Page 1

Operating and installation instructions

SmartLine downdraft extractor

To prevent the risk of accidents or damage to the appliance, it is

essential to read these instructions before it is installed and used for

the first time.

en-AU, NZ M.-Nr. 11 037 890

Page 2

Contents

Warning and Safety instructions...................................................................... 4

Caring for the environment .............................................................................. 14

Overview............................................................................................................. 15

Downdraft extractor............................................................................................. 15

Controls / Indicators............................................................................................ 16

Accessories supplied .......................................................................................... 17

Cleaning the SmartLine appliance for the first time ...................................... 18

Description of the functions............................................................................. 19

Tips on saving energy ...................................................................................... 20

Operation............................................................................................................ 21

FlameGuard......................................................................................................... 21

Switching the downdraft extractor on ................................................................. 21

Setting/Changing the power level ....................................................................... 21

Switching the downdraft extractor off ................................................................. 21

Run-on time......................................................................................................... 22

Cleaning and care ............................................................................................. 23

Ceramic surface .................................................................................................. 24

Moisture collection tray ....................................................................................... 24

Grease filter ......................................................................................................... 25

Problem solving guide ...................................................................................... 26

Optional accessories ........................................................................................ 27

Service................................................................................................................ 28

Contact in case of fault ....................................................................................... 28

Data plate ............................................................................................................ 28

Warranty .............................................................................................................. 28

Installation.......................................................................................................... 29

Safety instructions for installation ....................................................................... 29

Installation examples........................................................................................... 30

Surface-mounted ................................................................................................ 31

Installation notes – surface-mounted.................................................................. 31

Worktop cut-out – surface-mounted................................................................... 33

Spacer bars – surface-mounted.......................................................................... 36

Installation dimensions– Surface-mounted........................................................ 37

Air duct dimensions – surface-mounted – worktop depth 600mm.................... 38

Air duct dimensions – surface-mounted – worktop depth greater than 600mm 40

2

Page 3

Contents

Installation – surface-mounted............................................................................ 43

Flush-fit ............................................................................................................... 48

Installation notes – flush-fit ................................................................................. 48

Worktop cut-out – flush-fit .................................................................................. 50

Spacer bars – flush-fit ......................................................................................... 53

Installation dimensions–Flush ........................................................................... 54

Air duct dimensions – flush-fit – worktop depth 600mm ................................... 55

Air duct dimensions – flush-fit – worktop depth greater than 600mm............... 57

Installation – flush-fit ........................................................................................... 60

Exhaust ducting................................................................................................... 65

Electrical connection ........................................................................................... 67

3

Page 4

Warning and Safety instructions

This downdraft extractor complies with all relevant safety

requirements. However, inappropriate use can lead to personal

injury and damage to property.

Please read these operating and installation instructions carefully

before using the downdraft extractor for the first time. They

contain important information on safety, installation, use and

maintenance of the appliance. This prevents both personal injury

and damage to the downdraft extractor.

In accordance with standard IEC 60335-1, Miele expressly and

strongly advises that you read and follow the instructions in

"Installation" and in "Warning and Safety instructions".

Miele cannot be held liable for injury or damage caused by noncompliance with these instructions.

Keep these instructions in a safe place and pass them on to any

future owner.

For safe operation, please also refer to the operating and

installation instructions for the SmartLine appliances and cooktops

installed adjacent to the downdraft extractor.

4

Page 5

Warning and Safety instructions

Correct application

This downdraft extractor is designed for domestic use and for use

in similar environments by guests in hotel or motel rooms, bed &

breakfasts and other typical living quarters. This does not include

common/shared facilities or commercial facilities within hotels,

motels or bed & breakfasts.

The downdraft extractor is not suitable for outdoor use.

The downdraft extractor must only be used to extract vapours and

remove odours from cooking.

Any other usage is at the owner's risk. Miele cannot be held liable for

damage resulting from incorrect or improper use or operation.

This downdraft extractor is not intended for use by persons

(including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they are

supervised whilst using it or have been given instruction concerning

its use by a person responsible for their safety.

They must be able to recognise the dangers of misuse.

5

Page 6

Warning and Safety instructions

Safety with children

Young children must be kept away from the downdraft extractor.

Older children may only use the downdraft extractor without

supervision if they have been shown how to use it in a safe manner.

They must be aware of the potential dangers caused by incorrect

operation.

Cleaning work may only be carried out by older children under the

supervision of an adult.

Please supervise children in the vicinity of the downdraft extractor

and do not let them play with it.

Danger of suffocation! Whilst playing, children may become

entangled in packaging material (such as plastic wrapping) or pull it

over their head with the risk of suffocation. Keep packaging material

away from children.

6

Page 7

Warning and Safety instructions

Technical safety

Unauthorised installation, maintenance and repairs (including

removal of any cover) can cause considerable danger for the user.

Installation, maintenance and repairs must only be carried out by a

Miele authorised technician.

The downdraft extractor must only be installed and operated in

combination with those SmartLine appliances and cooktops

specified by Miele.

A damaged appliance is dangerous. Check it for any visible

damage. Never install or attempt to use a damaged appliance.

Reliable and safe operation of this downdraft extractor can only

be assured if it has been connected to the mains electricity supply.

The downdraft extractor must not be connected to the inverter of

an autonomous power supply, e.g. a solar power system. When the

downdraft extractor is switched on, power surges could result in a

safety switch-off. This may damage the electronic unit.

The electrical safety of this appliance can only be guaranteed

when continuity is complete between it and an effective earthing

system. It is most important that this basic safety requirement is

present and tested regularly and, where there is any doubt, the

household wiring system should be inspected by a qualified

electrician.

Before connecting the appliance to the mains electricity supply,

make sure that the rating on the data plate (voltage and frequency)

corresponds to that of the household supply.

This data must correspond in order to avoid risk of damage to the

appliance. Consult a qualified electrician if in any doubt.

Multi-socket adapters and extension leads do not guarantee the

required safety of the appliance (fire hazard). Do not use these to

connect the downdraft extractor to the mains electricity supply.

7

Page 8

Warning and Safety instructions

For safety reasons, this downdraft extractor may only be used

after it has been built in.

This downdraft extractor must not be installed and operated in

mobile installations (e.g. on a ship).

Touching or tampering with electrical connections or components

and mechanical parts is highly dangerous to the user and can cause

operational faults.

Only open the housing as described in the installation instructions

and in the Cleaning and care section of this booklet. Under no

circumstances should any other parts of the housing be opened.

The manufacturer's warranty will be invalidated if the appliance is

not repaired by a Miele authorised service technician.

Faulty components must only be replaced by genuine Miele spare

parts. The manufacturer can only guarantee the safety of the

appliance when Miele replacement parts are used.

The downdraft extractor is not intended for use with an external

timer switch or a remote control system.

If the plug is removed from the connection cable or if the cable is

supplied without a plug, the downdraft extractor must be connected

to the mains electricity supply by a suitably qualified electrician.

If the mains connection cable is damaged, it must be replaced

with a special mains connection cable by a qualified and competent

electrician in order to avoid a hazard (see “Installation - Electrical

connection”).

8

Page 9

Warning and Safety instructions

During installation, maintenance and repair work, the downdraft

extractor must be completely disconnected from the mains

electricity supply. It is only completely isolated from the electricity

supply when:

- the mains circuit breaker is switched off, or

- the screw-out fuse is removed (in countries where this is

applicable), or

- it is switched off at the wall socket and the plug is withdrawn from

the socket. Do not pull the mains connection cable but the mains

plug to disconnect your appliance from the mains electricity

supply.

