Page 1

Application Bulletin 320 e

Installation Instructions of TitrIC 6

The TitrIC 6 System is used for the fully automatic analysis of water samples using direct measurement,

titration and ion chromatography. The lids of the air protected sample beakers are discovered with the

DIS-COVER function of the 815 and the following parameters are determined in a very short time:

temperature, conductivity, pH, acid capacity and, in parallel, the concentrations of the individual anions

and cations. Further Metrohm instruments can be incorporated in the existing system at any time and

used to determine additional parameters.

Analytical sequence

1. Conductivity is measured in the sample vessel on the sample processor.

2. First sample transfer to the 850 Professional IC for anions and cations.

3. The IC determinations are started automatically.

4. Second sample transfer to the external cell of the 815 Robotic USB Sample Processor XL.

5. Temperature, pH and acid capacity (p and m values) are determined.

The whole procedure is controlled by the TitrIC software: The user enters the sample position and

sample identification, MagIC Net and tiamo

information to tiamo

automatically generates a joint report containing all results. This report can be exported as an Excel file.

TM

TM

and MagIC Net. When the measurement has been concluded, TitrIC

method, after which TitrIC transfers all the relevant

Page 2

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 2/16

Table of contents

1 Delivery package.................................................................................................................................. 3

2 Installation ............................................................................................................................................ 5

2.1 815 Robotic USB Sample Processor XL ....................................................................................... 5

2.2 856 Conductometer (2.856.0010) ................................................................................................. 5

2.3 Titrando (2.905.0010) .................................................................................................................... 5

2.4 Dosino holder (6.2055.100) ........................................................................................................... 5

2.5 850 Professional IC AnCat – MCS (2.850.3030) .......................................................................... 5

3 Cable connections ............................................................................................................................... 6

4 Tubing connections .............................................................................................................................. 7

4.1 External cell ................................................................................................................................... 7

4.2 Installation of the 10 mL and 50 mL Dosing Units ......................................................................... 8

4.3 Overview of all the tubing connections .......................................................................................... 9

5 Miscellaneous .................................................................................................................................... 10

5.1 Membrane Pumps of 815 ............................................................................................................ 10

5.2 Stirrer ........................................................................................................................................... 10

5.3 Length of the aspiration tips in the external cell .......................................................................... 10

5.4 Electrodes .................................................................................................................................... 10

6 Software ............................................................................................................................................. 10

6.1 Installation of the software ........................................................................................................... 10

6.2 Configuration of tiamoTM .............................................................................................................. 11

6.2.1 Devices ................................................................................................................................. 11

6.2.2 Swing Head configuration ..................................................................................................... 11

6.2.3 Special beaker definition ....................................................................................................... 11

6.2.4 Lift positions .......................................................................................................................... 11

6.2.5 Solutions ............................................................................................................................... 12

6.2.6 Electrodes ............................................................................................................................. 12

6.2.7 Methods ................................................................................................................................ 12

6.2.8 Configuration of the export template ..................................................................................... 13

6.3 Configuration of MagIC Net ......................................................................................................... 14

6.3.1 Configuration of the export template ..................................................................................... 14

6.4 Configuration of TitrIC ................................................................................................................. 16

