Service Manual

Model : Belinea 101725

Art. No. 111707

MAXDATA Systeme GmbH

Elbestr. 12-16

45768 Marl / Germany

Contents

1. Precautions

Safety Precautions 4

Servicing Precautions

Electrostatically Sensitive Devices (ESD) Precautions

2. Product Specifications

Specifications 8

Dimensions

Pin Assignment Table D-Sub 15 Pin Connector

Timing Chart

3. Disassembly and Reassembly

4. Troubleshooting

6

7

9

10

10

11

No Power 14

No Video

No Picture

No Sound

5. Exploded View & Parts List

6. Packing & Unpacking

7. Electrical Parts List

Main Board 20

OSD Key Board

Others

15

16

16

17

19

22

22

2

Service Manual

Contents

8. Block Diagram

9. Wiring diagram

10. PCB Layout

Main PCB 28

Key PCB

Semiconductor Aead Identification

11. Schematic Diagram

CONTENTS

25

27

31

31

32

Copyright

2003 by Maxdata Systeme GmbH

All rights reserved.

This manual may not, in whole or in part, be copied,

photocopied, reproduced, translated, or converted to any

electronic or machine readable form without prior written

permission of Maxdata Systeme GmbH.

Belinea 101725 Service Manual

First edition April 2003

111707 Service Manual

3

Precautions

1. Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against

potential hazards such as electrical shock.

1-1 Safety Precautions

1-1-1 Warnings

1. For continued safety , do not attempt to modify the circuit board.

2. Disconnect the AC power Jack before servicing.

1-1-2 Servicing the LCD Monitor

1. When servicing the LCD Monitor Disconnect the AC line cord from the AC outlet.

2. It is essential that service technicians have an accurate voltage meter available at all times.

Check the calibration of this meter periodically .

1-1-3 Fire and Shock Hazard

Before returning the monitor to the user,perform the following safety checks :

1. Inspect each lead dress to make certain that the leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in the monitor.

2. Inspect all protective devices such as nonmetallic control knobs, insulating materials, cabinet

backs, adjustment and compartment covers or shields, isolation resistor-capacitor networks,

mechanical insulators, etc.

