Page 1

Page 2

IMPORTANT SAFETY INSTRUCTIONS

THESE INSTRUCTIONS ARE TO PROTECT YOU AND THE MclNTOSH INSTRUMENT. BE SURE TO FAMILIARIZE

YOURSELF WITH THEM.

1. Read all instructions - Read the safety and

operating instructions before operating the

instrument.

2. Retain Instructions - Retain the safety and

operating instructions for future reference.

3. Heed warnings - Adhere to warnings and

operating instructions.

4. Follow Instructions - Follow all operating and use

instructions.

WARNING: TO REDUCE RISK OF FIRE OR

ELECTRICAL SHOCK, DO NOT EXPOSE THIS

INSTRUMENT TO RAIN OR MOISTURE.

5. Power Sources - Connect the power supply only to

the type described in the operating instructions or

as marked on the unit.

6. Power-Cord Protection - Route power-supply cords

so that they are not likely to be walked on or

pinched by items placed upon or against them,

paying particular attention to cords at plugs,

convenience receptacles, and the point where they

exit from the instrument.

7. Ventilation - Locate the instrument for proper

ventilation. For example, the instrument should

not be placed on a bed, sofa, rug, or similar

surface that may block ventilation openings; or,

placed in a built-in installation, such as a bookcase

or cabinet, that may impede the flow of air

through the ventilation openings.

8. Heat - Locate the instrument away from heat

sources such as radiators, heat registers, stoves, or

other appliance (including amplifiers) that produce

heat.

9. Wall or Cabinet Mounting - Mount the instrument

in a wall or cabinet only as described in the

owners manual.

10. Water and Moisture - Do not use the instrument

near water - for example, near a bathtub,

washbowl, kitchen sink, laundry tub, in a wet

basement, or near a swimming pool, etc.

11. Cleaning - Clean the instrument by dusting with a

dry cloth. Clean the panel with a cloth moistened

with a window cleaner.

12. Object and Liquid Entry - Do not permit objects to

fall and liquids to spill into the instrument through

enclosure openings.

13. Power Lines - Locate any outdoor antenna away

from power lines.

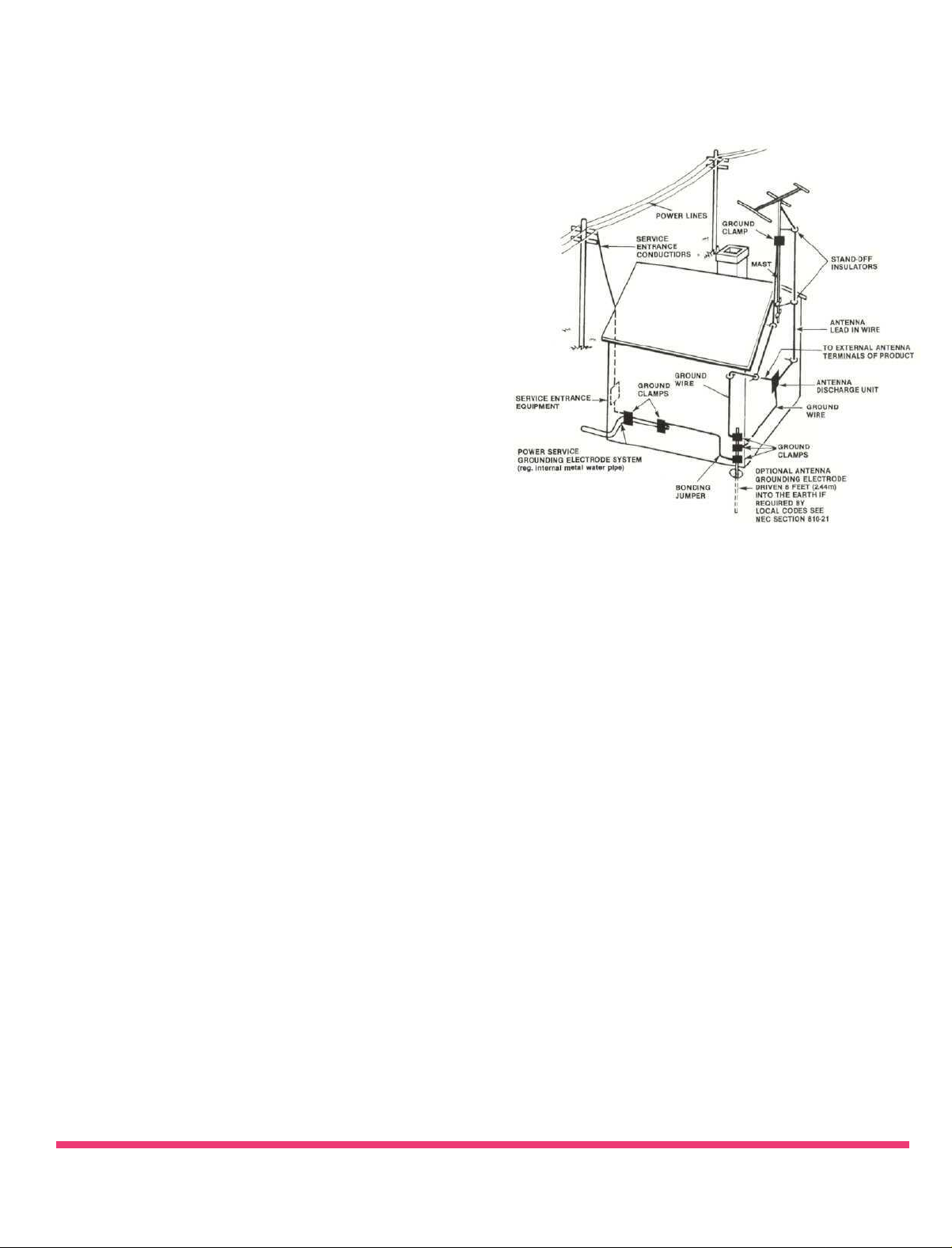

14. Outdoor Antenna Grounding - If an outdoor

antenna is connected to the antenna terminal, be

sure the antenna system is grounded to provide

some protection against voltage surges and built

up static charge.

In the U.S.A., section 810 of the National Electrical

Code, ANSI/NFPA No. 70-1987, provides

information on the proper ground for the mast

and supporting structure, ground for the lead-in

wire to an antenna discharge unit, and size of

ground conductors, location of antenna-discharge

unit, connection to grounding electrodes, and

requirements for the grounding electrode.

For ground wire:

a) Use No. 10 AWG (5.3 mm2) copper No. 8 AWG

(8.4 mm2) aluminum, No. 17 AWG (1.0 mm2)

copper-clad steel, bronze wire, or larger as ground

wire.

b) Secure antenna lead-in and ground wires to

house with stand-off insulators spaced from 4 feet

(1.22 meters) to 6 feet (1.83 meters) apart.

c) Mount antenna discharge unit as closely as

possible to where lead-in enters house.

d) Use jumper wire not smaller than No. 6 AWG

(13.3 mm2) copper or equivalent when separate

antenna grounding electrode is used.

