Page 1

p

K

Operating instructions

Lab washers

PLW 6011

PLW 6111

Read the operating instructions carefully before

installing and using the machine. This will help

protect users from personal injury and help

revent damage to the machine.

en – U

Page 2

Page 3

CONTENTS

Contents

1. GENERAL RULES ..................................................................................................... 6

1.1Limitation of liability ............................................................................................................... 6

1.2Validity, content and storage ................................................................................................ 6

2. PRODUCT INFORMATION ....................................................................................... 7

2.1Appropriate use ...................................................................................................................... 8

2.2Safety instructions and warnings ......................................................................................... 9

Appropriate use .................................................................................................................... 9

Risk of injury ......................................................................................................................... 9

Quality assurance ............................................................................................................... 11

Safety with children ............................................................................................................ 12

Using accessories .............................................................................................................. 13

Disposing of your old appliance ......................................................................................... 13

Warning signs ..................................................................................................................... 13

2.3Technical data ...................................................................................................................... 14

2.4Recommendations for proper operation ........................................................................... 15

2.5Training .................................................................................................................................. 16

User profiles ........................................................................................................................ 16

3. INSTALLATION ....................................................................................................... 17

3.1Water connection ................................................................................................................. 17

Water quality ....................................................................................................................... 17

Information: ......................................................................................................................... 18

3.2Electrical connection ........................................................................................................... 19

4. BUILT-IN WATER SOFTENER (OPTIONAL) .......................................................... 20

4.1Salt refill indicator ................................................................................................................ 20

4.2Refilling the salt .................................................................................................................... 21

5. DISPENSING ........................................................................................................... 22

5.1Fill level sensor ..................................................................................................................... 22

5.2Dispensing quantity control ................................................................................................ 22

5.3Refilling process chemicals ................................................................................................ 22

5.4Caution! ................................................................................................................................. 23

6. OPERATION ............................................................................................................ 24

6.1Checking consumption ........................................................................................................ 24

6.2Opening and closing the door ............................................................................................. 24

Emergency release ............................................................................................................. 25

6.3Switching on ......................................................................................................................... 26

6.4Preparation ........................................................................................................................... 26

Checks after a programme ................................................................................................. 27

7. CONTROL PANEL AND SYMBOLS USED ............................................................ 28

7.1Control panel ........................................................................................................................ 28

REV.0.01_COD.650138_A4

Page 3

Page 4

CONTENTS

7.2Buttons .................................................................................................................................. 29

Buzzer ................................................................................................................................. 29

7.3Display ................................................................................................................................... 30

8. PROGRAMMES ....................................................................................................... 33

8.1Programme blocks ............................................................................................................... 34

8.2Programme overview ........................................................................................................... 35

8.3Starting the programme ...................................................................................................... 39

9. MACHINE STATUS ................................................................................................. 40

9.1Ready for operation ............................................................................................................. 40

9.2Programme ........................................................................................................................... 40

9.3Malfunctioning ...................................................................................................................... 40

9.4Power failure ......................................................................................................................... 41

9.5Reset ...................................................................................................................................... 41

10. MENU ....................................................................................................................... 42

10.1Accessing the menu ............................................................................................................. 42

10.2Parameter settings ............................................................................................................... 43

10.3Parameter list ....................................................................................................................... 43

11. CLOCK ..................................................................................................................... 44

12. BUZZER ................................................................................................................... 44

13. HISTORICAL DATA (batch protocols) ................................................................... 44

13.1Outputting batch protocols retrospectively ...................................................................... 44

External software ................................................................................................................ 44

14. WARNINGS AND EVENTS LIST ............................................................................. 45

14.1Warnings list ......................................................................................................................... 45

14.2List of display messages ..................................................................................................... 47

15. USB port (optional) ................................................................................................. 48

16. Process documentation ......................................................................................... 49

16.1Serial interface ...................................................................................................................... 49

16.2User administration .............................................................................................................. 49

16.3USB port ................................................................................................................................ 49

17. MAINTENANCE ....................................................................................................... 50

17.1General recommendations on maintenance ..................................................................... 50

Machine status ................................................................................................................... 50

Safety systems ................................................................................................................... 50

Procedure ........................................................................................................................... 50

Decontamination procedures ............................................................................................. 50

17.2Maintenance reminder ......................................................................................................... 51

17.3Routine maintenance ........................................................................................................... 51

17.4Table of routine maintenance tasks ................................................................................... 51

17.5Drying air filtration ................................................................................................................ 56

17.6Special maintenance ............................................................................................................ 56

REV.0.01_COD.650138_A4

Page 4

Page 5

CONTENTS

Table of special maintenance work .................................................................................... 56

18. PROBLEMS – CAUSES – Remedy ......................................................................... 57

18.1Introduction ........................................................................................................................... 57

18.2Problem (P) – Cause (C) – Remedy (R) ............................................................................... 57

19. DISPOSING OF YOUR OLD MACHINE ................................................................. 58

REV.0.01_COD.650138_A4

Page 5

Page 6

GENERAL RULES

1. GENERAL RULES

The washer-disinfector is generally referred to as “the machine” in these operating instructions.

Reprocessable laboratory glassware and utensils are referred to as “load items” if they are not

more closely defined.

1.1 Limitation of liability

The manufacturer shall not be held liable for faults or problems which arise due to tampering or

incorrect or improper use/operation of the machine.

The operator must comply with all instructions set forth in the operating instructions, most

notably:

Always consider the intended use of the machine

Always carry out the required maintenance work

Use of the machine should be limited to persons who have been properly trained and

instructed on the use of the machine

Use only original spare parts

Any modifications, adaptation or similar which may be made to machines which are subsequently

placed on the market do not oblige the manufacturer to intervene on previously supplied

machines, nor to consider the related operating instructions lacking and inadequate.

The operating instructions on the following pages are designed to guarantee the longevity and

functionality of your machine.

The instructions in this manual do not replace, but rather supplement employer requirements to

adhere to current legislation on standards of prevention and safety.

1.2 Validity, content and storage

It is important to keep this instruction manual with the machine for future reference.

If the machine is sold or transferred, the manual must be handed over to the new owner or users

so that they can become acquainted with its functioning and the relevant safety instructions and

warnings.

Read the warnings carefully before installing and using the machine.

REV.0.01_COD.650138_A4

Page 6

Page 7

2. PRODUCT INFORMATION

Before starting work, the user must be completely familiar with the functions and proper operation

of the machine. The user must know the precise functions of all command and control devices of

the machine.

PRODUCT INFORMATION

PLW 6011 PLW 6111

REV.0.01_COD.650138_A4

Page 7

Page 8

PRODUCT INFORMATION

2.1 Appropriate use

This machine is used to reprocess laboratory glassware and laboratory utensils using water. The

process includes cleaning, rinsing and, where required, disinfection and drying. Due to the wide

variety of laboratory glassware and laboratory utensils on the market, it may be necessary in some

cases to establish whether the item is suitable for reprocessing in a washer-disinfector.

This will depend on its use and the type of soiling present as well as the disinfection parameters.

Please refer to the information provided by the manufacturer of the laboratory glassware and

laboratory utensils.

Laboratory glassware and laboratory utensils suitable for reprocessing include:

Vessels such as test tubes, beakers, flasks, cylinders, etc.

Measuring vessels such as measuring cylinders, pipettes, volumetric flasks, etc.

Dishes such as Petri dishes, watch glasses, etc.

Plates such as slides, sequencing plates, etc.

Small items such as lids, spatulas, magnetic stirring rods, stoppers, etc.

Other items such as funnels, pipe/hose pieces, etc.

