Operating and Installation

Instructions

Laboratory Glassware

Washer

PG 8527 / PG 8528

To prevent accidents

and machine damage

read these instructions

before

installation or use.

en - US, CA

M.-Nr. 07 777 030

Contents

IMPORTANT SAFETY INSTRUCTIONS.................................4

Function of the laboratory glassware washer...........................8

Guide to the laboratory glassware washer .............................9

Electronic controls .................................................12

Optional equipment ...............................................14

Context menu ....................................................15

Change the display language ........................................16

Change the operating level ..........................................17

Delay start .......................................................19

Change the heating type ............................................21

Current faults .....................................................21

Loading package..................................................21

Automatic mobile unit recognition (AWK).............................22

Mobile unit coding .................................................22

Setting mobile unit coding ........................................23

Application ......................................................25

Process validation .................................................25

Protein detection ..................................................25

Adding liquid detergents and neutralizers ............................28

Dispensing systems................................................29

Effects of Processing Chemicals ....................................31

Operation .......................................................36

Main Switch - On/Off ...............................................36

Turning On .......................................................36

Starting a program.................................................37

Program sequence ................................................39

End of program ...................................................39

Turning off .......................................................39

Canceling a program...............................................39

Interrupting a program..............................................40

Barcode scanner (optional) ........................................41

Barcode scan functions.............................................41

User scan load....................................................42

User scan unload..................................................42

Scan the load.....................................................43

Loading packages.................................................46

2

Contents

Serial interface (data transfer) ......................................51

Maintenance .....................................................52

Routine checks ...................................................53

Cleaning the filters in the wash cabinet.................................54

Cleaning the fine filter ............................................54

Cleaning the flat filter ............................................54

Cleaning the filter system for the circulation pump .....................55

Cleaning the spray arms ............................................56

Cleaning the control panel and glass door (optional) ......................57

Cleaning the exterior ...............................................57

Cleaning the wash cabinet ..........................................57

Cleaning the door seal..............................................57

Baskets and inserts ................................................58

Report printer (optional).............................................59

Replacing the print paper.........................................59

Replacing the ribbon cartridge.....................................59

After sales service ................................................60

INSTALLATION INSTRUCTIONS.....................................61

Electrical connection..............................................62

Plumbing........................................................63

Technical data ...................................................65

Caring for the environment.........................................66

3

IMPORTANT SAFETY INSTRUCTIONS

Please pay attention to the following

This machine conforms to current

safety requirements. However,

inappropriate use can lead to

personal injury and property

damage. Read the operating

instructions carefully before using

this machine.

Keep these instructions in a safe

place and pass them on to any

future user.

Use

This machine is designed for

~

commercial use and for specialized

applications only, as described in these

Operating Instructions. Do not use for

purposes other than those for which it

was designed, as this could be

dangerous.

notes to maintain safe procedures.

The machine should be

~

commissioned and maintained only by

a Miele Service Technician. Repairs by

unqualified persons could be

dangerous.

Do not install the machine in an area

~

where a danger of explosion or freezing

may be present.

Be certain this appliance is properly

~

installed and grounded by an

authorized technician. To guarantee the

electrical safety of this appliance,

continuity must exist between the

appliance and an effective grounding

system. It is imperative that this basic

safety requirement be met. If there is

any doubt, have the electrical system

checked by a qualified technician.

This machine in intended for indoor

~

use only.

The installation of this unit in non

~

stationary locations must be performed

by a qualified installer or service

agency in strict accordance with

national and local safety regulations

and standards.

4

A damaged machine is dangerous.

~

Turn off the machine immediately at the

power switch and call the Miele Service

Department.

Personnel operating the machine

~

should be trained regularly. Children

and untrained personnel must not be

allowed access to the machine or its

controls.

Take care when handling liquids

~

such as detergents, neutralizing

agents, wetting agents and rinse aids.

These may contain irritant or corrosive

ingredients, acids or alkalis. Wear

protective gloves and goggles. The

manufacturer’s safety conditions must

be observed at all times.

IMPORTANT SAFETY INSTRUCTIONS

The lab washer is only designed to

~

operate with water and the

recommended processing chemicals.

The machine must NOT be operated

with organic solvents or flammable

liquids. This may cause an explosion or

damage to rubber and plastic

components, which in turn allows liquid

substances to leak out.

The water in the machine must not

~

be used as drinking water.

Be careful when sorting items with

~

sharp pointed ends. Position them in

the machine so that you do not hurt

yourself or create a danger for others.

When using this machine regard the

~

high temperatures and be especially

careful not to scald or burn yourself.

When opening the door bypassing the

electrical lock, a danger of burning,

scalding and corrosion exist. Let mobile

units, inserts and cleaned items cool

before touching them. Any water which

may remain in containers will be very

hot and must be emptied into the wash

cabinet.

If toxic chemical substances can

~

form in the wash water during

processing (e.g. aldehydes in the

disinfection agent), the door seal and, if

applicable, the function of the steam

condensor must be checked regularly.

In that case, opening the lab washer

door during a program interruption can

be dangerous.

If you are exposed to toxic vapors or

~

processing chemicals, consult the

manufacturer's material safety data

sheets for emergency procedures.

Always allow mobile units, modules,

~

inserts, and loads to cool before

removing. Be sure to empty any water

from concave items into the wash

cabinet before removing.

After drying with the drying unit

~

open the door to allow the items and

inserts to cool.

If the pre-heater has been

~

programmed to "Pre-heater standby",

be particularly careful of hot water and

steam when opening the door. Danger

of burning or scalding. The water inlet

pipe to the wash cabinet is located, as

viewed from the loading side,

underneath the basket runner on the

left hand side.

Steam heating is permissible up to a

~

pressure of 145 psi. This corresponds

to a water steam temperature of 354°F

(179 °C).

Never clean the machine near or

~

with a water or high pressure hose.

Before servicing, disconnect the

~

power supply by either removing the

fuse, unplugging the unit or manually

"tripping" the circuit breaker.

,

Mount on non-combustible floors

only!

5

IMPORTANT SAFETY INSTRUCTIONS

The following points should be

observed to assist in maintaining

quality standards for critical labware

and to avoid damage to the loads

being cleaned.

Only use process chemicals that are

~

approved by their manufacturer for the

application involved. Any negative

effects on labware and the washer itself

are the liability of the chemical

manufacturer.

Use only Miele approved cleaning

~

agents with this machine. Use of

unsuitable cleaning agents could

adversely affect the components of the

machine. Damages resulting from using

unsuitable cleaning agents are not

covered by the warranty.

Pre-treating (e.g. with cleaning

~

agents), certain soiling and cleaning

agents with a chemical interaction, can

cause foam. For pre-treatment and/or

cleaning only use low-sudsing

detergents which have been approved

by Miele. Suds can have an adverse

effect on the operation of the machine.

Use of a chemical disinfectant at

~

moderate temperatures (for example

149°F / 65°C or lower) do NOT fulfill the

official requirements for disinfection

pursuant to FDA regulations. Always

note their specifications for handling,

application conditions and efficacy. The

operator is responsible for the use of

any such thermo-chemical processes.

The process must be set so that no

~

foam escapes the wash compartment.

Escaping foam jeopardizes the safe

operation of the lab washer.

The process must be checked

~

regularly in order to detect any

foaming.

In order to prevent damage to the

~

lab washer and any accessories

through processing chemicals or dirt as

well as any interaction between them,

see "Effects of Processing Chemicals".

When a chemical additive is

~

recommended, the manufacturer of the

machine takes no responsibility for the

effect of the chemical on the items

being cleaned.

In critical applications where very

~

high requirements have to be met, it is

strongly recommended that all the

relevant factors for the process, such

as cleaning agent, quality of water, etc.

are discussed with the Miele

Applications Specialists.

If the cleaning result is subject to

~

particularly stringent requirements

(e.g. chemical analysis, specialized

processes), a regular quality control

test should be carried out by the user to

ensure that the required standards of

cleanliness are being achieved.

The mobile units and special inserts

~

should only be used for their specific

application.

Empty any containers or utensils

~

before arranging them in the machine.

6

IMPORTANT SAFETY INSTRUCTIONS

Do not allow any remains of acids,

~

solvents or corroding ferrous material,

and in particular hydrochloric acid or

chloride solutions to get into the wash

cabinet. Similarly avoid any materials

with a corrosive effect. The presence in

compounds of any solvents should be

minimal, (especially those in hazard

class A1).

To avoid any corrosion damage

~

ensure that solutions or steam

containing hydrochloric acid do not

come in contact with the stainless steel

casing of the machine.