Page 3

15. Nonuse Periods - Unplug the power cord from the

AC power outlet when left unused for a long

period of time.

16. Damage Requiring Service - Service must be

performed by qualified service personnel when:

A. The power supply cord or the plug has been

damaged; or

B. Objects have fallen, or liquid has been spilled

into the instrument; or

C. The instrument has been exposed to rain; or

D. The instrument does not appear to operate

normally or exhibits a marked change in

performance; or

E. The instrument has been dropped, or the

enclosure damaged.

17. Servicing - Do not attempt to service beyond that

described in the operating instructions. All other

service should be referred to qualified service

personnel.

18. Grounding or Polarization - Do not defeat the

inherent design features of the polarized plug.

Non-polarized line cord adaptors will defeat the

safety provided by the polarized AC plug.

19. CAUTION: TO PREVENT ELECTICAL SHOCK DO

NOT USE THIS (POLARIZED) PLUG WITH AN

EXTENSION CORD, RECEPTACLE OR OTHER

OUTLET UNLESS THE BLADES CAN BE FULLY

INSERTED TO PREVENT BLADE EXPOSURE.

Note to CATV system installer:

This reminder is provided to call the CATV system

installer's attention to Article 820-22 of the NEC

that provides guidelines for proper grounding

and, in particular, specifies that the cable ground

shall be connected to the grounding system of

the building, as close to the point of cable entry

as practical.

ATTENTION; POUR PREVENIR LES CHOCS

ELECTRIQUES PAS UTILISER CETTE FICHE

POLARISEE AVEC UN PROLONGATEUR, UNE PRISE

DE COURANT OU UNE AUTRE SORTIE DE

COURANT, SAUF SI LES LAMES PEUVENT ETRE

INSEREES A FOND

PARTIE A DECOUVERT.

SANS

EN

LAISSER

AUCUNE

The lightning flash with arrowhead, within an

equilateral triangle, is intended to alert the user to

the presence of uninsulated "dangerous voltage"

within the product's enclosure that may be of

sufficient magnitude to constitute a risk of electric

shock to persons.

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION: TO PREVENT THE RISK OF ELECTRIC

SHOCK, DO NOT REMOVE COVER (OR BACK). NO

USER-SERVICABLE PARTS INSIDE. REFER SERVICING

TO QUALIFIED PERSONNEL.

The exclamation point within an equilateral triangle

is intended to alert the user to the presence of

important operating and maintenance (servicing)

instructions in the literature accompanying the

appliance.

The serial number, purchase date, and Mclntosh

Laboratory Service Contract number are important to

you for possible insurance claim or future service.

Record this information here.

Serial Number

Purchase Date

Service Contract Number

Upon application, Mclntosh Laboratory

provides a Service Contract to the original

purchaser. Your Mclntosh Authorized

Service Agency can expedite repairs when

you provide the Service Contract with the

instrument for repair.

Copyright 1989 © by Mclntosh Laboratory Inc.

Page 4

Contents

INTRODUCTION 3

INSTALLATION 4, 5

HOW TO CONNECT 6

FRONT PANEL

CONTROLS 7, 8

OPERATION 9, 10, 11,

HELPFUL HINTS 14, 15

PERFORMANCE DATA 16

Take Advantage of 3 Years of

Contract Service. . .

Fill in the Application NOW.

12, 13

Your MCD 7007 Compact Disc Player will give you

many years of satisfactory performance. If you have

any questions, please contact,

CUSTOMER SERVICE

Mclntosh Laboratory Inc.

2 Chambers Street

Binghamton, New York 13903-9990

Phone: 607-723-3512

MclNTOSH THREE YEAR SERVICE CONTRACT

An

application

The terms of the contract are:

1. If the instrument covered by this contract

becomes defective, Mclntosh will provide all parts,

materials, and labor needed to return the

measured performance of the instrument to the

original performance limits free of any charge. The

service contract does not cover any shipping costs

to and from the authorized service agency or the

factory.

2. Any Mclntosh authorized service agency will

repair all Mclntosh instruments at normal service

rates. To receive the free service under the terms

of the service contract, the service contract certificate must accompany the instrument when

taken to the service agency.

3. Always have service done by a Mclntosh

authorized service agency. If the instrument is

for A

THREE YEAR SERVICE

CONTRACT

4. The service contract is issued to you as the

5. Units in operation outside the United States and

is

included

modified or damaged as a result of unauthorized

repair the service contract will be cancelled.

Damage by improper use or mishandling is not

covered by the service contract.

original purchaser. To protect you from

misrepresentation this contract cannot be

transferred to a second owner.

Canada are not covered by the Mclntosh Factory

Service Contract, irrespective of the place of

purchase. Nor are units acquired outside the USA

and Canada, the purchasers of which should

consult with their dealer to ascertain what, if any,

service contract or warranty may be available

locally.

with

this manual.

2

Page 5

The third generation Compact Disc player

continues the world-wide Mclntosh reputation for

technological advancement as the reason for a new

model. Every aspect of performance is improved:

focusing and tracking, decoding, error correction,

digital filtering, digital to analog conversion

(converters are specially selected for matched

channel to channel linearity.)

The MCD7007 uses a new integral massive cast

disc drive platform whose variable reluctance

suspension system is adjusted and tuned to reduce

or eliminate both high and low frequency

resonances, and the impact of vibrations and shock.

There is a low mass, low inertia, high compliance

single beam laser pen. The laser pen assembly

achieves exceptional radial trackability through a

sub-miniature, resonance damped, precisely balanced

rigid system design.

The single-spot laser - which was already

recognized for its readout purity - stays even more

precisely on track and in focus, and the digital signal

that is read out is processed even more truthfully.

Even in the face of disc eccentricity and warp and of

disc defects or dirt that would interrupt play in the

majority of players, the sound of the Mclntosh

MCD 7007 Compact Disc player sets superlative

standards of purity.

The focus and collimator lenses, the receiver and

transmitter faces employ flat glass replica technology.

• The motorized front-loading tray is a new anti-

jamming design protected from damage by forced

closure. If forced, it will close directly to play the

disc or to stand by for additional instruction.

• The 10 key access pad permits direct access to

the track desired, any sequence of selected tracks,

preprogramming by track, index time or combination

of these:

1. Button programming in any order of up to

twenty tracks.

2. Programability directy from a short scan of each

track.

3. Three speed search forward or backward with

the sound muted only in the high speed mode

in either direction.

The full 18-bit dynamic range is derived from

matched linear input to output dual 16-bit digital to

analog converters with 4-times oversampling.