Page 3

Application Bulletin 320 e

1

Installation Instructions of TitrIC 6

Page 3/16

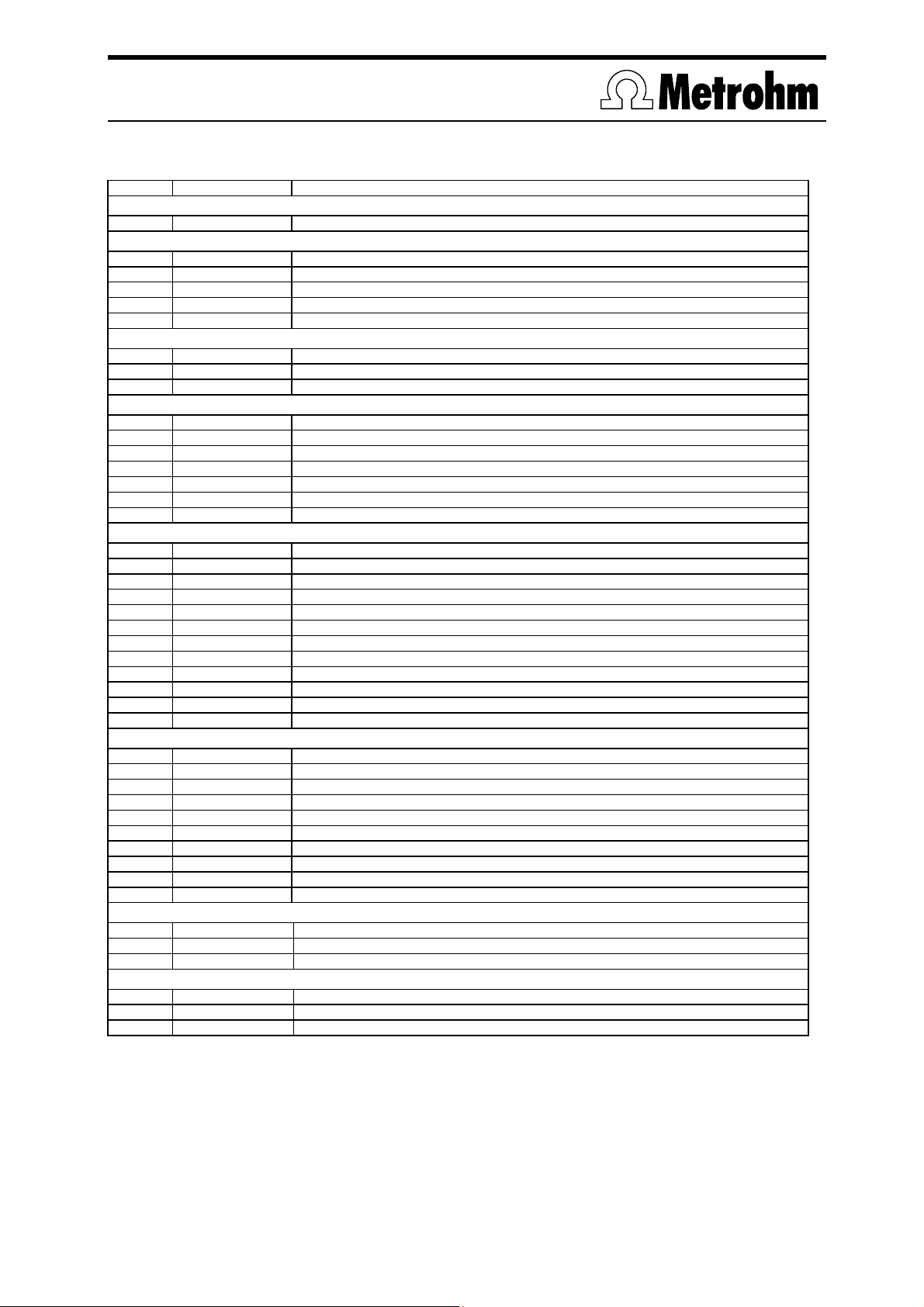

1 Delivery package

- delivered with TitrIC 6 package:

Number Article no. Article designation

IC

1 2.850.3030 850 Professional IC AnCat – MCS

Sample processor

1 2.815.0110 815 Robotic Titrosampler

2 2.786.0040 Swing Head

1 6.1462.050 Titration head

1 6.1462.080 Robotic Arm DIS-COVER

1 6.1808.170 Distributor Rinse/Aspirate

Conductometry

1 2.856.0010 856 Conductometer

1 6.0915.100 Five-ring conductivity measuring cell, c = 0.7 cm

1 6.2151.000 Cable USB A – mini-DIN 8 pins

p and m value titration (pH measurement)

1 2.905.0010 Titrando

1 6.0257.300 iAquatrode; combined pH glass electrode (Pt1000)

1 6.2151.000 Cable USB A – mini-DIN 8P

1 62307100 Pufferlösung pH=4 (500 mL)

1 62307110 Pufferlösung pH=7 (500 mL)

1 62307120 Pufferlösung pH=9 (500 mL)

1 62325000 Phit kit

Liquid Handling

3 2.800.0010 800 Dosino

1 6.3032.210 807 Dosing Unit, glass, 10 mL

1 6.3032.220 807 Dosing Unit, glass, 20 mL

1 6.3032.250 807 Dosing Unit, glass, 50 mL

1 6.2055.100 Dosino holder

2 6.1608.030 Glass bottle GL45 1L (round)

2 6.5620.000 Connecting set for Dosing Unit: Dosino port 4

2 6.2744.080 Coupling M6-UNF 10/32 (Dosing Unit – IC screw)

