Page 1

Installation instructions

Ceramic hobs

KM 6220 / 6223 / 6224 / 6226

KM 6227 / 6229 / 6230

To avoid the risk of accidents or

damage to the appliance it is

essential to read these instructions

before it is installed and used for the

first time.

en-GB

M.-Nr. 09 198 700

Page 2

Contents

Safety instructions for installation....................................3

Hob with frame or bevelled edge .....................................8

Building-in dimensions ..............................................8

KM 6220 .......................................................8

KM 6624 .......................................................9

KM 6226 ......................................................10

KM 6229 ......................................................11

KM 6230 ......................................................12

Installation .......................................................13

Flush-fitted hobs .................................................16

Building-in dimensions .............................................16

KM 6223 ......................................................16

KM 6227 ......................................................17

Installation .......................................................18

External mains connection box .....................................21

Electrical connection..............................................22

Wiring diagram ...................................................23

2

Page 3

Safety instructions for installation

The appliance must only be installed

and connected to the electricity

supply by a suitably qualified and

competent person in strict

accordance with current national

and local safety regulations.

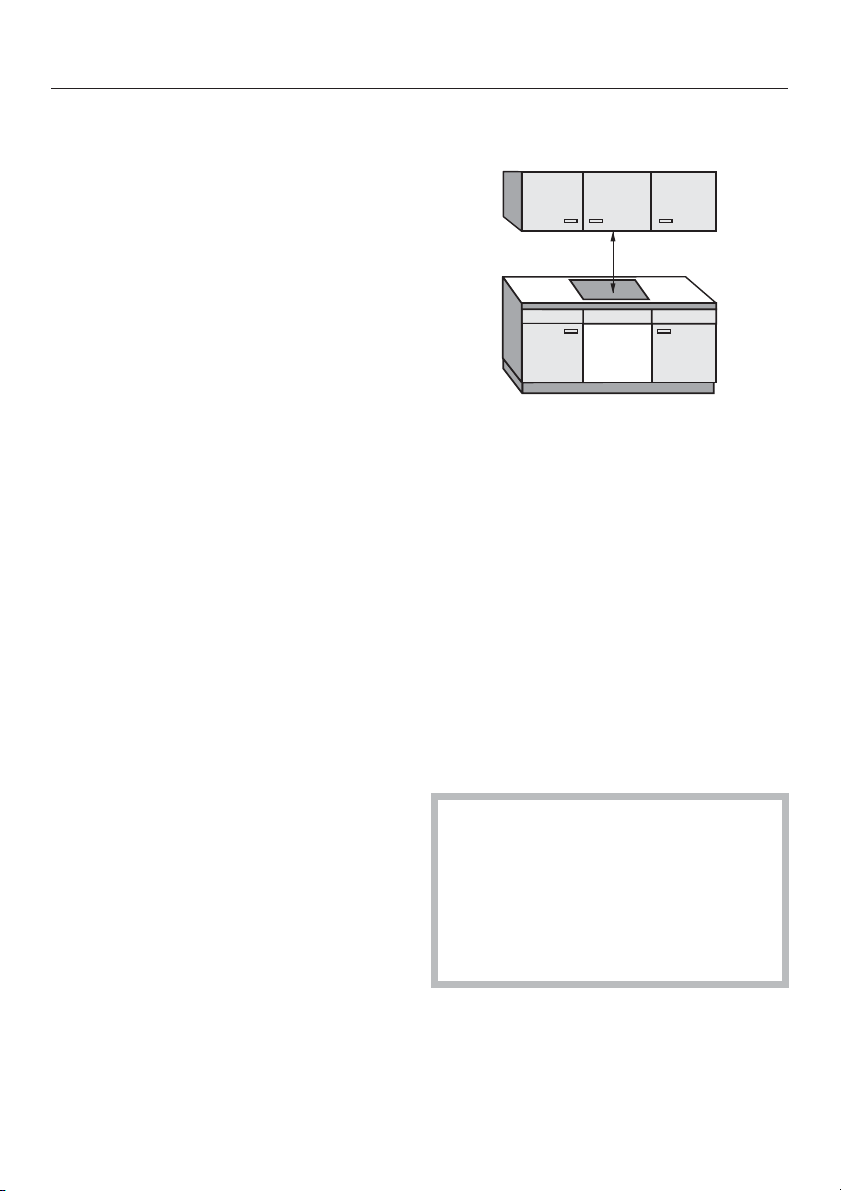

Fit the wall units and extractor hood

before fitting the hob to avoid

damaging the appliance.