A large FIFO memory can adsorb any data stream

fluctuations with adaptive error corrections which

can handle bursts to 15 audio frames.

The single DAC chip - specifically selected for high

performance - incorporates separate 16-bit converters

for left and right channels. There is no multiplexing,

no delay time between channels, and an extra 4 dB

of channel separation.

Both high-precision servos are integrated to a

higher degree than ever, embodying many functions

that have to be performed with discreet components

in other players. For these functions, there is no

wear, no deterioration with time no setting-up

adjustment to go wrong. Thus a permanent

improvement in readout accuracy is achieved.

Enhanced performance Cross Interleave Reed

Solomon Code (CIRC) provides maximum error

detection and correction. Error correction has soft

muting reinforced with enhanced error concealment

of up to 8 uncorrectable samples.

Volume can be controlled from either the hand

held remote or the front panel buttons.

With the MCD7007 Mclntosh Compact Disc Player

performance moves to a new pinnacle of cutting

edge technological achievement and highest quality

music reproduction. Even with dirty or damaged

discs, even when the player is bumped or knocked,

the music retains its surpassing purity. The full

integrity of the sound is preserved beginning with

the readout from the compact disc through to the

gold-plated connectors on the output.

Your selection of the MCD7007 will be continously

strenghtened by your day to day use of this superb

instrument. Happy listening.

INTRODUCTION 3

Page 6

PLAYER LOCATION

The MCD 7007 may be installed in a Mclntosh

cabinet or custom installed in furniture of your

choice. Always provide adequate ventilation. Never

place it above heat generating components such as

high powered amplifiers. Provide 1½ inches (3 cm) of

space above the player to maintain with a cooling air

flow. Always use the compact disc player horizontally, out of direct sunlight and away from other heat

sources.

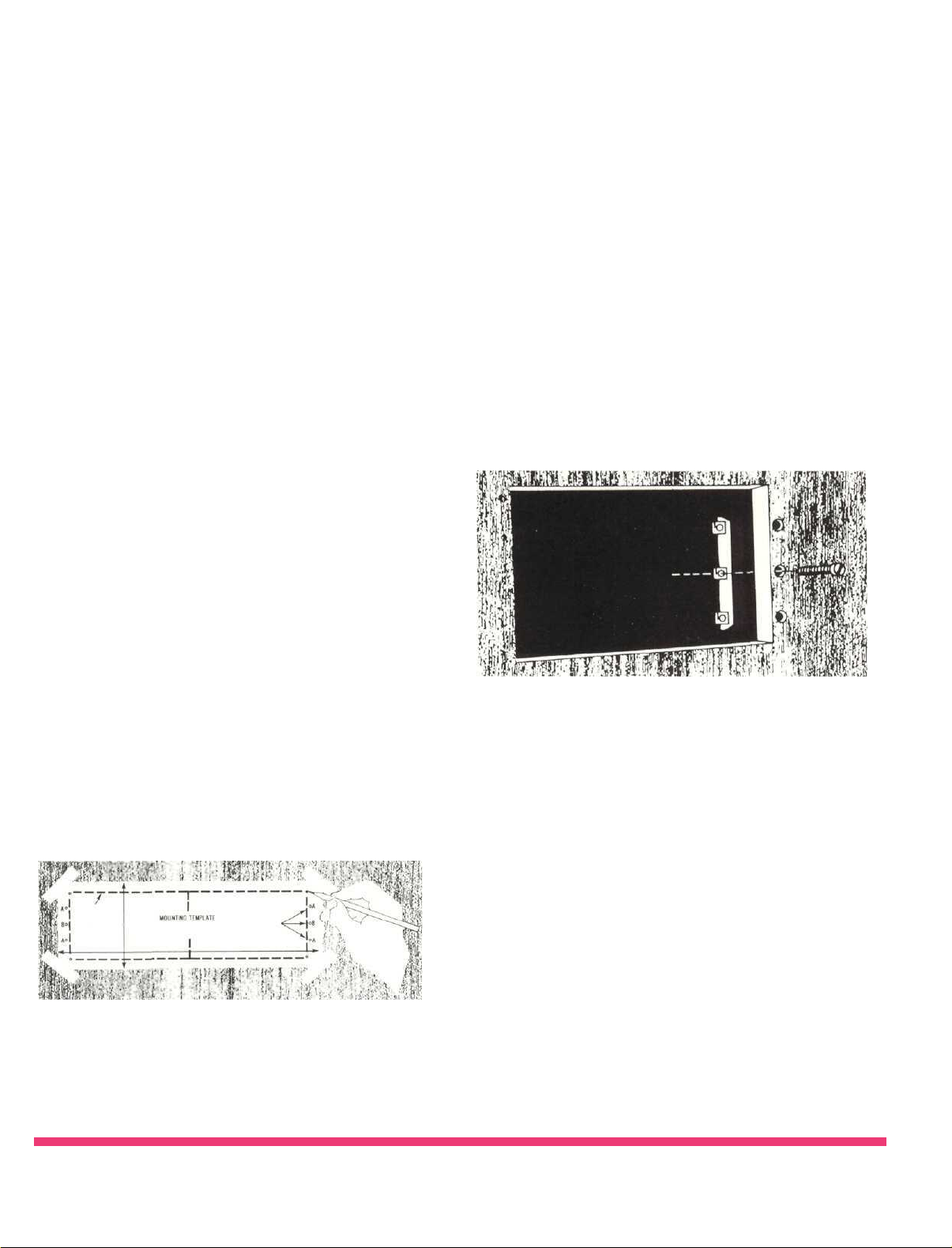

REMOVE THE TRANSIT SCREWS

On the bottom of the player are two screws which

lock the player mechanism to protect it during

transportation. Remove these screws and keep them

in a safe place. If the player is to be transported

these screws must be replaced to prevent damage.

CUSTOM INSTALLATION

The PANLOC system of installing equipment con-

veniently and securely, is a product of Mclntosh

research. The PANLOC buttons on the front panel

will lock the unit firmly in place when turned approximately one-quarter turn clockwise. A onequarter counterclockwise turn of the PANLOC buttons unlocks the chassis from its mounting,

To install the instrument in a Mclntosh cabinet,

follow the instructions that are enclosed with the

cabinet. For any other type of installation follow

these instructions:

cd. The broken lines that represent the outline of

the rectangular cutout also represent the outside

dimensions of the chassis. Make sure these lines

clear shelves, partitions, or any equipment. With the

template in place, first mark the six A and B holes

and the four small holes that locate the corners of

the cutout. Then, join the four corner markings with

pencil lines, using the edge of the template as a

straightedge.

3. Drill Holes

Use a drill with a 3/16 inch (5 mm) bit held perpendicular to the panel and drill the six A and B holes.

