Loading...

Loading...P

- PG8056208V2

- PG8056240V4

- PG8056U2402

- PG8056UAE208V2

- PG8061240V4

- PG8061UAE208V3

- PG8061UAE240V

- Pg8080BW

- PG8080I240

- PG8083SCVI120V6

- PG8083SCVI240V6

- PG8130I240V2

- PG8132SCIXXL2

- PG8133SCVI240V

- PG 850441

- PG 852738

- PG 8527 D7

- PG 8527 EL15

- PG 8527 EL AV2

- PG 852840

- PG 8528 D7

- PG 8528 EL16

- PG 853524

- PG 8535 OXIVARIO12

- PG 853630

- PG 8536 LFM

- PG 8536 OXIVARIO

- PG 8536 RU

- PG 85627

- PG 858139

- PG 858243

- PG 8582 CD39

- PG 858350

- PG 8583 CD44

- PG 859134

- PG 859242

- PG 859348

- PG 85952

- PG 8596

- PG 85972

- PG 88213

- PG 88225

- PG 88255

- PG 88304

- PG89222

- PG89302

- PIB 10021

- PLATINUM2

- Platinum Plus3

- Plus G686

- PLW 601133

- PLW 611135

- PLW 85052

- PLW 861527

- PLW 861626

- PLW 861725

- PM 121064

- PM121466

- PM 121766

- PM 131828

- PM 1318 EL9

- PM 1318 G6

- PM 1318 G L

- PM 1318 G L-GE

- PM 141830

- PM 1418 EL7

- PM 1418 G6

- PM 1418 G L

- PM 1418 G L-GE

- PM 142130

- PM 1421 EL8

- PM 1421 G6

- PM 1421 G L

- PM 1421 G L-GE

- PM 162117

- PM 162517

- PM 163017

- PM 163517

- PM 182517

- PM 183017

- PM 183517

- POIGNE

- Polaris

- PowerLine Complete C3 Allergy SGFF5

- Prasek

- Preformance 1600

- Premier

- Premier 300

- Premier 3000

- Premier 5202

- PREMIER NOVO2

- PREMIER NOVO W842

- Premier Plus2

- Premier W 500

- Premier W520

- Premier W522

- PRESTIGE

- Prestige Plus

- Prestige Plus 62

- PRI 2105

Loading...

Loading... Loading...

Loading...Nothing found

PLW 6011

Installációs terv [hu]

19 pgs515.35 Kb0

Installatietekening [nl]

19 pgs514.08 Kb0

Installation diagram

17 pgs513.03 Kb0

Installation diagram [cs]

19 pgs515.9 Kb0

Installation diagram [de]

19 pgs516.54 Kb0

Installation form [no]

19 pgs513.8 Kb0

Installation Manual [zh]

64 pgs2.43 Mb0

Installation plan [el]

19 pgs518.67 Kb0

installation plan [es]

18 pgs513.63 Kb0

Installation Plan [hr]

19 pgs514.99 Kb0

Installation plan [sl]

19 pgs514.19 Kb0

Installation Plan [tr]

18 pgs512.34 Kb0

Instructions Manual

64 pgs1.75 Mb0

Instructions Manual [bg]

64 pgs1.78 Mb0

Instructions Manual [el]

64 pgs1.79 Mb0

Instructions Manual [ro]

60 pgs1.75 Mb0

Instructions Manual [sl]

64 pgs1.75 Mb0

Operating instructions

60 pgs1.72 Mb0

Plan de instalare [ro]

19 pgs514.95 Kb0

User manual

60 pgs1.74 Mb0

User manual

60 pgs1.74 Mb0

User manual

60 pgs1.7 Mb0

User manual

60 pgs1.74 Mb0

User manual

60 pgs1.74 Mb0

User manual [cs]

60 pgs1.76 Mb0

User manual [de]

60 pgs1.74 Mb0

User manual [hr]

60 pgs1.76 Mb0

User manual [hu]

60 pgs1.8 Mb0

User Manual [nl]

60 pgs1.74 Mb0

User manual [no]

60 pgs1.74 Mb0

User manual [pt]

60 pgs1.75 Mb0

User Manual [ru]

68 pgs1.9 Mb0

User manual [tr]

60 pgs1.77 Mb0

Table of contents

Loading...

