Loading...

Loading...P

- PG8056208V

- PG8056240V4

- PG8056U2402

- PG8056UAE208V2

- PG8061240V4

- PG8061UAE208V3

- Pg8080BW

- PG8083SCVI120V6

- PG8083SCVI240V6

- PG 8110 SmartBiz2

- PG 81203

- PG 8120 Series 120

- PG 8123

- PG 8123 SCVi XXL

- PG 8123 SCVi XXL Series 120

- PG 813045

- PG 8130-60 i

- PG 8130-60 U

- PG 8130i29

- PG8130I240V2

- PG 8130 U26

- PG 813115

- PG 8131-60 i3

- PG 8131i31

- PG 813215

- PG 8132-60 SCi3

- PG 8132 SCi25

- PG8132SCIXXL2

- PG 813318

- PG 8133-60 SCVi3

- PG 8133 SCVi26

- PG8133SCVI240V

- PG 8133 SCVi XXL2

- PG 81644

- PG 8164 AE RO

- PG 8164 AE RO DOS

- PG 81654

- PG 8165 AE RO

- PG 8165 AE RO DOS

- PG 81664

- PG 81694

- PG 81726

- PG 8172 ECO5

- PG 850441

- PG 852738

- PG 8527 D7

- PG 8527 EL15

- PG 8527 EL AV2

- PG 852840

- PG 8528 D7

- PG 8528 EL16

- PG 853524

- PG 8535 OXIVARIO12

- PG 853630

- PG 8536 LFM

- PG 8536 OXIVARIO

- PG 8536 RU

- PG 85627

- PG 858139

- PG 858243

- PG 8582 CD39

- PG 858350

- PG 8583 CD44

- PG 859134

- PG 859242

- PG 859348

- PG 85952

- PG 8596

- PG 85972

- PG 88213

- PG 88225

- PG 88255

- PG 88304

- PG89222

- PG89302

- PIB 10021

- PLATINUM2

- Platinum Plus3

- Plus G686

- PLW 601133

- PLW 611135

- PLW 85052

- PLW 861527

- PLW 861626

- PLW 861725

- PM 121064

- PM 121766

- PM 131828

- PM 1318 EL9

- PM 1318 G6

- PM 1318 G L

- PM 1318 G L-GE

- PM 141830

- PM 1418 EL7

- PM 1418 G6

- PM 1418 G L

- PM 1418 G L-GE

- PM 142130

- PM 1421 EL8

- PM 1421 G6

Loading...

Loading... Loading...

Loading...Nothing found

PG 8583 CD

Instructions Manual

188 pgs7.42 Mb0

Instructions Manual

184 pgs7.2 Mb0

User manual

184 pgs7.24 Mb0

User manual

180 pgs6.6 Mb0

Installation diagram

11 pgs1.03 Mb0

Installation diagram

9 pgs524.22 Kb0

Installation diagram

8 pgs544.9 Kb0

Installation diagram

14 pgs606.14 Kb0

Operating instructions

184 pgs6.61 Mb0

Operating instructions

180 pgs6.61 Mb0

Installation diagram [cs]

8 pgs517.88 Kb0

User manual [cs]

184 pgs6.63 Mb0

Installation diagram [de]

11 pgs1.59 Mb0

User manual [de]

200 pgs5.12 Mb0

Instructions Manual [el]

192 pgs6.69 Mb0

installation plan [es]

10 pgs1.02 Mb0

installation plan [es]

16 pgs862.89 Kb0

Operating instructions [es]

188 pgs6.64 Mb0

Installation Plan [hr]

10 pgs1 Mb0

User manual [hr]

180 pgs6.61 Mb0

Installációs terv [hu]

10 pgs1.02 Mb0

User manual [hu]

188 pgs6.65 Mb0

Installation plan [ja]

8 pgs546.73 Kb0

operating instructions [ja]

164 pgs7.1 Mb0

User's Guide [ko]

176 pgs6.66 Mb0

Installatietekening [nl]

16 pgs768.46 Kb0

User Manual [nl]

184 pgs6.61 Mb0

User manual [pt]

188 pgs6.63 Mb0

Instructions Manual [ro]