Then, using a drill bit slightly larger than the tip of

your saw blade, drill one hole at each of two diagonally opposite corners. The holes should barely

touch the inside edge of the penciled outline. Before

taking the next step, make sure that the six A and B

holes have been drilled.

1. Unpack from Carton

Open the carton and remove the PANLOC brackets,

hardware package, and mounting template. Remove

the instrument from its plastic bag and place it up-

side down on the shipping pallet. Unscrew the four

plastic feet from the bottom of the chassis and

unscrew and remove the transit screws. When the instrument is transported, damage can occur unless its

transit screws are in place. Keep the transit screws in

a safe place for use should you transport the unit.

2. Mark the Cabinet Panel

Tape the mounting template in position on the

cabinet panel where the instrument is to be install-

4. Saw the Panel Cutout

Saw carefully on the inside of the penciled lines.

First make the two long cuts and then the two short

cuts. After the rectangular opening has been cut out,

use a file to square the corners and smooth any irregularities in the cut edges.

5. Install the Mounting Strips

In the hardware package you will find two mounting

strips, and two sets of machine screws. For panels

that are less than 1/2 inch (12.7 mm) thick, use the

3/4 inch (19.1 mm) screws; for panels that are more

than 1/2 inch (12.7 mm) thick, use the 1-1/4 inch (31.8

mm) screws.

Starting at the right-hand side of the panel, insert a

screw of the proper length into the center hole in

the panel, marked B on the template. On the back of

the panel, align a mounting strip with the holes in

the panel and tighten the screw until the screwhead

is pulled into the wood.

4 INSTALLATION

Page 7

Repeat this procedure to attach the mounting strip

to the (eft side of the panel.

6. Attach the PANLOC Brackets

Using two screws of the proper length in the A holes

on each side, attach the PANLOC brackets to the

cabinet panel; the short flange is mounted against

the front (face) of the cabinet panel. The screws pass

through the PANLOC bracket flange, the cabinet

panel, and then through the mounting strips

previously mounted.

7. Install the Instrument

Guide the AC power cord through the panel opening

to the back of the cabinet; then, slide the instrument

into the opening carefully so that the rails on the

bottom of each side of the chassis engage the tracks

on the mounting brackets. Continue to slide the instrument into the cabinet until the front panel is

flush with the cabinet panel. Turn the PANLOC buttons at the lower left and right corners of the instru-

ment panel clockwise to lock the unit firmly in the

cabinet. Turn the PANLOC buttons counterclockwise

to unlock the instrument. It can then slide outward

to permit the removal of the instrument from the

cabinet.

INSTALLATION 5

Page 8

The back cover of this manual folds out to show

photographs of the front and rear panels of the MCD

7007. Fold it out to assist you in identifying and

locating the connections. The letters refer to the

paragraphs that follow.

The back panel of the MCD 7007 has connectors

labeled FIXED OUTPUT, VARIABLE OUTPUT,

REMOTE, a port marked DIGITAL OUTPUT and the

AC power cord. The VARIABLE OUTPUT is adjusted

by the front panel VOLUME buttons while the

FIXED OUTPUT is unaffected by these controls.

Use shielded cables to connect the output signal to

a preamplifier or power amplifier. To minimize the

possibility of hum, the shielded cables should be of

parallel construction or loosely twisted together and

located away from the speaker connecting cables

and AC power cords. Be certain to use good quality

shielded cables for all interconnections. Your dealer

can advise you on the kind and length of cables that

will best suit your installation.

A. FIXED OUTPUT

The FIXED OUTPUT jacks are used to feed

program to a stereo preamplifier or other

equipment with its own volume control.

B. VARIABLE OUTPUT

Use the VARIABLE OUTPUT jacks to connect to

a power amplifier or a tape recorder where

control of the volume at the player is desired.

There is no difference in the signal quality at

either pair of output jacks. Both pairs of output

jacks may be used simultaneously.

Connect the audio output of the player to the

"CD", "AUX", or other high level input on the

preamplifier. Do not connect to the "PHONO"

input. Connect the Right player output to the

right preamplifier input and the Left player

output to the left preamplifier input.

E. AC POWER

Plug the AC power cord into a 120 volt 50/60

Hz receptical. The plug blades are polarized so

be certain the plug is fully inserted in the outlet

to prevent blade exposure.

CAUTION: TO PREVENT ELECTRIC SHOCK, DO

NOT USE THE (POLARIZED) PLUG ON THIS UNIT

WITH AN EXTENSION CORD, RECEPTACLE, OR

OTHER OUTLET UNLESS THE BLADES CAN BE FULLY

INSERTED TO PREVENT BLADE EXPOSURE.

INSERTING THE BATTERIES IN THE

REMOTE CONTROL

Your Mclntosh Compact Disc Player includes an

infrared Remote Controller. In your hand you have

the ability to control normal operating functions of

the disc player.

The controller runs on two AA, 1.5 Volt batteries.

Slide open the cover on the back of the remote

controller and insert the batteries as shown in the

diagram in the battery compartment, then slide the

cover closed again.

Battery life is normally about one year. Remove the

batteries as soon as they are dead to prevent damage

by possible battery leakage. The batteries should be

removed, also if the remote controller is not used for

a long time.

C. REMOTE

The REMOTE control connector is designed for

use with the Mclntosh multi-area infrared remote

control systems. With these systems, you can,

from a hand-held remote control, operate the

disc player and the entire system from various

listening areas.

D. DIGITAL OUTPUT

The digital data stream is available from this

port for use in systems that can accept digital

data directly.

6 HOW TO CONNECT

Page 9

Fold out this manual's back cover to assist you in

locating the controls. The numbers on the photographs

refer to the paragraphs that follow,

The glass upper half of the MCD 7007 front panel

contains the CD drawer, the IR REMOTE SENSOR,

the REMOTE response LED, the DAMAGED DISC

indicator and the message center. The message

center displays the current status of the mode of

operation, disc time, the CD functions in use and

the horizontally displayed volume level indicator.

The black anodized lower half of the front panel

contains the buttons to program the player, activate

the various player functions, and to control the

VOLUME. A headphone jack with its own volume

control and PANLOC loading buttons are also on this

panel.

Before operating your Compact Disc player,

familiarize yourself with the controls and what they

do.

1. POWER

Touch to switch the AC power to the player on or

off.

2. LOAD

Touch to open or close the disc drawer. An LED

above the LOAD button illuminates when the drawer

is operating.

3. PLAY

Touch to close the disc drawer and to start play.

Touch to return to the beginning of the track being

played.

4. VOLUME

Volume may be adjusted by using the VOLUME

or on the front panel or on the remote

controller. The volume is adjusted by an electronically

switched, precision, ladder attenuator. The Mclntosh

electronic precision ladder attenuator adjusts volume

using C2 MOS transistor switches to select the right

combinations of deposits of resistive material for the

volume programmed. The entire range of volume

adjustment is 66 dB in 2 dB increments. Left and

right tracking is controlled to a fraction of a dB.

