MAXDATA PLATINUM 7200 Server

Product Guide

1MAXDATA PLATINUM 7200 Server

2 Contents 3MAXDATA PLATINUM 7200 Server

Contents

1 Important Safety Information ........................................................................7

Important Safety Information................................................................................................... 7

Intended Application Uses....................................................................................................... 7

Safety Instructions and Information......................................................................................... 7

Checking the Power Cords ...................................................................................................... 7

Multiple Power Cords .............................................................................................................. 7

Earth Grounded Socket-Outlets............................................................................................... 8

Before You Remove the Access Cover ................................................................................... 8

Power Supply Modules............................................................................................................ 8

Fans ......................................................................................................................................... 8

Electrostatic Discharge (ESD) .................................................................................................. 8

Cooling and Airflow.................................................................................................................. 9

Lifting and Moving ................................................................................................................... 9

Equipment Rack Precautions................................................................................................... 9

2 Getting Started..............................................................................................11

Selecting a Site ...................................................................................................................... 11

Space and Power Requirements ........................................................................................... 11

General Site Criteria............................................................................................................... 12

Turning On the Server and Running the Power-On Self-Test (POST).................................... 12

Hot Keys for POST................................................................................................................. 13

Installing the Service Partition (Recommended).................................................................... 13

Installing the Operating System............................................................................................. 14

System Security..................................................................................................................... 14

Using Passwords .............................................................................................................. 15

3 System Management.................................................................................... 17

Baseboard Management Controller....................................................................................... 17

Field Replaceable Units and Sensor Data Records ........................................................... 17

System Event Log............................................................................................................. 17

Platform Event Management ............................................................................................ 18

Emergency Management Port .......................................................................................... 18

Intel® Server Management .................................................................................................... 18

Using the System Setup Utility.............................................................................................. 19

Creating SSU Diskettes..................................................................................................... 19

Running the SSU............................................................................................................... 19

Working with the GUI ....................................................................................................... 20

Customizing the SSU Interface ......................................................................................... 20

Exiting the SSU ................................................................................................................. 21

Setting Boot Device Priority................................................................................................... 21

Setting Passwords and Security Options............................................................................... 21

Setting the Admin Password ............................................................................................ 21

Setting the User Password ............................................................................................... 21

Setting Security Options ................................................................................................... 22

Viewing the System Event Log ............................................................................................. 22

Viewing FRU Information....................................................................................................... 22

Viewing Sensor Data Records ............................................................................................... 23

Saving and Restoring the System Configuration ................................................................... 23

Saving a Configuration ...................................................................................................... 24

Restoring a Configuration.................................................................................................. 24

Alerting for Platform Events................................................................................................... 24

Setting Up Paging Alerts ................................................................................................... 24

5MAXDATA PLATINUM 7200 Server

Setting Up LAN Alerts....................................................................................................... 25

Managing the Server Remotely ............................................................................................. 26

Setting Up Remote LAN Access....................................................................................... 26

Setting Up Remote Modem or Serial Access ................................................................... 27

4 Installing and Removing Components ........................................................ 29

Removing and Installing the Bezel......................................................................................... 29

Memory ................................................................................................................................ 29

Installing DIMMs............................................................................................................... 29

Removing DIMMs............................................................................................................. 30

Hot-Swap SCSI Drives ........................................................................................................... 31

Checking a Hot-Swap SCSI Drive Status Indicator............................................................ 31

Installing a Hot-Swap Drive in a Carrier............................................................................. 32

Removing a Hot-swap Drive from a Carrier ...................................................................... 33

Removing and Installing Hot-Swap Disk Drives ................................................................ 34

DC Power Supplies................................................................................................................ 35

Checking the Power Status LEDs.......................................................................................... 35

Removing a Power Supply Module................................................................................... 36

Installing a Power Supply Module..................................................................................... 36

PCI Add-In Boards.................................................................................................................. 37

Operating System Support for Hot-Plug Add-In Boards......................................................... 38

Checking the Status Indicators for a Hot-Plug Add-In Board............................................. 38

Installing a Hot-Plug PCI Add-In Board .............................................................................. 39

Removing a Hot-Plug PCI Add-In Board ............................................................................ 40

Cooling System Fans ............................................................................................................ 40

Checking a Fan Status Indicator........................................................................................ 41

Removing a Fan Module ................................................................................................... 42

Installing a Fan Module ..................................................................................................... 42

5 Solving Problems ..........................................................................................43

Resetting the System ............................................................................................................ 43

Initial System Startup............................................................................................................. 43

Running New Application Software....................................................................................... 43

Application Software Checklist ......................................................................................... 43

After the System Has Been Running Correctly................................................................. 44

Monitoring POST ................................................................................................................... 44

Verifying Proper Operation of Key System Lights............................................................. 44

Confirming Loading of an Operating System......................................................................... 44

Specific Problems and Corrective Actions............................................................................. 45

Power Light Does Not Light.............................................................................................. 45

No Beep Codes ................................................................................................................. 45

No Characters Appear on Screen...................................................................................... 45

Characters Are Distorted or Incorrect ............................................................................... 46

System Cooling Fans Do Not Rotate Properly .................................................................. 46

Diskette Drive Activity Light Does Not Light .................................................................... 46

Hard Drive Activity Light Does Not Light .......................................................................... 47

CD-ROM Drive Activity Light Does Not Light ................................................................... 47

Network Problems................................................................................................................. 47

The server hangs when the drivers are loaded. ................................................................ 47

Diagnostics pass, but the connection fails........................................................................ 47

The Link LED does not light. ............................................................................................. 47

The Activity LED doesn’t light........................................................................................... 47

The onboard network interface controller (NIC) stopped

working when an add-in adapter was installed. ................................................................ 48

The add-in adapter stopped working without apparent cause. ......................................... 48

4 Contents

PCI Installation Tips ............................................................................................................... 48

Problems with Application Software...................................................................................... 48

Bootable CD-ROM Is Not Detected....................................................................................... 48

A Server Description......................................................................................... 49

Feature Summary .................................................................................................................. 49

Chassis Access...................................................................................................................... 50

Main Chassis Components.................................................................................................... 51

Electronics Bay Components................................................................................................. 51

Front Control Panel ................................................................................................................ 52

Rear Panel.............................................................................................................................. 53

Power Supplies...................................................................................................................... 53

System Cooling...................................................................................................................... 53

Server Board Set Features..................................................................................................... 54

Baseboard Connector and Component Locations ................................................................. 55

Baseboard Jumpers............................................................................................................... 56

Boot Block Jumpers .............................................................................................................. 56

Main Jumpers........................................................................................................................ 56

Serial Port B Jumpers ............................................................................................................ 57

DIMM Memory...................................................................................................................... 57

Onboard Video ....................................................................................................................... 57

Network Interface Controllers................................................................................................ 58

NIC Connector and Status LEDs ....................................................................................... 58

Network Teaming Features............................................................................................... 59

Adapter Fault Tolerance .................................................................................................... 59

Preferred Primary Adapter ............................................................................................... 59

Adaptive Load Balancing ................................................................................................... 60

Cisco Fast EtherChannel ................................................................................................... 60

ACPI....................................................................................................................................... 60

Hyper-Threading Technology ................................................................................................. 60

B Regulatory Information................................................................................. 61

Product Regulation Compliance Information ......................................................................... 61

Product Safety................................................................................................................... 61

Electromagnetic Compatibility (EMC) - Emissions ............................................................ 61

Electromagnetic Compatibility - Immunity ........................................................................ 61

Power Line Harmonics / Voltage Flicker ........................................................................... 61

Regional EMC Compliance Information................................................................................. 62

5MAXDATA PLATINUM 7200 Server

Figures

1. MAXDATA PLATINUM 7200.......................................................................................... 11

2. Attaching the Bezel to the Chassis ................................................................................ 29

3. Installing Memory........................................................................................................... 30

4. Removing DIMMs .......................................................................................................... 31

5. Hot-Swap SCSI Drive Bay and Status Indicators............................................................ 31

6. Removing a Plastic Air Bafe from a Carrier .................................................................. 32

7. Installing a SCSI Hard Disk Drive in a Carrier.................................................................. 33

8. Removing a Drive Carrier ............................................................................................... 34

9. Installing a Drive Carrier ................................................................................................. 34

10. Power and Standby LEDs............................................................................................... 35

11. Removing a Power Supply Module ................................................................................ 36

12. PCI Add-In Board Locations............................................................................................ 37

13. Status Indicators for Hot-Plug PCI Add-In Boards .......................................................... 38

14 Installing a Hot-Plug PCI Add-In Board ........................................................................... 39

15. Removing a Hot-Plug PCI Add-In Board ......................................................................... 40

16 Fan Status Indicator........................................................................................................ 41