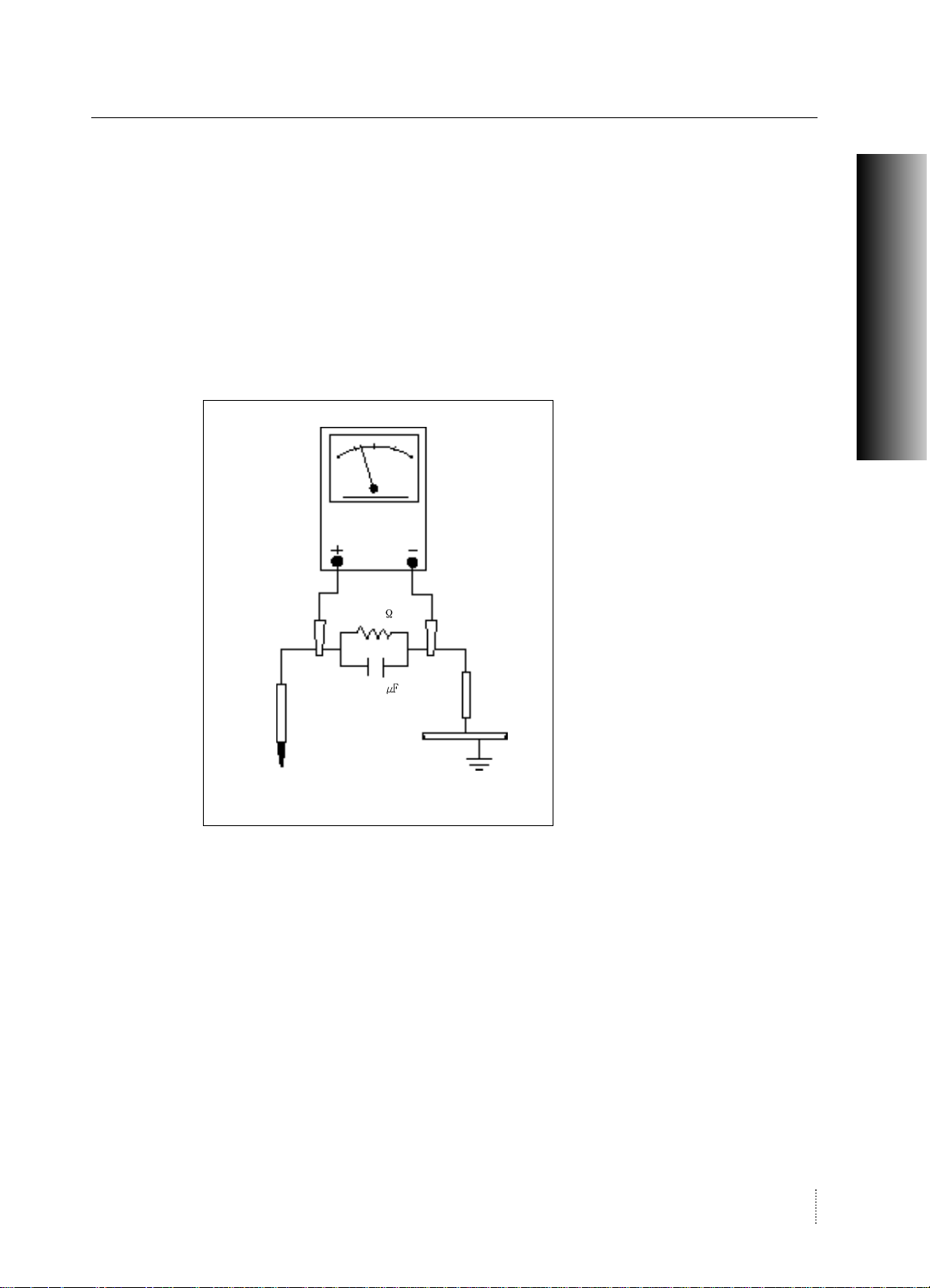

3. To be sure that no shock hazard exists, check for leakage current in the following manner.

Warning : Do not use an isolation transformer during this test.

a. Plug the AC line cord directly into a 120 Volt AC outlet.

b. Unisg two clip leads, connect 1.5

with an exposed metal cabinet part and a known earth ground, such as an electrical conduit or

electrical ground connected to an earth ground.

, 10 watt resistor paralleled by a 0.15

capacitor in series

111707 Service Manual

4

Precautions

c. Use a SSVM or VOM with 1000 ohms per-volt or higher sensitivity to measure the AC voltage

drop across the resistor (see Figure 1-1).

d. Connect the resistor to an exposed metal part having a return path to the chassis(metal cabinet,

screw heads, knobs, shafts, escutcheon, etc.) and measure the AC voltage drop across the

resistor.

e. Any reading of 5.25 Volt RMS ( this corresponds to 3.5 milliampere AC ) or more is excessive

and indicates a potential shock hazard. Correct the shock hazard before returning the monitor to

the user.

AC Voltmter

1500

Test Probe

PRECAUTION

0.15

To Exposed

Metal Parts

To Known

Earth Ground

Figure 1-1.

Leakage Current Test Circut

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special safety-related characteristics which are often not

evident from visual inspection. The protection they give may not be obtained by replacement that

does not have the same safety characteristics as the recommended replacement part may create

shock, fire and /or other hazards. Product safety is under review continuously and new instructions

are issued whenever appropriate.

111707 Service Manual

5

Precautions

1-2 Servicing Precautions

WARNING : An electrolytic capacitor installed with the wrong polarity might explode.

Caution : Before servicing instruments covered by this service manual and its supplements,

read and follow the Safety Precautions section of this manual.

Note : If unforeseen circumstances create conflict between the following servicing preautions

and any of the safety precautions, always follow the safety precautions.

1-2-1. General Servicing Precautions

1. Servicing precautions are printed on the cabinet, and should be followed closely .

2. Always unplug the unit's AC power cord from the AC power source before attempting to :

(a) remove or reinstall any component or assembly , (b) disconnect PCB plugs or connectors,

(c) connect a test component in paralled with an electrolytic capacitor.

3. Some components are raised above the printed circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is sometimes clamped to prevent contact with thermally hot

components. Reinstall all such elements to their original position.