Please follow the installation advice

~

in these instructions and the separate

Installation Instructions.

Using accessories

Only specific additional equipment

~

made by Miele should be connected to

this machine. Consult a Miele

Application Specialist on the type and

application of such equipment.

Disposal of an old appliance

When discarding a labwasher,

~

disconnect it from the power supply

and cut off the power cord.

For environmental and safety reasons

ensure the machine is completely

drained of any residual water and

cleaning agent. (Observe safety

regulations and wear safety goggles

and gloves). Make the door lock

inoperative or remove the door

completely, so that children cannot

accidentally shut themselves in. Make

appropriate arrangements for the safe

disposal of the machine.

Machines with a tank system: remove

the water from the tank before

disposing the machine.

SAVE THESE

INSTRUCTIONS

Only Miele mobile units, modules

~

and inserts should be used. If

equipment from another manufacturer

is used, Miele cannot ensure the

cleaning results. Damage or injury

caused by this are excluded from the

warranty.

Please note the following symbols on

the machine:

Caution : See the Operating

Instructions!

Caution : Danger of electric

shock!

7

Function of the laboratory glassware washer

The Miele PG 8527/ 8528 Laboratory

Glassware Washer is designed for

high-throughput, centralized wash

areas. This unit is ideal for cleaning

both large volumes of small items, and

difficult to clean large items.

Typical applications include:

laboratory equipment for research

–

and production,

laboratory equipment for analytical

–

and preparation applications,

microbiology and biotechnology

–

labware,

Labware can include anything from

evaporation dishes to centrifuge tubes.

In these operating instructions, the

general terms labware and glassware

are used to cover a range of laboratory

equipment and medical items.

For standardized results, it is preferable

to machine-wash lab instruments and

equipment.

The cleaning parameters should always

be optimally matched to the type of

soiling and labware involved.

The processing chemicals used also

should be matched to the particular

cleaning needs / analysis / analytical

methods involved.

8

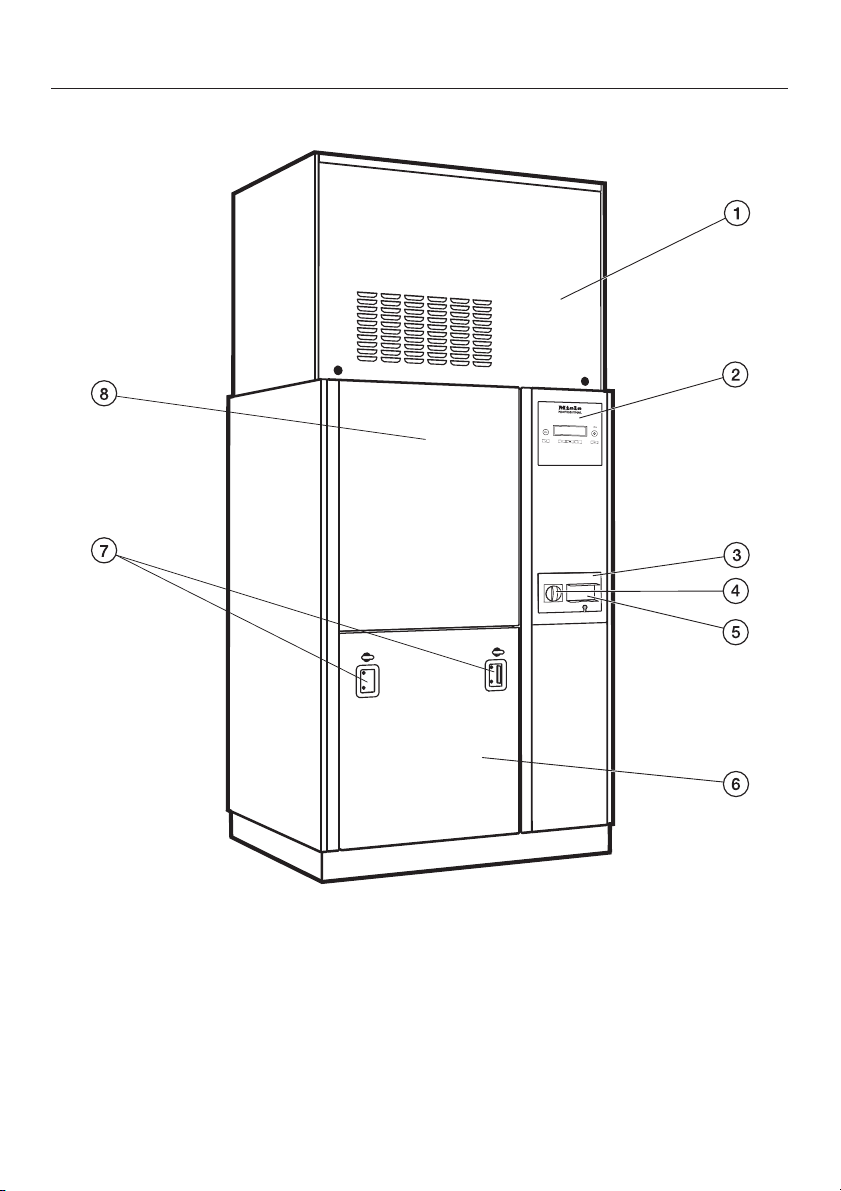

Loading side

Guide to the laboratory glassware washer

a Housing unit for Drying System DS

and/or Steam Condensor SC

b "Profitronic" electronic control system

(see "Programming manual")

c Multiport

d Main Switch "On/Off"

e Barcode scanner mount (optional)

f Service panel

g Docking station for transfer cart

MF 27/28

h Lift door (closed)

9

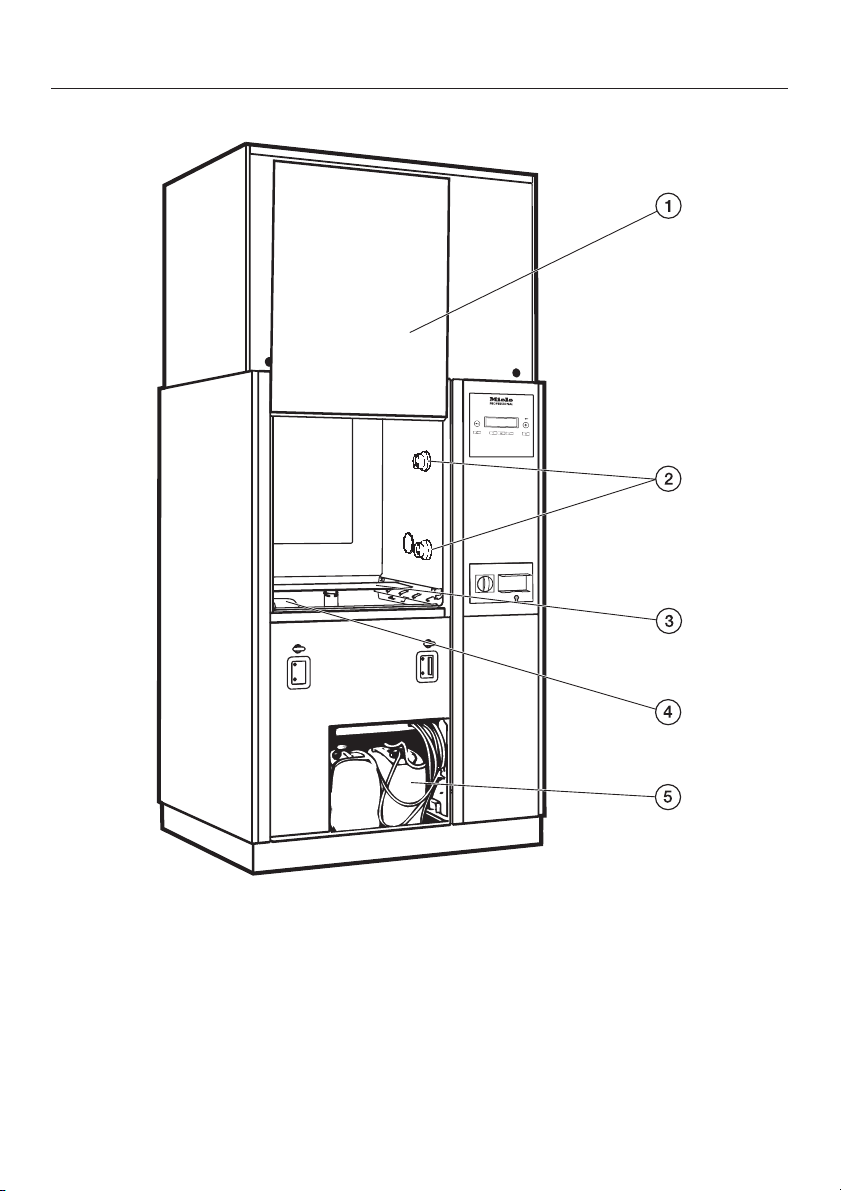

Guide to the laboratory glassware washer

Loading side

a Lift door (open)

