MAXDA T A PLA TINUM SERVER

Mainboard

Users’ Manual

MAXDATA PLATINUM Server Mainboard Manual

1

2

Contents

1 Description.......................................................................................................9

Server Board Features ............................................................................................................. 9

Back Panel Connectors.......................................................................................................... 10

Server Board Connector and Component Locations ..............................................................11

Processor...........................................................................................................................11

Memory ............................................................................................................................ 12

Add-in Board Slots ................................................................................................................. 12

Video...................................................................................................................................... 13

SCSI Controller ...................................................................................................................... 14

IDE Controller ........................................................................................................................ 14

USB Interface ........................................................................................................................ 14

Network Controller ................................................................................................................ 14

Network T eaming Features ............................................................................................... 15

Adapter Fault Tolerance ..................................................................................................... 15

Preferred Primary Adapter ................................................................................................ 15

Mixed Adapter Teaming..................................................................................................... 15

Adaptive Load Balancing ................................................................................................... 15

Keyboard and Mouse............................................................................................................. 16

ACPI.................................................................................................................................. 16

Security ................................................................................................................................. 16

Security with Mechanical Locks and Monitoring .............................................................. 16

Software Locks ................................................................................................................. 16

Using Passwords .............................................................................................................. 17

Secure Mode .................................................................................................................... 17

Summary of Software Security Features .......................................................................... 17

2 Server Board Installation..............................................................................19

Tools and Supplies Needed ................................................................................................... 19

Before Y ou Begin ................................................................................................................... 19

Emissions Disclaimer ............................................................................................................19

Safety Cautions ..................................................................................................................... 19

Safety and Regulatory Compliance........................................................................................ 20

Minimum Hardware Requirements ....................................................................................... 20

Processor.......................................................................................................................... 20

Memory ............................................................................................................................ 20

Power Supply ....................................................................................................................20

Installation Notes................................................................................................................... 21

Installation Procedures .......................................................................................................... 21

Installing the I/O Gasket and Shield.................................................................................. 21

Attaching the Gasket to the I/O Shield.............................................................................. 21

Attaching the Label to the I/O Shield ................................................................................ 22

Installing the I/O Shield..................................................................................................... 22

Installing the Processor(s)................................................................................................. 23

Installing a Terminator ....................................................................................................... 26

Installing Memory ............................................................................................................. 26

Configuring Chassis Standoffs.......................................................................................... 28

Installing the Server Board................................................................................................ 29

Making Connections to the Server Board......................................................................... 30

Cable Routing ........................................................................................................................ 31

IDE or SCSI Cables ........................................................................................................... 31

Floppy and Front Panel USB Cables.................................................................................. 31

MAXDATA PLATINUM Server Mainboard Manual

3

Installing the COM2 Cable................................................................................................ 32

Finishing Up ...................................................................................................................... 32

Getting Started with Intel® Server Management (Optional) .................................................. 34

Installing the Service Partition .......................................................................................... 34

Preparing the Server to Boot from the CD-ROM Drive..................................................... 34

Creating the Service Partition ........................................................................................... 34

Formatting the Service Partition........................................................................................ 34

Installing your operating system....................................................................................... 34

Installing Intel® Server Control .......................................................................................... 35

3 Upgrading ......................................................................................................37

Tools and Supplies Needed ................................................................................................... 37

Cautions................................................................................................................................. 37

Memory ................................................................................................................................. 38

Processors............................................................................................................................. 38

Adding or Replacing a Processor ...................................................................................... 39

Removing a Processor...................................................................................................... 42

Installing or Removing a Terminator .................................................................................. 42

Replacing the Back up Battery............................................................................................... 43

4 Configuration Software and Utilities ..........................................................45

Hot Keys ................................................................................................................................ 45

Power-On Self-Test (POST) .................................................................................................... 46

Using BIOS Setup.................................................................................................................. 47

Record Your Setup Settings............................................................................................... 47

If You Cannot Access Setup .............................................................................................. 47

Starting Setup ................................................................................................................... 47

Setup Menus .................................................................................................................... 48

Main Menu........................................................................................................................ 49

Primary Master/Slave Submenu ....................................................................................... 50

Processor Settings Submenu............................................................................................ 51

Advanced Menu................................................................................................................ 51

Memory Reconfiguration Submenu.................................................................................. 52

PCI Configuration Submenu ............................................................................................. 52

On-board SCSI, LAN, VGA Submenu ................................................................................ 52

PCI slot Submenu ............................................................................................................. 53

PCI Device Submenu........................................................................................................ 53

I/O Device/Peripheral Configuration Submenu.................................................................. 53

Advanced Chipset Controller Submenu............................................................................ 54

Security Menu .................................................................................................................. 55

Server Menu .....................................................................................................................56

System Management Submenu....................................................................................... 57

Console Redirection Submenu ......................................................................................... 57

Boot Menu........................................................................................................................ 58

Boot Device Priority Submenu .......................................................................................... 58

Hard Drive Submenu......................................................................................................... 58

Removable Devices .......................................................................................................... 58

Exit Menu.......................................................................................................................... 59

Using the System Setup Utility.............................................................................................. 59

What You Need to Do........................................................................................................ 59

Running the SSU from the CD.......................................................................................... 59

Running the SSU Remotely via an Emergency Management Card.................................. 60

Starting the SSU ............................................................................................................... 60

Customizing the SSU........................................................................................................ 61

Launching a Task ............................................................................................................... 61

4

Contents

SEL Manager Add-in ......................................................................................................... 62

SDR Manager Add-in ........................................................................................................ 62

FRU Manager Add-in......................................................................................................... 63

Exiting the SSU.................................................................................................................63

FRUSDR Load Utility .............................................................................................................64

When to Run the FRUSDR Load Utility ............................................................................ 64

What You Need to Do........................................................................................................ 64

How You Use the FRUSDR Load Utility ........................................................................... 64

Upgrading the BIOS............................................................................................................... 67

Preparing for the Upgrade................................................................................................. 67

Recording the Current BIOS Settings ............................................................................... 67

Obtaining the Upgrade Utility ........................................................................................... 67

Creating a Bootable Diskette ............................................................................................ 67

Creating the BIOS Upgrade Diskette ................................................................................ 68

Upgrading the BIOS.......................................................................................................... 68

Recovering the BIOS......................................................................................................... 68

Changing the BIOS Language........................................................................................... 69

Using the Firmware Update Utility.................................................................................... 69

Making a BMC Firmware Update Diskette ....................................................................... 69

Making the Update Diskette Bootable ......................................................................... 69

Updating the BMC Firmware............................................................................................ 69

Recovering the BMC Firmware......................................................................................... 70

Making a FRUSDR File Update Diskette ........................................................................... 70

Making the Update Diskette Bootable ......................................................................... 70

Updating the FRUSDR Files.............................................................................................. 71

Using the Adaptec SCSI Utility .............................................................................................. 71

Running the SCSI Utility ................................................................................................... 71

5 Solving Problems ..........................................................................................73

Resetting the System ............................................................................................................73

Initial System Startup............................................................................................................. 73

Checklist ........................................................................................................................... 73

Running New Application Software........................................................................................74

Checklist ............................................................................................................................74

After the System Has Been Running Correctly ......................................................................74

Checklist ............................................................................................................................74

More Problem Solving Procedures........................................................................................ 75

Preparing the System for Diagnostic Testing .................................................................... 75

Verifying Proper Operation of Key System Lights ............................................................. 75

Confirming Loading of the Operating System................................................................... 75

Specific Problems and Corrective Actions............................................................................. 76

Power Light Does Not Light.............................................................................................. 76

No Characters Appear on Screen...................................................................................... 76

Characters Are Distorted or Incorrect............................................................................... 77

System Cooling Fans Do Not Rotate Properly .................................................................. 77

Diskette Drive Activity Light Does Not Light..................................................................... 77

Hard Disk Drive Activity Light Does Not Light .................................................................. 78

CD-ROM Drive Activity Light Does Not Light ................................................................... 78

Cannot Connect to a Server.............................................................................................. 78

Problems with Network.................................................................................................... 78

PCI Installation Tips ...........................................................................................................79

Problems with Application Software...................................................................................... 79

Bootable CD-ROM Is Not Detected ...................................................................................... 79

MAXDATA PLATINUM Server Mainboard Manual

5

6 Technical Reference.......................................................................................81

Server Board Jumpers........................................................................................................... 81

7 Regulatory and Integration Information .....................................................83

Product Regulatory Compliance ............................................................................................ 83

Product Saf ety Compliance ................................................................................................... 83

Product EMC Compliance ..................................................................................................... 83

Product Regulatory Compliance Markings ............................................................................ 83

Electromagnetic Compatibility Notices ................................................................................. 84

FCC (USA)......................................................................................................................... 84

Europe (CE Declaration of Conformity)............................................................................. 84

6

Contents

Figures

1. Back Panel Connectors ................................................................................................... 10

2. Server Board Connector and Component Locations........................................................11

3. Attaching the Gasket to the I/O Shield............................................................................ 21

4. Attaching the Label to the I/O Shield .............................................................................. 22

5. Installing the I/O Shield ................................................................................................... 22

6. Lifting the Locking Bar..................................................................................................... 23

7. Inserting the Processor................................................................................................... 24

8. Attaching the Heat Sink and Retention Clip .................................................................... 24

9. Locking the Heat Sink Retention Clip.............................................................................. 25

10. Attaching the Heat Sink Fan............................................................................................ 25

11. Installing a Terminator ..................................................................................................... 26

12. Installing Memory ........................................................................................................... 27

13. Configuring Chassis Standoffs ........................................................................................ 28

14. Placing the Server Board in the Chassis ......................................................................... 29

15. Making Connections to the Server Board....................................................................... 30

16. Routing Cables ................................................................................................................ 31

17. Routing the Floppy and USB Cables ............................................................................... 31

18. Installing the COM2 Cable .............................................................................................. 32

19. Making Back Panel Connections..................................................................................... 33

20. Raise the Locking Bar...................................................................................................... 39

21. Insert the Processor........................................................................................................ 40

22. Attach the Heat Sink and Retention Clip ......................................................................... 40

23. Lock the Heat Sink Retention Clip................................................................................... 41

24. Attach the Fan................................................................................................................. 41

25. Installing a Terminator ..................................................................................................... 42

26. Replacing the Back up Battery ........................................................................................ 43

27. Jumper Locations............................................................................................................ 81

Tables

1. Server Board Features ...................................................................................................... 9

2. Video Modes...................................................................................................................13

3. Software Security Features............................................................................................. 18

4. Configuration Utilities...................................................................................................... 45

5. Hot Keys.......................................................................................................................... 45

6. Configuration Jumper (CN42).......................................................................................... 81

7. Configuration Jumper (CN46).......................................................................................... 82

8. Configuration Jumper (CN47).......................................................................................... 82

9. Configuration Jumper (CN48).......................................................................................... 82

10. Configuration Jumper (CN49).......................................................................................... 82

11. Configuration Jumper (CN50).......................................................................................... 82

