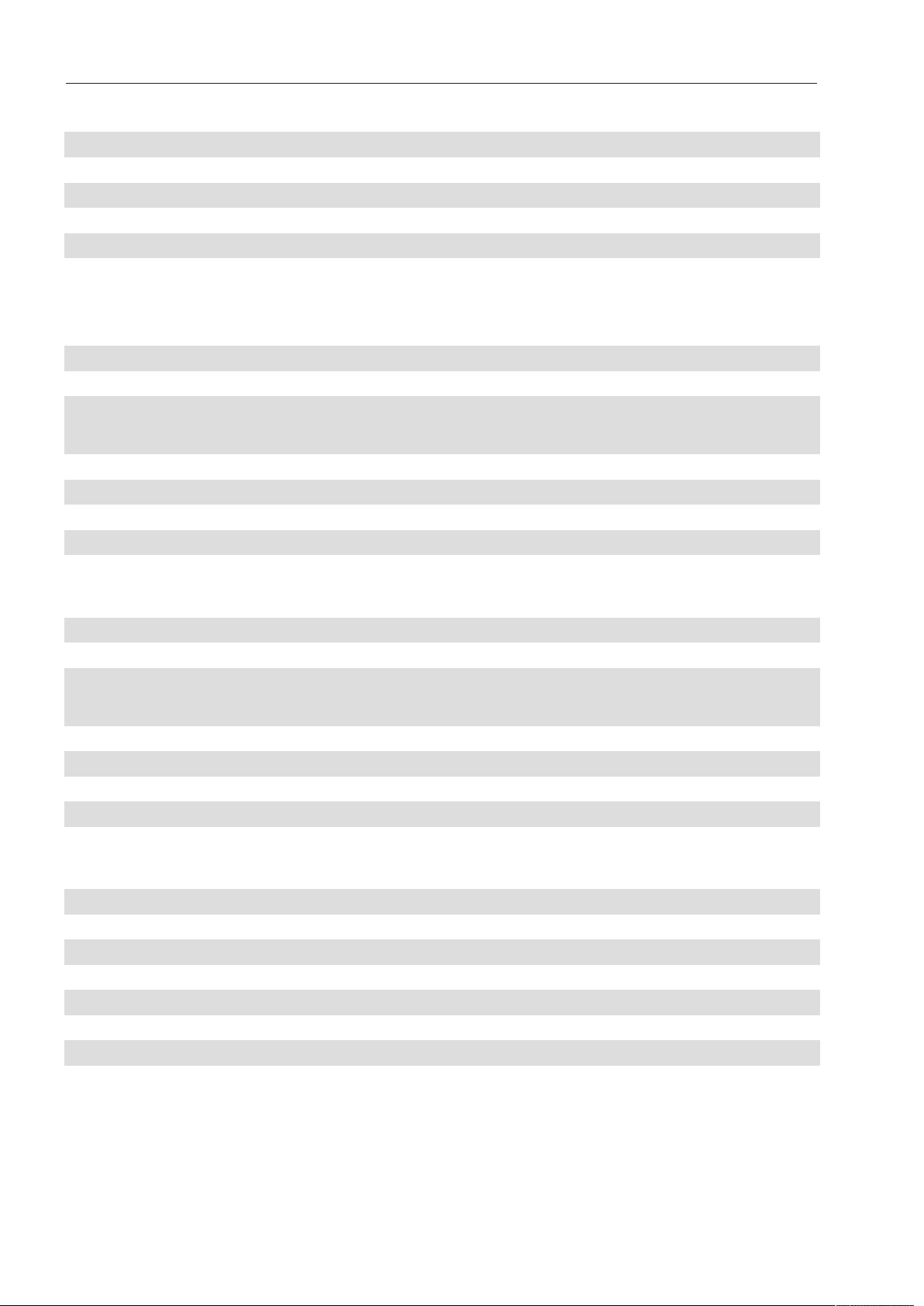

Miele PLW 6111 Installation diagram

Installation plan

PLW6111

It is essential to read the operating instructions as

well as the service documentation before the

machine is installed or used for the first time.

en - US

M.-Nr. 11 206 630

Installation notes

Installation requirements

Surrounding area

Installation

Electrical connection

This machine must be installed by a suitably qualified person with

the appropriate electrical and plumbing qualifications in accor-

dance with the installation instructions supplied.

This machine must be installed in accordance with all applicable

standards and guidelines, including legal requirements and health

and safety regulations.

The machine must be commissioned and operatives trained in its

use by Miele Service or by an approved Miele Service Partner only.

Condensate can build up in the area surrounding the machine. Any

cabinetry and fixtures in the room must be suitable for such an environment.

The machine must be installed on a level surface.

Connection to the electrical supply must be carried out in accordance

with local and national safety regulations. The power cord must be

protected from the risk of thermal damage.

It is recommended to make electrical connections via a plug and

socket so that service and maintenance can be carried out easily.

For hard-wired machines this must be via a main switch to be pro-

vided on site, which must completely isolate the machine from the

power supply with a contact gap of at least 1/8’’ (3mm).

The plug and socket as well as the main switch must be easily accessible after the machine has been installed.

Equipotential

bonding and

grounding

Equipotential bonding should be carried out if required. The screw

connection point for equipotential bonding (size M8) is located at the

back of the machine. Equipotential bonding and grounding must

be carried out before the machine is commissioned.

2 PLW6111

Installation notes

Vented Air

Connection

Vent to atmosphere with steam condenser.

In order to improve room climate as far as temperature and humidity

is concerned the chamber vent can be connected to an external venting conduit. Prevent condensate backflow into laboratory glassware

washer.

Pitch vent ducting and discharge condensate at lowest point. The

conduit must be in stainless steel A304 (V2S) or in a plastic material

suitable for high temperatures (constant 203 °F)

or in polypropylene (PP).

In case of connection with an external system, provide the air break.

Vent to atmosphere with steam condenser. Vent multiple laboratory

glassware individually (do not use manifold).

PLW6111 3

Technical details

Electrical connection

Voltage (standard version) 3 AC 208V/60Hz

Power rating 8.25kW

Fuse rating 3 x 30A

Power cord, min. cross-section 4 x AWG 8

Power cord length 6' 6'' (2 m)

Voltage fluctuation, max. permitted +/- 10%

Cold water

Length of cold water inlet hose 6' 6''

Maximum temperature 59 °F (15 °C)

Water hardness, max. permitted without water softener

(If the water hardness is more than 4gpg, a water softener must be used. Connection for liquid

dispensing system is available.)

Minimum flow pressure 29psi

Maximum pressure 116psi

Flow rate 3.2gal/min

On-site threaded union 3/4" Pipe thread

4gpg

Hot water

Inlet hose length 6' 6''

Maximum temperature 140°F

Water hardness, max. permitted without water softener

(If the water hardness is more than 4gpg, a water softener must be used. Connection for liquid

dispensing system is available.)

Minimum flow pressure 14.5psi

Maximum pressure 116psi

Flow rate 3.2gal/min

On-site threaded union 3/4" Pipe thread

4gpg

Demineralized water

Length of demin. water inlet hose 6' 6''

Maximum temperature 140°F

Max. water hardness 0.82gpg

Minimum flow pressure 14.5psi

Maximum pressure 116psi

Flow rate 3.2gal/min

On-site threaded union in accordance with DIN44991 (flat sealing) 3/4" Pipe thread

4 PLW6111

Loading...

Loading...