9

Page 10

Warning and Safety instructions

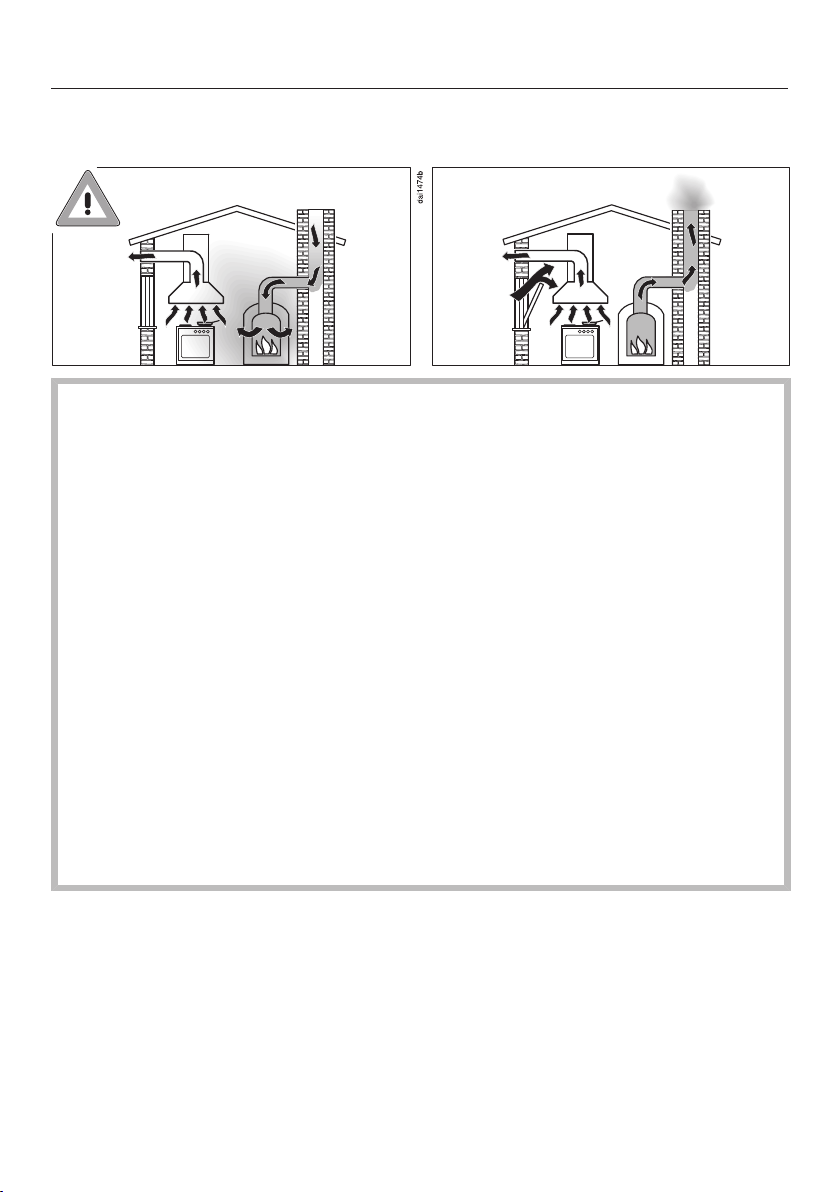

Using at the same time as other heating appliances that depend on the air from the room

Warning - danger of toxic fumes!

Great care should be taken when using the downdraft extractor at

the same time and in the same room or area of the house as

another heating appliance which depends on the air in the room.

Such appliances include gas, oil, wood or coal-fired boilers and

heaters, continuous flow or other water heaters, gas cooktops, or

ovens which draw air in from the room and duct exhaust gases out

through a chimney or extraction ducting.

When used in extraction mode, with or without an external motor

fitted, or in recirculation mode with a recirculation box installed

outside the room, the downdraft extractor draws air in from the

room in which it is installed and from neighbouring rooms.

If there is insufficient air, an underpressure will occur. The heating

appliance will be starved of oxygen, impairing combustion.

Harmful gases could be drawn out of the chimney or extraction

ducting back into the room, with potentially fatal consequences.

10

Page 11

Warning and Safety instructions

In order to ensure safe operation, and to prevent gases given off

by the heating appliances from being drawn back into the room

when the downdraft extractor and the heater are in operation

simultaneously, an underpressure in the room of 0.04 mbar (4 pa)

is the maximum permissible.

Ventilation can be maintained by air inlets which cannot be

blocked, in windows, doors or outside wall vents, or by other

technical measures, such as ensuring that the downdraft extractor

can only be switched on when the heating appliance is switched

off or vice versa. A ventilation brick alone is not generally sufficient

to ensure safe ventilation.

The overall ventilation condition of the dwelling must be taken into

account. If in any doubt, the advice of a competent builder or, for

gas, a qualified gas fitter (registered with an official gas safety

body in accordance with national safety regulations) must be

sought.

If the downdraft extractor is used in recirculation mode, where the

air is directed back into the room in which it is located, operating a

heating appliance which depends on the room air at the same time

is not hazardous.

11

Page 12

Warning and Safety instructions

Correct use

Open flames are a fire hazard!

Never use an open flame beside the downdraft extractor. To avoid

the danger of fire, do not flambé or grill over an open flame. When

switched on, the downdraft extractor could draw flames into the

filter. Kitchen grease deposits could ignite.

Overheated oil and fat can ignite, causing fire damage to the

downdraft extractor.

When cooking with oil or fat, chip pans and deep fat fryers etc., do

not leave the pans unattended. Similarly, never leave an open grill

unattended when grilling.

Do not use the downdraft extractor without the filter in place. This

way you will avoid the risk of grease and dirt getting into the

appliance and hindering its smooth operation.

The downdraft extractor can get very hot during cooking due to

the heat from the cooktop.

Do not touch the housing or the grease filter until the downdraft

extractor has cooled down.

Do not use the downdraft extractor for resting objects on.

Keep liquids away from the downdraft extractor.

Liquids can damage the extractor if they get into it.

Light objects can be drawn into the downdraft extractor and

impair its operation.

Do not place any light objects (e.g. paper towels) within close

proximity of the downdraft extractor.

If you are operating a gas cooking appliance directly next to the

downdraft extractor, the FlameGuard must be placed between the

downdraft extractor and the appliance.

12

Page 13

Warning and Safety instructions

Cleaning and care

The steam from a steam cleaning appliance could reach electrical

components and cause a short circuit.

Do not use a steam cleaner to clean the downdraft extractor.

There is a risk of fire if cleaning is not carried out as described in

these operating instructions.

Accessories

Use only genuine original Miele spare parts. If spare parts or

accessories from other manufacturers are used, the warranty will be

invalidated, and Miele cannot accept liability.

13

Page 14

Caring for the environment

Disposal of the packing material

The transport and protective packaging

has been selected from materials which

are environmentally friendly for

disposal, and can normally be recycled.

Recycling the packaging reduces the

use of raw materials in the

manufacturing process and also

reduces the amount of waste in landfill

sites. Ensure that any plastic

wrappings, bags etc. are disposed of

safely and kept out of the reach of

babies and young children. Danger of

suffocation.

Disposing of your old appliance

Electrical and electronic appliances

often contain valuable materials. They

also contain specific materials,

compounds and components, which

were essential for their correct function

and safety. These could be hazardous

to human health and to the environment

if disposed of with your domestic waste

or if handled incorrectly. Please do not,

therefore, dispose of your old appliance

with your household waste.

Please dispose of it at your local

community waste collection / recycling

centre for electrical and electronic

appliances. You are also responsible for

deleting any personal data that may be

stored on the appliance prior to

disposal. Please ensure that your old

appliance poses no risk to children

while being stored prior to disposal.

