Page 1

GB Operator’s manual 2-21

SE Bruksanvisning 22-41

DK Brugsanvisning 42-61

NO Bruksanvisning 62-81

FI Käyttöohje 82-101

DE Bedienungsanweisung 102-121

FR Manuel d’utilisation 122-141

NL Gebruiksaanwijzing 142-161

ES Manual de instrucciones 162-181

PT Instruções para o uso 182-201

IT Istruzioni per l’uso 202-221

EE Käsitsemisõpetus 222-241

LV Lieto‰anas pamÇc¥ba 242-261

LT Naudojimosi instrukcijos 262-281

CZ Návod k pouÏití 282-301

SK Návod na obsluhu 302-321

HU Használati utasítás 322-341

PL Instrukcja obs∏ugi 342-361

HR Priruгnik

RU уководство по

BG ъководство за

RO

GR

BA

RS

SL

TR

362-381

эксплуатации

експлоатациЯ

Instrucöiuni de utilizare

√‰ËÁ›Â˜ ¯Ú‹Ûˆ˜

Uputstvo o upotrebi

Priruãnik

485-504

Navodila za uporabo

Kullanım kılavuzu

382-402

403-423

444-464

465-484

505-524

525-544

424-443

SUPERLITE 4528

ERGOLITE 6028

Page 2

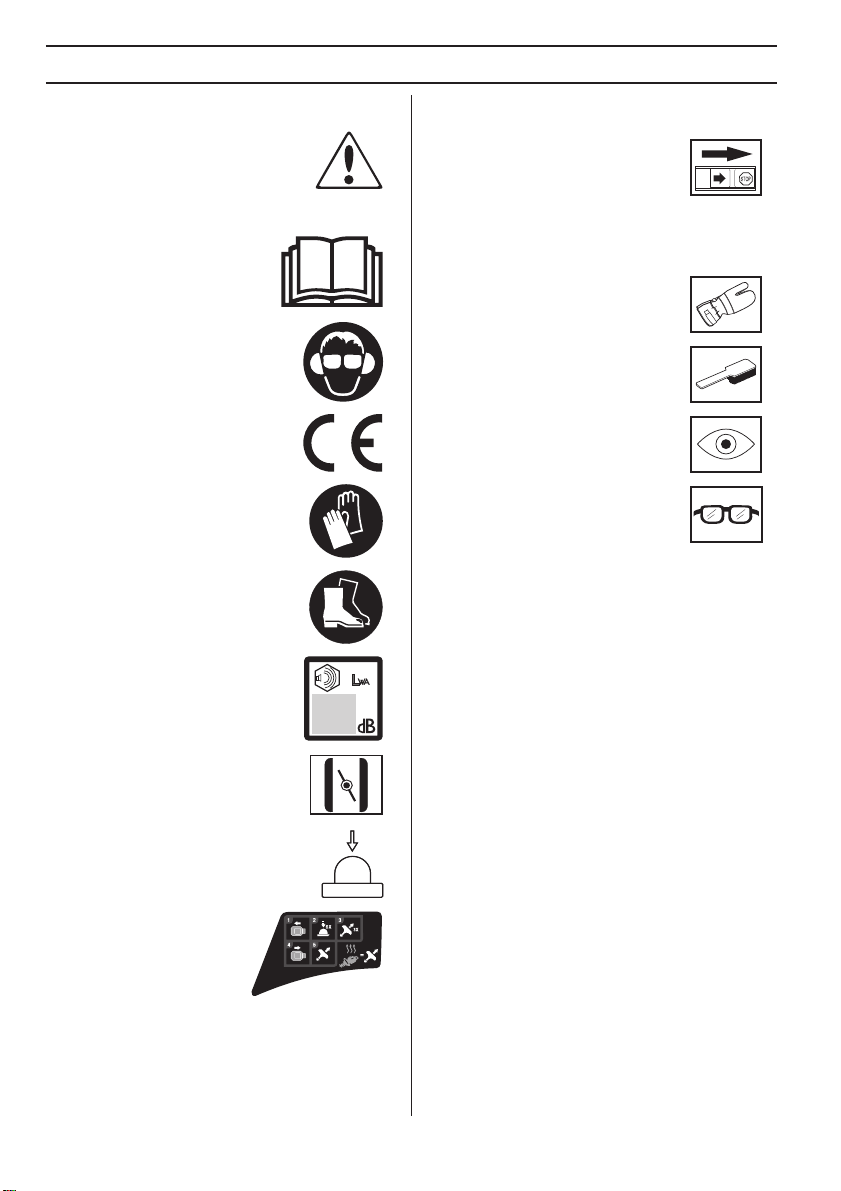

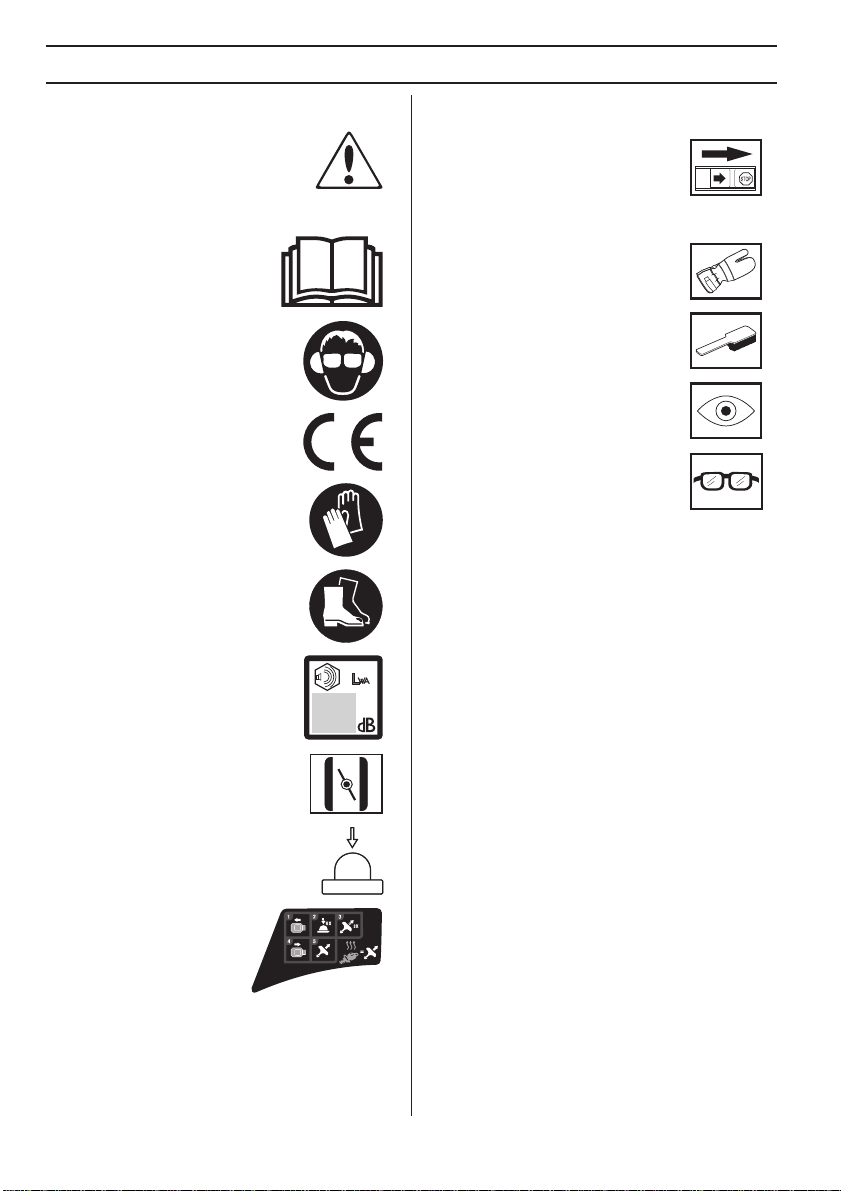

Symbols

WARNING! Incorrect or careless use of a

hedge trimmer can turn it into a

dangerous tool that can cause serious or

even fatal injury. It is extremely important

that you read and understand the

contents of this operator’s manual.

Please read the operator’s manual

carefully and make sure you

understand the instructions before

using the machine.

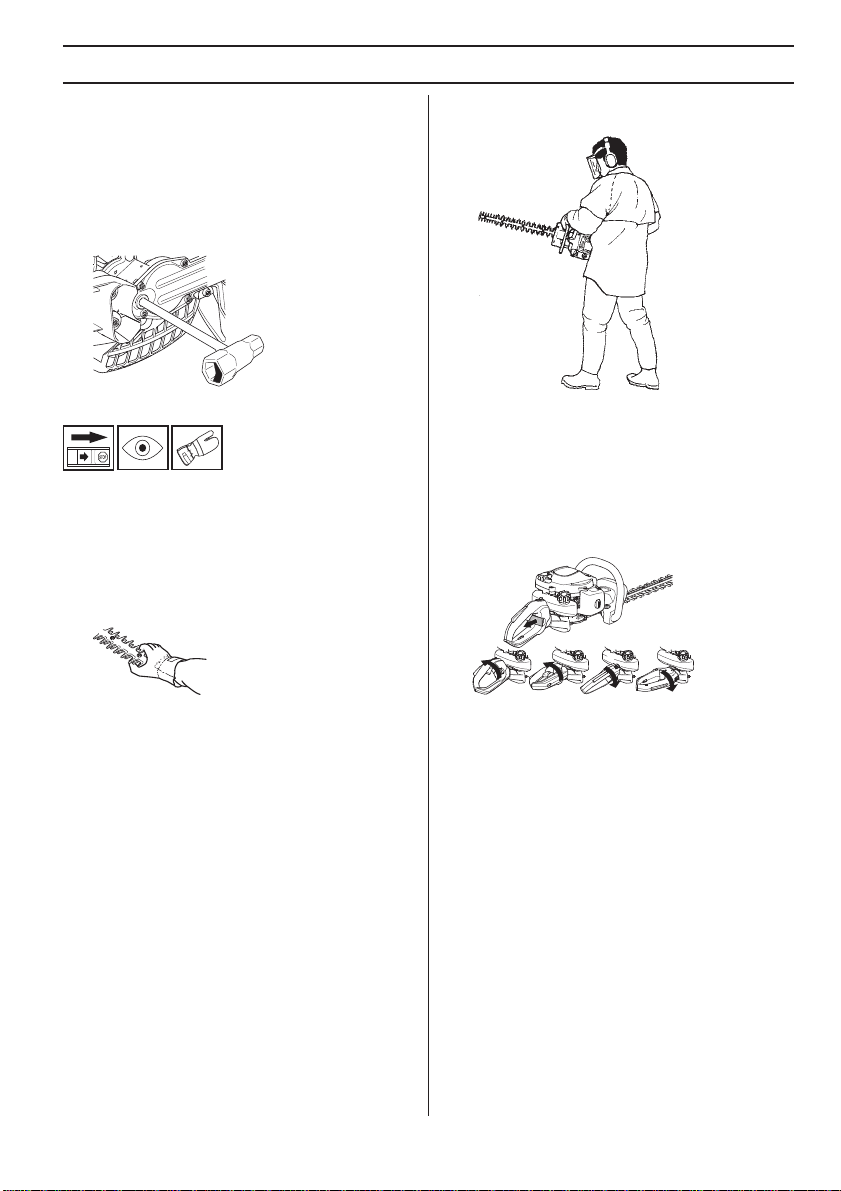

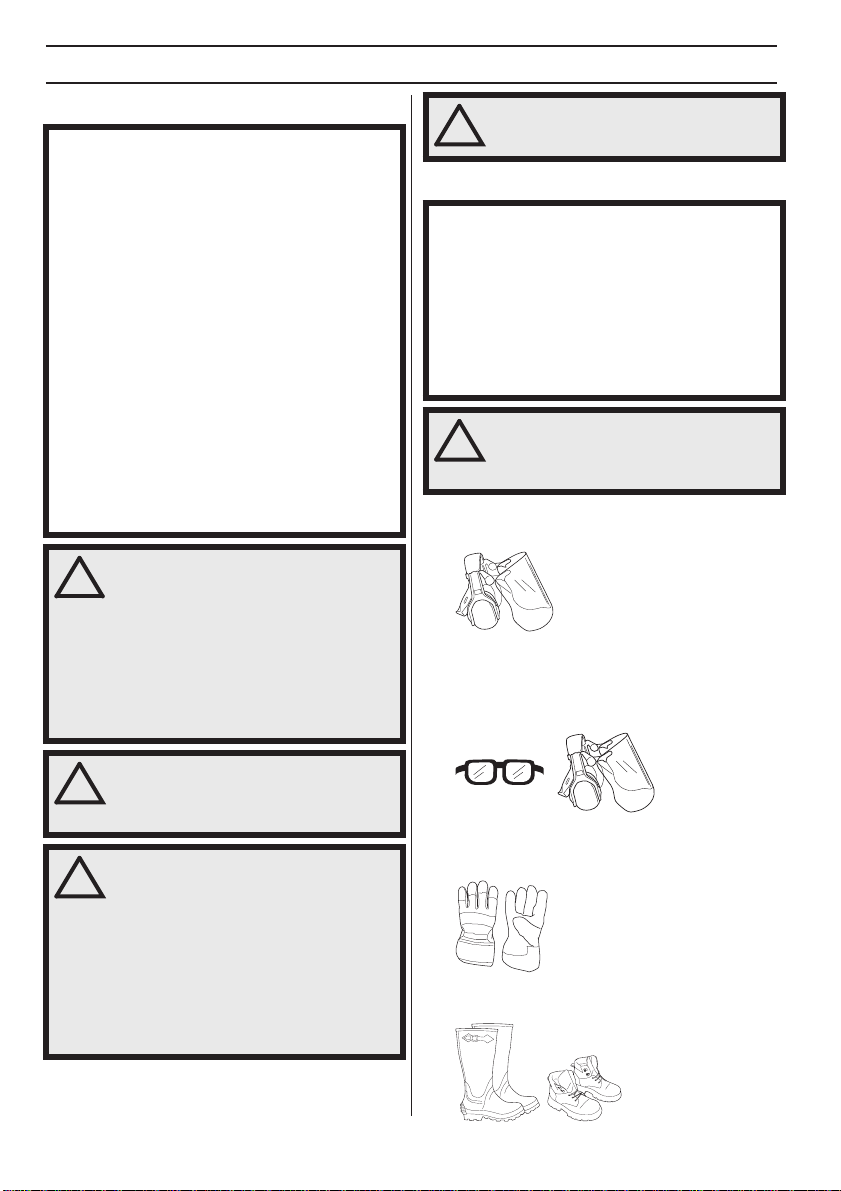

Always wear:

• Approved hearing protection

• Approved eye protection

KEY TO SYMBOLS

Other symbols/decals on the machine refer to special

certification requirements for certain markets.

The engine is switched off by moving the

stop switch to the stop position.

CAUTION! The stop switch

automatically returns to the start

position. In order to prevent

unintentional starting, the spark plug cap must be

removed from the spark plug when assembling, checking

and/or performing maintenance.

Always wear approved protective

gloves.

Regular cleaning is required.

This product is in accordance with

applicable EC directives.

Always wear approved protective

gloves.

Wear sturdy, non-slip boots or shoes.

Noise emission to the environment

according to the European

Community’s Directive. The machine’s

emission is specified in chapter

Technical data and on label.

Ignition; choke: Set the choke control

in the choke position.

Air purge.

Starting instructions See the

instructions under the heading

Start and stop.

Visual check.

Protective goggles or a visor must be

worn.

2 – English

Page 3

!

!

!

CONTENTS

Contents Note the following before

KEY TO SYMBOLS

Symbols ................................................................ 2

CONTENTS

Contents ............................................................... 3

Note the following before starting: ........................ 3

INTRODUCTION

Dear Customer, .................................................... 4

WHAT IS WHAT?

What is what? ....................................................... 5

GENERAL SAFETY PRECAUTIONS

Important .............................................................. 6

Personal protective equipment ............................. 6

Machine

′

s safety equipment ................................. 7

FUEL HANDLING

Fuel safety ............................................................ 10

Fuel ...................................................................... 10

Fueling .................................................................. 11

STARTING AND STOPPING

Check before starting ........................................... 12

Starting and stopping ........................................... 12

WORKING TECHNIQUES

General working instructions ................................ 14

MAINTENANCE

Carburettor ........................................................... 16

Muffler .................................................................. 16

Cooling system ..................................................... 16

Spark plug ............................................................ 16

Air filter ................................................................. 17

Gear ..................................................................... 17

Cutting unit ........................................................... 17

Cleaning and lubrication ....................................... 18

Maintenance schedule ......................................... 19

TECHNICAL DATA

Technical data ...................................................... 20

EC-declaration of conformity ................................ 21

starting:

Please read the operator’s manual carefully.

WARNING! Long-term exposure to noise

can result in permanent hearing

impairment. So always use approved

hearing protection.

WARNING! Under no circumstances ma y

the design of the machine be modified

without the permission of the

manufacturer. Always use genuine

accessories. Non-authorized

modifications and/or accessories can

result in serious personal injury or the

death of the operator or others.

WARNING! Incorrect or careless use of a

hedge trimmer can turn it into a

dangerous tool that can cause serious or

even fatal injury. It is extremel y important

that you read and understand the

contents of this operator’s manual.

