Installation plan

PG 8528 D/EL

Mat. no.

06812184

Version 05

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 1

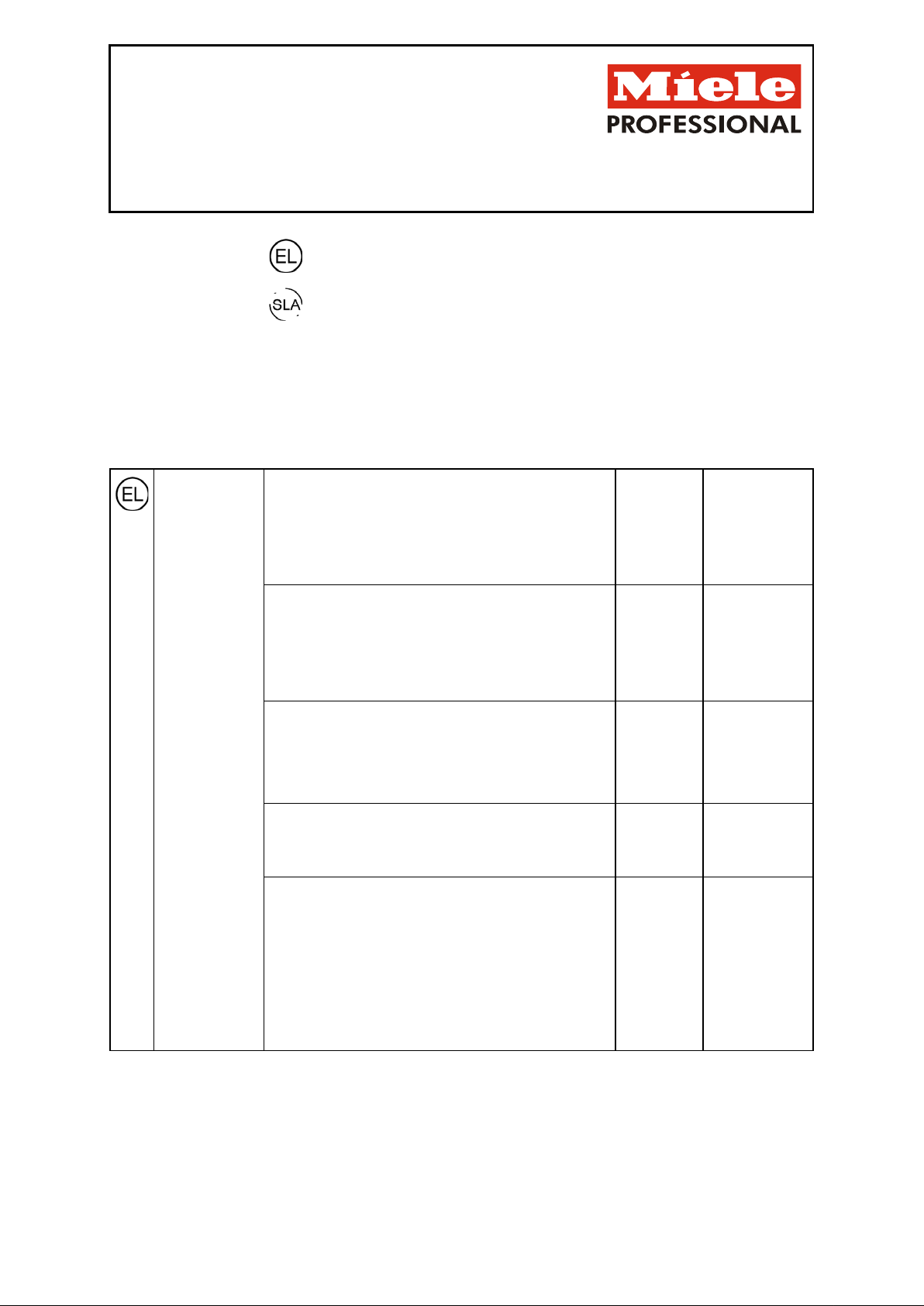

Labwasher

PG 8528

connection

(DU/S)

Voltage

3 AC 208/60

V/Hz

3 AC 208/60

V/Hz

Connected load

2.1 kW

2.1 kW

Fuse rating

3 x 15 A

3 x 15 A

Connecting cable, minimum cross-section

4 x 12 AWG

4 x 12 AWG

(DU/E)

Voltage

3 AC 208/60

V/Hz

3 AC 208/60

V/Hz

Connected load

9.0 kW

9.0 kW

Fuse rating

3 x 30 A

3 x 30 A

Connecting cable, minimum cross-section

4 x 10 AWG

4 x 10 AWG

3. Type of heating: Steam/electric switchable

Voltage

3 AC 208/60

V/Hz

3 AC 208/60

V/Hz

Connected load

21 kW

21 kW

Fuse rating

3 x 60 A

3 x 60 A

Connecting cable, minimum cross-section

4 x 6 AWG

4 x 6 AWG

Connecting cable, minimum length

from upper edge of top panelling in installations

from the ceiling

13 ft.