MAXDATA PLATINUM Server Mainboard Manual

7

8

1 Descr iption

Server Board Features

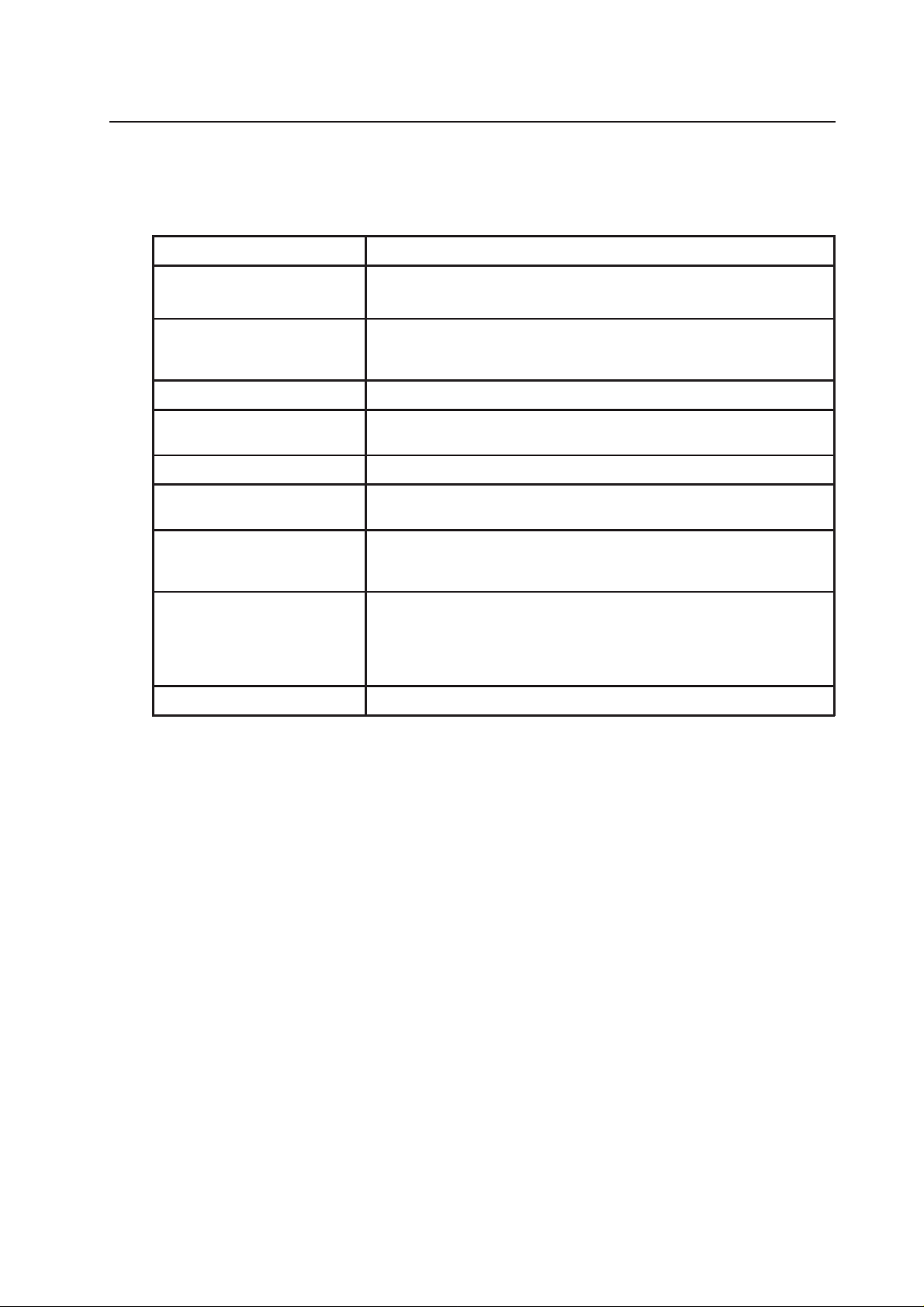

Table 1. Server Board Features

Feature Description

Processor

Memory (DRAM)

Video Memory 4 MB SDRAM of video memory.

PCI bus

Graphics Integrated onboard ATI Rage XL 32 bit SVGA controller.

SCSI

Network

System I/O

Form Factor

Up to two In tel® Pentium® III processors in a Socket-370 Flip Chip Pin Grid

Array (FC-PGA) pa ckage.

Six 72 bit sockets for 168-pin, 133 MHz, 3.3V, PC/133 compliant, registered,

ECC, SDRAM single-sided or double-sided memory modules (DIMM)

Two standard PCI (PCI-33/32 bit) expansion slots for add -in boards.Four PCI-

66 MHz/64 bit expansion slots.

Adaptec AIC-7899W dual channel Ul t ra160 SCSI, supporting onboard Ul t ra 2

(LVD) wide, Ul t ra-wide, and Ultra160 SCSI interfaces.

Integrated onboard NICs, an Intel® 82550 single chip PCI LAN controller for

10 or 100 MbpsTX Fast Ethernet networks. Two RJ-45 Ethernet connectors

at the I/O back pa nel.

PS/2-compatible keyboard and mouse ports, 6 pin DIN.Advanced parallel port,

supporting Enhanced Parallel Port (EPP), compatible 25 pin.VGA video port,

15 pin.Two serial ports, one 9 pin on the rear I/O and one through a 10 pin

header on the baseboard.Two RJ-45 Ethernet por ts.Four USB ports, three on

the rear I/O and one through a 10 pin h eader on the baseboard.

Server ATX form factor, ATX 2.03 compliant I/O.