English

3

–

Page 4

INTRODUCTION

Dear Customer,

Thank you for choosing a McCulloch product. You are thereby part of a story that started long ago, when the McCulloch

Corporation started its manufacturing of engines during World War II. In 1949, when McCulloch introduced its first light

one-man chainsaw, woodworking would never be the same again.

The line of innovative chainsaws would continue over the decades, and business was expanded, first by airplane and

kart engines in the 1950s, then by mini chainsaws in the 1960s. Later, in the 1970s and 80s, trimmers and blower vacs

were added to the range.

Today, as a part of the Husqvarna group, McCulloch continues the tradition of powerful engines, technical innovations,

and strong designs that have been our hallmarks for more than half a century. Lowering fuel consumption, emissions

and noise levels are of top priority to us, as is improving safety and user-friendliness.

We certainly hope that you will be satisfied with your McCulloch product, as it is designed to be your companion for a

long time. By f ollowing this operators manual’ s advice on usage, service, and maintenance, its lif espan can be extended.

If you should need professional help with repair or service, please use the Service Locator at www.mcculloch.biz.

McCulloch has a policy of continuous product development and therefore reserves the right to modify the design and

appearance of products without prior notice.

This manual can also be downloaded at www.mcculloch.biz.

4 – English

Page 5

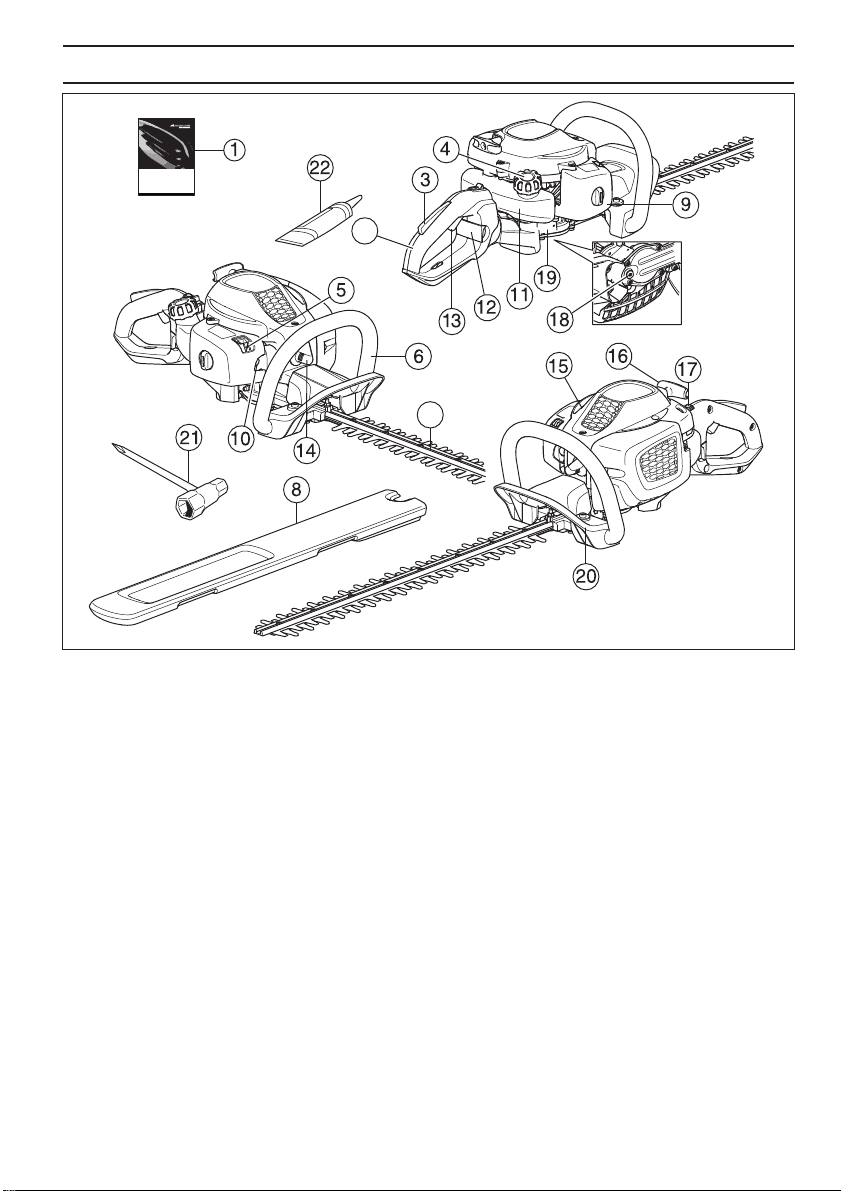

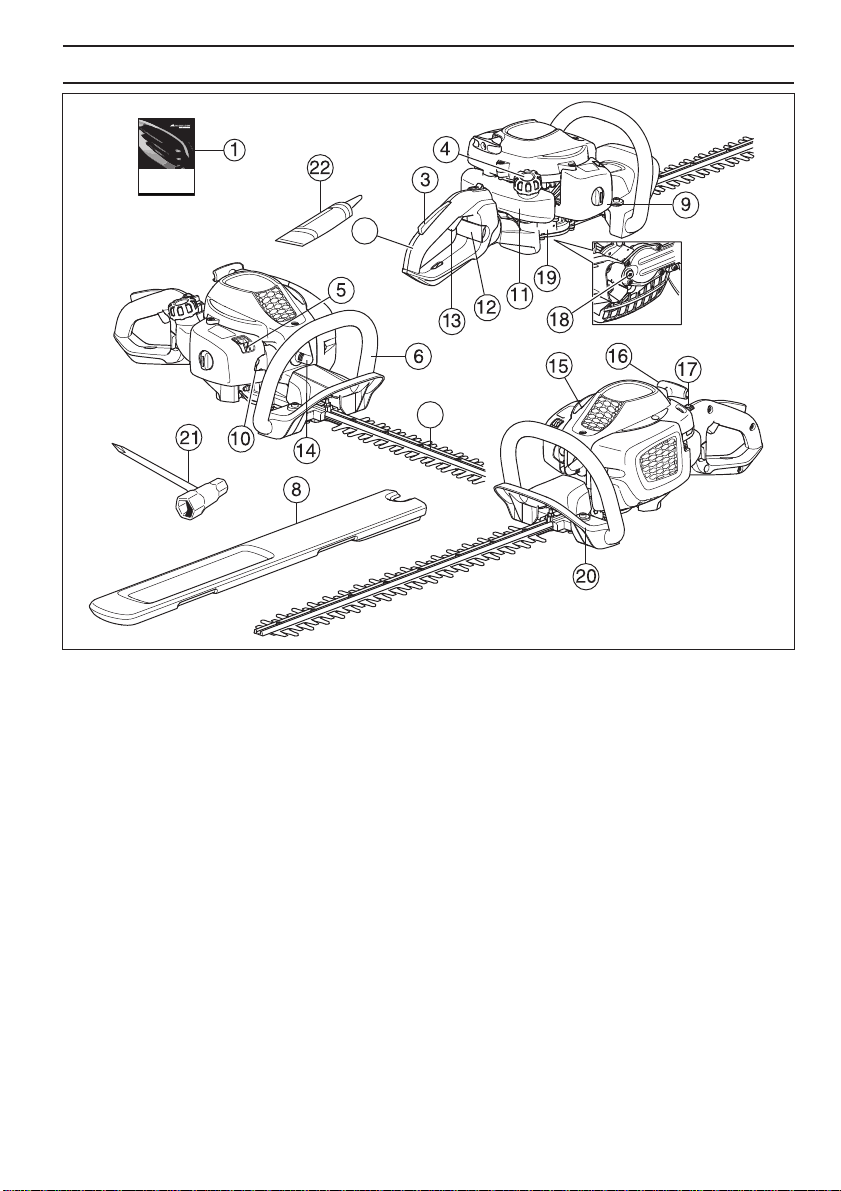

WHA T IS WHA T?

2

7

What is what?

1 Operator′s manual

2 Handle

3 Throttle lock

4 Fuel cap

5 Choke control

6 Front handle

7 Blade and blade guard

8 Transport guard

9 Air filter cover

10 Air purge.

11 Fuel tank

12 Lock for handle (ErgoLite 6028)

13 Throttle trigger

14 Spark plug cap and spark plug

15 Cylinder cover

16 Starter handle

17 Stop switch

18 Lubricant filler cap, gear

19 Gear

20 Hand guard

21 Combination spanner

22 Tube of grease

English – 5

Page 6

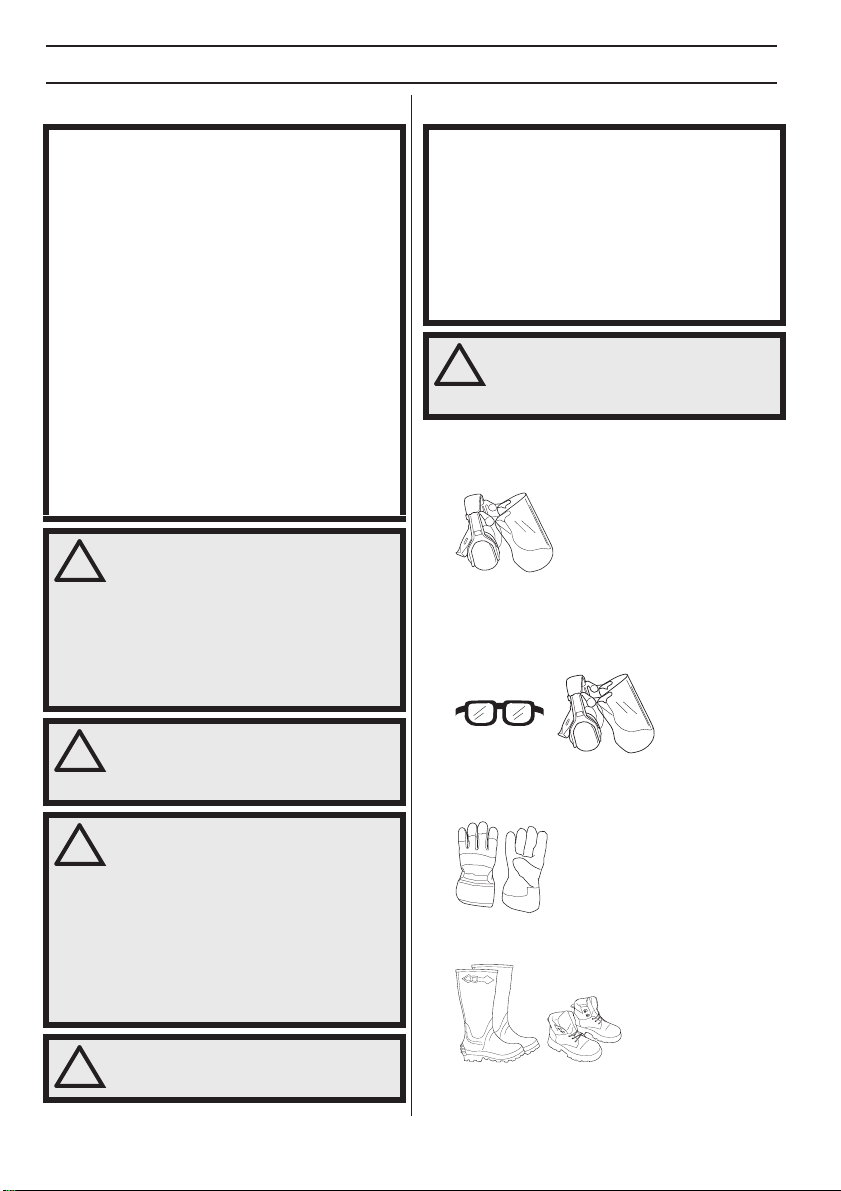

GENERAL SAFETY PRECAUTIONS

Important Personal protective equipment

IMPORTANT!

The machine is only designed for cutting branches and

twigs.

Never use a machine that has been modified in any wa y

from its original specification.

Never use the machine if you are tired, if you ha ve drunk

alcohol, or if you are taking medication that could affect

your vision, your judgement or your co-ordination.

Wear personal protective equipment. See instructions

under the heading ”Personal protective equipment”.

Never use the machine in extreme weather conditions

such as severe cold, very hot and/or humid climates.

Never use a machine that is faulty. Carry out the checks,

maintenance and service instructions described in this

manual. Some maintenance and service measures

must be carried out by trained and qualified specialists.

See instructions under the heading Maintenance.

All covers and guards must be fitted before starting.

Ensure that the spark plug cap and ignition lead are

undamaged to avoid the risk of electric shock.

WARNING! This machine produces an

electromagnetic field during operation.

!

This field may under some

circumstances interfere with active or

passive medical implants. To reduce the

risk of serious or fatal injury, we

recommend persons with medical

implants to consult their physician and

the medical implant manufacturer before

operating this machine.

IMPORTANT!

Incorrect or careless use of a hedge trimmer can turn it

into a dangerous tool that can cause serious or even

fatal injury. It is extremely important that you read and

understand the contents of this operator’s manual.

You must use approved personal protective equipment

whenever you use the machine. Personal protective

equipment cannot eliminate the risk of injury but it will

reduce the degree of injury if an accident does happen.

Ask your dealer for help in choosing the right equipment.

WARNING! Listen out for warning signals

or shouts when you are wearing hearing

!

protection. Always remove your hearing

protection as soon as the engine stops.

HEARING PROTECTION

Wear hearing protection that provides adequate noise

reduction.

EYE PROTECTION

Always wear approved eye protection. If you use a visor

then you must also wear approved protective goggles.

Approved protective goggles must comply with standard

ANSI Z87.1 in the USA or EN 166 in EU countries.

!

!

!

6 – English

WARNING! Running an engine in a

confined or badly ventilated area can

result in death due to asphyxiation or

carbon monoxide poisoning.

WARNING! Never allow c hildren to use or

be in the vicinity of the machine. As the

machine is equipped with a springloaded stop switch and can be started by

low speed and force on the starter

handle, even small children under some

circumstances can produce the force

necessary to start the machine. This can

mean a risk of serious personal injury.

Therefore remove the spark plug cap

when the machine is not under close

supervision.

WARNING! Faulty blades can increase

the risk of accidents.

GLOVES

Gloves should be worn when necessary, e .g., when fitting

cutting attachments.

BOOTS

Wear sturdy, non-slip boots or shoes.

Page 7

GENERAL SAFETY PRECAUTIONS

CLOTHING

Wear clothes made of a strong fabric and avoid loose

clothing that can catch on twigs and branches. Always

wear heavy, long pants. Do not wear jewellery, shorts

sandals or go barefoot. Secure hair so it is abo ve shoulder

level.