4.0 m

above top of floor in installations from the floor

5 ft.

1.5 m

e.g. during repair or maintenance.

The plug connection must be accessible after the

installation of the machine.

Connect the device in phase with the clockwise field

of rotation.

The installations must comply with the CAT II

installation category.

Permissible maximum voltage fluctuations

Technical Data Sheet

Type of heating:

Steam/Electric

Legend:

Notes on supply connections:

Cold, hot, DI water, high pressure steam, condensate, and compressed air may be connected

from the ceiling (standard installation) or from the floor (alternative installation). A mixed

installation of these media is possible.

Electrical

2. Type of heating: Steam with electric drying unit

Circled bold-type abbreviations mean:

Connection required

Abbreviations in dashed circles mean:

Connection optional or required for a specific model

1. Type of heating: Steam with steam drying unit

EN

We recommend connecting the appliance via a plug

so that an electrical safety check can be carried out,

+/- 10%

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 2

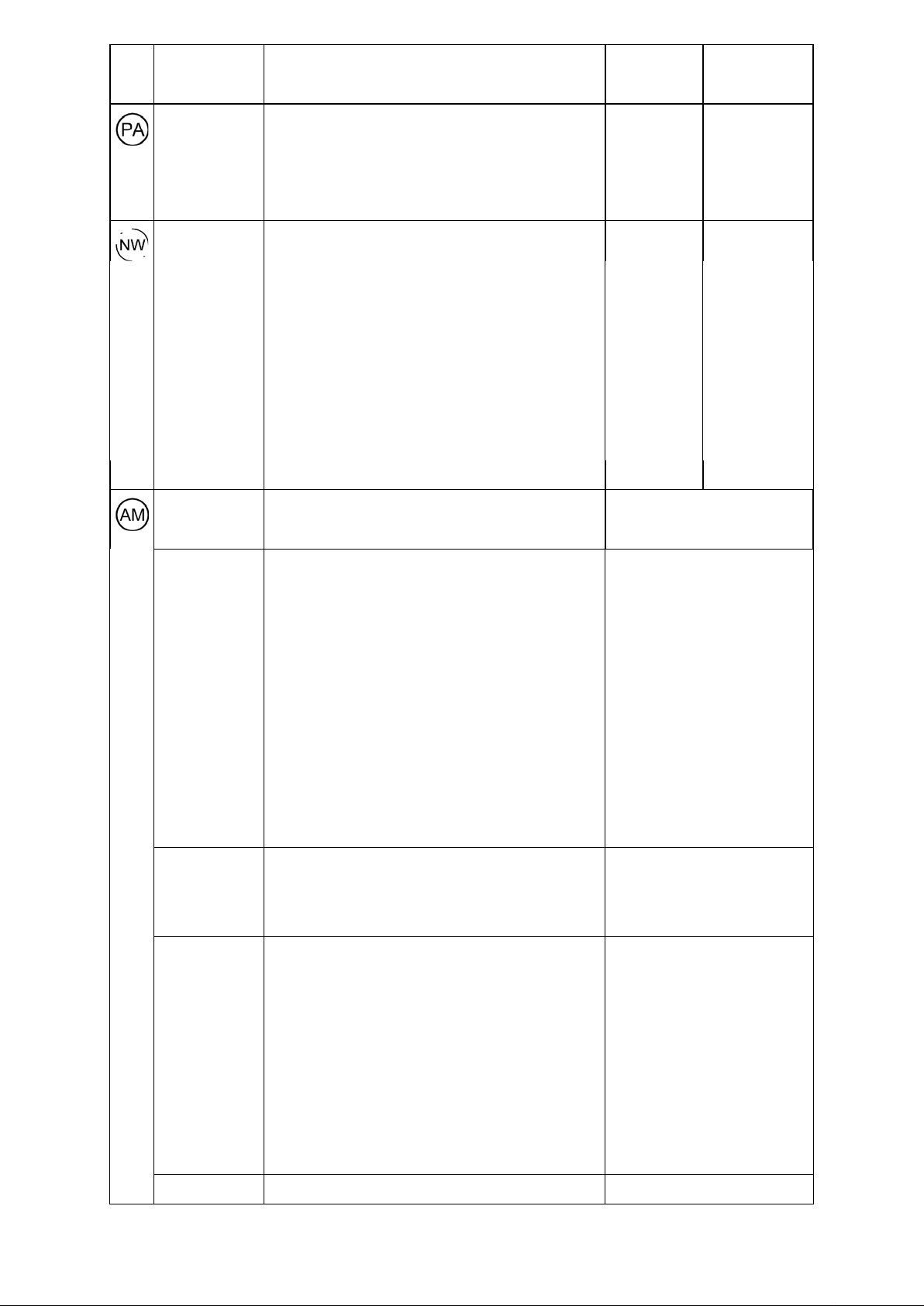

conductor

Equipotential bonding and grounding must be

Ethernet interface (for transmission)

Length of connecting cable, incl. RJ45 plug (scope of

delivery)

16.5 ft.

5.0 m

The user must install an RJ45 socket above the

machine.

Or:

Serial interface (for output on HPGL-compatible printer):

Length of connecting cable, incl. RS232 plug (scope of

delivery)

16.5 ft.

5.0 m

The user must install an RS232 socket above the

machine.

The connections/installations must be designed according

to IEC 60950.

Maximum cont act current capacity:

TA OPERATION

Contact is closed during drying block

200-240/1/50-60 V/A/Hz

PRG RUNS

Contact is closed during rinsing, drying and cooling return

time.

200-240/1/50-60 V/A/Hz

OPERATION

Contact is closed while machine is switched on

200-240/1/50-60 V/A/Hz

MALFUNCTION

Contact is closed if there is a malfunction

200-240/1/50-60 V/A/Hz

PRG END

Contact is closed between program end and door opening.

200-240/1/50-60 V/A/Hz