14

Page 15

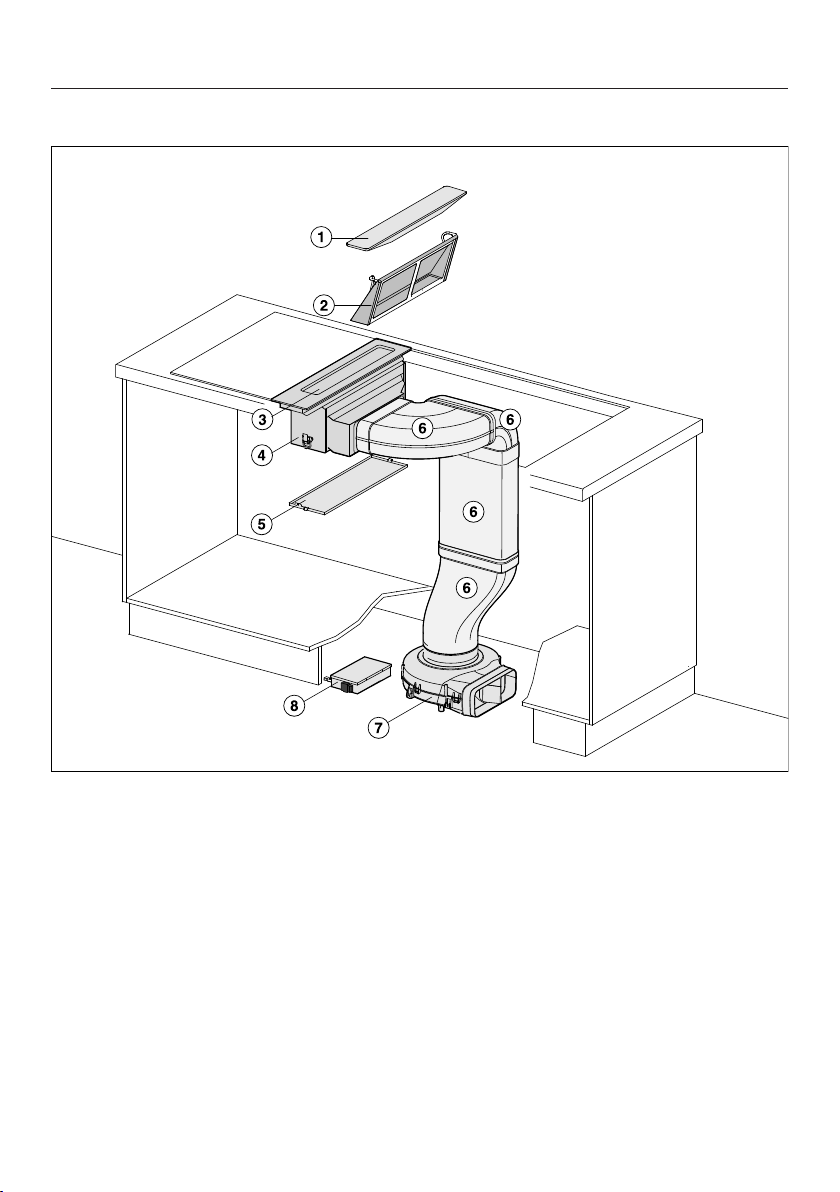

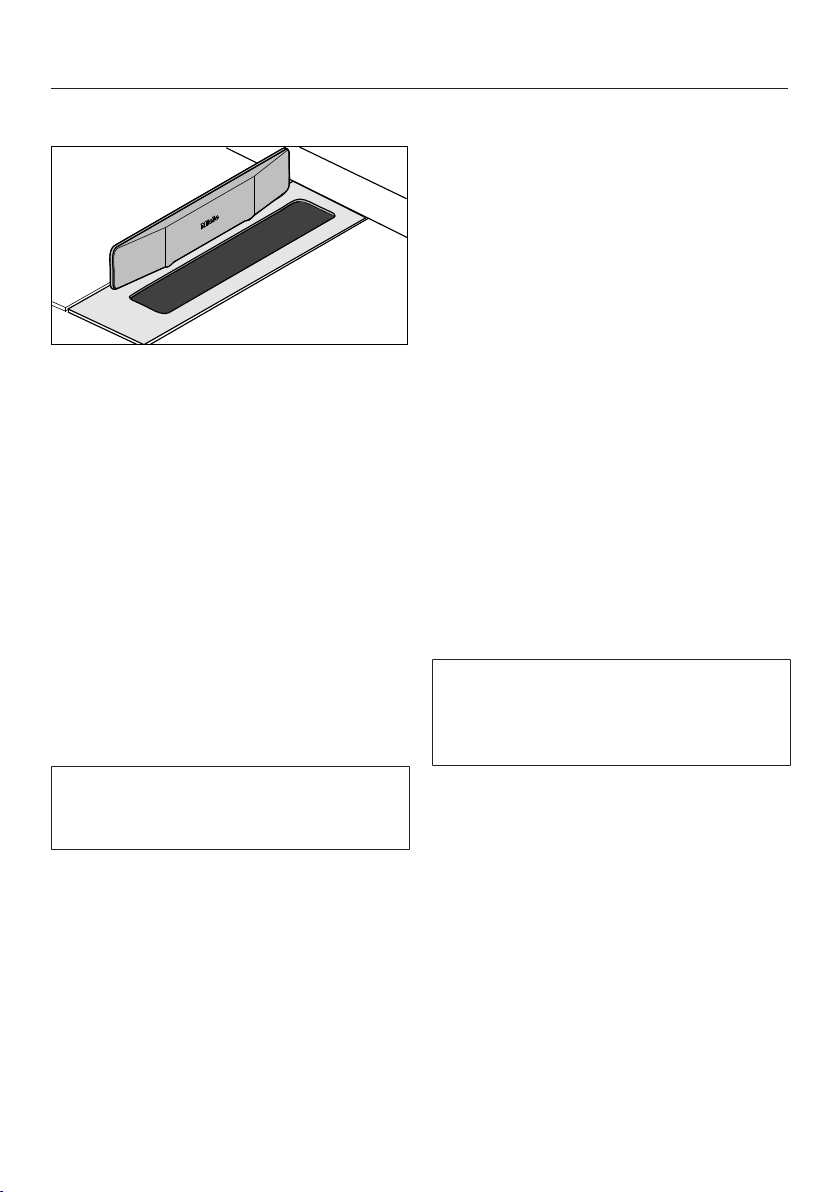

Downdraft extractor

Overview

a

FlameGuard

b

Grease filter

c

Cover with control unit

d

Casing

e

Moisture collection tray

f

Air duct

g

Fan

h

E-box

15

Page 16

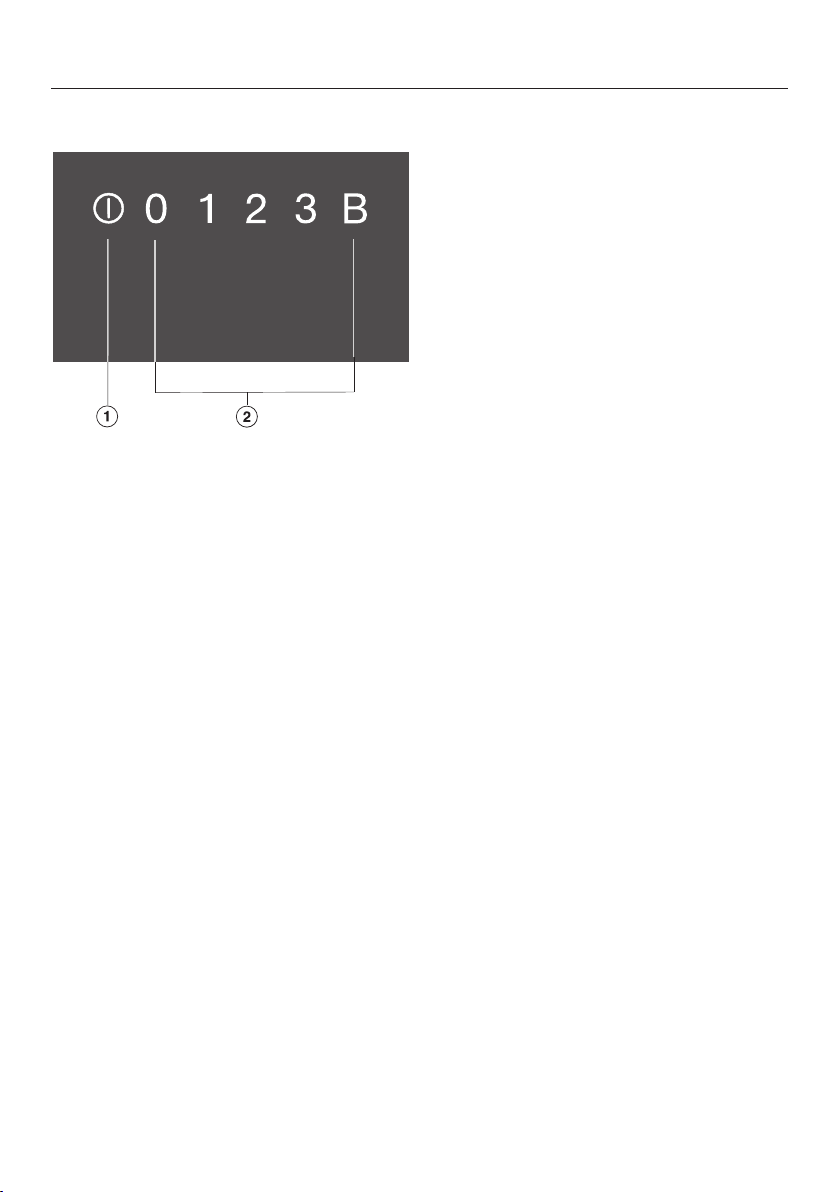

Overview

Controls / Indicators

a

For switching the downdraft extractor on/off

b

Numerical keybank for setting the power level

16

Page 17

Overview

Accessories supplied

The accessories supplied with your

appliance, as well as a range of optional

ones, are available to order from Miele

(see “Optional accessories”).

FlameGuard

For fitting in place between the

downdraft extractor and a gas cooking

appliance.

17

Page 18

Cleaning the SmartLine appliance for the first time

Please stick the extra data plate for

the appliance supplied with this

documentation in the space provided

in the “Service” section of this

booklet. Alternatively, the additional

label can be stuck near the appliance

if the appliance markings are not

visible after installation.

Remove any protective wrapping and

stickers (except the data plate).

Clean the ceramic surface with a

damp cloth, and then wipe dry.

18

Page 19

Depending on the model of the

downdraft extractor, the following

options are available:

Air extraction mode

The air is drawn in and cleaned by the

grease filter and directed outside.

Recirculation mode

(DUU 1000(-1) conversion kit required)

The air is drawn in and cleaned by the

grease filter. The air is then directed into

the recirculation box where it is also

cleaned by the charcoal filter. The

cleaned air is then recirculated back

into the kitchen.

Description of the functions

19

Page 20

Tips on saving energy

This downdraft extractor operates very

efficiently and economically. The

following will help you to save even

more energy when using it:

- It is important to ensure that the

kitchen is well ventilated during

operation. In extraction mode if there

is insufficient air flow, the downdraft

extractor cannot operate efficiently

and this causes increased operating

noise levels.

- Always cook with the lowest possible

cooking setting. This produces fewer

cooking vapours, so you can use a

lower extractor power level and

therefore benefit from reduced energy

consumption.

- Check the selected power level on

the downdraft extractor. A low power

level is usually sufficient. Only use the

Booster setting when necessary.

- When a large volume of cooking

vapours are being produced, switch

to a high power level in good time.

This is more efficient than operating

the downdraft extractor for longer to

try to capture cooking vapours which

have already been distributed

throughout the kitchen.

- Switch the downdraft extractor off

after cooking.

- Clean or replace the filters at regular

intervals. Heavily soiled filters reduce

performance, increase the risk of fire

and are unhygienic.

20

Page 21

Operation

FlameGuard

Fit the magnetic FlameGuard in

position next to the downdraft

extractor when you are operating a

gas cooking appliance directly next to

the extractor.

Switching the downdraft extractor on

The downdraft extractor must only be

operated when the FlameGuard has

been removed from completely

covering the extractor.

Remove the FlameGuard.

Touch the sensor.

The sensor controls will light up.

Setting/Changing the power level

For light to heavy cooking vapours and

odours, select from power levels 1 to 3.

For short periods of cooking food with