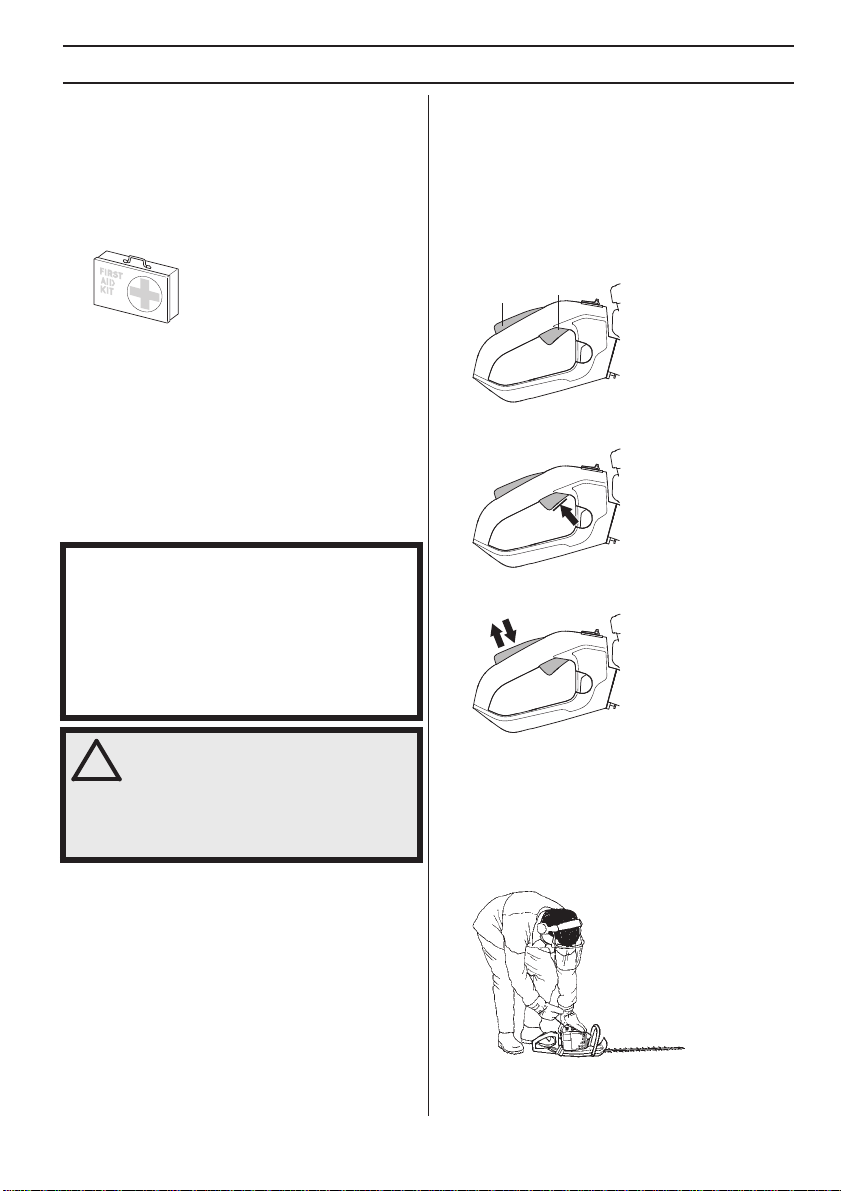

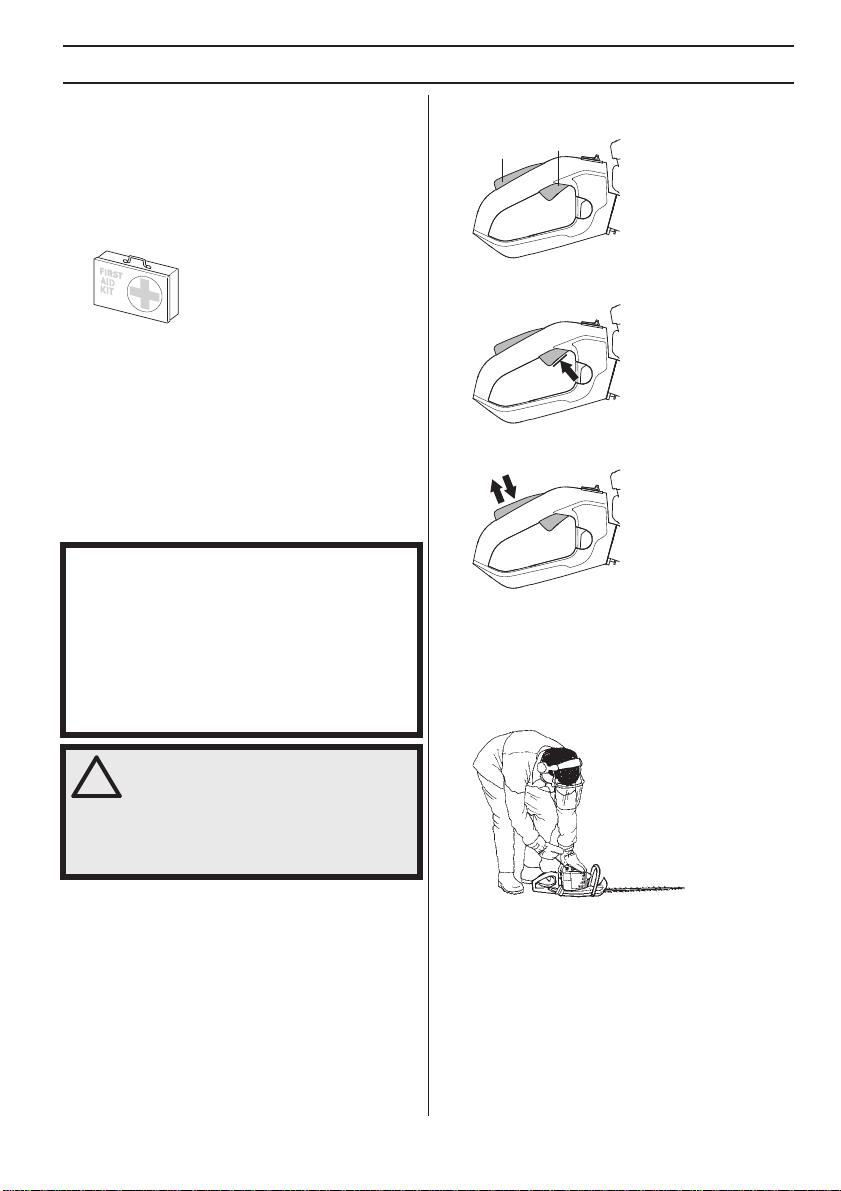

FIRST AID KIT

Always have a first aid kit nearby.

Machine′s safety equipment

This section describes the machine′s safety equipment,

its purpose, and how checks and maintenance should be

carried out to ensure that it operates correctly. See the

”What is what?” section to locate where this equipment is

positioned on your machine.

The life span of the machine can be reduced and the risk

of accidents can increase if machine maintenance is not

carried out correctly and if service and/or repairs are not

carried out professionally. If you need further information

please contact your nearest service workshop.

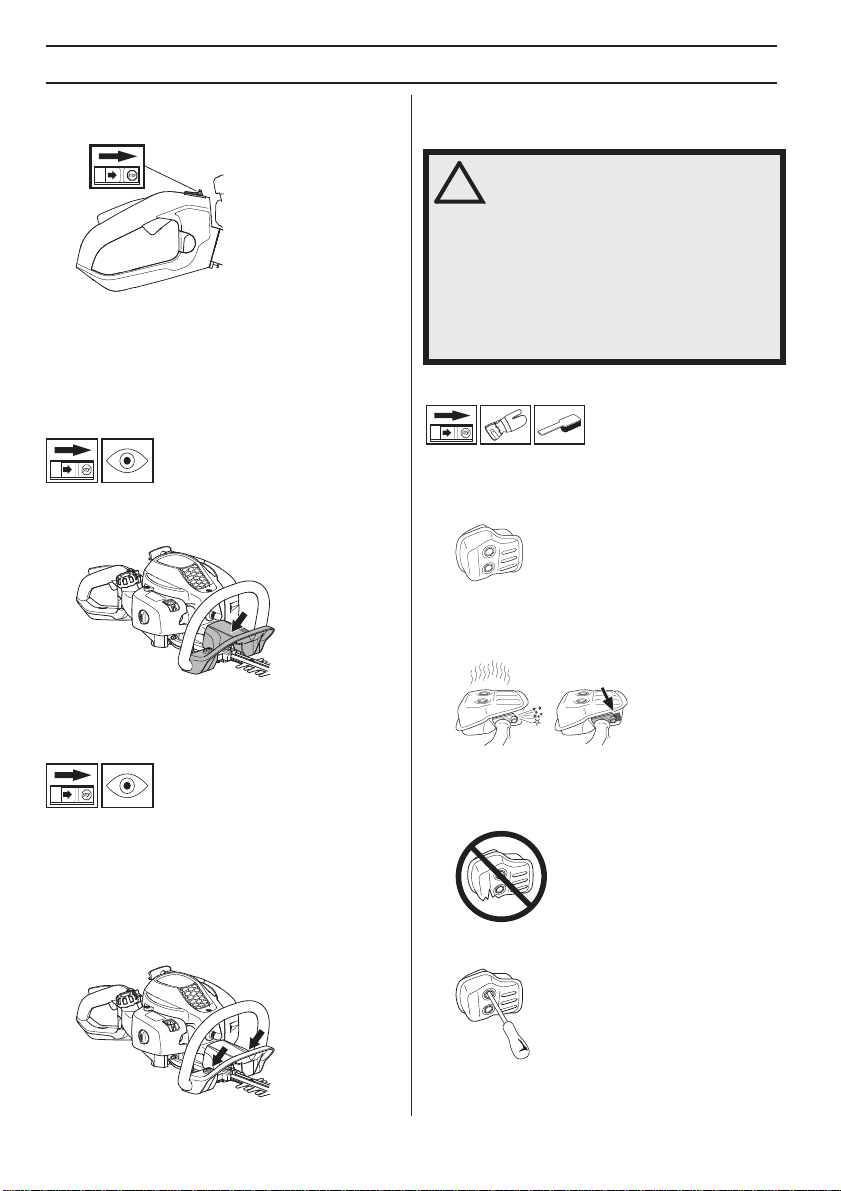

Throttle lockout

The throttle lockout is designed to prevent accidental

operation of the throttle control. When you press the lock

(A) (i.e. when you g rasp the handle) it releases the throttle

control (B). When you release the handle the throttle

control and the throttle lockout both move back to their

original positions. This movement is controlled by two

independent return springs. This arrangement means that

the throttle control is automatically locked at the idle

setting.

B

A

Make sure the throttle control is locked at the idle setting

when the throttle lockout is released.

IMPORTANT!

All servicing and repair work on the machine requires

special training. This is especially true of the machine

safety equipment. If your machine fails any of the

checks described below you must contact your service

agent. When you b uy any of our products we guar antee

the availability of professional repairs and service. If the

retailer who sells your machine is not a servicing dealer,

ask him for the address of your nearest service agent.

WARNING! Never use a machine with

faulty safety equipment. The machine’s

!

safety equipment must be checked and

maintained as described in this section.

If your machine fails any of these checks

contact your service agent to get it

repaired.

Press the throttle lockout and make sure it returns to its

original position when you release it.

′

s

Check that the throttle trigger and throttle lockout move

freely and that the return springs work properly.

See instructions under the heading Start. Start the hedge

trimmer and apply full throttle. Release the throttle trigger

and check that the blades stop and remain stationary. If

the blades move when the throttle trigger is in the idle

position then the carburettor idle setting must be adjusted.

See instructions under the heading Maintenance.

English – 7

Page 8

GENERAL SAFETY PRECAUTIONS

Stop switch

Use the stop switch to switch off the engine.

Start the engine and make sure the engine stops when

you move the stop switch to the stop setting. The stop

switch automatically returns to the start position. In order

to prevent unintentional starting, the spark plug cap must

be removed from the spark plug when assembling,

checking and/or performing maintenance.

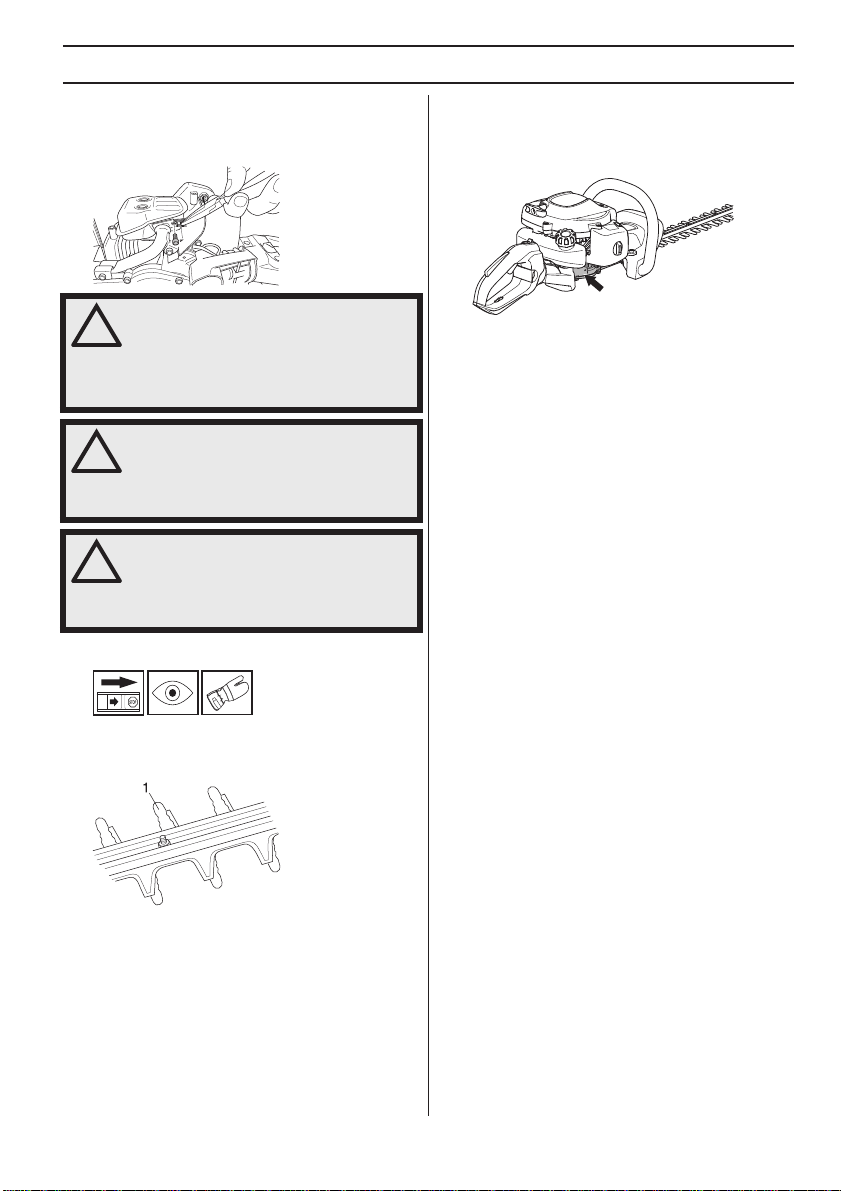

Hand guard

The hand guard prevents hands from coming into contact

with the moving blades, for e xample, if the oper ator loses

grip on the front handle.

Regularly check the vibration damping units for cracks or

deformation. Check that the vibration damping element is

undamaged and securely attached.

WARNING! Overexposure to vibration

can lead to circulatory damage or nerve

!

damage in people who have impaired

circulation. Contact your doctor if you

experience symptoms of overexposure

to vibration. Such symptoms include

numbness, loss of feeling, tingling,

pricking, pain, loss of strength, changes

in skin colour or condition. These

symptoms normally appear in the

fingers, hands or wrists. The risk

increases at low temperatures.

Muffler

The muffler is designed to keep noise levels to a minimum

and to direct exhaust fumes away from the user . A muffler

fitted with a catalytic converter is also designed to reduce

harmful exhaust gases.

In countries that have a warm and dry climate there is a

significant risk of fire. We therefore fit certain mufflers with

a spark arrestor mesh. Check whether the muffler on your

machine is fitted with this kind of mesh.

Check that the hand guard is fitted correctly.

Check that the hand guard is undamaged.

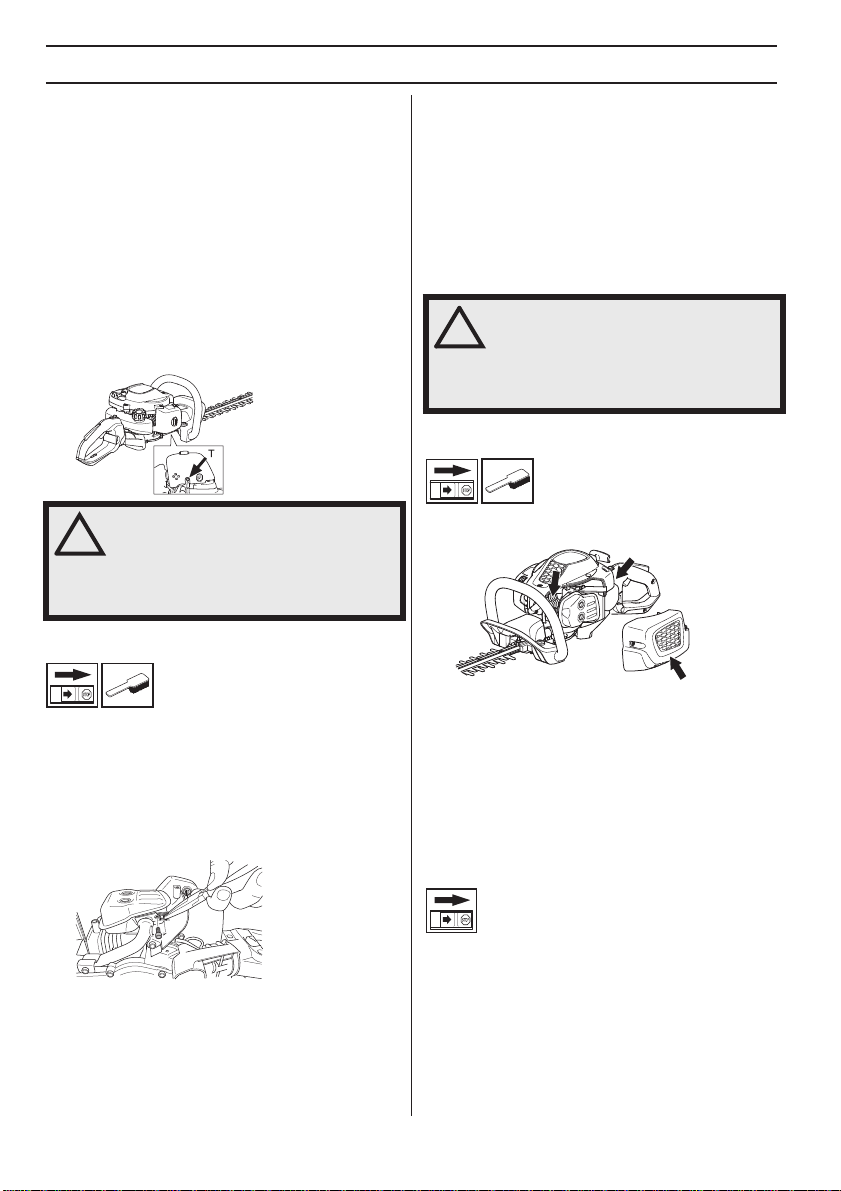

Vibration damping system

Your machine is equipped with a vibration damping

system that is designed to minimize vibration and make

operation easier.

The machine′s vibration damping system reduces the

transfer of vibration between the engine unit/cutting

equipment and the machine′s handle unit.

The engine body, including the blades, is suspended on

the handlebar using four rubber bushings.