4. After servicing, always check that the screws, components and wiring have been correctly

reinstalled. Make sure that the portion around the serviced part has not been damaged.

5. Check the insulation between the blades of the AC plug and accessible conductive parts

(examples; metal panels, input terminals and earphone jacks)

6. Insulation Checking Procedure : Disconnect the power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter(500V) to the blades of the AC plug.

The insulation resistance between each blade of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Always connect a test instrument's ground lead to the instrument chassis ground before connecting

the positive lead; always remove the instrument's ground lead last.

111707 Service Manual

6

Precautions

1-3 Electrostatically Sensitive Devices(ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity . such

components are commonly called Electrostatically Sensitive Devices(ESD). Examples of typical ESD

devices are integrated circuits and some field-effect transistors. The following techniques will reduce

the incidence of component damage caused by static electricity .

1. Immediately before handling any semiconductor components or assemblies, drain the electrostatic

charge from your body by touching a known earth ground. Alternatively , wear a discharging

wrist strap device. To avoid a shock hazard, be sure to remove the wrist strap before applying

power to the monitor.

2. After removing an ESD-equipped assembly , place it on a conductive surface such as aluminum foil

to prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can generate electrical charges Sufficient to damage

ESDs.

4. Use only a ground-tip soldering iron to solder ESDs.

PRECAUTIONS

5. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-

static" can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective package until you are ready to install it. Most

relacement ESDs are packaged with leads that are electrically shorted together by conductive

foam, aluminum foid or other conductive materials.

7. Immediately before removing the protective material from the leads of a replacement ESD, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution : Be sure no power is applied to the chassis or circuit and observe all other safety

precautions.

8. Minimize body motions when handling unpackaged replacement ESDs. Motions such as brushing

clothes together, or lifting your font from a carpeted floor can generate enough static electricity to

damage an ESD.