EXAMPLES OF APPLICATION AREAS:

Laboratories in schools, colleges and universities

Research, quality assurance, development, technology and production

Different areas of inorganic, organic, analytical and physical chemistry

Biology, microbiology and biotechnology

Hospital laboratories

Reprocessing conditions must be suitable for the load and for the type of soiling. Process

chemicals must be suitable for the type of soiling and for methods of analysis being used.

The use of a suitable load carrier (mobile unit, basket, module, insert, etc.) is important to ensure

adequate reprocessing of the load.

The machine can be qualified for process validation.

The machine fulfils the requirements of the EU Machinery Directive 2006/42/EC.

REV.0.01_COD.650138_A4

CAUTION

Inappropriate use can lead to personal injury and damage to property.

Miele cannot be held liable for damage caused by improper or incorrect use or

operation of the machine.

Page 8

Page 9

2.2 Safety instructions and warnings

This machine complies with all statutory safety requirements. Inappropriate use can lead to

personal injury and damage to property.

Read the operating instructions carefully before using this machine. This will prevent both

personal injury and damage to the machine.

Keep these instructions in a safe place where they are accessible to users at all times.

Appropriate use

Use of the machine is only approved for the applications stated in the operating instructions.

Alterations or conversion of the machine, or using it for purposes other than those for which it was

intended, are not permitted and could be dangerous.

The cleaning and disinfection processes are only designed for laboratory glassware and utensils

which are designated as reprocessable by the manufacturer. The information provided by the

manufacturer of the load items must be observed.

Miele cannot be held liable for damage caused by improper or incorrect use or operation of the

machine.

This machine is intended for indoor use only.

PRODUCT INFORMATION

Risk of injury

Please pay attention to the following notes to avoid injury

Customer Service Department or a suitably qualified service technician. A Miele service contract

is recommended to ensure full compliance with GLP guidelines. Incorrect repairs can cause

considerable danger to users.

conditions.

furniture and fittings that are designed for use in commercial environments.

protective gloves when transporting and setting up the machine.

essential that this standard safety requirement is observed and regularly tested. If in any doubt,

please have the electrical installation inspected by a qualified electrician. Miele cannot be held

liable for the consequences of an inadequate earthing system (e.g. electric shock).

or leaking machine immediately and contact the Miele Customer Service Department.

Untrained personnel must not be allowed access to the machine or its controls.

application. The manufacturer of the process chemicals is liable for any negative influences on the

material of the load and the machine.

toxic.

The relevant safety regulations and safety data sheets issued by the process chemical

manufacturers must be observed.

Wear gloves and protective goggles.

The machine may only be installed, commissioned, repaired and maintained by the Miele

Do not install the machine in an area where there is any risk of explosion or of freezing

In order to reduce the risk of water damage, the area around the machine should be limited to

With some metal parts, there is a risk that you may be injured or cut. Wear cut-resistant

The electrical safety of the machine can only be guaranteed when it is correctly earthed. It is

A damaged or leaking machine can pose a threat to your safety. Always switch off a damaged

Machine operators must be instructed on the use of the machine and trained regularly.

Only use process chemicals which have been approved by their manufacturer for the relevant

Take care when using process chemicals. Some chemicals may be caustic, irritating and

REV.0.01_COD.650138_A4

Page 9

Page 10

PRODUCT INFORMATION

The machine is only designed for use with water and appropriate process chemicals. The use

of organic solvents or inflammable liquids is not permitted.

This could cause an explosion or damage rubber or plastic components in the machine and cause

liquids to leak out.

The water in the wash chamber must not be used as drinking water.

Do not lift the machine by protruding parts such as the door handle or the opened service flap

as these could be damaged or torn off.

Do not sit or lean on the opened door. This could cause the machine to topple over and

become damaged or cause you an injury.

Be careful when sorting items with sharp, pointed ends. Position them in the machine so that

you will not hurt yourself or create a danger for others.

Broken glass can result in serious injury when loading or unloading. Broken glass items must

not be processed in the machine.

Please be aware that the machine may be operating at high temperatures. Deactivating the

lock to open the door can result in a risk of burning or scalding, or contact with corrosive

substances. Where disinfectant is in use, there is also a risk of inhaling toxic vapours.

Should personnel accidentally come into contact with toxic vapours or process chemicals,

follow the emergency instructions given in the manufacturer's safety data sheets.

Load carriers such as baskets, mobile units and inserts must be allowed to cool down before

they are unloaded. Any water remaining in containers could still be very hot. Empty this water into

the wash chamber before removing items.

Never clean the machine or near vicinity with a water hose or a pressure washer.

The machine must be disconnected from the power supply before any maintenance or repair

work is carried out.

REV.0.01_COD.650138_A4

Page 10

Page 11

Quality assurance

The following points should be observed to assist in maintaining quality standards when

reprocessing laboratory glassware and utensils and to avoid damage to the loads being

cleaned.

Only authorised personnel may interrupt a programme in exceptional circumstances.

It is the responsibility of the operator to demonstrably ensure reprocessing standards in

routine operation. Process results must be inspected and documented on a regular basis.

For thermal disinfection, use temperatures and temperature holding times to achieve the

required infection prophylaxis in accordance with current health and safety regulations.

Only reprocess undamaged and suitable items. When washing plastic items, ensure that they

are thermally resistant. Nickel-plated items and items made of aluminium require special

procedures and are not generally suitable for machine reprocessing. Ferrous materials that can

rust or corrode must not be introduced into the wash chamber as wash items or soiling.

Under certain circumstances, process chemicals may damage the machine. Users are urged

to follow the recommendations issued by manufacturers of process chemicals. Contact Miele in

the event of damage and any suspicion of material incompatibility.

Cleaning agents containing chlorine can damage the elastomers of the machine.

If cleaning agents containing chlorine have to be used, a maximum temperature of 70 °C in the

“Main wash” programme blocks is recommended (see programme chart).

Abrasive substances should not be introduced into the machine as these could cause

damage to mechanical components in the water circuit. Abrasive residues on the load must be

removed completely before reprocessing.

Pre-treatment with cleaning or disinfecting agents, some types of stains and the interaction of

certain process chemicals can create foam. Foam can have an adverse effect on the disinfection

and cleaning result.

Reprocessing should not result in foam being discharged from the chamber. Foam discharge

can compromise the operation of the machine.

The process used must be monitored on a regular basis by the operator to check foaming

levels.

Even when a process chemical, e.g. detergent, is recommended, Miele takes no responsibility

for the effect of such chemicals on the load items. Please note that changes in product

formulation, storage conditions, etc., which are not announced by manufacturers of process

chemicals may impair the quality of cleaning results.

Always follow the relevant manufacturer's instructions on storage and disposal of process

chemicals.

In critical applications where very stringent requirements have to be met, it is strongly

recommended that all the relevant factors for the process, such as detergents, water quality, etc.,

are discussed with Miele.

If the cleaning result is subject to particularly stringent requirements (e.g. chemical analysis),

regular quality control should be carried out by the operator to ensure that required standards of

cleanliness are being achieved.

Load carriers such as mobile units, baskets and inserts which hold the load must be used only

as intended.

Lumened items must be thoroughly cleaned, internally and externally.

Secure small and light items with cover nets or place in a mesh tray for small items, so that

they do not block the spray arms.

Empty any containers or utensils before loading them.

The amount of residual solvents on items going into the wash chamber should be minimal.

There should be no more than a trace of any solvents with a flash point of below 21 °C.

PRODUCT INFORMATION

REV.0.01_COD.650138_A4

Page 11

Page 12

PRODUCT INFORMATION

Chloride solutions, in particular hydrochloric acid, or ferrous materials that can rust or corrode

must not be placed in the chamber.

Ensure that solutions or steam containing chlorides or hydrochloric acid do not come into

contact with the stainless steel outer casing of the machine in order to avoid any damage through

corrosion.

After any plumbing work, the water pipework to the machine will need to be vented. If this is

not done, machine components can be damaged.