8 – English

For mufflers it is very important that you follow the

instructions on checking, maintaining and servicing your

machine.

Never use a machine that has a faulty muffler.

Regularly check that the muffler is securely attached to

the machine.

Page 9

GENERAL SAFETY PRECAUTIONS

If the muffler on your machine is fitted with a spark

arrestor mesh this must be cleaned regularly. A blocked

mesh will cause the engine to overheat and may lead to

serious damage.

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

!

remain so for some time after stopping.

This also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fire!

WARNING! The inside of the muffler

contain chemicals that may be

!

carcinogenic. Avoid contact with these

elements in the event of a damaged

muffler.

WARNING! Bear in mind that: The

exhaust fumes from the engine are hot

!

and may contain sparks which can start

a fire. Never start the machine indoors or

near combustible material!

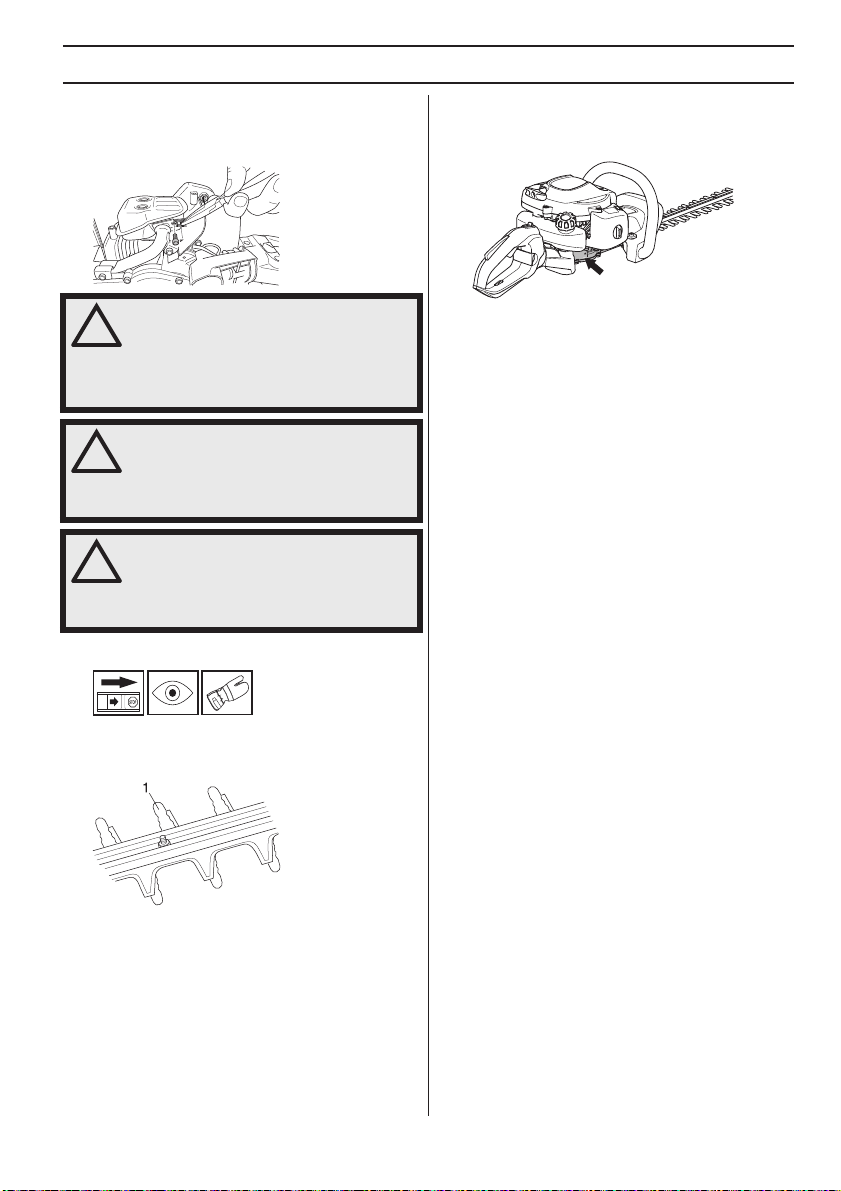

Gear

The gear housing gets hot when the machine has been in

use. To avoid burning yourself do not touch the gear

housing.

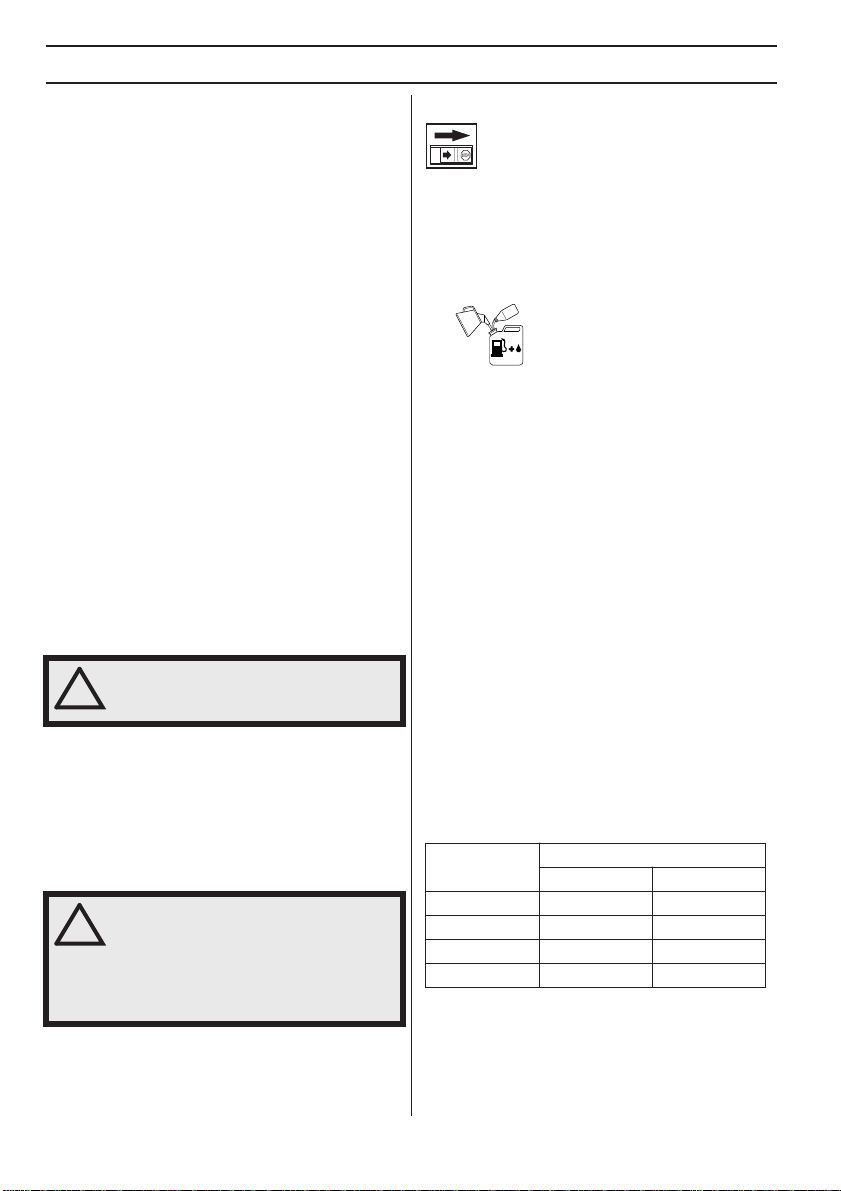

Blade and blade guard

The outer part of the blades (1) are shaped as blade

guards. The blade guard is intended to protect against

any part of the body coming into contact with the blades.

Check that the blade guard is not damaged or distorted.

Replace the cutting unit if it is bent or damaged.

English – 9

Page 10

FUEL HANDLING

Fuel safety

Never start the machine:

1 If you have spilt fuel on it. Wipe off the spillage and

allow remaining fuel to evaporate.

2 If you have spilt fuel on yourself or your clothes,

change your clothes. Wash any part of your body that

has come in contact with fuel. Use soap and water.

3 If the machine is leaking fuel. Check regularly for

leaks from the fuel cap and fuel lines.

Transport and storage

• Allow the hedge trimmer to cool down after use before

putting it away for storage.

• Store and transport the machine and fuel so that there

is no risk of any leakage or fumes coming into contact

with sparks or naked flames, for example, from

electrical machinery, electric motors, electrical relays/

switches or boilers.

• When storing and transporting fuel always use

approved containers intended for this purpose.

• When storing the machine for long periods the fuel

tank must be emptied. Contact your local petrol

station to find out where to dispose of excess fuel.

• Ensure the machine is cleaned and that a complete

service is carried out before long-term storage.

• The transport guard must always be fitted to the

cutting attachment when the machine is being

transported or in storage.

• Secure the machine during transport.

WARNING! Take care when handling fuel.

Bear in mind the risk of fire, explosion

!

and inhaling fumes.

Fuel

CAUTION! The machine is equipped with a two-stroke

engine and must always been run using a mixture of

petrol and two-stroke oil. It is important to accurately

measure the amount of oil to be mixed to ensure that the

correct mixture is obtained. When mixing small amounts

of fuel, even small inaccuracies can drastically affect the

ratio of the mixture.

WARNING! Fuel and fuel fumes are

highly inflammable and can cause

!

serious injury when inhaled or allowed to

come in contact with the skin. For this

reason observe caution when handling

fuel and make sure there is adequate

ventilation.

Petrol

CAUTION! Always use a quality petrol/oil mixture at least

90 octane (RON). If your machine is equipped with a

catalytic converter (see chapter on T echnical data) alw ays

use a good quality unleaded petrol/oil mixture. Leaded

petrol will destroy the catalytic converter.

Use low-emission petrol, also known as alkylate petrol, if

it is available.

• The lowest octane recommended is 90 (RON). If you

run the engine on a lower octane grade than 90 socalled knocking can occur. This gives rise to a high

engine temperature, which can result in serious

engine damage.

• When working at continuous high revs a higher octane

rating is recommended.

Two-stroke oil

• For best results and performance use Universal,

Universal powered by McCULLOCH two-stroke

engine oil, which is specially formulated for our aircooled two-stroke engines.

• Never use two-stroke oil intended for water-cooled

engines, sometimes referred to as outboard oil (rated

TCW).

• Never use oil intended for four-stroke engines.

• A poor oil quality and/or too high oil/fuel ratio may

jeopardise function and decrease the life time of

catalytic converters.

• Mixing ratio

1:50 (2%) with Universal, Universal powered by

McCULLOCH two-stroke oil.

1:33 (3%) with oils class JASO FB or ISO EGB

formulated for air-cooled, two-stroke engines.

Petrol, litre

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Two-stroke oil, litre

2% (1:50) 3% (1:33)

10 – English

Page 11

FUEL HANDLING

Mixing

• Always mix the petrol and oil in a clean container

intended for fuel.

• Always start by filling half the amount of the petrol to

be used. Then add the entire amount of oil. Mix

(shake) the fuel mixture. Add the remaining amount of

petrol.

• Mix (shake) the fuel mixture thoroughly before filling

the machine’s fuel tank.

• Do not mix more than one month’s supply of fuel at a

time.

• If the machine is not used for some time the fuel tank

should be emptied and cleaned.

WARNING! The catalytic converter

muffler gets very hot during and after

!

use. This also applies during idling. Be

aware of the fire hazard, especially when

working near flammable substances and/

or vapours.

Fueling

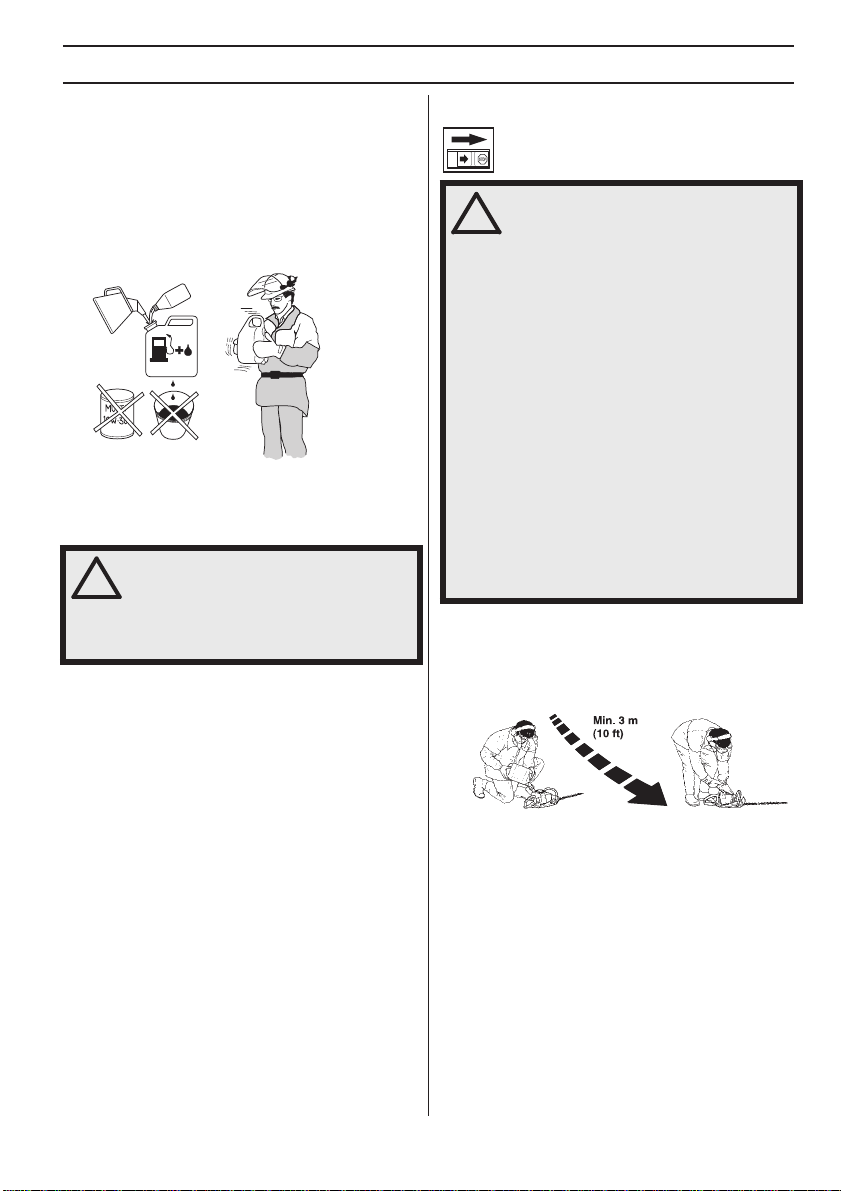

WARNING! Taking the following

precautions, will lessen the risk of fire:

!

Do not smoke or place hot objects near

fuel.

Always shut off the engine before

refuelling.

Refuel in a well ventilated area. Never

fuel the machine indoors.

Always stop the engine and let it cool for

a few minutes before refuelling.

When refuelling, open the fuel cap slowly

so that any excess pressure is released

gently.

Tighten the fuel cap carefully after

refuelling.

Always move the machine awa y from the

refuelling area and source before

starting.

• Always use a fuel container with an anti-spill valve.

• Clean the area around the fuel cap. Contamination in

the tank can cause operating problems.

• Ensure that the fuel is well mixed by shaking the

container before filling the tank.

English – 11

Page 12

STARTING AND STOPPING

Check before starting

• Inspect the working area. Remove any objects that

could be thrown out.

• Check the cutting attachment. Never use blades that

are dull, cracked or damaged.

• Check that the machine is in perfect working order.

Check that all nuts and screws are tight.

• Make sure the gear housing is lubricated correctly.

See instructions under the heading Gear housing.

• Check that the cutting attachment always stops when

the engine is idling.

• Only use the machine for the purpose it was intended

for.

• Make sure that the handle and safety features are in

good working order. Nev er use a machine that lacks a

part or has been modified outside its specifications.

• All covers must be correctly fitted and undamaged

before you start the machine.

Starting and stopping

WARNING! The complete gear housing

must be fitted before the machine is

!

started, otherwise the clutch may loosen

and cause personal injury.

Always move the machine about 3

metres from the refuelling position

before starting. Place the machine on a

firm surface. Remember that the blades

may start to move when the engine is

started. Make sure the blades cannot

come into contact with any object. Make

sure that no unauthorised persons are in

the working area, otherwise there is a

risk of serious personal injury. The safety

distance is 15 metres.