b Connection for transfer cart and

modules

c Lower spray arm

d Filter combination

10

e Container for dispensing systems

DOS 1 - DOS 4

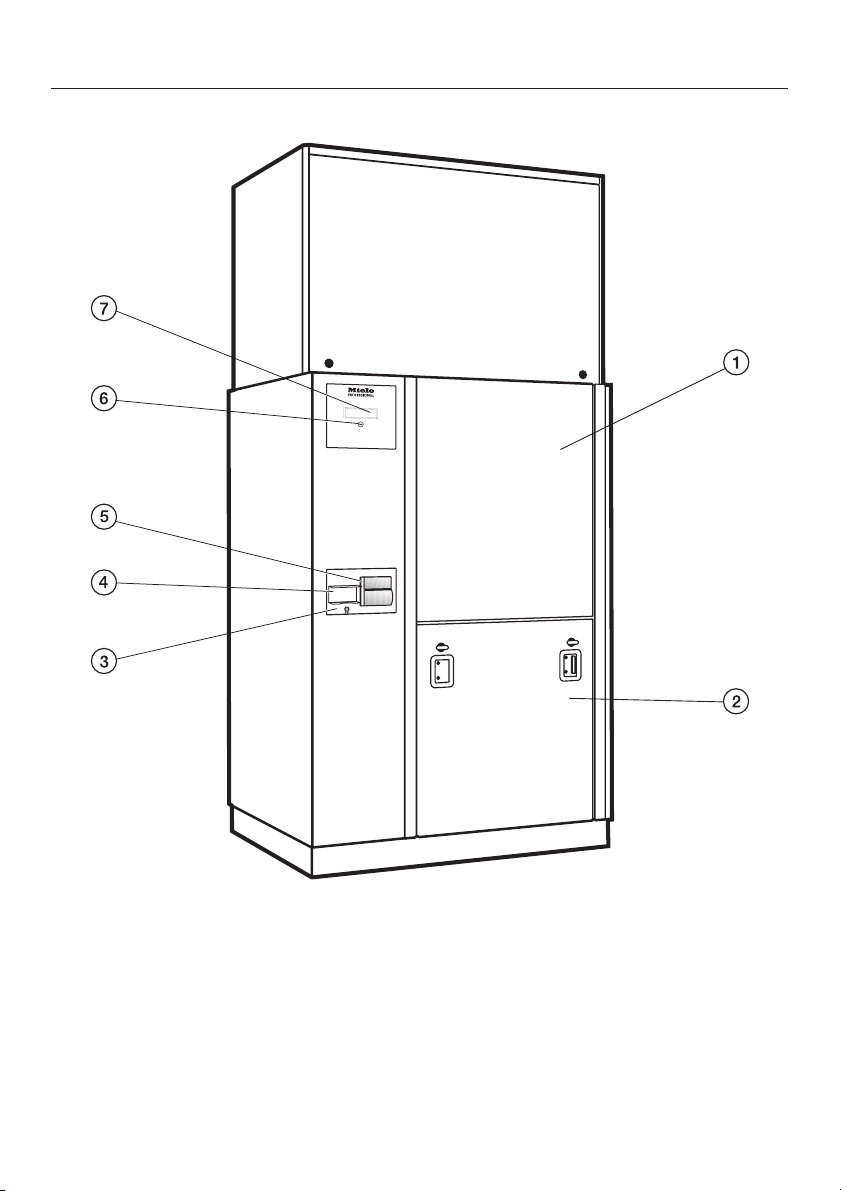

Guide to the laboratory glassware washer

Unloading side (PG 8528 only)

a Lift door (closed)

b Service panel with docking station

for transfer cart MF 27/28

c Multiport

d Barcode scanner mount (optional)

e Printer (optional)

f "Door" button

g Display

11

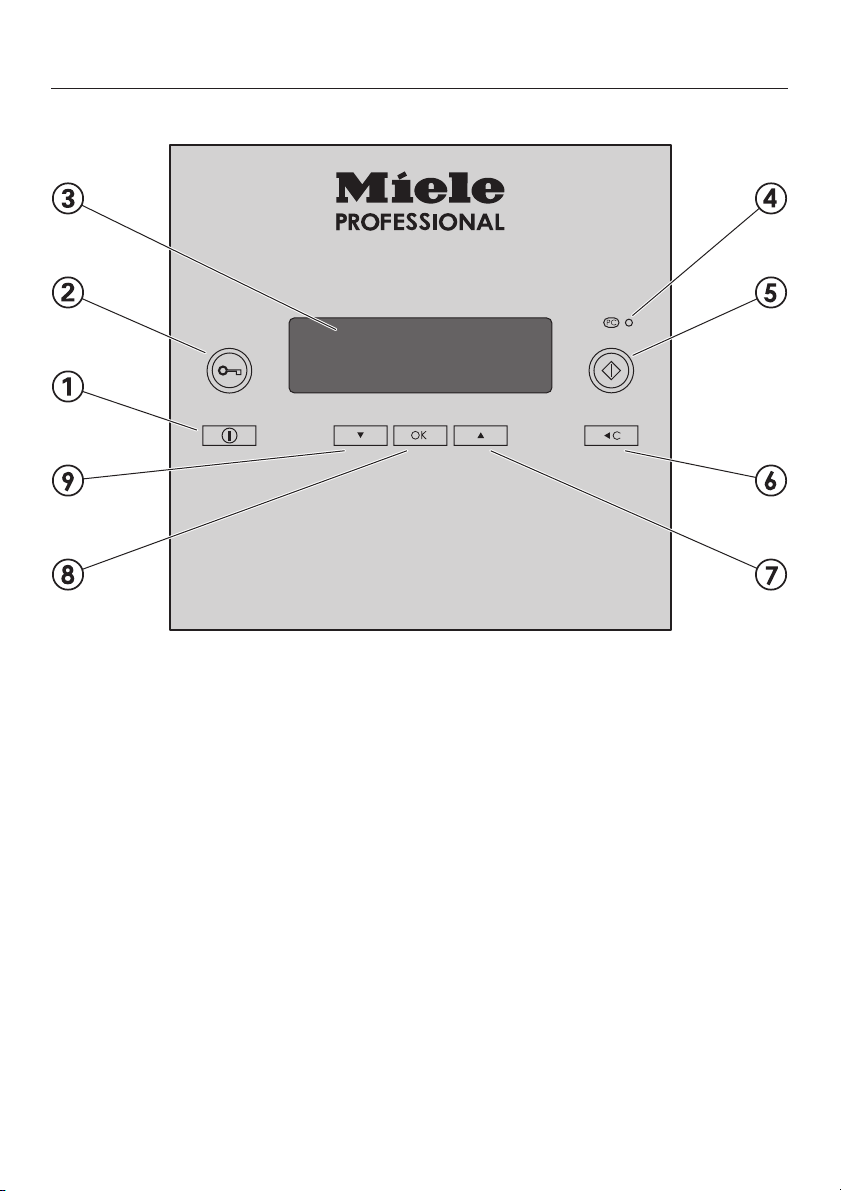

Guide to the laboratory glassware washer

Electronic controls

12

Guide to the laboratory glassware washer

a On/Off button s

turn washer on and off

b Door button a

open and close the door

c Display

If the washer is not in use, the

display automatically switches off

after approx. 10 min.

To turn the display back on, touch

^

any button.

Fault messages are shown in the

display, together with a corresponding

number. See the "Programming manual"

for more information.

d Optical Interface #

used by Miele Service Technicians

e Start button h

start a program

f Clear button +C

– return to the previous level

– discard entry

– cancel a program

g and i Selection buttons - e

– shift position of marking in display

– changed marked value

– scroll

– retrieve menu

– display user-defined operating

parameters during program

operation

h OK Button

- confirm marked menu item or

selected value,

- erase fault messages,

- erase dialogue messages,

- access A

-Graph during program

0

operation.

13

Optional equipment

Optional modules:

Drying unit

–

Steam condensor

–

Pre-heater

–

Conductivity meter

–

Report printer

–

Barcode scanner connection

–

up to 3 additional internal dispensing

–

systems

Glass doors and wash cabinet

–

lighting

– combination steam/electric wash

cabinet heating

14

Context menu

Certain functions are available through the context menu at

any time, regardless of the operating level:

change display language

–

change operating level,

–

enter Delay Start

–

for convertible washers:

–

change heating type,

loading package to arrange barcode scanner.