17. Removing and Installing a Fan Module .......................................................................... 42

18. MAXDATA PLATINUM 7200 Server Hot-Swap Access ................................................. 50

19. Chassis with Bezel and Access Covers Removed ......................................................... 51

20. Electronics Bay Internal Components ............................................................................ 51

21. MAXDATA PLATINUM 7200 Front Control Panel ......................................................... 52

23. MAXDATA PLATINUM 7200 Server Rear Panel View ................................................... 53

23. Baseboard Connector and Component Locations.......................................................... 55

24. Baseboard Jumpers ....................................................................................................... 56

Tables

1. Safety Symbols ................................................................................................................ 7

2. MAXDATA PLATINUM 7200 Server Physical Specications ......................................... 11

3. Hot Keys......................................................................................................................... 13

4. Software Security Features............................................................................................ 14

4. Software Security Features (Continued) ........................................................................ 15

5. LED States for Hot-Swap SCSI Drive Status.................................................................. 32

6. LED Power Supply Status Indicators ............................................................................. 35

7. LED Hot-Plug PCI Status Indicators .............................................................................. 38

8. Feature Summary........................................................................................................... 49

9. Front Control Panel Features.......................................................................................... 52

10. Server Board Set Features ............................................................................................. 54

11. Boot Block Jumper Descriptions.................................................................................... 56

12. Main Jumper Descriptions ............................................................................................. 57

13. Serial Port B Jumper Descriptions ................................................................................. 57

14. Product Regulatory Compliance Markings ..................................................................... 61

15. Regional EMC Compliance Information ......................................................................... 62

6 Contents 7MAXDATA PLATINUM 7200 Server

1 Important Safety Information

Important Safety Information

Only a technically qualied person shall access, integrate, congure, and service this product.

Intended Application Uses

This product was evaluated as Information Technology Equipment (ITE), which may be

installed in ofces, schools, computer rooms, and similar commercial type locations. The

suitability of this product for other Product Categories and Environments (such as medical,

industrial, alarm systems, and test equipment), other than an ITE application, may require

further evaluation.

Safety Instructions and Information

To avoid personal injury or property damage, before you begin installing the product, read,

observe, and adhere to all of the following safety instructions and information. The following

safety symbols may be used throughout this product guide, and may be marked on the

product and or its packaging.

Table 1. Safety Symbols

Indicates the presence of a hazard that may cause minor personal injury or

CAUTION

WARNING

property damage if the CAUTION is ignored.

Indicates the presence of a hazard that may result in serious injury or death if the

WARNING is ignored.

Checking the Power Cords

WARNING

To avoid electrical shock, do not attempt to modify or use the supplied AC power cord(s), if

they are not the exact type required. If a power cord(s) supplied is not compatible with the

AC wall outlet in your region, get one that meets the following criteria:

• The power cord must be properly rated for the AC voltage in your region.

• The power cord plug cap must have an electrical current rating that is at least 125% of

the electrical current rating of the product.

• The power cord plug cap that plugs into the wall socket-outlet must have a grounding type male plug designed for use in your region.

• The power cord must have safety certifications for your region, and shall be marked

with the certification markings.

• The power cord plug cap that plugs into the AC receptacle on the power supply must

be an IEC 320, sheet C13, type female connector.

• In Europe, the power cord must be less than 4.5 meters (14.76 feet) long, and it must

be flexible <HAR> (harmonized) or VDE certified cordage to comply with the chassis’

safety certifications.

The power supply cord(s) is the main disconnect device to AC power. The socket outlet(s)

shall be near the equipment and shall be readily accessible for disconnection.

Multiple Power Cords

WARNING

To avoid electrical shock, disconnect all AC power cords before accessing inside the

system.

9MAXDATA PLATINUM 7200 Server

Earth Grounded Socket-Outlets

WARNING

To avoid electrical shock, the system power cord(s) must be plugged into socket-outlet(s)

that is provided with a suitable earth ground. The system will be provided with the following

marking:

Connect only to properly earthed socket outlet.

Before You Remove the Access Cover

WARNING

To avoid personal injury or property damage, the following safety instructions apply whenever

accessing inside the product:

• Turn off all peripheral devices connected to this product.

• Turn off the system by pressing the power button on the front of the product.

• Disconnect the AC power by unplugging all AC power cords from the system or wall

outlet.

• Disconnect all cables and telecommunication lines that are connected to the system.

• Retain all screws or other fasteners when removing access cover(s). Upon completion

of accessing inside the product, refasten access cover with original screws or fasten ers.

• Do not access inside power supply. There are no serviceable parts in the power supply.

Return to manufacturer for servicing.

Power Supply Modules

CAUTION

Power supply modules have double-pole/neutral fusing.

Fans

WARNING

To avoid injury do not contact moving fan blades.

Electrostatic Discharge (ESD)

CAUTION

Perform the procedures in this chapter only at an electrostatic discharge (ESD) workstation,

because the server components can be extremely sensitive to ESD. If no such station is available,

you can reduce the risk of electrostatic discharge ESD damage by doing the following:

• Wear an antistatic wrist strap and attach it to a metal part of the server.

• Touch the metal on the server chassis before touching the server components.

• Keep part of your body in contact with the metal server chassis to dissipate the static

charge while handling the components. Avoid moving around unnecessarily.

• Hold the server components (especially boards) only by the edges.

• Place the server components on a grounded, static-free surface. Use a conductive foam

pad if available but not the component wrapper.

• Do not slide the components over any surface.

8 Important Safety Information

Cooling and Airflow

CAUTION

For proper cooling and airow, always install all access covers before turning on the system.

Operating the system for longer than ve minutes without the covers in place can cause

overheating and damage to system components.

Lifting and Moving

CAUTION

Do not attempt to lift or move the server by the handles on the power supplies.

Equipment Rack Precautions

Follow the rack manufacturer’s safety and installation instructions for proper rack installation.

The following additional rack safety installation measures shall be considered:

CAUTION

The equipment rack must be anchored to an unmovable suitable support to prevent the rack

from falling over when one or more systems are fully extended out of the rack assembly.

You must also consider the weight of any other devices installed in the rack assembly. The

equipment rack must be installed according to the manufacturer’s instructions.

CAUTION

You are responsible for installing an AC power disconnect for the entire rack unit. This main

disconnect must be readily accessible, and it must be labeled as controlling power to the

entire unit, not just to the system(s).

CAUTION

To avoid the potential for an electrical shock hazard, the rack assembly itself must be suitably

earth grounded, according to your local regional electrical codes. This typically will require

the rack to have its own separate earth ground. We recommend you consult your local

approved electrician.

CAUTION

The system is designed to operate on a 20A AC voltage source that is provided with 20A

over current protection. If the AC source for the rack exceeds 20A over current protection,

each system must be provided with 20A or less over current supplemental protection. The

supplementary over current protection must have the appropriate regional safety certifications

for the over current application.

CAUTION

The operating temperature of the system, when installed in the rack, must not go below

10° C (50° F) or rise above 35° C (95° F). Extreme fluctuations in temperature may cause a

variety of problems in system, and safety limits may be broken.

CAUTION

The equipment rack must provide sufficient airflow to the front of the system to maintain

proper cooling. The rack selected and the ventilation provided must be suitable to the

environment in which the system will be used.

9MAXDATA PLATINUM 7200 Server

10 Important Safety Information 11MAXDATA PLATINUM 7200 Server

2 Getting Started

Selecting a Site

This section describes the space and power requirements and general site criteria for

installing the server.