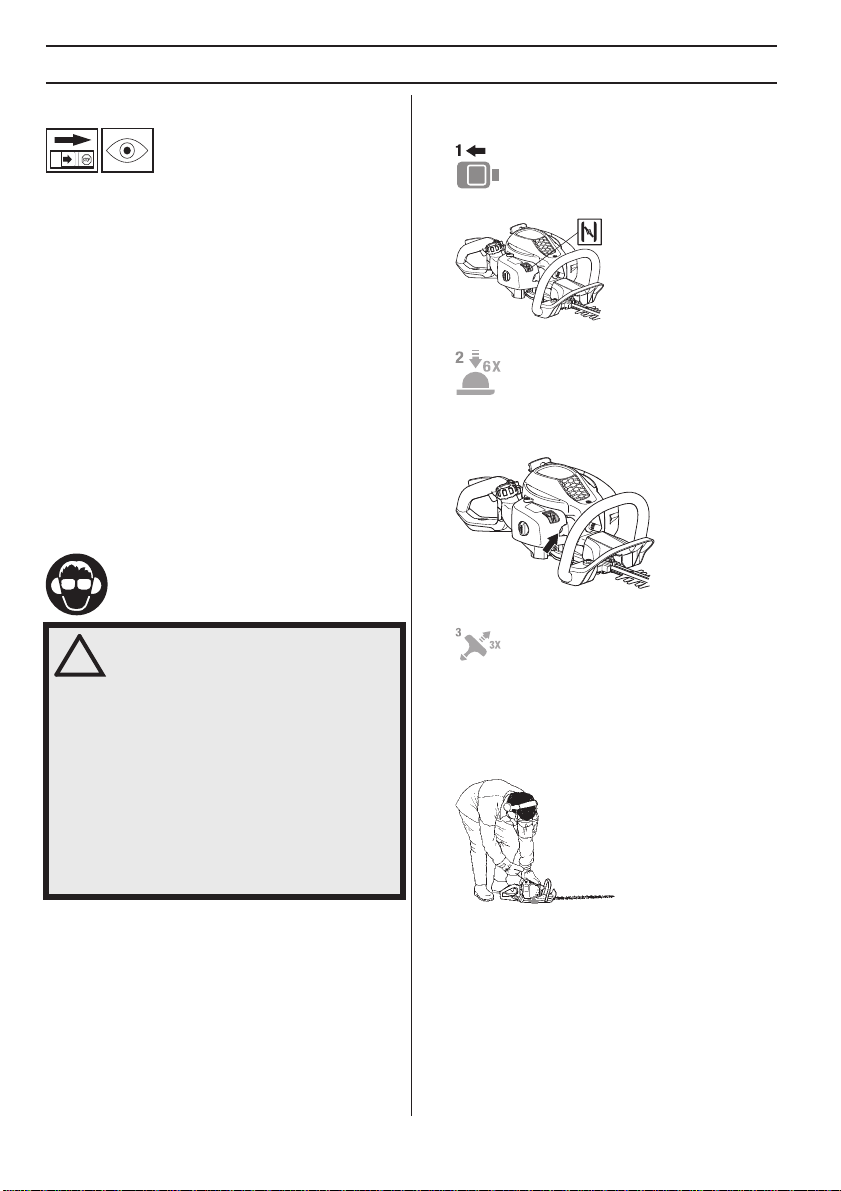

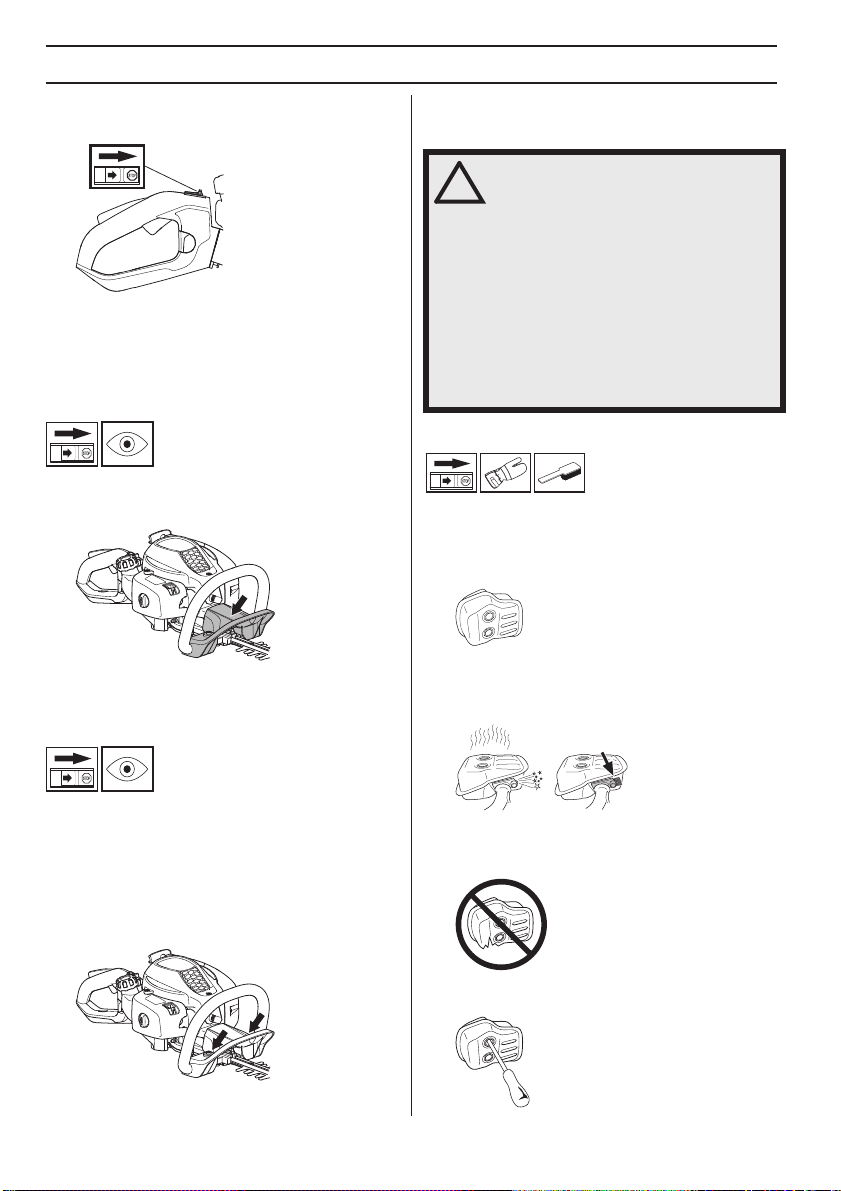

Cold engine

(1) Choke control

Set the choke control in the choke position.

(2) Primer bulb:

Press the air purge diaphragm repeatedly until fuel

begins to fill the diaphragm (about 6 times). The

diaphragm need not be completely filled.

(3) Starting

Hold the body of the machine on the ground using your

left hand (CAUTION! Not with your f oot!). Grip the starter

handle, slowly pull out the cord with your right hand until

you feel some resistance (the starter pawls grip), now

quickly and powerfully pull the cord. Never twist the

starter cord around your hand.

12 – English

Page 13

STARTING AND STOPPING

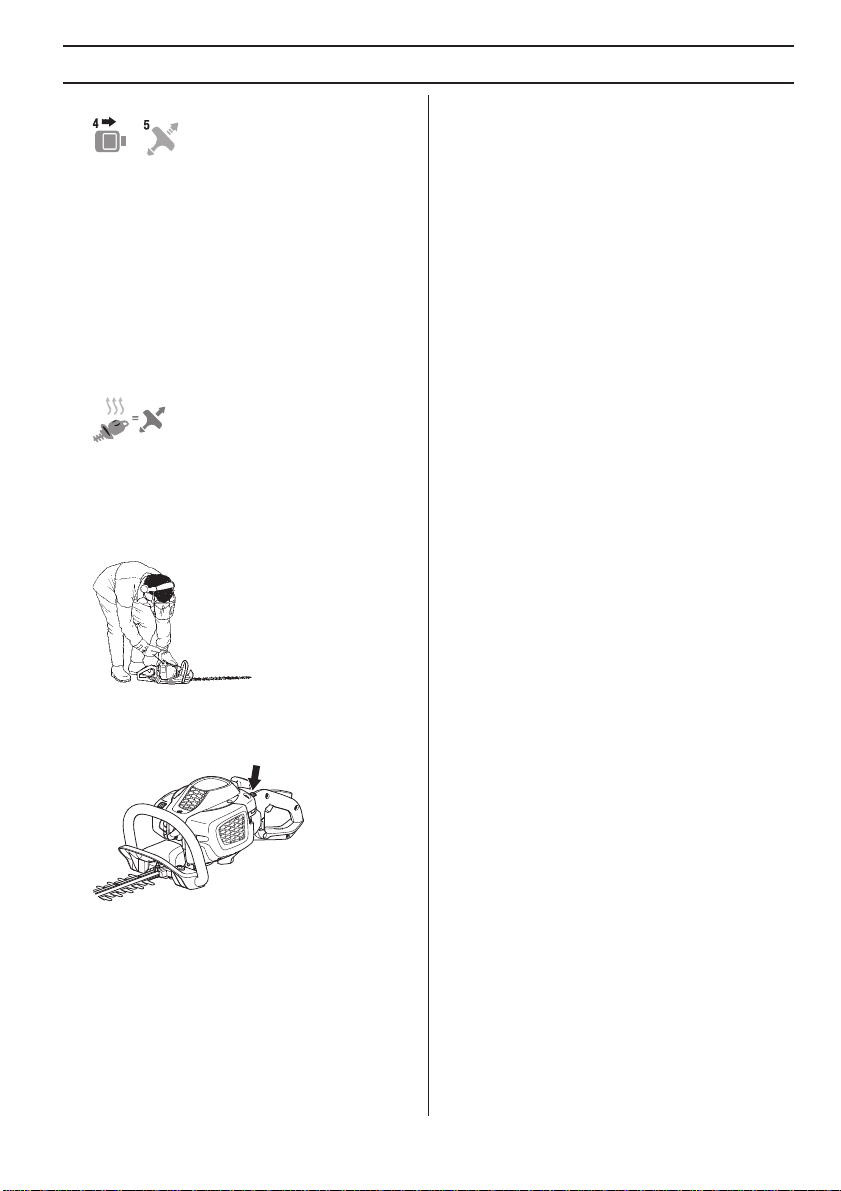

(4, 5)

Push the choke control back to its original position as

soon as the engine fires, and continue trying to start until

the engine starts.

CAUTION! When the choke control is pushed back to its

original position, the engine runs at a heightened speed,

the so called start throttle position, and the blades then

move. Start throttle position is released by throttling using

the throttle lever.

CAUTION! Do not pull the starter cord all the way out and

do not let go of the starter handle when the cord is fully

extended. This can damage the machine.

Warm engine

Hold the body of the machine on the ground using your

left hand (CAUTION! Not with your f oot!). Grip the starter

handle, slowly pull out the cord with your right hand until

you feel some resistance (the starter pawls grip), now

quickly and powerfully pull the cord. Never twist the

starter cord around your hand.

Stopping

The engine is switched off by moving the stop switch to

the stop position.

CAUTION!

The stop switch automatically returns to the start position.

In order to prevent unintentional starting, the spark plug

cap must be removed from the spark plug when

assembling, checking and/or performing maintenance.

English – 13

Page 14

WORKING TECHNIQUES

General working instructions

IMPORTANT!

This section takes up the basic safety precautions for

working with a hedge trimmer.

If you encounter a situation where you are uncertain

how to proceed you should ask an expert. Contact y our

dealer or your service workshop.

Avoid all usage which you consider to be beyond your

capability.

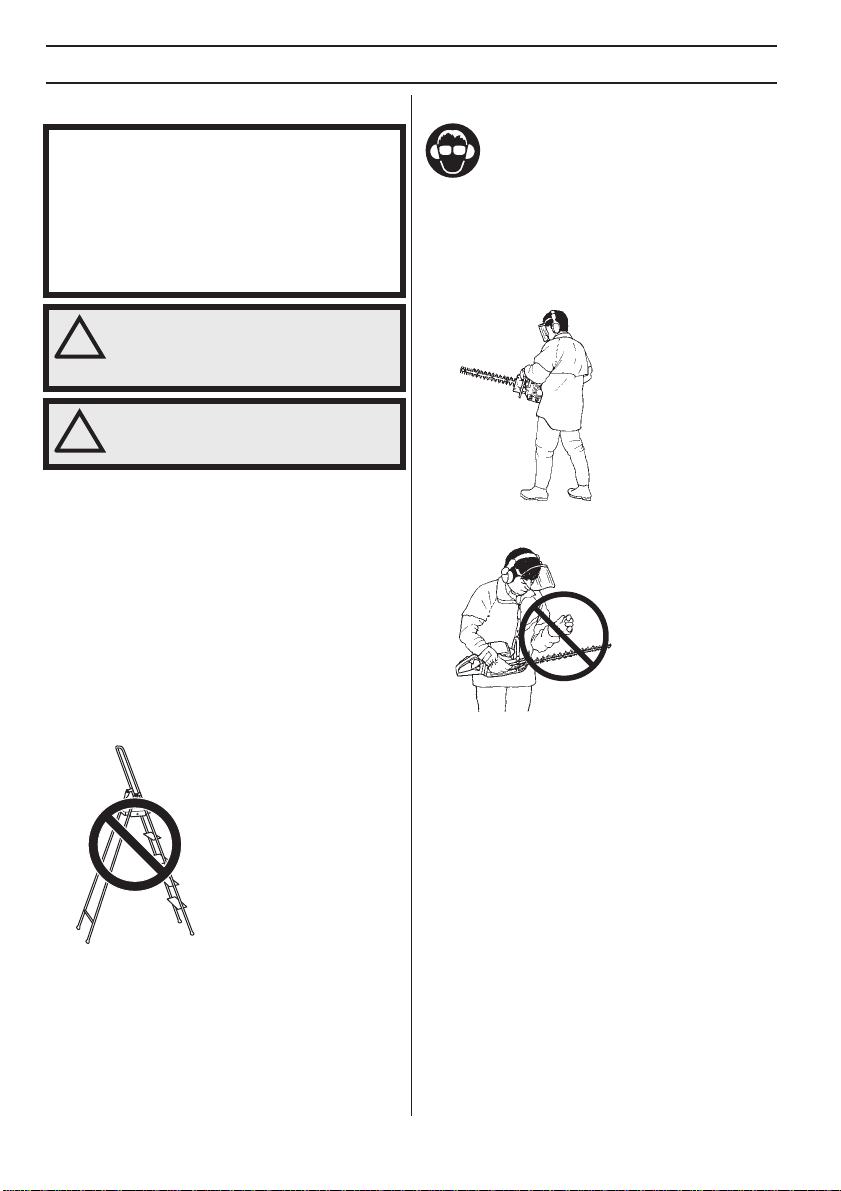

WARNING! The machine can cause

serious personal injury. Read the safety

!

instructions carefully. Learn how to use

the machine.

WARNING! Cutting tool. Do not touch the

tool without first switching off the

!

engine.

Safety instructions regarding the

surroundings

• Never allow children to use the machine.

• Observe your surroundings and make sure that there

is no risk of people or animals coming into contact

with the cutting equipment.

• Ensure that no-one comes closer than 15 m while you

are working.

• Never allow anyone else to use the machine without

first ensuring that they have understood the contents

of the operator’s manual.

• Never work from a ladder, stool or any other raised

position that is not fully secured.

• Keep in mind that the operator is responsible for

accidents or hazards occuring to other people or their

property.

Safety instructions while working

• Always ensure you have a safe and stable working

position.

• Never leav e the machine unsupervised with the motor

running.

• Always use both hands to hold the machine. Hold the

machine in front of your body.

• Make sure that your hands and feet do not come near

the cutting attachment when the engine is running.

• When the engine is switched off, keep y our hands and

feet away from the cutting attachment until it has

stopped completely.

• Watch out for stumps of branches that can be thrown

out during cutting.

• Do not cut too close to the ground. Stones and other

objects can be thrown out.

• Check the working area for foreign objects such as

electricity cables, insects and animals, etc, or other

objects that could damage the cutting attachment,

such as metal items.

• If any foreign object is hit or if vibrations occur stop the

machine immediately. Disconnect the HT lead from

the spark plug. Check that the machine is not

damaged. Repair any damage.