intensive vapours and a strong aroma,

e.g. when searing meat, select Booster

settingB.

Touch the required power level.

Booster

The maximum duration for the Booster

is 10minutes.

To switch the Booster off early, set a

different power level.

Switching the downdraft extractor off

Touch the sensor.

The sensor controls go out.

If the downdraft extractor is not

switched off, it will switch itself off

12hours after the last automatic

operation.

If no further entry is made, the

downdraft extractor will switch itself

off after a few seconds.

21

Page 22

Operation

Run-on time

In order to rid kitchen air of steam and

odours, the downdraft extractor

continues to run for 5minutes on the

power level that was set last. The

power level is gradually reduced during

the run-on time. The current power level

pulsates during the run-on time.

Useful tip: To help release vapours

effectively with pans over 15cm high,

place a wooden spoon between the lid

and the pan.

22

Page 23

Cleaning and care

Risk of burning due to hot

surfaces.

The surfaces will be hot after use.

Switch the downdraft extractor and

the cooking elements off.

Allow the surfaces to cool down

before cleaning the downdraft

extractor.

Risk of damage due to moisture

ingress.

The steam from a steam cleaning

appliance could reach electrical

components and cause a short

circuit.

Do not use a steam cleaner to clean

the downdraft extractor.

The use of unsuitable cleaning

agents can cause the surfaces to

discolour or alter. All surfaces are

susceptible to scratching.

Remove any residual cleaning agent

immediately.

Never use abrasive sponges or

cleaning agents.

Allow the SmartLine appliance to

cool down before cleaning.

Clean the SmartLine appliance and

accessories after each use.

Dry the SmartLine appliance

thoroughly every time after cleaning

to avoid limescale residue.

Unsuitable cleaning agents

To avoid damaging the surfaces of the

appliance, do not use:

- washing-up liquid,

- cleaning agents containing soda,

alkalines, ammonia, acids or

chlorides,

- cleaning agents containing descaling

agents,

- stain and rust removers,

- abrasive cleaning agents, e.g.

powder cleaners and cream cleaners,

- solvent-based cleaning agents,

- dishwasher cleaner,

- grill and oven cleaners,

- glass cleaning agents,

- hard, abrasive brushes or sponges

(e.g. pot scourers), or sponges which

have been previously used and still

contain abrasive cleaning agents,

- dirt erasers.

23

Page 24

Cleaning and care

Ceramic surface

Risk of damage by pointed

objects.

The seal between the SmartLine

element and the worktop could

suffer damage.

Do not use pointed objects for

cleaning.

Do not use washing-up liquid to

clean the appliance. Using washingup liquid will not remove all soiling

and residues. An invisible film can

develop that can lead to

discolouration of the ceramic glass.

This discolouration cannot be

removed.

Clean the ceramic surface regularly

with a proprietary ceramic glass

cleaning agent.

Remove any coarse soiling with a

damp cloth and more stubborn

soiling with a glass scraper.

Then clean the ceramic glass surface

with the Miele ceramic and stainless

steel cooktop cleaner (see “Optional

accessories”) or with a proprietary

ceramic glass cleaner applied with

paper towel or a clean cloth. Please

follow the cleaning agent

manufacturer's instructions.

Moisture collection tray

Clean the moisture collection tray if

liquids have boiled over or spilled into

the downdraft extractor.