The gaps between a built-in machine and adjacent cabinetry must not be sealed, e.g. with

silicone sealant, as this could compromise ventilation of the circulation pump.

Follow the installation instructions in the operating and installation instructions.

Safety with children

Children should be supervised in the vicinity of the machine. Do not allow children to play with

the machine. There is a danger that children might shut themselves in the machine.

Children must not use the machine.

Keep children away from process chemicals. These contain irritant and corrosive ingredients

which can cause burning in the eyes, mouth and throat, or inhibit breathing. It is therefore

important to keep children away from the machine when the door is open. There could still be

residual process chemicals in the machine. Observe the safety data sheets for the process

chemicals and seek medical advice immediately if a child has swallowed process chemicals or

got them in their eyes.

REV.0.01_COD.650138_A4

Page 12

Page 13

Using accessories

Only use genuine Miele original spare parts and accessories suitable for the application they

are required for. Model designations are available from Miele.

Only use Miele load carriers, such as mobile units, baskets, modules and inserts. Using

mobile units, baskets and inserts made by other manufacturers or making modifications to Miele

accessories can result in an unsatisfactory cleaning and disinfection result. Any resultant damage

would not be covered by the warranty.

Disposing of your old appliance

Please note that the machine may contain contamination from blood and other bodily fluids,

pathogens, facultative pathogens, genetically modified material, toxic or carcinogenic substances,

heavy metals, etc., and must be decontaminated before disposal.

For environmental and safety reasons, dispose of all process chemical residues in accordance

with safety regulations. Wear gloves and protective goggles.

Make the door lock inoperable, so that children cannot accidentally shut themselves in. Then

make appropriate arrangements for safe disposal of the machine.

PRODUCT INFORMATION

Warning signs

To inform operating personnel of their obligations and to warn of residual risks, the machine is

equipped with safety labels in accordance with the relevant legislation.

General warning signs

Caution!

Danger of electric shock!

Observe the operating

The evaluation of risks for the health and safety carried out on-site, as well as the evaluation of

residual risks, determine the safety equipment which the supervisor must provide for the user.

Miele cannot be held liable for damage or injury caused by non-compliance with the safety

instructions and warnings.

Caution!

instructions!

Caution!

Hot surfaces!

REV.0.01_COD.650138_A4

Page 13

Page 14

PRODUCT INFORMATION

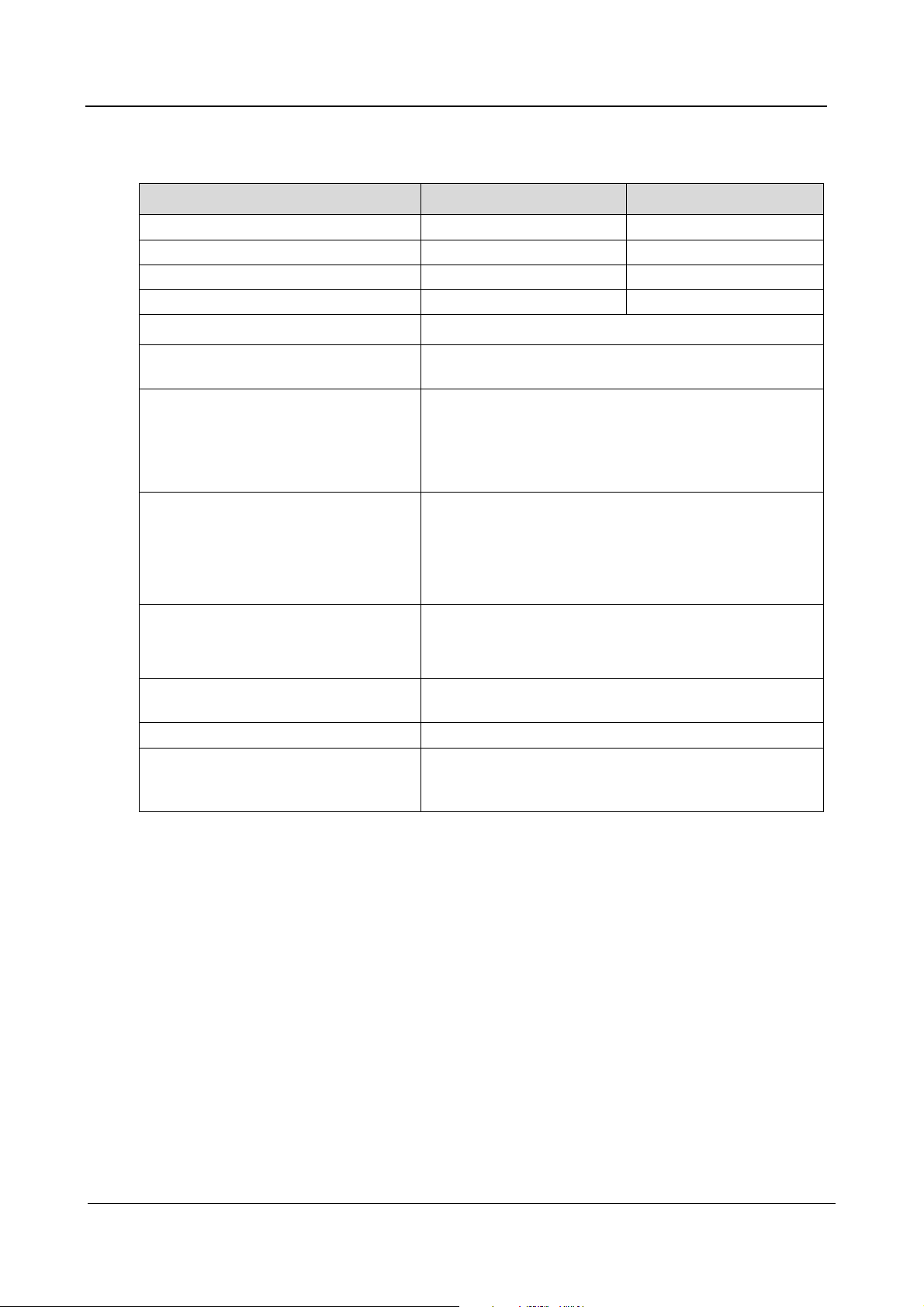

2.3 Technical data

Width (mm) 650 650

Depth with closed door (mm) 660 687

Height (mm) 1685 1840

Total weight (kg) 185 236

Average sound pressure level < 70 dB(A)

PLW 6011 PLW 6111

Protection rating (according to

IEC 60529)

Backflow preventer

(according to EN 1717)

Operation Temperature range +5 to +40 °C

Storage and transportation conditions -5 ... +50 °C

Overvoltage category

(according to IEC EN 60664)

CE mark 2006/42/EC Machinery Directive

Manufacturer address Steelco S.p.A

IP 21

The hexagonal symbol indicates that the equipment is

provided with a backflow preventer; the two letters

inside the hexagon indicate the protection family and the

protection type of that family. (EN 1717)

AA – Air gap not limited

Relative humidity range 20 to 90 % without

condensation

Maximum altitude: 2000 m (special versions of the

device are available for higher altitudes)

20 % to 90 % without condensation

500 hPa to 1060 hPa

II

Via Balegante, 27

31039 Riese Pio X (TV), Italy

REV.0.01_COD.650138_A4

Page 14

Page 15

PRODUCT INFORMATION

2.4 Recommendations for proper operation

The user must supervise the machine during operation.

Only use process chemicals which have been approved by their manufacturer for the

relevant application. The manufacturer of the process chemicals is liable for any negative

influences on the material of the load and the machine.

To prevent contact with contaminated material, appropriate personal protective equipment

must be worn during reprocessing.

Do not reprocess items containing substances which, in accordance with the current

legislation, must not be discharged into the sewage system. These substances must be

disposed of separately.