Loading...Specifications and Main Features

Frequently Asked Questions

User Manual

Page 1

Page 2

Page 3

Page 4

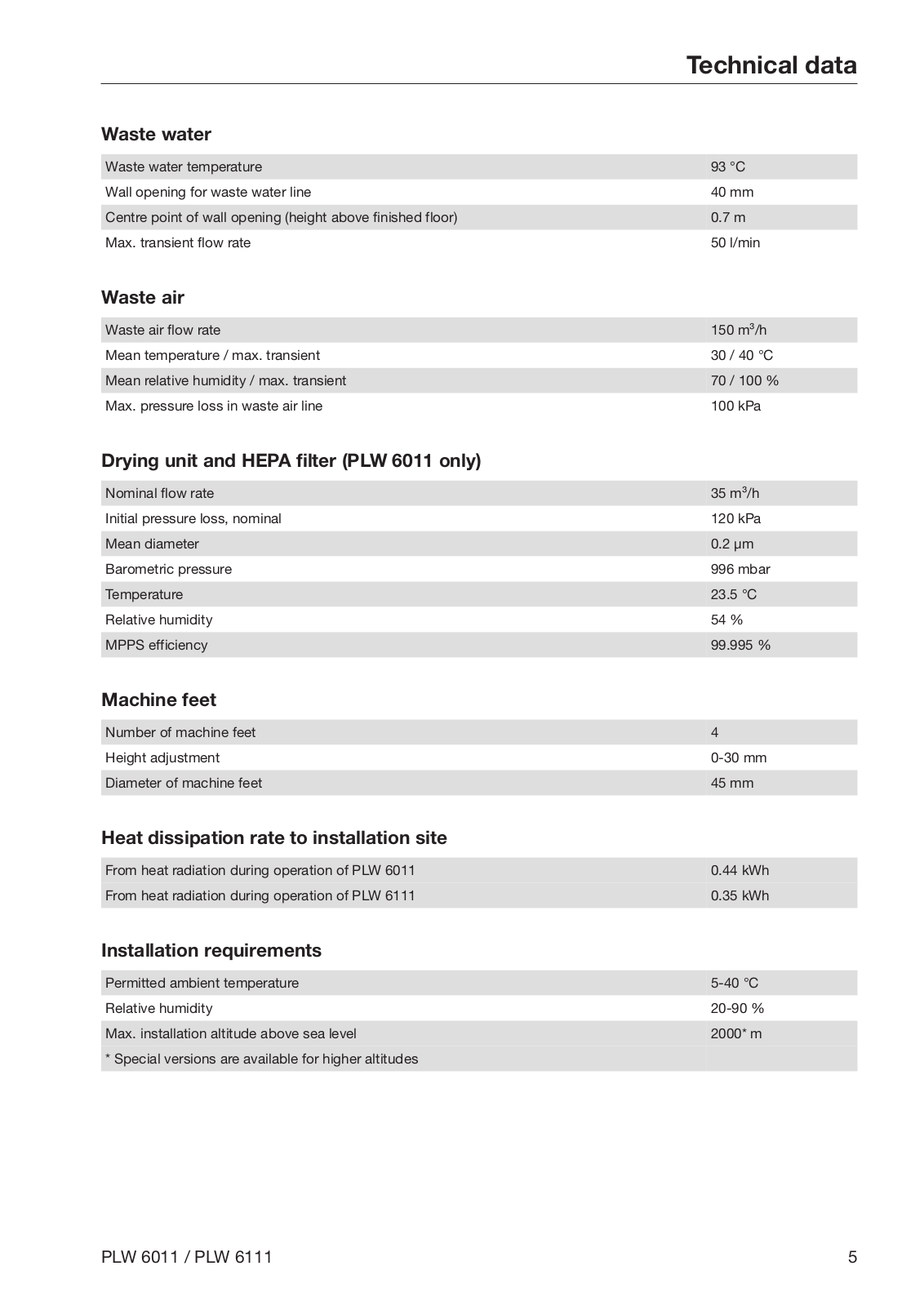