1 6.2744.070 Pressure screw made of PEEK, short

2 6.1543.080 Aspiration tip 1.5 / 240 mm

1 6.1602.160 Eluent bottle attachment GL45

1 6.1609.000 Absorber tube

External cell

1 2.802.0020 802 Rod Stirrer

1 6.2001.070 Stand support for 804

1 6.1414.060 Titration vessel lid micro

1 6.1415.220 Titration vessel

7 6.2730.030 Stopper with nipple and O-ring

2 6.2730.080 Screw nipple

1 6.2730.020 Septum stopper

1 6.2730.070 Screw nipple M16/8mm

1 6.2730.060 Screw nipple for electrodes

1 6.1543.170 Aspiration tip M8

Connection tubings

1 6.1805.510 Connection tubing FEP, L = 60 cm, 2 x M8 thread

3 6.1805.030 Connection tubing FEP, L = 150 cm, 2 x M6 thread

1 6.1803.020 PTFE capillary, L = 5 m, i.d.= 0.97 mm

Software

1 6.6056.212 TiamoTM 2.1 full

1 6.6059.202 MagIC Net 2.0 Professional CD: 1 License

1 6.6062.000 TitrIC 2.0

-

, with integrated Pt 1000

Page 4

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 4/16

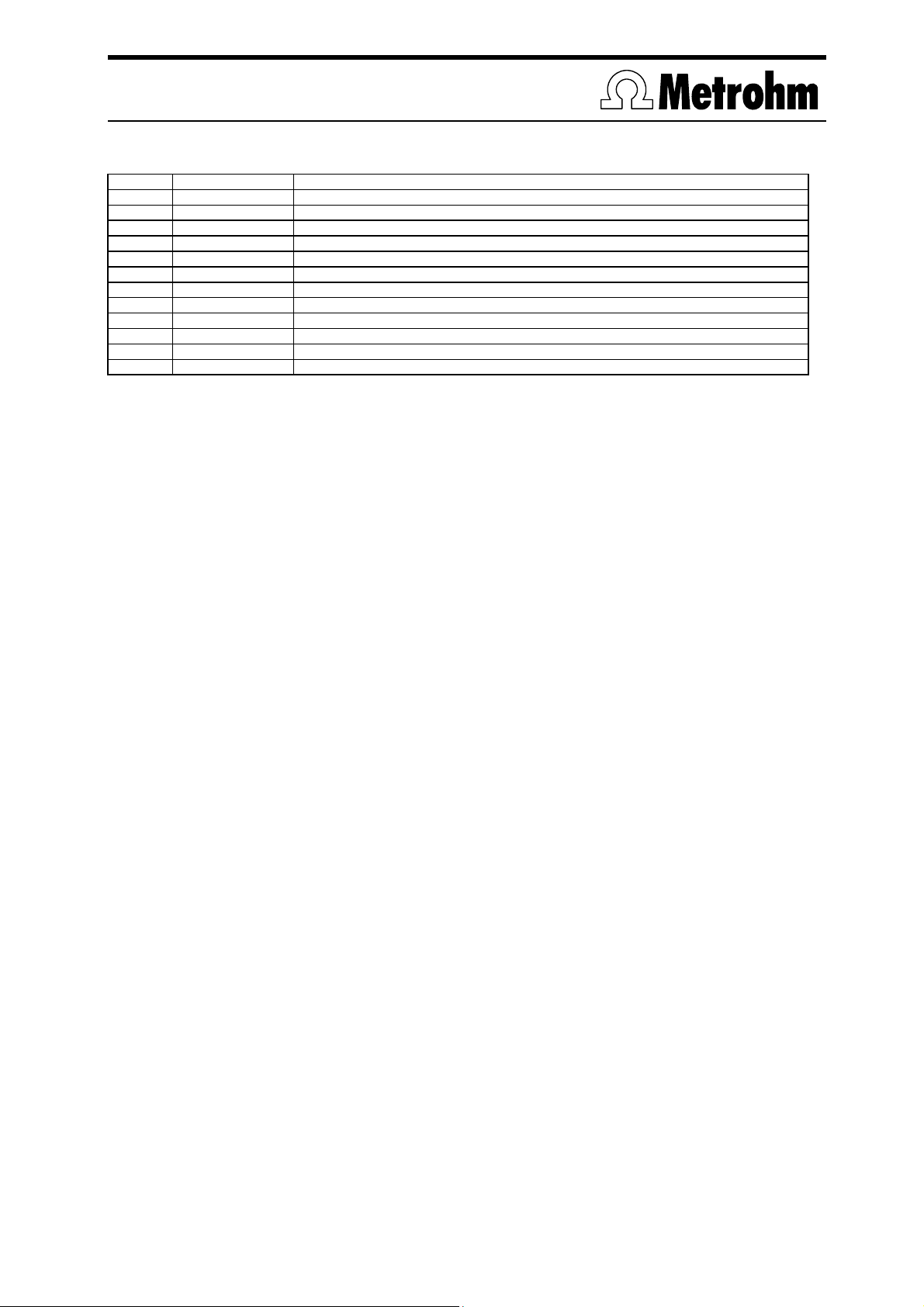

- optional accessories:

1 6.2041.xxx Sample rack made of PVC

1 6.1432.xxx Sample beaker

1 6.1030.xxx Anion column Metrosep A Supp 15

1 6.1030.xxx Guard column Metrosep A Supp 15

1 6.1050.xxx Cation column Metrosep C 4

1 6.1050.xxx Guard column Metrosep C 4

1 6.2323.000 Storage solution

1 6.2308.020 Electrolyte solution (3 mol/L KCl)

1 6.2324.000 Conductivity standard (100 µS/cm)

1 6.2301.060 Conductivity standard (12.88 mS)

1 6.2307.100/110/120 Buffer solutions 500 mL, pH 4 / 7 / 9

1 6.2307.230 Buffer solutions 3 x 10 x 30mL of pH 4 / 7 / 9

1 6.2065.000 Stacking frame for 846 Dosing Interface, 856 Conductivity Module,867 pH Module

Page 5

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 5/16

2 Installation

The following is a detailed description of the TitrIC 6 System's installation.

We strongly recommend that the individual steps are carried out in the order given below!

2.1 815 Robotic USB Sample Processor XL

The sample processor is placed at the side at which it is most easily accessible. Please note that the

following procedure refers exclusively to the version in which the sample processor is located at the lefthand side of the system.

On the right-hand side of the 815 Robotic USB Sample Processor XL, attach the stand

support (6.2001.070) without the horizontal brace to the tower of the 815 (hexagon screw

beneath membrane pump 1). The brace will be installed later.

Mount both Swing Heads (2.786.00 10) onto the 815 (see installation instructions 2.2.7, p 19).

Do not screw the swing arm (6.1462.050) nor the titration arm onto the Swing Head!

The Sample Rack supplied is screwed onto the 815.

In the vicinity of the 815 the two canisters (standard equipment of 815) are placed on the floor:

One 10 L canister is used as a waste container, the second one as a reservoir for deionized

(DI) water used for rinsing the external cell.

From the smaller opening of the canisters containing DI water, an M8 PTFE tubing connection

of suitable length is led to the connection box made of white plastic of membrane pump 1 /

tower 1 and connected.

From the front opening of the waste canister an M8 PTFE tubing connection of suitable length

is led directly to membrane pump 1 / tower 2 (black plastic) and connected.

A more detailed description is given in the instructions for use of the 815 Robotic USB Sample

Processor XL.

2.2 856 Conductometer (2.856.0010)

The 856 Conductometer is placed directly at the right of the sample processor. For detailed information

about the usage check the Instructions of Use of the 856.

Before measurements it is recommended to carry out the calibration of the cell constant in tiamo

further information consult the Installation Instructions of the 856 Conductometer.