The veneer or laminate coatings of

~

worktops (or adjacent kitchen units)

must be treated with 100 °C

heat-resistant adhesive which will not

dissolve or distort.

Any backmoulds must be of

heat-resistant material.

This appliance must not be used in

~

a non-stationary location (e.g. on a

ship).

After installing the hob, ensure that

~

the connection cable cannot come into

contact with the underside of the

appliance. Make sure that there is no

mechanical obstruction, such as a

drawer, which could damage it.

Observe carefully the safety

~

distances given on the following pages.

All dimensions in this instruction booklet

are given in mm.

The hob may not be built in over a

~

fridge, fridge freezer, freezer,

dishwasher, washing machine or

tumble dryer.

3

Page 4

Safety instructions for installation

Safety distance above an interim

shelf

It is not necessary to fit an interim shelf

underneath the hob.

If an interim shelf is fitted underneath

the hob, a minimum safety distance of

110 mm must be maintained between

the top of the worktop and the top of

the interim shelf.

A gap of at least 10 mm must be

provided between the rear edge of the

interim shelf and the back panel of the

housing unit to allow the mains cable to

be fed through.

If the hob has an external mains

connection box, this gap must be at

least 30 mm.

Safety distance above the hob

A minimum safety distance must be

maintained between the appliance and

the cooker hood above it. See the

cooker hood manufacturer's operating

and installation instructions for details.

If the manufacturer's instructions are

not available for the cooker hood, a

minimum safety distance of at least

760 mm must be maintained. For any

flammable objects, e.g. utensil rails,

wall units etc. a minimum distance of at

least 760 mm must be maintained

between them and the appliance

below.

When two or more appliances are

installed together below a cooker

hood, e.g. a gas wok and a ceramic

hob, which have different safety

distances given in the installation

instructions, you should select the

greater distance of the two.