Recommending process chemicals does not render the manufacturer responsible for any

damage to processed materials and objects.

Follow the manufacturer’s instructions (in compliance with EN ISO 17664) as well as

national requirements and guidelines relating to the machine-based reprocessing of load

items.

The machine is designed for use with water and process chemicals.

The use of organic solvents or inflammable liquids is not permitted as there is a risk of

explosion. Such substances can result in premature wear on components.

Solvent residues, chloride solutions and acids, particularly hydrochloric acid, can damage

steel components and must not be introduced into the wash chamber.

Do not use powder cleaning agents.

Do not use domestic detergents.

Accessories which are not approved by the manufacturer may compromise reprocessing

results as well as user safety.

The user must carry out a general check-up and clean the appliance regularly as indicated

in the maintenance instructions.

Carry out a visual check of the load for cleanliness.

The on-site stopcock must be easily accessible so that the inlet can be turned off when not

in use.

REV.0.01_COD.650138_A4

Page 15

Page 16

PRODUCT INFORMATION

2.5 Training

Instructions for use of the machine will be provided by the Miele Customer Service Department or

an authorised service technician during machine commissioning.

It is the duty of the supervisor to ensure that users are sufficiently trained and instructed.

User profiles

User profiles are identified as follows:

SERVICE Service technician:

The machine may only be installed, commissioned, repaired and maintained by the

Miele Customer Service Department or an authorised service technician.

ADMIN Responsible for the machine in the workplace:

More advanced tasks, e.g. interrupting or cancelling a programme, require more

detailed knowledge of machine reprocessing of laboratory glassware and utensils.

Alterations or adaptations of the machine, e.g. to accessories used or on-site

conditions, require additional specific knowledge of the machine.

Validation processes assume specialist knowledge about machine reprocessing of

laboratory glassware and utensils, the processes involved and applicable standards

and legislation.

User User:

Users must be instructed in operating and loading the machine and trained

regularly to guarantee safe daily use.

They require knowledge of machine reprocessing of laboratory glassware and

utensils.

REV.0.01_COD.650138_A4

Page 16

Page 17

3. INSTALLATION

3.1 Water connection

Water quality

The quality of the water used in all the cleaning stages is essential in achieving good results.

The water must be compatible with the material from which the machine is made.

The water must be compatible with process chemicals.

The water must be compatible with process requirements for the various stages of the

process.

In order to achieve good reprocessing results, the machine requires a supply of soft water with a

low calcium content. Hard water results in the build-up of calcium deposits on the load and in the

machine.

Water with a hardness level higher than 0.7 mmol/l (4 °dH – German scale) must be softened. This

occurs automatically during a programme sequence on machines with a built-in water softener

(option ex works). The water softener must be set to the exact hardness of the water supply.

The water softener must be reactivated at regular intervals. This requires the use of special

reactivation salt. Reactivation is carried out automatically during a programme sequence.

Softened water must be provided on site for machines without a built-in water softener.

INSTALLATION

Note: The water hardness is set by the Miele Customer Service Department.

CAUTION

Water from the chamber is not suitable for drinking!

The machine must be connected to the water supply in strict accordance with local regulations.

The water used must comply with European regulations for drinking water quality as a minimum. If

the water supply has a high iron content, there is a danger of corrosion occurring on items being

cleaned in the machine, as well as the machine itself. If the chloride content of the water exceeds

100 mg/l, the risk of corrosion to the load in the machine will be further increased.

In certain regions (e.g. mountainous areas), the water composition may cause precipitates to form,

requiring the use of softened water in the steam condenser.

The machine is supplied as standard for connection to cold water (blue coded hose) and hot

water up to max. 60 °C (red coded hose). Connect the inlet hoses to the valves for cold and hot

water.

If no hot water supply is available, the red coded inlet hose for the hot water connection must also

be connected to the cold water supply.

The minimum flow pressure for cold water, hot water and DI water connections is 100 kPa.

The recommended flow pressure is ≥ 200 kPa for the cold and hot water connections and

≥ 200 kPa for the DI water connection in order to avoid excessively long water intake times.

The maximum permissible static water pressure is 800 kPa.

A booster pump is required if the flow pressure is below 100 kPa. If the pressure is higher than

800 kPa (8 bar), a pressure reducer must be installed.

If water pressure is not within the specified range, contact the Miele Customer Service

Department or an authorised service technician for advice.

REV.0.01_COD.650138_A4

Page 17

Page 18

INSTALLATION

A stopcock valve with a ¾” male threaded union must be provided on site. The valve should be

easily accessible, since the water supply should be shut off whenever the machine is not in use.

CAUTION

Do not overtighten the threaded unions on the hoses.

Information:

If no hot water supply is available, the red coded inlet hose for the hot water connection

must also be connected to the cold water supply.

A Y-piece can be used to connect both hoses to the cold water supply.

Miele cannot be held liable for damage or injury caused by non-compliance with the safety

instructions and warnings.

Non-compliance with the above conditions will render the warranty invalid.

CAUTION

When the machine is not in operation, always close the stopcocks.

REV.0.01_COD.650138_A4

Page 18

Page 19

3.2 Electrical connection

CAUTION

Only qualified, skilled personnel may connect the machine to the power

supply.

It is recommended that the machine is connected to the mains electrical supply via a

suitably rated plug and socket that complies to all local and national standards.

The machine must only be operated with the voltage, frequency and fuse rating shown on

the data plate.

The power supply voltage must not differ from its nominal value by more than

+/-10 %.

The frequency of the power supply must not differ from its nominal value by more than

1 %.

The electrical safety of the machine can only be guaranteed when it is correctly earthed.

Equipotential bonding is required.

Make sure that the electrical systems are properly earthed.

INSTALLATION

The earth conductor is to be connected to the earth terminal

identified by the standard symbol.

If the machine is hard-wired to the power supply, it must be

connected via a power switch with all-pole isolation. The power

switch must be designed to operate at the rated current.

It is recommended that the machine is connected to the mains

electrical supply via a suitably rated plug and socket.

For increased safety, it is recommended to protect the machine with a suitable residual

current device (RCD) with a trip current of 30 mA (DIN VDE 0664).

The machine should be disconnected from the power supply when not used for a longer

period of time.

The electrical connection and fuse rating must comply with local and national regulations.

CAUTION

Please refer to the installation plan provided.

REV.0.01_COD.650138_A4

Page 19

Page 20

BUILT-IN WATER SOFTENER (OPTIONAL)

4. BUILT-IN WATER SOFTENER (OPTIONAL)

The built-in water softener is designed to prevent residues from the water supply in the machine.

Salt consumption depends on the water hardness.

French scale

(°fH)

0–10 0–1.01 0–5.60 Value 10

11–15 1.11–1.51 6.16–8.40 Value 15

16–20 1.61–2.02 8.96–11.20 Value 20

21–25 2.12–2.52 11.76–14.00 Value 25

26–30 2.62–3.03 14.56–16.80 Value 30

31–35 3.13–3.53 17.36–19.60 Value 35

36–40 3.64–4.04 20.16–22.40 Value 40

41–45 4.14–4.55 22.96–25.20 Value 45

46–50 4.65–5.05 25.76–28.00 Value 50

51–55 5.15–5.56 28.56–30.80 Value 55

56–60 5.66–6.06 31.36–33.60 Value 60

Water hardness

(mmol/l)

German scale

(°dH)

Parameter setting

4.1 Salt refill indicator

If the salt level in the salt container is low, the following reminder will appear in the display: “salt

loading”.

REV.0.01_COD.650138_A4

Page 20

Page 21

4.2 Refilling the salt

Use only special, coarse-grained dishwasher salt or other pure evaporated salt for reactivation.