14 – English

Page 15

WORKING TECHNIQUES

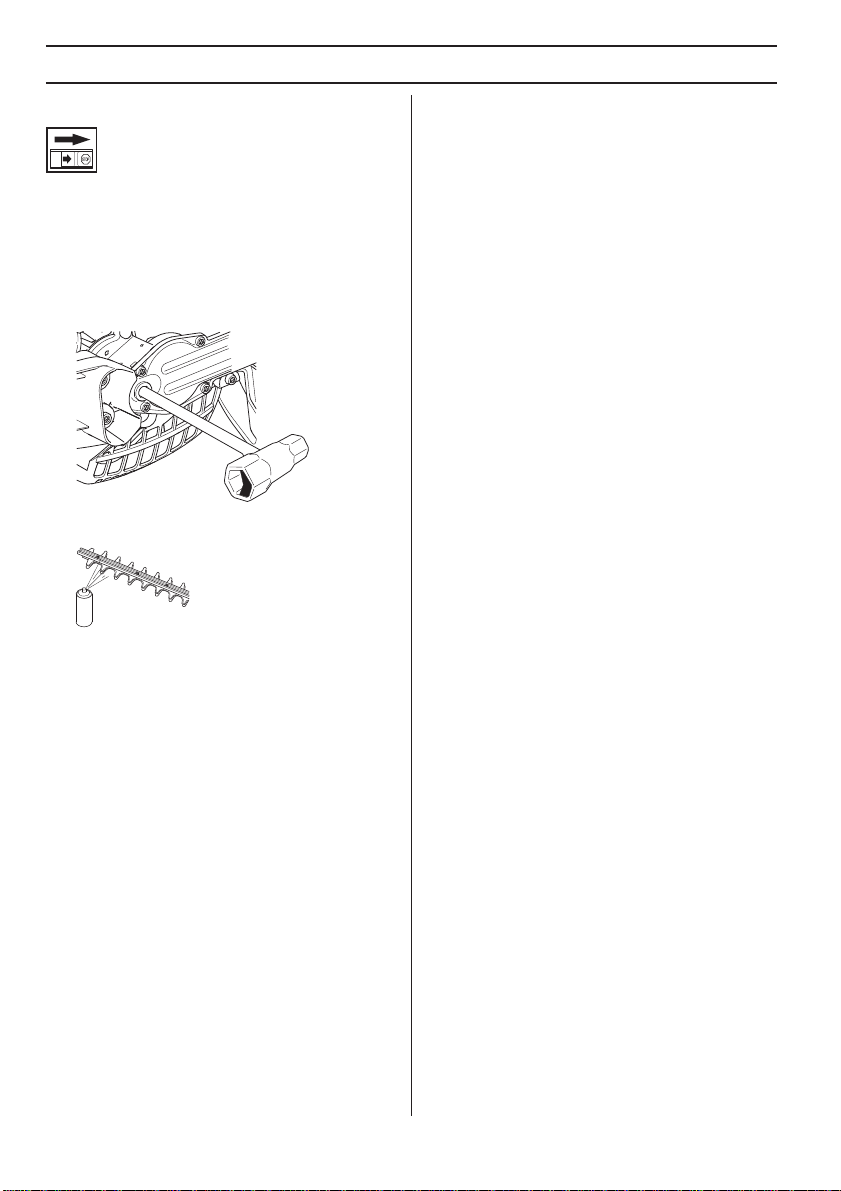

• If anything jams in the blades while you are working,

switch off the engine and wait until it has stopped

completely before cleaning the blades. Disconnect the

HT lead from the spark plug.

If the blades get stuck, they can be loosened by

sticking the combination spanner into the gear

housing. Remove the lubricant plug and stick the

combination spanner into the gearing and turn it back

and forth.

• Hold the machine as close to your body as possible to

get the best balance.

Safety instructions after completing work

• The transport guard should always be fitted to the

cutting attachment when the machine is not in use.

• Make sure the cutting attachment has stopped before

cleaning, carrying out repairs or an inspection.

Disconnect the HT lead from the spark plug.

• Always wear heavy-duty gloves when repairing the

cutting attachment. This is extremely sharp and can

easily cause cuts.

• Store the machine out of reach of children.

• Use only original spare parts for repairs.

Basic working techniques

• Work with a swinging action from the bottom upwards

when trimming sides.

• Adjust the throttle setting to suit the load.

• When trimming a hedge the engine should always

face away from the hedge.

• Make sure that the tip does not touch the ground.

• Do not rush the work, but work steadily until all the

branches have been cut back cleanly.

ERGOLITE 6028

The hedge trimmer’s rear handle can be set in five

positions by pulling out the catch. See figure. When the

handle is adjusted, the hedge trimmer must be idling or

not running.

• While working the handle should always be facing

upwards irrespective of how the hedge trimmer is

directed.

English – 15

Page 16

MAINTENANCE

Carburettor

Adjustment of the idle speed

Before any adjustments are made, make sure that the air

filter is clean and the air filter cover is fitted. Make sure the

start throttle position is disengaged.

Adjust the idle speed using the idle adjustment screw T, if

it is necessary to readjust. First turn the T screw clockwise

until the cutting attachment starts to move. Then turn the

screw anticlockwise until the cutting attachment stops.

The idle speed is correctly adjusted when the engine runs

smoothly in every position. The idle speed should also be

well below the speed at which the cutting attachment

starts to move.

Rec. idle speed: See the Technical data section.

is incorrectly adjusted or that too much oil has been mixed

with the petrol.

On mufflers fitted with a catalytic converter, the mesh

must be checked, and if necessary cleaned, monthly. If

the mesh is damaged it must be replaced. If the mesh

is frequently blocked, this can be a sign that the

performance of the catalytic converter is impaired.

Contact your dealer to inspect the muffler. A blocked

mesh will cause the machine to overheat and result in

damage to the cylinder and piston.

CAUTION! Ne v er use a machine with a def ective m uffler .

WARNING! Mufflers fitted with catalytic

converters get very hot during use and

!

remain so for some time after stopping.

This also applies at idle speed. Contact

can result in burns to the skin.

Remember the risk of fire!

Cooling system

WARNING! If the idle speed cannot be

adjusted so that the cutting attachment

!

stops, contact your dealer/service

workshop. Do not use the machine until

it has been correctly adjusted or

repaired.

Muffler

CAUTION! Some mufflers are fitted with a catalytic

converter. See chapter on Technical data to see whether

your machine is fitted with a catalytic converter.

The muffler is designed to reduce the noise level and to

direct the exhaust gases away from the operator. The

exhaust gases are hot and can contain sparks, which may

cause fire if directed against dry and combustible

material.

Some mufflers are equipped with a special spark arrestor

mesh. If your machine has this type of muffler, the mesh

must be cleaned. This is best done with a wire brush.

On mufflers without a catalytic converter, the mesh should

be cleaned or replaced if necessary once a week. If the

mesh is damaged it must be replaced. If the mesh is

frequently blocked, this can be a sign that the carburettor

To keep the working temperature as low as possible the

machine is equipped with a cooling system.

The cooling system consists of:

1 Cooling fins on the cylinder.

2 Cylinder cover (directs cold air over the cylinder).

3 Air intake through the crankcase (inside the tank).

Clean the cooling system with a brush once a week, more

often in demanding conditions. A dirty or blocked cooling

system results in the machine overheating which causes

damage to the piston and cylinder.

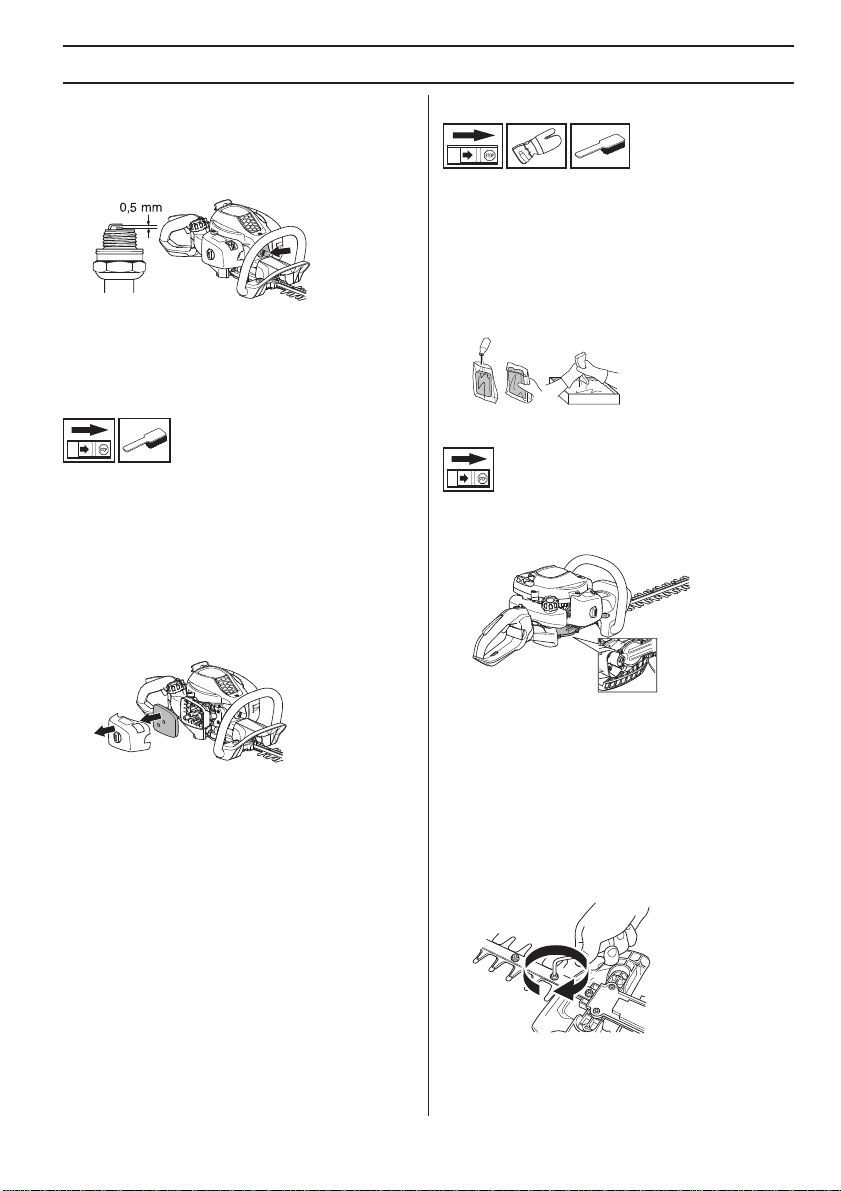

Spark plug

The spark plug condition is influenced by:

• Incorrect carburettor adjustment.

• An incorrect fuel mixture (too much or incorrect type

of oil).

• A dirty air filter.

These factors cause deposits on the spark plug

electrodes, which may result in operating problems and

starting difficulties.

16 – English

Page 17

MAINTENANCE

If the machine is low on power, difficult to start or runs

poorly at idle speed: always check the spark plug first

before taking any further action. If the spark plug is dirty,

clean it and check that the electrode gap is 0,5 mm. The

spark plug should be replaced after about a month in

operation or earlier if necessary.

CAUTION! Always use the recommended spark plug

type! Use of the wrong spark plug can damage the piston/

cylinder. Check that the spark plug is fitted with a

suppressor.

Air filter

The air filter must be regularly cleaned to remove dust

and dirt in order to avoid:

• Carburettor malfunctions

• Starting problems

• Loss of engine power

• Unnecessary wear to engine parts.

• Excessive fuel consumption.

Clean the filter every 25 hours, or more regularly if

conditions are exceptionally dusty.

Oiling the air filter

Always use filter oil, art. no. 531 00 92-48. The filter oil

contains a solvent to make it spread evenly through the

filter. You should therefore avoid skin contact.

Put the filter in a plastic bag and pour the filter oil over it.

Knead the plastic bag to distribute the oil. Squeeze the

excess oil out of the filter inside the plastic bag and pour

off the excess before fitting the filter to the machine. Nev er

use common engine oil. This would drain through the filter

quite quickly and collect in the bottom.

Gear

There is a plug for filling lubricant on the gear housing.

Use the grease tube to fill with grease and repeat every

25 hours. Use Husqvarna’s special grease.

Cleaning the air filter

Remove the air filter cover and tak e out the filter. Wash it

clean in warm, soapy water. Allow the filter to dry and then

oil it in according to the instructions.

An air filter that has been in use for a long time cannot be

cleaned completely . The filter must therefore be replaced

with a new one at regular intervals. A dama ged air filter

must always be replaced.

CAUTION! The gear housing must not be filled

completely with grease. The grease expands as the

machine heats up during operation. If the gear housing

was completely filled with grease it could damage the

seals and lead to leakage of grease.

The grease in the bevel gear does not normally need to

be changed except if repairs are carried out.

Cutting unit

Check that the cutting units' screws are fitted correctly.

Tighten them with a tightening torque of 7-10 Nm.

English – 17

Page 18

MAINTENANCE

Cleaning and lubrication

Clean any resin and plant residue from the blades using

cleaning agent 531 00 75-13 (UL22) before and after

using the machine.

Check that the blade edges are not damaged or

deformed. File away any burrs.

Check that the blades move freely. Remove the

lubrication plug in the gear housing and stick in the

combination spanner and turn back and forth.

Lubricate the blade bars with special grease, part no. 531

00 75-12 (UL 21) before long periods of storage.

18 – English

Page 19

MAINTENANCE

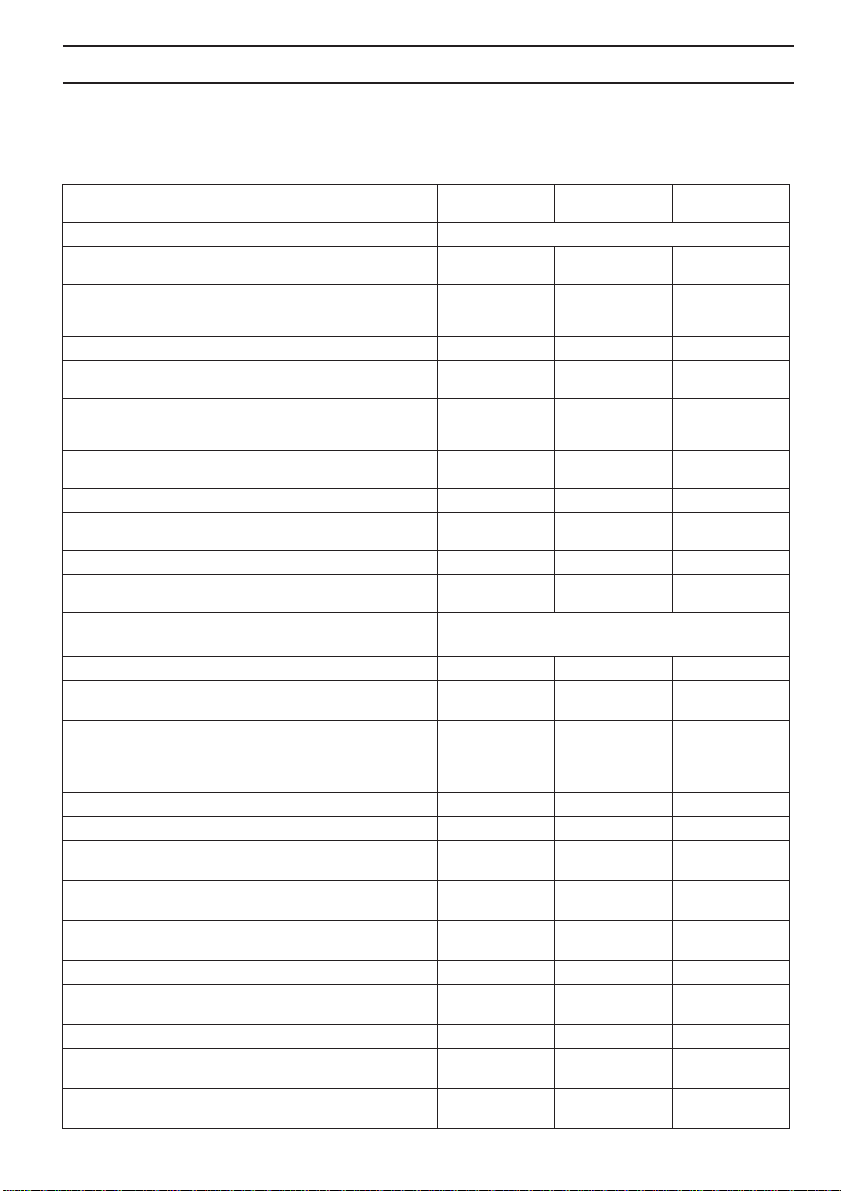

Maintenance schedule

The following is a list of the maintenance that must be performed on the machine. Most of the items are described in the

Maintenance section. The user must only carry out the maintenance and service work described in this Operator’s

Manual. More extensive work must be carried out by an authorized service workshop.

Maintenance Before use:

Clean the outside of the machine. After each time the machine is used

Make sure the throttle trigger lock and the throttle function

correctly from a safety point of view.

In order to reduce the risk of fire, dirt, leaves and surplus

lubricant, etc must be cleaned from the muffler, exhaust

pipe and engine.

Check that the stop switch works correctly. X

Check that the blades do not move when the engine is

idling.

Check that the blades are undamaged and show no signs

of cracking or other damage. Replace the blades if

necessary.

Check that the blade guard is not damaged or distorted.

Replace the blade if the blade guard is bent or damaged.

Replace the cutting unit if it is bent or damaged. X

Check that the hand guard is not damaged. Replace the

guard if damaged.

Check that nuts and screws are tight. X

Check that there are no fuel leaks from the engine, tank or

fuel lines.

Clean the air filter and oil it in.

Clean more often if conditions are exceptionally dusty.

Check the starter and starter cord. X

Check that the vibration damping elements are not

damaged.

Clean the outside of the spark plug. Remove it and check

the electrode gap. Adjust the gap to 0.5 mm or replace the

spark plug. Check that the spark plug is fitted with a

suppressor.

Clean the machine’s cooling system. X

Clean the outside of the carburettor and the space around it.

Fill the gear housing with grease. This should be carried out

approximately every 25 working hours.

Check that the screws that hold the blades together are

correctly tightened.

Check and clean the spark arrestor mesh on the muffler

(only applies to mufflers fitted with a catalytic converter).

Clean the inside of the fuel tank. X

Check the inside of the fuel filter for any dirt or if the fuel

hose has any cracks or other defects. Replace if necessary.

Check all cables and connections. X

Check the clutch, clutch springs and the clutch drum for wear .

Replace if necessary by an autorized service workshop.

Replace the spark plug. Check that the spark plug is fitted

with a suppressor.

X

X

X

X

X

X

X

After 40 hours

in use

(25 tim).