4

Page 5

Safety instructions for installation

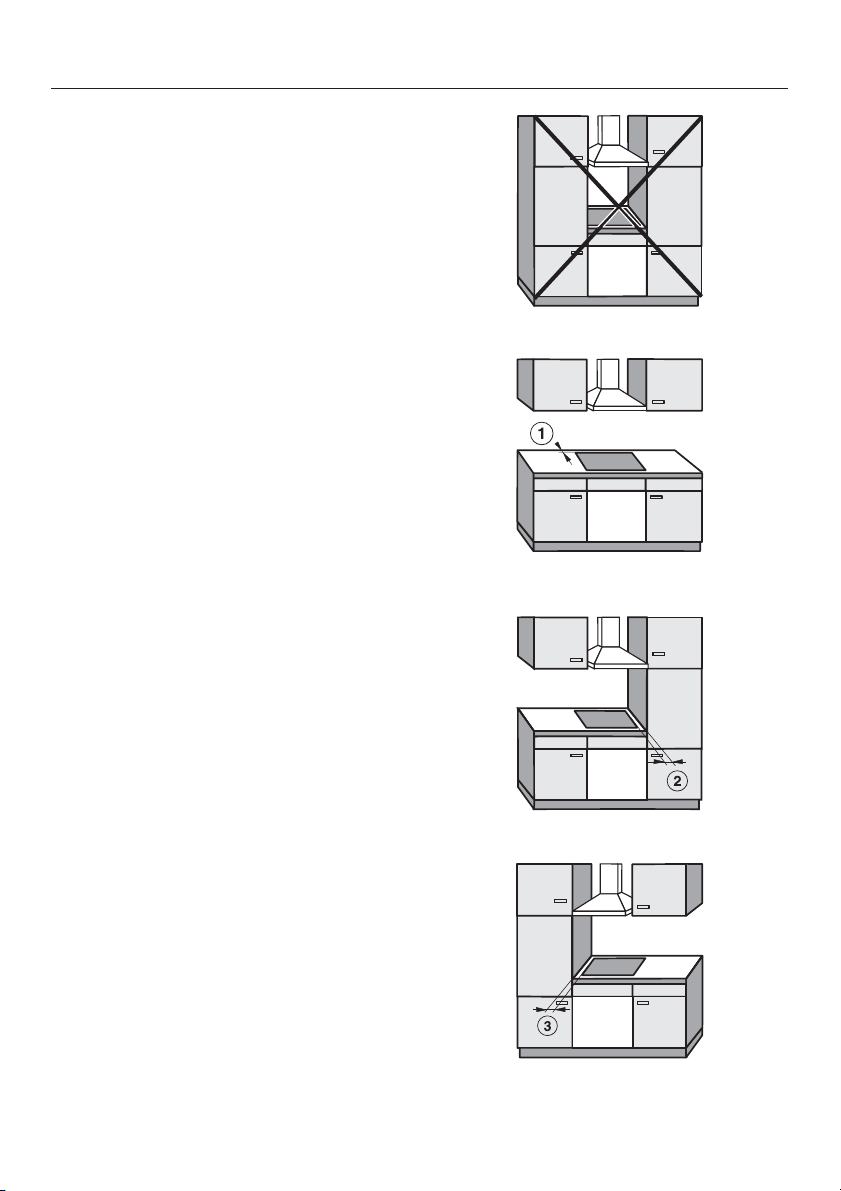

Safety distances to the sides and

back of the hob

Ideally the hob should be installed with

plenty of space on either side. There

may be a wall at the rear or a tall unit or

wall on one side (right or left) (see

illustrations).

a Minimum distance at the back of the

worktop cut-out to the rear edge of

the worktop: 50 mm.

b Minimum distance to the right of the

worktop cut-out to the nearest piece

of furniture (e.g. tall unit) or wall:

50 mm = KM 6220 / 6223

KM 6224

70 mm = KM 6226 / 6227

KM 6229 / 6230

c Minimum distance to the left of the

worktop cut-out to the nearest piece

of furniture (e.g. tall unit) or wall:

70 mm

Not allowed

Recommended

Not recommended

Not recommended

5

Page 6

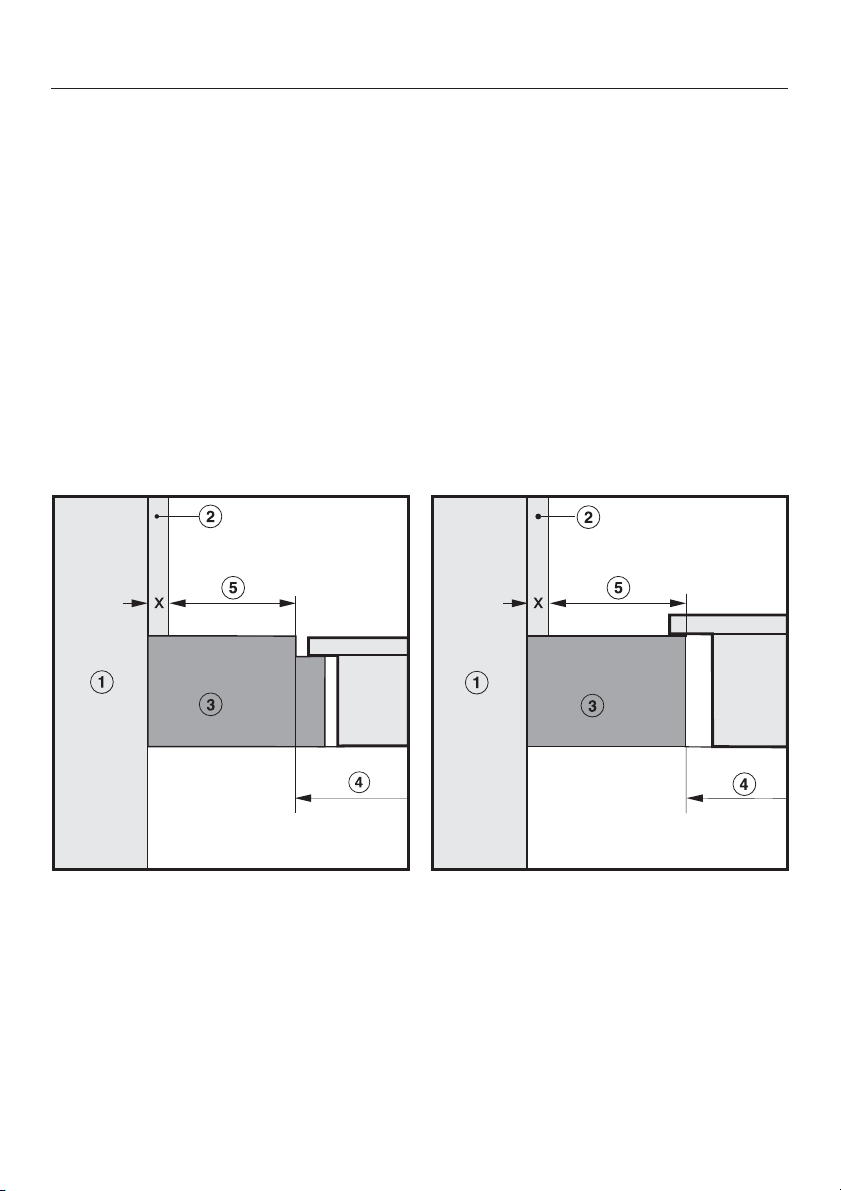

Safety instructions for installation

Safety distance when installing the appliance near a wall with additional

niche cladding

A minimum safety distance must be maintained between the worktop cut-out and

any niche cladding to protect it from heat damage.

If the niche cladding is made from a combustible material (e. g. wood) a

minimum safety distance e of 50 mm must be maintained between the cut-out

and the cladding.

If the niche cladding is made from a non-combustible material (e. g. metal,

natural stone, ceramic tiles) a minimum safety distance e of 50 mm less the

thickness of the cladding must be maintained between the cut-out and the

cladding.