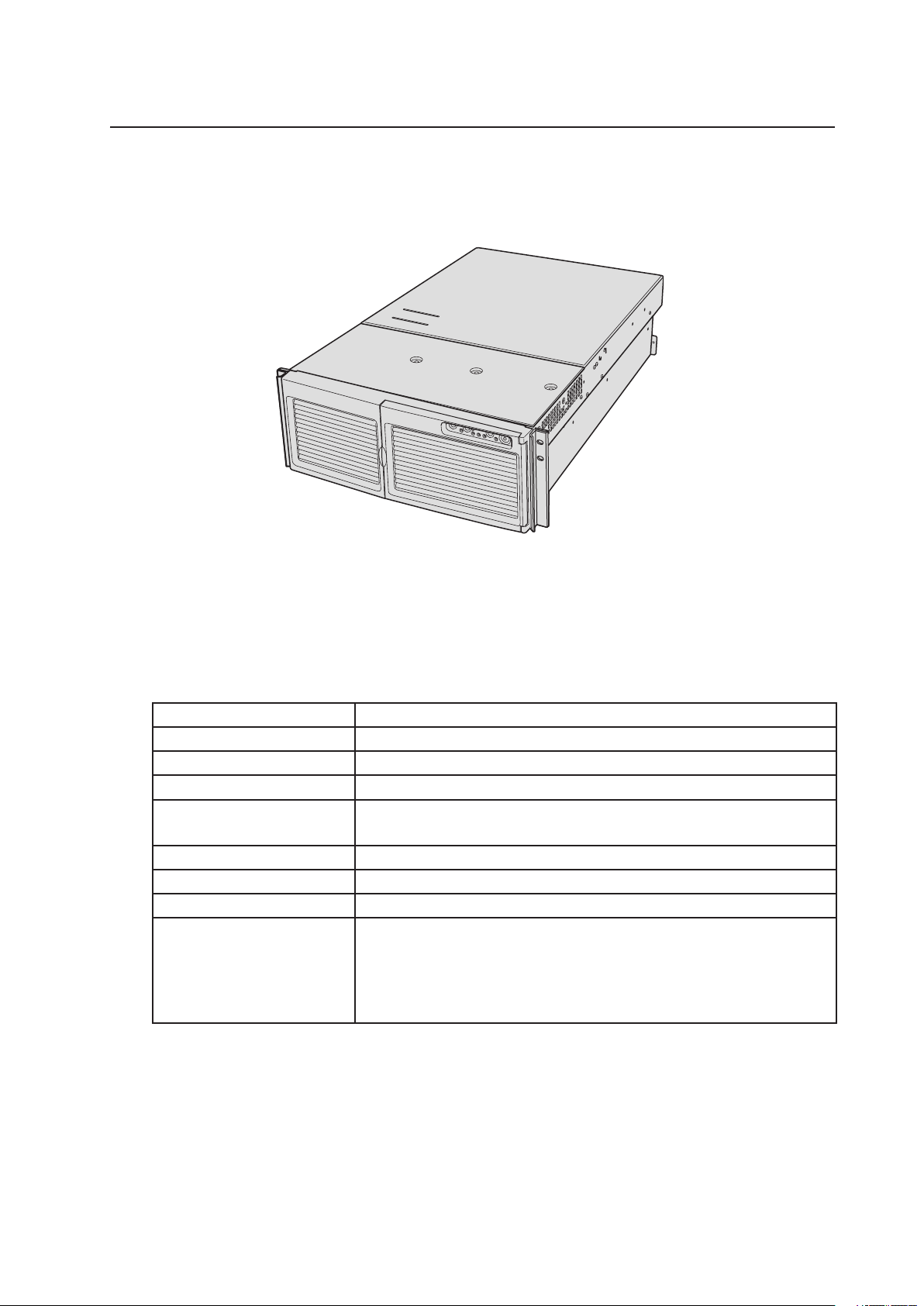

Figure 1. MAXDATA PLATINUM 7200 Server

Space and Power Requirements

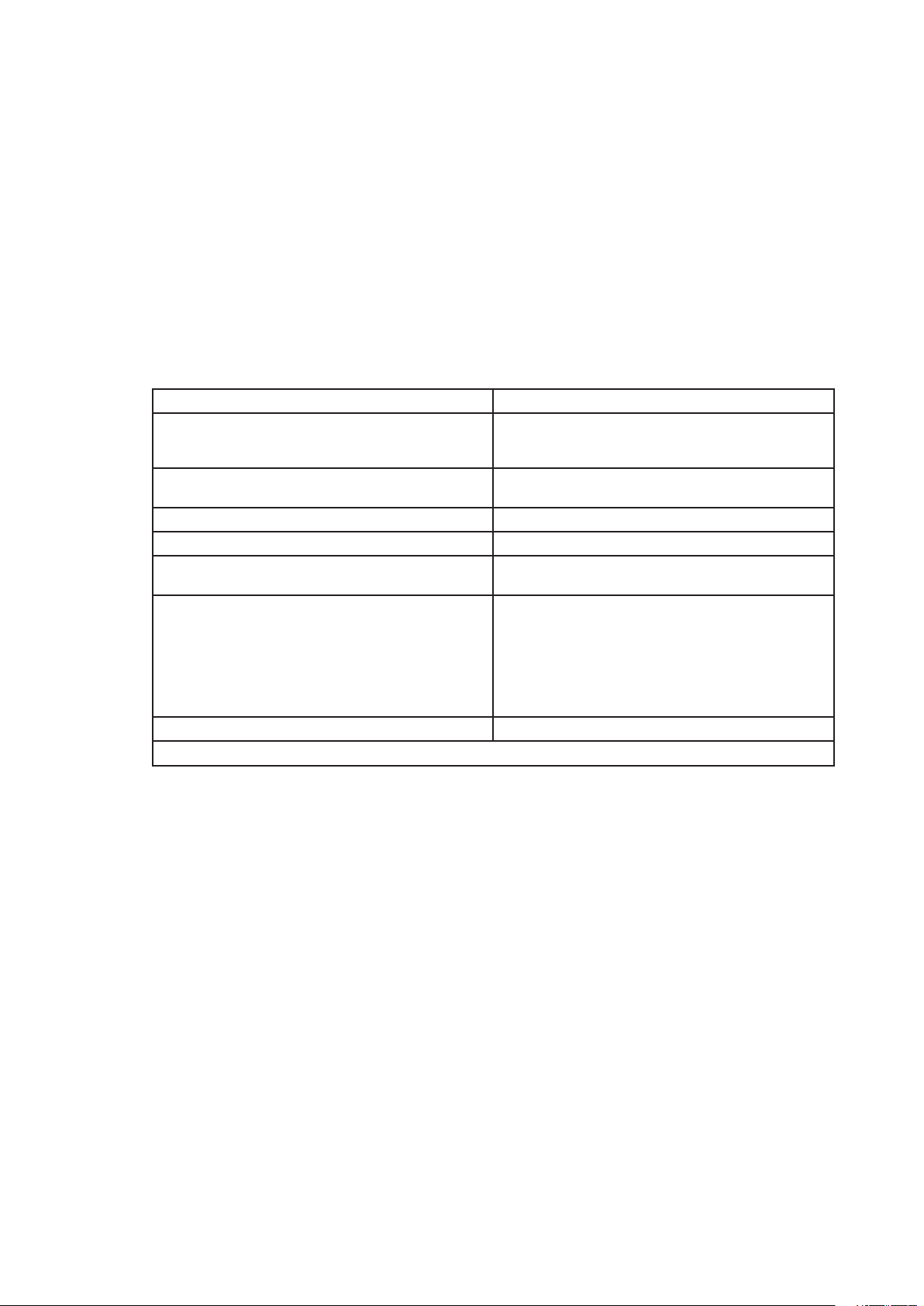

Table 2. MAXDATA PLATINUM 7200 Server Physical Specications

Specication

Height

Width

Depth

Weight

Required front clearance

Required rear clearance

Required side clearance

Power requirements

Voltage (110)

Voltage (220)

Frequency

Rack Mode Only

7 inches (178 mm) (4u)

17.5 inches (445 mm)

28.0 inches (711 mm)

57 pounds (25.9 kg), minimum configuration

88 pounds (39.9 kg), maximum configuration

3 inches (76 mm), inlet airflow <35° C (95° F)

4.5 inches (114 mm), no airflow restriction

1 inch (25 mm)

90 Vrms min, 132 Vrms max, 8 Arms*

180 Vrms min, 264 Vrms max, 4 Arms*

47 Hz min, 63 Hz max

* Amperage is total system power, with two or three power supply modules installed, with one or two AC cords.

13MAXDATA PLATINUM 7200 Server

General Site Criteria

The server operates reliably within normal office environmental limits. Select a site that meets

these criteria:

• Near a properly grounded, three-pronged power outlet.

– In the United States and Canada: a NEMA 6-15R outlet for 100-120 V and for 200-240 V.

– In other geographic areas: a properly grounded outlet in accordance with the local

electrical authorities and electrical code of the region.

• Clean and relatively free of excess dust.

• Well ventilated and away from sources of heat, with the ventilating openings on the

server kept free of obstructions.

• Maximum ambient air temperature should not exceed 35° C (95° F).

• Away from sources of vibration or physical shock.

• Isolated from strong electromagnetic fields and noise caused by electrical devices such

as elevators, copy machines, air conditioners, large fans, large electric motors, radio and

TV transmitters, and high-frequency security devices.

• Access space provided so the server power cords can be unplugged from the power

supply or the wall outlet; this is the only way to remove AC power from the server.

• Clearance provided for cooling and airflow.