Never use any other kind of salt, e.g. table salt, animal feed salt or de-icing salt. Other salts may

contain insoluble additives which can impair the functioning of the water softener.

The following prompt reminds the user to refill the salt container:

“salt loading”

The container for dishwasher salt is located in the base of the wash chamber inside the machine.

Open the door.

Remove the load carrier.

Unscrew the plastic cap on the container.

Fill the funnel with salt.

Raise the funnel by the handle and place it on the container.

Release the handle. The salt then passes from the funnel into the container.

Repeat the process until the container is visibly full.

BUILT-IN WATER SOFTENER (OPTIONAL)

The supply container contains approx. 780 g of salt.

CAUTION!

The container must always be completely filled. If filled to less than full, the

water softening capacity is reduced and limescale deposits may occur on the

load and on wash chamber surfaces.

Refit the plastic cap on the salt container and screw tight.

Place the load carrier in the machine.

Start the “Rinse” programme.

CAUTION!

Always run the “Rinse” programme after refilling the salt. This removes and

dissolves spillages of salt and brine. Excess salt and brine which has

overflowed can cause corrosion damage if they are not rinsed away.

CAUTION!

During reactivation, the following appears on the display: “regeneration”.

REV.0.01_COD.650138_A4

Page 21

Page 22

DISPENSING

5. DISPENSING

The dispensing system for process chemicals comprises:

1 dispenser pump (DOS1) for cleaning agent

1 dispenser pump for neutralising agent

Fill level sensor

The system is equipped with flow meters.

Additional dispenser pumps can be fitted by the Miele Customer Service Department or an

authorised service technician.

5.1 Fill level sensor

Each dispenser pump is fitted with a fill level sensor that monitors the fill level in the process

chemical canisters. A lack of product is indicated on the display.

5.2 Dispensing quantity control

Each dispenser pump is monitored by a flow meter. This electronic device monitors the volume of

product dispensed.

5.3 Refilling process chemicals

Replace an empty container as follows:

Have a new container with process chemicals ready.

Open the door in the plinth of the machine.

Remove the siphon and place it on a chemical-resistant and easy-to-clean surface.

Insert the siphon into the new container.

Place the container in the plinth of the machine.

Close the door in the plinth.

Start the appropriate programme for venting the DOS pump (see the “Fill DOS (1–4)”

programme table).

CAUTION

Only use process chemicals designed specifically for use in the machine and

follow the chemical manufacturer's instructions.

Take care when using process chemicals. Some agents may be corrosive

and irritant. The relevant safety regulations and safety data sheets issued by

the process chemical manufacturers must be observed. Wear protective

gloves and goggles.

The chemical compartment in the plinth of the machine is accessed using a

key. The compartment may only be accessed by authorised personnel.

REV.0.01_COD.650138_A4

Page 22

Page 23

5.4 Caution!

Consult the relevant manufacturer's instructions for the maximum amount of process

chemical permitted for each programme.

To ensure the efficiency of the dispensing system, maintenance as described in the

“MAINTENANCE” chapter must be performed regularly.

Only use liquid cleaning agents. Do not use powder cleaning agent.

Always follow the relevant manufacturer's instructions on storage and disposal of process

chemicals.

Check that the process chemical is suitable for the programme used.

DISPENSING

CAUTION

The machine must be completely emptied before you carry out maintenance

work or move/relocate the machine.

This is necessary to prevent contact with chemicals and to protect machine

components which may suffer damage.

REV.0.01_COD.650138_A4

Page 23

Page 24

OPERATION

6.

OPERATION

6.1 Checking consumption

Check consumption regularly by checking the fill levels in the supply containers and replace

containers in good time to avoid the dispensing system being sucked completely dry.

Wear protective gloves and goggles.

Follow the instructions for dispensing chemicals.

CAUTION

Take care when using process chemicals. Some agents may be corrosive

and irritant. The relevant safety regulations and safety data sheets issued by

the process chemical manufacturers must be observed. Wear protective

gloves and goggles.

6.2 Opening and closing the door

Open and close the door using the door handle.

The door is locked electronically and cannot be opened while a programme is running.

There is a risk of burning if contact is made with the door glass while a programme is running.

PLW 6011 PLW 6111

REV.0.01_COD.650138_A4

Page 24

Page 25

Emergency release

The emergency release may only be used when it is no longer possible to open the door normally,

e.g. in the event of a power cut.

OPERATION

CAUTION

Hold the door during opening and closing. Jerking the door open or

slamming it shut may break the glass.

Insert baskets into the chamber slowly to avoid breaking the glass.

Before opening the door, check that the door area is free of obstacles.

CAUTION

If the emergency release is operated during a programme sequence, hot

water and process chemicals can escape.

The load, the load carrier and the wash chamber may be very hot.

Danger of scalding, burning and chemical burns. Where disinfecting agents

are used, there is also a danger of inhaling toxic fumes.

In the event of a power cut or if the door lock is damaged, the door can be opened as follows:

1. An emergency release device is located between the door and the

cover plate and is identified by a sticker (see image).

2. Insert the tool contained in the accessory kit into the emergency

release opening.

3. Push the tool to the left until you hear the door open.

4. To close the door, continue to press in the tool as described in point

3.

REV.0.01_COD.650138_A4

Page 25

Page 26

OPERATION

6.3 Switching on

The machine is switched on and off using the power switch.

Take note of any fault or warning messages on the display when starting the machine.

6.4 Preparation

Follow the manufacturer's instructions for reprocessing.

Make sure that the items are suitable for reprocessing in a cleaning machine and check the

compatibility with the chemicals used during the wash programmes.

Place the items carefully into the load carriers.

Make sure that load items are not shielded or concealed by other items.

Position load items in such a way that fluids can drain off freely.

Tall or heavy items should be placed towards the middle of the basket if possible to

facilitate washing.

Make sure that items do not block the spray arms and that the arms can turn freely.

Distribute the load evenly across the baskets.

The mobile units, baskets, modules and inserts that hold the load must be used only as

intended.

Empty any containers or utensils before loading them.

Take apart any items which can be dismantled according to the manufacturer's

instructions and process the individual parts separately from each other.

Do not place items to be cleaned inside other items where they may be concealed. Do not

place items so close together that cleaning is hampered.

Arrange the load so that water can access all surfaces.

Only reprocess small items and micro components in special inserts, mesh trays with lids

or mesh inserts.

Plastic items must be thermally resistant.

REV.0.01_COD.650138_A4

CAUTION

Connectors that are not in use must be closed using the caps provided.

New caps are available from Miele.

Page 26

Page 27

OPERATION

CAUTION

The maximum load for each cycle is 35 kg (incl. basket).

Never operate the machine without a load carrier in place.

Before starting to use the machine, make sure that all the routine checks have been carried out.

Check the spray arm rotation.

The list below provides examples of load carriers and inserts which may be used when

reprocessing laboratory glassware and utensils:

Other accessories are available from Miele.

Upper basket with nozzles Upper basket with spray arm

Lower basket with nozzles Lower basket for pipettes

Insert for glassware Insert for Petri dishes

Checks after a programme

Carry out a visual check of the load for cleanliness.

Are all lumened instruments still attached to the appropriate nozzles?

Are the lumens free from obstructions?

REV.0.01_COD.650138_A4

CAUTION

Any lumened items which have become disconnected during reprocessing

must be reprocessed.

Page 27

Page 28

CONTROL PANEL AND SYMBOLS USED

7. CONTROL PANEL AND SYMBOLS USED

7.1 Control panel

The control panel is used to operate the machine.

A

B

C

D

Display

E

F

G

H

REV.0.01_COD.650138_A4

Page 28

Page 29

7.2 Buttons

The buttons on the display are touch-sensitive and backlit (LED). There are 8 buttons available

with the following functions:

BUTTON DESCRIPTION

A

B

CONTROL PANEL AND SYMBOLS USED

Press once to interrupt a programme.