TM

. For

2.3 Titrando (2.905.0010)

Directly to the right of the 856 Conductometer, place the Titrando with the two bottles of the titration

solution (0.1 mol/L HCl, at the rear, with 20 mL Dosing Unit and 800 Dosino) and the acidification

solution (0.1 mol/L HNO

, at the front, with eluent bottle attachment).

3

2.4 Dosino holder (6.2055.100)

The Dosino holder (6.2055.100) is placed behind the Titrando and the 856 Conductometer; the 50 mL

(6.3032.250) and 10 mL (6.3032.210) Dosing Units are screwed on to this holder at a later stage.

2.5 850 Professional IC AnCat – MCS (2.850.3030)

Place the 850 Professional IC AnCat - MCS (2.850.3030) to the right of the Titrando. The IC

instruments can already be installed. Please consult the Instructions for Use for the Professional IC

instruments.

Page 6

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 6/16

3 Cable connections

First all the power cables are connected to the instruments. Both the instruments and the PC remain

switched off.

Cable USB A - mini-DIN 8P (6.2151.000) from 856 Conductometer to PC, do not connect!

USB cable (6.2151.000) from 850 Professional IC to PC

USB cable (6.2151.000) from PC to 905 Controller, do not connect!

MSB cable from Dosino 800, 50 mL (anions) to 905 MSB 1, do not connect!

MSB cable from Dosino 800, 10 mL (cations) to 905 MSB 2, do not connect!

MSB cable from Dosino 800, 20 mL (0.1 M HCl) to 905 MSB 3, do not connect!

USB cable (6.2151.000) from 905 to 815 Controller – supplied with 815, do not connect!

Page 7

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 7/16

4 Tubing connections

4.1 External cell

The numbers given here (

In the next step the external cell is prepared. The following components are inserted in the titration

vessel lid (6.1414.060):

The small 6.2730.030 stoppers (with the black rubber ring) are screwed loosely into openings 1, 2, 3, 5

and 7 and fixed in position when the buret tips, etc. are inserted.

The large 6.2730.080 stoppers are screwed into openings 4 and 8 and the screw nipple (6.2730.070)

into opening 9.

The titration vessel lid is attached to the stand support (6.2001.070) using opening 10. It is fixed at the

required height with the clamping ring and the horizontal brace of the stand support is mounted on the

815 with the socket head screw.

6.2730.070

screw nipple

) and «opening 1,...» refer to the drawing below.

,…

6.2730.030

stopper

8

10

6.2730.080

screw nipple

1

2

3

9

4

7

5

6

6.2740.020

rinsing nozzle

Numbers and connections on the titration vessel lid (6.1414.060)

The PTFE aspiration tip (6.1543.170, M8) is inserted in opening 1 and connected to

membrane pump 1 / tower 2 of the 815 with the M8-PTFE-tubing connection (6.1805.510).

The rinsing nozzle (6.2740.020, supplied with 815) is inserted into opening 2, which is

connected to membrane pump 1 / tower 1 of the 815 with the FEP-tubing connection

(6.1805.060, supplied with 815).

The buret tip (6.1543.200) is inserted through opening 3 and connected to port 1 of the 20 mL

Dosing Unit (0.1 mol/L HCl) with the FEP-tubing connection (6.1805.100, supplied with 807).

This is where the pH electrode will later be inserted.

The rinsing nozzle (6.2740.020, supplied with 815) is inserted into opening 5, which is

connected to membrane pump 1 / tower 1 of the 815 with the FEP-tubing connection

(6.1805.060).

The septum stopper (6.2730.020) is placed into opening 6.

The rinsing nozzle (6.2740.020, supplied with 815) is inserted into opening 7, which is

connected to membrane pump 1 / tower 1 of the 815 with the FEP-tubing connection

(6.1805.060).

This is where the 802 Rod Stirrer will be inserted.

6.2730.020

septum stopper

Page 8

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 8/16

After the screw nipple (6.2730.070) has been screwed into opening 9, the aspiration tip

(6.1543.100) is pushed through it. An FEP-tubing connection (6.1805.060, supplied with 815)

will be connected to the connection set of Dosing Unit port 4 of the 50 mL Dosing Unit.

4.2 Installation of the 10 mL and 50 mL Dosing Units

6.5620.000

Luer: Port 4

Port 3

6.1805.030

6.2744.070

Port 1

M6: Port 2

6.2744.080

6.1803.020

6.1805.110

Connections on the bottoms of the 10 mL and 50 mL Dosing Units

Port 1 is used for emptying the Dosing Units into the wa ste canister.

Port 2 is used by the 50 mL and 10 mL Dosing Unit for aspirating the sample via the titration

arm.

Port 3 is used for sample transfer to the IC system. The transition from M6 to the IC screw size

(1/16 in.) is achieved with the 6.2744.080 adapter.

Port 4 is used for the 50 mL and 10 mL Dosing Unit. This requires a coupling between Luer and

M6: The PEEK connection (6.5620.000) is attached to the Luer connection on the bottom of the

Dosing Unit. With the 50 mL Dosing Unit this port is used to realize «liquid handling» to the

external cell; in contrast to the 10 mL Dosing Unit it is used to aspirate the nitric acid for

acidification.

Once the tubing connections have been made, the Dosing Units are attached to the Dosino holder

(6.2055.100) with the screw attachment and the distance ring of the Connecting Set for Dosing Unit

(6.5620.000).

Page 9

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 9/16

4.3 Overview of all the tubing connections

The three 60 cm FEP-tubing connections (6.1850.060, supplied with 815) are used to connect

membrane pump 1 / tower 1 of the 815 and the three rinsing nozzles (6.2740.020, supplied with

815) to openings 2, 5 and 7 of the external cell (see page 7 and 11, chapter 5.1).