Remove and clean the grease filter as

described in the “Grease filter”

section.

Hold the moisture collection tray and

open the 2 clips (1x front, 1x rear).

Carefully remove the tray from the

casing, making sure it is kept

horizontal.

Pour out the liquid.

Clean and dry the moisture collection

tray.

Clean and dry the accessible inside

of the downdraft extractor.

Fasten the moisture collection tray

back onto the casing.

Refit the grease filter and the cover.

Clean the ceramic surface with a

damp cloth, and then wipe dry.

Ensure that all cleaner residues are

removed.

Any marks left by limescale and

water residues can be removed using

Miele's ceramic and stainless steel

cooktop cleaner.

24

Page 25

Cleaning and care

Grease filter

The reusable metal grease filter in the

downdraft extractor removes solid

particles from kitchen vapours (grease,

dust, etc.) and therefore prevents

soiling of the downdraft extractor.

Accumulated grease solidifies over a

longer period of time and makes

cleaning more difficult. The grease filter

should therefore be cleaned at least

every 3 to 4 weeks.

Risk of fire due to soiled grease

filter.

Grease collected in the grease filter

can ignite.

Clean the grease filter regularly.

Removing the grease filter

Remove the FlameGuard if

necessary.

Carefully remove the grease filter.

Ensure that you do not tilt the grease

filter.

Use a standard household

dishwasher detergent.

Select a dishwasher programme with

a wash temperature between 50°C

and 65°C.

Depending on the detergent used,

cleaning the grease filter in a

dishwasher can cause permanent

discolouration to the internal surfaces

of the filter. This will not affect the

functioning of the grease filter in any

way.

Fitting the grease filter

Pour out any liquid which has

collected at the bottom of the grease

filter.

Cleaning the grease filter by hand

Clean the grease filter with a soft

nylon brush in a mild solution of hot

water and a little washing-up liquid.

Do not use concentrated washing-up

liquid.

Cleaning the grease filter in the dishwasher

Place the grease filter with its base

facing upwards in the lower basket.

Ensure the spray arm is not

obstructed.

Fit the grease filter so that the straight

side of the grease filter is on the side

that connects to the air duct.

Interior of the casing

When removing the grease filter for

cleaning, also clean off any

accessible oil or fat build-up from the

casing. Doing so will prevent a fire

hazard.

25

Page 26

Problem solving guide

With the help of the following guide, minor faults in the performance of the

appliance, some of which may result from incorrect operation, can be remedied

without contacting Miele. This will save you time and money because you won't

need a service call.

Please note that a call-out charge will be applied to unnecessary service visits

where the problem could have been rectified as described in these operating

instructions.

Problem Possible cause and remedy

The SmartLine

appliance cannot be

switched on.

The power levels 1 to B

light up one after the

other.

There is no power to the SmartLine appliance.

Check if the circuit breaker has tripped. Contact

an electrician or Miele (for the minimum fuse

rating, see data plate).

There may be a technical fault.

Disconnect the SmartLine appliance from the

mains electricity supply for approx. 1 minute by

– switching off at the wall socket and withdrawing

the plug, or

– switching off the main circuit breaker or residual

current device.

If, after resetting the fuse in the mains fuse box or

the residual current protection device, the

SmartLine appliance will still not switch on,

contact a qualified electrician or Miele.

An automatic reset is performed after an

interruption to the power supply.

26

Page 27

Optional accessories

Miele offers a range of useful

accessories, as well as cleaning and

conditioning products for your

appliance.

These products can be ordered from

the Miele online shop.

They can also be ordered directly from

Miele (see end of this booklet for

contact details).

FlameGuard

For fitting in place between the

downdraft extractor and a gas cooking

appliance.

Original Miele ceramic and

stainless steel cleaner 250ml

Removes heavy soiling, limescale

deposits and aluminium residues.

Original Miele all purpose microfibre cloth

Removes finger marks and light soiling.

27

Page 28

Service

Contact in case of fault

In the event of any faults which you cannot remedy yourself, please contact Miele.

You can book a Miele customer service call-out online at www.miele.com/

service.

Contact information for Miele can be found at the end of this booklet.

Please quote the model and serial number of your appliance when contacting

Miele. This information can be found on the data plate.

Data plate

Adhere the extra data plate supplied with the appliance in the space below. Make

sure that the model number matches the one specified on the back cover of these

operating and installation instructions.

Warranty

The manufacturer's warranty for this appliance is 2years.

For further information, please refer to your warranty booklet.

28

Page 29

*INSTALLATION*

Installation

Safety instructions for installation

Risk of damage from incorrect installation.

Incorrect installation can cause damage to the SmartLine appliance.

The SmartLine appliance must only be installed by a suitably qualified and

competent person.

Damage from falling objects.

Take care not to damage the SmartLine appliance when fitting wall units above

it.

Fit the wall units before the SmartLine appliance.

After installation, the mains connection cable of the SmartLine

appliance must not come into contact with any moving kitchen

component (e.g. a drawer) or be subject to mechanical loads which

could damage it.

Combination with gas appliances

Only Miele CS 7xxx gas appliances may be installed next to the

downdraft extractor.

Carefully observe the safety clearances listed on the following

pages.

All pipework, ducting and fittings must be of non-flammable

material and comply with all relevant national and local building

regulations.

The appliance must not be connected to a chimney or vent flue

which is in current use for exhausting fumes from appliances burning

gas or other fuels. Neither should it be connected to ducting which

ventilates rooms with fireplaces.

If exhaust air is to be extracted into a chimney or ventilation duct

no longer used for other purposes, seek professional advice.

29

Page 30

*INSTALLATION*

Installation

Installation examples

Recirculation mode

Air extraction mode

30

Page 31

*INSTALLATION*

Installation

Surface-mounted

Installation notes – surface-mounted

Sealing between the SmartLine appliance and the worktop

The SmartLine appliance and

worktop may be damaged if the

appliance needs to be removed after

it has been sealed with a sealant.

Do not use any sealant between the

SmartLine appliance and the

worktop.

The sealing strip under the edge of

the top part of the appliance

provides a sufficient seal for the

worktop.

Tiled worktop

Grout lines and the hatched area

underneath the SmartLine appliance

frame must be smooth and even. If they

are not, the SmartLine appliance will

not sit flush with the worktop and the

sealing strip underneath the top part of

the appliance will not provide a good

seal between the appliance and the

worktop.

Sealing strip

Dismantling the SmartLine appliance

for service purposes may damage

the sealing strip underneath the edge

of the SmartLine appliance.

Always replace the sealing strip

before reinstalling the cooktop.

31

Page 32

*INSTALLATION*

Installation

Installing several SmartLine appliances

The gaps between the individual

SmartLine appliances must be sealed

with a silicone sealant that is heatresistant to at least 160°C. With flushfit installation, the gap between the

SmartLine appliance(s) and the worktop

must also be sealed with a silicone

sealant that is heat-resistant to at least

160°C.

After installation, the SmartLine

appliances must be easily accessible

from below, so that the bottom half of

the casing can be removed for

maintenance. If the SmartLine

appliances are not accessible from

below, the sealant must be removed so

that they can be removed.

Worktop depth

The downdraft extractor can be

installed with the connector for the air

duct on either the right or the left-hand

side.

Minimum worktop depth for

- right connector 600mm

- left connector 665mm

32

Page 33

*INSTALLATION*

B

500

+1

ß

R 4

B

10

0

10

Worktop cut-out – surface-mounted

Installation

Information for calculating the cut-out

The appliances overlap the worktop by 10mm.

When installing several appliances, a distance of 2mm must be observed between

the individual appliances.

Calculating cut-out dimensionB

1 appliance = width of the appliance minus 10mm on the right, minus 10mm on

the left

Several appliances = total width of the appliances plus 2mm distance between

the appliances, minus 10mm on the right, minus 10mm on the left.