MAXDATA PLATINUM Server Mainboard Manual

9

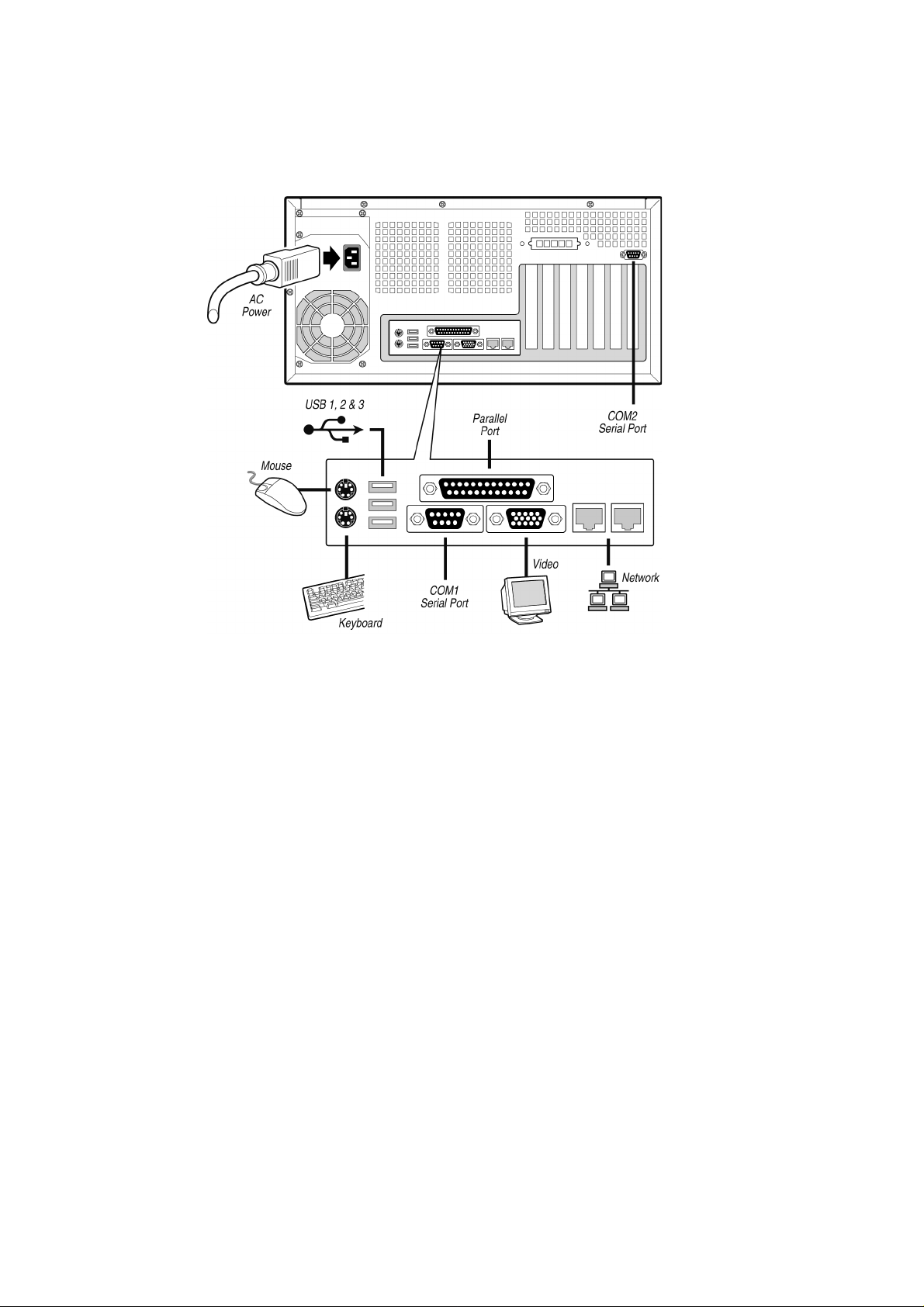

Back Panel Connectors

Figure 1. Back Panel Connectors

10

Description

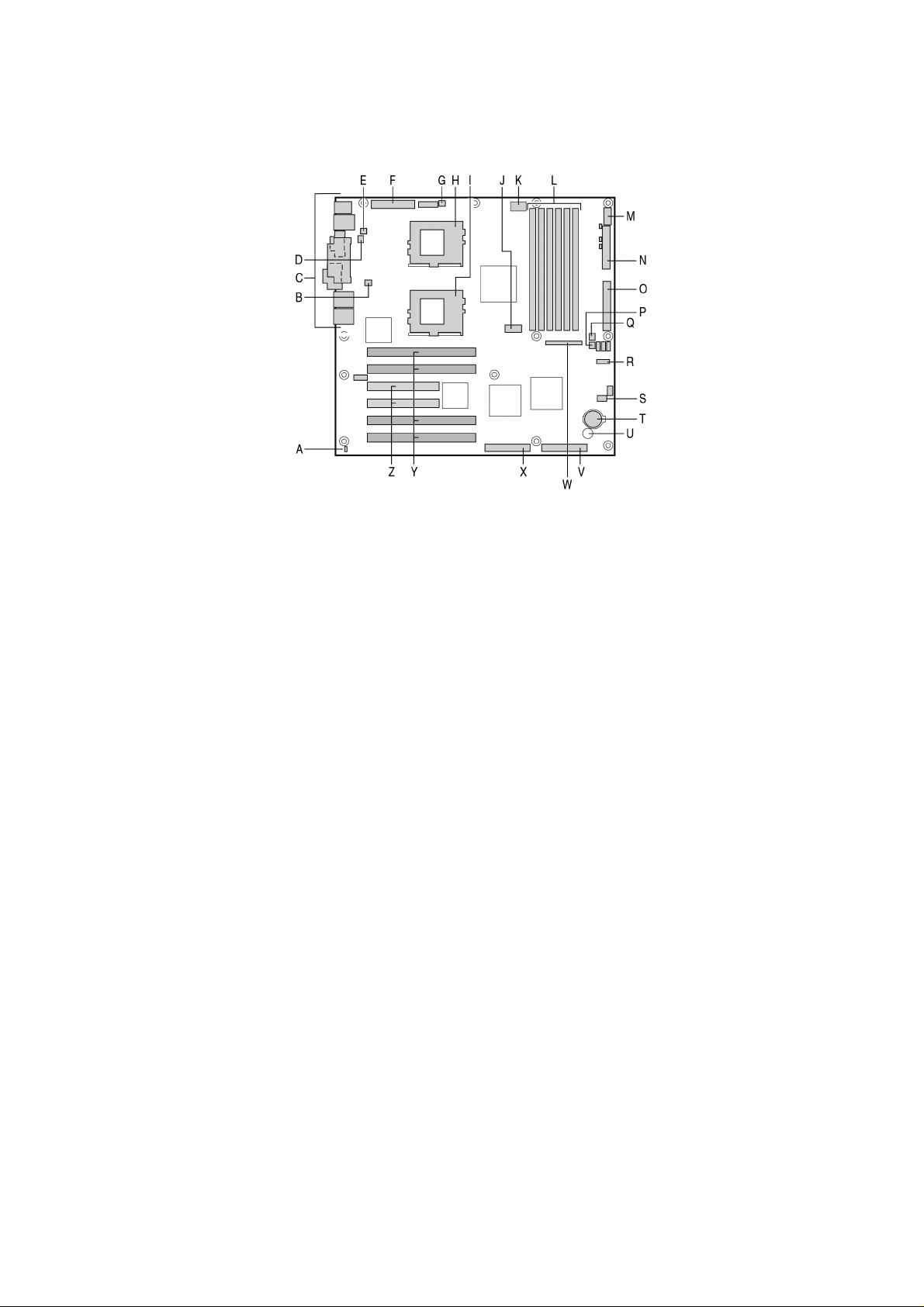

Server Board Connector and Component Locations

Figure 2. Server Board Connector and Component Locations

A. Chassis intrusion connector

B. CPU Fan 2

C. Back panel I/O ports

D. Fan 4

E. Fan 3

F. Main power connector

G. CPU Fan 1

H. CPU 1

I. CPU 2

J. COM2/EMP

K. +12 V CPU power connector

L. DIMMs

M. USB

N. Floppy drive connector

O. IDE

P. Fan 2

Q. Fan 1

R. Configuration jumper block CN42

S. Configuration jumper block CN46-CN49

T. Battery

U. Speaker

V. SCSI B

W. Front panel connector

X. SCSI A

Y. 66 MHz/64-bit PCI connectors

Z. 33 MHz/32-bit PCI connectors

Processor

The MAXDATA PLATINUM 1200/3200 server board accommodates one or two Intel

Pentium® III processors for the PGA370 socket. The processor external interface operates

at a maximum of 133 MHz.

When two processors are installed, both processors must be of identical bus/core speed.

When only one processor is installed, the other socket must ha v e an AGTL terminator card

installed.

®

MAXDATA PLATINUM Server Mainboard Manual

11

Memory

The MAXDATA PLATINUM 1200/3200 Ser ver Board contains six 168-pin DIMM sockets.

Memory is partitioned as three banks. DIMMs must be populated in identical pairs.

The MAXDATA PLATINUM 120 0/3200 Server Board supports up to six 3.3-V, registered

ECC SDRAM DIMMs that are compliant with the JEDEC PC133 specification. A wide range

of DIMM sizes are supported, including 64 MB, 1 28 MB, 256 MB , 512 MB , and 1 GB DIMMs.

The minimum supported memory configuration is 128 MB, using two identical 64 MB

DIMMs. The maximum configurable memory size is 6 GB using six 1 GB DIMMs.

The SDRAM interface runs at the same frequency as the processor bus. The memory

controller supports 2-way interlea ved SDRAM, memory scrubbing, single bit error correction

and multiple bit error detection. Memory can be implemented with either single-sided (one

row) or double-sided (two row) DIMMs.

✏ NOTE

Use DIMMs that have been tested for compatibility with the ser ver board. Contact your

sales representative or dealer for a current list of approved memory modules.

Add-in Board Slots

The server board has two full-length standard PCI (PCI-33/32 bit) connectors. PCI features:

• Bus speed up to 33 MHz

• 32 bit memory addressing

• 5 V signaling environment

• Burst transfers of up to 133 Mbps

• 8, 16, or 32 bit data transfers

• Plug and Play ready

• Parity enabled

The server board has four full-length PCI-66/64 connectors. PCI features:

• Bus speed up to 66 MHz

• 32 bit memory addressing

• 3.3 V signaling environment

• Burst transfers of up to 528 Mbps

• 8, 16, 32, or 64 bit data transfers

• Plug and Play ready

• Parity enabled

✏ NOTE

If you install a PCI-33 card into one of the PCI-66 slots, the bus speed for all two slots will be

lowered to 33 MHz.

12

Description

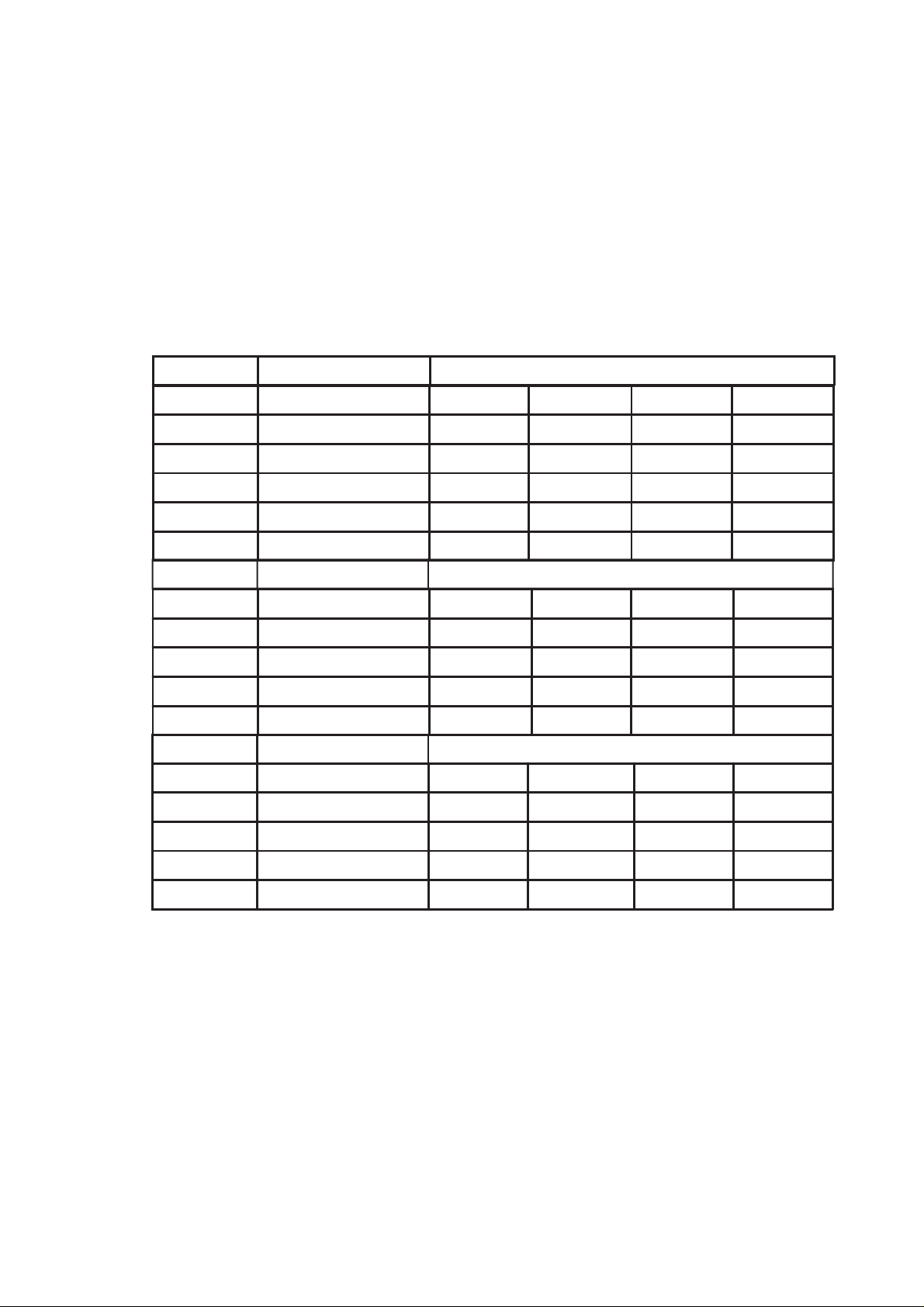

Video

The system has an integrated ATI Rage XL 32 bit high-performance SVGA subsystem that

supports the following:

• BIOS compatibility with all standard VGA modes

• 4 MB of video memory

• Pixel resolutions up to 1024 x 768 resolution in 8/1 6/24/32 bpp modes under 2D and up

to 800 x 600 resolution in 8/16/24/32 bpp modes under 3D

• Both CRT and LCD monitors up to 10 0 Hz vertical refresh rate

Table 2. Video Modes

2D Mode Refresh Rate (Hz) 2D Mo de Vide o Supp ort

640x480 60, 72, 75, 90, 100 Suppo rted Suppo rted Supported S upported

8 00x600 60, 70, 75, 90, 100 Supported Sup ported Suppo rted Suppo rted

1024x768 60, 72, 75, 90, 100 Suppo rted Suppo rted Supported Sup ported

1280 x102443, 60 Supported Supported Supported -

1280x1024 70, 72 Supported - Supported -

1600x1200 60, 66, 76, 85 Supported Supported -

3D Mode Refresh Rate (Hz)

640x480 60, 72, 75, 90, 100 Suppo rted Suppo rted Suppo rted Suppo rted

8 00x600 60, 70, 75, 90, 100 Supported Sup ported Sup ported -

1024x768 60, 72, 75, 90, 100 Suppo rted ---

1280 x102443, 60, 70, 72 ----

1600x1200 60, 66, 76, 85 ---

3D Mode Refresh Rate (Hz) 3D Mode Video Support with Z Buffer Disabled

640x480 60, 72, 75, 90, 100 Suppo rted Suppo rted Suppo rted Suppo rted

8 00x600 60, 70, 75, 90, 100 Supported Sup ported Sup ported Sup ported

1024x768 60, 72, 75, 90, 100 Suppo rted Suppo rted --

1280 x102443, 60, 70, 72 Supported ---

1600x1200 60, 66, 76, 85 Supported --

3D Mode Video Support with Z Buffer Enabled

-

-

-

MAXDATA PLATINUM Server Mainboard Manual

13

SCSI Controller

The embedded A daptec AIC-7899W dual function SCSI controller provides Ultra1 60 (LVDS),

(Ultra 2), and Ultra wide (SE) SCSI interfaces as two independent PCI functions.

The MAXDATA PLATINUM 1200/3200 baseboard provides active terminators, termination

voltage, resetable fuse, and protection diode for both SCSI c hannels. Onboard terminators

can be enabled/disabled using the BIOS setup menu.

IDE Controller

The system includes a single c hannel enhanced IDE 32 bit interf ace controller for intelligent

disk drives with disk controller electronics onboard. The controller has a connector located

on the system board that supports a master and a slave device.

The device controls:

• PIO, ATA-10 0 Synchronous DMA, and bus master IDE transfer modes

• Ultra DMA 66 capable

• Transfer rates up to 100 MB/s

• Master/slave IDE mode

• Up to two devices

USB Interface

The MAXD A T A PLA TINUM 1 200/3200 Server Board provides three e xternal USB connectors

on the rear I/O panel. T he external connectors are defined by the USB Specification, R evision

1.1. One additional USB connector is supported internally through a 10-pin header on the

server board that can be cabled to a front panel board. All four ports function identically and

with the same bandwidth.