X

X

X

X

X

X

After 100 hours

in use

X

X

X

English – 19

Page 20

TECHNICAL DATA

Technical data

Technical data SUPERLITE 4528 ERGOLITE 6028

Engine

Cylinder displacement, cm

Cylinder bore, mm 32 32

Stroke, mm 27 27

Idle speed, rpm 2800 2800

Recommended max. speed, rpm 9000 9000

Max. engine output, acc. to ISO 8893, kW/ rpm 0,6/7800 0,6/7800

Catalytic converter muffler Yes Yes

Speed-regulated ignition system Yes Yes

Ignition system

Spark plug NGK CMR6A NGK CMR6A

Electrode gap, mm 0,5 0,5

Fuel and lubrication system

Fuel tank capacity, litre 0,3 0,3

Weight

Weight without fuel, kg 4,8 5,0

Noise emissions

(see note 1)

Sound power level, measured dB(A) 100 100

Sound power level, guaranteed L

Sound levels

(see note 2)

Equivalent sound pressure level at the operator’s ear, measured

according to EN ISO 10517, dB(A):

Vibration levels

(see note 3)

Equivalent vibration levels (a

ISO 10517, m/s

Front/rear handles: 3,5/4,4 4,1/4,2

Blades

Type Double sided Double sided

Length, mm 450 590

Blade speed, cuts/min 4050 4050

Note 1: Noise emissions in the environment measured as sound power (LWA) in conformity with EC directive 2000/14/

EC. Reported sound power le v el f or the machine has been measured with the original cutting attachment that giv es the

highest level. The difference between guaranteed and measured sound power is that the guaranteed sound pow er also

includes dispersion in the measurement result and the variations between different machines of the same model

according to Directive 2000/14/EC.

Note 2: Reported data for equivalent sound pressure level for the machine has a typical statistical dispersion (standard

deviation) of 1 dB (A).

Note 3: Reported data for equivalent vibration level has a typical statistical dispersion (standard deviation) of 1 m/s

2

3

dB(A) 101 101

WA

) at handles, measured according to EN

hv,eq

21,7 21,7

93 93

2

.

20 – English

Page 21

TECHNICAL DATA

EC Declaration of Conformity (Applies to Europe only)

Husqvarna AB, SE-561 82 Huskvarna, Sweden, tel: +46-36-146500, declare under sole responsibility that the hedge

trimmers McCULLOCH SUPERLITE 4528, ERGOLITE 6028 from 2016’s serial numbers and onwards (the year is

clearly stated in plain text on the type plate with subsequent serial number), are in conformity with the standards or or

other normative documents following the provisions in the COUNCIL’S DIRECTIVES:

- of May 17, 2006 ”relating to machinery” 2006/42/EC.

- of February 26, 2014 ”relating to electromagnetic compatibility” 2014/30/EU.

- of May 8, 2000 ”relating to the noise emissions in the environment” 2000/14/EC. Conformity assessment according

to Annex V .

For information relating to noise emissions, see the Technical data chapter. The following standards ha v e been applied:

EN ISO 12100-2:2010, CISPR 12:2007/A1:2009, EN ISO 10517:2009/A1:2013

SMP Svensk Maskinprovning AB, Box 7035, SE-750 07 Uppsala, Sweden, has performed voluntary type examination

on behalf of Husqvarna AB. The certificates are numbered:

SEC/11/2327, 01/094/017 - SUPERLITE 4528, ERGOLITE 6028

Huskvarna March 30, 2016

Per Gustafsson, Development manager (Authorized representative for Husqvarna AB and responsible for technical

documentation.)

English – 21

Page 22

SYMBOLFÖRKLARING

Symboler

VARNING! En häc ksax kan felaktigt eller

slarvigt använd vara ett farligt redskap,

som kan orsaka allvarlig, till och med

livshotande, skada. Det är mycket viktigt

att du läser och förstår innehållet i denna

bruksanvisning.

Läs igenom bruksanvisningen

noggrant och förstå innehållet

innan du använder maskinen.

Övriga på maskinen angivna symboler/dekaler avser

specifika krav för certifieringar på vissa marknader.

Motorn stängs av genom att

stoppkontakten förs till stoppläge. OBS!

Stoppkontakten återgår automatiskt till

startläge. För att undvika ofrivillig start,

måste därför alltid tändhatten avlägsnas

från tändstiftet vid montering, kontroll och/eller underhåll.

Använd alltid godkända

skyddshandskar.

Använd alltid:

• Godkända hörselskydd

• Godkända ögonskydd

Denna produkt överensstämmer med

gällande EG-direktiv.

Använd alltid godkända

skyddshandskar.

Använd halkfria och stadiga stövlar eller

skor.

Bulleremissioner till omgivningen enligt

Europeiska Gemenskapens direktiv.

Maskinens emission anges i kapitel

Tekniska data och på dekal.

Tändning; choke: Ställ chokereglaget i

chokeläge.

Bränslepump.

Regelbunden rengöring krävs.

Okulär kontroll.

Skyddsglasögon eller visir måste

användas.

Startinstruktion Se

anvisningar under rubrik Start

och stopp.

22 – Svenska

Page 23

INNEHÅLL

!

!

!

Innehåll Innan start måste följande

SYMBOLFÖRKLARING

Symboler .............................................................. 22

INNEHÅLL

Innehåll ................................................................. 23

Innan start måste följande observeras: ................ 23

INLEDNING

Bäste kund! .......................................................... 24

VAD ÄR VAD?

Vad är vad? .......................................................... 25

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Viktigt .................................................................... 26

Personlig skyddsutrustning ................................... 26

Maskinens säkerhetsutrustning ............................ 27

BRÄNSLEHANTERING

Bränslesäkerhet ................................................... 30

Drivmedel ............................................................. 30

Tankning ............................................................... 31

START OCH STOPP

Kontroll före start .................................................. 32

Start och stopp ..................................................... 32

ARBETSTEKNIK

Allmänna arbetsinstruktioner ................................ 34

UNDERHÅLL

Förgasare ............................................................. 36

Ljuddämpare ........................................................ 36

Kylsystem ............................................................. 36

Tändstift ................................................................ 37

Luftfilter ................................................................. 37

Växel ..................................................................... 37

Klippaggregat ....................................................... 38

Rengöring och smörjning ..................................... 38

Underhållsschema ................................................ 39

TEKNISKA DATA

Tekniska data ....................................................... 40

EG-försäkran om överensstämmelse ................... 41

observeras:

Läs igenom bruksanvisningen noggrant.

VARNING! Långvarig exponering för

buller kan ge bestående hörselskador.

Använd därför alltid godkända

hörselskydd.

VARNING! Under inga förhållanden får

maskinens ursprungliga utformning

ändras utan tillstånd från tillverkaren.

Använd alltid originaltillbehör. Icke

auktoriserade ändringar och/eller

tillbehör kan medföra allvarliga skador

eller dödsfall för föraren eller andra.

VARNING! En häcksax kan felaktigt eller

slarvigt använd vara ett farligt redskap,

som kan orsaka allvarlig, till och med

livshotande, skada. Det är mycket viktigt

att du läser och förstår innehållet i denna

bruksanvisning.

Svenska – 23

Page 24

INLEDNING

Bäste kund!

Tack för att du använder en McCulloch-produkt! Du är därmed en del av en historia som tog sin början för länge sedan,

när McCulloch Corporation startade sin tillverkning av motorer under andra världskriget. Från och med 1949, när

McCulloch lanserade den första lätta enmansmotorsågen, skulle skogsarbetet aldrig bli sig likt igen.

Utvecklingen av innovativa motorsågar skulle fortsätta genom årtiondena, och verksamheten utökades, först med

motorer för flygplan och gokarts på 1950-talet, och sedan med minimotorsågar på 1960-talet. På 1970- och 80-talet

utökades sortimentet med trimmers och lövblåsare.

Idag bygger McCulloch som en del av Husqvarna-koncernen vidare på den tradition av kraftfulla motorer, tekniska

innovationer och utmärkande design som varit vårt kännetecken i mer än ett halvsekel. Minskad bränsleförbrukning,

minskade utsläpp och lägre ljudnivåer är av högsta prioritet för oss, på samma sätt som att förbättra säkerheten och

användarvänligheten.

Vi hoppas att du kommer att vara nöjd med din McCulloch-produkt, som är utformad för att vara din följeslagare under

en lång tid framöver. Genom att följa råden i bruksanvisningen gällande användning, service och underhåll kan

produktens livslängd utökas. Om du behöv er professionell hjälp med reparation eller service, kan du an vända dig av vår

Service Locator på www.mcculloch.biz.

McCulloch arbetar ständigt med att vidareutveckla sina produkter och förbehåller sig därför rätten till ändringar

beträffande bl.a. form och utseende utan föregående meddelande.

Den här bruksanvisningen kan också laddas ned från www.mcculloch.biz.

24 – Svenska

Page 25

V AD ÄR V AD?

2

7

Vad är vad?

1 Bruksanvisning

2 Handtag

3 Gasspärr

4 Tanklock

5 Chokereglage

6 Främre handtag

7 Kniv och knivskydd

8 Transportskydd

9 Luftfilterkåpa

10 Bränslepump.

11 Bränsletank

12 Spärr för handtaget (ErgoLite 6028)

13 Gasreglage

14 Tändhatt och tändstift

15 Cylinderkåpa

16 Starthandtag

17 Stoppkontakt

18 Påfyllning av smörjmedel, växel

19 Växel

20 Handskydd

21 Kombinyckel

22 Fettub

Svenska – 25

Page 26

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Viktigt

VIKTIGT!

Maskinen är endast konstruerad för klippning av grenar

och kvistar.

Använd aldrig en maskin som modifierats så att den ej

längre överensstämmer med originalutförandet.

Använd aldrig maskinen om du är trött, om du har

druckit alkohol eller om du tar mediciner, som kan

påverka din syn, ditt omdöme eller din kroppskontroll.

Använd personlig skyddsutrustning. Se anvisningar

under rubrik ”Personlig skyddsutrustning”.

Använd aldrig maskinen vid extrema klimatförhållanden

såsom sträng kyla eller mycket varmt och/eller fuktigt

klimat.

Använd aldrig en maskin som är felaktig. Följ

underhålls-, kontroll- och serviceinstruktioner i denna

bruksanvisning. Vissa underhålls- och serviceåtgärder

skall utföras av tränade och kvalificerade specialister.

Se anvisningar under rubrik Underhåll.

Samtliga kåpor och skydd måste vara monterade före

start. Se till att tändhatt och tändkabel är oskadade för

att undvika risk för elektrisk stöt.

VARNING! Denna maskin alstrar under

drift ett elektromagnetiskt fält. Detta fält

!

kan under vissa omständigheter ge

påverkan på aktiva eller passiva

medicinska implantat. För att reducera

risken för allvarliga eller livshotande

skador rekommenderar vi därför

personer med implantat att rådgöra med

läkare samt tillverkaren av det

medicinska implantatet innan denna

maskin används.

VARNING! Felaktiga knivar kan öka

risken för olyckor.

!

Personlig skyddsutrustning

VIKTIGT!

En häcksax kan felaktigt eller slarvigt använd vara ett

farligt redskap, som kan orsaka allvarlig, till och med

livshotande, skada. Det är myc ket viktigt att du läser och

förstår innehållet i denna bruksanvisning.

Vid all användning av maskinen skall godkänd personlig

skyddsutrustning användas. P ersonlig skyddsutrustning

eliminerar inte skaderisken, men den reducerar effekten

av en skada vid ett olyckstillbud. Be din återförsäljare

om hjälp vid val av utrustning.

VARNING! Var alltid uppmärksam på

varningssignaler eller tillrop när

!

hörselskydd används. Tag alltid av

hörselskydden så snart motorn stoppats.

HÖRSELSKYDD

Hörselskydd med tillräcklig dämpeffekt ska användas.

ÖGONSKYDD

Godkända ögonskydd skall alltid användas. An vänds visir

måste även godkända skyddsglasögon användas. Med

godkända skyddsglasögon menas de som uppfyller

standard ANSI Z87.1 för USA eller EN 166 för EU-länder.

!

!

26 – Svenska

VARNING! Att köra en motor i ett instängt

eller dåligt ventilerat utrymme kan

orsaka dödsfall genom kvävning eller

kolmonoxidförgiftning.

VARNING! Tillåt aldrig barn att använda

eller vara i närheten av maskinen.

Eftersom maskinen är utrustad med

återfjädrande stoppkontakt och kan

startas med låg hastighet och kraft på

starthandtaget, kan även små barn under

vissa omständigheter åstadkomma den

kraft som behövs för att starta maskinen.

Detta kan innebära risk för allvarlig

personskada. Avlägsna därför

tändhatten när maskinen inte är under

uppsikt.

HANDSKAR

Handskar ska användas när det behövs, t ex vid

montering av skärutrustning.

STÖVLAR

Använd halkfria och stadiga stövlar eller skor.

Page 27

ALLMÄNNA SÄKERHETSINSTRUKTIONER

KLÄDSEL

Använd rivstarkt material i klädseln och undvik alltför vida

kläder som lätt hakar fast i ris och grenar. Använd alltid

kraftiga långbyxor. Bär inte smycken, kortbyxor eller

sandaler och gå inte barfota. Se till att håret inte hänger

nedanför axlarna.

FÖRSTA FÖRBAND

Första förband ska alltid finnas till hands.

Maskinens säkerhetsutrustning

I detta avsnitt förklaras vilka maskinens säkerhetsdetaljer

är, vilken funktion de har samt hur kontroll och underhåll

skall utföras för att säkerställa att de är i funktion. Se

kapitel Vad är vad?, för att hitta var dessa detaljer är

placerade på din maskin.

Maskinens livslängd kan förkortas och risken för olyckor

kan öka om underhåll av maskinen inte utförs på rätt sätt

och om service och/eller reparationer inte utförs

fackmannamässigt. Om du behöver ytterligare

upplysningar kontakta närmaste serviceverkstad.

VIKTIGT!

All service och reparation av maskinen kräver

specialutbildning. Detta gäller särskilt maskinens

säkerhetsutrustning. Om maskinen inte klarar någon av

nedan listade kontroller ska du uppsöka din

serviceverkstad. Ett köp av någon av våra produkter

garanterar att du kan få en fackmannamässig reparation

och service utförd. Om inköpsstället för maskinen inte

är en av våra servande fackhandlare, fråga dem efter

närmaste serviceverkstad.

varandra oberoende returfjädersystem. Detta läge

innebär att gasreglaget automatiskt låses på tomgång.

B

A

Kontrollera att gasreglaget är låst i tomgångsläge när

gasreglagespärren är i sitt ursprungsläge.

Tryck in gasreglagespärren och kontrollera att den

återgår till sitt ursprungsläge när den släpps.

Kontrollera att gasreglaget och gasreglagespärren går lätt

samt att deras returfjädersystem fungerar.

Se anvisningar under rubrik Start. Starta häcksaxen och

ge full gas. Släpp gasreglaget och kontroller a att knivarna

stannar och förblir stillastående. Om kniv arna rör sig med

gasreglaget i tomgångsläge skall förgasarens tomgång

justeras. Se anvisningar under rubrik Underhåll.

VARNING! Använd aldrig en maskin med

defekt säkerhetsutrustning. Maskinens

!

säkerhetsutrustning ska kontrolleras och

underhållas som beskrivits i detta

avsnitt. Om din maskin inte klarar alla

kontrollerna ska serviceverkstad

uppsökas för reparation.

Gasreglagespärr

Gasreglagespärren är konstruerad att förhindra ofrivillig

aktivering av gasreglaget. När spärren (A) trycks ner i

handtaget (= när man håller om handtaget) frikopplas

gasreglaget (B). När greppet om handtaget släpps

återställes både gasreglaget samt gasreglagespärren till

sina respektive ursprungslägen. Detta sker via två av

Svenska – 27

Page 28

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Stoppkontakt

Stoppkontakten ska användas för att stänga av motorn.

Starta motorn och kontrollera att motorn stängs av när

stoppkontakten förs till stoppläget. Stoppkontakten

återgår automatiskt till startläge. För att undvika ofrivillig

start, måste därför alltid tändhatten avlägsnas från

tändstiftet vid montering, kontroll och/eller underhåll.

Handskydd

Handskyddet skall skydda handen från att komma i

kontakt med de arbetande knivarna, t ex om användaren

förlorar greppet om främre handtaget.

Kontrollera regelbundet avvibreringselementen efter

materialsprickor och deformationer. Kontrollera att

avvibreringselementen är hela och fast förankrade.

VARNING! Överexponering a v vibrationer

kan leda till blodkärls- eller nervskador

!

hos personer som har

blodcirkulationsstörningar. Uppsök

läkare om ni upplever kroppsliga

symptom som kan relateras till

överexponering av vibrationer. Exempel

på sådana symptom är domningar,

avsaknad av känsel, ”kittlingar”,

”stickningar”, smärta, avsaknad eller

reducering av normal styrka,

förändringar i hudens färg eller dess yta.

Dessa symptom uppträder vanligtvis i

fingrar, händer eller handleder. Riskerna

kan öka vid låga temperaturer.

Ljuddämpare

Ljuddämparen är konstruerad för att ge så låg ljudnivå

som möjligt samt för att leda bort motorns avgaser från

användaren. Ljuddämpare utrustad med katalysator är

även konstruerad för att reducera skadliga ämnen i

avgaserna.

Kontrollera att handskyddet sitter fast.