PAUSE M.

RINSE

Contact is closed during "Pause with rinse" program

segment.

200-240/1/50-60 V/A/Hz

DRAIN STD

Contact is closed during Draining - Standard

200-240/1/50-60 V/A/Hz

DRAIN RECY.

Contact is closed during Draining - Recycling

200-240/1/50-60 V/A/Hz

User-defined

Contact is activated during water outflow, as long as

"External contact" in the block is set to "Water outflow".

200-240/1/50-60 V/A/Hz

COLD

Contact is closed during "Cold" water intake.

200-240/1/50-60 V/A/Hz

WARM

Contact is closed during "Warm" water intake.

200-240/1/50-60 V/A/Hz

AD COLD

Contact is closed during "AD Cold" water intake.

200-240/1/50-60 V/A/Hz

AD WARM

Contact is closed during "AD Warm" water intake.

200-240/1/50-60 V/A/Hz

Cold delayed

Depending on the parameter

200-240/1/50-60 V/A/Hz

Hot delayed

"switch-off delay valve", outflow will be:

200-240/1/50-60 V/A/Hz

DI-cold delayed

a. delayed (start of water inflow)

200-240/1/50-60 V/A/Hz

DI-hot delayed

b. advanced (end of water inflow)

200-240/1/50-60 V/A/Hz

DOS1-EXTERN

Activation signal for external metering pump 1

200-240/1/50-60 V/A/Hz

DOS2-EXTERN

Activation signal for external metering pump 2

200-240/1/50-60 V/A/Hz

DOS3-EXTERN

Activation signal for external metering pump 3

200-240/1/50-60 V/A/Hz

DOS4EXTERNAL

Activation signal for external metering pump 4

200-240/1/50-60 V/A/Hz

DOS5EXTERNAL

Activation signal for external metering pump 5

200-240/1/50-60 V/A/Hz

DOS6EXTERNAL

Activation signal for external metering pump 6

200-240/1/50-60 V/A/Hz

DOS7EXTERNAL

Activation signal for external m etering pum p 7

200-240/1/50-60 V/A/Hz

DOS8EXTERNAL

Activation signal for external metering pump 8

200-240/1/50-60 V/A/Hz

DOS9EXTERNAL

Activation signal for external metering pump 9

200-240/1/50-60 V/A/Hz

Message DOS 1

Contact is established when the corresponding pump is

activated during the program.

200-240/1/50-60 V/A/Hz

Equipotential

bonding and

equipment

grounding

Network and

printer connection

Connection

module

Outputs

Connection to the electrical supply must be carried

out in accordance with local and national safety

regulations.