Network Controller

The server board includes a 10BASE-T/100BASE-TX network solution based on the

Intel®82550 single chip F ast Ethernet PCI Bus Controller. As a PCI bus master , the controller

can burst data at up to 132 MB/s. The controller contains two receive and transmit FIFO buff ers

that prevent data ov erruns or underr uns while waiting for access to the PCI bus. The controller

has the following:

• 32 bit PCI bus master interface (direct drive of bus), compatible with PCI Bus Specification,

Revision 2.2

• Chained memory structure with improved dynamic transmit chaining for enhanced

performance

• Programmable transmit threshold for improved bus utilization

• Early receive interrupt for concurrent processing of receive data

• Onchip counters for network management

• Autodetect and autoswitching for 10 or 100 Mbps network speeds

• Support for both 10 Mbps and 100 Mbps networks, capable of full or half duplex, with

back-to-back transmit at 100 Mbps

• Integrated IP Security (IPSec) encryption engine

• Alert on LAN functionality

14

Description

Network T eaming Features

The network controller provides sev eral options for increasing throughput and fault tolerance

when running Windows® NT 4.0, Windows® 2000 or NetWare® 4.1x or newer:

• Adapter Fault Tolerance (AFT) - provides automatic redundancy for your adapter. If the

primary adapter fails, the secondary takes over. AFT works with any hub or switch.

• Adaptive Load B alancing (ALB) - creates a team of 2 - 4 adapters to increase transmission

throughput. Also includes AFT. Works with any 10Base-TX or 100Base-TX switch.

• Fast EtherChannel

and reception throughput. Also includes AFT. Requires an FEC-enabled switch.

®

(FEC) - creates a team of 2, 3 or 4 adapters to increase transmission

Adapter Fault Tolerance

Adapter Fault Tolerance (AFT) is a simple, effective, and fail-safe approach to increase the

reliability of server connections. AFT gives you the ability to set up link recovery to the

server adapter in case of a cable, port, or network interface card failure. By assigning two

PRO/100 Intelligent Server adapters as a team, AFT enables you to maintain uninterrupted

network performance.

AFT is implemented with two PRO/100 Intelligent Server adapters: a primary adapter and

a backup, or secondary, adapter. During normal operation, the backup will have transmit

disabled. If the link to the primary adapter fails, the link to the backup adapter automatically

takes over.

Preferred Primary Adapter

With multiple adapters installed, you can specify one as the Preferred Primary adapter. For

example if you have a server with a PRO/100 Intelligent Ser ver adapter as the primary

adapter and a PRO/1 00+ adapter as the secondary, y ou would w ant the PRO/100 Intelligent

Server adapter to be the preferred primary . In this scenario, if the PRO/1 00 Intelligent Server

adapter fails, the PRO/1 00+ will take ov er . T hen when the PRO/1 00 Intelligent Server adapter

is replaced, it will automatically revert to being the primary adapter in the team.

If a Pref erred Primary is not selected, PROSet will at tempt to select the best adapter , based

on adapter model and speed.

Mixed Adapt er Teaming

AFT supports up to four PRO/1000 or PRO/100 adapters per team, in any mix.

Adaptive Load Balancing

Adaptive Load B alancing (ALB) is a simple and efficient w ay to increase your server’ s transmit

throughput. With ALB you group PRO/1 00 Intelligent Server adapters in teams to provide an

increased transmit rate (up to 400 Mbps) using a maximum of four adapters. T he ALB sof tware

continuously analyzes transmit loading on each adapter and balances the rate across the

adapters as needed. Adapter teams configured for ALB also provide the benefits of AFT.

Receive rates remain at 100 Mbps.

T o use ALB, y ou must hav e two, three, or four PRO/100 Intelligent Server adapters installed

in your server or workstation and linked to the same network switch.

MAXDATA PLATINUM Server Mainboard Manual

15

Keyboard and Mouse

The ke yboard/mouse controller is PS/2-compatible. The server may be lock ed automatically

if there is no keyboard or mouse activity for a predefined length of time, if specified through

the System Set up Utility (SSU). Once the inactivity (lockout) timer has e xpired, the keyboard

and mouse do not respond until the previously stored password is entered.

ACPI

The MAXDATA PLATINUM 1200/3200 supports the Advanced Configuration and Power

Interface (ACPI) as defined by the ACPI 1.0b. An ACPI aware operating system can put the

system into a state where the hard drives spin down, the sy stem fans stop, and all processing

is halted. Howev er , the po wer supply will still be on and the processors will still be dissipating

some power, so the power supply fan and processor fans will still run.

The MAXD ATA PLATINUM 1200/3200 supports sleep states s0, s1, s4, and s5.

• s0: Normal running state.

• s1: Processor sleep state: No context will be lost in this state and the processor caches

will maintain coherency .

• s4: Hibernate or Save to Disk: The memory and machine state are saved to disk. Pressing

the power button or other wakeup e vent will restore the system state from the disk and

resume normal operation. This assumes that no hardware changes have been made to

the system while it was off.

• s5: Soft off: Only the RTC section of the chipset and the BMC are running in this state.

CAUTION

The system is off only when the AC power is disconnected.

Security

To help prevent unauthorized entry or use of the server, Intel® Server Control server management software monitors the system intrusion switch.

Security with Mechanical Locks and Monitoring

If installed, you can activate the c hassis intrusion alarm switc h. When the side door is opened,

the switch transmits an alarm signal to the server board, where BMC firmware and ser ver

management software process the signal. The system can be programmed to respond to an

intrusion by locking the keyboard, for example.

Software Locks

The BIOS Setup and the System Setup Utility (SSU) provide a number of security features

to prevent unauthorized or accidental access to the system. Once the security measures

are enabled, you can access the system only after you enter the correct password(s). For

example:

• Enable the keyboard lockout timer so that the server requires a password to reactivate

the keyboard and mouse after a specified time out period 1 to 120 minutes.

• Set and enable a supervisor password.

• Set and enable a user password.

• Set secure mode to prevent keyboard or mouse input and to prevent use of the front

panel reset and power switches.

• Activate a hot key combination to enter secure mode quickly.

• Disable writing to the diskette drive when secure mode is set.

• Disable access to the boot sector of the operating system hard disk drive.

16

Description

Using Passwords

You can set either the user password, the supervisor password, or both passwords. If only

the user password is set, you:

• Must enter the user password to enter BIOS Setup or the SSU.

• Must enter the user password to boot the server if Password on Boot is enabled in

either the BIOS Setup or SSU.

• Must enter the user password to exit secure mode.

If only the supervisor password is set, you:

• Must enter the supervisor password to enter BIOS Setup or the SSU.

• Must enter the supervisor password to boot the server if Password on Boot is enabled

in either the BIOS Setup or SSU.

• Must enter the supervisor password to exit secure mode.

If both passwords are set, you:

• May enter the user password to enter BIOS Set up or the SSU. Ho wev er , you will not be

able to change many of the options.

• Must enter the supervisor password if you want to enter BIOS Setup or the SSU and

have access to all of the options.

• May enter either password to boot the server if Password on Boot is enabled in either

the BIOS Setup or SSU.

• May enter either password to exit secure mode.

Secure Mode

Configure and enable the secure boot mode by using the SSU. When secure mode is in

effect:

• You can boot the server and the operating system will run, but you must enter the user

password to use the keyboard or mouse.

• You cannot turn off system power or reset the server from the front panel switches.

Secure mode has no effect on functions enabled via the Server Manager Module or power

control via the real time clock.

Taking the server out of secure mode does not change the state of system power. That is,

if you press and release the power switch while secure mode is in effect, the system will

not be powered of f when secure mode is later remo ved. Ho we ver, if the front panel power

switch remains depressed when secure mode is removed, the server will be powered off.

Summary of Software Security Features

The table below lists the software security features and describes what protection each

off ers. In general, to enable or set the features listed here, you must run the SSU and go to

the Security Subsystem Group, menu. The table also refers to other SSU menus and to the

Setup utility.

MAXDATA PLATINUM Server Mainboard Manual

17

Table 3. Software Security Features

erutaeFnoitpircseD

•

.edom

•

edomeruceS

otgnitirwelbasiD

etteksid

:edomerucesretneotwoH

erucesnimetsysehtsecalpyllacitamotuasdrowssapgnilbanednagnitteS

metsysehterucesnacuoy,)puteShguorht(noitanibmocyek-tohatesuoyfI

roftiawotevahtonoduoysnaemsihT.noitanibmocyekehtgnisserpybylpmis

nacrevresehT:edomerucesnisimetsysehtnehW.doireptuo-emitytivitcanieht

detpeccatonsitupnidraobyekdnaesuomtub,metsysgnitarepoehtnurdnatoob

-DCehtnidetcetedsiDCafi,emittoobtA.deretnesidrowssapresuehtlitnu

nehW.drowssaparofstpmorpmetsyseht,AevirdnietteksidaroevirdMOR

ehtselbasiddnaetteksidroDCmorfstoobrevreseht,deretnesidrowssapeht

eht,AevirdnietteksidroevirdMOR-DCehtniDConsierehtfI.edomeruces

delbanellA.edomerucesotniseogyllacitamotuadnaCevirdmorfstoobrevres

retnE:edomerucesevaeloT.emittoobtatceffeotniogserutaefedomeruces

.)s(drowssaptcerroceht

asselnuetteksidaotetirwromorftoobtonlliwrevreseht,edomerucesnI

nisirevresehtrehtehwetteksidotsseccatcetorpetirwoT.deretnesidrowssap

yficepsdna,snoitpOyppolF,unemniamputeSehtesu,tonroedomeruces

.ylnodaersasseccAyppolF

osdoireptuoemitateS

esuomdnadraobyektaht

.detpeccatoneratupni

ebnacneercs,oslA

otsetirwdna,deknalb

detibihniebnacetteksid

gnisuotsseccalortnoC

rosivrepustes:USSeht

drowssap

.repmujdrowssaPraelCehtegnahc

ehtotsseccalortnoC

:USSnahtrehtometsys

drowssapresutes

.repmujdrowssaPraelC

draobyektuohtiwtooB

.egassemasyalpsiddnatneserpsitifidraobyekeht

toobehtyficepS

ecneuqes

.)s(drowssaptcerrocehtretnE:ytivitcaemuseroT.)puteShguorht

.tupniesuomrodraobyekynagnitpeccaerofebdrowssapaeriuqer

onfI.setunim021ot1morffodoireptuoemitytivitcaninaelbanednayficepS

draobyekdetpmetta,doirepdeificepsehtrofsrucconoitcaesuomrodraobyek

ehtdna,knalboglliwyalpsidrotinomehT.detpeccaebtonlliwtupniesuomdna

delbaneeraserutaefytirucesesehtfi(detcetorpetirweblliwevirdetteksid

ates,noitarugifnocmetsysehtgnignahcrognittesotsseccalortnocoT

resudnarosivrepusehthtobfI.puteShguorhttielbanednadrowssaprosivrepus

ehtelbanerorevresehttoobotdesuebnacrehtie,delbaneerasdrowssap

ebotputeSwollalliwdrowssaprosivrepusehtylnotub,esuomro/dnadraobyek

ehtniD-LRTCsserproyrtneknalbaottiegnahc,drowssapaelbasidoT.degnahc

ehtnidnuofunemnoitpOdrowssaProsivrepuSehtfounemdrowssaPegnahC

,puteSsseccatonnacuoyfidrowssapehtraelcoT.puorGmetsysbuSytiruceS

hguorhttielbanednadrowssapresuates,metsysehtgnisuotsseccalortnocoT

ehtniD-LRTCsserproyrtneknalbaottiegnahc,drowssapaelbasidoT.puteS

ytiruceSehtnidnuofunemnoitpOdrowssaPresUehtfounemdrowssaPegnahC

ehtegnahc,puteSsseccatonnacuoyfidrowssapehtraelcoT.puorGmetsysbuS

ehterofeb,TSOPgniruD.draobyekatuohtiwrohtiwtoobnacmetsysehT

stsetdnastcetedyllacitamotuaSOIBeht,ecneuqestoobehtsetelpmocmetsys

erucesfI.redrotoobehtenimretedlliwputeSniyficepsuoytahtecneuqesehT

arofdetpmorpeblliwuoyneht,)tessidrowssapresua(delbanesiedom

ehtdnadelbanesiedomerucesfI.stoobyllufrevresehterofebdrowssap

lliwtubtoobylluflliwrevreseht,delbaneoslasinoitpo"edoMtooBeruceS"

18

Description

2 Server Boar d Installation

Tools and Supplies Needed

• Phillips (cross head) screwdriver (#1 bit and #2 bit)

• Flat blade screwdriver

• Needle nosed pliers

• Antistatic wrist strap and conductive foam pad (recommended)

Before Y ou Begin

Emissions Disclaimer

To ensure EMC compliance with your local regional rules and regulations, the final

configuration of your end system product may require additional EMC compliance testing.