The 60 cm M8-PTFE-tubing connection (6.1805.510) is used to connect membrane pump 1 /

tower 2 of the 815 and the M8-PTFE-aspiration tip (6.1543.170) to opening 1 of the external cell

(see page 7 and 11, chapter 5.1).

The two buret tips (6.1543.080) are each attached by a stopper (6.2730.030) to the titration head

(6.1462.070).

The two 80-cm-FEP-tubing connections (6.1850.110) are used to connect the buret tips

(6.1543.200) at the titration head (6.1462.070) and port 2 of the 10 mL and 50 mL Dosing Units.

The 60-cm-FEP-tubing connection (6.1850.060) is used to connect port 4 of 50 mL Dosing Unit

and opening 9 of the external cell (see page 7).

The 40-cm-FEP-tubing connection (6.1850.100, supplied with 807) is used to connect port 4 of

the 10 mL Dosing Unit and the M6 opening of the eluent bottle attachment (6.1602.160); the FEP

aspiration tubing (6.1829.010, supplied with 807) should previously be inserted. The absorber

tube (6.1609.000) is filled as usual with lime and cotton wool and inserted into the opening

provided for it in the eluent bottle attachment in order to protect the nitric acid from CO

2

.

The 40-cm-FEP-tubing connection (6.1850.100, supplied with 807) is used to connect port 1 of

the 20 mL Dosing Unit and the buret tip in opening 3 of the external cell (see page 7).

The three 150-cm-FEP-tubing connections (6.1805.030) are connected to port 1 of the 10 mL

and the 50 mL Dosing Units, as well as port 3 of the 20 mL Dosing Unit; all three tubing

connections are then connected to the 10 L PE waste canister (6.1621.000).

Suitable lengths of the 0.97 mm PTFE capillary (6.1803.020, supplied with 850) are used to

connect port 3 of the 10 mL and the 50 mL Dosing Units (using the screws 6.2744.080 and

6.2744.070) and the injection valves of the 850 Professional IC instrument. The 10 mL Dosing

Unit must be connected to the valve for cations and the 50 mL Dosing Unit to the valve for

anions.

Page 10

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 10/16

5 Miscellaneous

5.1 Membrane Pumps of 815

The membrane pump at tower 1 is used to supply the DI water for rinsing of the external vessel, the

membrane pump at tower 2 is used to empty the external vessel.

Therefore, dismount the Distributor Rinse/Aspirate of tower 1 and mount the new one (6.1808.170).

This enables to connect the lower part of membrane pump at tower 2 to the left connector of the

Distributor leading to the M8 aspiration tip to empty the external vessel. The upper part of the

membrane pump is connected to the waste canister (see page 6).

The upper part of membrane pump at tower 1 is connected to the right connector of the Distributor

leading to the three M6 rinsing nozzles to rinse the external vessel. The lower part of the membrane

pump is connected to the DI-water canister.

5.2 Stirrer

The 802 Rod Stirrer is inserted through opening 8 of the external cell, and connected to the tower 1 of

the 815. The propeller (6.1909020) is pushed on from below.

5.3 Length of the aspiration tips in the external cell

Clamp the titration vessel to the titration vessel lid.

The M8 aspiration tip in opening 1 must reach right to the base of the titration vessel, as this is

the only way to ensure that the external cell is cleaned properly.

The buret tips in openings 3 and 4 should rea ch the middle of the titration vessel.

5.4 Electrodes

The pH electrode (Aquatrode Plus with Pt 1000; 6.0257.000) is inserted into opening 4 together

with the SGJ sleeve (6.1236.050). The cable is connected to the 815 Robotic Sample

Processor at the rear top right. The plug of the gray cable is connected to the opening marked

Ind.. The red plugs with the adapters 6.2103.140 and 6.2103.130 (supplied with 905) are

inserted in the openings marked

If the electrode is not used for some time then it should be returned to its holder and kept in the

storage solution (6.2323.000).

Conductivity cell (6.0915.100): The measuring cell cable is led through the guide chain of the

815 and the plug is inserted into the opening marked

(as soon as the titration head has been mounted) the measuring cell with the SGJ sleeve

(6.1236.050) will be inserted in the SGJ 14 opening of the titration head.

Temp.

Cond. Cell of the 856 Conductometer. Later

6 Software

6.1 Installation of the software

tiamoTM 2.1 – installation (tiamoTM CD): All the standard directories proposed by the program

should be accepted.

MagIC Net 2.0 – installation (MagIC Net CD): All the standard directories proposed by the

program should be accepted. Restart windows.

TitrIC 2.0 – installation (TitrIC CD): TitrIC 2.0 must only be installed after tiamo

MagIC Net 2.0 have already been installed. After installation the standard TitrIC directory can

be found under

files\Metrohm\tiamo\bin

Users\ApplicationData\TitrIC.

Æ All programs should be closed!

C:\Program files\ Metrohm\TitrIC, the TitrIC.exe file under C:\Program

. The TitrIC database and reports are found on C:\Documents and Settings\All

TM

2.1 and

Page 11

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 11/16

6.2 Configuration of tiamoTM

Æ The Controller cable (6.2151.000), which is already connected to the 815, is now connected to an

USB interface on the PC. Wait a few seconds. The driver installation for 905 and 815 follows. It’s not

necessary to start windows update, click on

Æ The controller cable (6.2151.000), which is already connected to the 856 conductivity module, is now

connected to an USB interface on the PC

automatic installation of the software for both.

Æ tiamo

TM

2.1 is started

6.2.1 Devices

Connected USB devices are automatically recognized when tiamoTM is started. After confirmation of the

automatically generated request the devices are stored in the configuration. Keep the proposed device

names.