External threaded pin with washers and nut at the

machine end, size

connected.

The following interfaces for the transmission or printing of

process data are provided at the machine:

Floating contacts (normally open contacts):

A maximum of 9 contacts may be set, possible assignment:

M 8 M 8

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 3

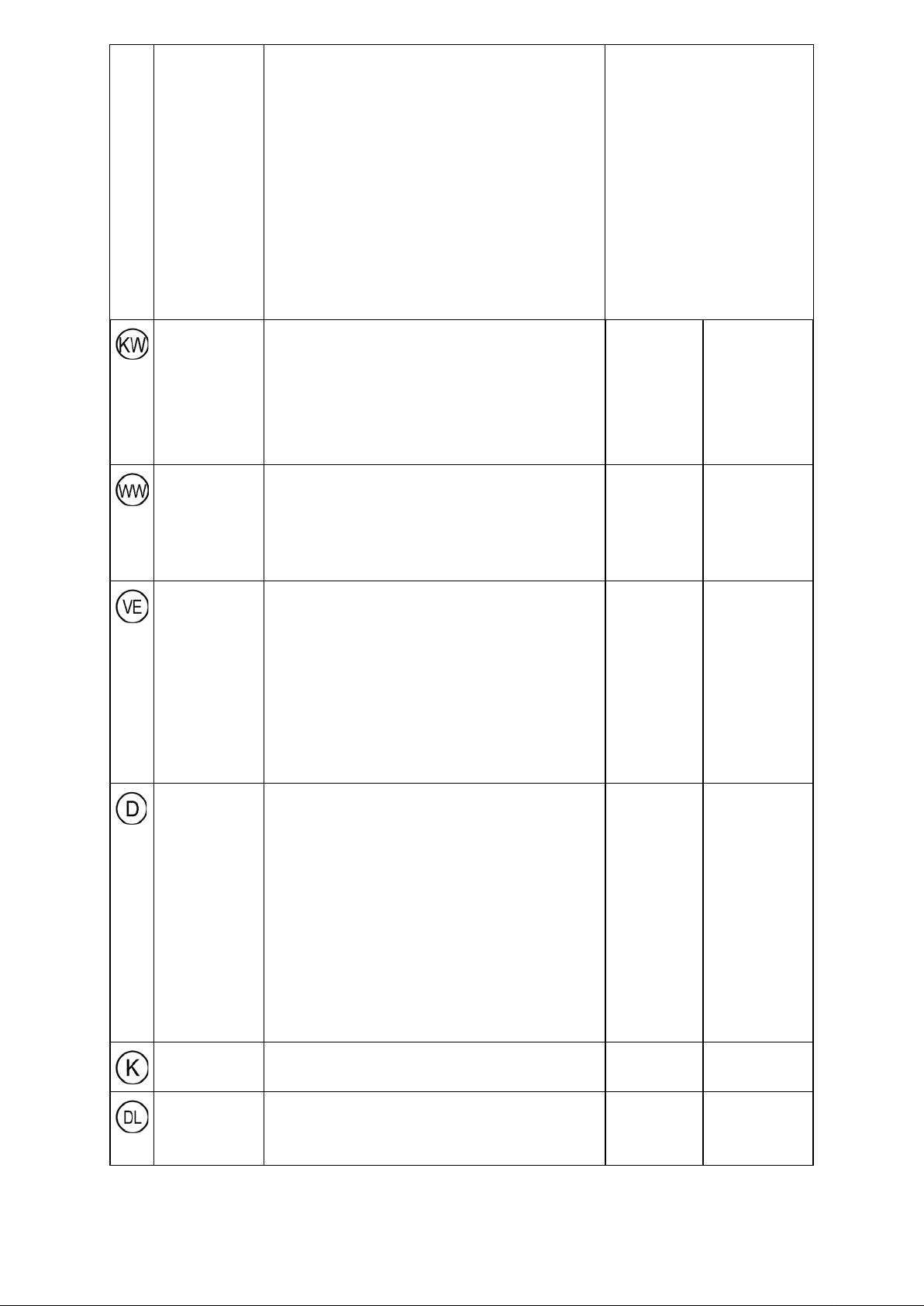

Message DOS 2

Contact is established when the corresponding pump is

activated during the program.

200-240/1/50-60 V/A/Hz

Message DOS 3

Contact is established when the corresponding pump is

activated during the program.