For more information please contact your local MAXDATA Representative.

See “Regulatory and Integration Information” for product Safety and EMC regulatory

compliance information. This is an FCC Class A device. Integration of it into a Class B c hassis

does not result in a Class B device.

Safety Cautions

CAUTION

Electrostatic discharge (ESD) & ESD protection: ESD can damage disk drives, boards, and

other parts. We recommend that you perform all procedures in this chapter only at an ESD

workstation. If one is not available, provide some ESD protection by wearing an antistatic

wrist strap attached to chassis ground∫any unpainted metal surface∫on your ser ver when

handling parts.

ESD and handling boards: Alwa ys handle boards carefully . They can be extremely sensitive

to ESD. Hold boards only b y their edges. Af ter removing a board from its protective wrapper

or from the server, place the board component side up on a grounded, static free surface.

Use a conductive foam pad if available but not the board wrapper. Do not slide board over

any surface.

MAXDATA PLATINUM Server Mainboard Manual

19

Safety and Regulatory Compliance

See “Regulatory and Integration Information” for product Safety and EMC regulatory

compliance information.

Intended uses: T his product was ev aluated for use in servers that will be installed in offices,

computer rooms, and similar locations. Other uses require further evaluation.

EMC testing: Before computer integration, make sure that the chassis, power supply, and

other modules have passed EMC testing using a server board with a microprocessor from

the same family (or higher) and operating at the same (or higher) speed as the microprocessor

used on this server board.

Server board diagram label provided: Place the label inside the chassis in an easy-to-see

location, preferably oriented similarly to the server board.

Minimum Hardware Requirements

To avoid integration difficulties and possible board damage, your system must meet the

following minimum requirements.

Processor

Minimum of one 1.0 GHz Intel® Pentium® III processor with 256 cache support.

Memory

Minimum of two identical 3.3 V, ECC, PC/133 compliant, registered SDRAM, 168-pin gold

DIMMs. Minimum size: 64 MB. DIMMs must be populated in identical pairs.

Power Supply

Minimum of 275 W with 1.2 A +5 V standby current (in order to support Wak e On LAN®(WOL))

and 12+ V CPU power support [A TX]. Y ou must pro vide standby current, or the board will not

boot.

20

Server Board Installation

Installation Notes

Installation Process Quick Reference

Step Where the information is located

Install the primary processor This guide

Install the secondary processor (optional) This guide

Install memory This guide

Remove the access cover Your chassis manual

Install the I/O shield This guide

Rearrange the standoffs This guide

Install the server board This guide

Connect cables to the server board This guide and your chassis manual

Finish setting up your chassis Your chassis manual

Installation Procedures

Installing the I/O Gasket and Shield

✏ NOTE

An A TX 2.03-compliant I/O shield is pro vided with the server board. T he shield is required by

Electromagnetic Interference (EMI) regulations to minimize EMI. If the shield does not fit

the chassis, obtain a properly sized shield from the chassis supplier.

The shield fits the rectangular opening in the back of a chassis. The shield has cutouts that

match the I/O ports. Install the shield from inside the chassis.

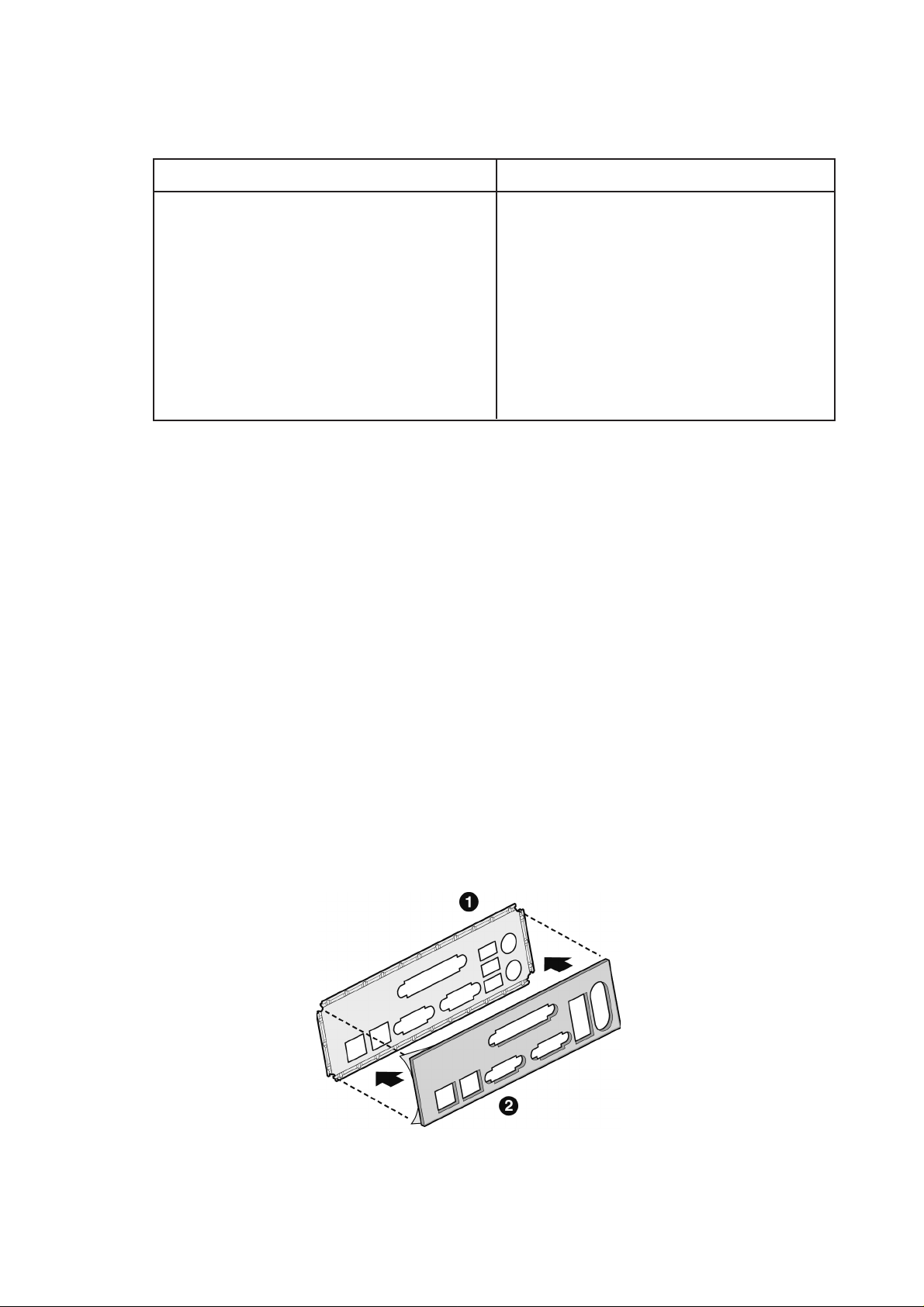

Attaching the Gasket to the I/O Shield

1. Remove the two backing strips from the gasket.

2. Press the gasket onto the inside face of the I/O shield as show.

Figure 3. Attaching the Gasket to the I/O Shield

MAXDATA PLATINUM Server Mainboard Manual

21

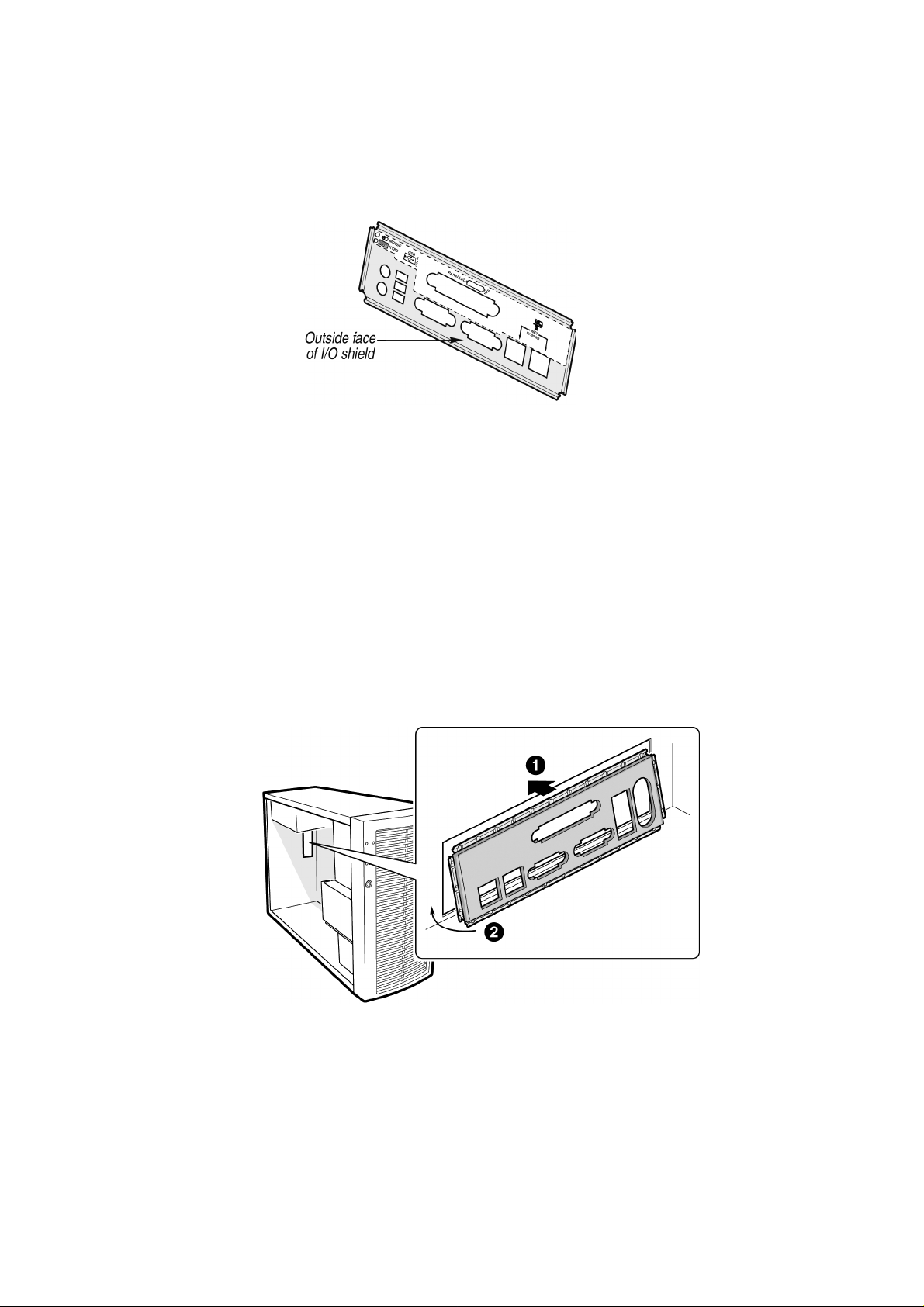

Attaching the Label to the I/O Shield

1. Remove the backing from the label included with your server board.

2. Press the label onto the outside face of the I/O shield.

Figure 4. Attaching the Label to the I/O Shield

Installing the I/O Shield

1. Position one edge so that the dot ted groove is outside the c hassis wall, and the lip of the

shield rests on the inner chassis wall.