111707 Service Manual

7

Precautions

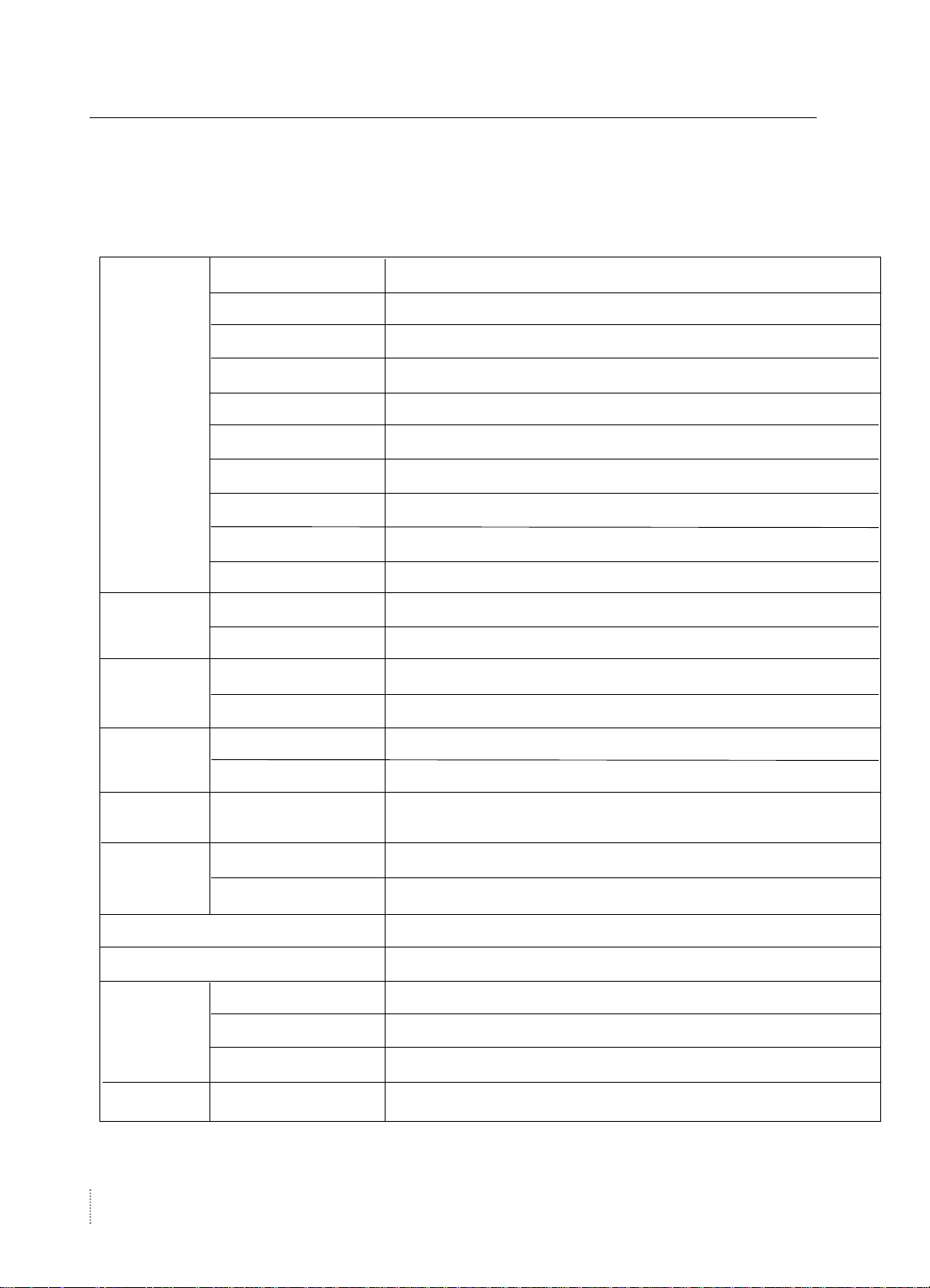

2. Product Specifications

2-1 Specifications

LCD PANEL

Synchornization

Video Input

Power

Consumption

Model

Type

Screen Size

Maximum Resolution

Pixel Range

Display Colors

Contrast Rate

Viewing Angle

Response Speed

Brightness

Horizontal Frequency

Vertical Frequency

Video Signal

Synchronous Signal Mode

Maximum

Power Saving Mode

Belinea 101725

Amorphous Active Matrix Super TFT LCD

43.2cm ( Diagonal )

1280 X 1024 @ 75Hz

0.264mm X 0.264mm

16.2M

350 : 1

70° / 70° / 60°/ 60° ( left / right / up / down )

25ms

250 cd/m2

79.9KHz( Max )

75HZ( Max )