Turning On the Server

and Running the Power-On Self-Test (POST)

Each time you start the server, the Power-On Self-Test (POST) runs automatically. POST is

stored in flash memory. To start the server, do the following:

1. Make sure all external devices, such as a monitor, keyboard, and mouse, are connected.

2. If a drive protection card or diskette is present in the diskette drive, remove it.

3. Plug the video monitor power cord into the power source or wall outlet. Turn on the video

monitor.

4. Plug the AC power cords into the power connectors on the back of the chassis and into

the power source or wall outlet.

5. If the server does not turn on when you plug it into the AC outlet, press the on/off power

button on the front panel.

6. Verify that the main power LED on the front panel is lit .

7. Insert the MAXDATA PLATINUM 7200 Server Platform System Resource CD into the CD-

ROM drive.

After a few seconds, POST begins and a splash screen is displayed (if the splash screen is

disabled in BIOS Setup, a diagnostics screen is displayed). POST discovers, configures, and

tests the processors, memory, keyboard, and most installed peripheral devices. The length of

time needed to complete POST depends on the amount of memory installed and the number

of option boards installed.

8. Shortly after the splash screen is displayed, POST displays the message “Press <F2>

to enter Setup…” at the bottom of the screen. If you enter BIOS Setup, the Service Partition,

or the Adaptec SCSISelect Utility, when you exit those features, the server might

reboot.

9. After POST completes, the system beeps once and then searches all boot devices in the

order dened by the boot priority settings in the BIOS. The system nds, loads, and runs

the limited operating system on the System Resource CD.

12 Getting Started

NOTE

If there is no device with a bootable operating system, the boot process continues, the

system beeps once, and the following message is displayed:

Operating System not found

If you have a device with a bootable operating system but see this message anyway, reboot

and use BIOS Setup to make sure your boot device settings are correct.

Hot Keys for POST

Table 3 lists the hot keys you can use during POST to access setup utilities and alter the

normal POST execution.

Table 3. Hot Keys

To Do This: Press These Keys:

Abort memory test during POST.

Resume after a POST error is displayed. (The

system pauses after displaying an error.)

Enter BIOS Setup during POST.

Boot to the service partition.

Boot from a network using Preboot Execution

Environment (PXE).

Remove the splash screen to view the diagnostic messages during POST and display a

menu for selecting the boot device.

Enter the Adaptec SCSISelect Utility during POST.

* Press any of these keys when the prompt “Press <F2> to enter Setup…” is displayed.

<Space>

Press while BIOS is updating memory size on

screen.

<F1>

<F2>*

<F4>*

<F12>*

<ESC>*

Note: Using BIOS Setup, you can enable the BootTime Diagnostic Screen, in which case POST does

not display the splash screen.

Note: If you use the displayed menu to change the

boot device, the change affects the current boot

only.

<Ctrl+A>*

Installing the Service Partition (Recommended)

When you are setting up your server system, you can install a service partition on your hard

drive. The service partition, in conjunction with Intel® Server Management (ISM) software,

provides emergency remote management and remote server setup. The service partition

lets you remotely access a local partition on the server and identify and diagnose server

health issues by using either a modem or network connection. The service partition uses

approximately 30 to 40 MB of hard disk space.

NOTE

MAXDATA strongly recommends that you install the service partition before installing an operating

system. If you skip this step now, and later decide to install a service partition, any operating

system or other data on the drive will be lost. To create and format the service partition:

1. Boot the server to the System Resource CD.

2. From the menu, select Utilities and press the <Enter> key.

3. Select Run Service Partition Administrator and press the <Enter> key.

4. From the list of available items, select Create Service Partition-first time.

5. Follow the instructions that appear on the screen. These instructions prompt you to

reboot the server. It will reboot from the CD-ROM.

13MAXDATA PLATINUM 7200 Server

15MAXDATA PLATINUM 7200 Server

6. After the system reboot, select the Utilities menu and press the <Enter> key.

7. Select Run Service Partition Administrator and press the <Enter> key.

8. Select Format Service Partition and Install Software.

9. Remove the System Resource CD from the CD-ROM drive and exit from the menu

screen.

You can now install the operating system.

Installing the Operating System

The System Resource CD contains a limited operating system with enough functionality to

boot the server and to copy and use the utilities and other files from the CD. This limited

operating system is not intended to be used to run applications. To run your server and

applications, you must install the operating system of your choice on the server. Follow the

installation instructions that came with the operating system.

System Security

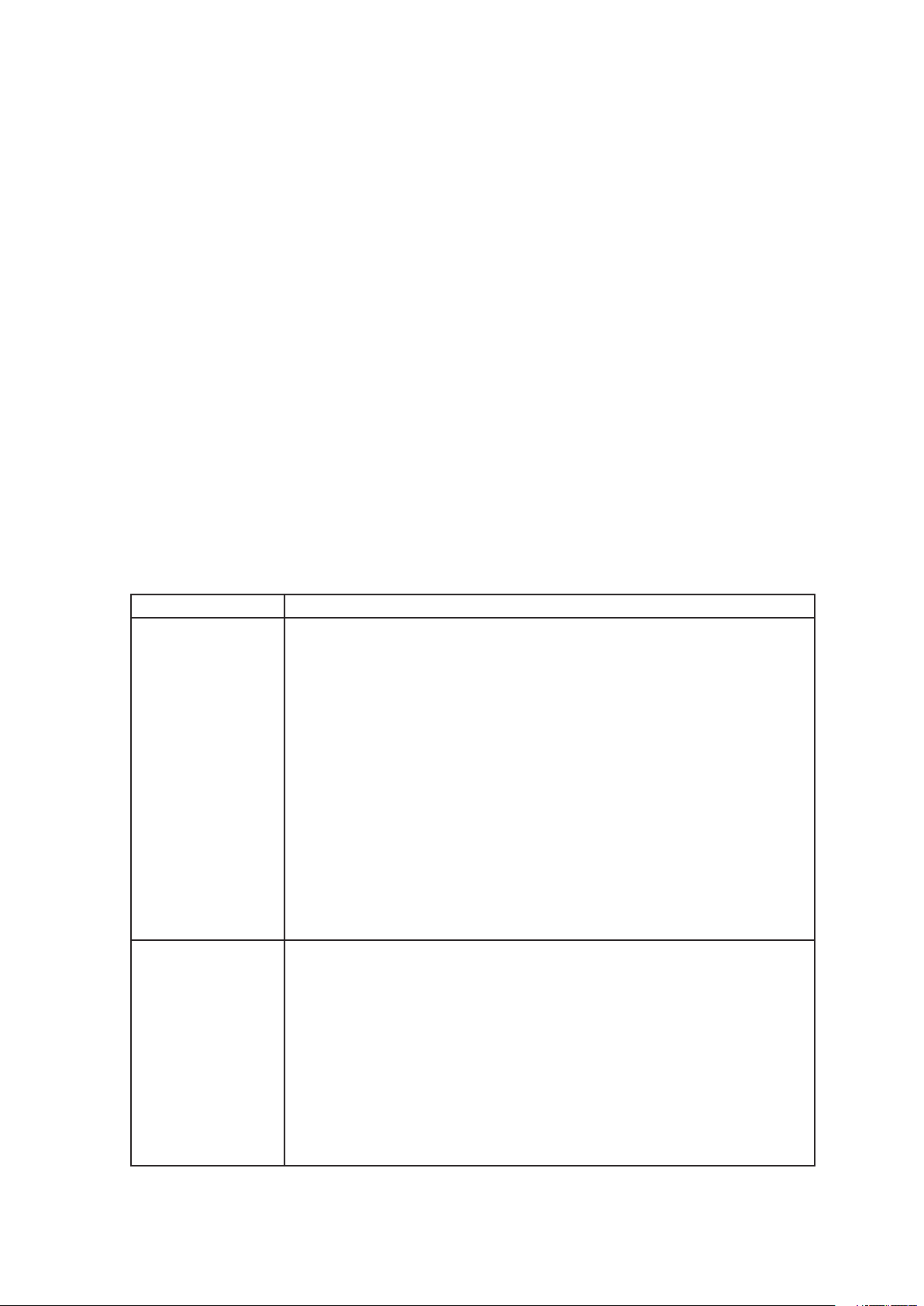

Table 4 summarizes the security features provided by the BIOS to prevent unauthorized or

accidental access to the system. You can enable these features using the Security section

of BIOS Setup. Most of the features can also be enabled using the System Setup Utility

(SSU). Additional information on passwords is provided following the table.

Table 4. Software Security Features

Feature Description

Secure Mode

Secure Mode Boot

To enable secure mode: Set a user password.