2. Hold the shield in place, and push it into the opening until it is seated. Make sure the I/O

shield snaps into place all the way around.

22

Figure 5. Installing the I/O Shield

Server Board Installation

Installing the Processor(s)

CAUTIONS

If only one processor is to be used, it must be installed in the Primary Processor Socket

(CPU1) and a Terminator must be installed in the Secondary Processor Socket (CPU2).

If you are adding a second processor to your system, you must verify that the second

processor is identical to the first Intel

®

Pentium® III, same voltage and speed.

This server board has “zero-insertion-force” sockets. If processor does not drop easily into

socket holes, make sure the lever is in the full-upright position.

1 . Observe the safety and ESD precautions at the beginning of this chapter and the additional

precautions given here.

2. When installing the primary processor, lif t the loc king bar on the processor soc ket (CPU1)

as shown. If adding a second processor, lift the locking bar on the secondary processor

socket (CPU2), and repeat steps 3 through 7 after installing the primary processor.

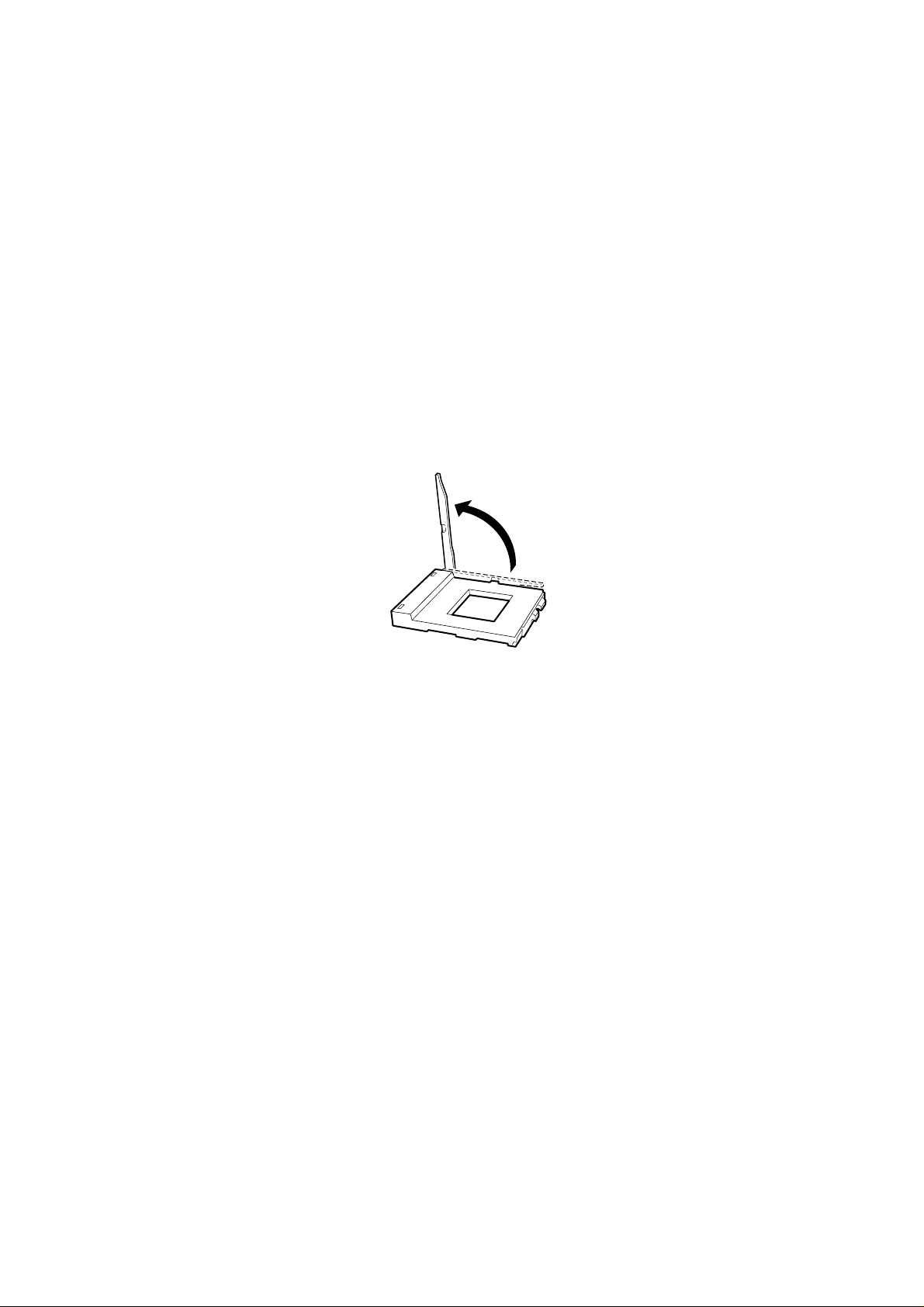

Figure 6. Lifting the Locking Bar

3. Align the pins of the processor with the soc k et and insert the processor into the soc ket.

Lower the locking bar completely.

MAXDATA PLATINUM Server Mainboard Manual

23

Figure 7. Inserting the Processor

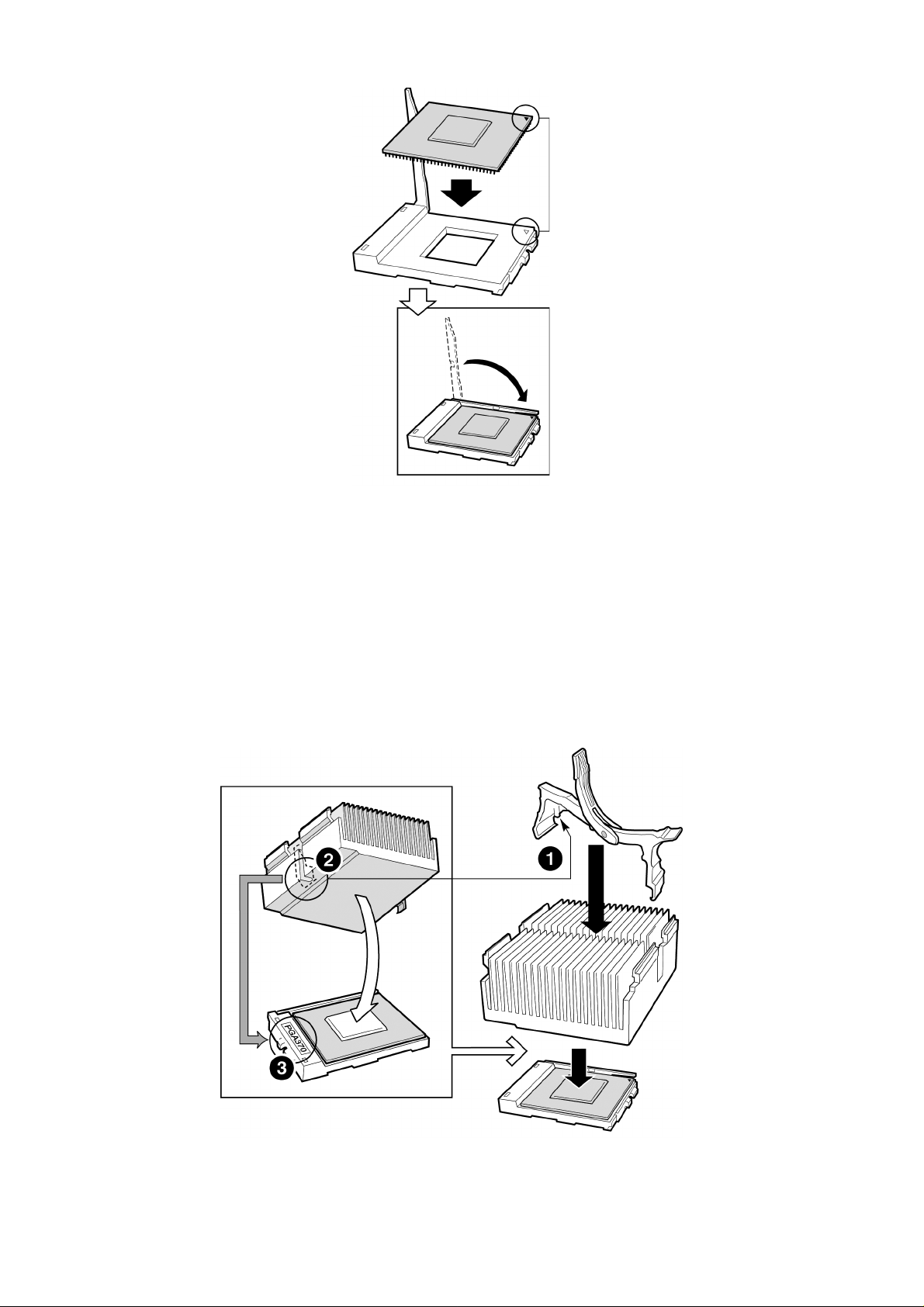

4. B efore inserting the retention clip into the heat sink slot, make sure the plastic pin (see

1 below) is aligned with the heat sink notc h (see 2 below). Align the notc hed side of the

heat sink (see 2 below) with the edge of the socket containing the “PG370” designation

(see 3 below) and place onto the processor as shown.