–

The current fault messages can be shown in operating

level D (if available).

^ To enter the context menu, press and hold the - e buttons

at the same time.

The context menu appears in the display:

Context menu B

Loading package

Change display language F

Change operating level

#

Use the buttons - e to move through the menu items.

15

Context menu

Change the display language

You can use the context menu to

change the language used in the

display.

This setting is stored until the washer is

switched off with the s button or the

main switch.

The language set under

"Settings - Language J" does not

change. All reports and print-outs

will continue to be completed in the

system language.

^ To select the menu item

display language

use - e , confirm

Change

with OK.

^ Select the desired language and

confirm with OK.

The selected language appears in the

display.

^ To leave the context menu, select

+C.

The J symbol indicates the Change

display language

setting.

If you accidently select an unfamiliar

language, simply select the menu

item with J and select the desired

language.

16

Context menu

Change the operating level

Four operating levels are available for selection.

Operating

levels

A and B selecting from a list of approved

C automatic program assignment by mobile

D open program selection through the

The context menu can be used to switch between operating

levels.

To help prevent unauthorized access to the settings, a code

is required to change operating levels.

To change the codes for existing users, or to enter new

users, you must be a registered administrator. The

Administrator can be registered by Miele.

^ Press and hold the - e buttons for at least 3 seconds.

The context menu appears in the display:

Authorized access for :

programs.

unit code.

Program overview, Programming and

Settings J menus.

Context menu B

Loading package

Change display language F

Change operating level

#

17

Context menu

Select the menu item

^

Change operating level, confirm

with OK.

Select the user B

User ABC

Administrator

Technical Service

Select the user group and confirm with OK.

^

Enter the required code.

^

Change operating level B

0 F F F

Enter code

^ Select - e to change the numbers.

^ Confirm with OK.

Repeat same process for each number.

Once complete the display will switch to the selected

operating level.

18

^

Select +C to exit the Context menu.

If an incorrect entry is made,

Code invalid will appear in the

display.

^

The message can be cancelled with OK.

Repeat the process to change the operating level.

Context menu

Delay start

The start time for a program can be pre-selected.

Select

^

To activate the Delay start option, go to the menu item

^

Activate and select Yes .

Delay start

Activate Yes

Delay start

To use this feature, select

^

Delay start and confirm.

Delay start and confirm.

The start time menu will appear.

Delay start

5:48

Enter time of day

^ Select - e to enter the desired start time, then confirm.

^ Press and hold the +C until the

display.

^

Select

Program overview to select a program.

Main menu appears in the

B

B

Program overview B

CHANGE DS-FINE

LAB-STANDARD

LAB-UNIVERSAL

^

Select a program.

^

Start with h.

#

19

Context menu

The selected program, the delay start time, the current time of

day, and the time remaining until the program starts are

displayed.

LAB-STANDARD

Start time 5:15

Remaining time 1:55 h

3:20

The selected program automatically starts at the delay start

time.

To cancel the automatic program start, press +C.

^

Cancel start time?

Yes No

^ Select

Yes and confirm.

The automatic program start is canceled. The display reverts

to the program overview. The

Delay Start option is

canceled.

If you select

Once the program has run through, the function

No, the Delay Start option will continue.

Delay Start

is automatically deactivated.

B

20

The function

Delay Start can also be deactivated

independent of a program start. To do so, go to the

Start

menu, and set the parameter Activate to No.

Delay

Context menu

Change the heating type

In convertible labwashers, you can use

the context menu to change the heating

type - e. g. from electric to steam

heating.

Select

^

OK to activate.

Change the heating type as desired,

^

e. g.,

OK.

The new heating type is saved.

To leave the context menu, use +C.

^

Steam/Electric, confirm with

Steam + Electric, confirm with

Current faults

The current fault messages can be

shown in operating level D.

^ Select the menu item and confirm

with OK.

The current fault messages are

displayed.

Loading package

If a barcode scanner is activated and

installed to the machine, loading

packages can be arranged in the

context menu under

See "Barcode scanner" for more

information.

Loading package.

^

Use OK to scroll through the fault

messages.

^

To leave the context menu, select

+C.

21

Automatic mobile unit recognition (AWK)

In operating level C the AWK (optional)

attributes a fixed program place to a

mobile unit with valid coding.

Program places 1-15 are reserved for

the AWK automatic mobile unit

recognition.

The unit coding (on the mobile unit) and

the program place with the

corresponding program (in the

"Profitronic" electronic control unit) must

match.

Each mobile unit must be coded

^

before being used for the first time.

See "Mobile unit coding".

^ The wash program through which the

mobile unit is coded has to be

assigned to the relevant program

place.

For program place changes, see the

Programming Manual.

Mobile unit coding

The automatic mobile unit recognition

feature assigns a program place to a

mobile unit. The mobile units must be

coded with a magnetic strip, via a bit

combination. In operating level C the

only program available for a coded

mobile unit is the one assigned to the

corresponding program place.

When a coded mobile unit is inserted in

the machine and the door closes, the

automatic mobile unit recognition

selects the assigned program. Be sure

no small items connect to the magnetic

strip.

^ Press 6 to start the program.

Important!

Before starting the program with the

"Start" button 6, check that the

program needed for this mobile unit

is displayed.

Otherwise insufficient wash results

may occur!

Always check that programs for

mobile units with AWK (on fixed

program places) are not exchanged.

22

The coding is made up of 5 bits:

–

Bits 1 to 4 define the mobile unit

code,

–

Bit 5 serves as a control (Parity-Bit).

Bit 6 controls the volume of water intake

and the circulation pump for mobile

units with side coupling. This setting

cannot be changed!

Mobile units without side coupling are

coded with tracks which do not contain

Bit 6!

Automatic mobile unit recognition (AWK)

Mobile unit coding strip

15 different codes can be set. They are

assigned to program places 1 to 15.

Under "System function - Selector

switch organization" the matching

programs have to be put into the first

15 program places.

Program

place

Bit 1 Bit 2 Bit 3 Bit 4 Bit 5

Parity-

Bit

- 00000

1l000l

2 0l00l

3ll000

400l0l

5 l0l00

60ll00

7 lll0l

8 000l l

9l00l0

10 0l0l0

11 l l 0 l l

12 0 0 l l 0

13 l0ll l

14 0 l l l l

15 llll0

Setting mobile unit coding

To set or alter the coding of a mobile

unit with automatic recognition (AWK)

proceed as follows:

^ Unscrew the track with an AWK (allen

wrench) and remove it from the

retainer.

The coded total must be an even

number. Bit 6 is not included in this

calculation.

If the coded total equals an odd number

the message CHECK MOBILE UNIT

RECOGNITION will appear. If the mobile

unit code equals 0, the message NO

MOBILE UNIT RECOGNITION will

appear. In both cases the program

cannot be started. The mobile unit

recognition must be reset.

^

Remove the magnetic strip from the

track.

23

Automatic mobile unit recognition (AWK)

Place the track in the holder of the

Set the program place coding.

^

^

mobile unit and screw firmly in place.

Bit 6 is not an integral part of the

modifiable magnetic strip.

Make sure that you code mobile

units with side coupling to a track

where Bit 6 is set to I.

Mobile units without side coupling

must be coded with a track that

does not have Bit 6.

^

Put the magnetic strip back in the

track.

Important:

The magnetic strip must be placed

in the track so that the Bit coding,

set according to the chart, is visible

through the round windows of the

track.

24

The magnetic strips for the

PG 8527 / PG 8527 are black.

Application

The labwasher can be fitted with a

variety of mobile units, baskets and

inserts, depending on the cleaning

application desired.

Check before cleaning

Are the items to clean correctly

–

sorted, loaded and connected?

Are the spray arms clean and can

–

they rotate freely?

Is the filter combination free of

–

coarse soiling? Clean if necessary.

Is the adapter to the water inlet in

–

place? The spray arms correctly

connected?

Are the detergent and neutralizer

–

containers full?

Check after cleaning

– Check the cleaning results visually.

– Are the jets and connections

securely connected with the mobile

unit / inserts?

Process validation

As a rule, it is the responsibility of the

user to ensure that items cleaned in the

machine meet the required standards.

Protein detection

The cleaning result should be checked

randomly with an analytic protein

inspection, e.g. use the Miele test kit.

25

Application

Loading tips

Select mobile units, baskets and

inserts appropriate for the

application.