Example: 15 mm niche cladding

50 mm - 15 mm = minimum safety distance of 35 mm

Flush-fitted hobs Hob with frame or bevelled edges

a Masonry

b Niche cladding

Dimension x = thickness of niche cladding material

c Worktop

d Worktop cut-out

e Minimum safety distance

for combustible materials is 50 mm

for non-combustible materials is 50 mm less dimension x

6

Page 7

Safety instructions for installation

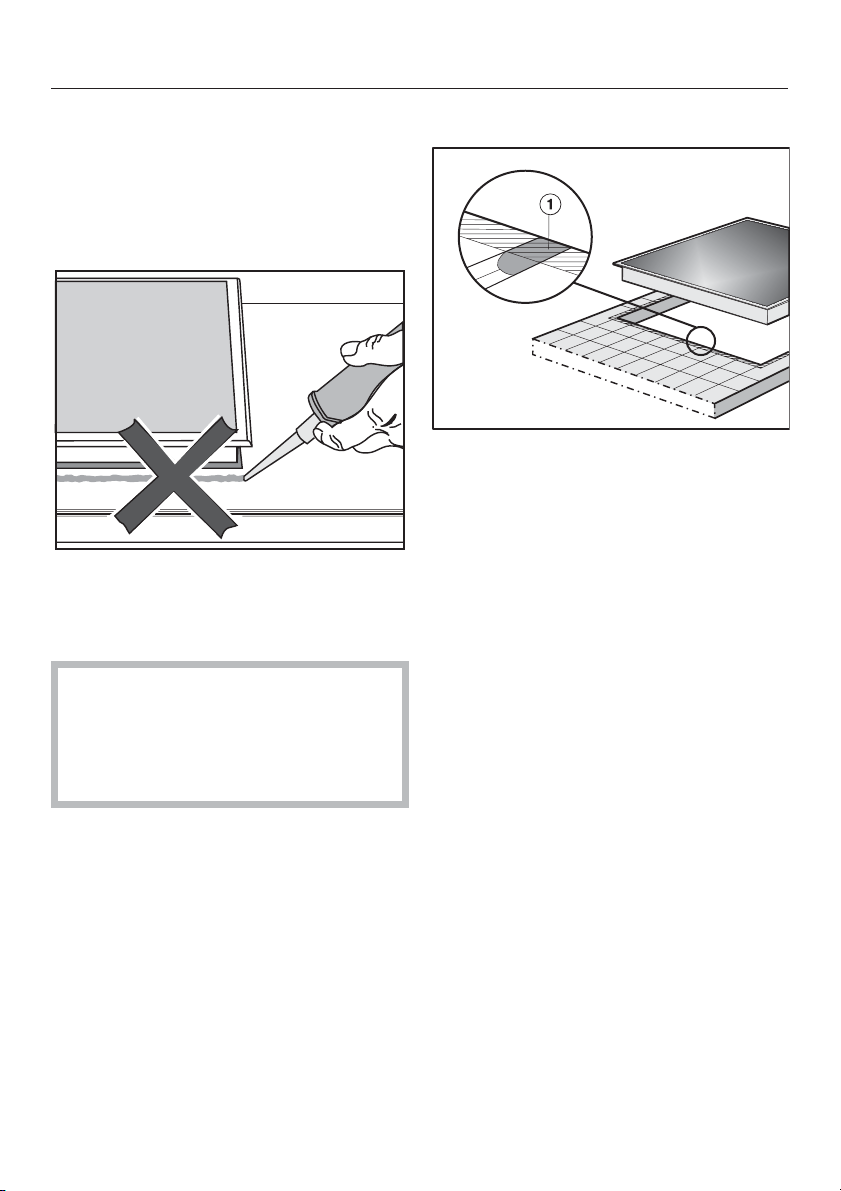

Hob with frame or bevelled

edges

Seal between the hob and the

worktop

The sealing strip under the edge of the

top part of the appliance provides a

sufficient seal for the worktop.

The hob must not be sealed with

sealant (e.g. silicone).

This could result in damage to the

hob or the worktop if the hob ever

needs to be removed for servicing.

Tiled worktop

Grout lines a and the hatched area

underneath the hob frame must be

smooth and even. If they are not the

hob will not sit flush with the worktop

and the sealing strip underneath the

hob will not provide a good seal

between the hob and the worktop.