6.2.2 Swing Head configuration

Under Configuration at the top left, double-click on 815_1 under Devices, click on the entry Tower 1 and

afterwards on

click on Configuration and Yes and then enter the following values:

Head

Configuration of the Swing Head at tower 1 Configuration of the Swing Head at tower 2

Tower 2, set the Axial distance to 196.0 mm and in the middle of the window under Swing

Confirm the entries twice with <

OK> and then mark 815_1 under Devices and click on Edit / Initialize. Wait a

few seconds. The titration arm (6.1462.050) is now mounted onto the Swing Head at tower 1, the DISCOVER arm (6.1462.080) onto the Swing Head at tower 2 and is connected to

Ext. Pump 2 of tower 2.

6.2.3 Special beaker definition

Under Configuration mark 815_1, select Edit / Properties / Rack / Rack data / Special beaker, Special beaker 1, click

Edit and define the position to be used for rinsing as Rack position. The last position is normally used

on

as the rinsing position. A sample vessel containing DI water should always stand in this position.

Confirm by clicking on

<OK> twice. No cap should be put on the DI water in the provided methods.

6.2.4 Lift positions

Under Configuration / Tools / Manual operation click on 815 Sample Changer / Tower 1 in the left-hand column

and use the entries

define suitable values (click on

Shift position for changing the rack position (approx. 53 mm)

Work position for aspirating of the sample (approx. 173 mm)

Special position for dipping for the conductivity measurement (approx. 130 mm)

For the special position, you must define the work position again, then at the right beside

click on

Tower and select Special position 1.

Please repeat these steps to define the settings for tower 2.

Move and Assign position (See 815 Instructions for Use, chapter 2.4.6, page 47) to

<Assign> each time) for:

Work position

Page 12

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 12/16

6.2.5 Solutions

The solutions to be used must, as usual, be defined in tiamoTM. Connect the Dosino of the 50 mL

Dosing unit to MSB 1 of the 905, the Dosino of the 10 mL Dosing unit to MSB 2 and the Dosino of the

20 mL Dosing unit to MSB 3. The user is automatically requested to save the solutions – click on

In order to ensure compatibility with the methods provided, they must be named as described below.

<Yes>.

At the left click on

appropriate (empty) entries and enter the following under

Configuration, then at the top right under Titrants/Solutions double-click on the

Solution name and Concentration:

Configuration table for titrants/solutions

Now the tubing lengths and ports are defined for each Dosing unit under

Edit/Properties…/ Dosing unit as

follows:

Anion Cation HCl

Dosing Port

Prep/Empty Special Port - Dosing Port 1 - Dosing Port 1 Dosing Port 1 Port 4 60 cm Port 1 60 cm Port 1 40 cm

Dosing Port 2 Port 3 0 cm Port 3 0 cm Port 3 0 cm

Fill Port Port 2 80 cm Port 2 80 cm Port 2 25 cm

Special Port Port 1 0 cm Port 4 40 cm Port 4 0 cm

Port Length Port Length Port Length

Configuration table of the three dosing units

6.2.6 Electrodes

pH electrode: Under Configuration/Sensors click on Edit/New/pH electrode and enter under Sensor

name Aquatrode Plus

<Ok>.

Conductivity sensor: Under

Sensor name Conductivity sensor type in the desired sensor information and click on <Ok>.

, type in the desired sensor information (e.g. serial number) and click on

Configuration/Sensors click on Edit/New/other sensor and enter under

6.2.7 Methods

The following seven methods are provided:

TitrIC 6 - complete run: With this method all the available parameters are measured and the IC

measurement is initiated.

TitrIC 6 - preparation of titration equipment: This method is used for preparing all titration instruments,

i.e., rinsing the tubing connections of the Dosing Units with reagents or deionized water and

rinsing the external cell. Start this method only from tiamo

TitrIC 6 - IC calibration - anion & cation: This method is used for calibrating the IC measurements

with standard solutions without the titration part of a typical TitrIC measurement; this means that

a lot of standard solution can be saved.

TitrIC 6 – manual pH calibration: Here the Aquatrode is taken out of the titration vessel and placed

into the buffer solutions. Start this method only from tiamo

TitrIC 6 – semi automated pH calibration: With this method the pH electrode is calibrated

automatically; the buffer solutions are flushed into the titration vessel. Start this method only

from tiamo

TM

– not from TitrIC!

TM

– not from TitrIC!

TM

!

Page 13

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 13/16

TitrIC 6 - titer determination: This method is used for the titer determination. Start this method only

from tiamo

TitrIC Calibrate 856 conductivity module This method is used for calibration of the conductivity

module. Start this method only from tiamo

TM

!

TM

!

Import: Click on

following directory on the CD you will find all methods:

Method at the left, then select under File / Method manager… / Edit / Import… in the

\Methods\Titration.

Note!

Alterations of these methods should only be carried out by a person at the administrator level

and who is thoroughly familiar with tiamoTM. Never forget that in TitrIC this new method must

be selected in the sample table under Methods tiamo.