Always load items in a way that all

–

surfaces are exposed. This ensures

that the items will be properly

cleaned.

Do not nest any items inside other

–

items. Keep each item separate.

Hollow vessels must be arranged for

–

complete inside exposure to the

cleaning water.

– Prior to loading the machine or

connecting to the machine ensure

that vessels with long, narrow

cavities they can be completely

flushed.

– Hollow vessels such as beakers,

measuring cylinders, flasks, etc.

should be inverted and placed in the

correct inserts so that water can flow

in and out unrestricted. A cover net

can be used to reduce the risk of

movement during the wash process.

–

Use a cover net (e.g. an A 6) or

mesh tray to secure small and/or

lightweight items to prevent them

from blocking the spray arms or

being caught in the magnetic strip on

the automatic mobile unit recognition

system.

Tall, narrow pieces should be placed

–

in the center of the baskets. This

ensures good water coverage.

Mobile units with an adapter must

–

engage correctly.

Engage inserts correctly into the

–

module carts.

The spray arms must not be blocked

–

by tall items or items which hang

down in their path. If necessary,

manually rotate the arms to test.

Petri dishes and the similar should

–

be placed in the correct insert with

the soiled side facing the center.

– Insert pipettes with the pointed end

downwards.

– Quarter inserts should be placed as

close to the middle of the unit as

possible.

– Glassware should not stick out of the

door area.

,

Ensure that no acid or solvent

residues, especially hydrochloric

acid or chlorides, get inside the

machine.

–

Deep based items should be placed

at an angle to allow water to run off

easily.

26

Application

Laboratory glassware (LG)

Wide-necked glassware, such as wide

necked erlenmeyer flasks and petri

dishes or glassware with a cylindrical

form, e.g. test tubes, can be cleaned

inside and out with the rotating spray

arm. General glassware such as

beakers, conical flasks, petri dishes,

test tubes, etc. can be arranged in

full-size, half or quarter inserts in an

empty basket with spray arms.

Mobile injector units are available for

direct injection spraying of narrow

necked flasks, pipettes, etc.

The following instructions relate only to

basic preparation and loading of

glassware.

Loading the machine

Removing excess soils

Empty all glassware before loading

^

into the machine. Take any hygienic

measures necessary to avoid

infection.

Ensure that no acid or solvent

,

residues, especially hydrochloric

acid or chlorides get into the wash

cabinet.

Remove all agar residues from petri

^

dishes.

^ Remove blood clots and residues

from test tubes, etc.

^ Remove all stoppers, corks, labels,

sealing wax residues, etc.

^ Small parts such as stoppers and

taps should be secured in suitable

basket inserts.

E 940 Injector mobile unit

Contains two levels, for narrow necked

laboratory glassware (can also be used

without the upper level).

27

Adding liquid detergents and neutralizers

The washer comes equipped, as

Use only detergents and

,

neutralizers specially designed for

labwashers. Always observe the

manufacturer's recommendations for

use.

The labwasher can be fitted with a

maximum of 5 internal dispensing

systems. They are color-coded to

match the dispensing pumps to the

corresponding siphon tubes.

standard, with two internal dispensing

systems:

Dispensing system DOS 1 for use

–

with alkaline products, e.g., liquid

detergents. The dosing rate is

200 ml/min.

Dispensing system DOS 3 for use

–

with acidic products,

e.g., neutralizers. The dosing rate is

105 ml/min.

Dispensing

system

1 blue

2 white

3 red

4 green

5 yellow

Color coding

Depending on the application(s)

chosen for this machine, the

appropriate amounts of detergent and

neutralizer are dispensed through these

systems.

Up to three additional dispensing

systems can be installed optionally:

Dosing rate Product(s)

465 ml/min alkaline

200 ml/min alkaline

105 ml/min acidic

Instead of the internal dispensing

system, up to five external dispensing

systems can be connected to the

washer.

For special applications, the external

dispensing systems can be activated,

in addition to the internal systems.

28

Adding liquid detergents and neutralizers

Dispensing systems

Four 10 l containers of processing

chemicals can be placed behind the

service panel in the washer.

Any additional containers will need to

be set up outside the washer.

Use caution when handling

,

processing chemicals. These

products can cause irritation and

burning.

Always follow all applicable safety

procedures and observe the

manufacturer's instructions.

Use protective eye wear and gloves.

Message "Fill DOS [X] container"

^ Refill or replace the container

indicated in the display.

Fill the container(s) when you are

prompted in the display, e.g.,

DOS1 container

containers from becoming

completely empty and needing to be

primed (cleared of air).

. This will prevent

Fill

Adding liquid detergents and

neutralizers

^ Open the service panel, then lift it up

and out at the bottom.

29

Adding liquid detergents and neutralizers

Message "Check dispensing system

[X]"

The currently running program pauses.

Check the container(s) and

^

dispensing hoses indicated in the

display.

Refill or replace as needed.

Containers and dispensing systems

that are not in use can be shut off, to

avoid fault messages in the display

(see "Machine function - Container

inquiry" in the Programming manual).

Remove the container from the

^

washer.

Priming the dispensing system

^ Unscrew the siphon tube and remove

it.

^ Fill the container with the required

product.

^

Insert the siphon tube into the

container opening and screw it into

place.

Once the containers have been filled,

the message clears from the display.

Whenever a container has been

allowed to completely empty, it must be

primed (cleared of air) after refilling.

^ Select the corresponding service

program, e. g.,

^ Press the h start button.

DOS1-FILL.

30

Effects of Processing Chemicals

General information

Effects Action

Damage to elastomer (seals and hoses)

or plastic components of the lab

washer may cause the materials to

swell, shrink, harden or become brittle,

possibly causing cracks to form in the

materials. This will impair their function,

which will generally lead to leaks.

Strong foaming during the program

prevents proper cleaning and rinsing of

the load. Foam escaping from the wash

compartment can result in damage to

the lab washer.

If foaming occurs, the cleaning process

is not standardized and not validated.

Stainless steel corrosion in the wash

compartment and/or accessories may

appear in various ways:

– rust formation (red spots / stains),

–

black spots / stains,

–

white spots / stains (smooth surface

is slightly corroded).

Corrosion that forms holes can result in

leaks in the lab washer. Depending on

the application, the corrosion may

impair the cleaning and rinsing results

(laboratory analysis) or cause corrosion

of the load (stainless steel).

Find and correct the causes of the

–

damage.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

Find and correct the cause of the

–

foaming.

The process must be checked

–

regularly in order to detect any

foaming.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information..

– Find and correct the cause of the

corrosion.

See "Connected processing

chemicals", "Soiling" and "Reactions

between processing chemicals and

soils" for more information.

31

Effects of Processing Chemicals

Connected processing chemicals

Effects Action

The ingredients of the processing

chemicals have a considerable effect

on the durability and functionality (feed

performance) of the metering systems.

The metering systems (feed hoses and

pump) are designed for a specific type

of processing chemicals.

General categories:

alkaline to neutral pH products,

–

acid to neutral pH products,

–

hydrogen peroxide.

–

The processing chemicals can damage

the elastomer and plastic components

of the lab washer and its accessories.

The following oxidizing processing

chemicals can damage the elastomer

components (hoses and seals) and, in

some cases, the plastic components of

the lab washer:

–

nitric acid,

–

peracetic acid,

–

products containing active chlorine.

Use only those processing chemicals

–

recommended by Miele.

Perform regular visual inspections of

–

the metering system.

Regularly check the feed

–

performance of the metering system.

– Use only those processing chemicals

recommended by Miele.

– Perform regular visual inspections of

all visible elastomer and plastic

components.

The washing temperature should not

exceed

– 122 °F (50 °C) for nitric acid,

– 95 °F (35 °C) for peracetic acid,

–

176 °F (80 °C) for products

containing active chlorine.

The following processing chemicals

can release large quantities of oxygen:

–

hydrogen peroxide,

–

peracetic acid.

32

–

Use only tested processes such as

OXIVARIO or OXIVARIO PLUS

(if available).

–

In the case of hydrogen peroxide,

the washing temperature should be

below 158 °F (70 °C).

–

Consult Miele.

Effects of Processing Chemicals

Connected processing chemicals

Effects Action

The following processing chemicals

can result in excessive foaming:

cleaning and rinsing agents that

–

contain tensides,

emulsifiers.

–

The foaming can occur:

in the program block in which the

–

processing chemical is added,

in the subsequent program block

–

due to carry-over,

in the case of rinsing agents, in the

–

subsequent program due to

carry-over.