Some examples are illustrated below.

33

Page 34

*INSTALLATION*

Installation

Installation with a downdraft extractor

Sample combinations Numberxwidth [mm] Dimension

Cooking

appliances

Downdraft

extractor

1 x 378 1 x 120

B

[mm]

480

+1

2 x 378 1 x 120

1x378

2 x 120

1x620

3 x 378 2 x 120

2x378

2 x 120

1x620

4 x 378 2 x 120

1 x 620 2 x 120

860

1224

1362

1604

1742

844

+1

+1

+1

+1

+1

+1

34

Page 35

*INSTALLATION*

Installation without a downdraft extractor

Sample combinations Numberxwidth [mm] DimensionB

Cooking appliances

1 x 378

Installation

[mm]

+1

358

2 x 378

1x378

1x620

3 x 378

2x378

1x620

4 x 378

738

980

1118

1360

1498

+1

+1

+1

+1

+1

35

Page 36

*INSTALLATION*

Installation

Spacer bars – surface-mounted

When installing several SmartLine appliances, an additional spacer bar must be

fitted in between the individual appliances.

The clips supplied with the spacer bars are only required for installing a

CSDA700xFL.

Installing 3 appliances and 2 spacer bars

Spacer bars for the downdraft extractor – surface-mounted

a

Brackets

36

Page 37

*INSTALLATION*

Installation dimensions– Surface-mounted

All dimensions in this instruction booklet are given in mm.

Installation

a

Front

b

Fan (in the plinth on the floor)

c

Air duct

d

E-box

37

Page 38

*INSTALLATION*

Installation

Air duct dimensions – surface-mounted – worktop depth

600mm

Side view

a

For maintenance work, it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the exhaust ducting.

b

After installation, the removable moisture collection tray must be accessible

from below.

Two quick-release catches have to be opened to remove the tray.

c

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

d

Plinth fan

38

Page 39

*INSTALLATION*

Installation

Front view

View from above

39

Page 40

*INSTALLATION*

Installation

Air duct dimensions – surface-mounted – worktop depth greater

than 600mm

View from the side – right air duct connection

a

For maintenance work, it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the exhaust ducting.

b

Variable length of middle section

c

After installation, the removable moisture collection tray must be accessible

from below.

Two quick-release catches have to be opened to remove the tray.

d

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

e

Plinth fan

x Dimension of which the worktop is deeper than 600mm.

40

Page 41

*INSTALLATION*

View from the front – right air duct connection

Installation

View from above – right air duct connection

41

Page 42

*INSTALLATION*

Installation

If you want to install the air duct to the left of the downdraft extractor, the

worktop must be at least 665mm deep.

View from the front – left air duct connection

View from above – left air duct connection

42

Page 43

*INSTALLATION*

Installation

Installation – surface-mounted

If the worktop is more than 24mm

deep, it must be cut out underneath

on the building-in side on the right or

left-hand side.

a

Worktop

b

Maximum 24mm

c

12 mm

Securing the bracket

1 bracket (supplied with the spacer bar)

must be secured centrally to the right or

left-hand side of the cut-out.

Wooden worktops

Fit the bracket so that it sits flush

with the top edge of the worktop cutout.

Secure the bracket with the

3.5x25mm wood screws supplied.

Granite and marble worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

bracket.

Stick the tape along the top edge of

the worktop cut-out.

Fit the bracket so that it sits flush

with the top edge of the worktop cutout.

Press the bracket firmly into position.

43

Page 44

*INSTALLATION*

Installation

Preparing the worktop

Create the worktop cut-out.

Remember to maintain the minimum

safety distances (see "Installation –

Safety distances").

Seal the cut surfaces of wooden

worktops with a suitable sealant to

avoid swelling caused by moisture.

The sealant must be heat-resistant.

Make sure the sealant does not

come into contact with the top

surface of the worktop.

Fitting the spacer bars

Use the middle screw holes if one of the

following SmartLine appliances is

installed to the right or left of the spacer

bar: CS7611, CS 7641, CS7101(-1),

CS7102(-1)

Wooden worktops

Position the spacer bars flush onto

the upper edge of the cut-out.

Secure the spacer bars with the

3.5x25mm wood screws supplied.

Granite and marble worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

spacer bars.

44

Stick the tape along the top edge of

the worktop cut-out.

Position the spacer bars flush onto

the upper edge of the cut-out.

Press the spacer bars firmly into

place.

Page 45

*INSTALLATION*

Installing the downdraft extractor

The downdraft extractor can be

installed with the connector for the air

duct on either the right or the left-hand

side.

Installation

Remove the moisture collection tray

from the casing.

a

Connector for air duct on the right

b

Connector for air duct on the left

Stick the supplied sealing strip under

the edge of the cover. Do not apply

the sealing strip under tension.

Fit the clips onto the spacer bars.

Guide the control cable downwards

between the spacer bars.

Fit the cover onto the spacer bars.

Fasten the casing from the inside with

the screws on the right and left

sides (3 in each case).

Fasten the moisture collection tray.

Mount the air duct.

Ensure that the air duct is not under

mechanical tension after installation!

45

Page 46

*INSTALLATION*

Installation

E-box

a

Mains connection cable

b

Connection to window contact

c

Connection socket for the fan power

cable

d

Connection socket for the fan

control cable

e

Connection socket for the control

unit cable

Connection to window contact, if required

The window contact is

connected to the mains voltage.

Danger of electric shock!

Disconnect the downdraft extractor

from the mains electricity supply

before connecting the switching

system.

The connection cable of the

switching system must only be

connected by a suitably qualified and

competent electrician.

The connection cable of the

switching system must be of the

correct type and cross-sectional area

in strict accordance with current

national and local safety regulations

and must not exceed 2.0m in length.

The switching system must be

equipped with a potential-free

contact suitable for 230V, 1A. The

extractor is switched off when the

switch is open.

Only use suitable switching systems

(e.g. window contact switches,

pressure switches).

The switching system must be

suitable for use with inductive loads

(BLDC motor).

Use switching systems in strict

accordance with current national and

local safety regulations.

46

Page 47

*INSTALLATION*

Installation

Loosen the lug and pull the plug out.

Loosen the strain relief screw and

unlock the casing on both sides.

Open the casing.

Remove the stopper.

Exchange the jumper with the

connection cable of the switching

system.

Close the casing.

Connecting the e-box

Connect the fan power cable and fan

control cable to the e-box and the

fan.

Connect the control unit cable to the

e-box.

The socket positions are designed in

such a way that they cannot be mixed

up.

Connect the downdraft extractor to

the mains electricity supply.

Check that the downdraft extractor

works.

Sealing the gaps

Seal the gaps between the individual

SmartLine appliances, and between

the flush-fit SmartLine appliances

and the worktop, with a silicone

sealant that is heat-resistant to at

least 160°C.

Unsuitable sealant can damage

natural stone.

For natural stone worktops and

natural stone tiles, only use silicone

sealant that is specially formulated

for natural stone.

Please follow the manufacturer's

instructions.

Tighten the strain relief screw.

Reinsert the plug.

47

Page 48

*INSTALLATION*

Installation

Flush-fit

Installation notes – flush-fit

Flush-fit installation is only possible in

natural stone (granite, marble), solid

wood and tiled worktops. For

installation in worktops made of other

materials, please consult the relevant

manufacturer as to whether their

worktops are suitable for flush-fit

installation.

The internal width of the base unit

underneath the appliance must be at

least as wide as the inner worktop cutout (see “Installation – Installation

dimensions – Flush”), so that the

SmartLine appliance is easily

accessible from underneath after

installation and the bottom half of the

casing can be removed for

maintenance. If the appliance is not

freely accessible from below after

installation, the sealant must be

removed so that the appliance can be

removed.

Natural stone worktops

The SmartLine appliance is set directly

in the cut-out.