7

Page 8

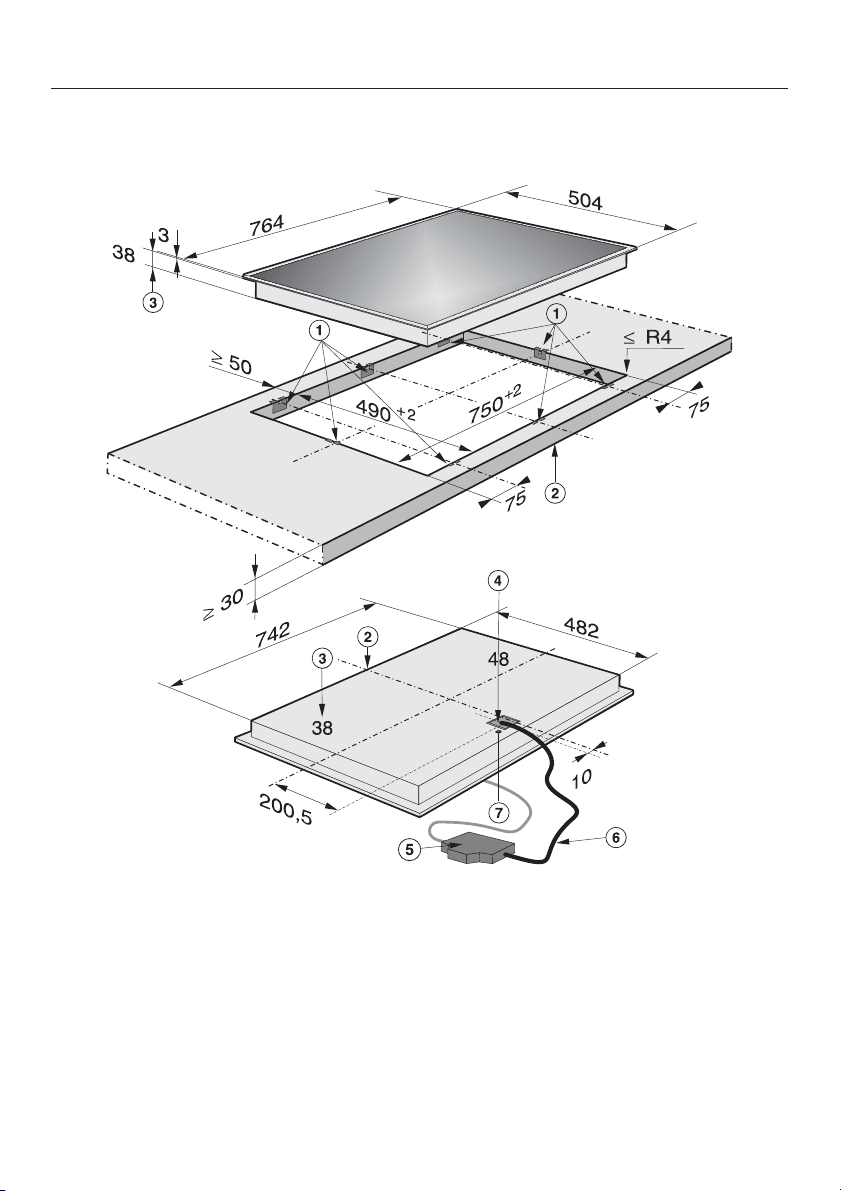

Hob with frame or bevelled edge

Building-in dimensions

KM 6220

a Spring clamps

b Front

c Casing depth

d Casing depth including cable exit

e Mains connection box with mains connection cable, L = 1440 mm

f Wiring harness, L = 1550 mm

g Connection for Miele|home

8

Page 9

KM 6624

Hob with frame or bevelled edge

a Spring clamps

b Front

c Casing depth

d Casing depth including cable exit

e Mains connection box with mains connection cable, L = 1440 mm

f Wiring harness, L = 1550 mm

g Connection for Miele|home

9

Page 10

Hob with frame or bevelled edge

KM 6226

a Spring clamps

b Front

c Casing depth

d Casing depth including cable exit

e Mains connection box with mains connection cable, L = 1440 mm

f Wiring harness, L = 1550 mm

g Connection for Miele|home

10

Page 11

KM 6229

Hob with frame or bevelled edge

a Spring clamps

b Front

c Casing depth

d Casing depth including cable exit

e Mains connection box with mains connection cable, L = 1440 mm

f Wiring harness, L = 1550 mm

g Connection for Miele|home

h Safety brackets

11

Page 12

Hob with frame or bevelled edge

KM 6230

a Spring clamps

b Front

c Casing depth

d Casing depth including cable exit

e Mains connection box with mains connection cable, L = 1440 mm

f Wiring harness, L = 1550 mm

g Connection for Miele|home

12

Page 13

Hob with frame or bevelled edge

Installation

The exact positions of the spring

clamps and the safety brackets (only

for hobs with bevelled edge) are

shown in the building-in dimensions

for the particular hob.

Hobs with bevelled edge:

The sealing strip will ensure that the

hob sits securely in the cut-out. Any

gap between the frame and worktop

will reduce with time.