Because there aren't any moving parts, the volume

adjustment cannot generate noise or misalignment.

5. MESSAGE CENTER

The message center presents information about the

number of tracks on the disc, the playing time, the

progress of play, the particular functions of the

player, and signals errors during operation or

programming. (See also: MESSAGE CENTER pg. 10).

6.-7.

REV AND FF

Touch and hold to provide quick access to a

particular passage.

8. REPEAT

Touch to repeat the disc or a program.

9. PAUSE

Touch to interrupt and hold play. Touch again to

continue the playback.

10. STOP

Touch to stop play during playback and to delete a

program.

11. TIME

Displays, in the message center, the eLAPsed

playing time or the time REMaining on the disc.

12. BACK TRACK

Touch, during play to return to the previous track.

13. NEXT TRACK

Touch, during play to move to the next track.

14. PHONES

Jack provided for private headphone listening.

15. LEVEL

Adjust the loudness in the headphones.

16. SCAN

Touch to close the disc drawer and/or to

automatically play the beginning 10 seconds of each

track on the disc.

17.

Touch at beginning and end when a section of a

Compact Disc is to be played repetitively.

18. REVIEW

Once a disc has been programmed, the program

can be displayed in the message center when the

REVIEW button is touched. If there isn't a program

entered, ERROR will illuminate.

19. SELECT

Each time the SELECT button is touched when

programming, the programming mode is advanced

through TRACK, to INDEX, to MINutes and to SEConds.

20. 0 thru 9

Buttons permit direct access programming. The

MCD 7007 can be programmed by TRACK, INDEX,

MINutes and SEConds or combinations of these.

21. STORE

Each detail of the programming will be inserted in

the memory by a touch on the STORE button.

FRONT PANEL 7

Page 10

22. CLEAR

When touched will erase from the memory an

entry error or break out of an continuous

loop.

23. REMOTE SENSOR

Receives the coded infrared signals from the

remote control.

24. DAMAGED DISC/MUTE

Lights when a playing disc is damaged or has

errors which are not correctable by electronic

interpolation. It also lights when the player is muted

by more seriously damaged discs, or when PAUSE,

STOP, REV, FF , BACK TRACK and NEXT

TRACK are used and when a disc is not playing.

25. REMOTE

This LED lights when the IR Remote Control is

used to operate the functions of the MCD 7007.

26. PANLOC

Turn to secure or release the player from the

cabinet.

8 FRONT PANEL

Page 11

POWER-1.

Touch the POWER button to turn the player on.

The TRACK, INDEX, TIME, eLAPsed time and

VOLUME indicators will light up in the display area.

Touch POWER again and the player is turned off

and the indicators turn off.

LOAD-2.

Touch the LOAD button and the LED above this

button will illuminate, then after 1 second the

drawer will open. If the drawer is obstructed, it will

not continue to open. Should this happen remove

the obstruction, touch LOAD twice in succession to

bring the drawer fully out.

Hold the disc at the rim and place it, label side up,

in the disc drawer.

Close the drawer by touching PLAY, SCAN or

LOAD. Use PLAY if you want to play the complete

disc, SCAN if you first want to preview each track on

the disc or store tracks from it, and LOAD if you

want to program the disc. In each case, the drawer

slides in when the button is touched. If the drawer is

obstructed as it closes, the drawer will come out

again after about 3 seconds.

Using LOAD to close the drawer, permits the laser

pen to read the contents list and then display the

number of tracks and the total time encoded on the

disc. After reading the contents list, the MCD 7007

switches to stand-by mode ready for further

instructions.

The DAMAGED DISC/MUTE indicator remains

lighted until play begins. If the light remains on and

the disc refuses to play, make sure that the disc is

properly in the drawer and label side is up.

To close the drawer when it is empty touch the

LOAD button. The DAMAGED DISC/MUTE sign will

light. To prevent the entry of dust, do not leave the

drawer open.

Opening the drawer during play, will stop the disc.

PLAY-3.

To play the complete disc, close the drawer by

touching PLAY. After the contents list on the disc has

been read, the number of tracks on the disc will be

displayed on the track indicator. When play begins,

elapse playing time is displayed and the eLAPsed

indicator lights.

To go back to the beginning of a track while it is

playing, touch PLAY. The track is then repeated from

the beginning. When all the tracks have been played,

the track indicator, the total elapsed time and the

DAMAGED DISC/MUTE indicator will light. All

indicators except the volume display turn off.

VOLUME-4.

Volume may be adjusted by using the VOLUME

or VOLUME on the front panel or on the remote

control. Adjustment of the volume is performed by

an electronically switched precision ladder

attenuator.

The Mclntosh electronic precision ladder

attenuator adjusts volume by C2 MOS transistor

switches that select the right combinations of highly

accurate deposits of resistive material for the volume

programmed.

The entire range of volume adjustment is 66 dB in

2 dB increments. Left and right tracking is controlled

to a fraction of a dB. Because there aren't any

moving parts, the volume adjustment cannot

generate noise or misalignment.

The VOLUME indicator in the message center is a

10 segment display. As volume is increased, more

segments are lighted to indicate relative volume.

SCAN-16.

The first 10 seconds of each track will be played

when the SCAN button is used to initiate play. As

each track is previewed the SCAN indicator, the

TRACK number and the eLAPsed TIME is displayed.

When the tracks have been previewed, the SCAN

indicator turns off, the laser pick-up returns to the

beginning of the first track. The total number of

tracks and the total time will be displayed in the

message center.

If, before you have previewed all tracks, you

decide to listen to all of the remaining tracks on the

disc, touch PLAY. The SCAN indicator will go off and

the remaining tracks will play in their entirety,

beginning with the track indicated in the message

center.

Any track can be entered in the memory for later

playing while using SCAN. To enter a track, touch

STORE while the track is playing and the TRACK will

be inserted in the memory. The player will preview

the next track and the indicator for that track will be

displayed.

When all tracks have been previewed, SCAN will

go off. To listen to the stored program, touch PLAY

And the disc will play the stored tracks in the

sequence selected.

OPERATION 9

Page 12

MESSAGE CENTER DISPLAY-5.

Disc symbol flashes

during loading and

starting

Track or index symbols flash during programming.

Minutes or Seconds

symbols flash during

programming.

Play is in continuous

loop between selected

points A (start) and B

(end). Flashes during

programming.

Indicates REMaining

Total Time or eLAPsed

Track Time.

SCAN function

is active.

Indicates program

has been stored.

PAUSE function

is active.

REPEAT function

is active.

Indicates Relative

volume level

Encoded program is

being displayed.