24

Figure 8. Attaching the Heat Sink and Retention Clip

Server Board Installation

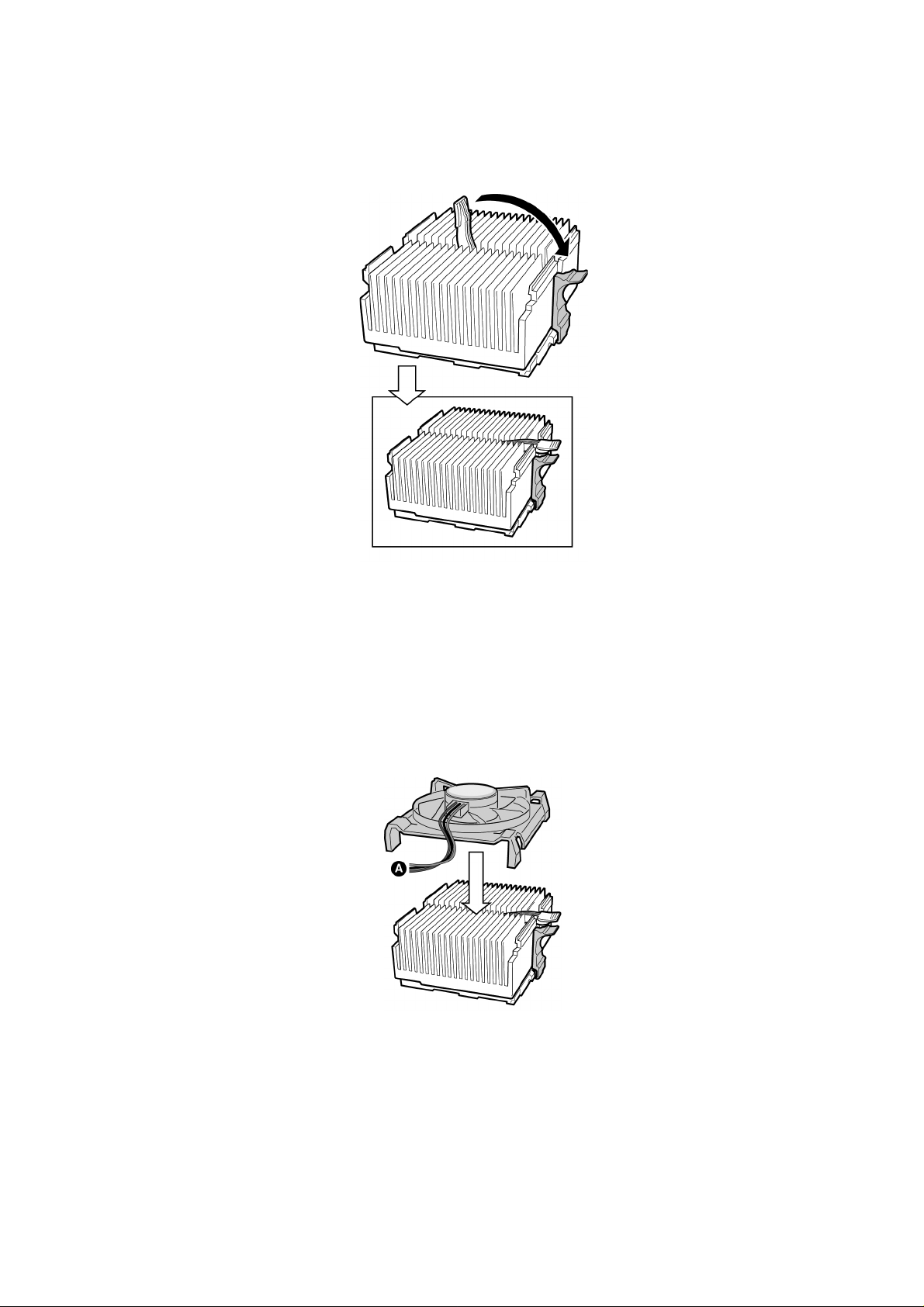

5. Close the heat sink retention clip as shown. Use slow, constant pressure to close the

retention clip lever.

Figure 9. Locking the Heat Sink Retention Clip

6. Attach the fan heat sink clip to the processor socket as shown.

Figure 10. Attaching the Heat Sink Fan

7. Connect the processor fan cable(s) to the correct connector in the “Making Connections

to the Server Board” section below.

MAXDATA PLATINUM Server Mainboard Manual

25

Installing a Terminator

If only one processor is to be installed, a terminator must be installed in Secondary Processor

Socket (CPU 2).

1. Align the corner mark on the terminator with the handle side of the processor socket.

2. Close and latch the socket lever.

Figure 11. Installing a Terminator

✏ NOTE

It is not necessary to install a heat sink on the processor terminator.

Installing Memory

The MAXDATA PLATINUM 1200/3200 Server Board contains six 1 68-pin DIMMs. Memory

is partitioned as three banks. DIMMs must be populated in identical pairs.

The MAXDATA PLATINUM 120 0/3200 Server Board supports up to six 3.3-V, registered

ECC SDRAM DIMMs that are compliant with the JEDEC PC133 specification. A wide range

of DIMM sizes are supported, including 64 MB, 1 28 MB, 256 MB , 512 MB , and 1 GB DIMMs.

The minimum supported memory configuration is 128 MB, using two identical 64 MB

DIMMs. The maximum configurable memory size is 6 GB using six 1 GB DIMMs.

The SDRAM interface runs at the same frequency as the processor bus. The memory

controller supports 2-way interlea ved SDRAM, memory scrubbing, single bit error correction

and multiple bit error detection. Memory can be implemented with either single-sided (one

row) or double-sided (two row) DIMMs.

✏ NOTE

Use DIMMs that have been tested for compatibility with the ser ver board. Contact your

sales representative or dealer for a current list of approved memory modules.

26

Server Board Installation

1. Open both DIMM socket levers

2. Insert DIMM making sure the connector edge of the DIMM aligns correctly with the

slot.

3. Check that socket levers are securely latched. DIMMs must be populated in identical

pairs.

Figure 12. Installing Memory

MAXDATA PLATINUM Server Mainboard Manual

27

Configuring Chassis Standoffs

If your chassis does not have standoffs placed as shown below, you must rearrange them

so they matc h the holes in the server board. Failure to properly rearrange the metal standoffs

may cause the server board to malfunction and may permanently damage it. Your chassis

may be different from the illustration.

For the MAXDATA PLATINUM chassis:

1 . Install standoffs in positions 7 and 1 7. Standoff numbering in other c hassis may be diff erent.

Standoffs are included with your chassis.

28

Figure 13. Configuring Chassis Standoffs

Server Board Installation

Installing the Server Board

1. Place the board into the chassis, making sure that the back panel I/O shield openings

and chassis standoffs align correctly.

2. Attach the board with the screws included with your chassis.

Figure 14. Placing the Server Board in the Chassis

MAXDATA PLATINUM Server Mainboard Manual

29

Making Connections to the Serv er Board

Figure 15. Making Connections to the Server Board

A. Main power connector

B. +12 V CPU Power

C. Front Panel USB

D. Floppy disk drive connector

E. ATA 100/IDE Chassis Fans

F. Front Panel connector

G. SCSI B

H. SCSI A

I. CPU2 Fan

J. Chassis Fans

K. CPU1 Fan

L. COM2/EMP

M. Chassis Intrusion

N. Chassis Fans

30

Server Board Installation

Cable Routing

To ensure proper air flow within the chassis, follow the cable routing guidelines below.

IDE or SCSI Cables

Cables that connect to devices in the lower device bays should be routed around the epac

as shown below.

1. Route cables as shown.

2. Replace the top half of the epac.

Figure 16. Routing Cables

Floppy and Front Panel USB Cables

Route the floppy drive cable as shown.

Floppy Disk Cable

Route the floppy drive

cable as shown.

Figure 17. Routing the Floppy and USB Cables

MAXDATA PLATINUM Server Mainboard Manual

31

Installing the COM2 Cable

For the MAXDATA PLA TINUM chassis, you can connect the COM2 serial port cable to either

the front or back panels. Connecting it to the back panel is illustrated below.

1. Install the COM2 cable by inserting it into the c hassis bac k panel cutout and attaching it

as shown.

2. At tac h the other end of the COM2 connector located on y our server board between the

CPU2 Processor soc ket and the DIMMs. See “Making Connections to the Server Board”

for the exact COM2 connector location.

Figure 18. Installing the COM2 Cable

32

Server Board Installation

Finishing Up

WARNING

An electrical shock hazard exists if the chassis cov er is not replaced before connecting the

chassis AC power.

1. Install the chassis cover according to the instructions for your chassis.

2. See your chassis documentation to complete rack or pedestal installation.

3. Connect the keyboard, mouse and monitor cables to the back panel.

4. Connect the power cable to the back panel and to an AC outlet.

Figure 19. Making Back Panel Connections

MAXDATA PLATINUM Server Mainboard Manual

33

Getting Star ted with Int el® Server Management (Optional)

Intel® Server Control and the hard drive Service Partition provide real-time monitoring and

alerting for your SDS2 server hardware, emergency remote management, and remote server

setup. Intel® Server Control is implemented by installing it within client-server architecture.

The Service Partition provides you with the ability to remotely access a local partition on the

server and to identify and diagnose server health issues. Remote access is provided through

either a modem or network connection.

To get st arted with Intel

the system’s operating system, and finally Intel® Server Control. The information here

describes installation on a system running a Microsoft Windows® operating system.

Installing the Service P artition

Installing the Service Partition consists of three tasks:

• Preparing the server to boot from the CD-ROM drive

• Creating the Service Partition

• Formatting the Service Partition

Preparing the Server to Boot from the CD-ROM Drive

1. Insert the Intel® Server Board SDS2 Resource CD into the server’s CD-ROM drive.

®

Server Management, you install the Service Partition first, then

2. Restart the server.

3. Press <F2> at the prompt to enter the BIOS setup utility during the boot cycle.

4. Select Boot Menu.

5. In Boot Device Priority, press the <+> key to move ATAPI

priority than the system hard drive.

6. Press the <F10> key to save the set tings. Af ter pressing this ke y , the system resets and

boots from the CD-ROM drive.

®

CD-ROM device higher in

Creating the Service Partition

7. From the CD-ROM menu, select Utilities and press the <Enter> key.

8. Select Run Service Partition Administrator and press the <Enter> key.

9. From the list of available items, select Create Service Partition-first time.

10. Follow the instructions that appear on the screen. These instructions prompt you to

reboot the server. It will reboot from the CD-ROM.

Formatting the Service Partition

11. After the system reboot, select the Utilities menu and press the <Enter> key.

12. Select Run Service Partition Administrator and press the <Enter> key.

13. Select Format Service Partition and Install Software.

14. Remove the System Resource CD from the CD-ROM drive and exit from the menu

screen. You can now install the server’s operating system.

Installing your operating system

Install your operating system now.

34

Server Board Installation

Installing Intel® Server Contr ol

15. Insert the Intel® Server Board SDS2 Resource CD into the system’s CD-ROM drive and

wait for the auto-launcher to display a start-up web page local to the System Resource CD.

16. F rom the start-up web page, open server management in the blue menu on the lef t side

of the screen.

17. Open make a selection in the green box.

18. Choose to either view the Intel

software installation.

19. To continue with the inst allation, click on Intel

After clicking on run installer, follow the screen instructions.

®

Server Control Installation Guide or to proceed with the

®

Server Control and then on run installer.

MAXDATA PLATINUM Server Mainboard Manual

35

36

3 Upgrading

Tools and Supplies Needed

• Phillips (cross head) screwdriver (#1 bit and #2 bit)

• Jumper removal tool or needle nosed pliers

• Pen or pencil

• Antistatic wrist strap and conductive foam pad (recommended)

Cautions

These warnings and cautions apply throughout this c hapter . Only a tec hnically qualified person

should configure the server board.

CAUTION

System pow er on/of f: T he power but ton DOES NO T turn of f the system A C power . T o remo ve

power from system, you must unplug the AC power cord from the wall outlet. Make sure

the A C power cord is unplugged bef ore you open the chassis, add, or remo ve any components.