Antifoaming agents, particularly

silicone-based antifoaming agents, can

cause the following:

– deposits in the wash compartment,

– deposits on the wash load,

– damage to the elastomer and plastic

components of the lab washer,

–

attack certain plastics (e.g.

polycarbonates, plexiglass, etc.) in

the wash load.

The process parameters of the wash

–

program, e.g. metering temperature,

metering concentration, etc. must be

set so that the overall process

creates little or no foam.

Observe the instructions of the

–

manufacturer of the processing

chemicals.

– Use antifoaming agents only in

exceptional cases or when they are

absolutely necessary for the process.

– Periodic cleaning of the wash

compartment and accessories

without a load and without an

antifoaming agent using the

ORGANICA program (if available).

–

Consult Miele.

33

Effects of Processing Chemicals

Soiling

Effects Action

The following substances can damage

the elastomer components (hoses and

seals) and, in some cases, the plastic

components of the lab washer:

oils, waxes, aromatic and

–

unsaturated hydrocarbons,

softeners,

–

cosmetics, hygiene and skin care

–

products such as creams (analysis

and filling sections).

The following substances can cause

excessive foaming during washing and

rinsing:

– agents such as disinfection agents,

dish detergents, etc.

– reagents for analysis, e.g. for

microtitration plates,

– cosmetics, hygiene and skin care

products such as creams (analysis

and filling sections).

–

foaming substances in general, for

instance tensides.

Retrofit the lab washer with more

–

grease-resistant elastomers.

Depending on what the lab washer is

–

used for, periodically wipe the lower

door seal with a lint-free cloth or

sponge.

Clean the wash compartment and

accessories without a load using the

ORGANICA program.

To process the load, use the

–

program "OIL" (if available) or use the

special program with emulsifier

metering.

– First rinse the load with a sufficient

quantity of water.

– Select a wash program with one or

more short pre-rinses with cold or

warm water.

– Taking the specific application into

account, add an antifoaming agent,

one without silicone oils if possible.

The following substances can cause

corrosion of the stainless steel in the

wash compartment and accessories:

–

hydrochloric acid,

–

other substances that contain

chloride, e.g. sodium chloride, etc.

–

conc. sulphuric acid,

–

chromic acid,

–

iron particles.

34

–

First rinse the load with a sufficient

quantity of water.

–

Let the load drip dry before putting it

on the carts, baskets and inserts and

placing in the lab washer.

Effects of Processing Chemicals

Reactions between processing chemicals and soils

Effects Action

Natural oils and greases can be

saponified with alkaline processing

chemicals. This may cause a lot of

foaming.

In combination with alkaline processing

chemicals, loads with soiling that

contains proteins, e.g. blood, can

cause excessive foaming.

In combination with very acidic or

alkaline processing chemicals, base

metals such as aluminum, magnesium

and zinc can release hydrogen

(detonating gas).

Use the program OIL (if available).

–

Use the special program with

–

emulsifier (neutral pH) metering for

pre-rinsing.

Taking the specific application into

–

account, add an antifoaming agent,

one without silicone oils if possible.

Select a wash program with one or

–

more short pre-rinses with cold

water.

– Observe the instructions of the

manufacturer of the processing

chemicals.

35

Operation

Main Switch - On/Off

The main switch disconnects the

labwasher from the power supply

Turn the main switch to I-ON.

^

Once the start procedure is completed,

the labwasher is ready to for use.

The following message may appear:

"New power frequency 50 Hz Flow

rate automatically adjusted" or "New

power frequency 60 Hz Flow rate

automatically adjusted".

During the start procedure, the

Profitronic system detected a

different power frequency, and

adjusted the flow rate of the

dispensing pump accordingly.

Before operation, you will need to

check if the change in power

frequency was caused by a fault in

the power supply.

If so, incorrect amounts of

processing chemicals would be

dispensed during the program.

Turning On

Press and hold the s button .

^

The activating time for the s button

can be set to a maximum of 10

seconds (see "System functions On/Off button activation time" in the

Programming Manual).

Depending on the set operating level,

the following will appear in the display:

Operating

levels

A and B A list of approved

C Instructions for

D Select from:

Displayed

programs.

Automatic Mobile Unit

recognition.

– Program Overview

– Programming

– Settings J.

The fault message can only be

confirmed in operating level D and

in the service mode.

36

If the washer is not in use, the

display automatically switches off

after approx. 10 min.

To turn the display back on, touch

any button.

Operation

Opening and closing the door

Press the a button.

^

The door opens or closes.

To open the door on the clean side

(PG 8528), note the following:

programs with a process

–

requirement must have been

completed without faults according

to the program parameters set,

or

the gate function is activated,

–

i.e., door mechanism is set to one of

the following parameters:

- Sluice,

- Door clean + Sluice,

- Door unclean + Sluice.

(see "Machine functions / Door

mechanism" in the Programming

manual).

,

If the pre-heater has been

programmed for heating, beware of

hot water or steam exiting the open

door. Looking from the unclean side,

the inlet pipe for the pre-heater is

located beneath the right basket

guide rail.

Starting a program

You can find detailed and important

information regarding the Miele

default programs in the Program

charts in the Appendix of the

Programming Manual.

If a barcode scanner is connected

to the labwasher and the user or

load scan is activated, the selected

program cannot be started until

scanning has been completed.

For more information see "Barcode

scanner".

37

Operation

Operating levels A and B

A list of all selectable programs

appears in the display.

Select the desired program with - e,

^

confirm with OK.

Press the h start button.

^

The program begins.

Operating level D

Select the menu item

^

overview

Select the desired program with - e,

^

confirm with OK.

^ Press the h start button.

The program begins.

, confirm with OK.

Program

Operating level C

Make sure that no metallic parts

,

or pieces are stuck to the magnetic

strip or its underside.

These objects can cause the coding

to be misread or unreadable.

Push the coded basket into place in

^

the washer.

Close the door a and press the

^

start button h.

The program begins.

^

38

Operation

Program sequence

Once started, the program proceeds

automatically. The program steps are

shown in the display.

Detailed information on the program

sequences is available in the

"Programming Manual".

Do not change the printer paper

,

roll or ribbon cartridge during a

running program.

End of program

^ Once the program ends,

program

appears in the display.

End of

Turning off

^ Press the s button.

If the machine is to be left off for several

days, be sure to turn the main switch to

0-OFF.

Canceling a program

A program can only be interrupted

or canceled in operating levels B

and D.

Press the +C button.

^

The program is interrupted.

The following prompts appear in the

display:

Program Cancel (OK)

or Continue (Clear)?

Confirm the program cancellation

^

with the OK button.

Program canceled or Water drainage

appears in the display.

After the water has drained away, the

program sequence appears in the

display.

39

Operation

Interrupting a program

A program can only be interrupted

or cancelled in operating levels B

and D.

Only interrupt a program if the door

must be opened for urgent reasons,

e.g., if items are moving around too

much, or the cleaning performance

needs to be checked.

If a program with a defined process

requirement is interrupted then

continued, make sure to check the

display upon program completion. If

the display reads

parameter not achieved

was opened after process

parameter monitoring began, and so

the defined requirements were not

achieved. If necessary, repeat the

program.

In operating levels B or D

^

Press the +C button.

The program is interrupted.

The following prompts appear in the

display:

Program Cancel (OK)

or Continue (Clear)?

^

Open the door a

Process

, the door

Note PG 8528:

Which door can be opened depends

on which setting has been programmed

under "Machine Function - Automatic

door" (see the Programming Manual).

The door on the unclean side can

always be opened, no matter which

parameter has been set.

The door on the clean side can only be

opened if one of the following

parameters are set:

- Sluice,

- Door clean + Sluice,

- Door unclean + Sluice.

Caution! Items in the machine

,

may be hot. There is the danger of

burning or scalding.

^ Arrange items securely.

^ Close the door a.

^ Press the +C button.

The program continues.

40

Barcode scanners can be connected to

the labwasher via the multiport on the

unclean side and, if available, on the

clean side as well.

The configuration of the serial interface

for the barcode scanner is described in

the section "PC / Print functions - Serial

Interface configuration" in the

Programming Manual.

Barcode scan functions

All barcode scanner functions are

available at every operational level:

User scan load

–

– User scan unload

– Scan the load

The scanned bar codes are transmitted

to the record of users and/or loads.

User scan and load scan can be

activated independently of each other.

Activation is described in the section

"System functions - Barcode" in the

Programming Manual.

Barcode scanner (optional)

41

Barcode scanner (optional)

User scan load

When User scan load is activated, after

program selection the following

message is displayed (immediately in

the case of automatic mobile unit

recognition on operating level C):

Scan user

Once the user barcode has been

scanned, the program can be started.