“NO DISINFECTION” appears on the display. The

door remains locked. An additional warning appears

STOP

Press twice to cancel a programme.

(cancel) For cancelling a process in the user interface.

START For starting the programme.

(confirm) For selecting or confirming entries in the user interface.

at a chamber temperature of more than 65 °C.

Continue the programme by pressing the START

button. The current wash phase is then repeated.

The programme is cancelled and the door unlocked.

C

D

P+ For accessing the list of all additional programmes.

The menu incorporates all relevant functions.

PRG

P1 Universal programme

During standby: Press the button for 5 seconds to access

the menu.

E

(down) For navigating in the user interface.

P2 Standard programme

F

(up) For navigating in the user interface.

G

H

P3 Intensive programme

Drying function.

DRY

The drying function can be activated or deactivated before

starting a programme.

Buzzer

The machine has an integrated buzzer. An audible signal sounds each time a button is pressed. If

the machine develops a fault, a warning signal sounds (see “Warning and safety instructions”).

REV.0.01_COD.650138_A4

Page 29

Page 30

CONTROL PANEL AND SYMBOLS USED

7.3 Display

1

2

3

4

5

6

7

FIG. 1

The following information may appear on the display:

1. Date and time

2. Selected programme

3. Current wash phase

4. Temperature in wash chamber (sensor 1) with A0 value

5. Target temperature for current programme phase

6. Remaining time

7. Instructions and error messages

8. Cycle counter

9. Temperature in wash chamber (sensor 2) with A0 value

When the machine is ready for operation, the last selected programme, the temperature, the date

and the time are displayed.

When one of the programme buttons (P1 , P2 or P3 ) is pressed, the display shows

the programme linked to that button and the following message appears in the bottom left: “press

start” or “open door” (see 7).

By pressing the P+ button, it is possible to scroll through all the available programmes.

8

9

REV.0.01_COD.650138_A4

Page 30

Page 31

CONTROL PANEL AND SYMBOLS USED

FIG. 2

The temperature and pressure values can be

displayed while a programme is running by

pressing the PRG button (Fig. 2).

FIG. 3

Press the PRG button twice to display warning

messages (Fig. 3).

FIG. 4

In the event of a fault, a window appears indicating

the fault code and a brief description

(Fig. 4).

In the event of an error which does not lead to the programme being interrupted (e.g. lack of

salt), a message is shown in the bottom left of the display (see Figs. 1 to 6) or can be called

up by pressing the PRG button (see Fig. 3).

REV.0.01_COD.650138_A4

Page 31

Page 32

CONTROL PANEL AND SYMBOLS USED

FIG. 5

At the end of the programme, a window appears

(Fig 5).

FIG. 6

Fig. 6.A

If a programme was cancelled, a window appears

indicating that disinfection did not take place (Fig.

6.A).

Fig. 6.B

If the temperature in a cancelled programme was

65 °C or lower, the message shown in Fig. 6.A is

displayed.

If the temperature was above 65 °C, the message

shown in Fig. 6.B is displayed.

REV.0.01_COD.650138_A4

Page 32

Page 33

8. PROGRAMMES

Programme Button Application

PROGRAMMES

Quick wash

Universal

Standard

Intensive

Inorganic

Organic

Short programme for lightly soiled items and loads that do not

require intensive cleaning.

For removing organic residues and certain inorganic residues.

For standard applications and analyses, light to medium levels of

soiling and medium rinse requirements.

Simple programme for a range of soiling.

For light soiling and low final rinse requirements:

Not suitable for denaturing and acid-soluble residues such as

proteins, metallic salts and amines.

For removing organic residues and certain inorganic residues.

For standard applications and analyses, medium to heavy soiling

and medium to high final rinse requirements.

For removing inorganic residues.

General programme for analysis and water analysis, and for

water-based cultures with acid-soluble metallic salts such as

2+

and Mg2+, etc., for light to medium levels of soiling and

Ca

medium to high rinse requirements.

For organic residues, e.g. heavy soiling or after sterilisation;

partially suitable for fats and waxes.

Not suitable for acid-soluble residues such as metallic salts and

amines.

For medium to heavy soiling and medium rinse requirements.

Connection to hot water and demineralised water

recommended.

Plastic

Pipettes

Oil

Disin 93/10

Cold water

rinse

REV.0.01_COD.650138_A4

For heat-sensitive loads such as plastic flasks (temperature

resistance: at least 55 °C).

For standard applications and analyses, light to medium levels of

soiling and medium rinse requirements.

For pipettes

For heavy oil soiling such as crude oil, synthetic oils/lubricants,

fuels and partially natural oils. The programme can also be used

for removing fats and waxes.

Connection to hot water and demineralised water

recommended.

For cleaning and thermal disinfection at 93 °C with 10 minutes'

temperature holding time.

Cold water rinse, holding time: 1 minute. For flushing out saline

solution, rinsing heavily soiled loads, e.g. for preliminary removal

of soiling, residual disinfecting agent, or to prevent residues from

drying on and forming incrustations before running a full load.

Page 33

Page 34

PROGRAMMES

Programme Button Application

AD rinse

Drying

Drain

Fill DOS1

Fill DOS2

Fill DOS3

Fill DOS4

8.1 Programme blocks

Drain

Drains water from the chamber.

Pre-wash

A pre-wash removes coarse soiling and substances which may cause foaming.

Main wash

Depending on the load, cleaning generally occurs at temperatures between 45 °C and

93 °C with the addition of appropriate cleaning agent (process chemicals).

Interim rinse

In the interim rinse stages, process chemicals from the previous phases are rinsed off and

neutralised.

Final rinse

To avoid deposits on the load and to reduce process chemical residues, demineralised

water should preferably be used, if available, for the final rinse.

Drying

Adequate drying reduces the risk of corrosion through residual moisture on the load.

Rinse with demineralised water (DI water, (ultra)pure water),

holding time: 3 minutes.

Additional drying after the end of a programme.

For draining wash water, e.g. after a programme cancellation.

Primes the cleaning agent dispensing system after replenishing

or replacing the container.

Primes the additional liquid agent dispensing system after

replenishing or replacing the container.

Primes the neutralising agent dispensing system after

replenishing or replacing the container.

Primes the additional liquid agent dispensing system after

replenishing or replacing the container.

REV.0.01_COD.650138_A4

Page 34

Page 35

60

s

60

s

8.2 Programme overview

PROGRAMMES

Drying

Washing

Washing

Washing

Washing

Drying

Final

rinse

2

rinse

Interim

1

rinse

Interim

sation

Neutrali-

*)

120 °C

1800 s

120 °C

1800 s

120 °C

1800 s

120 °C

1800 s

DI

60 s

60 °C

DI

70 °C

60 s

DI

75 °C

DI

DI

75 °C

1800 s

120 °C

60 s

70 °C

DI

60 s

DI

60 s

HW

HW

60 s

120 s

DOS 3

HW

120 s

DOS 3

HW50

HW

60 s

CW50

60 s

DI

60 s

120 s

DOS 3

HW

120 s

DOS 3

HW

120 s

DOS 3

Main

Washing

wash 3

Main

Washing

Washing

wash 2

Main

wash

Washing

Pre-wash

Function

HW

60 °C

DOS 1

Button

180 s

HW

HW

180 s

75 °C

DOS 1

70 °C

DOS 1

75 °C

DOS 1

CW50

HW

180 s

HW

180 s

60 s

CW50

180 s

80 °C

DOS 1

CW50

60 s

120 s

50 °C

DOS 3

Phase

REV.0.01_COD.650138_A4

Programme

Quick wash

Standard

Universal

Intensive

Inorganic

Page 35

Page 36

PROGRAMMES

Drying

Washing

Washing

Washing

Washing

Drying

Final rinse

2

rinse

Interim

1

rinse

Interim

sation

Neutrali-

*)