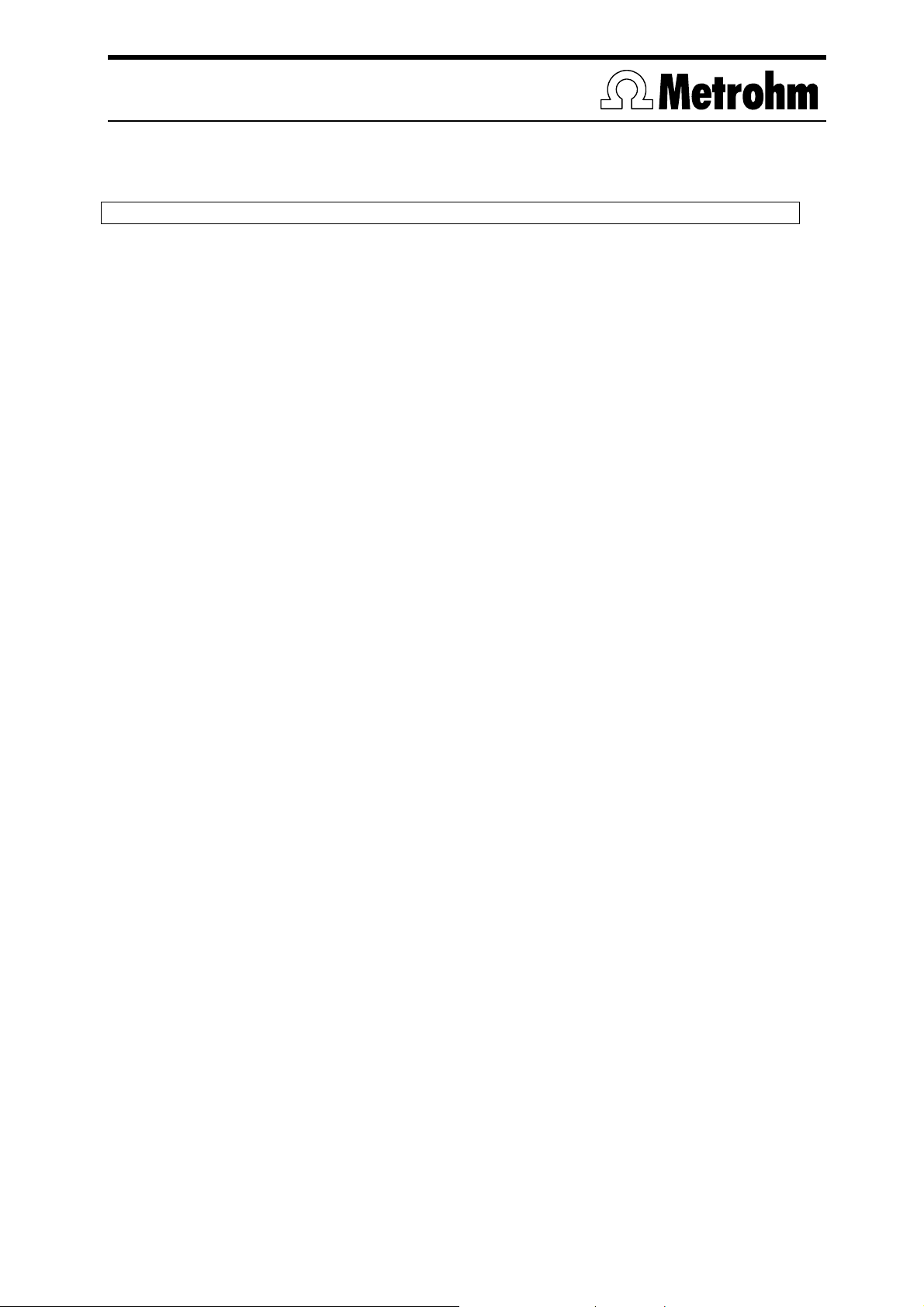

6.2.8 Configuration of the export template

Export template: tiamoTM must transfer its results to TitrIC in a particular way, which means that the

export template must be generated exactly in the following form:

Under

Database / Tools / Templates / Export templates / New enter the following:

Configuration of the export template in TitrIC

The target directory for the report is as following:

Windows 2000, Windows XP:

Vista, Windows 7:

C:\Dokumente und Einstellungen\All Users\Application Data\Titric\reports

C:\ProgramData\Titric\reports

In Windows Vista and Windows 7 hidden folders need to be made visible in the explorer to get access.

Then click on

Select fields and enter the following:

Page 14

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 14/16

Input window for the export template

The entry

are obtained at the left by clicking on

Start counter is obtained at the left by clicking on Determination/Identification, ID1.Name and ID1.value

Sample / Identifications, RS0x by clicking on Results / RS0xxx. By

clicking on the upper double arrow in the center, the entries can be moved to the right. Of course

another number of results than six is possible.

Æ Shut down tiamoTM 2.1 !