When Scan the load is also

activated, after the user scan you are

prompted to scan the load.

Cancelling User scan load

User scan load can be cancelled using

the +C key. The program overview is

displayed again.

User scan unload

If User scan unload is activated, you

will be prompted to scan the user

barcode once a program has ended:

End of program Scan user

The door cannot be opened until the

user barcode has been scanned.

Depending on the settings in the Menu

Machine functions / Automatic door

the door will open automatically.

after cancelling a program with +C

If

User scan unload is activated, the

following message is displayed after

cancelling the program:

Program canceled

Water drain

After the water has drained, the Scan

user prompt will appear:

Scan user

42

Skip user scan for unloading

On operating levels B and D, you can

skip

User scan unload by pressing OK.

At the end of the wash protocol, "Skip

user scan" is printed.

Barcode scanner (optional)

Scan the load

When load scan is switched on, the following message prompts the operators to

scan the load:

Scan the load

: Scan the load

Scan the first barcode of the load.

^

In the menu

^ Scan further bar codes if applicable.

If a scanned barcode already exists, the following query appears:

Load scanned, accept?

A maximum of 99 load bar codes can be scanned. Then the following message

appears:

Maximum number of entries reached

The last scanned barcode can be deleted from the list with +C. To prevent

unintentional removal from the list you will be prompted to confirm the deletion:

Delete last entry?

Scan the load the barcode numbers of the scanned load are listed.

Scan the load

0987664

A

A

43

Barcode scanner (optional)

Cancel load scan

If no load was scanned, the load scan

can be cancelled using +C. The

program overview is displayed again.

If load scans already exist, they must

be deleted prior to cancellation. To do

this, answer the query

entry

with Yes for each scanned load.

Delete last

Skip load scan

On operating levels B and D, you can

skip the load scan by pressing OK.

If you answer the query

scan?

with No, the program overview

Skip load

will be displayed.

If you answer the query with

Yes, the

program can be started by pressing h.

At the beginning of the wash

protocol, "User scan skipped" is

printed.

Finish load scan

After all the load bar codes have

^

been scanned, finish the process by

pressing OK.

h flashes and the program can be

started.

Using loading packages

When load scan is on, prior to program

start the Profitronic verifies that at least

one loading package has been saved.

44

Barcode scanner (optional)

If this is the case, the following message is displayed:

Use loading package?

Yes

A

No

Acknowledge the message by selecting

^

Yes.

All loading packages are displayed:

Select loading package A

1_14.02.2007_08:23

2_14.02.2007_09:11

^ Select a loading package and confirm with OK.

h flashes and the program can be started.

At the end of the program, the message

Process parameters achieved appears

and the completed program package is deleted.

The last processed loading package is not deleted:

– if the program is cancelled or if an error occurs during the program (

parameters not achieved

–

with programs in whose program header the parameter

),

Process information is

Process

not defined.

The next time the program is started the loading package will be processed

again. It can be manually deleted or moved on the list.

If none of the saved loading packages are to be used:

^

Select

^

The message

^

Scan the load manually as described in "Scan the load".

No and confirm.

Scan the load is displayed.

45

Barcode scanner (optional)

Loading packages

Loading packages can be created to optimize the function sequences when

loading the labwasher. To do this, the load scan must be activated, see "System

functions - Barcode" in the Programming Manual).

Context menu B

Loading package

Change display language F

Change operating level

After the context menu is opened and the menu item Loading package confirmed,

the following functions are available:

Add loading package

Display loading package

Delete loading package

Move loading package

#

46

Barcode scanner (optional)

Add loading package

To create a loading package, open the Context menu, then select and confirm

Loading package.

Loading package B

Move loading package

Add loading package

Display loading package

#

Select and confirm

^

Add loading package.

The following message appears:

Scan the load

Scan the individual components of the load.

^

^ Press OK to confirm the complete loading package.

Repeat the steps for further loading packages. The loading packages are stored

in a list (see "Display loading packages"). The last scanned loading package is

added to the end of the list.

A maximum of 50 loading packages can be stored.

If the max. amount has been reached, loading packages must be processed or

deleted before further packages can be added.

47

Barcode scanner (optional)

Display loading package

To display the loading packages, open the context menu, then select and confirm

Loading package.

Select and confirm the menu item

^

Display loading package.

The list with all the loading packages is displayed. Each loading package is

identified by a number, date and time.

Display loading package A

1_14.02.2007_08:23

2_14.02.2007_09:11

^ Select and confirm the desired loading package.

The components of the loading package are listed in the menu

Scan the load A

0987664

0983558

0991724

^ Press +C to return to the menu

^

Press +C to return to the menu

Display loading package.

Loading package.

Scan the load.

48

Barcode scanner (optional)

Delete loading package

To delete a loading package, open the context menu, then select and confirm the

menu item

Loading package.

Select and confirm

^

Delete loading package.

All existing loading packages are displayed with number, date and time.

Delete loading package A

1_14.02.2007_08:23

2_14.02.2007_09:11

Select and confirm the desired loading package.

^

The following message appears:

Delete loading package?

^ Confirm the request.

The loading package is deleted.

^ Press +C to return to the menu

Loading package.

49

Barcode scanner (optional)

Move loading package

To move a loading package, open the context menu, then select and confirm the

Loading package.

Select and confirm the menu item

^

Move loading package.

All existing loading packages are displayed with number, date and time.

Move loading package A

1_14.02.2007_08:23

2_14.02.2007_09:11

3_14.02.2007_10:31

Select the desired loading package.

^

^ Press e-to move the loading package, and confirm.

The list will be saved in the new sequence.

^ Press +C to return to the menu

Loading package.

50

Serial interface (data transfer)

Each washer comes supplied with a

16.5 ft. (5 m) interface cable and RJ45

plug, for data transfer between the

Profitronic system and an external

report printer or PC.

The interface cable is connected to

the Ethernet interface in the washer.

The supplied cable can be used to

connect the Ethernet connection of the

washer to suitable network components

(e. g., a hub or a switch).

For a direct Ethernet connection

between the washer and an external

device, you will need a crossover

cable.

The supplied cable can also be used to

connect the washer to an external

device via the RS 232 interface.

An RJ45 adapter / Sub-D plug is also

supplied.

Only a Miele Technician can

connect a different interface.

Pin position of the RJ45 plug (Ethernet):

1 Transmit Data +

2 Transmit Data 3 Receive Data +

6 Receive Data 4-5-7-8 empty

Pin position of the 9-pole Sub-D plug

(serial interface):

5 GND ground

3 TXD transmit

2 RXD receive

7 CTS clean to send

8 RTS ready to send

1-4-6-9 empty

The interface configuration is

described in the section "PC/Print

functions" in the Programming

manual.

Please note the following when

connecting a printer or PC:

– Only use an industry-standard

PC or printer.

– When installing the machine take the

dimensions of the printer/PC into

account.

– Any extension cable from the serial

interface to the printer or PC must not

exceed 32' 10" (10 m); from the

Ethernet interface the maximum

extension cable length is 328ft.

(100 m).

For external printers, only HP

LaserJets or compatible devices are

acceptable.

Settings for the external printer

functions are described in the section

"PC/Print functions" in the programming

manual.

51

Maintenance

Labwashers should undergo routine

maintenance by the Miele Technical

Service every 1000 operating hours

or at least once every 6 months.

Maintenance covers the following:

Electrical safety

–

Door mechanism and door seal

–

Screws and connections in the wash

–

cabinet

Water inlet and drain

–

Internal and external dispensing

–

systems

– Spray arms

– Triple filter system

– Drain pump and non-return valve

– Steam condensor

– All mobile units, baskets, and inserts

If applicable:

Also during maintenance, the following

function checks are conducted:

a test program is run

–

wash temperatures are measured

–

ensure a water tight door seal

–

all safety-relevant measuring

–

systems are checked (fault display).

– Drying unit

–

Connected printer

52

Routine checks

The user must complete these checks

every day before using the washer. A

checklist is supplied with the washer.

Check the following points:

the filters in the base of the wash

–

cabinet

the spray arms in the washer and in

–

the mobile units and inserts

the wash cabinet and the door seal

–

and

all mobile units, baskets, and inserts

–

Maintenance

53

Maintenance

Cleaning the filters in the wash

cabinet

The filters in the base of the wash

cabinet prevent large particles from

entering the system.

The filters can become clogged, they

need to be checked regularly and

cleaned as needed.

Do not use the washer unless all

,

the filters are in place.