The display in the message center presents many

different types of information. As soon as the

POWER button is touched to turn the player on, the

message center shows a series of zeros in TRACK,

INDEX and TIME. The eLAPsed time indicator and

the VOLUME bar are also lighted.

The LOAD button opens and closes the disc

drawer. Once opened, place a disc in the drawer

label side up. When the LOAD button is used to

close the drawer, the laser pen will read the contents

of the disc from the encoded data. The message

center information will change to show the number

of tracks and the total recorded time on the disc.

The player then goes to 'stand-by' mode until further

instructed.

The drawer can be closed and play begun by

touching SCAN or PLAY. The message center display

will change to show the track being played and the

eLAPsed time.

TRACK

Displays the total number of tracks on the disc

when activated by the LOAD button. When in other

modes of operation, the track being played is

displayed. When programming, the word TRACK

under the digits will flash to indicate that TRACK

data can be entered in the memory.

INDEX

When a disc has been encoded with index data the

INDEX area will display the index being played.

When programming, the word INDEX under the

digits will flash to indicate that INDEX data can be

entered in the memory.

MINutes/SEConds

Displays the total disc time when activated by the

LOAD button. When in other modes of operation,

the eLAPsed time on the track being played will

show. When programming, the MINutes or SEConds

will flash to indicate that data can be entered in the

memory.

eLAPsed/REMainder

This button changes the display in MINutes and

SEConds from elapsed (LAP) time on this track to the

remaining (REM) time on the disc. A second touch

returns the display to eLAPsed time.

DISC (flashing red)

When flashing indicates the laser pen has moved

to the contents area of the disc and is reading the

data into the digital memory for display. Should the

drawer not contain a disc the DISC indicator will

flash and the ERROR indicator light for a few

seconds then both will turn off.

ERROR

Should an inaccurate instruction be given the

ERROR indicator will light briefly. New instructions

must be instituted to put the player in action.

When illuminated, the player has been

programmed to play and repeat a portion of the disc

programmed by the button. A flashing

indicator reminds you that the programming

is not completed. When completed both the

and the PROGRAM indicators are lighted.

PROGRAM

Illuminates to show that the sequence of playback

10 OPERATION

Page 13

is controlled by the preselected program or the

continuous loop.

SCAN

If the SCAN button was used to activate the player

the SCAN indicator will light and remain lighted until

all tracks have been scanned.

REVIEW

When the REVIEW button is activated the indicator

is lighted and the program is displayed in sequence

on the appropriate TRACK, INDEX, and MIN/SEC

indicators.

REPEAT

The

REPEAT

disc or program will be replayed upon completion.

PAUSE

When the PAUSE button is pressed, the laser pen

stops instantly while the disc continues to rotate.

The player remains ready to play at the precise point

that the PAUSE was activated. Very useful in tape

recording, answering the phone, etc.

VOLUME

A 10 segment horizontal bar displays the relative

loudness of the volume. As volume is increased

more segments are illuminated.

REV - FF

During play, you can quickly locate a particular

music passage in a track by holding in REV or

FF . While you hold REV, the laser pick-up

moves toward the beginning of the track or disc;

while you hold FF , the laser pick-up moves

toward the end of the track or disc. By using

REV and FF alternately, you can find any

part of any passage. After release, play restarts at

once.

During REV and FF , the laser pick-up

moves at three successive speeds: for the first few

seconds relatively slowly, for the next few seconds

faster, and after approximately 10 seconds, at

maximum speed. During the two slower speeds, the

program material can be heard at reduced volume.

At high speed the sound is muted. If you continue

to hold down the FF or

of the time display run on at a corresponding rate.

When nearing the desired passage, release momentarily to go back to the lowest speed.

If, by holding in REV, the laser pick-up moves

to the run-in of the first track, the ERROR indication

lights and the laser pick-up stops at the beginning of

the track. The disc continues to spin, however, so

indicator

-6-7

will

light

to

show

REV the numbers

that

the

that play will resume upon release of the button.

If, by holding in FF , the laser pick-up moves

to the run-out of the last track, the ERROR indication

lights, and the laser pick-up moves back over the

disc about 20 seconds and remains at that point until

FF is released.

REPEAT-8.

To hear the whole disc or a program again, touch

REPEAT

light, and the disc will repeat continuously until you

touch

the disc will play to the end and stop. Touch LOAD

or

stop at once.

PAUSE-9,

start

the

again.

passage, or to interrupt the program, touch PAUSE.

To begin play again, touch PAUSE. It will resume at

the exact point it was interrupted. The PAUSE sign

will go off.

STOP-10.

STOP.

TIME-11.

display the eLAPsed time of the track playing. Touch

the TIME button to display the remaining (REM) time

on the disc. Touch again to return to eLAPsed time.

BACK TRACK-12.

TRACK. Each touch moves the laser pen and the

display on the track indicator back one track. Play is

temporarily interrupted while the laser pick-up

moves.

track,

there is no previous track. Play of the first track

continues.

NEXT TRACK-13

TRACK. Each touch moves the laser pen and the

display on the track indicator forward one track. Play

is temporarily interrupted while the laser pick-up

moves.

before

REPEAT

STOP,

The laser pick-up can be stopped exactly at the

of a

PAUSE

The

To hold play at the beginning of a track or a

To stop play before the end of the disc, press

Anytime the disc is playing the message center will

To play an earlier track on the disc, touch BACK

If you touch BACK TRACK during play of the first

the

To play a later track on the disc, touch NEXT

again.

the

REPEAT

track

or a

sign

PAUSE

ERROR

the

disc ends.

passage

will

light.

sign

sign

The

sign

will

will

The

REPEAT

REPEAT

will

To

light,

sign

go off and

by

touching

start play, touch

go

off.

as a

sign

will

will

go off and

play

will

PAUSE

reminder that

and

PAUSE

OPERATION 11

Page 14

If you touch NEXT TRACK during play of the last

track, the ERROR sign will light as a reminder that

there is no next track. Play of the last track

continues.

LISTENING WITH HEADPHONES-14.

With headphones connected to the PHONES jack,

you can listen to discs without having to use an

amplifier. Adjust

control.

The headphones must have a 0.25 inch (6.3 mm)

jack plug and an impedance between 8 and 1000

ohms.

-17.

Should you wish to hear a portion of the disc

repeatedly, touch the button at the start of

the section you wish repeated. Allow the disc to play

until the end of the repeat section and touch

again. The program between the two points will be

repeated until CLEAR, STOP or LOAD are touched.

0 thru 9-20.

These buttons provide a total sequence of direct

access input of 20 tracks selected from tracks 1

through 99 for storage in the memory of the

MCD 7007; any sequence of TRACKS, of INDEX

numbers or of time.