188 pgs6.63 Mb0

Plan de instalare [ro]

10 pgs1.02 Mb0

Installation plan [ru]

10 pgs1.02 Mb0

User Manual [ru]

200 pgs5.15 Mb0

User Manual [ru]

192 pgs6.76 Mb0

Installation plan [sl]

10 pgs1 Mb0

Instructions Manual [sl]

184 pgs6.62 Mb0

Instalaciona šema [sr]

10 pgs1 Mb0

User manual [sv]

180 pgs6.59 Mb0

Installation Plan [tr]

10 pgs1.01 Mb0

User manual [tr]

184 pgs6.57 Mb0

Installation plan [uk]

11 pgs1.09 Mb0

User Manual [uk]

188 pgs6.71 Mb0

User Manual [uk]

172 pgs8.31 Mb0

Installation Diagram [zh]

8 pgs1.12 Mb0

Installation Manual [zh]

160 pgs8.12 Mb0

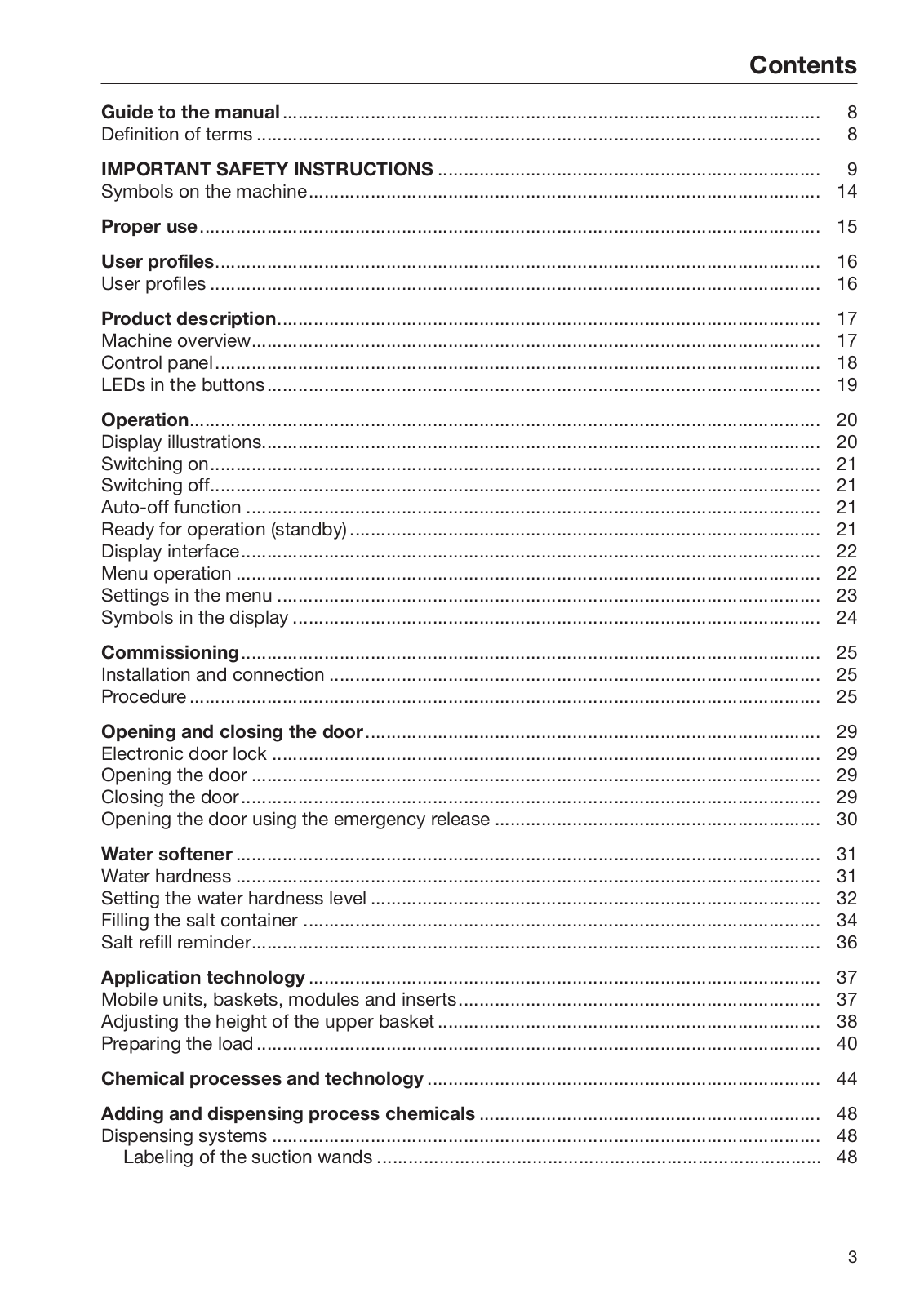

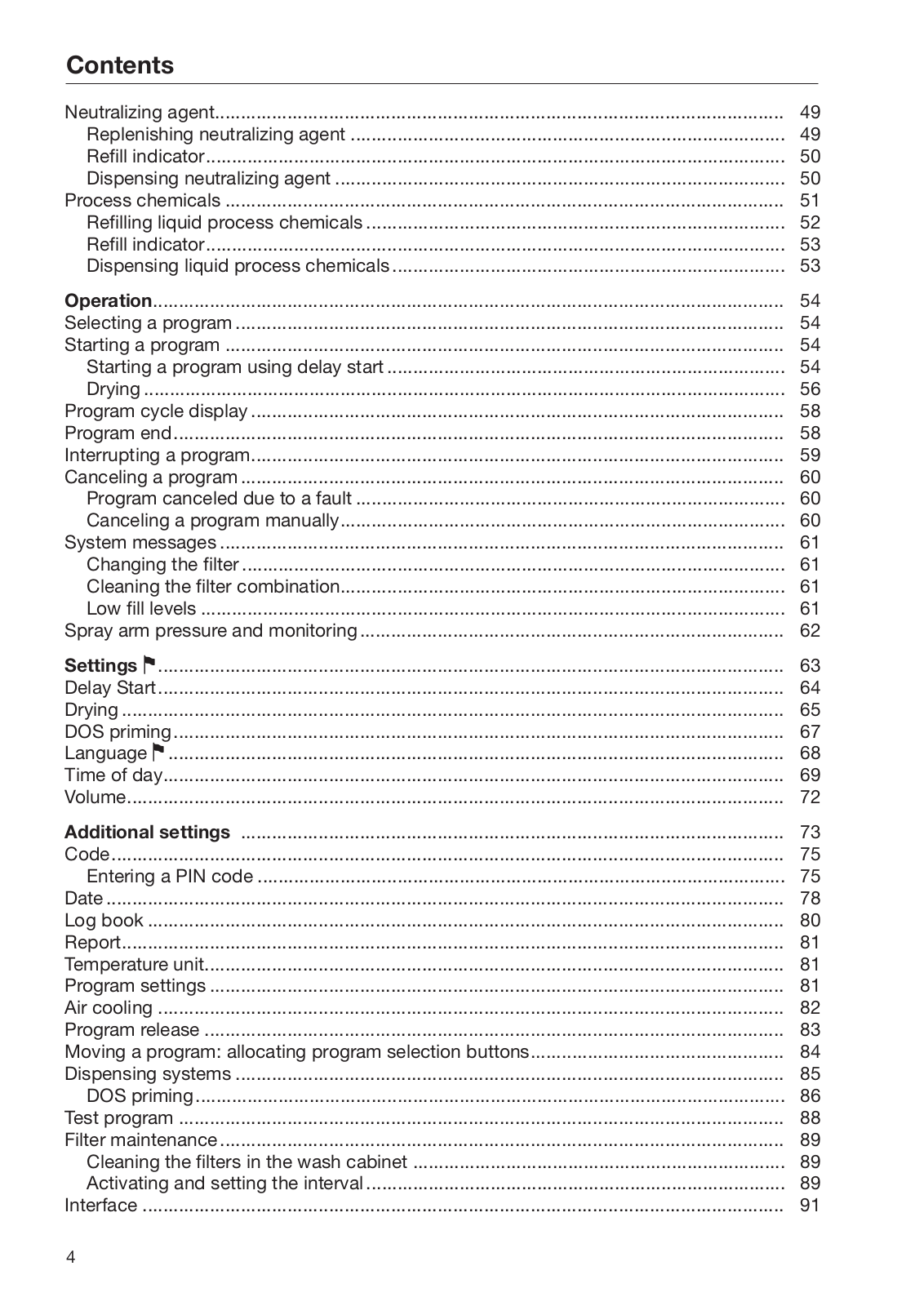