To enter secure mode, do one of the following:

• Press the hot-key combination for secure mode. You can specify a hotkey combination, which must consist of Ctrl+Alt plus one alphanumeric

character.

• Let the inactivity timer time out. If you don’t touch the keyboard during the

time-out period, the system enters secure mode automatically. You can set

the time-out period from two minutes to 120 minutes.

• Power on or reset the system. The system automatically enters secure

mode on power up.

When the system is in secure mode:

• Onboard video is blanked, if enabled.

• Diskette drive is write protected, if enabled.

• Power, Sleep, and Reset buttons on the front panel are disabled.

• Mouse and keyboard input are ignored, except for entering a password.

• The keyboard LEDs ash.

To enable, do both of the following:

• Set a user password.

• Enable Secure Mode Boot.

To activate: Power on or reset the server.

When enabled:

• If booting from drive A: the user must enter a password. After the user

enters the password, the system continues with the boot process. The

system doesn’t enter secure mode until activated by the hot-key or timer.

• If the system is not booting from drive A: the system boots normally. No

password is required, and the system enters secure mode automatically.

The system boots according to the boot device priority set in BIOS Setup.

continued

14 Getting Started

Table 4. Software Security Features (Continued)

Feature Description

Password on Boot

Fixed Disk Boot Sector Write Protect

Power Switch

Inhibit

To enable, do all of the following:

• Set a user password.

• Enable Password on Boot.

• Disable Secure Mode Boot.

To activate: Power on or reset the server.

When enabled: The user must enter a password to boot the system. The system

boots according to the boot device priority set in BIOS Setup.

To enable, do the following:

• Set Fixed Disk Boot Sector to Write Protect in the Security section of BIOS

Setup.

To activate: Power on or reset the server.

When enabled: Write protects the master boot record of the IDE hard disk drive

when the system boots from drive A:. Prevents viruses from corrupting the boot

sector under DOS. Works only with IDE drives.

To enable: Enable Power Switch Inhibit.

To activate: Power on or reset the server.

When enabled: The power switch can’t be used to power off the system.

Using Passwords

Passwords are up to seven characters long; may use only the alphanumeric characters a-z,

A-Z, and 0-9; and are not case sensitive.

You set administrator and user passwords in BIOS Setup and in the SSU. When you have

either password set, you must enter that password to do any of the following:

• Enter BIOS Setup and the SSU.

• Boot the server from drive A: when Secure Boot Mode is enabled.

• Boot the server when Password on Boot is enabled.

• Exit secure mode.

When you have both a user and an administrator password set, you may enter either

password. However, if you enter the user password for BIOS Setup or the SSU, you will be

able to modify only the time, date, language, user password, secure mode timer, and secure

mode hot-key. To modify any other features, you must enter the administrator password.

You can clear a password by setting it to a blank string. If you forget your passwords, you

can use the Password Clear jumper to clear the passwords on the next boot.

15MAXDATA PLATINUM 7200 Server

16 Getting Started 17MAXDATA PLATINUM 7200 Server

3 System Management

Baseboard Management Controller

The MAXDATA PLATINUM 7200 server incorporates a baseboard management controller

(BMC), which is a dedicated microcontroller for system management activities. The BMC

performs the following functions:

• Monitors system components and sensors, including processors, memory, fans,

power supplies, temperature sensors, and chassis intrusion sensors.

• Manages nonvolatile storage for the system event log (SEL), sensor data records (SDRs),

and baseboard field-replaceable unit (FRU) inventory.

• Interfaces with the emergency management port (EMP) and LAN1 port to send alerts

and interact with remote management systems.

• Provides the main front panel control functions (power on/off, reset, and so on).

Field Replaceable Units and Sensor Data Records

Field replaceable units (FRUs) are major modules in the chassis that contain active electronic

circuitry. FRUs can store information – such as board serial number, part number, name, and

asset tag – that can be read using the System Setup Utility. The BMC stores FRU information

for the baseboard in a nonvolatile storage component on the board.

The BMC uses Sensor Data Records (SDRs) to identify the sensors in the system for

monitoring. SDRs provide a list of the sensors, their characteristics, location, type, and

type-specific information, such as default threshold values, factors for converting a sensor

reading into the appropriate units (mV, rpm, degrees Celsius), and information on the types

of events that a sensor can generate. The BMC stores SDR information in a nonvolatile

storage component on the baseboard.

System Event Log

The BMC manages a system event log (SEL), where it records significant or critical system

events. Such events include temperatures and voltages out of range, fan failures, and other

sensor-related events. The BIOS, software, add-in cards, and other devices can also log

events by sending messages to the BMC. The SEL is stored in nonvolatile storage.

You can view the current contents of the SEL by using the System Setup Utility .

19MAXDATA PLATINUM 7200 Server

Platform Event Management

Events can trigger alerts and other actions by the BMC. The server is configured with the

following set of standard events:

• Temperature sensor out of range

• Voltage sensor out of range

• Fan failure

• Chassis intrusion

• Power supply fault

• BIOS uncorrectable ECC error

• BIOS POST error

• Processor fault resilient booting (FRB) failure

• Fatal nonmaskable interrupt (NMI) from a source other than the front panel switch

• Watchdog timer reset, power down, or power cycle

• System restart (reboot)

Alerts can take either of these forms:

• Platform event pages − the BMC dials a paging service and sends a predefined paging

string. To use platform event paging (PEP), you must attach an external modem to the

emergency management port (COM2).

• BMC LAN alerts − the BMC sends an alert to a predefined destination on the LAN.

You can configure PEP and BMC LAN alerts by using the System Setup Utility .

Emergency Management Port

The emergency management port (EMP) refers to the use of the COM2 port, with either

an external modem or direct serial connection, for remote management. The BMC controls

the port and interfaces with remote access software, such as the Direct Platform Control

application in Intel® Server Management. You can congure the EMP by using the System

Setup Utility .

Intel® Server Management

Intel® Server Management (ISM) is a system management package that is included on the

System Resource CD or on a separate ISM CD. ISM applications interact with the integrated

hardware system management features of the server to allow you to monitor and manage

a server from a remote workstation:

• Remote connection from a Windows®-based client workstation over a LAN, or over

a modem or direct serial connection to the emergency management port on the server.

• Real-time monitoring and alerting for server hardware sensors.

• Emergency management when the server is off (but still connected to AC power) lets

you verify the state of the server, diagnose hardware problems, and power on/off or

reset the server.

• Run the System Setup Utility to change the server configuration.

• Run diagnostics tools similar to those used during factory testing.

ISM depends on a service partition on the server that you are managing. The service partition

is a special disk partition on the system drive that contains a ROM-DOS operating system and

DOS-based utilities, including the System Setup Utility, FRU/SDR Load Utility, and Remote

Diagnostics. The server can be booted to the service partition, either locally or remotely, to

provide access to the utilities.

18 System Management

Using the System Setup Utility

The System Setup Utility (SSU) is located on the System Resource CD-ROM shipped with

the server.

Run the System Setup Utility to:

• Set boot device priority

• Set passwords and security options

• View system events

• View FRU information

• View sensor data records

• Update system firmware and BIOS

• Save and restore the system configuration

• Set up the server to send alerts for platform events

• Set up the server for remote management

Using either the System Setup Utility or BIOS Setup, you can specify the boot device

sequence and set up system passwords and security options. Both utilities access the

same stored configuration data for these items, and the result of making a change to these

settings using either utility is identical.

The SSU consists of a collection of task-oriented modules plugged into a common framework called the Application Framework (AF). The Application Framework provides a launching

point for individual tasks and a location for setting customization information.

Creating SSU Diskettes

You can run the SSU directly from the Utilities menu of the System Resource CD-ROM,

from a set of DOS diskettes, or from the service partition of the hard disk.

If you choose to run the SSU from a set of DOS diskettes, you must create the SSU diskettes

from the Resource CD-ROM as follows:

1. Boot to the System Resource CD-ROM.

2. Choose Create Diskettes > Create Diskettes by Device/Function > System Setup

Utility.

3. Follow the instructions displayed.

Alternatively, if you have a workstation with the Microsoft® Windows® operating system,

you can insert the CD into that system and create the diskettes on that system.

Running the SSU

When the SSU starts in the default local execution mode, the SSU accepts input from the

keyboard or mouse. The SSU presents a VGA-based GUI on the primary monitor.

If you run the SSU from read-only media, such as the CD-ROM, you cannot save user

preference settings (such as screen colors).

The SSU supports ROM-DOS version 6.22. The SSU will not operate from a “DOS box”

running under an operating system such as Windows®.