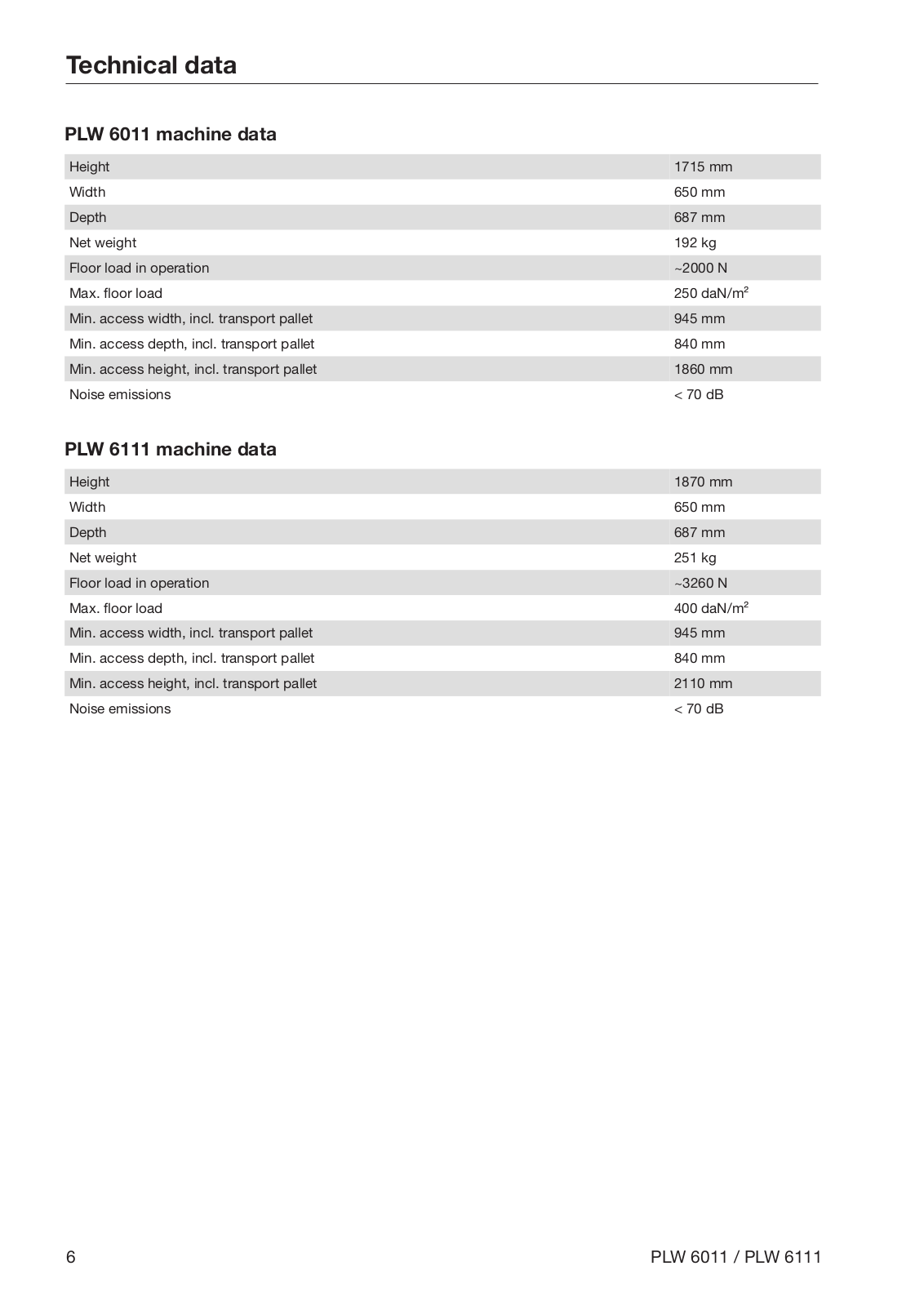

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Loading...

Loading...+ hidden pages