Analog RGB (0.714Vpp) 75 ohm

H,V separate TTL Sync,SOG,COMPOSITE

48W

Under 1W

Control Keys

Audio Output

Combo board

Wall Mount

Safety & EMI

Dimension

111707 Service Manual

8

Front part

Normal

Max

Safety Standard

EMI

Low Radiation

Size and Weight

MUTE,MENU,SELECT/AUTO,POWER,

- , + , VOL SWITCH

1W/Ch

1.5W/Ch

90~240Vac(50~60Hz),0.65A

VESA Standard

CB,TUV

CE

TCO' 99

380 X 176 X 368 / 5.8Kg

Product Specifications

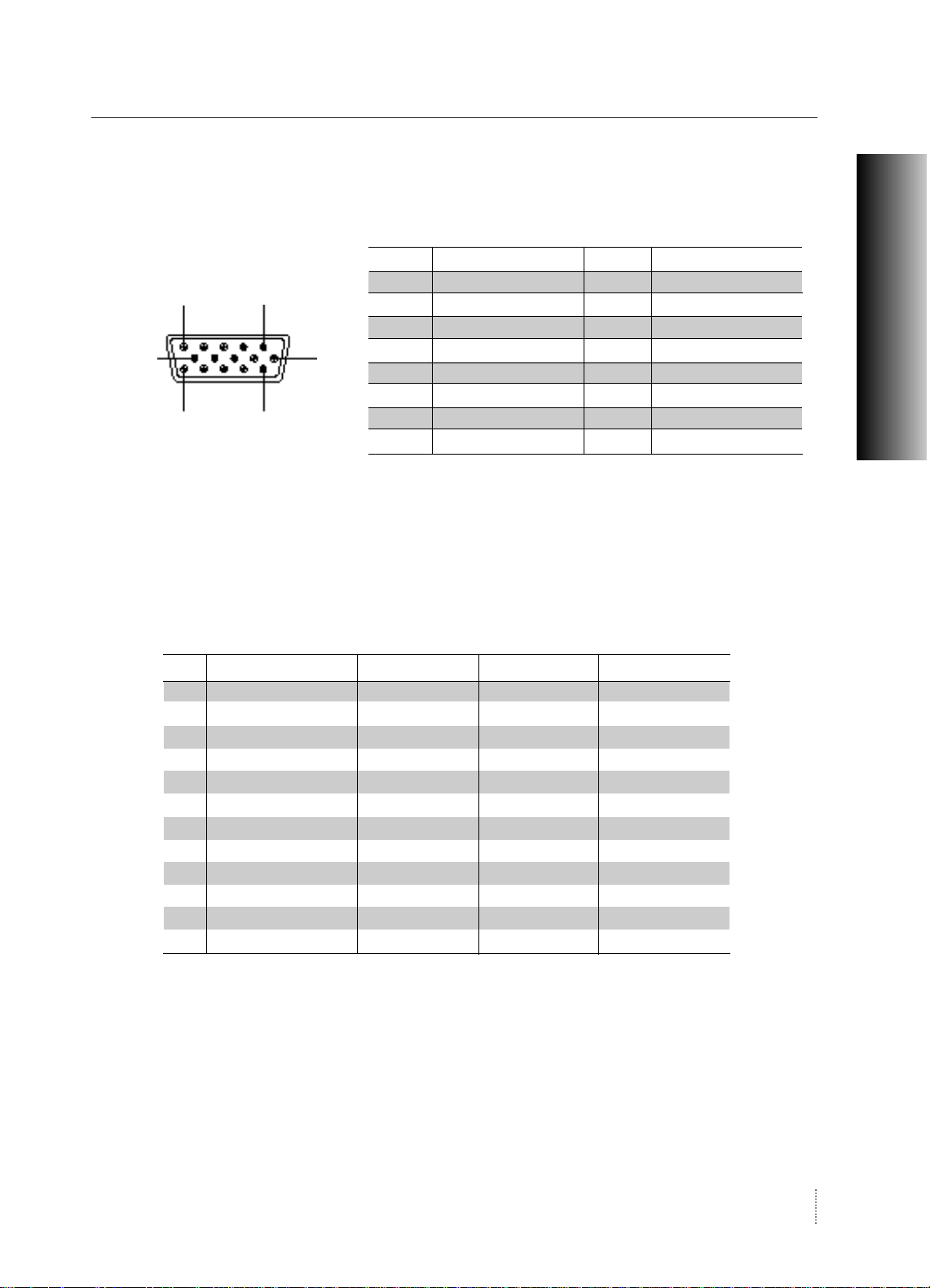

2-2 Pin Assignment

The 15-pin D-sub connector(male) of the signal cable(IBM systems)

Pin No Assignment Pin No Assignment

1

6

11

5

10

15

1 Red Video 9 5V Input

2 Green Video 10 Ground

3 Blue Video 11 Ground

4 N.C 12 SDA (DDC Data)

5 Ground 13 H-Sync

6 Red Video Ground 14 V-Sync

7 Green Video Ground 15 SCL (DDC Clock)

8 Blue Video Ground

2-3 Timing chart

This section of the service manual describes the timing that the computer industry recognizes as

standard for computer-generated video signals.

PRODUCT SPECIFICATIONS

No.

1

2

3

4

5

6

7

8

9

10

11

12

Display Mode

VGA (720 X 400)

VGA (640 X 480)

VGA (640 X 480)

SVGA (800 X 600)

SVGA (800 X 600)

XGA (1024 X 768)

XGA (1024 X 768)

SXGA (1280 X 1024)

SXGA (1280 X 1024)

MAC (640 X 480)

MAC (832 X 624)

MAC (1152 X 870)

Hor. Freq (kHz)

31.469

31.469

37.500

37.900

46.875

48.363

60.023

63.981

79.976

35.000

49.726

68.681

Ver. Freq (Hz)

70.087

59.940

75.000

60.320

75.000

60.004

75.029

60.020

75.025

66.667

74.551

75.062

Dot Clock (MHz)