19MAXDATA PLATINUM 7200 Server

21MAXDATA PLATINUM 7200 Server

To start the SSU:

1. Start the SSU using one of the following methods:

− From diskettes: Insert the first SSU diskette in drive A and boot the server from the

diskette. You are prompted to insert the second diskette. After loading completes the

SSU starts automatically.

− From the System Resource or ISM CD-ROM: Boot the server to the System Resource

CD and start the SSU from the Utilities menu.

− From the Service Partition: Boot the server to the Service Partition and execute the

following DOS commands:

C:\> cd ssu

C:\SSU> ssu.bat

2. The mouse driver loads if it is available; press <Enter> to continue.

3. When the SSU title appears on the screen, press <Enter> to continue.

Working with the GUI

You can access features of the GUI using the mouse or keyboard:

• Mouse − Click once to choose menu items and buttons or to select items in a list, such

as the Available Tasks list. To run a list item, such as one of from the Available Tasks

list, select the item and click OK or double-click the item.

• Keyboard − Use the tab and arrow keys to highlight buttons and press the spacebar

or <Enter> to execute. You can also execute a menu or button by using the <Alt> key

in combination with the underlined letter in the name of the menu or button.

You can have more than one task open at the same time, although some tasks might require

complete control to avoid possible conflicts. The tasks achieve complete control by keeping

the task as the center of operation until you close the task window.

The SSU has a build-in help system, which you access by clicking a Help button or choosing

the Help menu.

Customizing the SSU Interface

The SSU lets you customize your interface using the Preferences section of the main window.

The AF sets these preferences and saves them in the AF.INI file so that they take effect the

next time you start the SSU. There are four user customizable settings:

• Color − lets you change the default colors associated with different items on the

screen using predefined color combinations. The color changes take effect imme diately.

• Mode − lets you set the desired expertise level: novice, intermediate, or expert.

The expertise level determines which tasks are visible in the Available Tasks section and

which actions each task performs. For a new mode setting to take effect, you must exit the

SSU and restart it.

• Language − lets you change the text in the SSU to the appropriate language. For a

new language setting to take effect, you must exit the SSU and restart it.

• Other − lets you show or hide the status bar at the bottom of the SSU main window.

The change takes effect immediately.

NOTE

If you run the SSU from read-only media (CD-ROM, for example), these preferences are lost

when you exit the SSU.

20 System Management

Exiting the SSU

Exiting the SSU closes all SSU windows.

Setting Boot Device Priority

To change the boot priority of a device:

1. From the SSU Main window, choose Boot Devices.

2. In the Multiboot Options Add-in window, select a device.

3. Click the Move Up button to move it up in the list. Click the Move Down button to move

it down.

Setting Passwords and Security Options

You can set a user password and an admin password. On some systems, you must set an

admin password before you can set a user password. On other systems, the passwords are

independent. You can set the same passwords and security options by using BIOS Setup (37).

Setting the Admin Password

The Admin Password button lets you set or change the admin password used by both the

SSU and the system BIOS. This option is not available if both an admin and a user password

are set and you entered only the user password when you started the SSU. All changes to

the admin password take effect immediately.

To change or clear the administrator password:

1. From the SSU Main window, choose Security.

2. Click the Admin Password button.

3. If you are changing passwords, enter the old password.

4. Enter the new password (or leave blank to clear).

5. Confirm the password by entering it again (or leave blank to clear).

6. Click OK to save the password and return to the Security window.

Setting the User Password

The User Password button lets you set or change the user password used by both the SSU

and the system BIOS. All changes to the user password take effect immediately.

To change or clear the user password:

1. From the SSU Main window, choose Security.

2. Click the User Password button.

3. If you are changing passwords, enter the old password in the rst box.

4. Enter the new password (or leave blank to clear).

5. Conrm the password by entering it again (or leave blank to clear).

6. Click OK to save the password and return to the Security window.

21MAXDATA PLATINUM 7200 Server

23MAXDATA PLATINUM 7200 Server

Setting Security Options

To set the security options:

1. In the Security window, click the Options button.

2. For each option, select the desired setting from the list. The options are:

• Security Hot Key: The key combination that can be used to put the server into secure

mode.

• Secure Mode Timer: If no keyboard or mouse activity occurs during the chosen time

interval, the server enters secure mode.

• Secure Mode Boot: Enable forces the server to boot directly into secure mode.

• Video Blanking: Enable turns off the video when the server is in secure mode.

• Floppy Write: Enable prevents writing to the diskette drive while the server is in secure

mode.

• Power Switch Inhibit: Enable prevents the power and reset buttons from function-

ing when the server is in secure mode. Disable allows the power and reset buttons

to function normally when the server is in secure mode.

3. Click Save to save the settings and return to the Security window.

Viewing the System Event Log

To view the System Event Log (SEL):

1. From the SSU Main window, choose SEL Manager.

When you start the SEL Manager, it automatically loads the current list of events from nonvolatile memory.

2. Use the <F4> and <F5> keys to scroll the window contents to the left and right to view

all of the columns.

3. Use the File and SEL menu items to work with the SEL information:

• Open: Views data from a previously saved SEL file.

• Save As: Saves the currently loaded SEL data to a file.

• Properties: Displays information about the SEL.

• Clear SEL: Clears the SEL data from the nonvolatile storage area.

• Reload: Refreshes the display by reading the current SEL entries from the server.

• Sort By: Sorts the displayed events by event number, time stamp, sensor type and

number, event description, or event generator ID.

Viewing FRU Information

To view the Field Replaceable Unit (FRU) information:

1. From the SSU Main window, choose FRU Manager.

When you start the FRU Manager, it automatically loads the current list of events from nonvolatile memory.

The FRU Manager window has a navigation pane on the left that displays, in a tree format,

the inventory of components in the server. The tree has three categories: Chassis, Board, and

Product. Clicking on a category expands or collapses a list of components for that category.

Clicking on an individual component displays the FRU information for that component in

the presentation pane in the upper right. The description pane in the lower right displays a

description of the currently selected FRU area.

22 System Management

2. Use the <F4> and <F5> keys to scroll the window contents to the left and right to view

all of the columns.

3. Use the File and FRU menu items to work with the FRU information:

• Open: Views data from a previously saved FRU file.

• Save As: Saves the currently loaded FRU data to a file.

• Properties: Displays the number of FRU devices in the system and the number being

displayed. Only FRU devices with valid FRU areas are displayed.

• Reload: Refreshes the display by reading the current FRU entries from the server.

Viewing Sensor Data Records

To view the Sensor Data Records (SDR):

1. From the SSU Main window, choose SDR Manager.

When you start the SDR Manager, it automatically loads the SDR entries from non-volatile

memory.

The SDR Manager window has a navigation pane on the left that displays, in a tree format, the

sensor data records. The tree has categories for each type of record. Clicking on a category

expands or collapses a list of SDRs for that category. Clicking on an individual SDR displays

the information for that SDR in the presentation pane in the upper right. The description

pane in the lower right displays a description of the currently selected SDR type.

2. Use the <F4> and <F5> keys to scroll the window contents to the left and right to view

all of the columns.

3. Use the File and SDR menu items to work with the SDR information:

• Open: Views data from a previously saved SDR file.

• Save As: Saves the currently loaded SDR data to a file.

• Properties: Displays information about the SDR, including IPMI version, number of

SDR entries, time stamps for changes to the SDR information, and free space

remaining.

• Reload: Refreshes the display by reading the SDR data from the server.

Saving and Restoring the System Configuration

Using the SSU, you can save the following configuration information to a file:

• Platform type, BIOS revision, and firmware revision

• CMOS settings

• Extended system configuration data (ESCD)

• Settings for the emergency management port (EMP), platform event paging (PEP), and

BMC LAN alerts

Data is saved from all sources. There is no way to choose only certain pieces of configuration

data to save. You can also restore the information from a saved configuration file.

NOTE

BIOS passwords are stored in the le. Restoring a conguration can change passwords on

a server. EMP and LAN passwords are not stored in the le.

23MAXDATA PLATINUM 7200 Server

25MAXDATA PLATINUM 7200 Server

Saving a Configuration

To save the system configuration:

1. From the SSU Main window, choose Config Save/Restore. (Configuration Save/Restore

is available only in Expert mode.)

2. Click Save To File and specify a filename and location.

Restoring a Configuration

To restore the system configuration from a file:

1. From the SSU Main window, choose Config Save/Restore. (Configuration Save/Restore

is available only in Expert mode.)

2. Click Restore from File and specify a filename and location.

The CSR reads the platform type, BIOS revision, and firmware revision from the file and

compares that information with the same information retrieved from the server. If the two

do not match, an error message is displayed and the restore operation aborts. If they do

match, the CSR restores the configuration data to the server. It prompts you to reboot the

server for the new settings to take effect.