Solid wood worktops, tiled worktops,

glass worktops

The SmartLine appliance is set on a

wooden frame inside the cut-out. The

frame must be provided on site and is

not supplied with the appliance.

Sealing strip

Dismantling the SmartLine appliance

for service purposes may damage

the sealing strip underneath the edge

of the SmartLine appliance.

Always replace the sealing strip

before reinstalling the cooktop.

48

Page 49

*INSTALLATION*

Installation

Installing several SmartLine appliances

The gaps between the individual

SmartLine appliances must be sealed

with a silicone sealant that is heatresistant to at least 160°C. With flushfit installation, the gap between the

SmartLine appliance(s) and the worktop

must also be sealed with a silicone

sealant that is heat-resistant to at least

160°C.

After installation, the SmartLine

appliances must be easily accessible

from below, so that the bottom half of

the casing can be removed for

maintenance. If the SmartLine

appliances are not accessible from

below, the sealant must be removed so

that they can be removed.

Worktop depth

The downdraft extractor can be

installed with the connector for the air

duct on either the right or the left-hand

side.

Minimum worktop depth for

- right connector 600mm

- left connector 665mm

49

Page 50

*INSTALLATION*

B

A

524

500

+

1

+1

ß R 4

B

A

0 2

12

0

10

5,5

+

0,5 *

0 2

B

A

12

0

10

5,5

+

0,5 *

Installation

Worktop cut-out – flush-fit

Natural stone worktop Wooden worktop

0.5

+

* 7

mm with CS7611FL

Information for calculating the cut-out

The appliances overlap the stepped cut-out by 10mm.

When installing several appliances, a distance of 2mm must be observed between

the individual appliances.

Calculating cut-out dimensionA

1 appliance = width of the appliance plus 2mm on the right, plus 2mm on the left.

Several appliances = total width of the appliances plus 2mm distance between

the appliances, plus 2mm on the right, plus 2mm on the left

Calculating cut-out dimensionB = cut-out dimension A minus 12mm on the right,

minus 12mm on the left.

Some examples are illustrated below.

50

Page 51

*INSTALLATION*

Installation with a downdraft extractor

Sample combinations

Numberxwidth [mm]

Cooking

appliances

Downdraft

extractor

DimensionA

[mm]

Installation

DimensionB

[mm]

1 x 378 1 x 120

2 x 378 1 x 120

1x378

2 x 120

1x620

3 x 378 2 x 120

2x378

2 x 120

1x620

4 x 378 2 x 120

1 x 620 2 x 120

504

884

1248

1386

1628

1766

868

+1

+1

+1

+1

+1

+1

+1

480

860

1224

1362

1604

1742

844

+1

+1

+1

+1

+1

+1

+1

51

Page 52

*INSTALLATION*

Installation

Installation without a downdraft extractor

Sample

combinations

Numberxwidth

[mm]

Cooking

appliances

1 x 378

2 x 378

1x378

1x620

3 x 378

2x378

1x620

4 x 378

DimensionA

[mm]

+1

382

+1

762

+1

1004

+1

1142

+1

1384

+1

1522

DimensionB

[mm]

+1

358

+1

738

+1

980

+1

1118

+1

1360

+1

1498

52

Page 53

*INSTALLATION*

Installation

Spacer bars – flush-fit

When installing several SmartLine appliances, an additional spacer bar must be

fitted in between the individual appliances.

The clips supplied with the spacer bars are only required for installing a

CSDA700xFL.

Installing 3 appliances and 2 spacer bars

Spacer bars for the downdraft extractor – flush-fit

a

Brackets

53

Page 54

*INSTALLATION*

Installation

Installation dimensions–Flush

All dimensions in this instruction booklet are given in mm.

a

Front

b

Fan (in the plinth on the floor)

c

Stepped cut-out (for detailed

illustrations, see “Installation –

Worktop cut-out – flush-fit”)

54

d

12mm wooden frame (not supplied,

for detailed illustrations, see

“Installation – Worktop cut-out –

flush-fit”)

e

Air duct

f

E-box

Page 55

*INSTALLATION*

Air duct dimensions – flush-fit – worktop depth 600mm

Side view

Installation

a

For maintenance work, it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the exhaust ducting.

b

After installation, the removable moisture collection tray must be accessible

from below.

Two quick-release catches have to be opened to remove the tray.

c

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

d

Plinth fan

55

Page 56

*INSTALLATION*

Installation

Front view

View from above

56

Page 57

*INSTALLATION*

Air duct dimensions – flush-fit – worktop depth greater than

600mm

View from the side – right air duct connection

Installation

a

For maintenance work, it must be possible to remove the rear cabinet wall.

The cabinet wall and an adjoining room wall or a piece of furniture must be at

least 110mm apart to ensure sufficient room for the exhaust ducting.

b

Variable length of middle section

c

After installation, the removable moisture collection tray must be accessible

from below.

Two quick-release catches have to be opened to remove the tray.

d

Duct length must be adapted to the height of the base unit.

Standard delivery 500mm

e

Plinth fan

x Dimension of which the worktop is deeper than 600mm.

57

Page 58

*INSTALLATION*

Installation

View from the front – right air duct connection

View from above – right air duct connection

58

Page 59

*INSTALLATION*

If you want to install the air duct to the left of the downdraft extractor, the

worktop must be at least 665mm deep.

View from the front – left air duct connection

Installation

View from above – left air duct connection

59

Page 60

*INSTALLATION*

Installation

Installation – flush-fit

If the worktop is more than 28mm

deep, it must be cut out underneath

on the building-in side on the right or

left-hand side.

a

Worktop

b

Maximum 24mm

c

12 mm

Securing the bracket

1 bracket (supplied with the spacer bar)

must be secured centrally to the right or

left-hand side of the cut-out.

Wooden worktops

Fit the bracket so that it sits flush

with the top edge of the lower step of

the stepped cut-out.

Secure the bracket with the

3.5x25mm wood screws supplied.

Granite and marble worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

bracket.

60

Stick the tape onto the upper edge of

the lower step of the stepped cut-out.

Fit the bracket so that it sits flush

with the top edge of the lower step of

the stepped cut-out.

Press the bracket firmly into position.

Page 61

*INSTALLATION*

Installation

Preparing the worktop

Create the worktop cut-out.

Remember to maintain the minimum

safety distances (see "Installation –

Safety distances").

Seal the cut surfaces of wooden

worktops with a suitable sealant to

avoid swelling caused by moisture.

The sealant must be heat-resistant.

Make sure the sealant does not

come into contact with the top

surface of the worktop.

For wooden worktops, secure the

wooden frames 5.5mm below the

upper edge of the worktop.

For CS7611FL, the wooden frame

must be secured 7mm under the

upper edge of the worktop.

Fitting the spacer bars

Use the middle screw holes if one of the

following SmartLine appliances is

installed to the right or left of the spacer

bar: CS7611, CS 7641, CS7101(-1),

CS7102(-1)

Wooden worktops

Position the spacer bars flush onto

the lower step of the stepped cut-out.

Secure the spacer bars with the

3.5x25mm wood screws supplied.

Granite and marble worktops

You will need heavy-duty doublesided tape (not supplied) to secure the

spacer bars.

Stick the tape onto the lower step of

the stepped cut-out.

Position the spacer bars flush onto

the lower step of the stepped cut-out.

Press the spacer bars firmly into

place.

61

Page 62

*INSTALLATION*

Installation

Installing the downdraft extractor

The downdraft extractor can be

installed with the connector for the air

duct on either the right or the left-hand

side.

Remove the moisture collection tray

from the casing.

a

Connector for air duct on the right

b

Connector for air duct on the left

Stick the supplied sealing strip under

the edge of the cover. Do not apply

the sealing strip under tension.

Fit the clips onto the spacer bars.