28.322

25.175

31.500

40.000

49.500

65.000

78.750

108.000

135.000

30.240

57.284

100.000

111707 Service Manual

9

Product Specifications

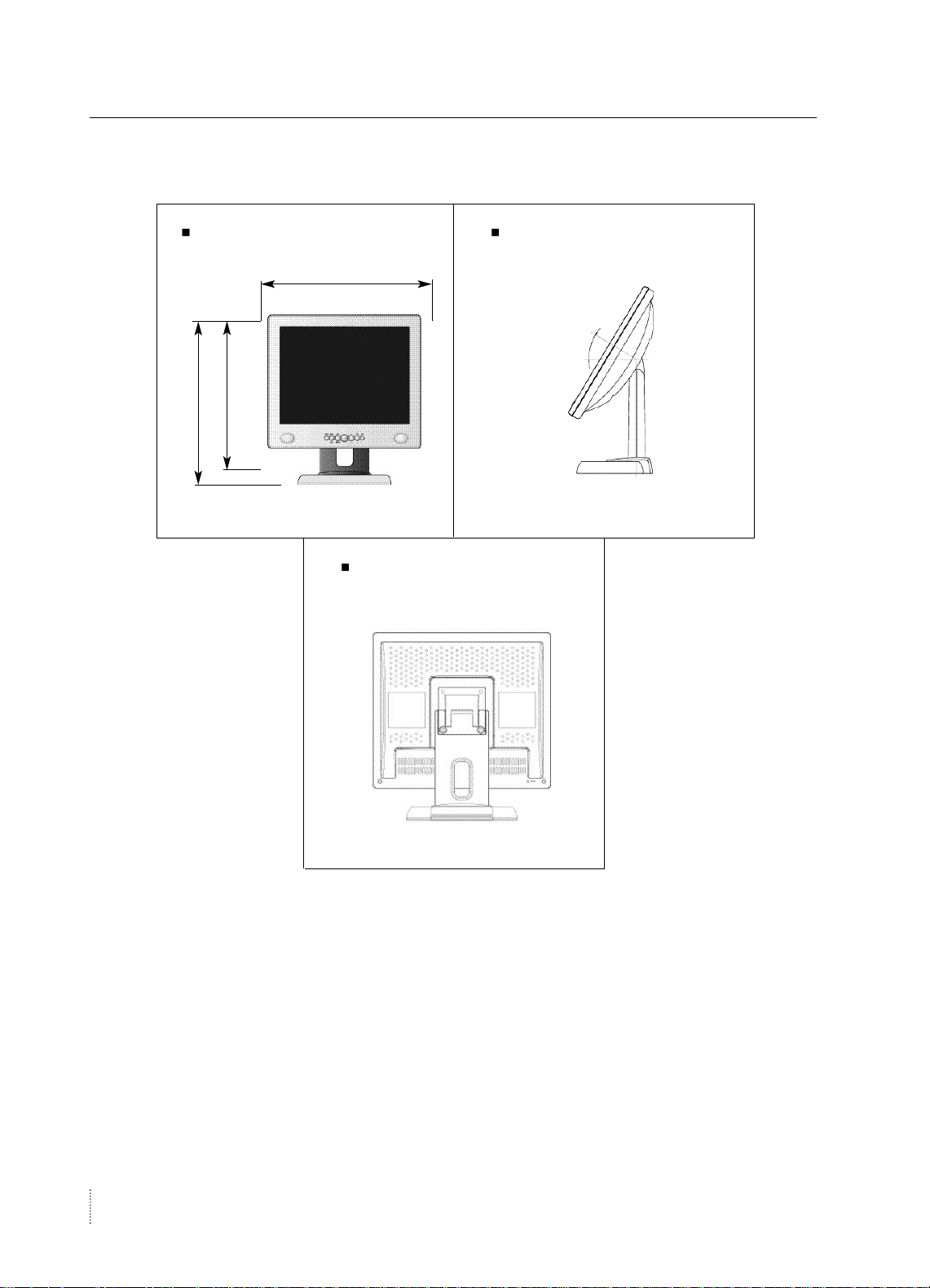

2-4 Dimensions

FRONT VIEW SIDE VIEW

176

368

380

REAR VIEW

10

Service Manual

Loading...

Loading...