200-240/1/50-60 V/A/Hz

Message DOS 4

Contact is established when the corresponding pump is

activated during the program.

200-240/1/50-60 V/A/Hz

Message DOS 5

Contact is established when the corresponding pump is

200-240/1/50-60 V/A/Hz

Control voltage

SLA HZG

Peak load shut-down, steam and/or electric heater

200-240/50-60 V/Hz

DOS-EXT

Filling level of external DOS containers

200-240/50-60 V/Hz

MEDIUM

Medium dispensing activated, signal for flow and volume

control

200-240/50-60 V/Hz

EXT-TEXT

External text

200-240/50-60 V/Hz

Cold water

Temperature, max.

158°F

70°C

Max. temperature when cooling the steam condenser with

cold water

68 °F

20°C

Max. water hardness

4 gpg

4°dH

Minimum flow pressure

29 psi

200 kPa

Maximum pressure

145 psi

1,000 kPa

Volume flow

4 gal/min

15 l/min

User's connection thread according to DIN 44 991 (flat

3/4" male hose

3/4" male hose

Temperature, max.

158°F

70°C

Max. water hardness

4 gpg

4°dH

Minimum flow pressure

29 psi

200 kPa

Maximum pressure

145 psi

1,000 kPa

Volume flow

4 gal/min

15 l/min

User's connection thread according to DIN 44 991 (flat

3/4" male hose

3/4" male hose

etc.

Temperature, max.

158°F

70°C

Max. temperature when cooling the steam condenser with

DI water (heat recovery of drying heat from exhaust air)

68 °F

20°C

Max. conductivity (e.g., surgical instruments)

15 µS/cm

15 µS/cm

Minimum flow pressure

29 psi

200 kPa

Maximum pressure

145 psi

1,000 kPa

Volume flow

4 gal/min

15 l/min

User's connection thread according to DIN 44 991 (flat

3/4" male hose

3/4" male hose

or pure steam)

Machine variant with electrically heated drying unit (DU/E)

Steam pressure (overpressure)

36-145 psi

250-1,000 kPa

Boiling temperature

282-363°F

139-184°C

Machine variant with steam-heated drying unit (DU/S)

Optimal steam pressure (overpressure)

29-87 psi

250-600 kPa

Boiling temperature

282-329°F

139-165°C

Designed capacity

110 lb/h

50 kg/h

User-side connection thread (flat sealing)

1/2" male pipe

thread

1/2" male pipe

thread

The user must provide a dirt trap and drainage directly

upstream of the appliance's steam connection.

The steam must be provided in dry form and in TRD 611

quality.

The steam pressure directly influences the program run

Designed capacity Qn

0.07 cfm

0.12 m³/h

Supply pressure

87-174 psi

600-1,200 kPa

User-side connection thread

1/2" female

1/2" inner thread

activated during the program.

Connection

module

Inputs

Warm water

Demineralized

water

sealing)

sealing)

Water quality based on requirement for rinsing result.

reverse osmosis, DI water, aqua destillata, ultra-pure water,

e.g.,

thread

thread

thread

thread

sealing)

Heating steam

(saturated steam

times. This must be taken into account when designing and

constructing the steam supply system.

Condensate User-side connection thread (flat sealing)

Compressed air

thread

1/2" male pipe

thread

pipe thread

thread

1/2" male pipe

thread

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 4

connect the SC to the cold water system.

Cooling circuit flow temperature

43°F

6°C

Max. cooling capacity

3.5 kW

3.5 kW

Maximum pressure, cooling circuit

116 psi

800 kPa

Pressure loss, steam condenser

4.3-7.2 psi

30-50 kPa

Cooling circuit volume flow

>1 gpm

>4.0 l/min

Hose nozzle, steam condenser Ø (da x l)

9/16” x 1”

14 x 25 mm

Installation of shut-off valve and dirt filter (by the user)!

To control the cooling circuit, electrically opening shut-off

valves must be installed at the connection point by the user:

To connect the steam condenser, the user must suspend a

Hose nozzle, steam condenser Ø (da x l)

9/16” x 1”

14 x 25 mm

Installation of shut-off valve (by the user)!

To connect the steam condenser, the user must suspend a

valve (DV):

Temperature, max.

199°F

93°C

Connection

2”

50 DN

Delivery, short-time, max.

39 gal/min

150 l/min

Odor trap to be provided by user

valve (DV):

Temperature, max.