DI

HW50

HW

120 °C

1800 s

60 °C

1800 s

100 °C

1800 s

1800 s

120 °C

60 s

75 °C

60 s

DI

DI50

60 s

55 °C

60 s

DI

DI

CW50

60 s

70 °C

60 s

60 s

DI

HW50

DI

60 s

75 °C

HW

60 s

120 s

DOS 3

CW50

120 s

DOS 3

HW

120 s

DOS 3

HW

HW

DOS 3

120 s

1800 s

120 °C

60 s

75 °C

60 s

120 s

DOS 3

3

Main

Washing

wash

HW

85 °C

DOS 1

180 s

Main

Washing

wash 2

Main

Washing

wash

HW

HW

85 °C

DOS 1

65 °C

DOS 1

180 s

180 s

55 °C

CW50

DOS 1

HW

65 °C

DOS 4

DOS 1

HW

180 s

70 °C

DOS 1

180 s

HW

45 °C

DOS 4

DOS 1

120 s

60 s

CW50

600 s

93 °C

DOS 1

Washing

Pre-wash

Function

CW50

60 s

CW50

60 s

Button

Phase

REV.0.01_COD.650138_A4

Programme

Organic

Plastics

Pipettes

Oil

Disin 93/10

Page 36

Page 37

PROGRAMMES

Drying

*)

Drying

1800 s

120 °C

Washing

Washing

Final rinse

2

rinse

Interim

1

rinse

Washing

Washing

Washing

Interim

ation

Neutralis

3

Main wash

HW

10 s

Washing

Washing

Washing

Phase

Main

wash 2

Main

wash

Pre-

wash

Function

Drain pump/valve is activated without the circulation pump.

HW

DOS 1

10 s

CW

120 s

DI

120 s

Button

Programme

Cold water

rinse

AD

rinse

Drying

Drain

Fill DOS1

REV.0.01_COD.650138_A4

Page 37

Page 38

PROGRAMMES

Drying

Washing

Washing

Washing

Washing

Drying

Final rinse

2

rinse

Interim

1

rinse

Interim

tion

Neutralisa

*)

HW

10 s

HW

10 s

HW

10 s

Main

Washing

Washing

wash 3

Main

wash 2

Washing

Washing

Main wash

Pre-

wash

HW

10 s

DOS 2

Function

Button

HW

DOS 3

10 s

HW

DOS 4

10 s

Phase

REV.0.01_COD.650138_A4

Programme

Fill DOS2

Fill DOS3

Fill DOS4

CW = Cold water

HW = Hot water

DI = (Ultra)pure water, demineralised water (DI)

CWxx = CW proportion in mixed water (CW + HW) as percentage (CW50 = 50 % CW + 50 % HW)

HWxx = HW proportion in mixed water (HW + DI) as percentage (HW50 = 50 % HW + 50 % DI)

DIxx = DI proportion in mixed water (DI + CW) as percentage (DI50 = 50 % DI + 50 % CW)

DOS 1 = Cleaning agent

DOS 2 = Additional liquid agent

DOS 3 = Neutralising agent

DOS 4 = Additional liquid agent (e.g. emulsifier, defoamer, etc.)

s = Holding time in s

*) Drying plus 120 s cooling down time

Page 38

Page 39

8.3 Starting the programme

To start, proceed as follows:

Select a programme.

Press the START button.

PROGRAMMES

REV.0.01_COD.650138_A4

Page 39

Page 40

MACHINE STATUS

9. MACHINE STATUS

9.1 Ready for operation

The machine is ready for operation. The diagnostics are active.

9.2 Programme

When the machine is ready for operation and the door is closed, it is possible to press the

START button.

The programme performs a defined series of phases. The diagnostics and regulators are active.

The user interface provides information on the phase in progress and the temperature in the

chamber.

The display indicates if the door is open and issues warning messages, e.g. lack of salt.

9.3 Malfunctioning

The diagnostics function has detected a fault which causes the programme to be cancelled. The

door remains locked.

The fault is indicated via the display. The machine can be made ready for use again using the

reset function (see “Reset”).

REV.0.01_COD.650138_A4

Page 40

Page 41

9.4 Power failure

In the event of a brief power failure while a programme is running, the current wash phase is

repeated and the programme continued.

9.5 Reset

In the event of a malfunction while a programme is running, the door remains closed and locked.

To acknowledge an error message, proceed as follows:

1. Press STOP and START together and hold for 5 seconds.

2. The display indicates the button combination.

3. Press the P2 button followed by the P1 button.

4. The reset is complete. The machine is once again ready for use and the door can be

opened.

Note:

If the fault persists, e.g. due to a defective component, the machine will remain locked.

If this is the case, contact the Miele Customer Service Department or an authorised service

technician.

MACHINE STATUS

REV.0.01_COD.650138_A4

Page 41

Page 42

MENU

10. MENU

The menu incorporates all administrative processes and settings.

Access to other sections of the menu is password-protected. The user password will be provided

during commissioning by the Miele Customer Service Department or an authorised service

technician.

Access to programming and the menu are protected by different passwords:

First level: The user (USER) and supervisor (ADMIN) password provides access to

programmes and time settings.

Second level: The technician (SERVICE) password allows unhindered access to all menus

and machine settings.

If the password is lost, contact the Miele Customer Service Department or an authorised service

technician.

10.1 Accessing the menu

To enter the menu, hold the PRG button for 5 seconds.

Press P1 and P2 to scroll through the menu.

Press START to confirm selection.

Press STOP to exit the menu and return to “Ready for use” or “Malfunction” mode.

Main menu

Standard programmes

View and copy programmes.

Customer programmes

Create new customer programmes.

Programme selection

Activate and deactivate programmes.

Settings

Access programming.

REV.0.01_COD.650138_A4

Page 42

Page 43

10.2 Parameter settings

Access to the programming mode is password-protected.

To select parameters, proceed as follows:

When setting parameters, a password will be requested, which is inserted using the

P1 and P2 buttons. If an incorrect password is entered, the menu is closed

immediately.

You can scroll through the parameters using the P1 and P2 buttons.

Press START to change a parameter.

Use the P1 and P2 buttons to increase or decrease the various parameter values.

To exit the programming mode, press the STOP button for 5 seconds.

10.3 Parameter list

MENU

CATEGORY

DESCRIPTION

MIN.

UDM

MAX.

SECTION

PARAMETER

SYSTEM DATA

MACHINE 1 01 User name (16 characters) ‚ ~ CHAR_STR

Graphic printout at the end of a

PRINTOUT 1 04

PRINTOUT 1 05

KEYBOARD 1 07

KEYBOARD 1 08

KEYBOARD 1 09

KEYBOARD 1 13 Show A0 value in display; 0=OFF 1=ON 0 1 SEL

programme

(0: no printout, 1: graphic printout 2: table

printout, 3: printout on USB)

Printout results of current programme;

0=OFF 1=ON

Buzzer volume – infeed side

(0=buzzer OFF)

Buzzer volume – end of programme (infeed

side)

Buzzer alarm volume – infeed side

(0=buzzer OFF)

0 3 NUM

0 1 SEL

0 50 NUM

0 50 NUM

0 50 NUM

MACHINE DATA

KEYBOARD

KEYBOARD

2 04

2 07

Select language 0=OFF 1=ON 0 7 SEL

Font types (0=European,

1=European+Japanese,

2=European+Cyrillic)

0 2 NUM

REV.0.01_COD.650138_A4

Page 43

Page 44

CLOCK

11. CLOCK

The controls have a real-time clock.

Times are saved to historical data.