Guide the control cable downwards

between the spacer bars.

Fit the cover onto the spacer bars.

62

Fasten the casing from the inside with

the screws on the right and left

sides (3 in each case).

Fasten the moisture collection tray.

Mount the air duct.

Ensure that the air duct is not under

mechanical tension after installation!

Page 63

*INSTALLATION*

Installation

E-box

a

Mains connection cable

b

Connection to window contact

c

Connection socket for the fan power

cable

d

Connection socket for the fan

control cable

e

Connection socket for the control

unit cable

Connection to window contact, if required

The window contact is

connected to the mains voltage.

Danger of electric shock!

Disconnect the downdraft extractor

from the mains electricity supply

before connecting the switching

system.

The connection cable of the

switching system must only be

connected by a suitably qualified and

competent electrician.

The connection cable of the

switching system must be of the

correct type and cross-sectional area

in strict accordance with current

national and local safety regulations

and must not exceed 2.0m in length.

The switching system must be

equipped with a potential-free

contact suitable for 230V, 1A. The

extractor is switched off when the

switch is open.

Only use suitable switching systems

(e.g. window contact switches,

pressure switches).

The switching system must be

suitable for use with inductive loads

(BLDC motor).

Use switching systems in strict

accordance with current national and

local safety regulations.

63

Page 64

*INSTALLATION*

Installation

Loosen the lug and pull the plug out.

Loosen the strain relief screw and

unlock the casing on both sides.

Open the casing.

Remove the stopper.

Exchange the jumper with the

connection cable of the switching

system.

Close the casing.

Connecting the e-box

Connect the fan power cable and fan

control cable to the e-box and the

fan.

Connect the control unit cable to the

e-box.

The socket positions are designed in

such a way that they cannot be mixed

up.

Connect the downdraft extractor to

the mains electricity supply.

Check that the downdraft extractor

works.

Sealing the gaps

Seal the gaps between the individual

SmartLine appliances, and between

the flush-fit SmartLine appliances

and the worktop, with a silicone

sealant that is heat-resistant to at

least 160°C.

Unsuitable sealant can damage

natural stone.

For natural stone worktops and

natural stone tiles, only use silicone

sealant that is specially formulated

for natural stone.

Please follow the manufacturer's

instructions.

Tighten the strain relief screw.

Reinsert the plug.

64

Page 65

*INSTALLATION*

Installation

Exhaust ducting

Before installation, it is important

to read the following information.

This is particularly crucial when using

the downdraft extractor at the same

time as a heating appliance that

relies on oxygen from the same

room, which could result in the buildup of toxic fumes.

It is particularly important that the

“Warning and Safety instructions”

are observed.

The downdraft extractor should be

installed according to local and

national building regulations. Seek

approval from the building inspector

where necessary.

The downdraft extractor has an exhaust

connection of 222x89mm.

In order to achieve optimum

extraction or recirculation

performance and low noise levels,

Miele recommends the installation of

a modular rectangular ducting system

made from approved non-flammable

materials.

- For the rectangular ducting, Miele

recommends not to exceed a

maximum total ducting length of 5 m,

with a maximum number of three

bends.

- Only use wide radius bends.

- The exhaust ducting must not be

kinked or compressed.

- Ensure that all connections are

strong and airtight.

Remember that any constriction of

the airflow will reduce extraction

performance and increase operating

noise.

To achieve the most efficient air

extraction with the lowest noise

levels, please note the following:

- The cross-section of the exhaust

ducting must not be smaller than the

cross-section of the exhaust

connection (see the appliance

dimensions).

- The exhaust ducting should be as

short and straight as possible.

65

Page 66

*INSTALLATION*

Installation

If the exhaust air is to be ducted into

a flue, the ducting must be directed in

the flow direction of the flue.

If ducting is to be laid horizontally, it

must be laid with a downwards

sloping gradient. This is to ensure

that condensate cannot drain back

into the extractor.

If the vent ducting is to run through

rooms, ceiling space, etc. there may

be great variations in temperature

between the different areas. The

problem of condensation will need to

be addressed. The exhaust ducting

will need to be suitably insulated.

Ensure that the ducting can easily be

disconnected from the exhaust

connection in the event the appliance

needs to be taken out of the worktop

for service purposes.

Stick the supplied sealing strip on the

exhaust connection if the ducting

does not sit securely up against the

exhaust connection.

66

Page 67

*INSTALLATION*

Installation

Electrical connection

We recommend that you connect the

SmartLine appliance to the mains via a

suitable switched electrical socket. This

simplifies servicing. The socket must be

easily accessible after the SmartLine

appliance has been installed.

Danger of injury!

Installation, repairs and other work

by unqualified persons could be

dangerous. Miele cannot be held

liable for unauthorised work.

Miele cannot be held liable for

damage or injury (e.g. electric shock)

caused by the lack of or inadequacy

of an on-site earthing system.

If the plug is removed from the

connection cable or if the cable is

supplied without a plug, the

SmartLine appliance must be

connected to the electricity supply

by a suitably qualified electrician.

If the socket is no longer accessible,

or if a hard-wired connection is

planned, an additional means of

disconnection must be provided for

all poles in accordance with the

wiring rules. Suitable means of

disconnection include switches with

an all-pole contact gap of at least

3mm. These include miniature circuit

breakers, fuses and relays. The

connection data can be found on the

data plate. Please ensure this

information matches the household

mains electricity supply.

After installation, ensure that all

electrical components are shielded

and cannot be accessed by users.

Total power output

See data plate.

Connection data

The connection data is given on the

data plate. Please ensure this

information matches the household

mains supply.

Residual current device

For extra safety, it is advisable to

protect the SmartLine appliance with a

suitable residual current device (RCD)

with a trip range of 30mA.

67

Page 68

*INSTALLATION*

Installation

Replacing the mains connection cable

Danger of electric shock!

Incorrect connection to the electricity

supply may result in an electric

shock.

The mains connection cable must

only be replaced in accordance with

current local and national safety

regulations.

When replacing the mains connection

cable, it must be replaced with cable

type H05VV-F by a Miele authorised

service technician or a suitably qualified

and competent electrician in order to

avoid a hazard. These cables are

available from Miele.

68

Page 69

Page 70

Page 71

Miele Experience Centre and

Head Office Melbourne:

1 Gilbert Park Drive

Knoxfield, VIC 3180

Miele Experience Centre South Melbourne:

206-210 Coventry Street

South Melbourne, VIC 3205

Miele Experience Centre and Office Sydney:

3 Skyline Place

Frenchs Forest, NSW 2086

Miele Experience Centre and Office Brisbane:

Tenancy 4C, 63 Skyring Terrace

Newstead, QLD 4006

Miele Experience Centre and Office Perth:

83-85 Sir Donald Bradman Drive

Hilton, SA 5033

Miele Experience Centre and Office Adelaide:

Miele Australia Pty. Ltd. Miele New Zealand Limited

Level 2, 10 College Hill

Freemans Bay, Auckland 1011

Miele Experience Centre

Auckland:

8 College Hill

Freemans Bay, Auckland 1011

Miele Global Headquarters

Germany

Miele & Cie. KG

Carl-Miele-Straße 29

33332 Gütersloh

Federal Republic of Germany

Head Office:

IRD 98 463 631

ACN 005 635 398

ABN 96 005 635 398

Miele Experience Centre Gold Coast:

131 Ferry Road

Southport, QLD 4215

Miele Experience Centre

Wellington:

183 Featherston Street

Wellington 6011

0800 464 353 (0800 4 MIELE)

www.miele.co.nz

205-207 Stirling Highway

Claremont, WA 6010

1300 464 353 (1300 4 MIELE)

www.miele.com.au

Page 72

CSDA7000 FL

M.-Nr. 11 037 890 / 03en-AU, NZ

Loading...

Loading...