158°F

70°C

Connection

2”

50 DN

Odor trap to be provided by user

Cooling circuit

flow (optional)

Cooling circuit

return flow

(optional)

Waste water

The steam condenser (SC, option) may be connected to a

cooling circuit. If a cooling circuit is not provided at the site,

connecting hose with an internal diameter of 9/16” (14 mm)

and a length of 5 ft. (1.50 m) from the ceiling.

Required for the connection of the steam condenser to a

cooling circuit:

connecting hose with an internal diameter of 9/16” (14 mm)

and a length of 5 ft. (1.50 m) from the ceiling.

Waste water connection, required for design with drain

Tray drain

Waste water connection, required for design with drain

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 5

Temperature, max.

199°F

93°C

Connection for drain pump, 2× each

2”

50 DN

Drain pump delivery head max.

9’ 10”

3.0 m

Delivery, short-time, max.

26 gal/min

100 l/min

Drain pump discharge hose, 2× each (di × s × l), scope

of delivery

7/8” x ¼” x 59

1/16”

22 x 6 x 1,500

mm

User hose nozzle 2x each

7/8” x 1 3/16”

22 x 30 mm

Connection for discharge hose from steam condenser

cold water supply:

2”

50 DN

Delivery head max.

9’ 10”

3.0 m

Delivery, short-time, max.

1-1.6 gal/min

4-6 l/min

Discharge hose (di × s × l)

1/2” x 1/8” x 8’

2 1/2”

14 x 3 x 2,500

mm

User hose nozzle

1/2” x 1 1/4”

14 x 30 mm

Connection for condensate discharge hose:

2”

50 DN

Delivery head max.

9’ 10”

3.0 m

Delivery, max.

0.26 gal/min

1 l/min

Discharge hose (di × s × l)

¼” x 1/16” x 8’

2 1/2”

6 x 2 x 2,500 mm

User hose nozzle

¼” x 3/ 4”

6 x 20 mm

Minimum diameter, discharge collecting hose

100 DN

100 DN

The use of an odour trap is recommended.

Drill hole diameter

1 7/16”

36 mm

Prior to the installation of the machine and depending on

Drain pump

(optional)

If the waste water cannot be drained through the floor, the

labwasher can be equipped with drain pumps (DP).

(optional), only if a steam condenser is connected to the

Housing bushings

for discharge

hoses, DP

machine variant

the structural conditions, openings must be provided in the

enclosure in the marked areas or at the specified points.

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 6

Corresponding to the exhaust air volume, fresh air must be

delivered to the installation space.

I. Exhaust air conduit directly to the exterior without steam

individually!):

Volume flow, exhaust air

147 cfm

250 m³/h

Temperature mean value/short-time max.

158/203°F

70/95°C

Relative humidity mean value/short-time max.

80/100%

80/100%

Exhaust air conduit, max. permissible pressure loss

0.10 psi

700 Pa

II. Exhaust air conduit directly to the exterior with steam

individually!):

Operation of the steam condenser at the cooling circuit

or cold-water connection:

Volume flow, exhaust air

147 cfm

250 m³/h

Temperature mean value/short-time max.

82/90°F

28/32°C

Relative humidity mean value/short-time max.

<70/100%

<70/100%

Exhaust air conduit, max. permissible pressure loss

0.07 psi

500 Pa

Operation of the steam condenser at the DI water

exhaust air:

Volume flow, exhaust air

147 cfm

250 m³/h

Temperature mean value/short-time max.

113-118°F

45/48°C

Relative humidity mean value/short-time max.

<65/100%

<65/100%

Exhaust air conduit, max. permissible pressure loss

0.07 psi

500 Pa

III. Connection without steam condenser to external exhaust

air system with blower:

Volume flow of the user's exhaust air system in "Rinse"

program

59 cfm

100 m³/h

Volume flow of the user's exhaust air system in "Dry"

program

206 cfm

350 m³/h

Temperature mean value/short-time max.

158/203°F

70/95°C

Relative humidity mean value/short-time max.

80/100%

80/100%

IV. Connection with steam condenser to external exhaust

air system with blower:

Operation of the steam condenser at the cooling circuit

or cold-water connection:

Volume flow of the user's exhaust air system in "Rinse"

program

59 cfm

100 m³/h

Volume flow of the user's exhaust air system in "Dry"

program

206 cfm

350 m³/h

Temperature mean value/short-time max.

82/90°F

28/32°C

Relative humidity mean value/short-time max.