Hazardous conditions, devices & cables: Hazardous electrical conditions may be present on

power , telephone, and communication cables. T urn of f the server and disconnect the power

cord, telecommunications systems, networks, and modems attached to the server before

opening it. Otherwise, personal injury or equipment damage can result.

Electrostatic discharge (ESD) & ESD protection: ESD can damage disk drives, boards, and

other parts. We recommend that you perform all procedures in this chapter only at an ESD

workstation. If one is not available, provide some ESD protection by wearing an antistatic

wrist strap attac hed to chassis ground - any unpainted metal surface - on your server when

handling parts.

ESD and handling boards: Alwa ys handle boards carefully . They can be extremely sensitive

to ESD. Hold boards only b y their edges. Af ter removing a board from its protectiv e wrapper

or from the server, place the board component side up on a grounded, static free surface.

Use a conductive foam pad if available but not the board wrapper. Do not slide board over

any surface.

Installing or removing jumpers: A jumper is a small plastic encased conductor that slips ov er

two jumper pins. Some jumpers have a small tab on top that you can grip with y our fingertips

or with a pair of fine needle nosed pliers. If your jumpers do not have such a tab, take care

when using needle nosed pliers to remove or install a jumper; grip the narro w sides of the

jumper with the pliers, never the wide sides. Gripping the wide sides can damage the

contacts inside the jumper, causing intermittent problems with the function controlled by

that jumper. Take care to grip with, but not squeeze, the pliers or other tool you use to

remove a jumper, or you may bend or break the stake pins on the board.

MAXDATA PLATINUM Server Mainboard Manual

37

Memory

The MAXDATA PLATINUM 1200/3200 Server Board contains six 1 68-pin DIMMs. Memory

is partitioned as three banks. DIMMs must be populated in identical pairs.

The MAXDATA PLATINUM 120 0/3200 Server Board supports up to six 3.3-V, registered

ECC SDRAM DIMMs that are compliant with the JEDEC PC133 specification. A wide range

of DIMM sizes are supported, including 64 MB, 1 28 MB, 256 MB , 512 MB , and 1 GB DIMMs.

The minimum supported memory configuration is 128 MB , using two identical 64 MB DIMMs.

The maximum configurable memory size is 6 GB using six 1 GB DIMMs.

The SDRAM interface runs at the same frequency as the processor bus. The memory

controller supports 2-way interlea ved SDRAM, memory scrubbing, single bit error correction

and multiple bit error detection. Memory can be implemented with either single-sided (one

row) or double-sided (two row) DIMMs.

✏ NOTE

Use DIMMs that have been tested for compatibility with the ser ver board. Contact your

sales representative or dealer for a current list of approved memory modules.

Processors

WARNING

If the server has been running, any installed processor and heat sink on the processor

board(s) will be hot. T o av oid the possibility of a burn, be careful when removing or installing

server board components that are located near processors.

38

Upgrading

CAUTION

Processor must be appropriate: You may damage the server if you install a processor that is

inappropriate for your server. Make sure your ser ver can handle a newer, faster processor

(thermal and power considerations).

ESD and handling processors: Reduce the risk of electrostatic discharge (ESD) damage to

the processor by doing the following: (1) Touch the metal chassis before touching the

processor or server board Keep part of your body in contact with the metal chassis to dissipate

the static charge while handling the processor. (2) Avoid moving around un-necessarily.

Adding or Replacing a Processor

If you are adding a second processor to your system, y ou must first remo v e the terminator

from the secondary processor socket. The second processor must be compatible with the

first processor.

1 . Observe the safety and ESD precautions at the beginning of this chapter and the additional

cautions given here.

2. Remove the side cover (see your system or chassis documentation for instructions).

Raise the locking bar on the socket.

Figure 20. Raise the Locking Bar

3. Aligning the pins of the processor with the soc k et, insert the processor into the socket.

Lower the locking bar completely.

MAXDATA PLATINUM Server Mainboard Manual

39

Figure 21. Insert the Processor

4. Before inserting the retention clip into the heat sink slot, make sure the plastic pin

located at 1 is aligned with the heat sink notc h at 2. Align the notched side of the heat

sink 2 with the edge of the socket containing the “PG370” designation 3 and place

onto the processor as shown below.

40

Figure 22. Attach the Heat Sink and Retention Clip

Upgrading

5. Lock the heat sink clip to the processor socket.

Figure 23. Lock the Heat Sink Retention Clip

6. Install the heat sink fan by snapping it into the top of the heat sink as shown.

Figure 24. Attach the Fan

MAXDATA PLATINUM Server Mainboard Manual

41

Removing a Processor

1 . Observe the safety and ESD precautions at the beginning of this chapter and the additional

cautions given here.

2. Unplug the heat sink fan.

3. Detach the heat sink clip from the processor soc k et. See the documentation that shipped

with your processor for more detail.

4. Remove the heat sink from the processor.

5. Raise the locking bar on the socket.

6. Remove the processor from the socket.

7. If you removed the processor from the secondary socket and are not replacing it, you

must install a terminator in its place.

Installing or Removing a Terminator

1 . Observe the safety and ESD precautions at the beginning of this chapter and the additional

cautions given here. Raise the locking bar on the socket.

2. Aligning the corner mark on the terminator with the “handle-side ” of the processor socket,

insert the terminator into the soc ket.

3. Lower the locking bar completely.

Do these steps in reverse to remove the terminator.

Figure 25. Installing a Terminator

✏ NOTE

It is not necessary to install a heat sink on the processor terminator.

42

Upgrading

Replacing the Back up Battery

The lithium battery on the server board powers the real time clock (RTC) for up to 10 years

in the absence of power . When the battery starts to weaken, it loses voltage, and the server

settings stored in CMOS RAM in the RTC (for example, the date and time) may be wrong.

Contact your customer service representative or dealer for a list of approved devices.

WARNING

Danger of explosion if bat tery is incorrectly replaced. Replace only with the same or equivalent

type recommended by the equipment manufacturer. Discard used batteries according to

manufacturer’s instructions.

1. Observe the safety and ESD precautions at the beginning of this chapter.

2. Open the chassis.

3. Insert the tip of a small flat bladed screw driver , or equiv alent, under the tab in the plastic

retainer. Gently push down on the screwdriver to lift the battery.

4. Remove the battery from its socket.

5. Dispose of the battery according to local ordinance. Remove the new lithium battery

from its package, and, being careful to observe the correct polarity , insert it in the bat tery

sock et.

6. Reinstall the plastic retainer on the lithium battery socket.

7. Close the chassis.

8. Run Setup to restore the configuration settings to the RTC.

Figure 26. Replacing the Back up Battery

MAXDATA PLATINUM Server Mainboard Manual

43

44

4 Configuration Sof tware and Utilities

This c hapter describes the P ow er-On Self-T est (POS T) and server configuration utilities. The

table below briefly describes the utilities.

Table 4. Configuration Utilities

Utility Description a n d brief proc ed ure

If the system does not have a diskette drive, or the drive is disabled or

misconfigured, use Setup to enable it.Or, you can move t he CMOS jumper

BIOS Setu p

System Setup Utility (SSU)

on the server board from the default setting (Protect CMOS memory) to the

Clear setting; this will allow most server configurations to boot. Then run the

SSU to configure the server.

Use for viewing and clearing the system event log, viewing the system

management FRU information, or viewing the system management SDR

repository.

FRUSDR Load Utility

BIOS Upgrade Utility Use to upgrade the BIOS.

Firmware Update Utility Use t o update the Firmware.

Using the Adaptec SCSI Utility

Use t o upda te the Field Replacement Unit (FRU), Sensor Data Record (SDR),

and SM BIOS (SMB) flash components.

Use t o configure or view the settings of the SCSI host adapters and onboard

SCSI devices in the server.

Hot Keys

Use the keyboard’s numeric pad to enter numbers and symbols.

Table 5. Hot Keys

To do thi s : Press these keys

Clear memory and reload the

operating system this is a

system reset.

<Ctrl+Alt+Del>

Secure your system immediately.

MAXDATA PLATINUM Server Mainboard Manual

<Ctrl+Alt>+hotkey (Set yo ur hot key combination with Setup.)

45

Power-On Self-Test (POST)

Each time you turn on the system, POST starts running. POST checks the server board,

processor, memory, keyboard, and most installed peripheral devices. During the memor y

test, POST displays the amount of memory that it is able to access and test. The length of

time needed to test memory depends on the amount of memory installed. POST is stored

in flash memory.

1. Turn on your video monitor and server. After a few seconds POST begins to run.

2. After the memory test, these screen prompts and messages appear:

Press <F2> key if you want to run SETUP

If you do not press <F2> and do NOT have a device with an operating system loaded,

the above message remains for a few seconds while the boot process continues, and

the system beeps once. Then this message appears:

Operating system not found

If you do not press <F2> and DO have an operating system loaded, the boot process

continues, and this message appears:

Press <Ctrl><A> to enter SCSI Utility

4. Press <Ctrl+A> if there are SCSI devices installed. When the utility opens, follow the

displayed instructions to configure the onboard SCSI host adapter settings and to run

the SCSI utilities. Also see “Using the Adaptec SCSI Utility” on page 71. If you do not

enter the SCSI utility, the boot process continues.

5. Press <Esc> during POS T to pop up a boot menu when POS T finishes. F rom this menu

you can choose the boot device or enter BIOS Setup.

After POST completes, the system beeps once.

What appears on the screen after this depends on whether you have an operating system

loaded and if so, which one.

If the system halts before POST completes running, it emits a beep code indicating a fatal

system error that requires immediate at tention. If POST can displa y a message on the video

display screen, it causes the speaker to beep twice as the message appears.

Note the screen display and write down the beep code you hear; this information is useful

for your service representative. For a listing of beep codes and error messages that POST

can generate, see the “Solving Problems” chapter in this manual.

46

Configuration Software and Utilities

Using BIOS Setup

This section describes the BIOS Setup options. Use Set up to change the server configuration

defaults. Y ou can r un Setup with or without an operating system being present. Set up stores

most of the configuration values in bat tery back ed CMOS; the rest of the v alues are stored

in flash memory. The values take ef fect when you boot the server . POS T uses these values

to configure the hardware; if the values and the act ual hardware do not agree, POST generates

an error message. You must then run Setup to specify the correct configuration.

Record Your Setup Settings

If the default values ever need to be restored (after a CMOS clear, for example), you must

run Setup again. Referring to the worksheets could make your task easier.

If You Cannot Access Setup

If the diskette drive is misconfigured so that you cannot access it to run a utility from a

disket te, you ma y need to clear CMOS memory. Y ou will need to open the server, change a

jumper setting, use Setup to check and set diskette drive options, and change the jumper

back. For a step-by-step procedure, see Chapter 5, under the heading, “CMOS Jumper.”

Starting Setup

You can enter and start Setup under several conditions:

When you turn on the server, after POST completes the memory test

• When you reboot the server by pressing <Ctrl+Alt+Del> while at the DOS operating

system prompt

• When you have moved the CMOS jumper on the server board to the “Clear CMOS”

position (enabled); for the procedure, see Chapter 5, under the heading “CMOS Jumper”

In the three conditions listed above, after rebooting, you will see this prompt:

Press <F2> to enter SETUP

✏ NOTE

If the BIOS setup option “POST Diagnostic Screen” is enabled (Default), you will not see

the message “P ress <F2> to enter SE TUP”. T his message is hidden b y the Manuf act urer’s

Splash screen. To see the message, press the <ESC> key while the splash screen is display ed.

This will temporarily disable the splash screen allowing you to see the message.