6.3 Configuration of MagIC Net

Æ Start MagIC Net 2.0

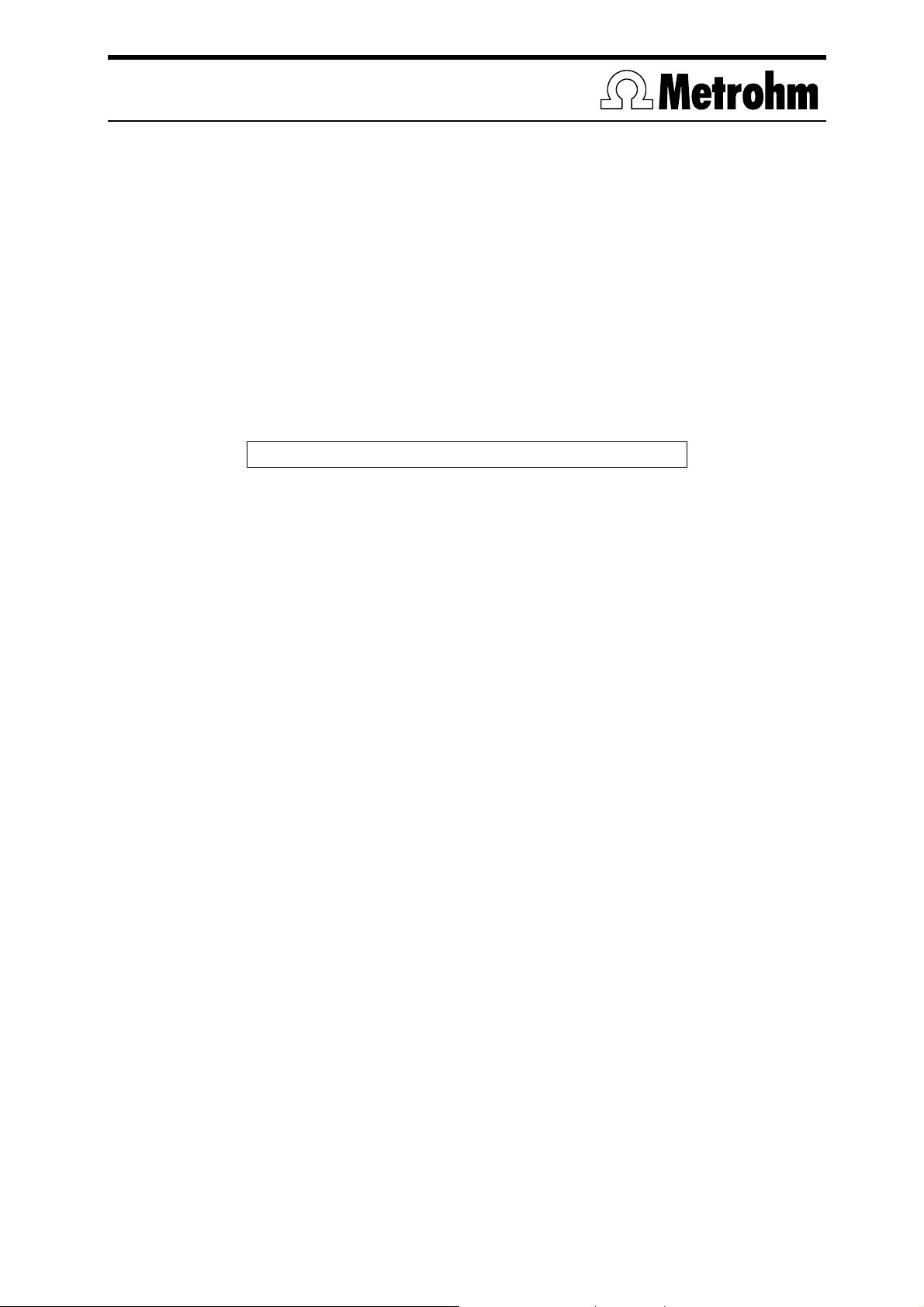

6.3.1 Configuration of the export template

Export template: MagIC Net must transfer its results to TitrIC in a particular way, which means that the

export template must be generated exactly in the following form:

Under

Database / Tools / Templates / Export templates / New enter the following:

Configuration of the export template in MagIC Net

Page 15

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 15/16

The target directory for the report is as following:

Windows 2000, Windows XP:

Vista, Windows 7:

C:\Dokumente und Einstellungen\All Users\Application Data\Titric\reports

C:\ProgramData\Titric\reports

In Windows Vista and Windows 7 hidden folders need to be made visible in the explorer to get access.

Then click on

Select fields and enter the following:

Input window for the export template

The entry

the left by clicking on

obtained at the left by clicking on

Start counter is obtained at the left by clicking on Determination/Identification, Info 1 is obtained at

Sample / Identifications and Ident by clicking on Sample / Sample Data. Results are

Results. By clicking on the upper double arrow in the center, the entries

can be moved to the right. Of course another number of results than six is possible.

On the CD under

\Methods\IC the TitrIC software contains predefined IC methods. Import the

TitrIC 4 method into MagIC Net. Herefore, go to the Method section on the left and follow the

path File/Method manager to choose Edit and Import.

The suppressor step is not made at the start of the measurement in the usual way, but with

<Fill> directly after the end of the chromatogram. This means that after long pauses between

measurements, the suppression may no longer function. This is why after longer pauses you

should carry out a suppressor step manually and ensure that the injection valve is in the <Fill>

position.

Depending on the application and column it may be necessary to adapt the time program in the

IC system: <Inject> should always be carried out right at the start of the time program, <Fill>

right at the end. In this way you can start to measure with a stable baseline immediately after

the sample loop has been filled by the Dosinos.

If a calibration is carried out later and the new calibration data are to be applied to a sample that

has already been measured, then please refer to the online help of the TitrIC software under

Database / Recalculate / Recalculate for the results of several samples.

Æ Shut down IC MagIC Net 2.0

Page 16

Application Bulletin 320 e

Installation Instructions of TitrIC 6

Page 16/16

6.4 Configuration of TitrIC

Æ TitrIC is started (MagIC Net and tiamoTM are started automatically after each other)

All paths have already been entered as defaults and the system is ready for work. If other paths

are used instead of the default paths, then this must be altered in the corresponding dialog

Workplace / Settings / ….

under

TitrIC starts first MagIC Net and afterwa r ds tiamo

If TitrIC is shut down then tiamo

TM

will also be shut down automatically. MagIC Net will ask you

if you want to shut down all devices.

TM

.

For further information please consult the TitrIC online help (

Metrohm agency. You can also report your problems to the following support email:

titric@metrohm.com.

Always start and shut down TitrIC first!

? / Show Help) or contact your local

Loading...

Loading...