<70/100%

<70/100%

Operation of the steam condenser at the DI water

exhaust air:

Volume flow of the user's exhaust air system in "Rinse"

program

59 cfm

100 m³/h

Volume flow of the user's exhaust air system in "Dry"

program

206 cfm

350 m³/h

Temperature mean value/short-time max.

113-118°F

45/48°C

Relative humidity mean value/short-time max.

<65/100%

<65/100%

A return of condensate into the labwasger must be

Height-adjustable

3/8”

10 mm

Foot diameter

1”

25 mm

Fittings

Scope of delivery, base/floor tray:

Chemical anchor stud (4 pieces)

5/16” x 5 7/8”

M 8 x 150 mm

Drill holes Ø

3/8”

10 mm

Exhaust air Connection nozzle, machine (da × s) 5” x 1/16” 125 x 1.25 mm

condenser (do not combine the exhaust air conduits of

multiple labwashers; exhaust air is to be removed

condenser (do not combine the exhaust air conduits of

multiple labwashers; exhaust air is to be removed

connection for heat recovery of drying heat from

connection for heat recovery of drying heat from

prevented. Installation of the exhaust air conduit in direction

of exhaust air flow with gradient and drainage at the lowest

point.

Machine feet

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 7

Unclean side

2,047 btu/h

0.6 kWh/h

Clean side

2,047 btu/h

0.6 kWh/h

Load on removal

btu/h

1.4 kWh/h

Height, incl. base and floor tray

65 3/8”

1,660 mm

Height, incl. base and floor tray and top panelling

95 ¼”

2,420 mm

Width

45 ¼”

1,150 mm

Depth

34 ¼”

870 mm

Net weight incl. base/floor tray, top panelling, etc.

1,260 lb

570 kg

Floor load during operation

~8,000 N

~8,000 N

Width including transport pallet

37 3/16”

944 mm

Height including transport pallet

70 7/8”

1,800 mm

Heat discharge

into the

installation room

Machine data

Please read and observe the instructions in the operating instruction manual and the service documents regarding installati on

and setting up of this machine.

Installation should only be carried out by authorized installers in accordance with valid standards and regulations.

The machine must be commissioned and operators trained in its use by Miele Service or by an approved Miele Service

Technician only.

Alteration rights reserved.

4,776

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 8

Notes on supply connections:

Cold, hot, DI water, high pressure steam, condensate, and compressed air may be connected from

the ceiling (standard installation) or from the floor (alternative installation). A mixed installation of these

media is possible. Waste water and floor tray drain (design with drain valve, DV) can only be

connected from the floor. The connections for the cooling circuit flow and return flow for a steam

condenser (optional) may only be installed via the ceiling. It is recommended to install central shut-off

valves and main switches at an easily accessible location.

Preparation:

Drill holes in the floor based on the drawing or drill template (drill templates can be ordered from Miele

Service). If media connections are installed from below (alternative installation), additional holes are

required for the media and electrical wiring.

Recommended core holes: Waste water connections Ø 4” (100 mm)

Electrical connection Ø 3 1/8” (80 mm)

Media connections 10 5/8” x 11” (270 x 280 mm) W x D

When multiple units are installed in series, the drill templates are placed directly next to each other.

The template size matches the divider cut-out, which is dimensioned slightly larger to allow for a 3/16”

(5 mm) gap between machines and a 1/8” (3 mm) gap between machine and divider. These gaps are

sealed by the user with a suitable, permanently elastic sealant.

Waste water connection, machines with drain valve (DV):

The collecting main (min. 4”) is run under the floor and must be equipped with an odour trap by the

user. From there, the connecting pipes (2”) must be installed vertically to the center distance. All

sleeves and/or Konfix couplings of the drain pipes must be terminated flush with top of floor and

fastened adequately and securely. For the waste water connection, an additional fitting piece 5 3/4”

(145 mm) in length (+ sleeve/Konfix) is required above top of floor. These pipe sections must be

prepared for the machine connection and removed again. The fitting pieces are only required after the

labwasher has been slid onto the base/floor tray. The pipe ends must be closed if the installation of

the base/floor tray is scheduled for a later time.

Waste water connection, machines with drain pumps (DP):

The waste water pipe for the connection of the discharge hoses should be located next to the

machine. In order to feed hoses from the machine, openings can be provided on-site in the specified

areas of the enclosure walls. The discharge hoses extend to the openings and must be extended

outside of the machine. The openings must have a diameter of 1 7/16” (36 mm). As edge protection

for the discharge hoses, caps with Mat. No. 27119630 (closed) or 2723340 (open) are required. When

multiple labwashers are installed in series, a corresponding floor tray may be manufactured in which

the discharge hoses can be installed.