12. BUZZER

The buzzer sounds when a button is pressed. In the event of a serious fault, a continuous tone will

sound depending on the settings for parameters P1.7, P1.8 and P1.9. The volume can be set

using the parameters.

13. HISTORICAL DATA (BATCH PROTOCOLS)

During a programme, operating data is recorded.

The internal memory is able to save up to 200 programmes. If the memory is full, the oldest data is

overwritten.

13.1 Outputting batch protocols retrospectively

Internally stored protocols can be output retrospectively from the machine.

The following options are available for documentation:

To open the menu, press and hold the PRG button for 5 seconds.

Scroll through the menu using the P1 and P2 buttons and select “History”.

Confirm your selection by pressing the START button.

Select the “Print” option using the P1 and P2 buttons and start the printout by

pressing the START button. “Printing in progress” is shown on the display.

Press the STOP button to cancel the printout. The menu will be exited.

External software

Data can be retrieved directly via the documentation software.

REV.0.01_COD.650138_A4

Page 44

Page 45

A

A

WARNINGS AND EVENTS LIST

14. WARNINGS AND EVENTS LIST

Messages and warnings may appear on the display during operation.

A warning remains on display until the underlying cause is dealt with. A warning interrupts the

current programme.

14.1 Warnings list

Warning Display message Description

1 power fail Power failure during programme

2 open load. door

4 load.door fail. Loading door locked but open.

7 unblock.door 1 Door fault.

9 unlocking 1fail. Door release timeout

11 no cold water Cold water impulse reading from flow meter

12 no hot water Cold water impulse reading from flow meter – timeout

13 no demin. water Cold water impulse reading from flow meter – timeout

14 no c.+hot water Cold and hot water level – timeout

15 no c.+demi water Cold and DI water level – timeout

16 no h.+demi water Hot and DI water level – timeout

17 no chemical 1 Lack of process chemicals (DOS1)

18 no chemical 2 Lack of process chemicals (DOS2)

19 no chemical 3 Lack of process chemicals (DOS3)

20 no chemical 4 Lack of process chemicals (DOS4)

21 heating element1 Fault with heating element 1

23 drain problem Minimum tank level during draining – timeout

24 fan problem Fan switch ON, pressure switch open

25 drying min°C

26 prewash max°C

27 tank probe lim°C

28 dryingprobelim°C

29 boilerprobelim°C

30 tank probe Chamber temperature sensor 1 fault

31 tank probe 2 Chamber temperature sensor 2 fault

32 drying probe Drying temperature probe fault

33 boiler probe Boiler temperature probe fault

Loading door open and/or unlocked during a

programme.

ir temperature does not reach the specified value

during drying.

Tank temperature exceeds specified value during prewash.

Chamber temperature exceeds 102 °C. (= max. setting

95 °C + safety level 7 °C)

(Tank heating switch or tank sensor defective)

ir temperature exceeds 162 °C. (= max. setting

150 °C + safety level 12 °C)

(Drying heating switch or air sensor defective)

Tank 1 temperature exceeds 100 °C. (= max.

setting 80 °C + safety level 20 °C)

(Tank 1 heating switch or tank 1 sensor defective)

REV.0.01_COD.650138_A4

Page 45

Page 46

WARNINGS AND EVENTS LIST

A

V

Warning Display message Description

34 check temp.

35 Serial connect.1

36 Serial connect.2

37 CANserialconnec. No connection between master and slave (CANbus).

39 no tank heating

40 no boilerheating Problem with boiler heating.

41 no boilerheating Problem with boiler heating.

42 magnetothermic Steam heating fault

43 Phase sequence Phase sequence is incorrect.

44 levels steamcond Steam condenser fault

45 pump steam cond. Min. and max. level active drain pump fault.

46 pump

47 flowmeter fail.1 DOS1 dispenser fault

48 flowmeter fail.2 DOS2 dispenser fault

49 flowmeter fail.3 DOS3 dispenser fault

50 flowmeter fail.4 DOS4 dispenser fault

51 flow.cold water Water intake fault (cold water).

52 flow.warm water Water intake fault (hot water).

53 flow.demi water Water intake fault (demineralised water).

54 airfilter obstr.

55 conduc. probe Conductivity sensor fault.

56 conductivity Conductivity exceeds maximum threshold.

58 no tank heating No temperature increase during allocated time.

59 no boilerheating No temperature increase during allocated time.

60 TIME Maximum time exceeded in main wash phase

72 DRYING

73 DRYING

74 boilerprobelim°C The boiler temperature is too high.

75 boiler probe Boiler probe 2 defective

76 BOILER

77 BOILER

78 BOILER

Temperature difference between the two sensors is

greater than 1 °C.

No connection between main PCB and loading

controller

No connection between the expansion board and the

keyboard (unloading side).

No heating in wash chamber. No temperature increase

during allocated time.

Circulation pump on; pressure switch closed.

Circulation pump is rotating in the wrong direction.

ir filter is obstructed. Change the air filter.

acuum switch defective. No compressed air available

(check compressed air supply).

Exhaust air pressure: fault when opening or closing

exhaust air valve.

Exhaust air pressure: exhaust air limit switch (open and

close both active at the same time).

The max. level on tank 3 is active and the min. level is

inactive.

The max. level on tank 1 is active and the min. level is

inactive.

The max. level on tank 2 is active and the min. level is

inactive.

REV.0.01_COD.650138_A4

Page 46

Page 47

A

14.2 List of display messages

WARNINGS AND EVENTS LIST

Display

Description

message

press start Programme can be started.

no chemical 1

no chemical 2

no chemical 3

no chemical 4 Lack of product in DOS 4.

salt loading Refill the dishwasher salt container.

pump steam

cond.

pressure probe Wash pump pressure monitoring fault

Lack of product in DOS 1.

Lack of product in DOS 2.

Lack of product in DOS 3.

Steam condenser activated for a specified time to bring the amount of condensate

below the max. level.

- open door - Door is open and not locked.

wait General reminder to wait before next input.

close door! Close the door.

ON PRINT

NO DISINFECTION

ppears when an attempt is made to start a programme with the START button

during printing.

Programme interrupted. Load not disinfected.

REV.0.01_COD.650138_A4

Page 47

Page 48

USB PORT (OPTIONAL)

15. USB PORT (OPTIONAL)

Testing and transmission point for the Miele Customer Service Department.

REV.0.01_COD.650138_A4

Page 48

Page 49

PROCESS DOCUMENTATION

16. PROCESS DOCUMENTATION

16.1 Serial interface

The RS232 interface is intended for connecting devices such as a PC or printer as per the RS232

standard protocol, in accordance with EN/IEC 60950.

Printers are connected as described below:

Interface: RS232

Baud rate: 2400 bps

Data length: 8 bits/chr

Parity: None

Handshake: XON/XOFF 40 COLUMNS

The format of the protocol is as follows:

Information on

programme phases.

Number of samples

16.2 User administration

Several user profiles can be created and managed in the controls. For further information, please

contact the Miele Customer Service Department or an authorised service technician.

Information on

programme

phases.

Data value.

Sing.samp.time

16.3 USB port

Testing and transmission point for the Miele Customer Service Department.

REV.0.01_COD.650138_A4

Page 49

Page 50

MAINTENANCE

17. MAINTENANCE

17.1 General recommendations on maintenance

Maintenance for the machine described in this manual can be divided into routine maintenance

and special maintenance.

Machine status

The machine must be completely switched off. The person performing the task must ensure that

the safety of others in the vicinity is not compromised.

Safety systems

The machine should only be operated in compliance with valid standards and regulations relating

to the use of disinfectants (cf. data sheets for individual products). Rules relating to contact with

machine parts potentially contaminated with pathogens also apply. Personal protective gear must

be worn.

Procedure

If possible, run a disinfection programme for the wash chamber. Open the wash chamber door

and wipe with a suitable disinfectant.