Beware of glass splinters,

,

needles, etc. danger of injury.

Cleaning the fine filter

^ Remove the fine filter and clean if

necessary.

Cleaning the flat filter

54

^

Remove the flat filter and clean if

necessary.

Cleaning the filter system for the

circulation pump

To protect the circulation pump, there

are two additional filters under the flat

filter.

^ Pull the filters up and out of the

holder to remove. Clean if necessary.

Maintenance

^ Replace the filter combination in

reverse order.

After replacing, check that all filters

are properly in place.

55

Maintenance

Cleaning the spray arms

The spray arms can become clogged.

Check daily and clean if needed.

Use a sharp, pointed object to push

^

any particles into the spray arm jets,

then rinse throughly under running

water.

To do so, remove the spray arms as

follows:

Remove the basket.

^

Labwasher spray arms

Spray arms on basket / inserts

Use a wrench to loosen the nut on

^

the spray arm guide, then pull the

spray arm downward.

Visible wear and tear on the

bearings or the gasket may cause a

fault to occur, please contact Miele.

After cleaning, put the spray arms

^

back in place and tighten the nut.

Make sure the nut is in the proper

position.

After replacing the spray arms make

sure that they rotate freely.

Make sure that no metallic parts

,

or pieces become attached to the

magnets at the ends of the spray

arms.

These objects can cause the spray

arm rotations to be miscalculated.

^

Loosen the nut with a wrench and

pull the spray arm either upward or

downward.

56

Cleaning the control panel and

glass door (optional)

Press s to turn off the washer.

^

Clean the control panel and the glass

^

door with a damp cloth or glass

cleaner.

To disinfect, use an approved

cleaning agent.

Do not use abrasive or

,

all-purpose cleaners.

The chemicals contained in these

products can seriously damage the

surface of the glass.

Maintenance

Do not hose down the washer or

,

the immediate vicinity, e.g., with a

water hose or pressure washer.

Cleaning the wash cabinet

The wash cabinet is mostly

self-cleaning.

If you notice a build-up of deposits,

contact Miele.

Cleaning the door seal

To remove soiling, clean the door seal

regularly with a damp cloth.

Cleaning the exterior

^ To clean the stainless steel exterior,

use a damp cloth and dish soap, or a

non-abrasive stainless steel cleaner.

^ To help prevent re-soiling

(fingerprints, etc.), a stainless steel

conditioner can be used after

cleaning.

,

Do not use thinner or

ammonium-based cleaners.

They can damage the surface.

Damaged or leaky door seals should

be replaced by Miele Technical

Service.

57

Maintenance

Baskets and inserts

To ensure that the mobile units, baskets

and inserts function properly, they must

be checked routinely. A checklist is

supplied with the labwasher.

Check the following points:

Are the rollers in proper condition,

–

and are they securely attached to the

basket / insert?

Are the counter-nuts on the guide

–

rails firmly secured?

Is the basket connection correctly

–

set and firmly screwed on?

– For baskets in the modular system,

are the caps in the module

connection working properly?

– Are all spray jets, spray sleeves, and

hose adapters securely attached to

the basket / insert?

– Are all spray jets, spray sleeves, and

hose adapters unclogged so that

wash water can flow through?

If there are spray arms:

Do the spray arms rotate freely?

–

Are the spray jets clogged? See the

–

section on "Cleaning and Care /

Cleaning the spray arms".

–

Are all caps, covers, and fasteners

securely attached to the spray

sleeves?

–

Are the magentic strips of the mobile

unit free of any metallic items?

–

Are the magnets in place on the

spray arm ends?

–

Are the magnets on the spray arms

free of attached metal parts?

58

Maintenance

Report printer (optional)

Replacing the print paper

When the red indicator light on the front

panel of the printer lights, the print

paper needs to be replaced.

Open the front panel of the printer by

^

the upper edge, and pull down.

Remove the paper roll and spindle

^

together from the holder, fit the new

roll onto the spindle, and install them

back into the printer.

Guide the paper up and over the

^

paper transport roller (slit behind the

ribbon cartridge). Press the green

paper transport button until the paper

re-emerges above the ribbon

cartridge.

^ Guide the paper through the slit in

the front panel. Shut the panel.

Replacement paper rolls (2 ¼" (58 mm)

wide / outer diameter approx. 2"

(50 mm) can be obtained from Miele.

Replacing the ribbon cartridge

Open the front panel of the printer by

^

the upper edge, and pull down.

The ribbon cartridge is above the

^

paper roll. Pull it forward and out of

the holder and replace it with a new

one. The paper must be guided

between the ribbon and the cartridge

housing.

On the right, turn the small wheel for

^

manual ribbon transport clockwise

until the ribbon is taut.

Guide the paper through the slit in

^

the front panel. Shut the panel.

Replacement ribbon cartridges can

be obtained from Miele.

59

After sales service

This lab washer must be

,

installed, maintained and repaired

by an authorized Miele service

technician. Maintenance and repair

work performed by unqualified

persons can place the user at risk.

In the event of a fault which you cannot

correct yourself please contact the

Miele Technical Service Department

U 1-800-991-9380

techserv@mieleusa.com

V 1-800-565-6435

service@miele.ca

Please quote the model of your lab

washer. This information can be found

on the lab washer’s front panel.

60

INSTALLATION INSTRUCTIONS

Electrical connection

All electrical work must be carried

out by a qualified electrician in

accordance with local and national

safety regulations.

Installation, repairs and other work

by unqualified persons could be

dangerous.

The machine must only be operated

with the voltage, frequency and

fusing shown on the data plate.

For technical data see the data plate

^

or wiring diagram supplied.

The data plate is on the cover plate

behind the service panel of the unclean

side.

The wiring diagram is secured to the

inner side of the service panel.

This unit is convertible for use with

steam or electric heating.

Hook up requirements are as follows:

1. Electric heat only:

208 V 3 phase 60 HZ 60 amp

2. Steam heat only:

without drying option

208 V 3 phase 60 HZ 20 amp

with drying option

208 V 3 phase 60 HZ 30 amp

WARNING:

THIS APPLIANCE MUST BE

GROUNDED

62

Plumbing

Water connection

This machine must be connected to

the water supply in accordance with

all national and local plumbing

codes.

Water in the machine is not

,

suitable for drinking.

The washer is constructed so that it

may be connected to a water supply

without an extra non-return valve,

unless required by code.

Water and drain connections should be

situated as close to the machine as

possible, and be easily accessible.

Water supply pressure

Hot + Cold water connection =

min. 22 psi - max.145 psi

DI water connection =

min. 9 psi - max. 145 psi

The machine cannot be operated with

an inflow pressure of less than 10 psi.

The machine is supplied with

3 connection hoses 5 ft. (1.5 m) long

3

with

/4" (19 mm) female hose thread

ends.

Large area filters, supplied with the

machine, are to be installed in the hose

attached to the water supply. See

"Cleaning and Care - Cleaning the

water inlet filters".

Do not shorten or damage the

,

hoses!

Do not remove the filters in the

hoses.

Recommended water pressure

Hot + Cold water connection =

over 37 psi - max.145 psi

DI water connection =

over 22 psi - max. 145 psi

to avoid long intake times

63

Plumbing

Requirements

(refer to the Installation Diagram for

more information)

1. Cold water connection

One ½" (13 mm) cold water supply line

with a standard

thread faucet is needed. The cold water

supply hose is marked with blue tape.

2. Hot water connection

One ½" (13 mm) hot water supply line

with a standard

faucet is needed. The water

temperature must not exceed 158°F /

70°C (recommended: 140°F / 60°C).

The hot water supply hose is marked

with red tape.

If no hot water line is available, the red

marked hose must be connected to the

cold water line.

3

/4" (19 mm) male hose

3

/4" male hose thread

3. DI water connection

One ½" (13 mm) deionized water

supply line with a standard

3

/4" (19 mm)

male hose thread faucet is needed. The

machine cannot be operated

conventionally with a flow pressure of

less than 10 psi. In this case the

installation of an optional DI pump is

required. The DI water supply hose is

marked with green tape.

If the water pressure is below 29 psi,

the intake time will increase.

If the machine will not be

,

connected to DI water, the

programs must be changed by

Miele Technical Service. The intake

hose stays at the rear of the

machine.

DI water connection (pressure less)

1.25 - 9 psi (optional)

For connection to 1.25 - 9 psi water

pressure the machine must be

converted if it was not ordered from the

factory as a special model. A feed

pump must be installed by Miele's

Technical Service Dept.

64

The discharge nipple of the DI water

container (pressure less) must be at