Make the worktop cut-out according

^

to the dimensions given in the

building-in dimensions. Remember to

maintain the minimum safety

disances (see "Safety instructions for

installation").

Worktops made of wood

Seal the cut surfaces with a suitable

^

heat-resistant sealant to avoid

swelling caused by moisture.

Make sure that the sealant does not

come into contact with the top of the

worktop.

^

Place the spring clamps and the

safety brackets (only for hobs with

bevelled edge) (supplied) on the

upper edge on or at the upper edge

of the cut-out.

^

Secure the spring clamps a and

safety brackets b using the

3.5 x 25 mm wood screws supplied.

13

Page 14

Hob with frame or bevelled edge

Granite and marble worktops

You will require double-sided tape

and silicone (not supplied).

^ Apply silcone to the side edges and

the lower edges of the spring clamps

and safety brackets.

^

Fix the spring clamps and safety

brackets (only for hobs with bevelled

edge) in place using double-sided

tape c.

The spring clamps and the safety

brackets must rest on or against the

top edge of the cut-out.

14

Page 15

Installing the hob

Feed the hob connection cable down

^

through the cut-out.

Position the hob on the spring

^

clamps.

Using both hands, press down

^

evenly on the sides of the hob until it

clicks into position. When doing this,

make sure that the seal under the

hob sits flush with the worktop on all

sides. This is important to ensure an

effective seal all round.

Do not use sealant (e.g. silicone).

If the corners of the frame are not

flush with the worktop surface, the

corner radius (ß R4) can be carefully

scribed to fit.

^ Connect the hob to the mains.

^ Check that the hob works.

Hob with frame or bevelled edge

The hob can now only be removed

with a special tool.

15

Page 16

Flush-fitted hobs

Building-in dimensions

KM 6223

a Front

b Casing height

c Casing depth including cable exit

d Stepped cutout

e Mains connection box with

mains connection cable,

L= 1440 mm

f Wiring harness, L = 1550 mm

g Connection for Miele|home

16

Please take careful note of the

detailed diagrams for the cut-out

dimensions in granite and marble

worktops.

Page 17

KM 6227

Flush-fitted hobs

a Front

b Casing height

c Casing depth including cable exit

d Stepped cutout

e Mains connection box with

mains connection cable,

L= 1440 mm

f Wiring harness, L = 1550 mm

g Connection for Miele|home

Please take careful note of the

detailed diagrams for the cut-out

dimensions in granite and marble

worktops.

17

Page 18

Flush-fitted hobs

Installation

Flush fit hobs are only suitable for

installation in granite, marble, tiled or

solid wood worktops.

When using a worktop made from

any other material, please check first

with the worktop manufacturer that it

is suitable for installing a flush fit

hob.

Certain models are suitable for

building into glass worktops - please

see advice under "Building-in

dimensions".

The internal width of the base unit

must be at least as wide as the

internal cut-out width for the hob

(see "Building-in dimensions"). This

is to ensure that the casing can be

easily removed for maintenance.

If the underside of the hob is not

freely accessible after installation,

any sealant used to plug the gaps

around the appliance must be

removed to enable the hob to be

lifted out of the cut-out should this

be necessary.

The hob can be installed

in a suitable cut-out in a granite or

–

marble worktop.

in a suitable cut-out in a tiled or solid

–

wood worktop or a glass worktop

with a wooden support frame. The

frame must be provided on site, and

is not supplied with the appliance.

18

Page 19

Flush-fitted hobs

Granite and marble worktops

Preparing the worktop

a Worktop

b Hob

c Gap

As the ceramic glass and the

worktop cut-out have a certain

dimensional tolerance, the size of

gap c can vary (min. 1 mm).

Make the worktop cut-out as shown

^

in "Building-in dimensions".

Observe the safety distances (see

"Safety instructions for installation").

Feed the mains connection cable

^

down through the cut-out.

Centre the hob b in the cut-out.

^

Connect the hob to the mains.

^

Check that the hob works.