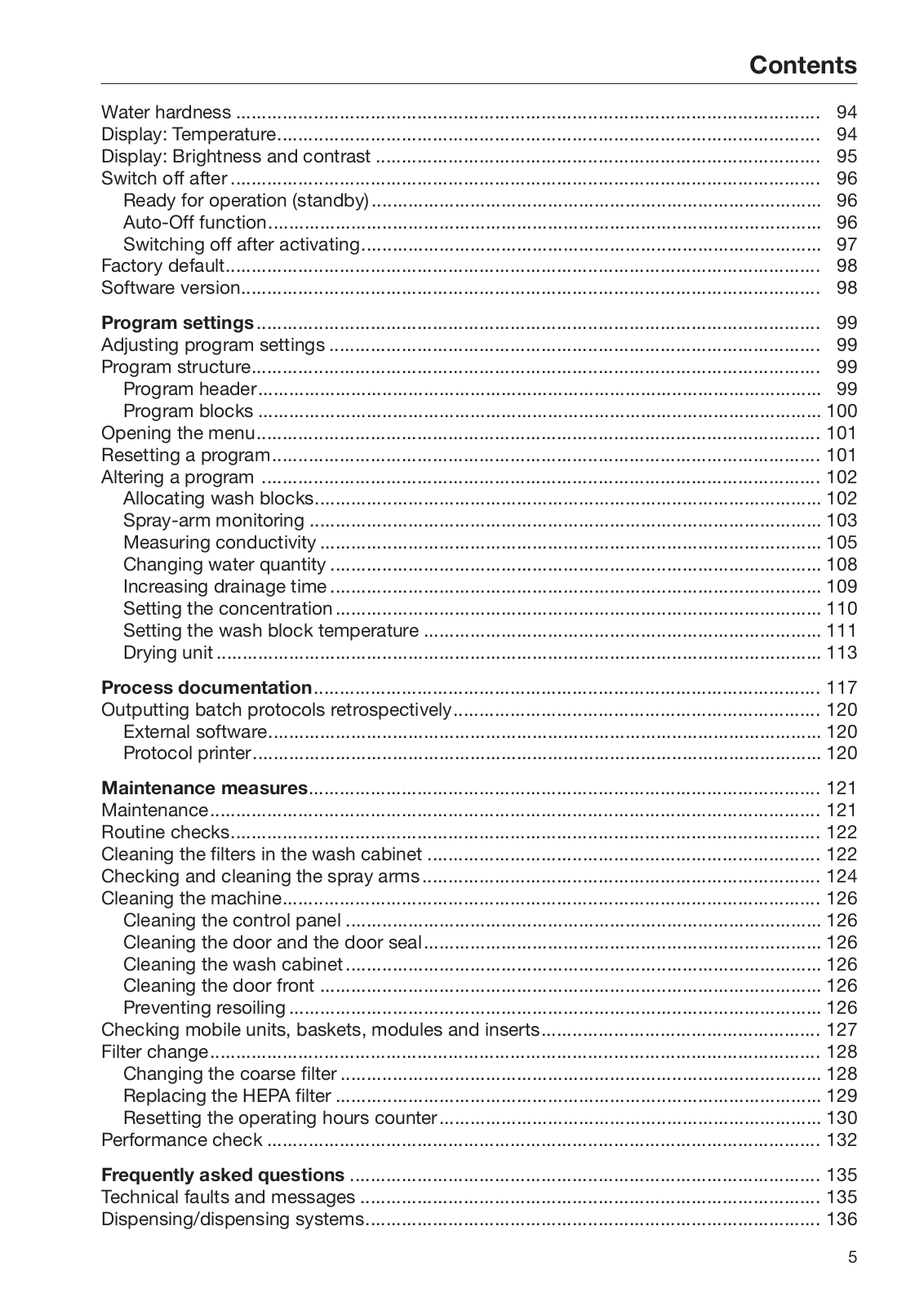

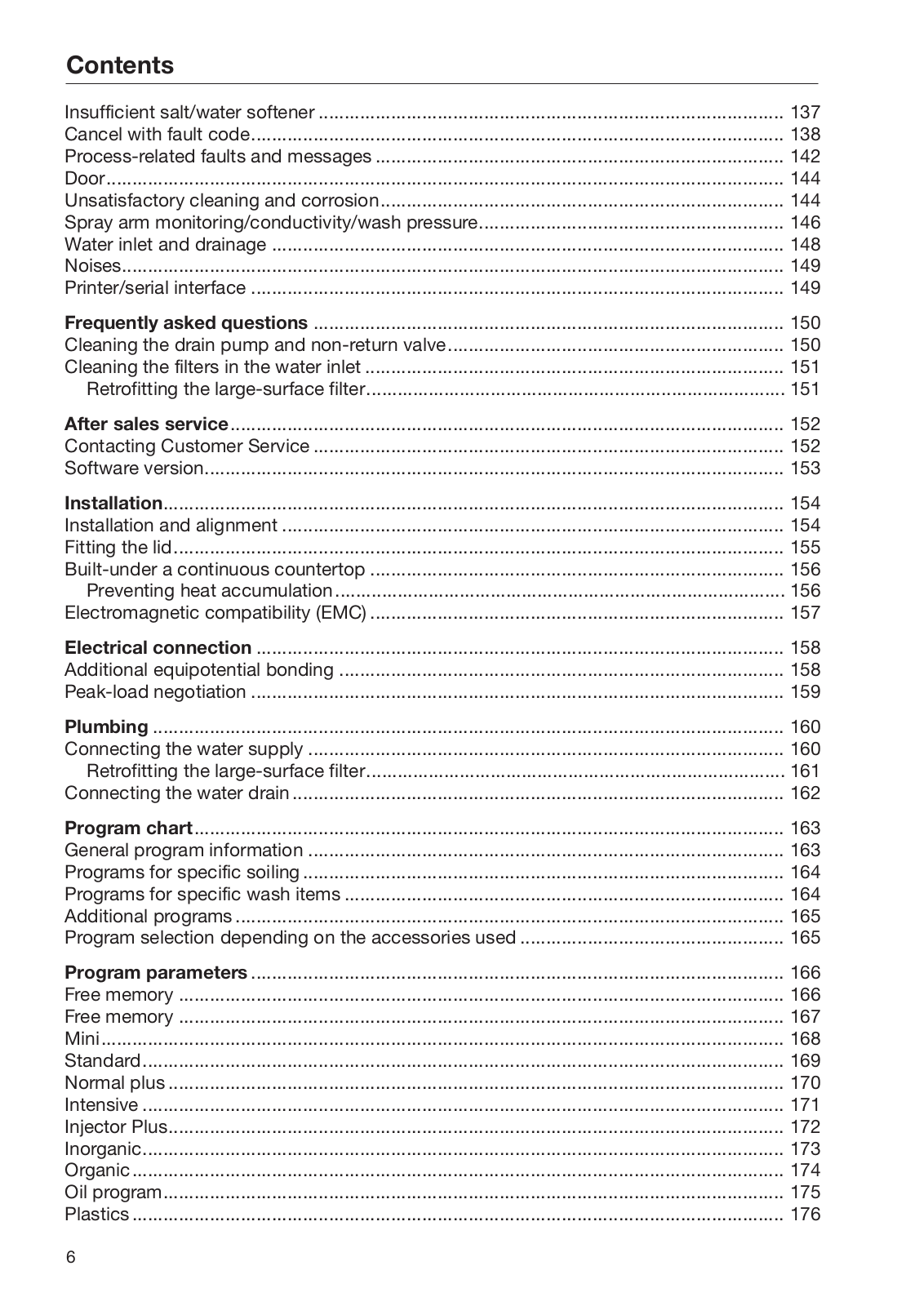

Table of contents

Loading...

Loading...Specifications and Main Features

Frequently Asked Questions

User Manual

Loading...

Loading...+ 154 hidden pages