Alerting for Platform Events

You can set up the server to alert you when various events occur. Alerts can be delivered

either as telephone pages or over the LAN. Instructions for setting up both telephone paging

alerts and LAN alerts are given below.

Setting Up Paging Alerts

To set up the server to send alerts as telephone pages:

1. Install an external modem on the Emergency Management Port (COM2).

2. From the SSU Main window, choose Platform Event Manager (PEM).

3. In the PEM window, click Configure EMP.

4. In the corresponding boxes, enter the following command strings for the modem attached

to the EMP port:

• ESC Sequence: the escape sequence. This string is sent to the modem before sending

command strings. The maximum length for the string is five characters; longer strings

are truncated.

• Hangup String: hang up or drop the connection. The EMP automatically sends an

<ENTER> character following this string. The maximum length for the string is

eight characters; longer strings are truncated.

• Modem Dial Command: the command to dial a phone number. This string is sent to

the modem before sending the paging string.

• Modem Init String: the initialization string for the modem. This string is sent every

time the EMP initializes. The maximum length for the string is determined at runtime

from firmware. You will be notified if the string is truncated. Following a save, the

actual string saved is displayed in the edit box.

5. Click Save to save the changes.

6. Click Close to return to the PEM window.

7. In the PEM window, click Configure PEP.

8. Select the Enable PEP check box.

24 System Management

9. In the Blackout Period box, enter the minimum time, in minutes, between successive

pages. The valid range is [0 - 255] where 0 disables the blackout period. Setting a blackout

period can save you from being flooded with repeat pages. After you receive a PEP page,

no additional pages are sent by PEP for the duration of the blackout period.

10. In the Paging String box, enter the phone number to dial for the page and the message

you want sent with the page. The maximum length for the paging string is determined

at runtime from firmware. You will be notified if the string is truncated. Following a save,

the actual string saved is displayed in the edit box.

11. From the Options menu, choose Configure Event Actions.

12. In the Platform Event Paging Actions window, move the events that you want to generate an

alert to the Enabled column and move all other events to the disabled column using

the following buttons:

>>: Moves all events from the enabled list to the disabled list.

>: Moves the selected event from the enabled list to the disabled list.

<: Moves the selected event from the disabled list to enabled the list.

<<: Moves all events from the disabled list to the enabled list.

13. Click Save to save the changes.

14. Click Close to return to the PEP Configuration window.

15. To send a test page to verify that you have correctly configured PEP, from the Options

menu, choose Send Alert.

16. Click Save to save the configuration.

17. Click Close to return to the Platform Event Manager window.

Setting Up LAN Alerts

To set up the server to send alerts over the LAN:

1. Configure the remote system to receive alerts. For more information, see the documen-

tation for Intel® Server Management software.

2. From the SSU Main window, choose Platform Event Manager (PEM).

3. In the PEM window, click Configure LAN.

4. Select the Enable LAN Alerts check box.

5. (Optional) In the SNMP Community String box, enter a string for the community field in the

Header section of the SNMP trap sent for an alert. The string must be from 5 to 16

characters. The default string is public.

6. In the IP Setup box, choose either:

• DHCP: the IP address for the server is automatically assigned by the DHCP

(dynamic host control protocol) server on the network. The Host, Gateway, and Subnet

Mask boxes in the dialog are ignored.

• Static: assign the IP address for the server using the Host, Gateway, and Subnet Mask

boxes in the dialog.

7. If you chose Static IP Setup in the previous step, fill in the IP addressing boxes:

• Host IP Address: the IP address of this server.

• Gateway IP Address: the IP address of the router for this server.

• Subnet Mask: the IP address for the server’s subnet. The server uses this to decide

if the alert destination is on the same subnet.

25MAXDATA PLATINUM 7200 Server

27MAXDATA PLATINUM 7200 Server

8. In the Alert IP Address box, fill in the IP address of the system you want to receive alerts

from this server. If you want the alert to be broadcast to an entire subnet, enter the IP

address for the subnet.

9. From the Options menu, choose Configure Event Actions.

10. In the BMC LAN Alerting Actions window, move the events that you want to generate

an alert to the Enabled column and move all other events to the disabled column

using the following buttons:

>>: Moves all events from the enabled list to the disabled list.

>: Moves the selected event from the enabled list to the disabled list.

<: Moves the selected event from the disabled list to enabled the list.

<<: Moves all events from the disabled list to the enabled list.

11. Click Save to save the changes.

12. Click Close to return to the BMC LAN Configuration window.

13. To send a test alert to verify that you have correctly configured BMC LAN alerts, from

the Options menu, choose Send Alert.

14. Click Save to save the changes.

15. Click Close to return to the PEM window.

Managing the Server Remotely

You can set up the server so that you can connect to it from a remote client system to

perform management tasks. You can make the connection over a LAN or by using a modem

or direct serial cable to the Emergency Management Port (EMP). Instructions for setting up

the server for remote LAN and serial/modem access are given below.

Setting Up Remote LAN Access

To configure remote LAN access:

1. From the SSU Main window, choose Platform Event Manager (PEM).

2. In the PEM window, click Configure LAN.

3. If you want to require a password for remote access, enter the password in the Enter New

Password box and in the Verify New Password box. Passwords can be from 1 to

16 characters long, using any ASCII character in the range [32-126]. To clear the passwords,

leave both boxes blank. (You can also clear the password by choose the menu Options >

Clear LAN Password.)

4. From the LAN Access Mode list, select the remote access mode:

• Full Access: a remote system can initiate a LAN connection regardless of the state

or health of the server.

• Restricted: a remote system can initiate a LAN connection, but cannot perform control

operations such as power down, reset, or front panel NMI.

• Disabled: remote systems are not allowed to initiate LAN connections.

5. In the IP Setup box, choose either:

• DHCP: the IP address for the server is automatically assigned by the DHCP

(dynamic host control protocol) server on the network. The Host, Gateway, and Subnet

Mask boxes in the dialog are ignored.

• Static: assign the IP address for the server using the Host, Gateway, and Subnet Mask

boxes in the dialog.

26 System Management

6. If you chose Static IP Setup in the previous step, fill in the IP addressing boxes:

• Host IP Address: the IP address of this server.

• Gateway IP Address: the IP address of the router for this server.

• Subnet Mask: the IP address for the server’s subnet. The server uses this to decide

if the alert destination is on the same subnet.

7. Click Save to save the changes.

8. Click Close to return to the PEM window.

Setting Up Remote Modem or Serial Access

To configure remote modem or serial access:

1. From the SSU Main window, choose Platform Event Manager (PEM).

2. In the PEM window, click Configure EMP.

3. If you want to require a password for remote access, enter the password in the Enter New

Password box and in the Verify New Password box. Passwords can be from 1 to

16 characters long, using any ASCII character in the range [32-126]. To clear the pass words, leave both boxes blank. (You can also clear the password by choose the menu

Options > Clear LAN Password.)

4. In the Modem Ring Time box, enter the number of 500ms intervals that the BMC should

wait before taking control of the COM2 port and answering an incoming call. A value

greater than zero gives the BIOS time to answer before the BMC takes control. A value of

zero causes the BMC to answer immediately. The maximum value, 63, tells the BMC to

ignore the call. Modem Ring Time applies only to Preboot access mode and is ignored

for other access modes.

5. In the System Phone Number box, enter the number for the phone line connected to

the modem on the EMP.

6. From the Access Mode list, choose the remote access mode:

• Always Active: the EMP is available at any time.

• Preboot: the EMP is available only when the server is powered down or is in the

running POST during startup.

• Disabled: remote systems are not allowed to initiate connections.

7. From the Restricted Mode list, choose either:

• Enabled: a remote system can initiate a connection, but cannot perform control

operations such as power down, reset, or front panel NMI.

• Disabled: the remote system has full control of the server.

8. From the Connection Mode list, choose either:

• Direct Connect: the COM2 port on the server is connected by a serial cable to the

remote system.

• Modem Connect: the COM2 port on the server is connected to a modem.

9. Click Save to save the changes.

10. Click Close to return to the PEM window.

27MAXDATA PLATINUM 7200 Server

28 System Management 29MAXDATA PLATINUM 7200 Server

4 Installing and Removing

Removing and Installing the Bezel

You need to remove the bezel to install and remove hot-swap power supplies and to install

and remove devices in the 5.25-inch peripherals bay. The bezel has ball studs on the back

that snap-fit into holes on the chassis front.

• To remove the bezel, pull it away from the chassis until the ball studs release from the

chassis.

• To install the bezel, align the ball studs with the holes in the chassis and push gently

until the ball studs snap into the holes.