^

Seal the remaining gap c with a

^

silicone sealant that is heat-resistant

to at least 160 °C.

For granite and marble worktops,

only use silicone sealant that is

especially formulated for granite and

marble, and observe the sealant

manufacturer's instructions.

19

Page 20

Flush-fitted hobs

Solid wood, tiled and glass

worktops

Preparing the worktop

a Worktop

b Hob

c Gap

d Wooden frame 13 mm

(to be provided on site)

As the ceramic glass and the

worktop cut-out have a certain

dimensional tolerance, the size of

gap c can vary (min. 1 mm).

Make the worktop cut-out as shown

^

in "Building-in dimensions".

Observe the safety distances (see

"Safety instructions for installation").

Fix the wooden frame d 7 mm below

^

the top edge of the worktop (see

diagram).

Feed the mains connection cable

^

down through the cut-out.

Centre the hob b in the cut-out.

^

Connect the hob to the mains.

^

Check that the hob works.

^

^ Seal the remaining gap c with a

silicone sealant that is heat-resistant

to at least 160 °C.

Observe the silicone sealant

manufacturer's instructions.

For granite and marble tiles, only

use silicone sealant that has been

especially formulated for granite and

marble.

20

Page 21

External mains connection box

A minimum safety distance of

150 mm must be maintained

between the connection box and the

hob and also any other source of

heat (cooker, oven etc).

The connection box can be sited as

follows:

placed in a base unit underneath the

–

hob

on the side wall of a base unit

–

underneath the hob

– on the wall behind the base unit

– in a neighbouring unit.

If an interim shelf is fitted beneath

the hob, the connection box must

not be sited between the hob and

the interim shelf.

21

Page 22

Electrical connection

All electrical work should be carried

out by a suitably qualified and

competent person, in strict

accordance with current local and

national safety regulations (BS 7671

in the UK).

Installation, repairs and other work

by unqualified persons could be

dangerous. The manufacturer

cannot be held liable for

unauthorised work.

A damaged cable must be replaced

by a suitably qualified electrician

with a special connection cable of

type H 05 VV-F, available from

Miele.

Connection should be made via a

suitable isolator which complies with

national and local safety regulations,

and the On/Off switch should be easily

accessible after the appliance has

been built in.

If the switch is not accessible after

installation (depending on country) an

additional means of disconnection must

be provided for all poles.

For extra safety it is advisable to protect

the appliance with a residual current

device (RCD). Please contact a

qualified electrician for advice.

When switched off there must be an

all-pole contact gap of at least 3 mm in

the isolator switch (including switch,

fuses and relays).

Ensure power is not supplied to the

appliance until after installation or

repair work has been carried out.

The appliance must only be

operated when built-in. This is to

ensure that all electrical parts are

shielded. Live parts must not be

exposed.

Do not connect the appliance to the

mains electricity supply by an

extension lead. These do not

guarantee the required safety of the

appliance.

Please make sure that the connection

data quoted on the data plate match

the household mains supply.

22

Important U.K.

The appliance is supplied for

connection to a 230-240 V, 50 Hz

supply with a 3-core cable.

The wires in the mains lead are

coloured in accordance with the

following code:

Green/yellow = earth

Blue = neutral

Brown = live

WARNING

THIS APPLIANCE MUST BE

EARTHED

Page 23

Electrical connection

The electrical safety of this appliance

can only be guaranteed when

continuity is complete between it and

an effective earthing system, which

complies with current local and national

safety regulations. It is most important

that this basic safety requirement is

present and regularly tested and where

there is any doubt, the electrical wiring

in the home should be inspected by a

qualified electrician. The manufacturer

cannot be held liable for the

consequences of an inadequate

earthing system such as an electric

shock.

The manufacturer cannot be held

liable for damage which is the direct

or indirect result of incorrect

installation or connection.

Wiring diagram

N.B. This appliance is supplied

single phase only in the U.K. / AUS /

NZ

23

Page 24

Alteration rights reserved / 3311

M.-Nr. 09 198 700 / 00

Loading...

Loading...