To start playing a disc other than at the beginning,

touch the track number to be played on the 0-9 key

pad followed by the PLAY button. The selected track

number will be displayed in the message center and

the track indicator will flash. The disc will begin at

the track selected and play the remaining tracks on

the disc. If you have selected a track which does not

exist ERROR will appear briefly on the display.

STORE-21

From the program list provided with the compact

disc, decide on the tracks you want to include in the

program. For each track, touch the appropriate

number buttons and then the STORE button to insert

the disc track in the program memory. Tracks may

be stored in the sequence on the disc when in the

SCAN mode. While listening to the preview of a

track in SCAN, touch the STORE button to store that

track for later playback. The PROGRAM indicator will

light and the TRACK display will immediately move

to the next track.

The total memory will store up to 20 tracks in any

order, these tracks may be selected from any

number of tracks up to 99. They do not need to be

sequential.

the

sound level

with

the

LEVEL

Your program can contain any combination of:

• TRACK

• TRACK and INDEX

• TRACK and TIME

• TRACK, INDEX and TIME

However, you are limited to 20 units of memory.

Each TRACK number takes up 1 unit each, TRACK

and INDEX number takes up 2 units and each

TRACK, INDEX and TIME takes up 5 units. If there is

an attempt to enter more than 20 units, ERROR

appears on the display.

To enter a program, insert a disc and use LOAD to

close the disc tray.

If you make a mistake or wish to change your

program at any time, touch the CLEAR button before

touching the STORE button to erase the memory,

then begin program entry again.

Follow this example of a program from a disc

containing 32 tracks. The program sequency desired

from the disc is: 3, 10, 31, 18, 2, etc. using the

numeric key pad, touch 3 then STORE, the TRACK

indicator will show 1 to indicate that block has been

used. Touch 1 then 0 then STORE, touch 3 then 1

then STORE, touch 1 then 8 then STORE, touch 2

then STORE, etc. until your entire program has been

entered into the memory. If ERROR appears on the

display make sure the selected track number exists

or whether all 20 memory blocks are full.

Touch PLAY to listen to the entire program as

entered. The program can be played again, before

touching STOP or LOAD by touching the PLAY

button. The program remains in the memory until

the STOP or LOAD button is touched.

CLEAR-22

Touch CLEAR to remove an incorrect selection

from the memory.

To erase any single TRACK entry from the program,

touch the REVIEW button to exhibit in the message

center the program entered. Each entry will be

briefly displayed. As soon as the entry to be deleted

is

seen, touch

that entry from the memory.

REVIEW-18

The program entered can be reviewed by touching

the REVIEW button. The TRACK numbers in the message center will be illuminated in the sequence

entered in the memory.

SELECT-19

Touch the SELECT button to change the input to

the

CLEAR

button

which

will

erase

12 OPERATION

Page 15

memory from TRACK to INDEX or to TIME.

Touch

SELECT

flash on and off which indicates the numeric key pad

TRACK selection is connected to the memory input.

Touch SELECT twice which causes the INDEX

indicator to flash and which connects the numeric

key pad INDEX selection to the memory input.

Touch SELECT three times and the MINutes flash

for programming by any given minute in a track.

When SELECT is touched four times programming

can be started on the second. Suppose you wish to

hear track 7 at 4 minutes and 18 seconds. Touch in

sequence

touch 7, then touch SELECT two times, the MINutes

indicator will flash, touch 4, then touch SELECT once,

the SEConds indicator will flash, touch 1, then 8, and

PLAY.

seconds and play to completion.

Programming in progressive numeric sequence by

TRACK is easily done when the SCAN button is used

to start the play sequence. As a TRACK number is

displayed in the message center a touch on the

STORE

memory. The display will immediately switch to the

next track. Up to 20 TRACKS can be stored.

To program TRACKs in random sequence use the

0-9 keypad. Twenty tracks in any order from 1 to 99

can be inserted in the memory. When the 20 tracks

have been programmed filling all units of memory,

further entries

indicator will light for a few seconds. Twenty units of

memory provide programming by direct TRACK

input, TRACK and INDEX TRACK AND TIME, TRACK,

INDEX and TIME and any combinations of the four,

the STORE and the SELECT buttons. Each TRACK

entered used one unit of memory; each TRACK and

INDEX, uses two units of memory and each TRACK

and TIME entry, five units of memory. Up to 20

TRACKS only may be programmed, up to 10 TRACKS

with INDEX or 4 TRACK and TIME entries.

To arrange TRACK in the sequence of your choice,

use the 0-9 keypad and STORE button. When the

disc drawer has been closed by using the LOAD

button, the message center will display the number of

tracks and the total recorded time on the disc. On

the 0-9 keypad touch the track number and then

touch STORE to program the sequence you desire.

The memory will be updated and the display will

show the number of entries made and the total time

of these entries and the PROGRAM will light.

SELECT,

The

button

disc

once

will

will

will

and the

the

TRACK

start track

insert,

not be

the

TRACK

indicator

7 at 4

displayed track

stored

minutes

and the red

indicator

will

flash,

and 18

into

ERROR

will

the

To program by TRACK and INDEX, the 0-9 keypad,

the SELECT and STORE buttons are used. First, close

the disc drawer using the LOAD button. Enter the

desired track by using the keypad. Upon entering

the track, the word TRACK, under the digits, will

flash. Move the flashing symbol to the INDEX space

by touching SELECT. When the word INDEX begins

to flash enter the desired INDEX number by using

the keypad, followed by touching the STORE button.

The PROGRAM block will light in the message center

and TRACK will switch to show the number of

entries made to the memory. The TIME indicator will

show only zeros.

DISC MAINTENANCE

For the best results, apply the same care in storing

and handling the Compact Disc as with conventional

records, Even though the music track in the disc is

covered by a protective layer, treat the disc carefully.

Always pick up discs by the edge, and put them

back in their protective cases immediately after use.

Wipe fingerprints, dust or dirt off with a soft,

lint-free cloth. Wipe in a straight line from center to

edge. You can breathe on the disc first if necessary.

Cleaning agents for conventional records, detergent

or abrasive cleaners must never be used.

Never write on the label side of the disc. Writing

will emboss the disc and destroy the digital data. If

you follow these suggestions, the Compact disc will

provide a lifetime of pure listening enjoyment.

PLAYER MAINTENANCE

The player mechanism has self-lubricating bearings,

and must mot be oiled or greased. The disc drawer

should be kept free of dust.

OPERATION 13

Page 16

The greatest care has been taken in the

manufacture of your Mclntosh Compact Disc player.

In case of operational difficulties and to save you

unnecessary service calls, here is a list of their

possible causes and suggested solutions. Should you

need further guidance, contact your dealer. He will

be able to advise you. Under no circumstances

should you open up the player. To do so can void

the service contract.

1. After touching POWER, the track indicator does not

light.