A connection to a collection line above the machines is also possible. In this case, you must install a

strain relief for the discharge hoses. If a steam condenser is supplied with cold water, an open pipe

interrupter must be used to secure the discharge hose. Note the maximum delivery height of the

pumps!

All discharge hoses of the labwashers must be connected pressure-sealed with the discharge line.

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 9

Electrical connection:

The electrical supply may be connected from the ceiling or from the floor. If the labwasher is

connected from the floor, a minimum cord length of 5 ft. (1,500 mm) over top of floor is required. If the

machine is connected from the ceiling, a power cord with a length of 13 ft. (4,000 mm) from the upper

edge of the MAV is required.

Standard installation, media conne ctions:

Supply lines are to be installed vertically downward from the ceiling, aligned and fastened securely. All

conduit components including insulation, fasteners, and valves with hand wheels must be installed in

the designated area 16” x 8” (400 mm × 200 mm). They must not protrude from this area.

Warm water, cold water and DI water terminate in a ¾“ male hose thread, at a height of 8 ft.

(2,400 mm) over top of floor. High-pressure steam and condensate terminate in a ½“ male pipe

thread, compressed air in a ½“ female pipe thread, at a height of 7.5 ft. (2,250 mm) over top of floor.

It is recommended to install a check valve directly downstream of the machine's condensate separator

to prevent shocks during start-up.

If the labwasher is fitted with a steam condenser, the flow and return flow of the cooling circuit must be

vertically installed from the ceiling, aligned, and securely fastened. Cooling circuit flow and return flow

terminate in the installation area of the labwasher with a hose nozzle at a height of 7.5-8 ft. (2,2502,400 mm) over top of floor. Both are connected to the steam condenser ports with a user-supplied

hose or with the available conversion kit. If a cooling circuit is not provided, the steam condenser must

be connected to the cold water supply.

The cover plate - Mat. No. 6757830 - can be used to cover the top panelling.

Alternative installation, media connections:

Supply lines must be installed vertically through the floor opening, terminated approximately 7 7/8”

(200 mm) over top of floor, aligned and securely fastened. They are shortened after the base/floor tray

has been installed. The pipe ends must be closed if the installation of the base/floor tray is scheduled

for a later time. Install and horizontally align the floor tray. Subsequently to the installation of the floor

tray, install the media shut-off valves in it. Shut-off devices for warm water, cold water and DI water

terminate vertically in a ¾“ male hose thread. High-pressure steam and condensate terminate in a ½“

male pipe thread, and compressed air terminates in a ½“ female thread. The construction must not

exceed a height of 3 9/16” (90 mm) above top of floor and must not protrude beyond the base/floor

tray. The floor opening must be properly sealed. After the pipes have been installed in the base/floor

tray, the tray floor opening must be sealed water-proof with a suitable, permanently elastic sealant.

If the labwasher is fitted with a steam condenser, the flow and return flow of the cooling circuit must be

vertically installed from the ceiling, aligned, and securely fastened. Cooling circuit flow and return flow

terminate in the installation area of the labwasher with a hose nozzle at a height of 7.5-8 ft. (2,2502,400 mm) over top of floor. Both are connected to the steam condenser ports with a user-supplied

hose or with the available conversion kit. If a cooling circuit is not provided, the steam condenser must

be connected to the cold water supply.

The cover plate - Mat. No. 6757830 - can be used to cover the top panelling.

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 10

Change No.

Date

Description:

-

01/07/2016

Value of steam pressure with steam TA adjusted.

A16155

01/09/2011

Heat recovery, DI water pre-heating

Exhaust air installation:

Connection with or without steam condenser to external exhaust air system:

Use a suction hood for the connection to an external exhaust system of the labwasher. The minimum

clearance required is 80 mm. A suitable suction hood is a component of the labwasher package. A

two-stage blower is recommended (for the regulation of the blower output, see technical data sheet

"Electric connection"). The exhaust air connection must be flexibly provided above the labwasher.

Exhaust air directly to the exterior:

The supplied suction hood must not be installed if the labwasher’s exhaust air hose is directly

conducted to the exterior.

Note on smoke detectors:

If any smoke detectors are to be installed near the labwasher, differential maximum or

ionization smoke detectors must be installed at a sufficient distance from the machine, due

to vapor formation upon opening of doors.

Installation Plan PG 8528 D/EL

Version: 01/07/2016 Page 11

Loading...

Loading...