Figure 2. Attaching the Bezel to the Chassis

Memory

Installing DIMMs

CAUTION

Use extreme care when installing a DIMM. Applying too much pressure can damage the

socket. Keyed DIMMs insert only one way.

NOTE

Load the DIMMs in the following order (Figure 3).

1. Bank 1: DIMMs #1, 2, 3, and 4

2. Bank 2: DIMMs #5, 6, 7, and 8

3. Bank 3: DIMMs #9, 10, 11, and 12

Always fill banks completely. Partially filled banks are ignored by the system.

31MAXDATA PLATINUM 7200 Server

To install DIMMs:

A

1. Remove the memory board, and place the board component-side up on a nonconductive,

static-free surface.

2. Holding the DIMM only by its edges, remove it from its antistatic package.

3. Open the plastic ejector levers at each end of the DIMM socket on the memory board.

4. Orient the DIMM so that the notch in the bottom edge of the DIMM aligns with the

keyed socket on the memory board.

5. Insert the bottom edge of the DIMM into the socket and press down firmly on the DIMM

until it seats correctly. The plastic ejector levers should snap into place when the DIMM

is seated.

6. Make sure that the plastic ejector levers on the socket ends are fully closed.

7. Reinstall the memory board .

Removing DIMMs

1. Remove the memory board. Place the board component-side up on a nonconductive,

static-free surface.

2. Locate the DIMM you want to remove and gently push down on the plastic ejector levers

to eject the DIMM from its socket.

3. Hold the DIMM only by its edges, being careful not to touch its components or gold

edge connectors. Carefully lift it away from the socket and store it in an antistatic

package.

Figure 3. Installing Memory

30 Installing and Removing Components

Figure 4. Removing DIMMs

Hot-Swap SCSI Drives

Hot-swap drives are installed in carriers that fit into the hot-swap drive bay. This section

describes the LED status indicators for the drive bays and gives instructions for using the

drive carriers to install and remove drives.

Checking a Hot-Swap SCSI Drive Status Indicator

Each hot-swap SCSI drive slot has an LED that indicates drive status (Figure 6). To view the

LEDs, open the access door on the right side of the bezel.

Figure 5. Hot-Swap SCSI Drive Bay and Status Indicators

A.

Bezel

B.

Access door, hot-swap drive bay

Table 5 lists the LED states and the drive status indicated by each state.

C.

LED status indicators

31MAXDATA PLATINUM 7200 Server

33MAXDATA PLATINUM 7200 Server

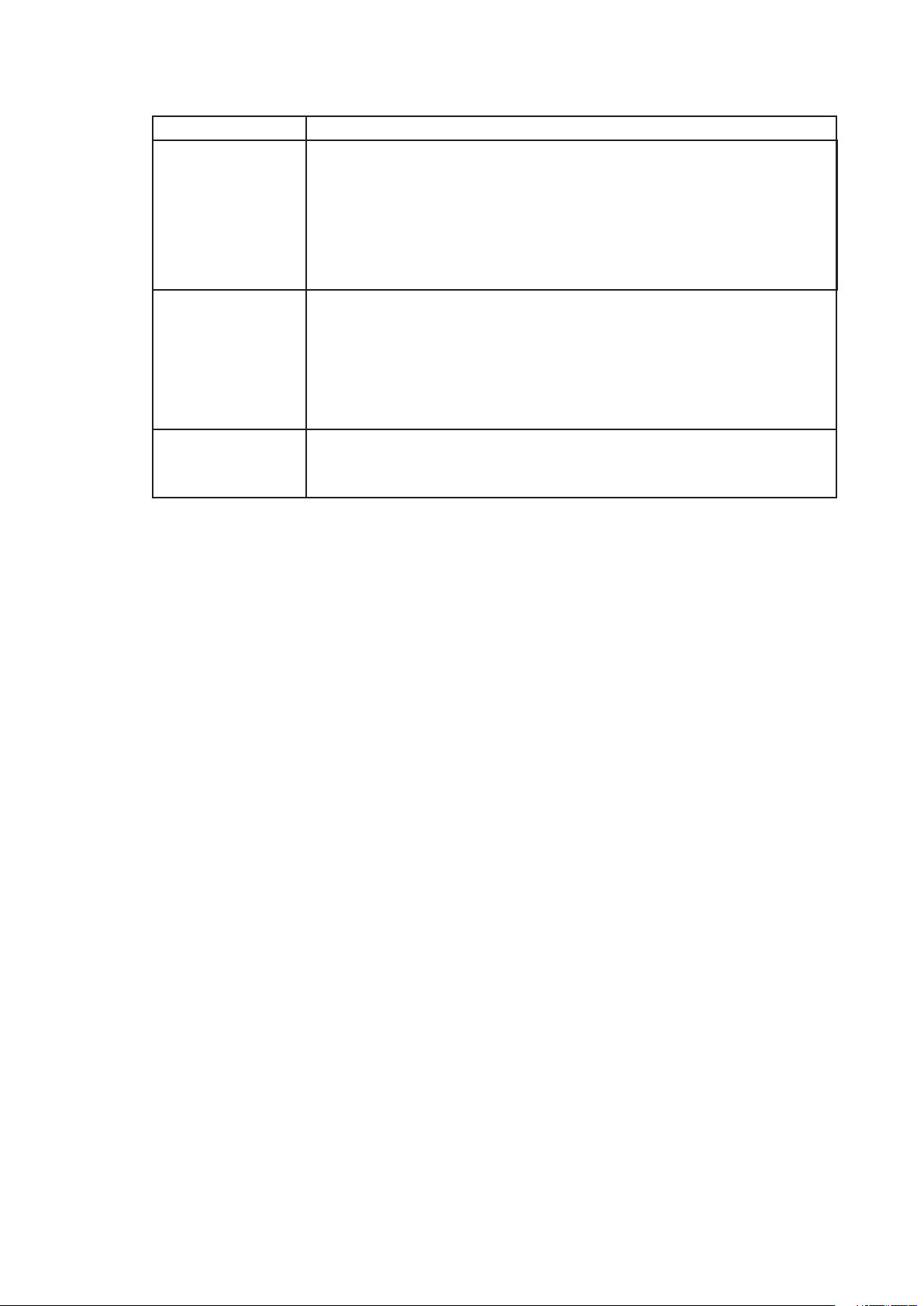

Table 5. LED States for Hot-Swap SCSI Drive Status

LED State Status

Solid green The hard drive is present and powered on.

Flashing green The hard drive is active.

Solid yellow There is an asserted fault status on the hard drive.

Flashing yellow A rebuild of the hard drive is in progress.

Off The hard drive is not powered on.

Before you can install a drive in the hot-swap drive bay, you must install the drive into a drive

carrier. To install a hot-swap drive in a carrier:

1. If the plastic air baffle is installed in the carrier, remove the four screws that attach the

air baffle to the carrier. Save the air baffle in case you later remove a drive.

Figure 6. Removing a Plastic Air Baffle from a Carrier

A.

B.

Air Baffle

Screw

C.

D.

Carrier

Plastic rail

2. Remove the hard drive from its wrapper and place it on an antistatic surface.

3. Record the new drive model and serial number in your equipment log.

4. Place the drive in the carrier with the component side down.

5. Using the four screws removed earlier, attach the drive to the carrier.

32 Installing and Removing Components

Figure 7. Installing a SCSI Hard Disk Drive in a Carrier

A.

SCA Connector

B.

Drive

C.

Carrier

D.

E.

Plastic Rail

Screw

Removing a Hot-swap Drive from a Carrier

To remove a hot-swap drive from a carrier:

1. Remove the carrier and drive from the drive bay.

2. Remove the four screws that secure the drive to the carrier.

3. Place the drive on an antistatic surface.

4. If you are going to reinstall the carrier without a drive, you must first replace the air baffle

in the carrier.

33MAXDATA PLATINUM 7200 Server

35MAXDATA PLATINUM 7200 Server

Removing and Installing Hot-Swap Disk Drives

CAUTION

Do not leave any drive slots without a drive or air baffle installed in the carrier. An empty

carrier installed in a drive slot reduces cooling efficiency and can affect performance or cause

damage due to overheating.

To replace a hot-swap disk drive:

1. Depress the green clip at the end of the plastic carrier handle. Pull the handle out to

disengage the carrier handle latch from the locking slot at the top of the drive bay.

Figure 8. Removing a Drive Carrier

A.

B.

Handle

Latch

C.

Locking slot

2. Carefully pull on the carrier handle and slide the carrier out of the bay.

3. Install a new drive into the carrier .

4. Hold the carrier handle in the fully open position and slide the carrier into the desired

bay.