• Touch the POWER button again. POWER was not

pressed in far enough. They require only .007"

movement to engage.

• The player is not properly plugged into the 120V

AC supply.

• There is no 120V AC supply. Plug in another

electrical appliance and see if it functions in the

same outlet.

2. After touching LOAD, the disc drawer does not slide

out.

• The player is not switched on and the message

center data will not light.

• The microprocessor has not received the

command correctly. Touch STOP and then touch

LOAD again to see if the drawer opens.

• The drawer drive is not functioning. You cannot

correct this yourself. If a disc is in position,

remove it by pulling the drawer open carefully,

then push the drawer in to close it again.

3. After touching LOAD, PLAY or SCAN, the disc

drawer does not slide in.

• The 120 VAC supply has been disconnected and

the track indicator will not light.

• The microprocessor has not received the correct

command. Touch STOP and then touch LOAD,

PLAY or SCAN again to see if the drawer closes.

• The drawer drive is not functioning. You cannot

correct this yourself. If a disc is in position,

remove it, than push the drawer in carefully to

close it.

4. After closing the drawer the Message Center Data

shows the 'OoOoo' and the DISC and ERROR light

and nothing further happens.

• The transport screws have not been removed.

• The disc is not inserted label up or there isn't a

disc in the drawer and you have missed the

ERROR DISC sign.

• The disc is dirty. Clean the disc, or use another,

clean disc.

• The disc is defective. See if another disc clears the

problem.

• There is an unwanted object in the disc drawer,

such as a piece of paper or a remnant of the

packaging.

• The player is not horizontal.

5. The disc is being played as shown by the time elaps-

ed indicator, but there isn't any sound.

• The microprocessor has not received the correct

command. Check if touching STOP and then restarting clears the problem.

• The preamplifier is not switched on.

• The preamplifier source selector is not turned to

the input to which the player is connected.

• The preamplifier, amplifier or the loudspeakers

connected to it are not working. Check with

another sound source.

• The connection between the player and the

preamplifier is broken.

• The input to which the player is connected is

defective. Check by connecting the player to

another input.

• Volume control is turned down.

• Player in PAUSE mode

6. The sound is poor or distorted or you can hear only

one channel.

• The transport screws have not been removed.

• The disc is dirty or badly scratched. Clean the disc

or use another clean, scratch-free disc.

• There is an unwanted object in the disc drawer,

such as a piece of paper or a remnant of

packaging.

• The preamplifier or the loudspeakers connected to

it are not working properly. Check with another

sound source.

• The player is connected to the PHONO input not

the CD, AUX, or other high level input of the

preamplifier.

• One of the plugs of the connecting cable is either

not connected or not properly connected.

• The player is not horizontal.

14 HELPFUL HINTS

Page 17

7. Programming is not working properly.

• The disc is dirty or badly scratched. Clean the disc

or try programming with a scratch-fee disc.

• The microprocessor has not processed the

commands properly. Clear the program by

touching STOP and store it again; re-start play.

• All 20 memory places are already programmed and

you have missed the ERROR sign that shows this.

Check by touching the REVIEW button to ensure

the program memory.

8. The following problems can be caused by the same

circumstances:

Playback does not begin with the first track on

the disc or of the program, but with another track.

Playback stops before the end of the disc or the

program.

• The microprocessor has not processed the

command correctly. Touch STOP and re-start to

clear the memory.

• The disc is dirty or badly scratched. Clean the disc

or use another, clean, scratch-free disc.

• The disc is defective. Try another disc.

• There is an unwanted object in the disc drawer

such as a piece of paper or a remnant of

packaging.

• The player is not horizontal.

9. The player does not react to commands from the

remote control.

• The batteries are low and the distance to the

player is too great. Aim in the direction of the

player.

• Direct sunlight or high intensity room light

shining on the remote sensor. Shade the sensor

from sunlight.

• The batteries are dead.

HELPFUL HINTS 15

Page 18

TYPICAL AUDIO PERFORMANCE

NUMBER OF CHANNELS

2, left and right

FREQUENCY RESPONSE

20-20,000 Hz, +0, -0.3 dB

DYNAMIC RANGE

96 dB

(114

dB

EIA)

SIGNAL-TO-NOISE RATIO

107 dB (A)

CHANNEL SEPARATION

102 dB (at

TOTAL HARMONIC DISTORTION

0.0012% (at 1000 Hz)

WOW AND FLUTTER

Quartz crystal precision

SAMPLING RATE

176.4

D/A CONVERSION

Quadruple oversampling (176.4 kHz) with digital

filter and two 16 bit D/A converters

ERROR CORRECTION SYSTEM

Cross Interleave Reed Solomon Code (CIRC)

AUDIO OUTPUT LEVEL

2.5V

IMPEDANCE HEADPHONES

8-1000 ohms

DIGITAL OUTPUT

kHz

1000

Hz)

Output for digital signal processing

OPTICAL READOUT SYSTEM

LASER

Semi-conductor AIGaAs

WAVE LENGTH

780 nm

SIGNAL FORMAT

SAMPLING FREQUENCY

44.1

kHz

QUANTIZATION

16 bit linear/channel

DISC

DIAMETER

120 mm

THICKNESS

1.2 mm

ROTATION (seen from reading side)

Counter-clockwise

SCANNING VELOCITY

1.2-1.4 m/s

ROTATION SPEED

500-200 rpm

PLAYING TIME (maximum)

74 minutes (stereo)

TRACK PITCH

1.6 um

MATERIAL

Plastic

BUTTONS

Power Load

Scan* Play*

A B* Rev*

Review FF

Select Repeat*

Store* Pause*

Clear Stop*

0 thru 9 Time

Volume* Back Track*

Volume * Next Track*

*also provided on HR7007 Remote Control Transmitter.

CONTROLS

Level for Headphones

Headphone Jack

SPECIAL FEATURE

Damaged Disc/Mute Error Correction Indicator

POWER SUPPLY

120V, 50/60 Hz, 30 watts

MECHANICAL INFORMATION

SIZE

Front panel measures 16 1/8 inches wide (41 cm) by

5 7/16 inches high (13.8 cm) by 13 inches deep

(33 cm), including connectors. Knob clearance

required is 3/4 inches (1.9 cm) in front of mounting

panel.

FINISH

Front panel is glass with gold/teal nomenclature

illumination and anodized gold and black aluminum.

Chassis is black.

MOUNTING

Exclusive Mclntosh developed professional PANLOC.

WEIGHT

18 pounds (8.2 kg) net, 30 pounds (13.6 kg) in

shipping carton.

16 PERFORMANCE DATA

Page 19

THE LOCATION OF

CONTROLS AND BUTTONS

The numbers and letters correspond to the paragraphs on pages 6 thru 13

Page 20

Loading...

Loading...