Kontrollera att handskyddet är helt.

Avvibreringssystem

Din maskin är utrustad med ett avvibreringssystem, vilket

är konstruerat att ge en så vibrationsfri och behaglig

användning som möjligt.

Maskinens avvibreringssystem reducerar överföringen av

vibrationer mellan motorenhet/skärutrustning och

maskinens handtagsenhet.

Motorkroppen inklusive knivar, hänger i handtagen via

fyra gummibussningar.

28 – Svenska

I länder med varmt och torrt klimat är risken för bränder

påtaglig. Vi har därför utrustat vissa ljuddämpare med ett

sk. gnistfångarnät. Kontrollera om din maskins

ljuddämpare har ett sådant nät.

För ljuddämpare är det mycket viktigt att instruktionerna

för kontroll, underhåll och service följs.

Använd aldrig en maskin som har en defekt ljuddämpare.

Kontrollera regelbundet att ljuddämparen sitter fast på

motorn.

Page 29

ALLMÄNNA SÄKERHETSINSTRUKTIONER

Är din maskins ljuddämpare utrustad med ett

gnistfångarnät, skall detta rengöras regelbundet. Ett

igensatt nät leder till varmkörning av motorn med allvarlig

motorskada som följd.

VARNING! Katalysatorljuddämparen blir

mycket het såväl vid användning som

!

efter stopp. Detta gäller även vid

tomgångskörning. Beröring kan orsaka

brännskador på huden. Var uppmärksam

på brandfaran!

VARNING! Ljuddämparen innehåller

kemikalier som kan vara

!

cancerframkallande. Undvik kontakt med

dessa kemikalier ifall ljuddämparen

skulle gå sönder.

VARNING! Tänk på att: Motorns avgaser

är heta och kan innehålla gnistor vilka

!

kan orsaka brand. Starta därför aldrig

maskinen inomhus eller nära eldfängt

material!

Växel

Efter arbete med maskinen blir växeln varm. Ta ej på

växeln för att undvika brännskador.

Kniv och knivskydd

Yttersta delen av knivarna (1) är formade som ett

knivskydd. Knivskyddet är avsett att skydda mot att någon

kroppsdel kommer i kontakt med knivarna.

Kontrollera knivskyddet så att det är oskadat och utan

deformeringar. Byt ut klippagg regatet om det är böjt eller

skadat.

Svenska – 29

Page 30

BRÄNSLEHANTERING

Bränslesäkerhet

Starta aldrig maskinen:

1 Om du spillt bränsle på den. Torka av allt spill och låt

bensinresterna avdunsta.

2 Om du spillt bränsle på dig själv eller dina kläder, byt

kläder. Tvätta de kroppsdelar som varit i kontakt med

bränsle. Använd tvål och vatten.

3 Om maskinen läcker bränsle. Kontrollera regelbundet

efter läckage från tanklock och bränsleledningar.

Transport och förvaring

• Låt häcksaxen svalna av efter arbetet innan ni stoppar

undan den för förvaring.

• Förvara och transportera maskinen och bränslet så

att eventuellt läckage och ångor inte riskerar att

komma i kontakt med gnistor eller öppen låga,

exempelvis från elmaskiner, elmotorer, elkontakter/

strömbrytare eller värmepannor.

• Vid förvaring och transport av bränsle ska för

ändamålet speciellt avsedda och godkända behållare

användas.

• Vid längre tids förvaring av maskin ska bränsletanken

tömmas. Hör med närmaste bensinstation var du kan

göra dig av med bränsleöverskott.

• Se till att maskinen är väl rengjord och att fullständig

service är utförd innan långtidsförvaring.

• Skärutrustningens transportskydd ska alltid vara

monterat under transport eller förvaring av maskinen.

• Säkra maskinen under transport.

VARNING! Var försiktig vid hantering av

bränsle. Tänk på brand-, explosions- och

!

inandningsrisker.

Drivmedel

OBS! Maskinen är försedd med en tvåtaktsmotor och

måste alltid köras på en blandning av bensin och

tvåtaktsolja. För att säkerställa rätt b landningsförhållande

är det viktigt att noggrant mäta den oljemängd som skall

blandas. Vid tillblandning av små bränslemängder

inverkar även små felaktigheter i oljemängden kraftigt på

blandningsförhållandet.

VARNING! Bränsle och bränsleångor är

mycket brandfarliga och kan ge allvarliga

!

skador vid inandning och

hudexponering. Var därför försiktig vid

hantering av bränsle och sörj för god

luftventilation vid bränslehantering.

Bensin

OBS! Använd alltid oljeblandad kvalitetsbensin med

minst 90 oktan (RON). Om din maskin är utrustad med

katalysator (se kapitel Tekniska data) skall alltid blyfri

oljeblandad kvalitetsbensin användas. En blyad bensin

förstör katalysatorn.

Där miljöanpassad bensin, s.k. alkylatbensin finns

tillgänglig ska sådan användas.

• Rekommenderat lägsta oktantal är 90 (RON). Om

man kör motorn på bensin med ett lägre oktantal än

90 kan så kallad spikning uppträda. Detta leder till

ökad motortemperatur, som kan orsaka svåra

motorhaverier.

• Vid arbete med kontinuerligt höga varvtal

rekommenderas högre oktantal.

Tvåtaktsolja

• För bästa resultat och funktion använd Universal,

Universal powered by McCULLOCH tvåtaktsolja, som

är speciellt tillverkad för våra luftkylda

tvåtaktsmotorer.

• Använd aldrig tvåtaktsolja avsedd för vattenkylda

utombordsmotorer, s.k. outboardoil (benämnd TCW).

• Använd aldrig olja avsedd för fyrtaktsmotorer.

• En låg oljekvalitet eller för fet olje/bränsle blandning

kan äventyra katalysatorns funktion och minska dess

livstid.

• Blandningsförhållande

1:50 (2%) med Universal, Universal powered by

McCULLOCH tvåtaktsolja.

1:33 (3%) med andra oljor gjorda för luftkylda

tvåtaktsmotorer klassade för JASO FB/ISO EGB.

Bensin, liter

5 0,10 0,15

10 0,20 0,30

15 0,30 0,45

20 0,40 0,60

Tvåtaktsolja, liter

2% (1:50) 3% (1:33)

30 – Svenska

Page 31

BRÄNSLEHANTERING

Blandning

• Blanda alltid bensin och olja i en ren behållare

godkänd för bensin.

• Börja alltid med att fylla i hälften av bensinen som

skall tillblandas. Fyll därefter i hela oljemängden.

Blanda (skaka) bränsleblandningen. Fyll återstående

mängd bensin.

• Blanda (skaka) bränsleblandningen omsorgsfullt

innan maskinens bränsletank fylls.

• Blanda inte bränsle för mer än max 1 månads behov.

• Om maskinen inte används under en längre tid skall

bränsletanken tömmas och rengöras.

VARNING! Katalysatorljuddämparen blir

mycket het såväl vid användning som

!

efter stopp. Detta gäller även vid

tomgångskörning. Var uppmärksam på

brandfaran, speciellt vid hantering nära

brandfarliga ämnen och/eller gaser.

Tankning

VARNING! Följande försiktighetsåtgär der

minskar brandrisken:

!

Rök inte eller placera något varmt

föremål i närheten av bränsle.

Tanka aldrig med motorn igång.

Tanka i väl ventilerade områden. Tanka

aldrig maskinen inomhus.

Stanna motorn och låt den svalna några

minuter före tankning.

Öppna tanklocket sakta vid

bränslepåfyllning så att eventuellt

övertryck sakta försvinner.

Drag åt tanklocket noga efter tankning.

Flytta alltid maskinen från

tankningsplatsen och bensindunken före

start.

• Använd bränslebehållare med överfyllnadsskydd.

• Torka rent runt tanklocket. Föroreningar i tanken

orsakar driftstörningar.

• Se till att bränslet är väl blandat genom att skaka

behållaren innan tanken fylls.

Svenska – 31

Page 32

Kontroll före start

START OCH STOPP

(2) Bränslepump:

• Inspektera arbetsområdet. A vlägsna föremål som kan

slungas iväg.

• Kontrollera skärutrustningen. Använd aldrig slöa,

spruckna eller skadade knivar.

• Kontrollera maskinen så att den är i fullgott skick.

Kontrollera att alla muttrar och skruvar är åtdragna.

• Se till att växeln är tillräckligt smord. Se anvisningar

under rubrik Växel.

• Kontrollera att skärutrustningen alltid stannar på

tomgång.

• Använd maskinen endast till det den är avsedd för.

• Se till att handtag och säkerhetsfunktioner är i

ordning. Använd aldrig en maskin som saknar någon

del eller som ändrats utanför specifikationen.

• Samtliga kåpor skall vara korrekt monterade och

felfria före start av maskinen.

Start och stopp

VARNING! Komplett växel måste vara

monterad innan maskinen startas,

!

annars kan kopplingen lossna och

orsaka personskador.

Flytta alltid maskinen ca 3 m från

tankningsplatsen före start. Placera

maskinen på ett fast underlag. Tänk på

att knivarna kan börja röra sig då motorn

startar. Se till att knivarna ej kan ta i

något föremål. Se till att inga obehöriga

finns inom arbetsområdet, annars finns

risk för allvarliga personskador.

Säkerhetsavståndet är 15 meter.

Kall motor

(1) Chokereglage

Tryck på bränslepumpens gummiblåsa upprepade

gånger tills bränsle börjar fylla blåsan (ca 6 gånger).

Blåsan behöver ej fyllas helt.

(3) Start

Tryck maskinkroppen mot marken med vänster hand

(OBS! Ej med foten!). Grip starthandtaget, drag med

höger hand långsamt ut startlinan tills ett motstånd känns

(starthakarna griper in) och gör därefter snabba och

kraftfulla ryck. Vira aldrig startlinan runt handen.

(4, 5)

För tillbaka chokereglaget till ursprungsläget omedelbart

när motorn tänder och gör förnyade startförsök tills

motorn startar.

OBS! När chokereglaget förts tillbaka till ursprungsläge

går motorn på ett förhöjt varvtal, sk. startgasläge, och då

rör sig knivarna. Startgasläge kopplas ur genom att ge

gas med gasreglaget.

OBS! Drag inte ut startlinan helt och släpp inte heller

starthandtaget från helt utdraget läge. Detta kan orsaka

skador på maskinen.

Ställ chokereglaget i chokeläge.

32 – Svenska

Page 33

START OCH STOPP

Varm motor

Tryck maskinkroppen mot marken med vänster hand

(OBS! Ej med foten!). Grip starthandtaget, drag med

höger hand långsamt ut startlinan tills ett motstånd känns

(starthakarna griper in) och gör därefter snabba och

kraftfulla ryck. Vira aldrig startlinan runt handen.

Stopp

Motorn stängs av genom att stoppkontakten förs till

stoppläge.

OBS!

Stoppkontakten återgår automatiskt till startläge. För att

undvika ofrivillig start, måste därför alltid tändhatten

avlägsnas från tändstiftet vid montering, kontroll och/eller

underhåll.

Svenska – 33

Page 34

ARBETSTEKNIK

Allmänna arbetsinstruktioner

VIKTIGT!

Detta avsnitt behandlar grundläggande säkerhetsregler

för arbete med häcksax.

När du råkar ut för en situation som gör dig osäker

angående fortsatt användning ska du rådfråga en

expert. Vänd dig till din återförsäljare eller din

serviceverkstad.

Undvik all användning du anser dig otillräckligt

kvalificerad för.

VARNING! Maskinen kan vålla allvarlig

personskada. Läs

!

säkerhetsinstruktionerna noga. Lär dig

hur du ska använda maskinen.

VARNING! Klippande verktyg. Vidrör ej

verktyget utan att först stänga av

!

motorn.

Säkerhetsinstruktioner under arbetet

• Se alltid till att du har en säker och stadig

arbetsposition.

• Lämna aldrig maskinen utan uppsikt med motorn

igång.

• Använd alltid båda händerna för att hålla i maskinen.

Håll maskinen framför kroppen.

Säkerhetsinstruktioner för omgivningen

• Tillåt aldrig barn att använda maskinen.

• Iaktta omgivningen och var säker på att det inte finns

risk att människor eller djur kan komma i kontakt med

skärutrustningen.

• Se till att ingen kommer närmare än 15 m under

arbetet.

• Låt aldrig någon annan använda maskinen utan att

försäkra dig om att de har förstått innehållet i

bruksanvisningen.

• Arbeta aldrig från en stege eller pall eller annan ej väl

förankrad upphöjd position.

• Tänk på att användaren är ansvarig för olyckor eller

faror för andra människor eller deras egendom.

• Se till att händer och fötter inte kommer åt

skärutrustningen när motorn är i gång.

• När motorn stängts av, håll händer och fötter borta

från skärutrustningen tills den stannat helt.

• Se upp för grenstumpar som kan slungas iväg under

klippningen.

• Klipp inte för nära marken. Stenar eller andra lösa

föremål kan slungas iväg.

• Undersök klippobjektet med avseende på främmande

föremål såsom elledningar, insekter och djur etc, eller

föremål som kan skada skärutrustningen t ex

metallföremål.

• Om något främmande föremål träffas eller om

vibrationer uppstår ska du stanna maskinen. Ta bort

tändkabeln från tändstiftet. Kontrollera att maskinen

inte är skadad. Reparera eventuella skador.

34 – Svenska

Page 35

ARBETSTEKNIK

• Skulle någonting fastna i knivarna under arbetets

gång skall motorn stängas av, stanna helt och

tändkabeln lossas från tändstiftet innan knivarna

rengörs.

Om knivarna fastnar går det att lossa knivarna genom

att föra in kombinyckeln i växeln. Ta bort fettpluggen

och för in kombinyckeln i växeln och vrid fram och

tillbaka.

• Se upp så att inte spetsen vidrör marken.

• Forcera inte arbetet, utan gå lagom fort fram, så att

alla kvistar klipps av till en jämn yta.

ERGOLITE 6028

Häcksaxens bakre handtag kan ställas in i fem riktningar

genom att dra ut spärren. Se fig. När handtaget ställs om

skall häcksaxen gå på tomgång eller vara stoppad helt.

Säkerhetsinstruktioner efter arbetets slut

• Transportskyddet ska alltid sättas på

skärutrustningen när maskinen inte används.

• Före rengöring, reparation eller inspektion ska du se

till att skärutrustningen har stannat. Tag bort

tändkabeln från tändstiftet.

• Använd alltid kraftiga handskar vid reparation av

skärutrustningen. Den är mycket v ass och skärskador

kan mycket lätt uppstå.

• Förvara maskinen oåtkomlig för barn.

• Använd endast originalreservdelar vid reparation.

Grundläggande arbetsteknik

• Arbeta med pendelliknande rörelser nedifrån och upp

vid klippning av sidor.

• Anpassa gaspådraget efter belastning.

• Vid häckklippning skall motorn vara vänd från häcken.

• För bästa balans, håll maskinen så nära kroppen som

möjligt.

• Under arbete skall handtaget alltid vara riktat uppåt

oavsett hur maskinen är riktad.

Svenska – 35

Page 36

UNDERHÅLL

Förgasare

Inställning av tomgångsvarvtalet

Innan några justeringar görs, se till att luftfiltret är rent och

att luftfilterlocket sitter på. Se till att startgasläget är

urkopplat.

Justera tomgångsvarvtalet med tomgångsskruven T, om

omjustering skulle behövas. Vrid först T-skruven medurs

tills skärutrustningen börjar röra sig. Vid sedan skruven

moturs tills skärutrustningen stannar. Ett korrekt justerat

tomgångsvarvtal har uppnåtts när motorn går jämnt i

varje läge. Det bör även vara en god marginal till det

varvtal då skärutrustningen börjar röra sig.

Rek. tomgångsvarvtal: Se kapitel Tekniska data.

VARNING! Kan tomgångsvarvtalet ej

justeras så att skärutrustningen står

!

stilla, kontakta din återförsäljare/

serviceverkstad. Använd inte maskinen

förrän den är korrekt inställd eller

reparerad.

Ljuddämpare

OBS! Vissa ljuddämpare är försedda med katalysator . Se

kapitel Tekniska data för att ta reda på om din maskin är

försedd med katalysator.

Ljuddämparen är utformad för att dämpa ljudnivån och för

att leda avgaserna bort från användaren. Avgaserna är

heta och kan innehålla gnistor vilka kan orsaka brand om

avgaserna riktas mot ett torrt och brännbart material.

På katalysatorljuddämpare ska nätet kontrolleras och

eventuellt rengöras en gång per månad. Vid ev. skador

på nätet ska detta bytas. Om nätet ofta är igensatt, kan

detta vara ett tecken på att katalysatorns funktion är

nedsatt. Kontakta din återförsäljare för kontroll. Med ett

igensatt nät överhettas maskinen med skador på cylinder

och kolv som följd.

OBS! Använd aldrig maskinen med en ljuddämpare som

är i dåligt skick.

VARNING! Katalysatorljuddämparen blir

mycket het såväl vid användning som

!

efter stopp. Detta gäller även vid

tomgångskörning. Beröring kan orsaka

brännskador på huden. Var uppmärksam

på brandfaran!

Kylsystem

För att erhålla en så låg driftstemperatur som möjligt är

maskinen utrustad med ett kylsystem.